Patents

Literature

194 results about "Chemical mixtures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

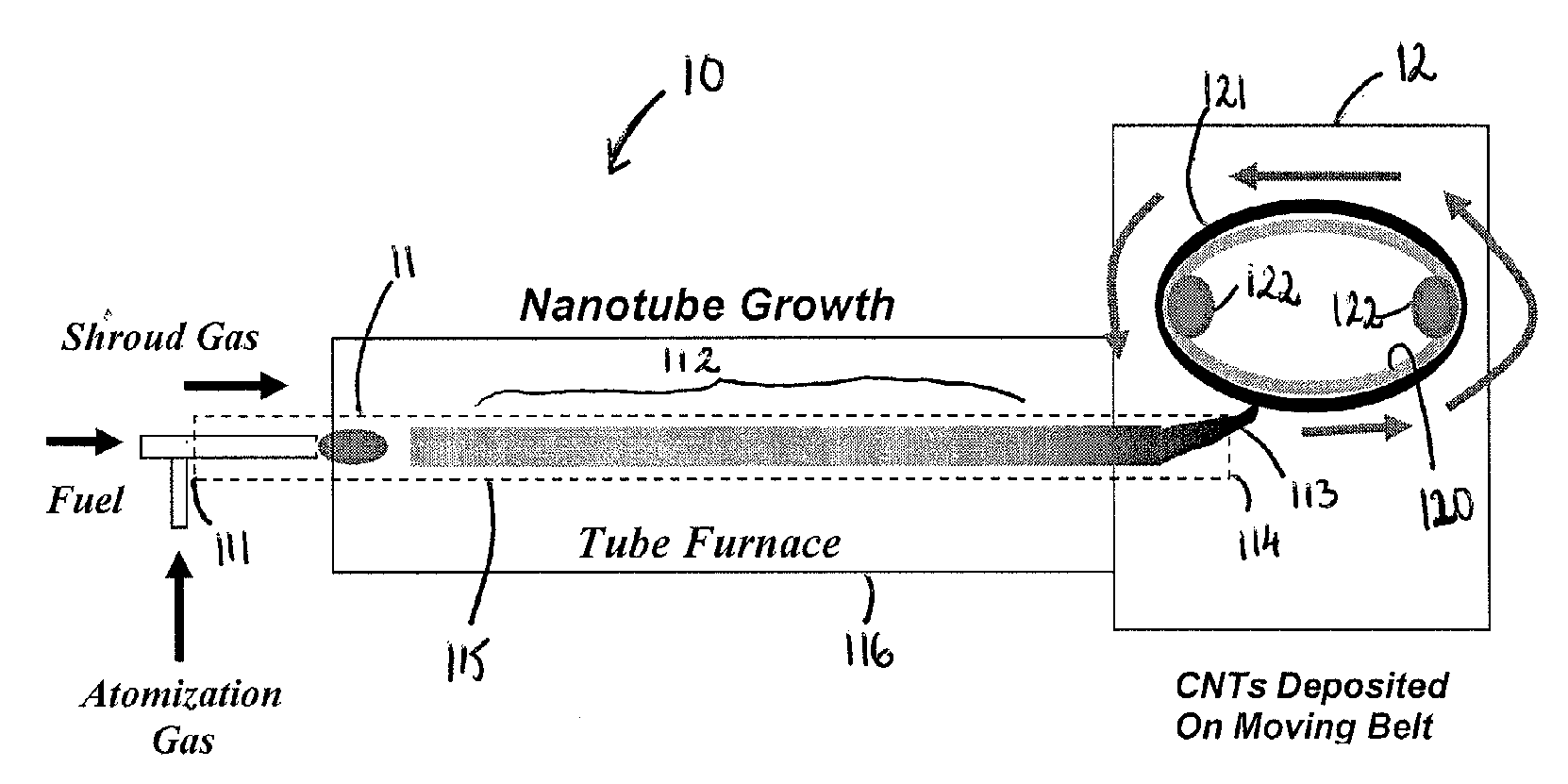

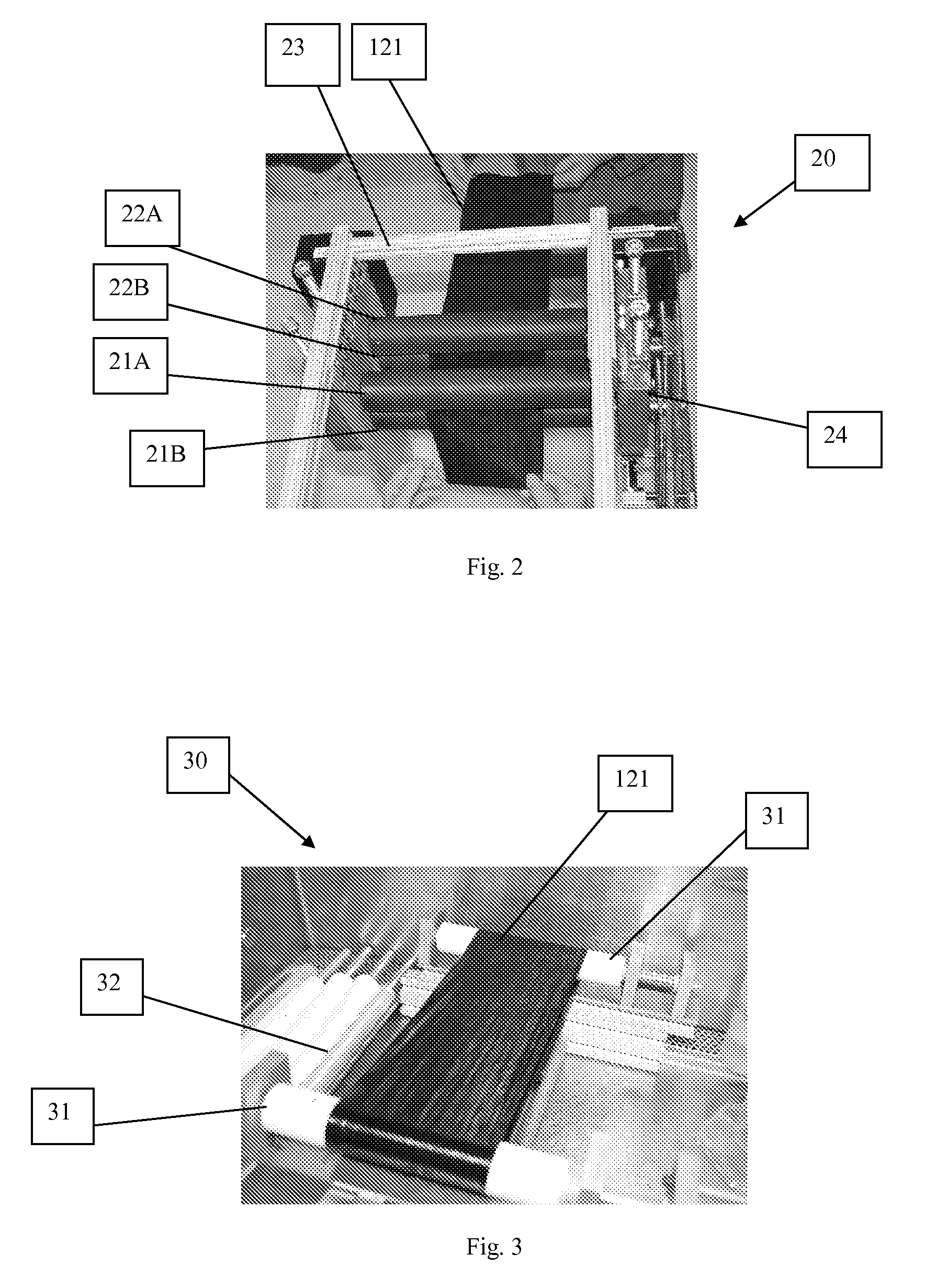

Chemically-Assisted Alignment of Nanotubes Within Extensible Structures

ActiveUS20090075545A1Smooth connectionImprove thermal conductivityArtificial filament physical treatmentHollow filament manufactureChemical mixturesYarn

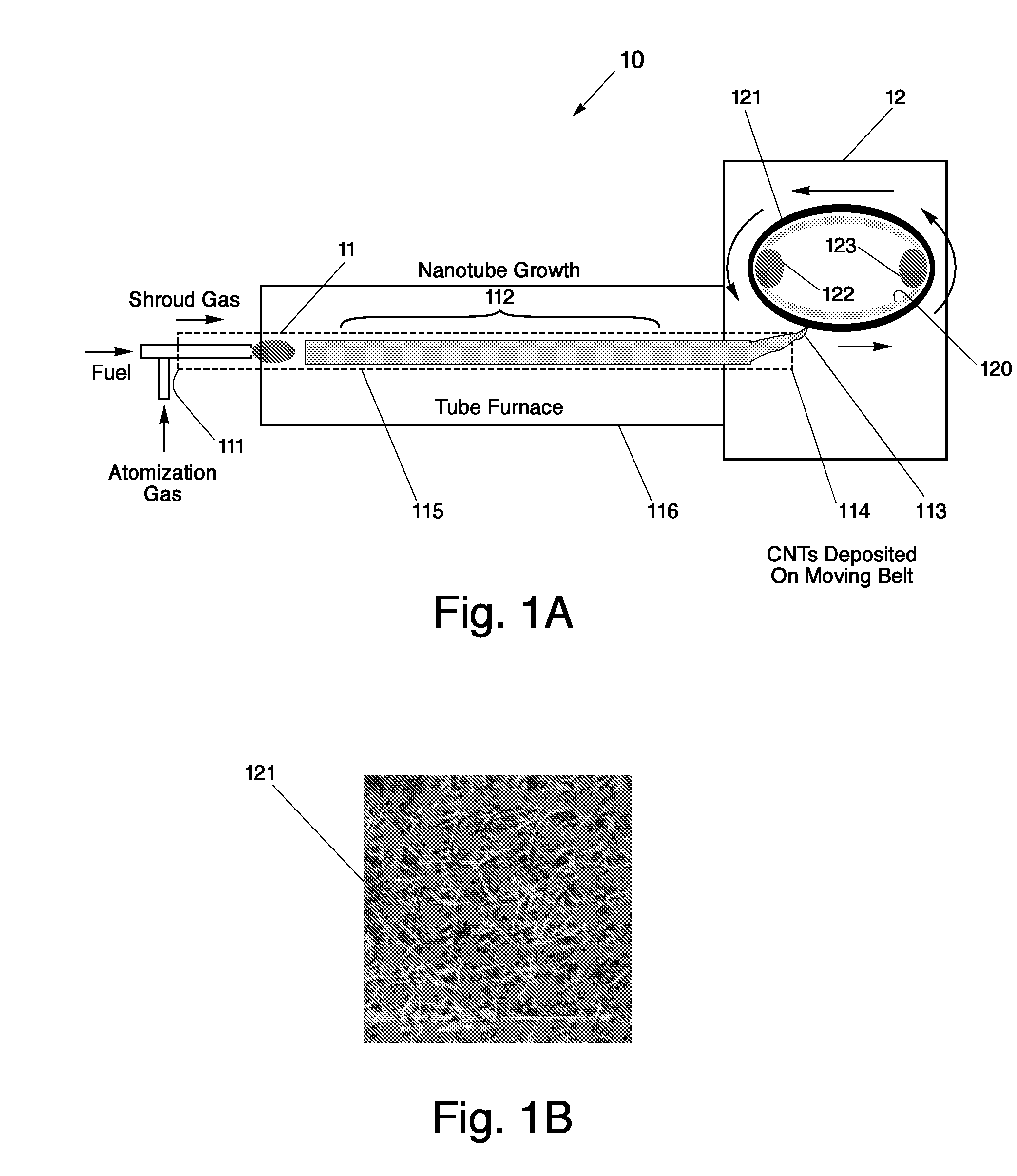

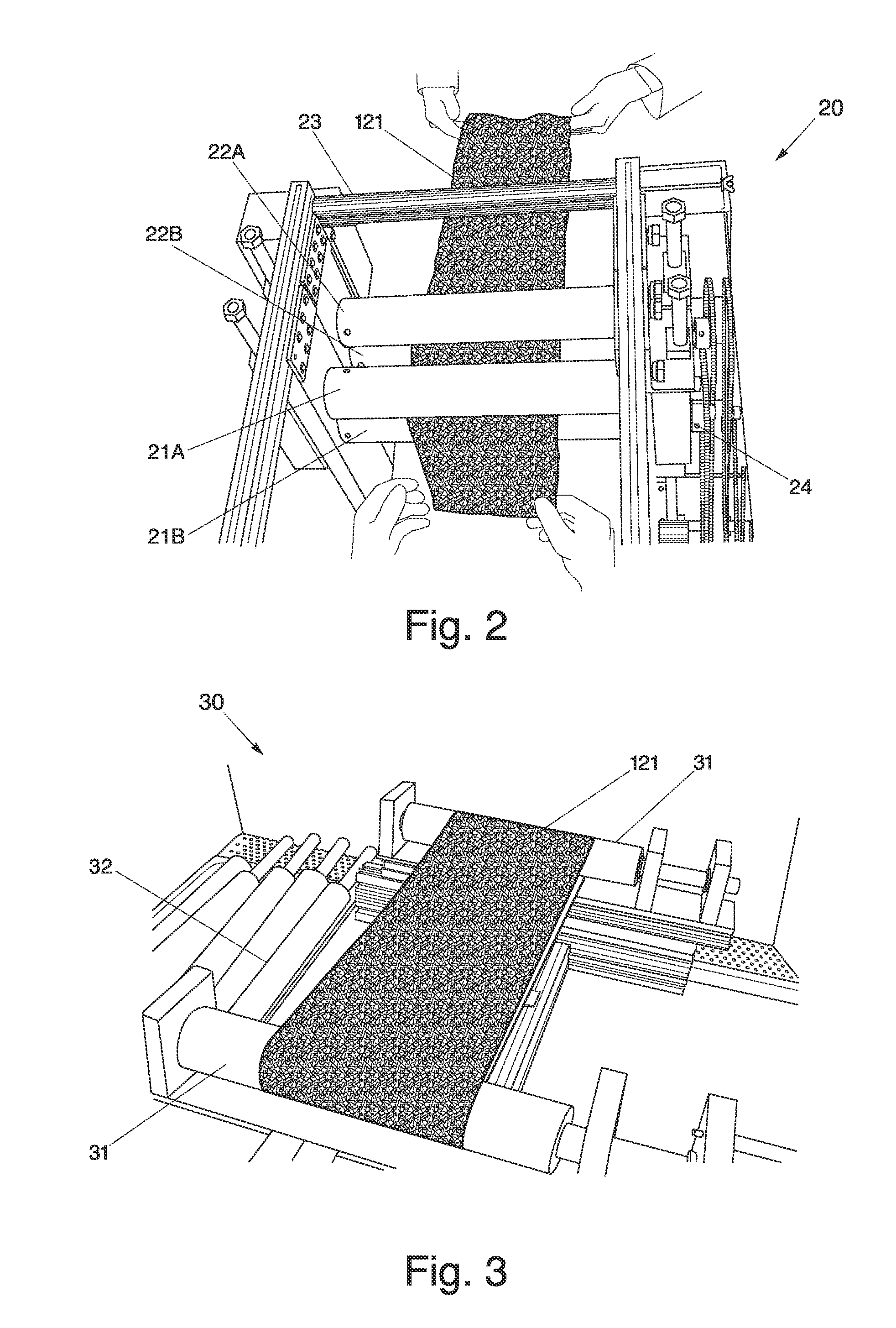

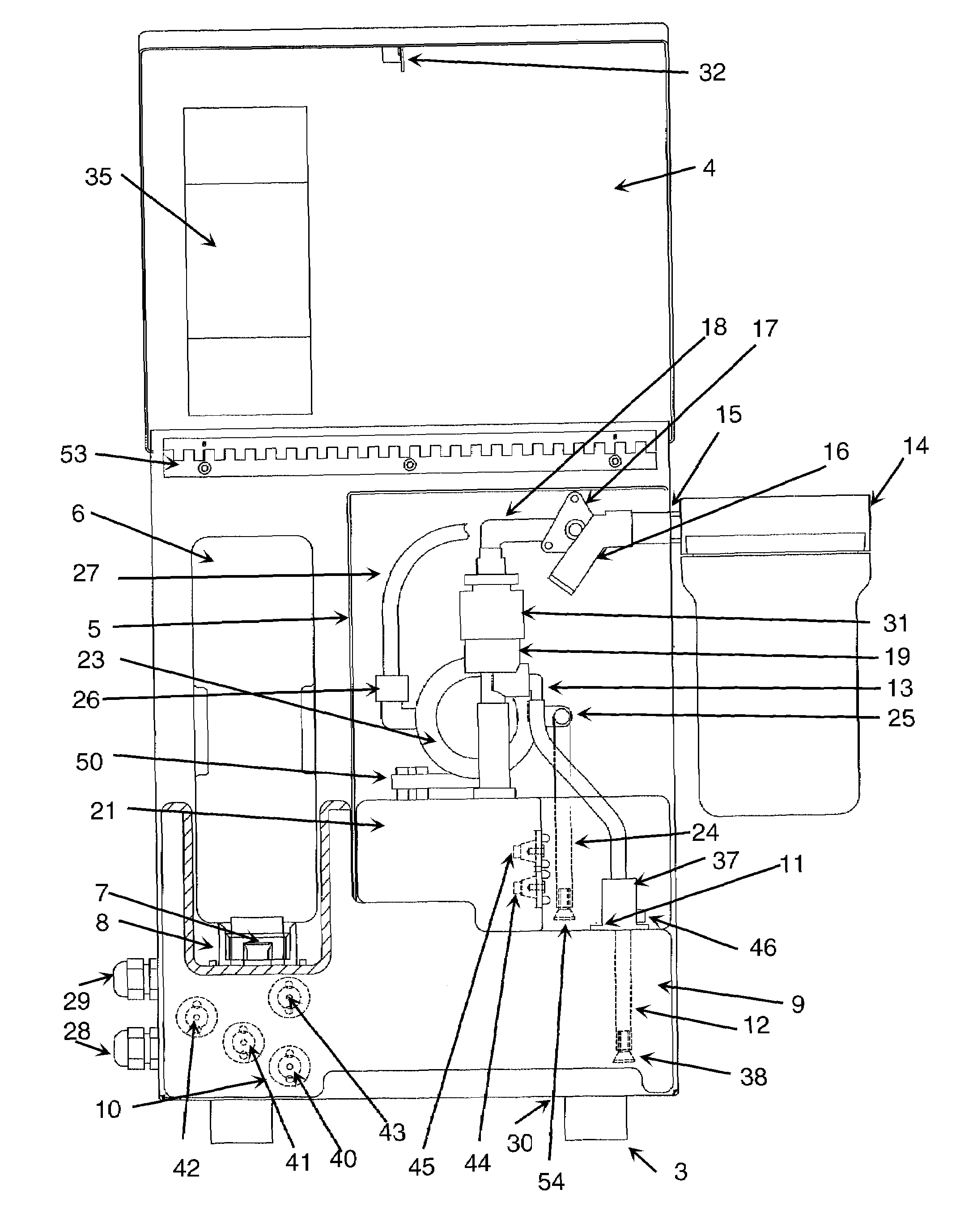

A method and system for aligning nanotubes within an extensible structure such as a yarn or non-woven sheet. The method includes providing an extensible structure having non-aligned nanotubes, adding a chemical mixture to the extensible structure so as to wet the extensible structure, and stretching the extensible structure so as to substantially align the nanotubes within the extensible structure. The system can include opposing rollers around which an extensible structure may be wrapped, mechanisms to rotate the rollers independently or away from one another as they rotate to stretch the extensible structure, and a reservoir from which a chemical mixture may be dispensed to wet the extensible structure to help in the stretching process.

Owner:NANCOMP TECHNOLOGIES INC

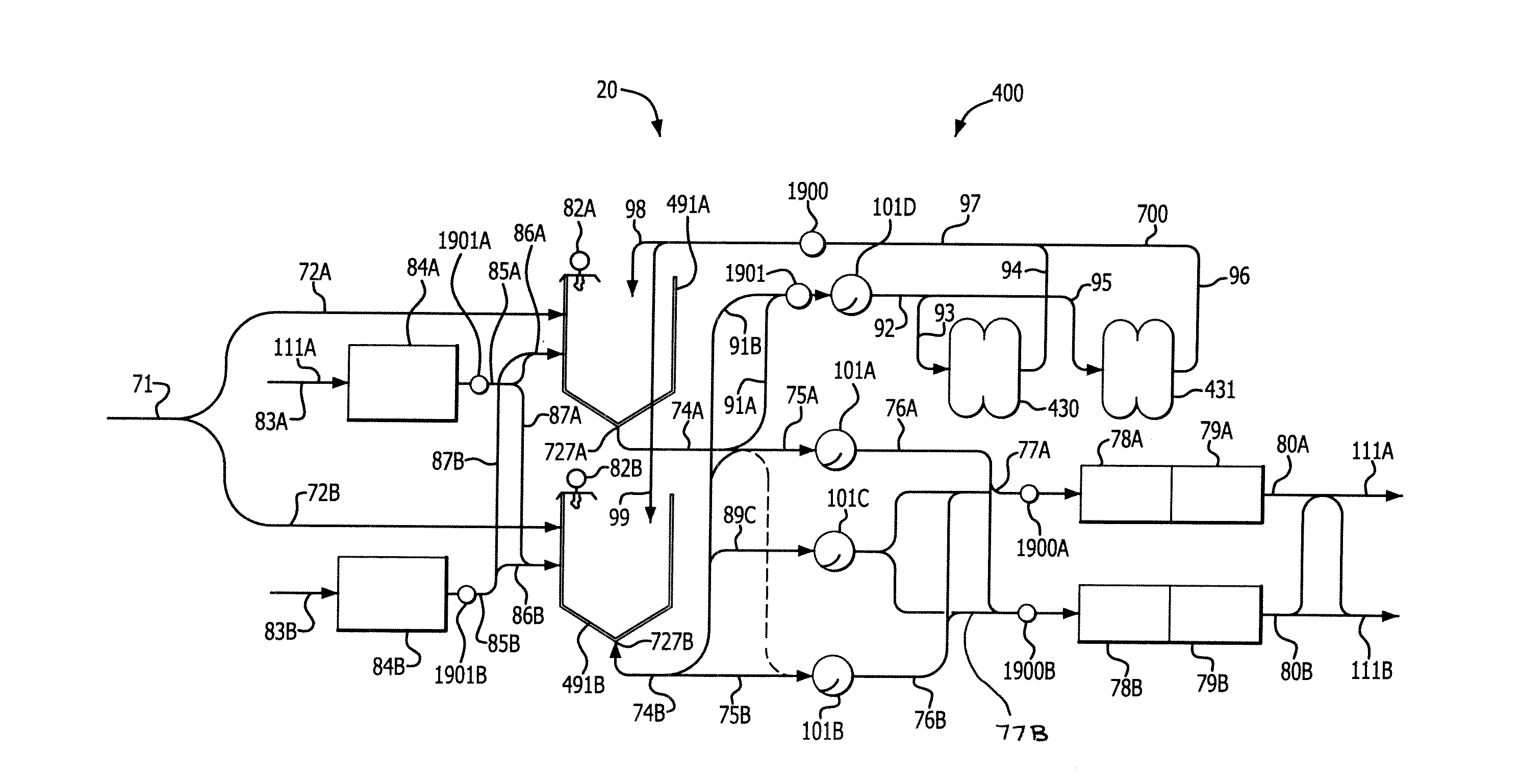

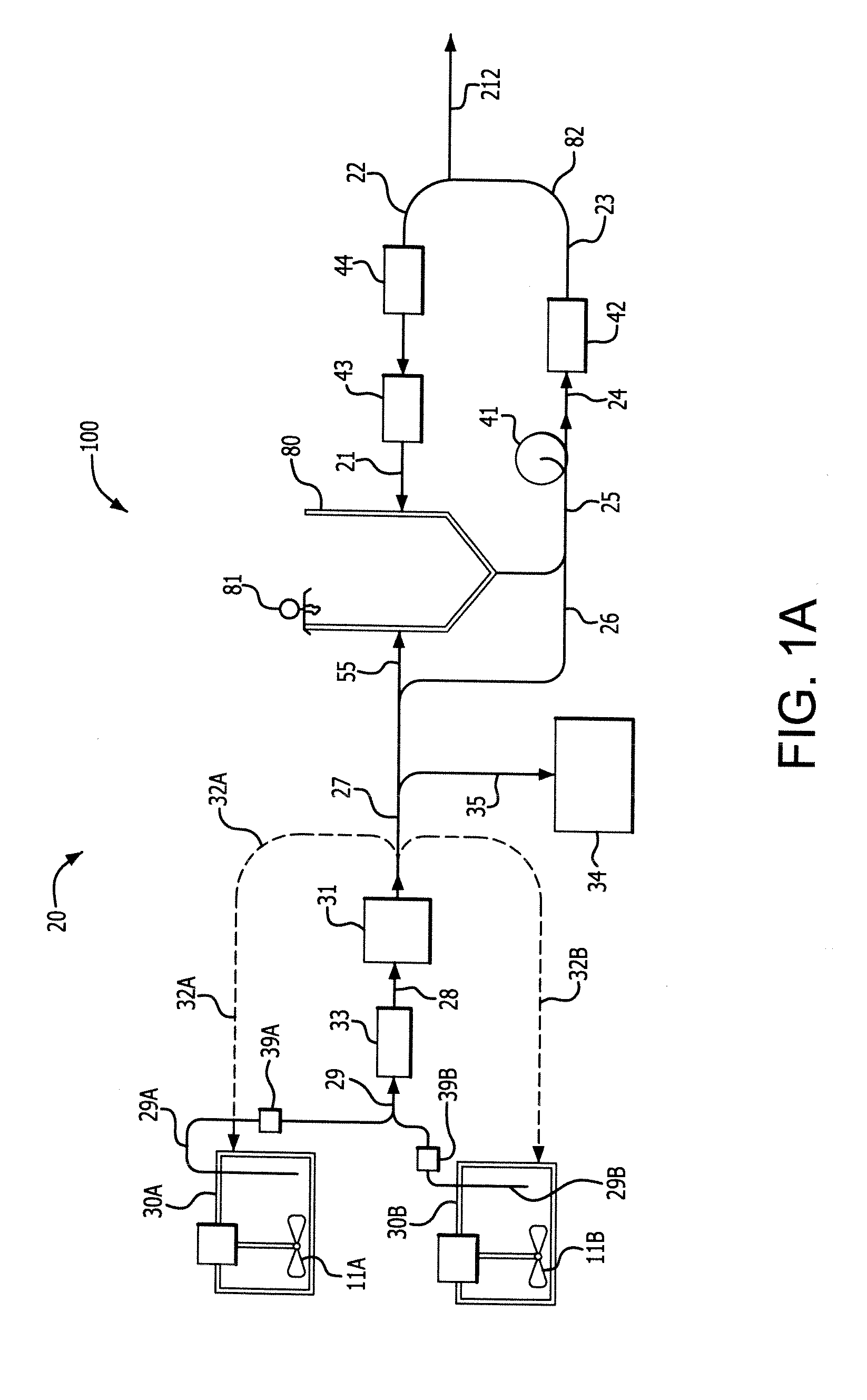

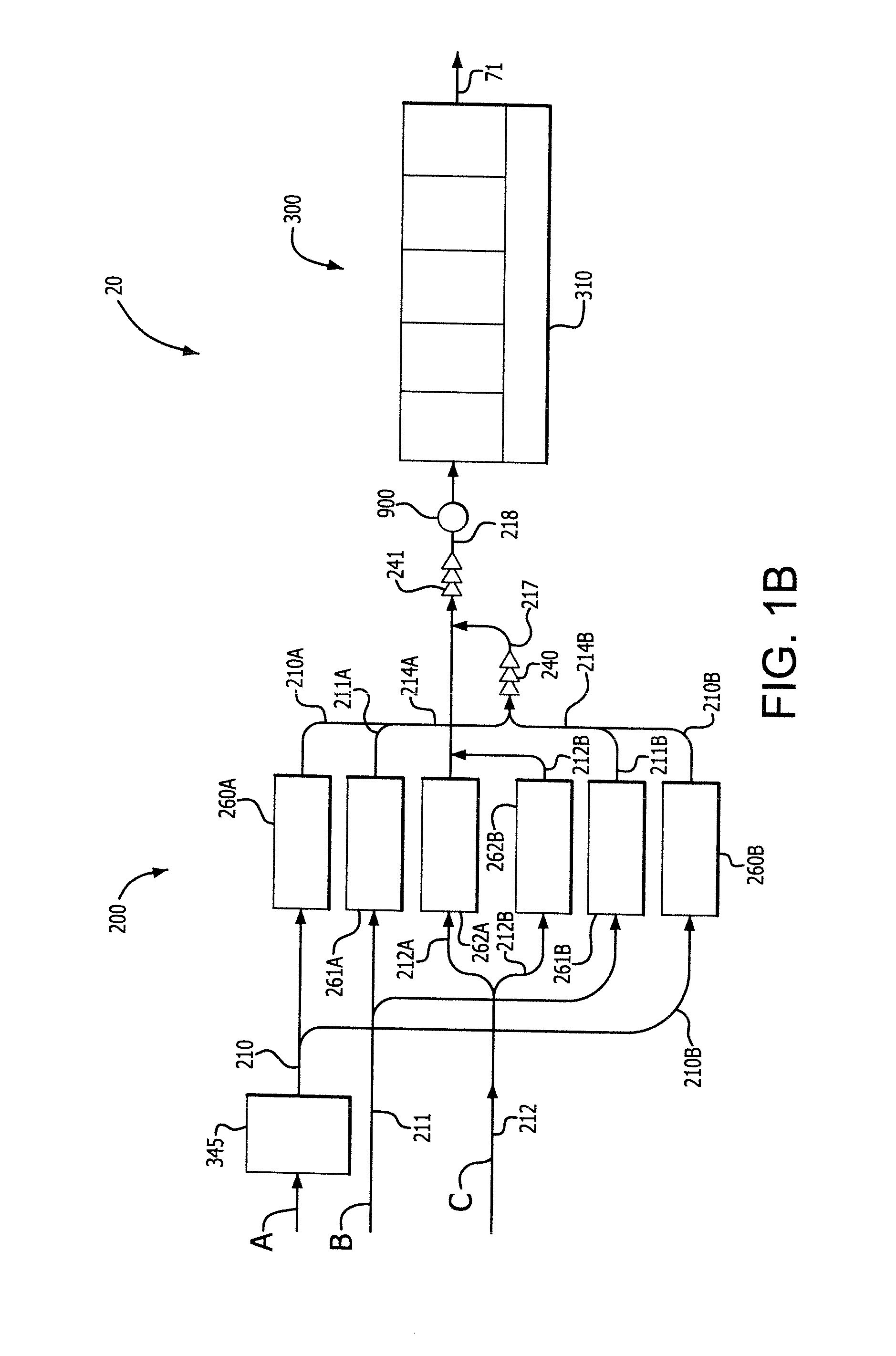

Slurry Supply and/or Chemical Blend Supply Apparatuses, Processes, Methods of Use and Methods of Manufacture

ActiveUS20140261824A1Avoid negative effectsQuick responseFlow mixersThin material handlingChemical mixturesProcess engineering

A slurry and / or chemical blend supply apparatus suitable for providing slurry and / or chemical blend to chemical mechanical planarization (CMP) tools or other tools in a semiconductor fabrication facility, related processes, methods of use and methods of manufacture. The slurry and / or chemical blend supply apparatus includes one or more of the following: feed module, blend module, analytical module and distribution module.

Owner:VERSUM MATERIALS US LLC

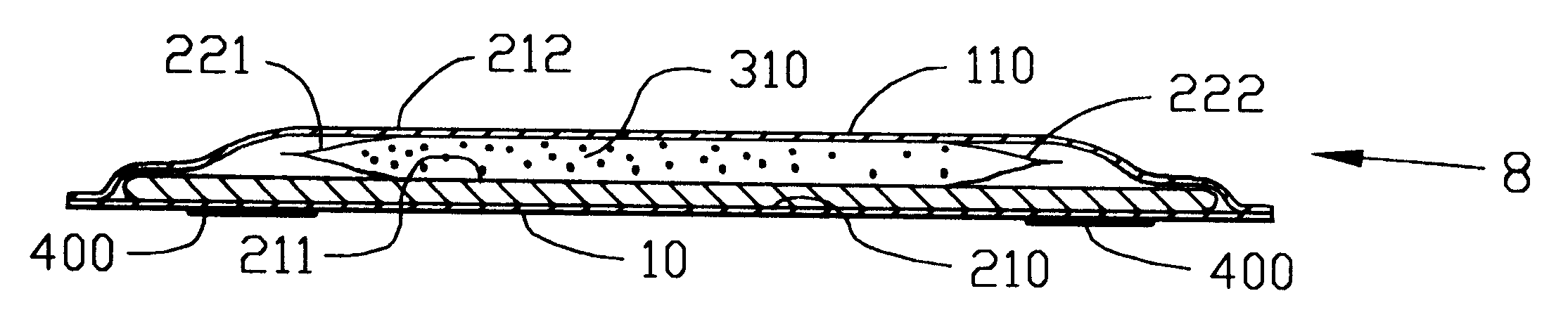

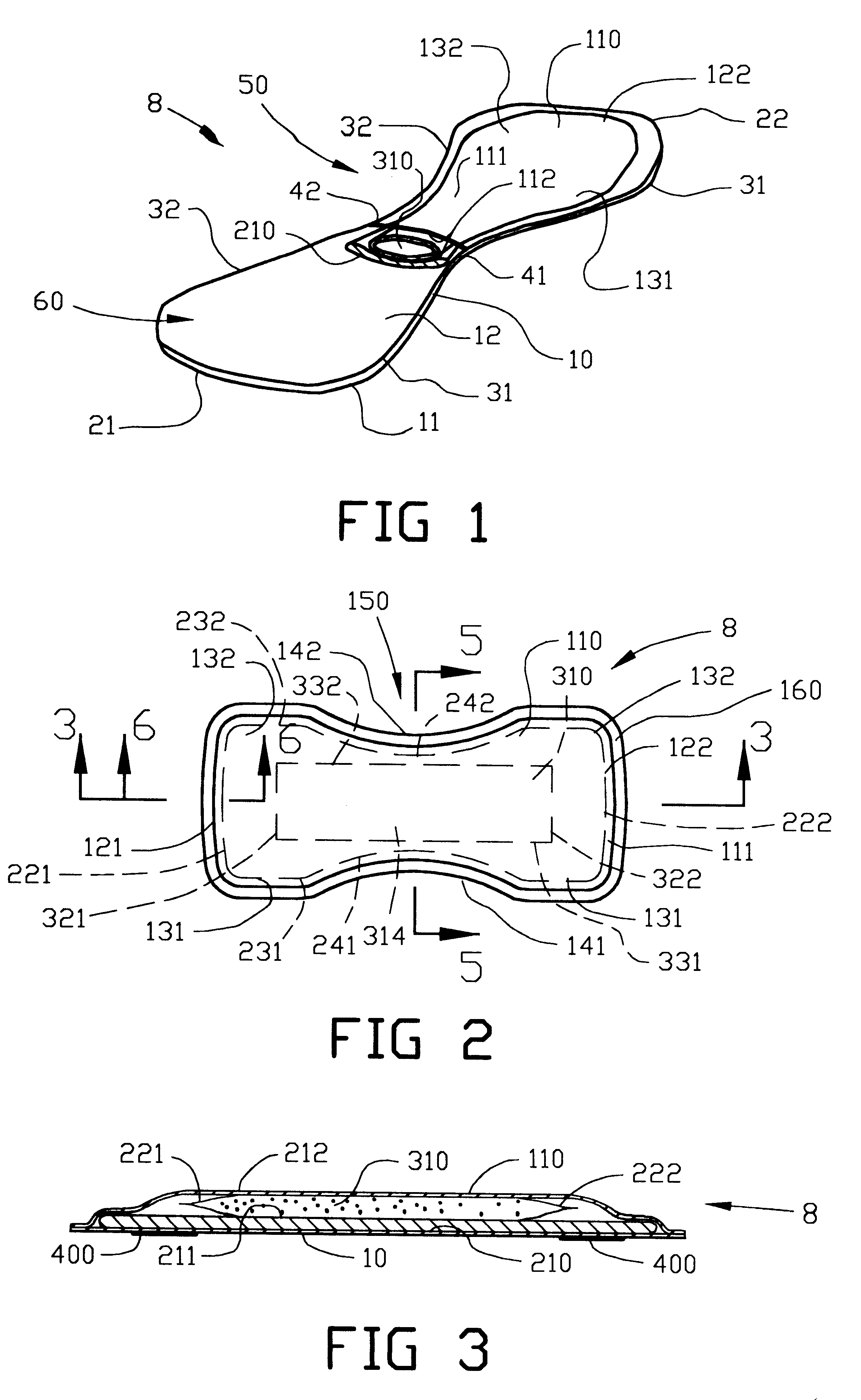

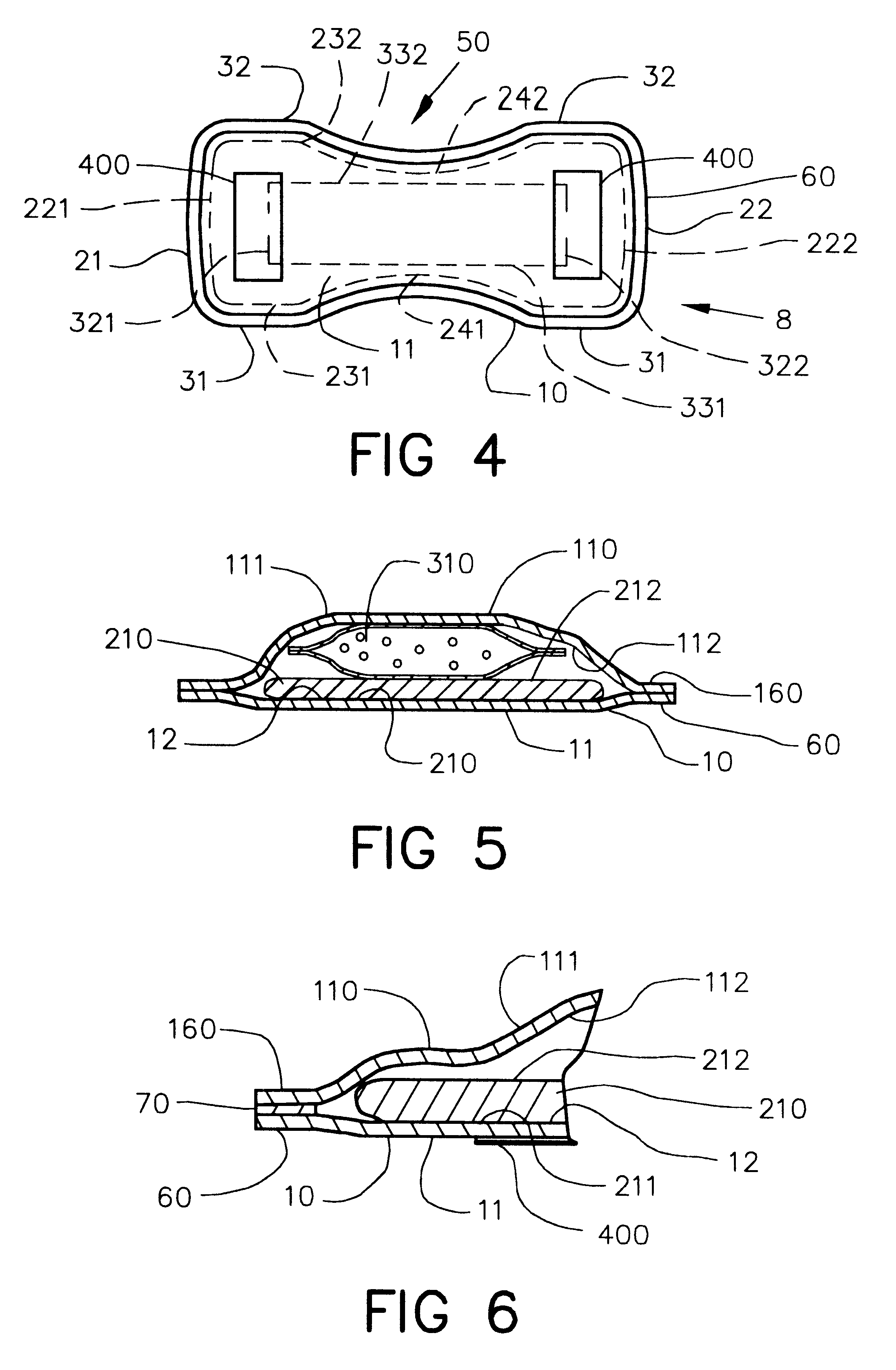

Absorbent pad and thermal pack

InactiveUS6265631B1Eliminate the problemCost of manufactureNon-surgical orthopedic devicesBaby linensChemical mixturesEngineering

An apparatus and method is disclosed for an improved absorbent pad and thermal pack for absorbing a liquid discharged from a patient. The absorbent pad and thermal pad comprises an outer sheet made of a liquid impermeable material and an inner sheet of a liquid permeable material. An absorbent sheet is disposed between the inner sheet and the outer sheet. A flexible liquid impermeable container having a chemical mixture which undergoes an thermal reaction upon activation thereof is interposed between the outer and inner sheets to enable the thermal source to be applied to the patient and to enable any liquid from the patient to permeate through the inner sheet to be absorbed by the absorbent sheet. The inner sheet of a liquid permeable material provides a moderate insulation barrier whereas the absorbent pad provides a substantial insulation barrier for directing the thermal source to the patient.

