Patents

Literature

186results about How to "Enhanced harvesting capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

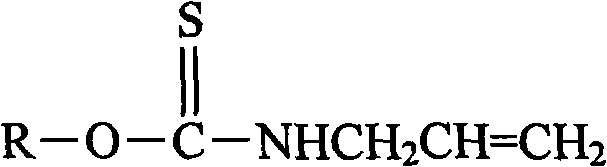

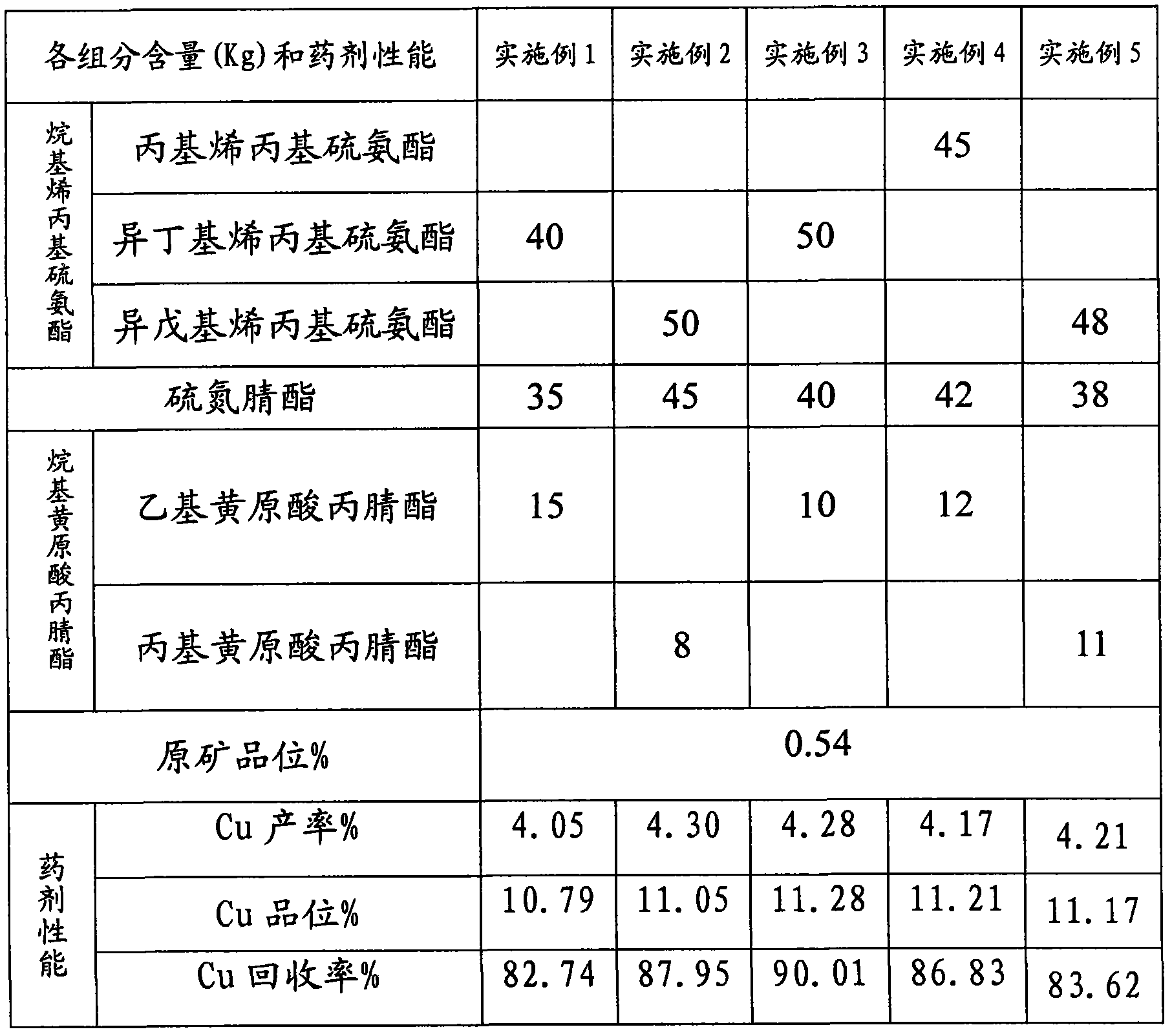

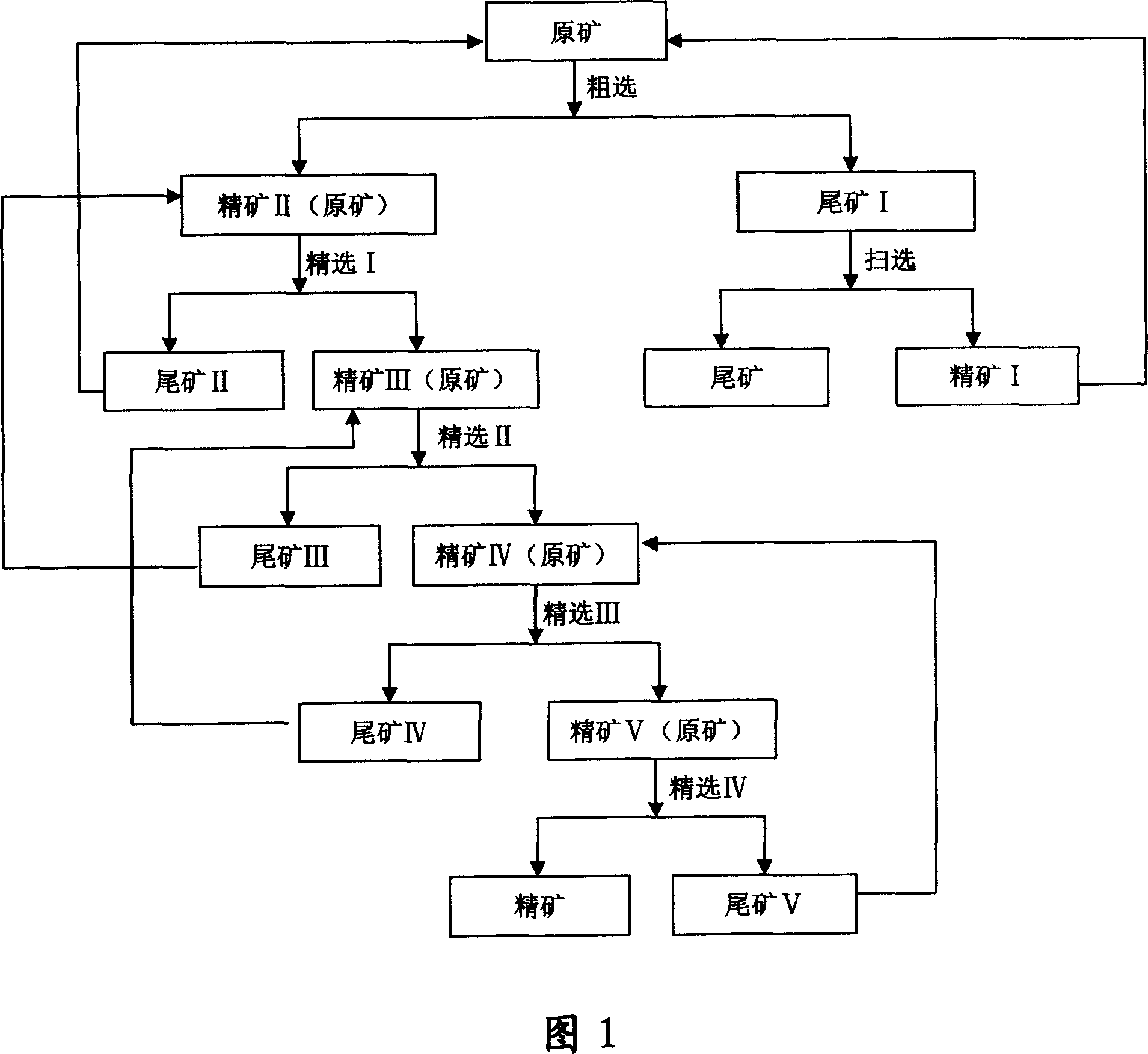

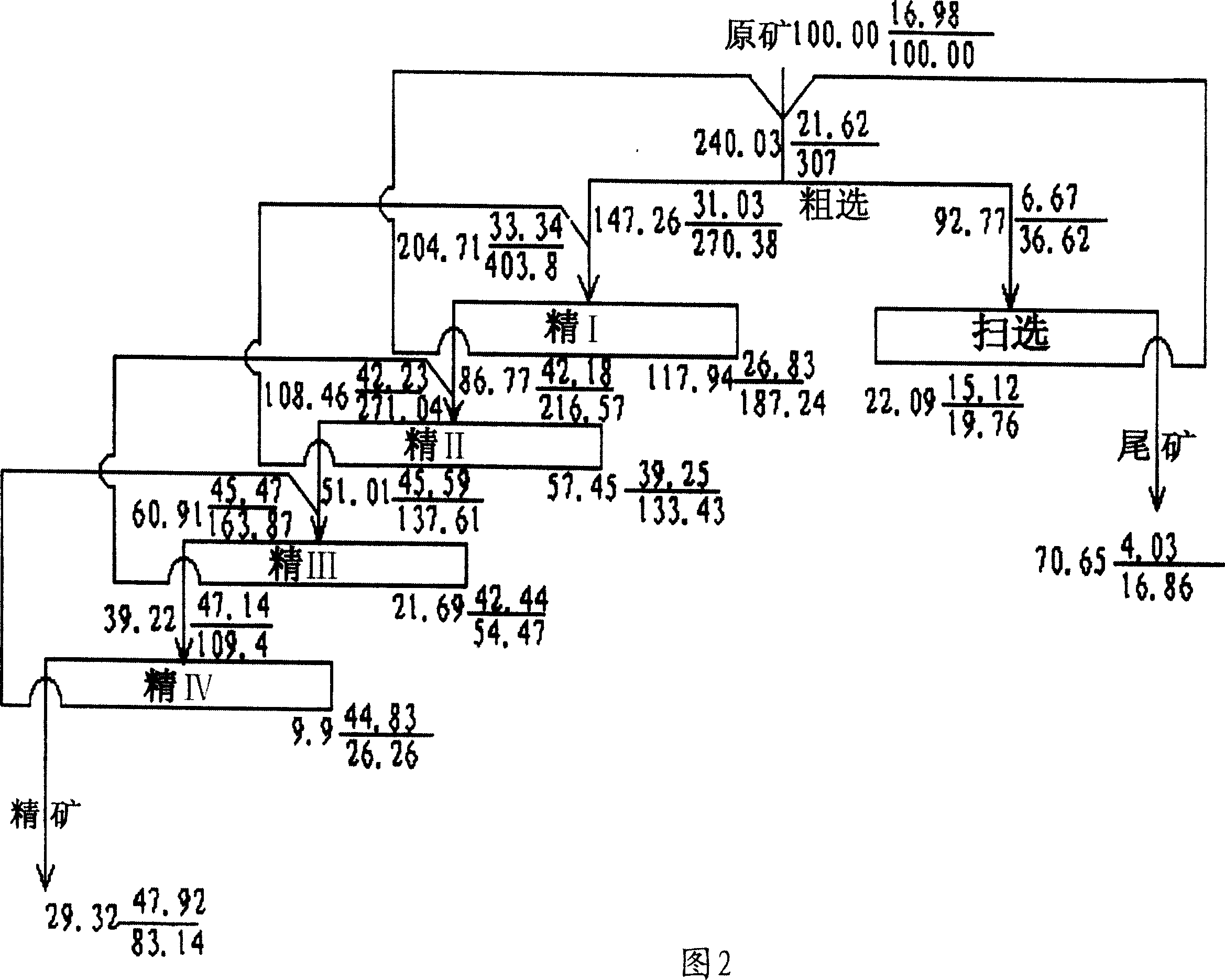

High sulfur copper ore collecting agent

The invention relates to a high sulfur copper ore collecting agent, which is characterized by consisting of the following materials in part by weight: 40 to 50 parts of alkyl allyl thionocarbamate, 35 to 45 parts of sulfur nitrogen nitrile ester and 8 to 15 parts of alkyl xanthonic acid propionitrile ester. The collecting agent has double properties of collecting and foaming, high selectivity and high collecting capacity, can realize high-efficiency separation of copper and sulfur when the pH value is in a range from 7 to 10, can effectively improve the concentrate grade and the recovery rate, and has a wider application range.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Direct flotation collector of collophanite at room temperature and preparation method thereof

InactiveCN103056036ARealization of normal temperature positive flotationImprove solubilityFlotationActive agentProcess engineering

The invention belongs to collophanite flotation technology, and relates to a direct flotation collector of collophanite at room temperature and a preparation method thereof. The collector comprises ingredients with the following weight ratio: fatty acids 95-100 parts, sodium hydroxide 10-15 parts, sodium dodecyl sulfate 3-8 parts, polyoxyethylene5-10 parts and pine oil 1-3 parts. The preparation method includes: according to a certain weight ratio, heating and stirring the mixture of sodium dodecyl sulfate, polyoxyethylene pine oil, and water to obtain a novel surfactant; subjecting the fatty acid to saponification; finally, compounding the saponificated fatty acid and the novel surfactant by a certain percentage, stirring uniformly so as to obtain the collector. The direct flotation collector is not only good in solubility, but adaptable to low and medium grade collophanite and different temperature. In addition, the direct flotation collector has the advantages of good stability and simple pharmaceutical preparation process, Information about residual glue in the glue container is determined according to forming of vacuum when the vacuum generating system extracts air in the detection tube and accordingly can be widely used in the beneficiation of collophanite.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Collector for flotation collecting ilmenite and its preparation method

The invention discloses a collector to float and collect ilmenite and preparing method, which comprises the following parts: oleic acid, powdered ore floatation agent, emulsifier and alkaline.

Owner:TITANIUM FILIALE PANZHIHUA STEEL

Ore dressing method for removing pyrrhotite from iron ore

InactiveCN104069937AEnhanced harvesting capacityGood beneficiation effectFlotationWet separationChemical mixturesIronstone

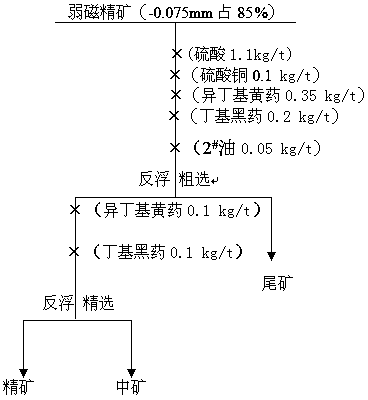

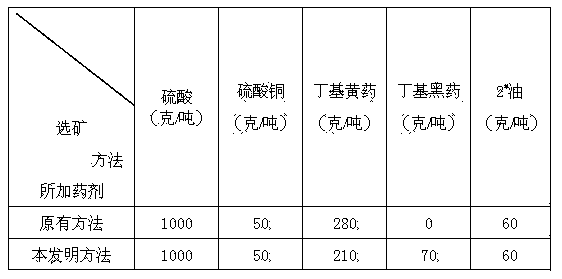

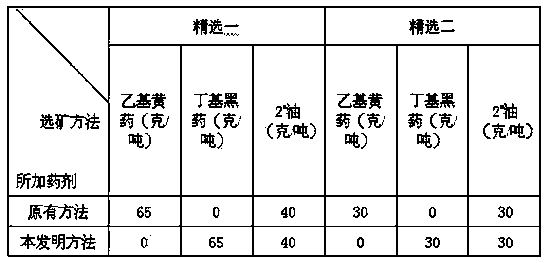

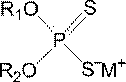

The invention discloses an ore dressing method for removing pyrrhotite from iron ore. The ore dressing method for removing the pyrrhotite from the iron ore includes that performing crushing, ore grinding, grading and low intensity magnetic separation techniques to obtain low intensity magnetic concentrate, wherein the TFE grade of the low intensity magnetic concentrate is more than or equal to 65.0%, and the low intensity magnetic concentrate comprises 0.5-1.4% of S; carrying out reverse flotation roughing and reverse flotation selection on the low intensity magnetic concentrate to obtain low-pyrite concentrate with less than 0.15% of S. Weighted by the dry ore amount for the reverse flotation, the reverse flotation roughing chemical comprises (1) pH regulating agent, to be specific, 800-1200 g / t of sulfuric acid; (2) activating agent, to be specific, 80-150 g / t of copper sulfate; (3) collecting agent, to be specific, 250-400 g / t of iso-butyl xanthate and 150-250 g / t of butyl dithiophosphate; (4) foaming agent, to be specific, 30-70 g / t of 2# oil. The ore dressing method for removing the pyrrhotite from the iron ore uses the butyl dithiophosphate and butyl xanthate or iso-butyl xanthate to form sulfur content reducing chemical mixture, the molecular arrangement between the chemical micelles is improved to form a synergistic effect, the chemical is good for mineralizing and adsorbing, the hydrophobicity and the floating speed are properly reinforced, and the sulfur content of the iron concentrate is reduced to less than or equal to 0.03-0.15%. The ore dressing method for removing the pyrrhotite from the iron ore is especially suitable for removing the pyrrhotite from the iron ore with pyrrhotite through reverse flotation.

