Patents

Literature

97results about How to "Good mineralization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing sulphate aluminum cement

The invention relates to a method for producing sulphate aluminum cement. The method comprises the following steps: preparing cement raw meal by proportioning limestone, phosphogypsum, low grade alumina and coke; uniformly grinding and calcining at high temperature; in the calcining process, promoting phosphogypsum to be decomposed as much as possible; replacing partial limestone by calcium oxide generated by decomposition; collecting sulfur dioxide to prepare sulfuric acid; and adding natural dihydrate gypsum in the cement clinker and grinding to prepare a cement product. Compared with the existing conventional production methods, according to the method, the utilization of phosphogypsum can be greatly improved, the utilization concentration of sulfur dioxide discharged by decomposition of little gypsum in the production process can be guaranteed to be reached, the use level of limestone is further reduced and emission of carbon dioxide is reduced. Cement calcined is wide in adaptability, can be widely applied to production of sulphate aluminum cement by phosphogypsum, and further can be suitable for producing high early strength cement, expansive cement and the like.

Owner:CHONGQING UNIV

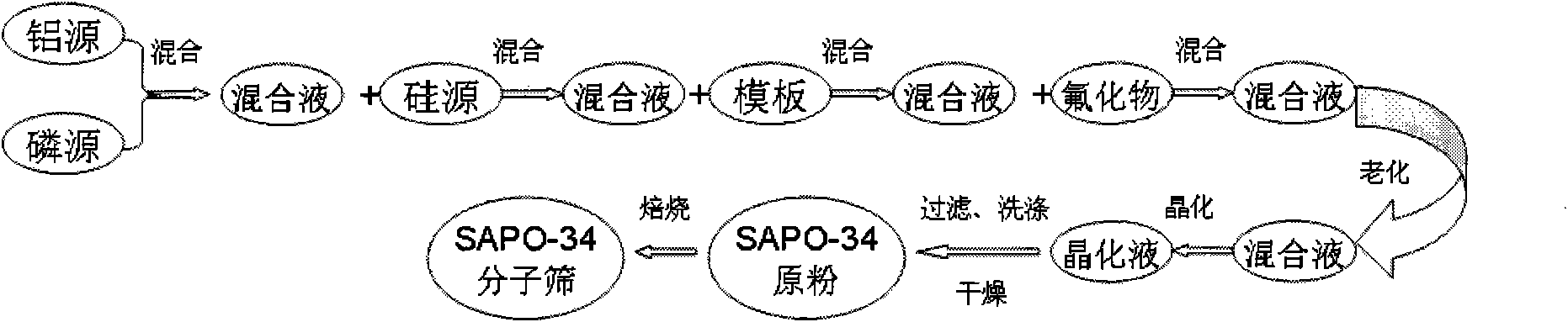

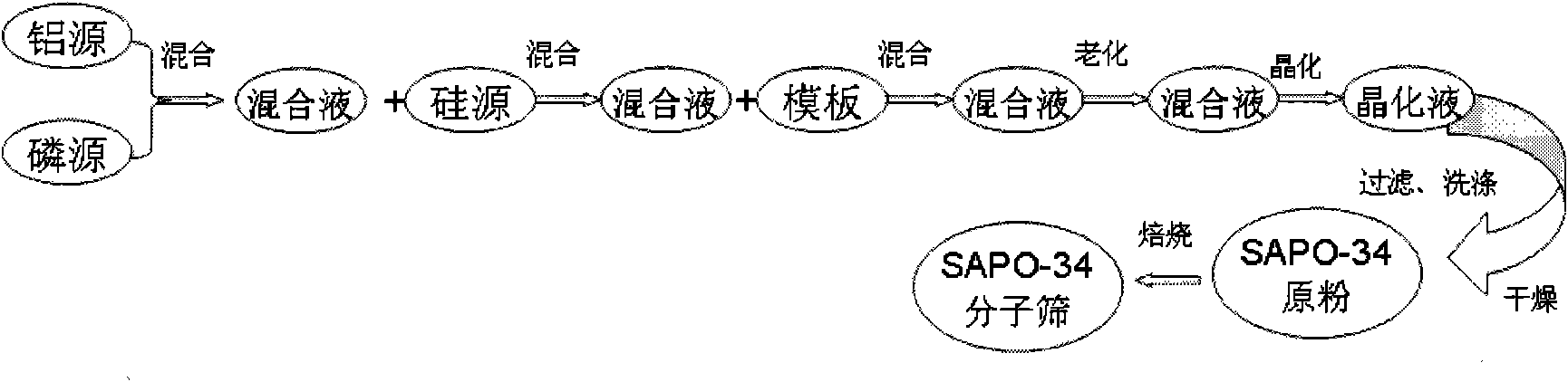

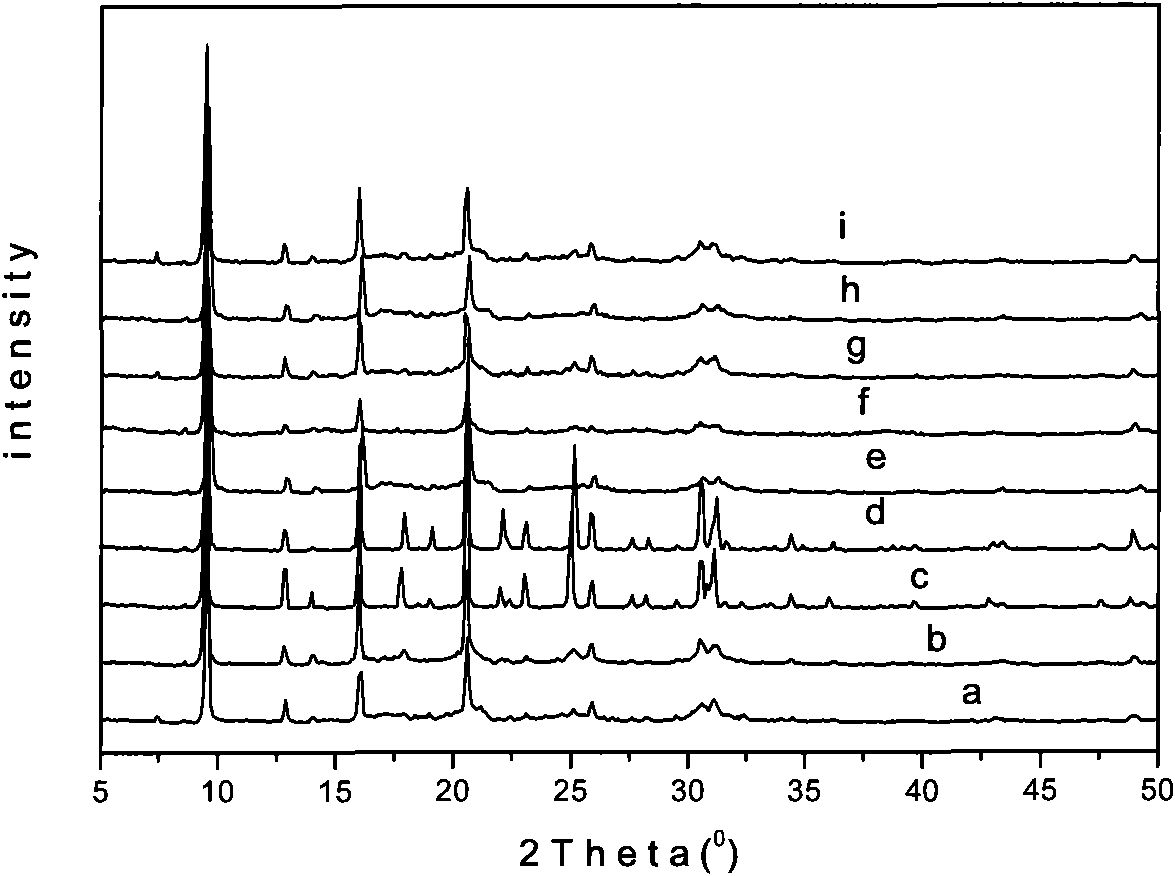

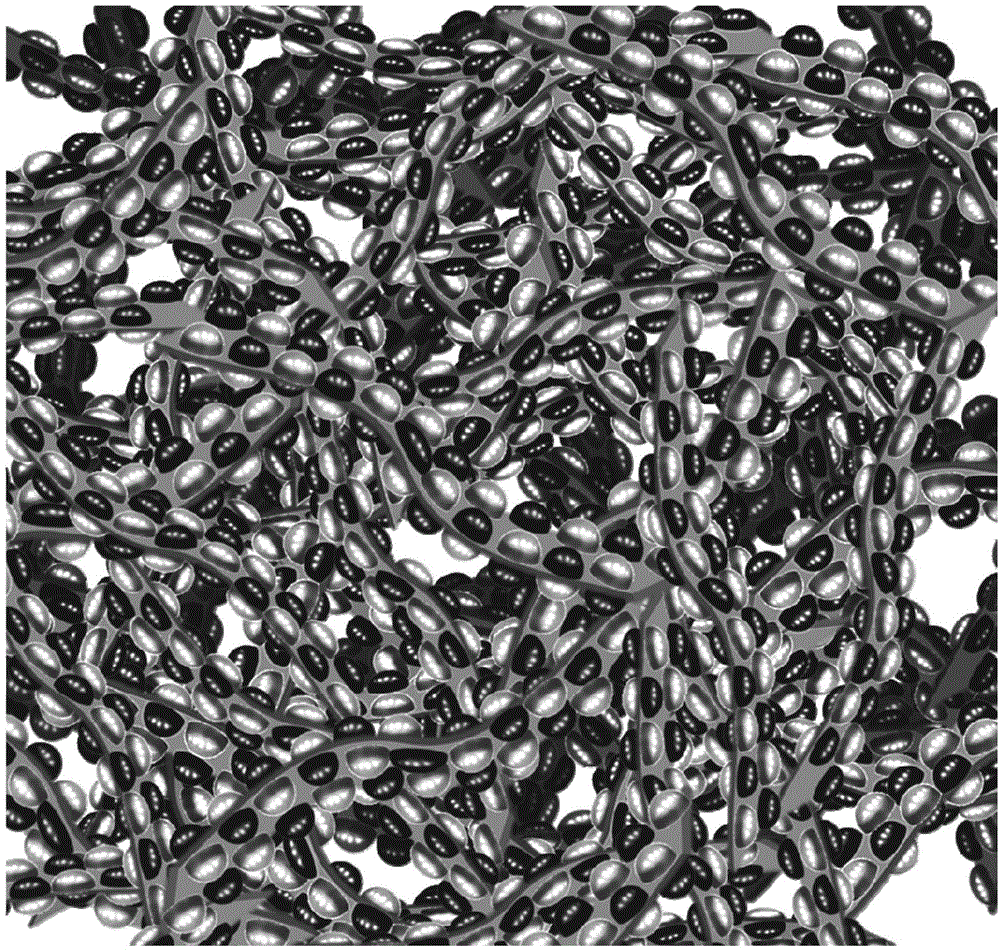

Method for preparing SAPO-34 molecular sieve

ActiveCN101767800AIncrease profitChange shapeMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveCrystallization temperature

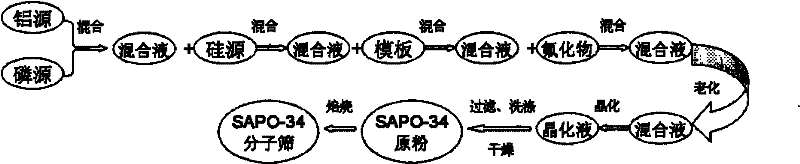

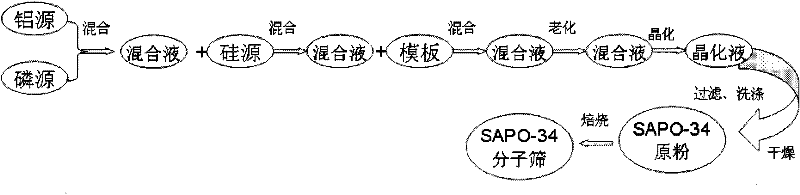

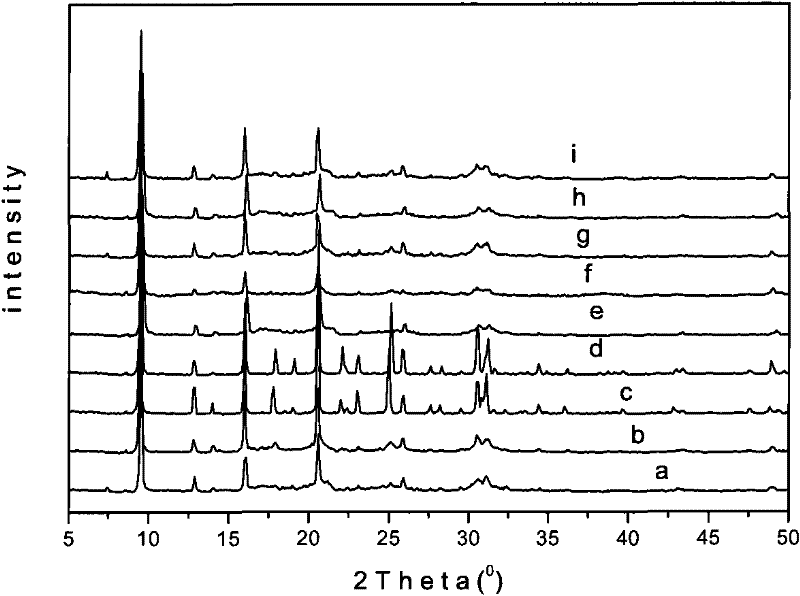

The invention provides a method for preparing a SAPO-34 molecular sieve. The method comprises the following steps of: 1, uniformly mixing a proper amount of phosphorus source, aluminum source, silicon source, template, auxiliary template and water at a proper temperature and under a stirring condition to obtain mixed solution, of which a molar ratio of all components, namely, the molar ratio of R to F- to SiO2 to Al2O3 to P2O5 to H2O, is a:b:c:1:d:e, wherein R represents the template, a is 0.2 to 5.0, b is 0 to 1.0, c is 0.2 to 1.5, d is 0.2 to 2.0 and e is 20 to 200; 2, ageing the mixed solution; and putting the aged mixed solution in a crystallization kettle, sealing the crystallization kettle, heating the mixed solution to a crystallization temperature, and crystallizing the mixed solution at the constant crystallization temperature; 3, performing centrifugal separation of the crystallized mixed solution, filtering, washing the mixed solution until a pH value of the mixed solution is 7 to 8, and drying a solid sample to obtain the SAPO-34 raw powder; and 4, baking the SAPO-34 raw powder at the temperature of between 450 and 650 DEG C for 4 to 8 hours to obtain the SAPO-34 molecular sieve. The SAPO-34 molecular sieve prepared by the method is characterized by high crystallinity and can show better low carbon olefin selectivity in an MTO reaction.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

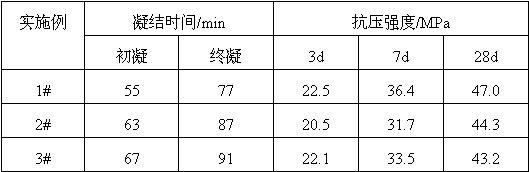

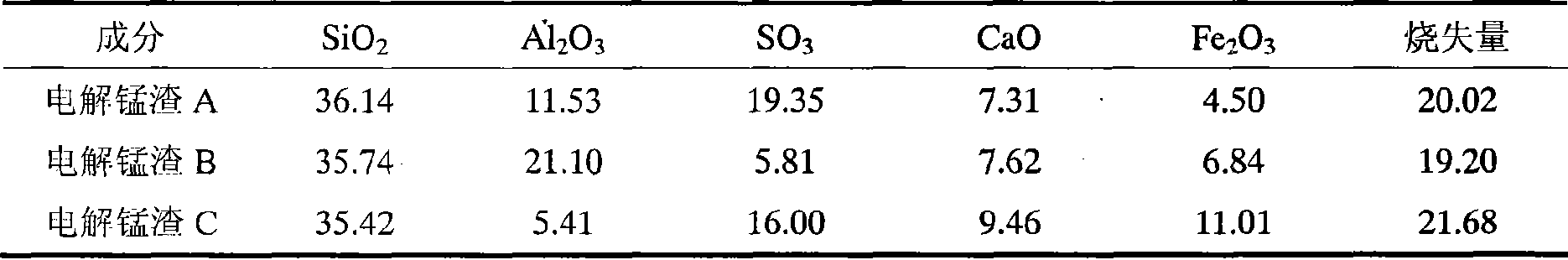

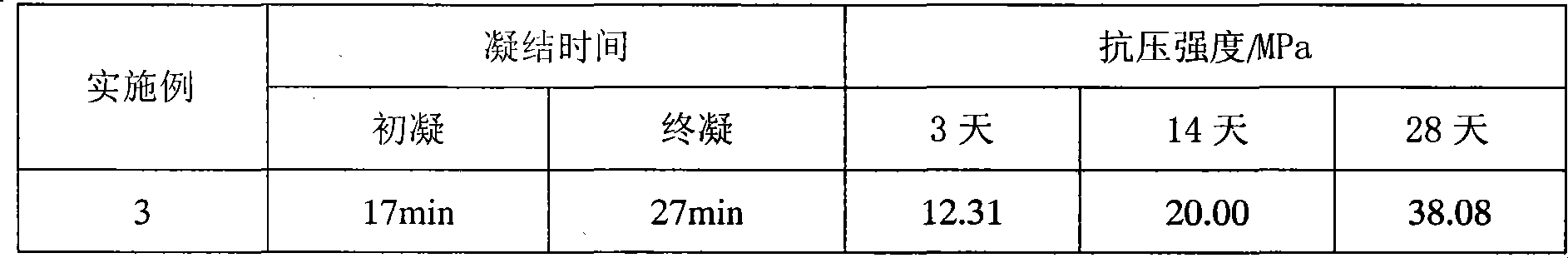

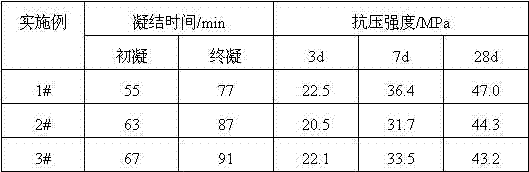

Manufacture of sulphur aluminate cements with electrolytic manganesium residue and method of manufacturing the same

A sulphate-aluminium-like cement produced by using electrolytic manganese slag and the preparation method of the cement relate to the production of the sulphate-aluminium-like by using industrial wastes and the preparation method of the cement. The raw materials of the cement clinker of the invention contain limestone, electrolytic manganese slag, kaolin and soft coal, and dihydrate gypsum is added to the fired cement clinker; the preparation method comprises the following steps: using the limestone, electrolytic Manganese slag, kaolin and soft coal as the raw materials of the clinker; first, levigating and homogenizing the raw materials, and calcining the raw materials into the clinker at a relatively low temperature; then adding the dihydrate gypsum to the clinker according to the requirement and then levigating the mixture to be the finished product. The cement is characterized in that the firing temperature ranges from 150 DEG C to 200 DEG C which is lower than that of the common Portland cement, and the energy-saving advantage is obvious; the mixture proportion range of the components is wide; the mixing amount of the manganese slag is great; and the fired cement has wide application, and so on. The preparation method can be widely used for producing the sulphate-aluminium-like cement by using electrolytic the manganese slag, and is in particular applicable to the production of early strength cement, rapid-hardening high-strength cement, expansive cement and low-alkali cement, and the like.

