Patents

Literature

239 results about "Automotive paint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automotive paint is paint used on automobiles for both protection and decoration purposes. Water-based acrylic polyurethane enamel paint is currently the most widely used paint for reasons including reducing paint's environmental impact.

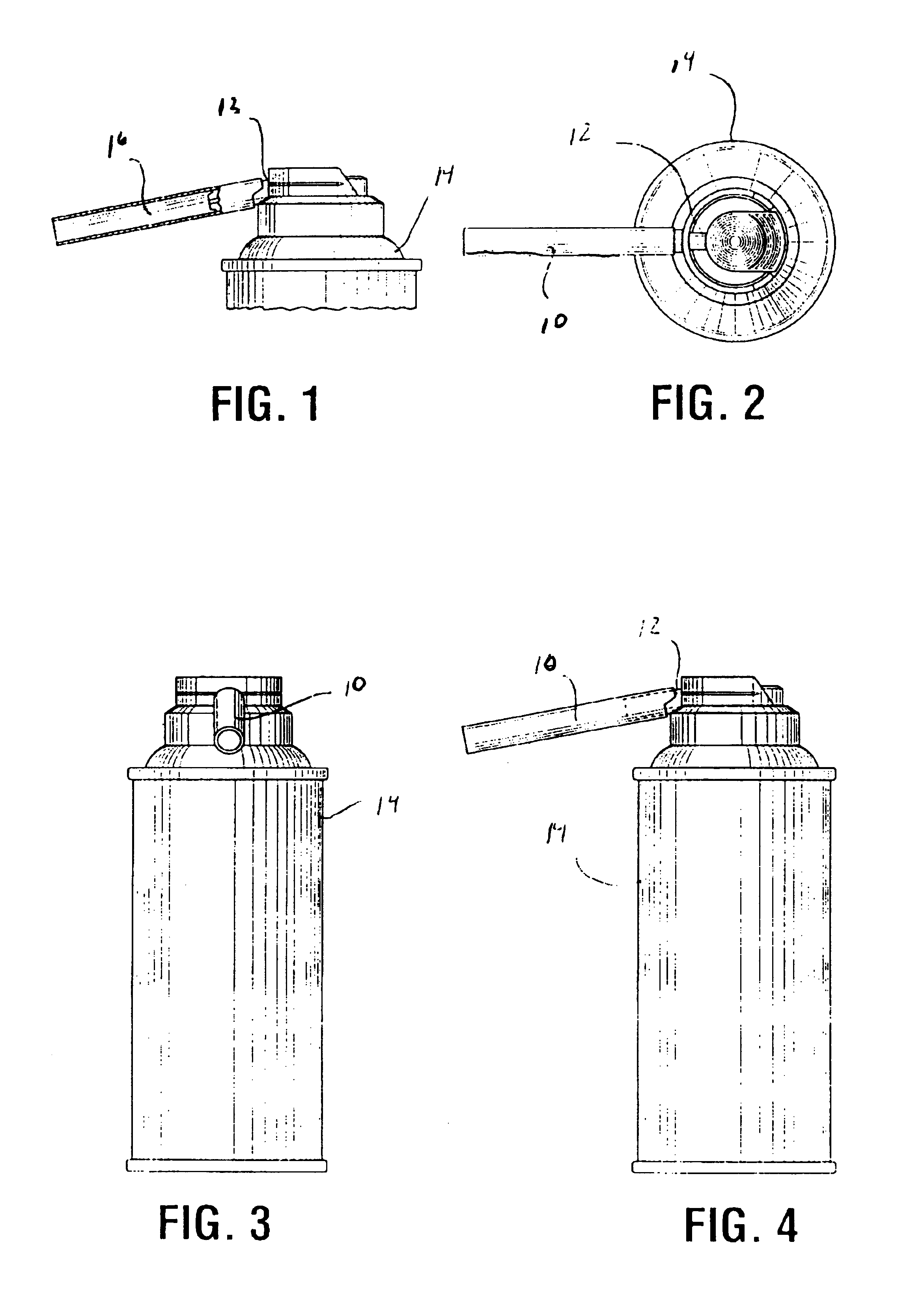

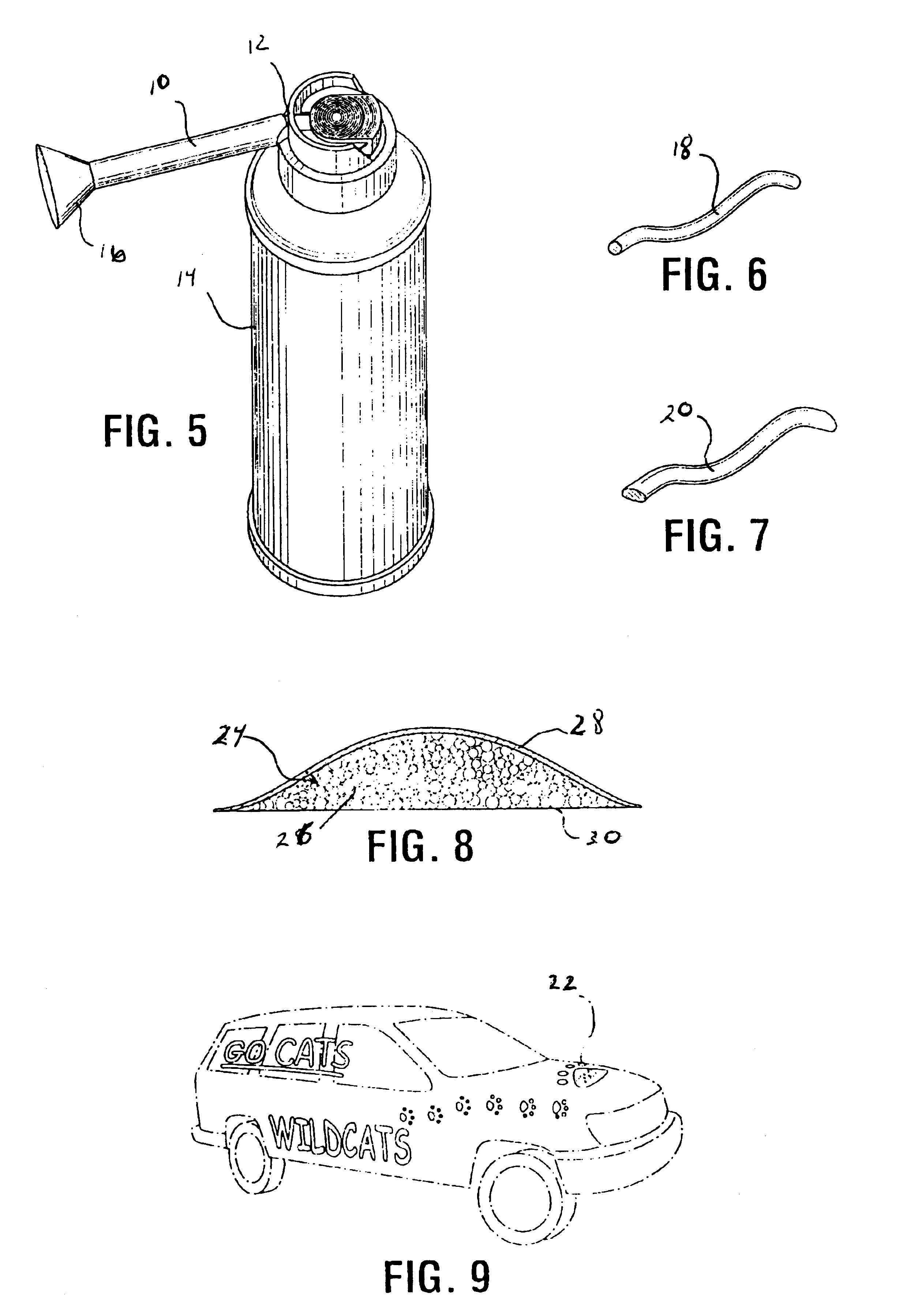

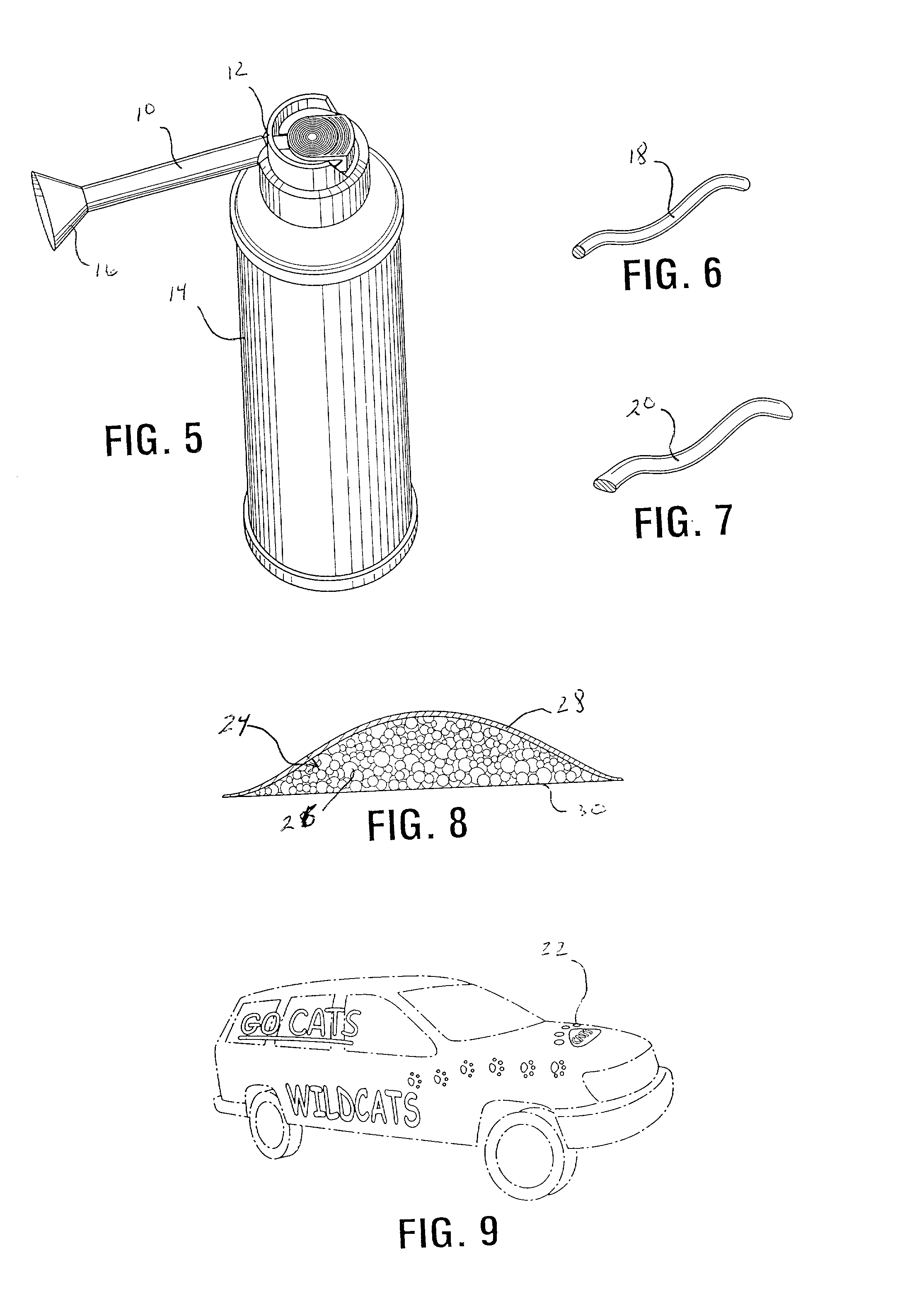

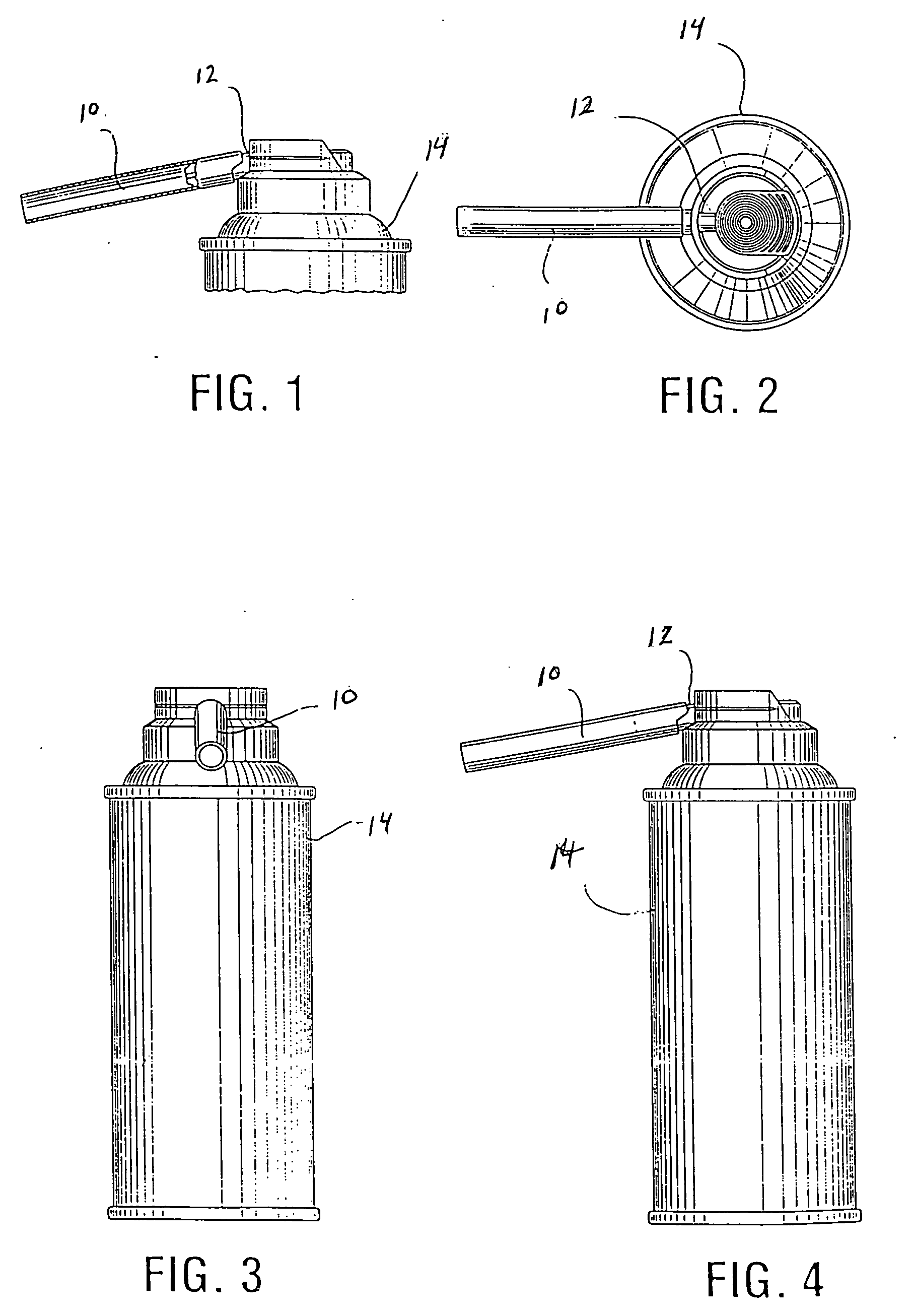

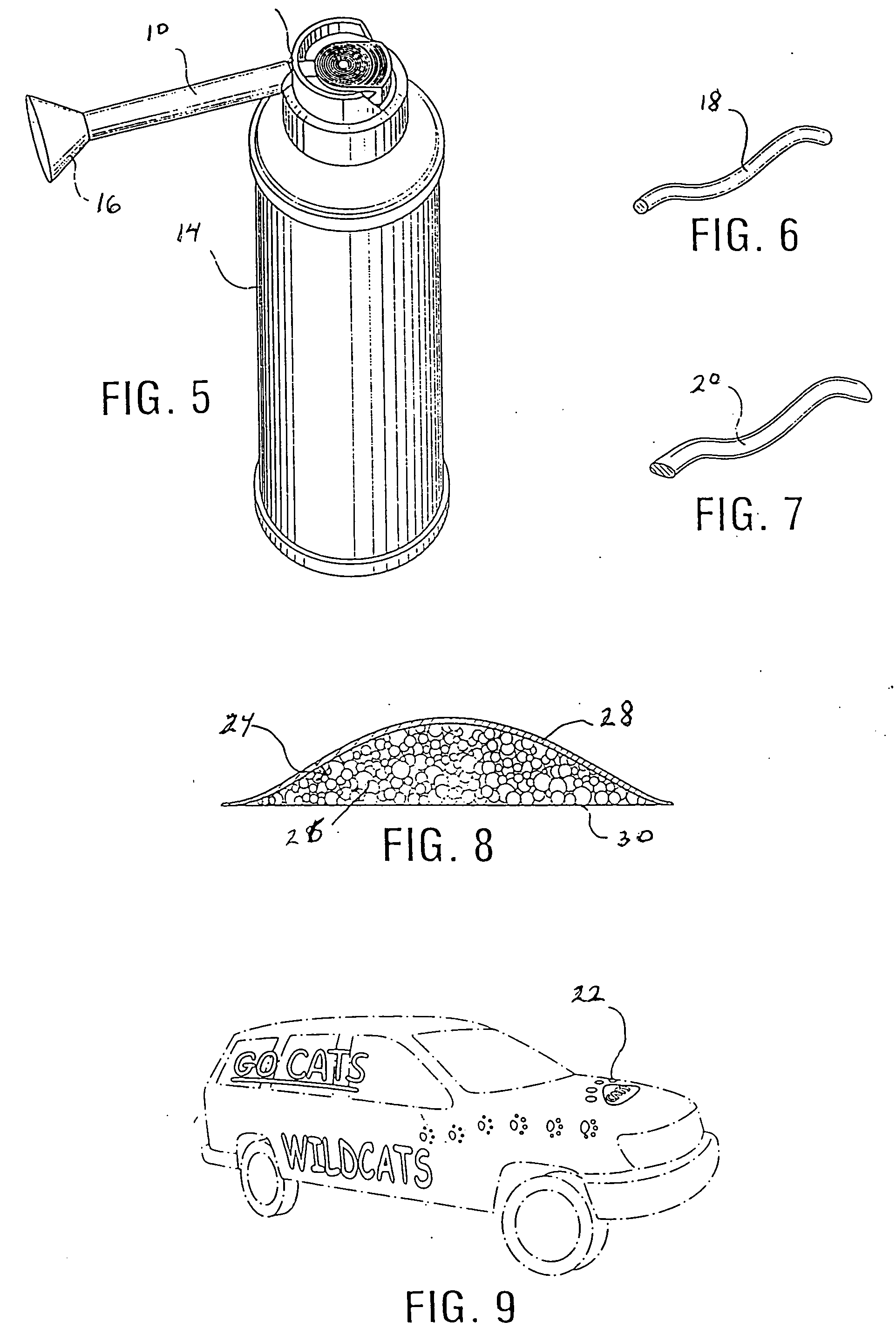

Peelable foam coating composition

This invention relates generally to water resistant peelable protective and decorative clear or pigmented foam coating compositions and, more specifically, to aqueous and solvent based, polymeric coating compositions which form a protective and / or decorative coating and is removably adheres to a variety of substrates, including automotive paints, metals, glass, vinyl, plastics, concrete, natural and synthetic elastomers, and ceramics. The coatings present a three-dimensional expandable foamy coating, and can be readily peeled off from the substrate as a whole piece. The coatings may be formulated for temporary or long-term protection depending upon the application. The peelable coatings can be applied as a paint, paste, film, or expandable foam cord whereby the expansion of the foam can be controlled by the formulation and applicator.

