Patents

Literature

998results about How to "Solve the emission problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

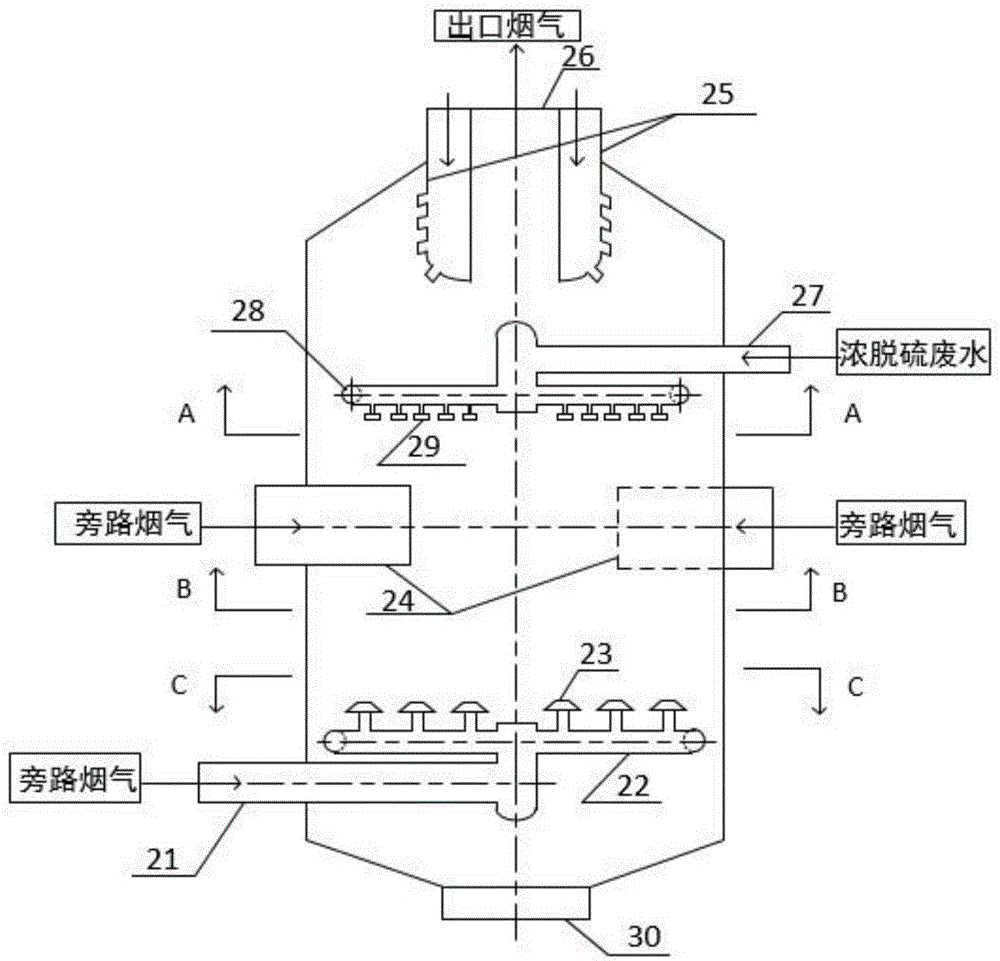

Control method for aerosol in flue gas desulfurization by utilizing ammonia method and master desulfurizing tower

InactiveCN102000490ASolve the emission problemSimple processDispersed particle separationThermodynamicsWater vapor

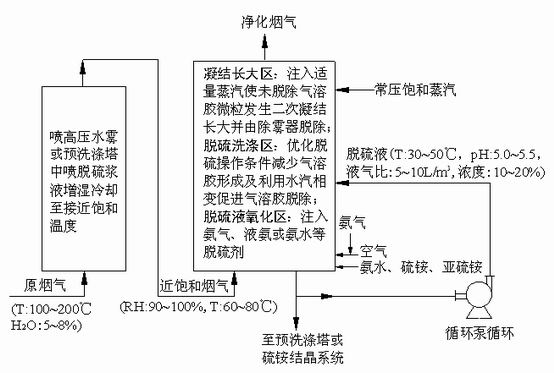

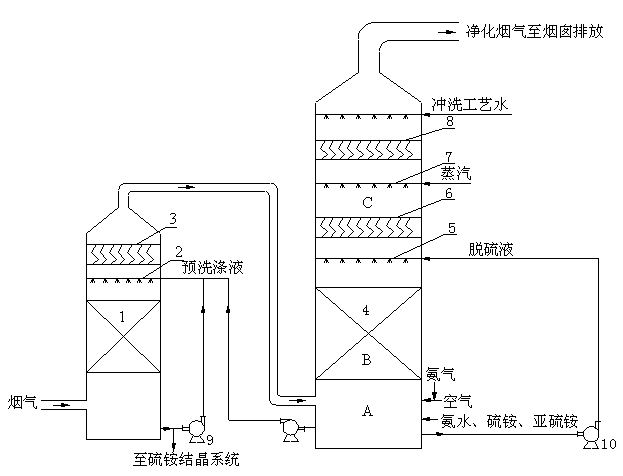

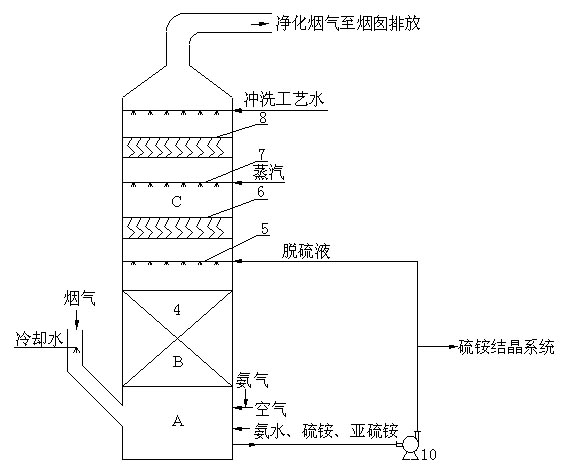

The invention discloses a control method for aerosol in flue gas desulfurization by utilizing an ammonia method and a master desulfurizing tower, and the control method is characterized in that flue gas enters the master desulfurizing tower after being cooled to the relative humidity of 90 to 100% and the temperature of 60 to 80 DEG C through high-pressure waster mist or prewashing temperature reduction; the generation of the aerosol particles in the desulfurization by utilizing the ammonia method is reduced by optimizing desulfurization operating conditions, and the formed aerosol particles are condensed to grow big and are partially washed to be eliminated through a desulfurizing solution; an appropriate amount of steam is injected into the saturated flue gas through desulfurizing and eliminating the partial aerosol particles; the oversaturated water vapor environment required by the secondary condensation and the growth of the aerosol particles is established on the top of the master desulfurizing tower; and the condensed and the grown aerosol particles are eliminated through a high-efficiency demister. The invention combines the formation mechanism of the aerosol in the flue gas desulfurization by utilizing the ammonia method; and the formation of the aerosol is reduced by optimizing the process conditions of the desulfurization operation and the elimination of the formed aerosol is promoted by utilizing a steam phase change principle at the same time so that the exhaust problem of the aerosol in the flue gas desulfurization by utilizing the ammonia method can be effectively solved.

