Silicon oxide-calcium phosphate class composite nano-filler and preparation method thereof

A nano-filler and silicon oxide technology, applied in medical science, prosthesis, etc., to achieve the effects of easy industrialization, good dispersibility, and strong modifiability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

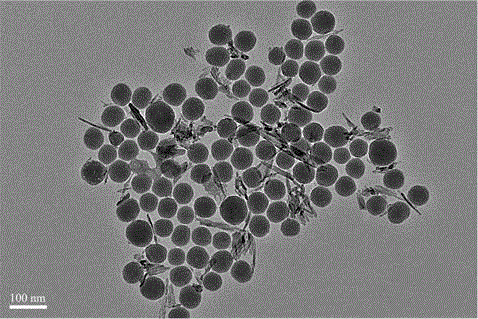

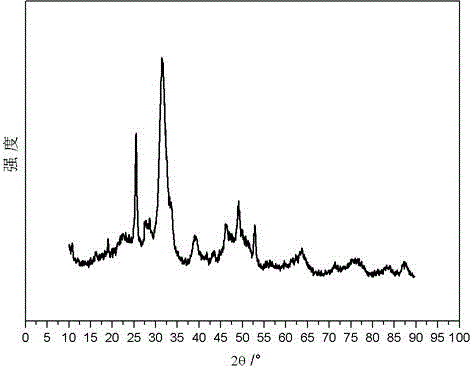

[0024] Mix 7ml of TEOS (tetraethyl orthosilicate) and 160ml of ethanol evenly, heat up to 50°C; then mix 7ml of ammonia water, 9ml of water and 20ml of ethanol into the above mixture, and continue the reaction for 5 hours. Stop heating, then stir at room temperature for 12 hours to obtain silicon oxide alcohol sol A; adjust the pH value of A to 10 with ammonia water, add 30 ml of KH570, and mix it with 5 ml of 0.5M diammonium hydrogen phosphate solution to obtain a mixed solution B; 8.2 milliliters of calcium nitrate solutions are added dropwise to the B solution at a certain rate to obtain solution C, and are continuously stirred at a certain rate during the dropping process; after the C solution is aged for 20 hours, acetone is used to carry out multiple centrifugal separation and washing, and then The silica-hydroxyapatite composite nanoparticles were obtained by freeze-drying. Such as figure 1 and 2 Shown are TEM (transmission electron microscope photos) and XRD (X-ray d...

Embodiment 2

[0026] Mix 7ml of TEOS (tetraethyl orthosilicate) and 160ml of ethanol evenly, and heat up to 50°C; then mix 9ml of ammonia water, 9ml of water and 20ml of ethanol into the above mixture, and continue to react for 4 hours. Stop heating, then stir at room temperature for 4 hours to obtain silicon oxide alcohol sol A; adjust the pH value of A to 10 with ammonia water, add 30 ml of KH570, and mix it with 5 ml of 0.5M diammonium hydrogen phosphate solution to obtain a mixed solution B; 8.2 milliliters of calcium nitrate solutions are added dropwise to the B solution at a certain rate to obtain solution C, and are continuously stirred at a certain rate during the dropping process; after the C solution is aged for 20 hours, acetone is used to carry out multiple centrifugal separation and washing, and then The silica-hydroxyapatite composite nanoparticles were obtained by freeze-drying.

Embodiment 3

[0028] Mix 9ml of TEOS (tetraethyl tetrasilicate) and 160ml of ethanol evenly, and control the temperature at 30°C; then mix 9ml of ammonia water, 9ml of water and 20ml of ethanol into the above mixture, and continue to react for 12 hours , stop heating, and then stir at room temperature for 48 hours to obtain silicon oxide alcohol sol A; adjust the pH value of A to 5 with ammonia water, add 30 ml of KH570, mix it with 5 ml of 0.5M diammonium hydrogen phosphate solution, and obtain a mixed Solution B; 8.2 milliliters of calcium nitrate solutions are added dropwise to the B solution at a certain rate to obtain solution C, and the dripping process is continuously stirred at a certain rate; after the C solution is aged for 20 hours, ethanol is used to carry out multiple centrifugation and washing, and then Silica-calcium phosphate composite nanoparticles are obtained by freeze-drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com