Owner:COVIDIEN AG

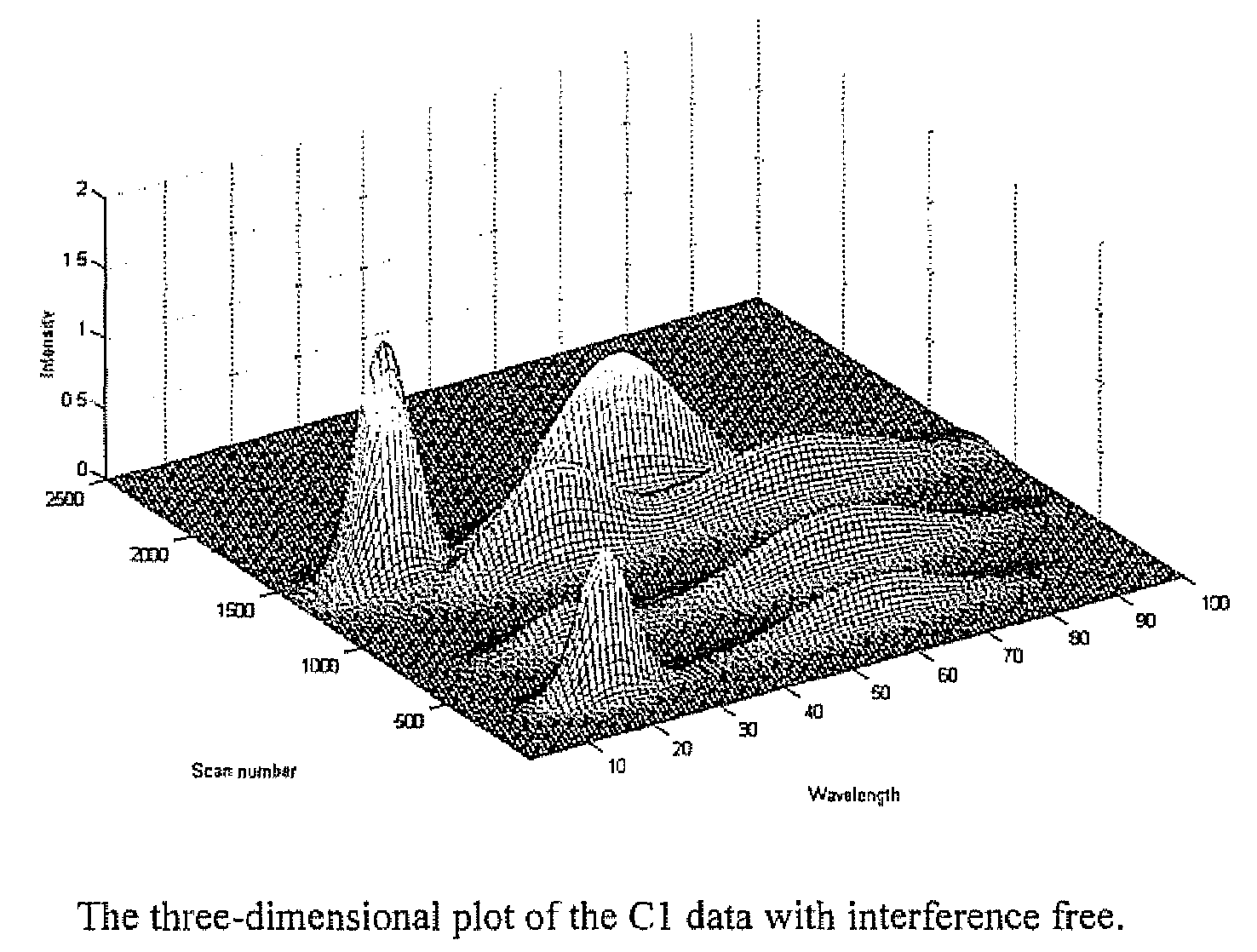

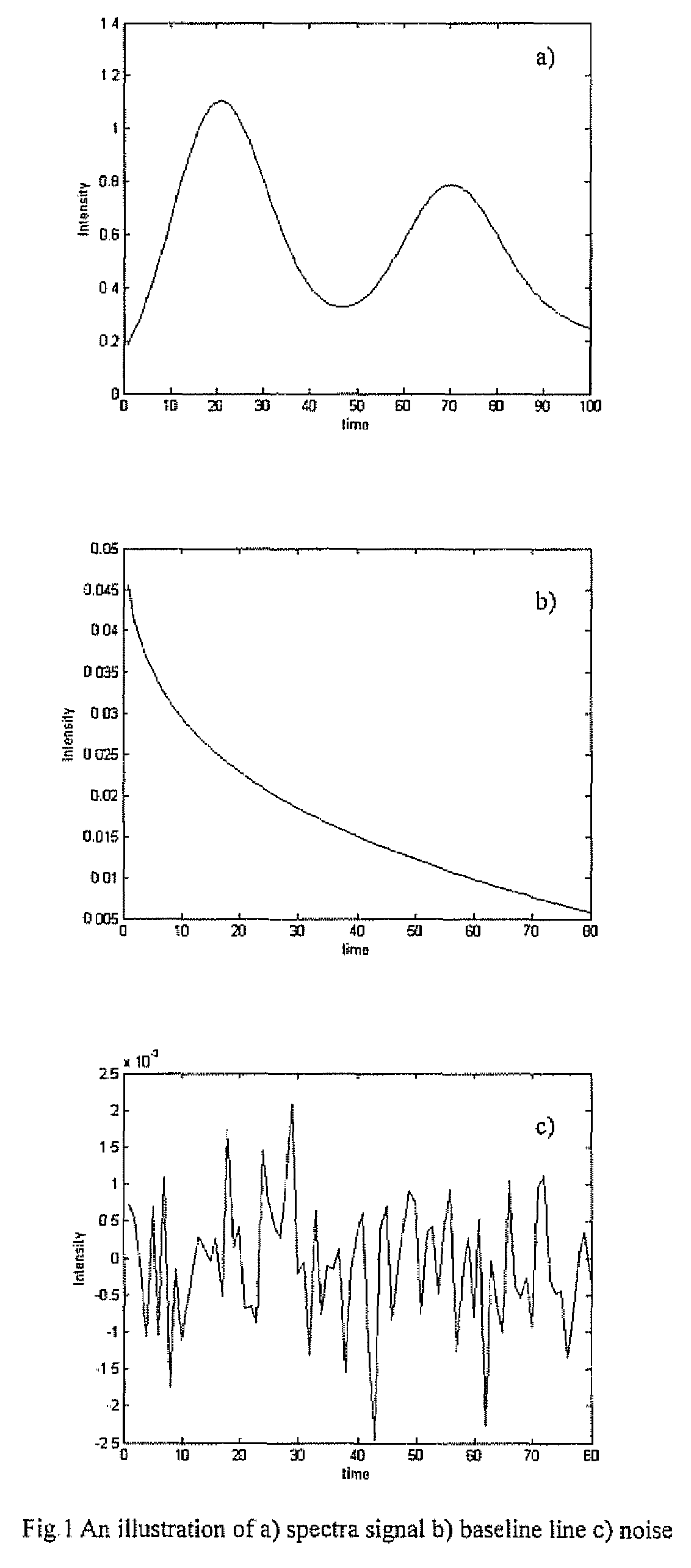

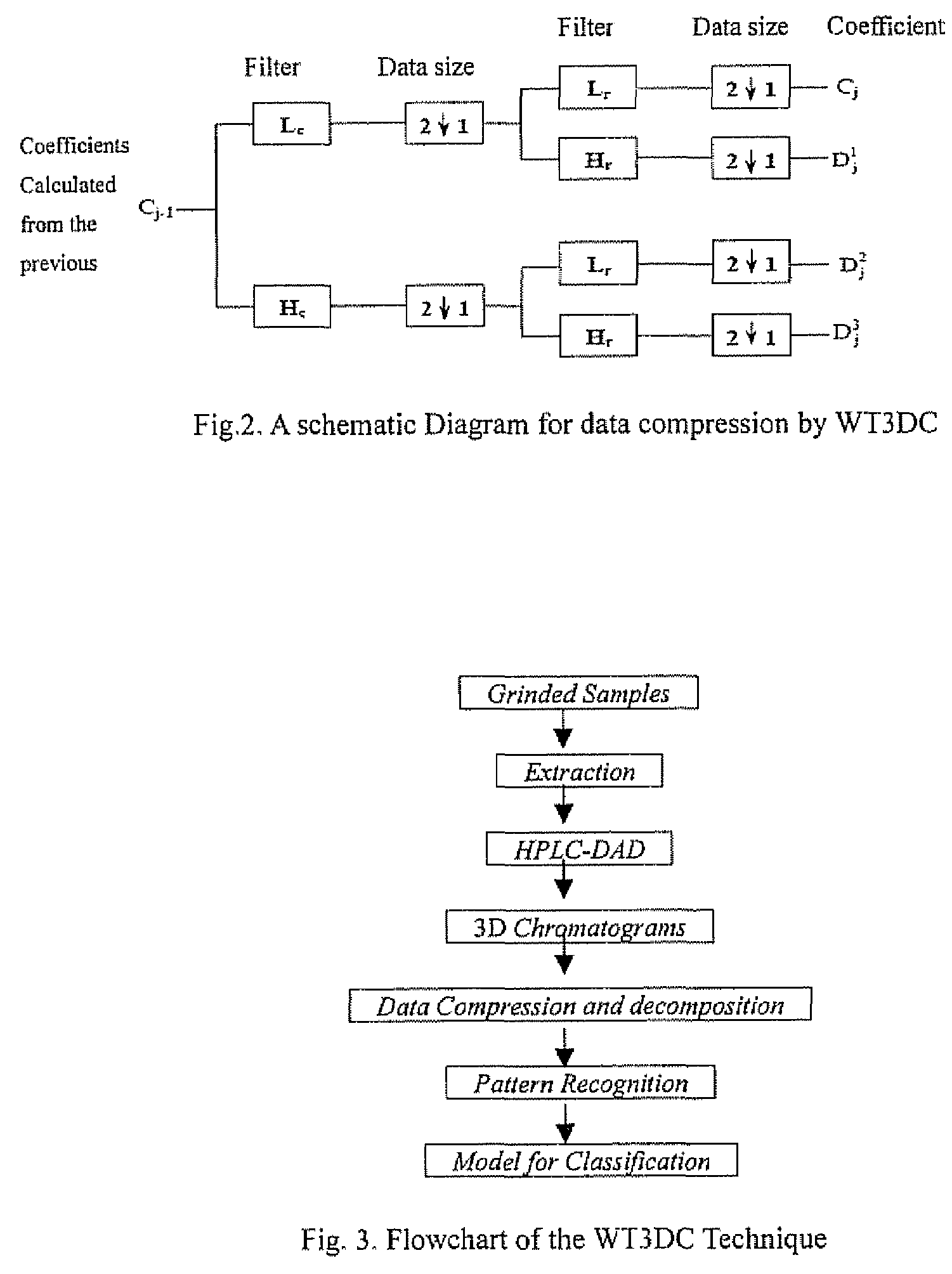

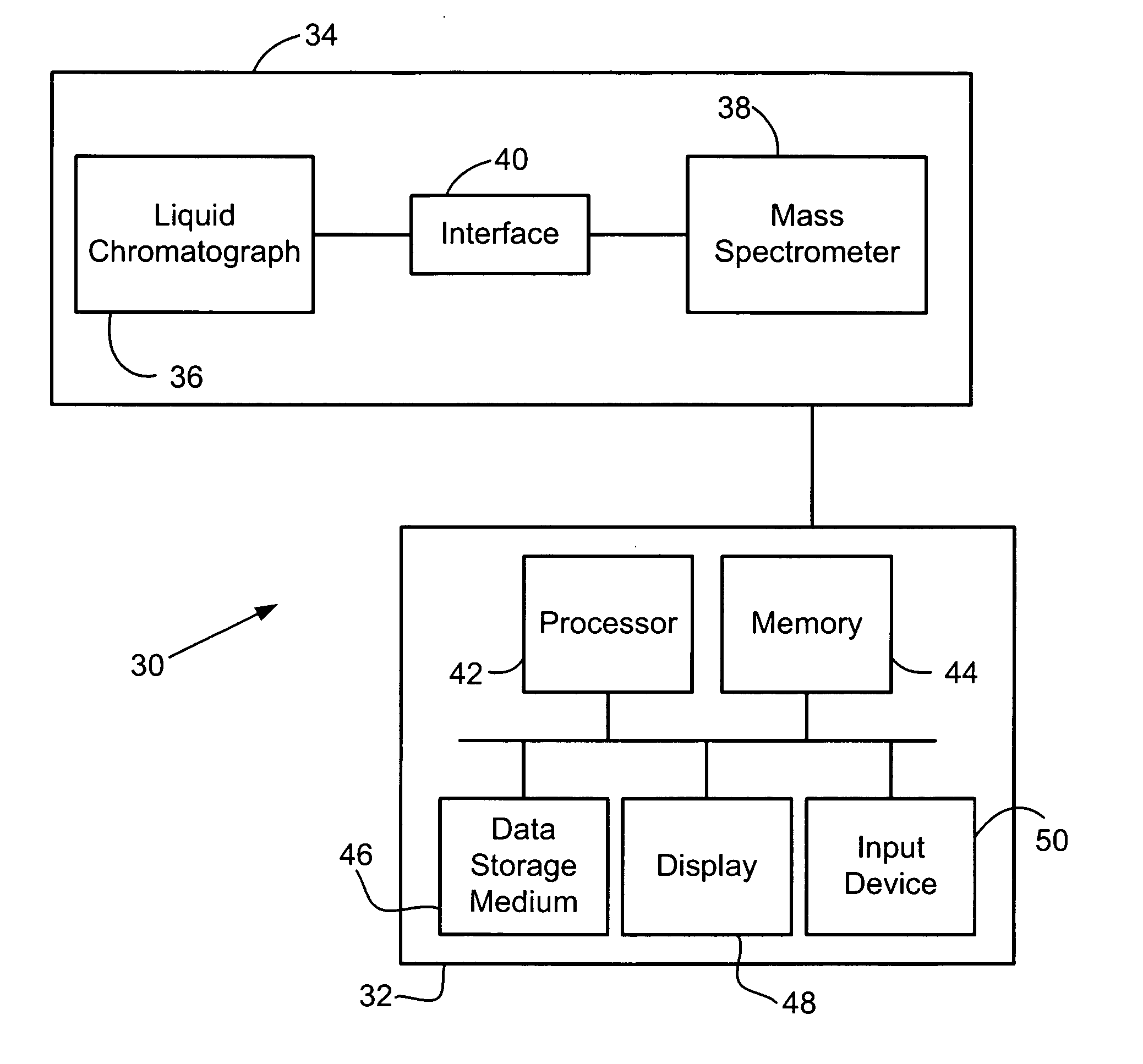

Alignment and autoregressive modeling of analytical sensor data from complex chemical mixtures

InactiveUS20060020401A1Accurate identificationSimple methodComponent separationSpecial data processing applicationsChemical mixturesData compression

The invention provides methods for aligning and filtering chromatograms representative of complex mixture samples. In one embodiment, the invention includes identifying and matching related peaks to determine a temporal offset, and applying a nonlinear temporal shift to account for the offset. In other embodiments, the invention provides methods for smoothing chromatographic data by application of an autoregressive filter to provide improved signal-to-noise ratio, data compression, and resolution. The alignment and filtering methods may be performed separately or combined. In certain embodiments, the invention provides improved chromatographic pattern recognition capability and improved classification of samples of complex chemical and / or biological mixtures.

Owner:CHARLES STARK DRAPER LABORATORY

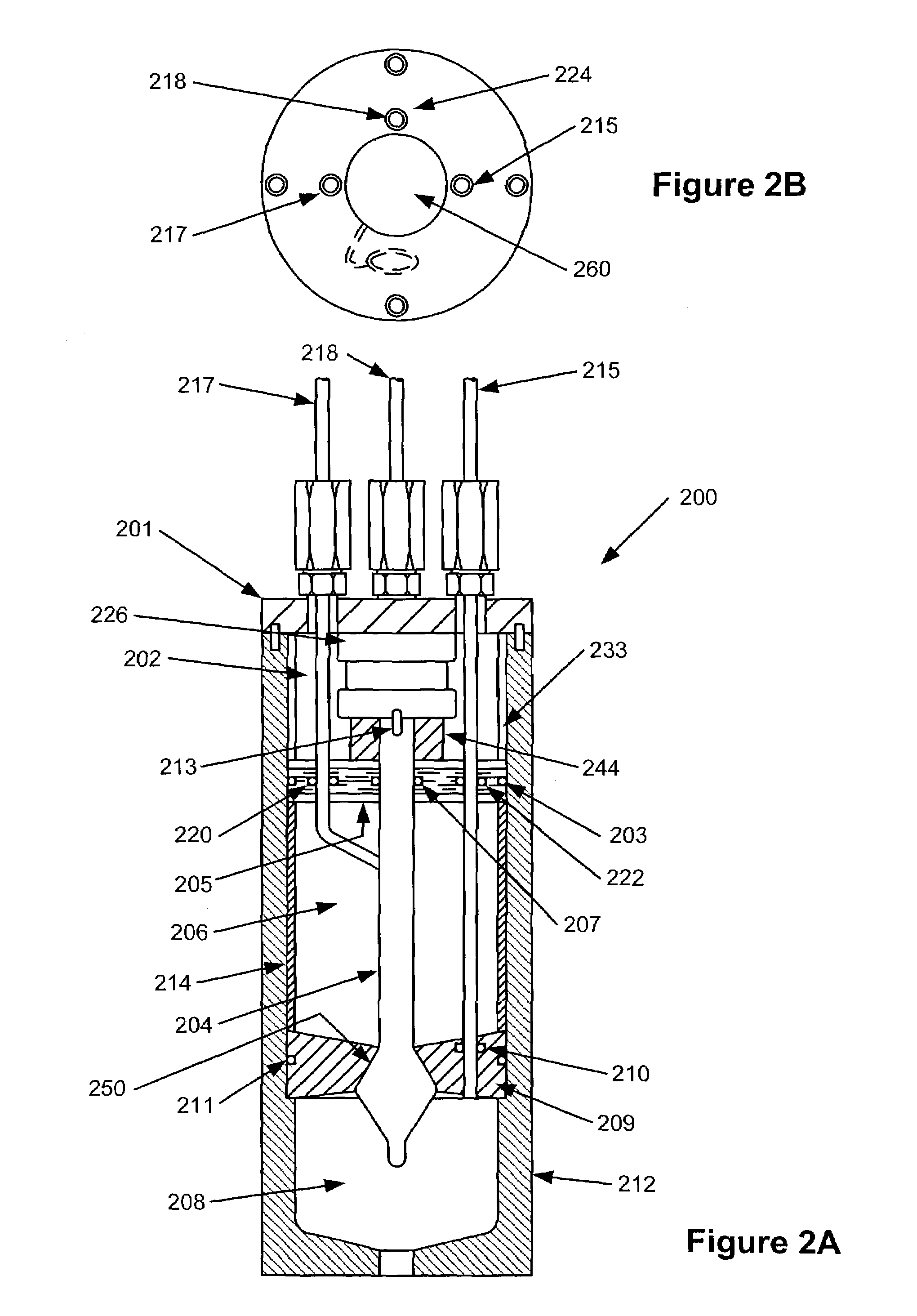

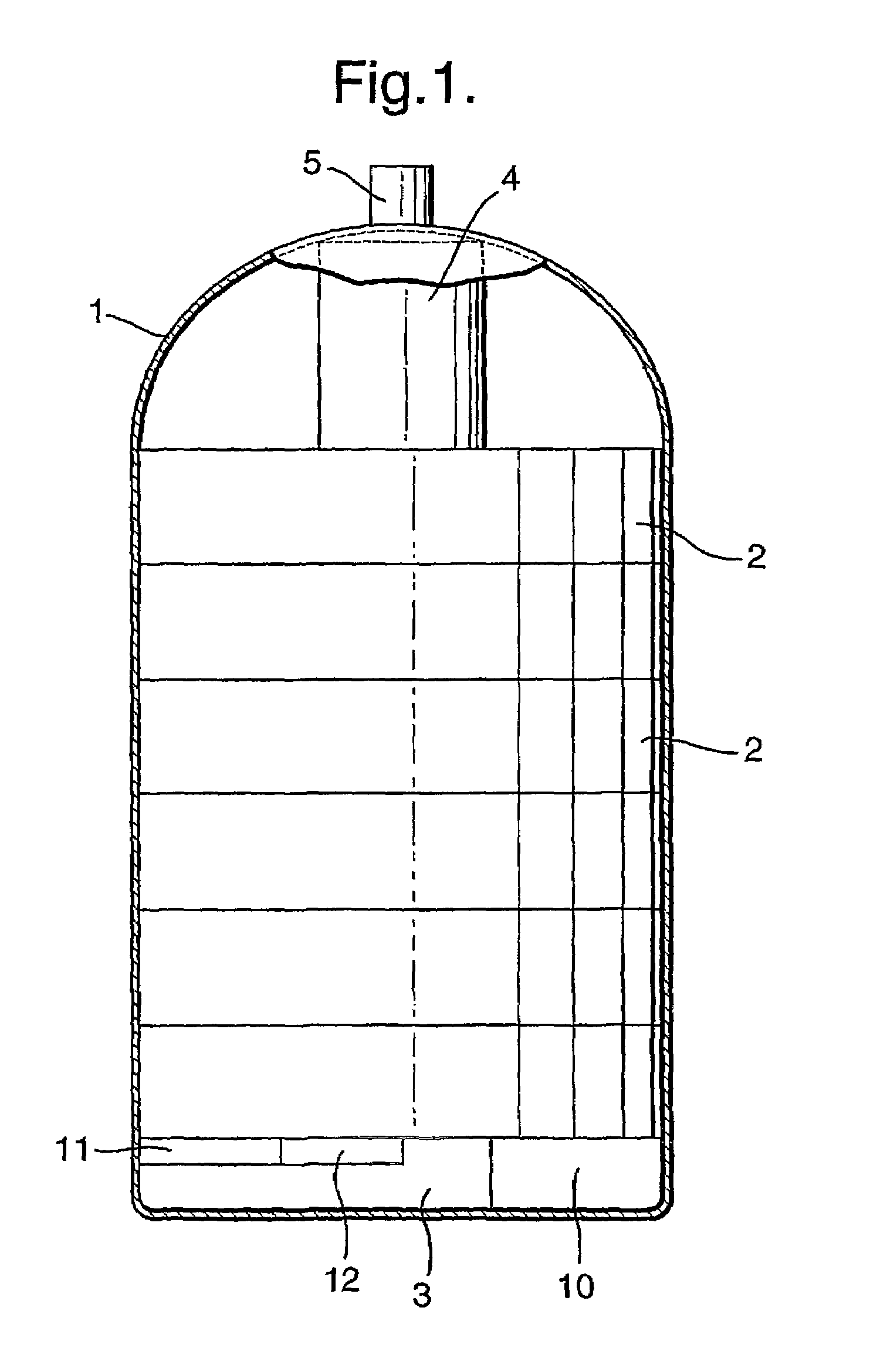

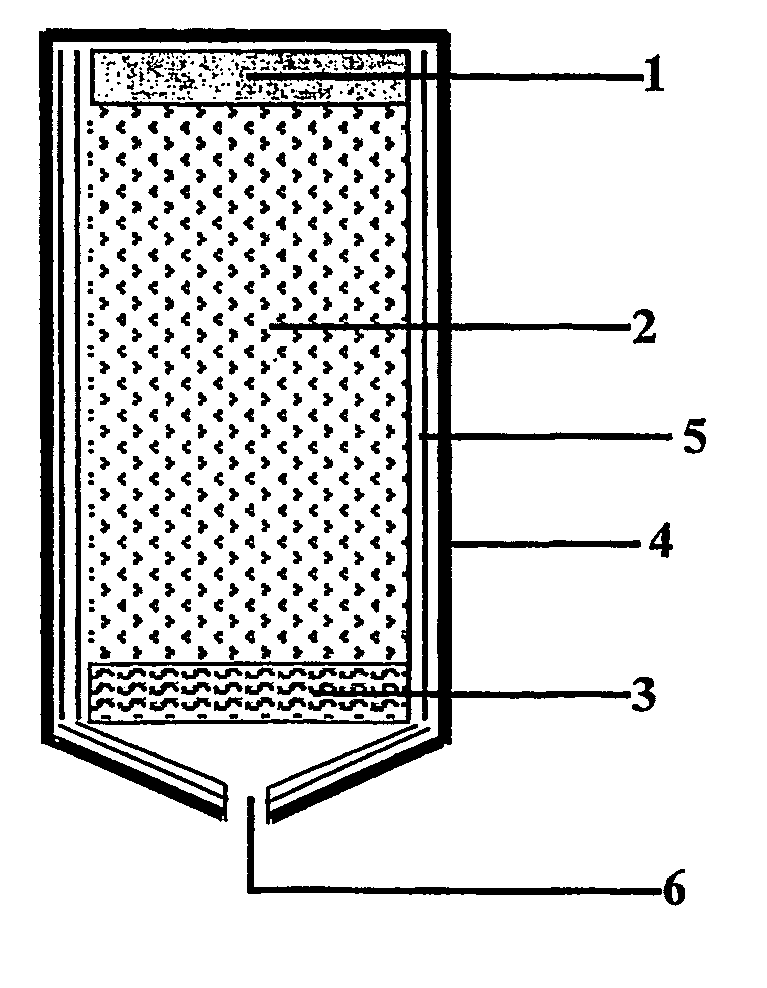

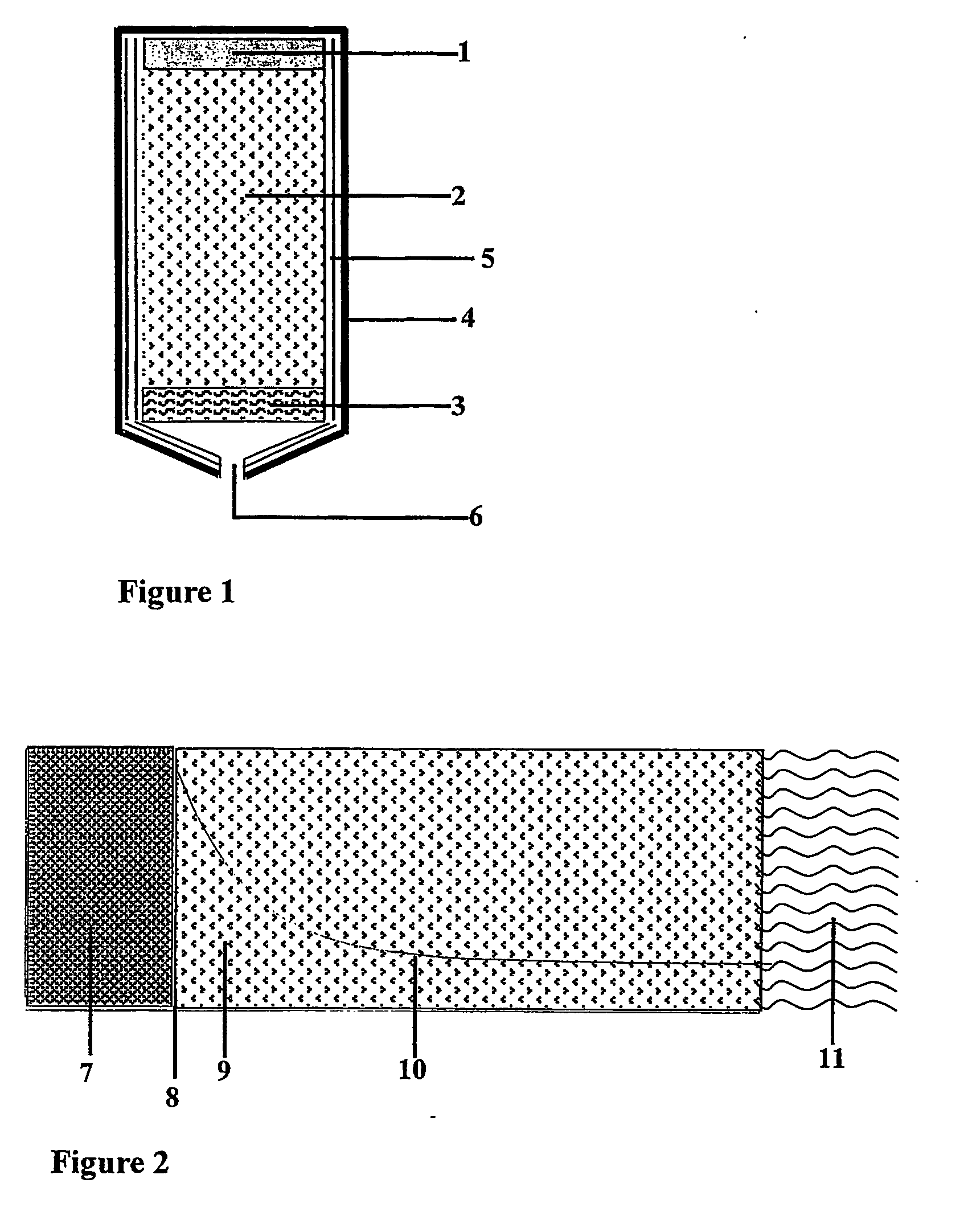

Portable hydrogen source

InactiveUS7682411B2Reduce the temperatureFast conductionFuel cell auxillariesHydrogen productionChemical mixturesHydrogen

A man portable hydrogen source, the source comprising one or more hydrogen generating elements, an ignition control system and a pressure vessel. Each hydrogen generating element comprises a pellet holder provided with one or more recesses and a thermal insulation layer to reduce heat transfer to adjacent hydrogen generating elements; wherein at least one recess contains a pellet of a chemical mixture which on thermal decomposition evolves hydrogen gas; wherein the ignition control system comprises one or more igniters, associated with an individual pellet, and activation means to activate the igniters; and wherein the evolved hydrogen and hydrogen generating elements are contained within the pressure vessel.

Owner:QINETIQ LTD

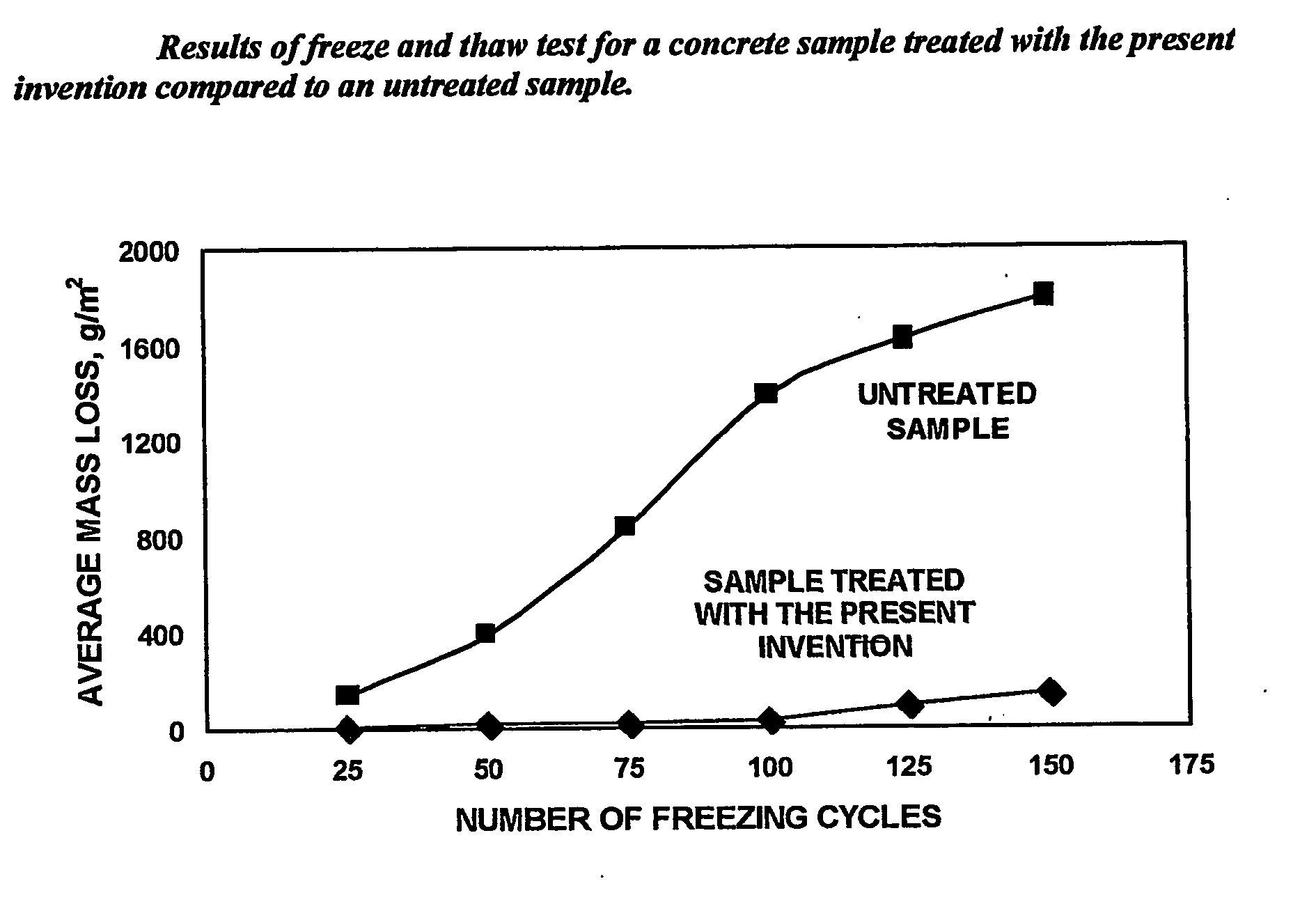

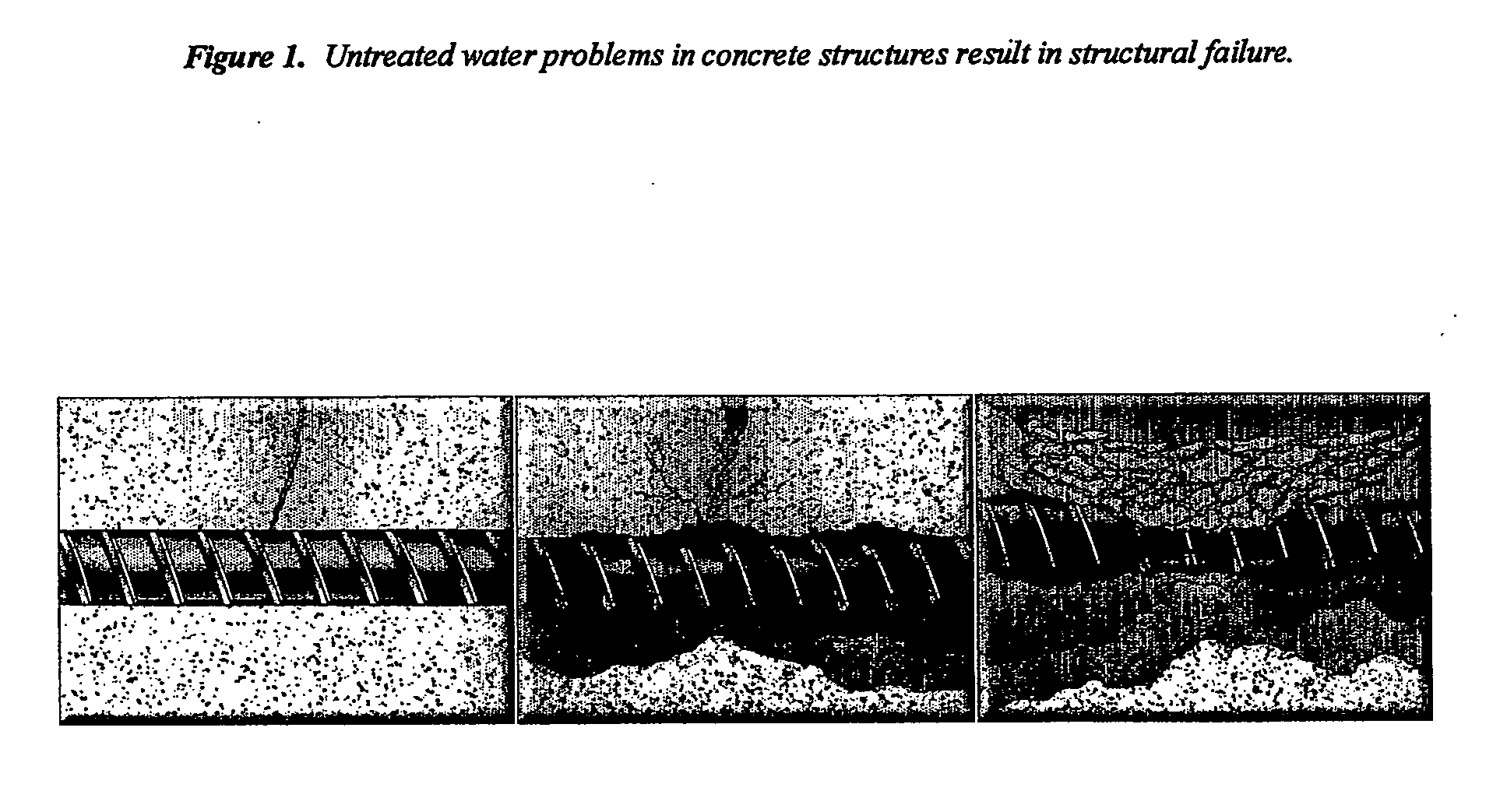

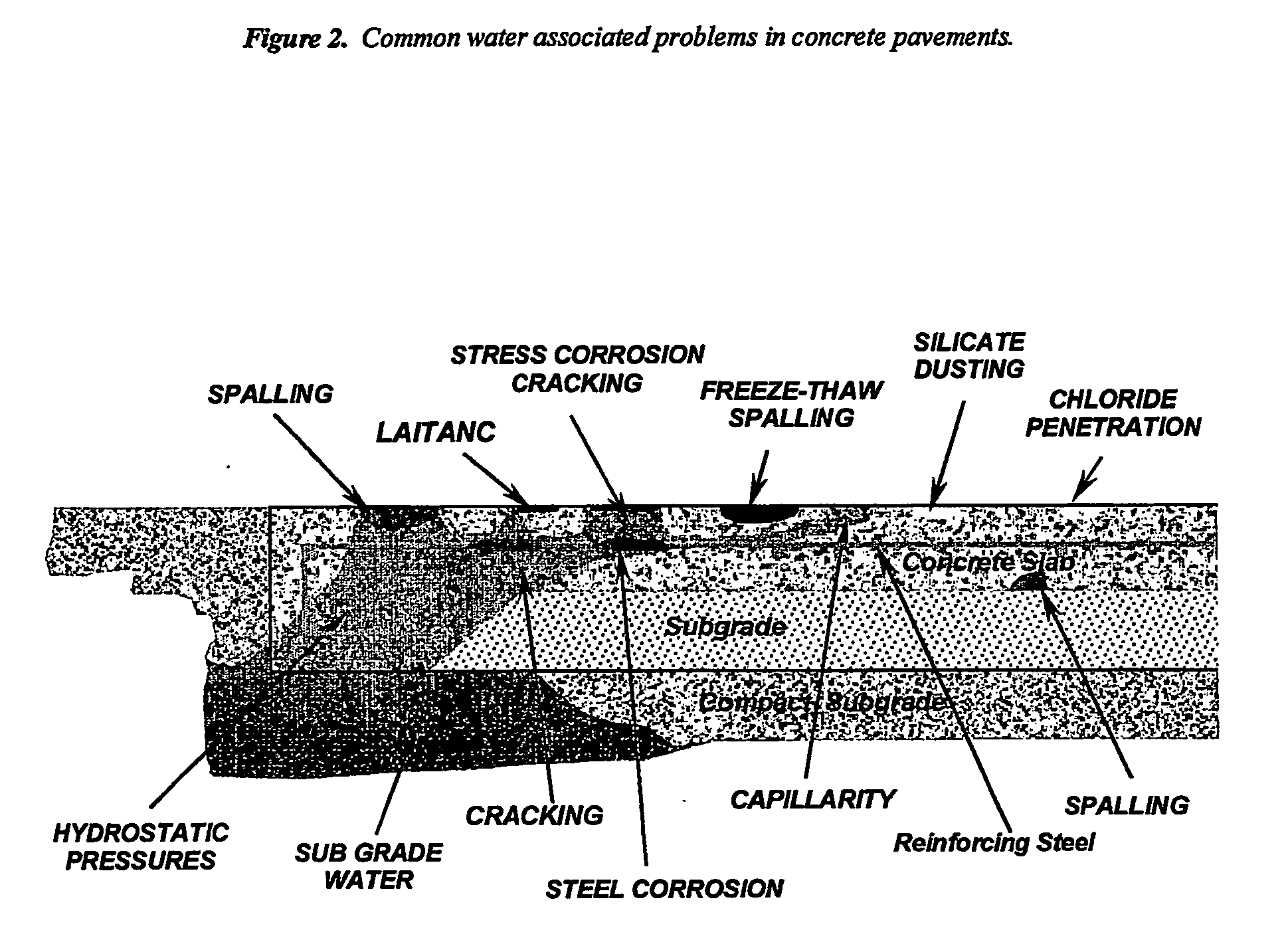

Aqueous chemical mixture to mitigate water associated problems in concrete pavements

InactiveUS20060048670A1Other chemical processesAlkali metal silicate coatingsChemical mixturesSoil science

A water-based mixture of multi compounds was invented for the purposes of treating and providing an ultimate protection for large areas of concrete pavements against moisture and moisture-associated problems. The mixture preferably works from within the concrete as well as at the surface. A water-repelling function prevents water from penetrating the concrete matrix. A hygroscopic and hydrophilic behavior of its crystallization system within a concrete matrix minimizes moisture transmission through capillaries and connected voids. As a result, the mixture promises to provide a permanent treatment for moisture related problems, such as damage caused by repeated freeze and thaw cycles and chloride ion penetration as from deicing salts, as well as a permanent treatment for the so-called alkali-silica reactions.