Owner:CHONGQING UNIV

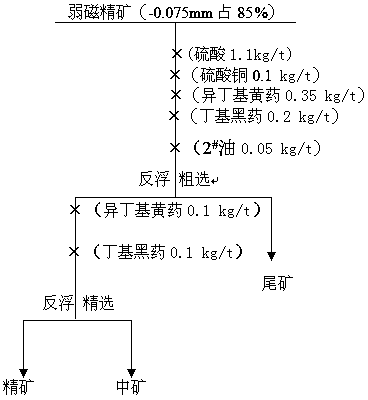

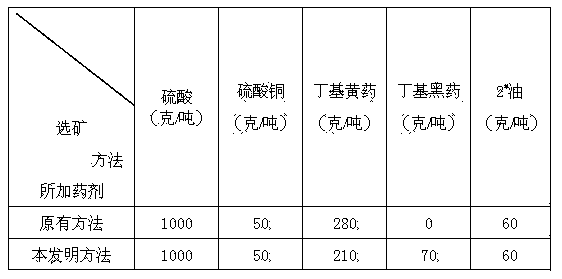

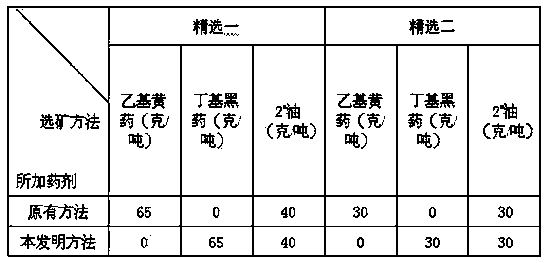

Ore dressing method for removing pyrrhotite from iron ore

InactiveCN104069937AEnhanced harvesting capacityGood beneficiation effectFlotationWet separationChemical mixturesIronstone

The invention discloses an ore dressing method for removing pyrrhotite from iron ore. The ore dressing method for removing the pyrrhotite from the iron ore includes that performing crushing, ore grinding, grading and low intensity magnetic separation techniques to obtain low intensity magnetic concentrate, wherein the TFE grade of the low intensity magnetic concentrate is more than or equal to 65.0%, and the low intensity magnetic concentrate comprises 0.5-1.4% of S; carrying out reverse flotation roughing and reverse flotation selection on the low intensity magnetic concentrate to obtain low-pyrite concentrate with less than 0.15% of S. Weighted by the dry ore amount for the reverse flotation, the reverse flotation roughing chemical comprises (1) pH regulating agent, to be specific, 800-1200 g / t of sulfuric acid; (2) activating agent, to be specific, 80-150 g / t of copper sulfate; (3) collecting agent, to be specific, 250-400 g / t of iso-butyl xanthate and 150-250 g / t of butyl dithiophosphate; (4) foaming agent, to be specific, 30-70 g / t of 2# oil. The ore dressing method for removing the pyrrhotite from the iron ore uses the butyl dithiophosphate and butyl xanthate or iso-butyl xanthate to form sulfur content reducing chemical mixture, the molecular arrangement between the chemical micelles is improved to form a synergistic effect, the chemical is good for mineralizing and adsorbing, the hydrophobicity and the floating speed are properly reinforced, and the sulfur content of the iron concentrate is reduced to less than or equal to 0.03-0.15%. The ore dressing method for removing the pyrrhotite from the iron ore is especially suitable for removing the pyrrhotite from the iron ore with pyrrhotite through reverse flotation.

Owner:马钢集团设计研究院有限责任公司 +1

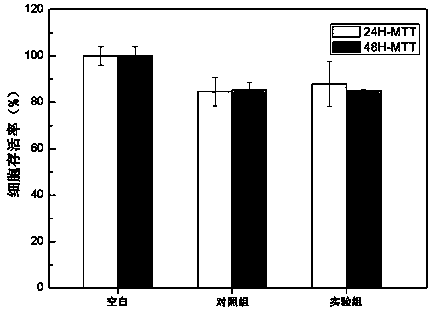

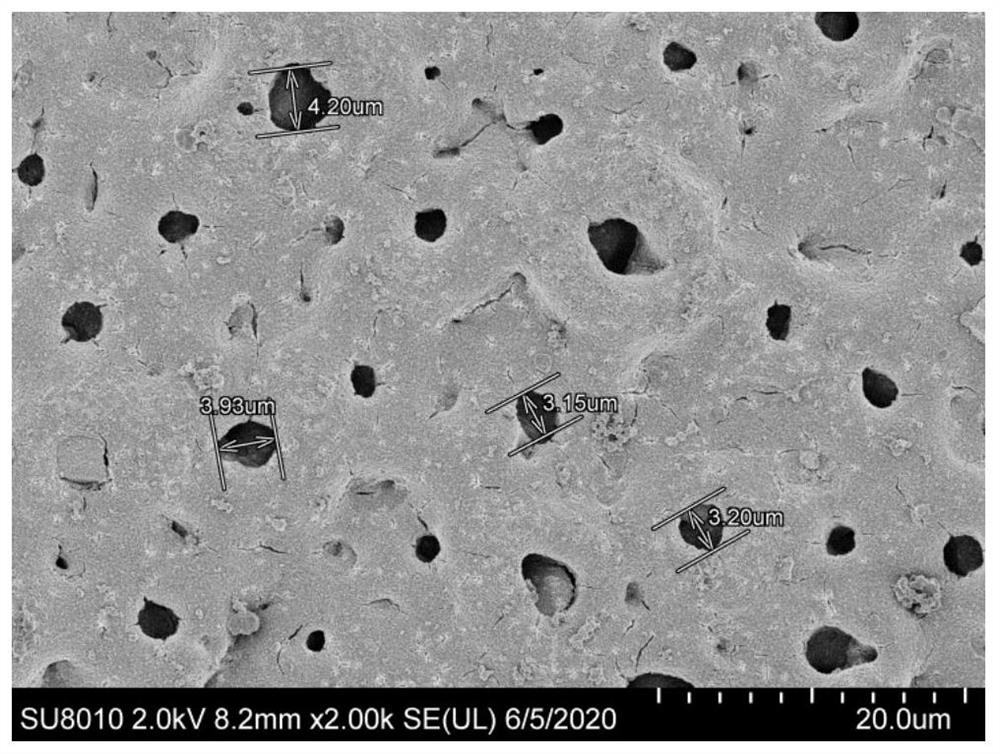

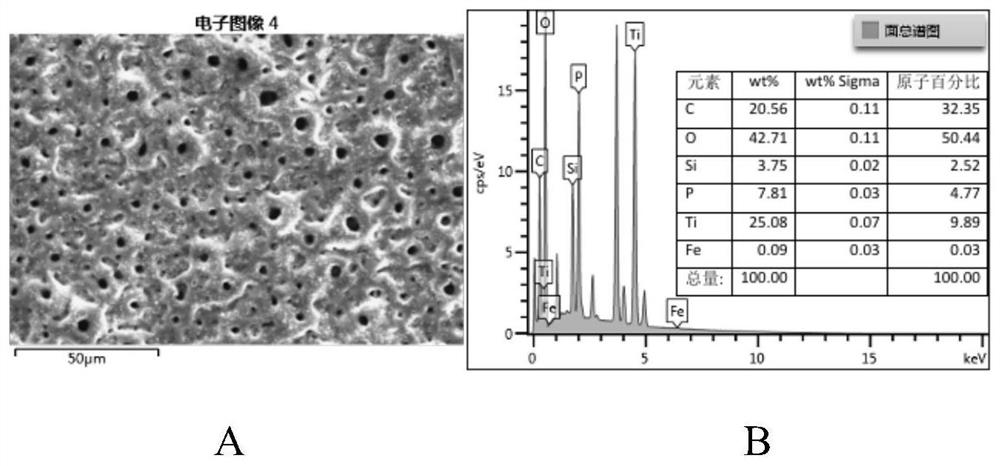

Application of femtosecond laser in pure titanium implantation material surface treatment

InactiveCN101264551AGood biocompatibilityReduce the impactTeeth fillingBone implantTitanium surfaceLaser processing

The invention relates to an application of femto-second laser in the surface treatment of the pure titanium implanting material, belonging to the technical field of application of laser in the material surface treatment. The application method comprises the following steps: in the air, the femto-laser impulse is in normal incidence and focused right on the top of the lump pure titanium implanting material which is ground and dried, a light spot with a radius of 5um is formed at the surface of the pure titanium implanting material, the femto-laser processing parameters are defined as follows: the impulse repeat frequency is 1 kHz, the single impulse power is from 5 to 200 micro joule, the impulse width is 50 femtosecond, the impulse center wavelength is 800 nanometer, the line interval of the laser processing is between 10 to 100 micron, the laser scanning speed is between 0.5 to 1.2 mm / sec, the laser polarization direction is regulated to be parallel to the laser scanning direction, the femto-laser scans the whole surface of the pure titanium implanting material, a titanium based biomedical material with an oxide layer generated on the titanium surface, even roughness, and a pattern of strips, holes, grooves or the combined pattern thereof formed on the pure titanium implanting material is made.

Owner:HEBEI UNIV OF TECH +2

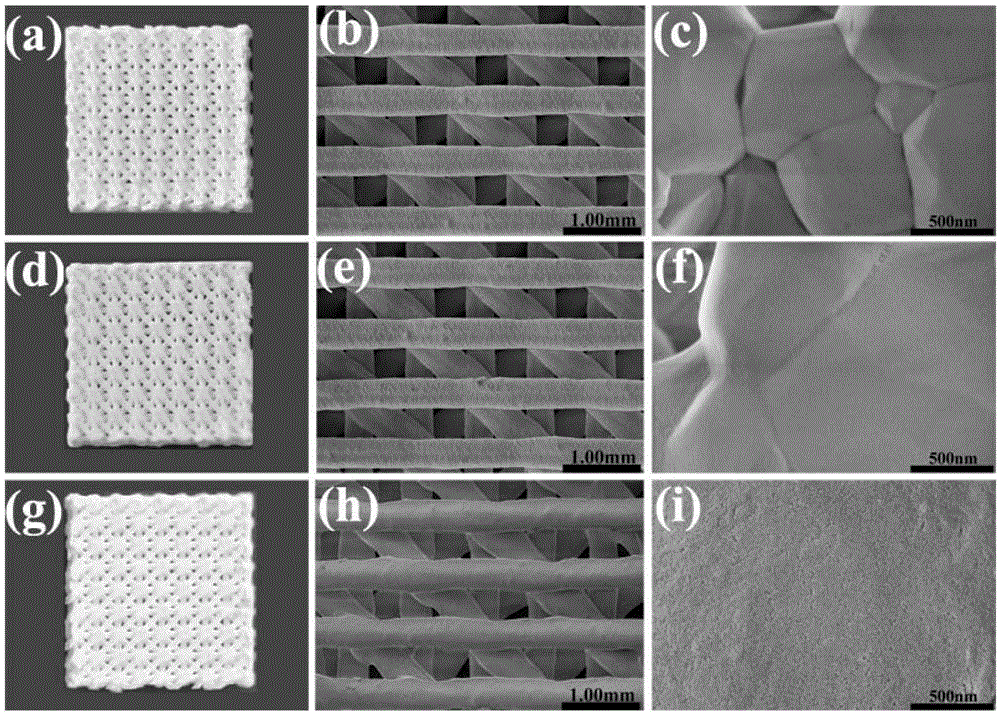

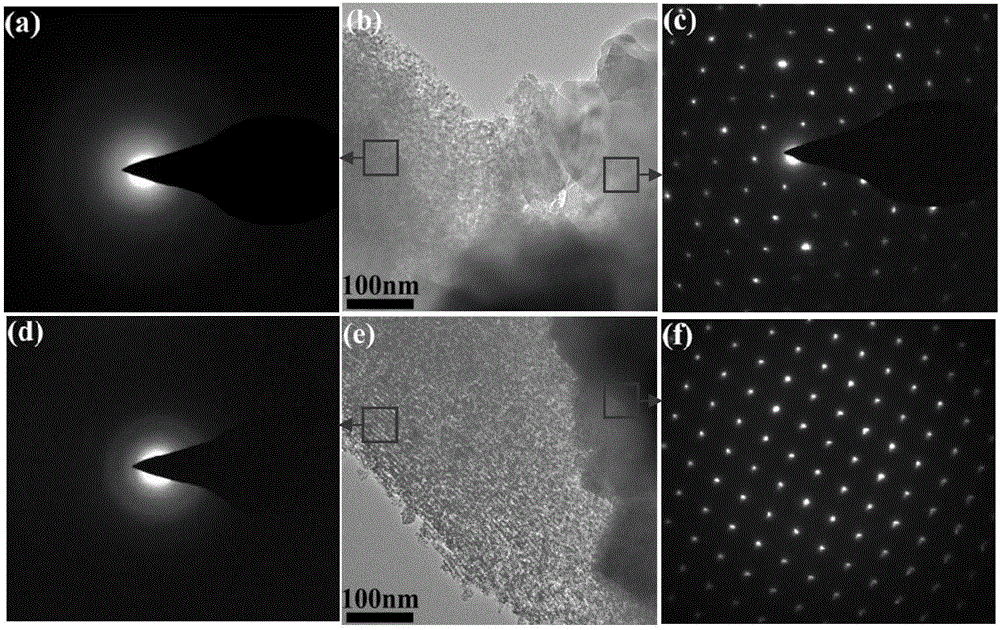

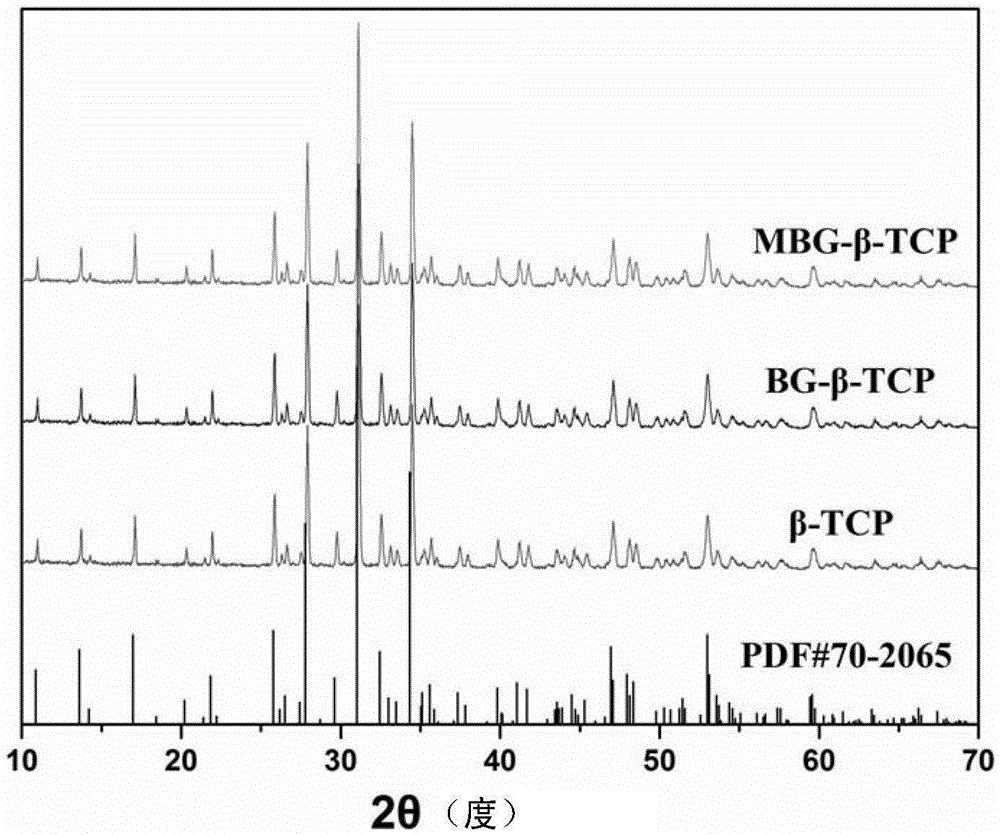

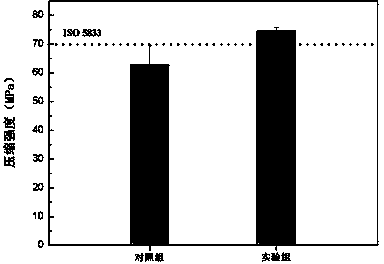

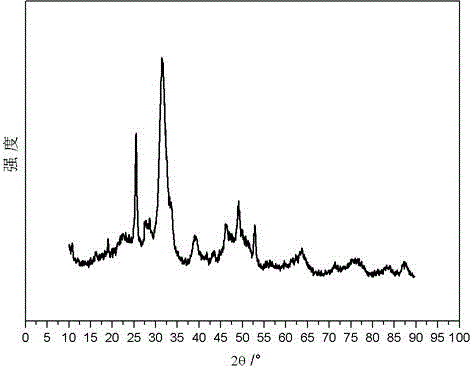

3D (three-dimensional) printing mesoporous bioactivity glass modified biological ceramic support, and preparation method and application thereof

ActiveCN105311673AGood mechanical propertiesGood mineralization effectAdditive manufacturing apparatusProsthesisBioactive glassTri calcium phosphate

The invention relates to a 3D (three-dimensional) printing mesoporous bioactivity glass modified biological ceramic support, and a preparation method and application thereof. The biological ceramic support comprises a beta-tricalcium phosphate bioactivity support prepared by using a three-dimensional printing technology and mesoporous bioactivity glass coating the surface of the support uniformly. The biological ceramic support has good mechanical property, mineralization capability and osteogenic and hematopoietic activities, is expected to serve as an effective bone repairing material, and is a potential multifunctional hard tissue bioactivity implanting material.

