Patents

Literature

59results about How to "Good beneficiation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ore dressing method for removing pyrrhotite from iron ore

InactiveCN104069937AEnhanced harvesting capacityGood beneficiation effectFlotationWet separationChemical mixturesIronstone

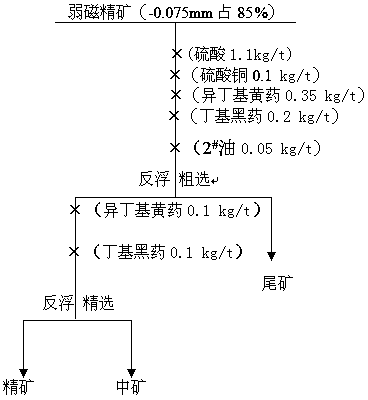

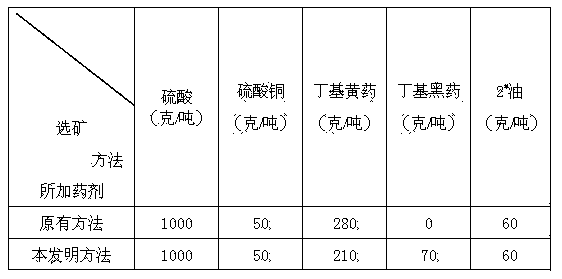

The invention discloses an ore dressing method for removing pyrrhotite from iron ore. The ore dressing method for removing the pyrrhotite from the iron ore includes that performing crushing, ore grinding, grading and low intensity magnetic separation techniques to obtain low intensity magnetic concentrate, wherein the TFE grade of the low intensity magnetic concentrate is more than or equal to 65.0%, and the low intensity magnetic concentrate comprises 0.5-1.4% of S; carrying out reverse flotation roughing and reverse flotation selection on the low intensity magnetic concentrate to obtain low-pyrite concentrate with less than 0.15% of S. Weighted by the dry ore amount for the reverse flotation, the reverse flotation roughing chemical comprises (1) pH regulating agent, to be specific, 800-1200 g / t of sulfuric acid; (2) activating agent, to be specific, 80-150 g / t of copper sulfate; (3) collecting agent, to be specific, 250-400 g / t of iso-butyl xanthate and 150-250 g / t of butyl dithiophosphate; (4) foaming agent, to be specific, 30-70 g / t of 2# oil. The ore dressing method for removing the pyrrhotite from the iron ore uses the butyl dithiophosphate and butyl xanthate or iso-butyl xanthate to form sulfur content reducing chemical mixture, the molecular arrangement between the chemical micelles is improved to form a synergistic effect, the chemical is good for mineralizing and adsorbing, the hydrophobicity and the floating speed are properly reinforced, and the sulfur content of the iron concentrate is reduced to less than or equal to 0.03-0.15%. The ore dressing method for removing the pyrrhotite from the iron ore is especially suitable for removing the pyrrhotite from the iron ore with pyrrhotite through reverse flotation.

Owner:马钢集团设计研究院有限责任公司 +1

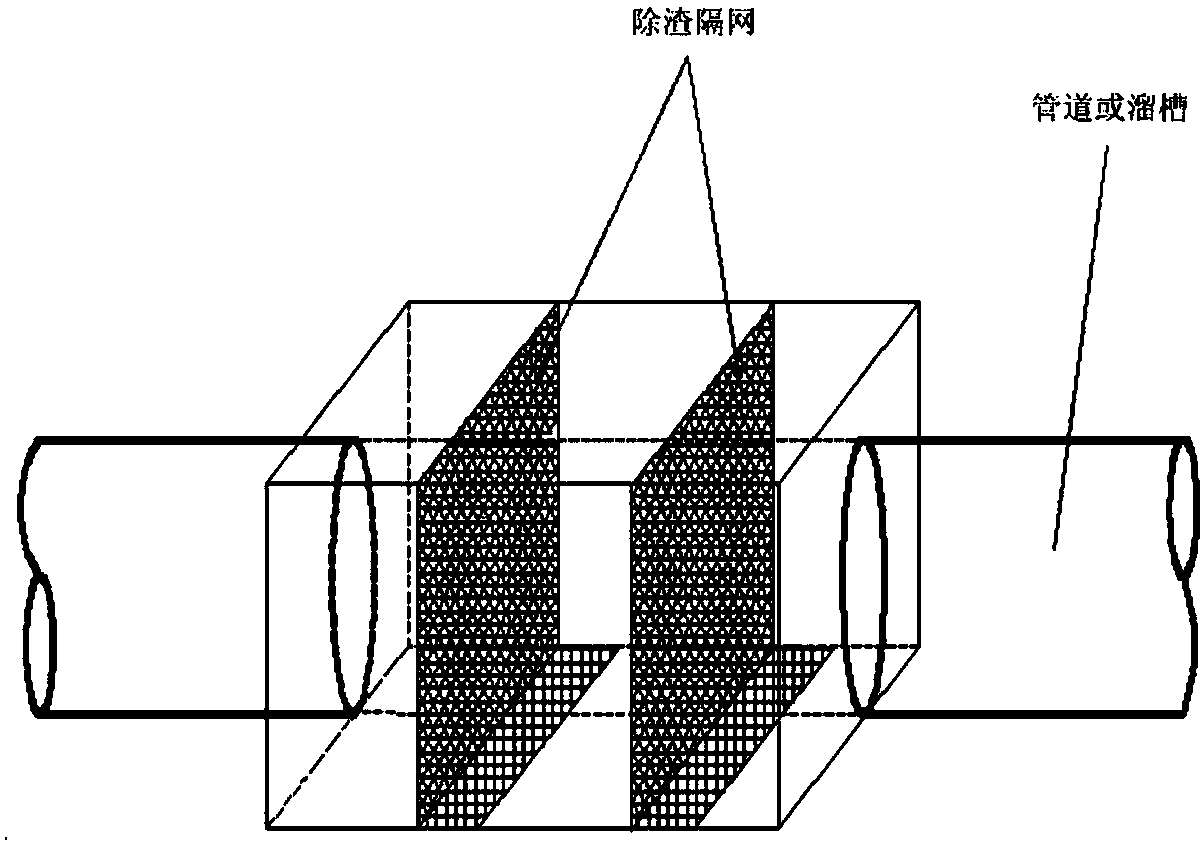

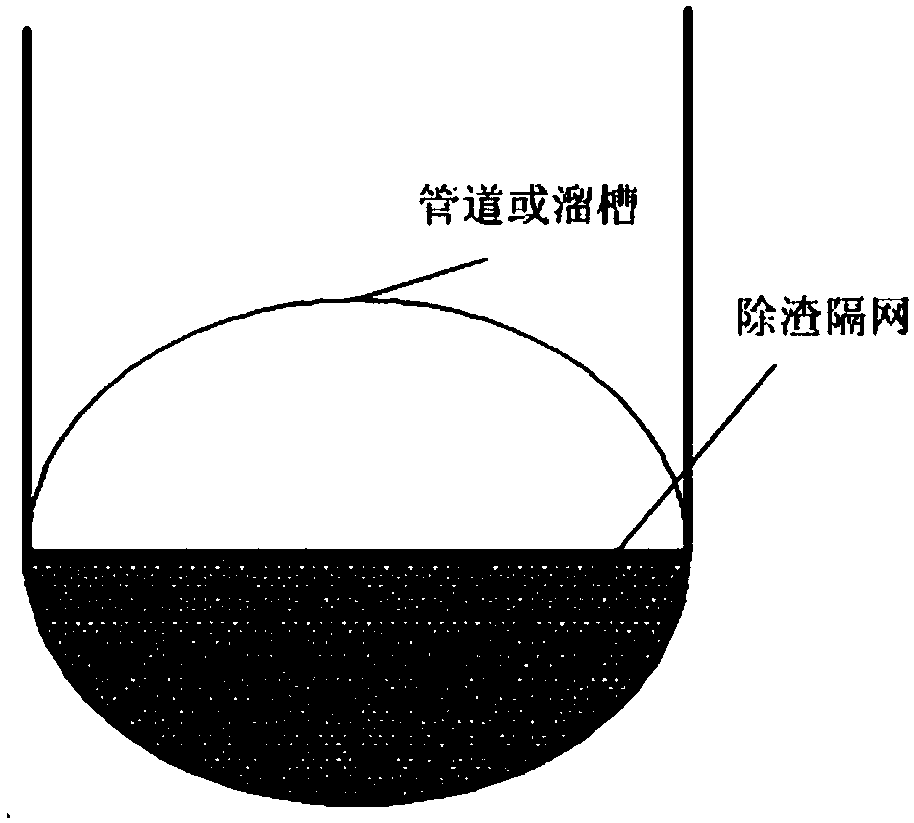

Quality improvement and impurity reduction ore dressing method of ferromagnetic minerals

InactiveCN104888959AImprove featured performanceEfficient selection effectFlotationMagnetic separationGranularityWater flow

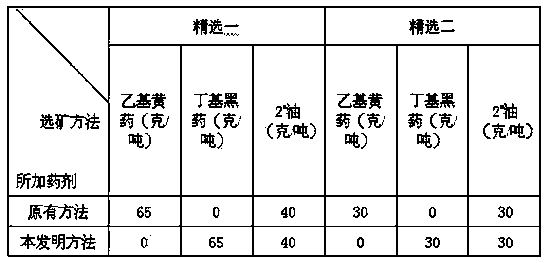

The invention provides a quality improvement and impurity reduction ore dressing method of ferromagnetic minerals. The method is characterized in that the ferromagnetic minerals are cleaned, and the cleaning process comprises the following steps: 1, adding a flotation agent to crude concentrates, and carrying out size mixing, wherein the weight of ores with the granularity of 0.07-4mm in the crude concentrates is 80-90% of the total weight of the crude concentrates, and the flotation agent comprises a collector and an inhibitor; and 2, adding a material obtained in step 1 into a floating agglomeration electromagnetic cleaning device, and controlling the magnetic field intensity of the floating agglomeration electromagnetic cleaning device to be 11.94-63.69kA / m, the magnetic field transformation period to be 2-6s and the rising water flow speed to be 2-6cm / s. The method allows high-quality ferromagnetic mineral products to be obtained, greatly reduces the content of impurities, greatly shortens the ore dressing process of the ferromagnetic minerals, and has huge market economic benefit.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

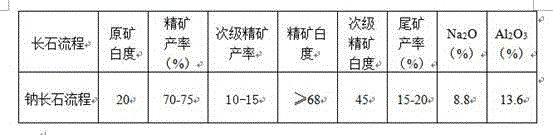

Method for efficiently preparing feldspar glazes for ceramics

The invention discloses a method for efficiently preparing feldspar glazes for ceramics. The method comprises the following specific steps: after raw feldspar ores are crushed, grinding the raw feldspar ores by a high-alumina ball grinding mill, classifying the raw feldspar ores in a spiral manner by a spiral classifier, and screening the raw feldspar ores by a high-frequency classifying screen, so that the sufficient dissociation of feldspar mines and the controlling the granularity can be ensured, the feeding granularity of the fed feldspar mines can be ensured, and conditions for the following magnetic separation and the classifying processes of a cyclone are created; separating and effectively removing magnetic impurities of the raw feldspar ores by the magnetic separation with various intensity in a classifying and multi-section manner of the granularity, increasing the kinds of products, and increasing the recovery of resources. Through the use of the technologies, such as the classification of the cyclone, the permanent magnet iron removal of a drum magnetic separator, the iron removal of a vertical ring pulsating high-gradient strong magnetic separator and the like, the adaptability and the reliability are greatly improved, the quality of the concentrates is effectively ensured and stabilized, the risk due to fluctuation of the impurity content is reduced, the separating efficiency and the comprehensive utilization of resources are improved, and the efficiently comprehensive utilization of the feldspar resources is realized.