Owner:马钢集团设计研究院有限责任公司 +1

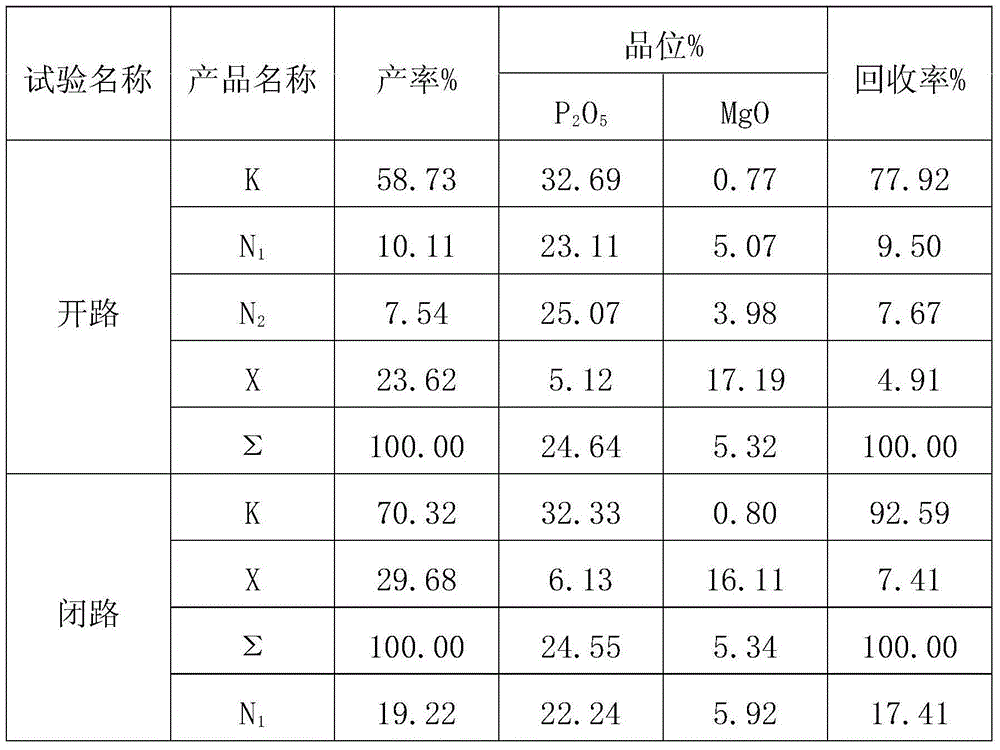

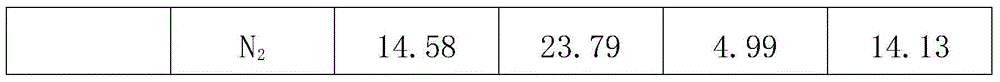

Composite collector for low-and-medium-temperature phosphate flotation and preparation method thereof

Disclosed are a composite collector for low-and-medium-temperature phosphate flotation and a preparation method thereof. The composite collector is composed of 100 parts of carboxylic acid collector, 50-100 parts of hydrocarbon type oil, 1-10 parts of non-ionic surface active agent, 1-10 parts of anionic surface active agent and 80-200 parts of water, wherein the carboxylic acid collector serves as the main collector, the hydrocarbon type oil serves as the auxiliary collector, the non-ionic surface active agent serves as the synergist, and the anionic surface active agent serves as the emulsifier. The preparation method includes steps of uniformly mixing and stirring the components according to the proportion in the speed of 300-1500rad / min at the temperature ranging from 40DEG C to 80 DEG C to obtain the composite collector for low-and-medium temperature phosphate flotation. When in use of the composite collector, the composite collector is added into a pulp mixing barrel to be mixed with pulp sufficiently according to dosage directly, so that floatation can be carried out in a floatation trough at the normal temperature and the operation of heating to pulp is omitted. The composite collector has the advantages that better low-and-medium-temperature flotation effect can be achieved, bubbles generated by the composite collector are favorable for concentrate deposition, the chemical agent usage is small, raw materials for the composite collector are wide in sources, and the composite collector is moderate in price.

Owner:SHENYANG RES INST OF NONFERROUS METALS

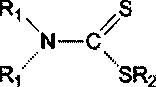

Flotation reagent for copper-nickel sulfide ores

The invention discloses a flotation reagent for copper-nickel sulfide ores. The flotation reagent comprises, by weight, 35-65 parts of alkyl-dithiocarbamate, 5-25 parts of second oil, 5-10 parts of terpilenol, 15-20 parts of hydrazide-group-dithio-formic ether and 5-15 parts of dialkyl-dithiophosphate. The flotation reagent is good in selection, strong in collecting capacity and good in bubble stability, especially has a stronger collecting effect on the copper-nickel sulfide ores, can achieve separation of valuable minerals from gangue minerals such as serpentine and olivine within the pH value of 7-10, and can effectively improve concentrate grade and the recovery rate.

Owner:LANZHOU UNIVERSITY

Silica-calcia bearing phosphate rock normal temperature direct flotation collecting agent and preparation method thereof

InactiveCN104741244AWide variety of sourcesThe synthesis process is simpleFlotationPhosphateActive agent

The invention relates to a silica-calcia bearing phosphate rock normal temperature direct flotation collecting agent and a preparation method thereof. The collecting agent comprises, by weight, 90-100 parts of plant fatty acid, 5-20 parts of citric acid, 15-20 parts of sodium hydroxide, 3-8 parts of OP-4, 3-8 parts of OP-7 and 5-10 parts of OP-10. The preparation method of the collecting agent includes the steps: stirring and melting the citric acid into liquid, and adding the heated plant fatty acid into the citric acid liquid for dewatering esterification reaction to obtain mixture containing fatty acid citrate and unreacted fatty acid; saponifying the mixture to obtain saponified matters; mixing, heating and stirring three surfactants to obtain mixed surfactants; finally, uniformly compounding and stirring the saponified matters and the mixed surfactants in proportion to obtain the collecting agent. The collecting agent is fine in solubility and high in selectivity and collecting capacity, the dosage of the collecting agent is less than that of similar agents, and normal temperature flotation of silica-calcia bearing phosphate rocks can be realized.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

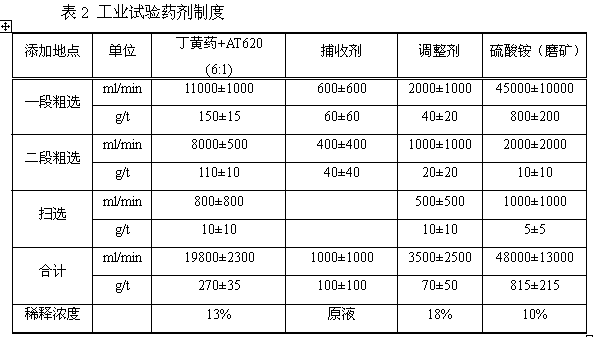

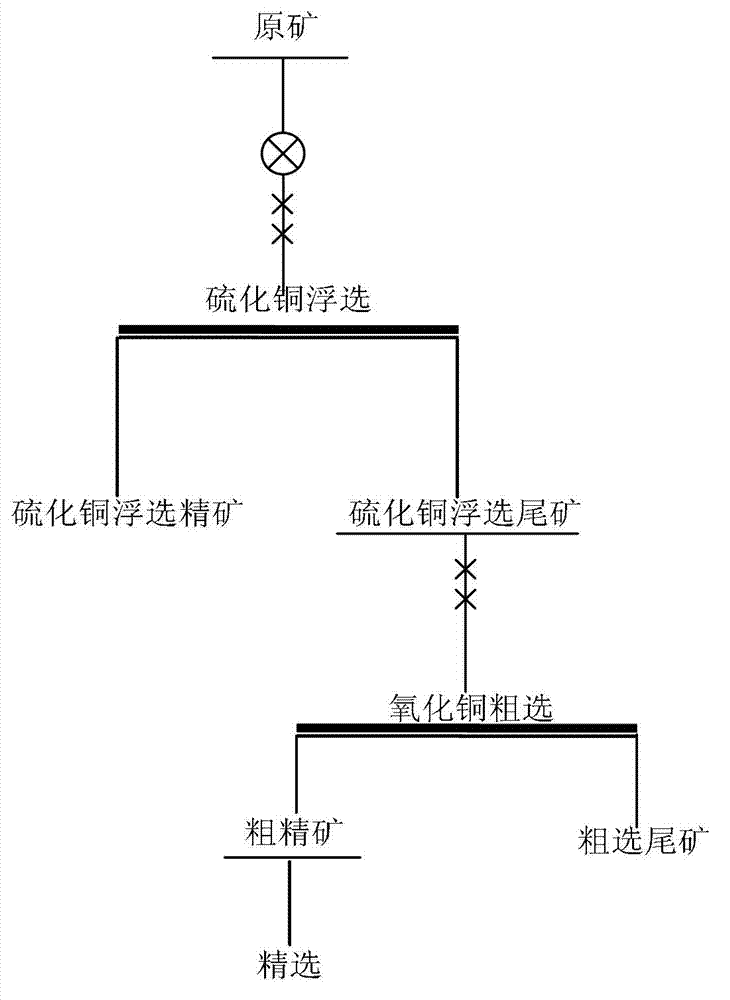

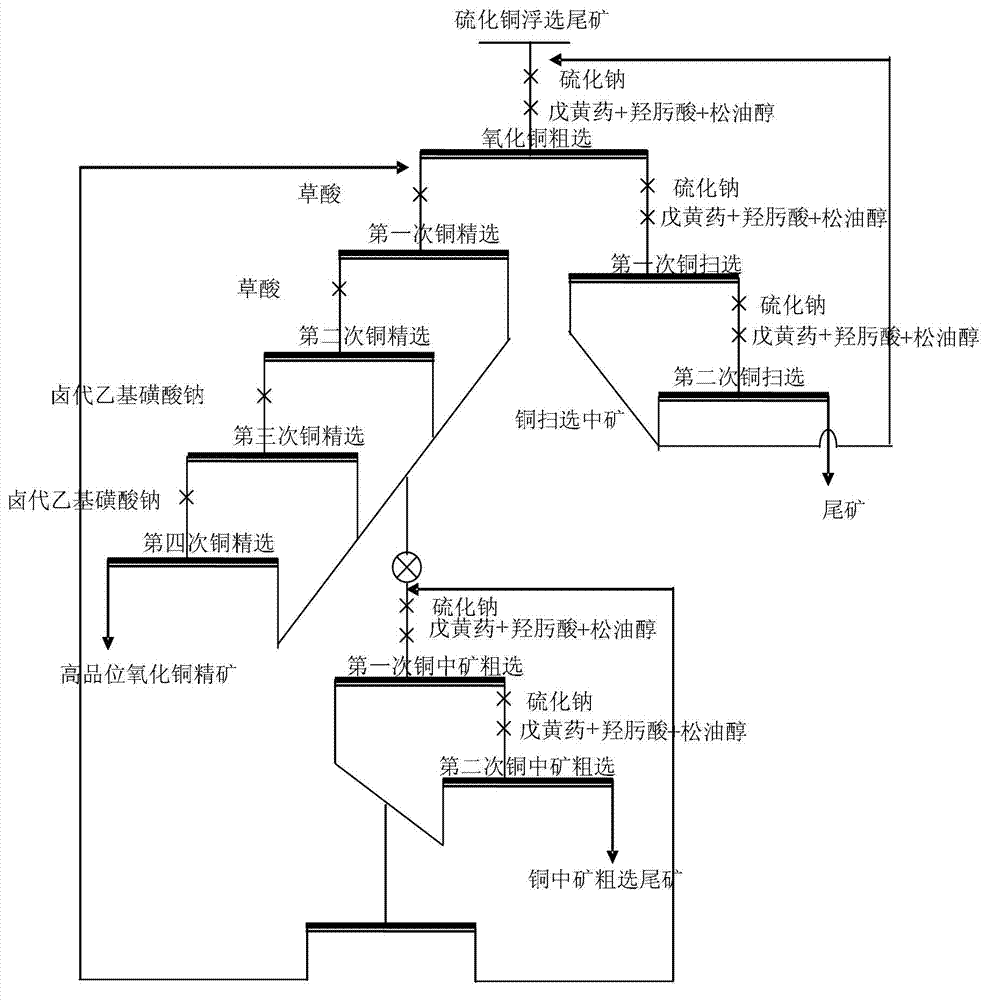

Preparation method of high grade copper oxide concentrate

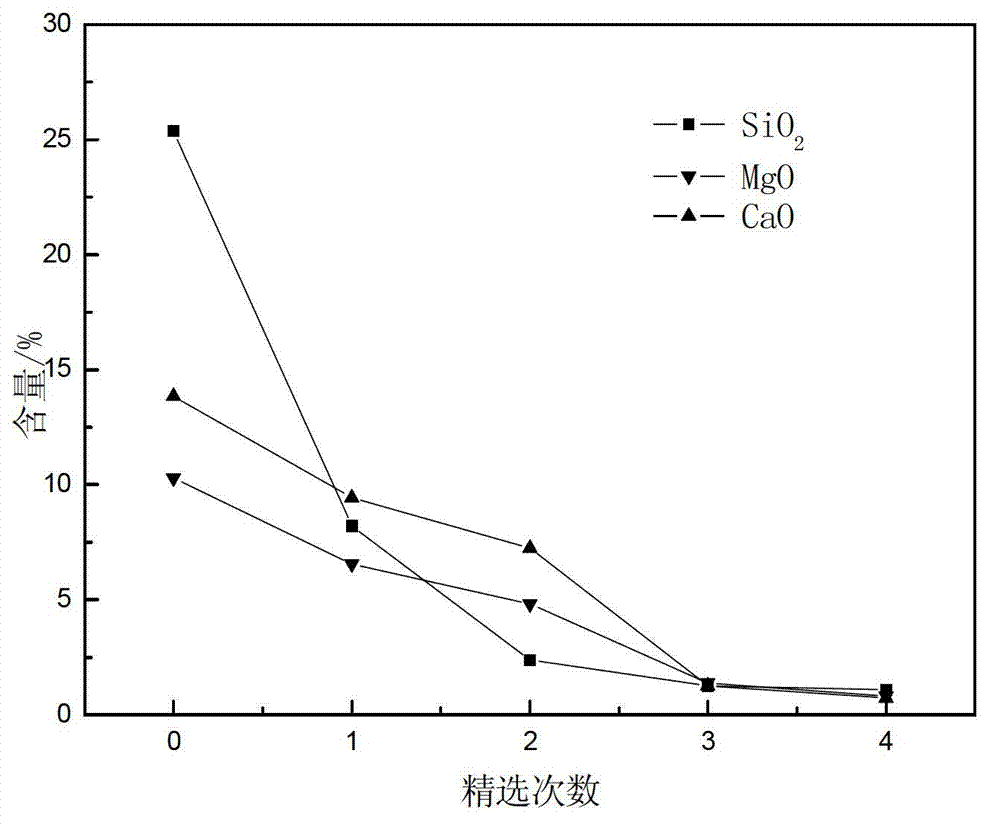

The invention discloses a preparation method of high grade copper oxide concentrate. The preparation method sequentially comprises complex copper oxide crude ore grinding, copper sulphide flotation and copper oxide flotation. The copper oxide flotation comprises rough flotation and fine flotation, wherein the rough flotation includes that flotation reagents are added into tailings of copper sulphide flotation after the copper sulphide flotation, and rough concentrate and rougher tailings are obtained after mixing, stirring and separating. The fine flotation includes that gangue mineral depressants are added into the rough concentrate to be stirred, and the gangue mineral depressants are halogenate ethyl sodium sulfonate. According to the preparation method, in the fine flotation process, the halogenate ethyl sodium sulfonate is added to serve as the depressants, impurity gangue minerals are water loving, and therefore the separating effect of target minerals and the impurity gangue minerals is improved in the fine flotation process. The method drastically reduces contents of silica, calcium oxide, magnesium oxide and other impurity gangue minerals, and obtains the high grade copper oxide concentrate. The mineral processing process is low in cost, and simple and feasible in operation.

Owner:HUNAN RES INST FOR NONFERROUS METALS +1

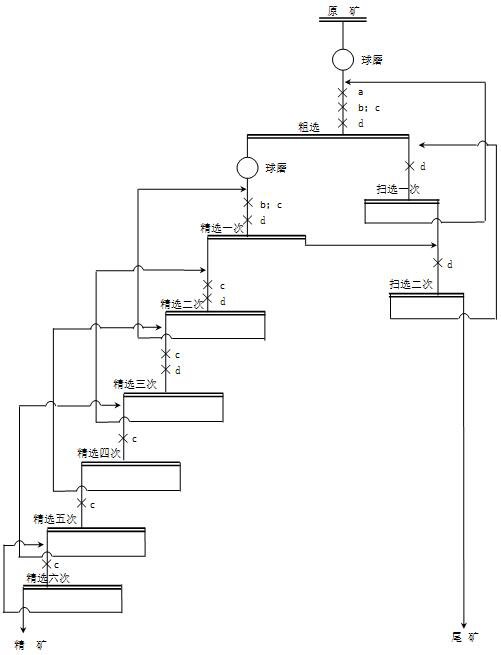

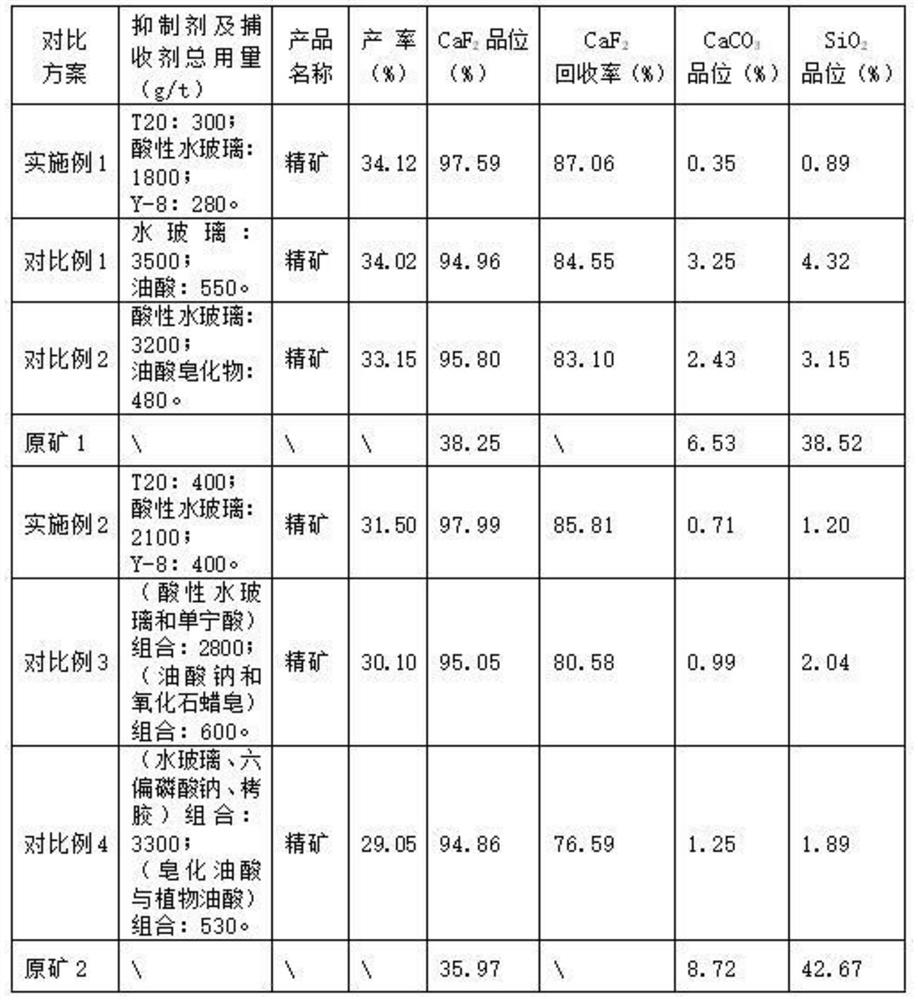

Beneficiation method for silicate and carbonate type fluorite ores

ActiveCN111632747AIncrease the grade of concentrateLow impurity contentFlotationWet separationSoluble glassPhenyl Ethers

