Composite mineralizer for barium calcium phosphoaluminate cement

A technology of barium aluminophosphate and mineralizer, applied in the field of building materials, can solve problems such as inability to apply barium-calcium aluminophosphate cement, achieve significant energy saving and consumption reduction effects, optimize mineralization effect, and improve the effect of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments.

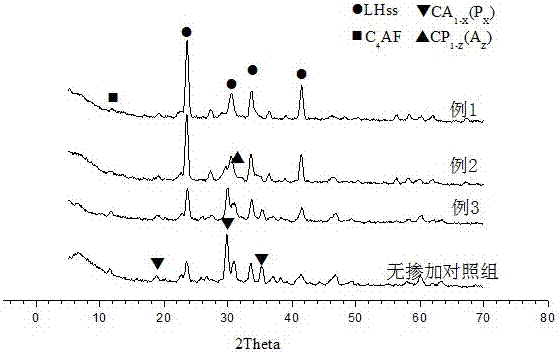

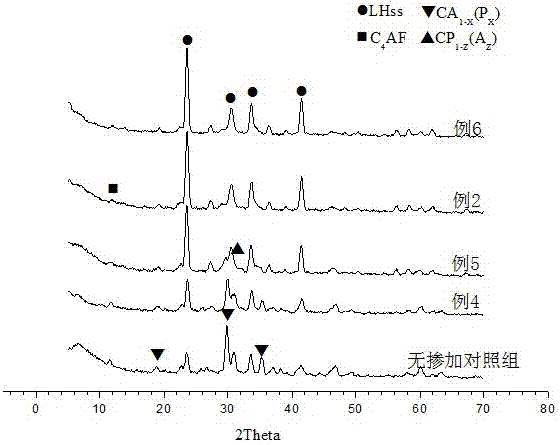

[0026] According to 32.5% of tricalcium phosphate, 28% of calcium carbonate, 19% of aluminum oxide, 16% of barium oxide, and 4.5% of silicon dioxide, the blank barium calcium aluminate phosphate cement raw material is prepared; the mineralizer is prepared according to the ratio in Table 1, and all raw materials Analytical grade reagents are used, the purity is greater than 99%, SO 3 CaSO 4 Added in the form of MgO as MgCO 3 form to join. The above components were mixed evenly with the blank barium calcium aluminum phosphate cement raw meal, and the blank barium calcium aluminum phosphate cement raw meal was respectively placed in a silicon-molybdenum rod high-temperature furnace, and the temperature was raised to the set temperature at a heating rate of 5°C / min. Keep it warm for a corresponding time, take it out and cool it with a fan to obtain barium calcium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com