Flotation cell without transmission

A flotation cell and cell technology, applied in flotation, solid separation, etc., can solve the problem of prolonging the induction time of high-energy micro-bubbles and fine particles, reducing the probability of collision between fine particles and bubbles and the probability of mineralization, flotation column Unable to produce a large number of uniform micro-bubbles, etc., to achieve the effect of concentrate filtration, high enrichment ratio and separation efficiency, and good mineralization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

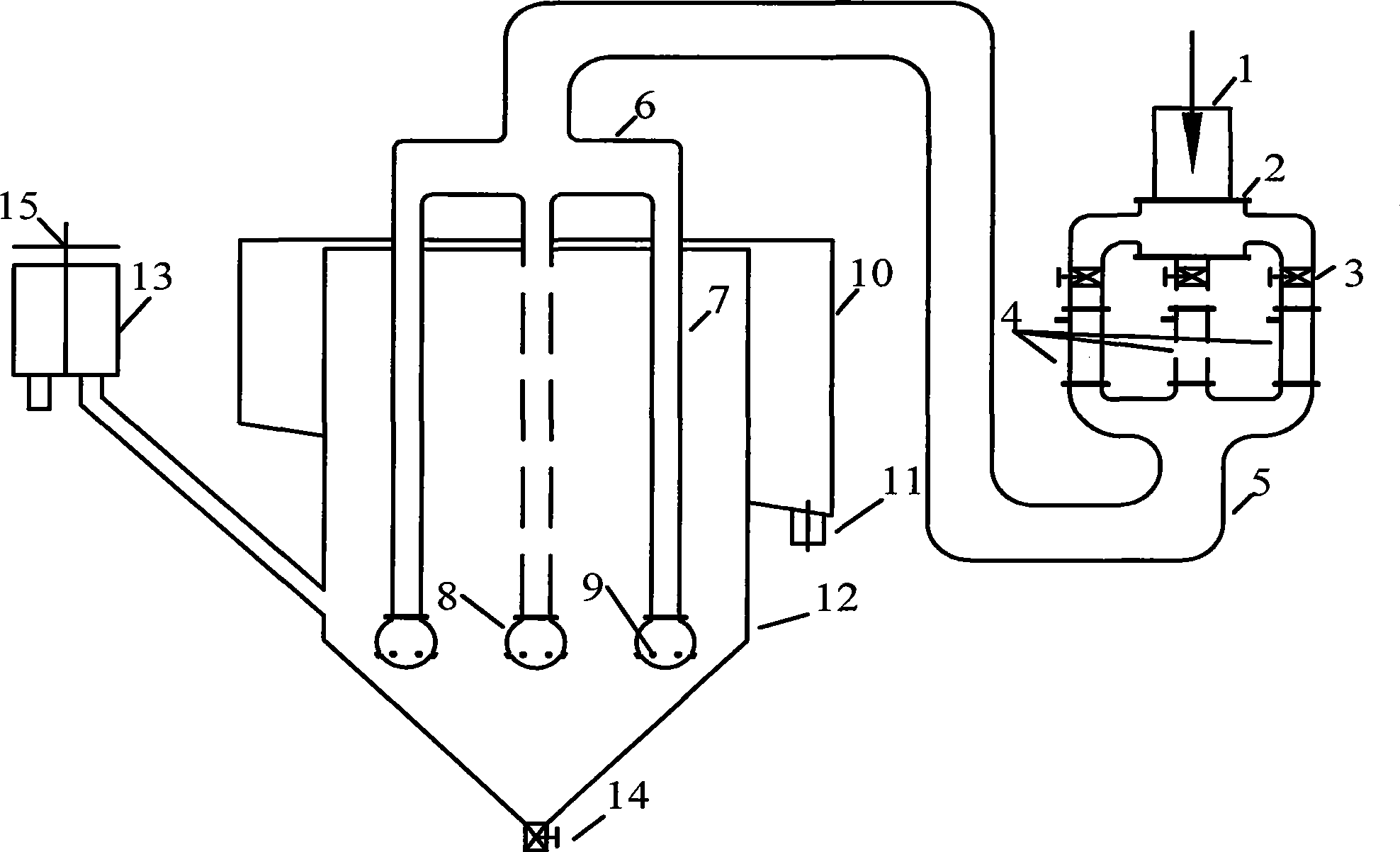

[0027] The driveless flotation cell of the present invention mainly includes a mineralization device and a spraying device, and the specific structure refers to the attached figure 1 :