The invention discloses a beneficiation method for silicate and carbonate type fluorite ores, and belongs to the technical field of non-metal ore beneficiation. The problems of low recovery rate and high impurity content of concentrate products in the conventional beneficiation method are solved. The method comprises the following steps of ore grinding; roughing, that is, a gangue inhibitor is a combination of T20 and acidic soluble glass, the collecting agent is Y-8, the gangue inhibitor T20 comprises polyaspartic acid, aluminum sulfate and hydroxyethylidene-1,1-diphosphonic acid in a mass ratio of 3-6: 4: 0.5-1, and the collecting agent Y-8 comprises sodium oleate, 4-epoxytetradecanoic acid and octylphenylpolyethylene glycol in the mass ratio is 6-7: 2-3: 1; scavenging operation, that is, a collecting agent Y-8 is added; regrinding rough concentrate; concentration, that is, an inhibitor T20 and acidic soluble glass are adopted, and Y-8 is adopted as the collecting agent. Under the condition of low temperature, the impurity content in the concentrate product can be effectively reduced, and the fluorite concentrate grade is improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

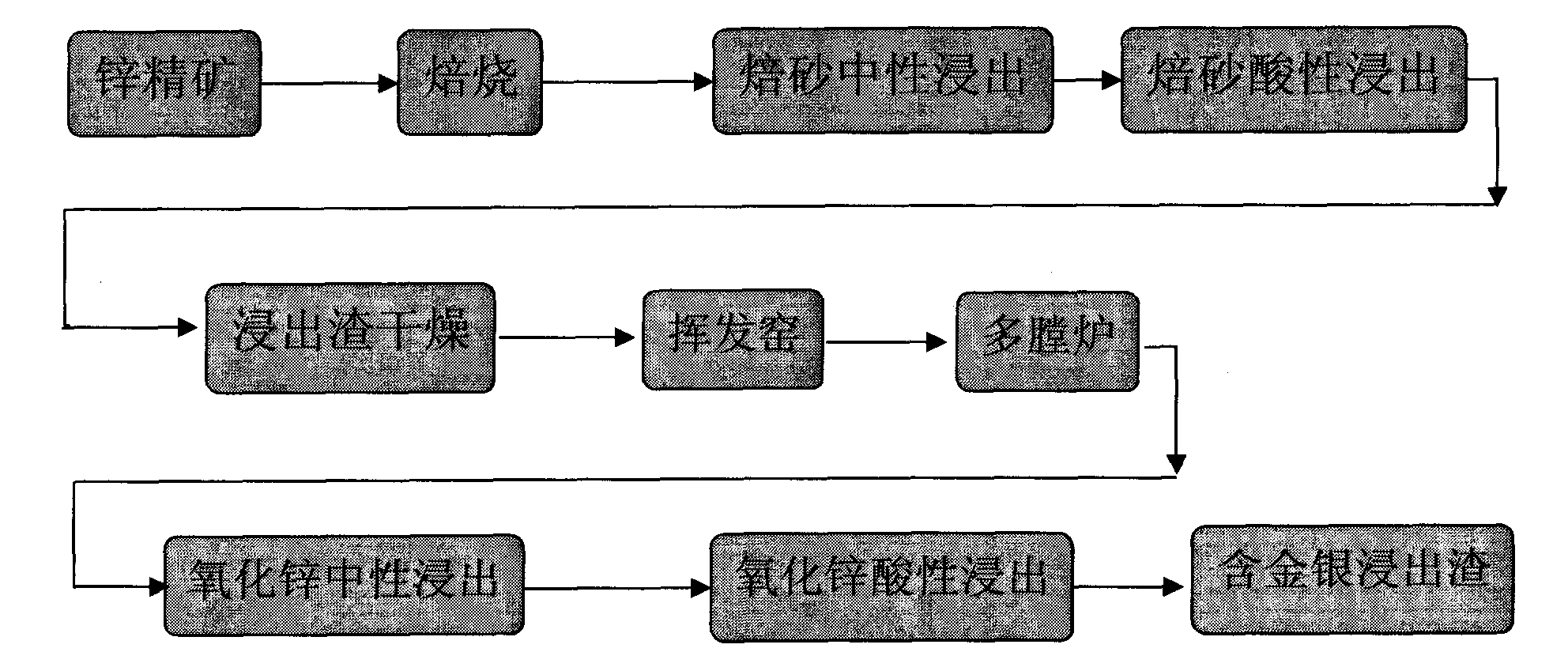

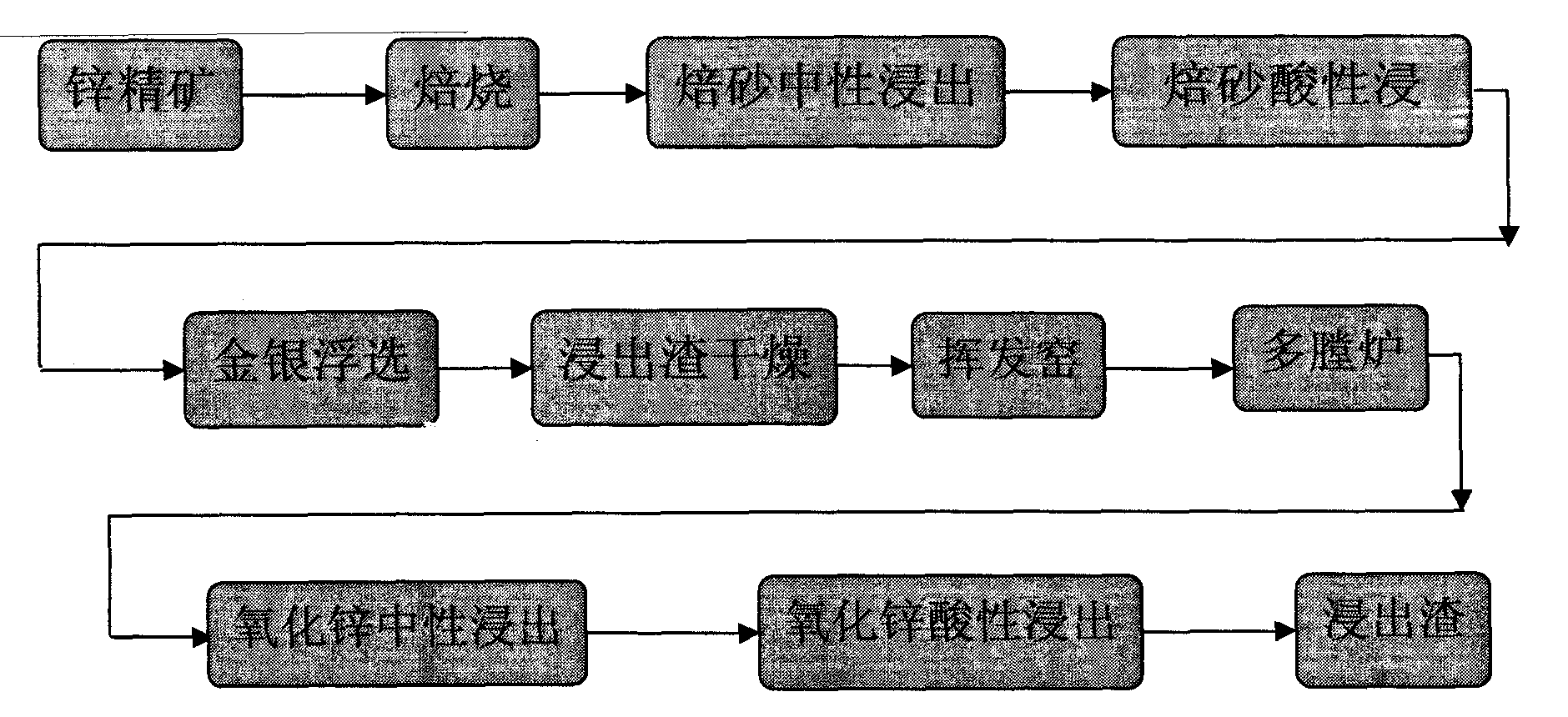

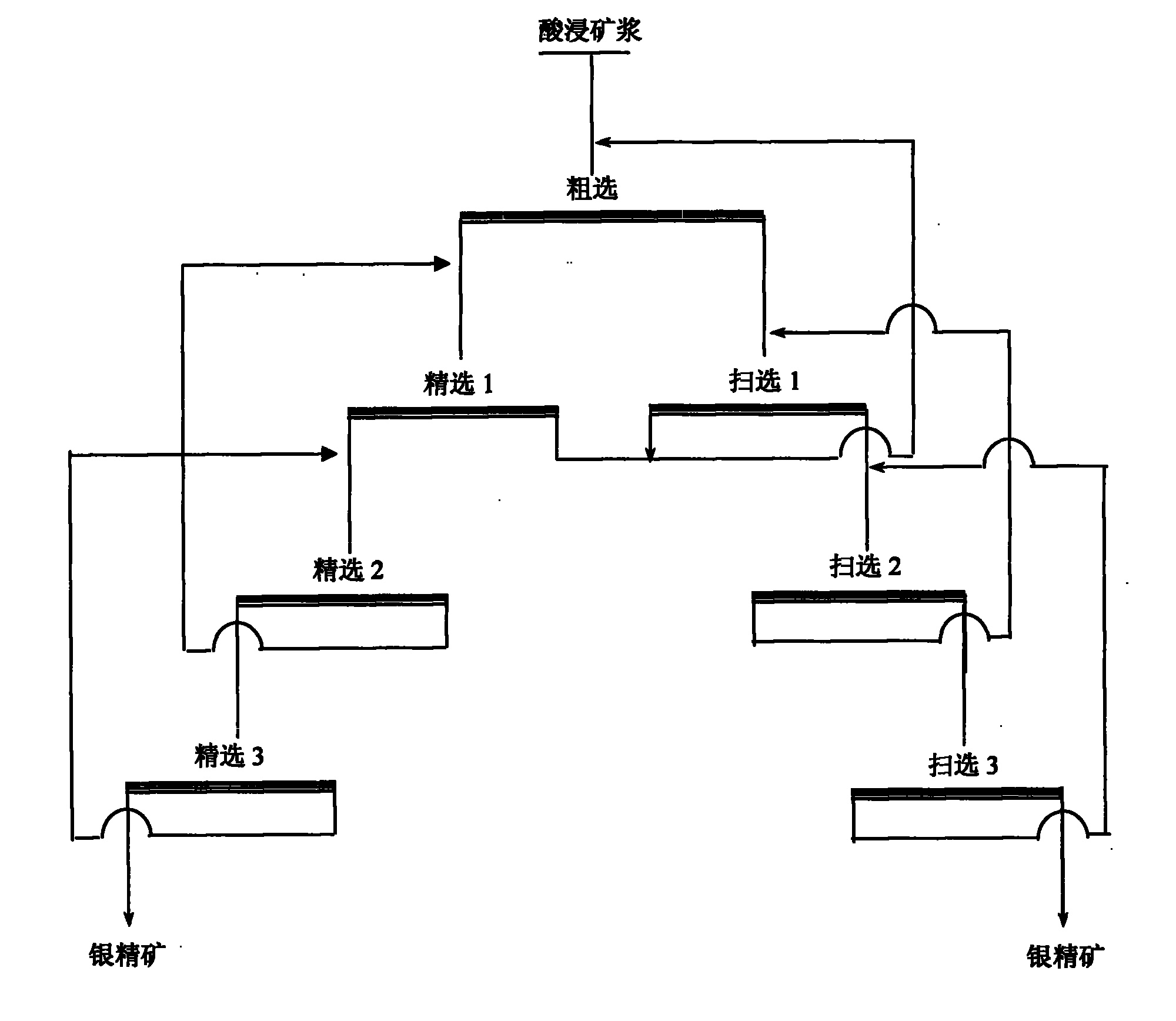

Process for reclaiming gold and silver by floatation from acid leaching ore pulp in wet zinc smelting

InactiveCN101829635AEffective harvesting effectEnhanced harvesting capacityFlotationFoaming agentEconomic benefits

The invention discloses a process for reclaiming gold and silver by floatation from acid leaching ore pulp in wet zinc smelting. The process reclaims the gold and the silver by floatation from the ore pulp after zinc concentrate calcined sand is leached by acid by using a known floatation system under the condition of keeping the primary zinc leaching system. The process comprises the following steps of: extracting the ore pulp after the zinc concentrate calcined sand is leached by acid, adding a collecting agent and a foaming agent for dressing sulfide ores into the ore pulp, fully stirring the ore pulp, then delivering the ore pulp to the flotation system, and adding the collecting agent and the foaming agent into the ore pulp in a flotation tank of each flotation process after the rough flotation process of the flotation system again so as to realize flotation reclamation of the gold and the silver in the ore pulp. The process efficiently reclaims the gold and the silver without affecting the normal operation of a main zinc system, realizes comprehensive utilization of resources, and brings great economic benefit to enterprises.

Owner:JIANGXI UNIV OF SCI & TECH

Low-temperature floatation composite collecting agent of low-grade bauxite

InactiveCN102744158AEvenly dispersedEnhanced harvesting capacityFlotationAlcoholResource utilization

The invention relates to a low-temperature floatation composite collecting agent of low-grade bauxite. The agent is capable of effectively solving the problems of being poor in low-temperature adaptability, high in preparation cost and low in resource utilization rate in the conventional bauxite floatation collecting agent. The technical proposal provided by the invention is as follows: the low-temperature floatation composite collecting agent is formed by sufficiently dissolving and homogenizing 90-95wt% of a first component and 5-10wt% of a second component; the first component is obtained by compounding 40-60wt% of sodium oleate, 20-40wt% of fatty alcohol polyethylene glycol ether sodium acid and 20-30wt% of senior alkyl C16-18-alcohol; the second component is sodium hexametaphosphate; various compositions of the low-temperature floatation composite collecting agent disclosed by the invention are solubilised and homogenized with one another, so that a synergy effect is generated; due to the synergistic action among the various components, the composite collecting agent is easily and uniformly dispersed in ore pulp; the collecting capability of the collecting agent is enhanced; simultaneously, the benefication temperature is 10-20 DEG C; and the low-temperature floatation composite collecting agent has the advantages of being good in low-temperature resistant property, low in use amount of the collecting agent, obvious in economical benefit and wide in application prospect.

Owner:HENAN DONGDA TECH CO LTD

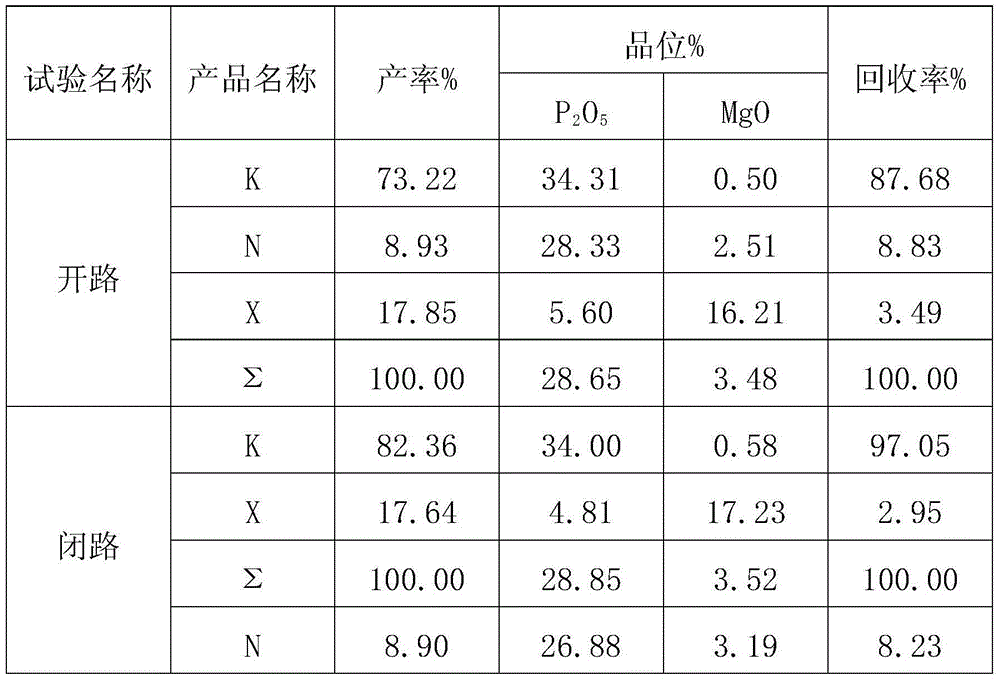

Formula and preparation method of phosphorite reverse flotation deoxidization magnesium collecting agent

The invention discloses a formula and a preparation method of a phosphorite reverse flotation deoxidization magnesium collecting agent which is simple in process and favorable in using effect. In a process of preparing a mixed material, the input ratios of the materials are as follows: the input ratio of oleic acid is 50-60%, the input ratio of stearic acid is 40-30%, and the input ratio of C5-C9 fatty acid is 10%; the input ratios of the materials in a process of heating and saponifying are as follows: the input ratio of the mixed material is 37.5%, the input ratio of water is 56.5% and the input ratio of solid natrium hyelroxide is 6%; in a compounding process of mixing fatty acid and a surfactant, the input ratios of the materials are as follows: the input ratio of the mixed material is 86.5-90.5%, the input ratio of terpilenol is 3-5%, the input ratio of lauric acid polyoxyethylene ether sulfonate is 3-5%, the input ratio of a TX emulgator is 1.5%, and the input ratio of sodium carbonate is 2%. The method is high in synthesis efficiency, low in equipment requirement, free of pollution and free of emission; the method serves as a clean, environment-friendly and efficient production process; the prepared product is high in water solubility, high in mobility, excellent in dispersion effect and stable and reliable in performance, can be simultaneously adaptive to high-concentration and fine-fraction flotation; the phosphorite reverse flotation deoxidization magnesium collecting agent serves as a beneficiation reagent with high competitiveness and good application prospect.