Owner:SOUTHEAST UNIV

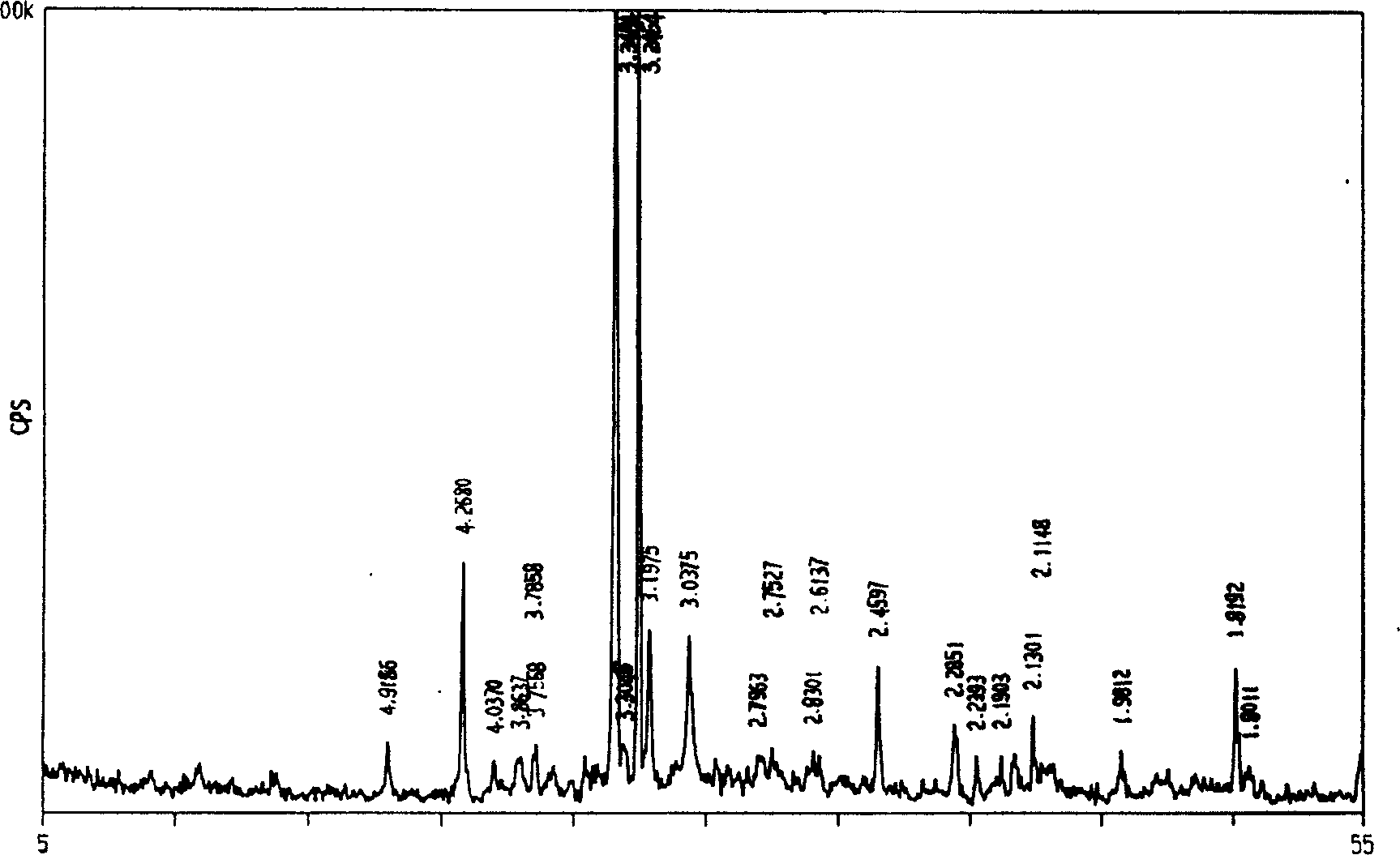

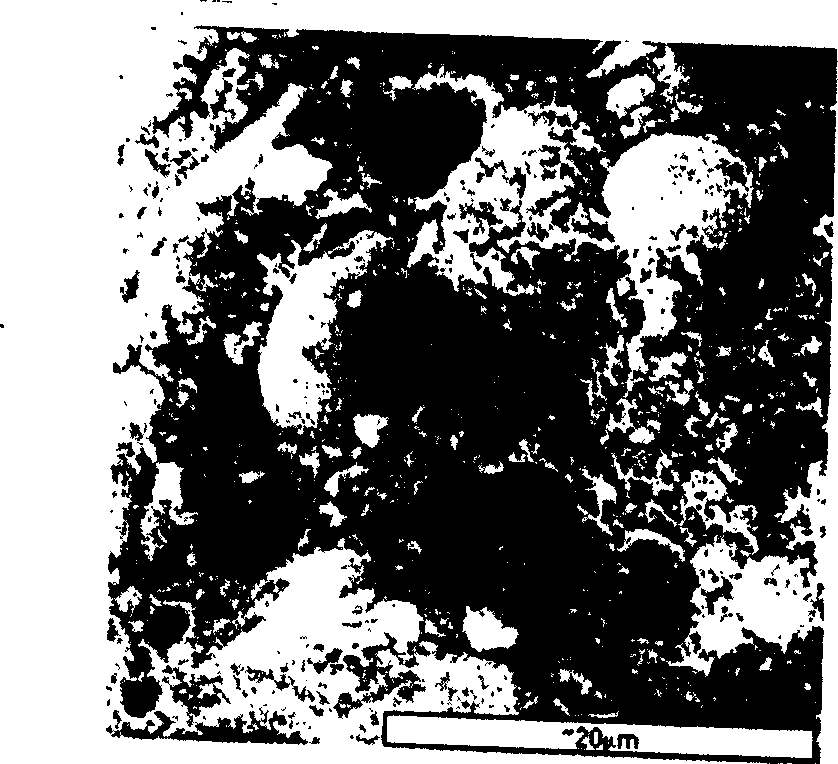

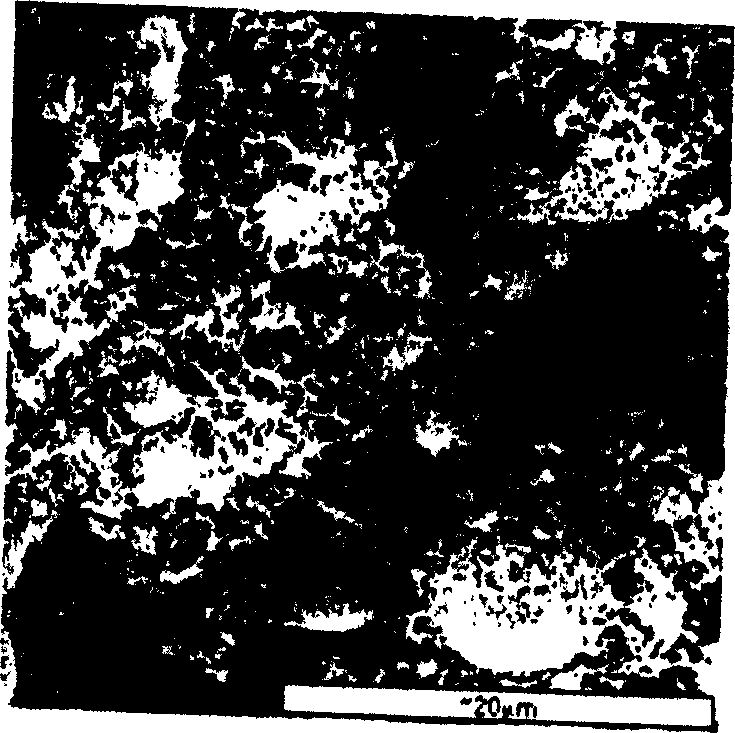

Method for producing porous nano silica and active carbon by utilizing rice hull ash

InactiveCN101920966AIncrease the reaction areaImprove reaction speedSilicaSolid waste disposalActive carbonChemistry

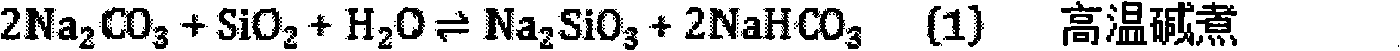

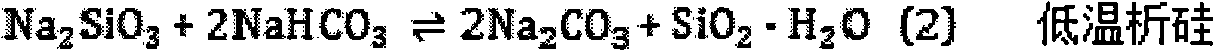

The invention discloses a method for producing porous nano silica and active carbon by utilizing rice hull ash, which comprises the following steps of: at lower temperature and normal pressure, performing secondary alkali dissolution on subcarbonate, and filtering to obtain alkali-dissolved filter liquor and filter residue; adding a certain amount of dispersing agent into the filter liquor, reducing temperature for ageing, filtering, washing, and removing the dispersing agent to obtain the porous nano silica; and adding an activating agent into the alkali-dissolved filter residue, activating, washing and drying to obtain the high specific surface area active carbon. The alkali and the active carbon can be recycled, and only a small amount of alkali and active carbon is lost. The method has the advantages of not seriously corroding equipment due to no high-temperature and high-pressure alkali boiling, sufficient raw materials, low price, no environmental pollution, and higher quality of the obtained active carbon and silica.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN +1

Method for processing garbage leachate

InactiveCN102786183AImprove biodegradabilityReduce CODGeneral water supply conservationTreatment with aerobic and anaerobic processesChemistryCapacitance

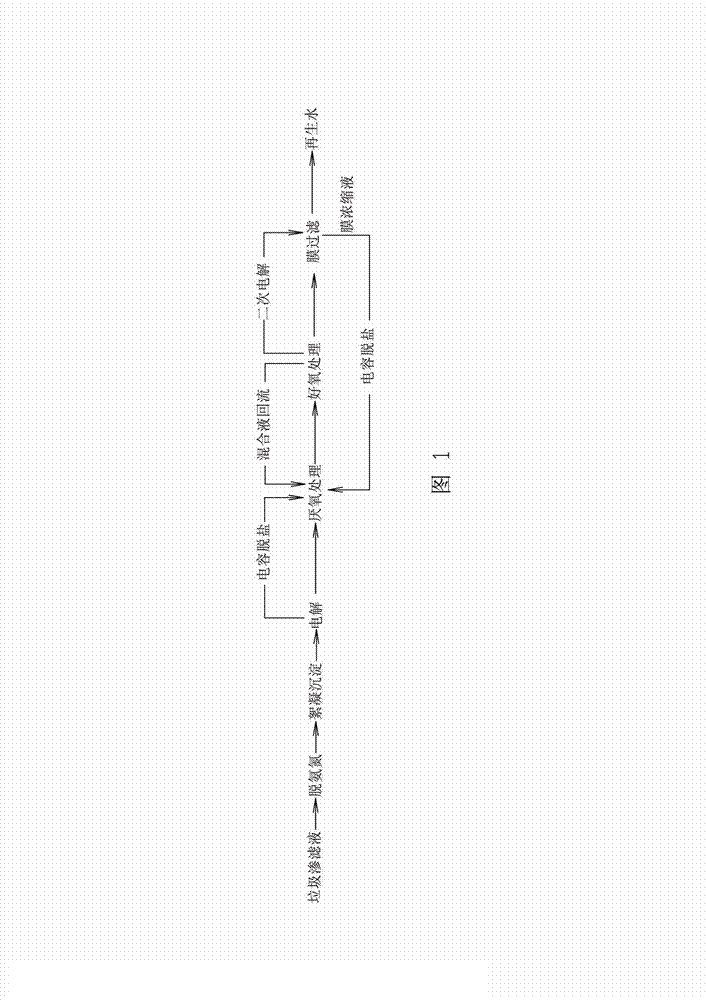

The invention discloses a method for processing a landfill leachate, which comprises the following steps of ammonia nitrogen removal, flocculent precipitate, electrolysis, capacitance desalination, anaerobic treatment, aerobic treatment, membrane filtration and membrane concentrate treatment. The method for processing the landfill leachate has the advantages that an electrolysis technology, a membrane technology and a bio-chemical technology are combined to form a method for processing the landfill leachate, the method has the characteristics of stable operation, strong adaptive capacity on water quality change, low cost, high treatment efficiency, effective reduction of index of ammonia nitrogen, COD, SS, chromaticity in the landfill leachate and standard discharge of effluent.

Owner:BOYING XIAMEN SCI & TECH

A method for the treatment and reuse of ammonia-nitrogen-containing high-salt catalyst wastewater

ActiveCN102295378ATake advantage of highly concentrated processingHigh salt contentWater contaminantsWater/sewage treatment bu osmosis/dialysisSocial benefitsSeparation technology

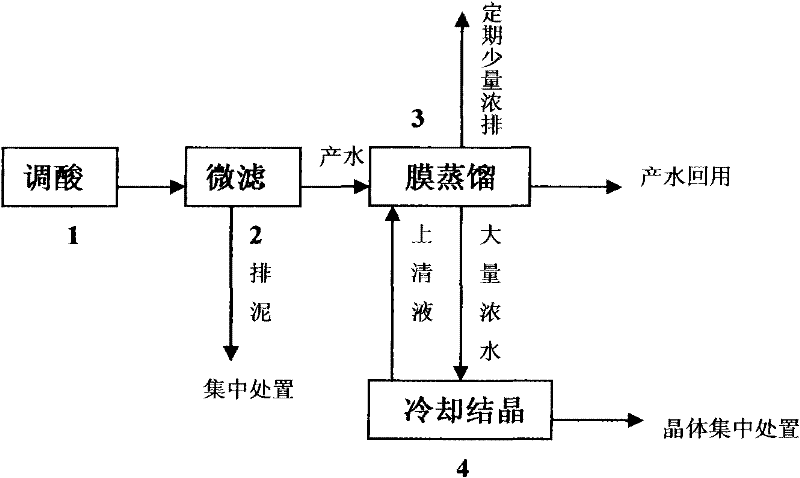

The invention relates to a recycling method for treating ammonia nitrogen containing high-salt catalyst wastewater by adopting a membrane separation technology. The process flow of 'acid regulation, micro-filtration, membrane distillation, cooling and crystallization' is adopted in the method. By adopting the process flow, salts, ammonia nitrogen and metal ions in the wastewater can be effectively removed, and deep treatment and recycle of the ammonia nitrogen containing high-salt catalyst wastewater are realized. The process flow makes full use of the technical advantages of membrane distillation, solves the problem that the discharge of high salts, ammonia nitrogen and metal ions of the ammonia nitrogen containing high-salt catalyst wastewater does not reach the standards, and realizes recycle of the produced water. After the ammonia nitrogen containing high-salt catalyst wastewater is treated by the process flow, the reclamation rate of the wastewater is more than 90 percent, and high recycle of the ammonia nitrogen containing high-salt catalyst wastewater is realized; and the method accords with the development strategies of energy conservation and emission reduction, and has remarkable social benefit and economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