Owner:赣州金环磁选科技装备股份有限公司

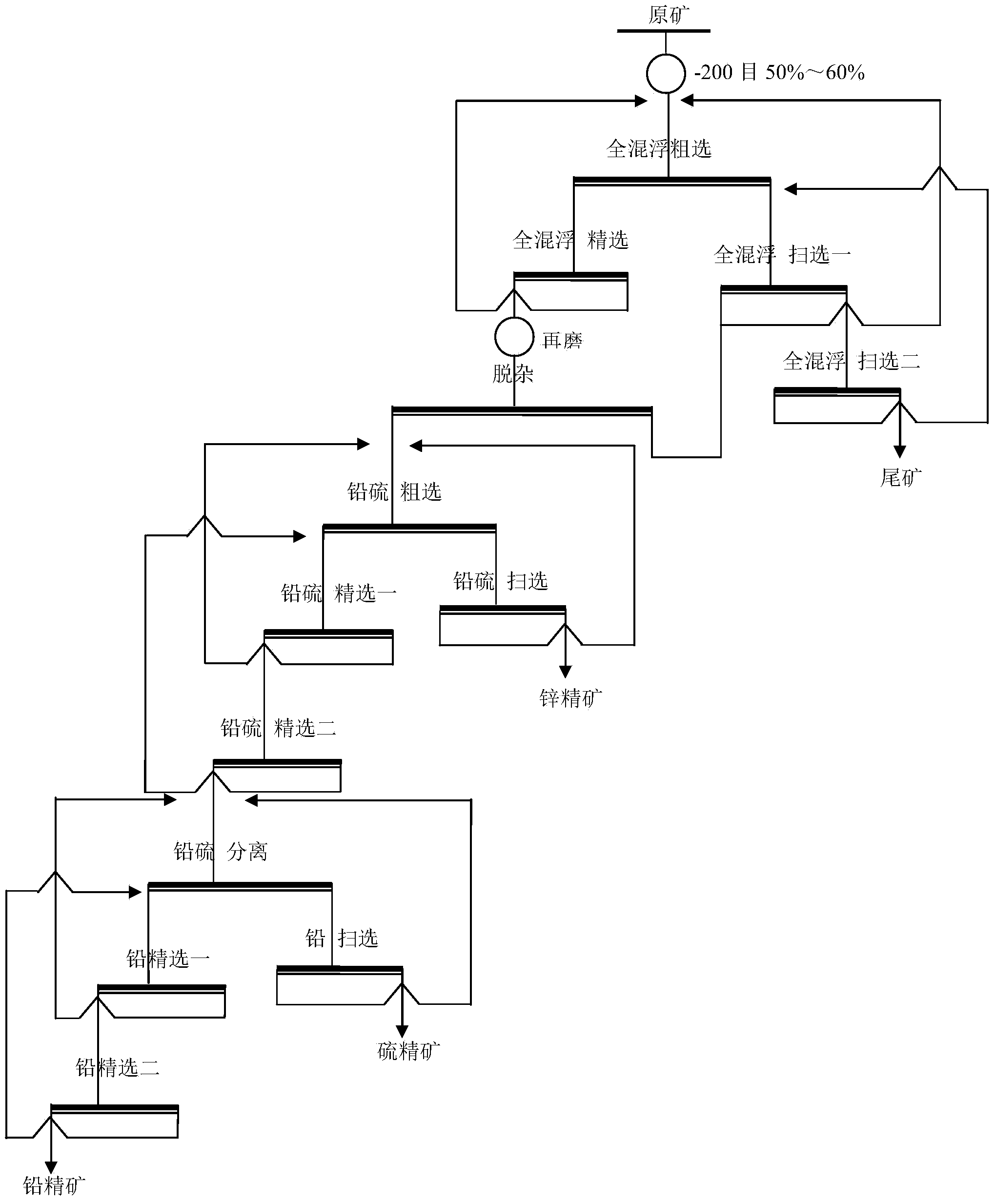

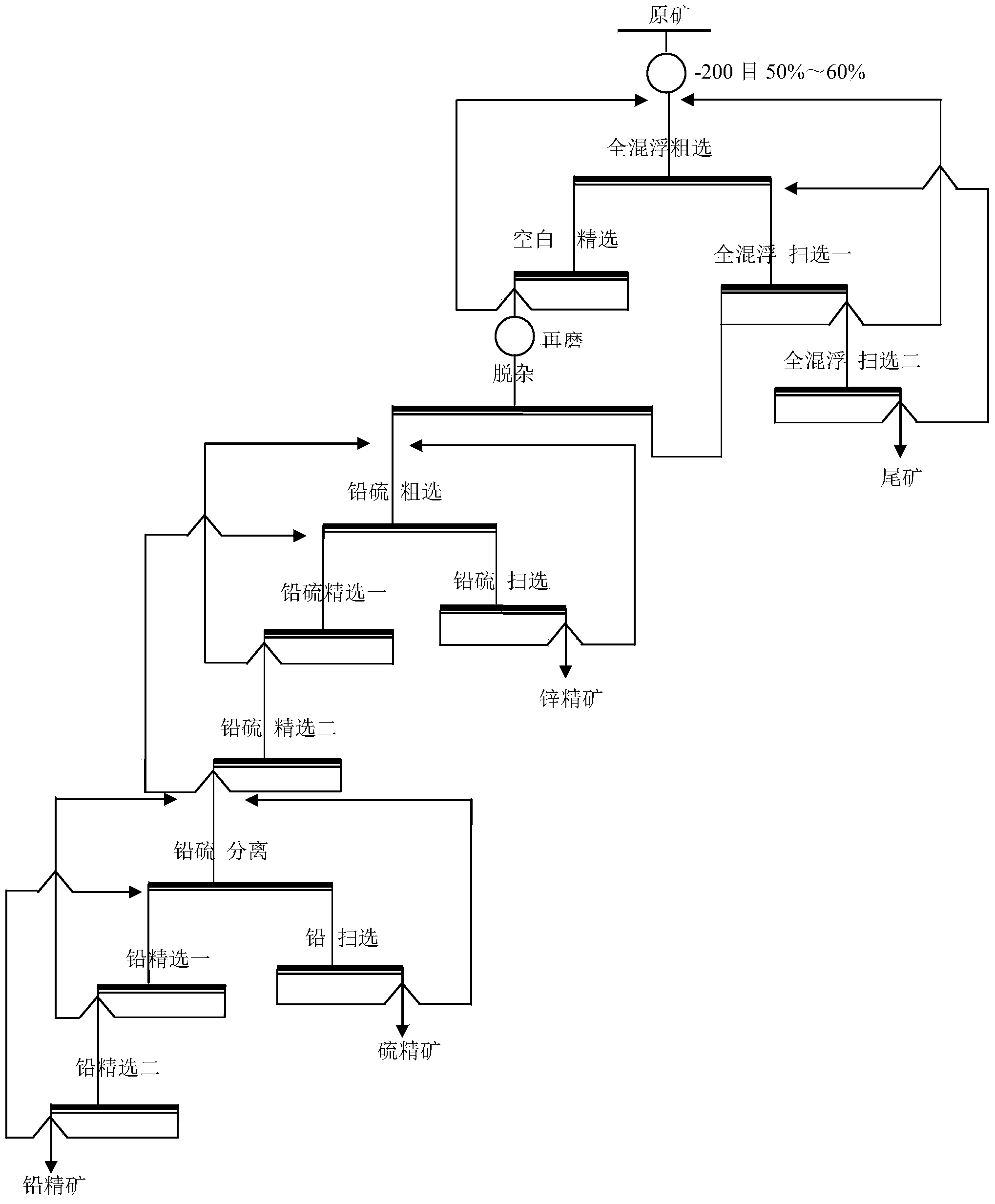

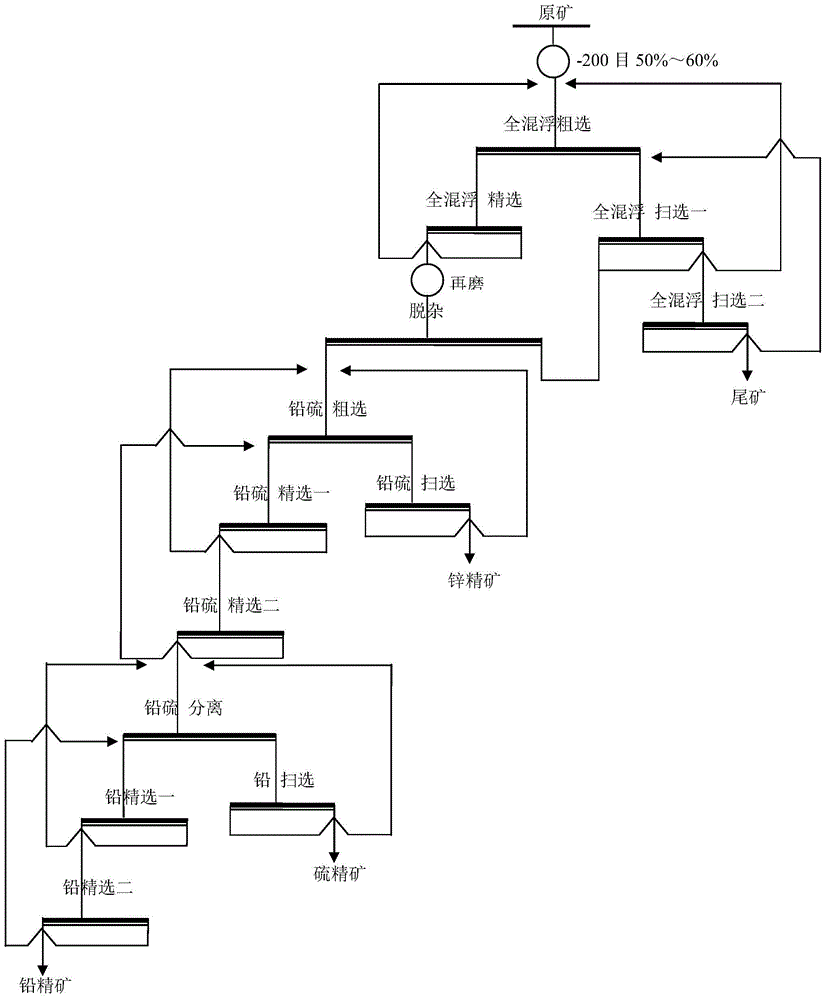

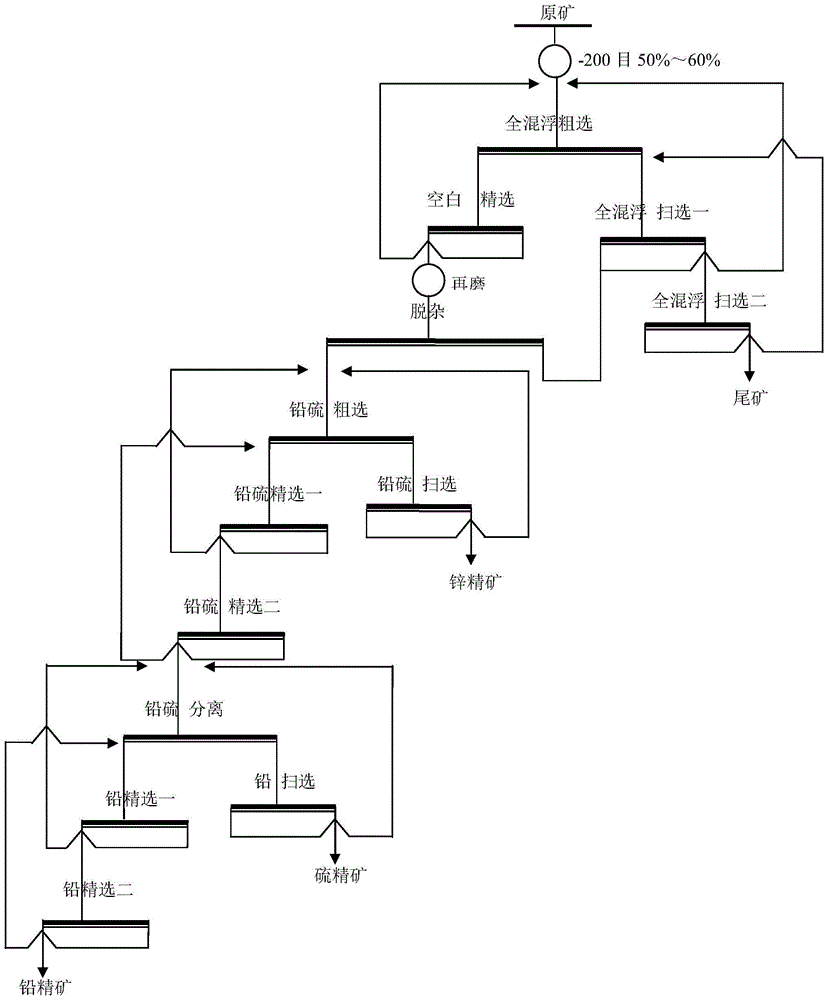

Method for obtaining valuable ores from multi-metal sulfide ores containing lead and zinc through flotation separation

ActiveCN104001626AReduce grinding energy consumptionImprove beneficiation efficiencyFlotationZincMaceral

The invention discloses a method for obtaining valuable ores from multi-metal sulfide ores containing lead and zinc through flotation separation. The method comprises the steps of firstly performing ore grinding on raw ores; then adding a combined flotation agent to perform complete-mixing rough flotation treatment on the raw ores subjected to the ore grinding; continuing to perform fine flotation on rough concentrates subjected to the rough flotation, and continuing to add the combined flotation agent to perform scavenging on tailings subjected to the rough flotation; re-grinding lead-zinc-sulfur mixed rough concentrates subjected to the fine flotation; adding the combined flotation agent into the grinded lead-zinc-sulfur mixed rough concentrates to perform impurity removal treatment, and performing scavenging on the tailings subjected to the impurity removal. On the basis of the method, lead-sulfur rough flotation, lead-sulfur fine flotation and lead-sulfur separation can be additionally performed to obtain lead concentrates, the tailings subjected to the flotation separation is subjected to lead scavenging, and finally sulfur concentrates are obtained. The method has the advantages of being simple and convenient to operate, reasonable in technological process, small in agent dosage, low in energy consumption, long in service life, good in separation effect and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