Owner:中科硅诺(太仓)生物材料科技有限公司

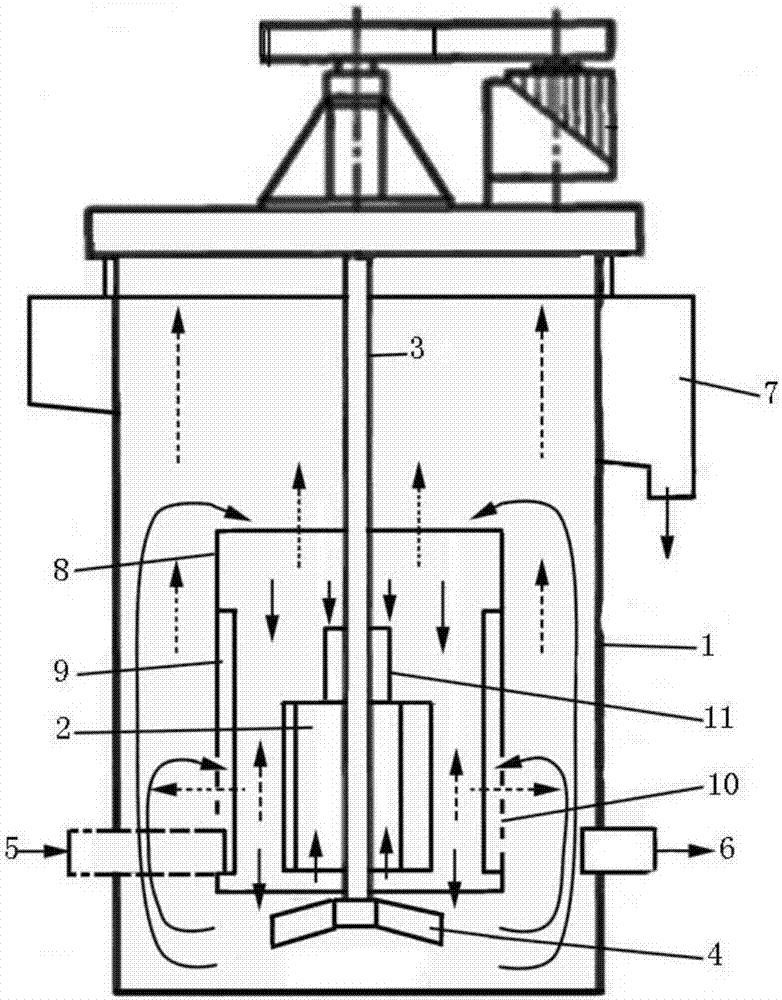

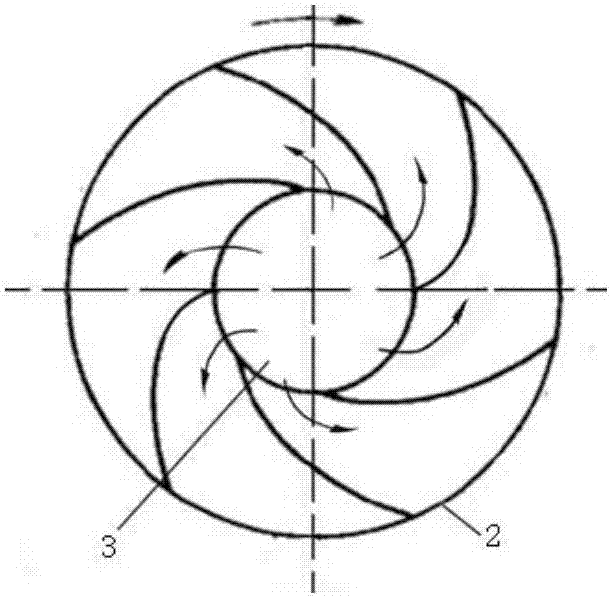

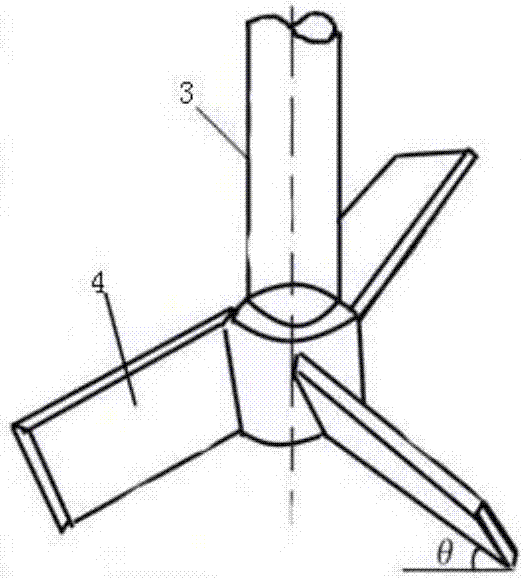

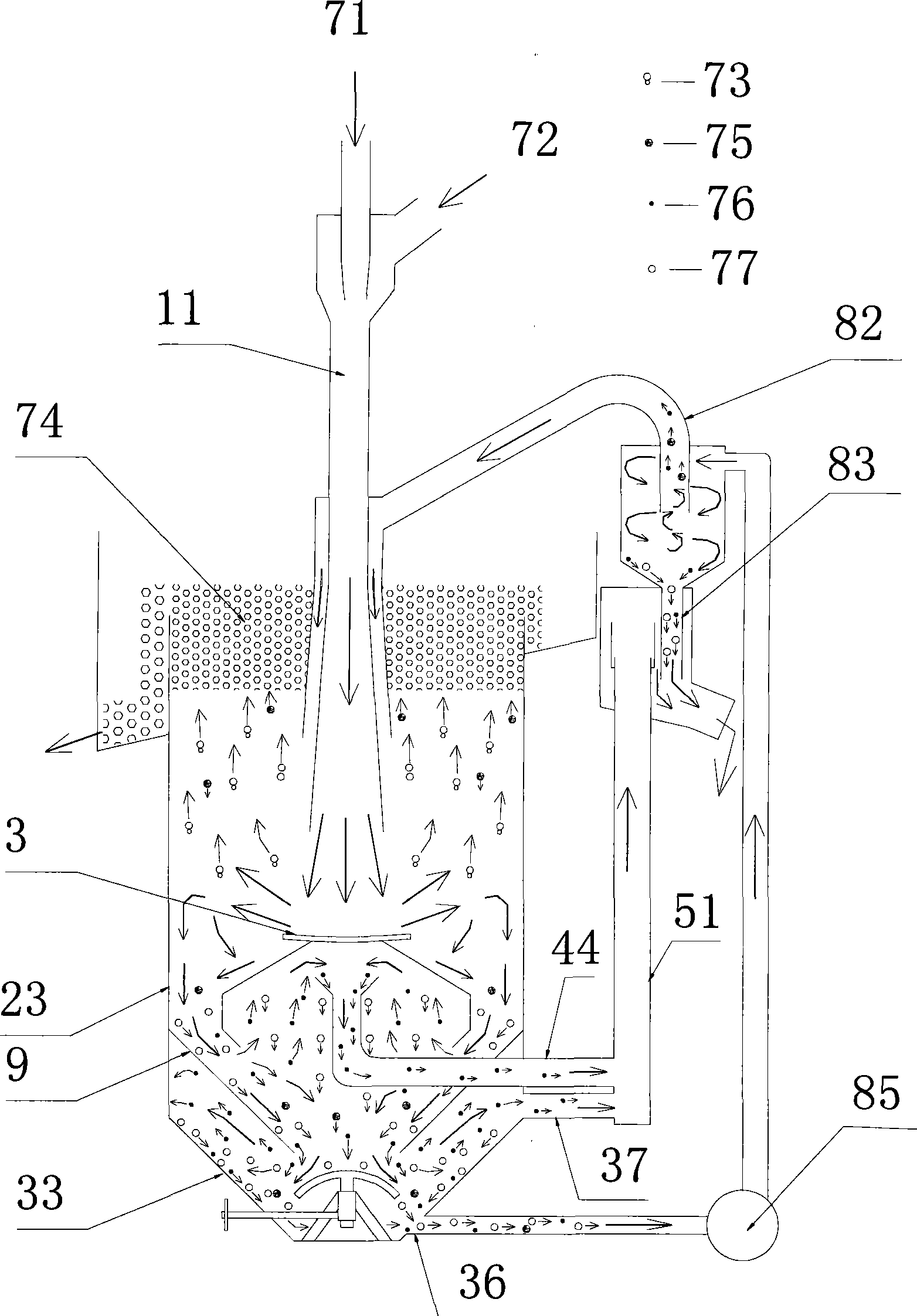

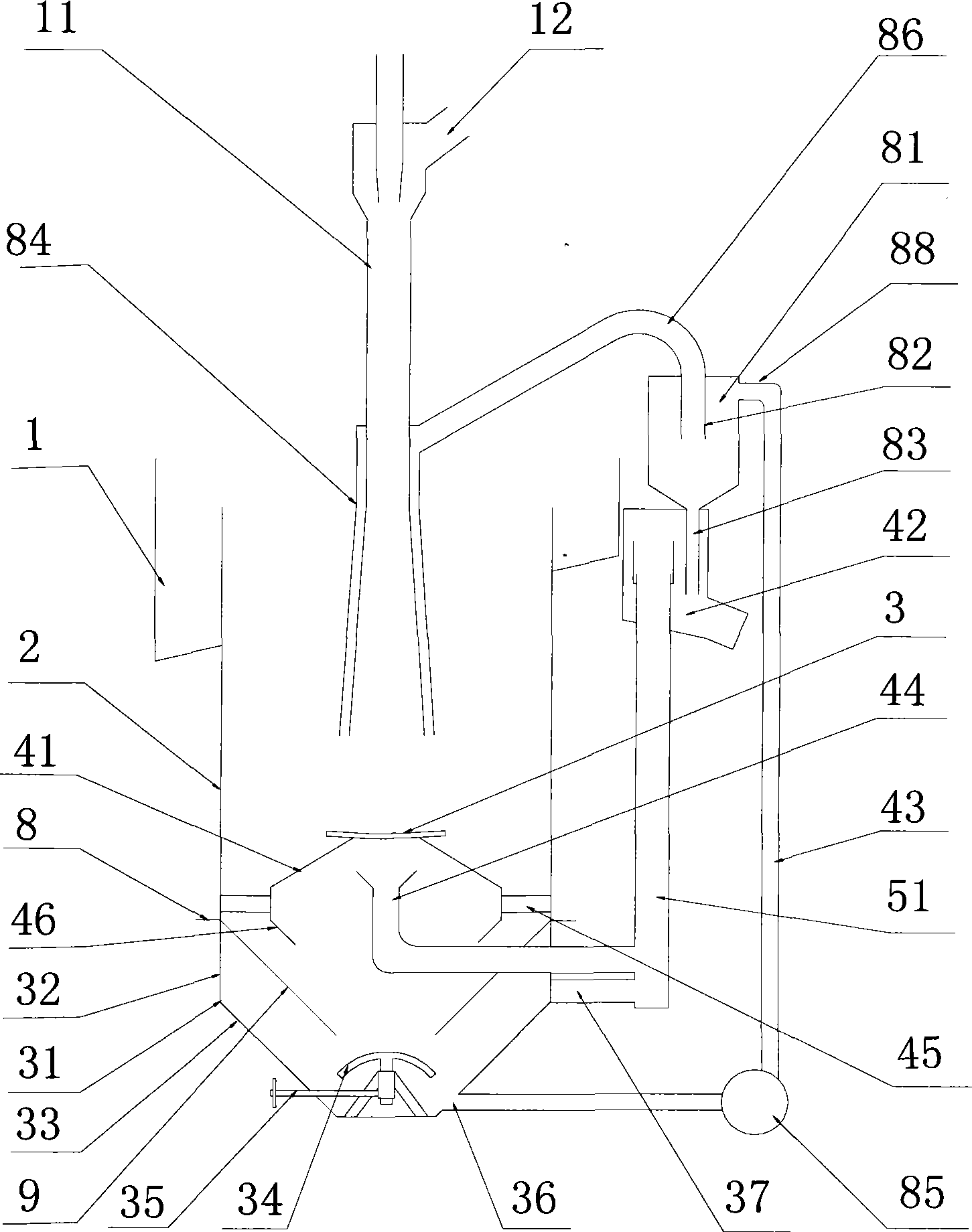

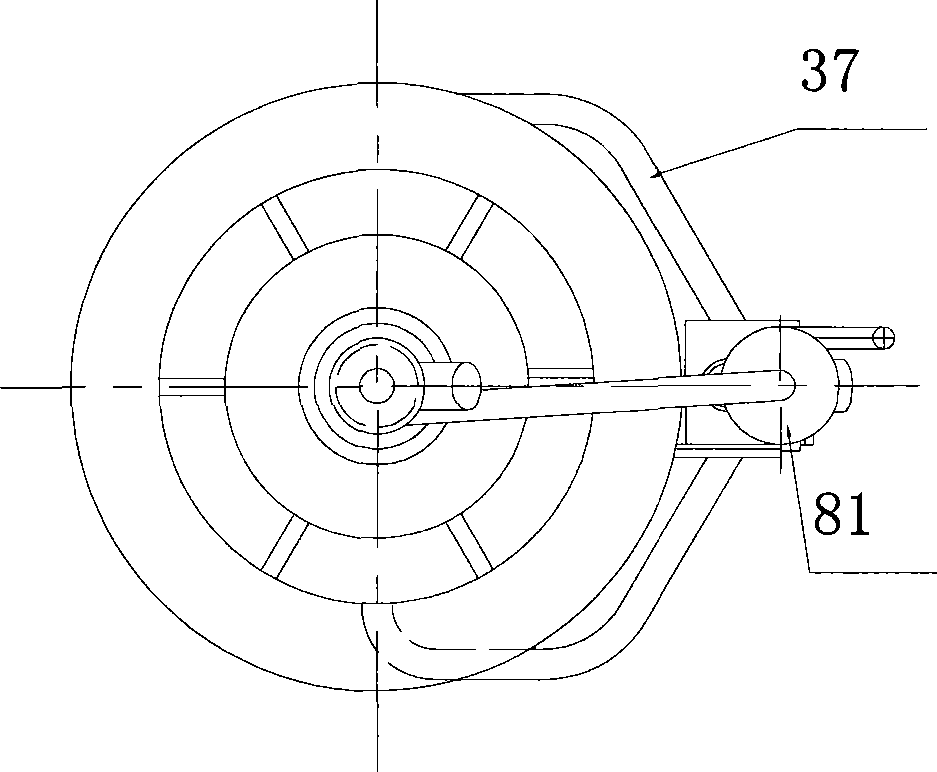

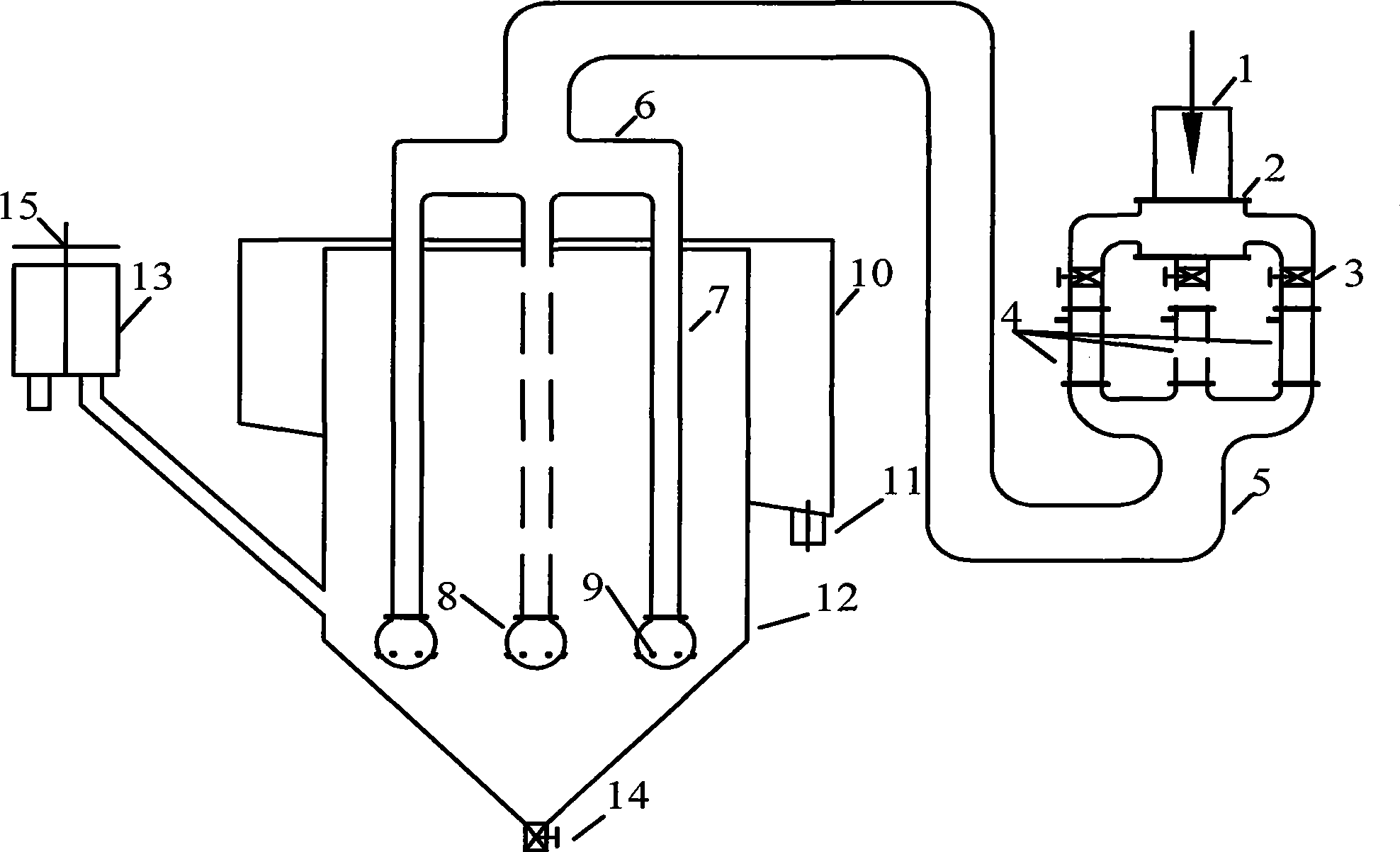

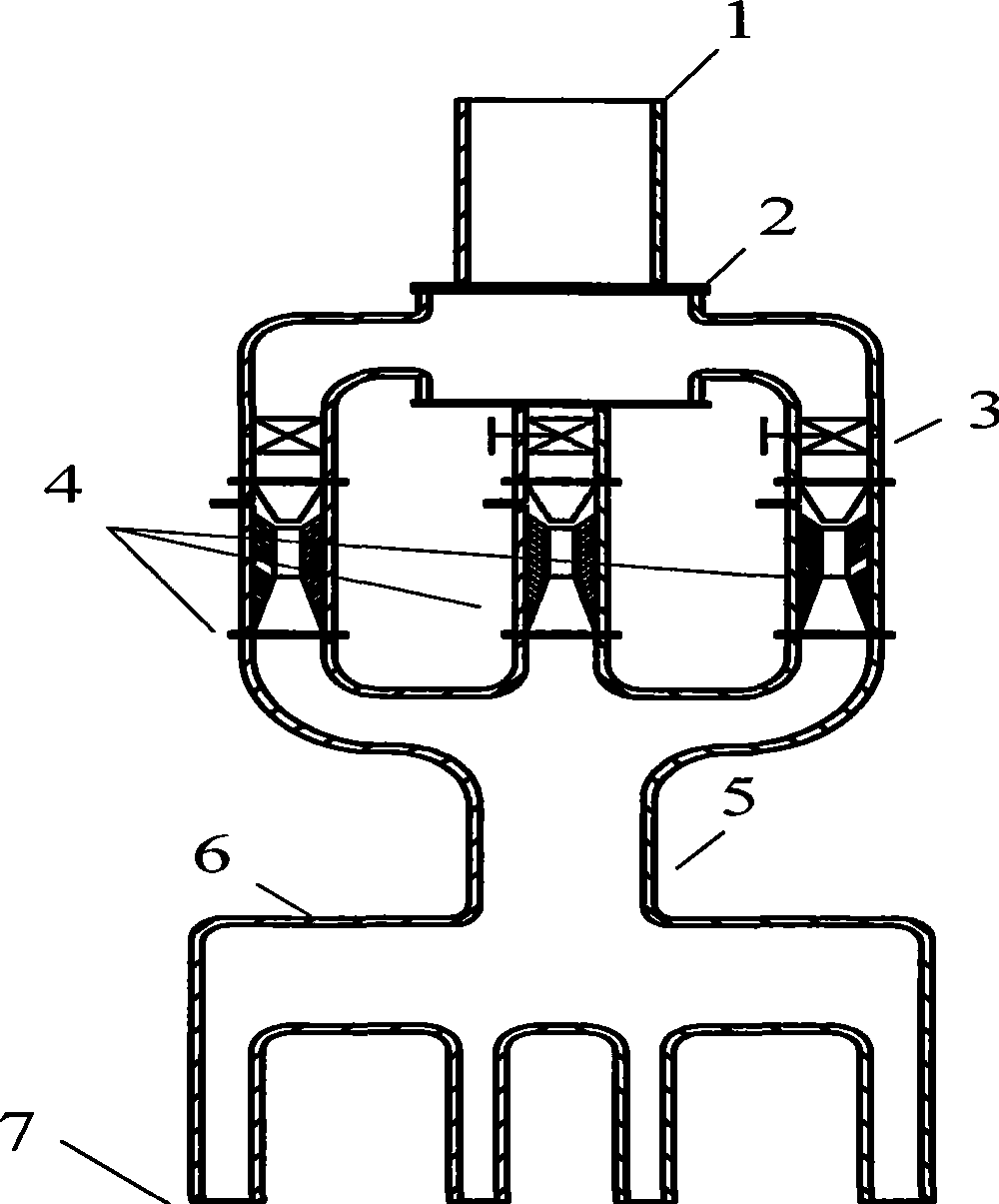

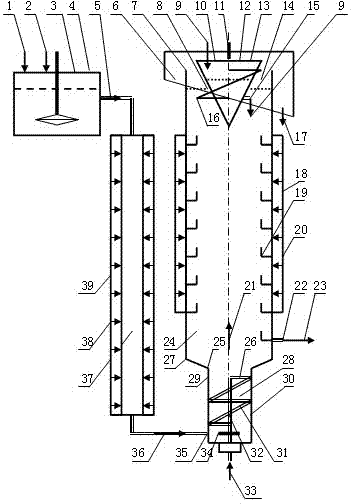

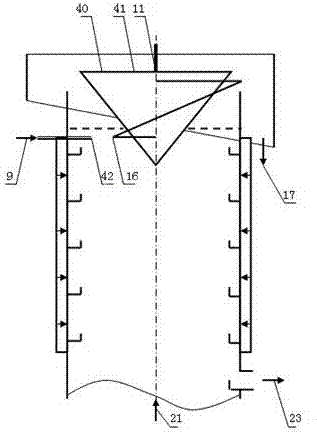

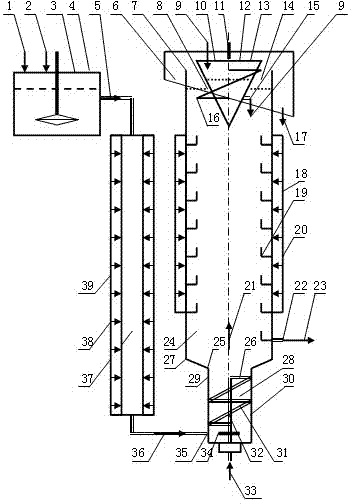

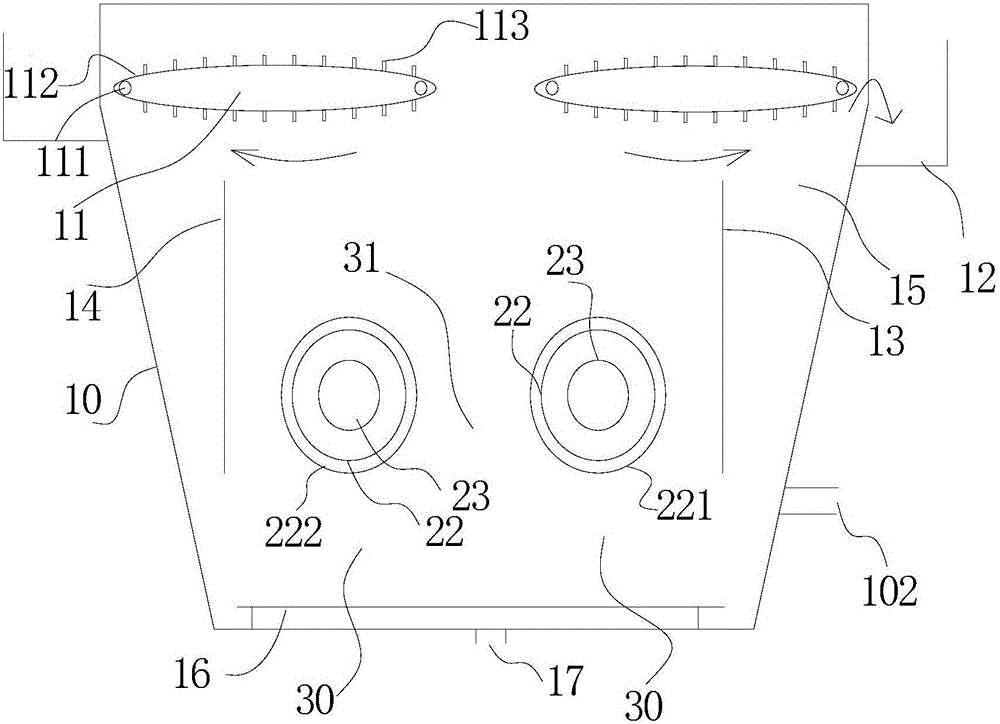

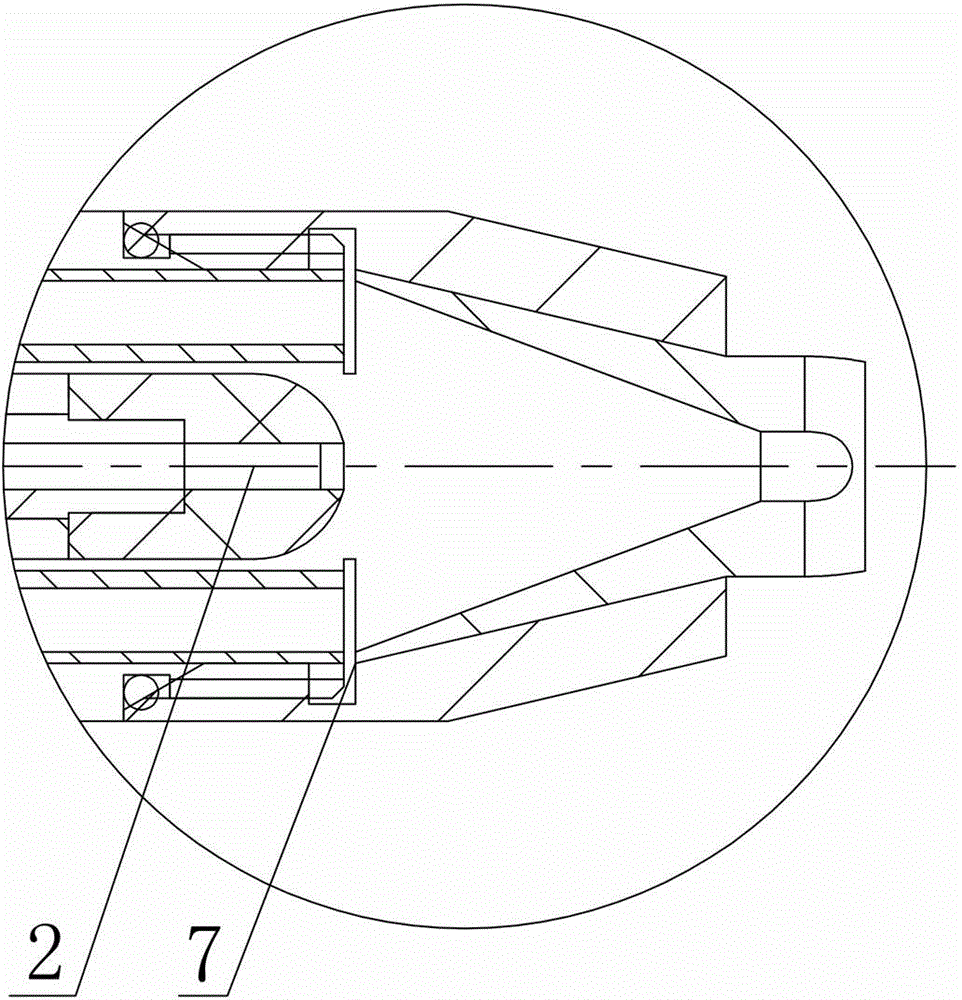

Double-impeller mechanical stirring self-suction flotation machine and flotation method

ActiveCN107971143AOptimizing the intensity of counterflowGood mineralization effectFlotationImpellerField separation

The invention provides a double-impeller mechanical stirring self-suction flotation machine and a flotation method. The double-impeller mechanical stirring self-suction flotation machine comprises a column type flotation cell, a rotary shaft, an upper impeller and a lower impeller, wherein the rotary shaft is vertically inserted into the center of the inner part of the column type flotation cell;the upper impeller is fixed to the middle lower part of the rotary shaft; the lower impeller is fixed to the lower part of the rotary shaft; a guide cylinder sleeves outside the upper impeller; the lower impeller is located on the outer side of the bottom part of the guide cylinder; guide plates are arranged on an inner wall of the guide cylinder along a circumferential direction at intervals; circulation holes are uniformly distributed on the lower part of the guide cylinder along the circumferential direction; an ore feeding pipe and an ore discharging pipeline are symmetrically arranged ontwo sides of the lower part of the flotation cell; the ore feeding pipe is connected with the guide cylinder; and a foam tank is arranged on the upper part outside the flotation cell. According to thedouble-impeller mechanical stirring self-suction flotation machine and the flotation method provided by the invention, a flotation bubble mineralization effect can be improved, a flotation three-phase flow field separation environment is optimized, the reverse flow of an ore pulp and bubbles is realized, and the efficiency and the separation precision of a flotation process are improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

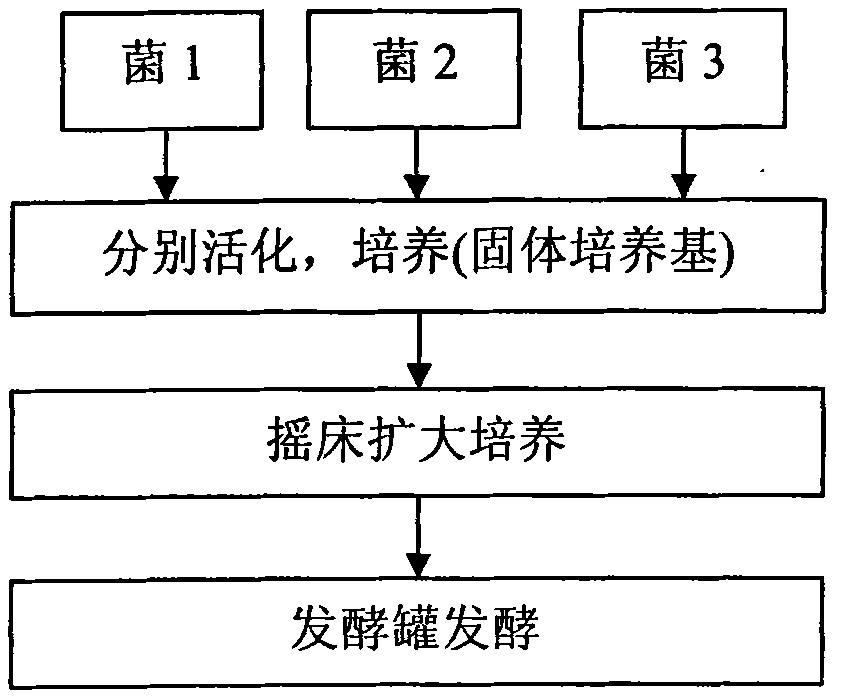

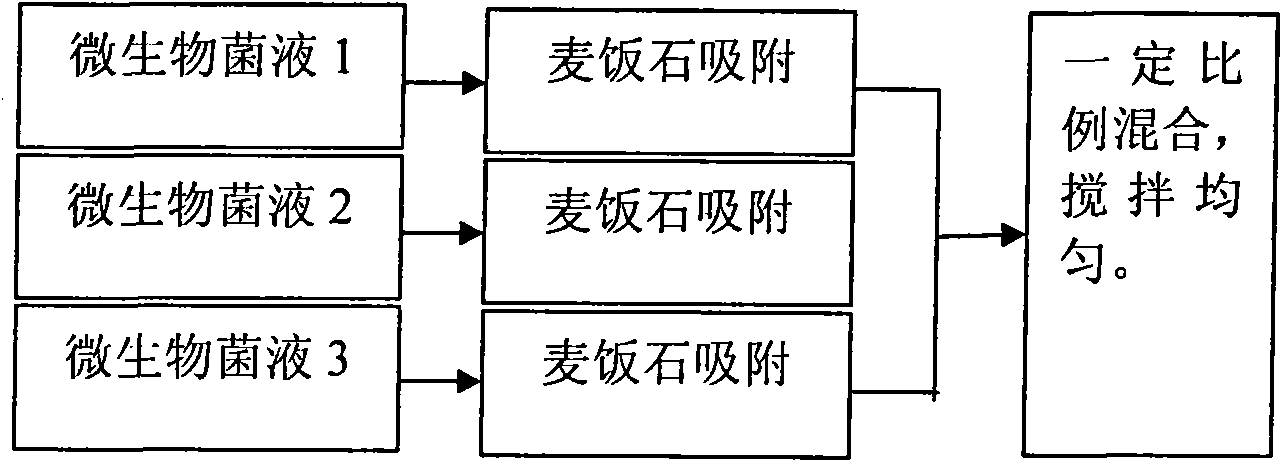

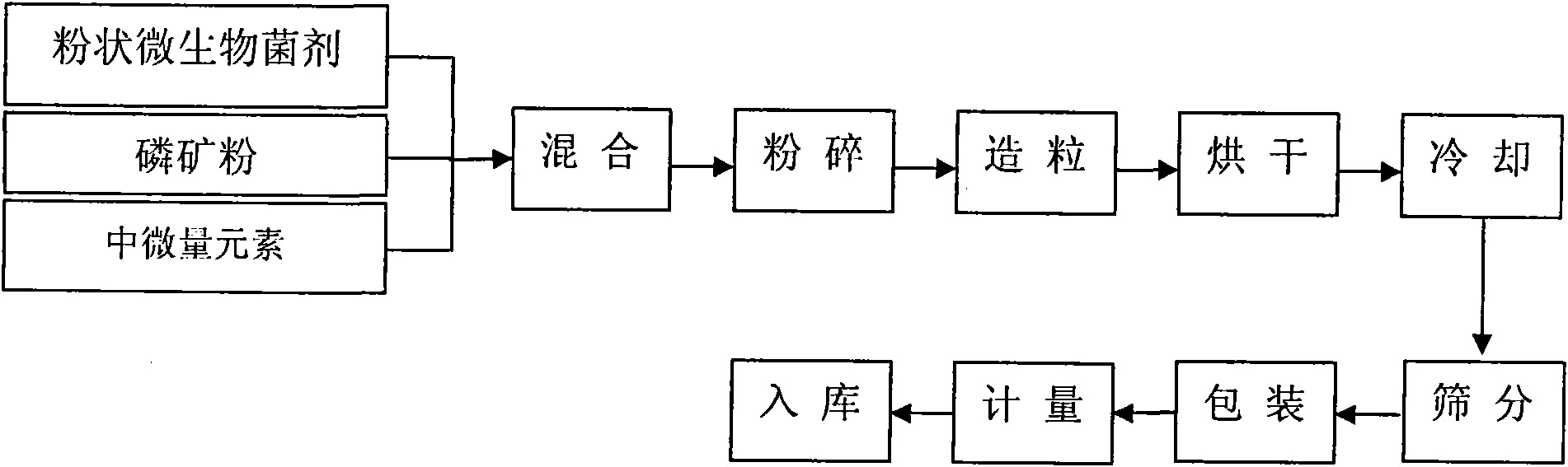

Granular type compound microbial bacterial agent as well as preparation method and application thereof

InactiveCN101935249AImprove adsorption capacityPromote dissolutionOrganic fertilisersFertilizer mixturesBiotechnologyMicroorganism

