Ore dressing method for removing pyrrhotite from iron ore

A technology of pyrrhotite and ore dressing methods, applied in chemical instruments and methods, flotation, wet separation, etc., can solve problems such as fluctuations and fluctuations in large-scale industrial production conditions, and achieve improved molecular arrangement, enhanced hydrophobicity and flotation speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

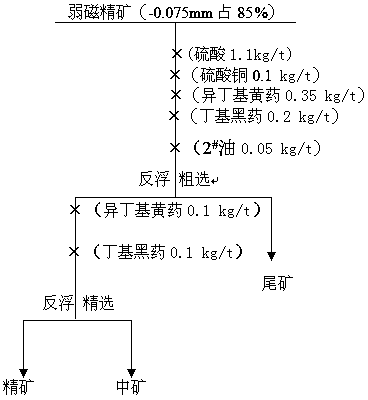

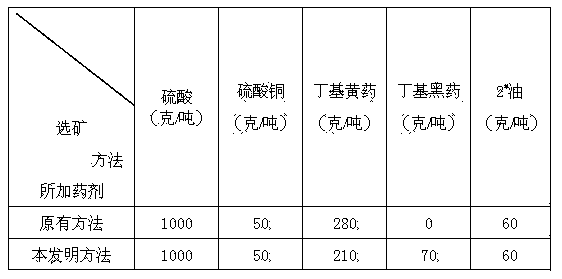

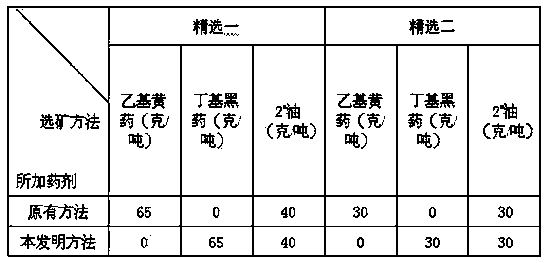

[0047] Grinding a certain magnetite concentrate in Shandong with a sulfur content of 0.9%~1.3% to a particle size of -200 mesh (-0.075mm) accounts for 85%, dissociates the basic monomer of magnetite, and desulfurizes with the patented method of the present invention and the original method In the comparative test, the original method is to add copper sulfate as an activator and butyl xanthate as a collector in an acidic medium for flotation. The method of the present invention is to introduce butyl black drug as a mixed collector to carry out flotation under the above conditions. The total amount of collector added is the same in both methods. The dosing system list of the comparative test is as follows:

[0048] Table 1 Rough selection and dosing

[0049]

[0050] Table 2 Selected dosing

[0051]

[0052] In the final result of flotation, the original method removes the sulfur content from 0.92% to 0.36%, and the method of the present invention removes the sulfur cont...

Embodiment 2

[0054] The iron grade of a foreign ore is 54.82%, and the sulfur content is 4.37%. After magnetic separation, the iron grade is 68.54%, and the sulfur content is 0.7%. / t, butyl black drug 200g / t, 2 # Oil 20g / t was carried out for flotation to obtain a final iron concentrate grade of 69.06%, sulfur content of 0.03%, iron recovery rate of 96.67%, sulfur crude concentrate grade of 15.28%, and sulfur recovery rate of 93.27% (sulfur crude concentrate can be used for sulfuric acid plant mixed with sulfur concentrate), the beneficiation effect is quite excellent.

Embodiment 3

[0056] A certain geopyrhotite was crushed and ground to -200 mesh, accounting for 85% of the particle size, adding sulfuric acid 1000g / t, copper sulfate 200g / t, butyl xanthate 600g / t, butyl black medicine 150g / t, 2 # The oil is 30g / t for primary selection, and then for two selections, each time only 300g / t sulfuric acid is added. The final open circuit flotation results: the sulfur concentrate grade is 36.21%, and the sulfur recovery rate is 91.25%. The test results are quite good.

[0057] In Example 3, pyrrhotite was used as the target mineral for flotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com