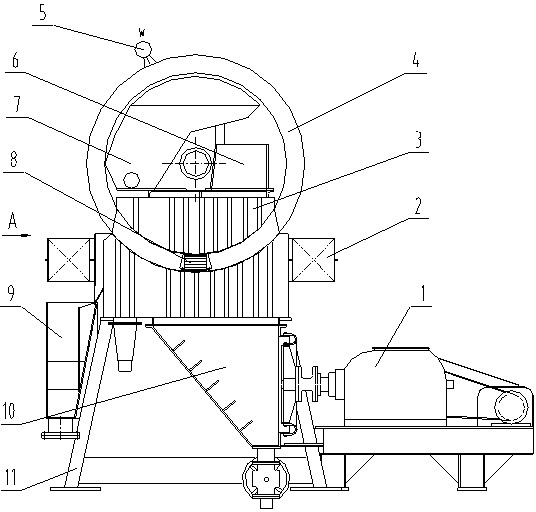

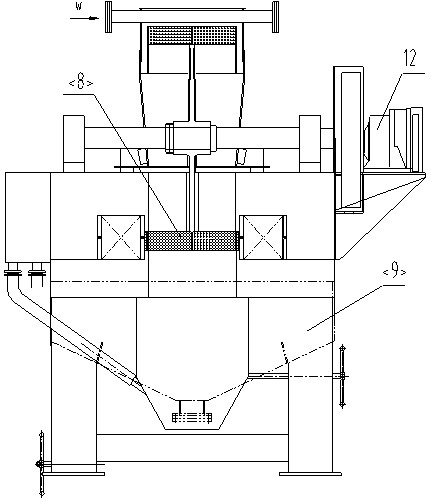

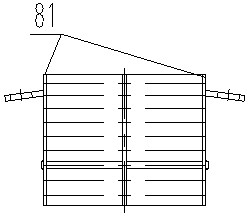

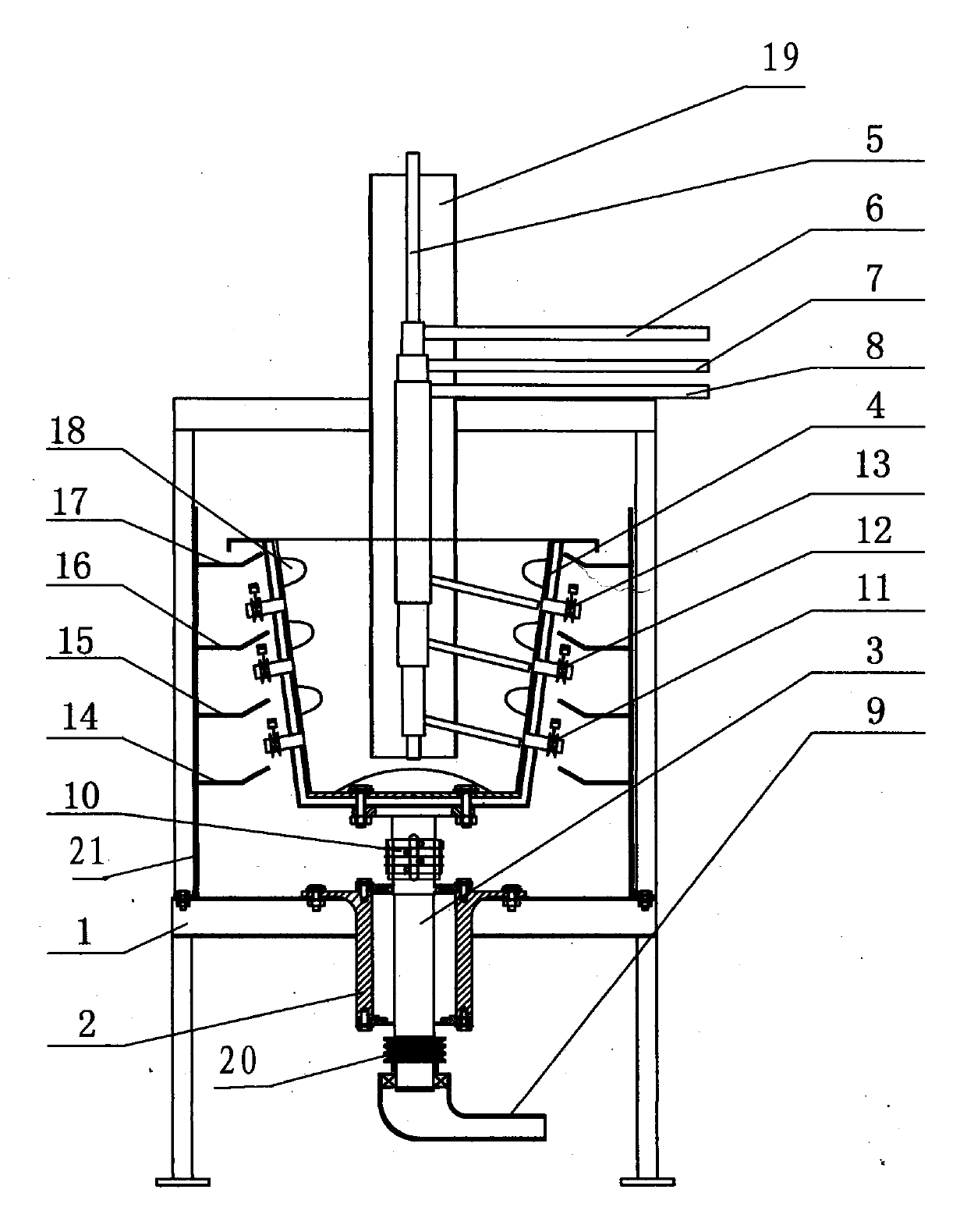

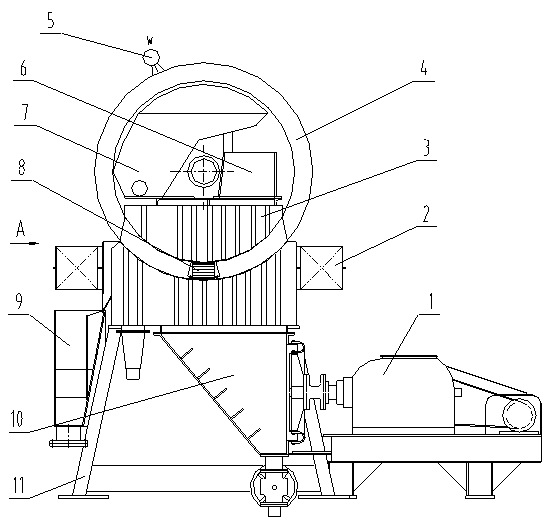

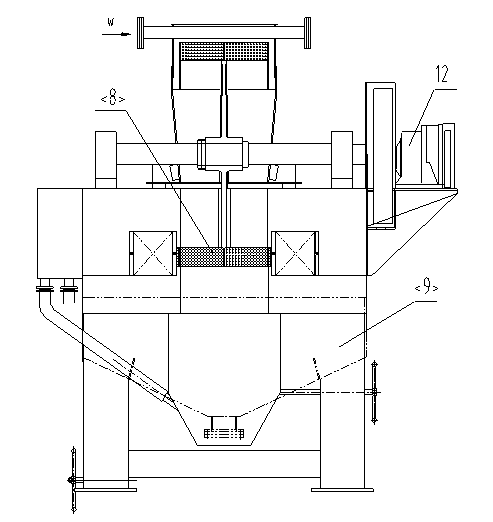

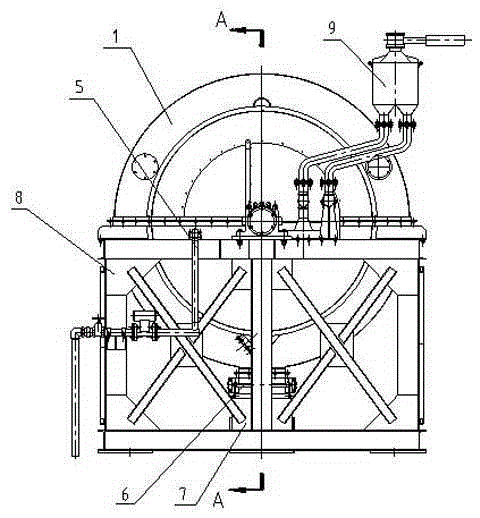

Large-particle vertical ring pulsation high-gradient magnetic separator

ActiveCN102614983AHigh enrichment ratioMeet the requirements of the sorting channelHigh gradient magnetic separatorsMagnetic mediaMagnetic separator

The invention discloses a large-particle vertical ring pulsation high-gradient magnetic separator. The large-particle vertical ring pulsation high-gradient magnetic separator comprises a machine frame, wherein magnetic yokes, excitation coils, a swivel, a concentrate bucket, a concentrate collecting tank and a tailing bucket are arranged on the machine frame; the swivel is provided with a magnetic medium pile; the tailing bucket is connected with a pulsation drive mechanism; the magnetic medium pile consists of thin stainless steel plates and medium rods inserted in the stainless steel plates; the high gradient of magnetic fields is ensured by selecting the diameters and the spatial arrangement ways of the medium rods under the condition that 2 to 5mm of material particles can smoothly pass; the outer side wall, the front side wall and the rear side wall of the concentrate bucket are arranged in a manner of inclining to a bottom discharge port, and a discharge pipe connected with the discharge port is arranged in a manner of inclining downwards; and the bottom wall of the concentrate collecting tank and the inclined side wall of the tailing bucket are horizontally provided with material baffle plates. Due to a series of improvement on the conventional magnetic separator, the vertical ring pulsation high-gradient magnetic separator can directly separate 2 to 5mm of large-particle materials and provides reliable technical guarantee for the exploitation and utilization of lean ore resources.

Owner:赣州金环磁选科技装备股份有限公司

Ore dressing combination reagent for rutile and ore dressing method of reagent

The invention provides an ore dressing combination reagent for rutile. The reagent comprises a collecting agent, the collecting agent is phenyl amino acid, a pH value modulation agent, an activating agent, an inhibitor and a foaming agent are further included, and through the technical scheme, the reagent has the beneficial effects that the amino acid rutile collecting agent is adopted, and is poisonless and harmless, green and environment-friendly. The phenyl amino acid is adopted to serve as the collecting agent, the collecting capacity and the selecting capacity of rutile are high, and efficient separation of rutile and gangue mineral in the actual ore flotation can be achieved. The phenyl amino acid is adopted as the collecting agent, in combination with the pH value modulation agent, the activating agent, the inhibitor and the foaming agent, the rutile is subject to ore dressing, the proper matching is adopted, concentrate products with high TiO2 grade and the high recycling rate can be obtained, and the ore dressing effect is far better than that of the prior art.

Owner:CENT SOUTH UNIV

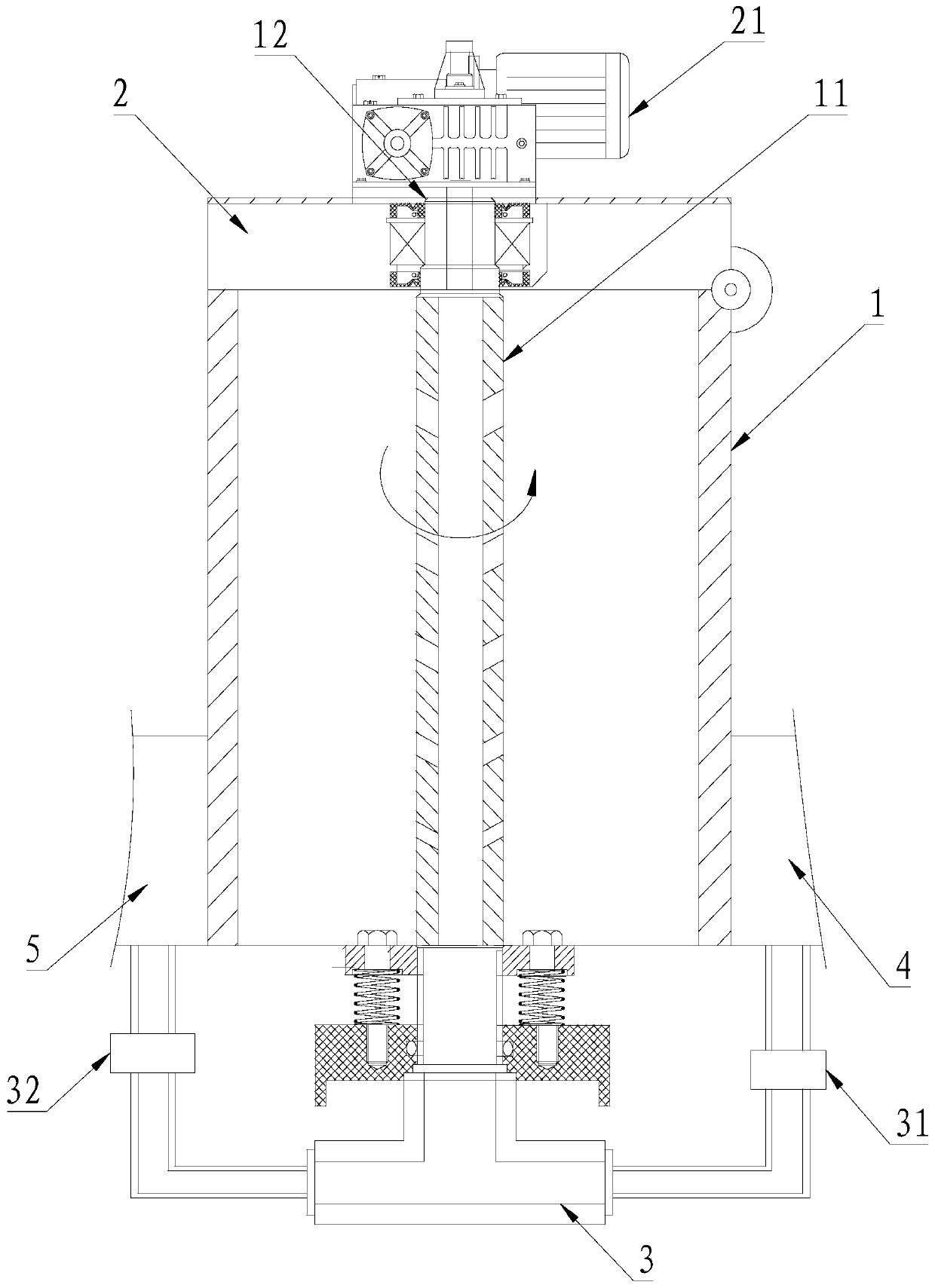

Multifunctional electromagnetic centrifugal continuous concentrating machine

ActiveCN104190532AImprove beneficiation efficiencyLarge amount of processingMagnetic separationWet separationHigh densityMedium density

The invention discloses a multifunctional electromagnetic centrifugal continuous concentrating machine comprising a main frame, an ore collecting barrel on the upper portion of the main frame, a sorting cone inside, an ore feeding tube, a bearing holder on the lower portion of the main frame, a hollow spindle connected to the bearing holder, a transmission wheel, a reverse water flushing pipe, a collecting ring mounted on the hollow spindle, a high-density ore sucking pipe and a medium-density ore sucking pipe and a low-density ore sucking pipe which are mounted on the main frame, weak-magnetic annular material collecting grooves, medium-magnetic annular material collecting grooves, strong-magnetic annular material collecting grooves, a waste collecting annular grooves, 3 to 5 rows of ribs welded to the circumference of the inner wall of the sorting cone, weak, medium and strong magnetic electromagnets mounted on the circumference of the inner wall of the sorting cone, and reverse water flushing holes; the weak-magnetic annular material collecting grooves, the medium-magnetic annular material collecting grooves, the strong-magnetic annular material collecting grooves and the waste collecting annular grooves are mounted on the inner wall of the ore collecting barrel sequentially, and the reverse water flushing holes are adjacent to the electromagnets and are formed in the inner wall of the sorting cone. The multifunctional electromagnetic centrifugal continuous concentrating machine can be applied to magnetic material concentrating and non-magnetic material concentrating, the concentrating efficiency is high, the processing quantity is large, the machine is adaptive to large-scale line production, the machine has the advantages of low power, fine concentrating effect and low cost, energy is saved, and the consumption is reduced.