Owner:HUBEI JUXIANG BENEFICIATION PHARMACY

Method for preparing feldspar iron removal floatation collecting agent

The invention discloses a method for preparing feldspar iron removal floatation collecting agent. The method comprises the following steps: on the basis of utilizing oil stock and acidification oil produced by refining vegetable oil and one or mixture of crude fatty acids produced by the oil stock and the acidification oil as basic raw materials, adding technical hydrochloric acid accounting for 3-20wt% of the basic raw materials, reacting at the temperature of 20-40 DEG C, adding 45-50% alkali liquor accounting for 35-50wt% of the basic raw materials, and adjusting the pH value to be 8-10, controlling the reaction temperature to be 90-100 DEG C, reacting for 2-3 hours; and then adding anion surfactant accounting for 2-10wt% of the basic raw materials, and uniformly mixing, thus the finalproduct is obtained. The method disclosed by the invention has the advantages of available raw materials, low production cost, stable properties, strong collection and good selectivity, the feldspar iron removal floatation collecting agent is used for feldspar floatation, the requirement of iron impurity content required by feldspar ore concentrates at the first grate can be met, and no other side effect is produced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

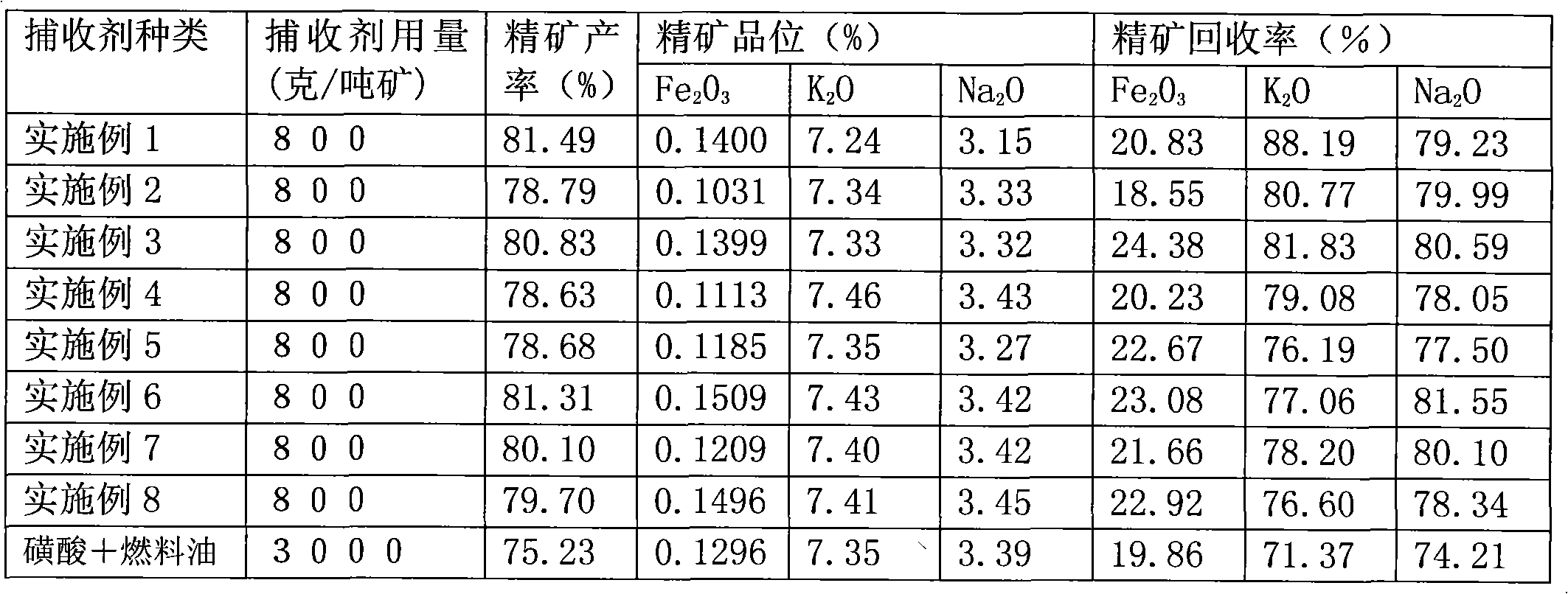

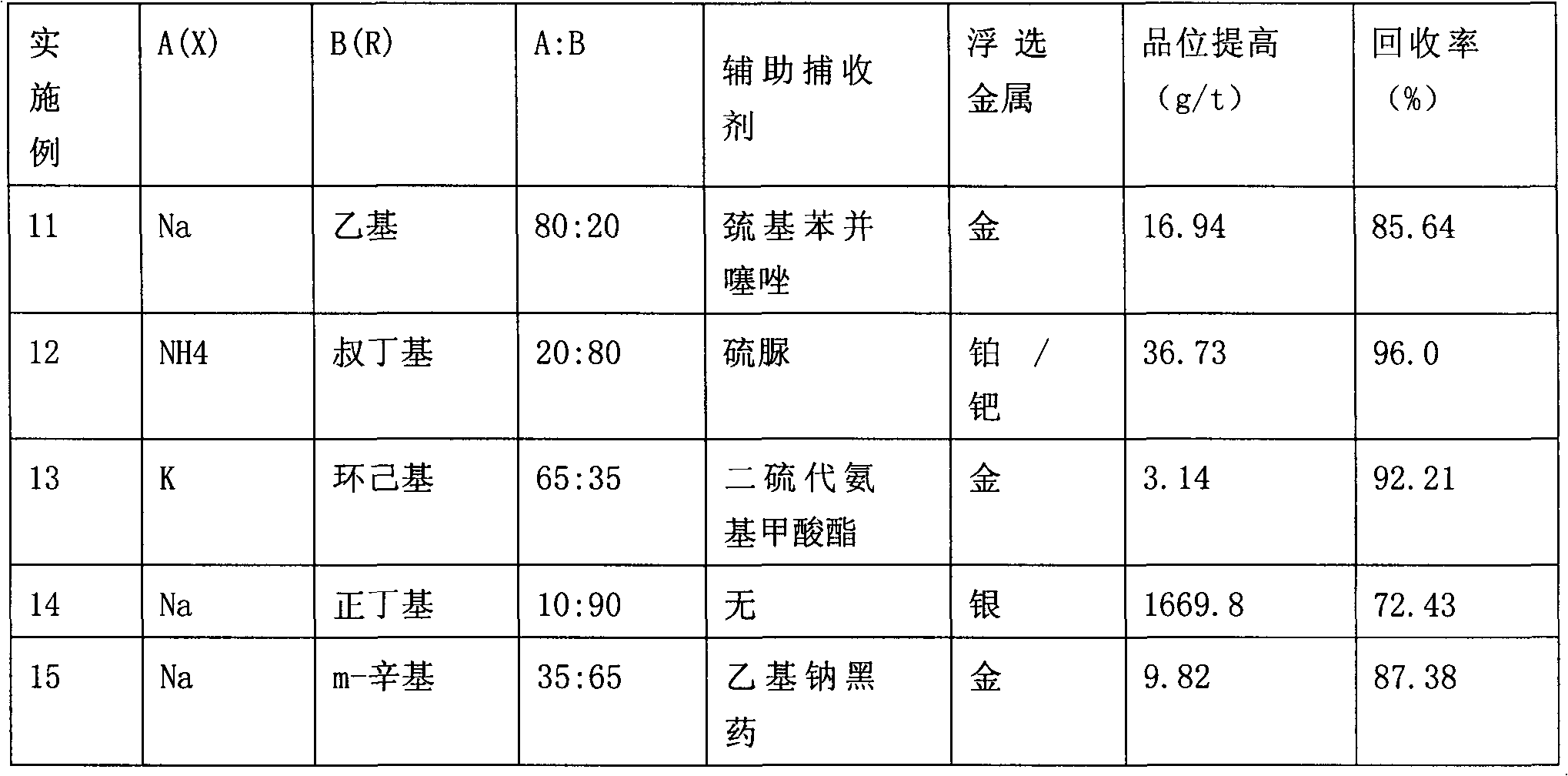

Method for preparing and using collecting agent for gold, silver and platinum family elements

The invention discloses a method for preparing collecting agent for gold, silver and platinum family elements. The collecting agent can be obtained by adding alkanol in a black powder solution of allylic alkyl sulfur ammonia ester and fully stirring at room temperature to be transparent. The invention also provides a use method of the collecting agent, comprising the following steps of: grinding ore to a proper fineness to ensure that the mass fraction of solids in ore pulp is 20-50 percent; then adding lime or sulfuric acid and adjusting the pH value of the ore pulp to be 8.0-11.0; and finally adding 4-30g / t foaming agent and 2-100g / t collecting agent and foaming the gold, silver and platinum family elements according to the conventional method. The collecting agent has the advantages of favorable selectivity, high collection performance and moderate foaming viscosity and greatly improves the grade and the recovery rate of gold, silver, platinum / palladium metals.

Owner:北京天任瑞创科技发展有限公司

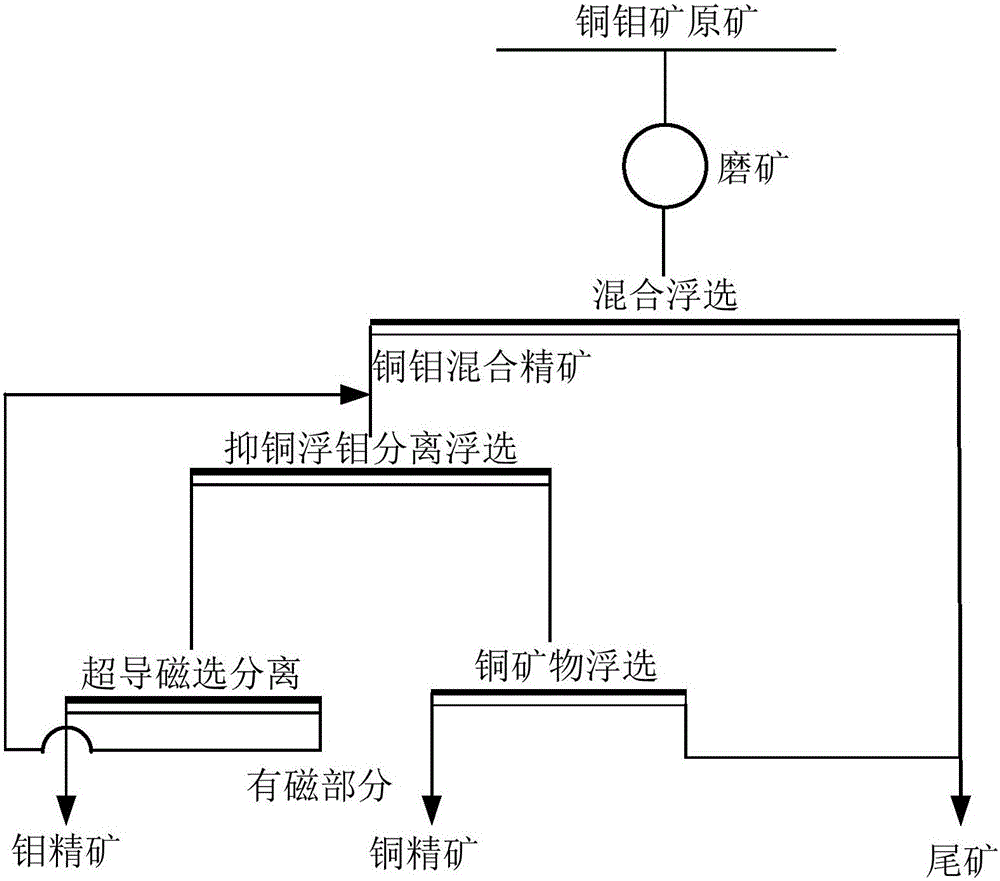

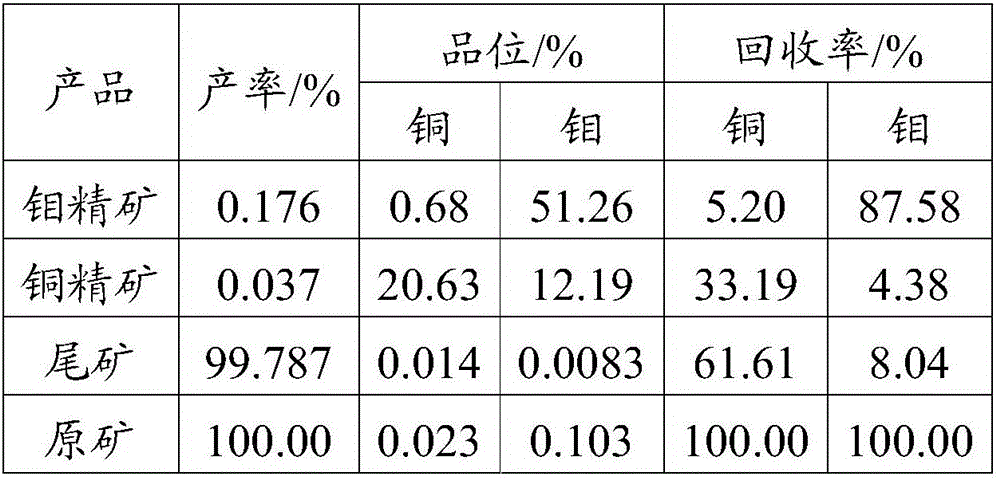

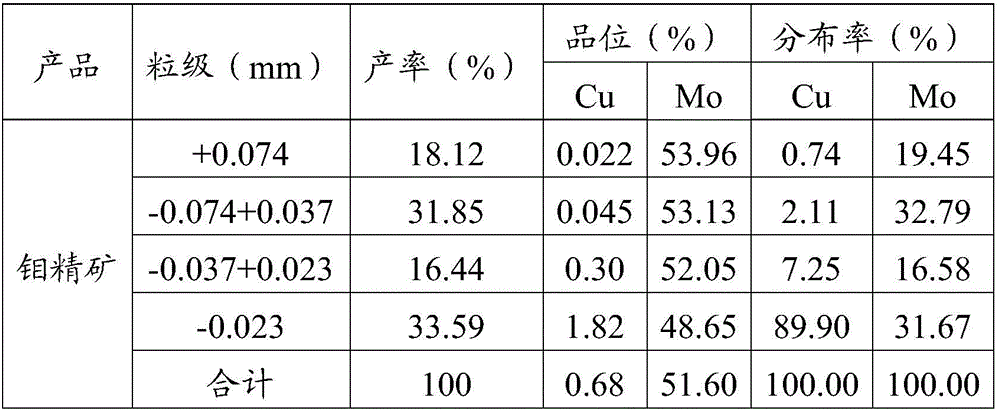

Floating magnetic combined copper-molybdenum sorting-separation method

ActiveCN106583026AReduce lossesGuaranteed RecoveryFlotationMagnetic separationMagnetic separatorNon magnetic

The invention discloses a floating magnetic combined copper-molybdenum sorting-separation method. Copper-molybdenum bulk concentrate is adopted as fed ore, copper-inhibiting molybdenum-floating flotation separation is carried out, and a foam product generated after copper-inhibiting molybdenum-floating flotation separation is subjected to copper-molybdenum re-separation with a superconductive magnetic separator with the background magnetic field strength being 3,200 kA / m to 4,800 kA / ml; an obtained non-magnetic part is a molybdenum concentrate product, and an obtained magnetic part serves as middling and is returned to be subjected to copper-inhibiting molybdenum-floating flotation separation roughing work; and an underflow product obtained after copper-inhibiting molybdenum-floating flotation separation is subjected to copper ore flotation, and copper concentrate is obtained. Collection of the copper ore is reinforced in a superconductive magnetic separation manner, the separation effect of copper and molybdenum is further improved, the copper content in later molybdenum concentrate is reduced, and then the recovery rate of molybdenum and copper is increased.