Owner:ASHLAND LICENSING & INTPROP LLC

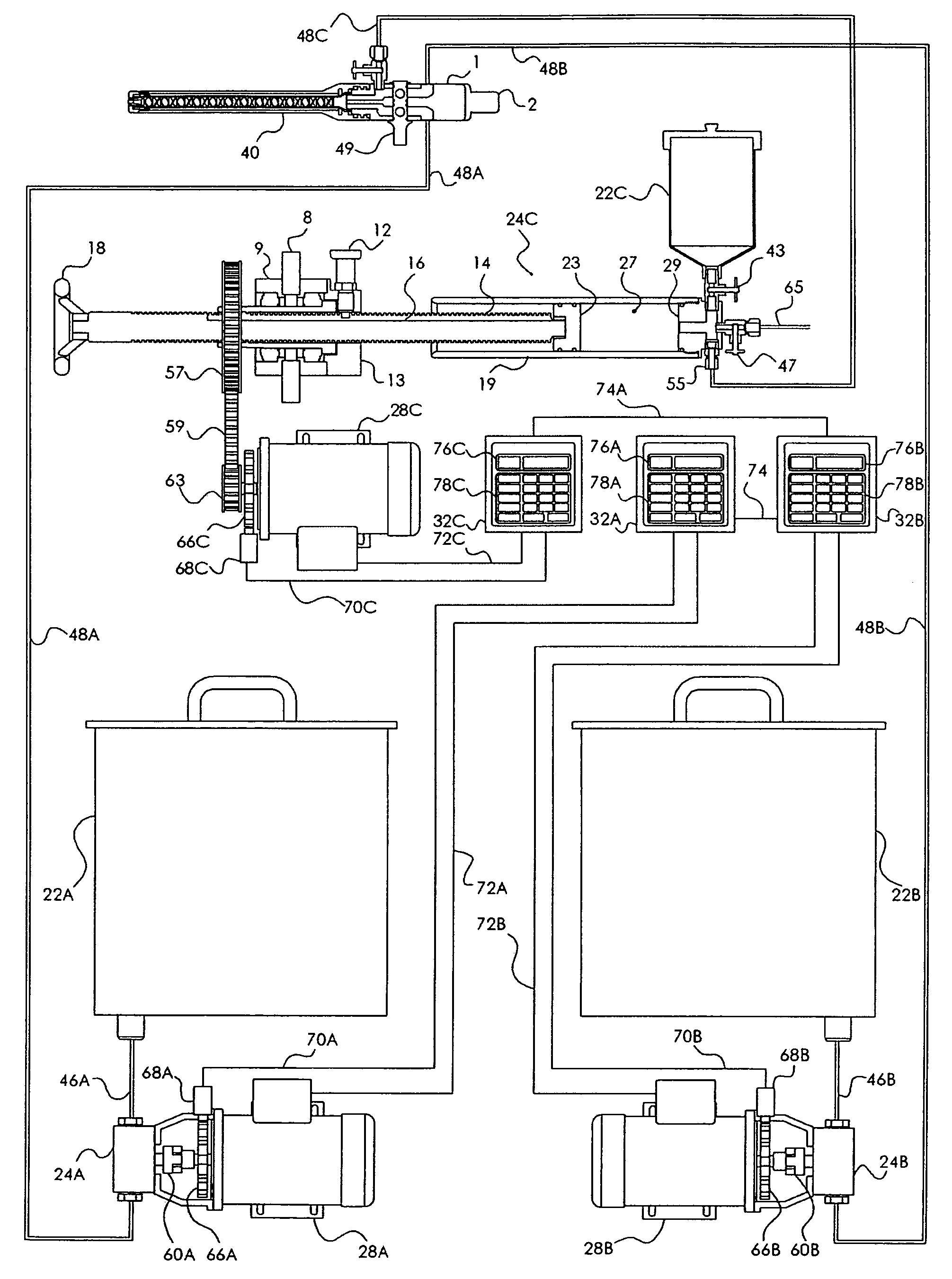

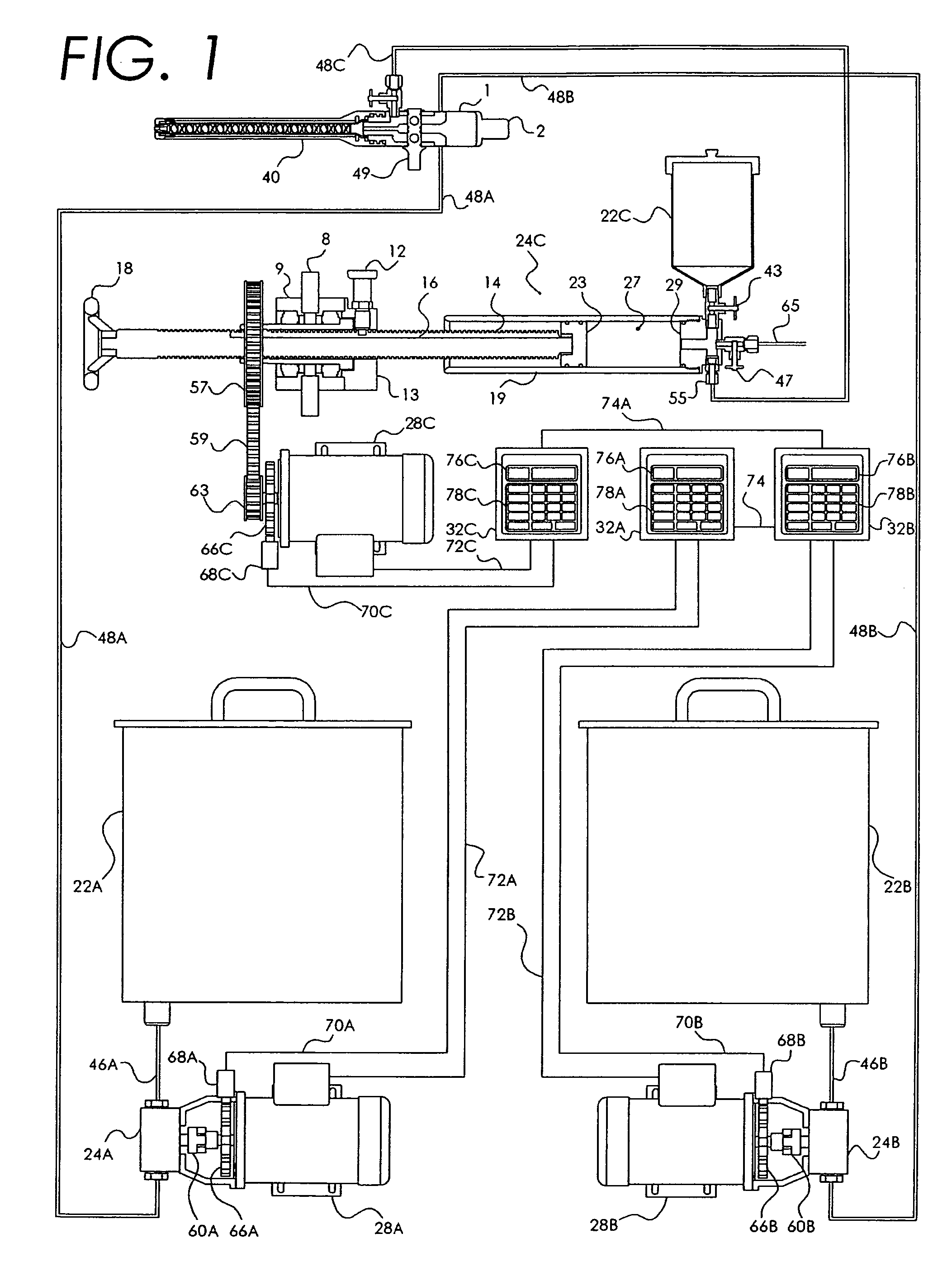

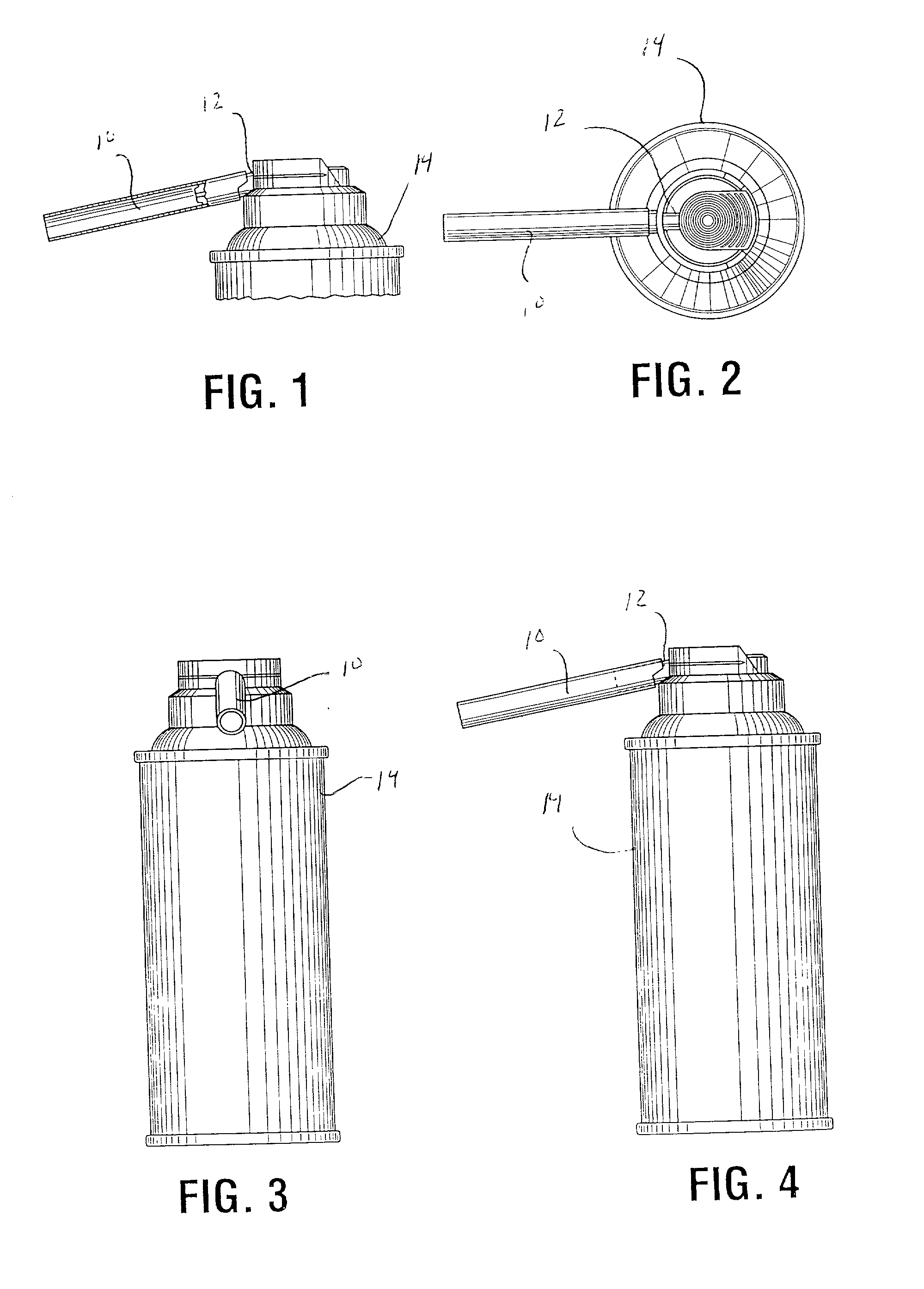

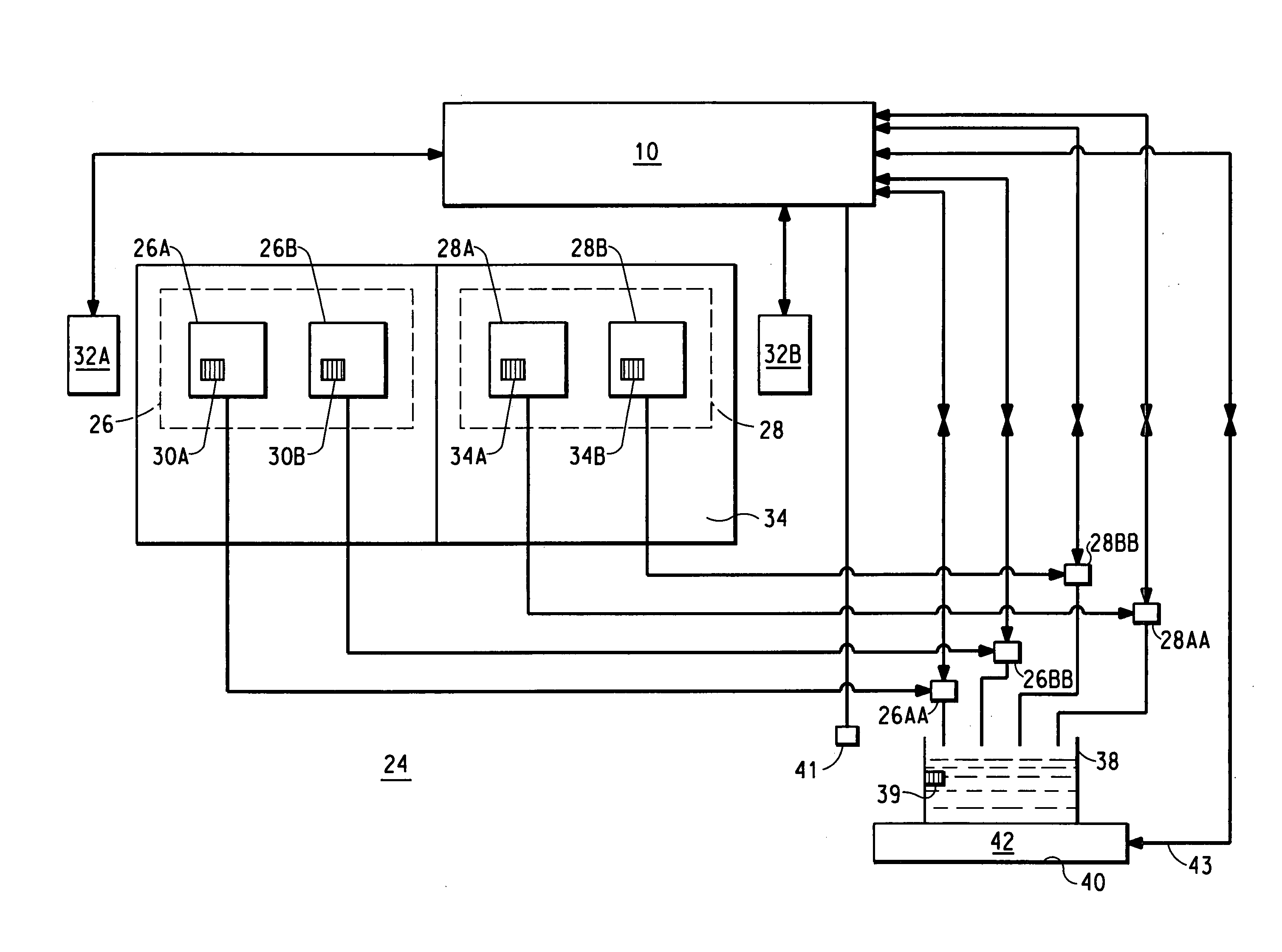

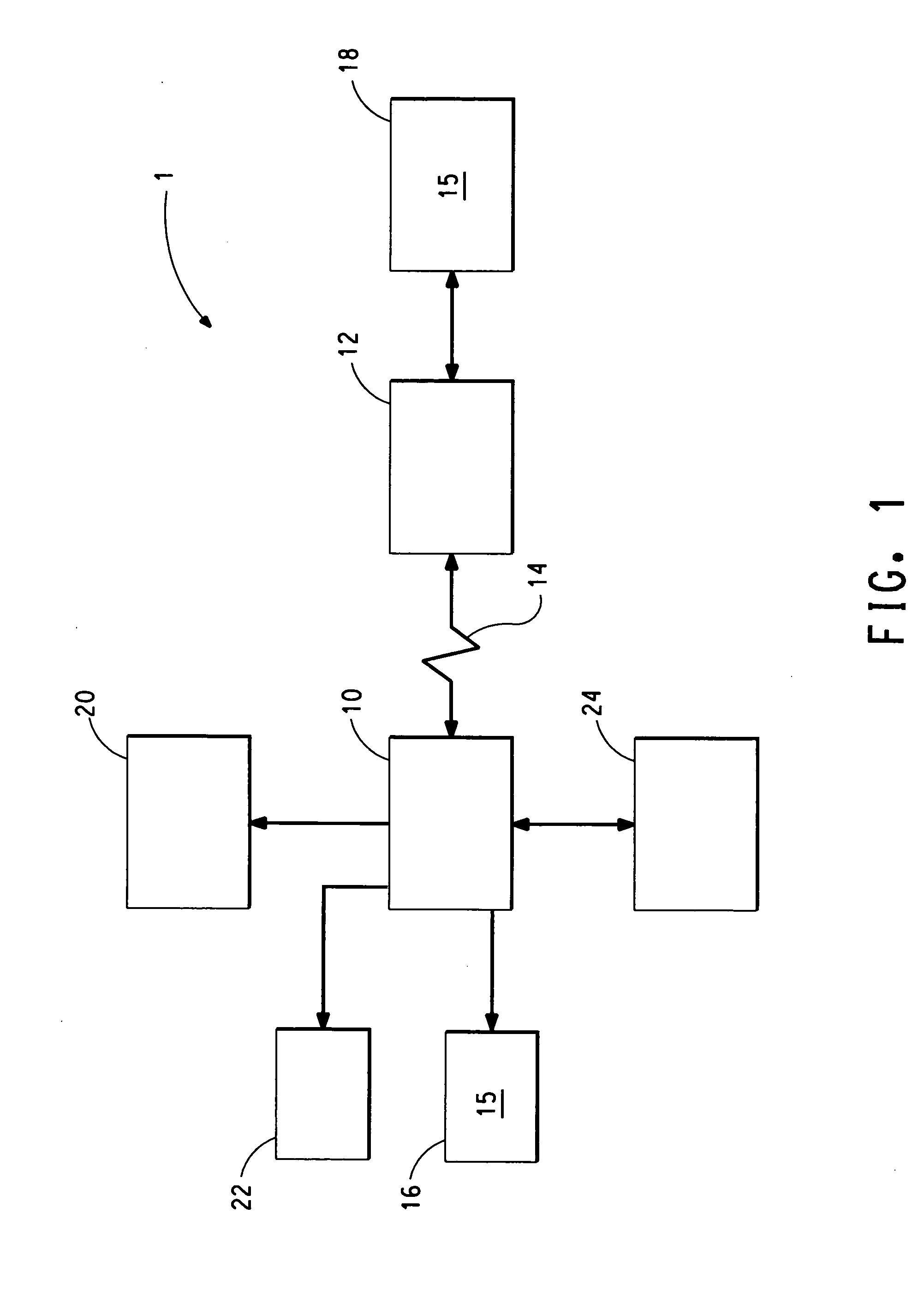

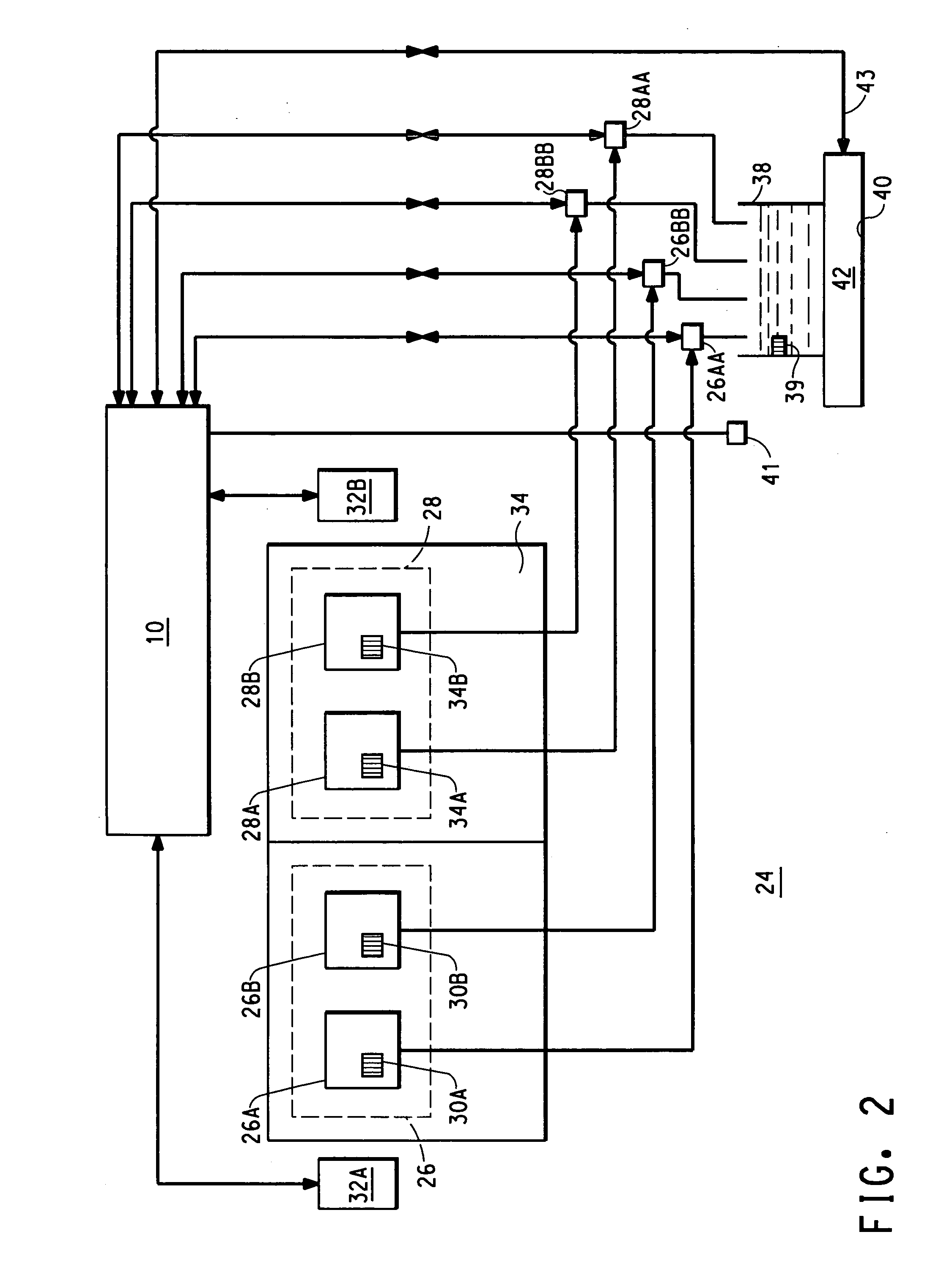

Third stream automotive color injection

InactiveUS20050103889A1Permit useImprove matchOpening closed containersBottle/container closureAutomotive paintEngineering

A method and system are provided for injecting a color component into a plural component coating dispensing system. Base, cure and color components are pumped from respective containers at metered volume. The color component, which is preferably a low-viscosity automotive paint is injected into the either the base or cure stream at a point immediately prior to mixing all components in a dispensing device for dispensing the resulting colored fluid mixture onto a surface to be coated. The mixture may be dispensed by pouring or spraying onto the surface. The method and system are particularly useful for mixing and dispensing colored polyurethane or polyurea coatings, such as for spray-on truck bed liners.

Owner:LANGEMAN GARY D

Peelable foam coating composition

This invention relates generally to water resistant peelable protective and decorative clear or pigmented foam coating compositions and, more specifically, to aqueous and solvent based, polymeric coating compositions which form a protective and / or decorative coating and is removably adheres to a variety of substrates, including automotive paints, metals, glass, vinyl, plastics, concrete, natural and synthetic elastomers, and ceramics. The coatings present a three-dimensional expandable foamy coating, and can be readily peeled off from the substrate as a whole piece. The coatings may be formulated for temporary or long-term protection depending upon the application. The peelable coatings can be applied as a paint, paste, film, or expandable foam cord whereby the expansion of the foam can be controlled by the formulation and applicator

Owner:ASHLAND LICENSING & INTPROP LLC

Heat-activated sound and vibration damping sealant composition

InactiveUS20050266237A1Improve soundImproved vibration damping propertiesOther chemical processesVehicle sealing arrangementsMedicineAutomotive paint

A heat-activated sound and vibration damping sealant composition is provided. The composition includes dried automotive paint powder and an unsaturated polymer, where the paint powder reacts with the unsaturated polymer when the composition is heated to greater than 200° F. (80° C.). Upon heating, composition expands and increases in tensile strength. The composition may be provided in the form of a tape which is adhered to a substrate such as an automotive or appliance part and then exposed to elevated temperatures such as those encountered in automotive, appliance, or other commercial paint bake processes. Thereafter, the composition provides sound and vibration damping properties.

Owner:ADCO PROD INC

Peelable coating composition

InactiveUS20050027024A1Fast dryingImprove toughnessOther chemical processesEmulsion paintsElastomerAutomotive paint

This invention relates generally to water resistant peelable protective and decorative clear or pigmented foam coating compositions and, more specifically, to aqueous, polymeric coating compositions which form a protective and / or decorative coating and removably adhere to a variety of substrates, including automotive paints, metals, glass, vinyl, plastics, concrete, natural and synthetic elastomers, and ceramics. The coatings present a three-dimensional expandable foamy structure, and can be readily peeled off from the substrate as a whole piece. The coatings may be formulated for temporary or long-term protection depending upon the application. The peelable coatings can be applied as expandable foam cord, and as a film, paste, gel, paint, etc. as well, whereby the expansion of the foam can be controlled by the formulation and applicator.