Owner:刘克俭

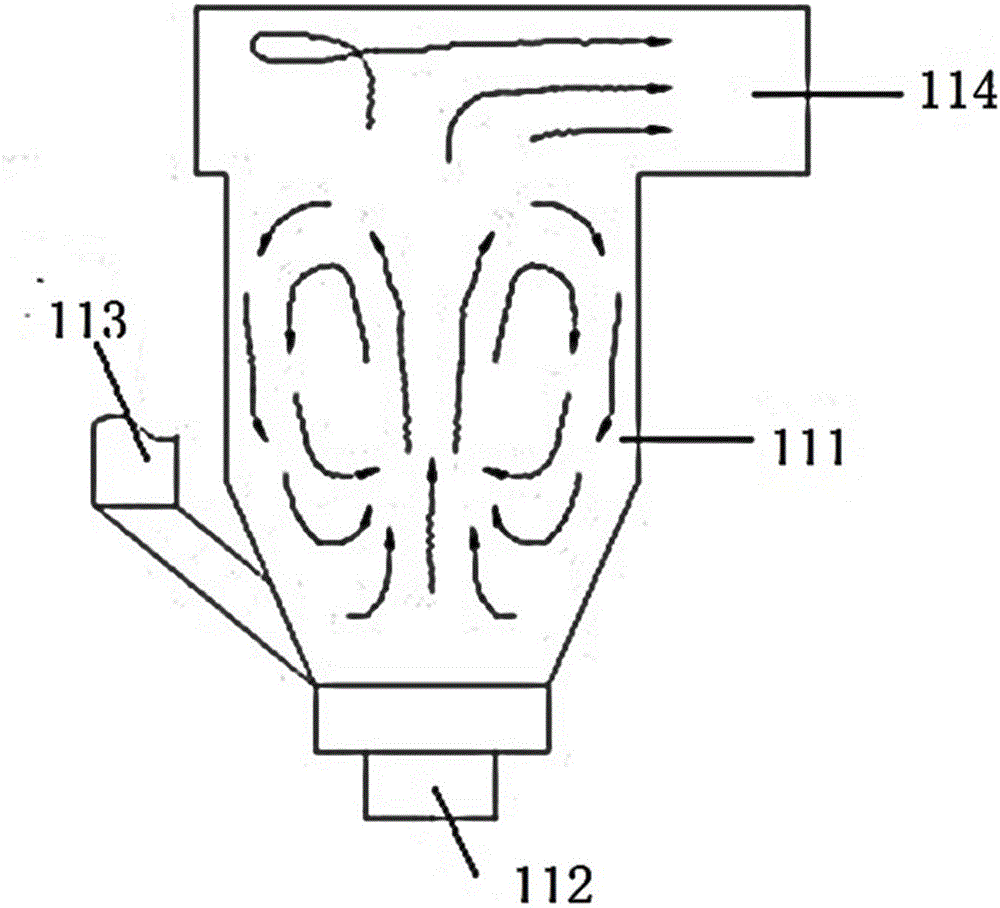

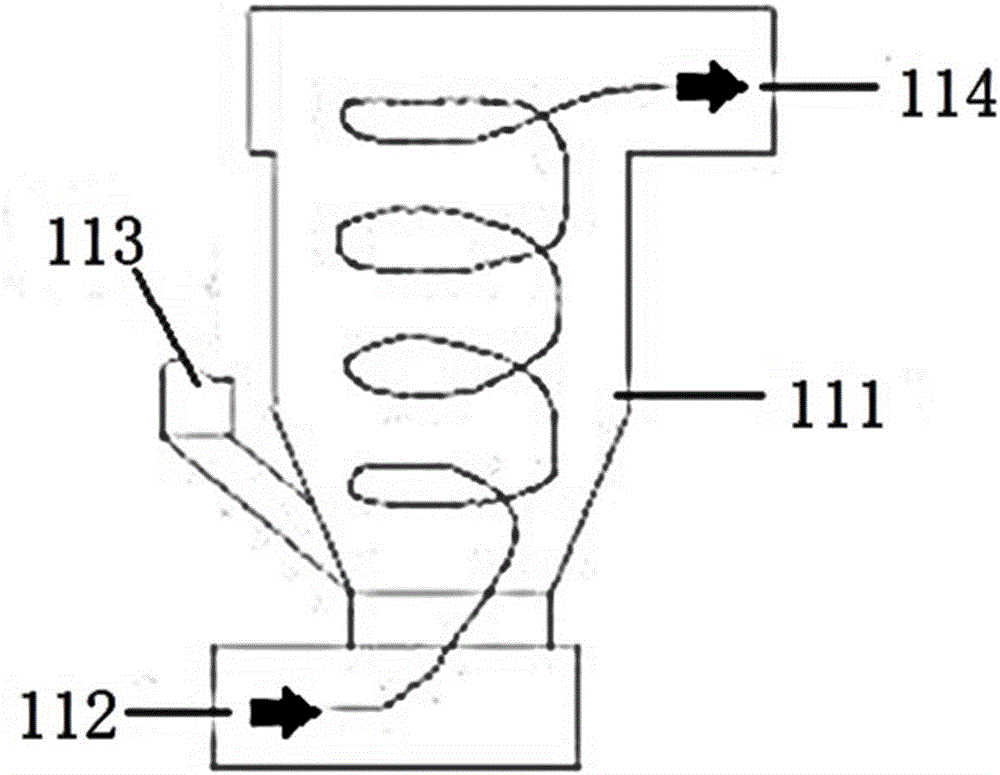

Fluidization roasting separation method of siderite-containing mixed iron ores

The invention discloses a fluidization roasting separation method of siderite-containing mixed iron ores. The fluidization roasting separation method comprises the following steps: carrying out multi-stage fluidization preheating on the siderite-containing mixed iron ores with the particle size of -0.5mm in an oxidizing atmosphere until the temperature of the mixed iron ores is 600-800 DEG C; roasting the preheated materials in a reducing atmosphere under the fluidized state condition, further carrying out fluidization cooling in air until reaching the room temperature, and carrying out ore grinding and magnetic separation, so as to obtain the siderite-containing mixed iron ores. The fluidization roasting separation method is applicable to the separation of multiple siderite-containing mixed ores, high in reaction speed and efficiency, low in energy consumption, good in separation effect and very suitable for being industrially popularized, and side products which are adverse to separation are few.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

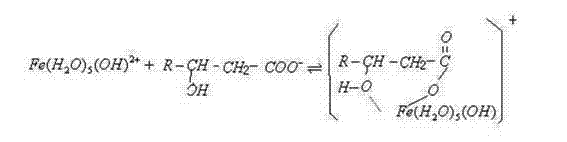

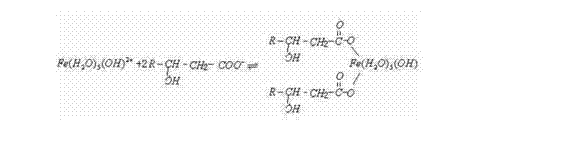

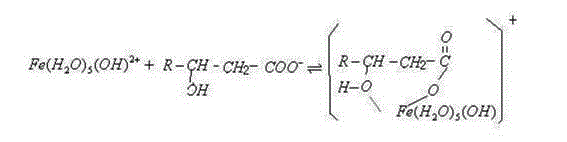

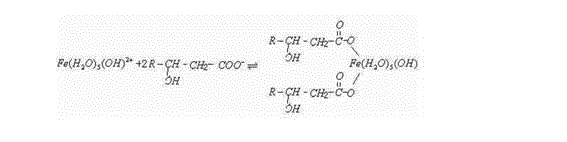

Beta-hydroxy fatty acid collecting agent for positive floatation of iron ore and application thereof

ActiveCN101632961AEnhanced harvesting capacityGood beneficiation effectFlotationImpurityMineral collecting

The invention relates to a beta-hydroxy fatty acid collecting agent for positive floatation of iron ore and application thereof. The beta-hydroxy fatty acid collecting agent is characterized in that the content of the weight percentage of beta-hydroxy fatty acid is over 85 percent of a total collecting agent, and the balance is water and inevitable impurities; the beta-hydroxy fatty acid of the collecting agent mainly comprises thirteen to eighteen carbon atoms; and the weight percent of the beta-hydroxy fatty acid with the thirteen to eighteen carbon atoms is over 95 percent. The beta-hydroxy fatty acid iron mineral collecting agent is a fatty acid class collecting agent capable of forming annular adsorption; and the collecting capacity of the beta-hydroxy fatty acid iron mineral collecting agent is remarkably larger than the adsorption of ore mineral and a common fatty acid class collecting agent carrying out positive anion floatation, thereby obviously increasing the collecting capacity of the collecting agent on the iron mineral.

Owner:ANSTEEL GRP MINING CO LTD

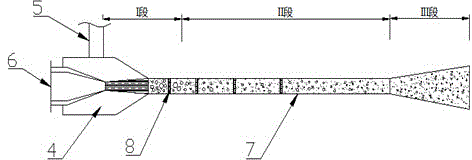

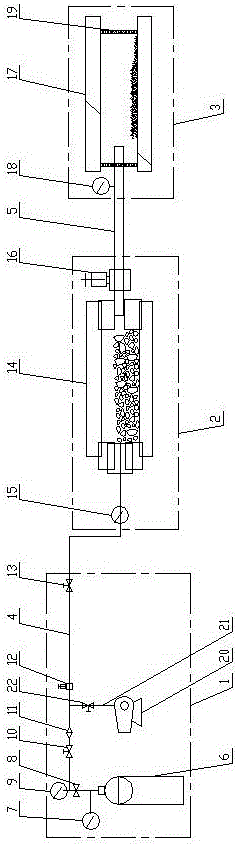

Device and method for crushing ores by pressure-relief gas explosion

ActiveCN105921239AGood dissociationGood beneficiation effectGrain treatmentsEconomic benefitsEngineering

The invention discloses a device for crushing ores by pressure-relief gas explosion. The device comprises a gas injecting system, a pressure-relief crushing system and a crushed ore collecting system, wherein the gas injecting system is connected with a gas inlet of the pressure-relief crushing system through a gas injecting tube; and a discharge hole of the pressure-relief crushing system is connected with a charge hole of the crushed ore collecting system through a pressure relief tube. The invention further discloses an ore crushing method adopting the device for crushing ores by pressure-relief gas explosion. According to the device and the method, special equipment is used to manually generate pressure-relief gas explosion, and the ores are crushed by utilizing high tensile stress generated during pressure relief of gas explosion; the tensile strength of the ores is much lower than compressive strength and shearing strength of the ores, so that the energy consumption for crushing the ores is low and the process links are less, and therefore, great economic benefits are brought to the industries such as ore dressing and metallurgy.

