The invention also discloses application of calcium-manganese oxide catalyst in degradation of organic pollutants in wastewater and soil

A technology for organic pollutants and catalysts, which is applied in the field of catalysis and organic pollutant treatment to achieve good degradation and mineralization effects, low metal dissolution, and easy storage and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A catalyst Ca x Mn y O z Preparation of:

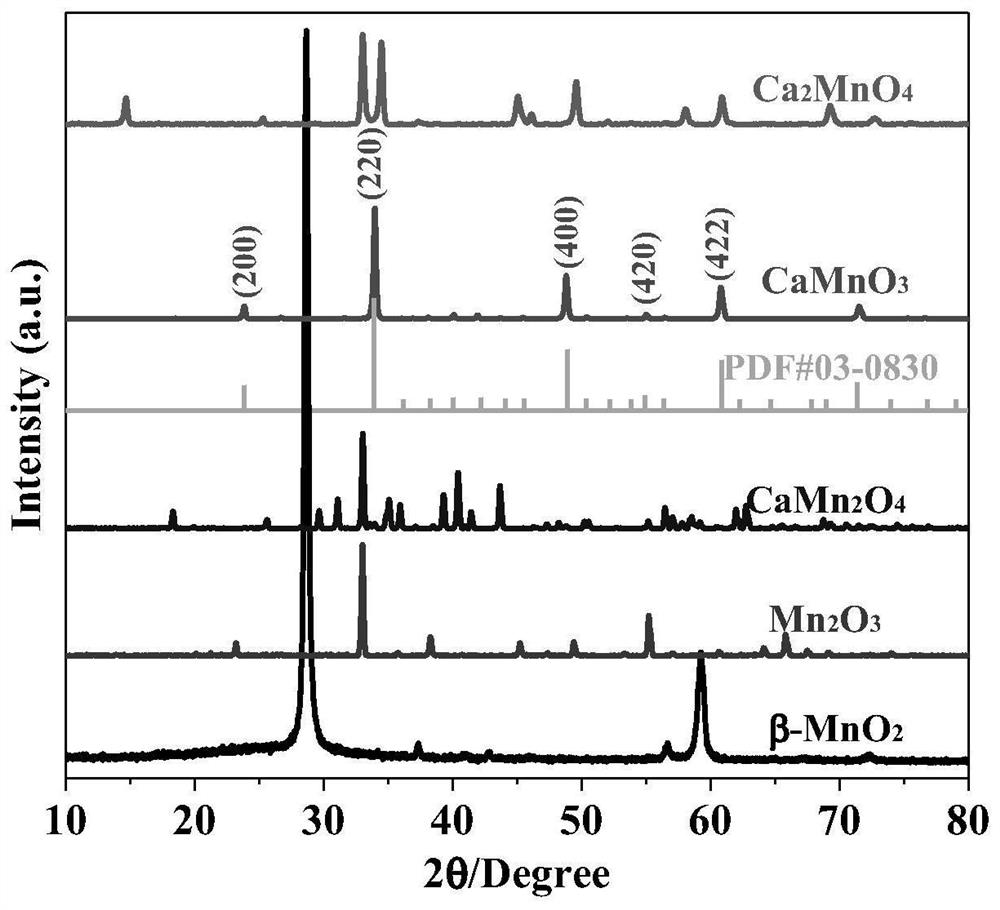

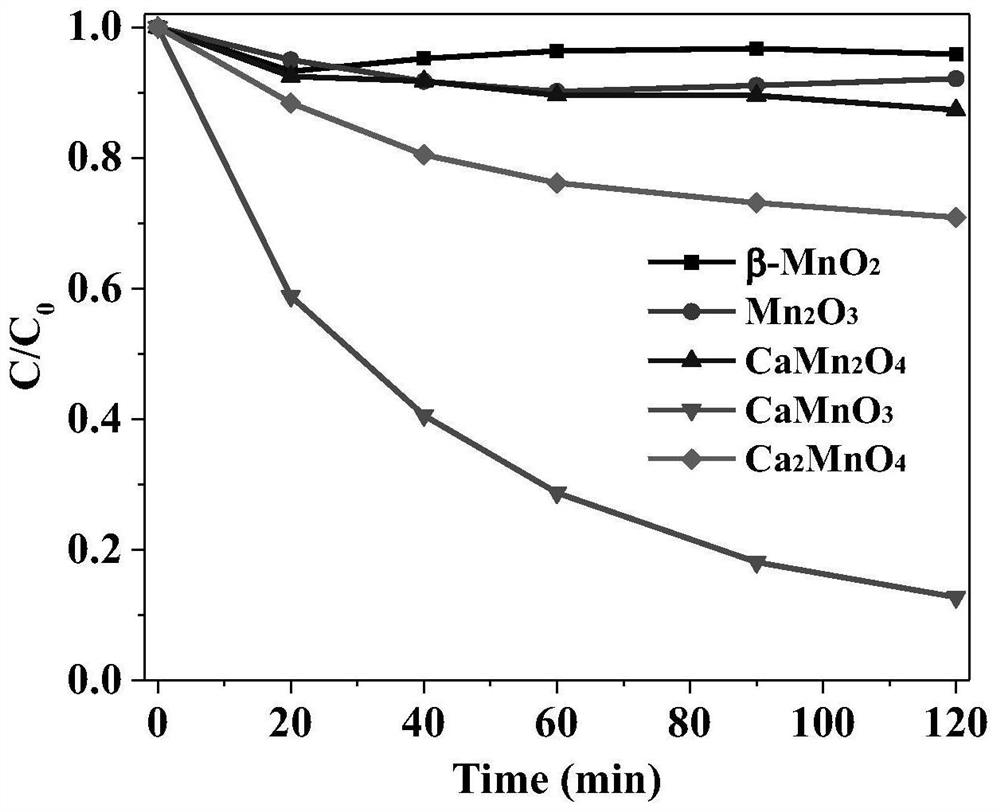

[0037] Calcium nitrate tetrahydrate and manganese nitrate in different stoichiometric ratios were added to 10 mL of deionized water, and the total molar amount of metal Ca and Mn was 4 mmol to synthesize Mn.2 O 3 , CaMn 2 O 4 , CaMnO 3 and Ca 2 MnO 4 The ratios of the added calcium nitrate tetrahydrate and manganese nitrate are 0:1, 1:2, 1:1 and 2:1 respectively, add 8 mmol of citric acid and 2 mL of ethylene glycol, and stir and dissolve at room temperature until uniform. The solution was then placed in an oven at 80 °C for 24 hours to obtain a homogeneous colloid; the obtained colloid was transferred to a crucible, and placed in a muffle furnace for calcination with a set program: the temperature was raised to 900 at a temperature of 5 °C / min. ℃ and maintained for 3 hours, and finally lowered to room temperature at a cooling rate of 5 ℃ / min; the calcined powder was collected and ground to obtain the corresponding cata...

Embodiment 2

[0040] A catalyst Ca x Mn y O z Preparation of:

[0041] Calcium nitrate tetrahydrate and manganese nitrate were added to 10 mL of deionized water, and the total molar amount of metal Ca and Mn was 4 mmol to synthesize CaMnO 3 The ratio of calcium nitrate tetrahydrate and manganese nitrate added was 1:1, 4 mmol of citric acid and 10 mL of ethylene glycol were added, stirred and dissolved at room temperature to obtain a uniform solution, and then placed in an oven at 60 ° C for 48 hours to obtain Homogeneous colloid; transfer the obtained colloid into a crucible, put it into a muffle furnace and calcine with a set program: raise the temperature at 2°C / min to 800°C and keep it for 6h, and finally cool at 2°C / min The rate is reduced to room temperature; the calcined powder is collected and ground to obtain the corresponding catalyst.