Owner:ASHLAND LICENSING & INTPROP LLC

Process for monitoring production of compositions

Owner:AXALTA COATING SYST IP CO LLC

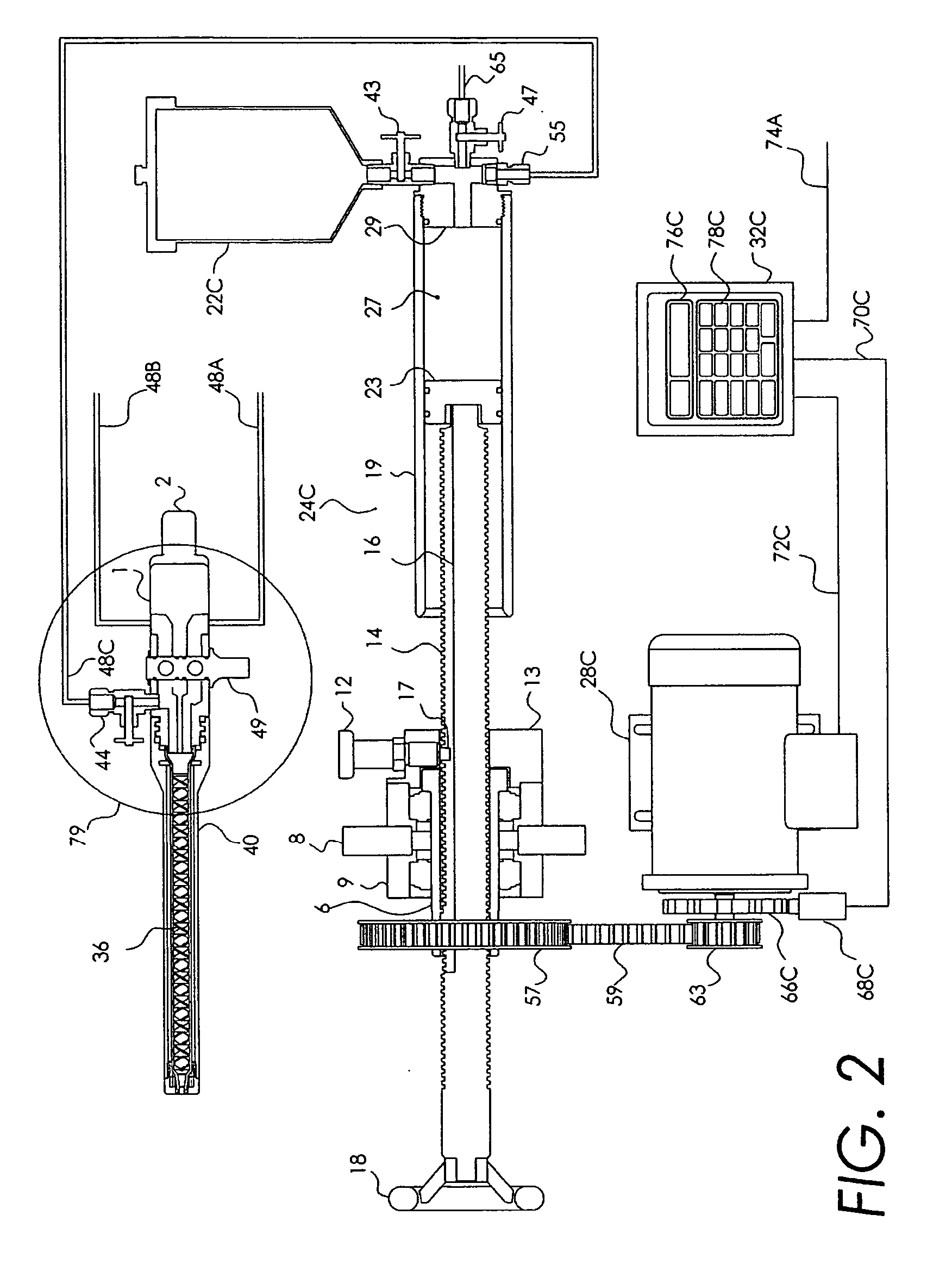

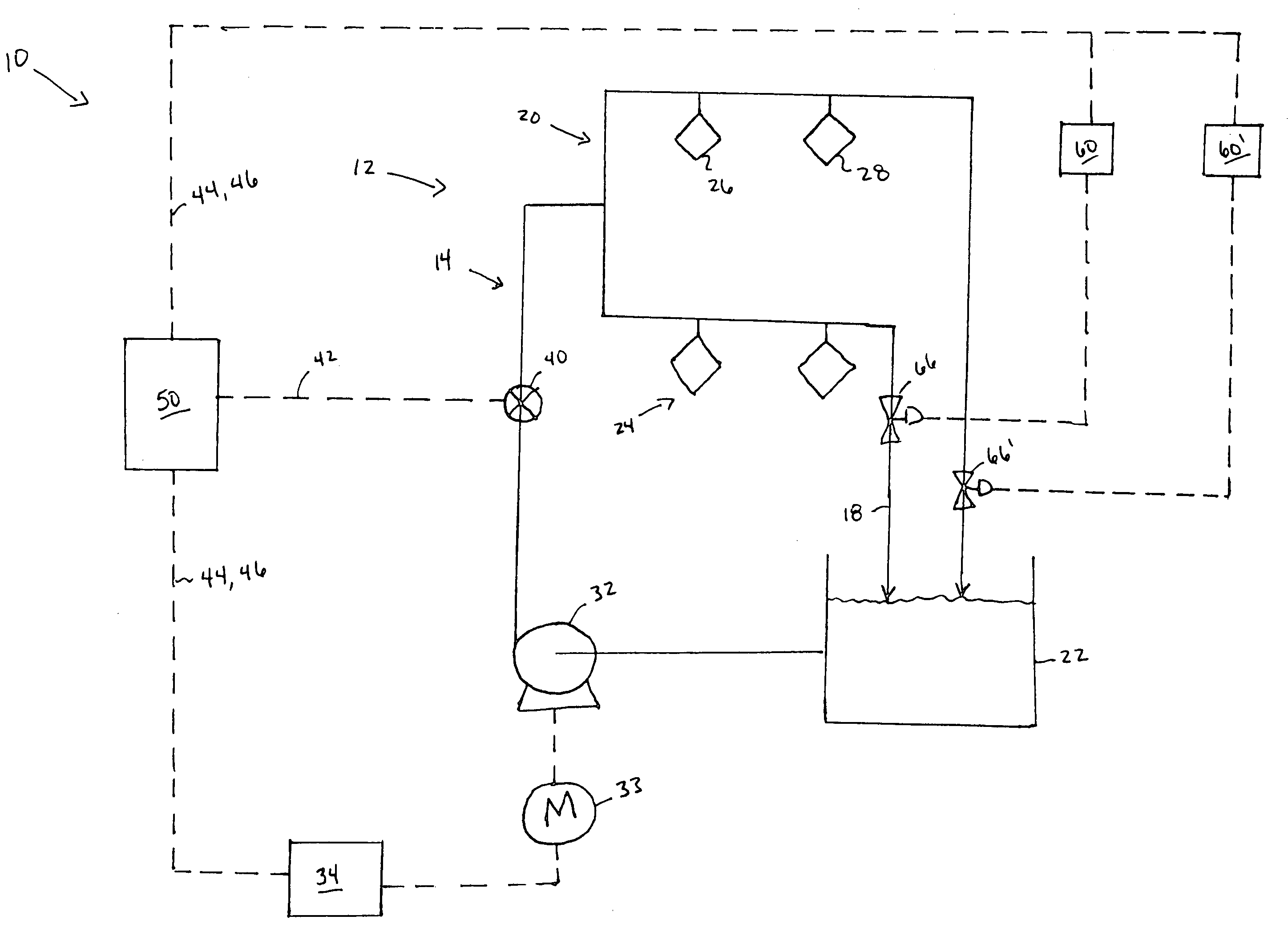

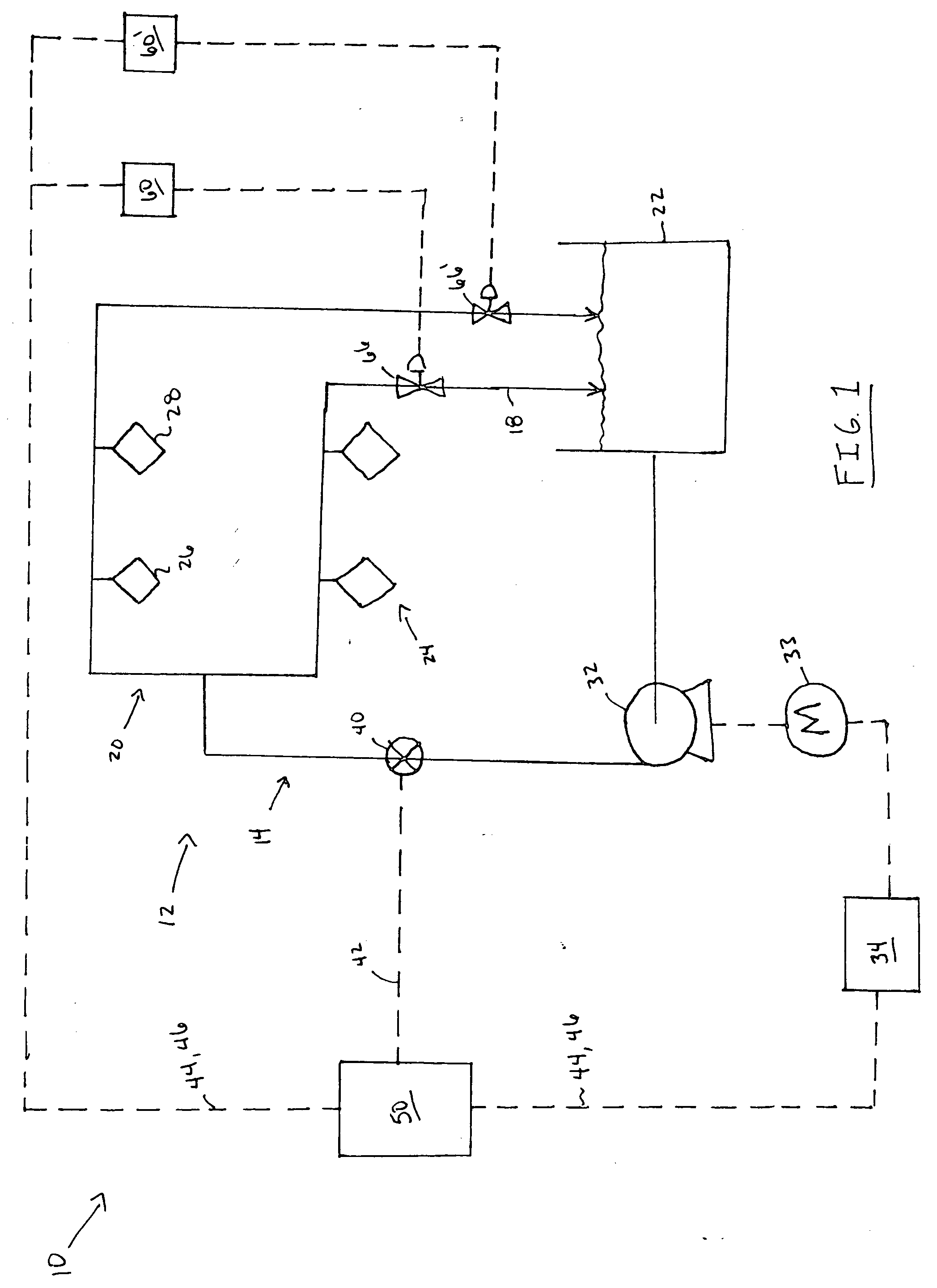

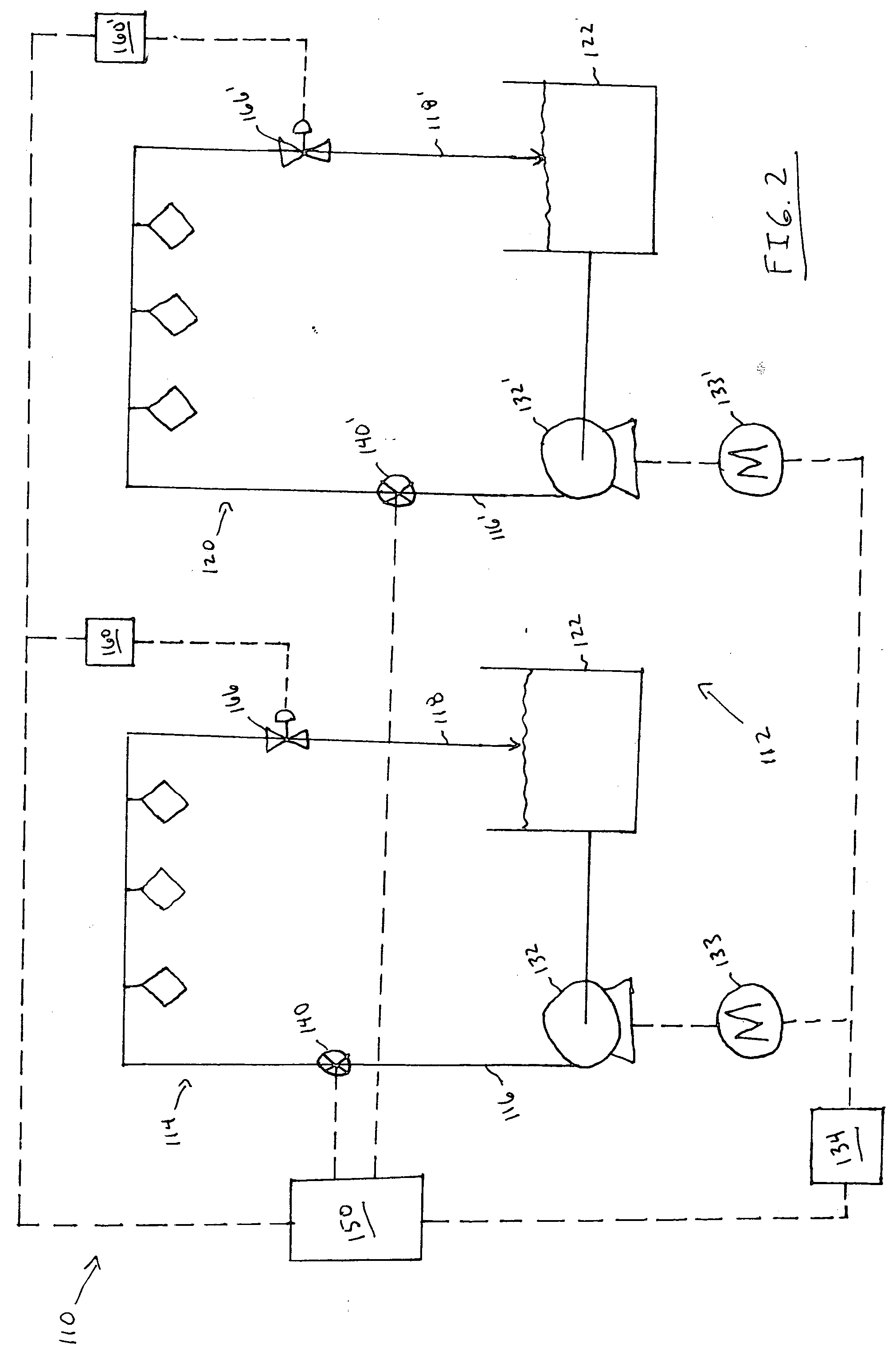

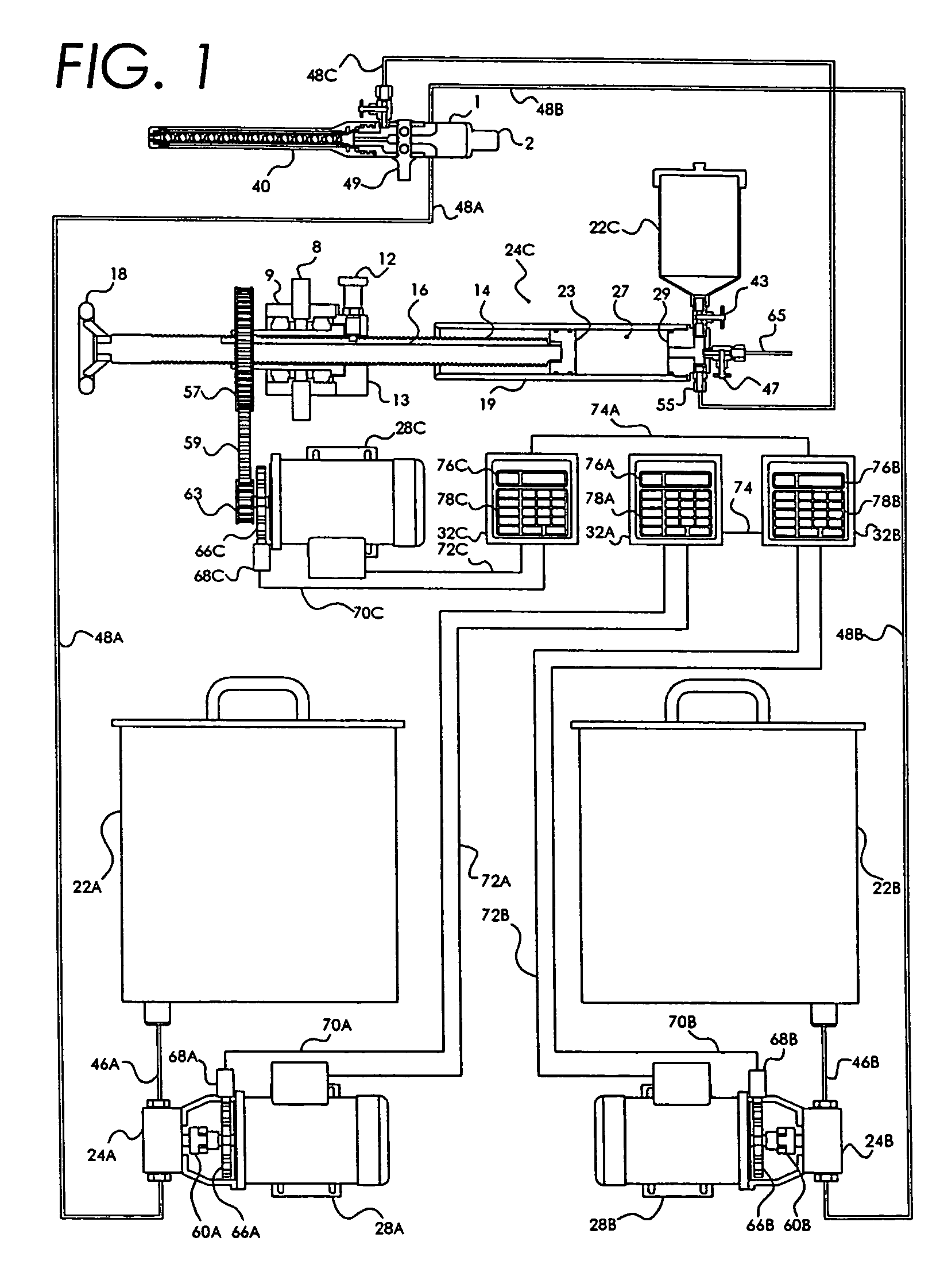

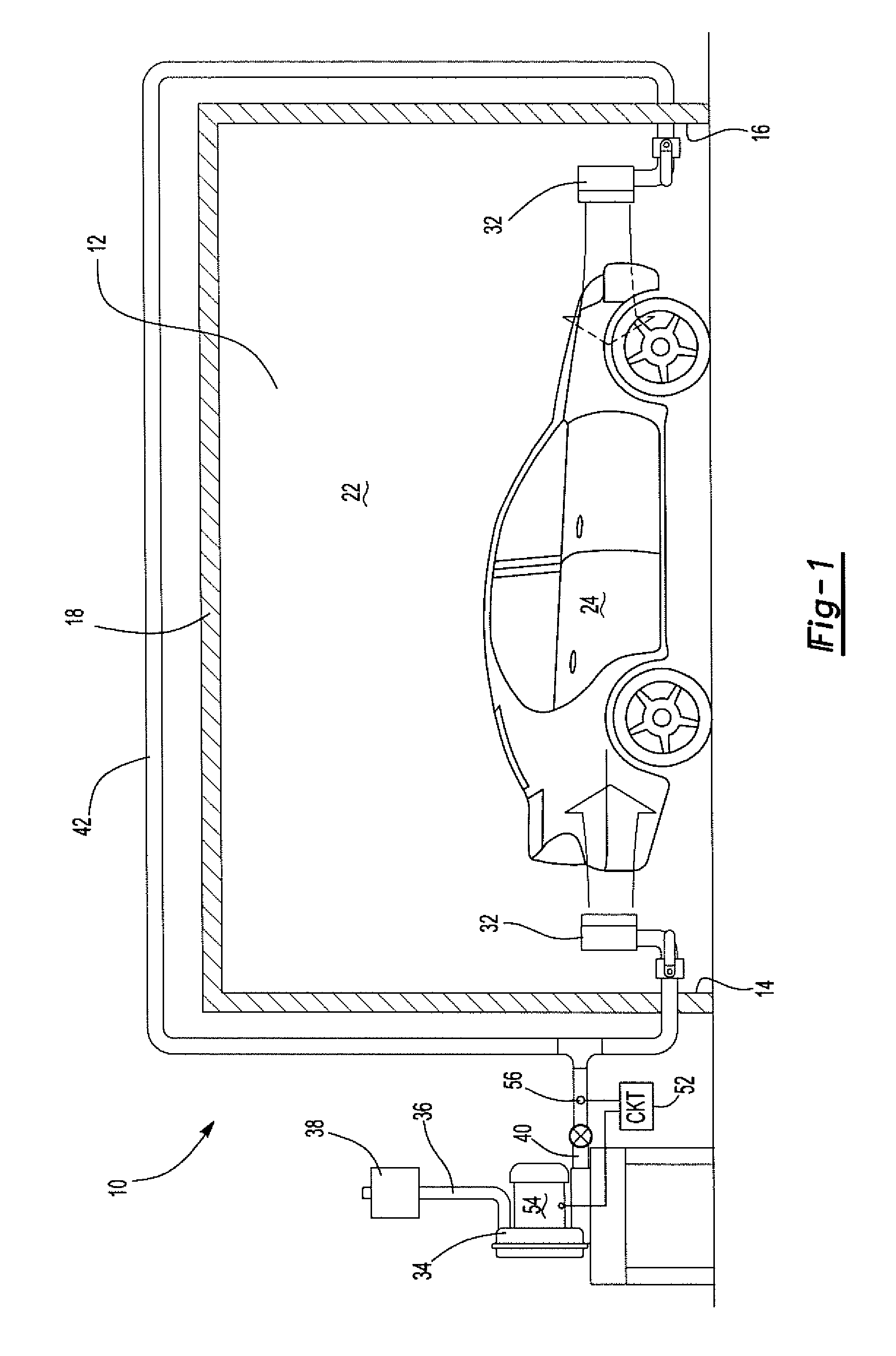

Paint circulation system

InactiveUS20060177565A1Liquid surface applicatorsLiquid spraying apparatusAutomotive paintEngineering

Circulation systems and methods for dispensing paint, more particularly those systems and methods which are configured to provide one or more paints to automotive paint applications are provided.