Owner:HENAN POLYTECHNIC UNIV

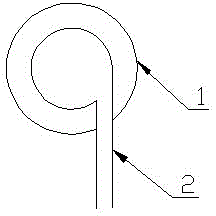

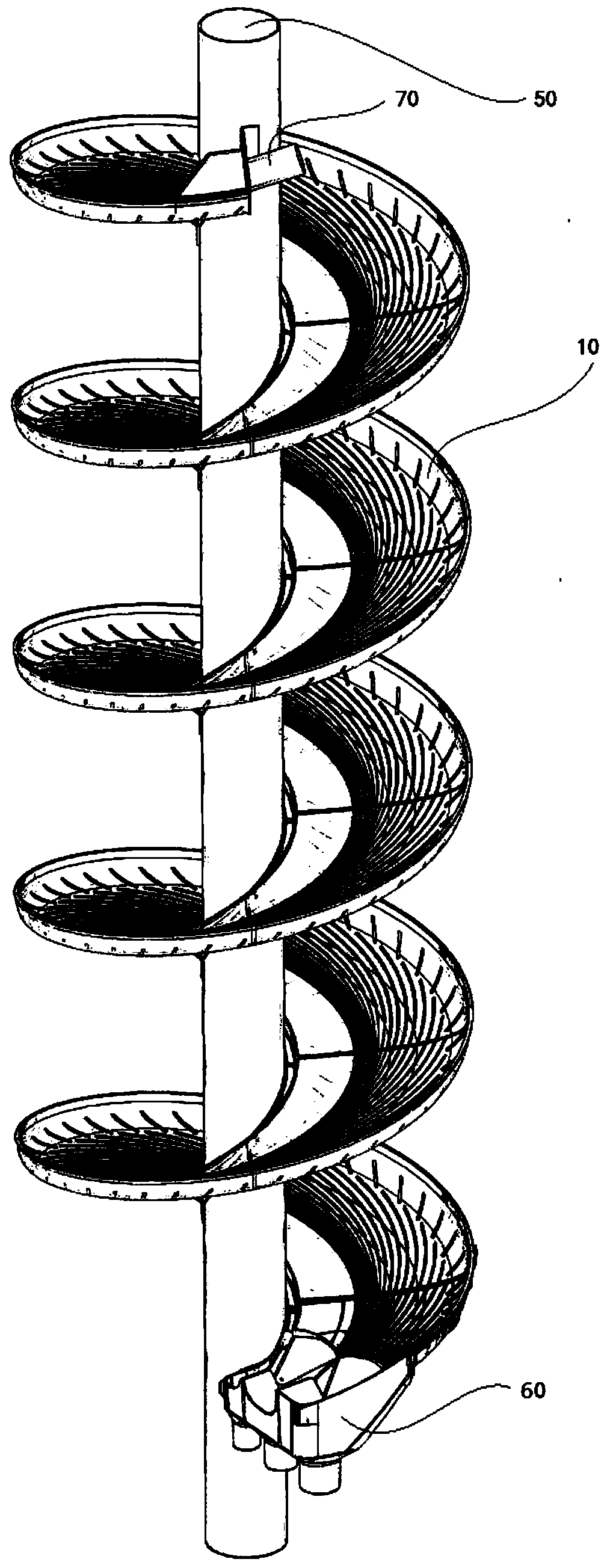

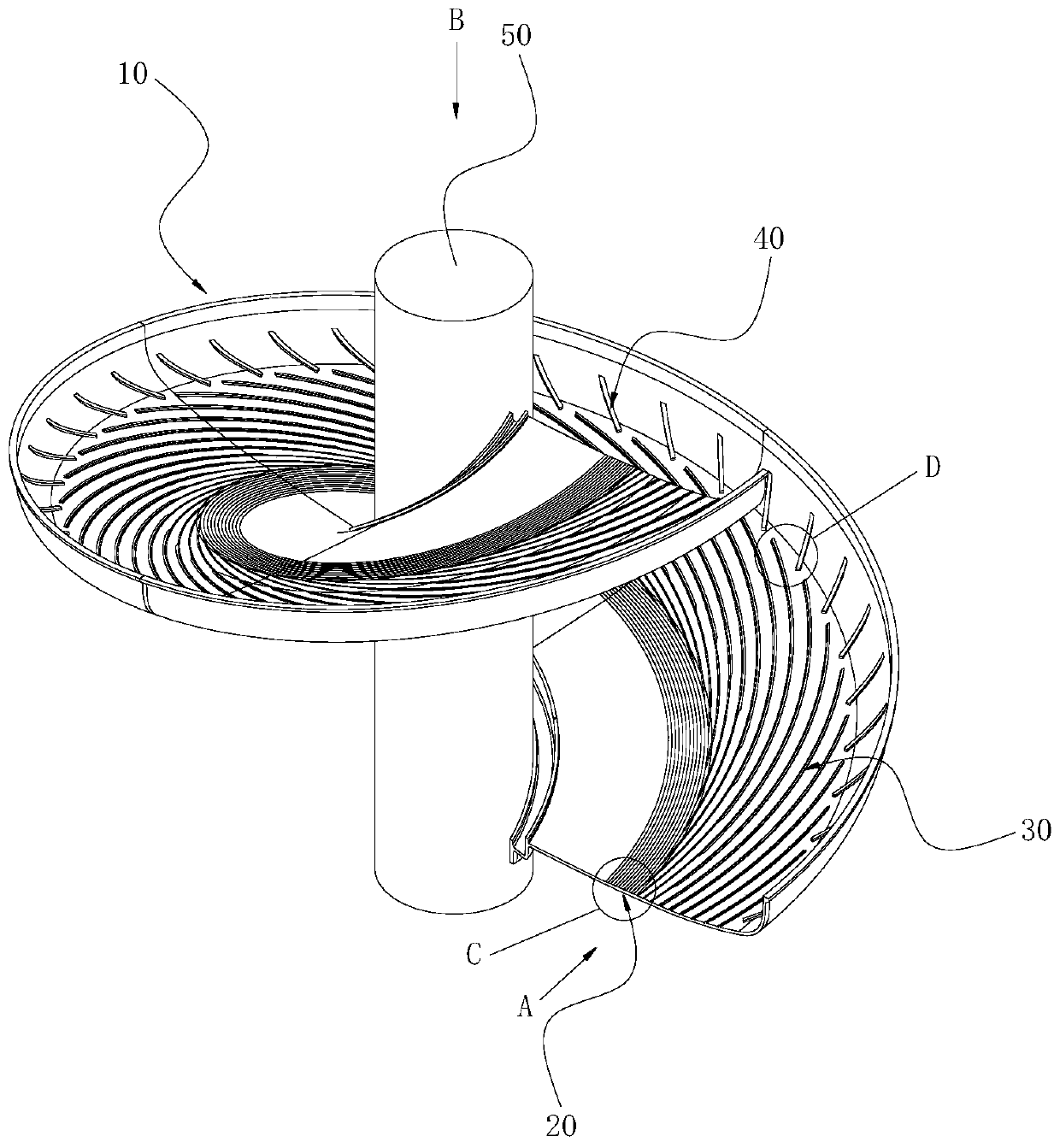

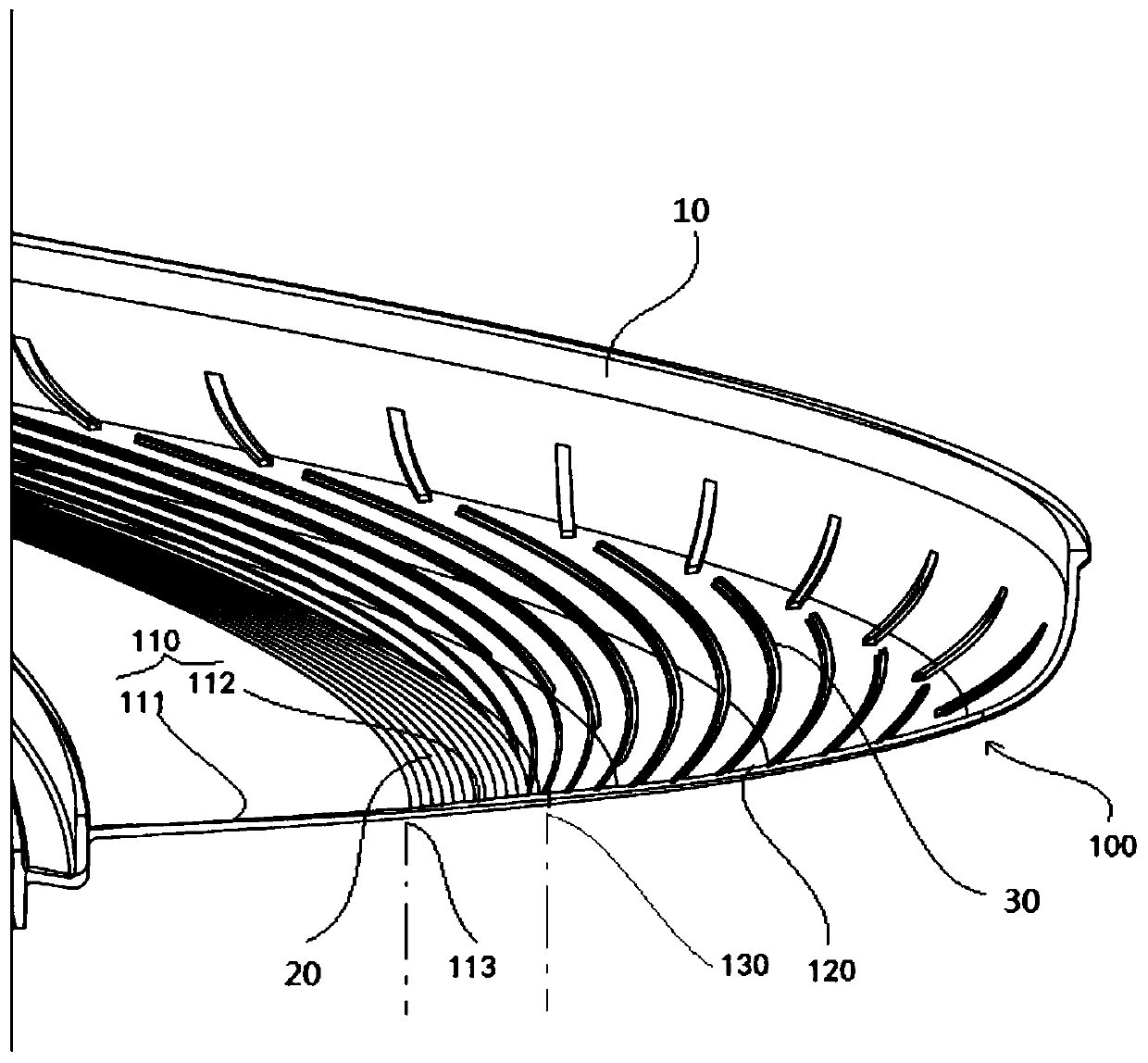

Beneficiation spiral chute

PendingCN109731672AImprove loosenessIncrease hourly throughputWet separationMineral particlesEngineering

The invention relates to a beneficiation spiral chute which comprises a spiral chute body supported to be vertical. A radial transverse section curve of the chute body gradually rises from the inner side of the chute body to the outer side of the chute body. The radial transverse section curve of the chute body is a compound curve. The compound curve comprises a first curve section and a second curve section which are successively arranged from the inner side of the chute body to the outer side of the chute body. The tail end of the first curve section and the head end of the second curve section are connected to a first connecting point. The included angle between a curve tangent line of the head end of the second curve section and the horizontal plane is smaller than that between the curve tangent line of the tail end of the first curve section and the horizontal plane. The beneficiation spiral chute not only can unfold and thin a dune high wall outward to improve the looseness of mineral particles, but also can increase the throughput per hour, so that the beneficiation efficiency and effect are better.

Owner:李春鸥

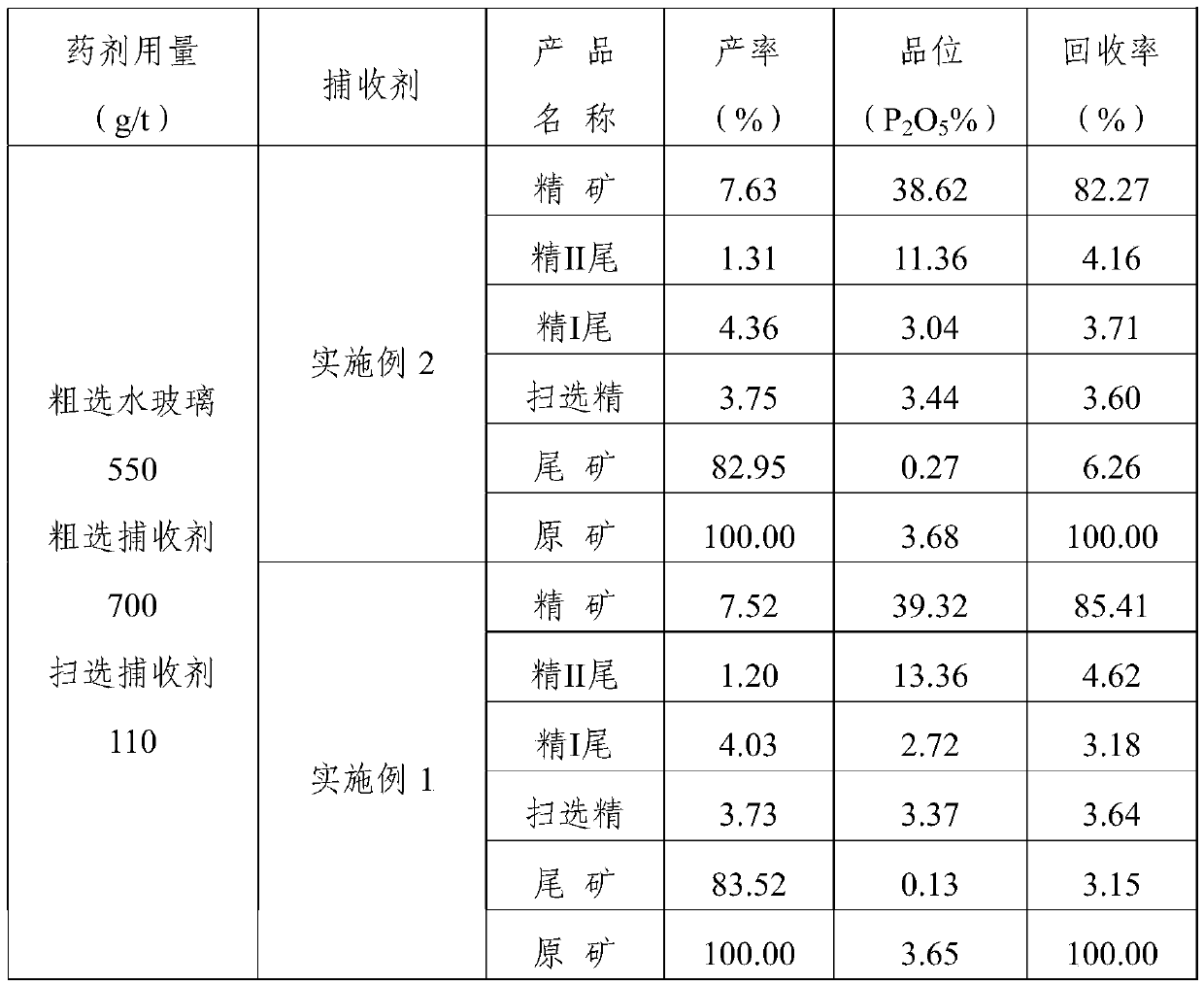

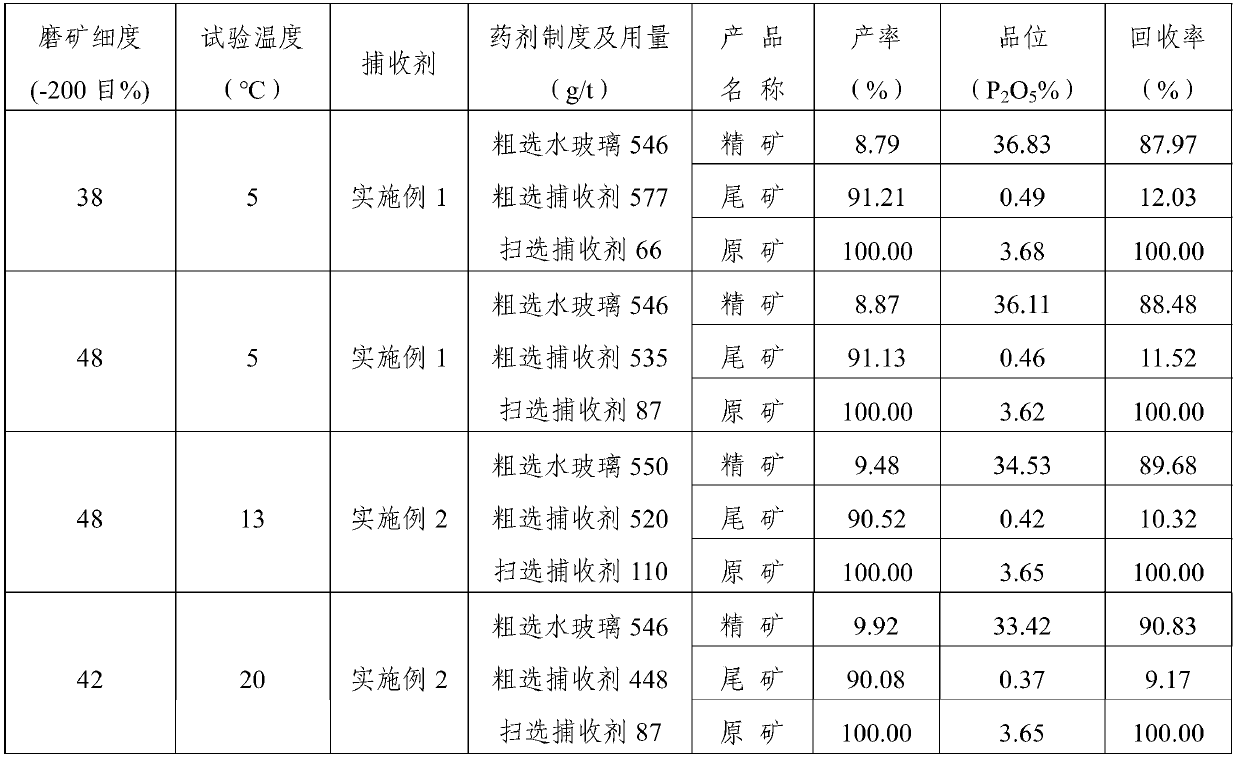

Low-temperature quick-dissolving phosphate ore flotation collector and preparation method thereof

ActiveCN106238216AGood beneficiation effect at low temperatureGood beneficiation effectFlotationHard waterSolubility

The invention relates to a low-temperature quick-dissolving phosphate ore flotation collector and a preparation method thereof. The preparation method comprises the steps that raw materials comprising, by weight, 40-44% of multiple-hydroxy fatty acid, 25-27% of oleic acid, 22-24% of water and 5-13% of AEO3 are added into a reaction kettle and are stirred and mixed at 70-90 DEG C for 20-40 minutes to obtain mixed materials; a caustic soda solution which accounts for 25-35% of the mixed materials is added into the mixed material, wherein the mass concentration of the caustic soda solution is 30%, the reaction temperature is controlled to be 90-100 DEG C, and the reaction is subjected to heat insulation for 100-140 min; and cooling is conducted, and the low-temperature quick-dissolving phosphate ore flotation collector is obtained. The low-temperature quick-dissolving phosphate ore floatation collector has the advantages that the product is quickly dissolved at low temperatures, and a collector solution with the mass concentration being 5% is dissolved within 40 min at the temperature of 40 DEG C; the product low-temperature mineral separation effect is good, a good mineral separation effect can still be achieved at 20 DEG C, and energy consumption is lowered; the product still does not gels at 15-17 DEG C, the equipment fault rate is lowered, and separation concentrator capacity is improved; and the Krafft point of the collector is lowered, the dissolving performance is improved, the collector has high lime soap dispersion, and softening water capability is high.