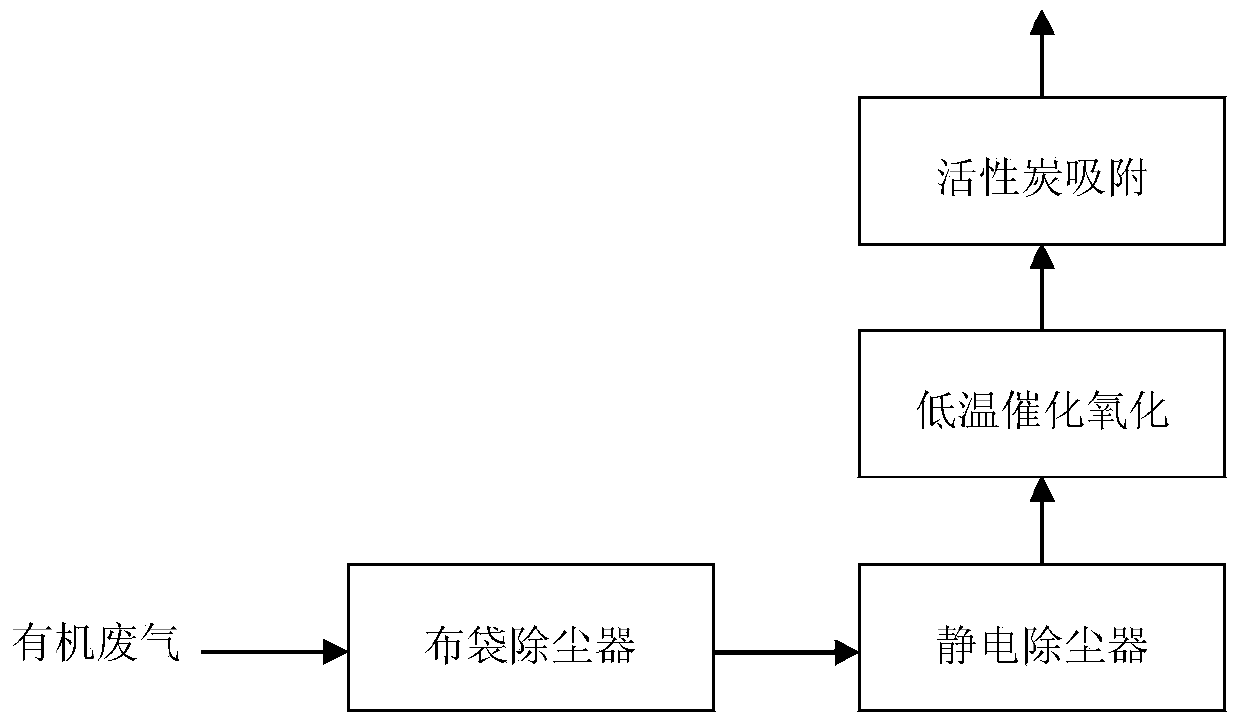

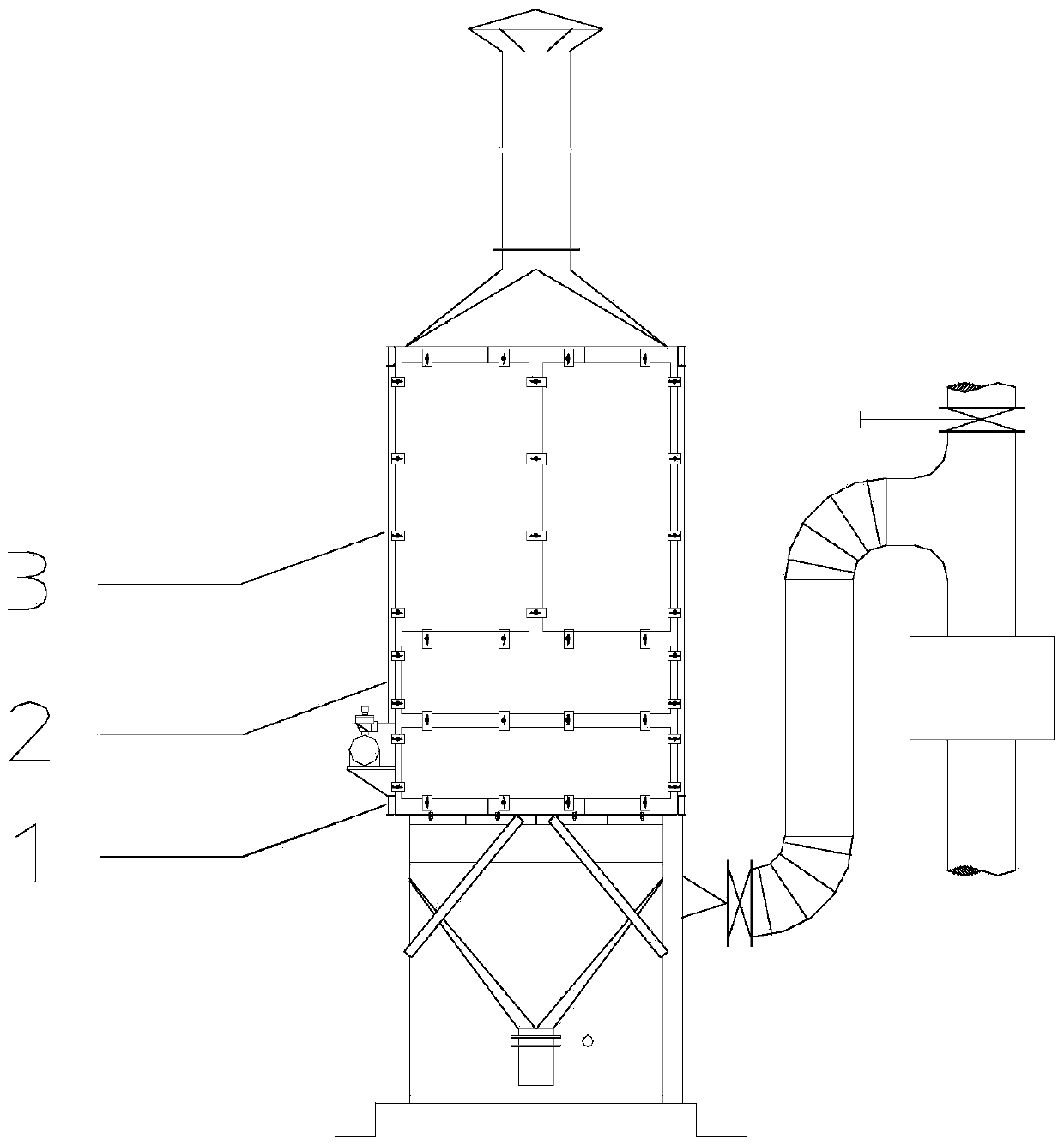

VOCs high-efficiency processing method

InactiveCN103721510AEasy to recycleGood emission concentrationCombination devicesHigh concentrationAdditive ingredient

The invention relates to a VOCs (Volatile Organic Compounds) high-efficiency processing method. In the method, dust removal processing, odor removal processing and tail gas processing are carried out on waste gas. Firstly, a bag-type dust collector is adopted to carry out preprocessing on the waste gas, parts of materials are recovered and then an electrostatic dust collector is introduced to further recovery the materials; then the waste gas is subjected to low-temperature catalytic oxidation processing; the waste gas is subjected to adsorption processing. According to the invention, the petrochemical industrial organic waste gas is processed by utilizing the combination of catalytic oxidation and adsorption processes, so that the materials can be well recovered, odor of the organic waste gas is eliminated and the problem of emission of petrochemical industrial tail gas is solved. The method disclosed by the invention has a good purifying effect and low consumption and is low in engineering cost; the materials can be recovered; flue gas emission concentration is lower than the emission standard by over 30 percent; the VOCs high-efficiency processing method has obvious economic benefits and social benefits and can be used for processing the petrochemical industrial organic waste gas with high concentration, high flow and complex ingredients.

Owner:JIANGSU ZHONGKE RUISAI POLLUTION CONTROL ENG +1

Novel production method for glutamic acid

ActiveCN102703537AReduce lossesLess waste waterOrganic compound preparationMicroorganism based processesHigh concentrationFluidized bed drying

The invention discloses a novel production method for glutamic acid, belonging to the technical field of the production of amino acid. The novel production method for the glutamic acid comprises the following steps of: removing thalli and insolubles by means of high-speed disc separation; evaporating and concentrating separated glutamic acid material liquid through a multi-effect plate type evaporator at low temperature, wherein the generated secondary steam condensed water is used for fermentation ingredients of the glutamic acid; performing continuous isoelectric extraction on the glutamic acid in the evaporated glutamic acid concentrated solution; absorbing the glutamic acid by making supernatant fluid pass through ion exchange columns; performing isoelectric reextraction on the analyzed glutamic acid; inputting high-concentration wastewater into a fertilizer workshop for producing fertilizer; squeezing heavy phase (mycoprotein) through a plate frame, and granulating; and drying through a fluid bed, and thus producing high-protein feed. The novel production method for the glutamic acid has the advantages of low unit consumption of liquid ammonia and sulfuric acid, high extraction yield of the glutamic acid, less ion exchange investment and the like; and meanwhile, the purity of the extracted glutamic acid is high, sodium glutamate can be produced without crystalloblast, resources are fully used in the whole process, the aims of energy conservation and consumption reduction are achieved, and the novel production method for the glutamic acid has a wide application prospect.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

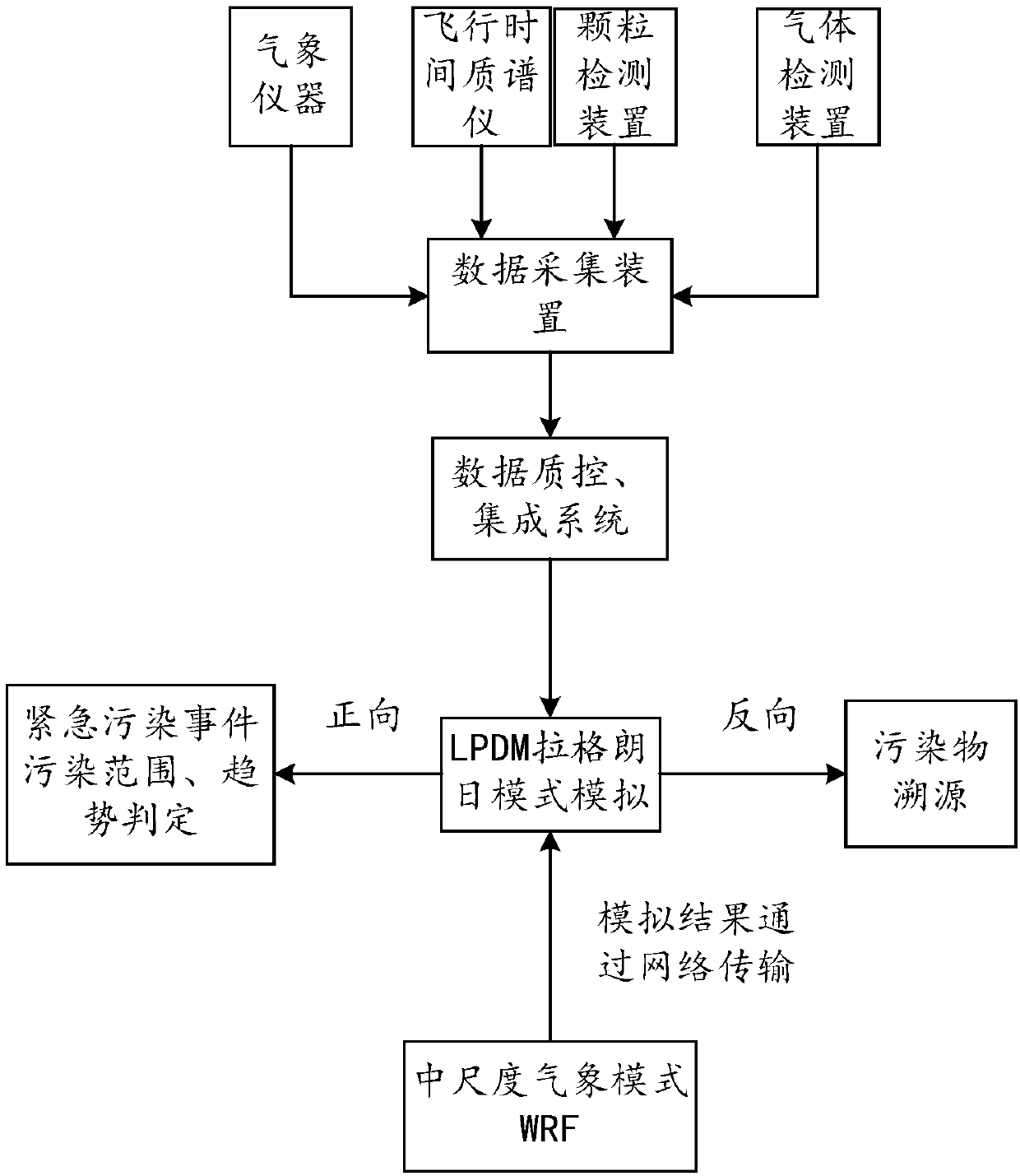

atmospheric pollution tracing method based on a Lagrangian model and a mobile observation platform

InactiveCN109583743AImprove ambient air qualitySolve the emission problemTechnology managementResourcesAtmospheric pollutionSource tracing

The invention provides an atmospheric pollution tracing method based on a Lagrangian model and a mobile observation platform, and relates to the technical field of cloud computing data analysis and application. The invention discloses an atmospheric pollution source tracing method based on a Lagrangian source tracing model and mobile super station observation. Aiming at the problem of park local atmospheric environment pollution, site data analysis and model small-scale pollution traceability analysis are carried out, targeted mobile over-station monitoring analysis is carried out on typical areas and time periods, and emergency guarantee measures are taken for emergencies in special periods. Specific components of the regional peculiar smell are measured, the source of peculiar smell pollution is tracked and locked, technical support is provided for solving the problem of peculiar smell pollution, and guidance is provided for law enforcement of related departments.