Owner:江苏旌凯中科超导高技术有限公司

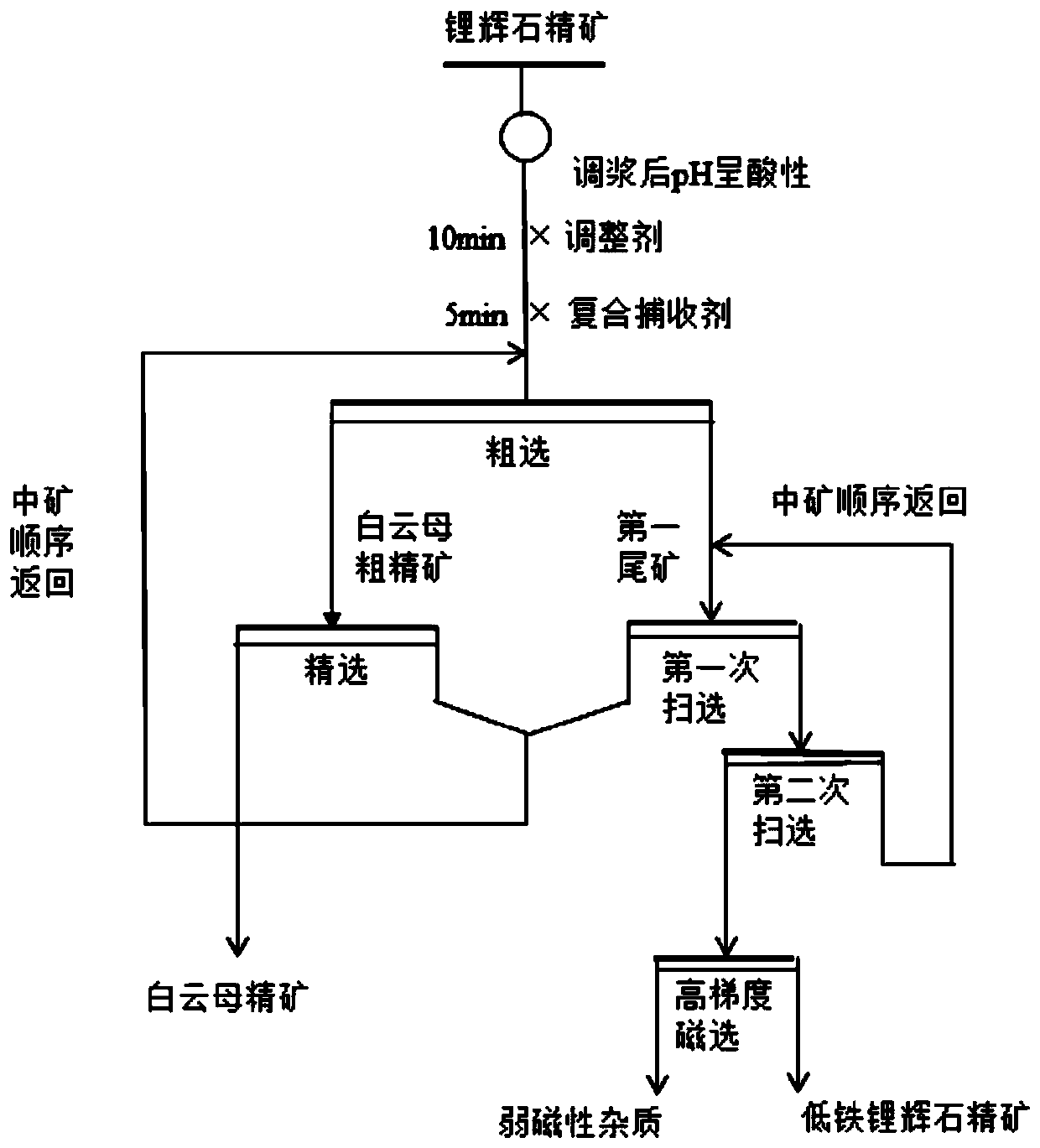

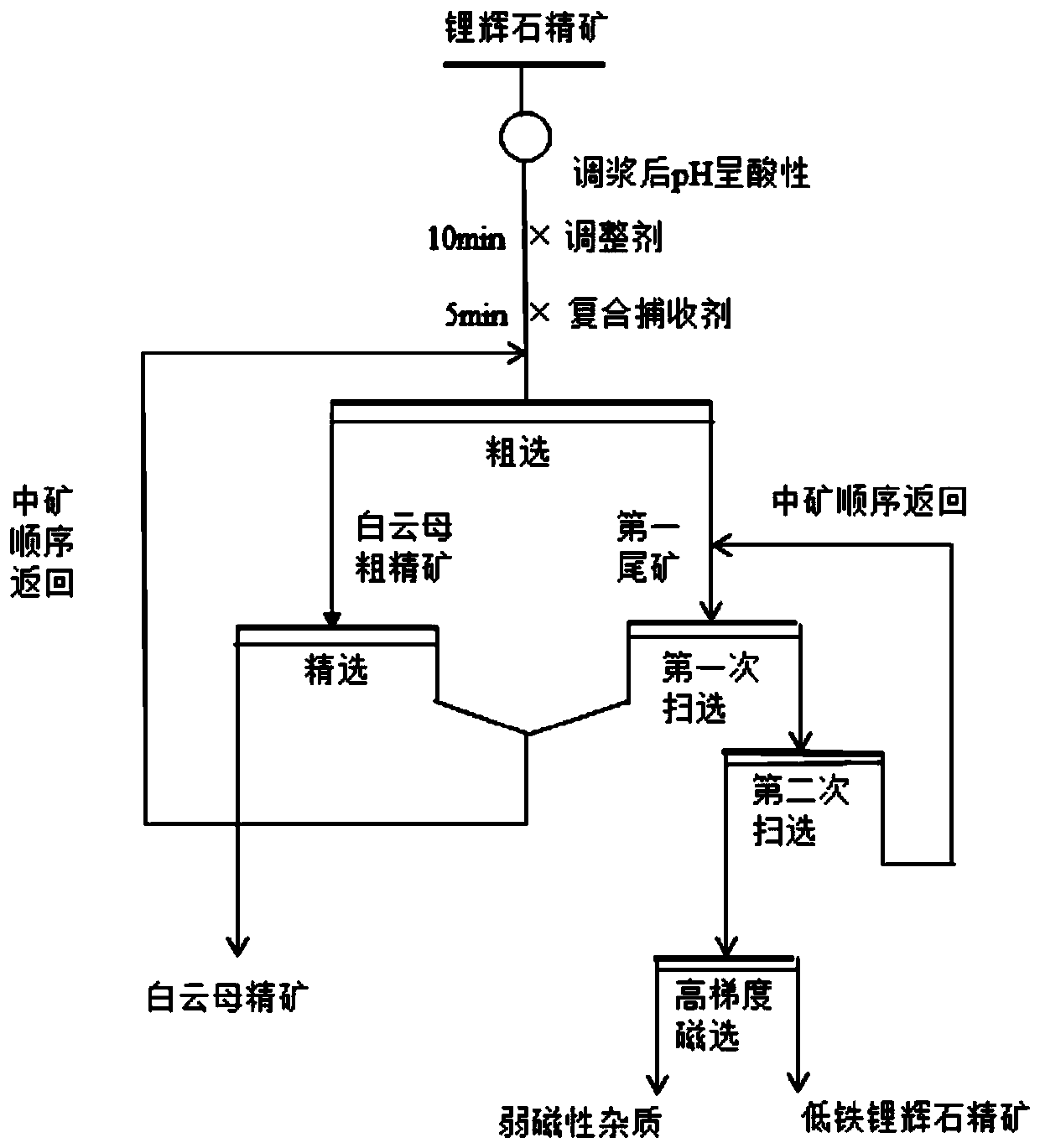

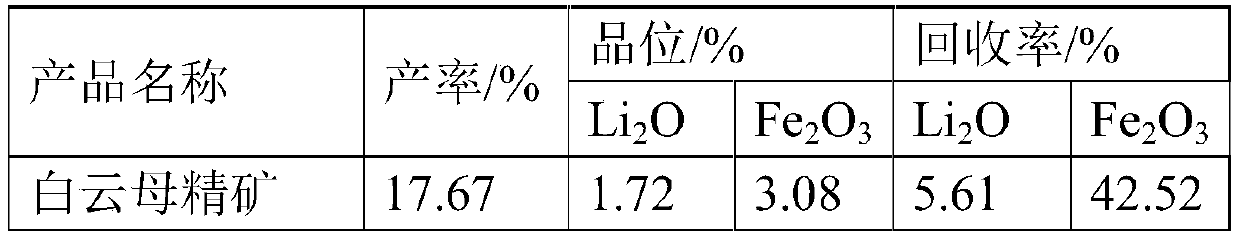

Composite collector, low-iron spodumene concentrate and preparation method for low-iron spodumene concentrate

The invention relates to a composite collector, low-iron spodumene concentrate and a preparation method for low-iron spodumene concentrate. The composite collector comprises amino acid, fatty acid anddiesel oil, wherein the weight ratio of the amino acid to the fatty acid to the diesel oil is (80 to 90): (5 to 10): (5 to 10). The composite collector is capable of increasing the grade of lithium in the spodumene concentrate, free from causing the waste of lithium resources, and capable of lowering the content of iron impurity.

Owner:GUANGDONG GUANGHUA SCI TECH

Beta-hydroxy fatty acid collecting agent for positive floatation of iron ore and application thereof

ActiveCN101632961AEnhanced harvesting capacityGood beneficiation effectFlotationImpurityMineral collecting

The invention relates to a beta-hydroxy fatty acid collecting agent for positive floatation of iron ore and application thereof. The beta-hydroxy fatty acid collecting agent is characterized in that the content of the weight percentage of beta-hydroxy fatty acid is over 85 percent of a total collecting agent, and the balance is water and inevitable impurities; the beta-hydroxy fatty acid of the collecting agent mainly comprises thirteen to eighteen carbon atoms; and the weight percent of the beta-hydroxy fatty acid with the thirteen to eighteen carbon atoms is over 95 percent. The beta-hydroxy fatty acid iron mineral collecting agent is a fatty acid class collecting agent capable of forming annular adsorption; and the collecting capacity of the beta-hydroxy fatty acid iron mineral collecting agent is remarkably larger than the adsorption of ore mineral and a common fatty acid class collecting agent carrying out positive anion floatation, thereby obviously increasing the collecting capacity of the collecting agent on the iron mineral.

Owner:ANSTEEL GRP MINING CO LTD

Collecting agent for separating gold from high-arsenic type gold ores and preparation method for collecting agent

ActiveCN103657868AStrong harvesting abilityEnhanced harvesting capacityFlotationSulfite saltXanthate

A collecting agent for separating gold from high-arsenic type gold ores is prepared by the following raw materials in part by weight: 2-3 parts of sodium sulfite, 1-2 parts of calcium oxide, 22-24 parts of alkyl xanthate acrylic nitrile ester, 2-3 parts of sodium carbonate, 3-4 parts of sodium pyrosulfite, 1-2 parts of sodium sulphide, 34-38 parts of xanthate, 2-3 parts of glycerin polyethenoxy ether propylene ether fatty acid ester, 14-16 parts of butylamine aerofloat, 12-14 parts of terpenic oil, 3-4 parts of ammonium citrate and 10-12 parts of activating agent. The collecting agent has a restraining effect on arsenic in the high-arsenic type gold ores, and is high in gold collecting ability; secondary environmental pollution is avoided; complex pre-treatment work procedures are not required; the process is simple; and the recycling cost is low. Moreover, by using the activating agent, the surface hydrophobicity of the gold ores is changed, the internal structure is activated, and the gold collecting performance of the collecting agent is improved.