The invention relates to a granular type compound microbial bacterial agent which comprises the following components in percentage by weight: 80-90 percent of powdered compound microorganism bacterial agent, 8-14 percent of phosphate rock powder and 2-6 percent of trace element, wherein the powdered compound microorganism bacterial agent is prepared by adsorbing zymocyte fluid with a single strain respectively with a medical stone, and the strains are bacillus subtilis, bacillus megateria and bacillus mucilaginosus. The invention also provides a preparation method and application of the granular type compound microbial bacterial agent. The invention provides a good carrier for the production of microbial bacterial agent granules; the medical stones have various characteristics of good adsorbability, leachability, mineralization, bioactivity, and the like and provide good carriers for the adsorption of the microbial bacterial agent; a produced fertilizer has better appearance, and the intensity of the fertilizer is obviously enhanced; and the invention greatly improves the utilization rate and the long-term effectiveness of the fertilizer and is beneficial to storing and transporting products.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

Double tail-removing gravity-flotation combined sorting method and device

The invention relates to a double-tailing discharging gravity-floating combined separation method and a device thereof, and belongs to a double-tailing discharging gravity-floating combined separation method aiming at slime and a device thereof. The aim of the invention is to solve the technical problems existing in the prior flotation machine that the separation effect of ultrafine grains is low and the upper limit of the column flotation is difficult to be effectively related with the lower limit of the heavy medium separation. The method comprises three steps of crude ore flotation and rough separation and graded tailing discharging, gravity scavenging tailing discharging and gravity separation finished ore reflotation. The double-tailing discharging gravity-floating combined separation machine comprises a jet flow flotation column, a first tailing discharging graded device and a secondary tailing discharging graded device; the first tailing discharging graded device is arranged below the jet flow flotation column, a cyclical middling underflow opening of the first tailing discharging graded device is connected with the secondary tailing discharging graded device, and a central ore feeding pipe of the secondary tailing discharging graded device is connected with the jet flow flotation column. The method and the device have multiple effects of coarse slime separation and highly selective floatation of fine coal and ultrafine coal, thereby improving the efficiency of the gravity-floating combined separation.