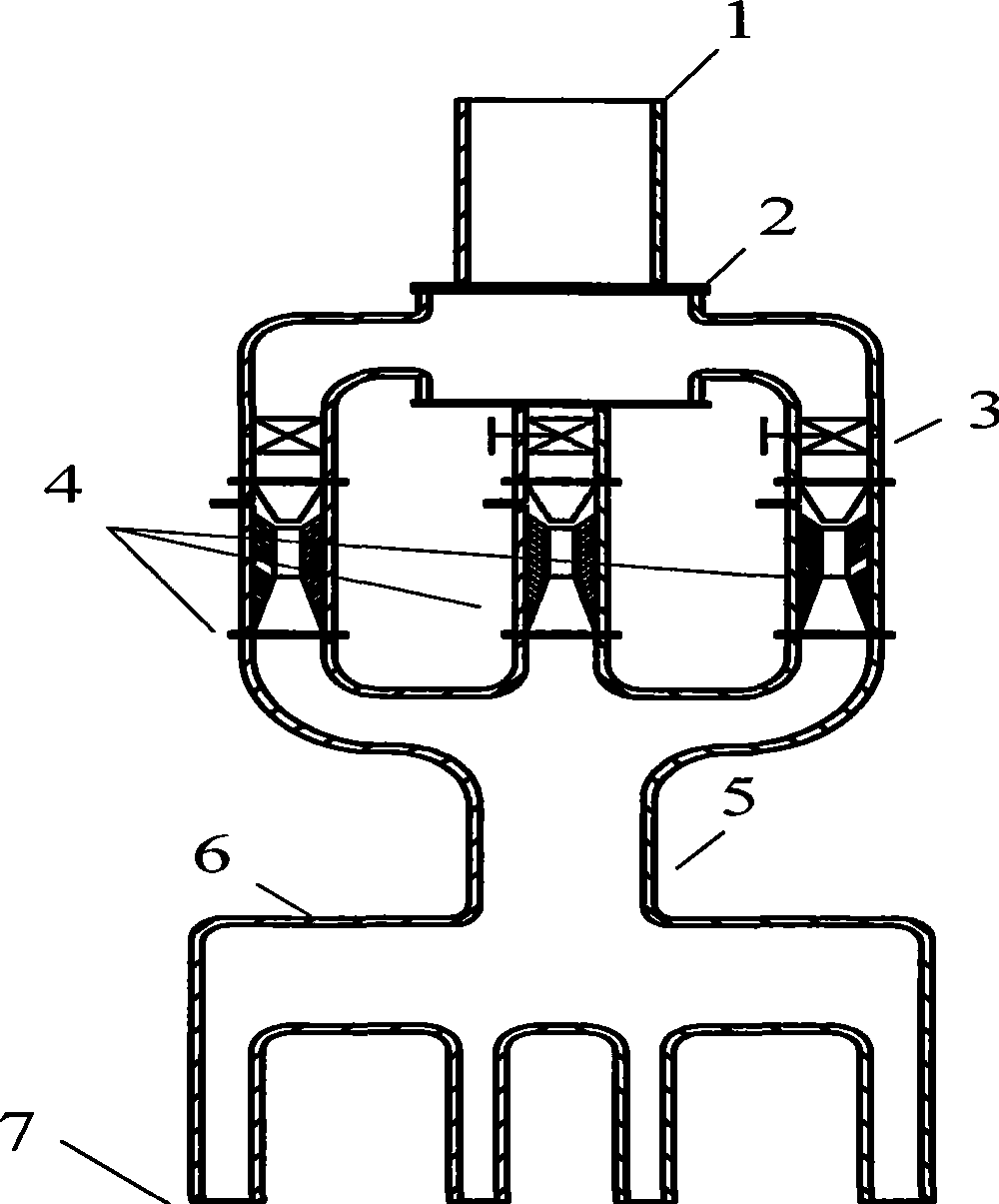

[0028] A feeding pipe 1 is arranged above the slurry distributor 2, and a group of Venturi tube groups 4 is arranged below, and a valve 3 is installed in each venturi tube of the Venturi tube group 4 . The bottom end of the Venturi tube group 4 is connected to the mineralization pipe 5, and the mineralization pipe 5 is connected to the pulp mixer 6, and a set of steel pipes 7 is arranged at the bottom end of the pulp mixer 6. The bottom end of the steel pipe 7 is provided with an ore slurry injection device 8 , and the ore slurry injection device 8 is provided with a nozzle 9 . The steel pipe 7 is installed in the tank body 12, the bottom of the tank body 12 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com