Owner:ANHUI CHAOSHAN NEW MATERIAL

Rutile flotation collector composition and application thereof

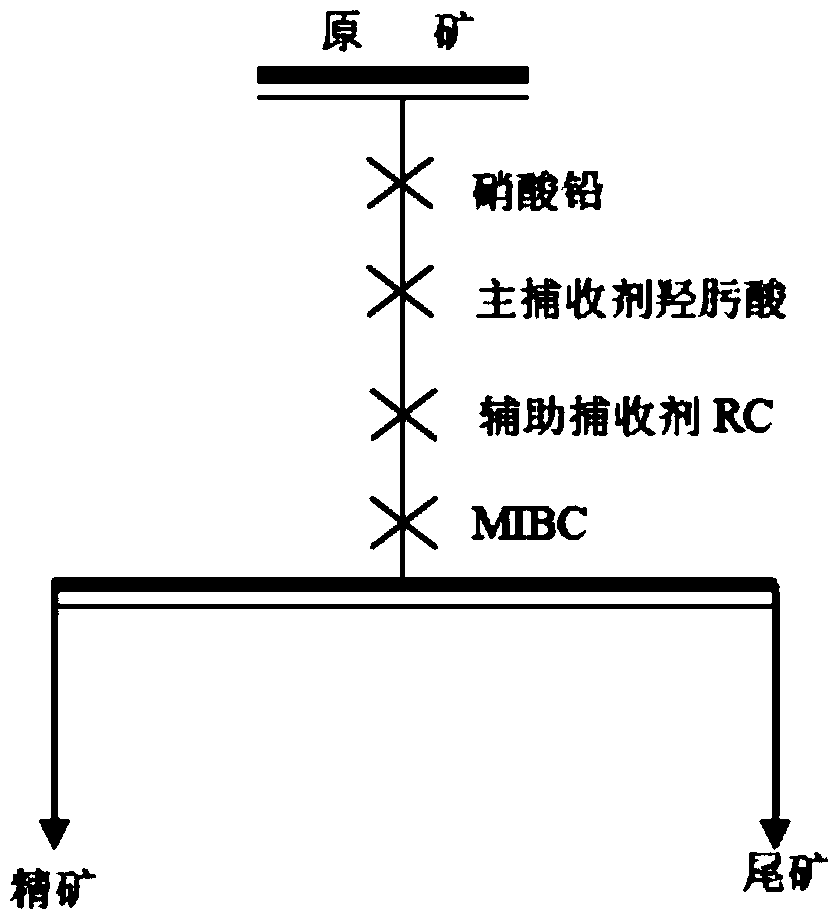

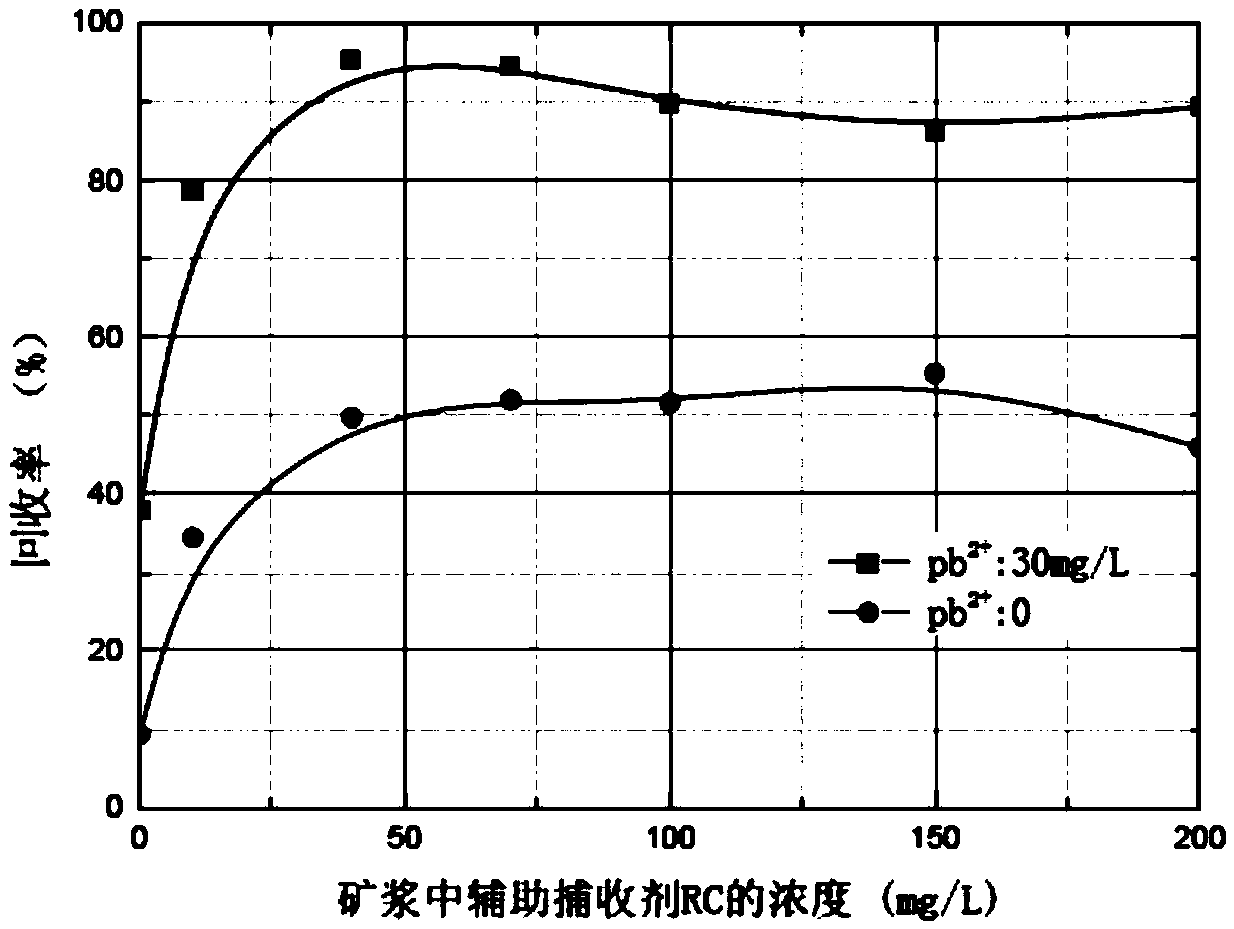

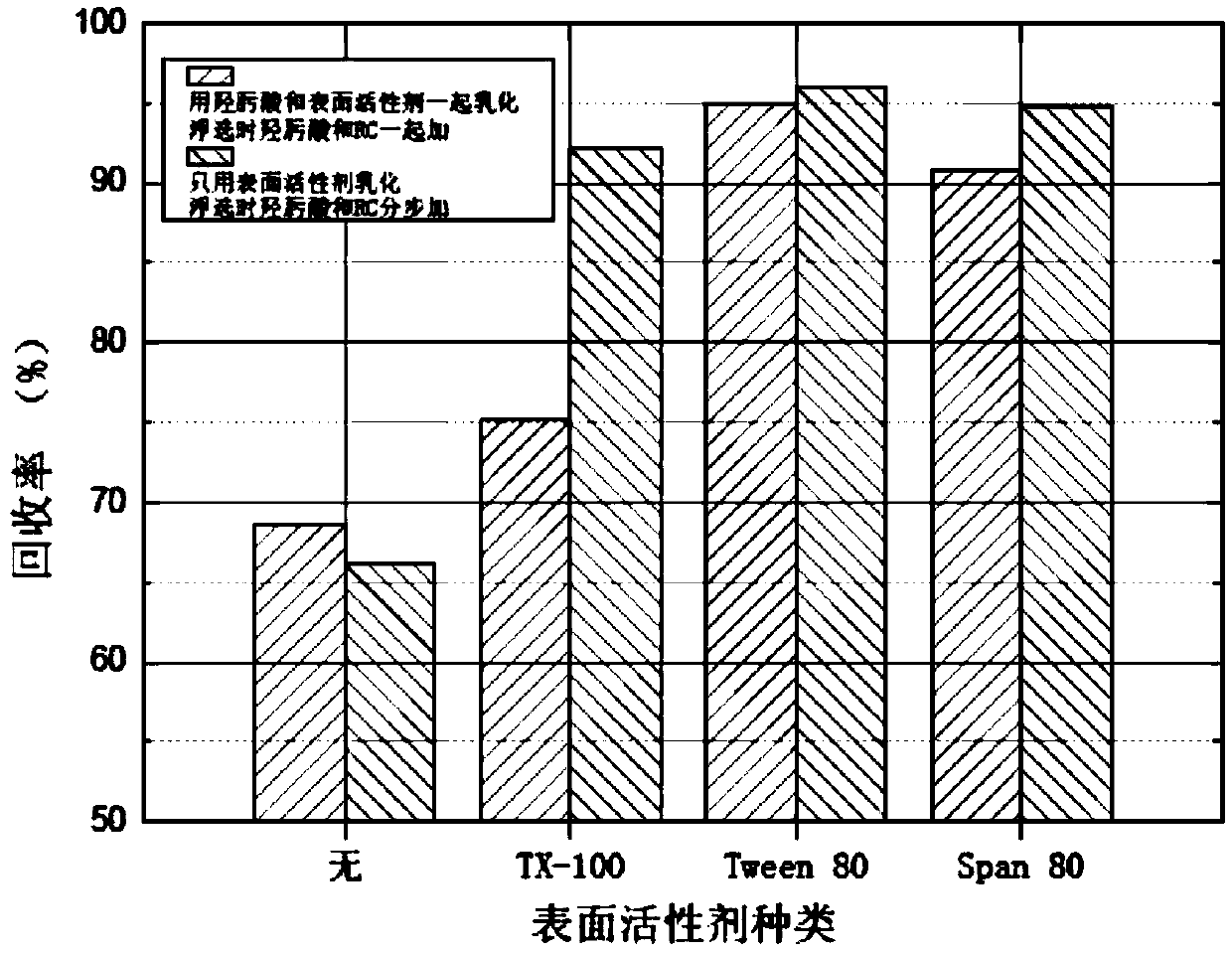

The invention belongs to the technical field of rutile flotation, and particularly relates to a rutile flotation collector composition and application thereof. The rutile flotation collector composition is composed of a main hydroximic acid collector and an assistant RC collector. According to the application, a lead nitrate activator, the main hydroximic acid collector, the assistant RC collector and an MIBC frother are sequentially added in rutile flotation pulp, wherein before the next agent is added, stirring is carried out for 3 min every time after each agent is added; after all the agents are added, ventilated flotation is carried out; after flotation is finished, an obtained froth product and tailings in a flotation tank are respectively filtered, dried and weighed finally. According to the rutile flotation collector composition and the application thereof, on the basis of the hydroximic acid collector with good selectivity, the assistant RC collector capable of achieving a synergistic effect with hydroximic acid is added, so that the collecting capability of the agents is substantially improved, and the flotation recovery rate of rutile is effectively improved; meanwhile, the use amount of hydroximic acid is reduced, so that the agent cost for rutile flotation is greatly reduced.

Owner:WUHAN UNIV OF TECH

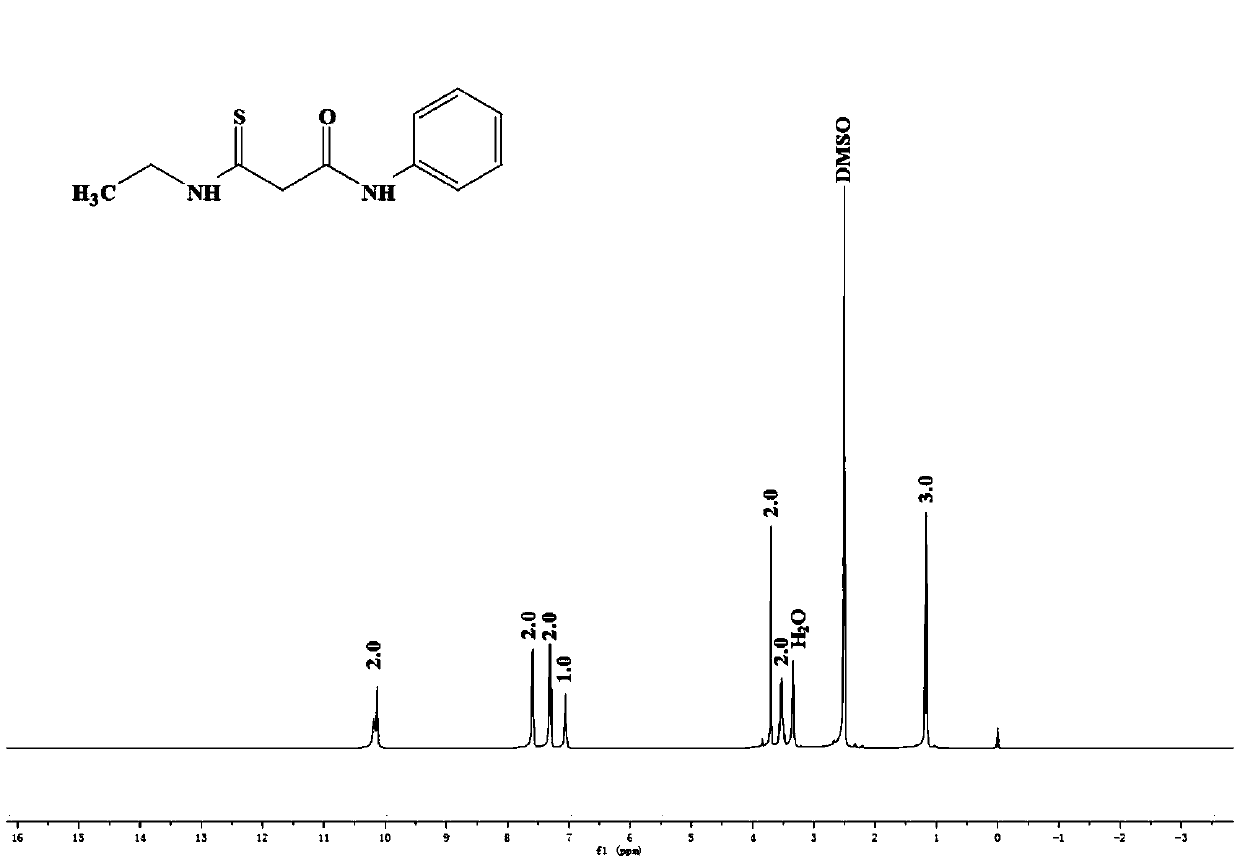

Collecting agent with amide group and thioamide group as well as preparation method and application thereof

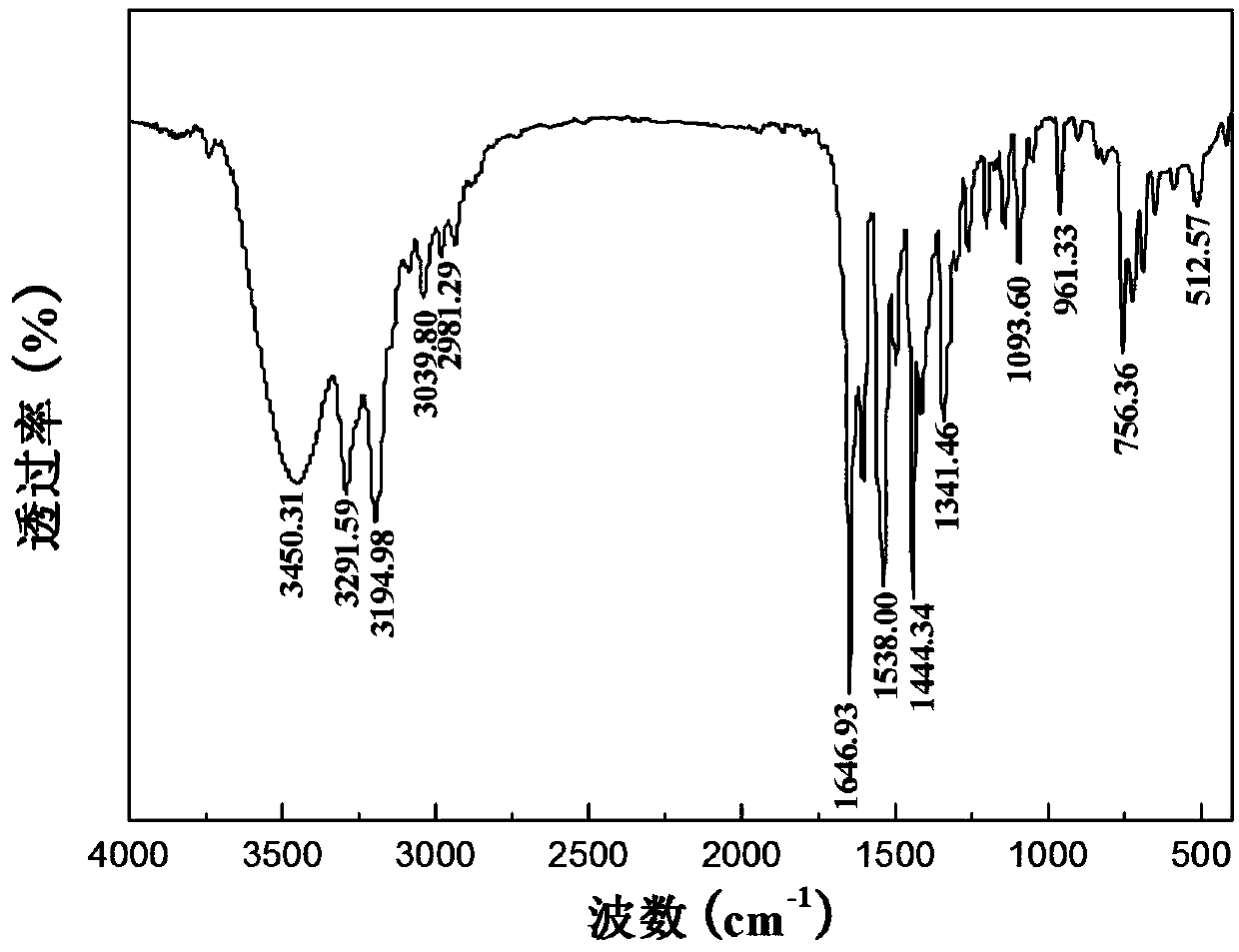

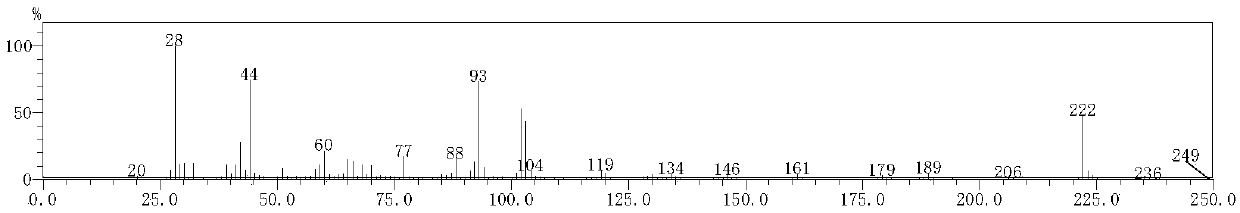

ActiveCN109675723AStrong harvesting abilityEnhanced harvesting capacityFlotationSolventIsothiocyanic acid

The invention relates to a collecting agent with an amide group and a thioamide group as well as a preparation method and application thereof. The collecting agent has both the amide group and the thioamide group and has stronger collecting capacity. The preparation method of the collecting agent comprises the following steps: carrying out a reflux reaction of ester containing an isothiocyano group or ester containing an isothiocyano group and an alkoxycarbonyl group, carbonate and amine containing an acetoacetyl group by taking ethanol as a solvent, removing the ethanol and adding hydrochloric acid, so as to obtain the collecting agent with the amide group and the thioamide group. The invention further provides the application of the collecting agent with the amide group and the thioamidegroup in flotation of metal sulfide minerals. The collecting agent in a structure with the amide group and the thioamide group has stronger collecting capacity for precious metal minerals such as chalcopyrites, galena, gold, silver and the like and also has good selectivity for minerals such as pyrites, sphalerites and the like, and the adaptive scope of the pH value of ore pulp is wide.

Owner:CENT SOUTH UNIV

Novel gold flotation catching agent

The invention discloses a novel gold flotation catching agent. The catching agent is composed of sodium n-butylxanthate, sodium isoamylxanthate and butylamine aerofloat. The weight ratio of the sodium n-butylxanthate to the sodium isoamylxanthate to the butylamine aerofloat is 4 to 8:1 to 5:0.5 to 2. Preferably, the weight ratio of the sodium n-butylxanthate to the sodium isoamylxanthate to the butylamine aerofloat is 6:3:1. The mode that in the traditional gold floatation process, the sodium n-butylxanthate with the single carbon chain is adopted is broken through, different catching properties and selectivity of different carbon chains are adopted, the catching properties of the sodium n-butylxanthate and the selectivity of the sodium isoamylxanthate are complemented, the selectivity of the butylamine aerofloat is added, the three agents are fully mixed, contradiction of the catching capability and the selectivity is resolved, and therefore the catching properties and the selectivity are developed to the great extent. Compared with a traditional agent, the recycling rate of the novel gold flotation catching agent is improved by 0.5 percent, the use number of the agents is reduced by 12 g / t, and the concentrate grade is improved by 0.74 g / t.

