Method for preparing feldspar iron removal floatation collecting agent

A collector and flotation technology, used in flotation, solid separation and other directions, can solve the problems of serious equipment corrosion, enlargement, and large amount of flotation reagents, and achieve simple production process, low production cost, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

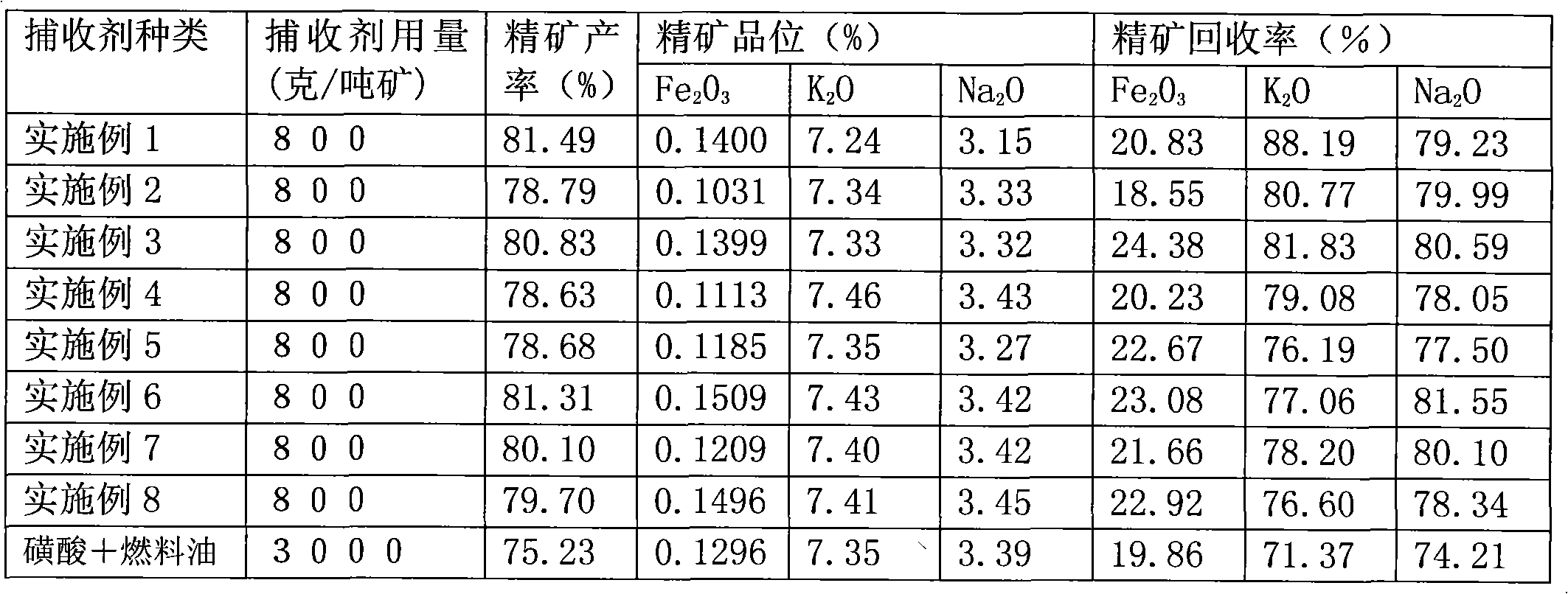

Examples

Embodiment 1

[0022] Take 100 grams of oil foot, add 15 grams of hydrochloric acid to it, control the reaction temperature between 20°C and 40°C, and the reaction time is 30 minutes, then add 20 ml of cold water (tap water) to stir and wash for 1-2 minutes, and let it stand for about 2 hours , divide and remove the lower water layer, add 35 grams of alkali (made into 45% solution) to it, make the pH value 10, be warming up to 95 ℃ and carry out hydrolysis reaction, fully stir 3 hours, add the dodecane of 2 grams under stirring Sodium base sulfate, after fully stirring, it becomes the product.

Embodiment 2

[0024] The add-on of hydrochloric acid is 10 grams, and the reaction time is 30 minutes, adds 25 gram alkalis to it (being made into 45% solution) lye adjustment value is 8, sodium lauryl sulfate add-on is 6 grams, other is the same as embodiment 1.

Embodiment 3

[0026] The add-on of hydrochloric acid is 7 grams, and the reaction time is 40 minutes, adds 20 gram alkalis (being made into 45% solution) to it, regulates pH value to be 9, sodium lauryl sulfate add-on is 6 grams, other is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com