Owner:南京创蓝科技有限公司

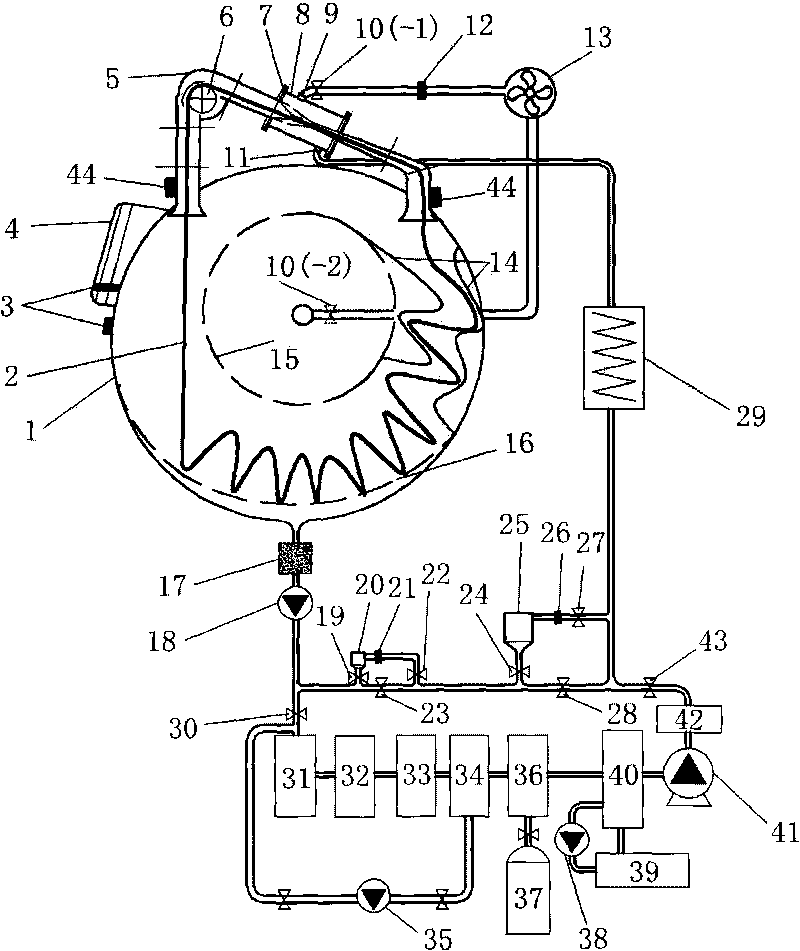

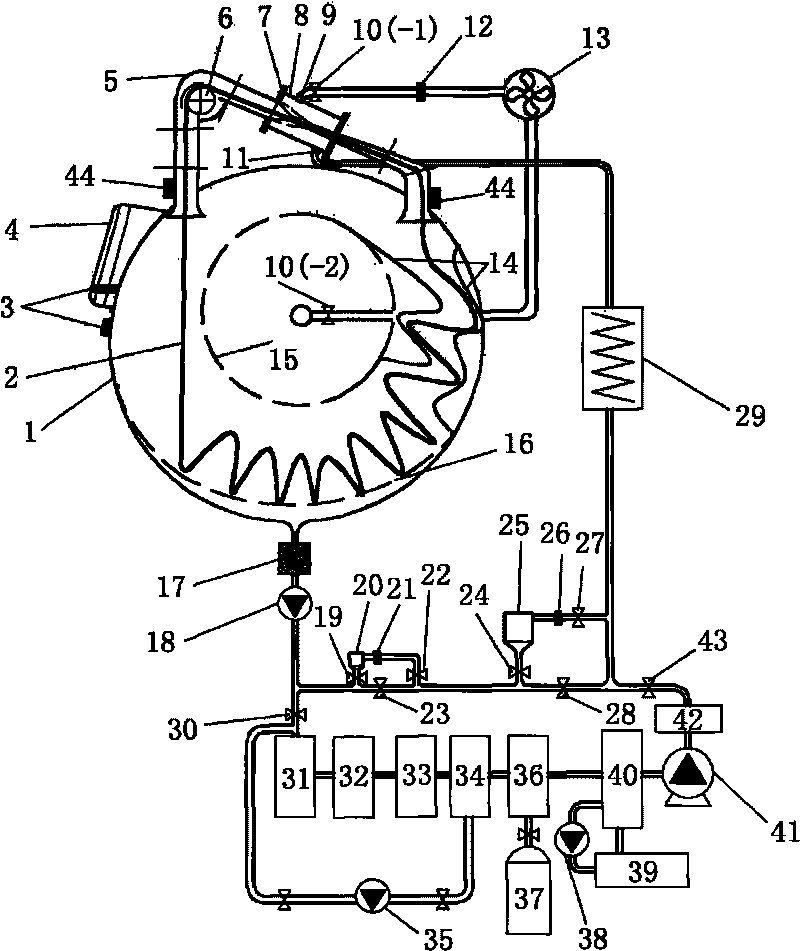

Supercritical fluid dyeing machine

ActiveCN101760914ASave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

The invention discloses a supercritical fluid dyeing machine. A horizontal type cylindrical dyeing kettle, a magnetomotive cloth lifting wheel, a spray cavity, a wave-shaped cloth guide passage in the dyeing kettle, a heat exchanger, a dye kettle or / and an entrainer kettle and a circulating pump are used as main components to form a dyeing circulation system; and both ends of a fan are respectively connected with fluid outlets under the spray cavity and the dyeing kettle and form a cloth feeding system together with the magnetomotive cloth lifting wheel, the spray cavity and an operating opening. A rope-shaped fabric realizes circulated dyeing under the common action of the fluid in the magnetomotive cloth lifting wheel and the spray cavity, and the fluid in the dyeing kettle carries out forced circulation by the circulating pump. The dye and the fluid can realize recycling by a separating and recycling system after dyeing, and the whole dyeing circulation system and the separating and recycling system are clean to achieve the requirement during color changing and dyeing. The supercritical fluid dyeing machine can realize anhydrous dyeing processing on the fabric in a loosening type tension-free state without the production and discharge of pollutants, and has the characteristics of ecology, environmental pollution, wide adaptability of fabric variety, and the like.

Owner:SUZHOU UNIV +2

Method for producing sulphate aluminum cement

The invention relates to a method for producing sulphate aluminum cement. The method comprises the following steps: preparing cement raw meal by proportioning limestone, phosphogypsum, low grade alumina and coke; uniformly grinding and calcining at high temperature; in the calcining process, promoting phosphogypsum to be decomposed as much as possible; replacing partial limestone by calcium oxide generated by decomposition; collecting sulfur dioxide to prepare sulfuric acid; and adding natural dihydrate gypsum in the cement clinker and grinding to prepare a cement product. Compared with the existing conventional production methods, according to the method, the utilization of phosphogypsum can be greatly improved, the utilization concentration of sulfur dioxide discharged by decomposition of little gypsum in the production process can be guaranteed to be reached, the use level of limestone is further reduced and emission of carbon dioxide is reduced. Cement calcined is wide in adaptability, can be widely applied to production of sulphate aluminum cement by phosphogypsum, and further can be suitable for producing high early strength cement, expansive cement and the like.

Owner:CHONGQING UNIV

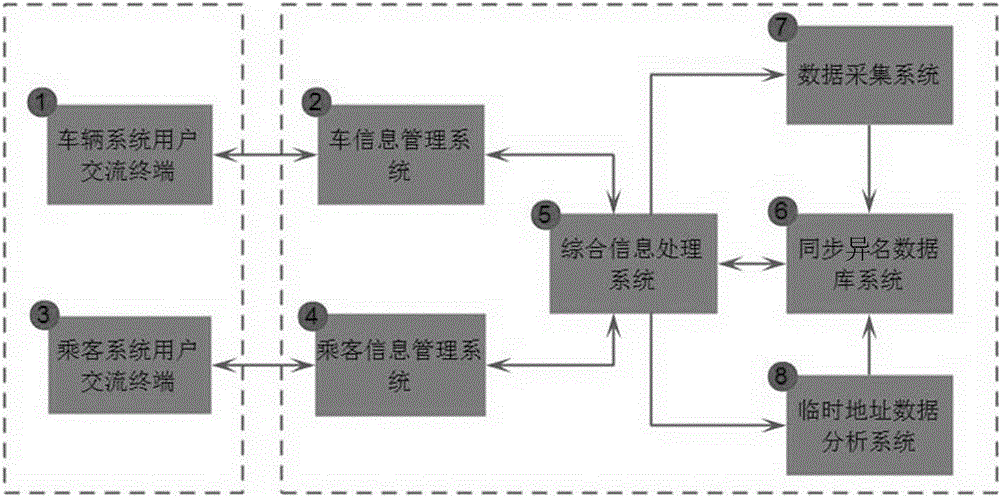

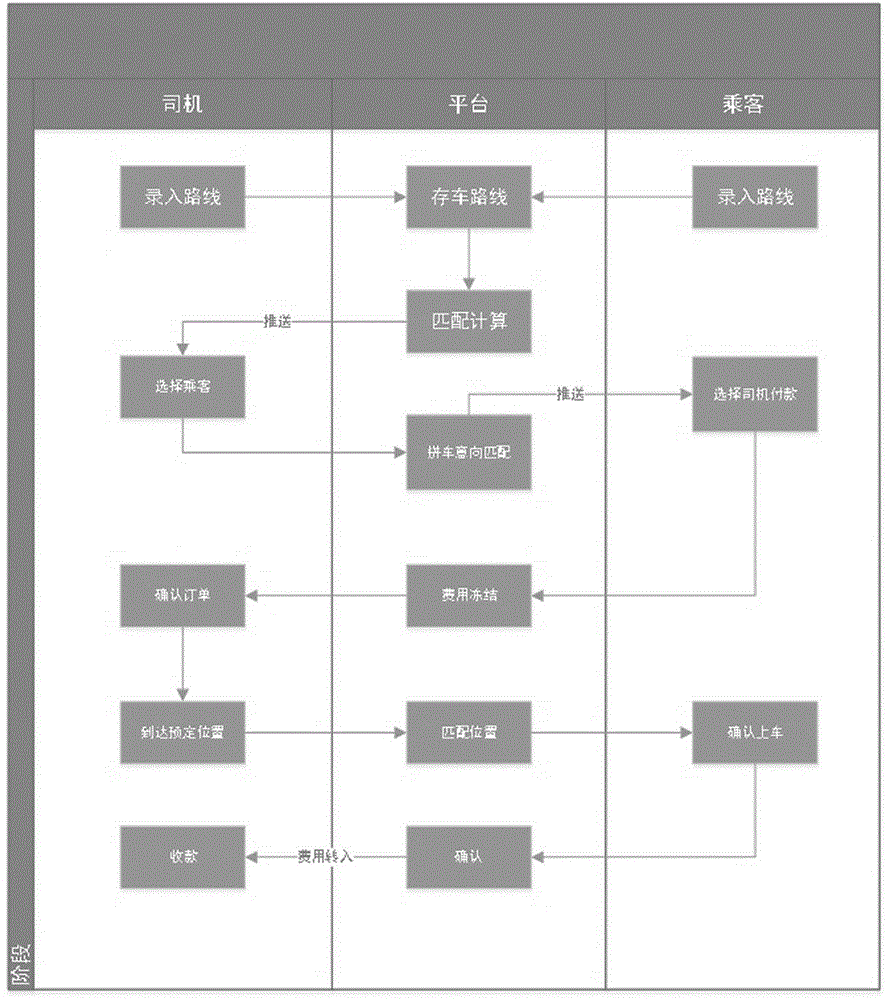

Automobile resource sharing system

PendingCN105701580ASolve commuting problemsAddressing Carpool SafetyMarket predictionsForecastingCar sharingOperations research

The invention relates to an automobile resource sharing system. In China, the problem of traffic jam becomes the key conflict of Chinese economical and social development, traffic jam makes people very inconvenient to travel, and emission of large quantity of tail gas lowers the quality of people's life. The automobile resource sharing system comprises a vehicle system user communication terminal, a vehicle management system, a passenger system user communication terminal, a passenger information management system, an integrated information processing system, a synchronous synonym database, a data acquisition system and a temporary address data analysis system. One-to-many car-pooling software system is disclosed to effectively solve the problems of commuting difficulty, car-pooling insecurity, illegal taxies, large quantity of tail gas emission, high travel expenses of passengers and expansive vehicle maintenance fees of vehicle owners.