Owner:TAIYUAN UNIV OF TECH

Flotation cell without transmission

ActiveCN101439315AImprove filtering effectIncrease the number ofFlotationPulp and paper industrySilicon

The invention discloses a flotation cell without transmission, which comprises a cell body and a pulp distributer; wherein, a feeding pipe arranged above the pulp distributer, and at least one venturi pipe is arranged under the pulp distributer; the venturi pipe is connected with a mineralized pipe which is connected with the pulp distributer, the bottom end of which is provided with at least onepiece of steel pipe, and a pulp ejector device is arranged at the bottom end of the steel pipe and is provided with a plurality of nozzles; the steel pipe is installed in the cell body, and a foam collecting groove is installed at the upper part of the cell body; the cell body is connected with a middling ore box by a pipeline; the flotation cell has high separation efficiency and low energy consumption, can meet the requirements of aluminum-silicon separation process of alumyte flotation desiliconization with different fractions, and has wide application scope.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Injectable bioactive bone cement as well as preparation method and application thereof

InactiveCN103690992AGood mineralization effectGood biocompatibilityProsthesisDimethyl terephthalateBenzoyl peroxide

The invention provides injectable bioactive bone cement which is divided into a powder part and a liquid part, wherein the powder part comprises hydroxyapatite powder subjected to surface modification, PMMA (polymethyl methacrylate) powder with high molecular weight, benzoyl peroxide, a contrast agent and hydroquinone; the liquid part comprises a dimethyl terephthalate solution and a methyl methacrylate solution. The invention further provides a preparation method and application of the injectable bioactive bone cement. The bone cement prepared by adopting the method has a solid-to-liquid ratio suitable for injection. The mechanical property of the bone cement can reach the national standard, and the biocompatibility is high.

Owner:SUN YAT SEN UNIV

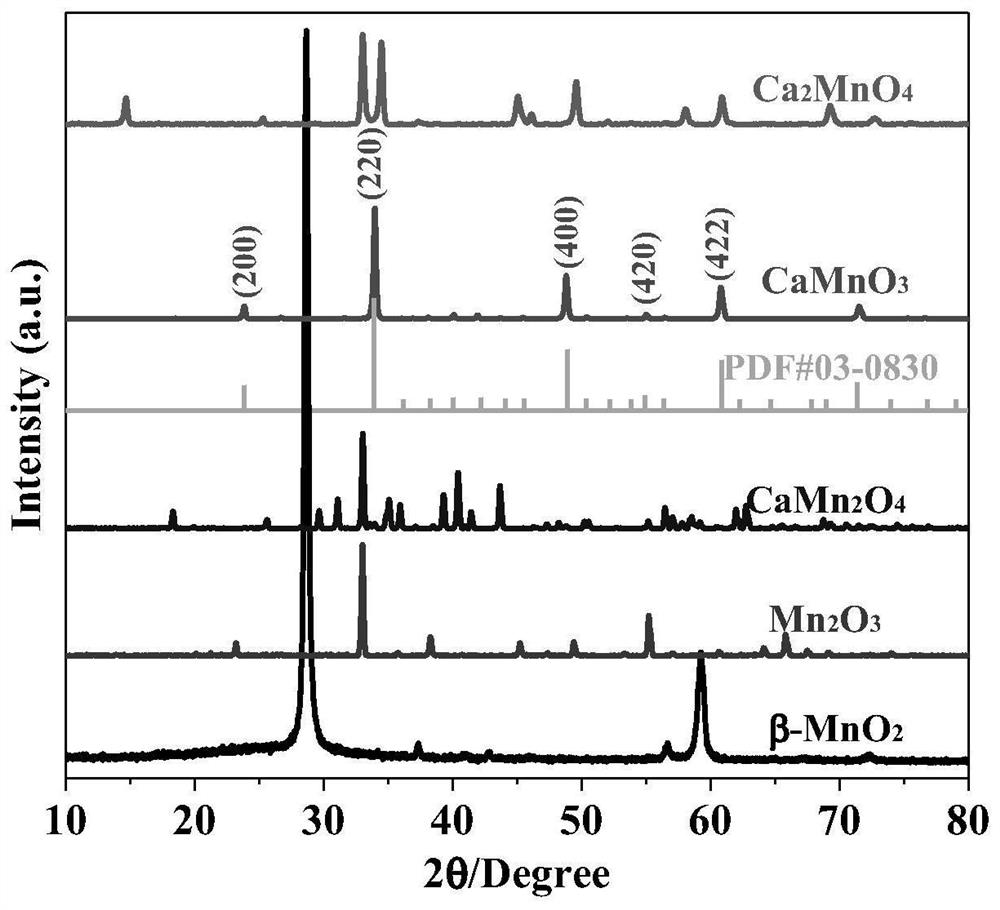

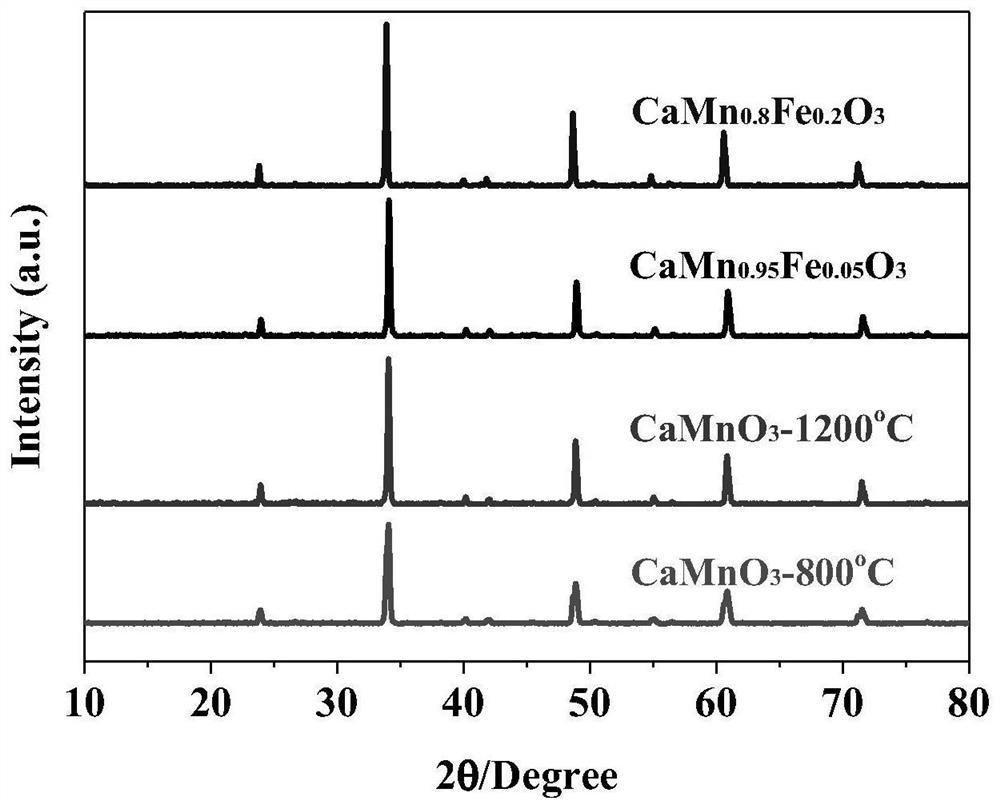

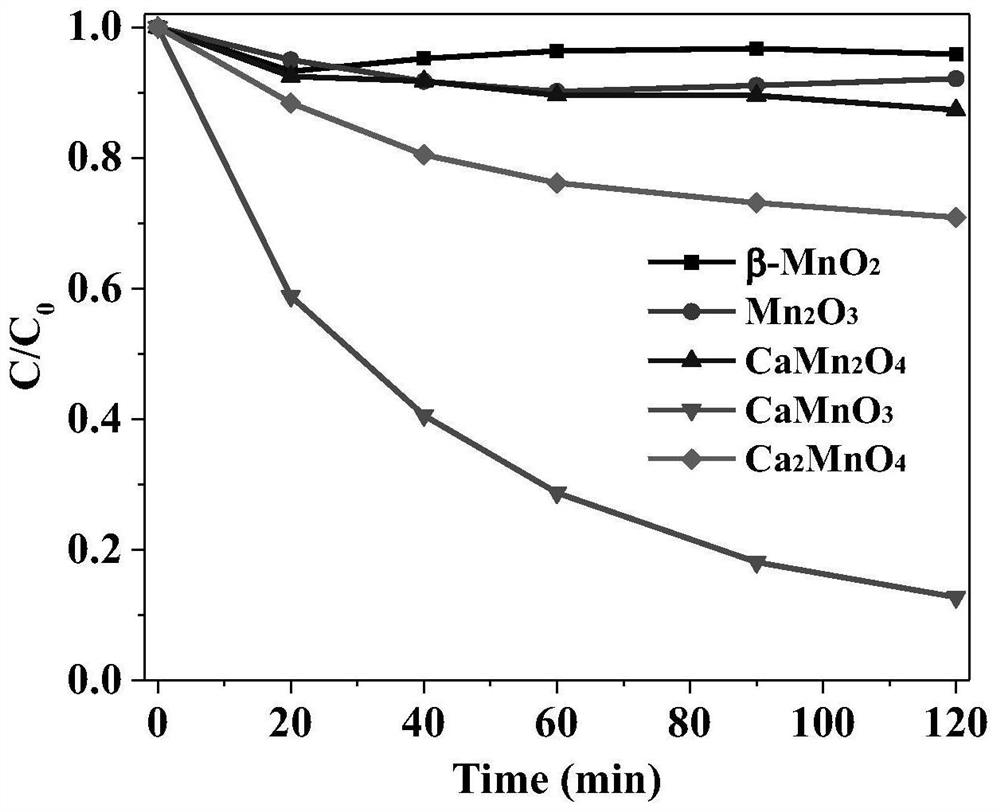

The invention also discloses application of calcium-manganese oxide catalyst in degradation of organic pollutants in wastewater and soil

PendingCN111871422ALow toxicityEasy to synthesizeWater contaminantsHeterogenous catalyst chemical elementsSulfate radicalsPtru catalyst

The invention provides an application of a calcium-manganese oxide catalyst in degradation of organic pollutants in wastewater and soil, and relates to the technical field of catalysis and environmental organic pollutant control. The calcium-manganese oxide (Cax(Mn1-aFea)yOz) catalyst is prepared by a sol-gel method and high-temperature calcination, and is used for activating persulfate to generate active substances with strong oxidizing property, such as sulfate free radicals, hydroxyl free radicals, singlet oxygen and the like, so that organic pollutants in water and soil are rapidly oxidized and removed. The catalyst disclosed by the invention is simple to prepare and environment-friendly, the contained elements are Ca and Mn elements which are low in toxicity, cheap and rich in the earth, the metal dissolution rate in the reaction process is low, and the problem of secondary pollution is avoided. In addition, the reaction system formed by the catalyst and persulfate can rapidly degrade phenol, bisphenol A, 2,6-dichlorophenol, parachlorophenol, paracetamol and other refractory organic pollutants, shows good performance in a wide pH range, and has great application potential.

Owner:SHANGHAI JIAO TONG UNIV

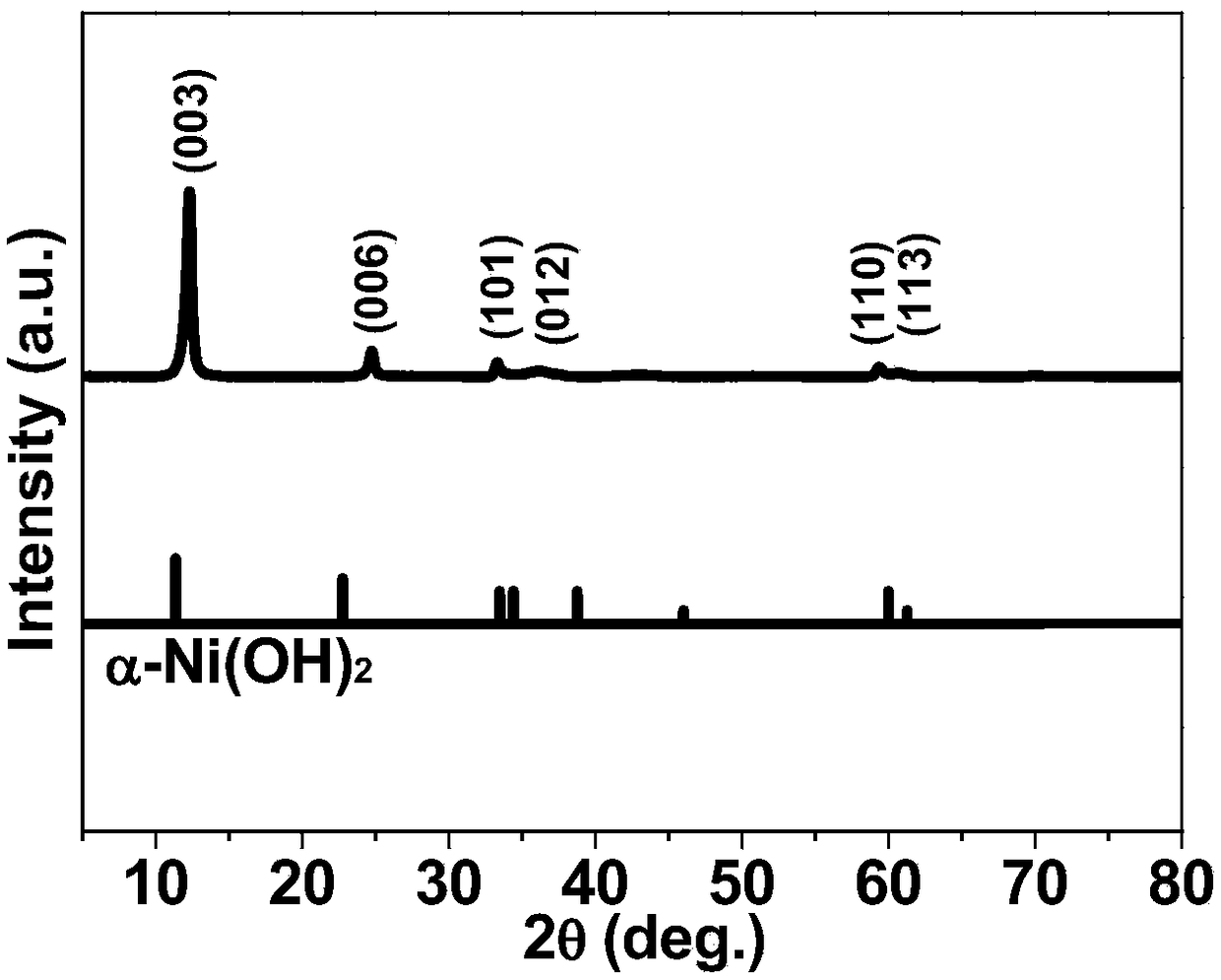

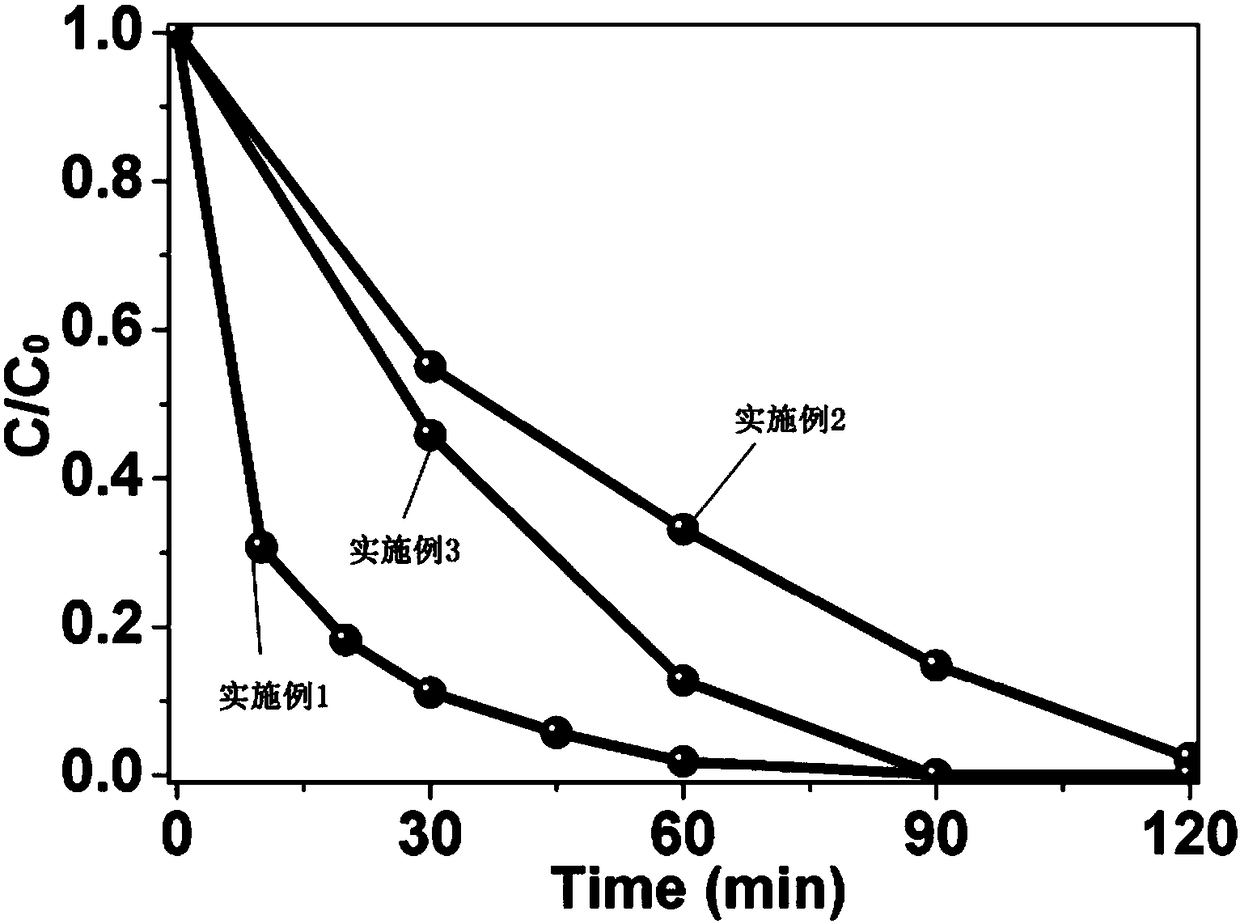

Degradation method of organic pollutants

InactiveCN108314172AImprove bindingCurb churnWater contaminantsWater/sewage treatment by oxidationNickel saltPersulfate