Owner:THE OHIO STATE UNIV RES FOUND

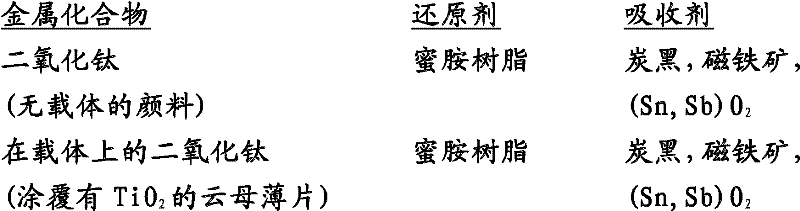

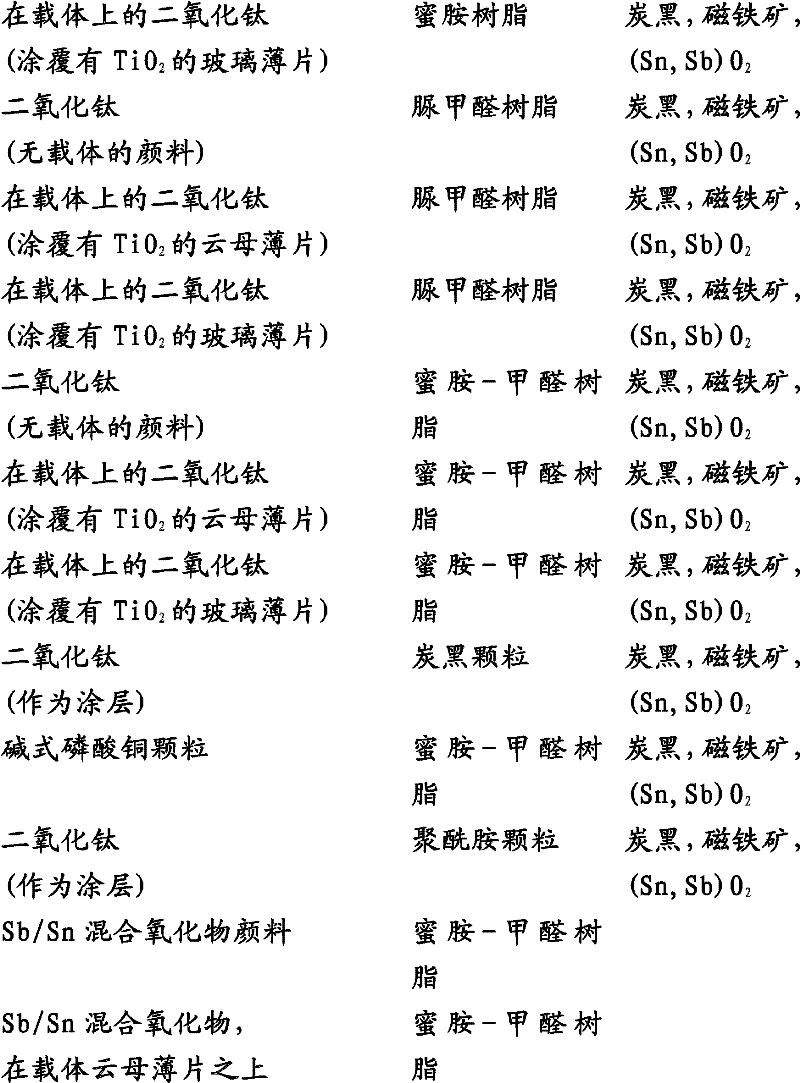

Highly reflective interference pigments with dark absorption color

InactiveUS7014700B2Reduced titanium oxideAbsorption colorPigmenting treatmentInksAutomotive paintSolvent

Highly reflective interference effect pigments with dark absorption color are obtained by reducing platy titanium dioxide.The present effect pigments may be used in cosmetics, plastics, inks, and coatings including solvent and water borne automotive paint systems.

Owner:ENGELHARD CORP

Highly reflective interference pigments with dark absorption color

InactiveUS20050154082A1Reduced titanium oxideAbsorption colorPigmenting treatmentInksAutomotive paintSolvent

Highly reflective interference effect pigments with dark absorption color are obtained by reducing platy titanium dioxide. The present effect pigments may be used in cosmetics, plastics, inks, and coatings including solvent and water borne automotive paint systems.

Owner:ENGELHARD CORP

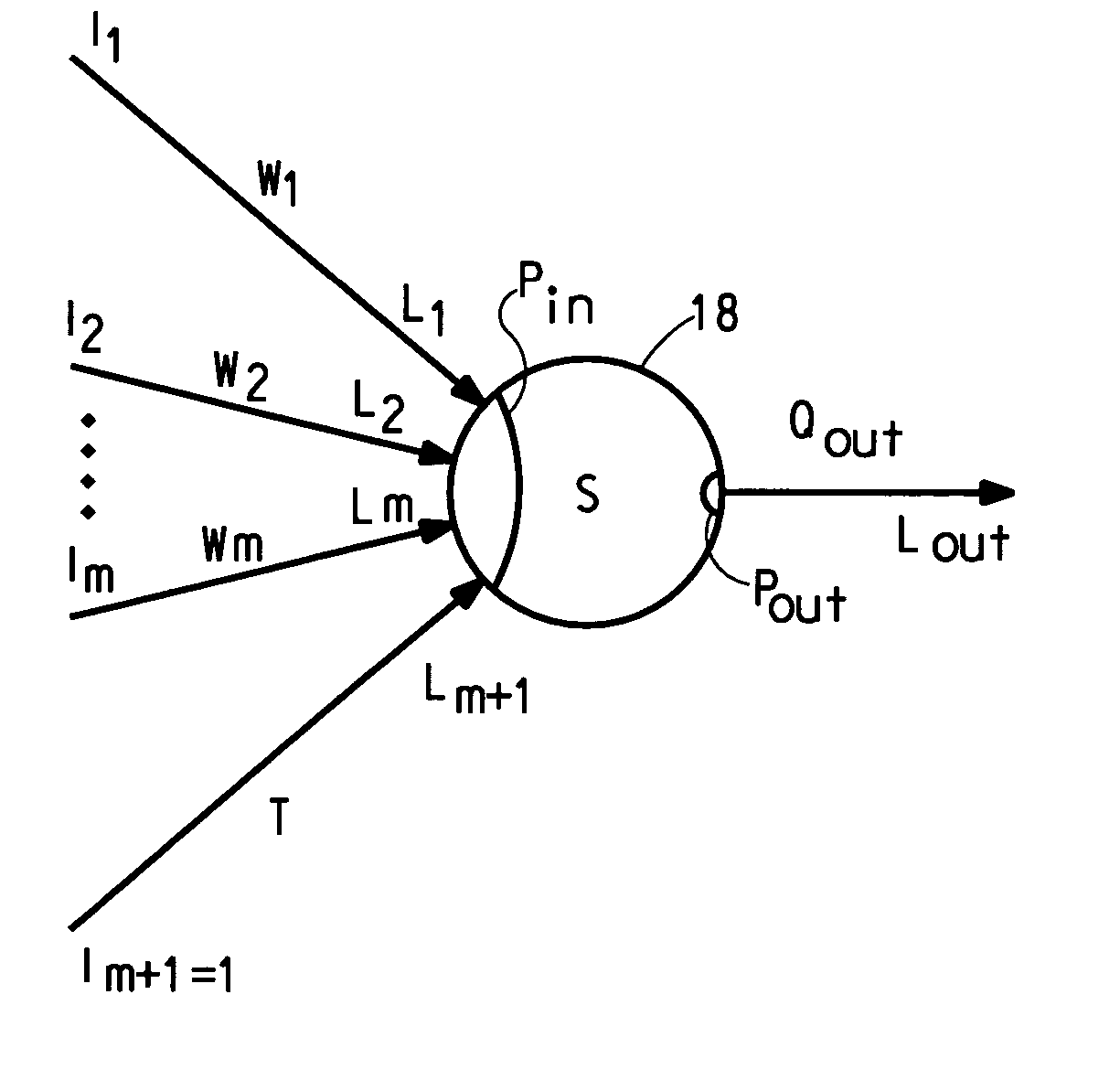

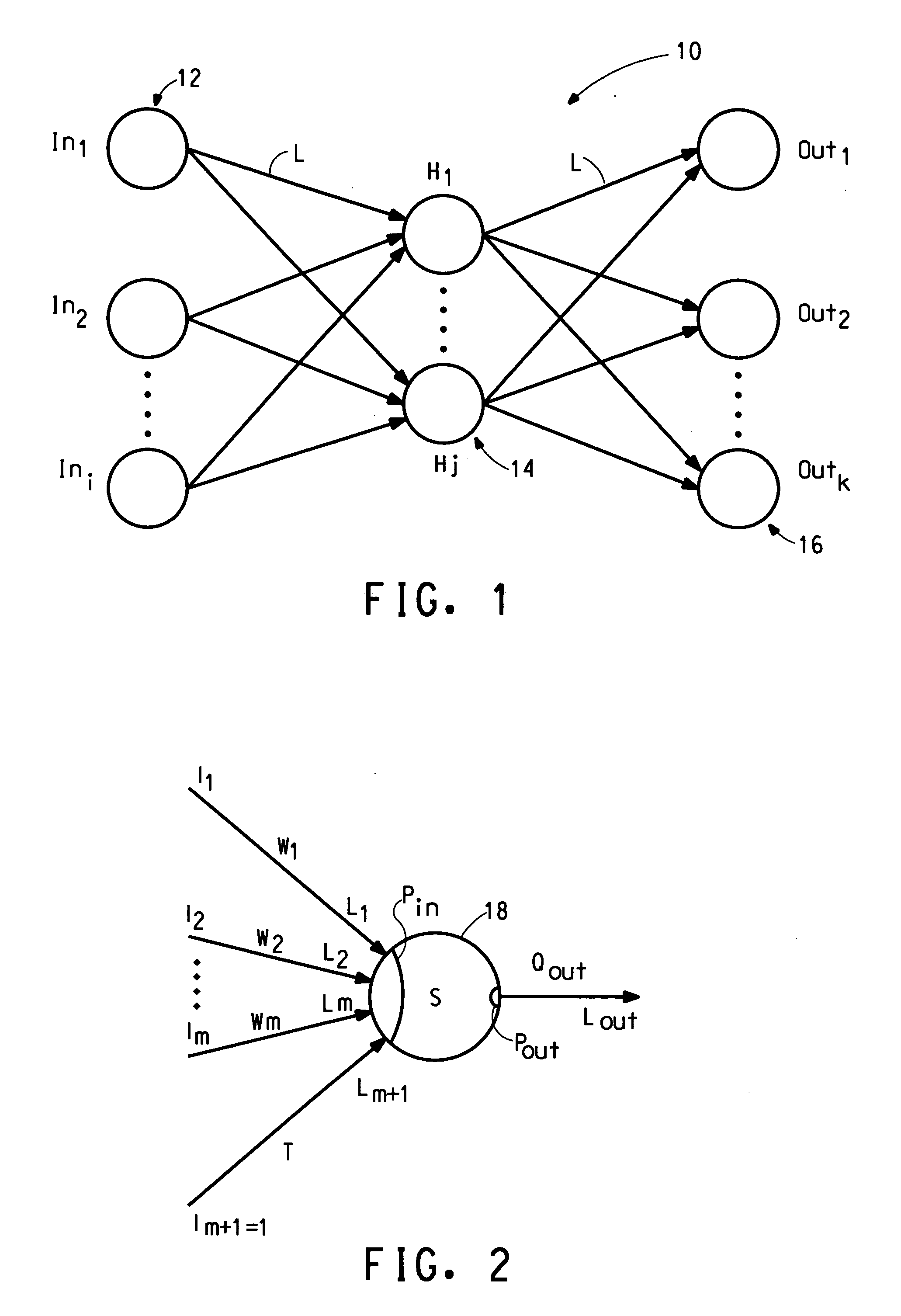

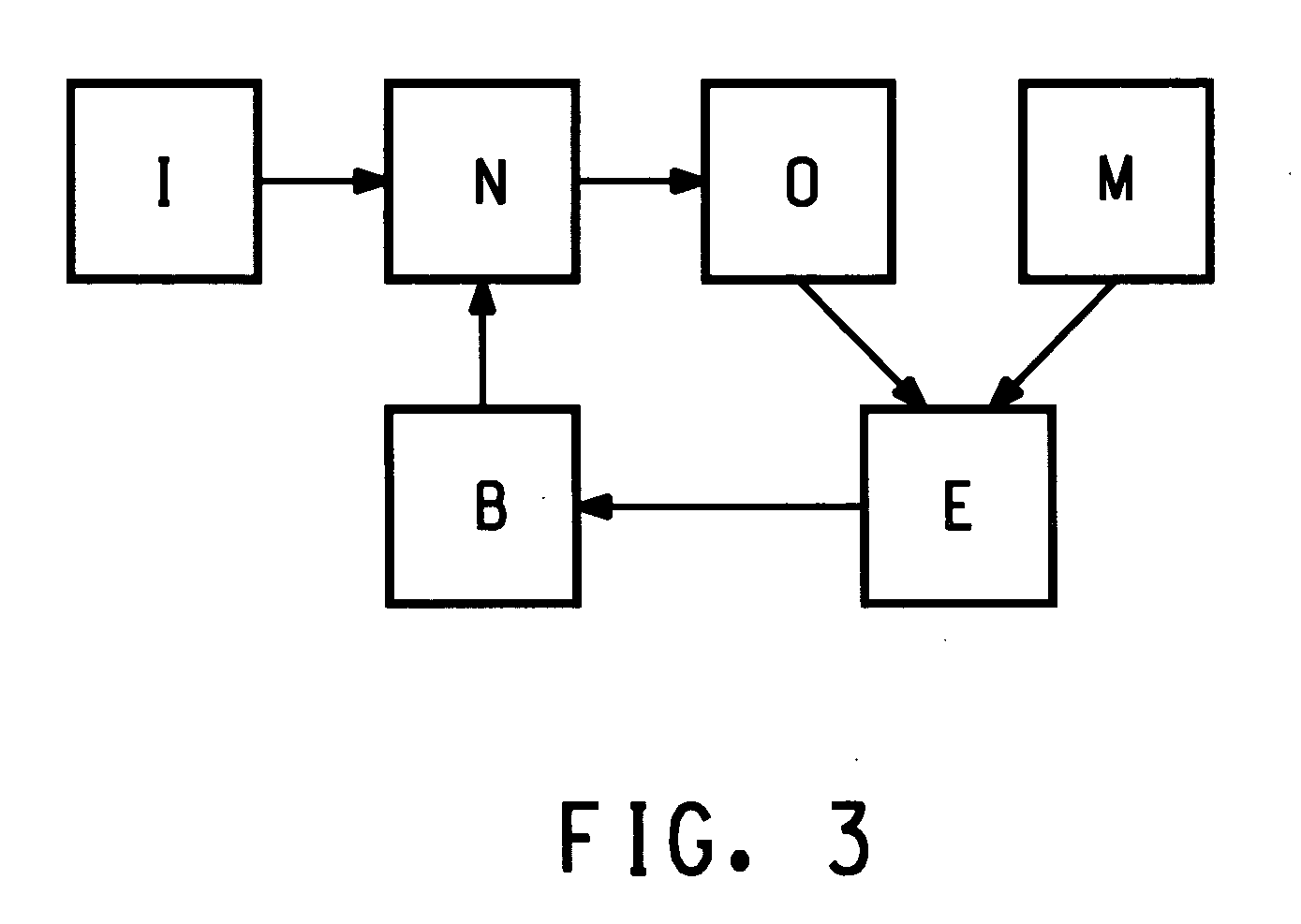

Method and apparatus for predicting properties of a chemical mixture

The present invention relates to a method and apparatus for predicting the non-color properties of a chemical mixture, such as an automotive paint, using an artificial neural network. The neural network includes an input layer having nodes for receiving input data related to the chemical components of the mixture and environmental and process conditions that can affect the properties of the mixture. An output layer having nodes generate output data which predict the properties of the chemical mixture as a result of variation of the input data. A hidden layer having nodes is connected to the nodes in the input and output layers. Weighted connections connect the nodes of the input, hidden and output layers and threshold weights are applied to the hidden and output layer nodes. The connection and threshold weights have values to calculate the relationship between input data and output data. The data to the input layer and the data to the output layer are interrelated through the neural network's nonlinear relationship. When implemented, accurate predictions of the final properties of the mixture can be obtained. The invention is especially useful in relating automotive paint formulation variables (e.g., paint ingredient amounts and application process conditions) to physical properties (e.g., viscosity, sag), appearance (e.g., hiding, gloss, distinctness of image) or other measured properties enabling comparison of formula properties to target values or tolerances without expensive experimental work.