Owner:RASHED RADI

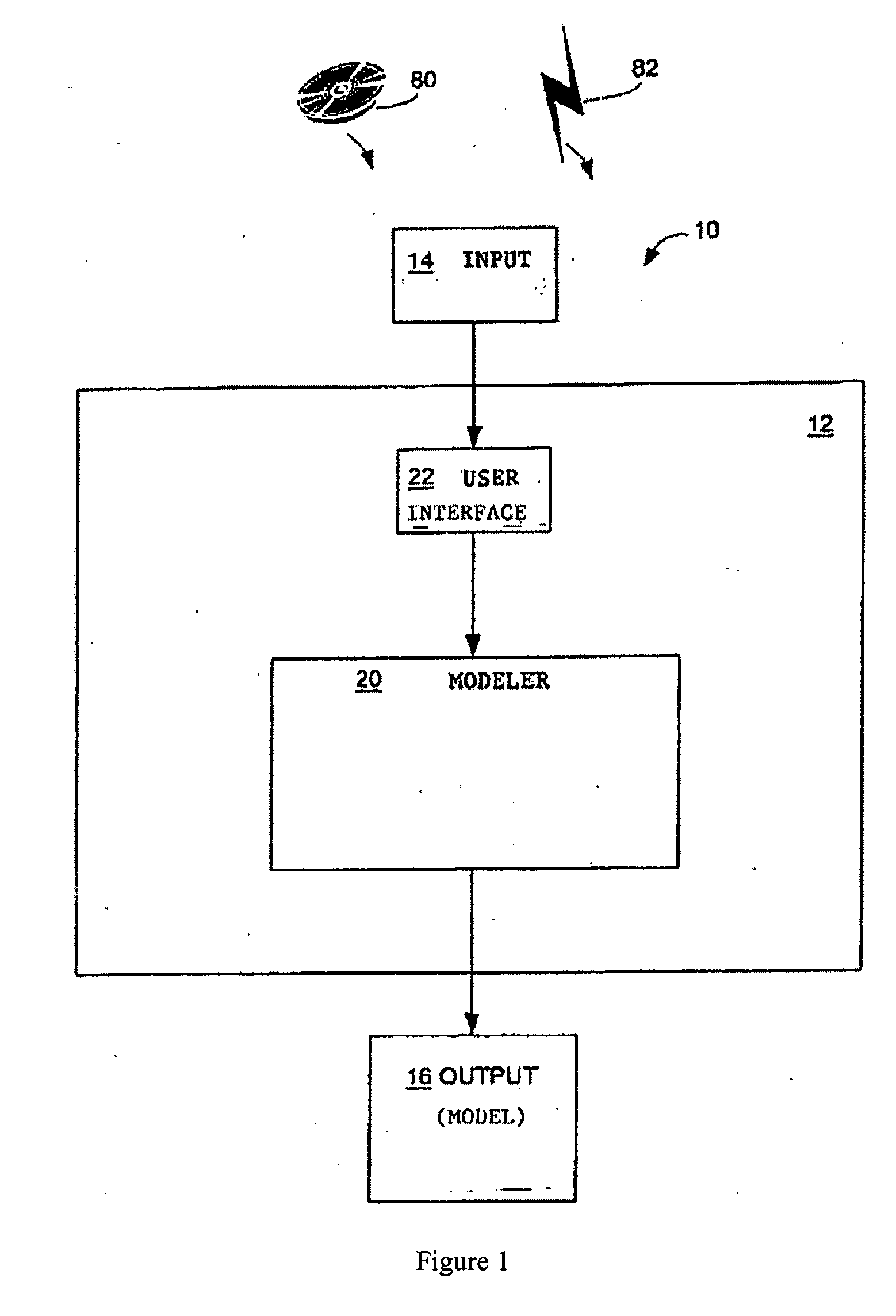

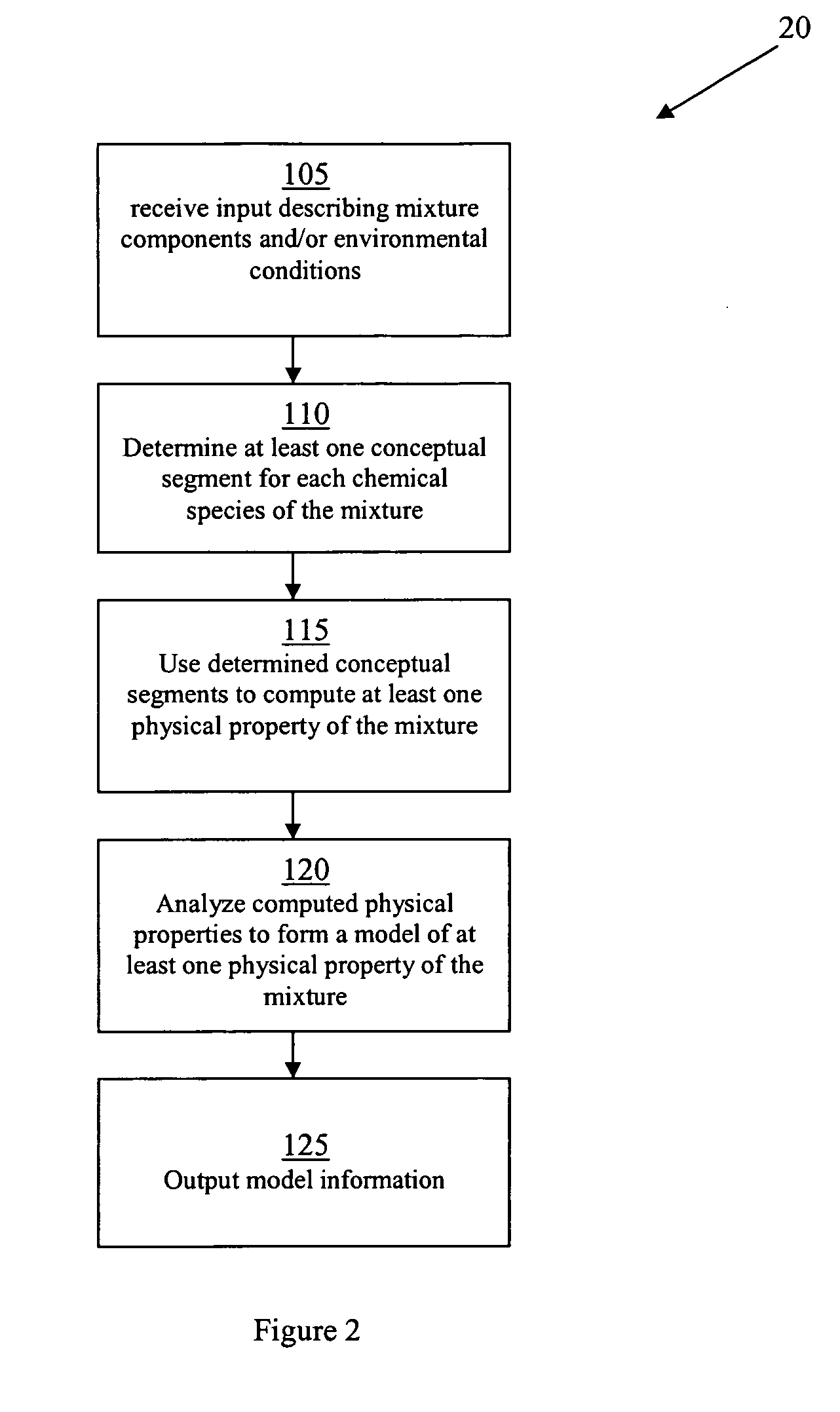

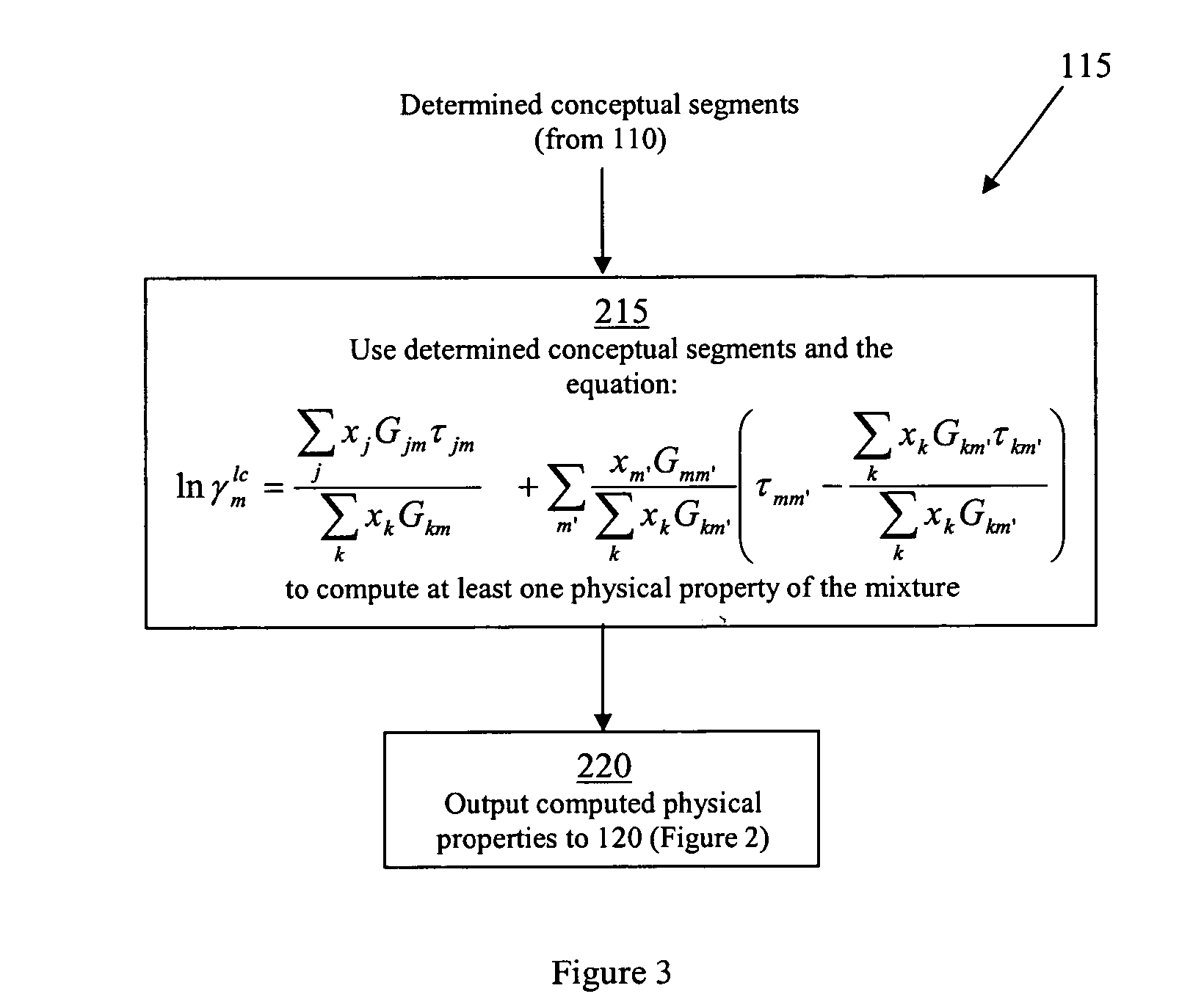

Methods of modeling physical properties of chemical mixtures and articles of use

ActiveUS20050187748A1Fast and practical modelingImprove accuracyChemical property predictionAnalogue computers for chemical processesChemical mixturesChemical species

Included are methods for modeling at least one physical property of a mixture of at least two chemical species. One or more chemical species of the mixture are approximated or represented by at least one conceptual segment. The conceptual segments are then used to compute at least one physical property of the mixture. An analysis of the computed physical properties forms a model of at least one physical property of the mixture. Also included are computer program products and computer systems for implementing the modeling methods.

Owner:ASPENTECH CORP

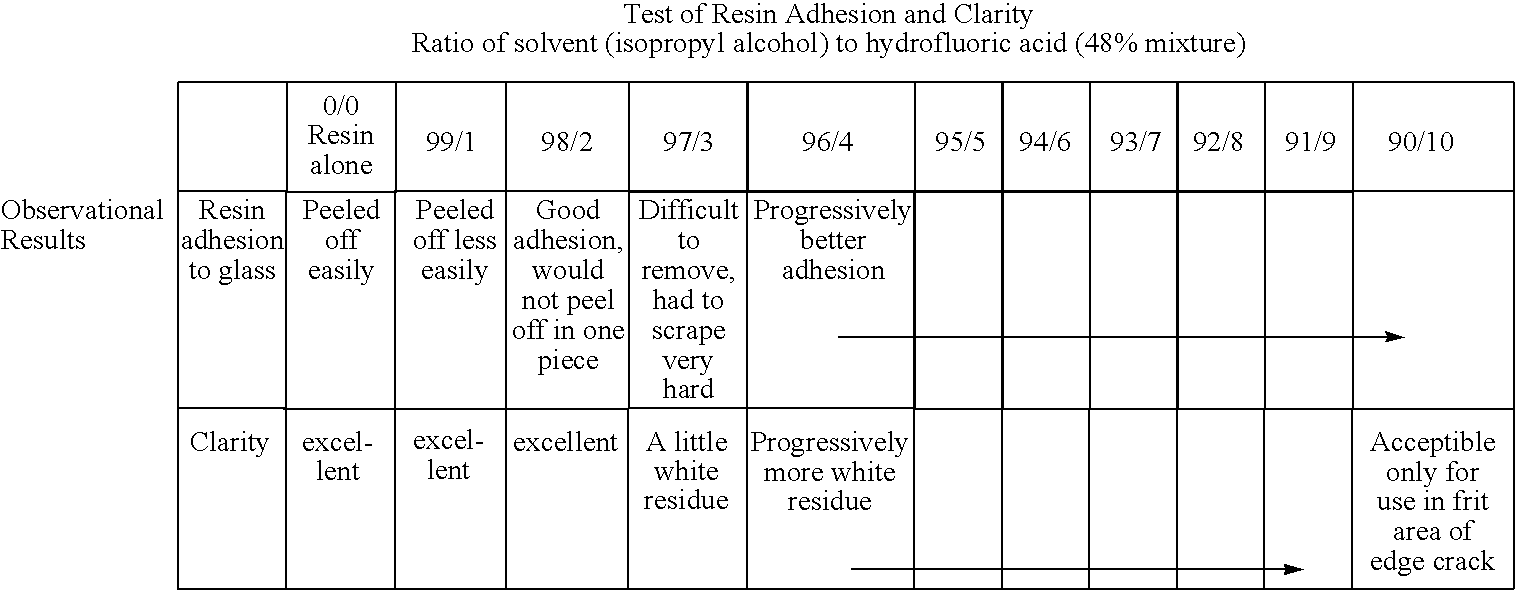

Method and System for Repair of Glass

A pre-treatment chemical mixture of hydrofluoric acid or ammonium bifluoride and isopropyl alcohol for glass adhesive applications. In one particular a pretreatment for the repair of stone breaks and long cracks in windshields. The pretreatment improves the repair by removing, through evaporation of the solvent, isopropyl alcohol, the hydrophobic coating that has been applied to the windshield when it was manufactured and simultaneously etching the sides of the stone break or long crack in a way that allows better adhesion by the adhesive repair resin while not leaving any trace of the etching after the repair is complete, thereby keeping the windshield or other glass, clear.

Owner:CAMPFIELD RICHARD +1

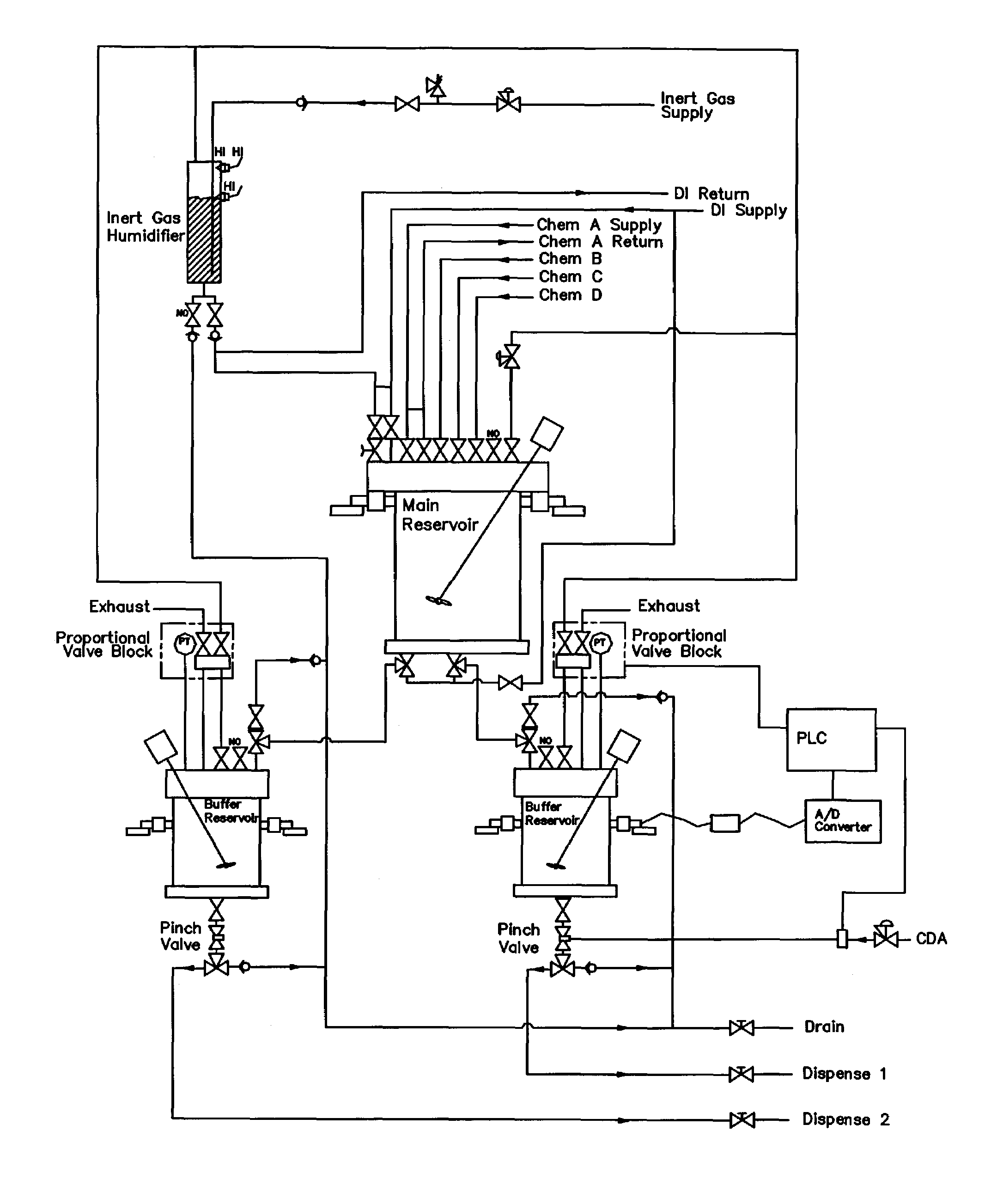

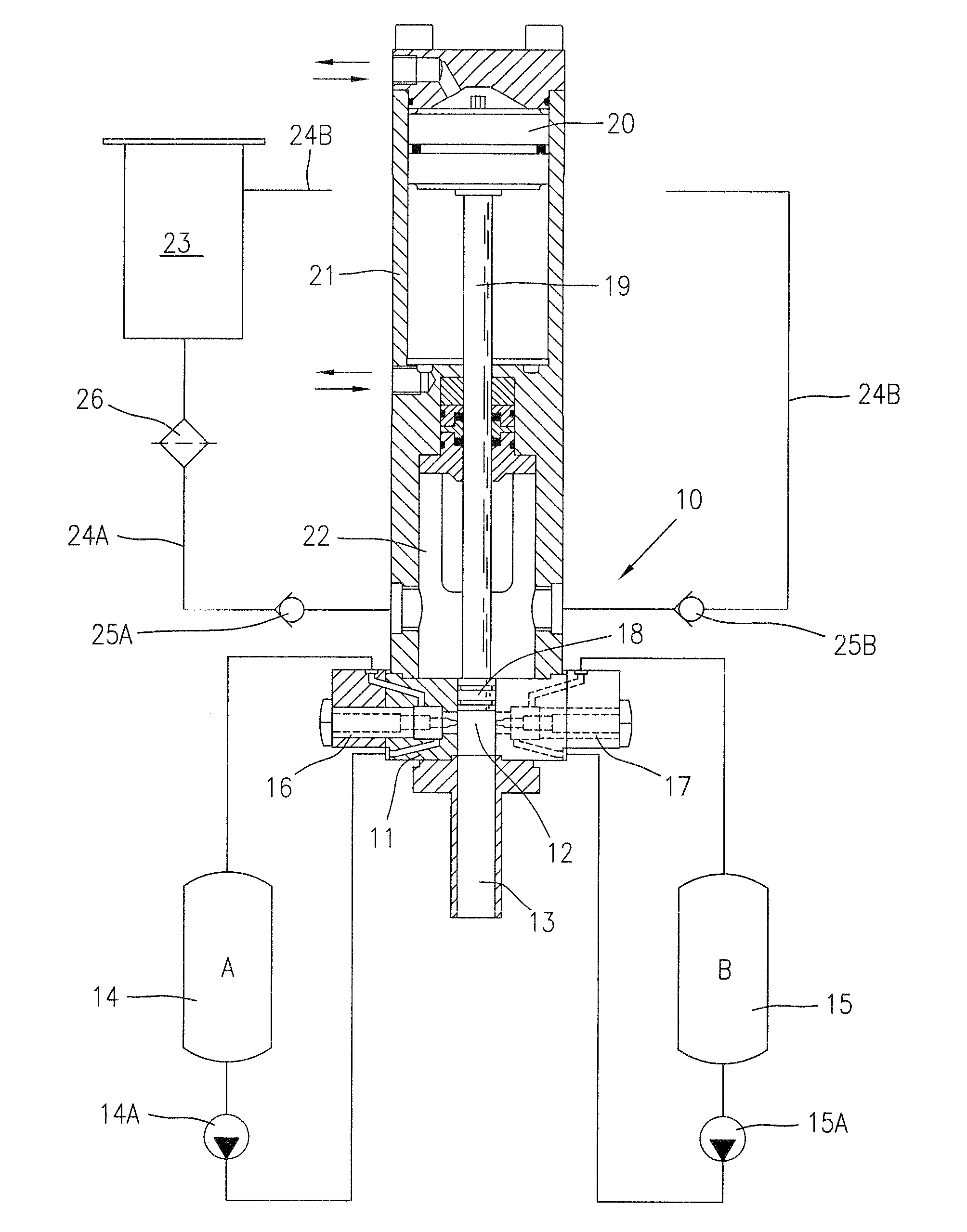

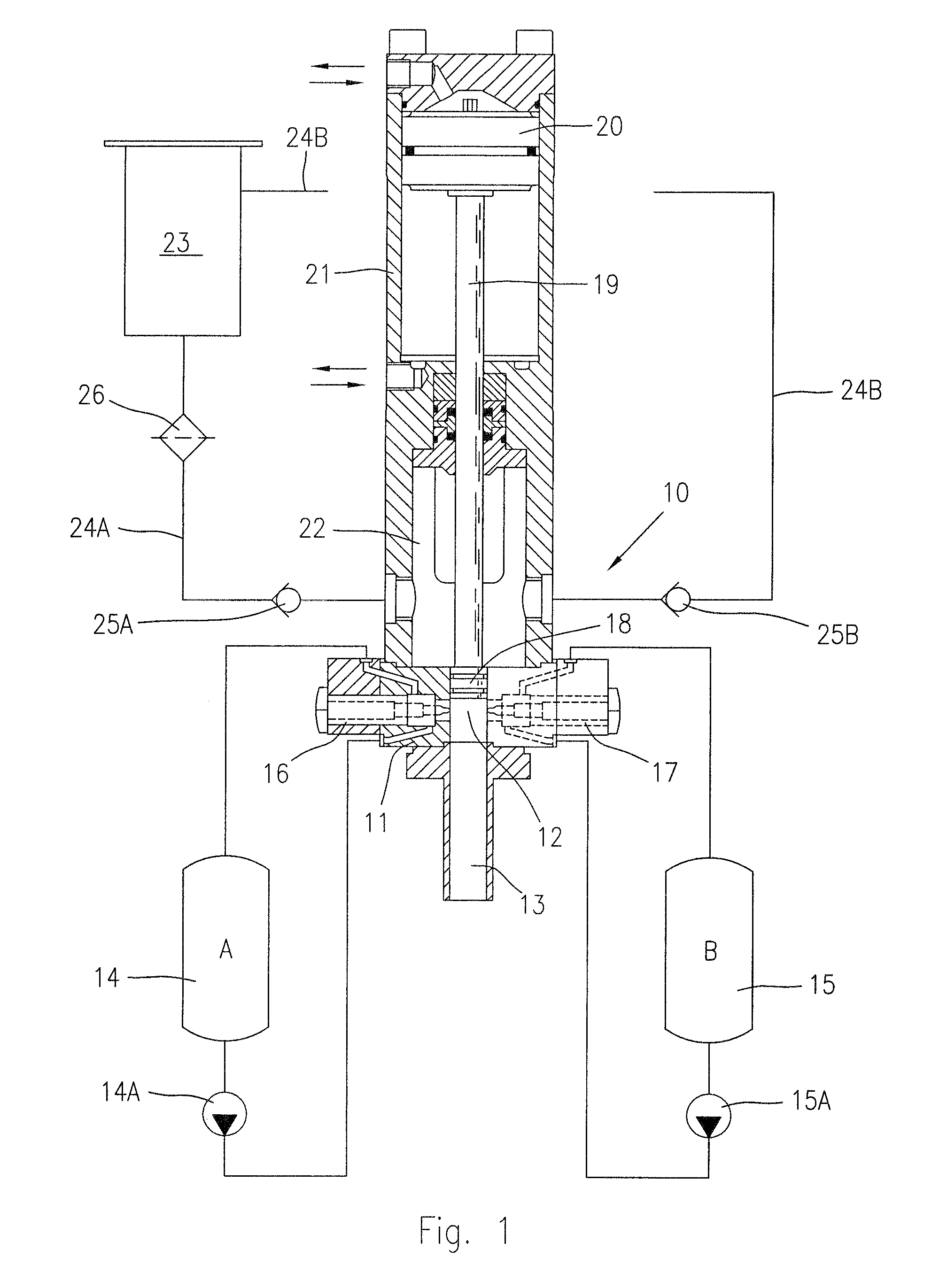

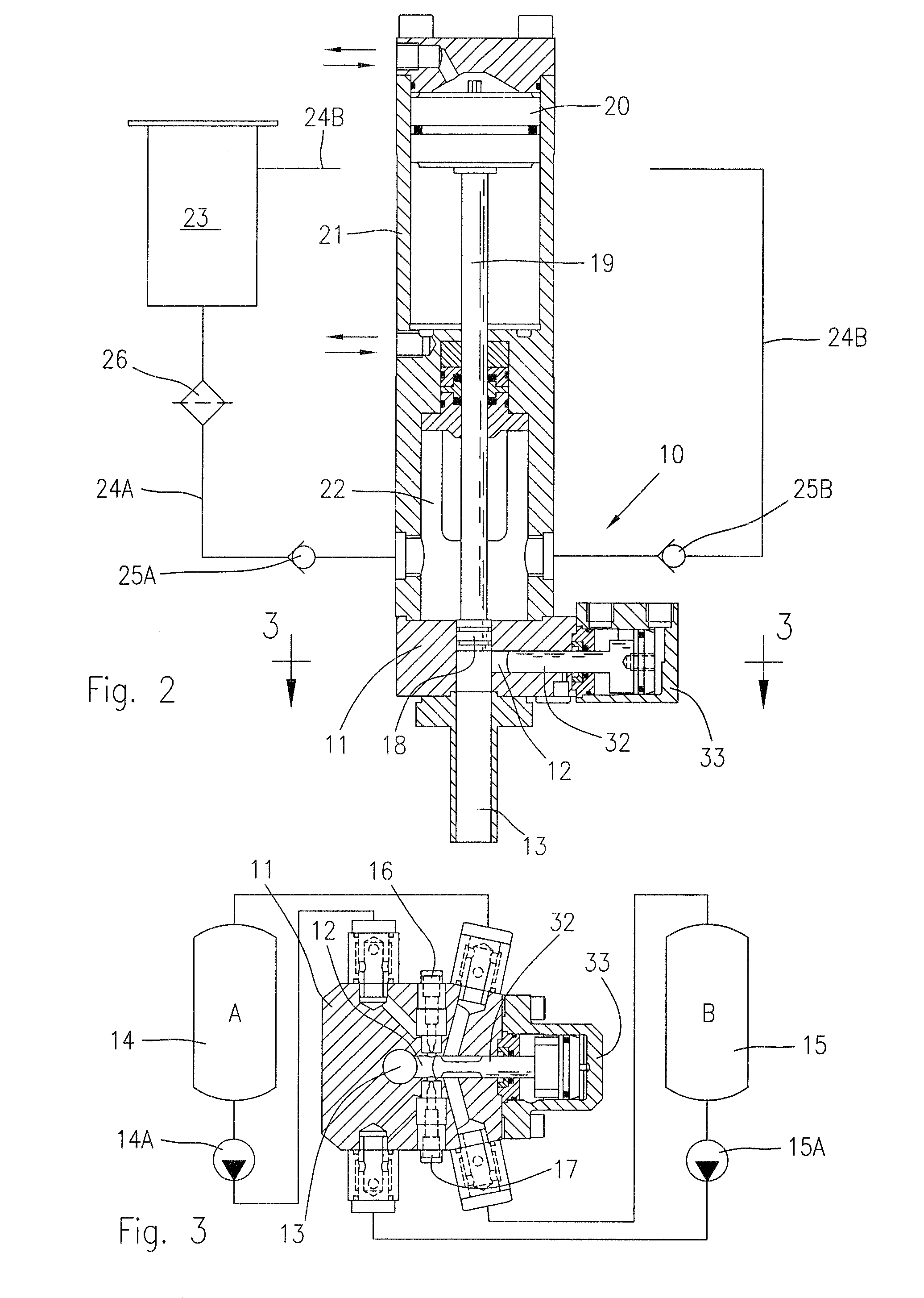

Chemical mix and delivery systems and methods thereof

InactiveUS7007822B2Accurate flowBlock deliveryLiquid flow controllersSemiconductor/solid-state device manufacturingChemical mixturesCompound (substance)

The present invention relates to chemical delivery systems and methods for delivery of liquid chemicals. In one embodiment, the present invention relates to systems having multi-reservoir load cell assemblies for delivering chemicals used in the semiconductor industry. In one embodiment, the present invention provides a multi-reservoir load cell assembly, including a controller, a buffer reservoir, a main reservoir, one or more load cells, coupled to the assembly and to the controller, operable to weigh the liquid in the reservoir(s), a plurality of supply lines, each supply line having a valve and connecting one of the supply containers to the main reservoir, and a gas and vacuum sources for withdrawing the liquid from the assembly when demanded by the controller and for refilling the assembly from the supply containers.

Owner:AIR LIQUIDE ELECTRONICS US LP

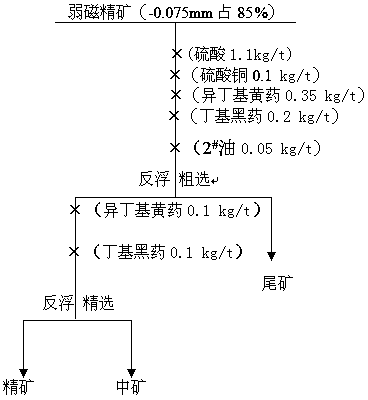

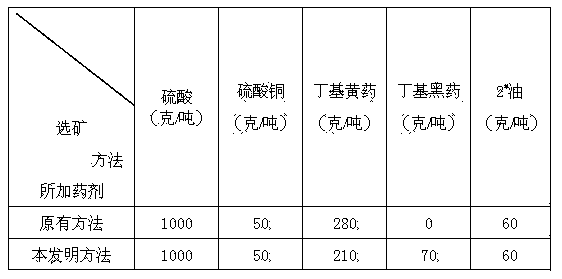

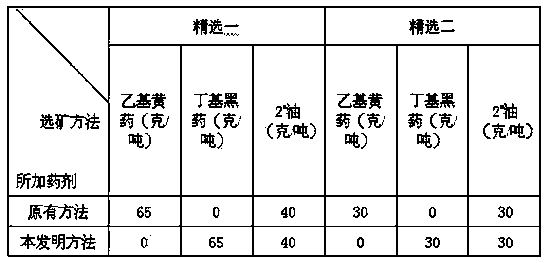

Ore dressing method for removing pyrrhotite from iron ore

InactiveCN104069937AEnhanced harvesting capacityGood beneficiation effectFlotationWet separationChemical mixturesIronstone

The invention discloses an ore dressing method for removing pyrrhotite from iron ore. The ore dressing method for removing the pyrrhotite from the iron ore includes that performing crushing, ore grinding, grading and low intensity magnetic separation techniques to obtain low intensity magnetic concentrate, wherein the TFE grade of the low intensity magnetic concentrate is more than or equal to 65.0%, and the low intensity magnetic concentrate comprises 0.5-1.4% of S; carrying out reverse flotation roughing and reverse flotation selection on the low intensity magnetic concentrate to obtain low-pyrite concentrate with less than 0.15% of S. Weighted by the dry ore amount for the reverse flotation, the reverse flotation roughing chemical comprises (1) pH regulating agent, to be specific, 800-1200 g / t of sulfuric acid; (2) activating agent, to be specific, 80-150 g / t of copper sulfate; (3) collecting agent, to be specific, 250-400 g / t of iso-butyl xanthate and 150-250 g / t of butyl dithiophosphate; (4) foaming agent, to be specific, 30-70 g / t of 2# oil. The ore dressing method for removing the pyrrhotite from the iron ore uses the butyl dithiophosphate and butyl xanthate or iso-butyl xanthate to form sulfur content reducing chemical mixture, the molecular arrangement between the chemical micelles is improved to form a synergistic effect, the chemical is good for mineralizing and adsorbing, the hydrophobicity and the floating speed are properly reinforced, and the sulfur content of the iron concentrate is reduced to less than or equal to 0.03-0.15%. The ore dressing method for removing the pyrrhotite from the iron ore is especially suitable for removing the pyrrhotite from the iron ore with pyrrhotite through reverse flotation.