The invention provides a degradation method of organic pollutants. The degradation method comprises following steps: nickel hydroxide nanometer sheets are prepared; the nickel hydroxide nanometer sheets are added into a solution containing organic pollutants, a persulfate is added, and stirring is carried out for degradation so as to realize mineralization of the organic pollutants. A preparationmethod of the nickel hydroxide nanometer sheets comprises following steps: a water soluble nickel salt and urea are dissolved in a mixed solution of water and glycol, an obtained mixture is mixed to be uniform, and is subjected to hydro-thermal reaction at 120 DEG C, and washing and drying are carried out so as to obtain the nickel hydroxide nanometer sheets. Compared with the prior art, the degradation method possesses following beneficial effects: 1, the adopted nickel hydroxide is of a nanometer sheet shaped structure, so that it is beneficial for combination of the catalyst with pollutantsand PS, and the loss of Ni metal can be inhibited effectively; and 2, the preparation method of nickel hydroxide nanometer sheets is simple and convenient.

Owner:SHANGHAI JIAO TONG UNIV

One-machine flotation method and device

InactiveCN102441494AImprove quality and productivityEliminate efficient desorptionFlotationEngineeringMechanical engineering

The invention provides a one-machine flotation method and a device. The device comprises a flotation cavity; a tailings shunting device is arranged on the inner wall surface of the flotation cavity, and comprises more than one spiral channel; an ultrasonic generation device is arranged on the outer wall surface of the flotation cavity; a spiral rotor floating device is arranged at the bottom of the flotation cavity; ore pulp enters into the flotation cavity, and then accomplishes the bubble formation process and the mineralization processes through the spiral rotor floating device synchronously to produce floated ore pulp; floated ore pulp upwards unidirectionally flows in the flotation cavity in a spiral flow state under the guidance of the spiral flow inertia force provided by a spiral rotor to form mineralized bubbles to be discharged from a mineralized bubble outlet; and finally, the flotation process is finished. In the invention, the tailings shunting device is adopted to achieve the continuous scavenging process to outflowing tailings; an ultrasonic dispersion device, the spiral rotor floating device, the tailings shunting device and a liquid medicine cleaning device jointly form a one-machine flotation flow, so that the bubble formation and mineralization effects are fully improved, and the separation of the mineralized bubble from the tailings particles is fully improved with a high efficiency.

Owner:株洲市兴民科技有限公司

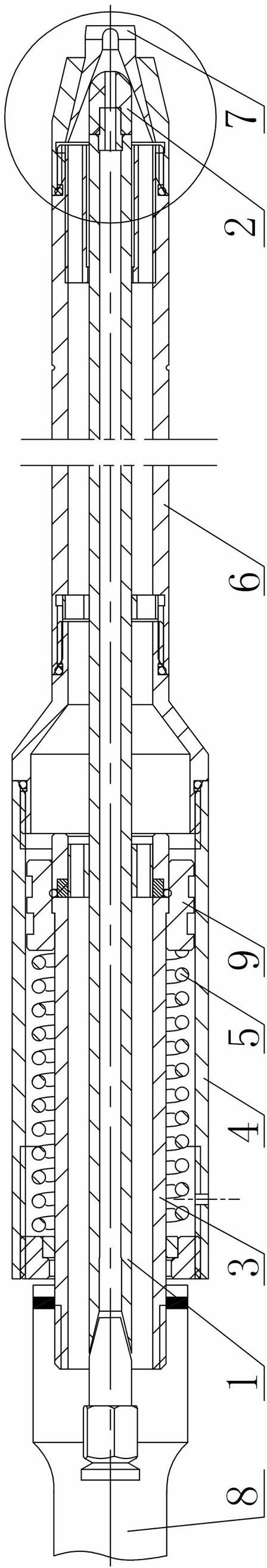

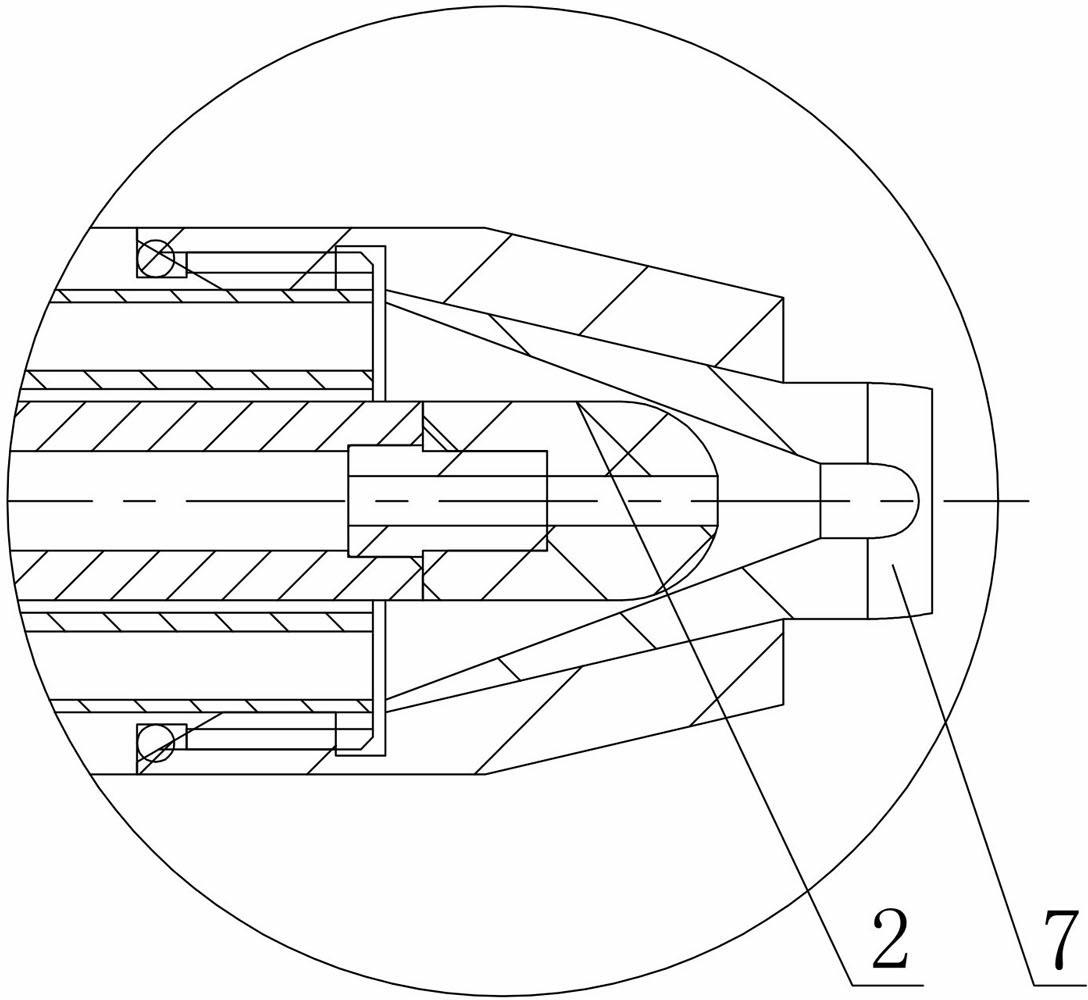

Foaming device

ActiveCN102423733AGood mineralization effectGood bubble effectLiquid spraying apparatusSpray nozzleEngineering

The invention discloses a foaming device comprising a liquid spray nozzle component and a gas spray nozzle component, wherein the liquid spray nozzle component comprises a liquid inlet pipe and a liquid spray nozzle positioned at the tail part of the liquid inlet pipe, the gas spray nozzle component comprises a gas inlet pipe and a gas spray nozzle, and the liquid inlet pipe is coaxially sleeved in the gas inlet pipe. The foaming device has the advantages of being simple and compact in structure, low in cost and good in foaming effect, being capable of improving the foam mineralization effect and the like.

Owner:CHANGGAO ELECTRIC GROUP CO LTD

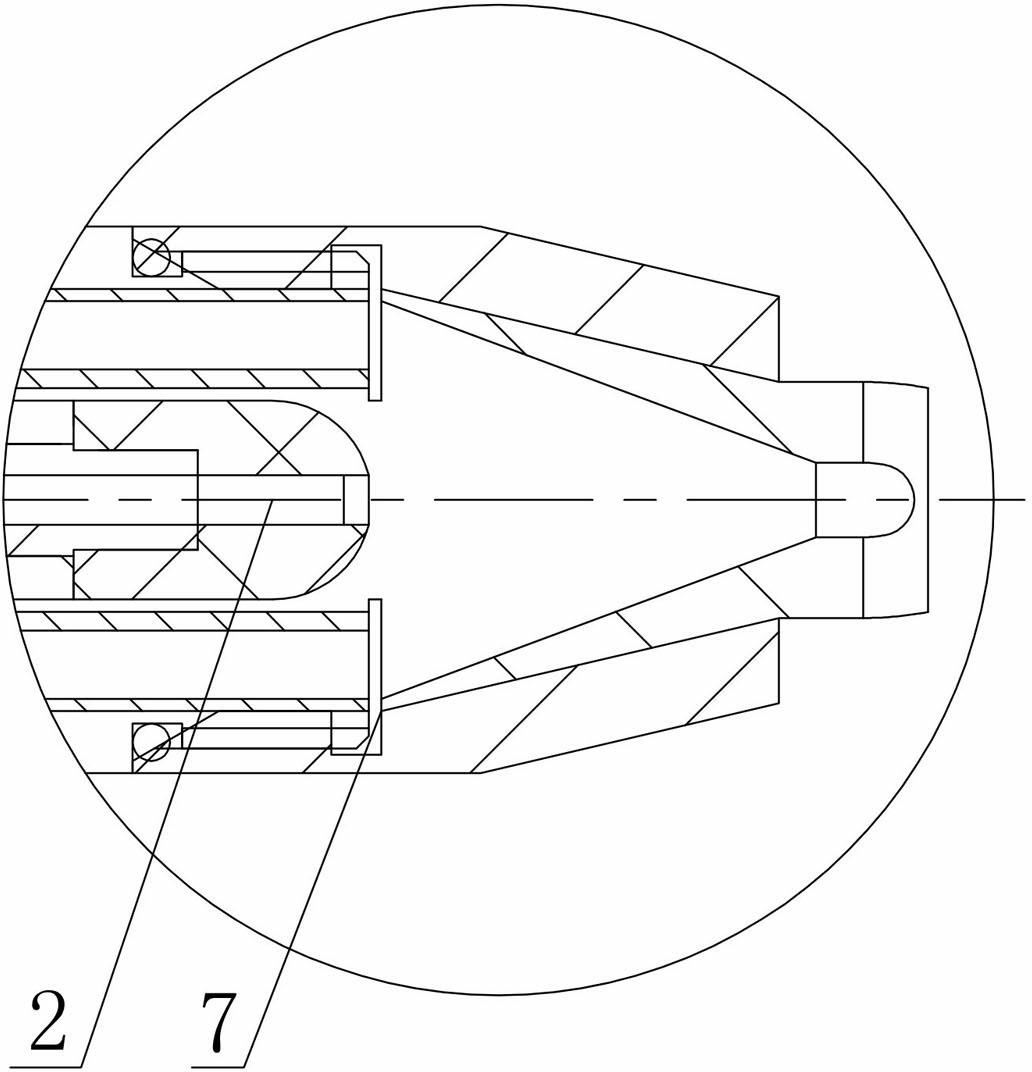

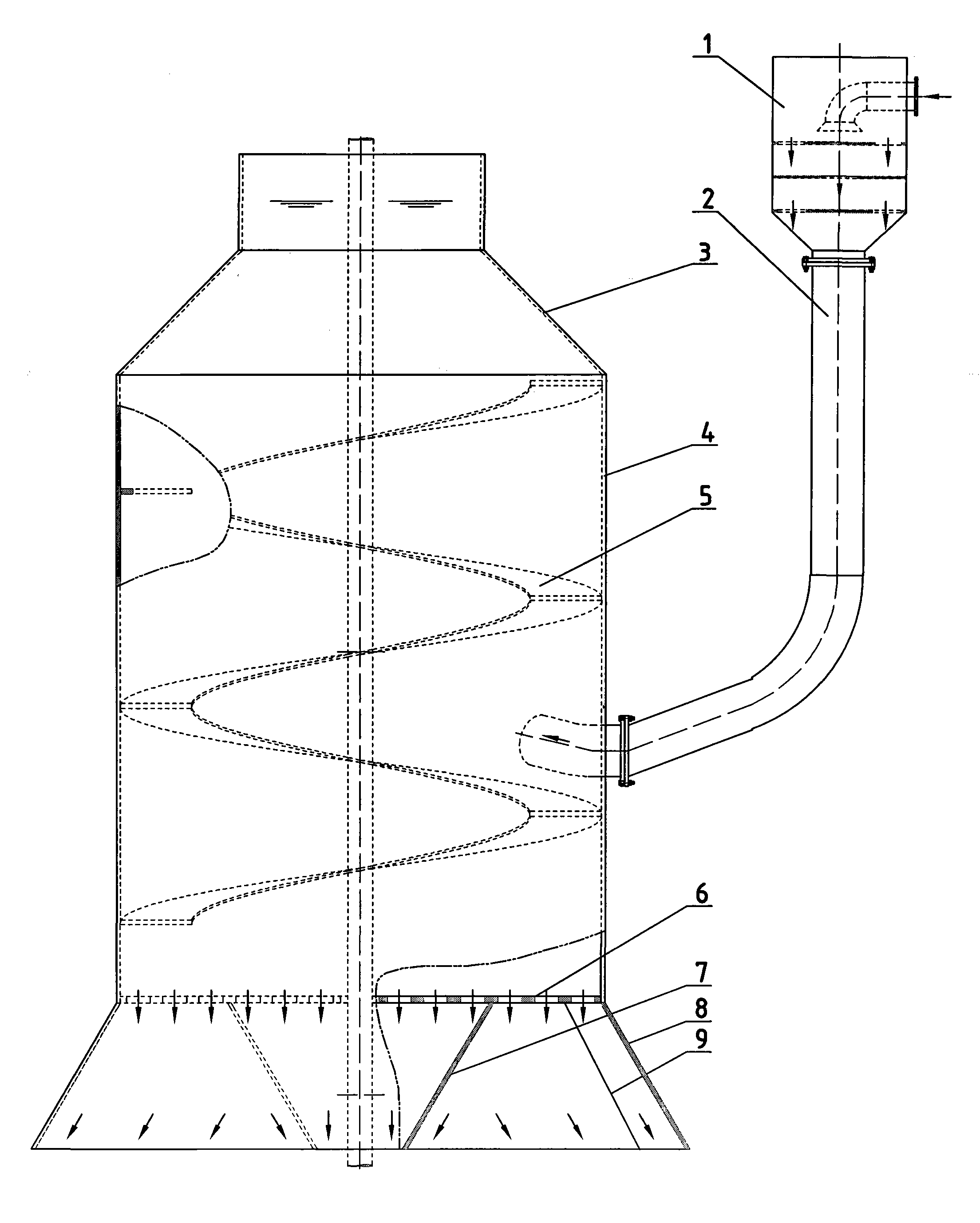

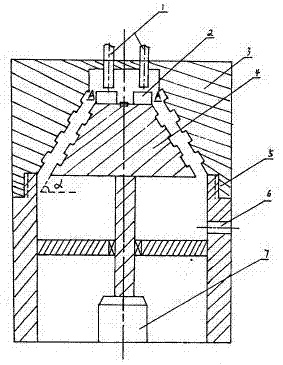

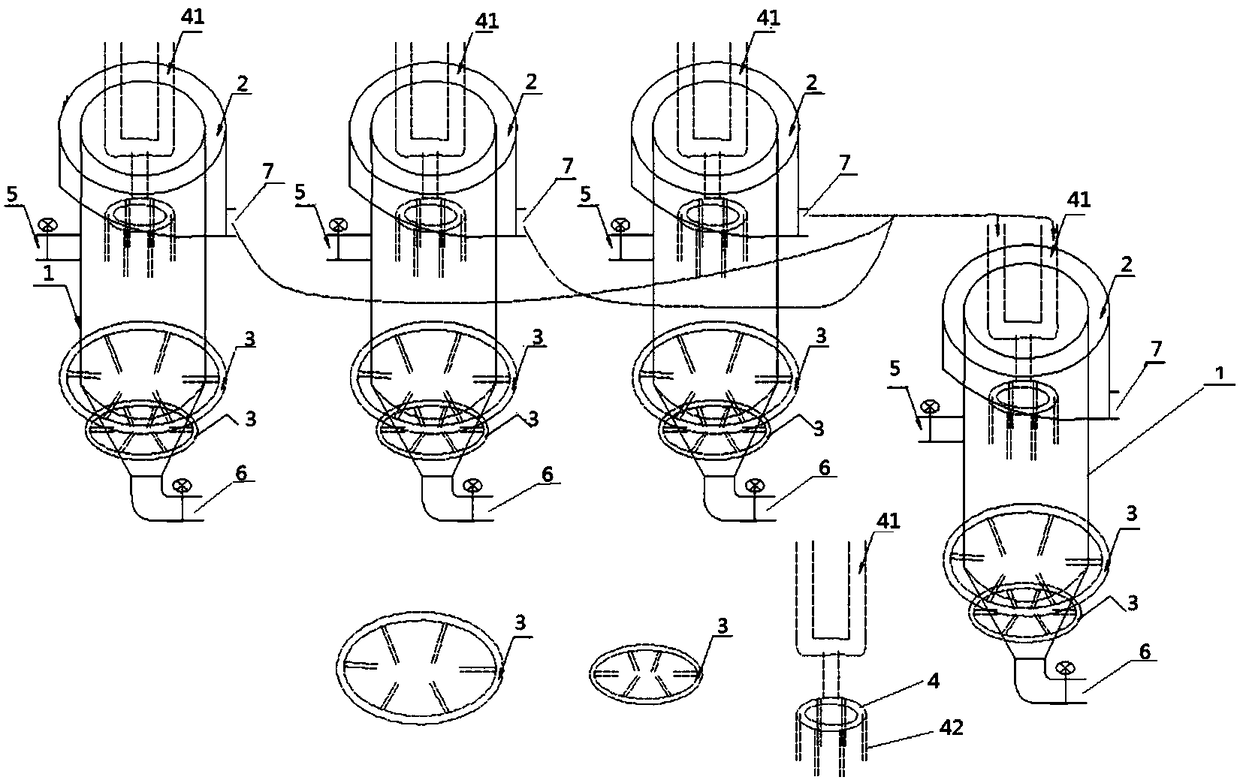

Material stabilization device of concentrator

ActiveCN103301659AGood mineralization effectImprove settlement performanceSettling tanks feed/dischargeSedimentation settling tanksHigh concentrationHelical blade