Owner:重庆喜玛拉雅科技有限公司

Method for recovering sandy oil-containing sludge

InactiveCN101734834ASolve the emission problemNo secondary pollutionSludge treatmentSolventChemistry

The invention belongs to the technical field of sludge treatment of oil fields and relates to a method for recovering sandy oil-containing sludge, which comprises the following steps: fully mixing extracting solvent with the sandy oil-containing sludge of the oil fields in a volume ratio of 0.5:1 at a temperature of between 10 and 80 DEG C to allow oil to dissolve in the extracting solvent to form a structure of three separated layers; then separating an extracting solvent layer, a water layer and a silt layer from one another; and performing distillation of the separated extracting solvent layer at an atmospheric pressure or reduced pressure to acquire oil and the extracting solvent respectively. The method can effectively extract and recover crude oil in the oil-containing sludge, and silt separated out reaches national stacking standards; the solvent can be recycled, and washing water can be sewage of the oil fields and can be recycled by electroflotation without causing secondary pollution, so that the oil and the water in the sandy oil-containing sludge of the oil fields can be recovered, and thus the original discarded resources are fully utilized, and the problem of discharging the sandy oil-containing sludge of the oil fields is solved effectively.

Owner:新疆油田勘察设计研究院 +1

Sand burning preventing coal dust free green sand for casting and preparation method thereof

ActiveCN101733361AReuseRaw sand consumption is lessFoundry mouldsFoundry coresProduction rateCoal dust

The invention relates to a sand burning preventing coal dust free green sand for casting and preparation method thereof. The green sand contains 50-90% of naturally clay-bonded sand, 2-40% of sand burning preventing assistant and 2.5-20% of water by weight percent; the preparation method includes that the naturally clay-bonded sand and the sand burning preventing assistant are mixed in a sand mixing machine and the water is added for mixing to uniform. The green sand of the invention contains no coal dust and can be recycled; the casting mould made by the green sand of the invention is utilized to produce castings, crude sand consumption is low, the surface of casting is not burning-on, surface quality is high, no coal dust is required to add, recycling of moulding sand is good, environmental protection is less, and high temperature mould dismantling improves productivity.

Owner:DONGHUA UNIV

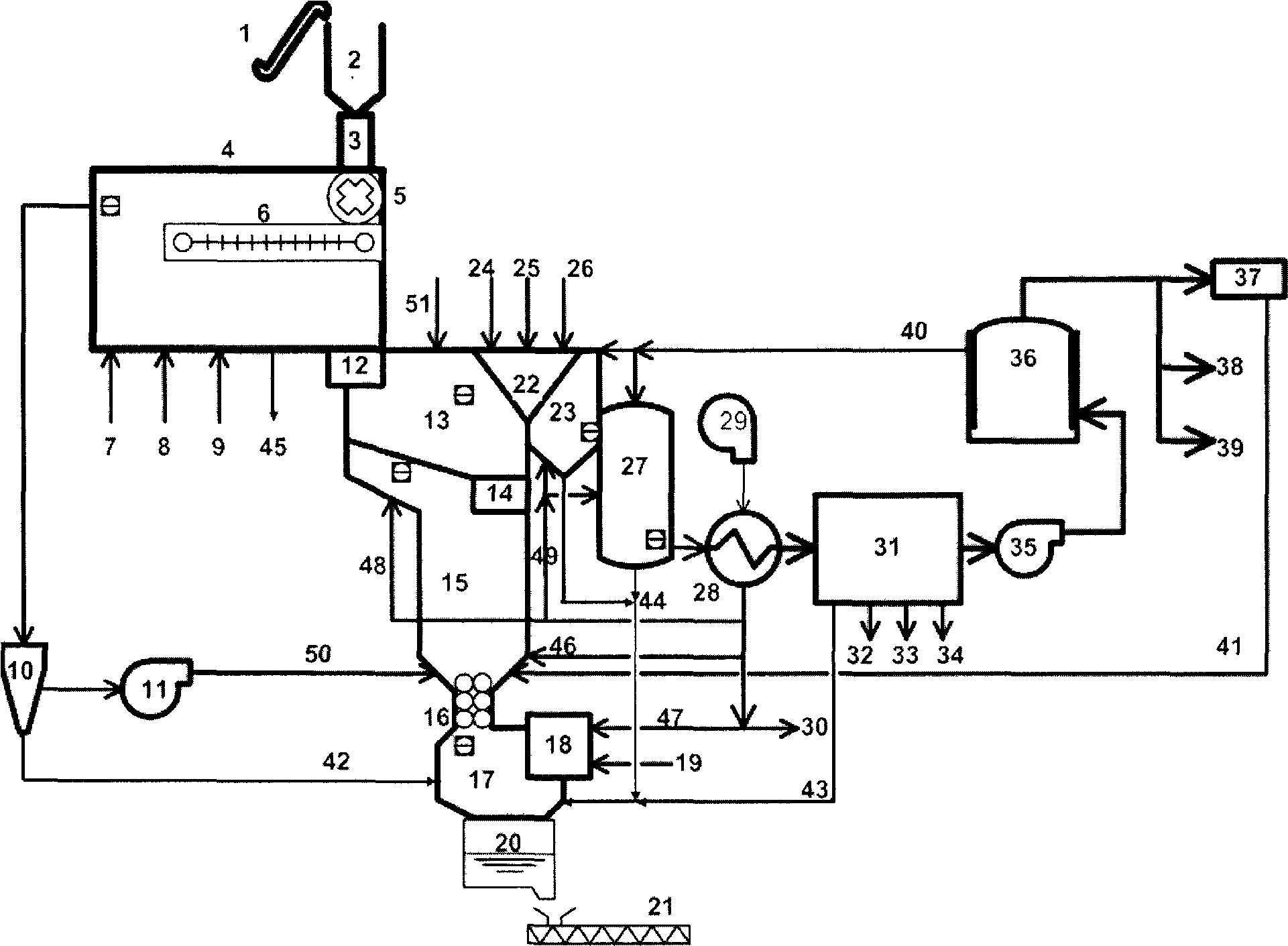

Multilevel-control polyradical biomass-gasification energy regeneration system

ActiveCN101519604AImprove gasification efficiencyHigh reforming efficiencyBiofuelsEnergy inputOxygenMoisture

The invention provides a multilevel-control free-polyradical biomass-gasification energy regeneration system, which can transform extensive biomass and carbon-containing raw materials, including energy crops, agriculture-forestry byproducts, organic waste, industrial and dangerous waste and the like, into high-grade energy. The system is designed for continuous operation. Gasification comprises the following steps of performing pretreatment, performing pyrolysis, transforming carbon, fusing ash, cracking tar, reforming syngas and utilizing waste heat, wherein the steps are precisely controlled one by one and integrated so as to achieve optimum; moisture from the pretreatment of the materials is led into a carbon-transforming unit so as to realize oxygen-free pyrolysis; gasification gas is in contact with a large number of free polyradicals in a free-polyradical reaction-accelerating unit; and the obtained product is purified and then enters downstream application, such as power generation, hydrogen production and biomass methanol / ethanol production. The system has the advantages of needing no auxiliary fuel, maximizing gasification efficiency and thoroughly cracking tar and clearing pollutants, and is an upstream technique for the application of biomass renewable energy. As energy utilization meets all strict environmental protection standards, the system is also an energy-saving environment-friendly technique for non-incineration harmless treatment.

Owner:浙江瑞拓展泰再生能源有限公司

Method for preparing organic fertilizer by using aminonitrile waste liquid

InactiveCN101391911AReduce manufacturing costImprove economic efficiencyBio-organic fraction processingClimate change adaptationAmino nitrilesChemistry

The invention provides a method for preparing an organic fertilizer by utilizing amino-nitrile waste liquor, which comprises the steps: catalyst and dispersant are added in the associated amino-nitrile waste liquor generated in the preparation of iminodiacetonitrile, aminoacetonitrile, ammonium dinitrile and EDTW, and mixed for reaction at the temperature of 30 to 150 DEG C and the pressure of 0 to 1.0MPa, so as to obtain base fertilizer which is added with biological strains for fermentation of 7 to 15 days at the temperature of 10 to 60 DEG C after nutrient allocation; and then hydrolysis is carried out to the base fertilizer to obtain a raw fertilizer which is carried out with nutrient allocation, pelleting and drying to be prepared into the organic fertilizer. The method can reduce the treatment cost, effectively utilizes the resources of the water liquor, and prepare the organic fertilizer by utilizing the amino-nitrile waste liquor.

Owner:四川省天然气化工研究院

No-baking brick made of oil field sludge and its production process

InactiveCN1526529AHigh strengthNo pollution in the processSolid waste disposalCeramic shaping apparatusBrickSludge

The present invention relates to no-baking brick, and is especially no-baking brick made of oil field sludge and its production process. The no-baking brick of the present invention is produced with the following material and through mixing and extrusion in extruder: oil field sludge 30-60 wt%, river sand 15-40 wt%, cement 15-30 wt%, flyash 0-35 wt% and curing agent 1-8 wt%. The no-baking brick of the present invention has high strength, no pollution and simple production process, and the present invention solves the problem of pollution and exhaust of oil field sludge.

Owner:UNIV OF JINAN

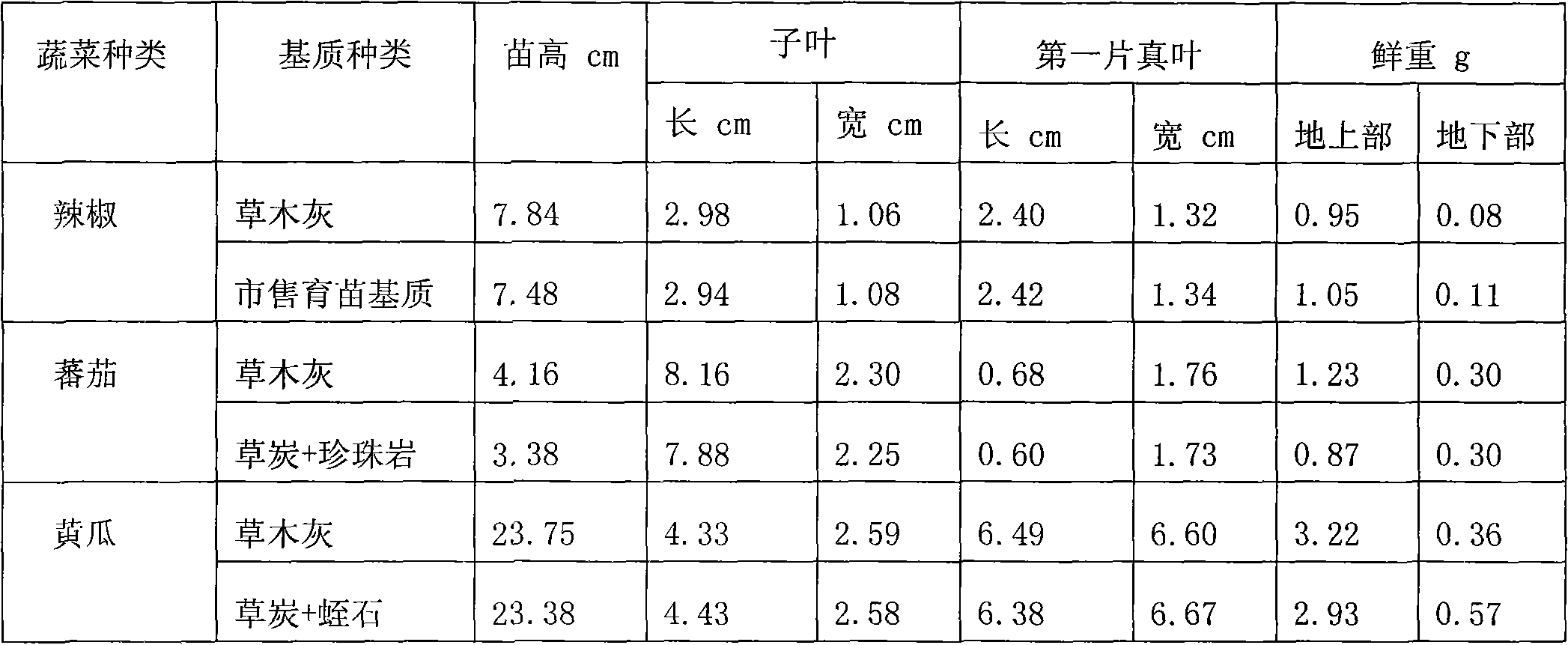

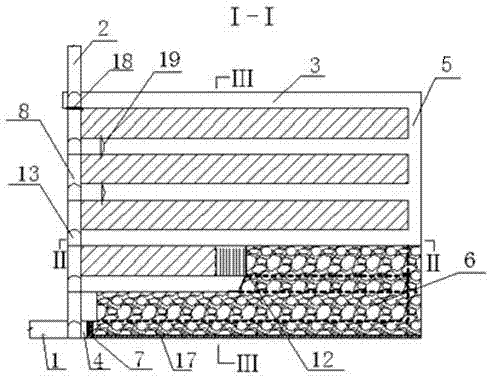

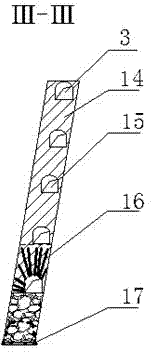

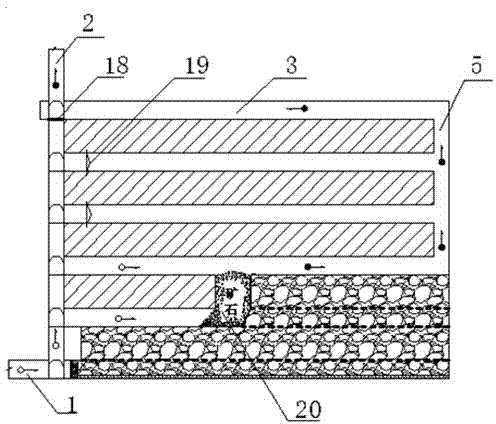

Plant ash seedling-growing matrix and preparation method thereof

InactiveCN102020506AReduce total usageSolve the emission problemFertilizer mixturesDiseaseHigh survival rate