Owner:EI DU PONT DE NEMOURS & CO

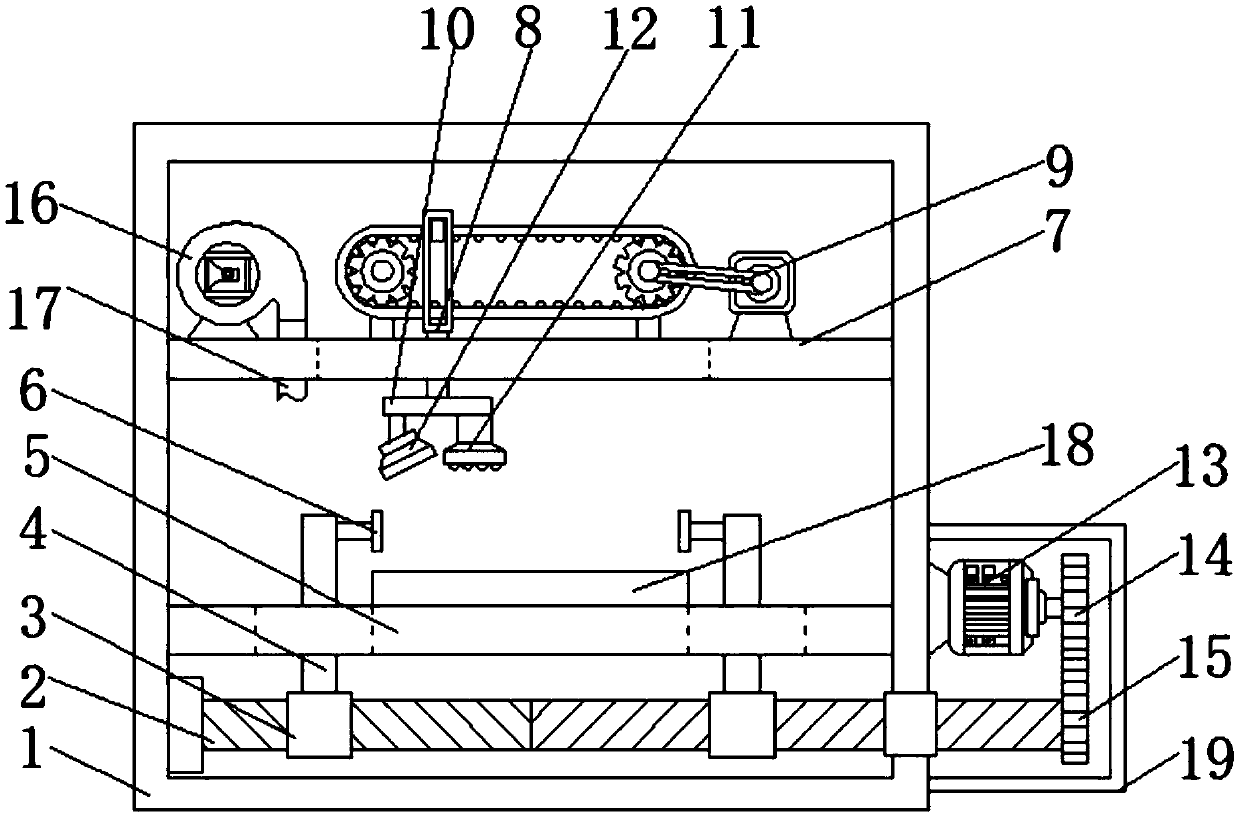

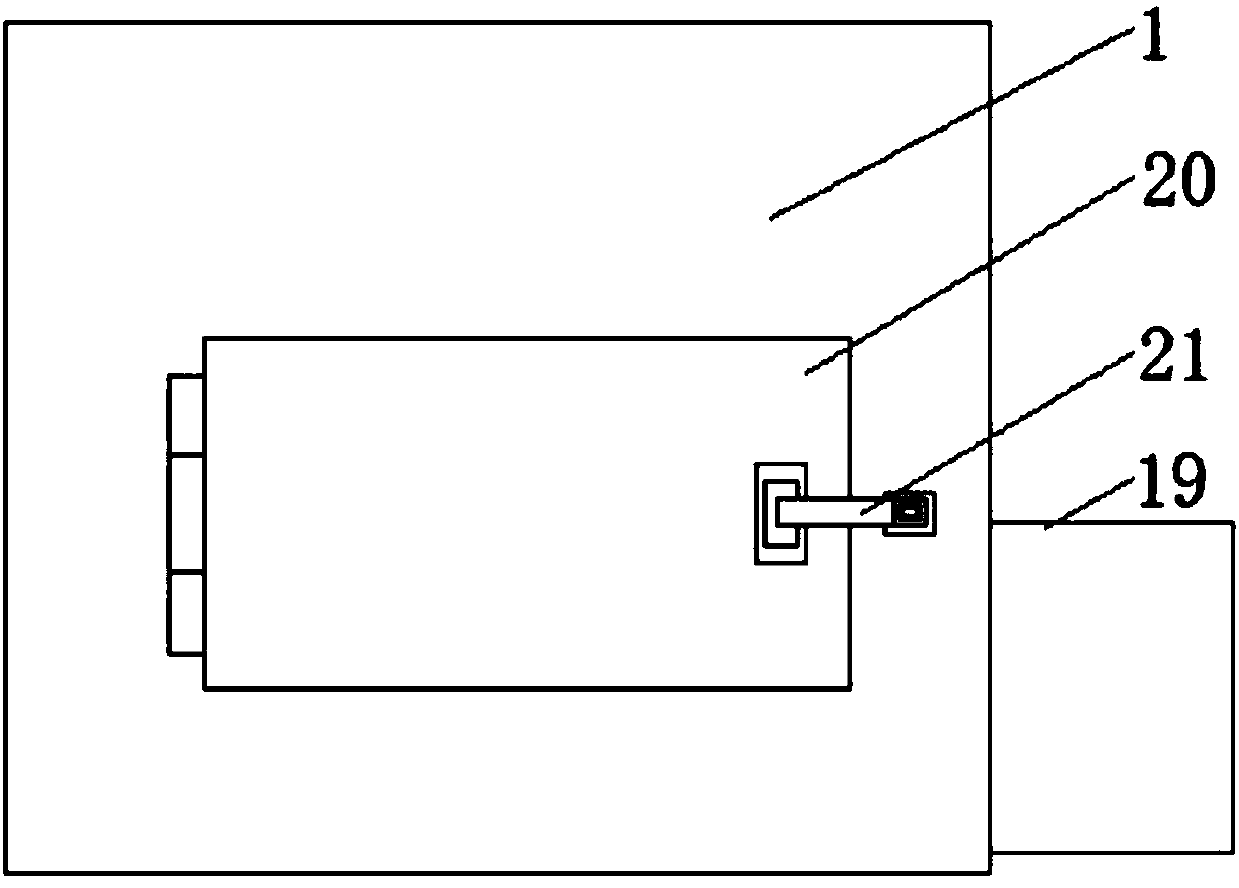

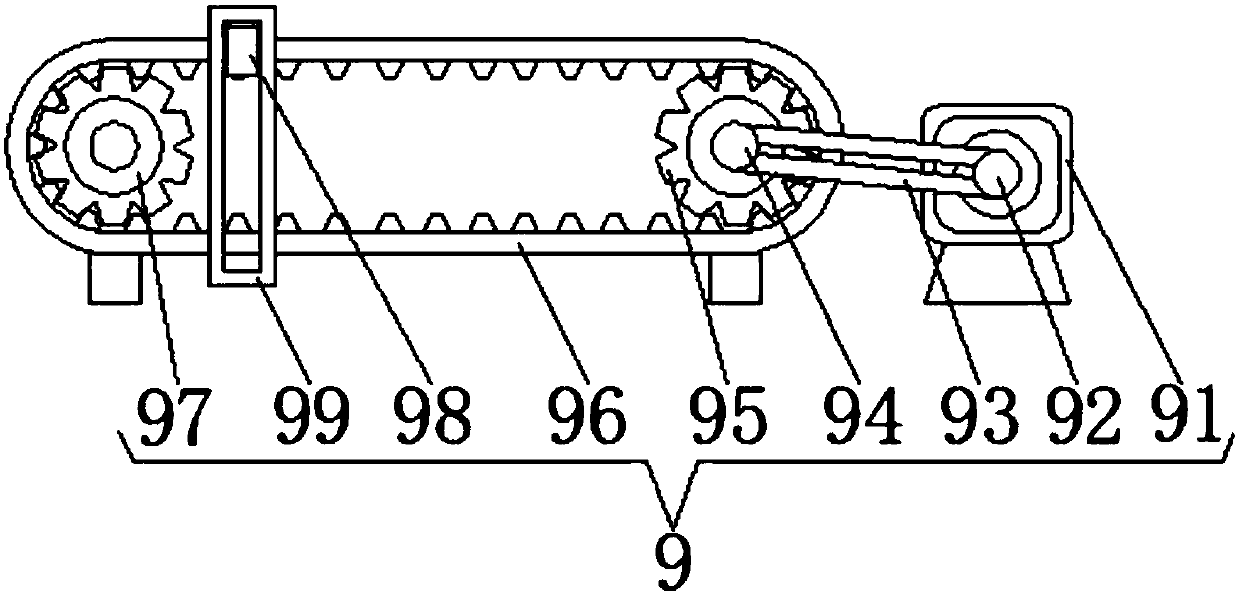

Plate paint spraying and drying device for automobile production

InactiveCN107899833AImprove drying rateFast processingSpray boothsAutomotive paintAgricultural engineering

The invention discloses a plate paint spraying and drying device for automobile production, which comprises a housing, a support plate is fixedly connected between the two sides of the inner wall of the housing, and a screw rod is rotatably connected between the two sides of the inner wall of the housing. Both sides of the surface of the screw rod are screw-connected with movable blocks, and the top of the movable block is fixedly connected with a vertical plate, and the top of the vertical plate passes through the support plate and extends to the top of the support plate, and the two vertical plates Both opposite sides are fixedly connected with clamping plates, and a horizontal plate is fixedly connected between the two sides of the inner wall of the housing. The invention relates to the technical field of painting of automobile panels. The paint spraying and drying device for plates used in automobile production blows air on the plates after painting to speed up the drying rate of the paint surface, which is beneficial to increase the processing speed and production efficiency, and fixes the plates so that the plates remain stable during processing It is beneficial to improve the uniformity of the paint surface and improve the production quality.

Owner:HEFEI DONGLU MACHINERY MFG

Process for monitoring production of compositions

InactiveUS7264160B2Inhibit productionGuarantee product qualityTicket-issuing apparatusDigital data processing detailsAutomotive paintEngineering

The present invention is directed to a process for monitoring production of a target composition, such as an automotive paint or an architectural paint and a monitoring device used therein. The process includes (a) identifying one or more formulas associated with identification criteria of the target composition, the formula providing a required inventory for making a desired amount of the target composition; (b) generating a current inventory; (c) terminating the process if the current inventory does not match with a stored inventory; or (d) continuing the process if the current inventory matches with the stored inventory. The process further comprises (d1) comparing the current inventory against the required inventory to ascertain whether said current inventory fulfills said required inventory; (d2) generating a supplementary inventory if the current inventory partially fulfills the required inventory; (d3) dispensing required items listed in the required inventory from current items listed in the current inventory, supplementary items listed in the supplementary inventory, or a combination thereof to make the desired amount of the target composition; and (d4) generating an updated inventory. The process can be also used to control the inventory by shipping just in time any components required to produce target compositions, such as refinish tints used in automotive refinish paints.

Owner:AXALTA COATING SYST IP CO LLC

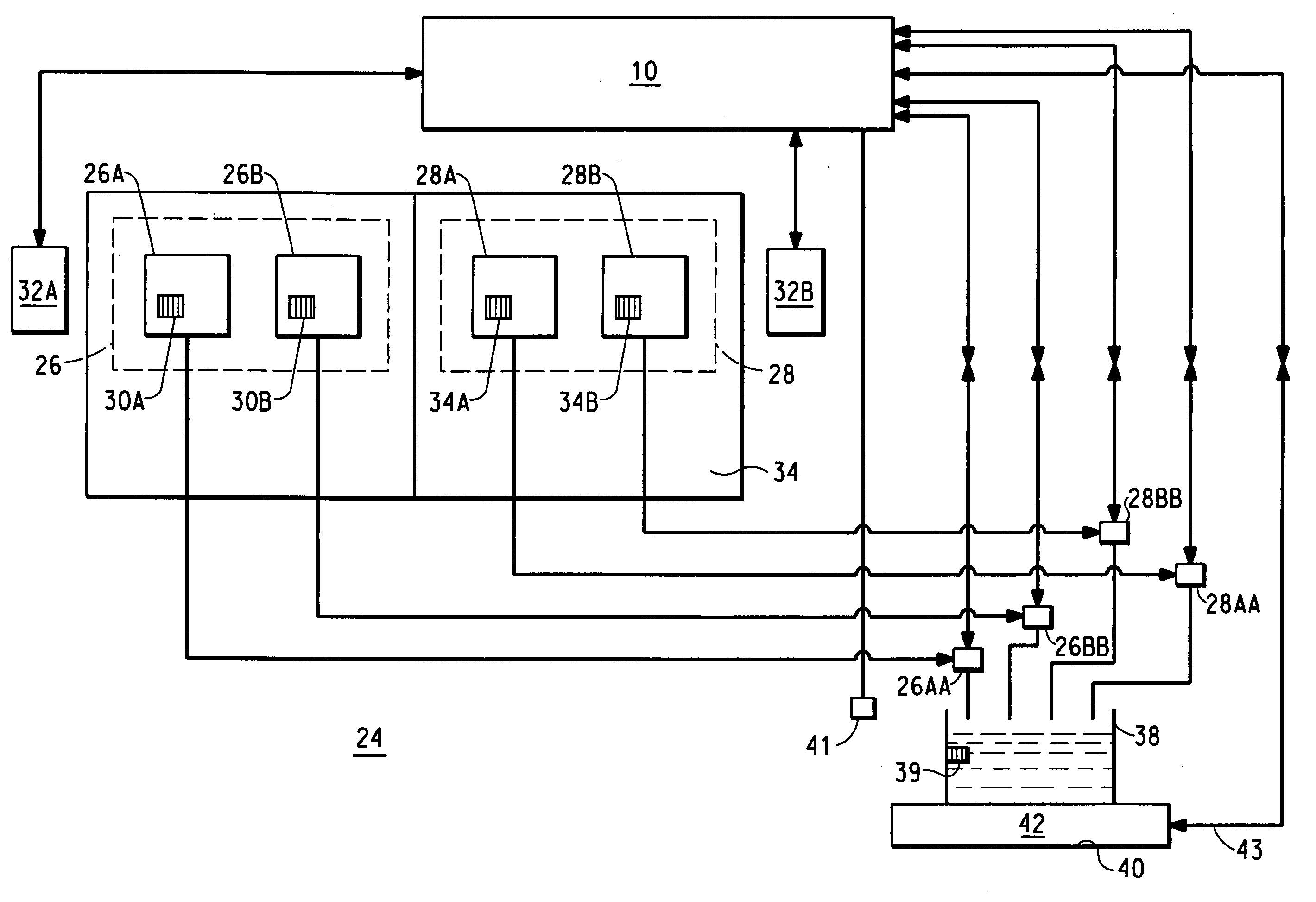

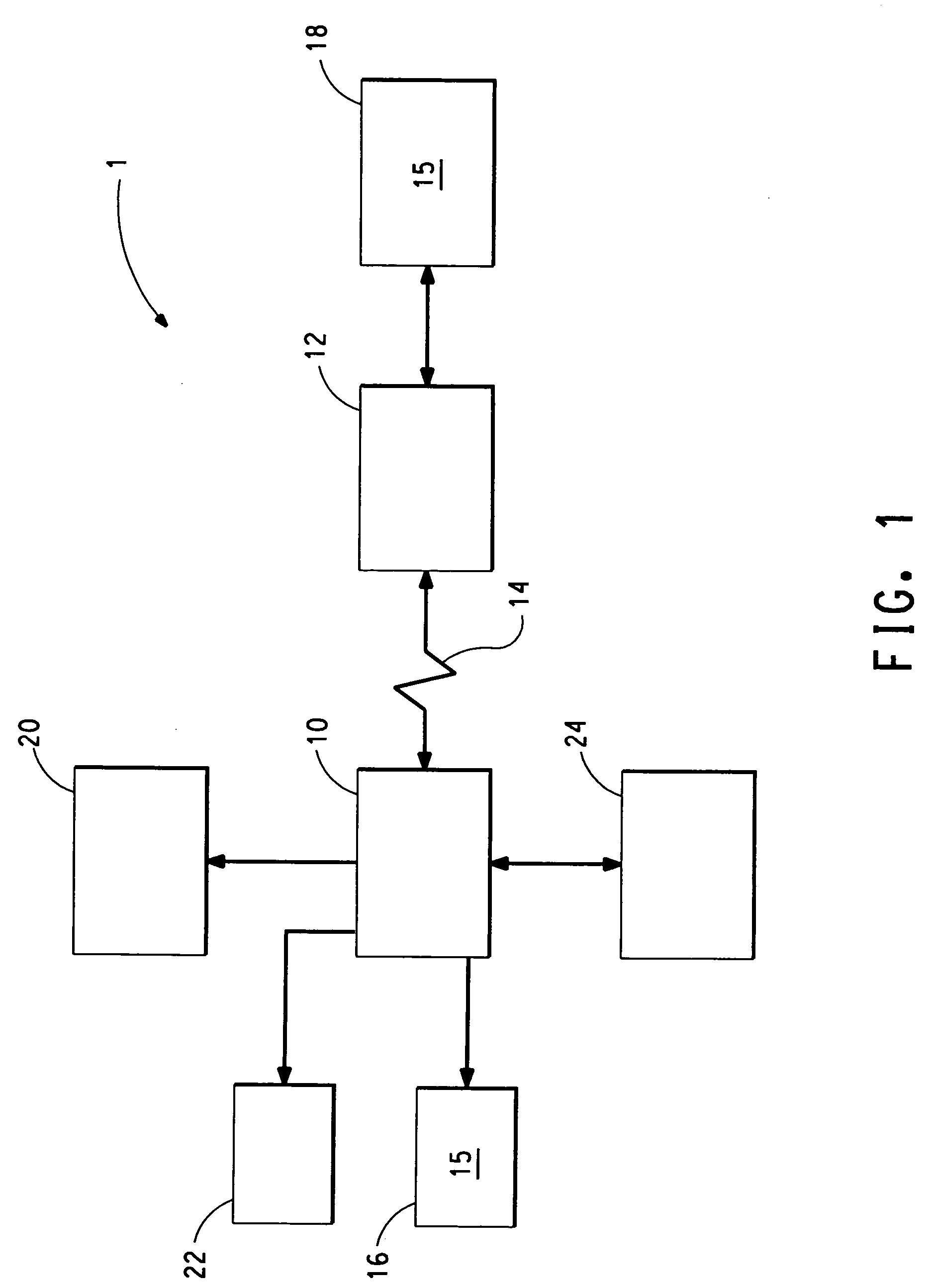

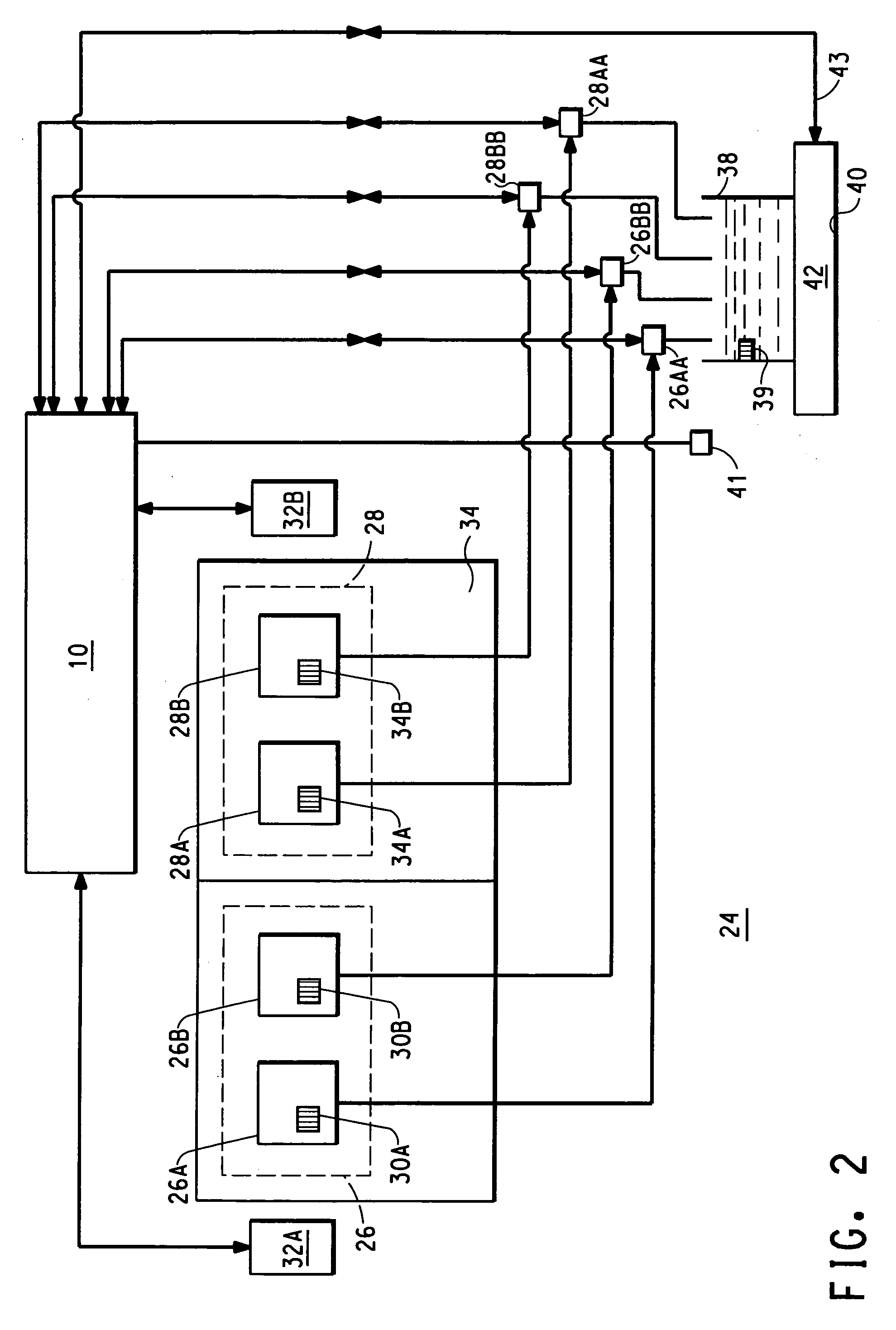

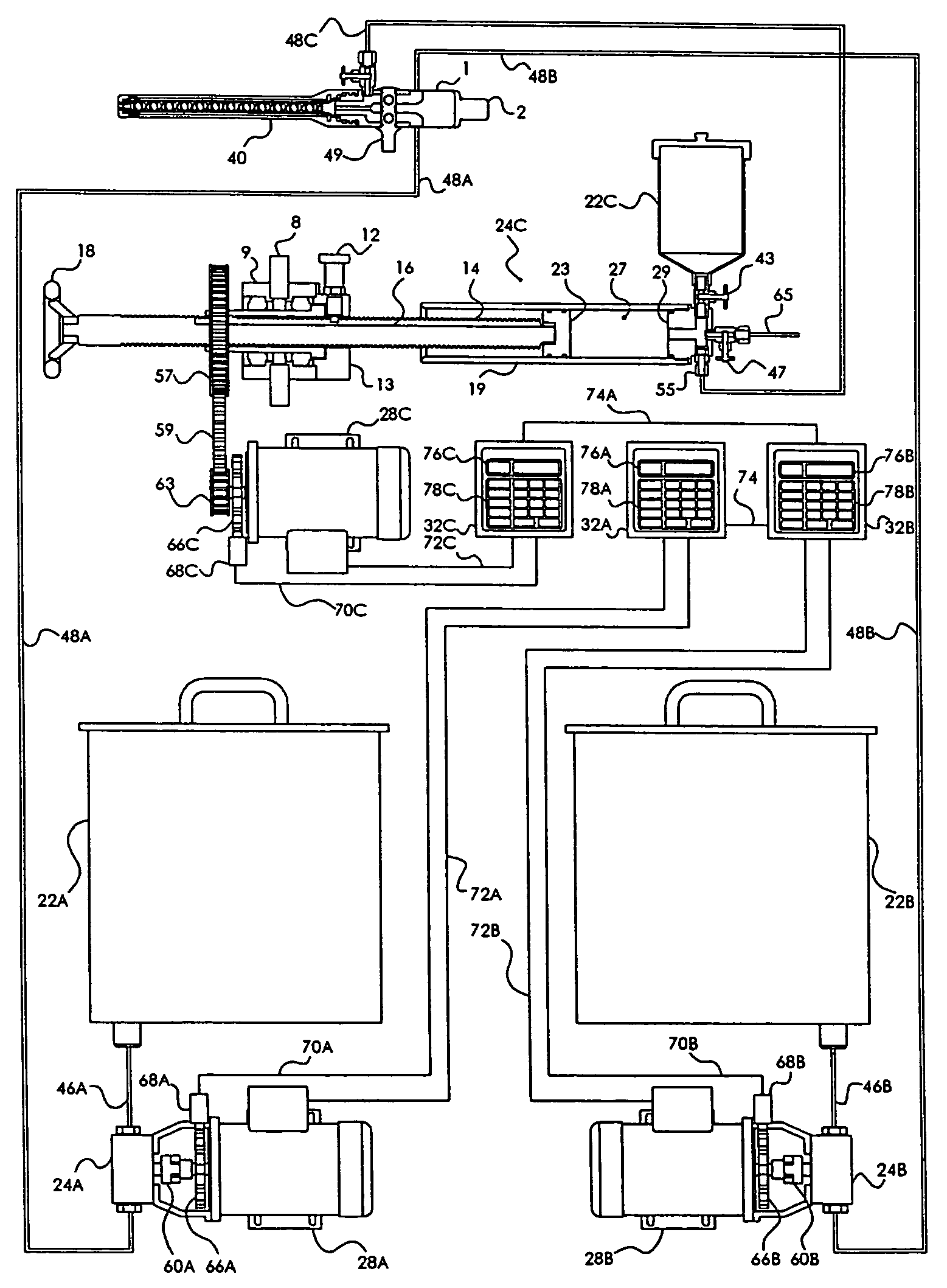

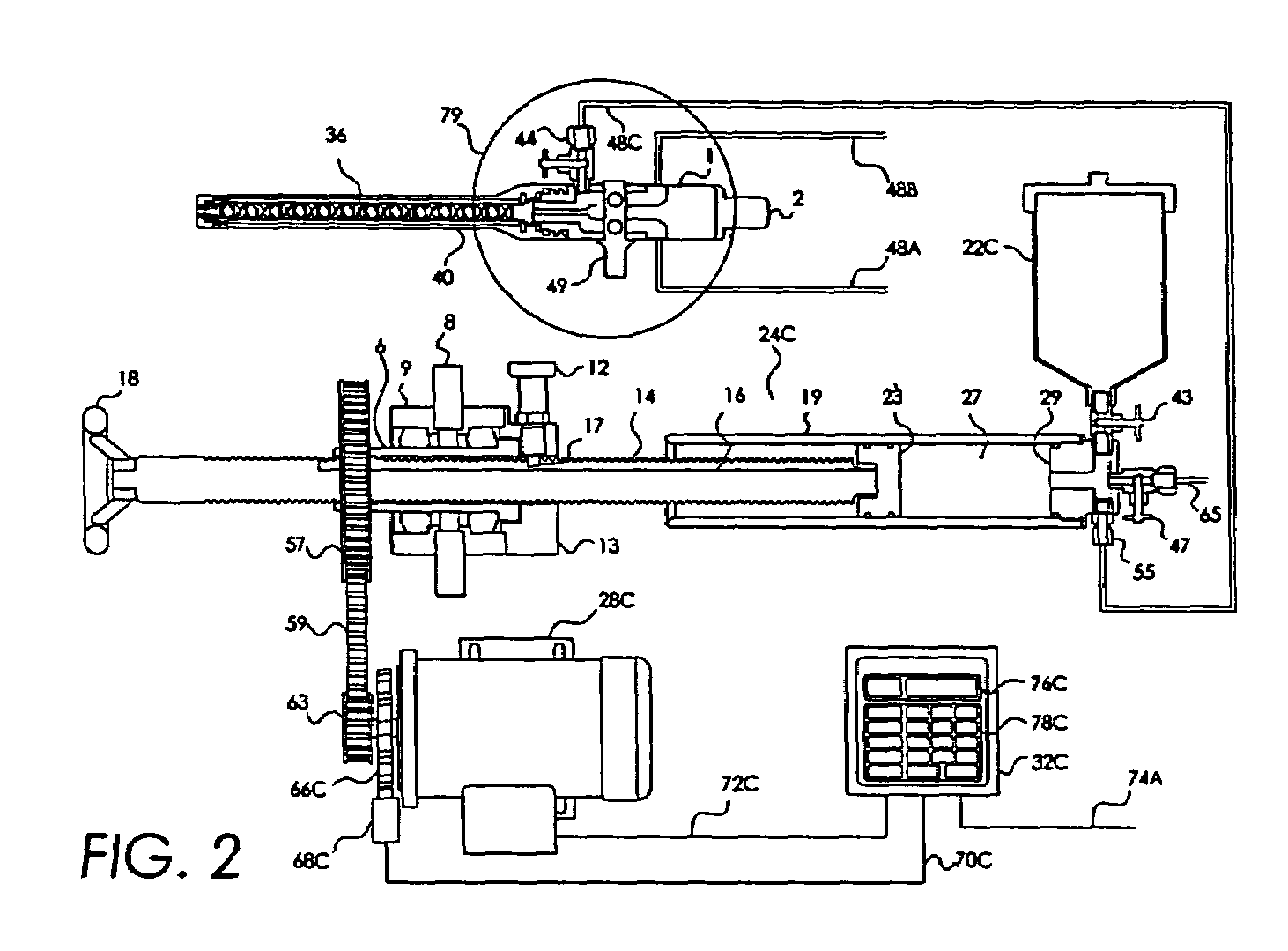

Third stream automotive color injection

InactiveUS7025286B1Improve matchFast and efficient change of colorOpening closed containersBurnersAutomotive paintEngineering

A method and system are provided for dispensing a colored polymerizing composition. Two reactive components and one color component are pumped from respective containers at a metered volume. The color component, which is preferably a low-viscosity automotive paint is injected into either the first or second stream of reactive component at a point immediately prior to mixing all components in a dispensing device for dispensing the resulting colored fluid mixture onto a surface to be coated. The mixture may be dispensed by pouring or spraying onto the surface. The method and system are particularly useful for mixing and dispensing colored polyurethane or polyurea coatings, such as for spray-on truck bed liners.

