Polycarbonate modified acrylic resin and preparation method thereof

A technology of acrylic resin and polycarbonate, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of yellowing of the coating film, insufficient weather resistance, and difficulty in realization, and achieve no damage to weather resistance, excellent mechanical properties, The effect of excellent hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 prepares polycarbonate modified acrylic resin

[0031] Concrete preparation steps are as follows:

[0032] ① Preparation of polycarbonate prepolymer

[0033] In the reaction vessel equipped with stirrer, water condenser, thermocouple, nitrogen inlet, heating mantle and feeding pump, add 90.9g aliphatic polycarbonate diol (Japanese Asahi Kasei Chemical Company product T5651) and 9.1g maleic anhydride , the molar ratio of the two is 1:1, then add 0.1g hydroquinone polymerization inhibitor, the amount is 1‰ of the total weight of aliphatic polycarbonate diol and maleic anhydride, heat up to 80°C for alcoholysis Reaction, measure the acid value every 30 minutes, until the acid value of the material drops to half of the initial acid value of the system, stop the reaction to obtain a polycarbonate prepolymer, cool down and discharge the material for future use;

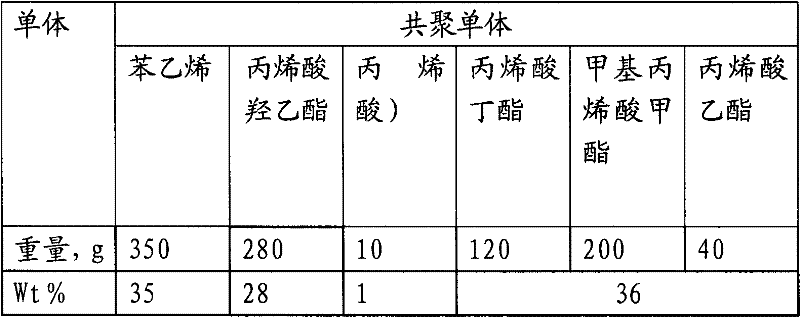

[0034] ② Weighing raw materials

[0035] 10% by weight of polycarbonate prepolymer, 10% by weight ...

Embodiment 2

[0040] Embodiment 2 prepares polycarbonate modified acrylic resin

[0041] Concrete preparation steps are as follows:

[0042] ① Preparation of polycarbonate prepolymer

[0043] In the reaction vessel equipped with stirrer, water condenser, thermocouple, nitrogen inlet, heating mantle and feeding pump, add 181.8g aliphatic polycarbonate diol (JSB10, product of China Jiangsu Chemical Research Institute Co., Ltd.) and 18.2 g maleic anhydride, the molar ratio of the two is 1: 1, then add 0.2g hydroquinone polymerization inhibitor, its amount is 1‰ of the total weight of aliphatic polycarbonate diol and maleic anhydride, heat up to 80 Carry out the alcoholysis reaction at ℃, measure the acid value every 30 minutes, until the acid value of the material drops to half of the initial acid value of the system, stop the reaction to obtain the polycarbonate prepolymer, cool down and discharge the material for storage for later use;

[0044] ② Weighing raw materials

[0045] 20% by wei...

Embodiment 3

[0051] Concrete preparation steps are as follows:

[0052] ① Preparation of polycarbonate prepolymer

[0053] In the reaction vessel equipped with stirrer, water condenser, thermocouple, nitrogen inlet, heating mantle and feed pump, add 272.7g aliphatic polycarbonate diol (Swiss Pers top company product OxymerM112) and 27.3g maleic anhydride , the molar ratio of the two is 1:1, then add 0.3g hydroquinone polymerization inhibitor, the amount is 1‰ of the total weight of aliphatic polycarbonate diol and maleic anhydride, heat up to 80°C for alcoholysis Reaction, measure the acid value every 30 minutes, until the acid value of the material drops to half of the initial acid value of the system, stop the reaction to obtain a polycarbonate prepolymer, cool down and discharge the material for future use;

[0054] ② Weighing raw materials

[0055] 30% by weight of polycarbonate prepolymer, 13% by weight of styrene monomer, 1% by weight of acrylic acid monomer, 30% by weight of hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com