Cassiterite flotation collecting agent and application thereof

A collector and flotation technology, applied in flotation, solid separation, etc., can solve the problems of poor selectivity of quartz and calcite, abnormal sensitivity of iron and copper ions, poor selectivity of calcite, etc., and achieve the improvement of collection capacity and selectivity , strong collection ability and selection ability, beneficial to the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

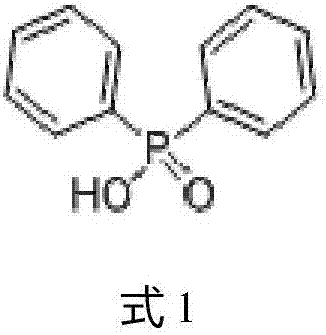

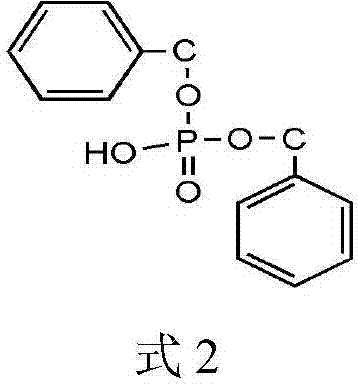

Embodiment 1

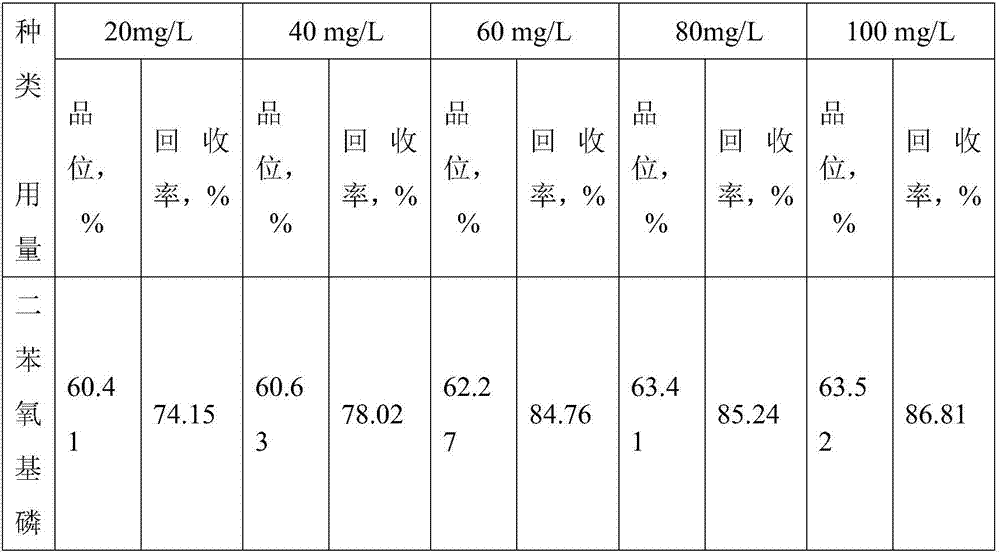

[0033]The application of a kind of phosphoric acid cassiterite flotation collector in cassiterite flotation specifically comprises the following steps: (1) the preparation of cassiterite pulp: the mixed ore (cassiterite, cassiterite, The mass ratio of quartz and calcite is 1:2:2) 2g and 40mL of distilled water are added to a 60mL hanging cell flotation machine, and the slurry is stirred at a speed of 1600r / min to obtain cassiterite pulp; (2) the cassiterite pulp is Control at 7, first add collectors (respectively diphenoxyphosphoric acid and dibenzyloxyphosphoric acid), control collector concentrations are 20mg / L, 40mg / L, 60mg / L, 80mg / L, 100mg / L L), stir 3min; Add terpineol foaming agent (concentration is 15mg / L) again, stir 3min; (3) Dry the foam product and the tailings separately, and calculate the yield by weighing, that is, the recovery rate. The pure mineral flotation results are shown in Table 1 below. It can be seen from the results that the two phosphoric acid colle...

Embodiment 2

[0042] mineral raw material

[0043] Take the raw ore from Xishi Mountain in Guangxi Province, with a tin content of 0.35%

[0044] The total dosage of flotation agent is:

[0045] Lead nitrate: 60g / t

[0046] Carboxymethyl cellulose: rough selection 100g / t, fine selection 50g / t

[0047] Sodium fluorosilicate: rough selection 100g / t, fine selection 50g / t

[0048] Diphenoxy phosphoric acid: roughing 600g / t and sweeping 300g / t

[0049] Terpineol: rough selection 50g / t, scanning 25g / t

[0050] The operation steps and technical conditions are as follows:

[0051] In the flotation process, the ore is added to the ore mill to grind until the mineral monomers are dissociated, and the pH value of the slurry is in the range of 6-8, and then lead nitrate is added as the activator of cassiterite, carboxymethyl cellulose and fluorine Sodium silicate is used as an inhibitor of calcite and quartz gangue minerals, diphenoxy phosphoric acid is used as a collector, and terpineol is used ...

Embodiment 3

[0064] mineral raw material

[0065] Take the raw ore from Xishi Mountain in Yunnan Province, with a tin content of 0.36%

[0066] The total dosage of flotation agent is:

[0067] Lead nitrate: 100g / t

[0068] Carboxymethyl cellulose: rough selection 200g / t, fine selection 100g / t

[0069] Sodium fluorosilicate: rough selection 200g / t, fine selection 100g / t

[0070] Dibenzyloxyphosphoric acid: roughing 1000g / t and sweeping 500g / t

[0071] Terpineol: roughing 100g / t and sweeping 50g / t

[0072] The operation steps and technical conditions are as follows:

[0073] In the flotation process, the ore is added to the ore mill to grind until the mineral monomers are dissociated, and the pH value of the slurry is in the range of 6-8, and then lead nitrate is added as the activator of cassiterite, carboxymethyl cellulose and fluorine Sodium silicate is used as an inhibitor of calcite and quartz gangue minerals, dibenzyloxy phosphoric acid is used as a collector, and terpineol is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com