Preparation method of super-hydrophobic TPU material automobile paint surface protective film self-repairing coating

A car paint and self-repair technology, applied in the field of protective coating and protective film, can solve the problems of lack of development and use, achieve rapid self-healing, prolong self-repair service life, and reduce the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

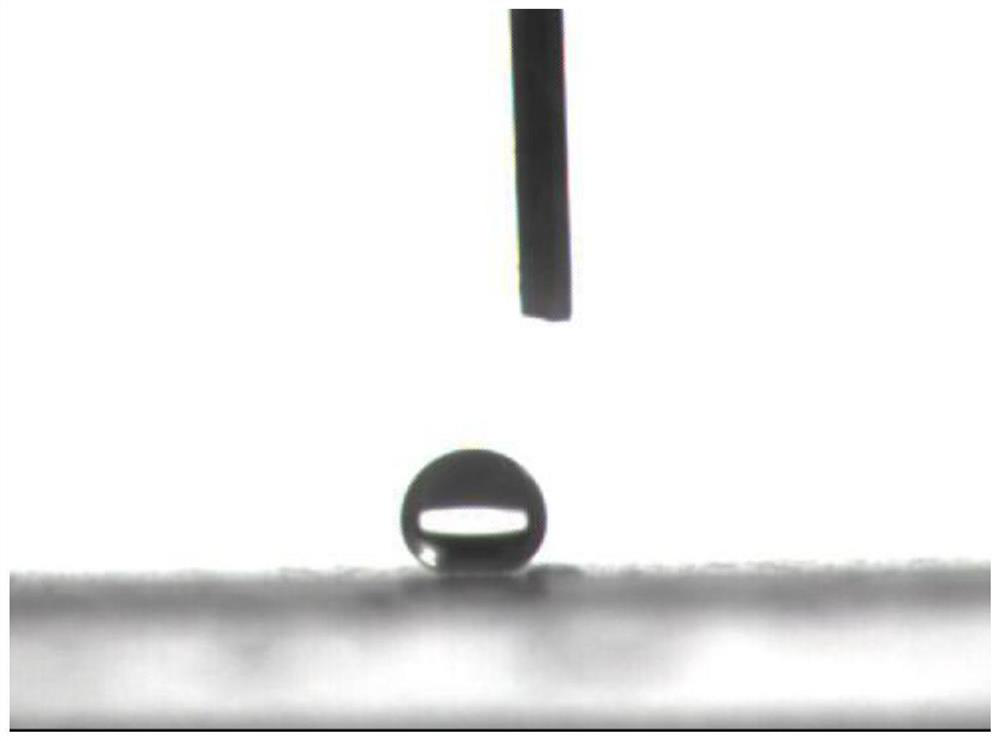

Image

Examples

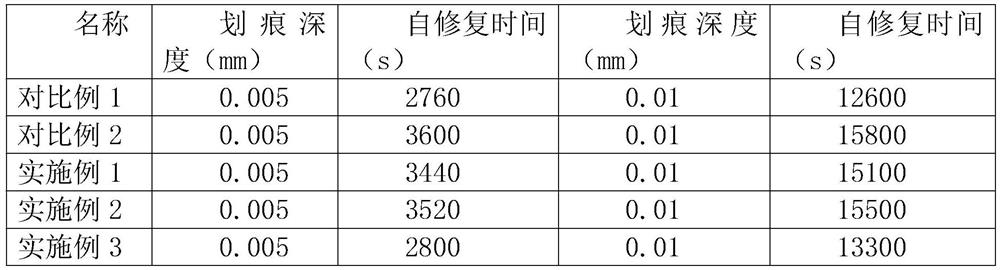

Embodiment 1

[0034] Embodiment 1: Specifically, the superhydrophobic TPU self-healing coating includes the following raw materials in parts by weight: 100 parts of aliphatic diisocyanate, 500 parts of hydroxyl polyether polyol, 20 parts of catalyst, 30 parts of chain extender, 5 parts of anti-ultraviolet auxiliary agent, 200 parts of solvent, 10 parts of inert silicone oil, 3 parts of nanoparticles modified by sodium citrate, 5 parts of dispersant, and 10 parts of defoamer.

[0035] Wherein, the aliphatic diisocyanate is selected from hexamethylene diisocyanate; the hydroxyl polyether polyol is selected from a hydroxyl polyether polyol with a molecular weight of 1000, and a trihydroxy polyether polyol with a molecular weight of 3000 is mixed in a ratio of 40:10; The catalyst is dibutyltin silicate; the chain extender is 1,4-butanediol; the anti-ultraviolet additive is benzotriazole; the solvent is xylene, butanone, ethyl acetate and tetrahydrofuran according to the ratio of 4:1:4 : 1 ratio...

Embodiment 2

[0045] Embodiment 2: This implementation provides a kind of preparation method of superhydrophobic TPU self-healing coating, and it is basically consistent with embodiment 1, and difference is following difference:

[0046] The superhydrophobic TPU self-healing coating includes the following raw materials in parts by weight: 120 parts of aliphatic diisocyanate, 600 parts of hydroxyl polyether polyol, 30 parts of catalyst, 45 parts of chain extender, 10 parts of anti-ultraviolet auxiliary agent, 200 parts of solvent, 20 parts of inert silicone oil, 5 parts of sodium citrate modified nanoparticles, 5 parts of dispersant, and 15 parts of defoamer.

[0047] Wherein, the aliphatic diisocyanate is selected from isophorone diisocyanate; the hydroxyl polyether polyol is selected from a hydroxyl polyether polyol with a molecular weight of 1000, and a trihydroxy polyether polyol with a molecular weight of 3000 is mixed in a ratio of 45:5; The catalyst is bismuth neodecanoate; the chain ...

Embodiment 3

[0057] Embodiment 3: This implementation provides a kind of preparation method of superhydrophobic TPU self-healing coating, and it is basically consistent with embodiment 1, and difference is following difference:

[0058] The superhydrophobic TPU self-healing coating includes the following raw materials in parts by weight: 110 parts of aliphatic diisocyanate, 500 parts of hydroxyl polyether polyol, 250 parts of catalyst, 40 parts of chain extender, 8 parts of anti-ultraviolet auxiliary agent, 250 parts of solvent, 15 parts of inert silicone oil, 4 parts of sodium citrate modified nanoparticles, 10 parts of dispersant, and 20 parts of defoamer.

[0059] Wherein, the aliphatic diisocyanate is selected from isophorone diisocyanate; the hydroxyl polyether polyol is selected from a hydroxyl polyether polyol with a molecular weight of 1000, and a trihydroxy polyether polyol with a molecular weight of 3000 is mixed in a ratio of 45:5; The catalyst is bismuth naphthenate; the chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com