Owner:马钢集团设计研究院有限责任公司 +1

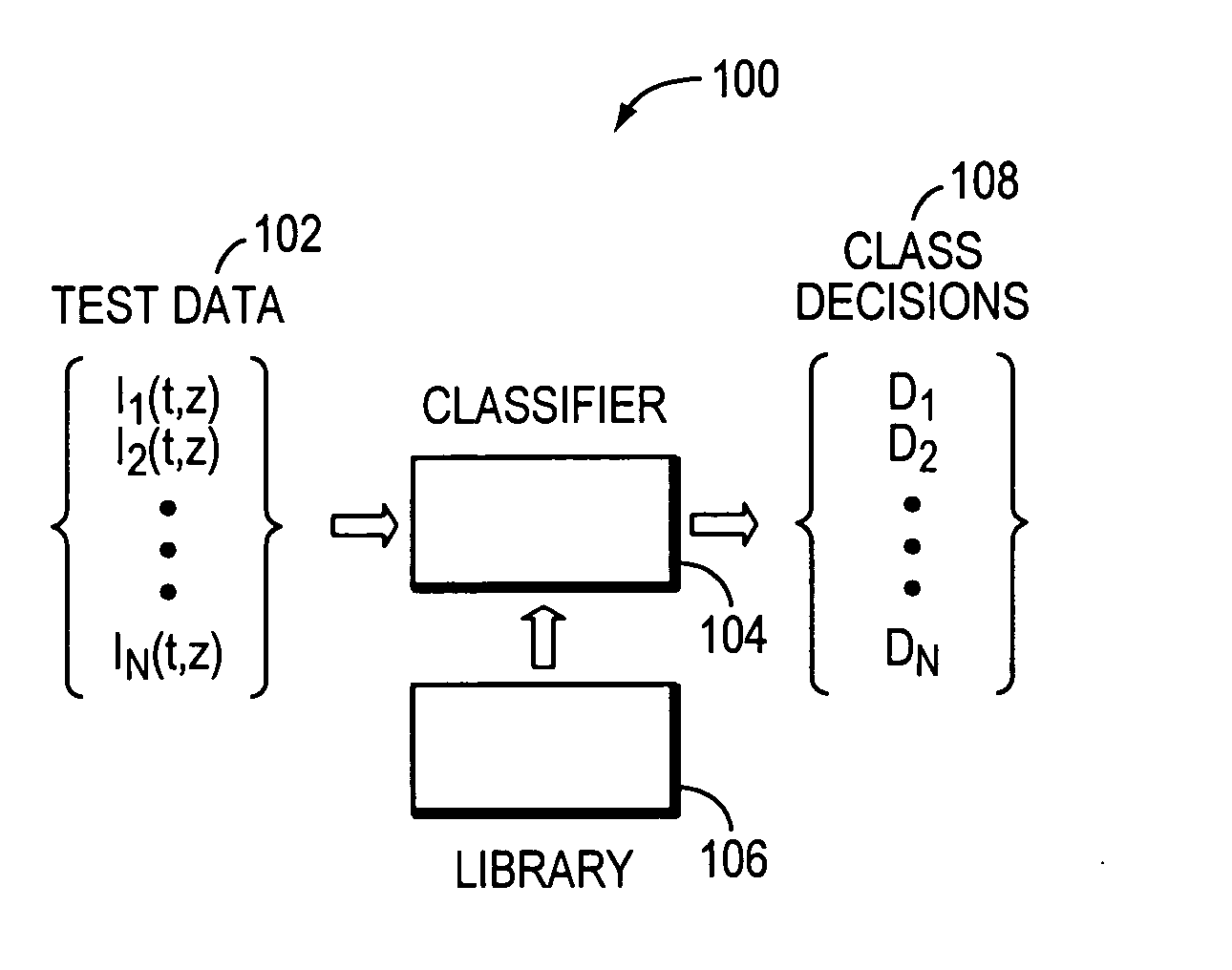

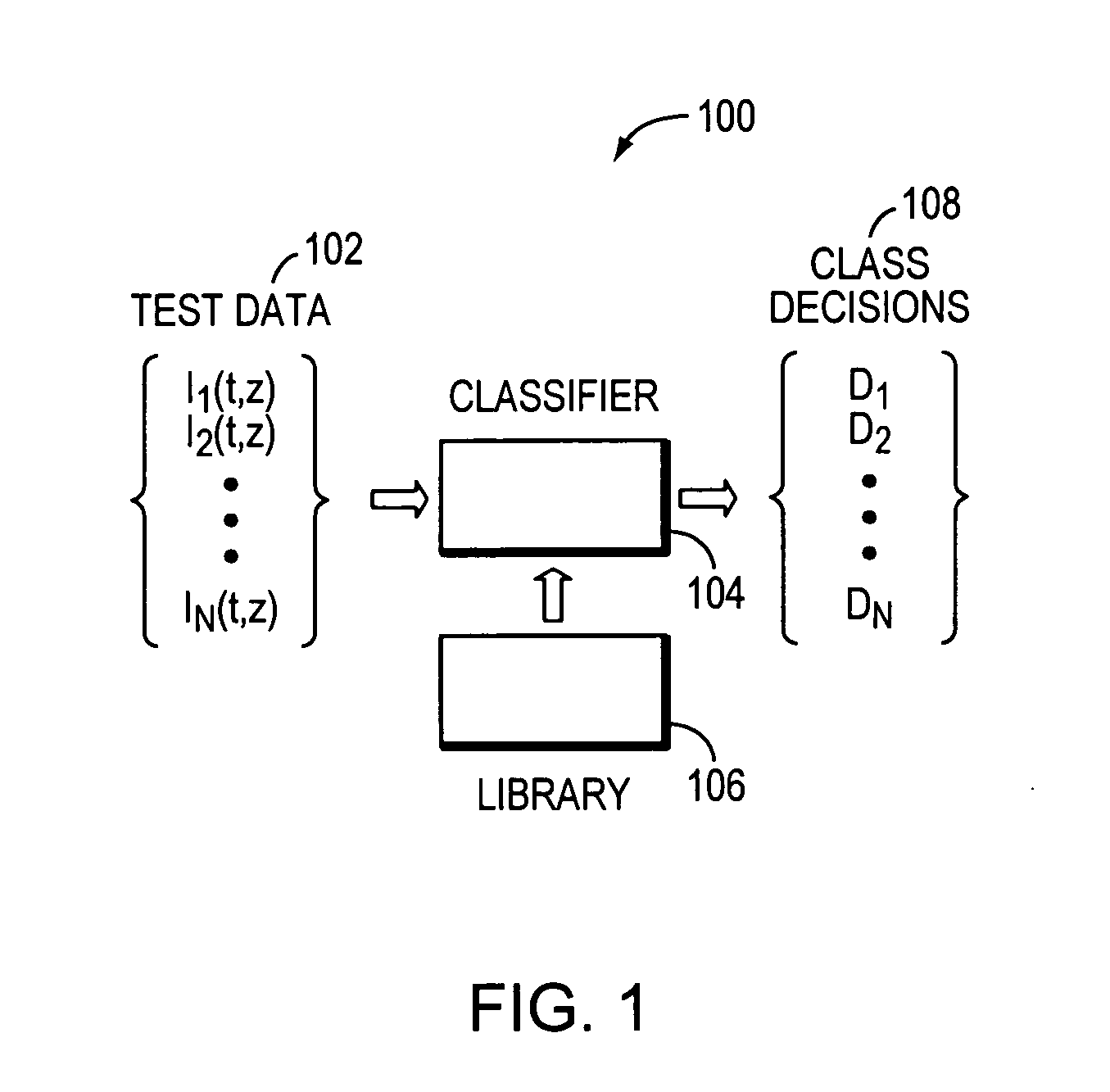

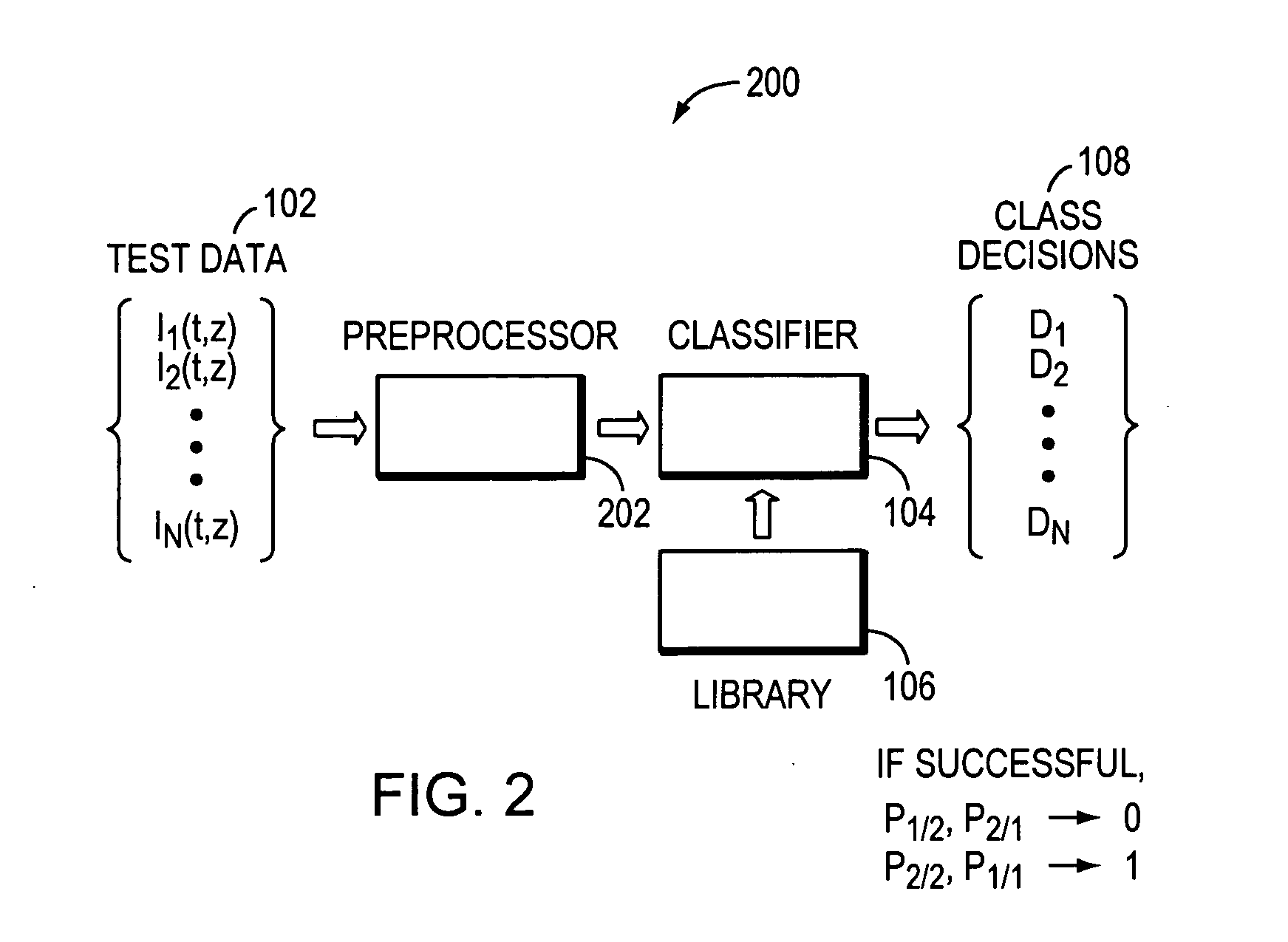

Classification of herbal medicines using wavelet transform

ActiveUS7496453B2Easy to useData eliminatedNoise figure or signal-to-noise ratio measurementDrug and medicationsChemical mixturesOriginal data

Owner:THE HONG KONG POLYTECHNIC UNIV

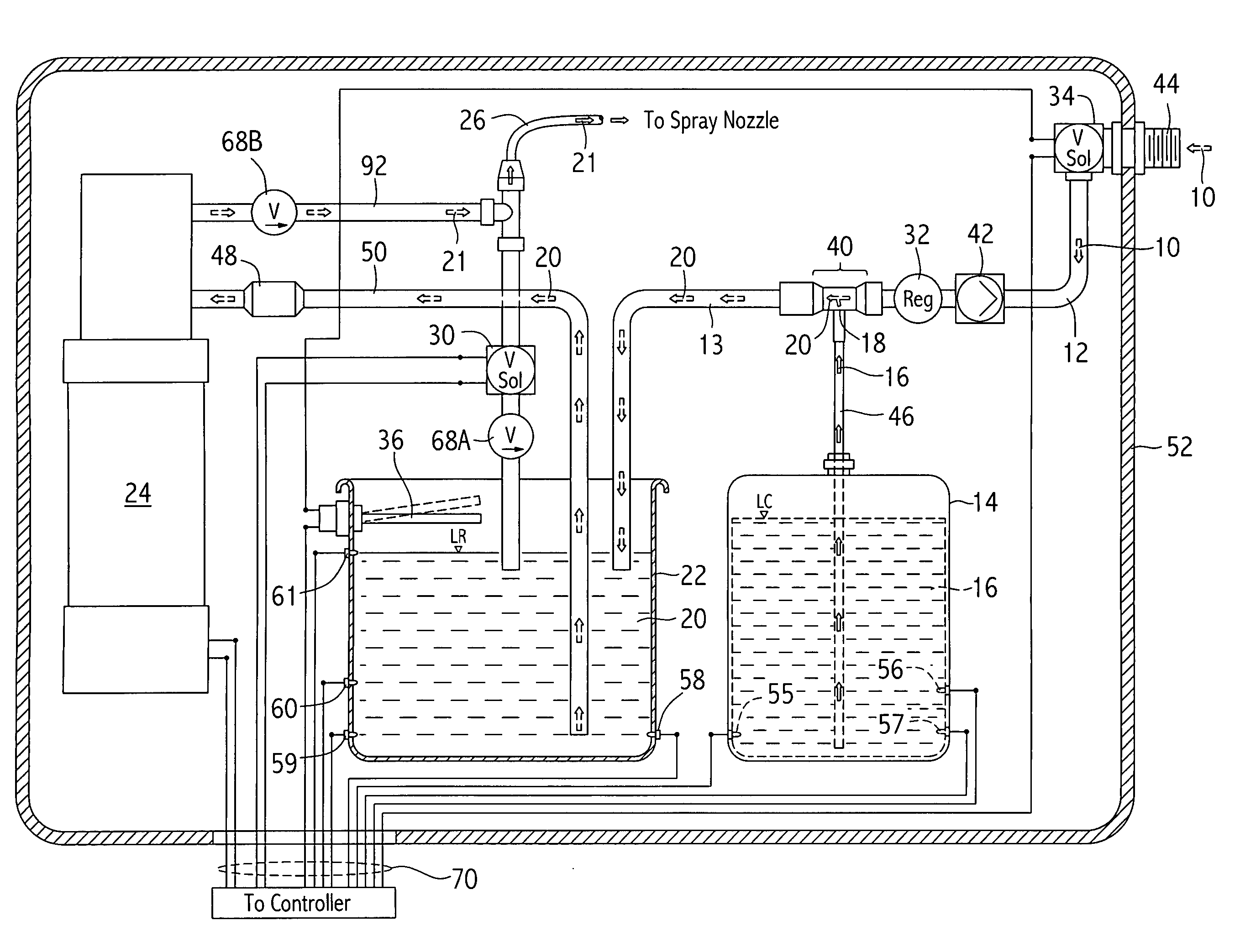

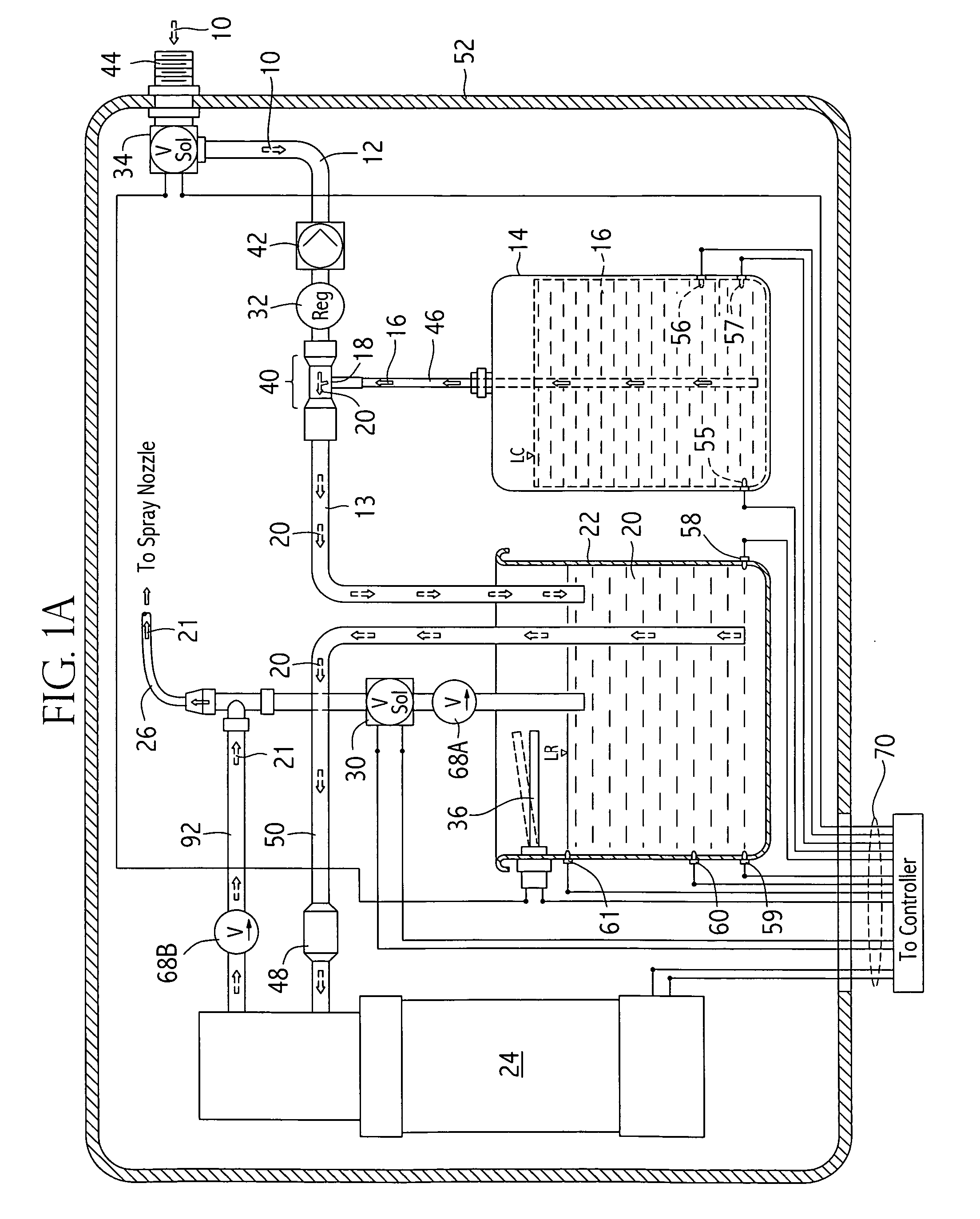

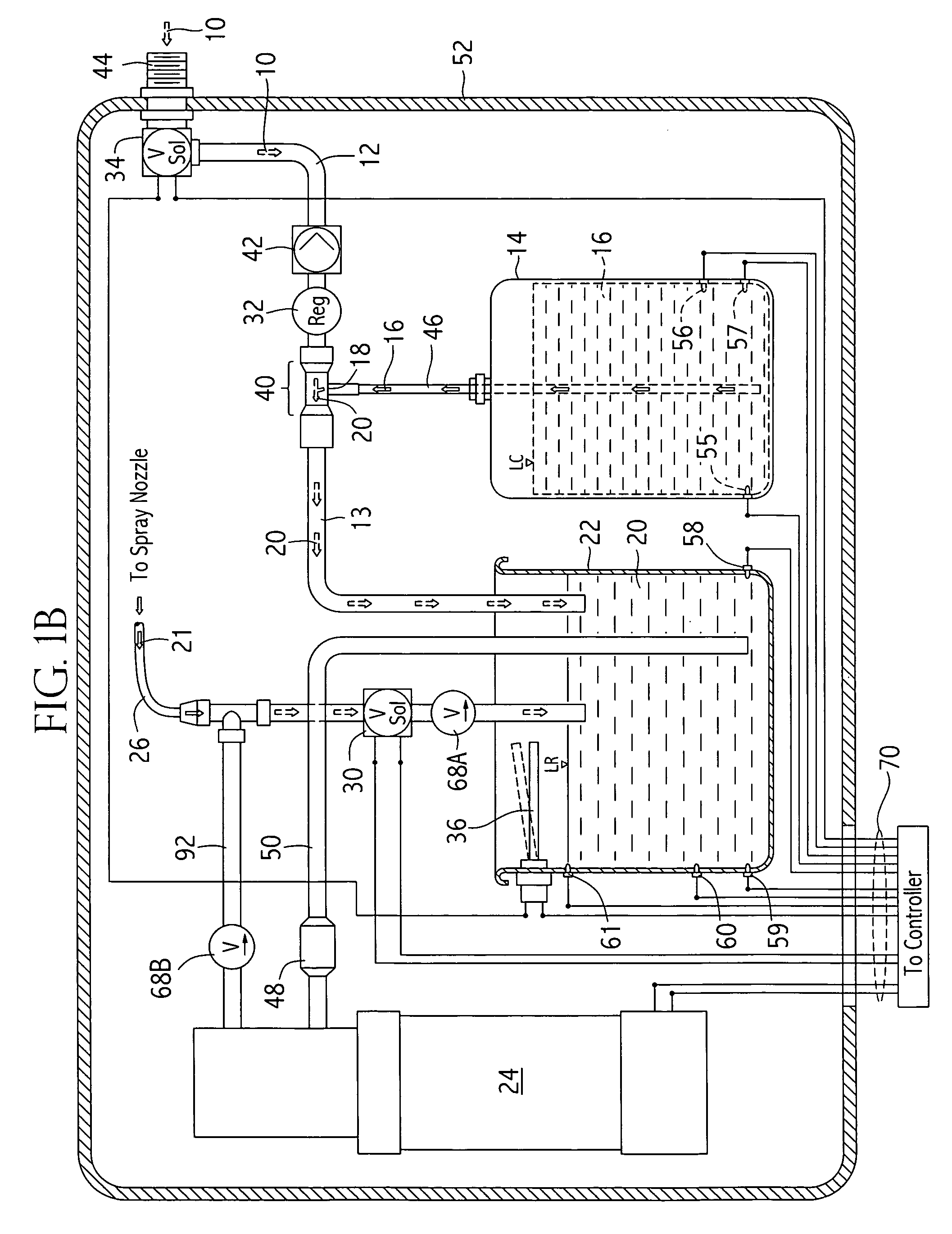

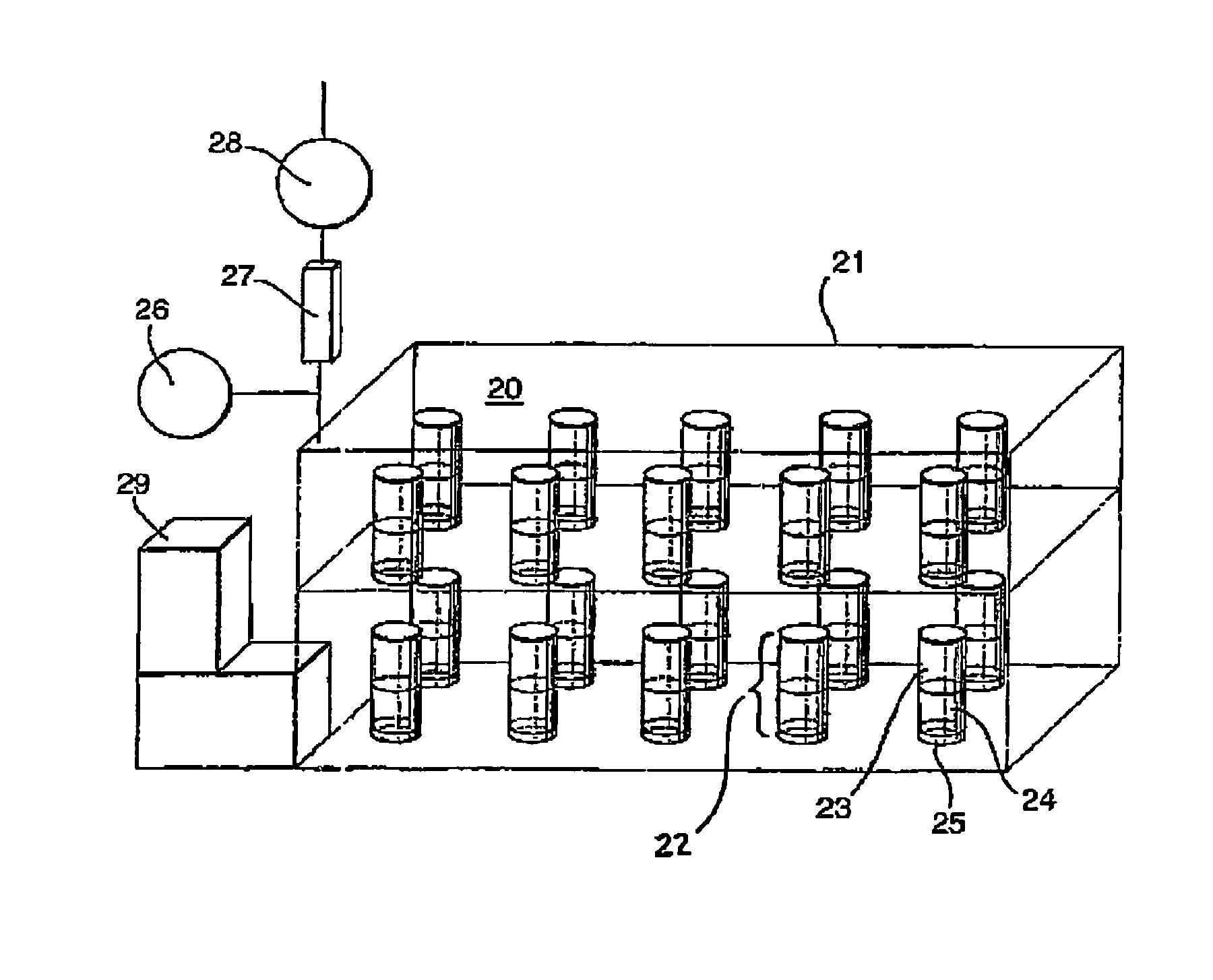

Systems and methods for dispensing liquids

InactiveUS20050236498A1Highly desirable flexibilityAvoid excessive frequencyFlow mixersTransportation and packagingChemical mixturesChemical composition

A system for applying a liquid chemical mixture to an area. The system comprises: a liquid conduit for supplying a flow of pressurized liquid to the system, which pressurized liquid enters the conduit through an inlet valve; a container for a liquid chemical composition, which container is in fluid communication with the conduit so that the composition contacts the pressurized liquid in the conduit to form the mixture; a reservoir in fluid communication with the conduit, which reservoir is configured to receive and store the mixture, at least one spray nozzle, through which spray nozzle, the mixture is dispensed to the area; a pump in fluid communication with the reservoir and with the spray nozzle, which pump forces the mixture through the spray nozzle; and an automated controller which is configured to at least (i) control operation of the inlet valve and (ii) control operation of the pump. Methods for dispensing a liquid chemical mixture to an area are also described.

Owner:CUNNINGHAM GREG A

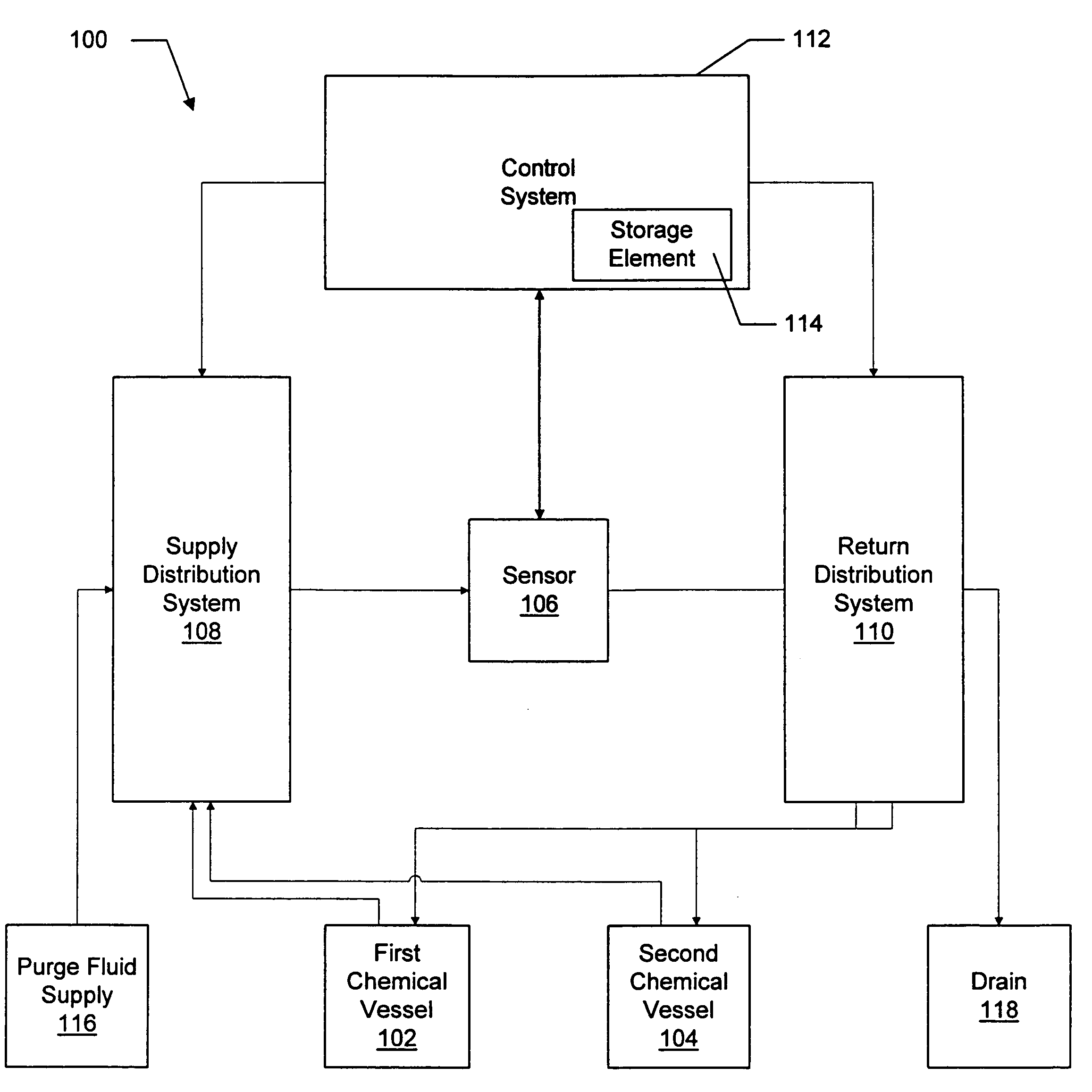

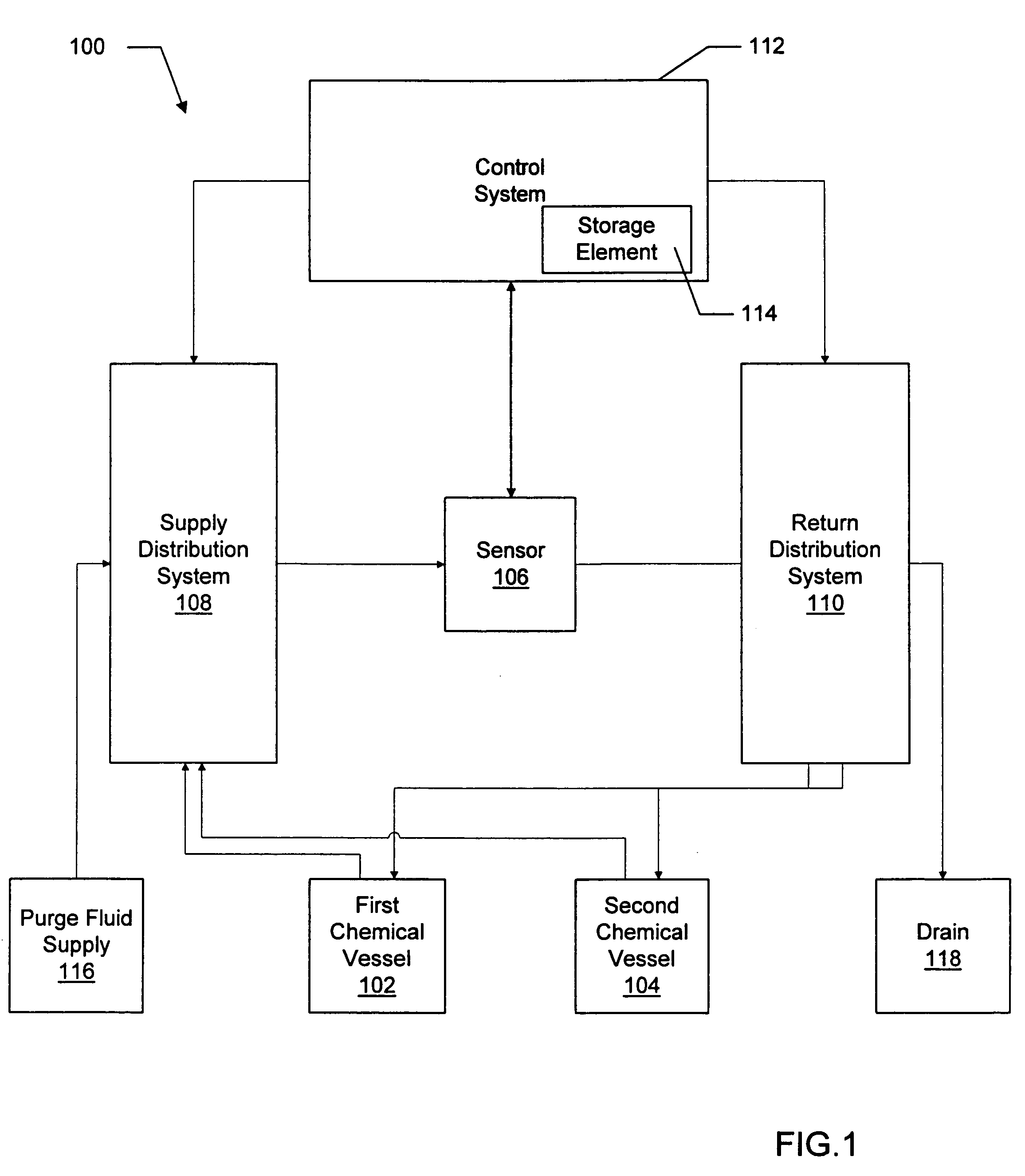

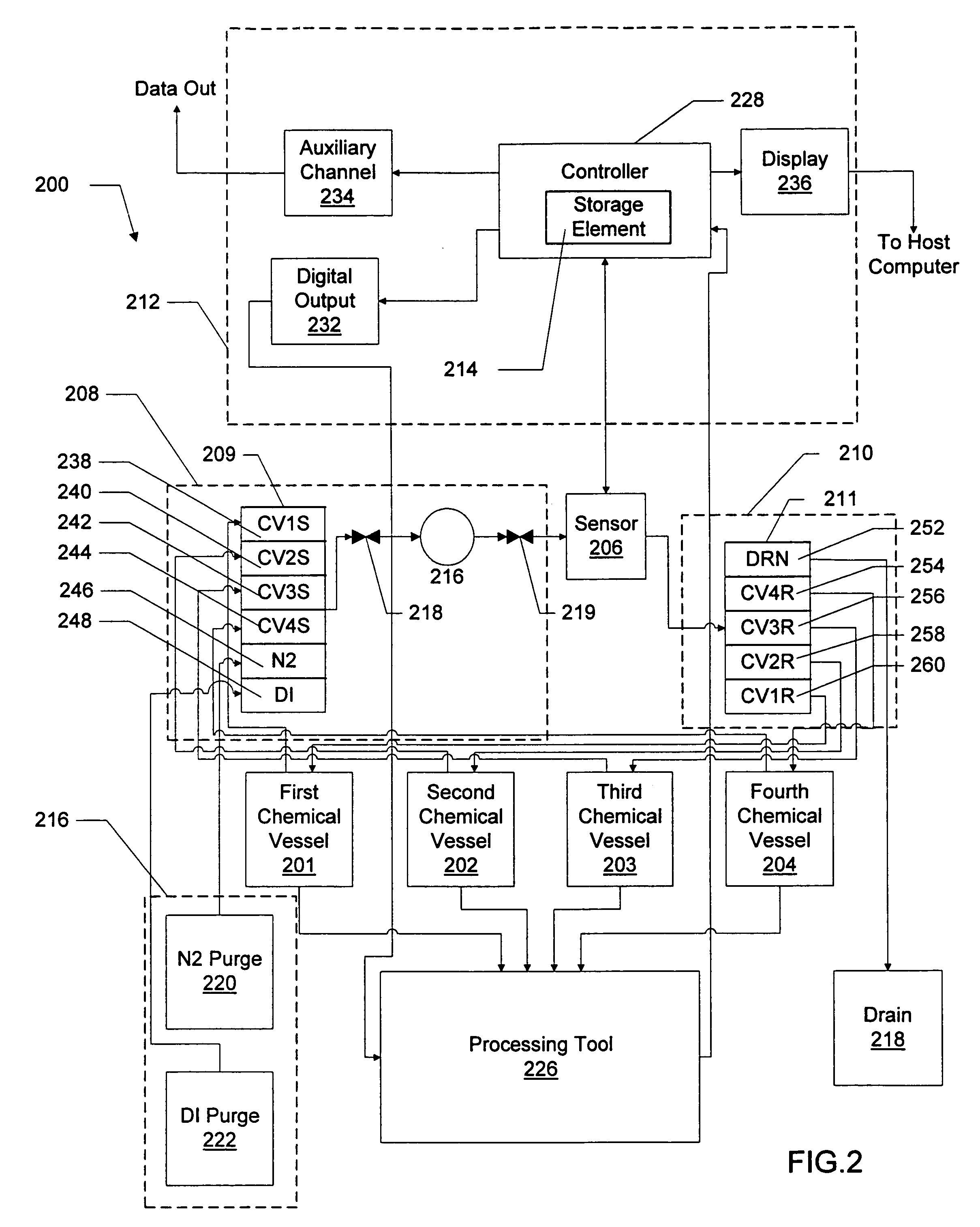

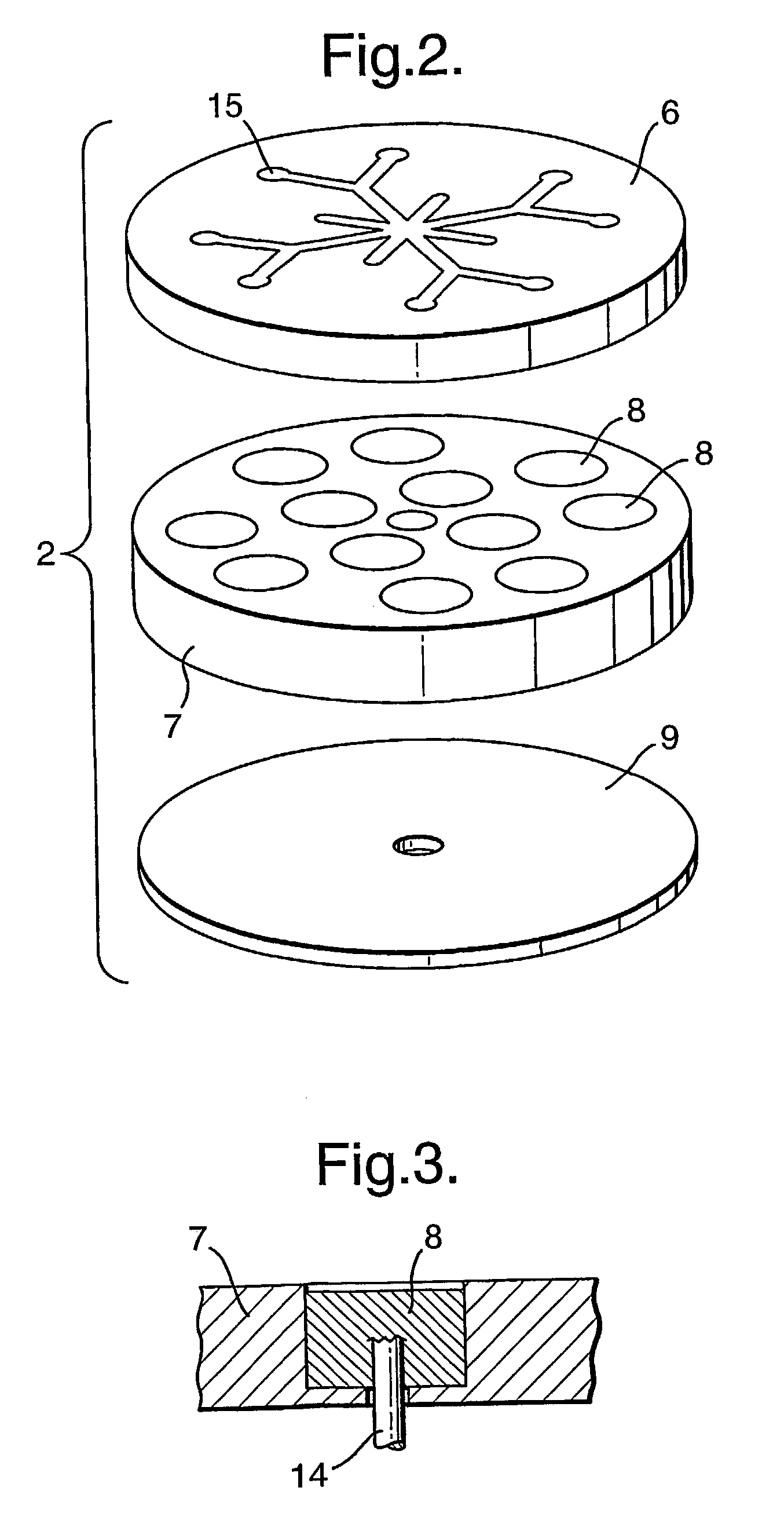

System and method for monitoring and/or controlling attributes of multiple chemical mixtures with a single sensor

InactiveUS7198753B1Less expensiveLow maintenanceComponent separationWithdrawing sample devicesMultiplexingChemical mixtures

A monitoring system is presented. The monitoring system may include a first chemical vessel containing a first chemical mixture and a second chemical vessel containing a second chemical mixture. The monitoring system may further include a sensor configured to selectively receive a first sample flow of the first chemical mixture from the first chemical vessel and a second sample flow of the second chemical mixture from the second chemical vessel. The sensor may be configured to measure a first sample attribute value of the first sample flow and a second sample attribute value of the second sample flow. By multiplexing multiple sample flows through a sensor, the monitoring system may monitor attributes of multiple chemical mixtures without requiring separate sensors for each chemical mixture monitored by the system.In an embodiment, the monitoring system is preferably configured to control an attribute of a chemical mixture. In such a case, the monitoring system may further include a control system configured to receive the first sample attribute value and the second sample attribute value from the sensor. The control system is further preferably configured to input the first sample attribute value into a first attribute control algorithm to calculate a first attribute control output. The first chemical mixture includes a first bulk attribute value, and the control system is preferably configured to direct the adjusting of the first bulk attribute value.

