Method for preparing SAPO-34 molecular sieve

A technology of SAPO-34 and molecular sieve, which is applied in the field of preparation of SAPO-34 molecular sieve to achieve obvious effect of mineralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

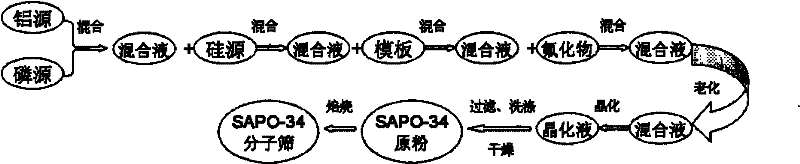

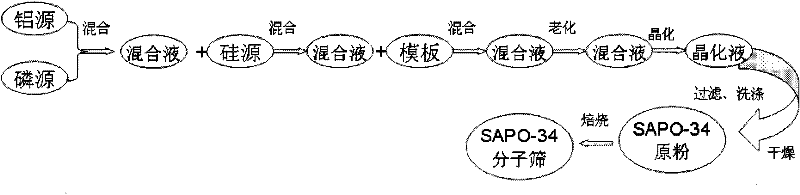

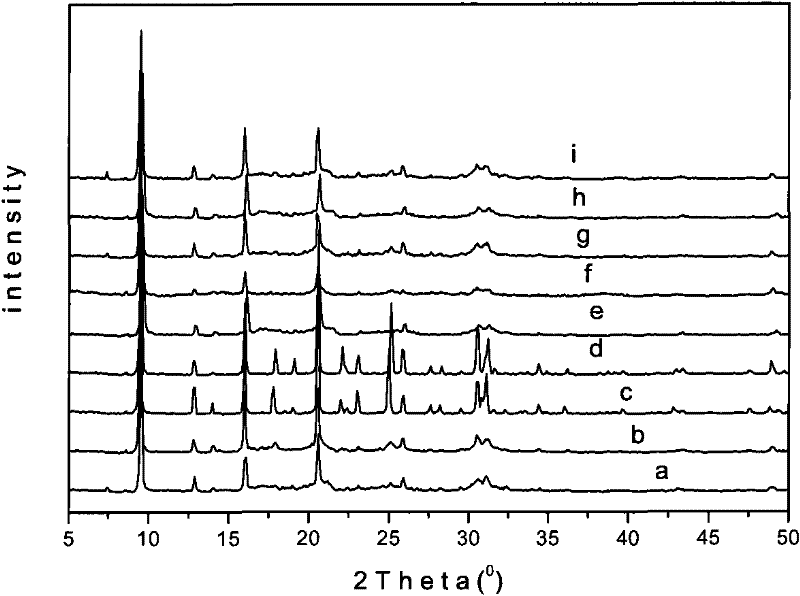

[0026] The 85% phosphoric acid of 13.84g, the pseudo-boehmite of 9.86g, the triethylamine of 18.18g, the deionized water of 55.73g, the 40% silica sol of 5.35g and the NaF of 0.152g according to figure 1 The process shown is for preparation, wherein the aging temperature is room temperature, and the aging time is 6 hours; the crystallization temperature is 200°C, and the crystallization time is 48 hours; the calcination temperature is 550°C, and the calcination time is 7 hours. The molar ratio of each component in the resulting mixed solution is: 3.0Et 3 N: 0.06NaF: 0.6SiO 2 : Al 2 o 3 :P 2 o 5 : 60H 2 O.

Embodiment 2

[0028] The 85% phosphoric acid of 17.77g, the pseudo-boehmite of 9.0g, the triethylamine of 25.0g, the deionized water of 36.58g, the 40% silica sol of 11.56g and 0.24gNaF according to figure 1 The process shown is for preparation, wherein the aging temperature is 50°C, and the aging time is 10 hours; the crystallization temperature is 180°C, and the crystallization time is 50 hours; the calcination temperature is 500°C, and the calcination time is 5 hours. The molar ratio of each component in the resulting mixed solution is: 4.5Et 3 N: 0.1NaF: 1.4SiO 2 : Al 2 o3 : 1.4P 2 o 5 :50H 2 O.

Embodiment 3

[0030] 15.38g of 85% phosphoric acid, 10.96g of pseudoboehmite, 16.34g of tetraethylammonium hydroxide (30wt%), 13.46g of triethylamine, 74.46g of deionized water, 4.95g of 40 % silica sol and 0.84gNaF according to figure 1 The procedure shown was carried out. The aging temperature is 80° C., and the aging time is 10 hours; the crystallization temperature is 200° C., and the crystallization time is 72 hours; the roasting temperature is 600° C., and the roasting time is 5 hours. The molar ratio of each component in the resulting mixed solution is: 0.5TEAOH: 0.3NaF: 2.0Et 3 N:0.5SiO2 2 : Al 2 o 3 :P 2 o 5 :80H 2 O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com