Flotation device

A flotation device and flotation cylinder technology, applied in flotation, solid separation and other directions, can solve the problems of cumbersome operation steps, affecting the beneficiation efficiency, single function, etc., to improve the mixing degree, improve the flotation effect and reduce labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

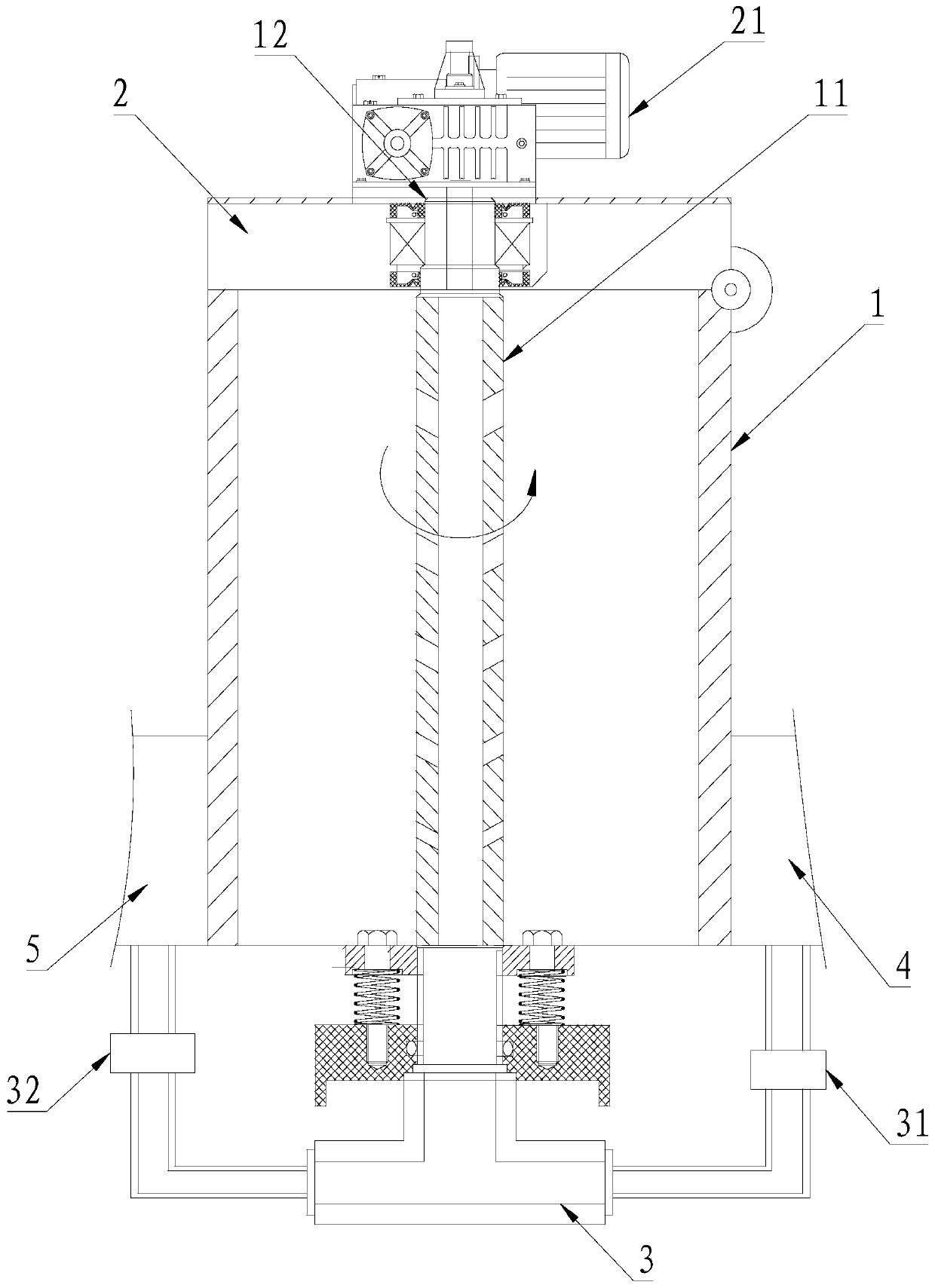

[0018] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0019] The most critical idea of the present invention is that the mixing degree of the liquid medicine and the mineral material solution is improved by feeding the medicine and the gas into the vertical flotation cylinder simultaneously, thereby improving the beneficiation effect.

[0020] Please refer to figure 1 As shown, a kind of flotation device of the present invention comprises a cylindrical vertical flotation cylinder, the axis of the vertical flotation cylinder is perpendicular to the horizontal plane;

[0021] The interior of the vertical flotation cylinder is hollow, and one end face of the vertical flotation cylinder has an opening, and the opening is provided with a corresponding sealing box cover;

[0022] The vertical flotation cell is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com