Owner:LANGEMAN GARY D

Pigment for laser marking

InactiveCN102356131AMaterial nanotechnologyThin material handlingAutomotive paintPulp and paper industry

The present invention relates to an intrinsically markable laser pigment in the form of a reducible metal compound present as a preparation, and to the use thereof in inorganic systems and in organic polymers, in particular plastics, paints, automotive paints, power paints, printing inks, paper coatings, and paper pulp.

Owner:MERCK PATENT GMBH

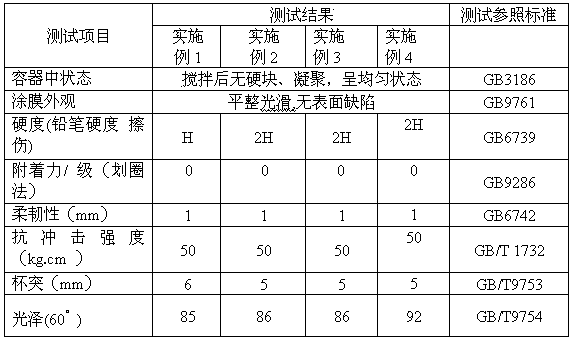

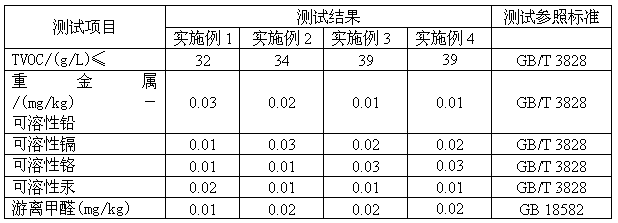

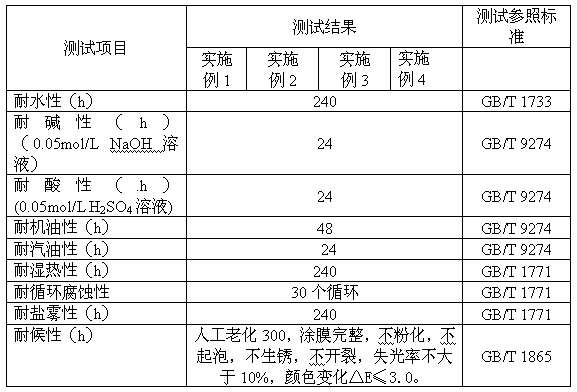

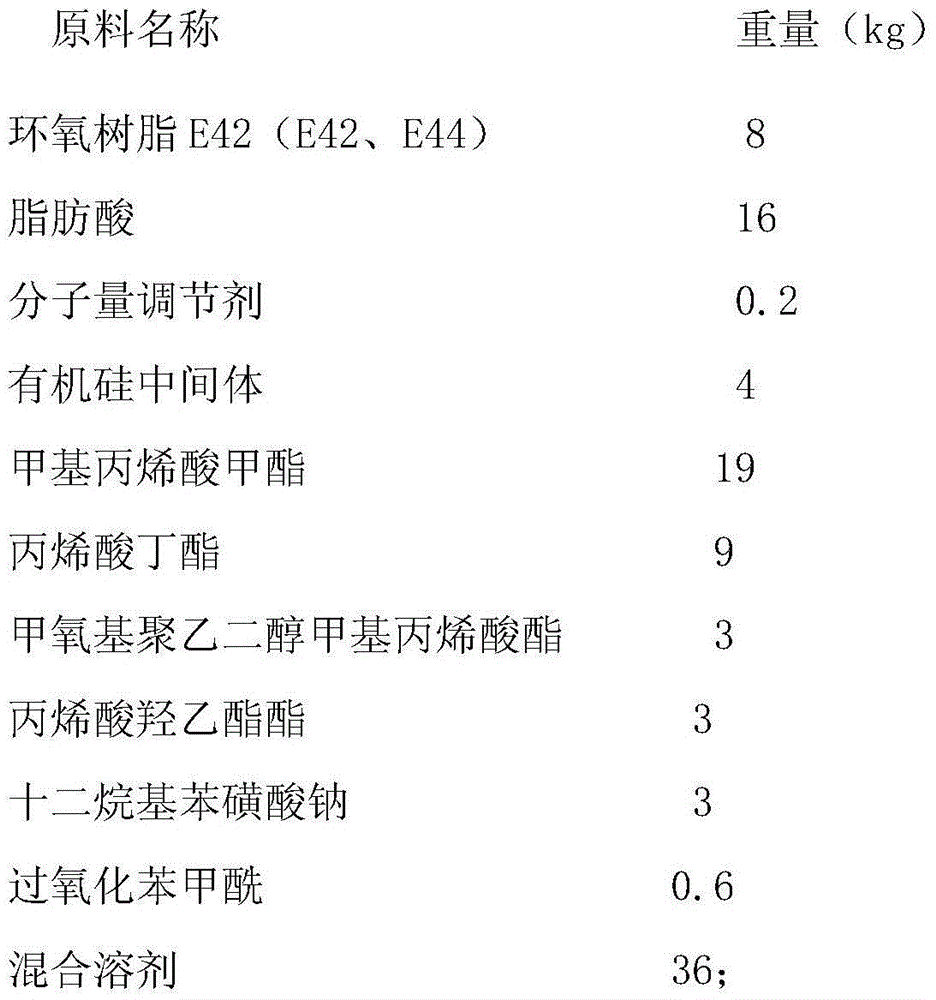

Water-based automotive paint, and preparation method and application method thereof

The invention discloses a water-based automotive paint, and a preparation method and an application method thereof. The water-based automotive paint is prepared from water-based castor oil-modified alkyd resin, water-based acrylic resin, water-based color paste, amino resin A, amino resin B, a coalescing agent, deionized water, a dispersing agent, a wetting agent, a pH regulator, a defoamer, anti-settling pulp, a corrosion remover, a thickener, an adhesion promoter and a flatting agent. The preparation method refers to orderly adding the raw materials to evenly agitate. The application method comprises the following steps: evenly mixing and stirring the water-based automotive paint and water according to the ratio of 1:(0.1-0.3), and then spraying, placing, baking and solidifying, so as to obtain a stoving varnish coating. A solvent stoving varnish is replaced by using the water-based automotive paint disclosed by the invention; a complete coating, of which the adhesive force is 0 level, and the flexibility is 1mm, which is excellent in weather fastness, high in fullness, and vivid in color and luster, and has excellent protectiveness and decorative property can be formed on the metal surface; the water-based automotive paint is safe in production procedure, environment-friendly, simple, and environment-friendly and convenient in construction.

Owner:肇庆千江高新材料科技股份公司

Aqueous thermochromic and photochromic motor vehicle paints and methods of use

InactiveUS20060116442A1Extending color lifeCommercially viableSpecial surfacesThermosensitive paintsJet aeroplaneThermochromism

The invention consists of the composition of reversible thermochromic and photochromic leuco dyes wherein the thermochromic and photochromic material is in the form of microencapsulated powder, or aqueous slurry and combined with non-solvent, aqueous based automotive paint for use in painting, coating, or covering the exterior surfaces of motor vehicles, more specifically automobiles, trucks, motorcycles, boats, airplanes, snowmobiles, bicycles, and any other propelled land, sea, or air vehicle, the process of applying these paints / coatings, and the methods of their use. The term “reversible leuco dye” refers to leuco dyes which have the property of going from a color state to a clear state when a stimulus is applied, and returning to the colored state when the stimulus is removed. The stimulus in this case would be exposure to heat for the thermochromic leuco dyes, or light for the photochromic ones. When applied to the exterior of a motor vehicle the reversible thermochromic leuco dye paint will cause the exterior of the motor vehicle to change colors with changes in the temperature thereof. When applied to the exterior of a motor vehicle the reversible photochromic paint described above will cause the exterior of a motor vehicle to change colors with exposure to light.

Owner:GALLO CLINTON E +1

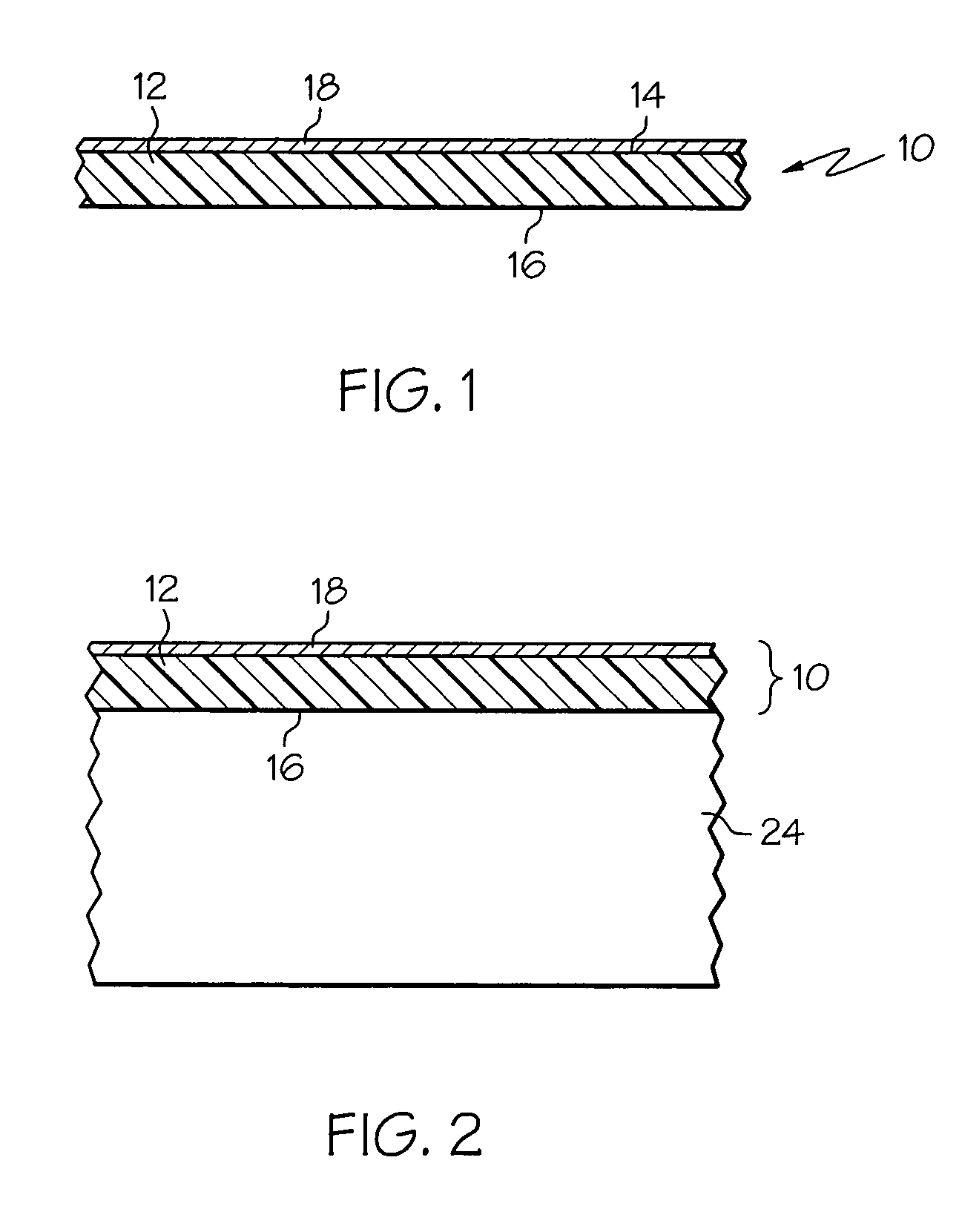

Automotive safety protective film and production process thereof

ActiveCN102807718AEnsure driving safetyAvoid collisionLamination ancillary operationsLaminationAging resistanceAutomotive paint

The invention discloses an automotive safety protective film and a production process thereof, and belongs to the technical field of automotive protection and safety. The automotive safety protective film comprises a PVC (polyvinyl chloride) material and a TPU (thermoplastic polyurethane) film, wherein colorful particles are added into the PVC material and the TPU film to be prepared into the protective film according to a mass fraction ratio. After the safety protective film is adopted, the colorful particles are added into the PVC material and the TPU film, so that the automotive paint can be prevented from being impacted by high-speed flying rocks, corroded by acid rain and irradiated by ultraviolet, and can also be prevented from being scratched mildly to achieve the safety effects of non-yellowing, no-fading and aging resistance; and the colorful paint can emit light in night lighting to remind a driver behind that a distance needs to be kept because a car is driven in front, and thus the traffic safety of vehicles is ensured.

Owner:袁少山

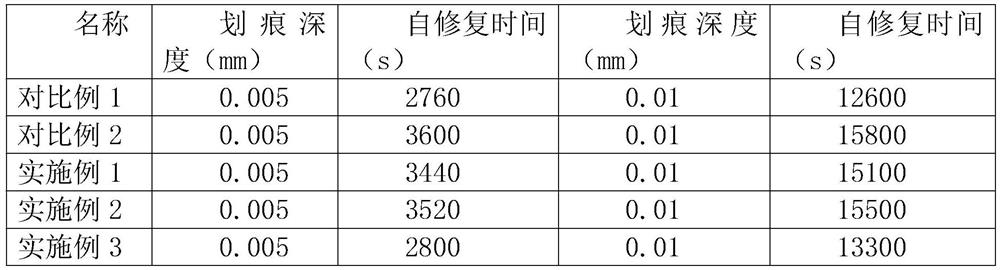

Production method of room-temperature self-repairing type waterborne polyurethane car cover with self-extinction effect

ActiveCN109517513AGood room temperature self-healing functionGood weather resistancePolyurea/polyurethane coatingsSolventIon

The invention discloses a production method of a room-temperature self-repairing type waterborne polyurethane car cover with a self-extinction effect. The production method comprises the following steps: firstly, pouring polycarbonate diol into a reaction container; slowly adding polyisocyanate and a catalyst to obtain a pre-polymer I; adding a hydrophilic chain-extending agent and a solvent; adding a small molecular chain-extending agent and a crosslinking agent and reacting to obtain a pre-polymer II; pouring into a high-speed dispersion device and adding a neutralizing agent; adding de-ionized water and dispersing and emulsifying; rapidly pouring a polyamine chain-extending agent diluted by the de-ionized water to obtain polyurethane emulsion; adding a de-foaming agent, a leveling agent, a wetting agent, a film-forming auxiliary agent and a thickening agent into a dispersion device; slowly adding the waterborne polyurethane emulsion to obtain waterborne polyurethane car cover emulsion and finishing spray coating. The car cover provided by the invention has a good room-temperature self-repairing function and also provides different glossiness and excellent weather resistance; after resin is compounded with the auxiliary agent, a mixture is sprayed on the surface of a car; a paint surface of the car can be protected for a long time and can be stripped at any time.