Owner:ADVANCED MICRO DEVICES INC

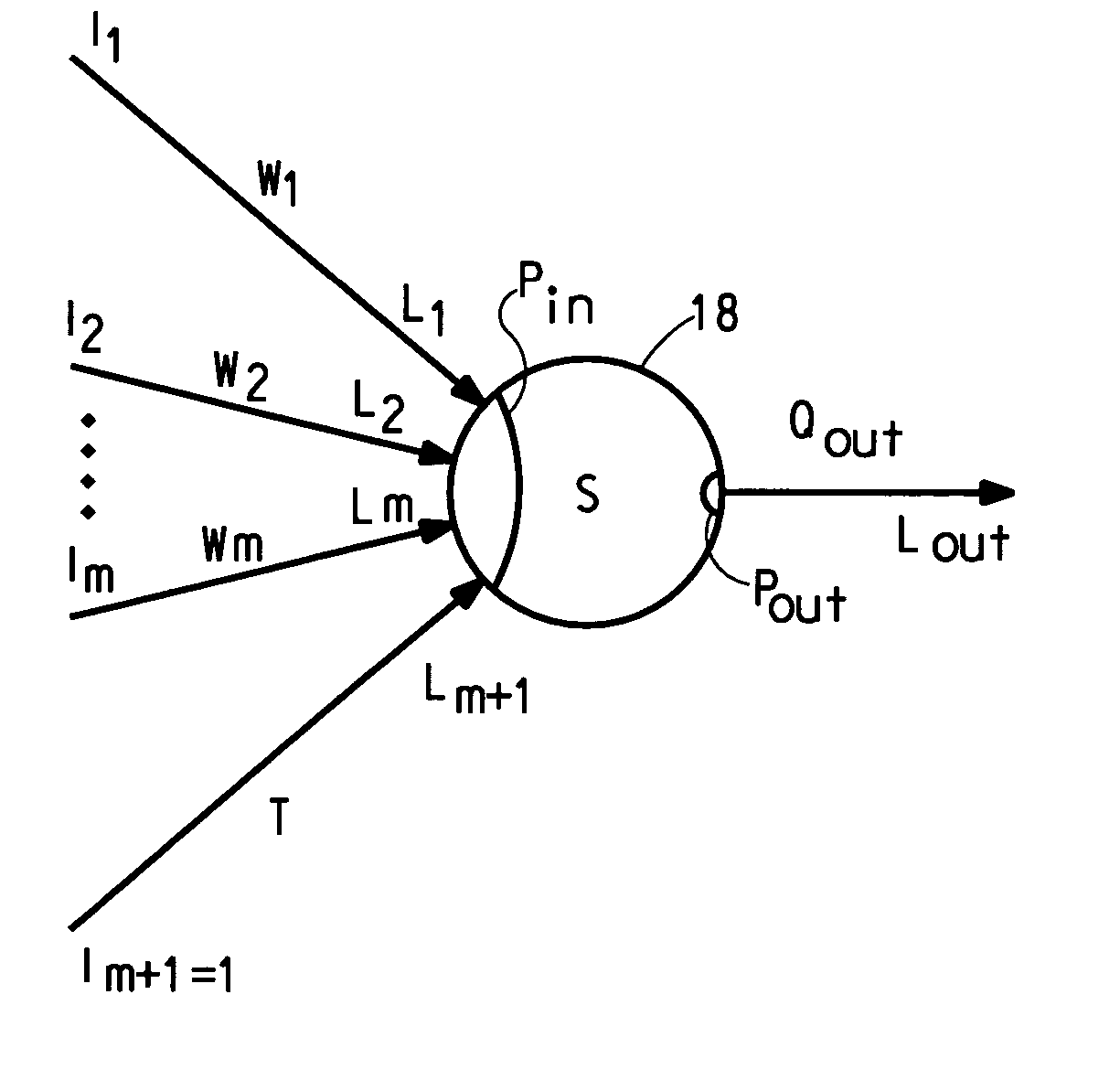

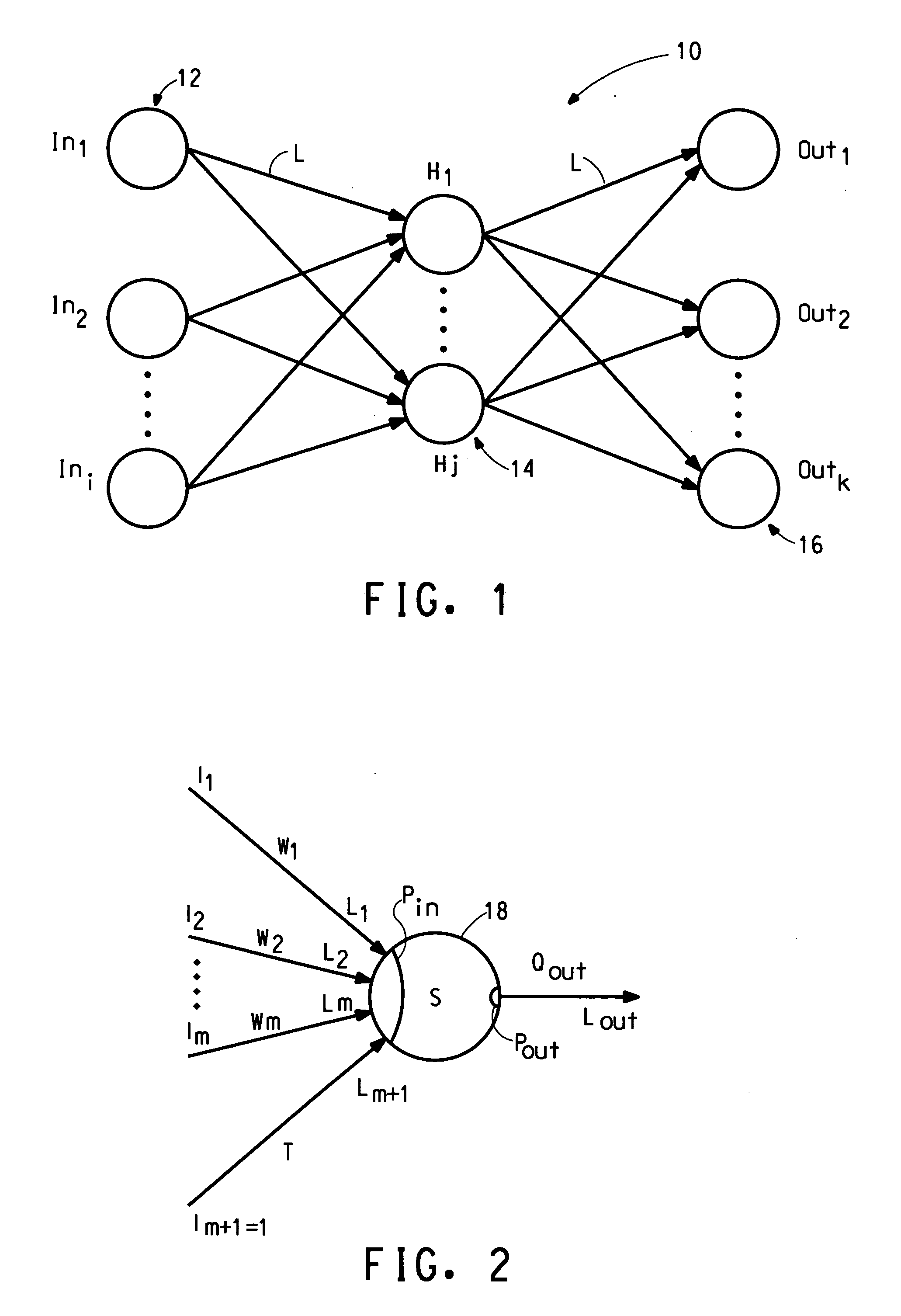

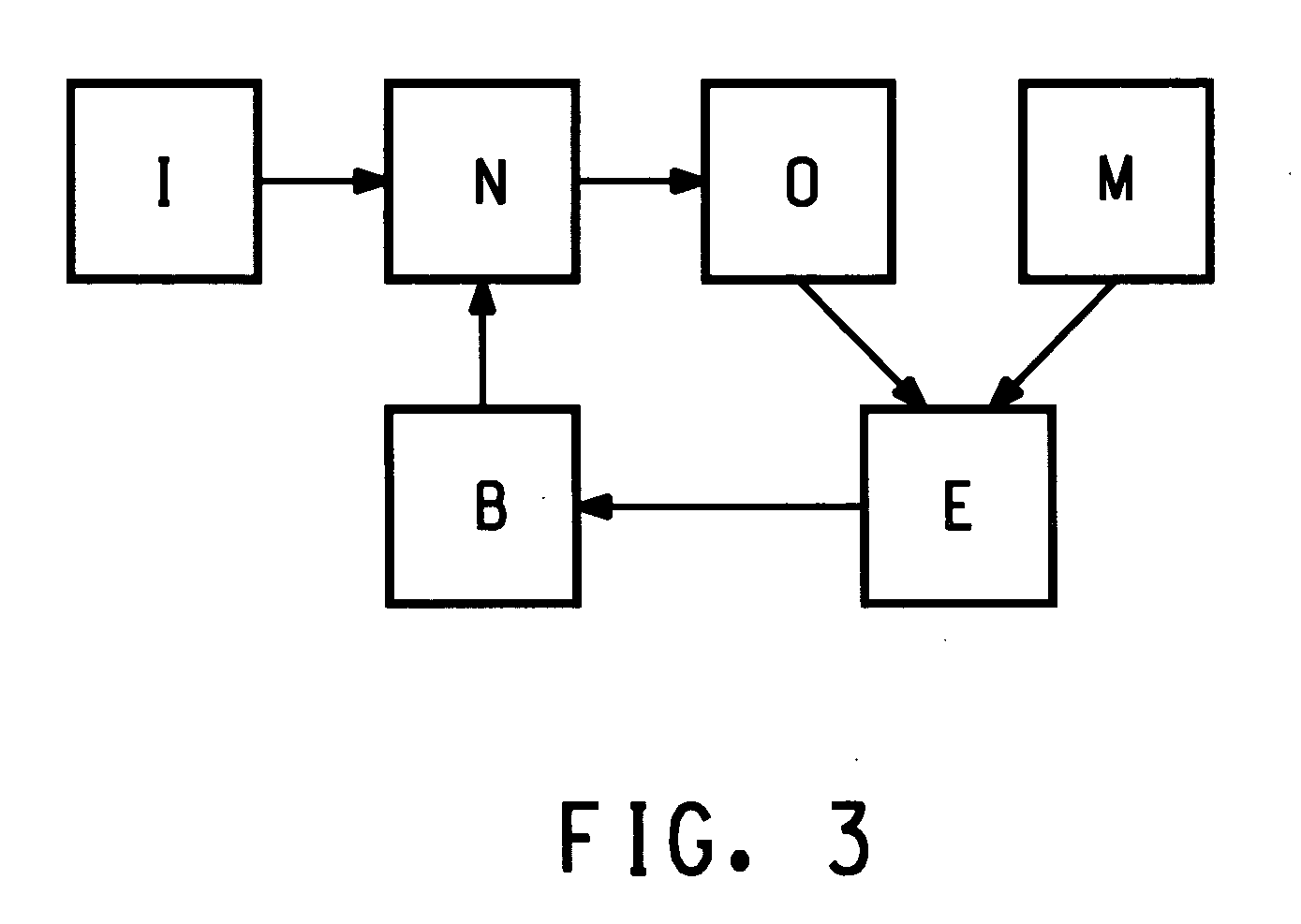

Method and apparatus for predicting properties of a chemical mixture

The present invention relates to a method and apparatus for predicting the non-color properties of a chemical mixture, such as an automotive paint, using an artificial neural network. The neural network includes an input layer having nodes for receiving input data related to the chemical components of the mixture and environmental and process conditions that can affect the properties of the mixture. An output layer having nodes generate output data which predict the properties of the chemical mixture as a result of variation of the input data. A hidden layer having nodes is connected to the nodes in the input and output layers. Weighted connections connect the nodes of the input, hidden and output layers and threshold weights are applied to the hidden and output layer nodes. The connection and threshold weights have values to calculate the relationship between input data and output data. The data to the input layer and the data to the output layer are interrelated through the neural network's nonlinear relationship. When implemented, accurate predictions of the final properties of the mixture can be obtained. The invention is especially useful in relating automotive paint formulation variables (e.g., paint ingredient amounts and application process conditions) to physical properties (e.g., viscosity, sag), appearance (e.g., hiding, gloss, distinctness of image) or other measured properties enabling comparison of formula properties to target values or tolerances without expensive experimental work.

Owner:EI DU PONT DE NEMOURS & CO

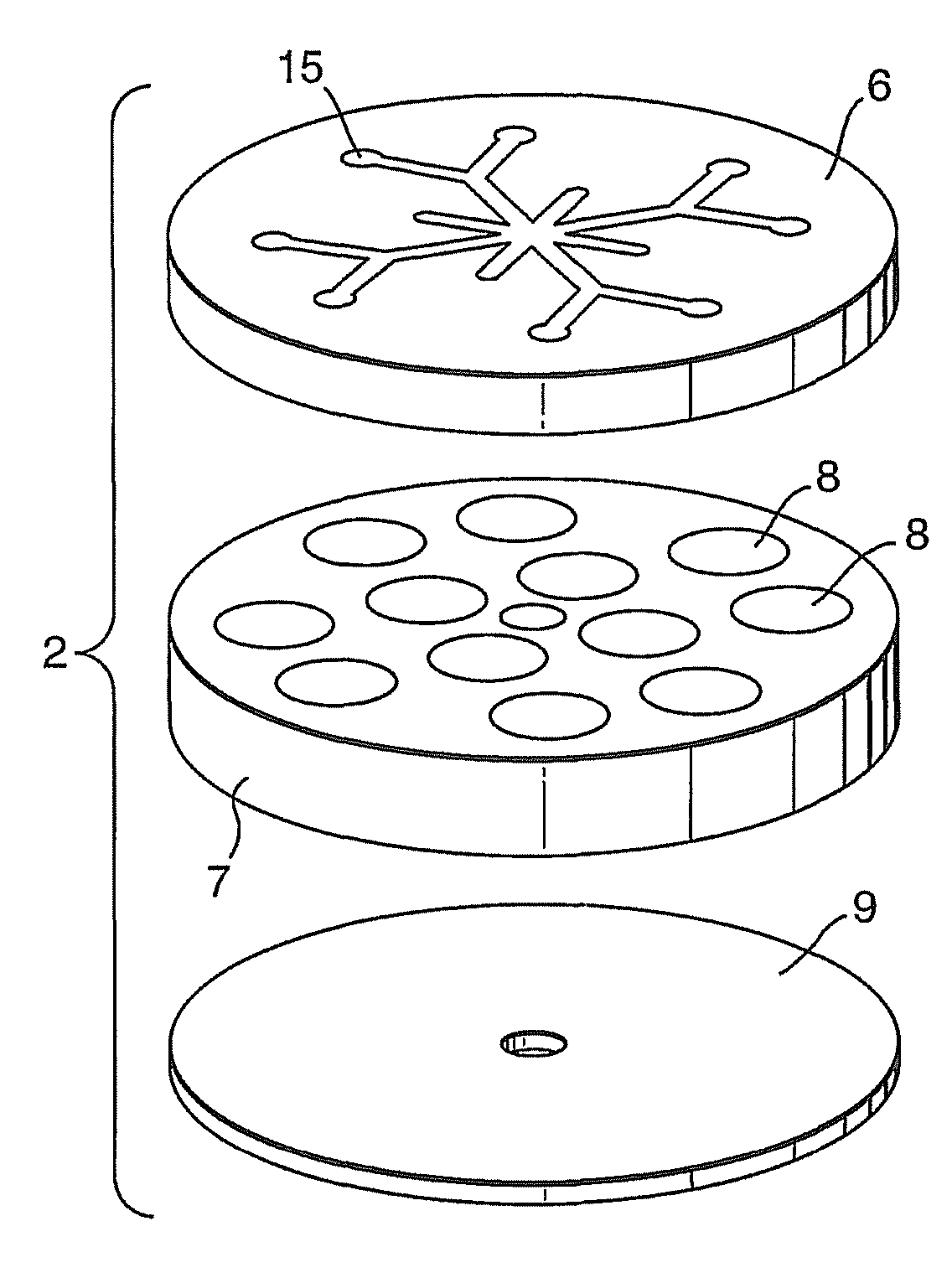

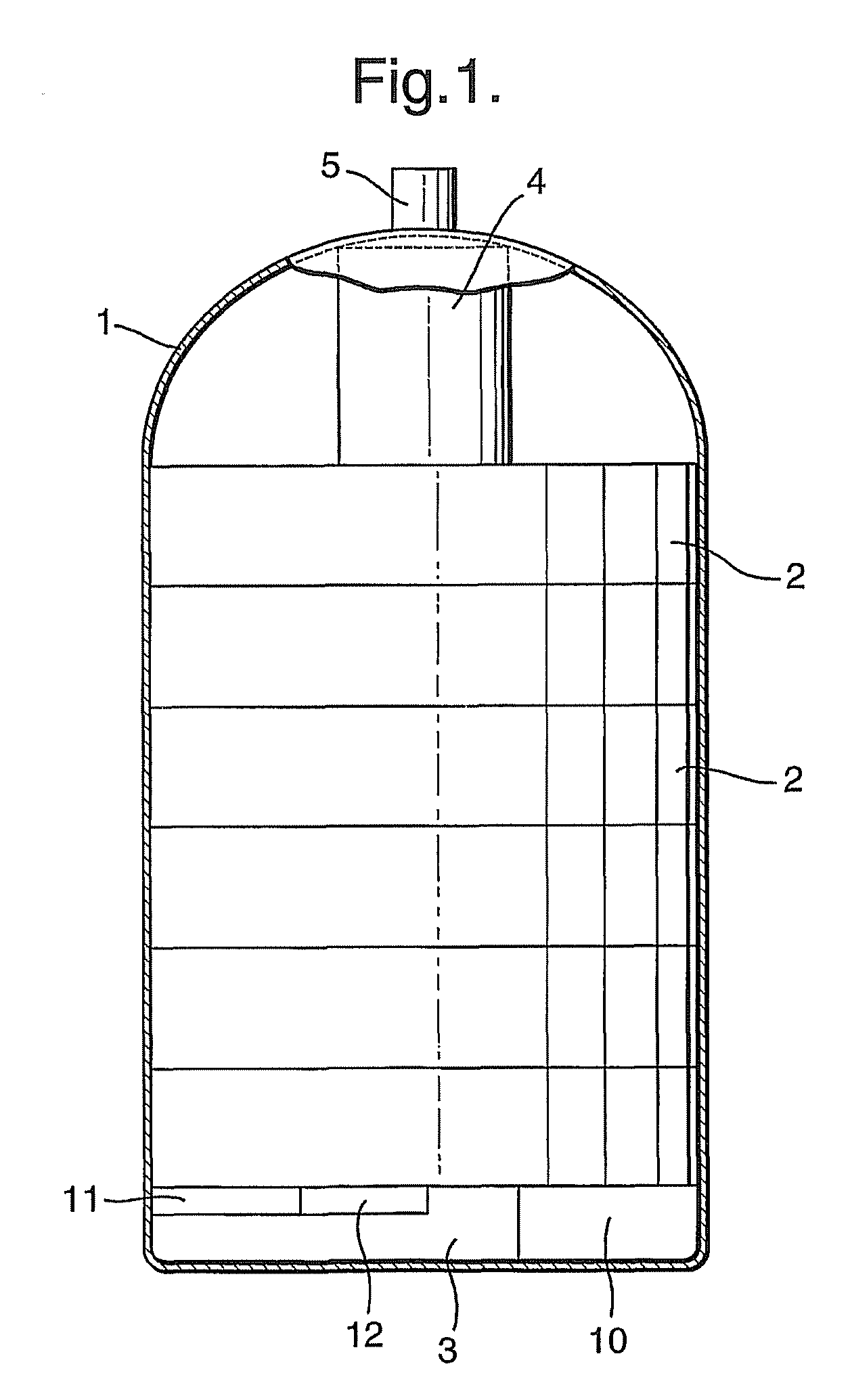

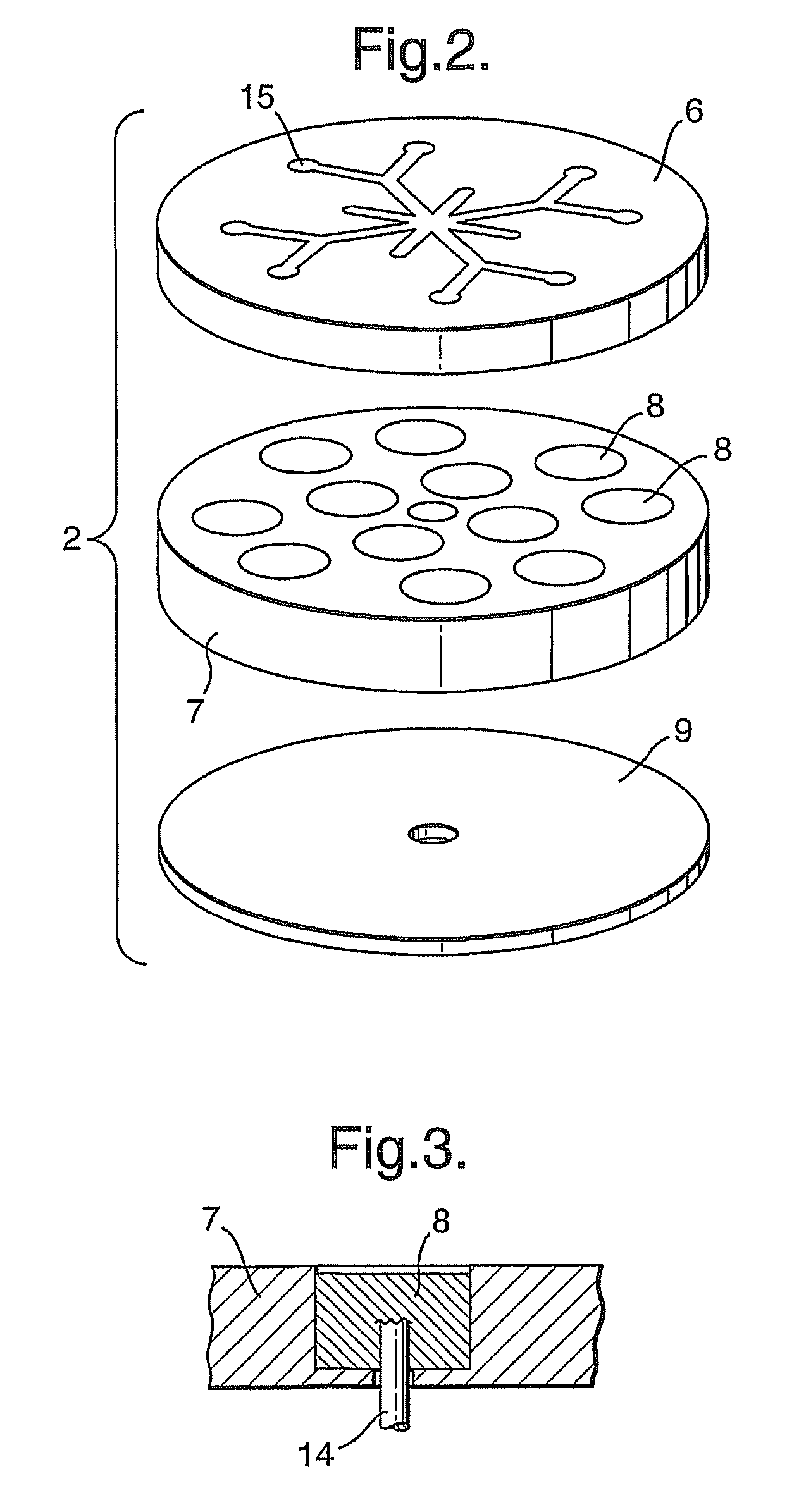

Portable hydrogen source

InactiveUS7261748B2Reduce the temperatureFast conductionFuel cell auxillariesHydrogen productionChemical mixturesHydrogen

A man portable hydrogen source, the source comprising one or more hydrogen generating elements (2), an ignition control system (3) and a pressure vessel (1). Each hydrogen generating element comprises a pellet holder (7) provided with one or more recesses and a thermal insulation layer (9) to reduce heat transfer to adjacent hydrogen generating elements; wherein at least one recess contains a pellet (8) of a chemical mixture which on thermal decomposition evolves hydrogen gas; wherein the ignition control system comprises one or more ignitors (14), associated with an individual pellet (8), and activation means to activate the ignitors; and wherein the evolved hydrogen and hydrogen generating elements are contained within the pressure vessel.

Owner:QINETIQ LTD

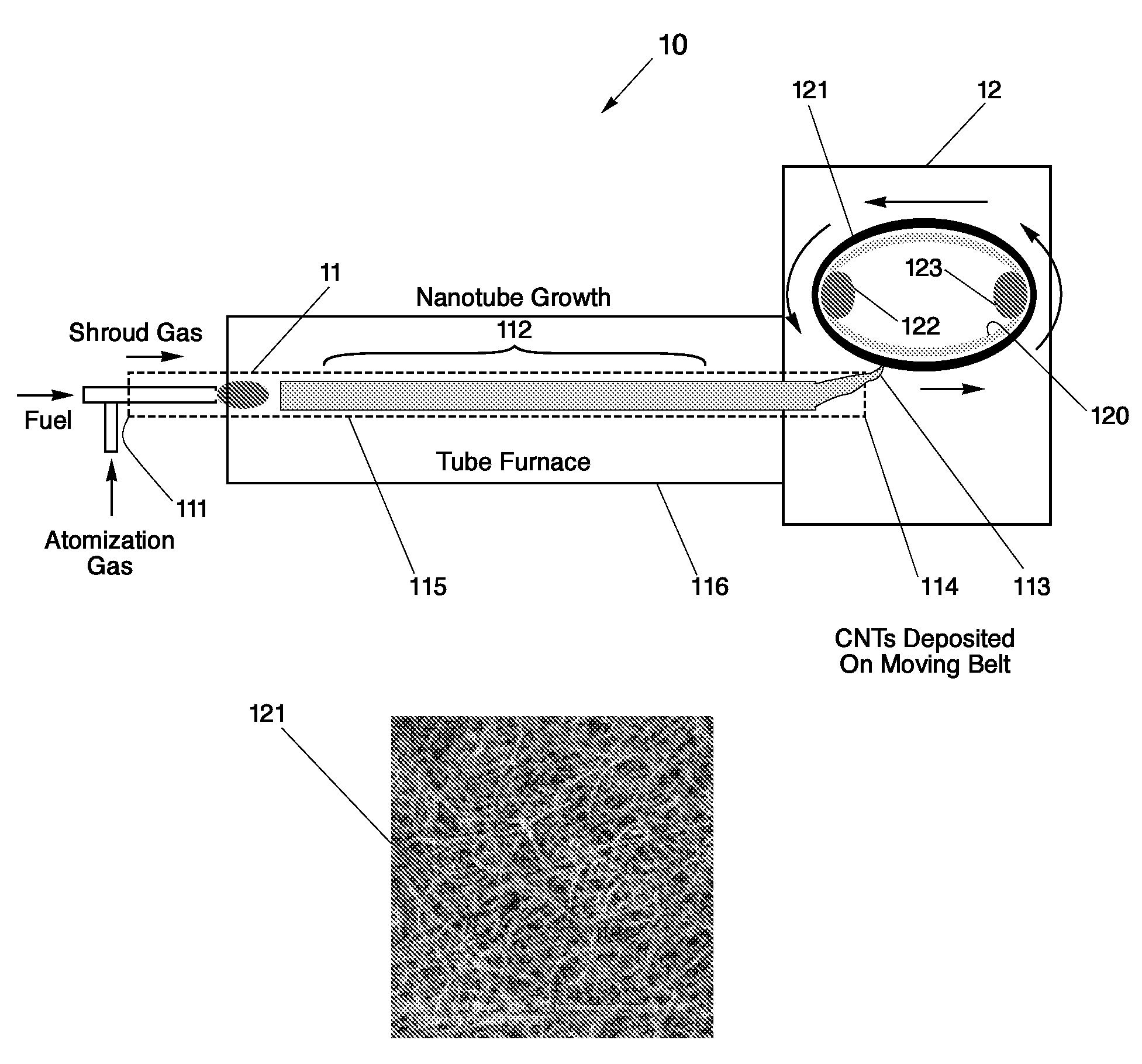

Chemically-assisted alignment of nanotubes within extensible structures

ActiveUS8246886B2Smooth connectionImprove thermal conductivityArtificial filament physical treatmentHollow filament manufactureYarnChemical mixtures

A method and system for aligning nanotubes within an extensible structure such as a yarn or non-woven sheet. The method includes providing an extensible structure having non-aligned nanotubes, adding a chemical mixture to the extensible structure so as to wet the extensible structure, and stretching the extensible structure so as to substantially align the nanotubes within the extensible structure. The system can include opposing rollers around which an extensible structure may be wrapped, mechanisms to rotate the rollers independently or away from one another as they rotate to stretch the extensible structure, and a reservoir from which a chemical mixture may be dispensed to wet the extensible structure to help in the stretching process.

Owner:NANCOMP TECHNOLOGIES INC

Self-contained insect repelling and killing apparatus

InactiveUS7320439B2Eliminate chanceRemain can be solvedFire rescueLiquid transferring devicesChemical mixturesEngineering

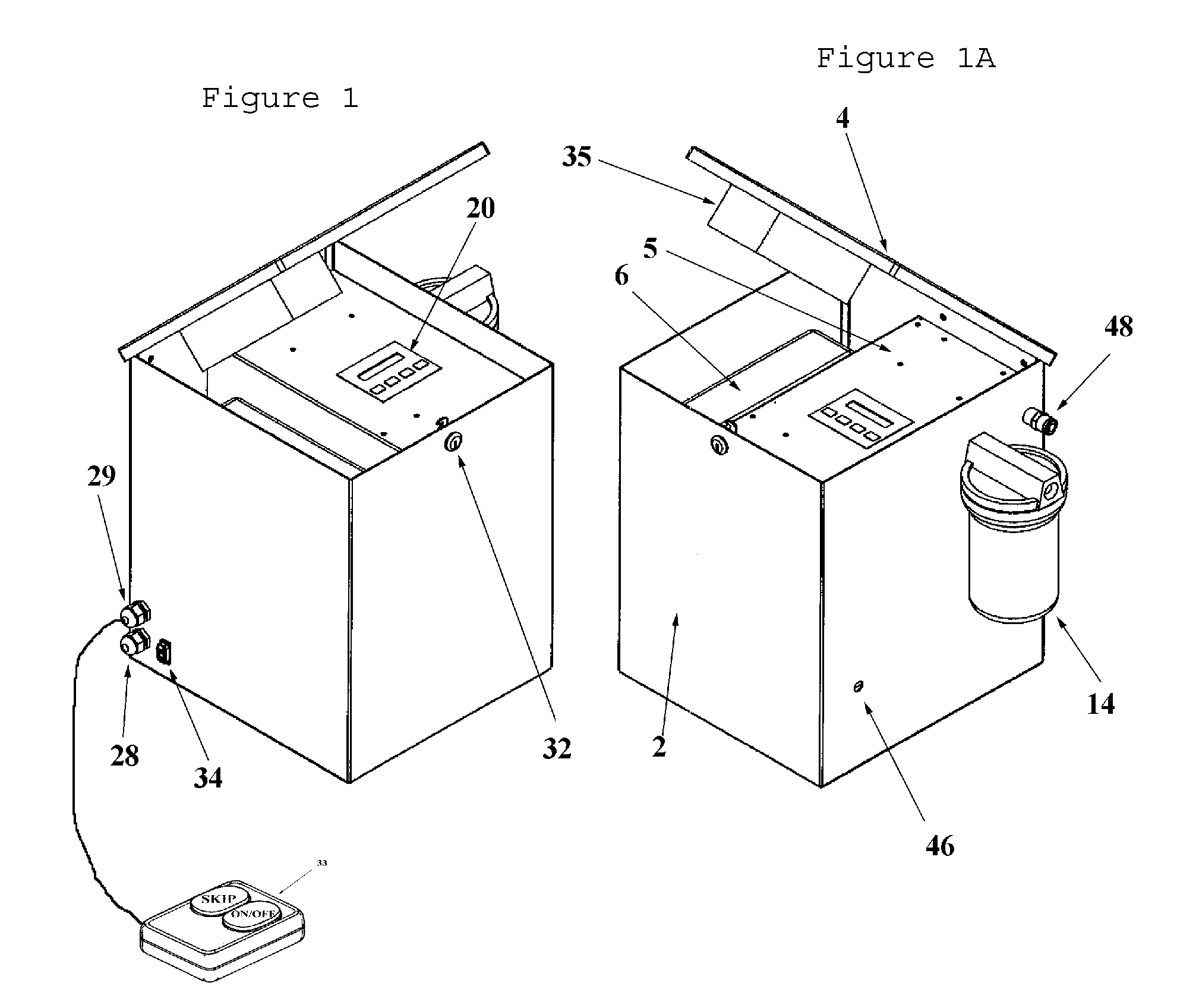

An apparatus for the purpose of dispensing a chemical agent whose function is to detract or alternatively attract and destroy, insects, in particular, flying insects. The apparatus consists of a chemical source, a connection to a fluid source, usually water, a reservoir for chemical mixing and a pump for mixing and creating pressure. Mixing reservoir is of such size to eliminate any chance of chemical mixture separation and where the chemical mixture is agitated prior to each dispensing cycle. Fluid is disbursed under pressure through a series of atomizing devices, interconnected to the apparatus through a flexible plastic delivery conduit. The Apparatus functions are controlled through the use of an electronic interface. Preferred agent used is pyrethrum based, naturally occurring or synthesized, which possesses an antagonistic effect toward targeted pests but apparatus is designed to be adaptable to a wide range chemicals.

