Floating magnetic combined copper-molybdenum sorting-separation method

A separation method and technology of copper and molybdenum, applied in the directions of magnetic separation, flotation, solid separation, etc., can solve the problems of substandard copper content in molybdenum concentrate, poor separation effect of copper and molybdenum, and high molybdenum content in copper concentrate. The effect of improving the harvesting effect, reducing the content of magnetic impurities and reducing the loss of molybdenum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

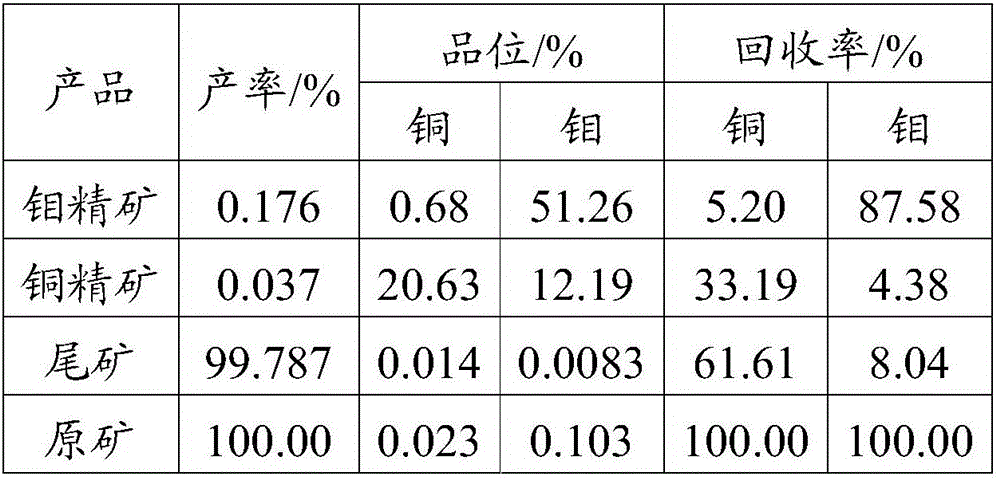

[0022] A porphyry-type copper-molybdenum mine in Inner Mongolia has a molybdenum grade of about 0.1% and a copper grade of about 0.02% in the raw ore. Metal minerals are mainly molybdenite (mineral content 0.12%), pyrite ((mineral content 1.12%)), chalcopyrite (mineral content 0.06%), followed by hematite, magnetite, pyrrhotite , also contains trace amounts of blue chalcocite, copper blue and bornite. The main gangue minerals are quartz, feldspar, biotite, sericite and clay minerals.

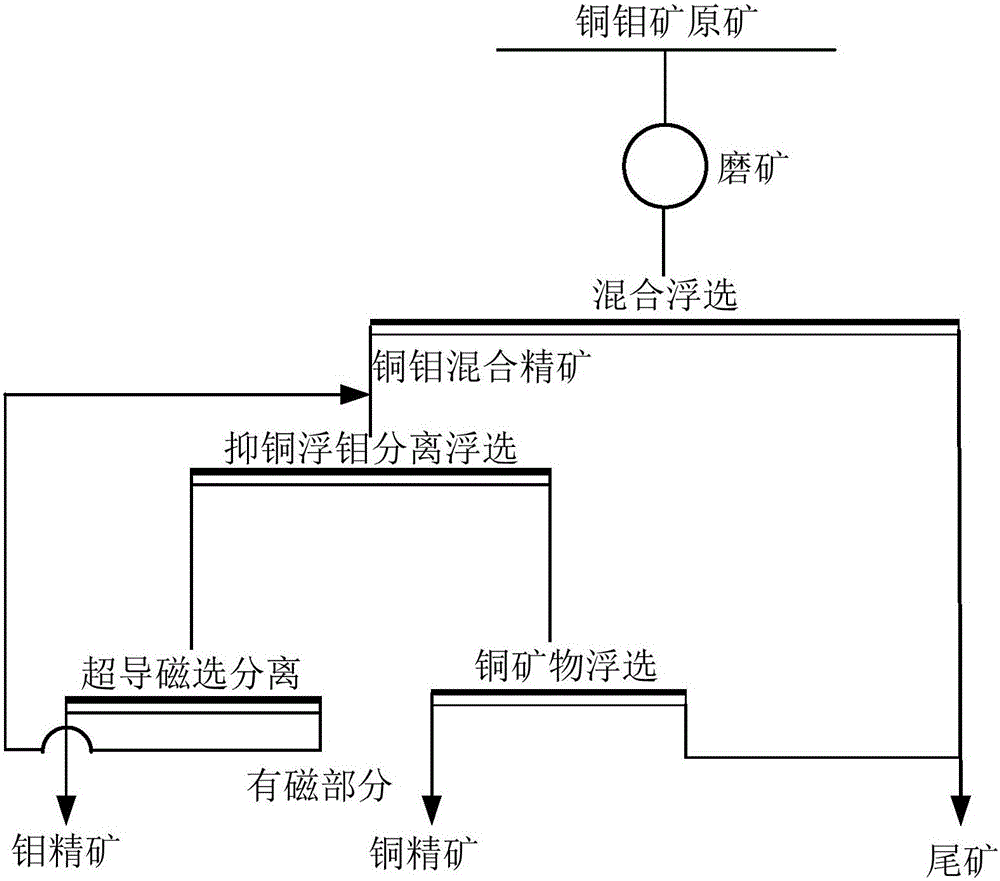

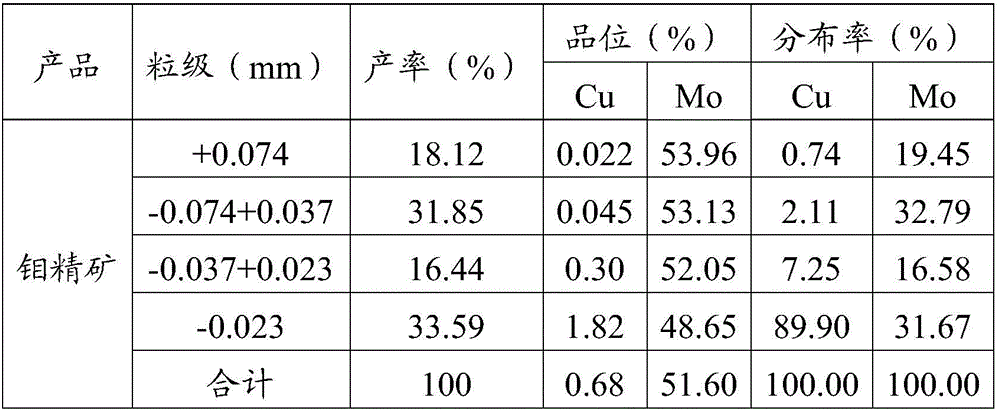

[0023] Conventional copper-molybdenum mixed flotation, copper-suppressed floating molybdenum separation process: the raw ore undergoes mixed flotation after a period of ball milling, and the mixed flotation process is "one-time roughing, three-time beneficiation, and three-time sweeping" to obtain mixed coarse concentrate and For tailings 1, the flotation agents are conventional kerosene and No. 2 oil. The mixed flotation rough concentrate is carried out for separation flotation, and the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com