The invention discloses a plant ash seedling-growing matrix and a preparation method thereof. The matrix is prepared by mixing the following raw materials: 100 parts of plant ash desalted through washing and dewatered through centrifugation, 10-35 parts of soil and 0.02-0.35 part of binder. The preparation method comprises the following steps of: adding a nitrogen element to increase the content of rapid available nitrogen to reach 100-300 mg / L, or adding the nitrogen element to increase the content of rapid available nitrogen to reach 100-300 mg / L and simultaneously adding a phosphorus element, adjusting the pH of a material to be 6-8 by using an acid, and adjusting the moisture content of the material to be 40-55%. The matrix is applicable to vegetables, flowers, tobaccos, nursery-grown plants and field crops, such as rice, corns, cotton and other various crops requiring seedling growing and transplanting. When the matrix is used for growing seedlings, the seedlings are strong and have no disease, good root system development, short seedling recovery period after transplanting and high survival rate.

Owner:JIANGSU XUHUAI DISTRICT HUAIYIN AGRI SCI RES INST

Non-phosphorus scale and corrosion inhibitor

InactiveCN101565241AAchieve emissionsSolve the emission problemTreatment using complexing/solubilising chemicalsCarbon steelGluconic acid

The invention discloses a non-phosphorus scale and corrosion inhibitor, which is characterized by comprising the following productive raw materials by weight portion: 5 to 80 portion of deionized water, 5 to 60 portions of polyepoxysuccinic acid, 1 to 10 portions of methylbenzotriazole, 3 to 20 portions of sodium gluconate, 1 to 10 portions of imidazoline and 2 to 15 portions of sodium tungstate. The non-phosphorus scale and corrosion inhibitor is a completely non-phosphorus medicament. Experiments show that the non-phosphorus scale and corrosion inhibitor has a scale inhibition rate of above 95 percent, a stainless steel and copper corrosion rate of less than or equal to 0.005mm / a and a carbon steel corrosion rate of less than or equal to 0.075mm / a and realizes phosphor-free discharge, wherein both the scale inhibition rate and the corrosion inhibition rate reach related national and industrial standards. The non-phosphorus scale and corrosion inhibitor has the advantages of radically solving the problem of the discharge of phosphor in circulating water, laying a good foundation for the governance and recycling of discharge water and providing a new environmental protection means.

Owner:李秀宁

Mining method of thin minor ore body

ActiveCN104847356AAvoid lostImprove recovery rateUnderground miningSurface miningMining engineeringCircular economy

The invention discloses a mining method of a thin minor ore body, which comprises the steps of ore recovery and goaf filling, which are alternatively circularly performed from bottom to top in a horizontal layering manner, propelling is performed along with a work surface, lime, loess, dead rock and the like are adopted and mixed layer by layer to fill a goaf, a filling body supports hanging wall and heading wall surrounding rocks, and serves as a work platform of upper layering recovery and ore removal, the ore is conveyed to an ore chute with a mechanical method, spallation ore removal of each recovery spallation step length and the filling procedure of the goaf are performed alternatively, when the uppermost horizontal layer of a chamber is recovered, mechanical and manual fill tightening are performed. The method solves the problem of discharge of tunneled dead rocks, effectively processes the goaf, prevents surface subsidence, accords with requirements of circular economic development and green ore construction. Compared with a shallow hole shrinkage method, the mining method has the advantages of improving ore recovery rate, reducing ore dilution rate and improving ore removal grade and ore removal efficiency through production practice.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

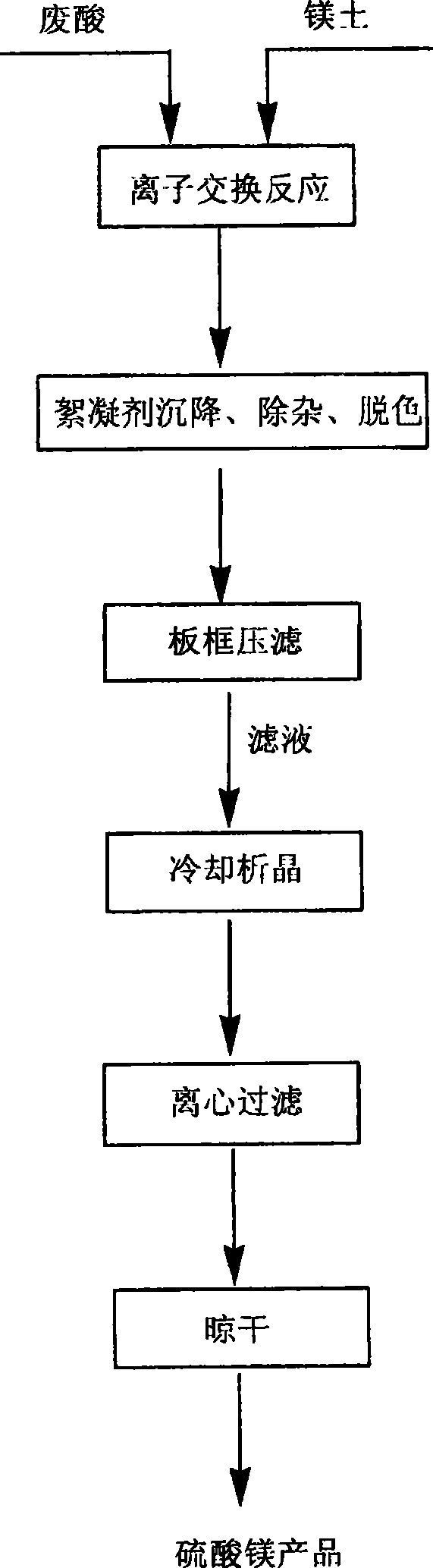

Process for preparing magnesium sulphate heptahydrate in treatment of industrial waste sulphuric acid liquid

The invention provides a method for producing the magnesium sulfate heptahydrate, which is characterized in that the waste sulfuric acid that is generated in the sulfonation alkaline fusion process is adopted as the raw material; the waste sulfuric acid solution is mixed with magnesia, so that the ion exchanging reaction can be adequately performed; after the adequate reaction, flocculating agent is adopted for precipitation, foreign matters removal and the color removal, and then the solution is compressed and filtered by a framework to get the magnesium sulfate clear solution; the magnesium sulfate clear solution is cooled down, crystallized and centrifugally filtered to get the solid magnesium sulfate heptahydrate. The method not only resolves the problems of the vast discharging of the waste sulfuric acid, but also can produce the product of the magnesium sulfate from the waste sulfuric acid solution; moreover, the method has less investment, simple craftwork and high recycling rate, thereby having remarkable social benefit and economic benefit.

Owner:苏州麒麟医药化学研发有限公司

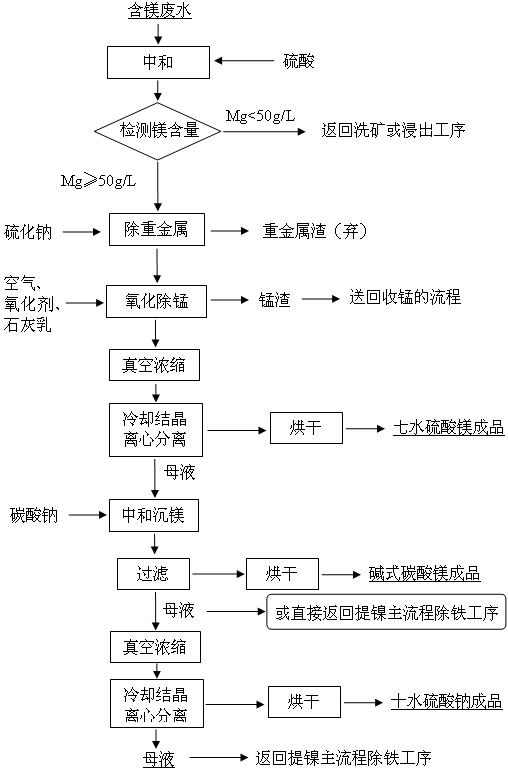

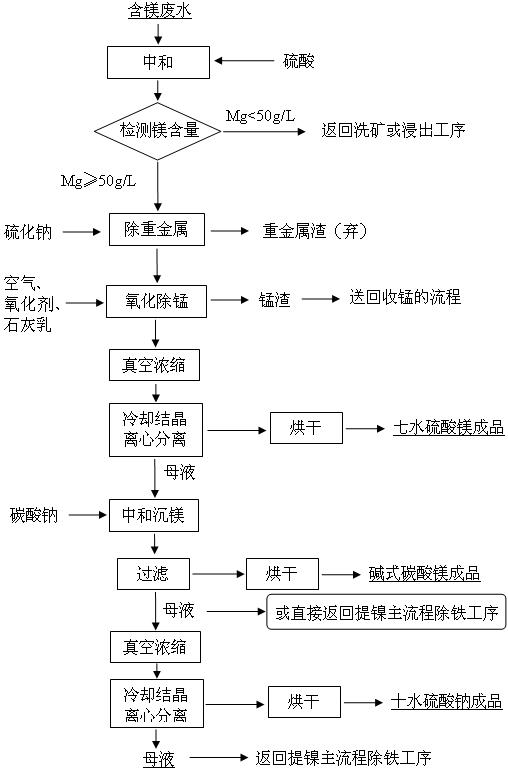

A comprehensive treatment method for laterite nickel ore hydrometallurgy wastewater

ActiveCN102276099ASolve the emission problemReduce manufacturing costMagnesium carbonatesMagnesium sulfatesManganeseEvaporation

The invention discloses a comprehensive treatment method of waste water from laterite-nickel ore wet smelting, which comprises the following steps: adjusting magnesium-containing waste water to be neutral so as to return the waste water to the ore-washing or leaching procedure for a process purpose, increasing the magnesium concentration of the waste water to above 50 g / L, performing heavy metal removal and manganese removal, performing negative pressure evaporation concentration, cooling crystallization, centrifugation separation, and drying to obtain magnesium sulfate heptahydrate, performing magnesium precipitation of the mother liquor after crystallization by sodium carbonate, separating basic magnesium carbonate, performing negative pressure evaporation concentration, cooling crystallization, centrifugation separation, and drying of the mother liquor after magnesium precipitation to obtain sodium sulfate decahydrate, or returning the mother liquor after magnesium precipitation directly to the iron-removing procedure of the nickel-extraction flow and to be used as a sodium source for iron removal by a sodium jarosite method. The method of the invention is simple and practical,has low cost, does not generate waste by-products, can both produce salable chemical products and reduce the production cost of the main flow for nickel recovery, and also prevents environment pollution.