The invention relates to a material stabilization device of a concentrator, particularly relates to a material stabilization device capable of treating high-concentration and fine-grain slurry which is difficult to concentrate and settle, and belongs to the technical field of concentration and dehydration. The material stabilization device of the concentrator consists of a static flow stabilization mixer, a material feeding pipe, an upper conical barrel, a middle barrel body, a helical blade, a material distribution plate, an inner conical barrel, a lower conical barrel and a partition plate, wherein the lower end of the upper cone barrel is connected with the middle barrel body; the helical blade is connected with the inner wall of the middle barrel body; a plurality of open slots are formed in the helical blade; the material distribution plate is connected with the inner wall of the lower end of the middle barrel body; a plurality of holes are formed in the material distribution plate; the inner conical barrel is a horn-shaped conical barrel which is arranged at the bottom of the middle barrel body and is provided with a large upper part and a small lower part; the lower conical barrel is connected with the lower end of the middle barrel body; and the partition plate is perpendicular to the inner wall of the lower conical barrel and the outer wall of the inner conical barrel. The material stabilization device has the beneficial effects that materials are fed stably, and a flocculating agent and slurry mineralization effect is good; the settling effect of the concentrator is good; and the working efficiency of the concentrator is high.

Owner:山东能源装备集团莱芜装备制造有限公司 +1

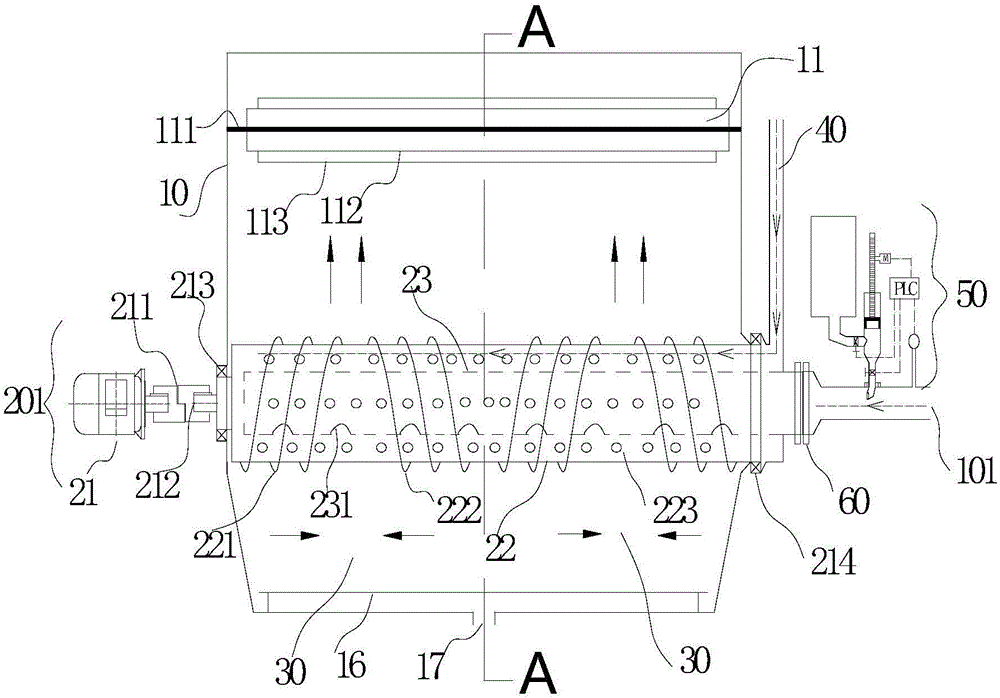

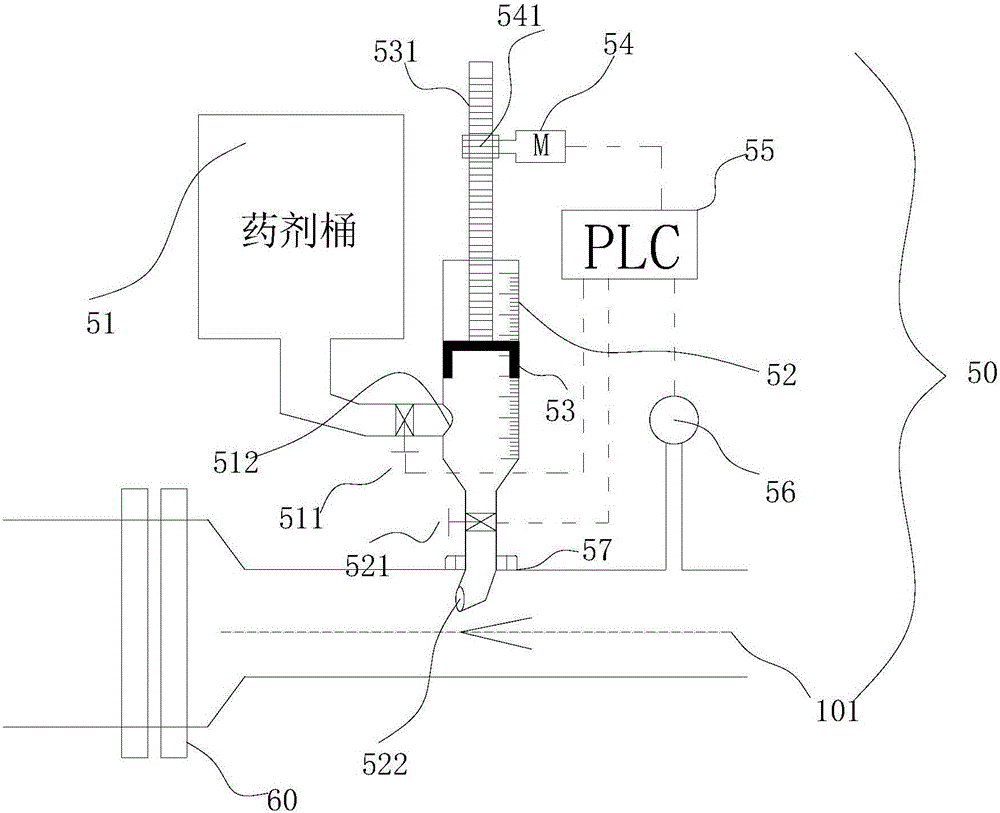

Flotation equipment integrating quantitative chemical adding, reverse stirring and central pulp conditioning

ActiveCN105964415ASimple structureReduce dosageRotary stirring mixersTransportation and packagingImpellerEngineering

The invention belongs to the technical field of pulp conditioning and floating of coal slime, and particularly relates to flotation equipment integrating quantitative chemical adding, reverse stirring and central pulp conditioning. The flotation equipment at least comprises a flotation tank, stirring mechanisms and a quantitative chemical adding system; the stirring mechanisms are horizontally arranged inside the flotation tank in a paired mode, forward spinning impellers and reverse spinning impellers are arranged on the surfaces of drums, and second discharge ports are formed in the surfaces of the drums; material feed pipes are installed inside the drums, first discharge ports are formed in the lower sides of the material feed pipes, and flow separating blocks are uniformly arranged on the inner walls of the material feed pipes; the stirring mechanisms have the cutting, spraying, spinning-spraying and stirring effects and have the effect of mixing three phases four times; gaps are reserved between the drums and the material feed pipes, when the drums rotate at high speed, negative pressure is formed in the gaps, air is sucked, and air flow is cut and dispersed by the second discharge ports; the quantitative chemical adding system is arranged on a pipeline of an ore pulp inlet, and chemicals can be quantitatively added according to the flow of the ore pulp. The flotation equipment further comprises a circulatory foam scraping mechanism for scraping all foam on the tank surface. The flotation equipment has the advantage that ore pulp pretreatment equipment is not needed.

Owner:ANHUI UNIV OF SCI & TECH

Preparation method of farmland heavy metal contaminated soil repairing mineralizer

InactiveCN107312543AReduce manufacturing costSmall particle sizeOrganic fertilisersSoil conditioning compositionsAluminateCalcium hydroxide

The invention relates to a preparation method of a farmland heavy metal contaminated soil repairing mineralizer. Calcium chloride, calcium aluminate, aluminum oxide, calcium hydroxide and water are simultaneously added into a fully backmixing liquid film reactor for liquid-liquid two-phase co-precipitation reaction according to certain ratios, then are dispersed by a liquid distributor, and are fully mixed in a gap between a rotor and a stator, and a mixture is discharged through a material outlet to a crystallizing kettle for crystallization, so that mineralizer powder with the particle size being 20 nm to 5 [mu]m and the purity being 99.9 percent or above. The preparation method has the advantages that the mineralizer prepared with the preparation method can adsorb heavy metal ions in soil of a farmland, and the heavy metal ions are stabilized and solidified in the mineralizer and are inactivated; meanwhile, all raw materials, such as the calcium chloride, the calcium aluminate, the aluminum oxide and the calcium hydroxide, are common raw materials, so that the raw materials are readily available, and the preparation cost of the mineralizer is greatly reduced.

Owner:JIANGSU LONGCHANG CHEM

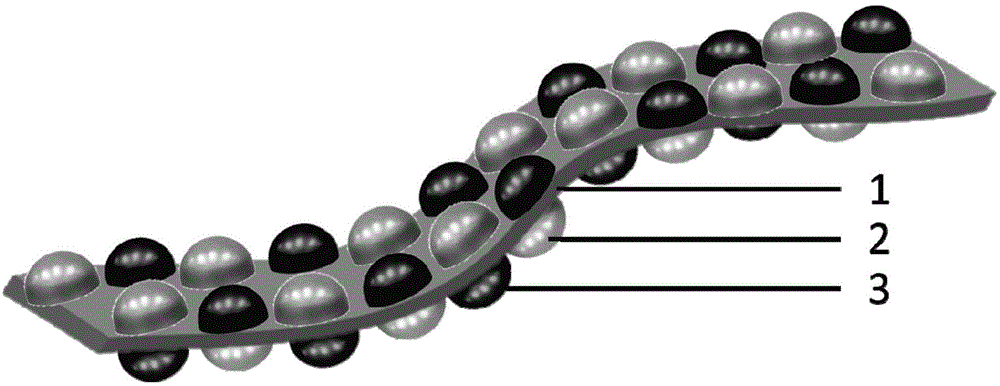

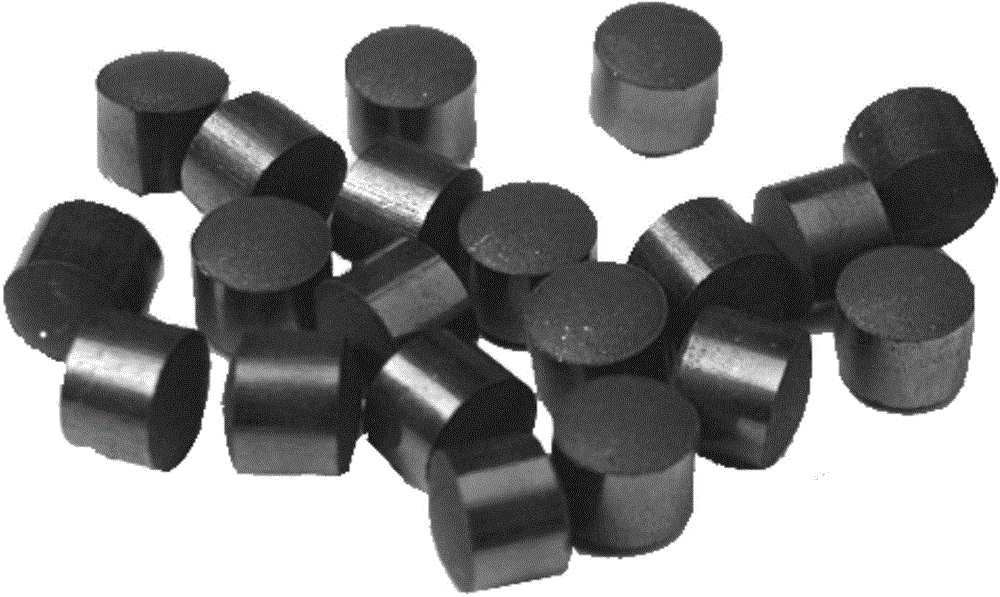

Reaction speed-controllable iron-titanium dioxide-carbon ternary micro-electrolysis composite nanometer catalyst and preparation method thereof

ActiveCN104607189AAchieve migrationInhibit sheddingMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationNano catalystElectrolysis

The invention discloses a reaction speed-controllable iron-titanium dioxide-carbon ternary micro-electrolysis composite nanometer catalyst. The catalyst adopts a cylindrical porous structure in shape and is formed by taking a titanium dioxide nano belt as a carrier and gathering a ribbon dispersed and embedded with carbon particles and metal iron particles on the surface, wherein the mass percentage of the titanium dioxide is 20-80 percent; the mass percentage of the carbon is 10-40 percent; the mass percentage of the iron is 10-40 percent; the ribbon has the length of 5-220 [mu]m, the width of 100-200 nm and the thickness of 20-40 nm; each of the carbon particles dispersed and embedded on the surface of the ribbon has the particle size of 30-50 nm, and each of metal iron particles has the particle size of 60-70 nm. The invention further discloses application of the catalyst. An experiment proves that the catalyst disclosed by the invention has high oxidation and catalysis ability and good mineralization effect and is widely applied to industrial water treatment.

Owner:浙江威尔森新材料有限公司

Foaming device

ActiveCN102423733BGood mineralization effectGood bubble effectLiquid spraying apparatusEngineeringNozzle

The invention discloses a foaming device comprising a liquid spray nozzle component and a gas spray nozzle component, wherein the liquid spray nozzle component comprises a liquid inlet pipe and a liquid spray nozzle positioned at the tail part of the liquid inlet pipe, the gas spray nozzle component comprises a gas inlet pipe and a gas spray nozzle, and the liquid inlet pipe is coaxially sleeved in the gas inlet pipe. The foaming device has the advantages of being simple and compact in structure, low in cost and good in foaming effect, being capable of improving the foam mineralization effect and the like.

Owner:CHANGGAO ELECTRIC GROUP CO LTD

Preparation for aquatic product culturing industry and preparation method

InactiveCN1579150AWith adsorptionImprove adsorption capacityClimate change adaptationPisciculture and aquariaDiseaseAquaculture industry

The invention discloses an aquiculture-used preparation and its preparing method, where its components in weight ratio: zeolite 70-80 kg, meaical stone 0.5-2 kg, CuSO4 0.5-2 kg, and Ca2O2 0.5-2 kg, and its preparing method: adding them to a blender to mechanically blend to make it. It has a synthetic function, such as absorbing harmful matters in the breeding water body, like amino nitrogen and sulfureted hydrogen, increasing the content of dissolved oxygen, sterilizing, increasing the content of trace elements, etc, and a synthetic effect, such as obvious abilities to improve and optimize ecological environment of breeding, promote the growth of bred living beings, and inhibit bacteria and prevent diseases, etc.