Owner:OUTDOOR SOLUTIONS

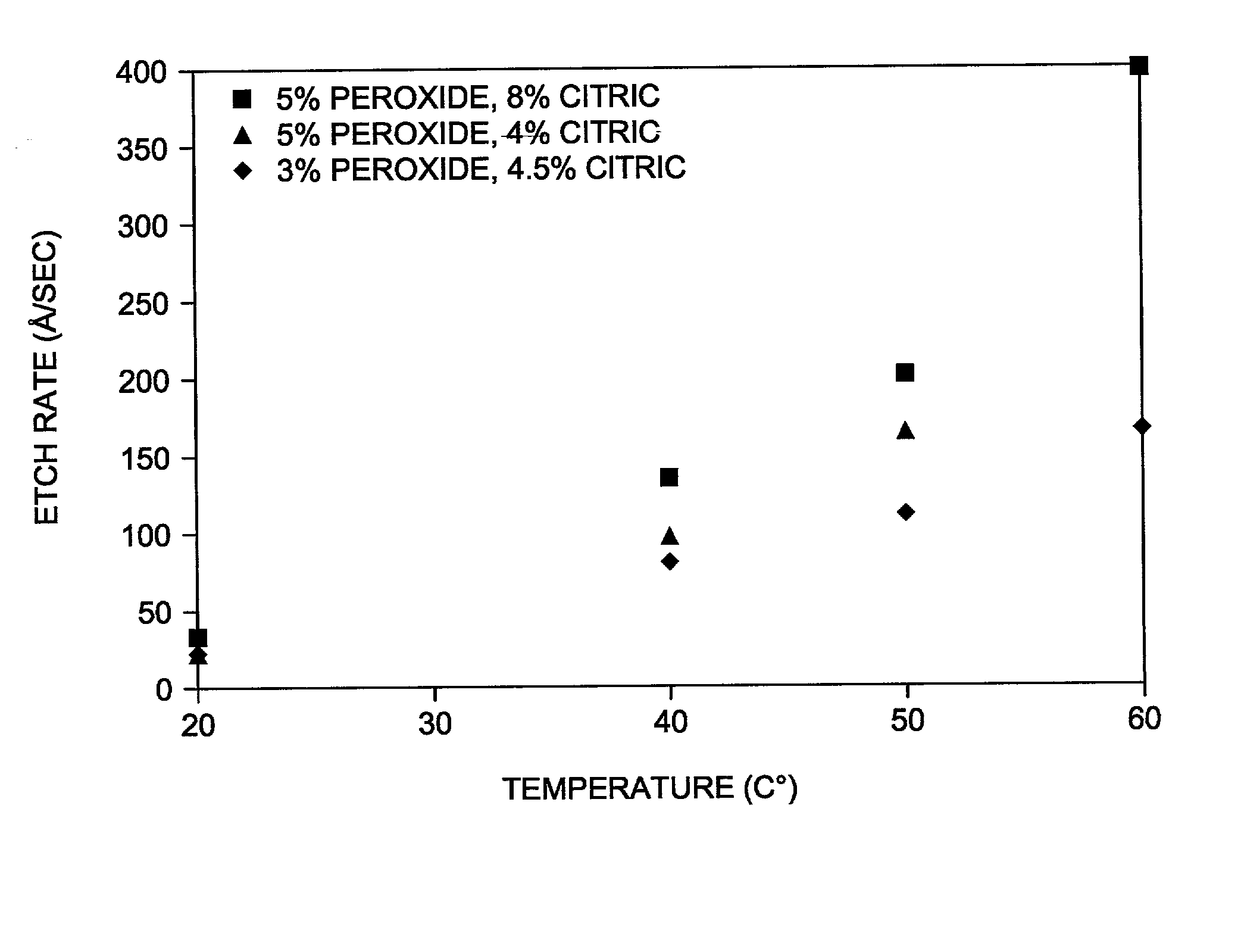

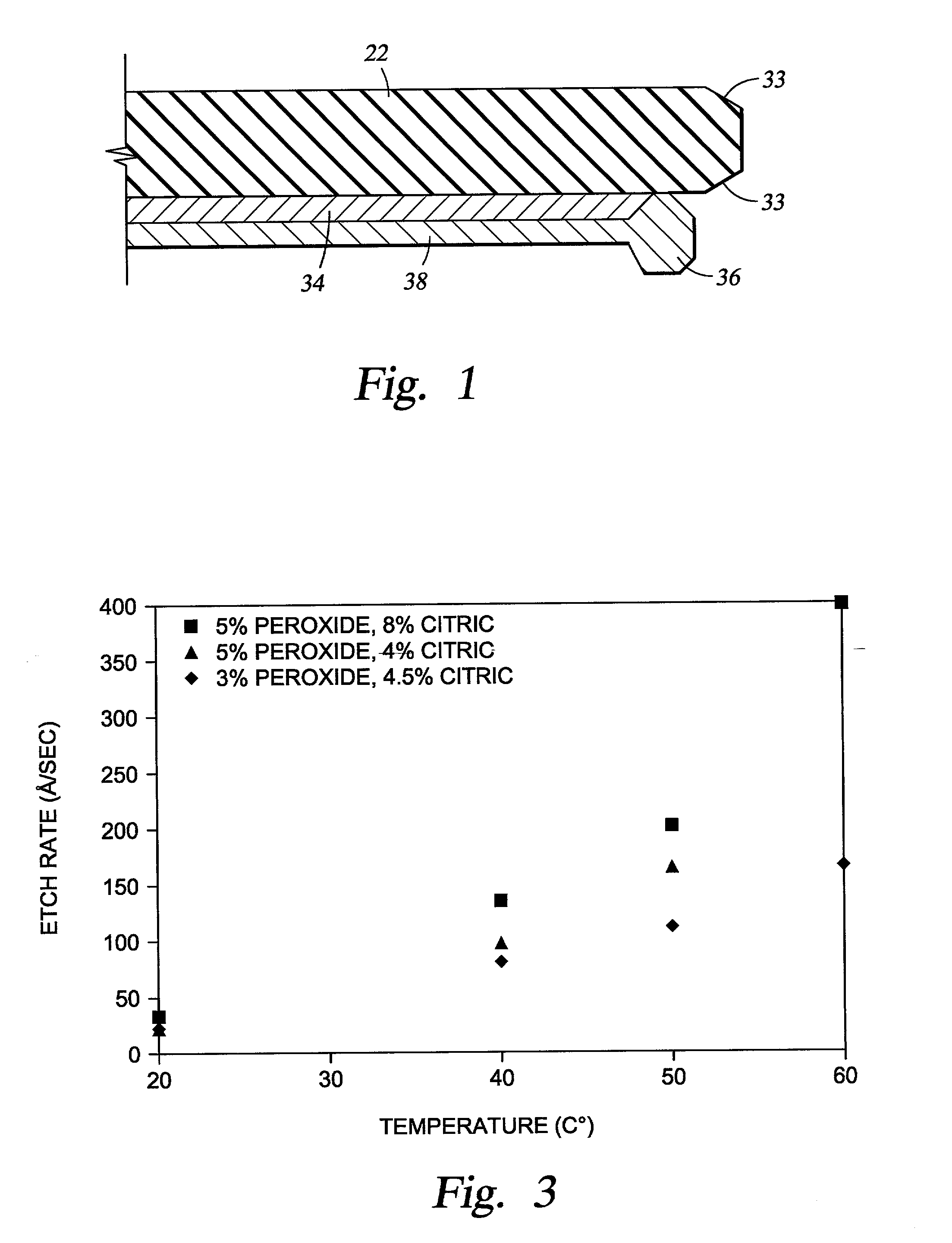

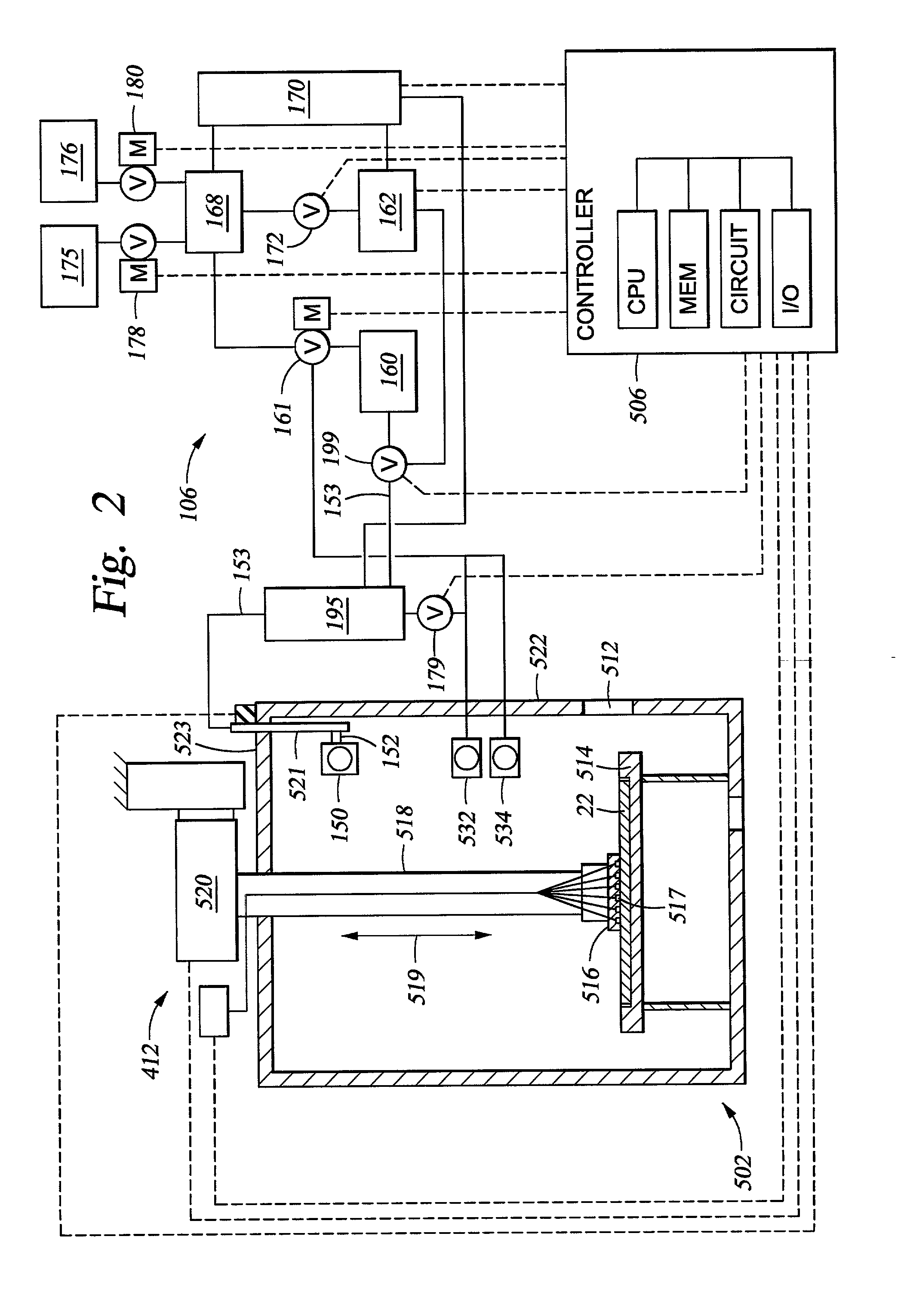

Chemical mixture for copper removal in electroplating systems

InactiveUS20020048953A1Detergent mixture composition preparationSemiconductor/solid-state device manufacturingChemical mixturesChemical composition

A method and chemical composition for selectively etching unwanted metal deposits on a surface of a wafer. In one aspect, a method of processing a substrate is provided which includes providing a substrate to an edge bead removal system, and applying a chemical etchant comprising citric acid and an oxidizing agent to the substrate. In one aspect, a chemical composition of citric acid and hydrogen peroxide is provided which is a relatively weak acid having a pH greater than about 1.0.

Owner:APPLIED MATERIALS INC

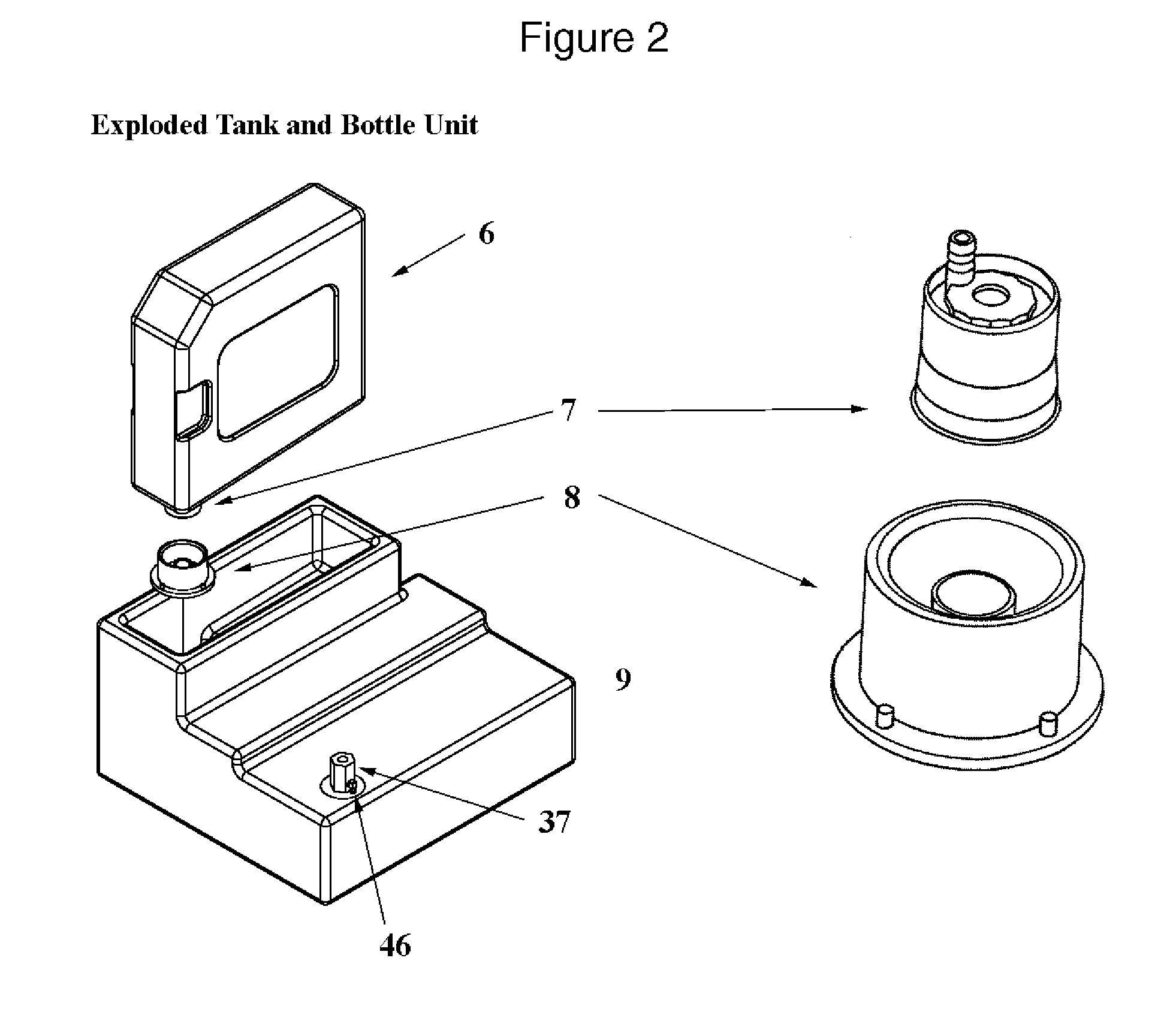

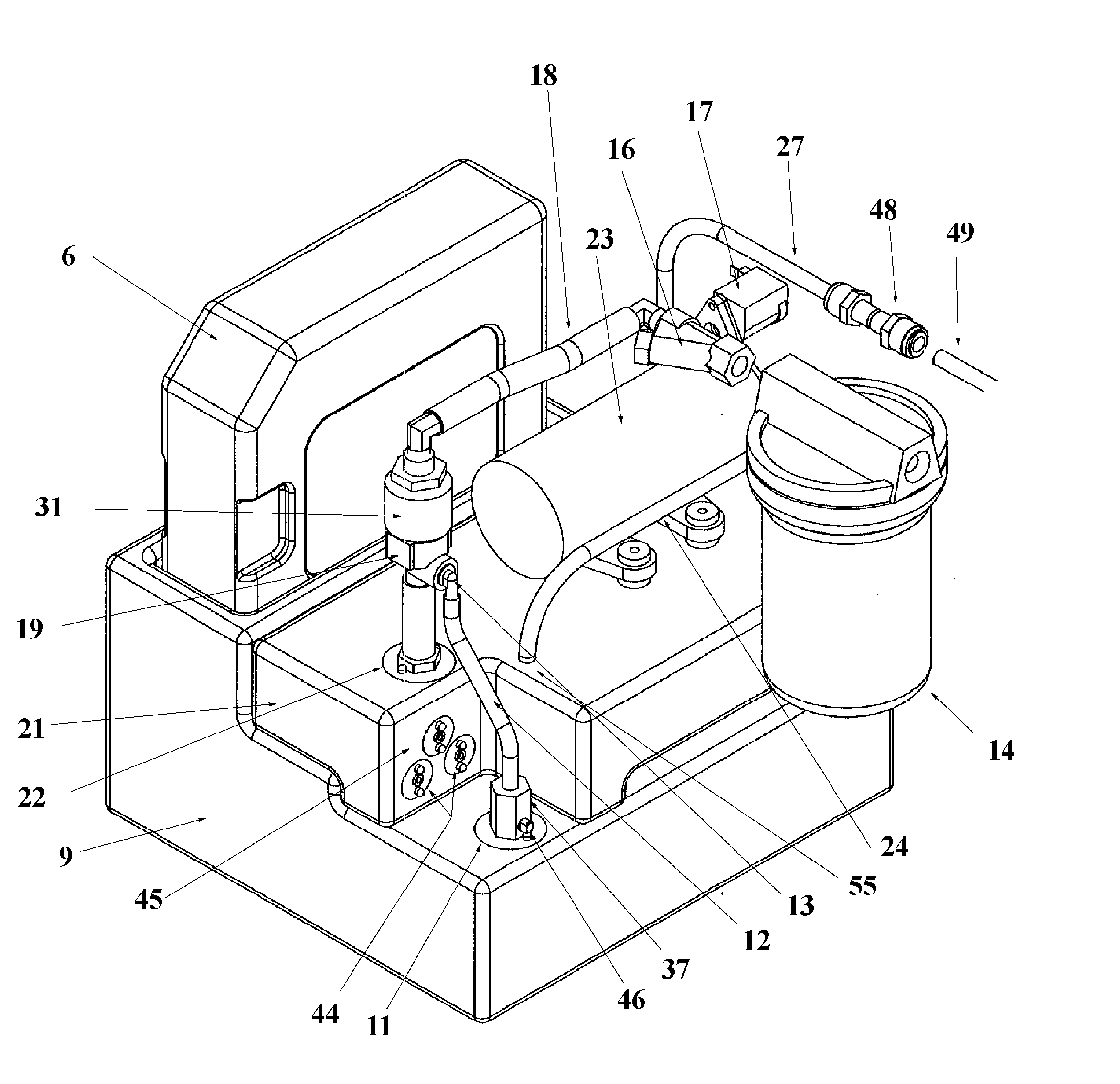

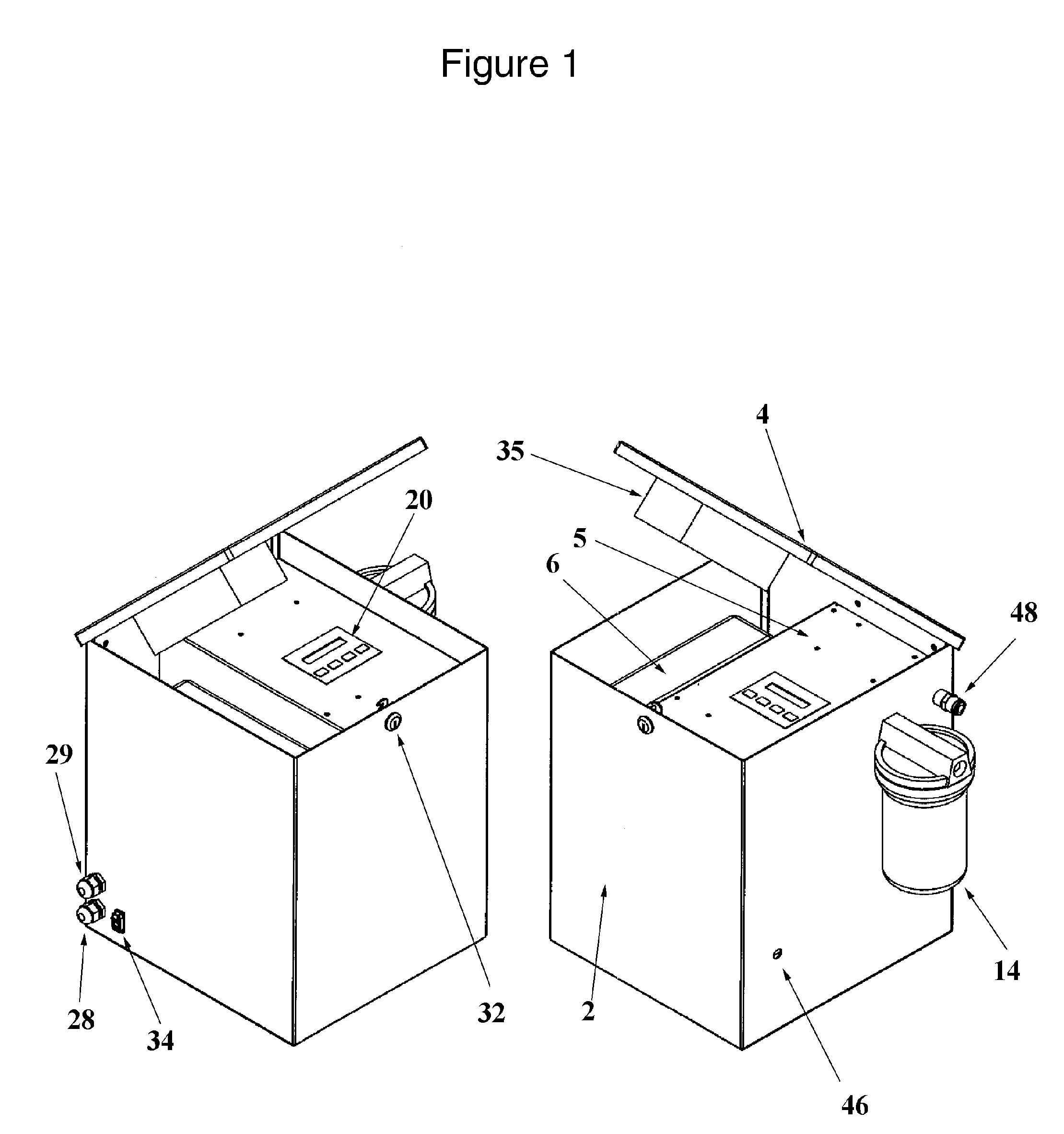

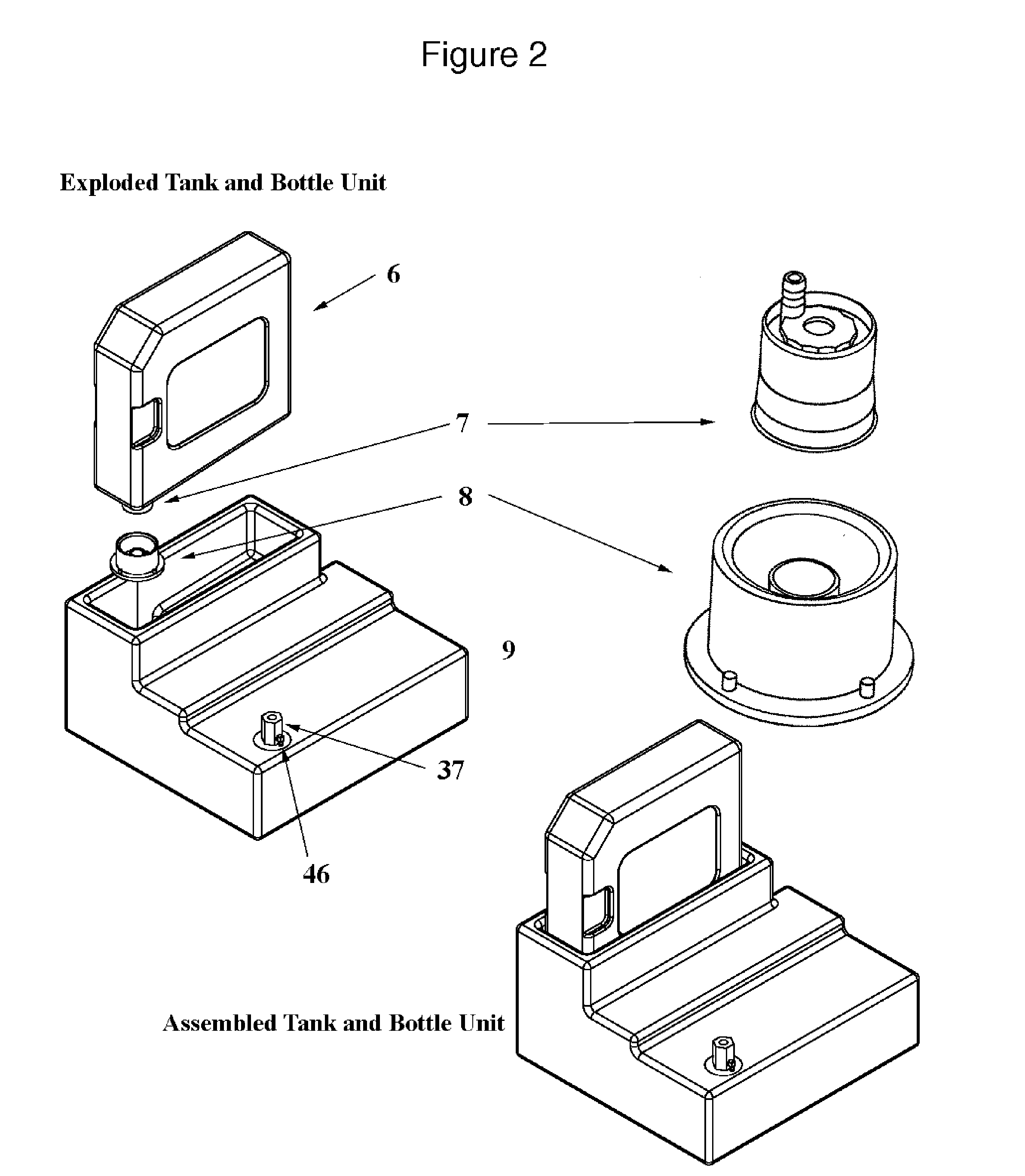

An Improved Self-Contained Insect Repelling and Killing Apparatus

InactiveUS20060006197A1Eliminate chanceRemain can be solvedFire rescueLiquid transferring devicesChemical mixturesChemical tank

An Improved Self-Contained Pyrethrum-Based Insect Repelling and Killing Apparatus for the purpose of dispensing a chemical agent whose function is to detract or alternatively attract and destroy, insects, in particular, flying insects, which serve to detract from human or canine enjoyment of the outdoors, especially in residential surroundings. Similarly, animals such horses and cows and other domesticated livestock are affected, often with deadly consequences, by infestations of these insects. The apparatus consists of a chemical source tank, a means of connecting a fluid source, usually water, a tank for chemical mixing and a pump means for mixing and creating pressure. All chemical tanks and mixing vessels are located inside of an encasement which is protected from outside intrusion. Mixing tank is of such size to eliminate any chance of chemical mixture separation and chemical mixture is agitated prior to each dispensing cycle. Fluid is disbursed under pressure through a series of narrow apertures fluid dispensing devices, interconnected to the apparatus through a flexible plastic delivery conduit. The Apparatus functions are controlled through the use of an attached electronic interface whose purpose is to effectively meter, sense and control apparatus functions. Preferred agent used is pyrethrum based, naturally occurring or synthesized, which possesses an antagonistic effect toward targeted pests but apparatus is designed to be adaptable to a wide range of natural or synthesized chemicals.

Owner:OUTDOOR SOLUTIONS

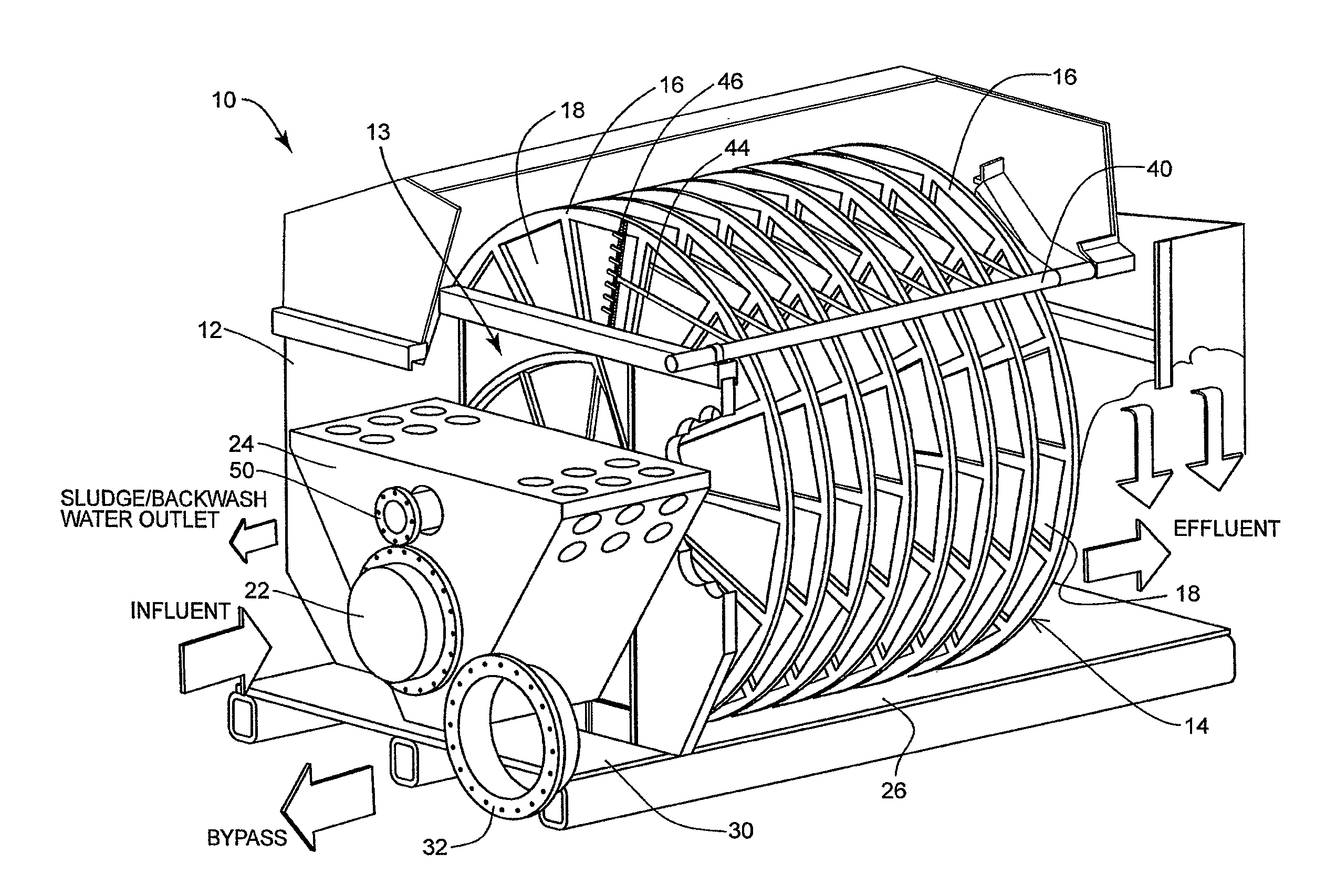

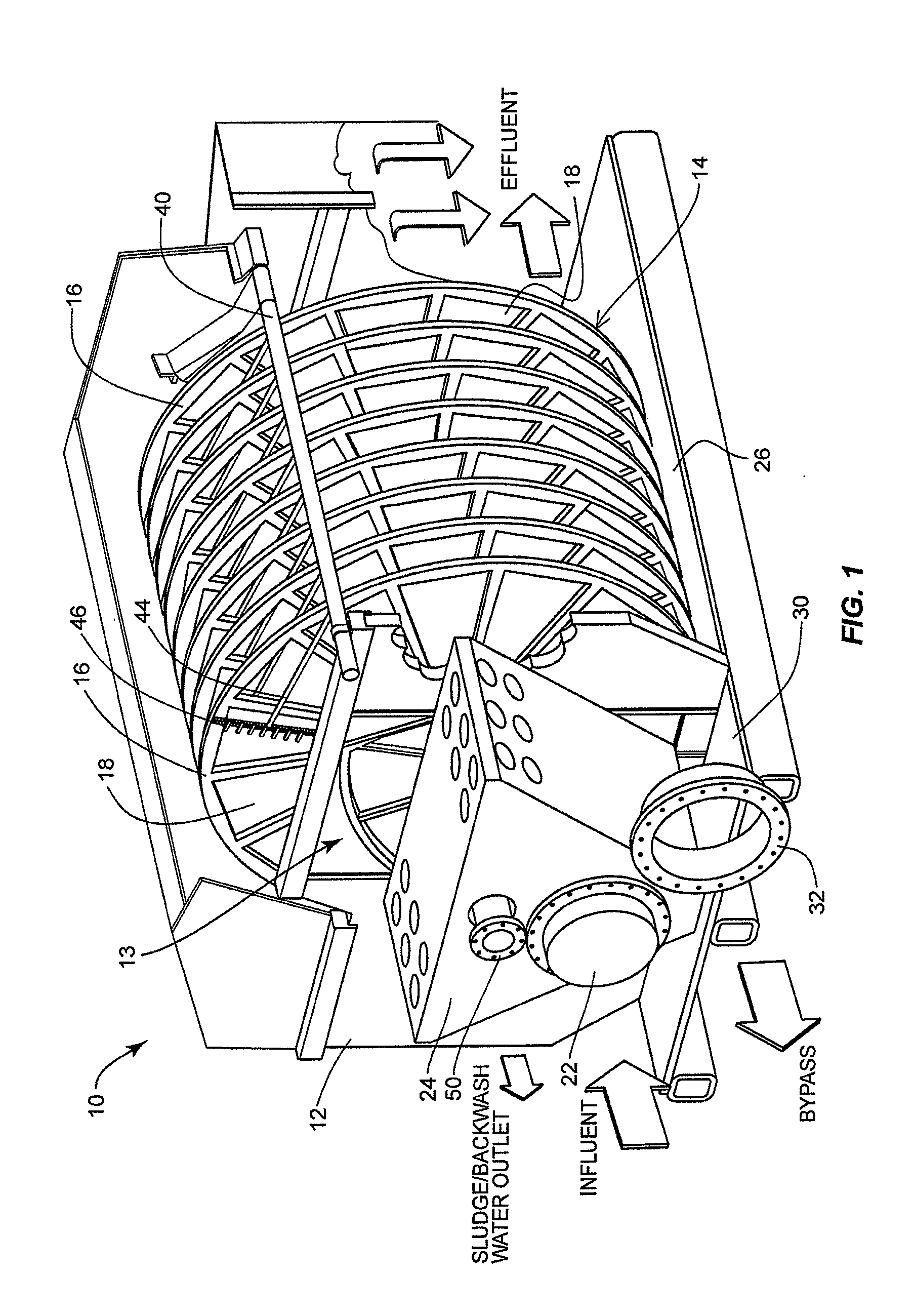

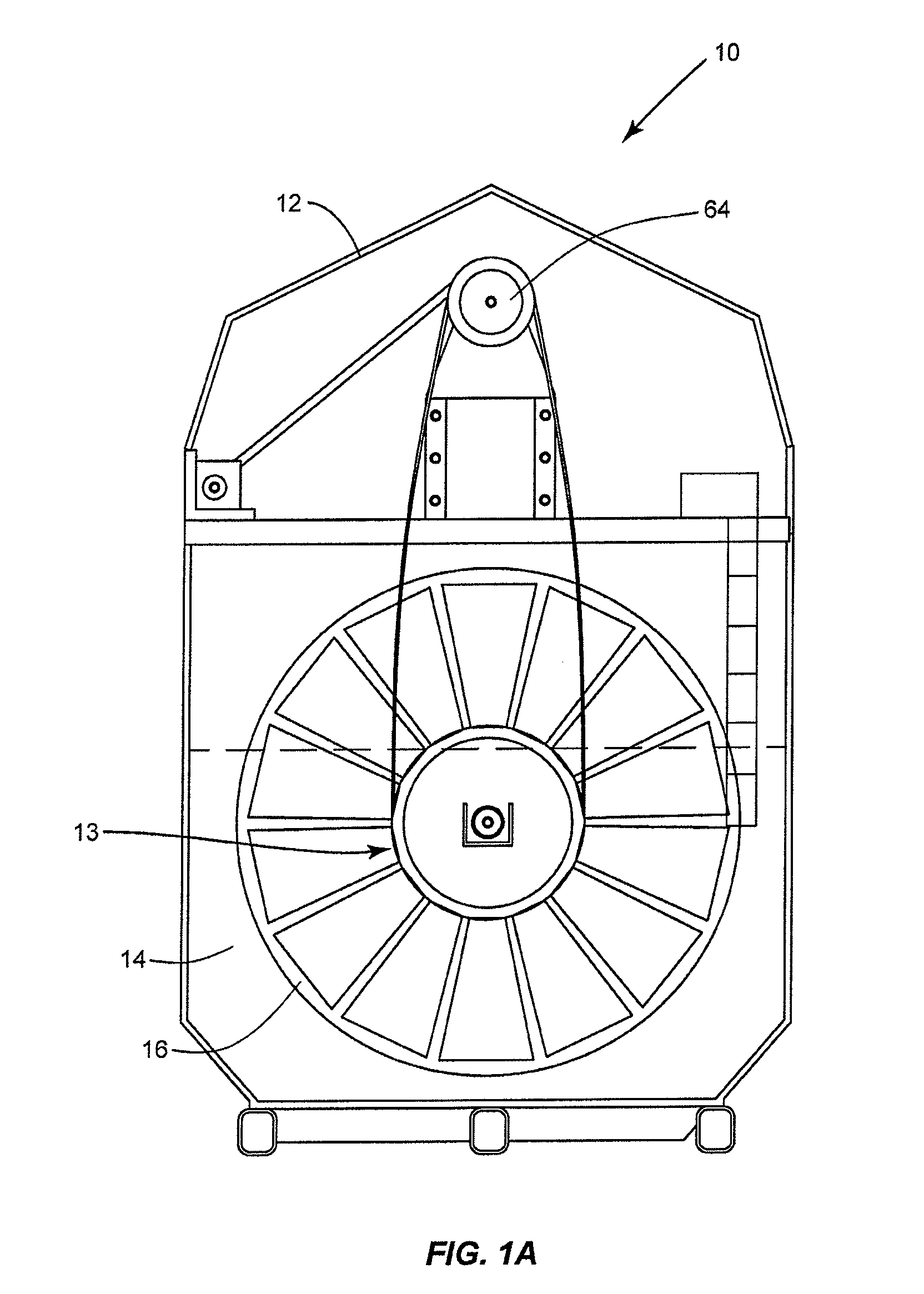

Rotary disc filter with automatic integrated backwash and chemical cleaning system