Owner:广西银亿新材料有限公司

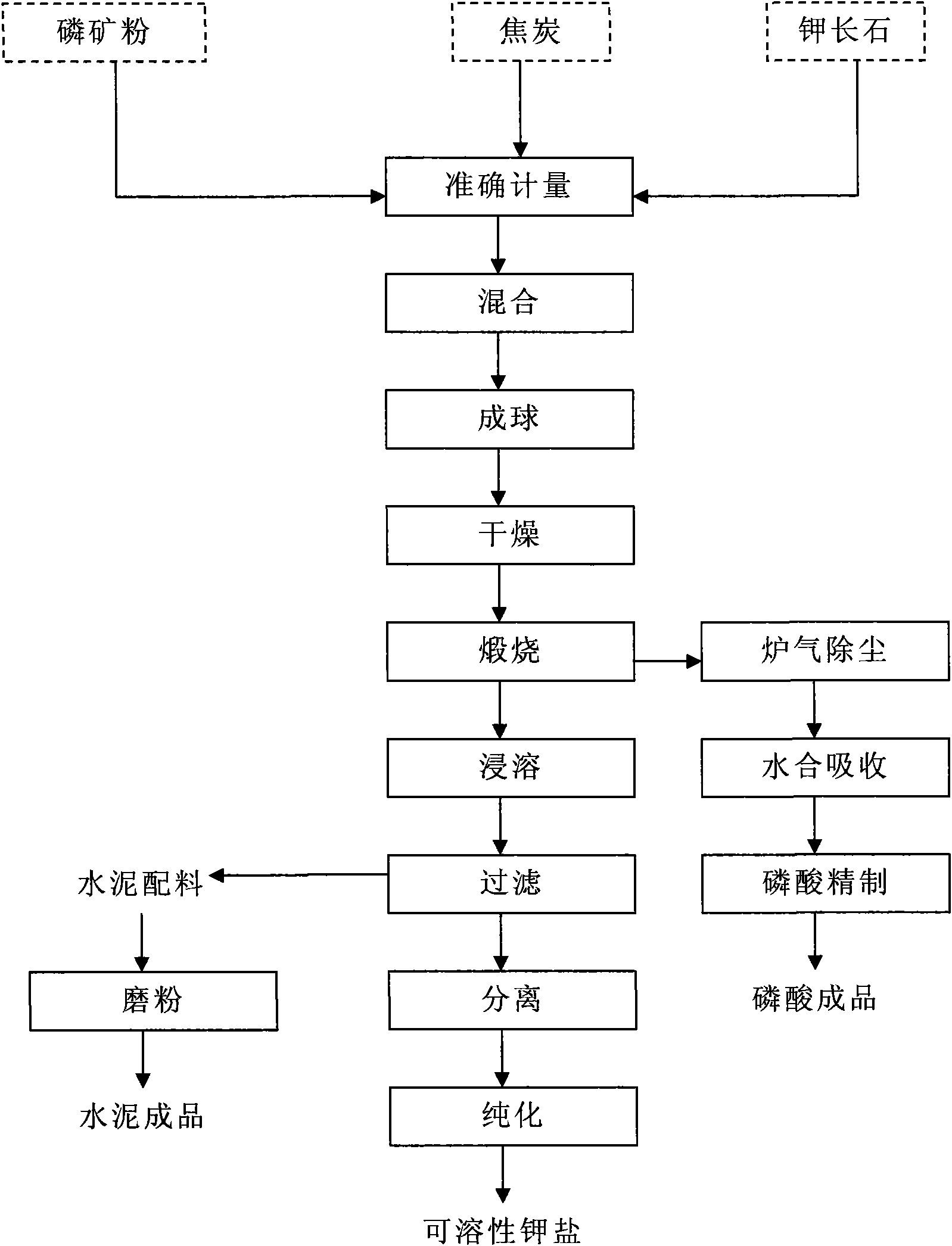

Method for producing phosphoric acid and soluble potassium salt by phosphorus ore and potash feldspar

InactiveCN101585521AReduce consumptionReduce external heating energyCement productionPhosphoric acidSlagPhosphor

The invention is a method for producing phosphoric acid and soluble potassium salt by phosphorus ore and potash feldspar, characterized in that, the method comprises: selecting phosphorus ore containing P2O5 15-30% and potash feldspar containing K2O 10-18% to mix with coke; crushing, ball milling, balling by adding water and drying; calcining for 10-30 minutes under temperature of 1100-1400DEG C; then soaking the calcined product in 1-5% citric acid solution for 12 hours, wherein, the soaking temperature is between room temperature and 60 DEG C; crystallizing and purifying the separated filtering solution; obtaining the soluble potassium salt; P2O5 in the phosphorus ore is reduced into phosphor vapor to be volatilized, the phosphor vapor above the material layer can be oxidized into P2O5 gas by the air introduced into the furnace, in the hydration apparatus, P2O5 gas can be absorbed to obtain the phosphoric acid. the invention solves the problems of waste slag and waste gas emissions during producing phosphoric acid, also alleviates the existing state that in our country, the soluble kalium resources are depended on importation, the method of the invention is economical and environment-protecting.

Owner:KUNMING UNIV OF SCI & TECH

Tin stripping agent based on sulfuric acid-ferric salt system and preparing method of tin stripping agent

The invention discloses a tin stripping agent based on a sulfuric acid-ferric salt system and a preparing method of the tin stripping agent, and belongs to the technical field of metal coating stripping. The tin stripping agent based on the sulfuric acid-ferric salt system is prepared by following components including, by content, 150-300 g / L of concentrated sulfuric acid, 100-200 g / L of the ferric salt, 0.1-1 g / L of ferrous sulfate, 0.1-5 g / L of a copper organic corrosion inhibitor, 2-10 g / L of an organic acid complexing agent, 2-3 g / L of a surface active agent, 10-100 g / L of an accelerant and the balance water. The water serves as a solvent of the tin stripping agent based on the sulfuric acid-ferric salt system, nitric acid and fluoride are not contained, toxic gas containing oxynitride is not generated in the tin stripping process, sludge is not generated, the corrosion to copper is extremely low, the copper face is bright, and the tin stripping agent is an environment-friendly tin stripping agent.

Owner:GUANGDONG LEAR ELECTROCHEM LTD

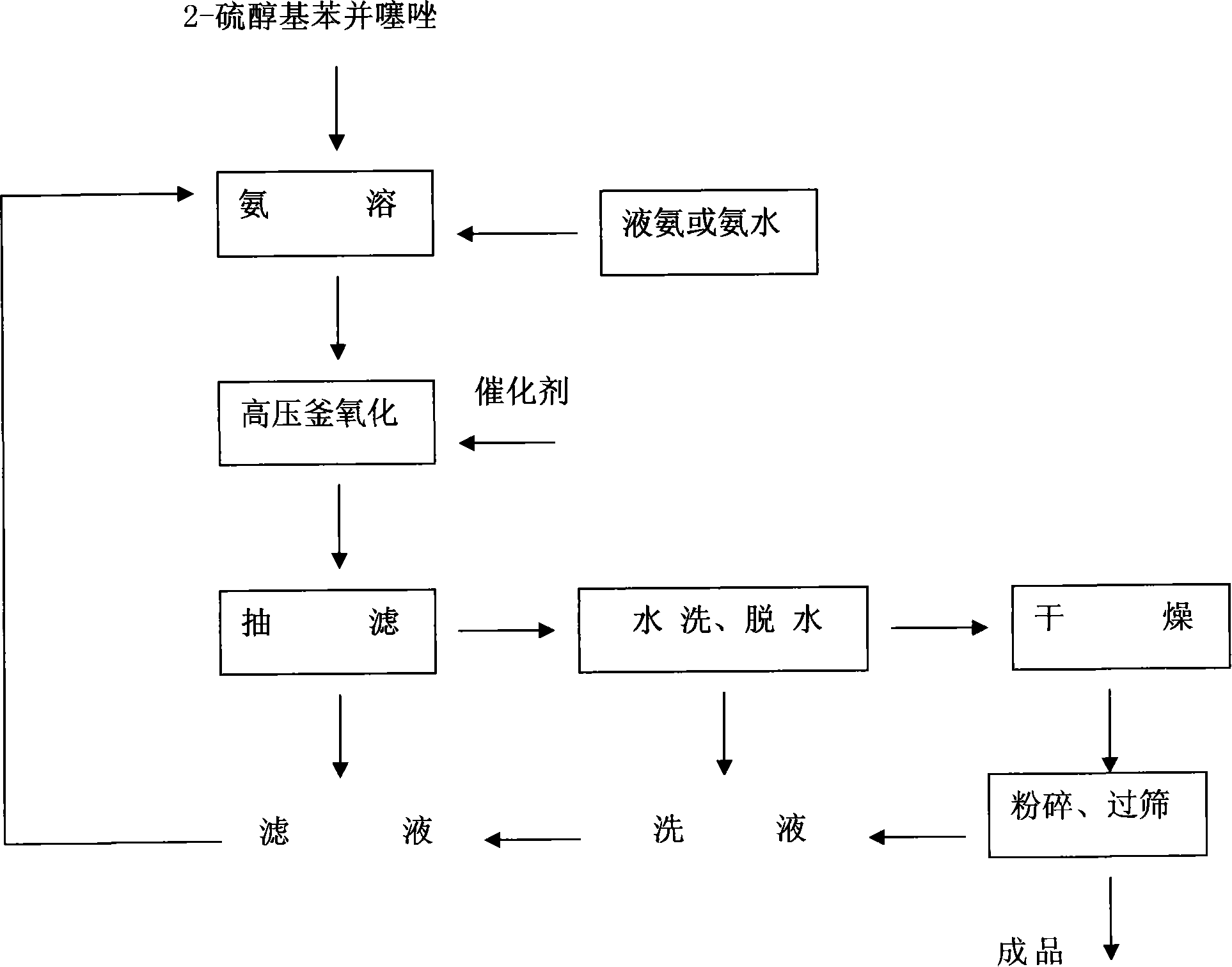

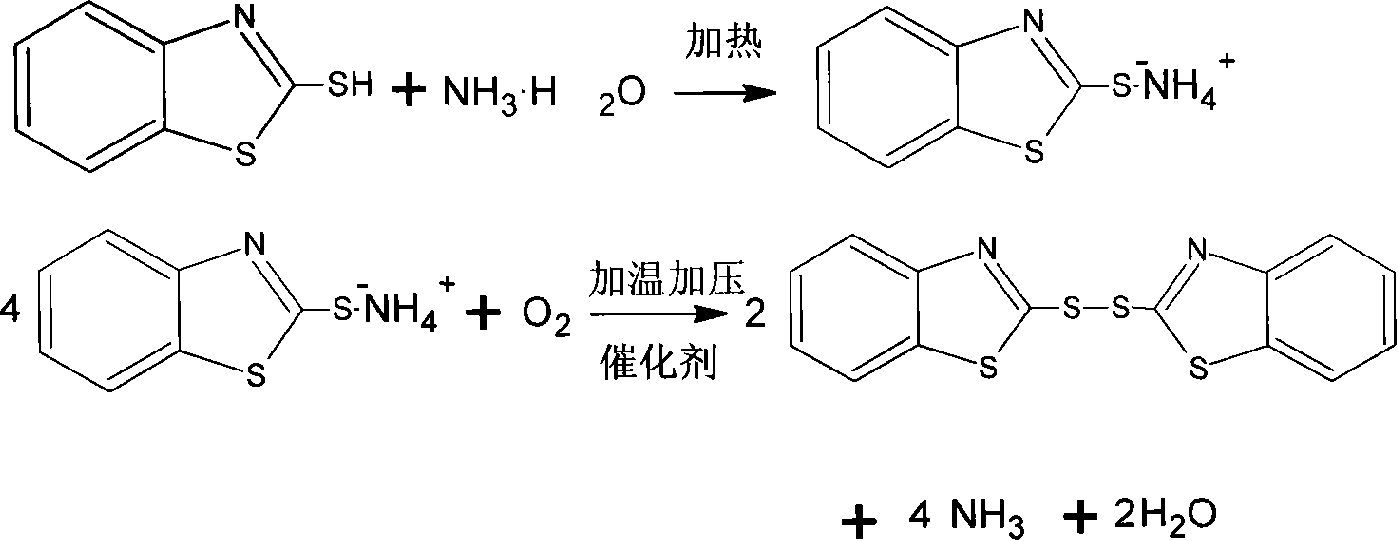

Preparation of 2,2-disulfo-dibenzopyrene by oxygen process based on 2-mercaptan benzothiazole ammonia salt

InactiveCN101139338ANo pollution in the processSolve the emission problemOrganic chemistryThiazoleWastewater

A method of preparing the 2, 2'-dithiocarbamate dibenzo thiazole based on the oxygen method of the 2-mercaptan benzothiazole ammonia salt is characterized in that the 2-mercaptan benzothiazole is added with ammonia or a compound for the dissolution reaction; the compound can produce the ammonia with the existence of water; in the dissolution process, the solution is heated and stirred; the solution of the ammonia salt is filtered after the dissolution; the catalyst is added; the air or oxygen is added under the condition with a certain temperature and pressure for the reaction of a certain period; the suspension produced after the reaction is pumped and filtered to get the filter cake; the filter cake is washes by water, dried and cracked to get the product 2, 2'-dithiocarbamate dibenzo thiazole; the filtered solution after being pumped and filtered and water for the washing process can return to the container to be used as the solvent for the cycling use after being supplemented with ammonia. The method has no wastewater and exhaust emission in the whole production process.