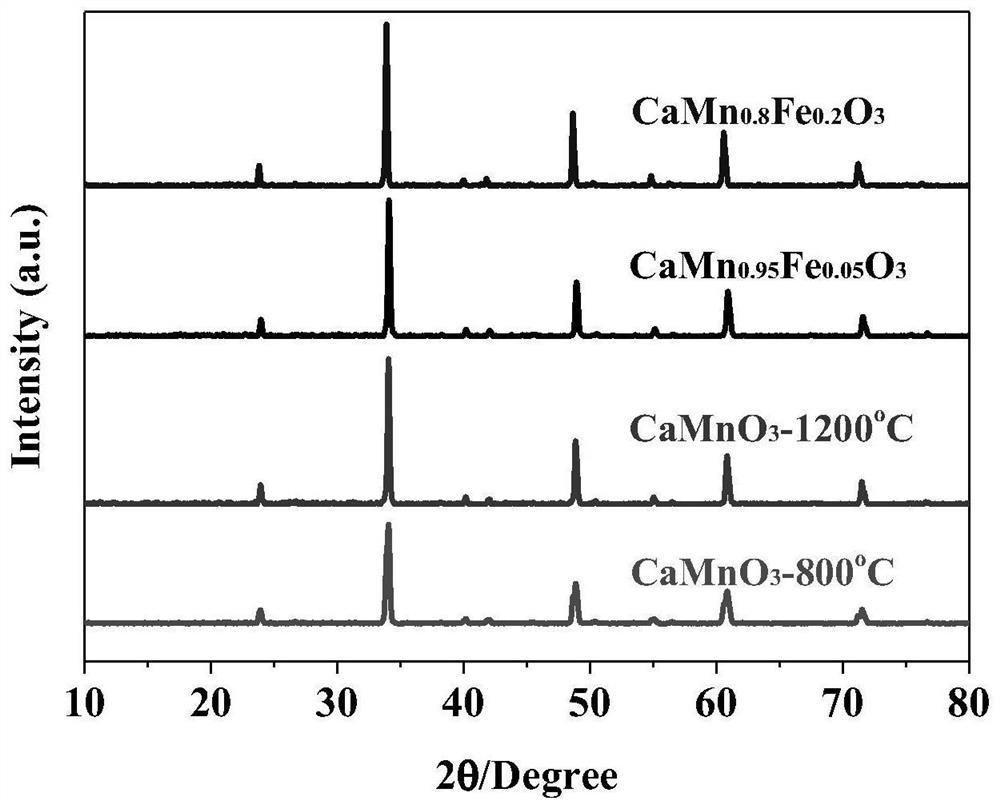

[0042] From the diffraction pattern ( figure 2 ), it can be seen that the pure phase CaMnO without impurities was successfully synthesized. ...

Embodiment 3

[0044] A catalyst Ca x Mn y O z Preparation of:

[0045] Calcium nitrate tetrahydrate and manganese nitrate were added to 10 mL of deionized water, and the total molar amount of metal Ca and Mn was 4 mmol to synthesize CaMnO 3 The ratio of calcium nitrate tetrahydrate and manganese nitrate added was 1:1, 4 mmol of acetic acid and 8 mL of ethylene glycol were added, stirred and dissolved at room temperature to obtain a uniform solution, and then placed in an oven at 100 ° C for 6 hours to obtain a uniform solution. Transfer the obtained colloid into the crucible, put it into the muffle furnace and calcine with the set program: raise the temperature at 10°C / min to 1200°C and keep it for 2h, and finally at the cooling rate of 10°C / min Reduce to room temperature; collect and grind the calcined powder to obtain the corresponding catalyst.

[0046] From the diffraction pattern ( figure 2 ), it can be seen that the pure phase CaMnO without impurities was successfully synthesize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com