Owner:HABAHE JINBA MINING

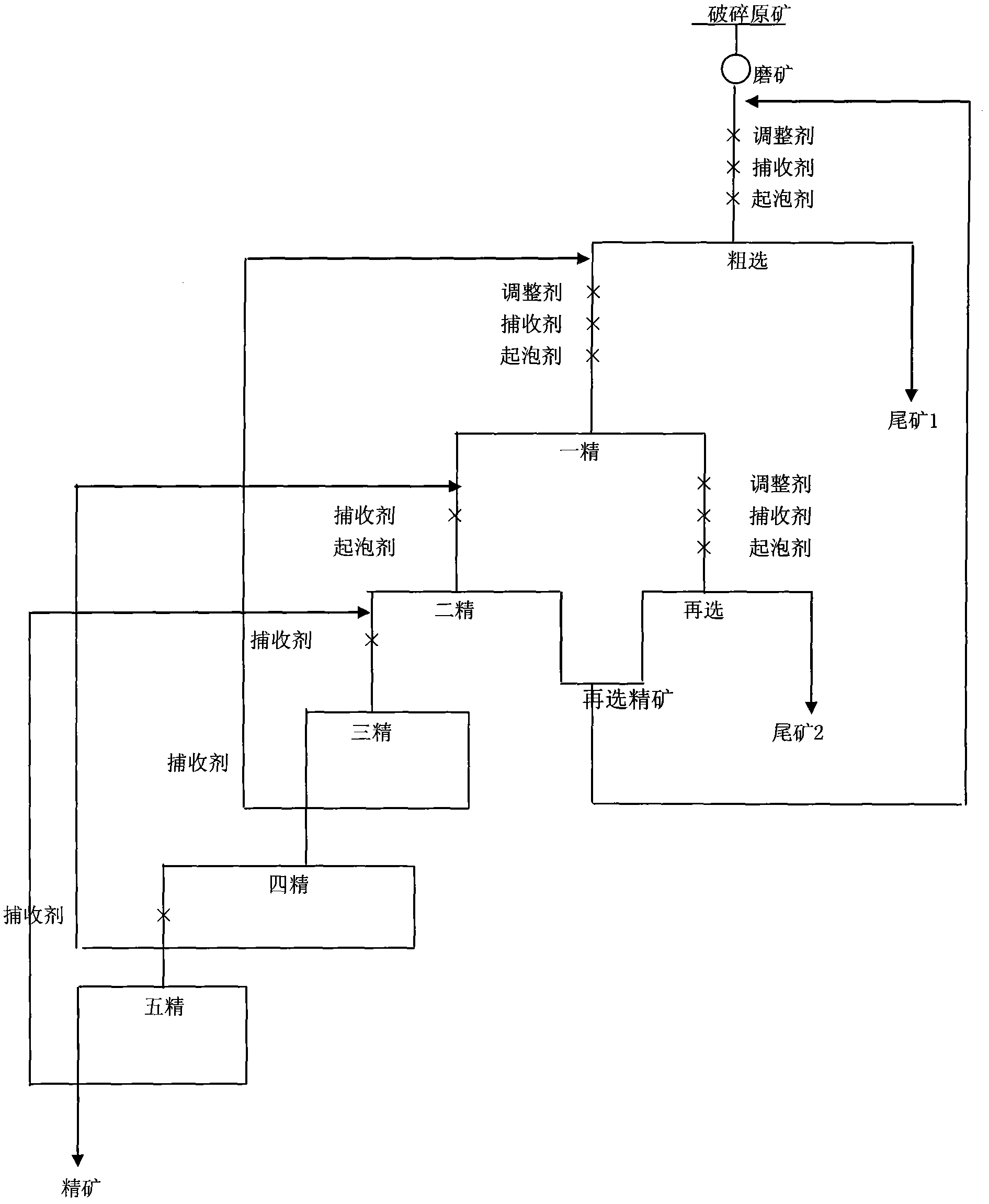

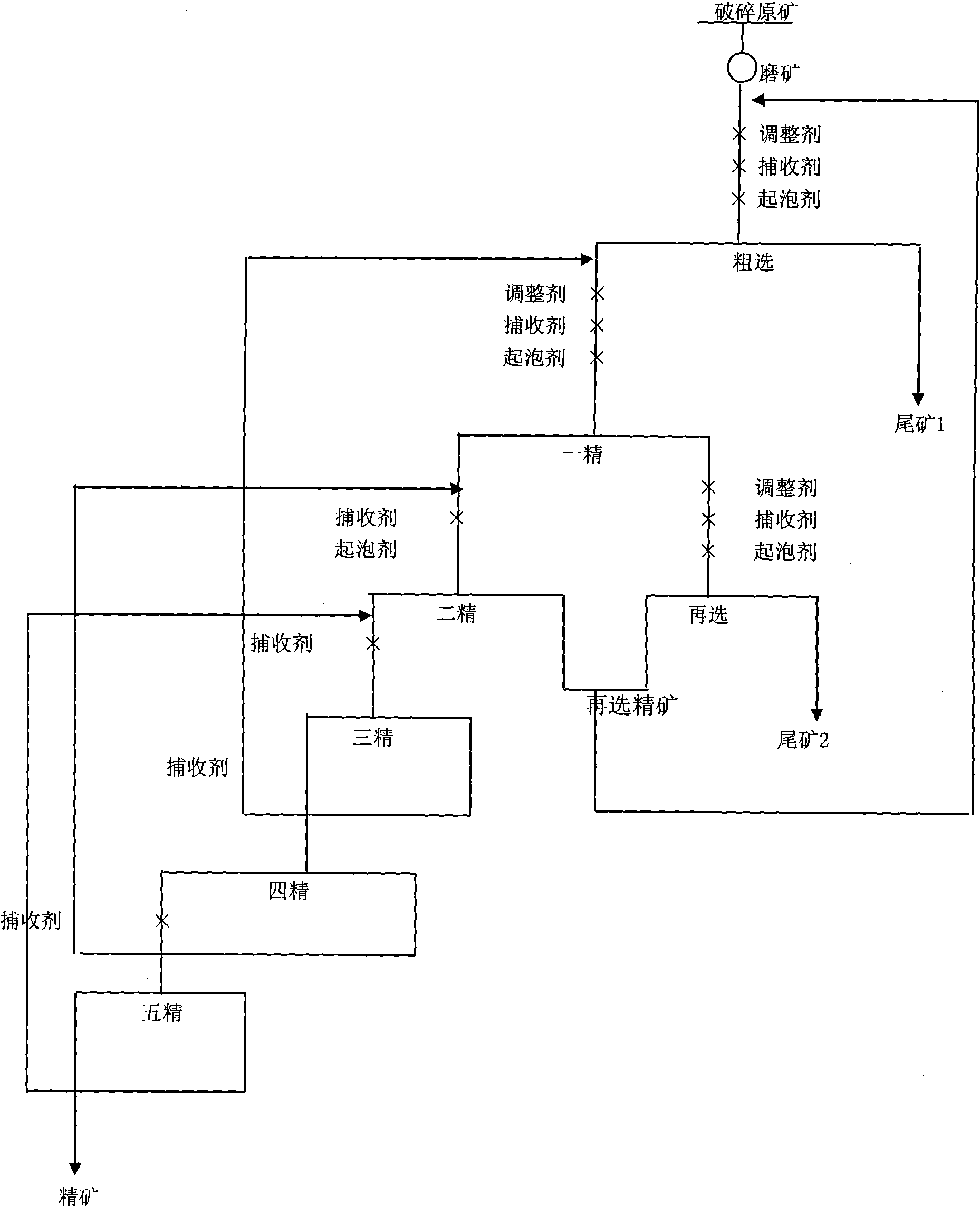

Flotation process for charcoal clay-containing pyrite

ActiveCN101972711ARealize beneficiation and enrichmentEffective dispersionFlotationFoaming agentPyrite

The invention discloses a flotation process for charcoal clay-containing pyrite. The flotation process comprises the following steps of: taking a pyrite ore raw material, crushing and grinding the pyrite ore to dissociate mineral monomer, and then adding water into the ground ore to form ore pulp; after the ore pulp flows into a stirring tank, adding an adjusting agent, a collecting agent and a foaming agent into the ore pulp to condition the pulp respectively; and feeding the pulp conditioned material into a flotation system to perform flotation, wherein the flotation process comprises one-time rough flotation, at least three times of fine flotation and one-time fine middling re-cleaning. One or more of the adjusting agent, the collecting agent and the foaming agent is or are added in each operation as required; and the adjusting agent for flotation is lignin, the collecting agent is mixed xanthate of ethyl xanthate and butyl xanthate, and the foaming agent is No.2 oil. The process successfully realizes ore dressing enrichment of the charcoal clay-containing pyrite, and has the advantages of high separation efficiency, excellent process index, high quality of the obtained pyrite concentrate and the like.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Collecting agent for separating gold from auriferous pyrite and preparation method for collecting agent

ActiveCN103657870AFoam stabilizationStrong harvesting abilityFlotationChemistryNitrilotriacetic acid

A collecting agent for separating gold from auriferous pyrite is prepared by the following raw materials in part by weight: 30-34 parts of xanthate, 12-14 parts of glycerin, 4-7 parts of sodium hexametaphosphate, 18-22 parts of terpenic oil, 10-12 parts of black powder, 2-3 parts of dimer acid, 1-2 parts of phthalic acid ester, 12-14 parts of diltiazem nitrile ester, 2-3 parts of 3-aminopropyltrimethoxysilane, 4-5 parts of nitrilotriacetic acid and 10-12 parts of activating agent. The collecting agent has a collecting function and a foaming function; foams are stable; the collecting ability is high, so that the recycling rate of the gold ores is high, the selectivity is high, and the grade of the gold ore is also high; and moreover, by using the collecting agent, the affinity of gold and iron can be reduced, collection on iron can be restrained, and then the grade of gold is improved. By using the activating agent, the surface hydrophobicity of the gold ore is changed, the internal structure is activated, and the gold collecting performance of the collecting agent is improved.

Owner:ANHUI CHAOSHAN NEW MATERIAL

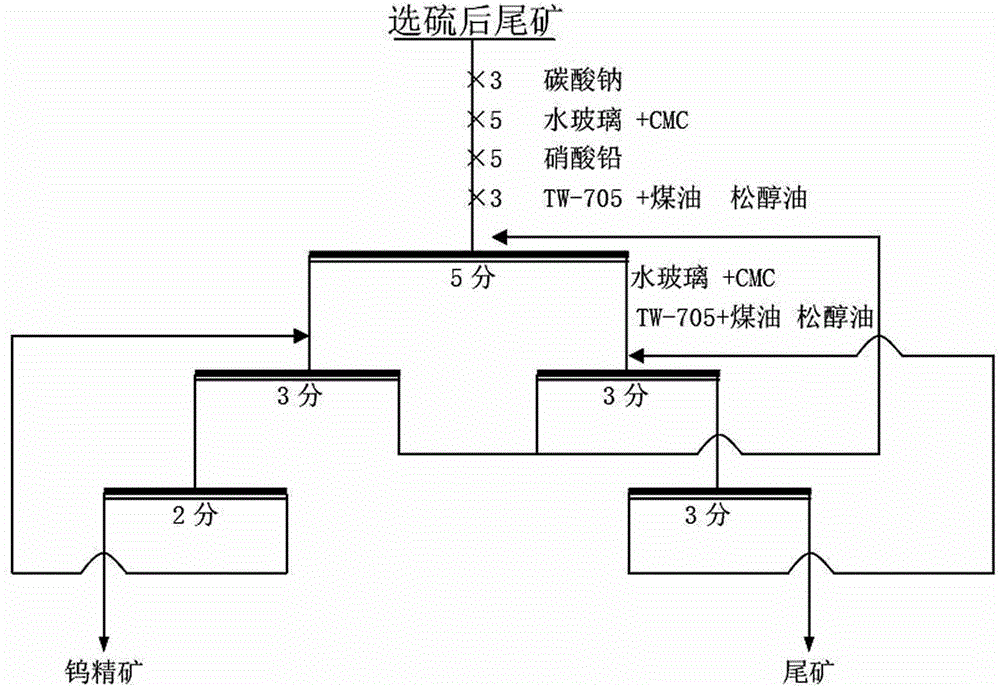

Flotation reagent system for fine wolframite in gravity concentration tailings

A flotation reagent system for fine wolframite in gravity concentration tailings is characterized in that 1, a gravity concentration tailing sample is put into a stirring tank, the concentration of ore pulp is controlled, sodium carbonate is added, the pH value of the ore pulp is controlled, and the mixture is stirred; 2, a gangue inhibitor and a fine silt dispersant are added and stirred; 3, a lead nitrate activator for the wolframite is added and stirred; 4, TW-705 serving as a collecting agent, kerosene serving as an auxiliary collecting agent and terpenic oil serving as a foaming agent are added and stirred; 5, the process flow path of carrying out rough concentration once, concentration twice and scavenging twice is adopted in tungsten flotation, the time for rough concentration is 5 min, the time for first-time scavenging and the time for second-time scavenging are 3 min, sodium silicate, a TW-705 and kerosene mixed collecting agent and terpenic oil are added in first-time scavenging, and the time for first-time concentration and the time for second-time concentration are 3 min and 2 min respectively. Tungsten concentrate is obtained through sorting. The tungsten grade of the fine wolframite in the gravity concentration tailings is improved, the tungsten recovery rate of the fine wolframite in the gravity concentration tailings is increased, and fine-fraction tungsten resources can be efficiently recovered.

Owner:SHENYANG RES INST OF NONFERROUS METALS

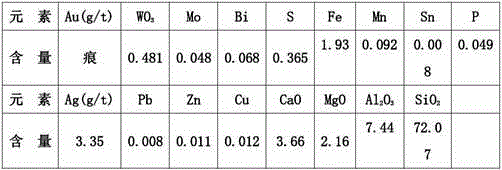

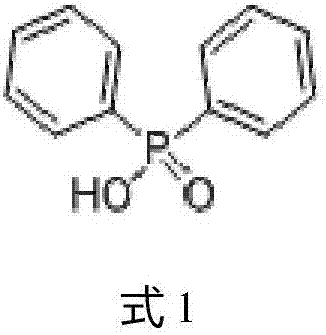

A kind of zircon beneficiation combination agent and beneficiation method

The invention discloses a zircon beneficiation composite reagent and a beneficiation method. Each ton of reagents for adding to crude ore comprises, by weight, 100-2000 g of sulfuric acid, 0-500 g of inhibitors and 100-1000 g of collecting agents. The inhibitors are sodium silicate, the collecting agents comprise petroleum sodium sulfonate and hydroximic acid, and a mass ratio of the petroleum sodium sulfonate to the hydroximic acid is 1:1-10. The zircon beneficiation composite reagent and the beneficiation method has the advantages that the zircon beneficiation composite reagent is good in zircon collecting property and selectivity, and the grade and the recovery of zircon concentrate can be further improved; the sodium silicate can be added to materials to be used as the inhibitors for fine silt or clay minerals when the materials contain few fine silt or clay minerals during flotation operation.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

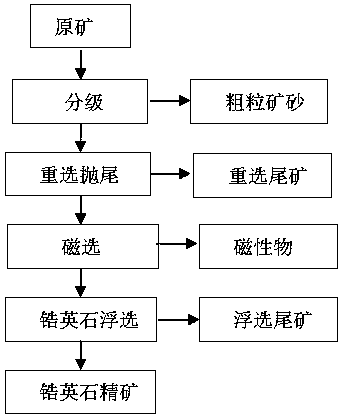

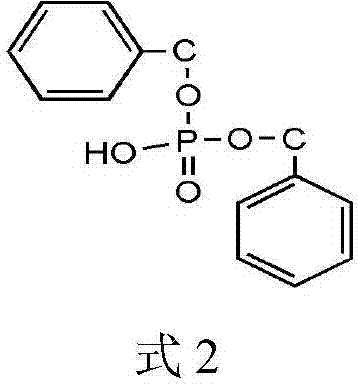

Cassiterite flotation collecting agent and application thereof

The invention discloses a cassiterite flotation collecting agent and application thereof, and belongs to the technical field of flotation. The cassiterite flotation collecting agent comprises diphenyl oxyphosphate and / or dibenzooxy phosphate and is applied to flotation separation of cassiterite and gangue. Compared with an existing common cassiterite collecting agent, the advantage of serving diphenyl oxyphosphate and dibenzooxy phosphate as the cassiterite flotation agent is obvious; normal-temperature solvable performance is achieved, the agent is poisonless and harmless, low in use amount, high in collecting capacity, high in selectivity and capable of achieving effective separation of cassiterite, quartz and calcite under the condition that pH is neutral.

