Reaction speed-controllable iron-titanium dioxide-carbon ternary micro-electrolysis composite nanometer catalyst and preparation method thereof

A nano-catalyst and titanium dioxide technology, applied in the field of water treatment catalyst and its preparation, can solve the problems of unanalyzed copper oxide effect, service life of secondary pollution, low pore volume and activity, etc. Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] ①Put 0.2kg of titanium dioxide nanobelt, 0.11Kg of carbon black and 0.6Kg of nano-iron powder with 45.5 grams of polyvinyl alcohol, 0.91Kg of water and 1.82Kg of balls into a ball mill for mixing. After ball milling for 2 hours, take out the slurry , filter, spare;

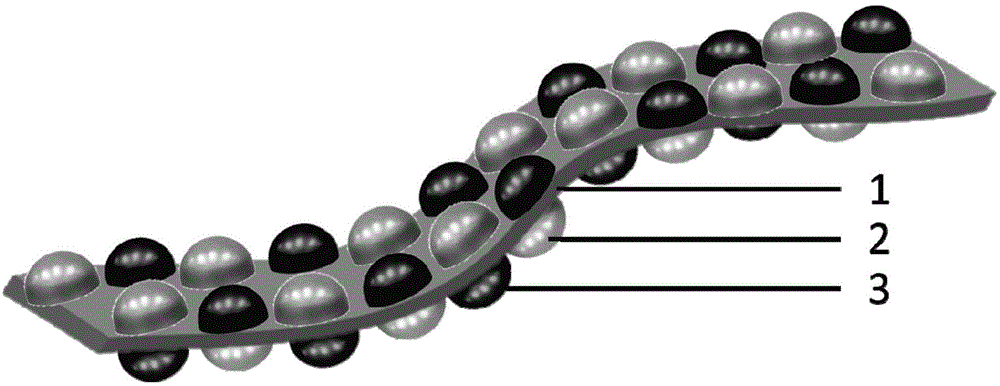

[0029] ②Spray-dry the obtained slurry, set the temperature in the drying chamber to 140°C, and prepare the dried powder for later use; the dried powder is the appearance of a single root of the composite catalyst as shown in the attached figure 1 shown;