Owner:成都德科立高分子材料有限公司

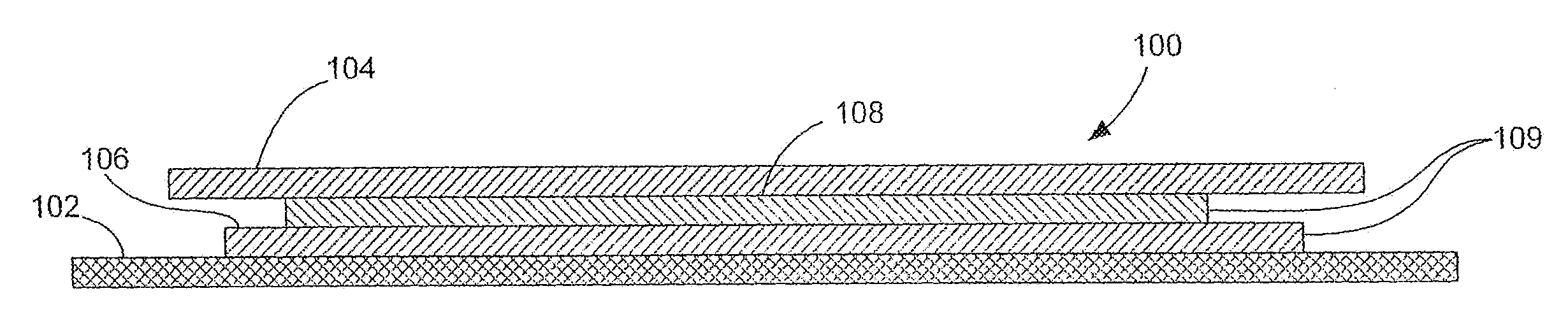

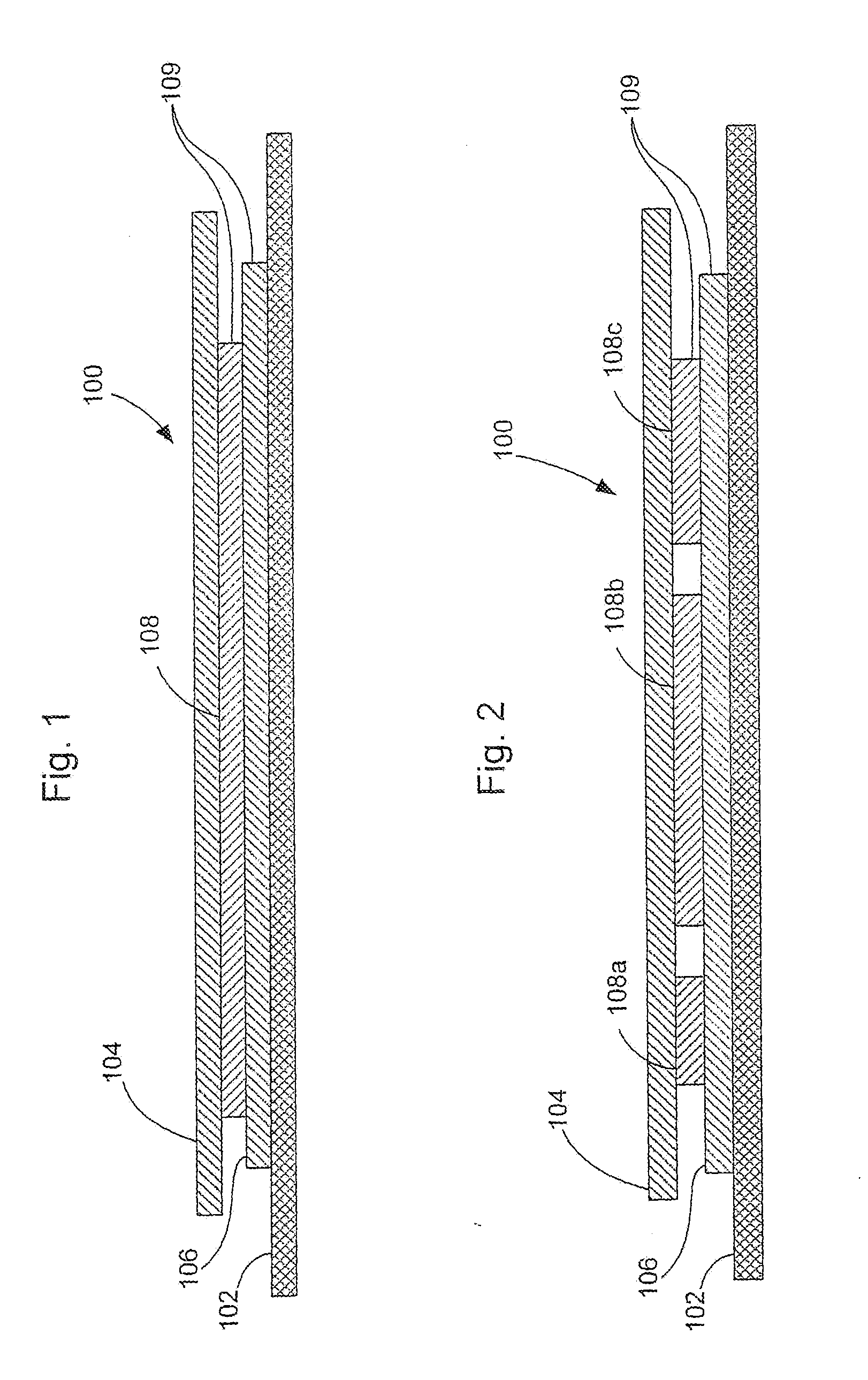

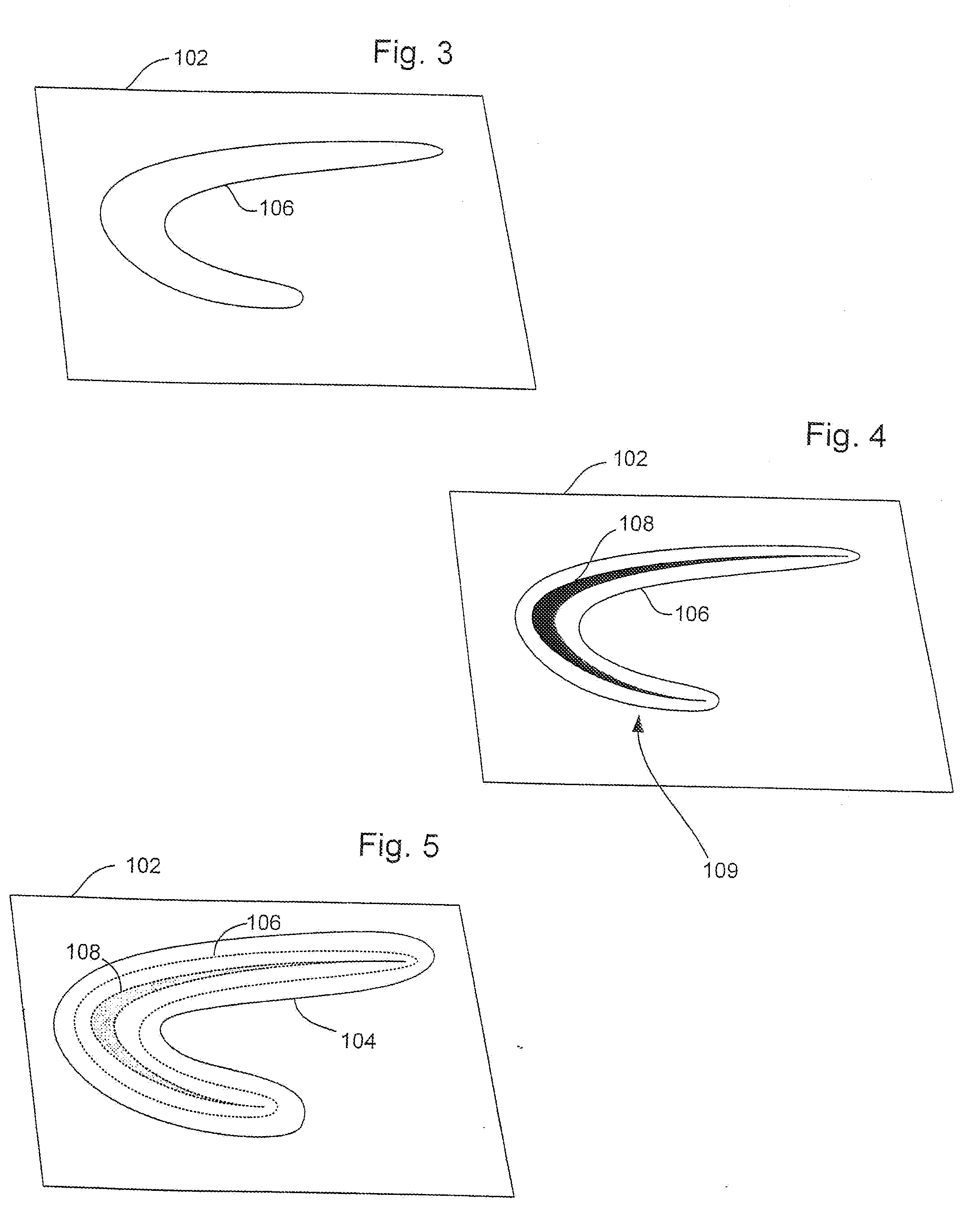

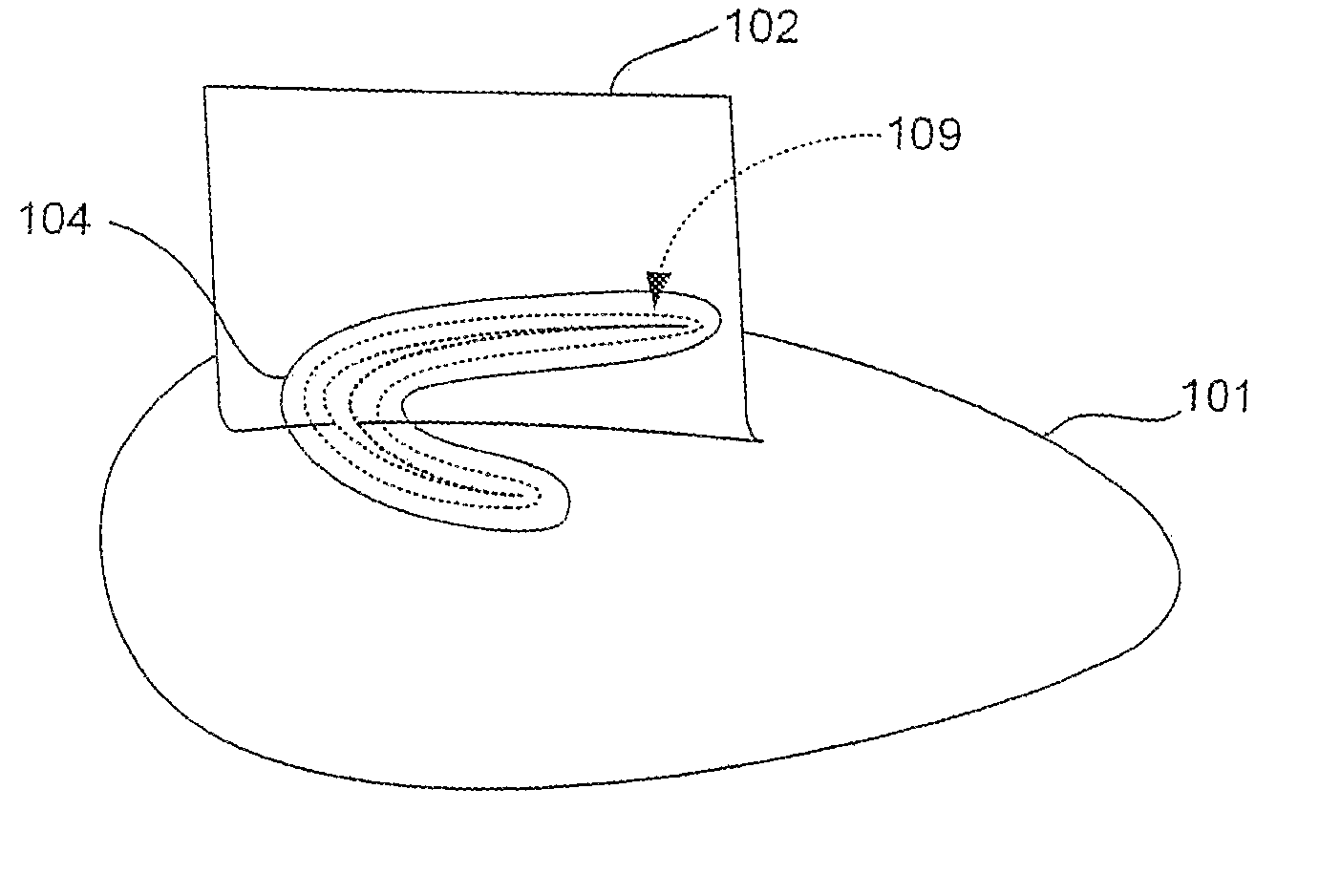

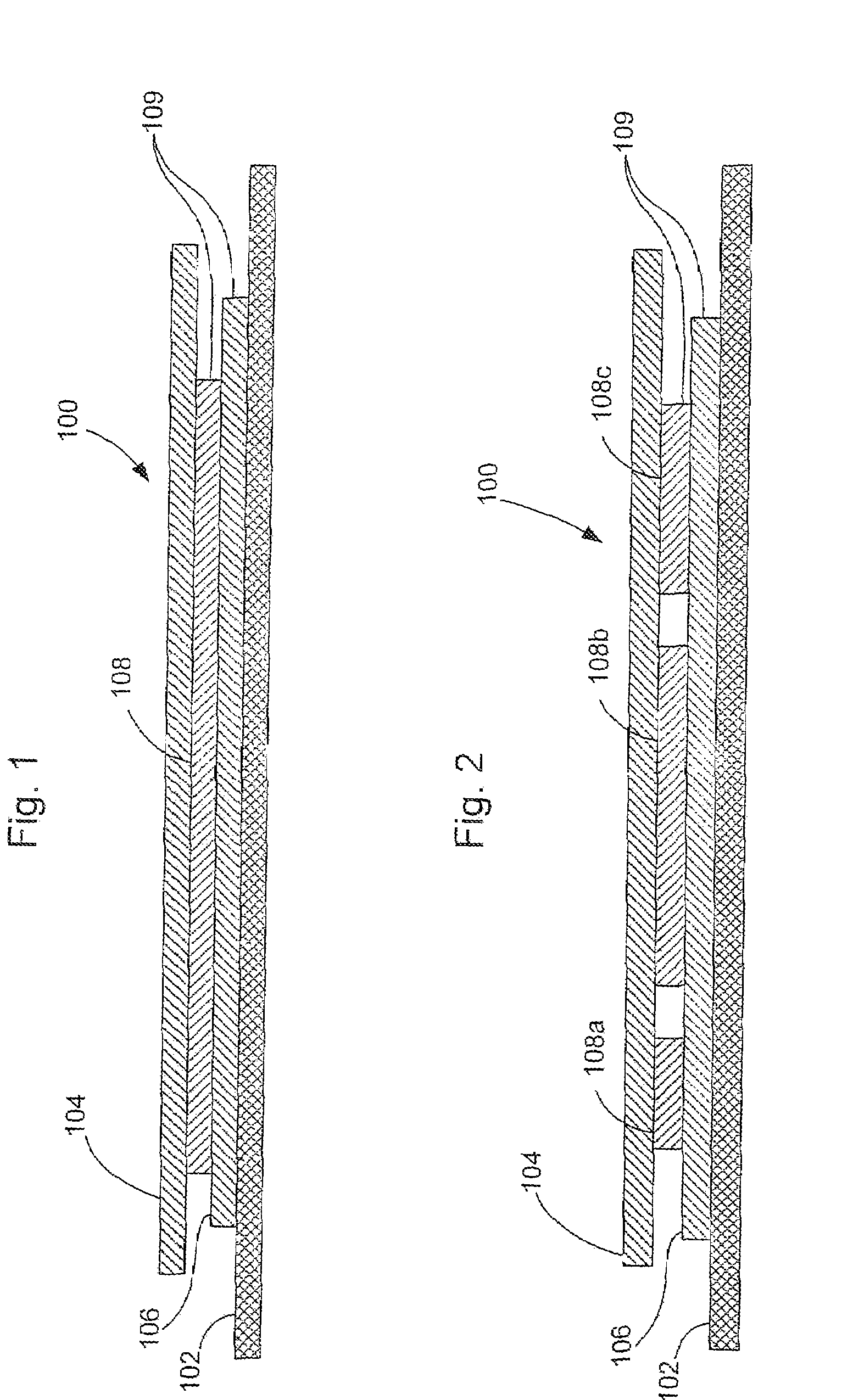

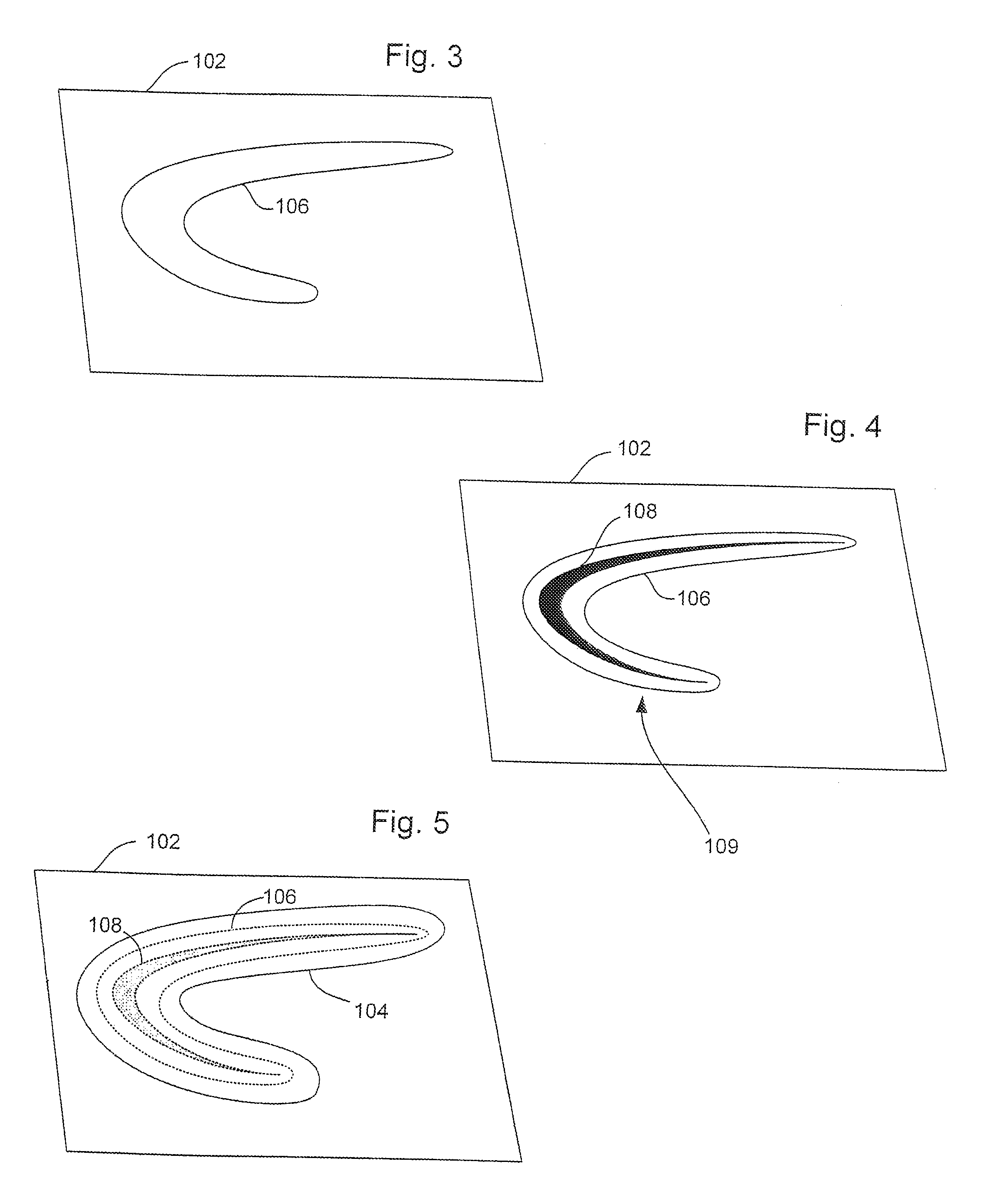

Thermally Reactive Ink Transfer System

InactiveUS20100243140A1Lamination ancillary operationsLayered product treatmentAutomotive paintAdhesive

An ink transfer system including an ink transfer decal that is transferable to a final substrate, such as a bare metal or pre-painted autobody part, without use of a separate adhesive. The transferred ink decal is capable of withstanding temperature elevations common during automotive paint baking without significant thermal degradation, discoloration, shrinkage or pealing.

Owner:DONALD D SLOAN TRUSTEE OF THE DONALD D SLOAN TRUST AND HIS SUCCESSOR & SUCCESSORS UNDER THE FOURTEENTH AMENDMENT TO & COMPLETE RESTATEMENT OF THE DONALD D SLOAN TRUST DATED JUNE 28 2012

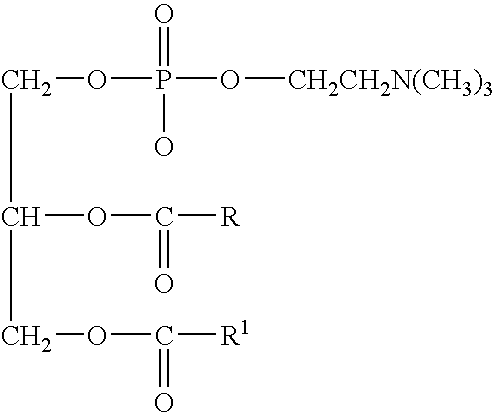

Polyamide modified polyester resin and preparation method thereof, and automotive primer surfacer containing polyester resin

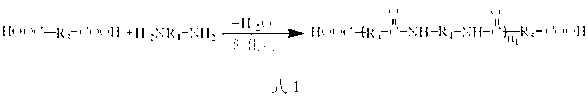

The invention provides a polyamide modified polyester resin having the following structure, wherein M represents -(R3-CO-NH-R4-NH-CO)n3-R3-. The invention also provides a preparation method of the polyester resin and an automotive primer surfacer containing the polyester resin. The strength and toughness of the polyester resin are enhanced by modifying saturated polyester resin by using polyamide polymer oligomer with terminal carboxyl groups, so that the saturated polyester resin having excellent mechanical properties used for coatings is obtained. The stone impact-resistant performance of paint films can be enhanced by using the polyester resin in the automotive primer surfacer.

Owner:BYD CO LTD

Thermally reactive ink transfer system

An ink transfer system including an ink transfer decal that is transferable to a final substrate, such as a bare metal or pre-painted autobody part, without use of a separate adhesive. The transferred ink decal is capable of withstanding temperature elevations common during automotive paint baking without significant thermal degradation, discoloration, shrinkage or pealing.

Owner:POLYMERIC U S INC

Multilayer pigments based on glass flakes

The present invention relates to multilayer pigments based on glass flakes and to a method for the production of such pigments. The resulting pigment can be used in any application for which pearlescent pigments have been heretofore used such as, for example, in plastics, paints, inks, cosmetic formulations, coatings including solvent or waterborne automotive paint systems, powder coatings, inks and agriculture foils, for the laser-marking of papers and plastics.

Owner:MERCK PATENT GMBH

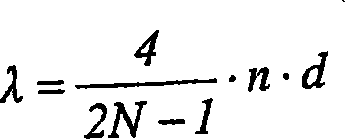

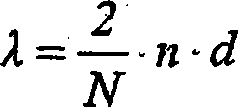

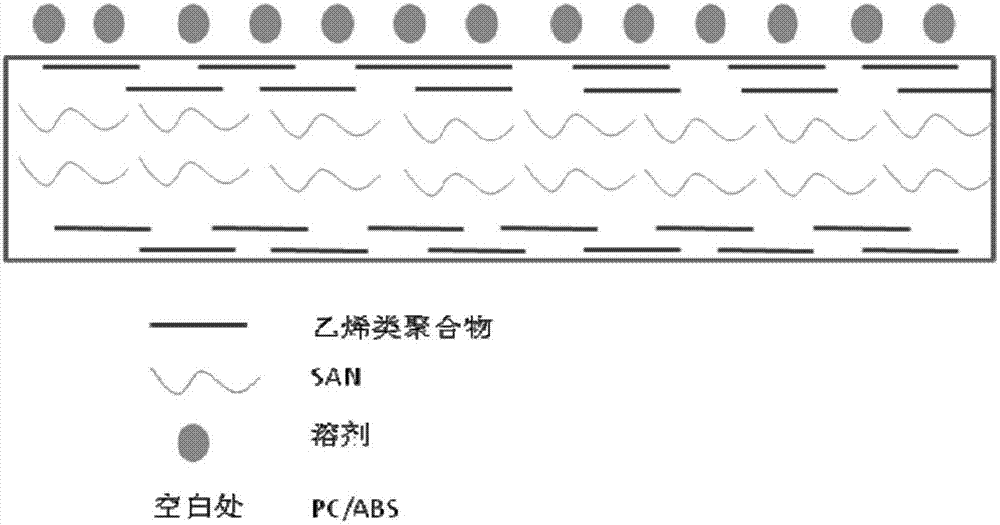

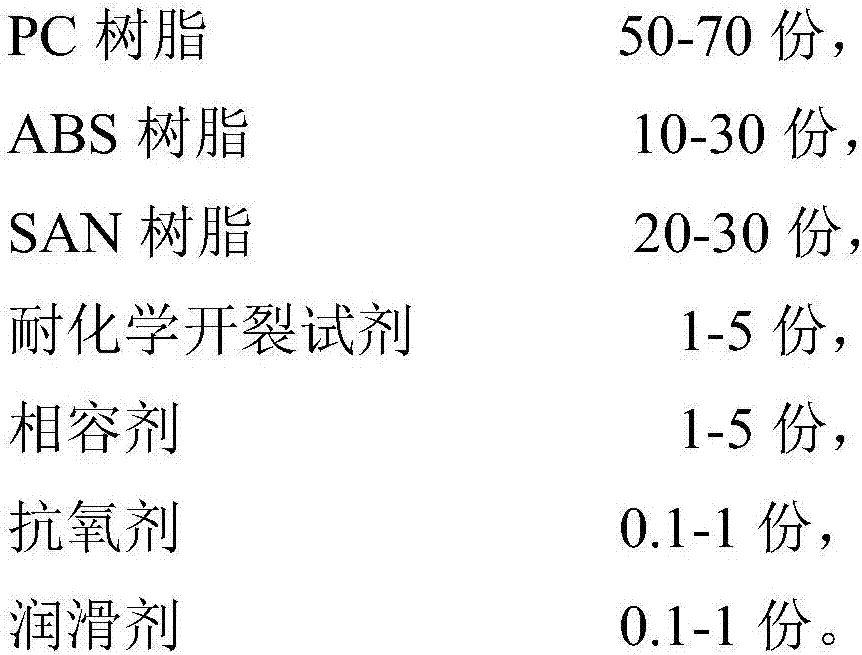

PC/ABS alloy with excellent automotive paint crack resistance and preparation method thereof

The invention relates to the field of high polymer materials, in particular to PC / ABS alloy with excellent automotive paint crack resistance. The PC / ABS alloy is prepared from the following components in parts by weight: 50-70 parts of PC resin, 10-30 parts of ABS resin, 20-30 parts of SAN resin, 1-5 parts of a chemical crack resistant reagent, 1-5 parts of compatibilizer, 0.1-1 part of antioxidant and 0.1-1 part of lubricant. The invention further provides a preparation method for the PC / ABS alloy with excellent automotive paint crack resistance. According to the PC / ABS alloy with excellent automotive paint crack resistance, through synergistic use of ethylene polymer and polystyrene-acrylonitrile with high nitrile (AN) content, very good paint crack resistance is achieved on the surface layer of PC / ABS and inside PC / ABS, so that the PC / ABS does not have a bad cracking phenomenon as a result of poor solvent resistance in a paint spraying process, and therefore, the product yield in the paint spraying process is greatly increased.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