Owner:王同明

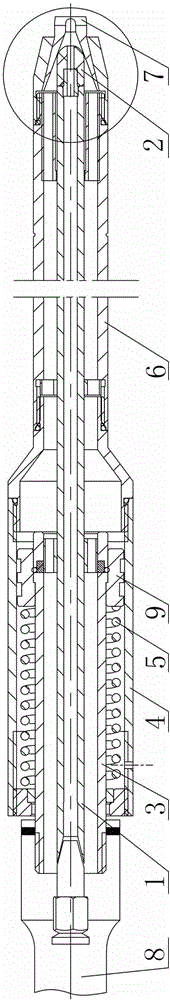

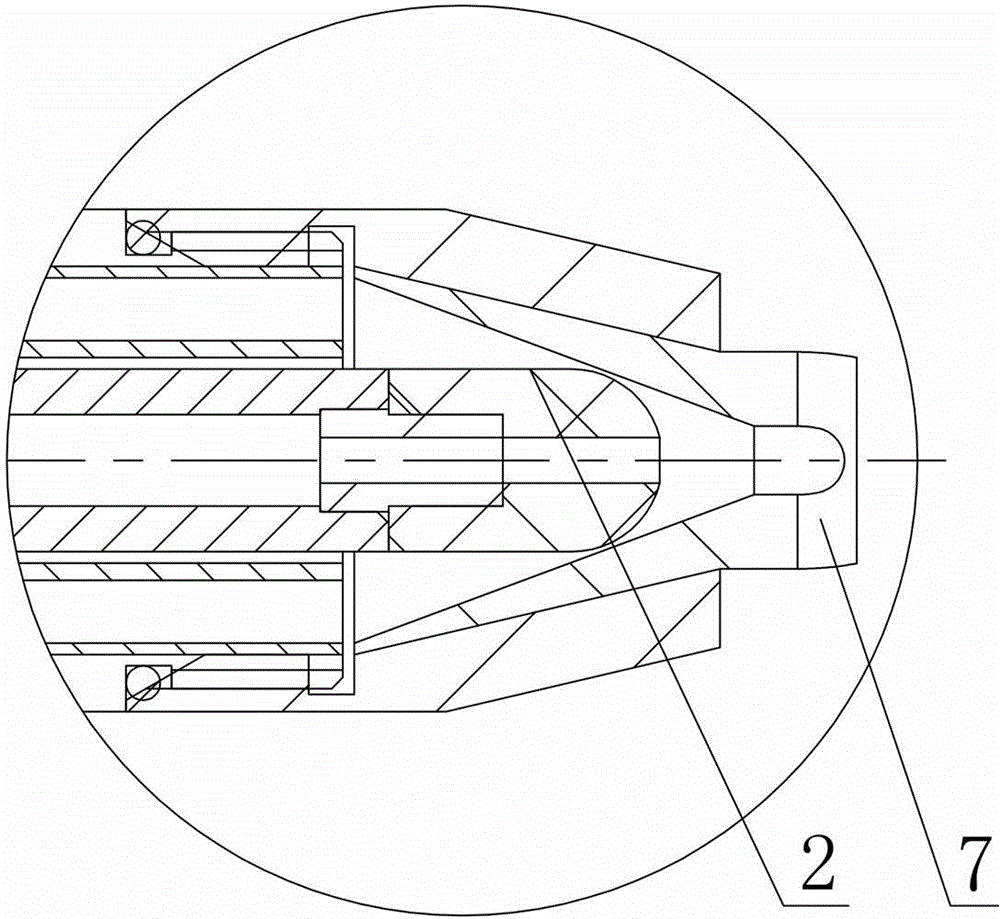

Columnar flotation device for micro-fine particle minerals

The invention discloses a columnar flotation device. The columnar flotation device comprises a flotation column columnar shell, a concentrate overflow trough located on the outer side of the upper portion of the shell, air pipes located at the inner bottom of the flotation column shell and a pulp feeder located on the inner upper portion of a flotation column. The pulp feeder is connected with a mineral feeding pipeline, and a tailing discharging opening is arranged in the middle of the flotation column shell. The shell is further provided with a concentrate discharging opening, and the position of the concentrate discharging opening is higher than that of the tailing discharging opening. The lower portion of the shell is of a cone structure, an accident emergency gate valve opening is mounted at the bottom of the cone structure, and the tailing discharging opening and the accident emergency gate valve opening are both provided with valves for control. The columnar flotation device ishigh in flotation pulp flow speed, large in collision probability with bubbles, high in turbulent degree, good in mineralization effect, capable of recycling micro-fine particle minerals well and meeting the requirement of the micro-fine particle mineral separation process and wide in application range.

Owner:甘肃省合作早子沟金矿有限责任公司 +1

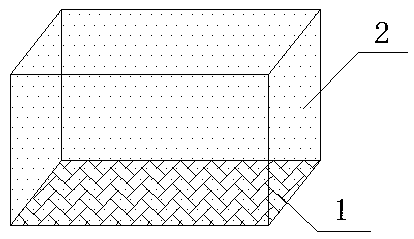

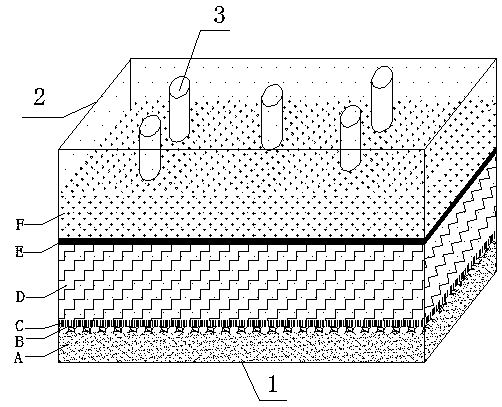

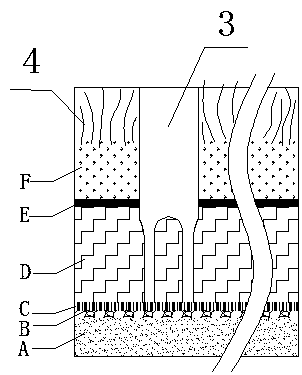

Camellia oleifera forest soil aging system and manufacturing method thereof

ActiveCN108738442AFlourishingPromote growthSoil lifting machinesBio-organic fraction processingSoil scienceCamellia oleifera

A camellia oleifera forest soil aging system relates to the technical field of agricultural soil improvement. Camellia oleifera forest soil aging system is characterized in that the system comprises an incubator consisting of a bottom plate and a side plate, the incubator is sequentially provided with a water-retaining layer, a cobble layer, a straw layer, an earthworm layer, a manure layer and amatrix layer from bottom to top; a feeding pipe is also arranged in the incubator. The system is simple and convenient to use in nursery scale and batch cultivation. By adopting the system, the soil aging is fast, the physical and chemical properties of the soil are obviously improved, the growth of the oil tea is promoted, and a large amount of field labor is saved, the productivity of the forestland can be quickly improved.

Owner:LISHUI ACAD OF FORESTRY

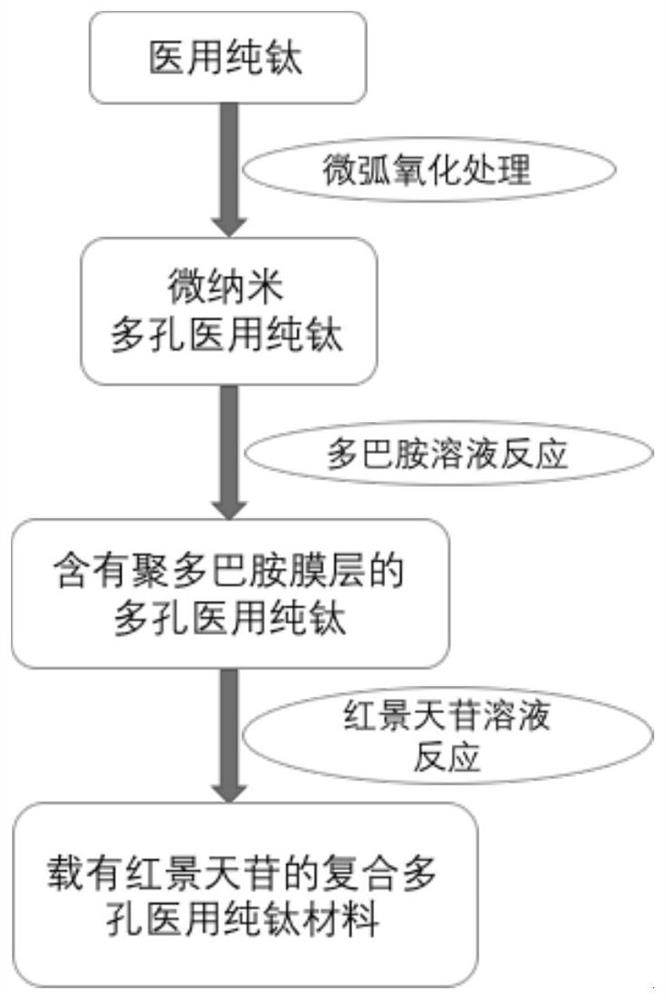

Orthopaedic implantation instrument with osteogenesis promoting coating on surface and preparation method

PendingCN112402693AEasy to prepareGood biocompatibilityTissue regenerationCoatingsMicro nanoDentistry

The invention provides an orthopaedic implantation instrument with an osteogenesis promoting coating on the surface and further discloses a preparation method of the orthopaedic implantation instrument. A polydopamine coating is arranged on the surface of a smooth orthopaedic implantation instrument base body or an orthopaedic implantation instrument base body with a micro-nano structure, and salidroside is fixed on the surface of the polydopamine coating to form the osteogenesis promoting coating. The preparation method of the orthopaedic implantation instrument comprises the following steps:1) pretreating the orthopaedic implantation instrument base body to obtain a smooth or micro-nano structure surface appearance on the surface; (2) after the orthopaedic implantation instrument base body is pretreated, adding the orthopaedic implantation instrument into a dopamine solution to react for a period of time to form the polydopamine coating on the surface of the orthopaedic implantationinstrument, then putting the orthopaedic implantation instrument into a solution containing the salidroside, and fixing the salidroside on the surface of the orthopaedic implantation instrument by utilizing the excellent bonding performance of the polydopamine coating on the surface of the orthopaedic implantation instrument; and 3) rinsing the material with deionized water, and naturally dryingthe rinsed material.

Owner:SHANGHAI CITY JIADING DISTRICT CENT HOSPITAL

Zinc mineralization composite sintered activated carbon filter element and preparation method thereof

InactiveCN107694215AEfficient releaseImprove practicalityWater/sewage treatment by neutralisationWater/sewage treatment by substance additionActivated carbonZinc

The invention discloses a zinc mineralization composite sintered activated carbon filter element which is prepared from the following raw materials in parts by weight: 2-200 parts of modified calaminepowder granules, 2-200 parts of modified zeolite powder granules, 2-200 part of modified medical stone powder granules, 2-200 parts of modified coral powder granules, 20-500 parts of activated carbonpowder and 5-150 parts of supra polymer polyethylene. The invention further discloses a preparation method of the zinc mineralization composite sintered activated carbon filter element. According tothe preparation method, raw materials such as modified zinc ore enriched calamine and carbon powder are uniformly mixed according to a certain ratio to prepare sintered activated carbon rods, the zincelement can be effectively and slowly released from ore in the continuous water introduction process, the content of the zinc of effluent is maintained within a certain range, long-term zinc requirements of human bodies are met, and wide application prospects and market popularization values are met.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for preparing SAPO-34 molecular sieve

ActiveCN101767800BIncrease profitChange shapeMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveCrystallization temperature

The invention provides a method for preparing a SAPO-34 molecular sieve. The method comprises the following steps of: 1, uniformly mixing a proper amount of phosphorus source, aluminum source, silicon source, template, auxiliary template and water at a proper temperature and under a stirring condition to obtain mixed solution, of which a molar ratio of all components, namely, the molar ratio of Rto F- to SiO2 to Al2O3 to P2O5 to H2O, is a:b:c:1:d:e, wherein R represents the template, a is 0.2 to 5.0, b is 0 to 1.0, c is 0.2 to 1.5, d is 0.2 to 2.0 and e is 20 to 200; 2, ageing the mixed solution; and putting the aged mixed solution in a crystallization kettle, sealing the crystallization kettle, heating the mixed solution to a crystallization temperature, and crystallizing the mixed solution at the constant crystallization temperature; 3, performing centrifugal separation of the crystallized mixed solution, filtering, washing the mixed solution until a pH value of the mixed solution is 7 to 8, and drying a solid sample to obtain the SAPO-34 raw powder; and 4, baking the SAPO-34 raw powder at the temperature of between 450 and 650 DEG C for 4 to 8 hours to obtain the SAPO-34 molecular sieve. The SAPO-34 molecular sieve prepared by the method is characterized by high crystallinity and can show better low carbon olefin selectivity in an MTO reaction.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for producing sulphate aluminum cement

The invention relates to a method for producing sulphoaluminate cement. Limestone, phosphogypsum, low-grade bauxite and coke are formulated into cement raw meal in a certain proportion, and calcined at high temperature after grinding and mixing. Promote the decomposition of phosphogypsum as much as possible, and the calcium oxide generated by the decomposition can replace part of the limestone. The sulfur dioxide gas can be collected to prepare sulfuric acid. The obtained cement clinker is mixed with natural dihydrate gypsum and ground to make cement products. Compared with the existing traditional production method, the method of the present invention can greatly improve the utilization rate of phosphogypsum, avoid the concentration of sulfur dioxide emitted by a small amount of decomposition of gypsum in the production process, which cannot reach the concentration used, and can also reduce the amount of limestone and carbon dioxide emissions. Burnt cement has wide adaptability and can be widely used in the production of sulphoaluminate cement using phosphogypsum, and is also suitable for the production of rapid hardening cement and expansive cement.

Owner:CHONGQING UNIV

Preparation method of siliceous hot repairing material with low cost and low water demand

The invention relates to a preparation method of a siliceous hot repairing material with low cost and low water demand, and belongs to the field of refractory materials. The siliceous hot repairing material is prepared from 30-65 wt% of fused quartz, 15-40 wt% of silica, 10-20 wt% of waste silica bricks, 6-15 wt% of silica micro-powder, 1-6 wt% of a mineralizing agent, 4-10 wt% of a binding agent,1-5 wt% of a sintering aid and 0.1-1 wt% of a superplasticizer. The waste silicon bricks are used as a raw material, so that the material cost is obviously reduced; the construction water demand is 7-11%, so the secondary damage degree to a furnace wall is reduced; the siliceous hot repairing material has a high bonding strength with the silicon bricks, and has small corrosivity, and the siliceous hot repairing material and the silicon bricks have thermal expansion synchronism; and the product provided by the invention has the characteristics of good wear resistance, high softening temperature under load, good thermal shock stability, high wall-climbing rate and the like.

Owner:江苏诺明高温材料股份有限公司

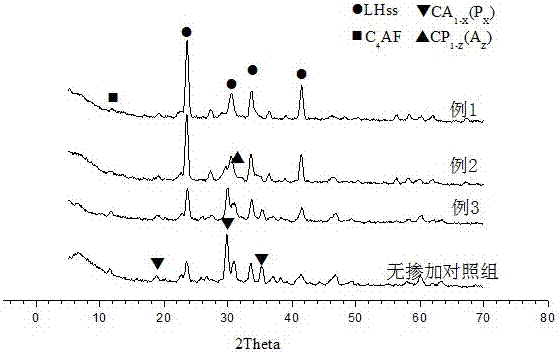

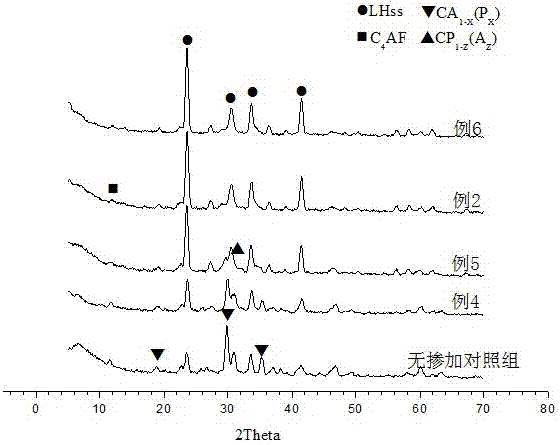

Composite mineralizer for barium calcium phosphoaluminate cement

The invention relates to a mineralizer for cement production, and in particular, relates to a composite mineralizer for barium calcium phosphoaluminate cement. The composite mineralizer for the barium calcium phosphoaluminate cement comprises the main chemical components by the mass percentage: 20-54% of Fe2O3, 13.5-33.3% of SO3, 13.5-20.8% of MgO, 5-10.4% of CaF2, and 13.5-16.5% of Na2O or K2O, wherein the mixing mass percentage of the composite mineralizer in a barium calcium phosphoaluminate cement raw material is 1.25-10%. According to the composite mineralizer, SO3 comes from a variety of industrial waste gypsums, MgO comes from high-magnesium limestone, Fe2O3 comes from steel slag, and Na2O or K2O comes from cement main raw material impurities. According to the composite mineralizer for the barium calcium phosphoaluminate cement, cement clinker formation is promoted by introducing the compound mineralizer, the calcination temperature is reduced by 150-200 DEG C, the formation of a main mineral phase barium calcium phosphoaluminate is significantly promoted, a conventional rotary kiln production line can be applied to production of the barium calcium phosphoaluminate cement, the large-scale production is facilitated, and energy saving and consumption reduction of the production process are achieved.

Owner:UNIV OF JINAN

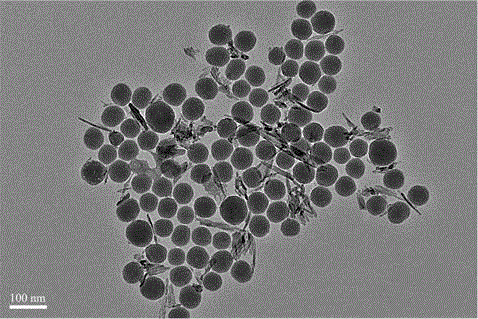

Silicon oxide-calcium phosphate class composite nano-filler and preparation method thereof

The invention provides a silicon oxide-calcium phosphate class composite nano-filler and a preparation method thereof. Tetraethoxysilane and ethyl alcohol are evenly mixed; temperature rises to 25 DEG C TO 60 DEG C; ammonium hydroxide, water and ethyl alcohol are evenly mixed to be added into the above mixed liquor; an reaction is continuously made for 4 hours to 12 hours; heating is stopped; and stirring is carried out for 4 hours to 48 hours at the normal temperature to obtain alcosol A of silicon oxide. The pH value of the alcosol A is adjusted to range from 4 to 11; a silane coupling agent is added into the alcosol A; and the mixture is mixed with a diammonium hydrogen phosphate solution to obtain a mixed solution B. A dissoluble calcium saline solution is dropped into the solution B to obtain a solution C; stirring is carried continuously in the dropping process; aging of the solution C is carried out for 4 hours to 48 hours, repeated centrifugal separation washing is carried out with a solvent; and drying is carried out to obtain the silicon oxide-calcium phosphate class composite nano-filler. The silicon oxide-calcium phosphate class composite nano-filler is good in dispersibility, high in modificability, simple in preparation method and prone to industrialization.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com