Owner:HUBEI FORBON NEW MATERIAL CO LTD

Method for comprehensive recycling of sandy kaolin containing mica

ActiveCN106829985AGuaranteed StrippingGuaranteed GranularitySilicaHigh gradient magnetic separatorsGranularityTitanium

The invention discloses a method for comprehensive recycling of sandy kaolin containing mica. The method specifically comprises the following steps of crushing raw ore of sandy kaolin containing mica, wiping, and grading, wherein the matter under a screen is kaolin, and the matter on the screen is ground by a high alumina ball mill, graded by a spiral grader, and screened by a high-frequency vibration screen, so as to obtain quartz sand and mica, thereby guaranteeing the stripping and granularity control of iron, titanium and other impurities in the quartz sand, and creating conditions for subsequent magnetic sorting process; magnetically sorting the kaolin and the quartz sand at two different strengths, so as to fully ensure the separation and effective removal of magnetic impurities in the kaolin and the quartz sand, effectively recycle the kaolin and the quartz sand, obtain a product with high quality and high added value, and greatly increase the comprehensive recycling rate of resources. The method has the advantage that while the high-quality kaolin and quartz sand are obtained, the valuable mica can be recycled, the discharge of tailings is effectively reduced, the comprehensive utilization rate of resources is increased, and the added value of the product is increased.

Owner:赣州金环磁选科技装备股份有限公司

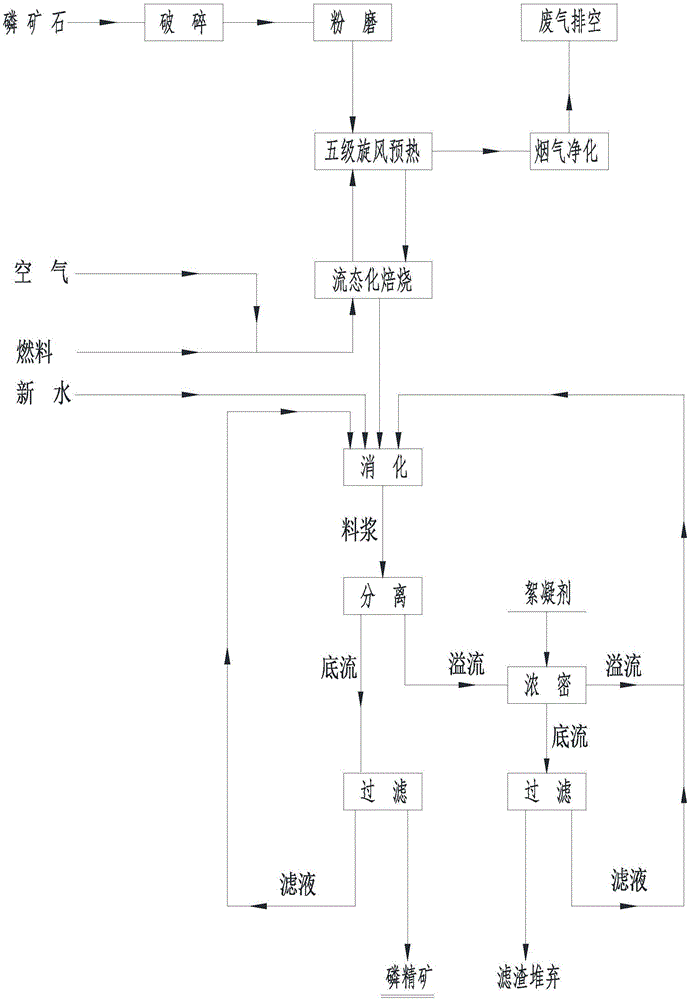

Beneficiation method and system for calcium or calcareous and siliceous phosphorite and application method of beneficiation system

InactiveCN106669962AImprove efficiencyImprove energy savingProcess efficiency improvementWet separationCarbonizationSizing

The invention discloses a beneficiation method for extracting phosphorus, reducing calcium and recovering magnesium for calcareous or calcareous and siliceous phosphorite containing high magnesium or low magnesium. The beneficiation method includes the steps that the phosphorite is subjected to multi-stage heat treatment and is then subjected to fluidized roasting, water is added to obtained phosphorite roasting powder for stirring, and sizing is obtained after digestive treatment; the sizing is separated to obtain underflow and overflow, and phosphorus concentrates and filter liquid are obtained after the underflow is filtered; and when the phosphorite contains high magnesium, the filter liquid is merged with the overflow, then carbonization pyrolysis treatment is conducted, and magnesium is recovered. The invention further discloses a beneficiation system which comprises a fluidized roasting system, a tail gas purifying system and a digestion separation system. The fluidized roasting system comprises a fluidized roasting decomposing furnace, a feeding assembly, a suspension preheating assembly, a gas supplying assembly and a combustion assembly; and the beneficiation system further comprises a carbonization pyrolysis system when being used for the high-magnesium phosphorite. The beneficiation system can be adopted for conducting treatment such as suspension preheating, fluidized roasting decomposing, digestion separation and carbonization pyrolysis. The beneficiation method and the beneficiation system have the beneficial effects of being high in efficiency, environment-friendly, capable of saving energy, high in valuable metal recovery rate and the like.

Owner:SICHUAN JIUCHANG SCI & TECH

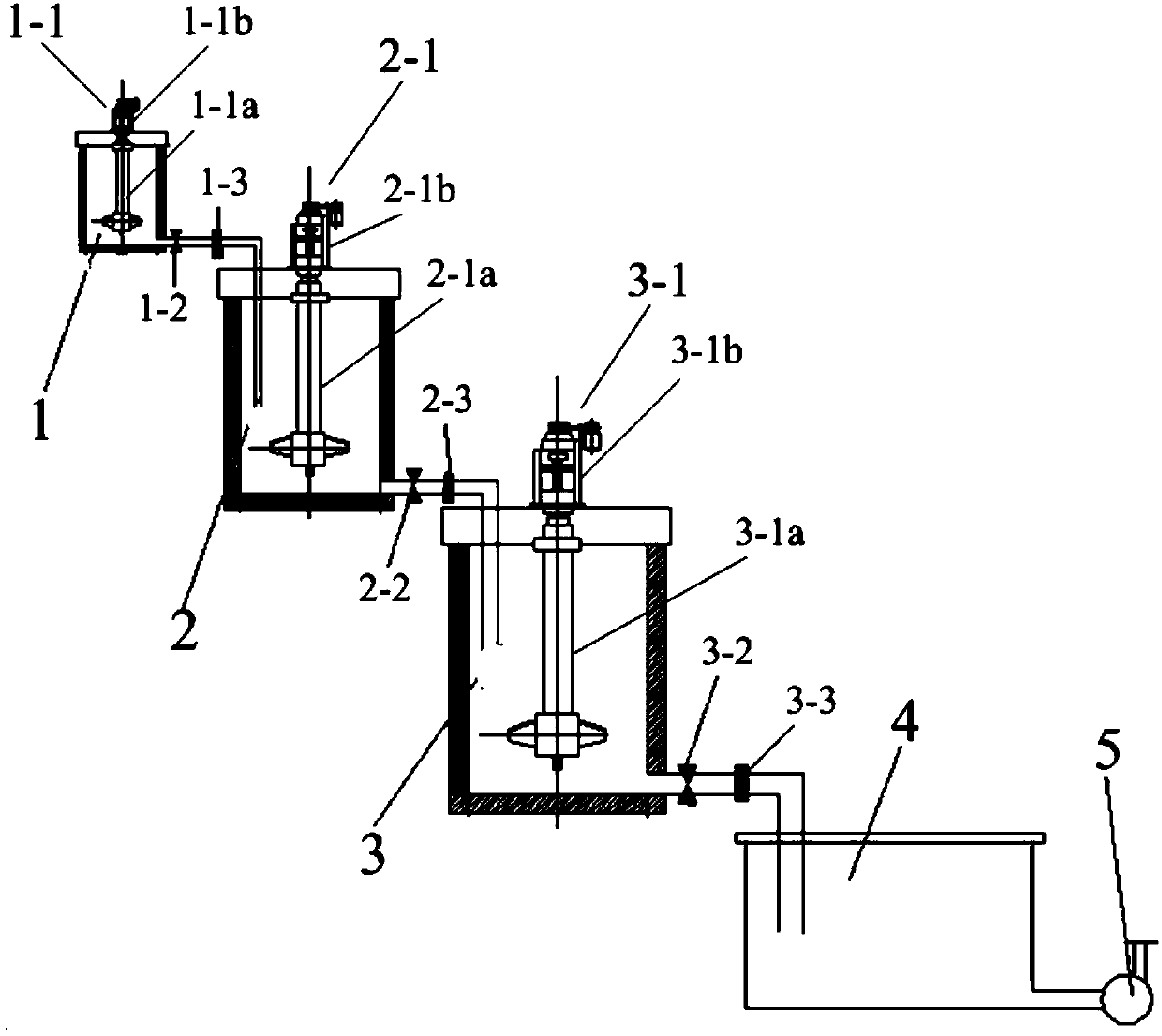

Preparation device of floating agent

ActiveCN107551942AReduce particulate matterFull flowRotary stirring mixersMixture aftertreatmentDrug reservoirParticulates

The invention provides a preparation device of a floating agent. The preparation device comprises a first stirring groove, a second stirring groove, a third stirring groove and an agent collecting pool in sequential series connection, wherein the first stirring groove, the second stirring groove, the third stirring groove and the agent collecting groove are in sequential step arrangement, so thatthe floating agent can sequentially and automatically flow to the second stirring groove, the third stirring groove and the agent collecting pool from the first stirring groove through the self gravity. The provided assembly device comprises three stirring grooves; water can be respectively added into each stirring groove for dilution stirring; the stirring effect of the pasty agent is improved, so that the floating agent is more uniform; particles are fewer; in addition, the three stirring grooves and the agent collecting pools are in step arrangement, so that the agent automatically flows tothe subsequent medication device, the agent of each stirring groove can sufficiently flow out; the agent utilization rate is improved; the simple and convenient agent transmission mode is also provided.

Owner:PANGANG GRP MINING

Large-particle vertical ring pulsation high-gradient magnetic separator

ActiveCN102614983BHigh enrichment ratioMeet the requirements of the sorting channelHigh gradient magnetic separatorsMagnetic mediaMagnetic separator

The invention discloses a large-particle vertical ring pulsation high-gradient magnetic separator. The large-particle vertical ring pulsation high-gradient magnetic separator comprises a machine frame, wherein magnetic yokes, excitation coils, a swivel, a concentrate bucket, a concentrate collecting tank and a tailing bucket are arranged on the machine frame; the swivel is provided with a magnetic medium pile; the tailing bucket is connected with a pulsation drive mechanism; the magnetic medium pile consists of thin stainless steel plates and medium rods inserted in the stainless steel plates; the high gradient of magnetic fields is ensured by selecting the diameters and the spatial arrangement ways of the medium rods under the condition that 2 to 5mm of material particles can smoothly pass; the outer side wall, the front side wall and the rear side wall of the concentrate bucket are arranged in a manner of inclining to a bottom discharge port, and a discharge pipe connected with the discharge port is arranged in a manner of inclining downwards; and the bottom wall of the concentrate collecting tank and the inclined side wall of the tailing bucket are horizontally provided with material baffle plates. Due to a series of improvement on the conventional magnetic separator, the vertical ring pulsation high-gradient magnetic separator can directly separate 2 to 5mm of large-particle materials and provides reliable technical guarantee for the exploitation and utilization of lean ore resources.

Owner:赣州金环磁选科技装备股份有限公司

Apatite low-temperature flotation collector and preparation method thereof

The invention relates to an apatite low-temperature flotation collector and a preparation method thereof. The apatite low-temperature flotation collector comprises the following components in parts byweight: 35-55 parts of oxidized paraffin soap, 20-40 parts of soybean oil fatty acid soap and 20-30 parts of sodium fatty acid methyl ester sulfonate. The apatite low-temperature flotation collectordisclosed by the invention can realize effective flotation under the low-temperature condition of 5 DEG C. The apatite low-temperature flotation collector has good biodegradability, and can keep the COD content (less than or equal to 50 mg / L) in flotation tailing water at a low level.