ActiveUS20160129377A1Membrane filtersLoose filtering material filtersChemical mixturesControl system

A rotary disc filter is provided with an integrated backwash and chemical cleaning system. In one mode of operation, backwash is directed through a control valve to one or more nozzles for spraying the backwash onto the filter media forming a part of a rotary disc filter. In a second mode, a chemical cleaning mode, the pump directs backwash through an eductor that induces a chemical into the inductor which is mixed with the backwash to form a backwash-chemical mixture that is sprayed onto the filter media. A control system is used in conjunction with the backwash and cleaning systems to monitor process information and / or filter media properties and to determine when to perform backwashes and regenerative cleanings in order to optimize the performance of the filter system.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

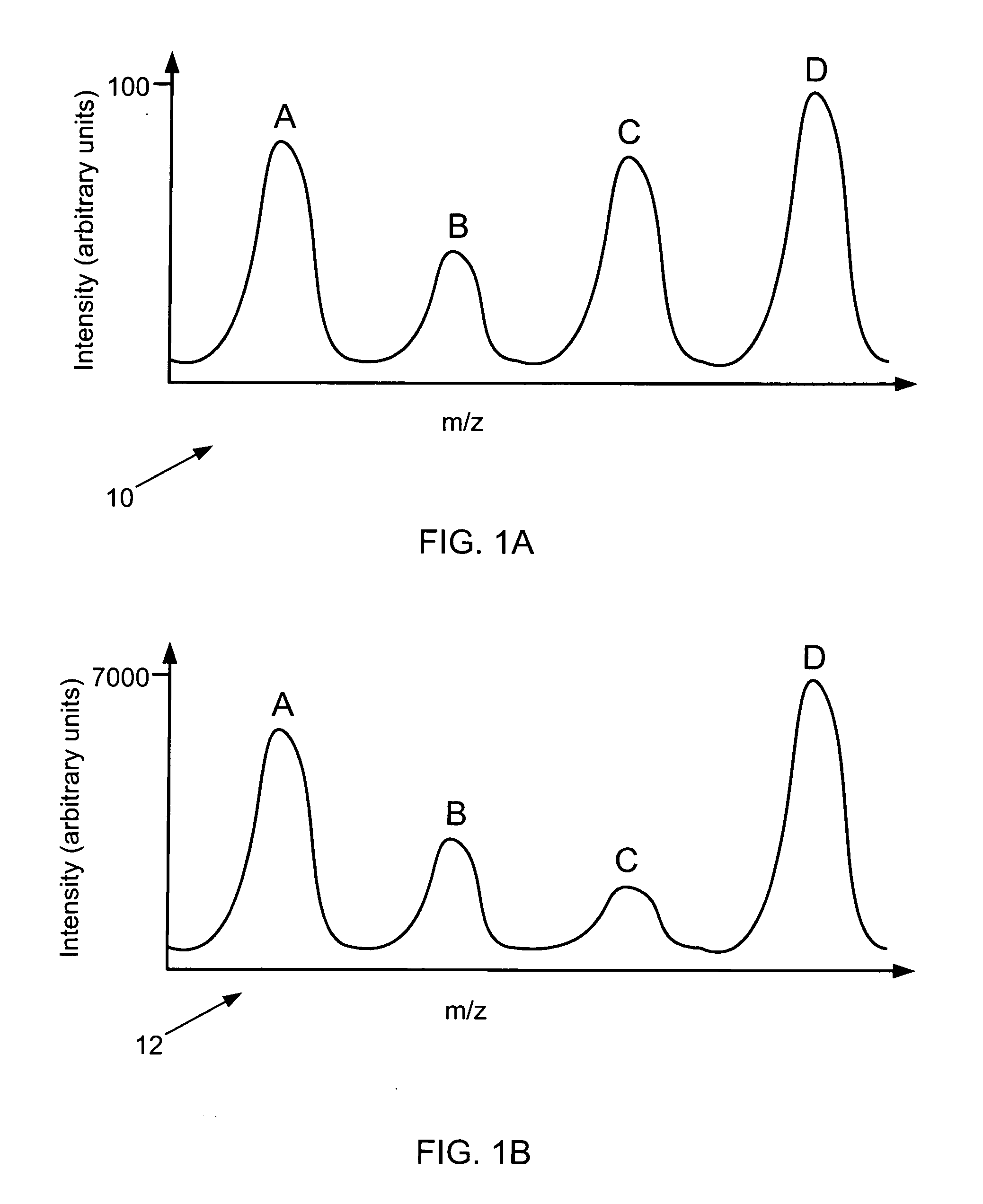

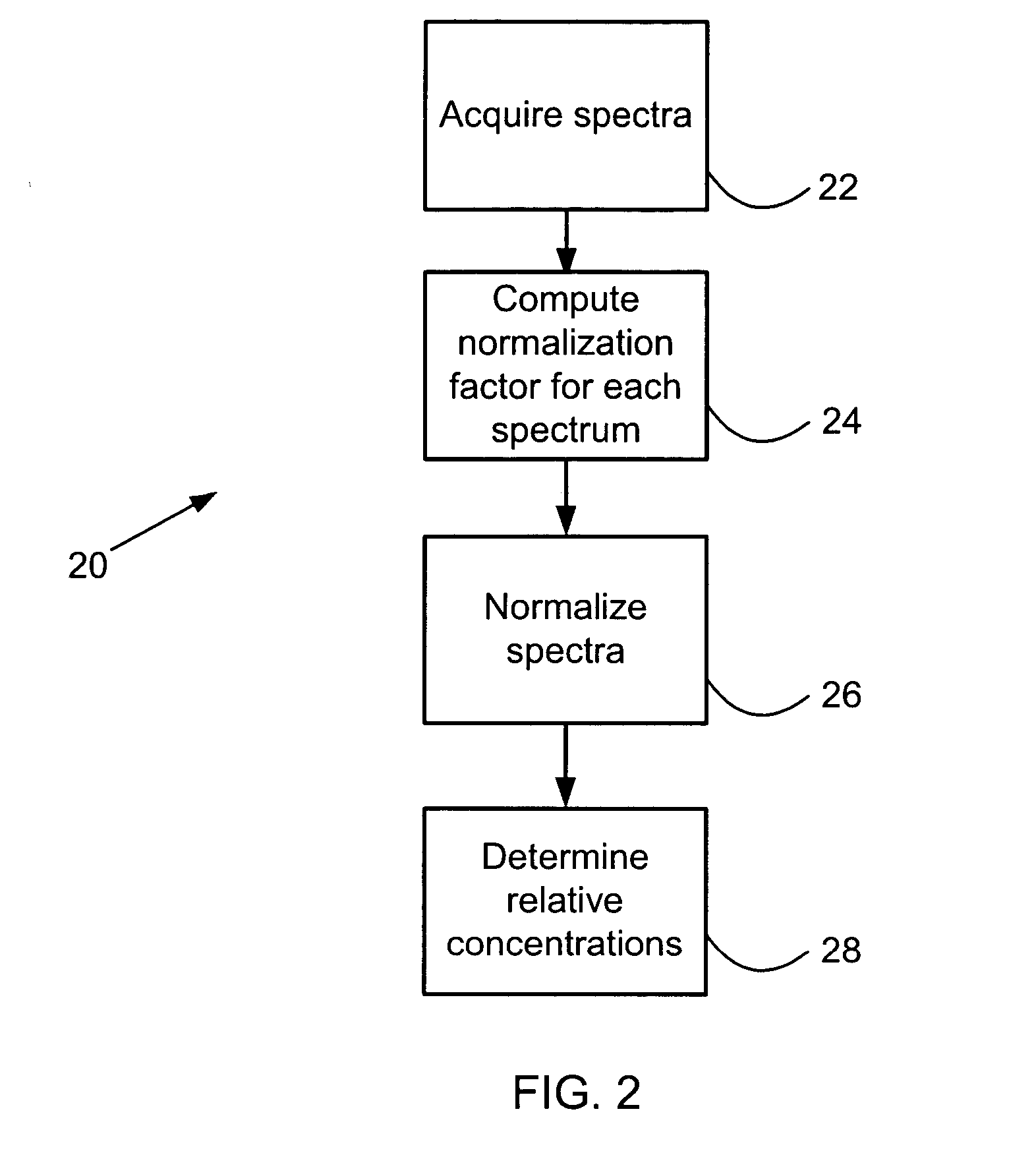

Mass spectrometic quantification of chemical mixture components

InactiveUS20050116159A1Samples introduction/extractionIsotope separationChemical mixturesInternal standard

Relative quantitative information about components of chemical or biological samples can be obtained from mass spectra by normalizing the spectra to yield peak intensity values that accurately reflect concentrations of the responsible species. A normalization factor is computed from peak intensities of those inherent components whose concentration remains constant across a series of samples. Relative concentrations of a component occurring in different samples can be estimated from the normalized peak intensities. Unlike conventional methods, internal standards or additional reagents are not required. The methods are particularly useful for differential phenotyping in proteomics and metabolomics research, in which molecules varying in concentration across samples are identified. These identified species may serve as biological markers for disease or response to therapy.

Owner:CAPRION PROTEOMICS INC

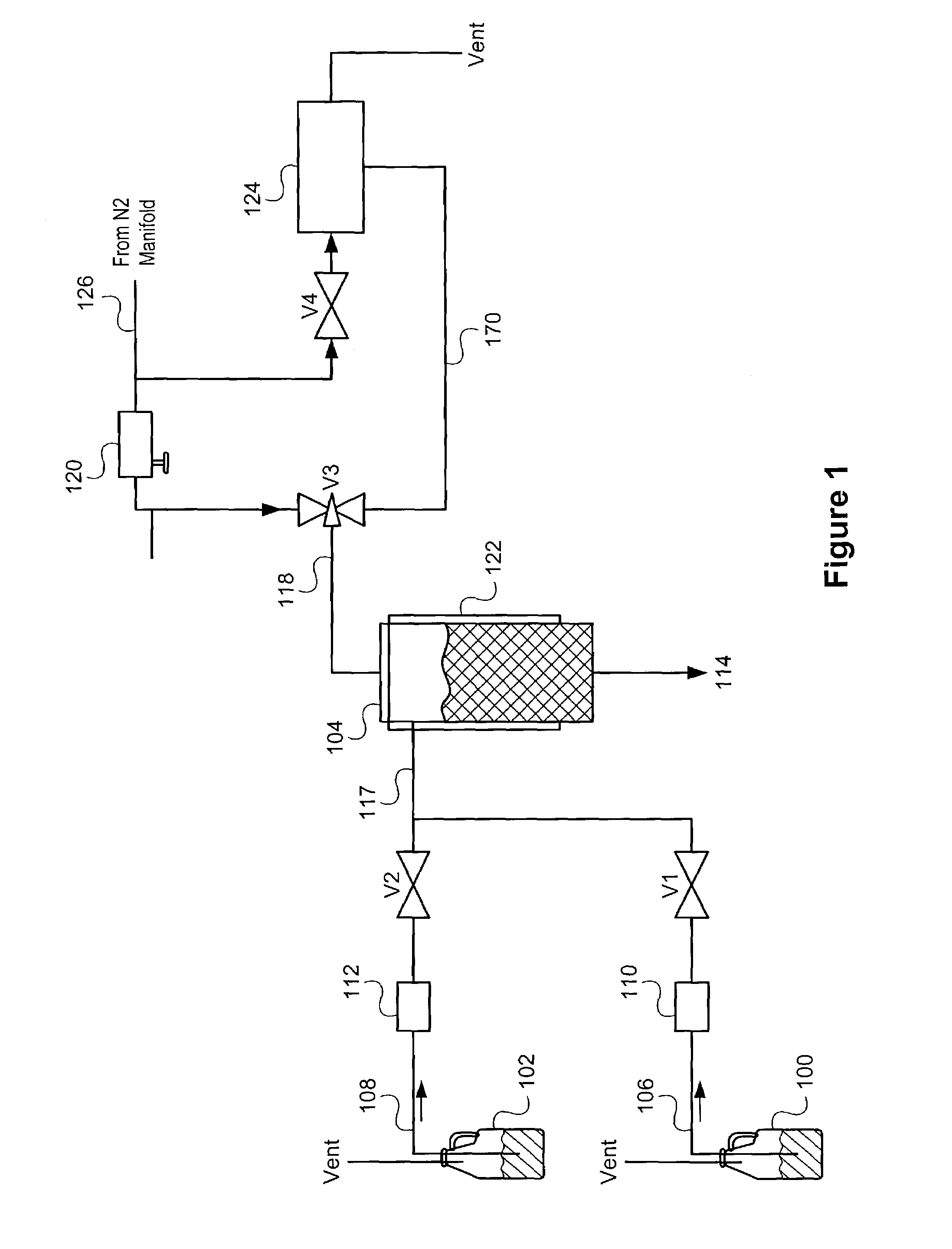

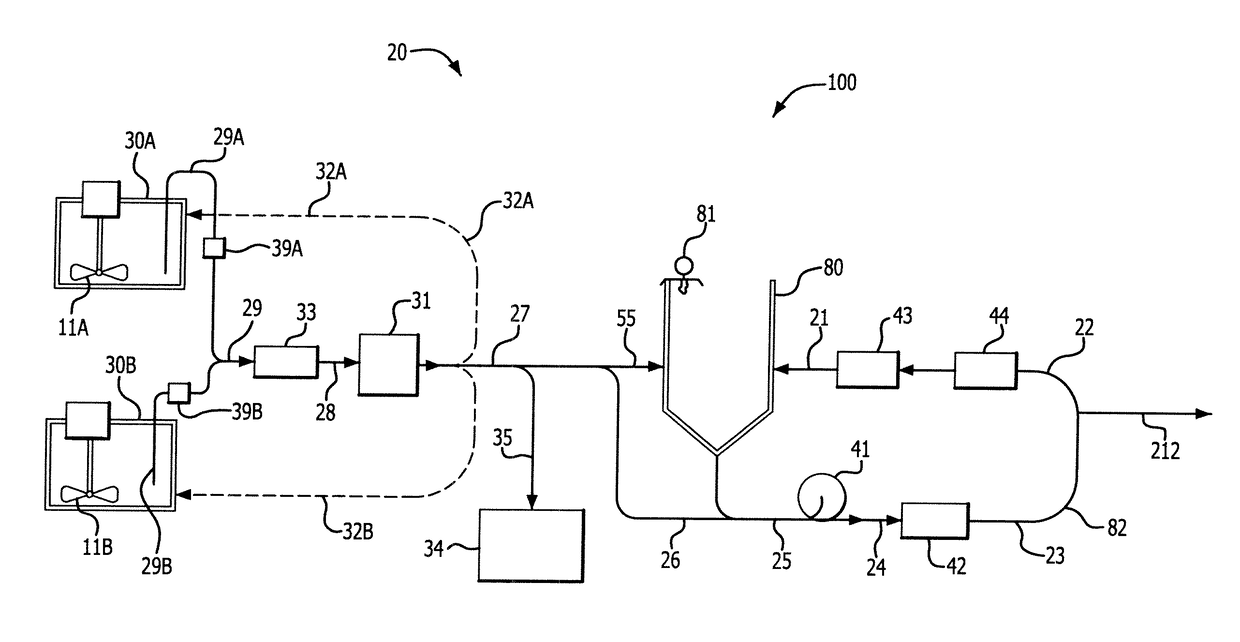

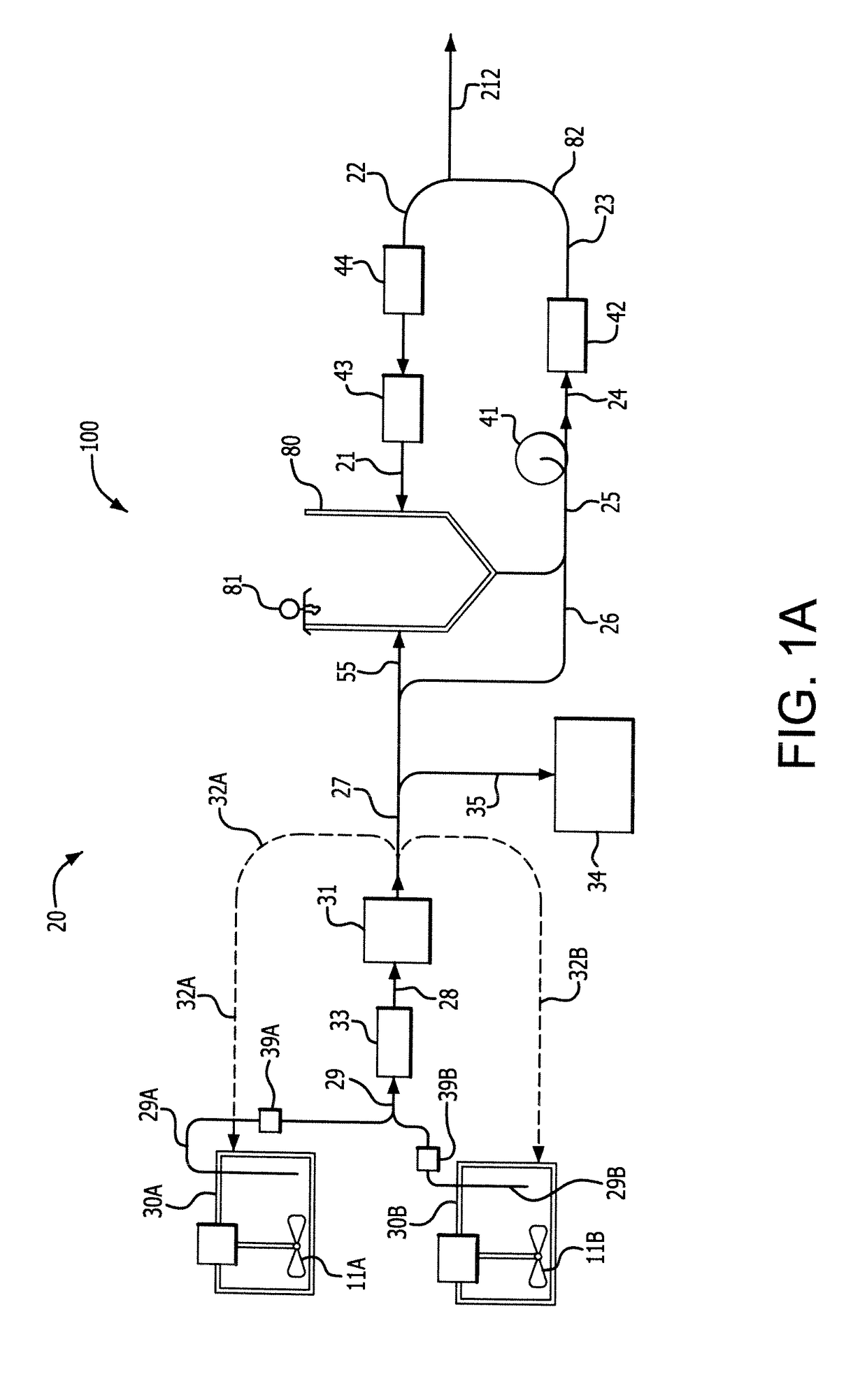

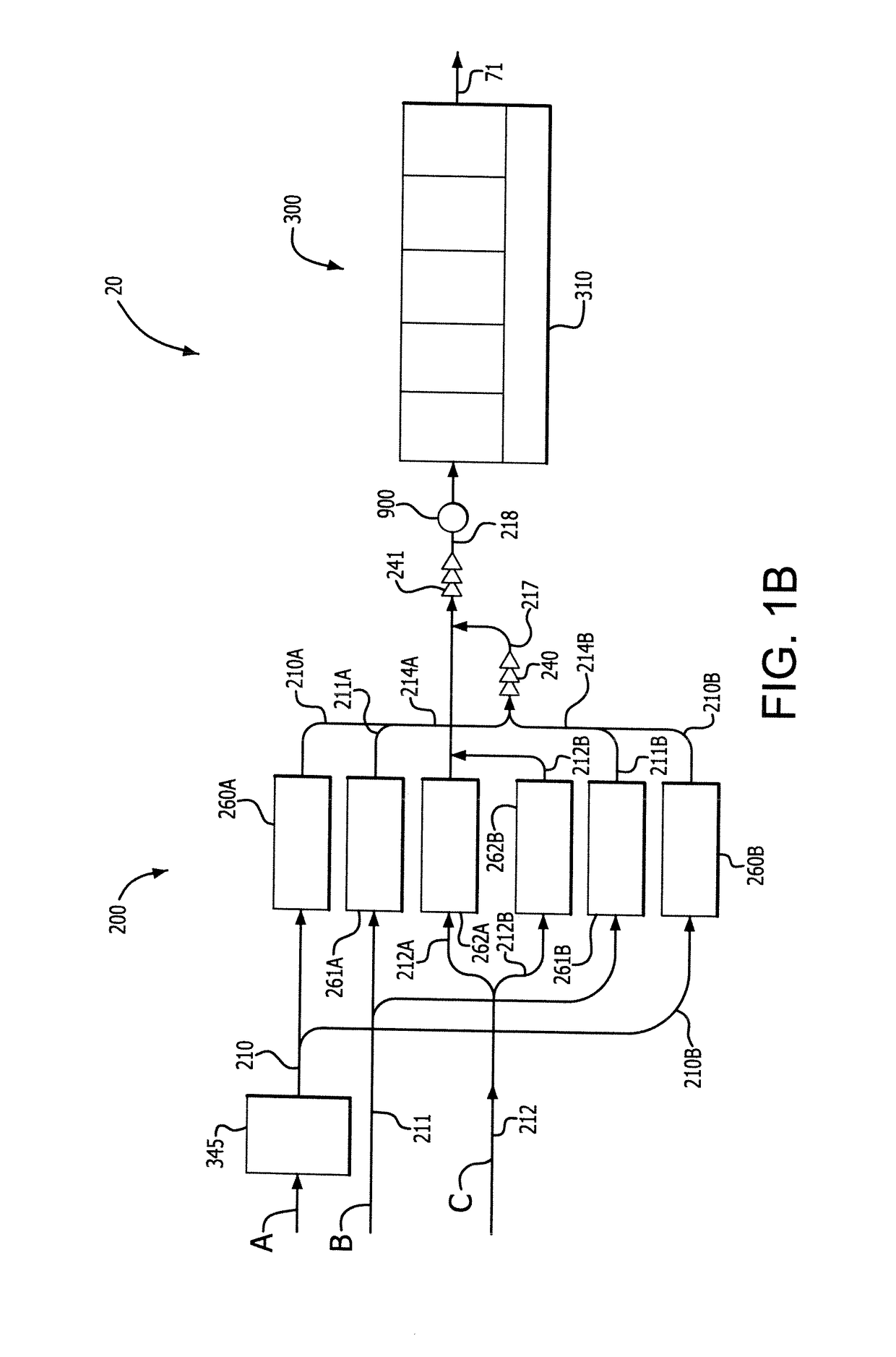

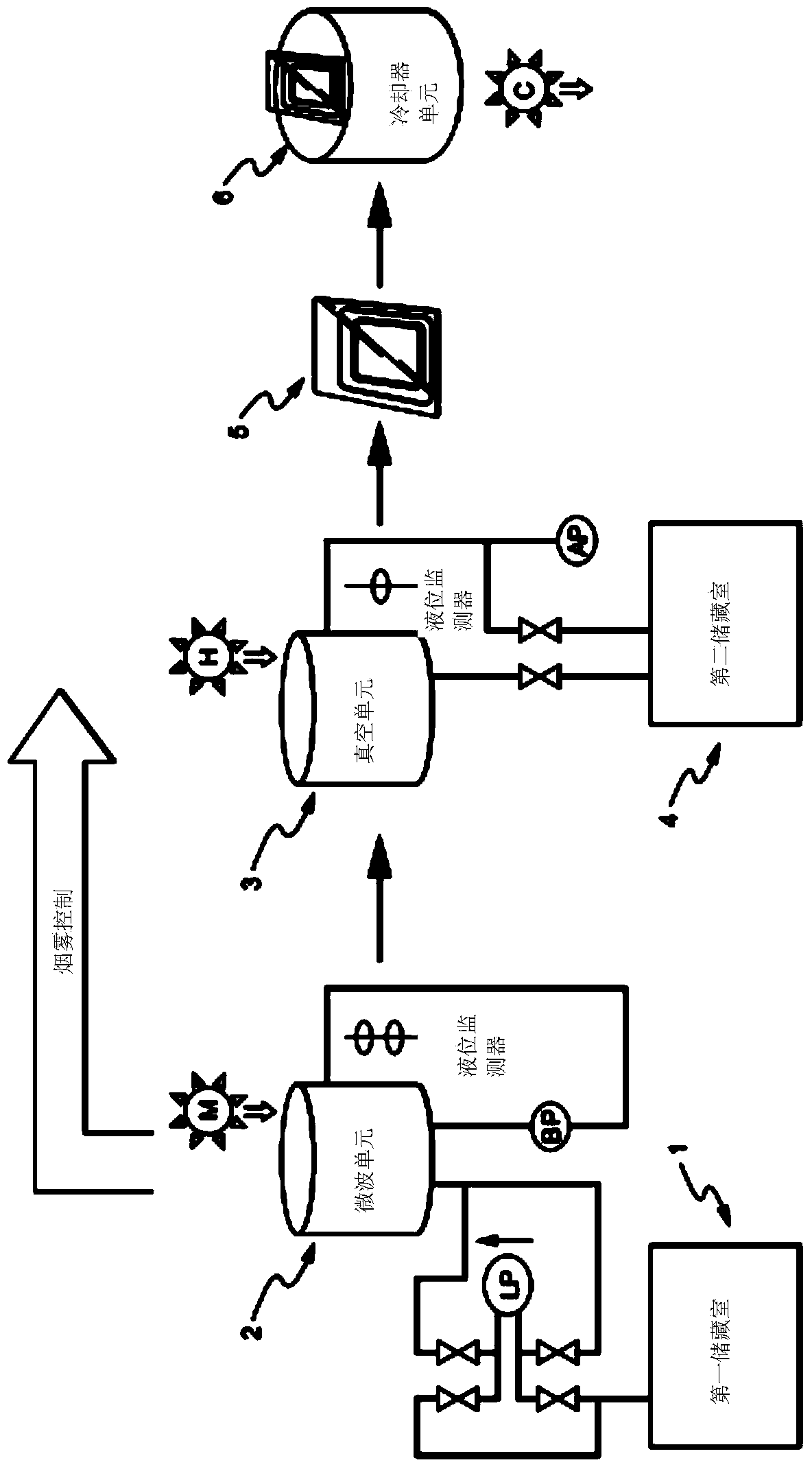

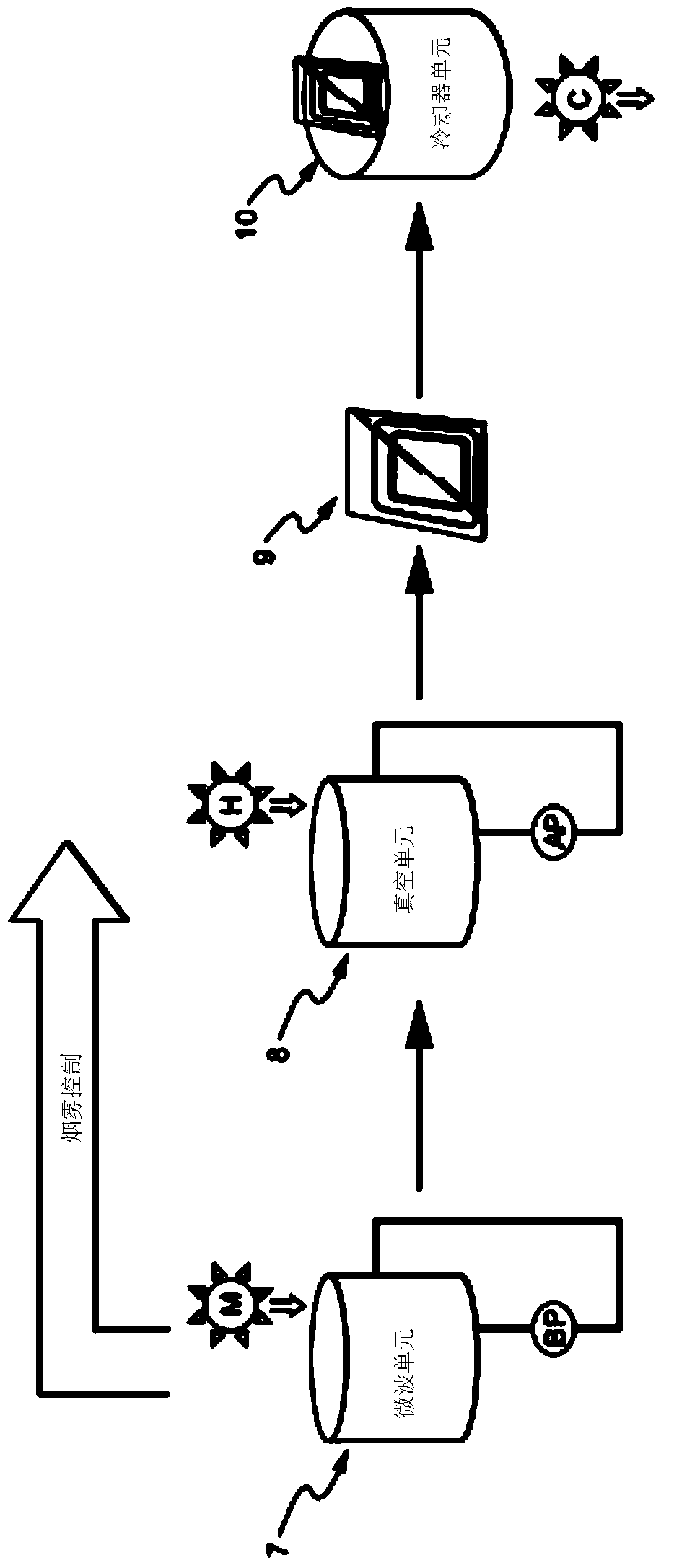

Slurry supply and/or chemical blend supply apparatuses, processes, methods of use and methods of manufacture

ActiveUS9770804B2Avoid negative effectsQuick responseThin material handlingGrinding/polishing apparatusChemical mixturesProcess engineering

A slurry and / or chemical blend supply apparatus suitable for providing slurry and / or chemical blend to chemical mechanical planarization (CMP) tools or other tools in a semiconductor fabrication facility, related processes, methods of use and methods of manufacture. The slurry and / or chemical blend supply apparatus includes one or more of the following: feed module, blend module, analytical module and distribution module.

Owner:VERSUM MATERIALS US LLC

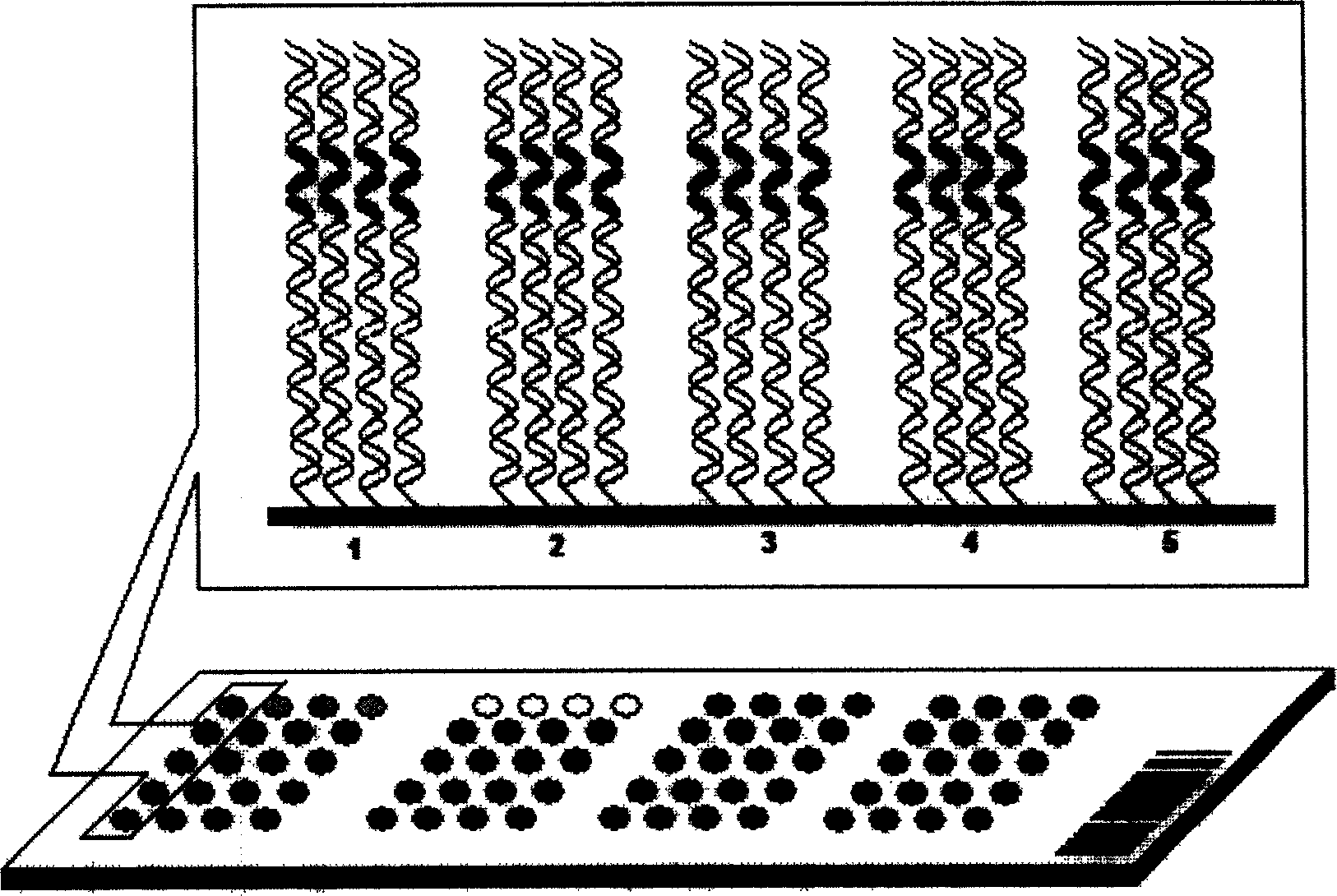

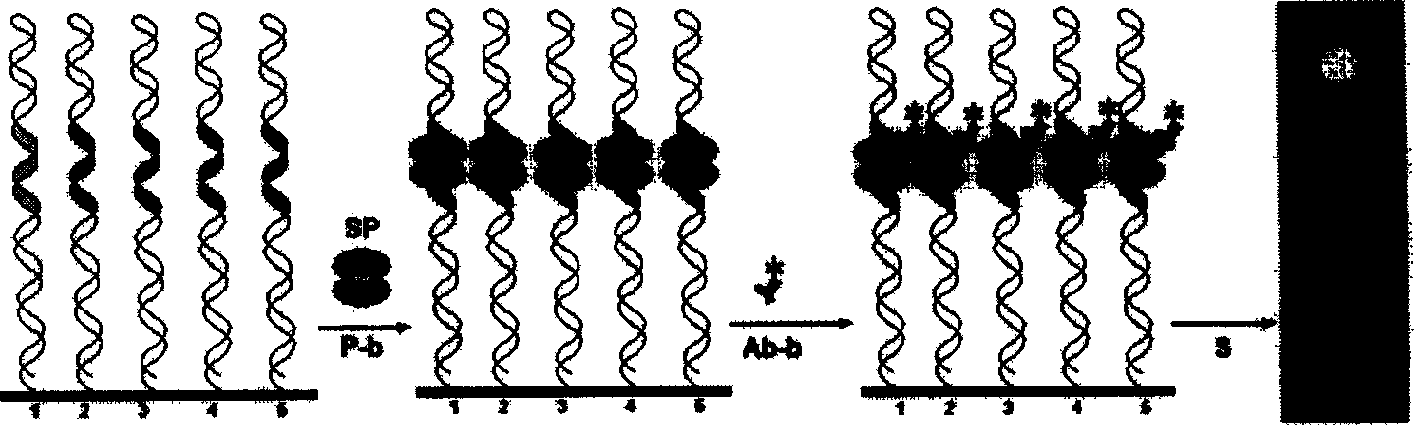

Method of high flux screening, capturing and separating target molecule from complex composition matter such as traditional Chinese medicine and chemical mixture

InactiveCN1590560AImprove bindingIncrease transcriptionMicrobiological testing/measurementDNA Microarray ChipDisease

A process for high-flux screening, capturing and separation of target moleculae from complex substance (Chinese medicine or chemical mixer) includes preparing a ds DNA microarray chip to make its probe have a binding sites of dsDNA bindin, measuring the affinity of the sites, creating the standard affinity parameter system, mixing the microarray chip with said complex substance, reacting, detecting the affinity variation, screening the varied targets, linking them to the surface of chromatographic column, filling the complex substance in it, capturing the effective moleculae by probes, eluting and collecting the effective moleculae.