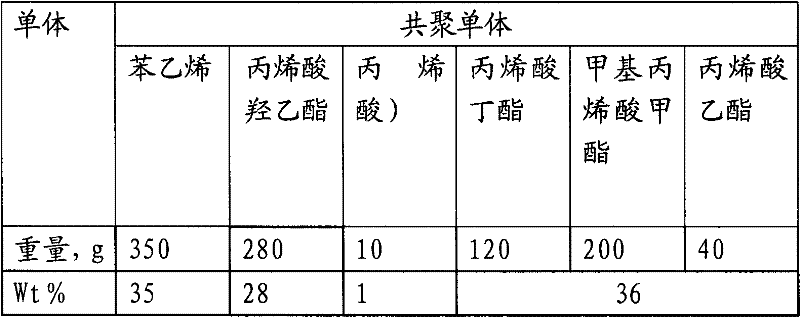

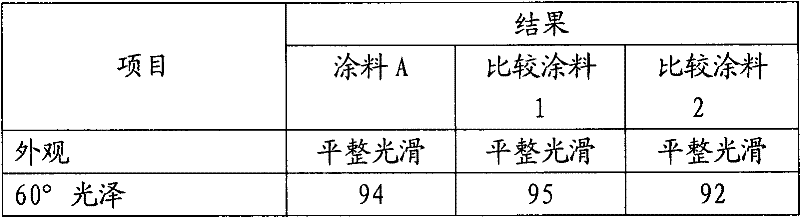

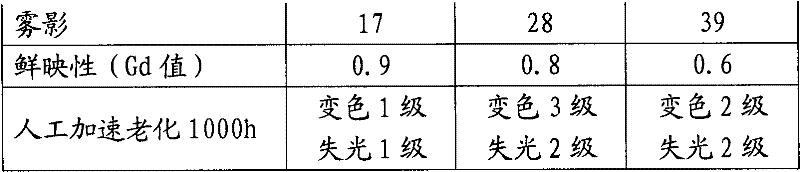

Polycarbonate modified acrylic resin and preparation method thereof

ActiveCN102391440AGood optical performanceImprove mechanical propertiesPolyurea/polyurethane coatingsAutomotive paintAcrylic resin

The invention relates to a polycarbonate modified acrylic resin and a preparation method thereof. The polycarbonate modified acrylic resin comprises the following raw materials in percentage by weight: 5-30 percent of polycarbonate prepolymer, 5-15 percent of styrene monomer, 1-3 percent of acrylic acid monomer, 20-30 percent of hydroxyethyl acrylate monomer, 10-30 percent of butyl acrylate monomer, 10-20 percent of methyl methacrylate monomer and 4-10 percent of ethyl acrylate monomer, and is formed in a solvent by using an initiator through free radical polymerization, wherein the resin content is 60-80 percent by weight based on solid; the weight-average molecular weight is 10,000-20,000; the viscosity at the temperature of 25 DEG C is 2,000-6,000mPa.s; the resin chain of the resin comprises a constitutional unit of the polycarbonate prepolymer; and the sum of said raw materials is 100 percent. In a double-component polycarbonate automotive paint prepared by using the polycarbonatemodified acrylic resin, the appearance of a coating is improved, and the weather resistance of the coating is also improved.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

Laser additive

InactiveCN102741360APigment treatment with macromolecular organic compoundsThermosensitive paintsLacquerPrinting ink

The invention relates to a laser additive in the form of particles comprising a white core and a casing that contains elemental carbon, to a method for the production thereof, and to the use of such a laser additive in organic polymers, in particular in plastics, paints, automobile paints, powder coatings, printing inks, paper coatings, and paper pulps to produce permanent light laser markings on a preferably dark base.

Owner:MERCK PATENT GMBH

Low-temperature-toughness peelable protective film paint and preparation method thereof

InactiveCN103242715AImprove toughnessExcellent peelabilityConjugated diene hydrocarbon coatingsNatural rubber coatingsPolymer scienceAutomotive paint

The invention belongs to the technical field of protective film paints, and particularly relates to a low-temperature-toughness peelable protective film paint and a preparation method thereof. The preparation method comprises the following steps: carrying out seed emulsion polymerization on raw materials emulsified rubber and polymerizable monomer to obtain a copolymer emulsion, wherein the particles of the copolymer emulsion are in a core-shell structure; and regulating the copolymer emulsion to obtain the low-temperature-toughness peelable protective film paint. The paint provided by the invention is suitable for air spraying construction, has high drying rate, and forms a peelable film after drying. The peelable protective film provided by the invention has excellent toughness and peelability at low temperature, can be used in a cold environment, and has wider application range. The peelable protective film paint provided by the invention can be used for transitional protection on fine surfaces of automobile paint films, automobile plastic parts, metal polishing sheets, camera lenses and the like.

Owner:FUDAN UNIV

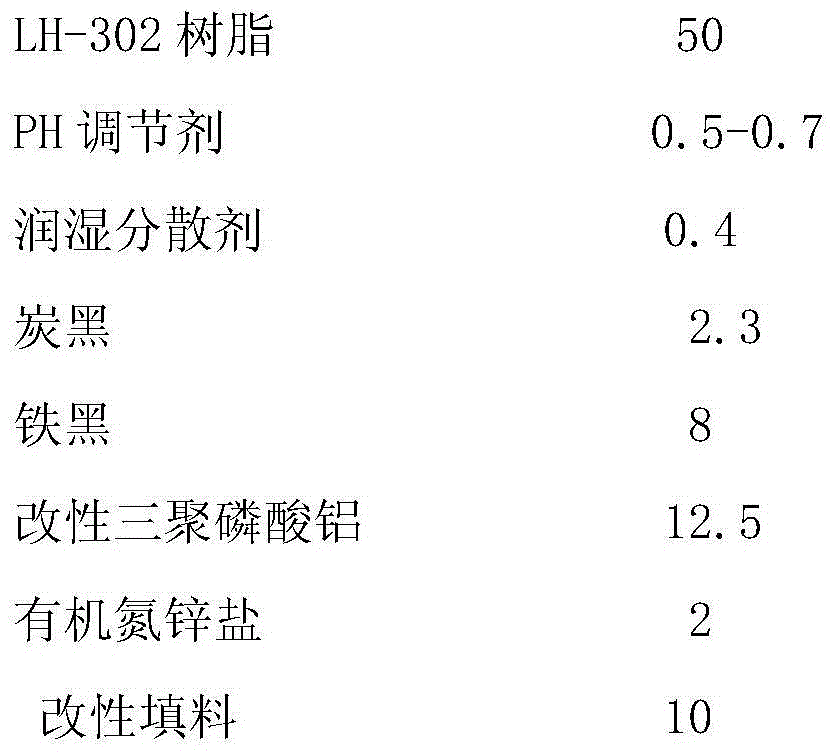

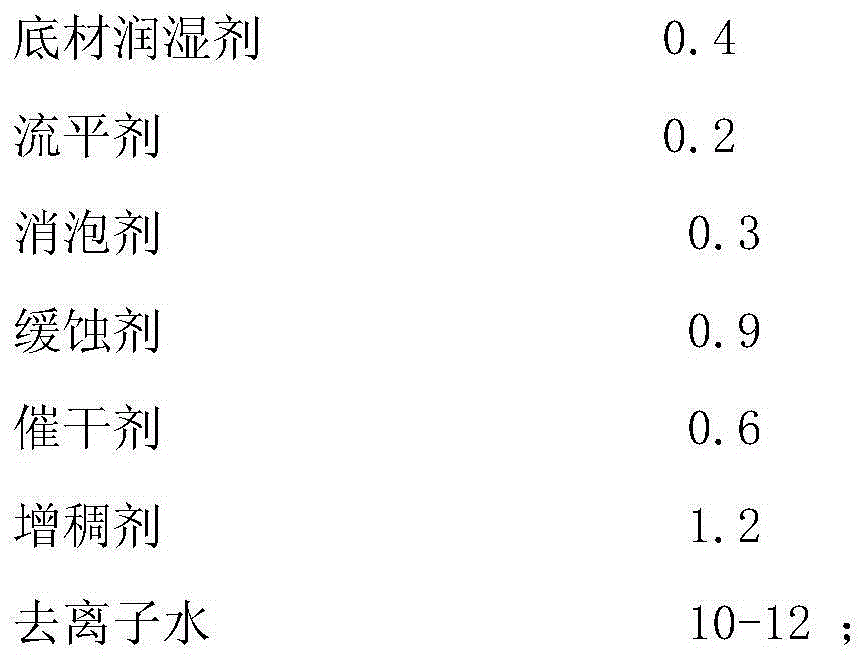

Water-based antiseptic paint for automotive chassis and preparation method thereof

ActiveCN103555121AImprove paint film performanceStrong adhesionAnti-corrosive paintsWater basedAutomotive paint

The invention provides a water-based antiseptic paint for an automotive chassis. The automotive paint is prepared by mixing the following components in parts by weight: 48-52 parts of LH-302 resin, 2.0-2.5 parts of carbon black, 7-9 parts of iron black, 12-13 parts of modified aluminum tripolyphosphate, 1-3 parts of organic nitrogen zinc salt, 9-11 parts of modified filler, 0.3-0.5 parts of wetting dispersant, 0.8-1.0 part of corrosion inhibitor, 0.3-0.5 parts of substrate wetting agent, 0.1-2.0 parts of assistant and 10-12 parts of deionized water. The water-based antiseptic paint for the automotive chassis provided by the invention can be naturally dried at normal temperature and can be dried at a low temperature (dried for 0.5 hour at 80-90 DEG C), the paint film property is remarkably enhanced, and the adhesive force, the hardness and the salt fog resistance are ideal. The paint is mainly used for automobile axles, automotive chassis, auto parts and the like.

Owner:ANQING LINGHU PAINT

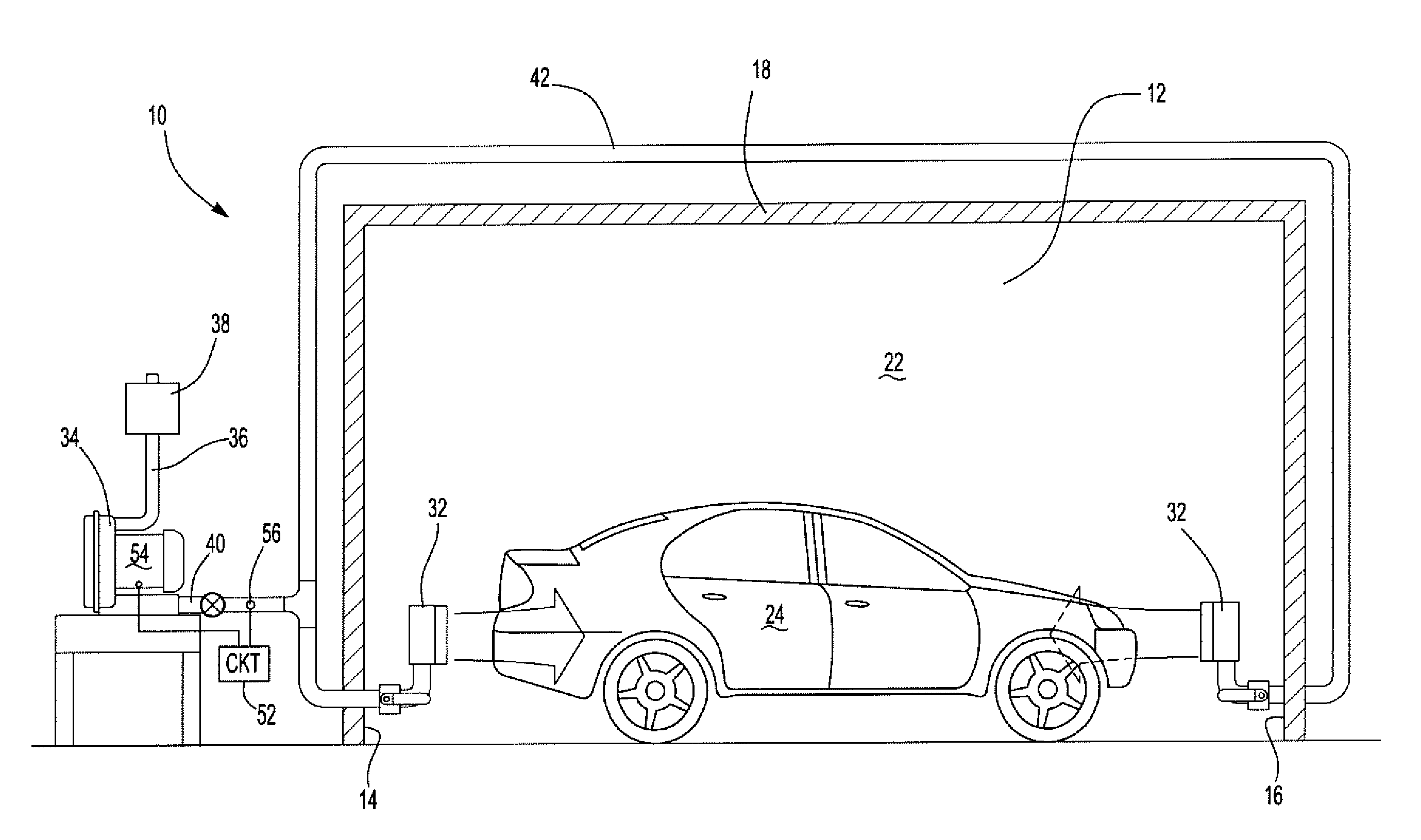

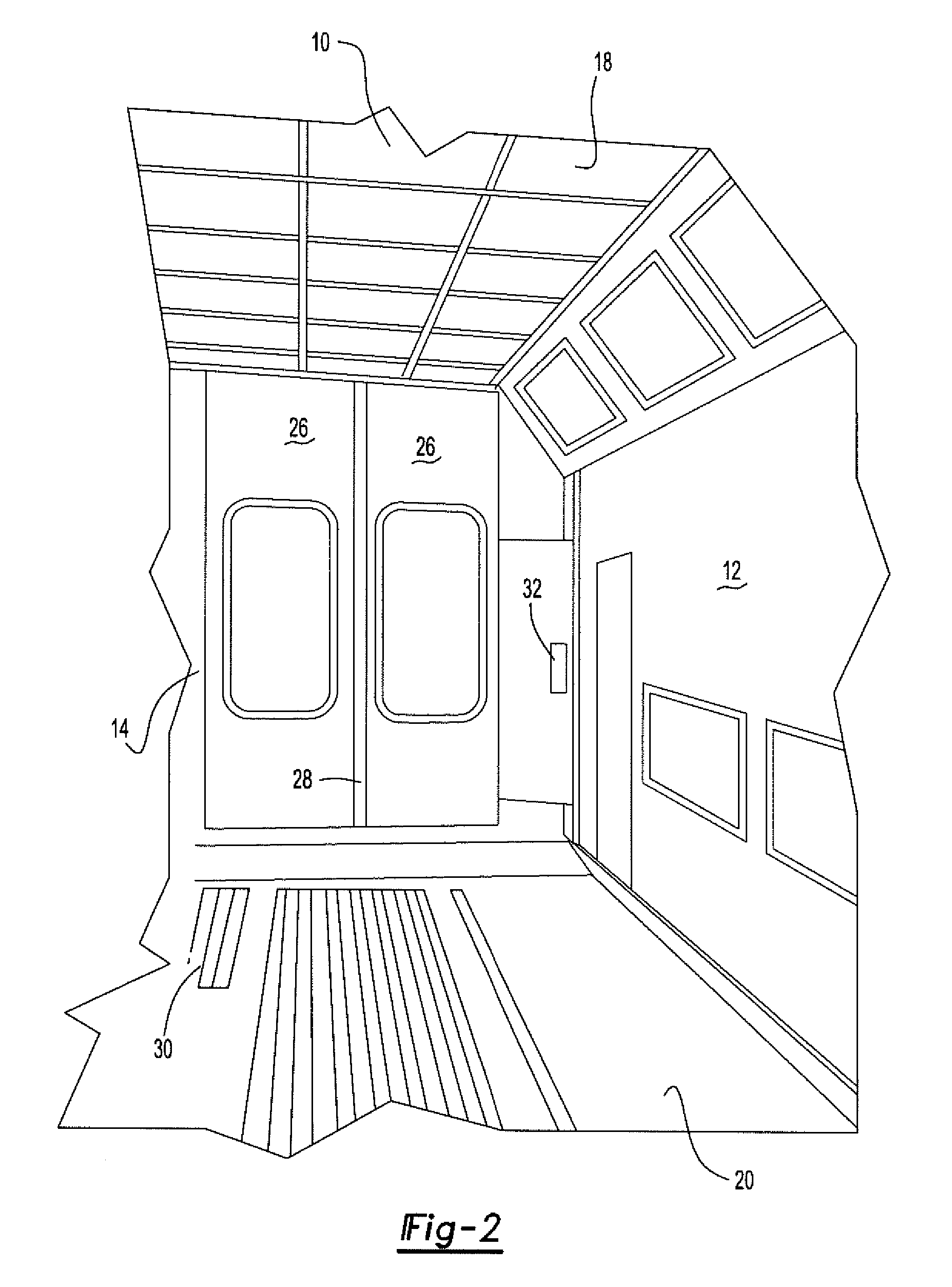

Automotive paint spray and drying booth

ActiveUS8826565B2Keep dryLiquid surface applicatorsDrying gas arrangementsAutomotive paintEngineering

An automotive paint spray and drying booth having a plurality of walls which, together, define a housing with a chamber sufficient in size to contain an automotive vehicle. An air dispenser is positioned within the chamber and the air dispenser includes an outlet positioned to direct air along one or more of the housing walls. A regenerative blower is positioned outside the housing chamber. The blower is connected to an inlet open outside of the housing chamber and includes an outlet which is fluidly connected to the air nozzle.

Owner:DEDOES IND LLC

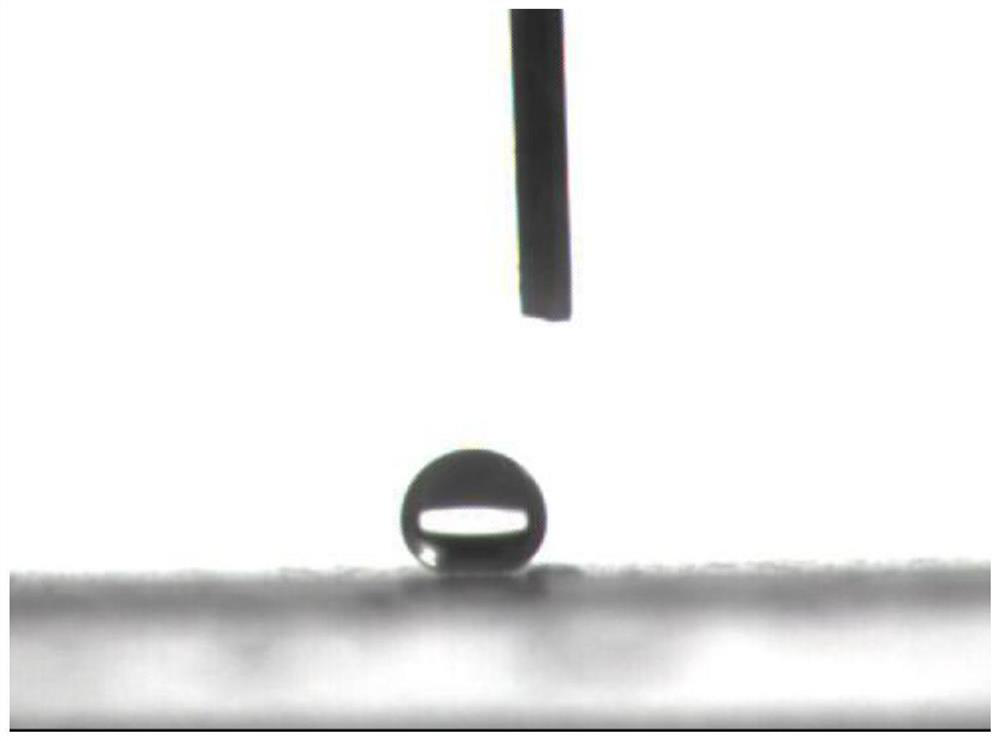

Preparation method of super-hydrophobic TPU material automobile paint surface protective film self-repairing coating

InactiveCN112126339AEfficient mixingHas a superhydrophobic "lotus leaf" morphologyAntifouling/underwater paintsPaints with biocidesPolymer sciencePtru catalyst

The invention discloses a preparation method of a super-hydrophobic TPU material automobile paint surface protective film self-repairing coating, and the automobile paint surface protective film self-repairing coating comprises the following raw materials by weight: 80-120 parts of aliphatic diisocyanate, 500-600 parts of hydroxyl polyether polyol, 20-30 parts of a catalyst, 25-45 parts (preferably 30-40 parts) of a chain extender, 5-10 parts of an anti-ultraviolet auxiliary agent, and 200-250 parts of a solvent. The coating is prepared from the following components in parts by weight: 100 parts of epoxy resin, 10-20 parts of inert silicone oil, 2-5 parts of sodium citrate modified nanoparticles, 5-10 parts of a dispersing agent and 10-20 parts of a defoaming agent. The preparation methodhas the beneficial effects that the synthesized polyurethane belongs to polyether polyurethane and has more soft segment structures, meanwhile, the soft segment structures contain a large number of hydroxyl groups, and migration movement of molecular chains can be realized after film formation, so that conditions are provided for self-repairing after a coating is damaged, and rapid self-healing after the coating is damaged is realized; the nanoparticles modified by sodium citrate can ensure that the protective film has an extremely high water contact angle, thereby ensuring that the coating has a super-hydrophobic characteristic.

Owner:航天思远材料科技(上海)有限公司

Construction method of automobile paint film defect recognition system based on deep learning

PendingCN110335238AAssisted identificationFully trainedImage enhancementImage analysisVisual inspectionRecognition system

The invention discloses a construction method of an automobile paint film defect recognition system based on deep learning. The method comprises the following steps: collecting and labeling a plurality of to-be-detected vehicle body paint film original images, labeling comprising labeling defect areas and categories in the vehicle body paint film original images, after labeling, generating an xmlformat file for each labeled picture, and forming a labeled sample set; performing multiple times of multi-angle clipping sampling on each defect area marked in each picture of the marked sample set by utilizing a sampling block to obtain a defect area sampling set; the sampling block being square; training and testing the defect area sampling set by using a deep learning algorithm, and constructing an automobile paint film defect recognition model based on deep learning; and constructing an automobile paint film defect identification system based on deep learning. The method can effectively assist the recognition of the defects of the automobile paint film, makes up the defects of manual visual detection, and improves the quality of the automobile body paint film.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com