Material stabilization device of concentrator

A technology for thickener and material stabilization, which is applied in thickener stabilizing devices, fine-grained slurry stabilizing devices, and high-concentration fields. It can solve the problems of unstable feeding, large kinetic energy of feeding, and poor settling effect of thickeners, etc. problem, to achieve the effect of good settlement and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

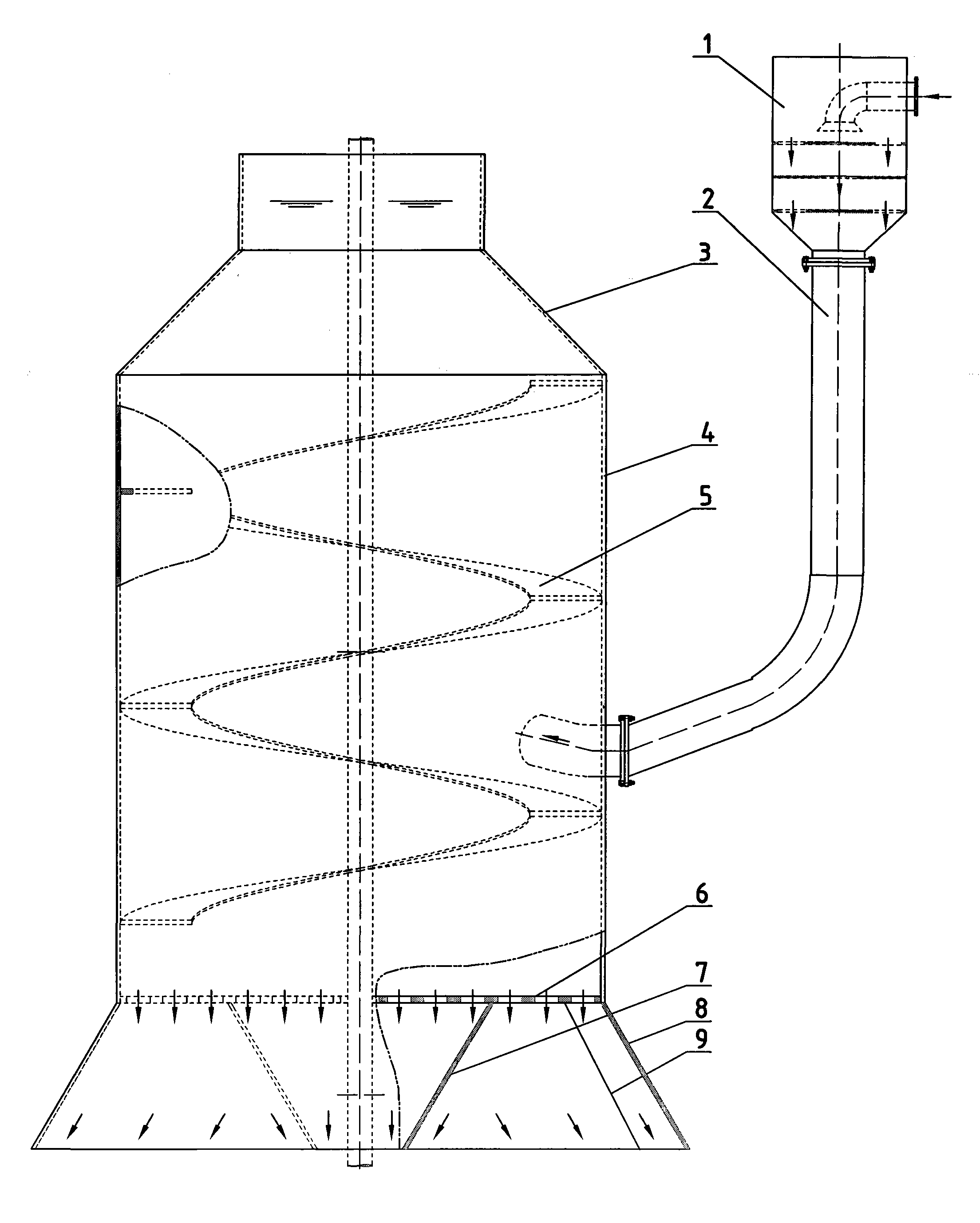

[0019] As shown in the figure: the slurry is conveyed into the static steady flow mixer 1, enters the middle cylinder 4 through the feed pipe 2, and is distributed along the spiral blade 5. The slurry itself is squeezed in the upper cone 3 to consume kinetic energy, and finally along the middle The middle part of cylinder body 4 flows downwards and is evenly distributed by distributing plate 6. Part of the slurry particles contact the inner surface of inner cone 7 and sink directly to the bottom of the concentrator. Partition plate 9 divides the gap between inner cone 7 and lower cone 8. The space is evenly divided into multiple areas, and the other part of the slurry is quickly settled downward under the resistance and impact of the outer surface of the inner cone 7 and the inner surface of the lower cone 8, and directly sinks to the bottom of the thickener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com