Owner:王进科 +2

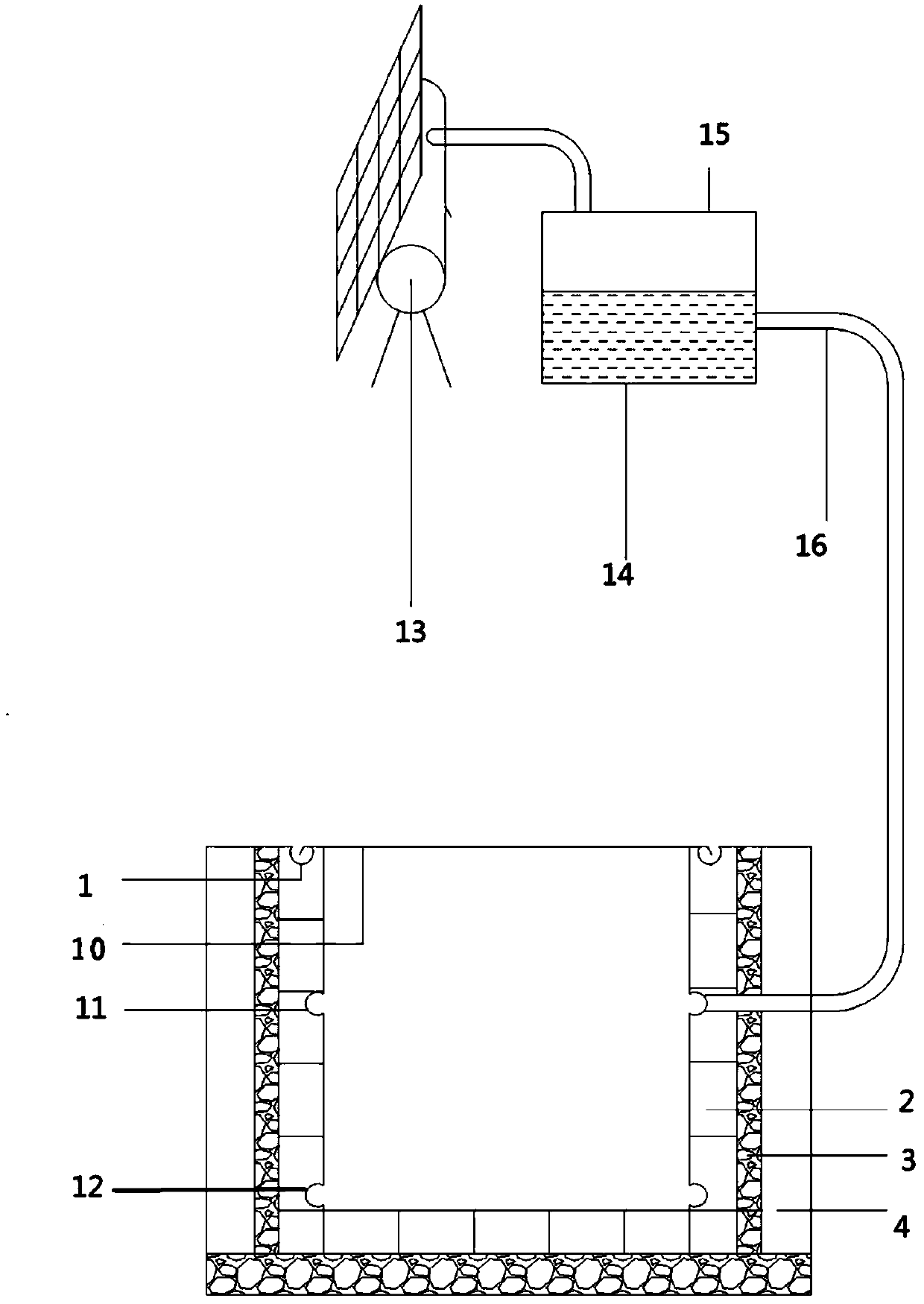

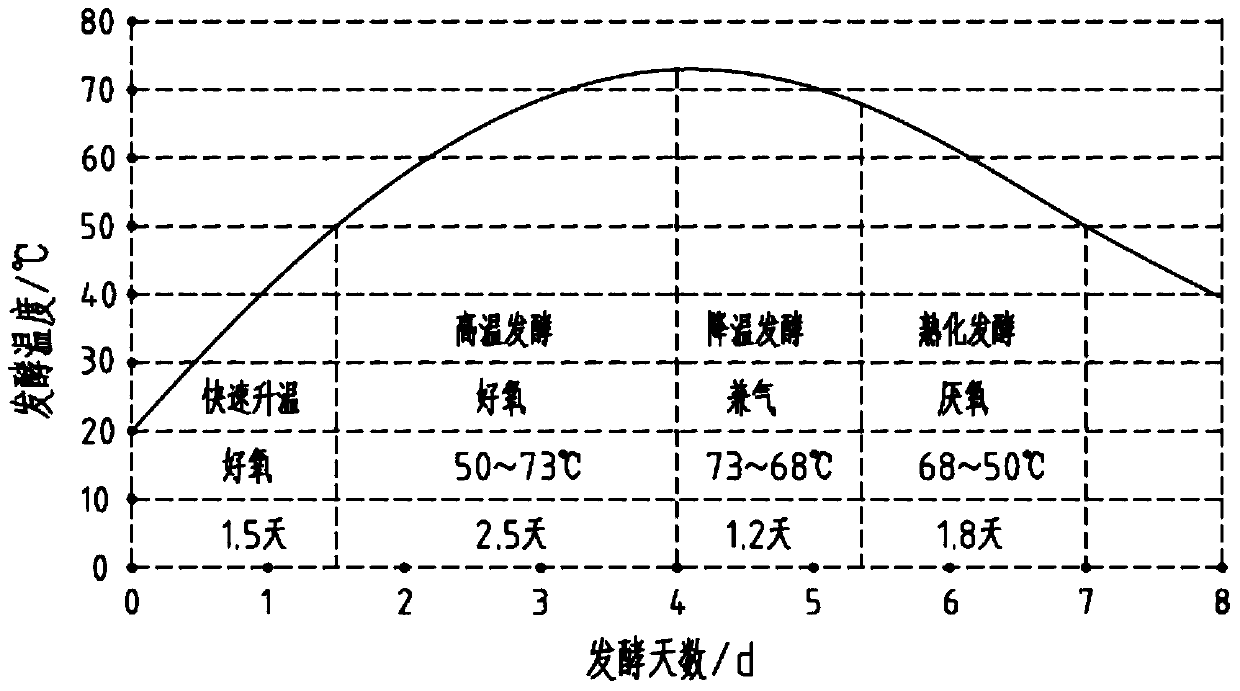

Specific tea-oil tree compound fertilizer containing tung oil

InactiveCN104045402APromote growthMaintain vigorous growthFertilizer mixturesChemical mixturesCamellia oleifera

The invention discloses a specific tea-oil tree compound fertilizer containing tung oil. The compound fertilizer is prepared from tung oil, tung oil cake, human urine, pig manure, cow dung, chicken manure, cornstalk, urea, diammonium phosphate, potassium chloride and humic acid in a certain weight ratio. The preparation method comprises the following steps: putting tung oil cake and the human urine into tung oil to prepare an oil-urine compound fertilizer, fermenting a humic acid organic fertilizer inside a clay frame, blending urea, diammonium phosphate and potassium chloride into a chemical mixture fertilizer, subsequently uniformly mixing the three fertilizers, and controlling the water content to be less than 14%, thereby obtaining a finished product. The invention aims at customizing a series of specific fertilizers containing tung oil that organic fertilizers and chemical fertilizers are combined, three elements, that is, nitrogen, phosphorus and potassium are combined, secondary elements and microelements are complete, rich activated organic substances are provided and the fertilization period and the fertilizers are determined according to the growth characteristics of tea-oil trees. The compound fertilizer is wide in raw material resource, scientific and reasonable in proportion and process, saved in the labor, lowered in the production cost by more than 30% and applicable to popularization.

Owner:湘西盛泰农业科技有限公司

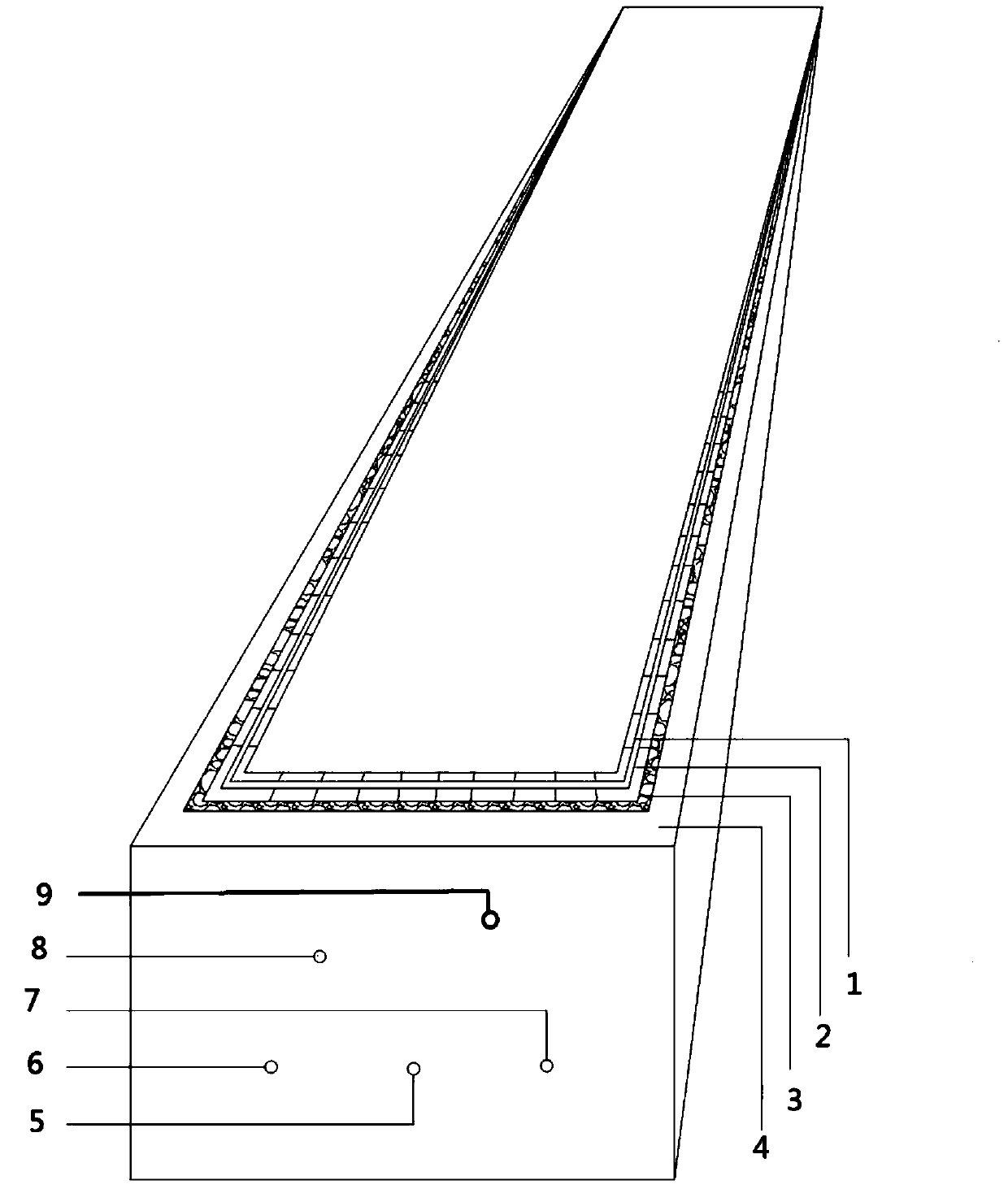

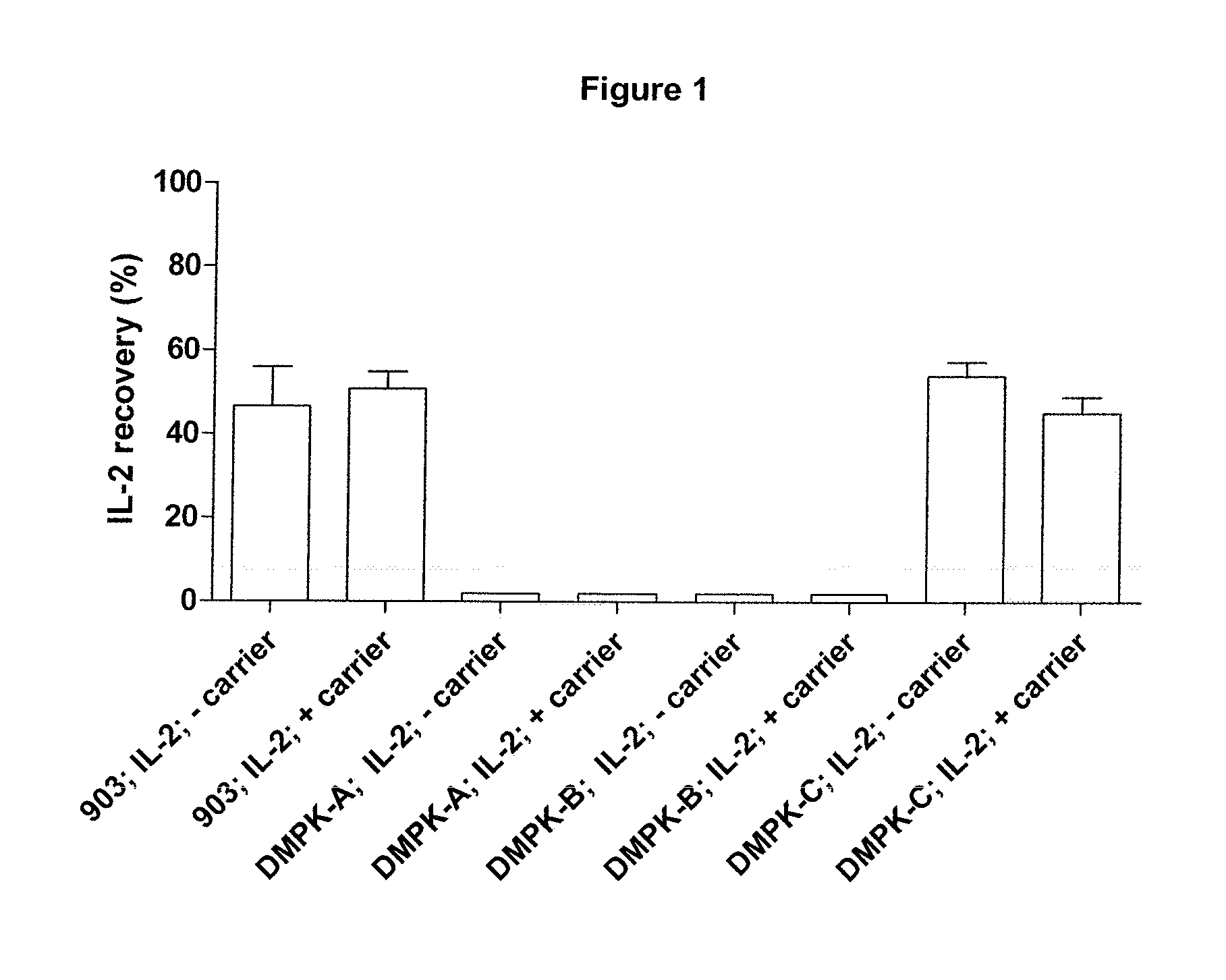

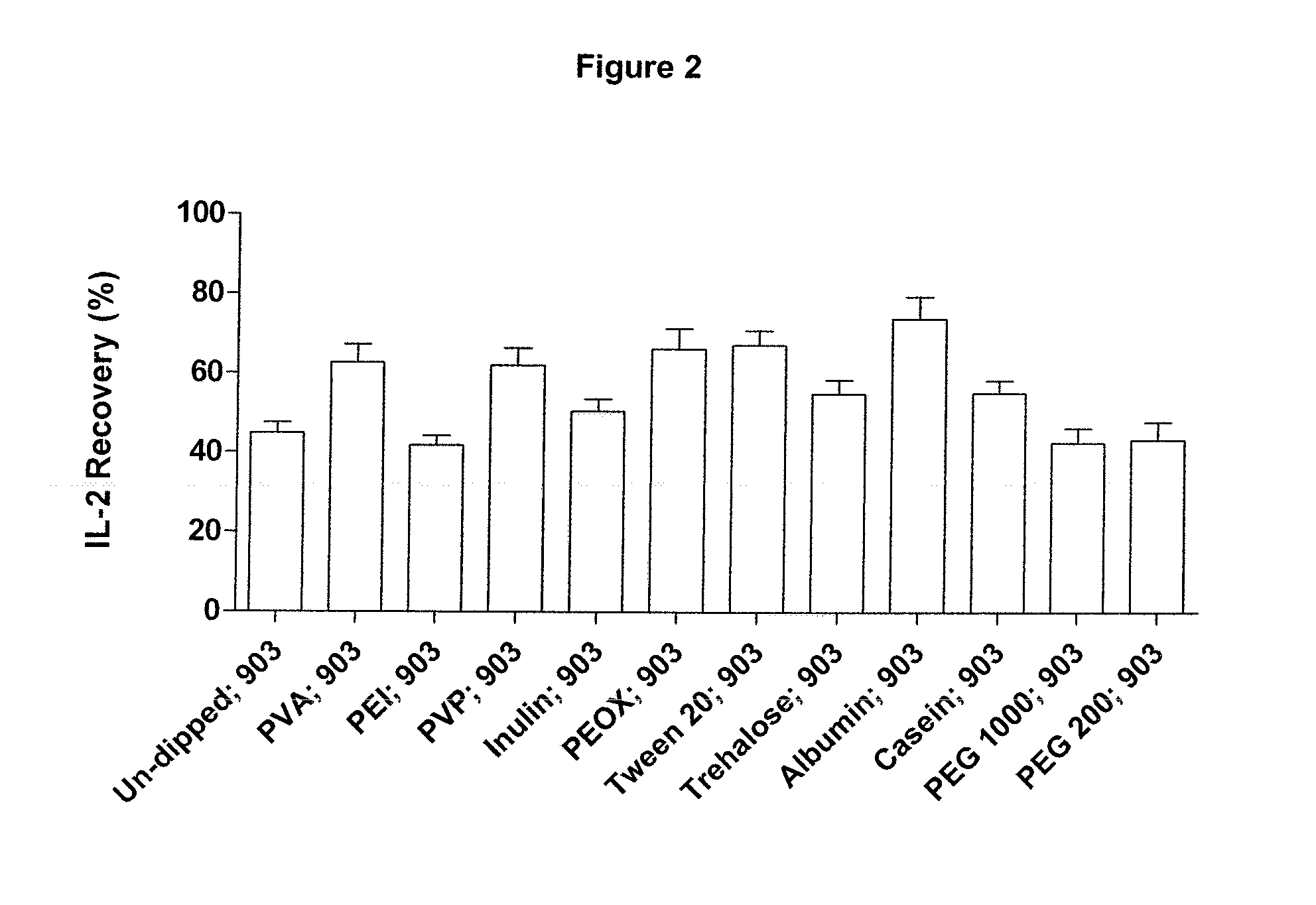

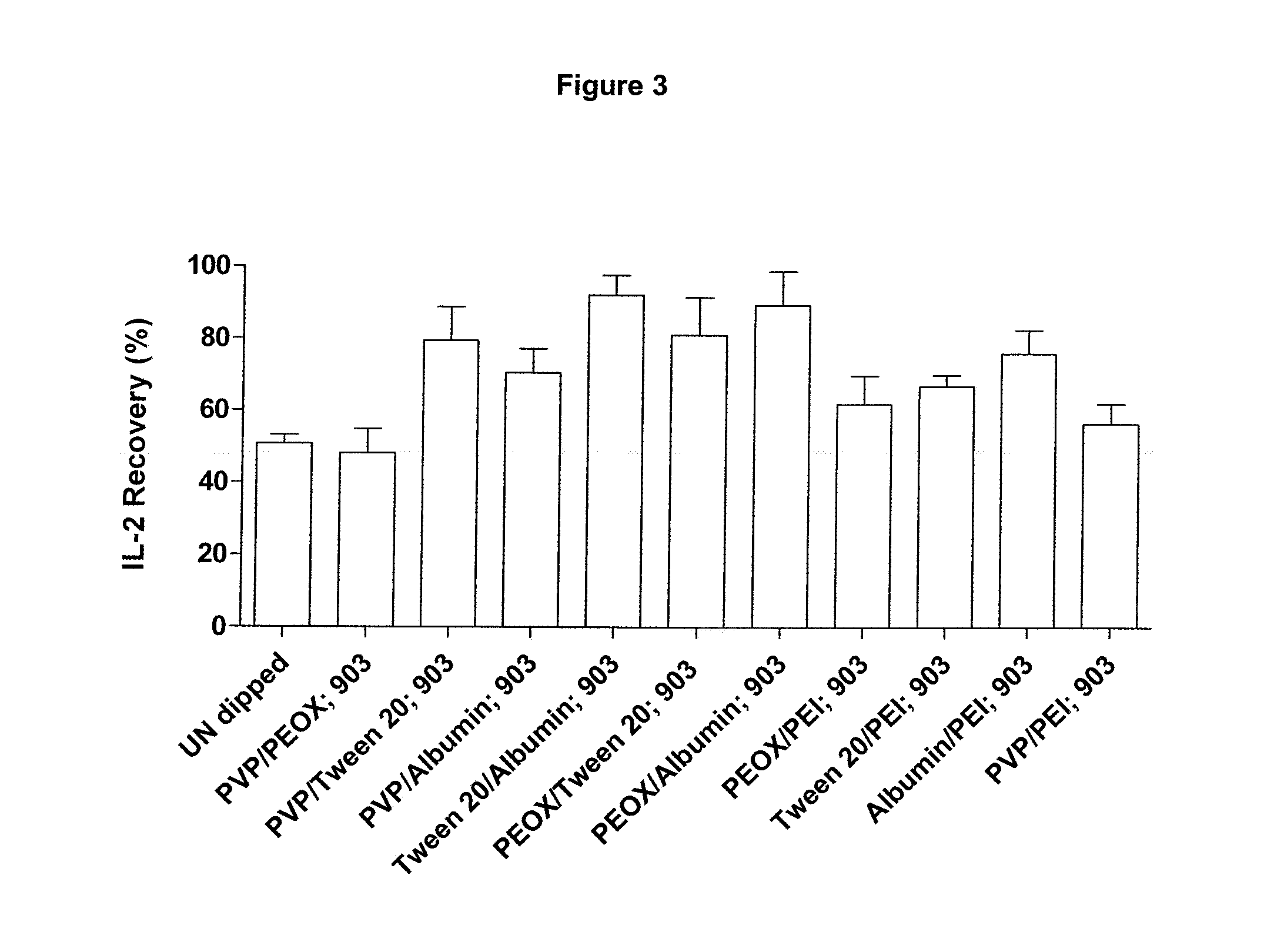

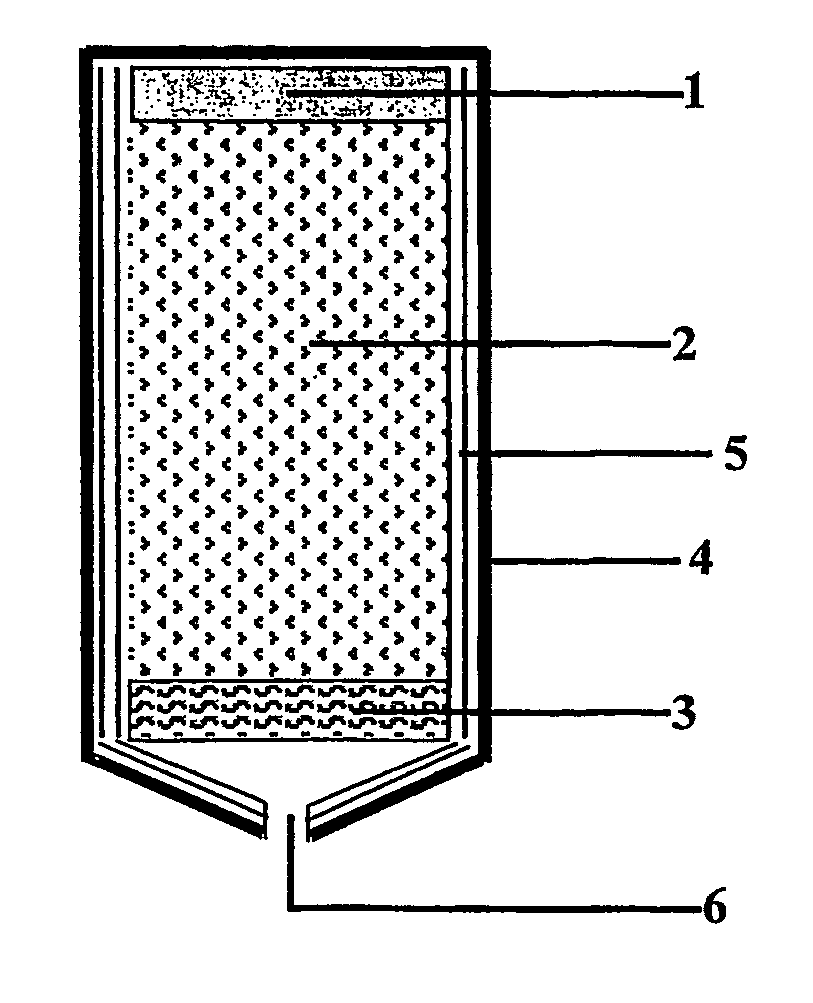

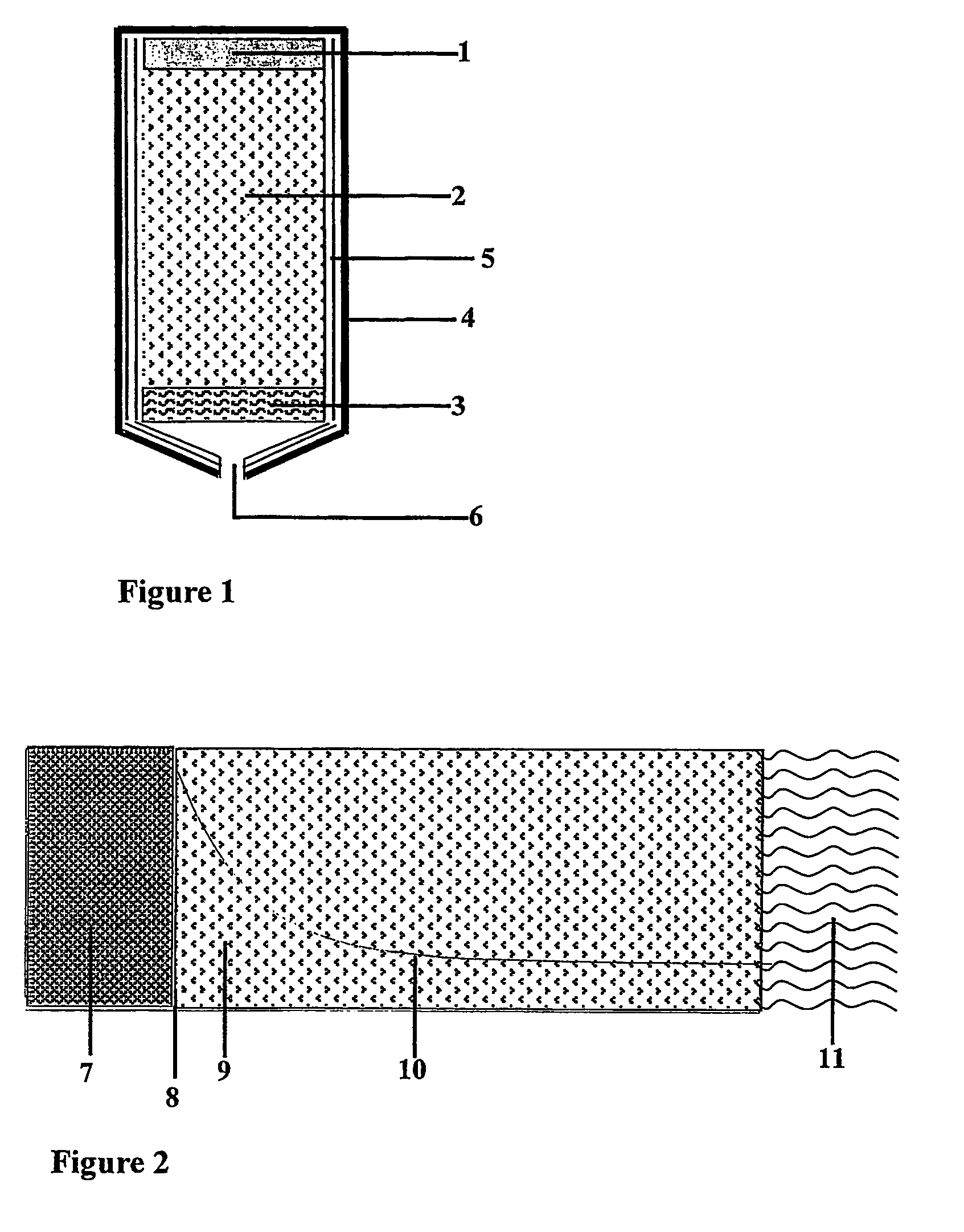

Solid support and method of recovering biological material therefrom

InactiveUS20130323723A1Promote recoveryBioreactor/fermenter combinationsBiological substance pretreatmentsChemical mixturesBiomaterial

The present invention relates to solid supports that are used for the storage and further processing of biological materials. The invention is particularly concerned with solid supports which have at least one surface coated with a chemical mixture that enhances the recovery of the biological material from the support. Methods of preparing and using the solid supports are also described.

Owner:GLOBAL LIFE SCI SOLUTIONS OPERATIONS UK LTD

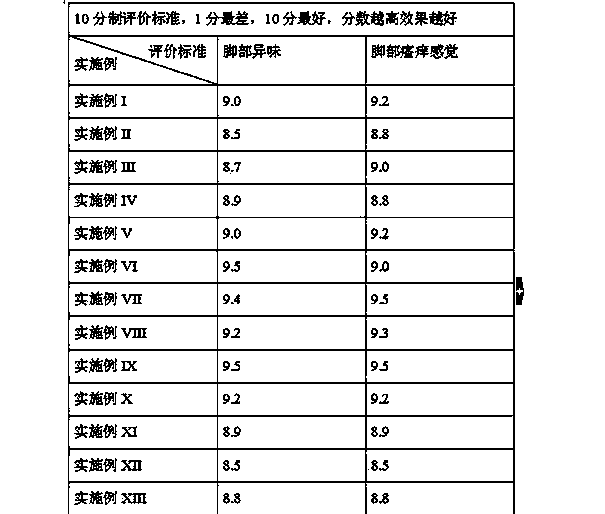

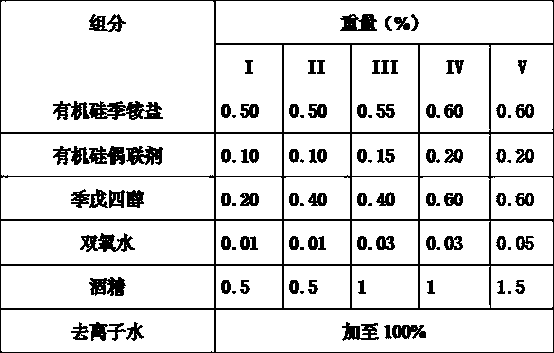

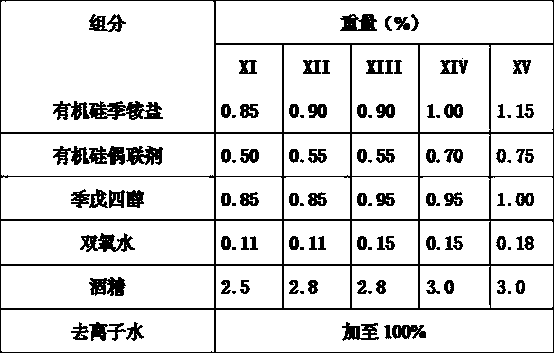

Bactericidal odor removing agent

InactiveCN103380784AInhibition of reproductionNo pollutionAntibacterial agentsBiocideChemical mixturesDisinfectant

The invention discloses a bactericidal odor removing agent in the chemical mixture agent field, and is characterized by comprising the components, in percentage by weight: (A) 0.25 to 5% of an organic silicon quaternary ammonium salt; (B) 0.1 to 2% of an organic silicon coupling agent; (C) 0.2 to 2% of a stabilizing agent; and (D) the balance being deionized water. The bactericidal odor removing agent has antibacterial, mildewproof, odor-removing and deodorant effects, has lastingly bacteriostatic effect and widely bacteriostatic range, simultaneously is safe and reliable for any product, and does not pollute the environment. The organic silicon quaternary ammonium salt has bactericidal and bacteriostatic effects, and non-toxic, gentle, soft and smooth properties of the organic silicon quaternary ammonium salt to human bodies are utilized, so the bactericidal odor removing agent is prepared into a spray medicament form, is used for disinfectant and bactericidal treatment of various traumatic infections and skin infections, can have rapidly bactericidal antipruritic effect for the various skin infections, and can kill bacteria and inhibit bacterial activity.

Owner:李萍

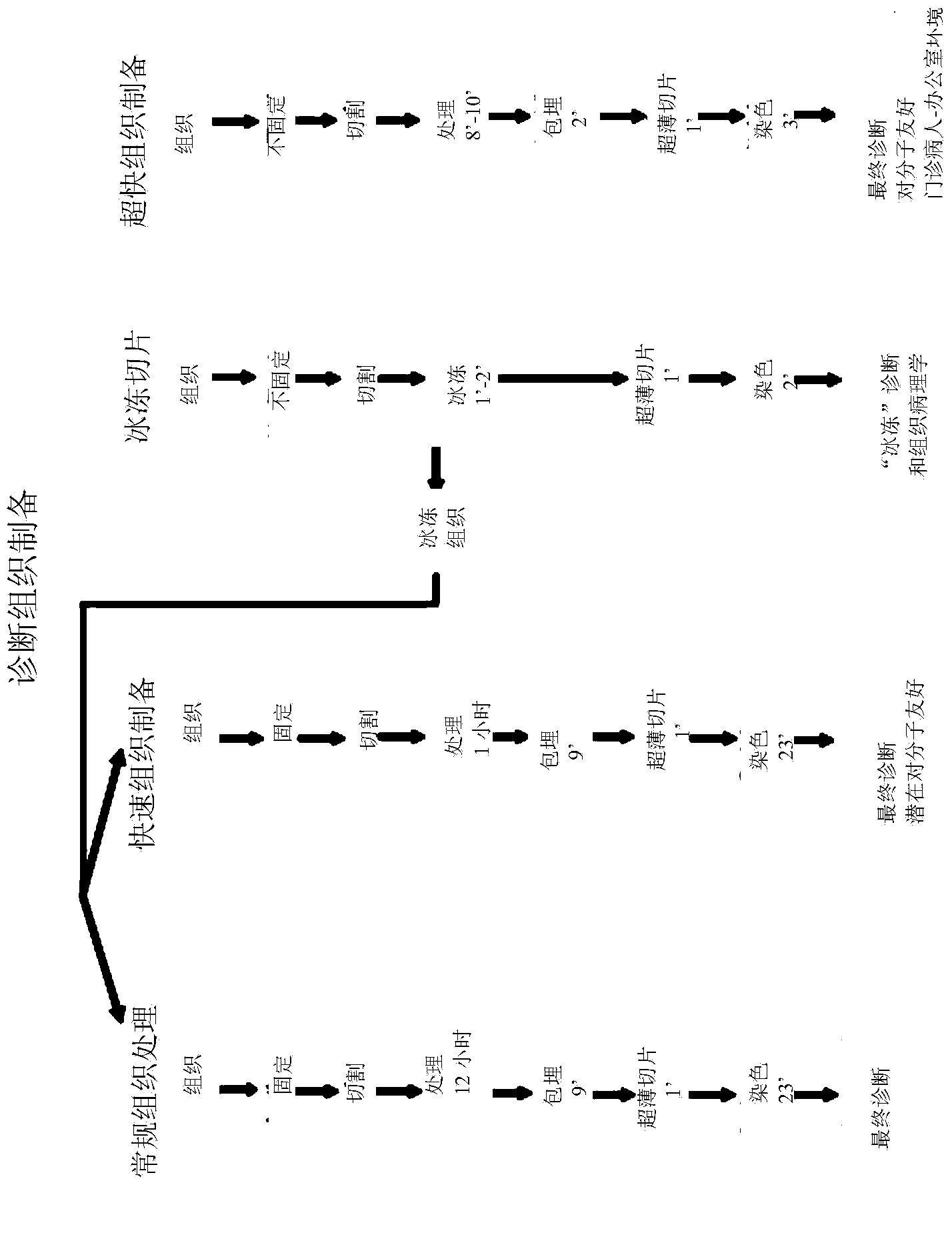

Ultra-rapid diagnostic tissue preparation as an alternative to frozen section

ActiveCN103975229AAnimal cellsMicrobiological testing/measurementSurgical operationChemical mixtures

Improved methods and systems for processing of solid tissue are described. The method may be performed manually or automatically. The system may have modules such as (i) a grossing module where a fresh tissue is sliced to prepare a tissue specimen, (ii) a hardening module that hardens the tissue specimen, (iii) an impregnating module that impregnates the tissue specimen that was hardened, and (iv) an embedding module that embeds a tissue specimen that was hardened and impregnated. Fresh (i.e., not fixed or frozen) tissue, which was excised to diagnose disease or to assess surgical treatment, is grossed to about 0.6 mm Preferably, the hardening of fresh tissue is initiated, but not completed, during grossing by contact with a chemical admixture. Preferably, dry ice, a thermoelectric device, or a gas condenser cools a metal mold containing the embedded specimen. It is sectioned and then microscopically examined as an alternative to histologic examination of a frozen section to avoid the known problems of discordant and deferred diagnosis.

Owner:UNIV OF MIAMI

High-pressure mixing method and apparatus, with a self-lubricating and scraping device

InactiveUS20080128209A1Efficient actionReducing and preventing formation of depositMixer accessoriesMachines/enginesChemical mixturesEngineering

The high-pressure mixing apparatus, for reactive chemical components, comprises a device for self-lubricating and scraping the outlet duct of the chemical mixture, and flushing out the scraped residues. The self-lubricating and scraping device comprises a delivery chamber for the lubricant material axially aligned and in fluid communication with the outlet duct; the lubricant delivery chamber is connected to a storage tank by a feeding and re-circulation circuit. The lubricant is sucked into the outlet duct and subsequently returned into the delivery chamber by a cleaning member in the form of a pumping piston sliding into the outlet duct, the pumping piston being provided with scraping rings for removing the reacted mixture adhered to the inner surface of the outlet duct.

Owner:AFROS

Cool oxygen chemical gas generator

ActiveUS8142726B2Large specific surface areaHigh surfacePressurized chemical processOxygen respiratorsChemical mixturesDecomposition

The present invention is directed to a chemical oxygen generator to produce cool oxygen gas comprising: a. a charge housing, b. a solid but porous charge contained in the said housing, the charge being made of a chemical mixture that generates oxygen upon decomposition and that will undergo a self-sustained exothermal decomposition after initiation, the said charge containing at most 3.0 wt. % of binder material, the said porous charge allows the generated oxygen to pass through the charge without damaging the virgin material and without creating volumetric burning, the said charge is mounted in the housing in such a way that the generated oxygen passes through the charge and under the pressure difference flows from the moving decomposition front towards the vent, c. an ignition device mounted at one end of the cartridge in such a way that it is capable to initiate a self-sustained decomposition of the charge at the charge surface adjacent to the initiator, d. one or more vents mounted in such a way that the generated oxygen that has passed through the generating porous charge leave the gas generator through the said vents.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST NATUURWETENSCHAPPELIJK ONDERZOEK TNO

Cool oxygen chemical gas generator

ActiveUS20050053527A1Large specific surface areaHigh surfacePressurized chemical processOxygen respiratorsChemical mixturesDecomposition

The present invention is directed to a chemical oxygen generator to produce cool oxygen gas comprising: a. a charge housing, b. a solid but porous charge contained in the said housing, the charge being made of a chemical mixture that generates oxygen upon decomposition and that will undergo a self-sustained exothermal decomposition after initiation, the said charge containing at most 3.0 wt. % of binder material, the said porous charge allows the generated oxygen to pass through the charge without damaging the virgin material and without creating volumetric burning, the said charge is mounted in the housing in such a way that the generated oxygen passes through the charge and under the pressure difference flows from the moving decomposition front towards the vent, c. an ignition device mounted at one end of the cartridge in such a way that it is capable to initiate a self-sustained decomposition of the charge at the charge surface adjacent to the initiator, d. one or more vents mounted in such a way that the generated oxygen that has passed through the generating porous charge leave the gas generator through the said vents.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com