Owner:中化地质矿山总局地质研究院

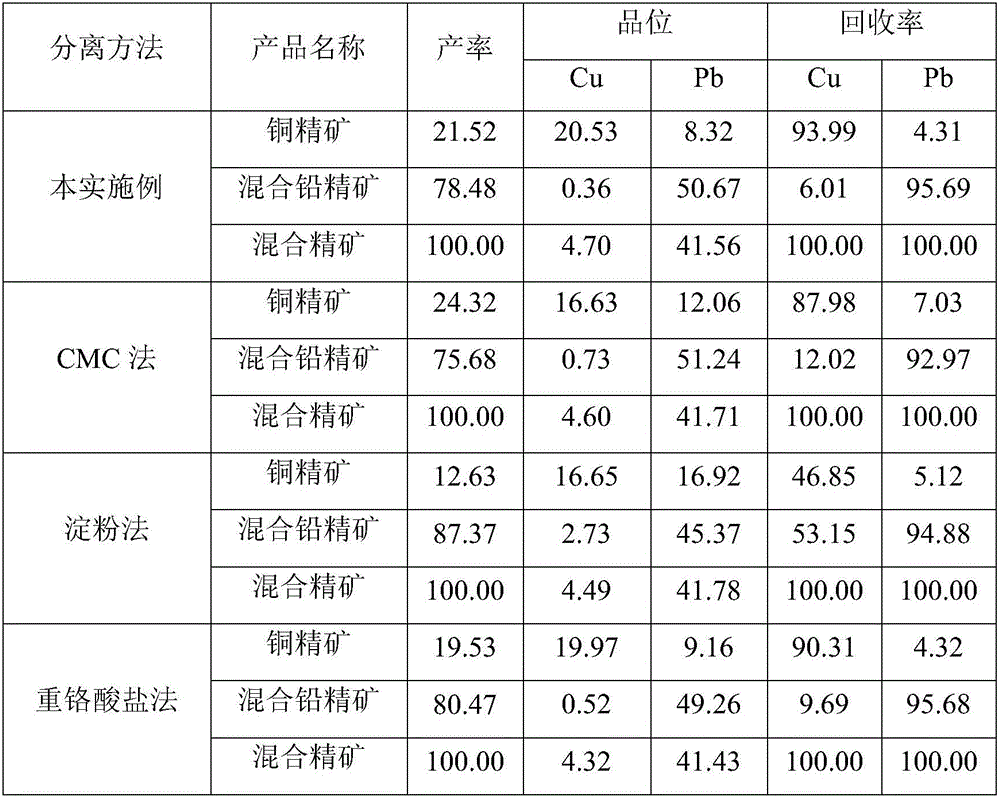

Separation method for tennantite and galena

ActiveCN105880007AStable in natureEfficient separationFlotationWet separationChemical agentTennantite

The invention discloses a separation method for tennantite and galena. The method includes the following steps that firstly, inflation and regrinding are conducted; secondly, lead concentrates A are obtained through screening and classifying; thirdly, chemical agent adding and size mixing are conducted; and fourthly, fast flotation separation is conducted so that lead concentrates B and tennantite concentrates can be obtained through floatation. By means of the method, selective ore grinding of the tennantite and the galena is achieved through inflation and regrinding, acid LR serves as the inhibitor of the galena, a beneficiation effect is good, high efficiency and environment friendliness are achieved, and the tennantite and the galena can be effectively separated.

Owner:HUNAN RES INST FOR NONFERROUS METALS

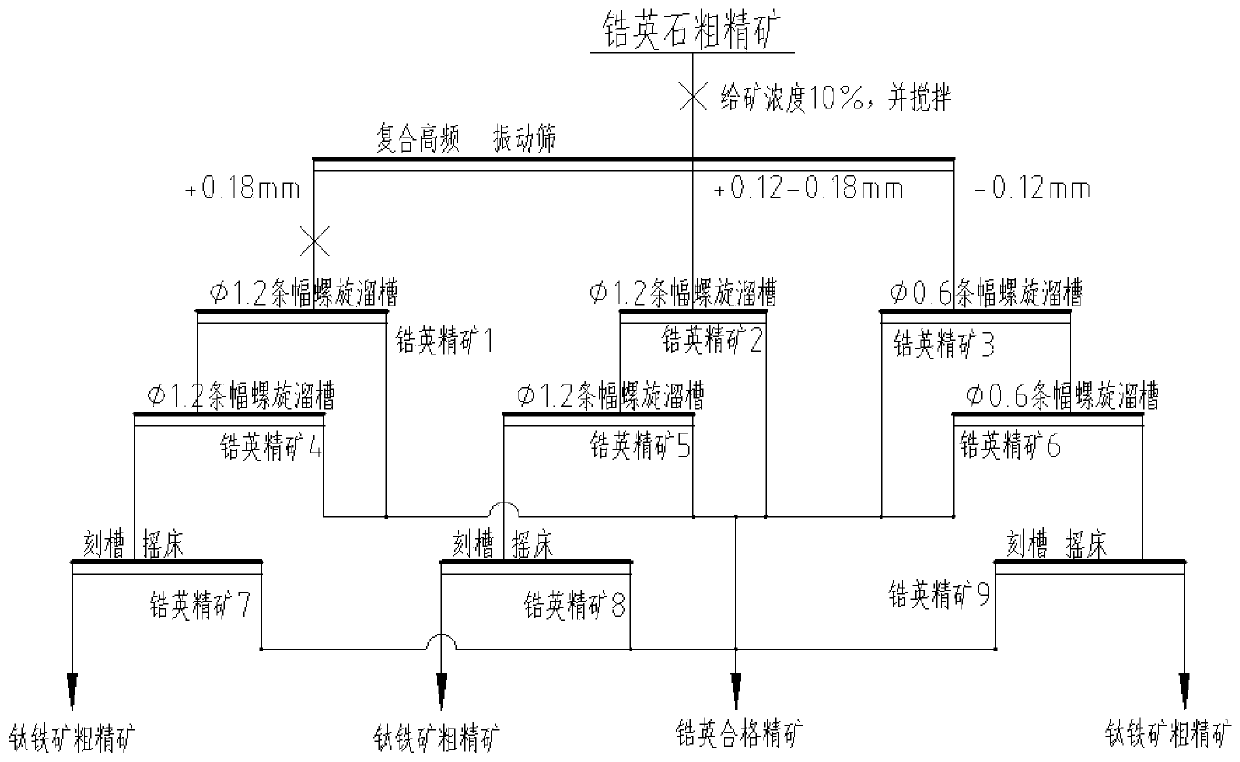

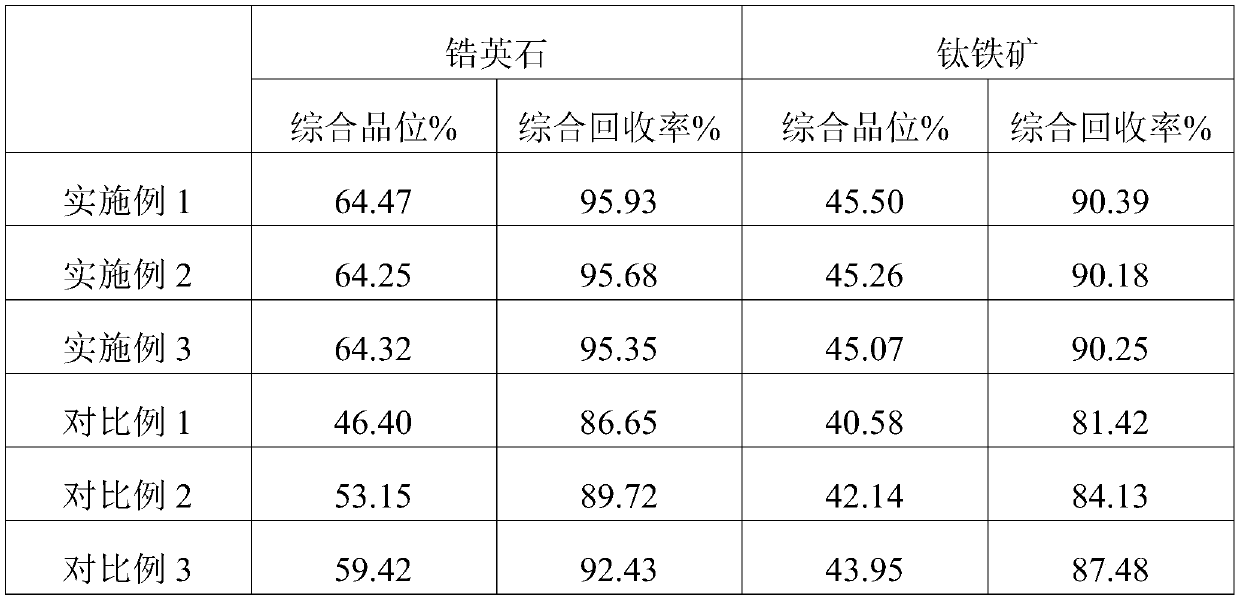

High-frequency vibrating screen and spiral chute combined mineral separation process for separating zircon-titanium ore

The invention provides a high-frequency vibrating screen and spiral chute combined mineral separation process for separating zircon-titanium ore. The mineral separation process comprises the steps ofconfiguring the concentration of a zircon rough concentrate raw material to be 5-10%, using a high-frequency vibrating screen to sieve the zircon rough concentrate raw material into three particle grades, namely +0.18 mm, +0.12 mm-0.18 mm and -0.12 mm, and obtaining ores of three grades; respectively feeding the ores of the three grades into different spiral chutes for roughing to obtain zircon concentrates 1-3 and ilmenite rough concentrates 1-3 respectively; respectively feeding the ilmenite rough concentrates 1-3 into the different spiral chutes again for spiral chute scavenging, and obtaining zircon concentrates 4-6 and ilmenite rough concentrates 4-6 respectively; finally, respectively feeding the ilmenite rough concentrates 4-6 into a shaking table for shaking table scavenging, and obtaining zircon concentrates 7-9 and ilmenite rough concentrates 7-9; combining the zircon concentrates 1-9 to obtain a zircon product; and combining the ilmenite rough concentrates 7-9 to obtain an ilmenite product. By means of the high-frequency vibrating screen and spiral chute combined mineral separation process for separating the zircon-titanium ore, the obtained zircon and ilmenite are highin grade and recovery rate.

Owner:JIANGXI UNIV OF SCI & TECH +3

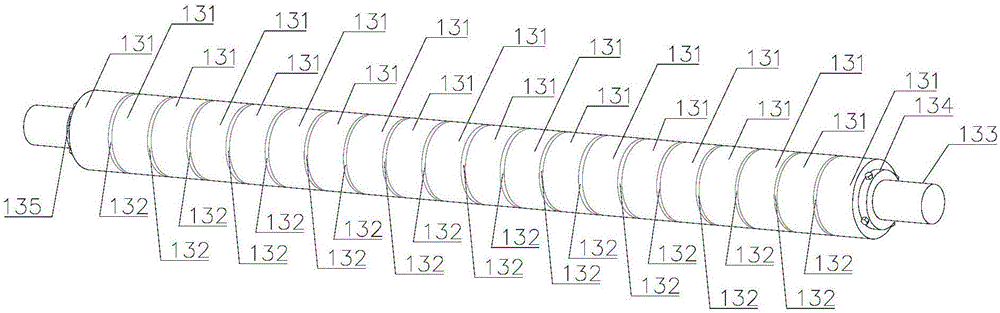

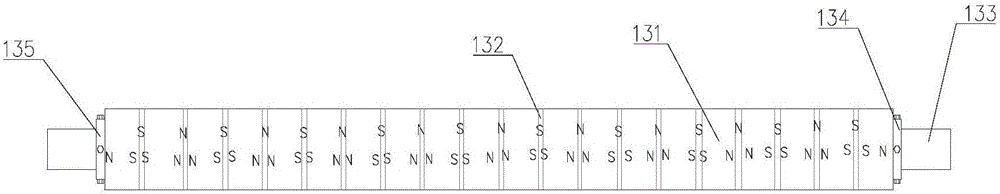

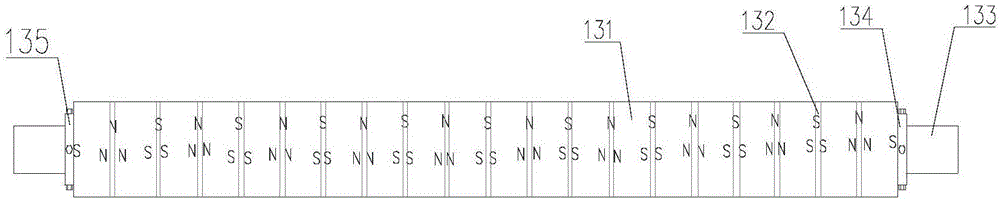

Magnetic roller and magnetic separator

InactiveCN106040427ALarge scanning areaGood beneficiation effectMagnetic separationMagnetic separatorEngineering

The invention belongs to the technical field of mineral processing equipment, particularly relates to a magnetic roller and a magnetic separator. The magnetic separator comprises a conveying mechanism, a feeding hopper and a plurality of magnetic rollers; the conveying mechanism comprises a machine frame and a conveyor belt. The feeding hopper and the magnetic rollers are all arranged on the machine frame; the conveyor belt is arranged on the upper surfaces of the magnetic rollers and is tightly adhered to the magnetic rollers; the magnetic rollers are arranged on the machine frame at intervals, wherein the material outlet of the feeding hopper is positioned above the conveyor belt. The commonly used magnetic separator at present generally has the defects of insufficient magnetic field, quick belt wear, high operating cost, low ore dressing efficiency and the like. The magnetic separator effectively overcomes above defects, improves the ore dressing efficiency, and is high in practicability and convenient to popularize and apply.

Owner:兰庆松

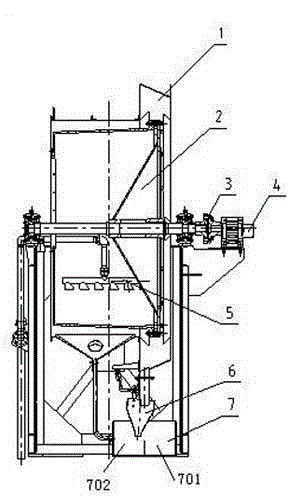

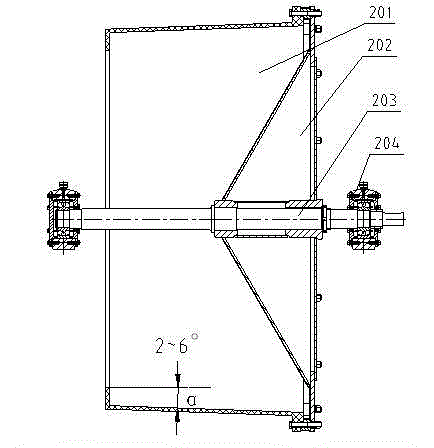

Horizontal novel centrifugal concentrator

ActiveCN103394405BWith braking functionEliminate slippageCentrifugesWet separationCouplingEngineering

A horizontal novel centrifugal concentrator comprises a frame (8), an outer cover (1), a rotating drum (2), a variable frequency reducing motor (4) connected with the rotating shaft of the rotating drum through a coupler (3), a flushing system (5) arranged in the outer cover and connected with an external water supply system, an ore distributor system (6) below the outer cover, an ore receiving bucket (7) below the outer cover, a feeding system (9) arranged outside the outer cover and communicated with the rotating drum, wherein the rotating drum comprises the rotating shaft, a horn-shaped rotating disc and a circular truncated cone-shaped rotary drum; the rotating shaft is sleeved with the rotating disc; the rotating disc is sleeved with the rotary drum; the large end surface of the rotary drum is connected with the outer edge of the rotating disc; the tilt angle of the opening in the internal face of the rotary drum is 2-6 degrees; the flushing system comprises a water inlet pipe with a pneumatic ball valve and flushing nozzles in the rotary drum; the ore distributor system comprises a cylinder, an oscillating shaft, a connecting arm and an ore distribution hopper; one end of the connecting arm is connected with the push rod of the cylinder and the other end of the connecting arm is connected with the oscillating shaft; a lifting arm at the top of the ore distribution hopper is connected with the oscillating shaft; the feeding system comprises an ore distribution box and at least two feeding nozzles; a pneumatic knife gate valve is arranged at the ore inlet of the ore distribution box; the feeding nozzles are mounted at the tail ends of feeding pipes of the ore distribution box and face to the internal face of the rotary drum. The horizontal type novel centrifugal concentrator has a simple structure and a good concentration effect, and is easy to control and maintain.