Owner:CENT SOUTH UNIV

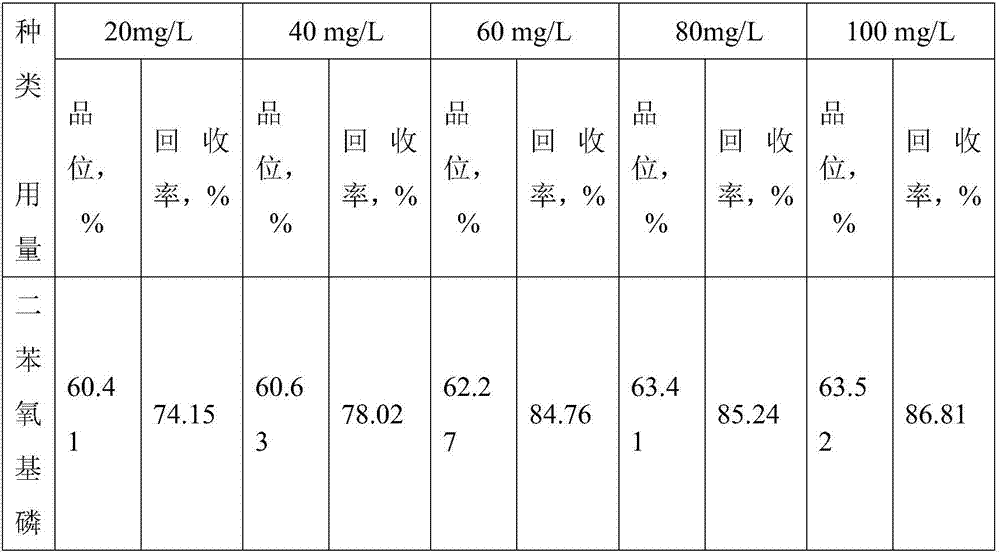

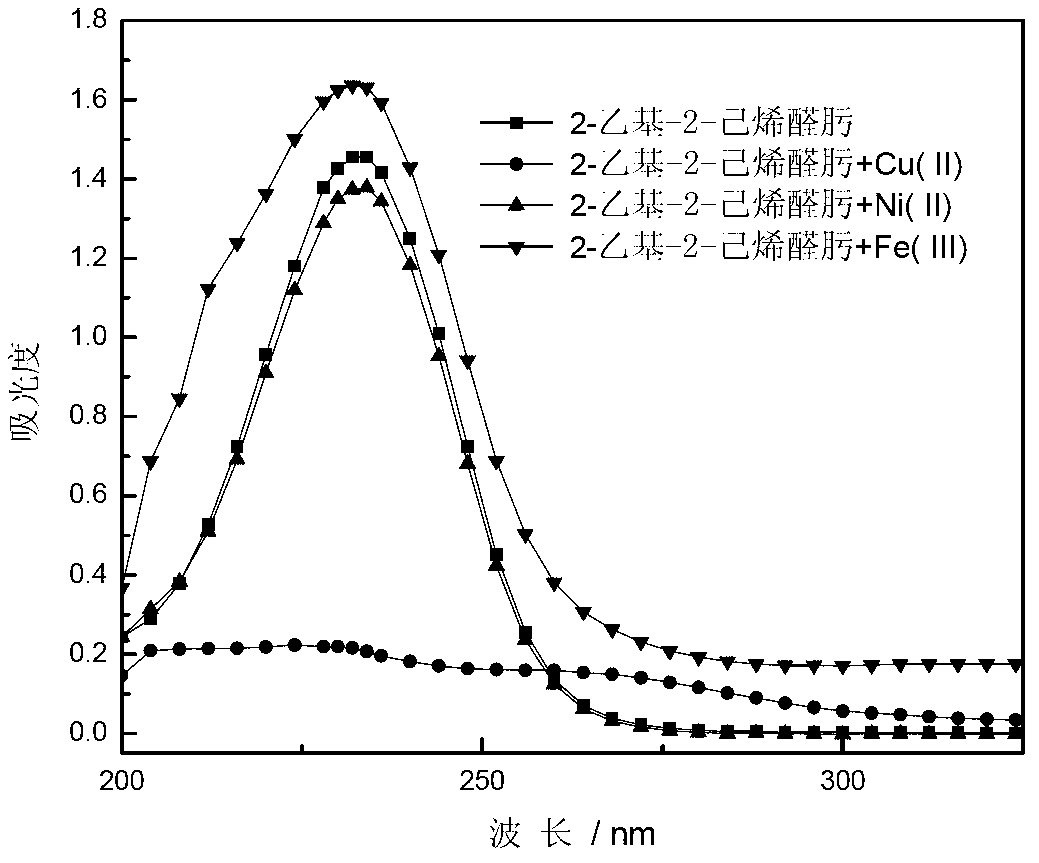

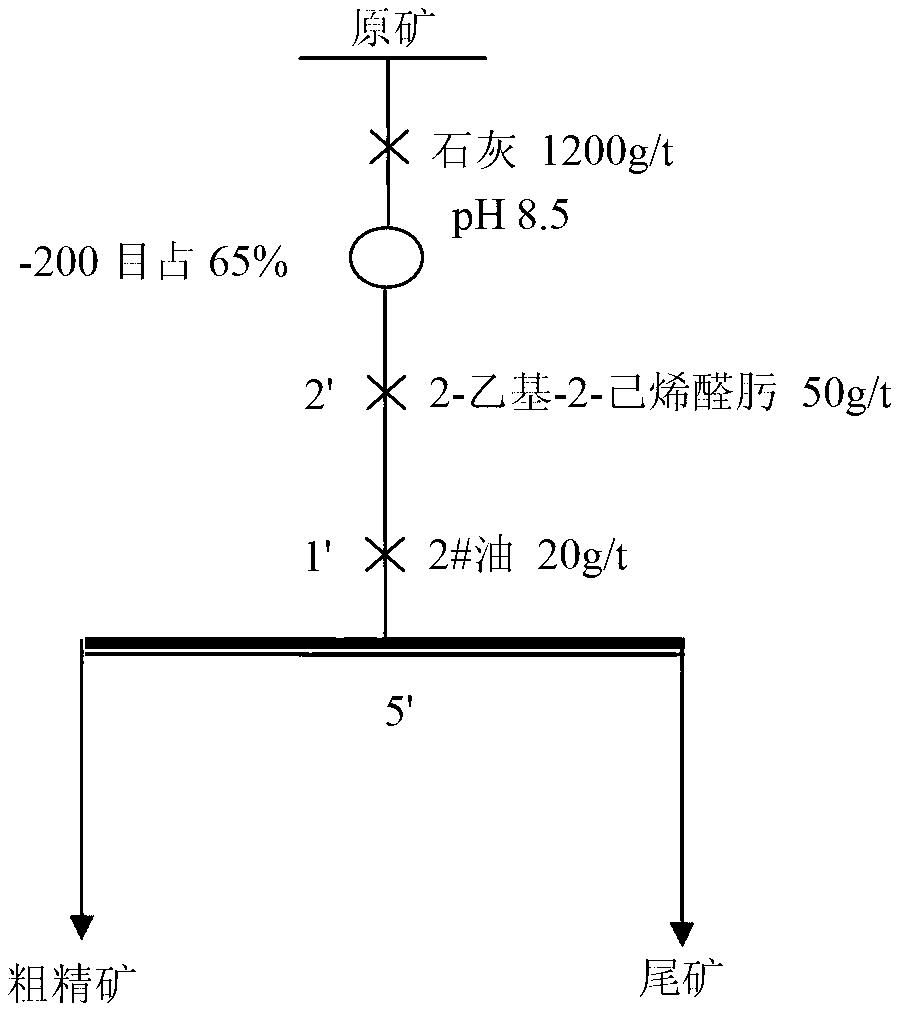

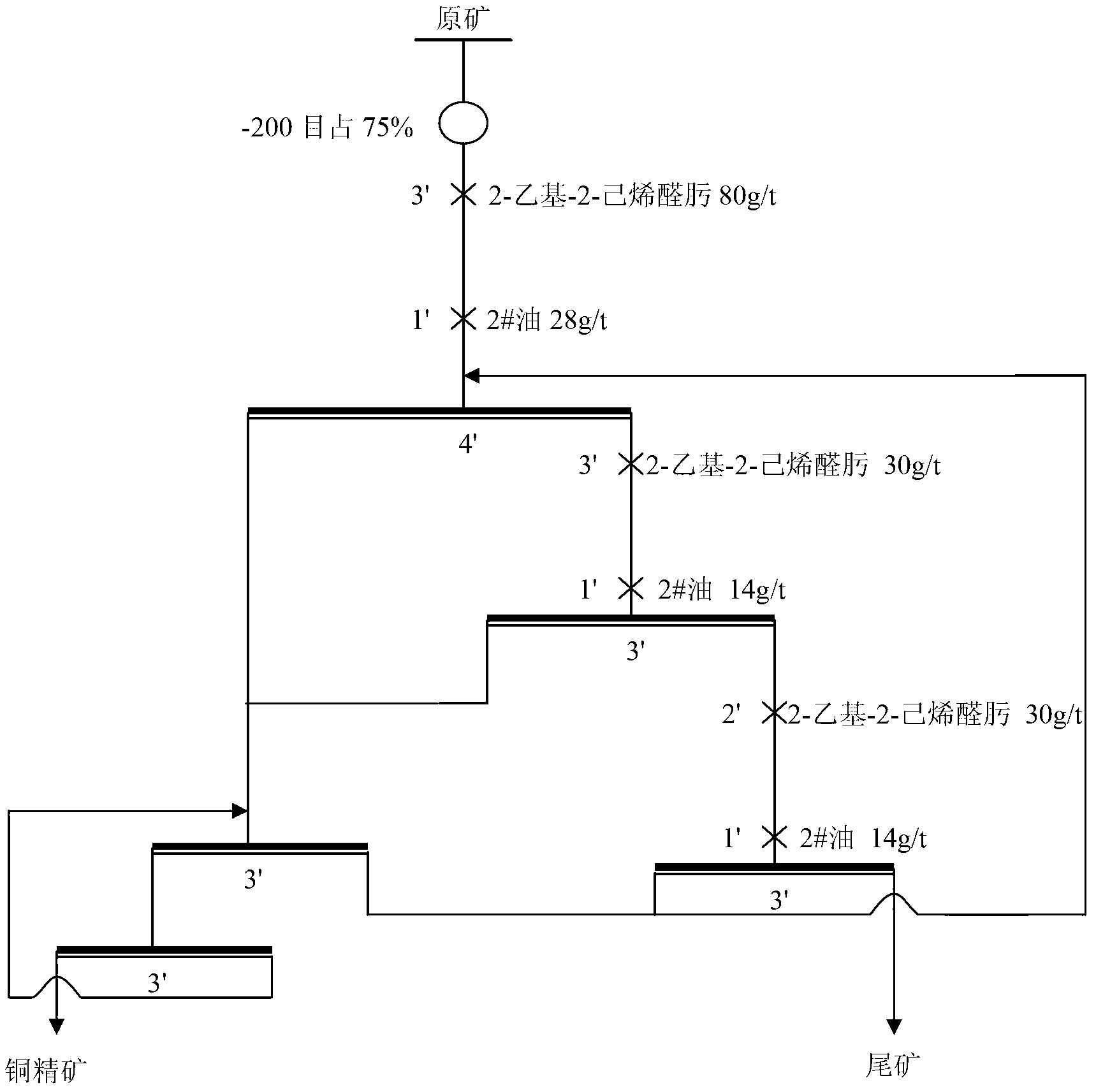

Application method of 2-ethyl-2-hexenealdoxime in mineral flotation

ActiveCN103301951AImprove the coordination effectHigh selectivityFlotationMineral flotationCopper oxide

The invention provides an application of 2-ethyl-2-hexenealdoxime serving as a new collecting agent in mineral flotation. The collecting agent has a high collecting capacity for copper sulfide ore, copper sulfide-copper oxide ore, tungsten ore and tin ore; the appropriate flotation pulp pH ranges from 8 to 13; when the collecting agent is used as a sulfide ore flotation collecting agent, the dosage ranges from 30g / t to 200g / t; and when the collecting agent is used as an oxidized ore flotation collecting agent, the dosage ranges from 200g / t to 1,500g / t. By virtue of good hydrophobic group structure and collecting selectivity, 2-ethyl-2-hexenealdoxime has strong collecting acting force and good hydrophobic floating capacity for targeted ore, and is suitable for treating fine grained ore which is difficult to select; and when the copper sulfide-copper oxide ore is in flotation, the flotation can be performed without adding a sulfurizing reagent such as sodium sulfide and the like.

Owner:CENT SOUTH UNIV

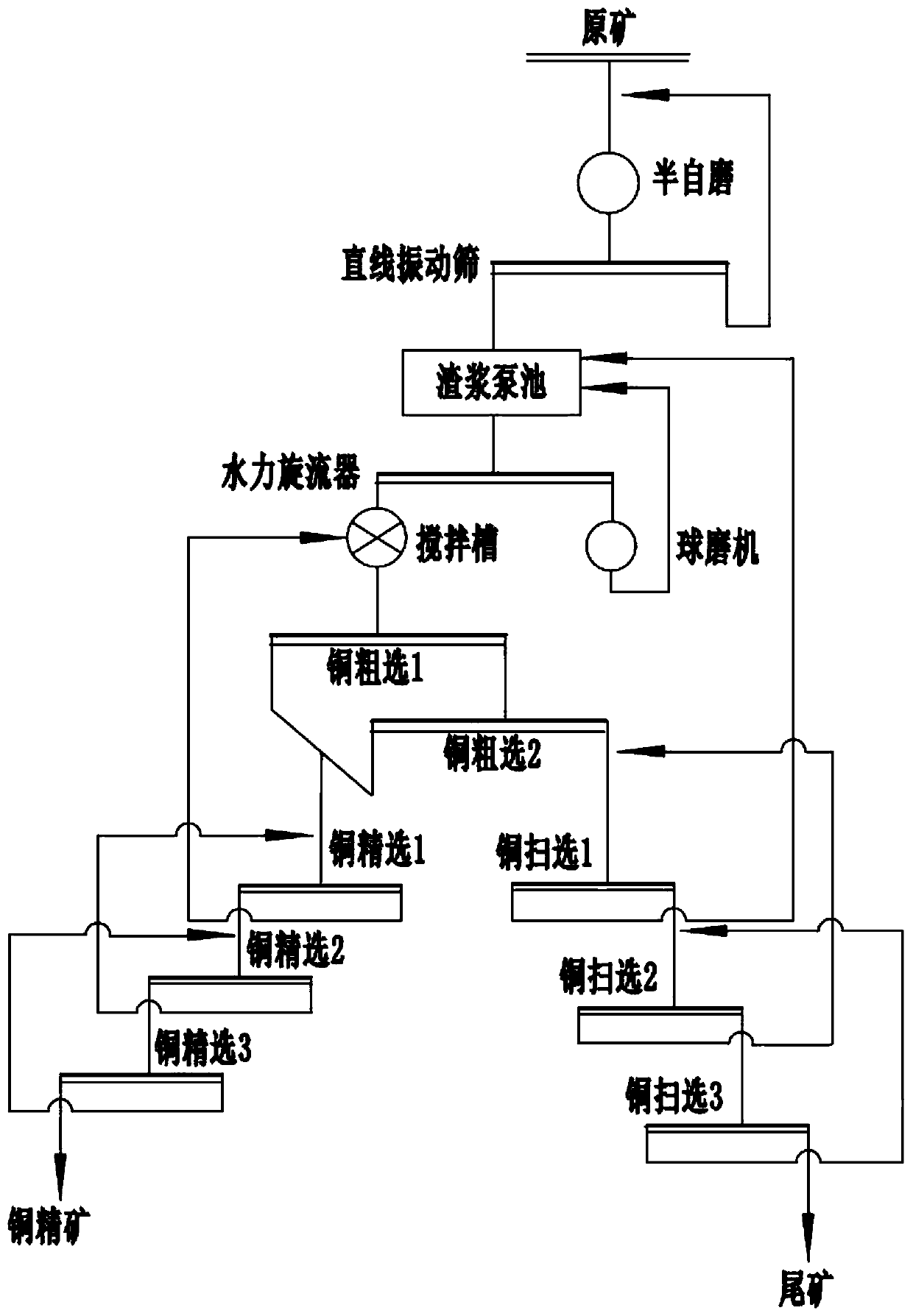

Beneficiation method of particulate sulfur oxygen mixed copper ore in high and cold area

ActiveCN110339936ARealize advanced pre-adsorptionImprove integrityFlotationWet separationHigh concentrationParticulates

The invention relates to a beneficiation method of particulate sulfur oxygen mixed copper ore in a high and cold area and belongs to the technical field of a copper ore beneficiation method. In orderto solve the problems that the target ore and a floating agent have bad action effect and low recovery rate in the beneficiation process of the sulfur oxygen mixed copper core in the high and cold area, the invention provides the beneficiation method of the particulate sulfur oxygen mixed copper ore in the high and cold area. The beneficiation method of the particulate sulfur oxygen mixed copper ore in the high and cold area comprises the steps of comminuting raw ore, performing high-concentration size mixing and dosing in a pulp pump pool, performing ore pulp grading, performing two-section reinforced roughing, performing three-time copper scavenging and performing three-time copper selection. Advanced preadsorption of the ore and the medicament is realized, the problems of bad action effect of the medicament, large use amount and instability of a mineralized foam layer are solved, the defects of low vulcanization efficiency and unfirm vulcanization film are overcome, the capturing ability of the copper ore is effectively improved, the flotation time of the ore difficult to float is prolonged and the selected copper recovery rate is increased. The beneficiation method provided bythe invention is particularly suitable for treating hard-to-select sulfur oxygen mixed copper ore in the high and cold area, so that the comprehensive recovery ability of valuable copper resources iseffectively improved.

Owner:HEILONGJIANG DUOBAOSHAN COPPER LTD

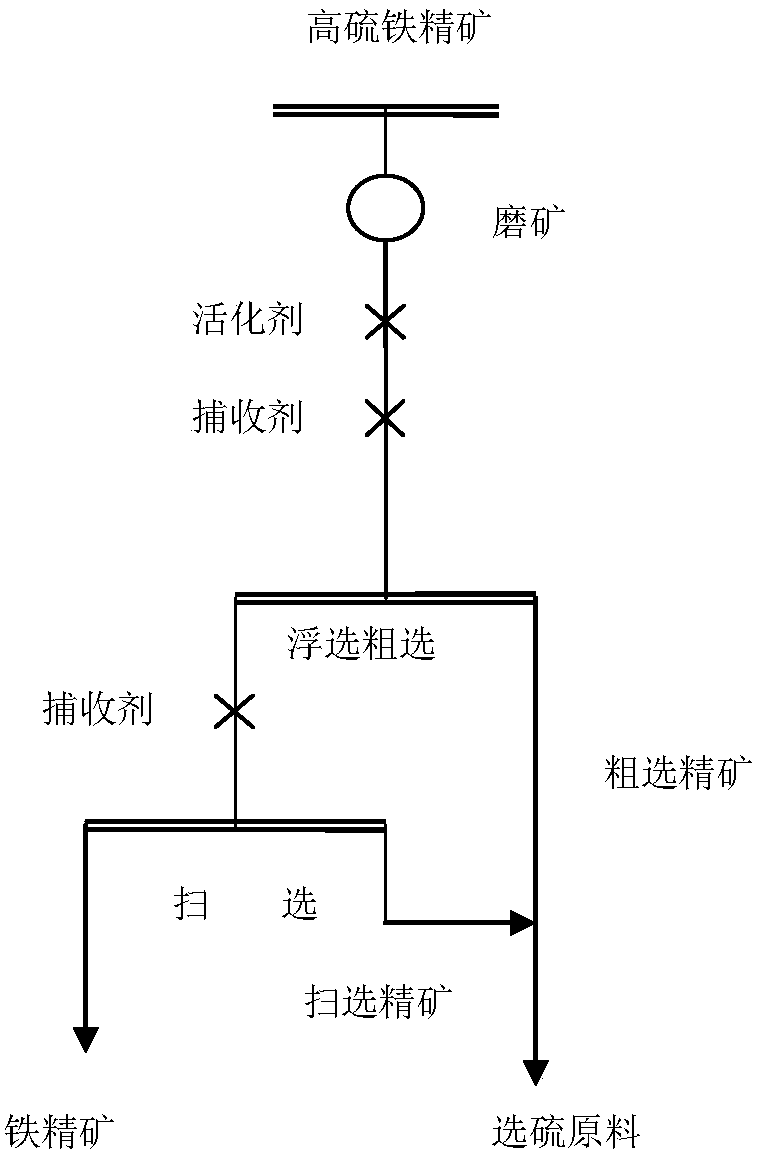

Method for removing pyrrhotite from high-sulfur iron ore concentrate

ActiveCN108097453ARaise the gradeHigh recovery rateFlotationWet separationAluminium sulfateSodium phosphates

The invention relates to a method for removing pyrrhotite from high-sulfur iron ore concentrate and belongs to the technical field of mineral engineering. The sulfur content of high-sulfur iron ore concentrate is higher to seriously affect the quality of the iron ore concentrate. Pyrrhotite is likely to have oxidation and argillization, and the oxidization degrees are different, so that the sulfurcontent in the iron ore concentrate is difficult to be reduced below 0.3%, and the recovery rate loss of the iron ore concentrate is larger. According to the method, through proper ore grinding, mostof monomers of pyrrhotite are separated and are prevented from excessively grinding to avoid argillization. Efficient and feasible aluminum sulfate or the mixture of aluminum sulfate, sodium phosphate and ammonium fluosilicate is adopted as an activator and a pH regulator of pyrrhotite, and a collecting agent with better selectivity and collecting performance is adopted to activate the mineral surface of pyrrhotite, and the electrical charge state of the surface of mineral in ore pulp is better controlled, so that magnetite and pyrrhotite are effectively separated and high-quality iron ore concentrate with high grade and high recovery rate and rough concentrate of pyrrhotite are obtained.

Owner:内蒙古薪宝高科技开发有限公司

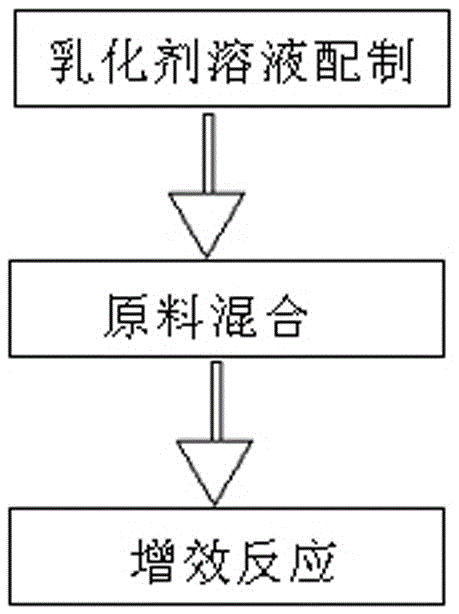

Preparation method for efficient collecting agent for floating and desiliconizing monohydrallite

The invention discloses a preparation method for an efficient collecting agent for floating and desiliconizing monohydrallite. The method comprises the following steps: A) preparing an emulsifier solution; B) mixing raw materials; C) performing synergic reaction. According to the method provided by the invention, on the basis of principle of synergistic effect generated by the combination of different agents, through the effective compounding combination of carboxylic acids collecting agent, emulsifier and synergist, the components in the collecting agent can have co-adsorption and synergistic effect on the surface of monohydrallite, so that the hydrophobic property of the mineral surface can be increased, the selectivity and the collecting capacity of the agents can be enhanced and the mineral separation technical index of the monohydrallite can be increased. The preparation method provided by the invention has the advantages that the collecting agent has the characteristics of high selectivity, high collecting capacity, high drug stability, less agent dosage, low temperature resistance, and the like, the concentrate grade and the recovery rate can be increased when the collecting agent is used for separating the monohydrallite and the alumina silica ratio of concentrate ore can be effectively increased.

Owner:KUNMING METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com