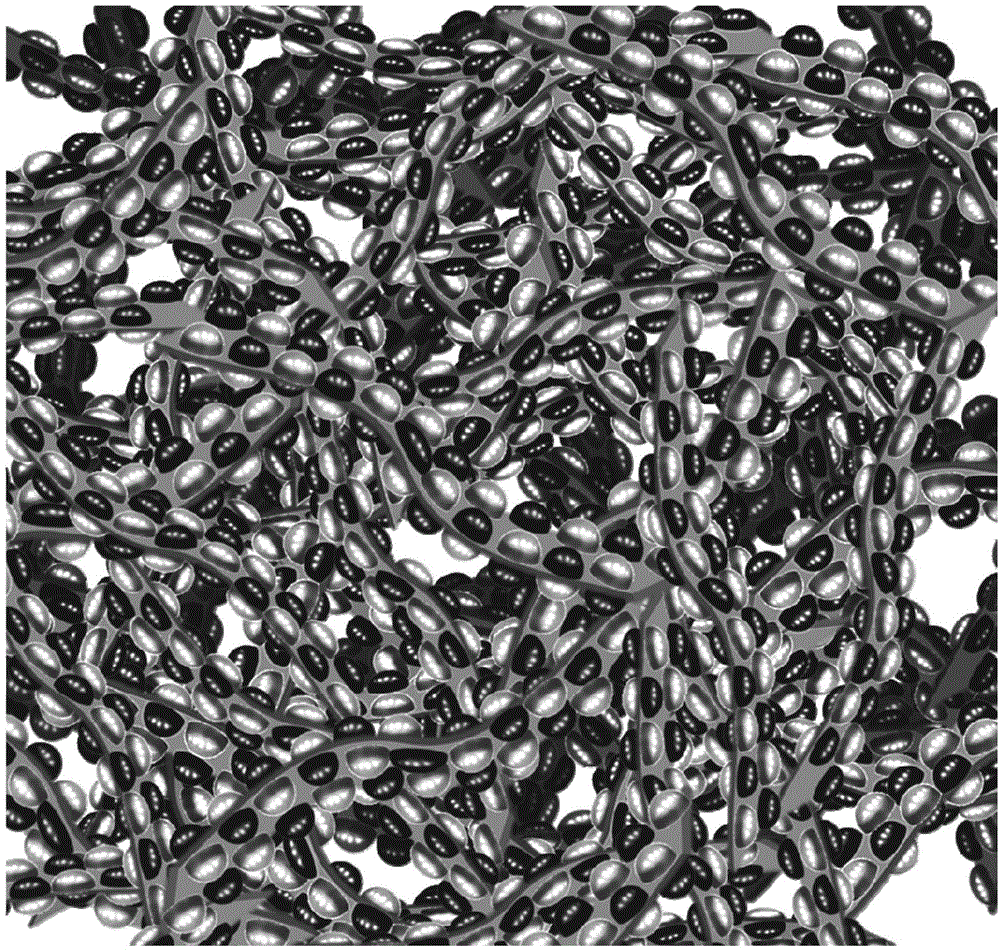

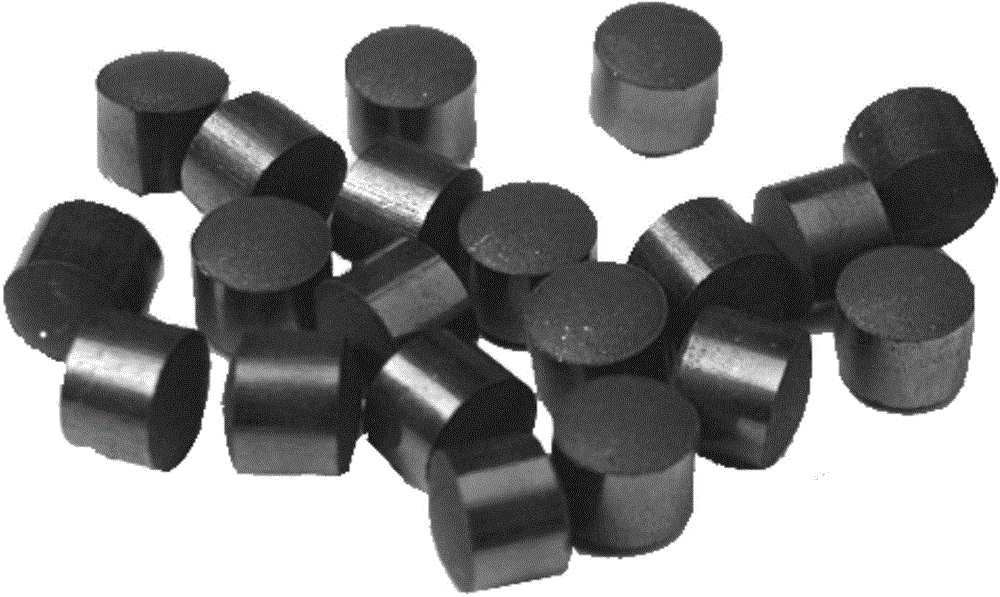

[0030] ③Press the obtained powder axially with a pressure of 10MPa in a dry press molding machine to obtain a cylindrical green body (the diameter of the cylinder is 2±0.2cm, and the height is 2±0.2cm). After dry pressing, the iron-titanium dioxide-carbon trioxide The arrangement of the nanobelts in the micro-electrolytic composite nano-oxidation catalyst body is as follows: figure 2 shown;

[0031] ④Dry the cylindrical green body at 110°C, in a nitrog...

Embodiment 2

[0035] ①Put 0.6kg of titanium dioxide nanobelt, 0.2Kg of carbon black and 0.315Kg of nano-iron powder with 55.75 grams of polyvinyl alcohol, 1.115Kg of water and 2.23Kg of balls into a ball mill for mixing. After ball milling for 11 hours, take out the slurry , filter, spare;

[0036] ②Spray-dry the obtained slurry, set the temperature in the drying chamber to 150°C, and prepare the dried powder for later use; the dried powder is the appearance of a single root of the composite catalyst as shown in the attached figure 1 shown;

[0037] ③Press the obtained powder axially with a pressure of 55MPa in a dry press molding machine to obtain a cylindrical green body (the diameter of the cylinder is 2±0.2cm, and the height is 2±0.2cm). After dry pressing, the iron-titanium dioxide-carbon trioxide The arrangement of the nanobelts in the micro-electrolytic composite nano-oxidation catalyst body is as follows: figure 2 shown;

[0038] ④Dry the cylindrical green body at 110°C, in a ni...

Embodiment 3

[0042] ①Put 1.0kg of titanium dioxide nanobelt, 0.02Kg of carbon black and 0.03Kg of nano-iron powder with 50.25 grams of polyvinyl alcohol, 1.05Kg of water and 2.1Kg of balls into a ball mill for mixing. After ball milling for 20 hours, take out the slurry , filter, spare;

[0043] ②Spray-dry the obtained slurry, set the temperature in the drying chamber to 160°C, and dry the powder for later use; the dried powder is the appearance of a single root of the composite catalyst as shown in the attached figure 1 shown;

[0044] ③Press the obtained powder axially with a pressure of 100MPa in a dry press molding machine to obtain a cylindrical green body (the diameter of the cylinder is 2±0.2cm, and the height is 2±0.2cm). After dry pressing, the iron-titanium dioxide-carbon trioxide The arrangement of the nanobelts in the micro-electrolytic composite nano-oxidation catalyst body is as follows: figure 2 shown;

[0045] ④Dry the cylindrical green body at 110°C, in a nitrogen atmo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com