Owner:云南锡业机械制造有限责任公司

Combined use method for iron ore anion reverse floatation agent

The iron core is fine-ground to attain the basis monomer dissociation, and made into ore slurry with proper concentration, then regulating agent NaOH is added and stirred, and the inhibitor saponified corn starch is added and stirred, and then the activating agent CaO is added and stirred, and finally collecting agent is added, fully stirred so as to obtain the invented product. It is characterized by that the saponified industrial oleic acid in adopted as said invented floatation collecting agent.

Owner:ANSTEEL GRP MINING CO LTD

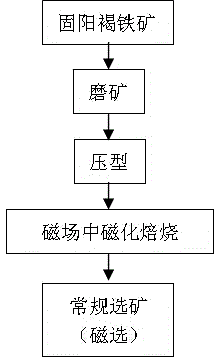

Method for converting limonite into magnetic iron mineral

The invention belongs to the field of comprehensive utilization of iron mineral, and particularly relates to a method for converting limonite into magnetic iron mineral. According to the method, the limonite is used as raw materials, mineral grinding, magnetizing roasting in a magnetic field and profiling are carried out, and the samples with 60-80% of limonite with particle size of 200 meshes are pressed into 10 mm x 10 mm columns through a forming press; the columns are put into a vacuumized magnetic field heat treatment device with circulating water pumped in to carry out magnetizing roasting, and drying, magnetizing and desulfurizing are complete in the process at the same time. The magnetic field intensity is 0.9-2T, the calcination temperature is 800-950 DEG C, heater preservation is carried out for 5 min after the preset temperature is reached, the mineral is modified as magnetic mineral, mineral samples are cooled through circulation water and ground, and magnetic separation normal mineral dressing is carried out. According to the method, no reducing agent is added, the magnetizing roasting process is carried out under an external magnetic field, conversion of magnetic mineral can be achieved better in a shorter time, and caking cannot generated in the roasting process. The technological process of the method is simple and easy to operate.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Fluidized Roasting Separation Method for Mixed Iron Ore Containing Siderite

The invention discloses a fluidized roasting and sorting method for mixed iron ore containing siderite, which is to preheat the mixed iron ore containing siderite with a particle size of 0.5 mm in an oxidizing atmosphere in a multi-stage fluidized state, Preheat until the mixed iron ore temperature is 600-800°C; then under fluidized conditions, roast the preheated material in a reducing atmosphere, and then place it in the air for fluidized cooling to room temperature, and then grind ore and magnetically separate Vested. The method of the present invention is applicable to the sorting of various siderite-containing mixed ores, with fast reaction speed and high efficiency, less by-products that are not conducive to sorting in the process, low energy consumption, good sorting effect, and is very suitable for for industrialization.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

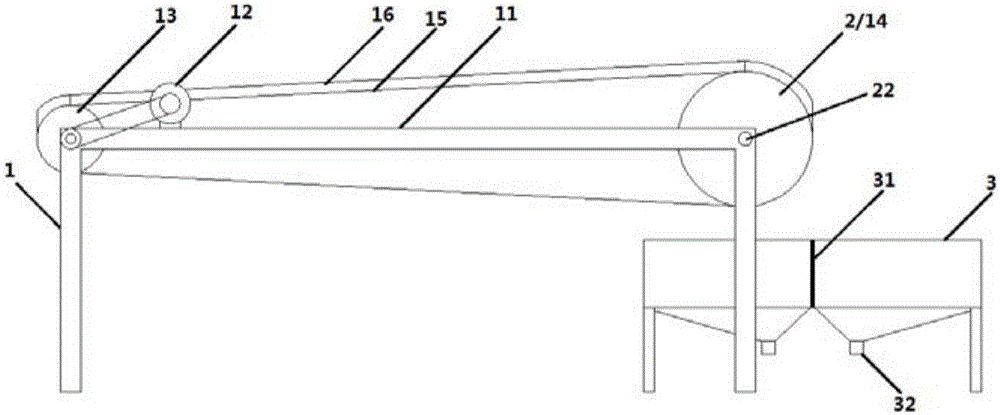

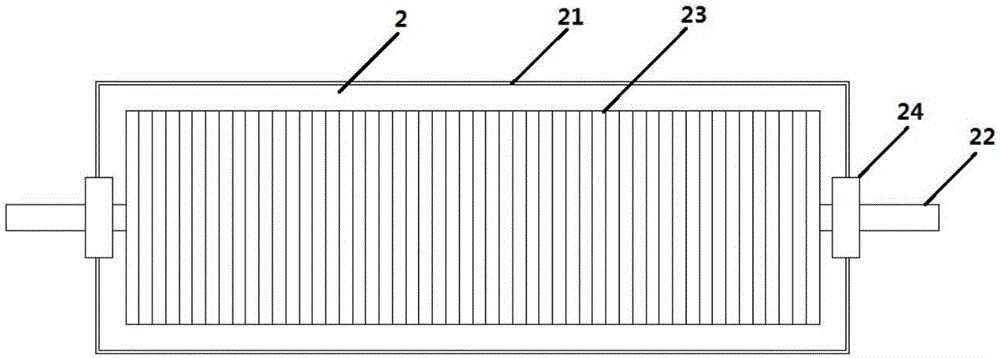

Belt conveyor type magnetic concentrator

InactiveCN106694219ASimple structureGood beneficiation effectMagnetic separationBeneficiationMagnetic separation

The invention discloses a belt conveyor type magnetic concentrator. The belt conveyor type magnetic concentrator comprises a belt conveyor, a magnetic separation barrel and a hopper. The belt conveyor comprises a rack, a motor, a drive roller, a driven roller and a conveying belt. The magnetic separation barrel serves as the driven roller of the belt conveyor to be installed and fixed to one end of the rack through a bearing, and the drive roller is installed and fixed to the other end of the rack through a bearing. The conveying belt wraps the two rollers. The motor is arranged on the rack. An output shaft of the motor is connected with the drive roller and drives the drive roller to rotate. The drive roller drives the driven roller to rotate through the conveying belt. The hopper is arranged below the magnetic separation barrel. A partition plate is arranged in the hopper and is located in the direction the same as the direction of a shaft of the magnetic separation barrel. According to the belt conveyor type magnetic concentrator, a material scraping device is not needed, the structure is simple, ore and the magnetic separation barrel are separated through the belt, and the belt conveyor type magnetic concentrator is convenient to use, simple, efficient, good in beneficiation effect and low in manufacturing cost and using cost.

Owner:方松

Flotation device

The invention relates to the technical field of mineral processing, in particular to a flotation device. The flotation device includes a cylindrical vertical flotation cylinder, and an axis of the vertical flotation cylinder is perpendicular to the horizontal plane; the vertical flotation cylinder is internally hollow, an opening is formed in one end face of the vertical flotation cylinder, and the opening is provided with a corresponding sealed box cover; the vertical flotation cylinder is provided with a rotating shaft along the axis, a motor is arranged at the top of the sealed box cover, one end of the rotating shaft penetrates through the sealed box cover and is connected with an output shaft of the motor; the rotating shaft is internally hollow, and an opening is formed in the otherend of the rotating shaft. The flotation device is in ingenious in structure, manpower and flotation steps are reduced, by means of simultaneous injection of agents and gases into the vertical flotation cylinder, the mixing degree of a liquid medicine and a mineral aggregate solution is increased, and thus the mineral processing effect is improved.

Owner:福建省大田县上丰矿业有限公司

Low-grade iron ore flotation collector

ActiveCN102259060AGood beneficiation effectIncreased job recoveryFlotationLower gradeMineral flotation

The invention relates to a low-grade iron mineral flotation collecting agent, which consists of alpha hydroxyl-fatty acids and beta hydroxyl-fatty acids, namely 14 to 16 weight percent of total components of alpha hydroxyl-below-dodecyl carbon chain alpha hydroxyl-fatty acid, alpha hydroxyl-dodecyl fatty acid and alpha hydroxyl-tridecyl fatty acid, 4 to 6 weight percent of total components of beta hydroxyl-below-dodecyl fatty acid, beta hydroxyl-dodecyl fatty acid and beta hydroxyl-tridecyl fatty acid, 14 to 16 weight percent of total components of alpha hydroxyl-heptadecyl fatty acid, alpha hydroxyl-octadecyl fatty acid and over-octadecyl carbon chain alpha hydroxyl-fatty acid, 4 to 6 weight percent of total components of beta hydroxyl-heptadecyl fatty acid, beta hydroxyl-octadecyl fattyacid and over-octadecyl carbon chain beta carbon chain hydroxyl-fatty acid, 39 to 41 weight percent of total components of alpha hydroxyl-tetradecyl fatty acid, alpha hydroxyl-pentadecyl fatty acid and alpha hydroxyl-hexadecyl fatty acid, and 19 to 21 weight percent of total components of beta hydroxyl-tetradecyl fatty acid, beta hydroxyl-pentadecyl fatty acid and beta hydroxyl-hexadecyl fatty acid. By the low-grade iron mineral flotation collecting agent, technical indexes such as over 66.0 percent of concentrate grade and over 82 percent of operation recovery rate can be obtained, and the operation recovery rate can be improved by 10 to 14 percent.

Owner:ANSTEEL GRP MINING CO LTD

Low-grade iron mineral flotation collecting agent

ActiveCN102259060BGood beneficiation effectIncreased job recoveryFlotationCarbon chainMedicinal chemistry

The invention relates to a low-grade iron mineral flotation collecting agent, which consists of alpha hydroxyl-fatty acids and beta hydroxyl-fatty acids, namely 14 to 16 weight percent of total components of alpha hydroxyl-below-dodecyl carbon chain alpha hydroxyl-fatty acid, alpha hydroxyl-dodecyl fatty acid and alpha hydroxyl-tridecyl fatty acid, 4 to 6 weight percent of total components of beta hydroxyl-below-dodecyl fatty acid, beta hydroxyl-dodecyl fatty acid and beta hydroxyl-tridecyl fatty acid, 14 to 16 weight percent of total components of alpha hydroxyl-heptadecyl fatty acid, alpha hydroxyl-octadecyl fatty acid and over-octadecyl carbon chain alpha hydroxyl-fatty acid, 4 to 6 weight percent of total components of beta hydroxyl-heptadecyl fatty acid, beta hydroxyl-octadecyl fattyacid and over-octadecyl carbon chain beta carbon chain hydroxyl-fatty acid, 39 to 41 weight percent of total components of alpha hydroxyl-tetradecyl fatty acid, alpha hydroxyl-pentadecyl fatty acid and alpha hydroxyl-hexadecyl fatty acid, and 19 to 21 weight percent of total components of beta hydroxyl-tetradecyl fatty acid, beta hydroxyl-pentadecyl fatty acid and beta hydroxyl-hexadecyl fatty acid. By the low-grade iron mineral flotation collecting agent, technical indexes such as over 66.0 percent of concentrate grade and over 82 percent of operation recovery rate can be obtained, and the operation recovery rate can be improved by 10 to 14 percent.

Owner:ANSTEEL GRP MINING CO LTD

A method for comprehensive recovery of mica-containing sandy kaolin

ActiveCN106829985BGuaranteed GranularityGuaranteed separation effectSilicaHigh gradient magnetic separatorsGranularityTitanium

The invention discloses a method for comprehensive recycling of sandy kaolin containing mica. The method specifically comprises the following steps of crushing raw ore of sandy kaolin containing mica, wiping, and grading, wherein the matter under a screen is kaolin, and the matter on the screen is ground by a high alumina ball mill, graded by a spiral grader, and screened by a high-frequency vibration screen, so as to obtain quartz sand and mica, thereby guaranteeing the stripping and granularity control of iron, titanium and other impurities in the quartz sand, and creating conditions for subsequent magnetic sorting process; magnetically sorting the kaolin and the quartz sand at two different strengths, so as to fully ensure the separation and effective removal of magnetic impurities in the kaolin and the quartz sand, effectively recycle the kaolin and the quartz sand, obtain a product with high quality and high added value, and greatly increase the comprehensive recycling rate of resources. The method has the advantage that while the high-quality kaolin and quartz sand are obtained, the valuable mica can be recycled, the discharge of tailings is effectively reduced, the comprehensive utilization rate of resources is increased, and the added value of the product is increased.

Owner:赣州金环磁选科技装备股份有限公司

Method for flotation separation of valuable minerals from polymetallic sulfide ores containing lead and zinc

ActiveCN104001626BReduce grinding energy consumptionImprove beneficiation efficiencyFlotationSulfurSulfide

The invention discloses a method for flotation separation of valuable minerals from lead-zinc-containing polymetallic sulfide ores, which comprises the following steps: firstly grinding the raw ore; then adding a combined flotation agent to grind the raw ore after grinding Full mixed flotation roughing treatment; continue to select the coarse concentrate after roughing, continue to add combined flotation agent to sweep the tailings after roughing; Carry out regrinding; add a combined impurity remover to the regrinded lead-zinc-sulfur mixed rough concentrate for impurity removal, and the tailings after deimpurity return to the sweeping process. On the basis of the aforementioned method, lead-sulfur roughing, lead-sulfur concentration, and lead-sulfur separation can be added to obtain lead concentrate, and the tailings after flotation and separation are subjected to lead sweeping to finally obtain sulfur concentrate. The method of the invention has the advantages of simple and convenient process operation, reasonable process, less dosage of medicine, low energy consumption, long service life of equipment, good separation effect and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com