Owner:QINGDAO UNIV OF SCI & TECH +1

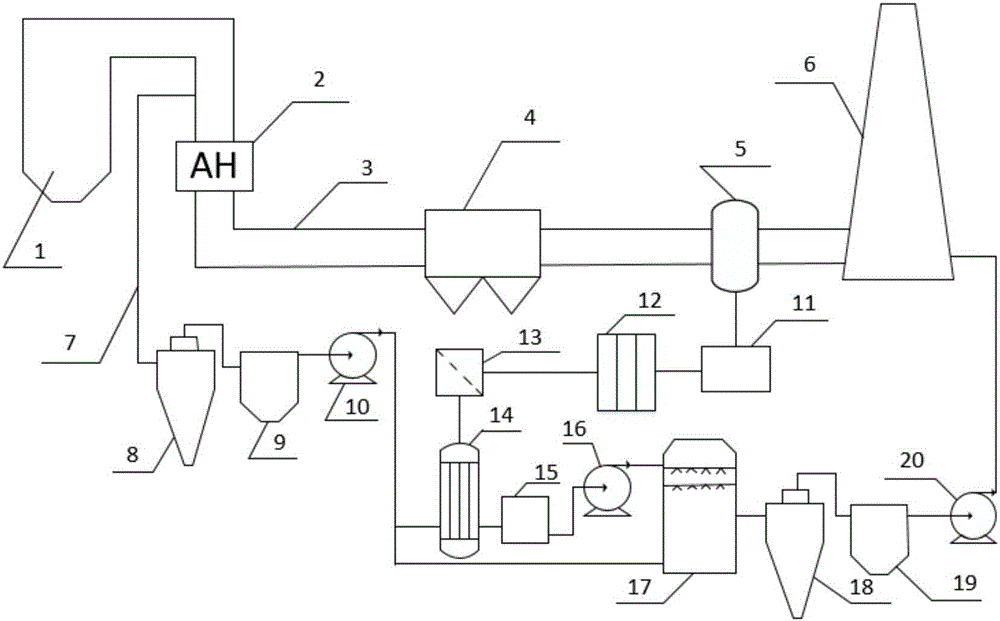

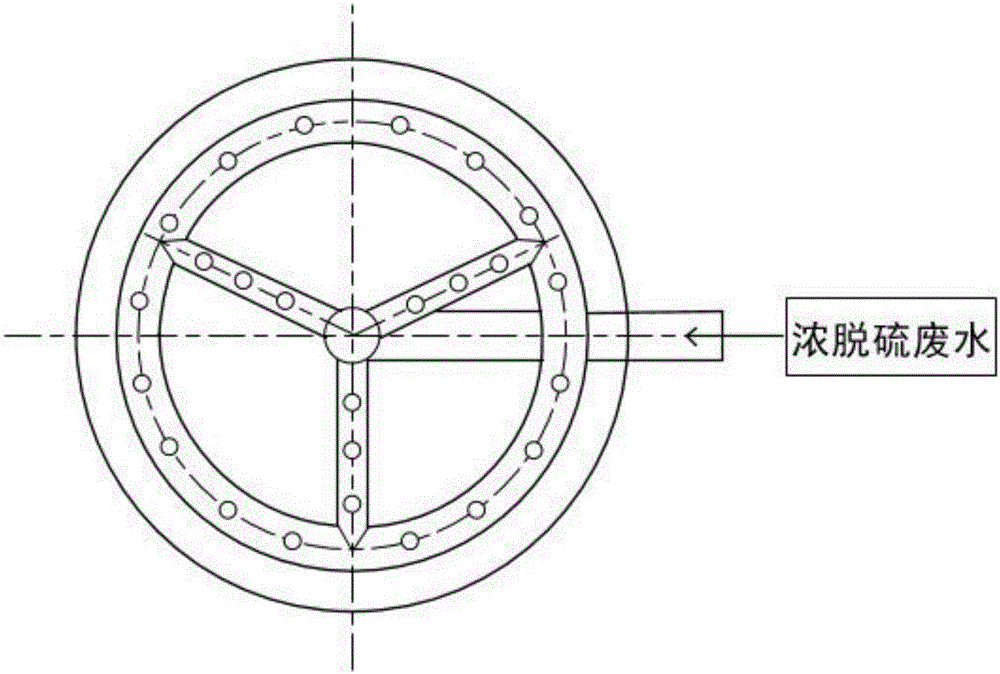

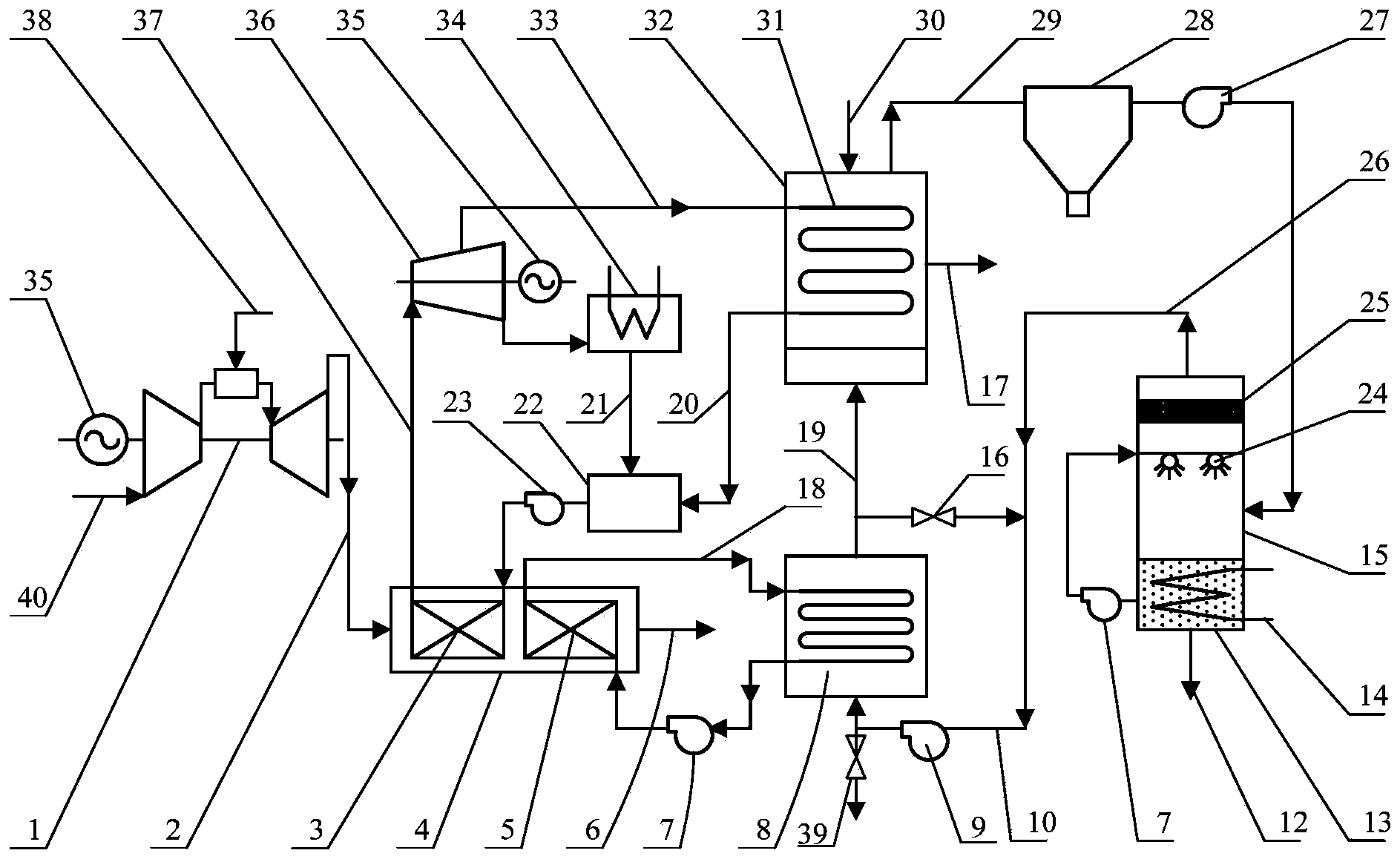

Desulfurization wastewater concentrating and flue gas drying integrated treatment system and method

InactiveCN106477794ASolve the emission problemReduce the temperatureGas treatmentDispersed particle separationCyclonic separationEvaporation

The invention discloses desulfurization wastewater concentrating and flue gas drying integrated treatment system and method. The desulfurization wastewater concentrating and flue gas drying integrated system comprises a desulfurization wastewater pool arranged at the bottom of a desulfurization tower, a three-stage sedimentation tank connected with the desulfurization wastewater pool and used for pretreatment of desulfurization wastewater, a filter connected with the three-stage sedimentation tank and used for solid-liquid separation, an evaporator connected with the filter and used for concentration of the desulfurization wastewater, a wastewater pool connected with the evaporator and used for storing the concentrated desulfurization wastewater, a water pump connected with the water pool and used for delivering the concentrated desulfurization wastewater, a concentrated desulfurization wastewater evaporation crystallization device connected with the water pump and a bypass flue system connected with a chimney and the concentrated desulfurization wastewater evaporation crystallization device, and the bypass flue system comprises a cyclopneumatic separator used for gas-liquid separation, a dust remover and a fan used for delivering bypass hot flue gas. The desulfurization wastewater concentrating and flue gas drying integrated treatment system is simple in structure and process, the problem about drainage of the desulfurization wastewater is solved, running cost of the system can be effectively reduced, flue gas temperature can be lowered, and heat released to the environment is decreased.

Owner:CHONGQING UNIV

Organic fertilizer for killing underground injurious insect and preparation method thereof

InactiveCN101781153AImprove aggregate structurePromote growthBio-organic fraction processingOrganic fertiliser preparationFecesLivestock manure

The invention belongs to organic fertilizer, and in particular relates to organic fertilizer for killing underground injurious insects and a preparation method thereof. The organic fertilizer comprises the following components in part by weight: 1000 parts of tobacco stalk, 25 to 30 parts of dry livestock manure, 5 to 10 parts of urea and 3 to 5 parts of solid high-efficient microorganism zymogeneous bacteria. The preparation method comprises the following steps that: the tobacco stalk is smashed; the livestock manure is dried and dehydrated; the urea is added to be uniformly mixed; the zymogeneous bacteria is inoculated; the moisture and the pH value are adjusted, fermentation stocks are piled up, and black plastic film covers the fermentation stocks, so the fermentation stocks are undertaken the anaerobic fermentation; after the temperature is increased, the stocks are turned for a plurality of times until the materials are fermented and matured and the size is reduced to two thirds of that of the original stocks; and the fermented stocks are naturally ventilated and dried and are bagged to store. The organic fertilizer has the advantages that the fertilizer efficiency is high, the underground injurious insects can be killed, the content of the organic colloid of the soil is increased after the application of the fertilizer, the fertilizer and water maintaining capacity of the soil is improved, the period of validity of the fertilizer is prolonged, and the probiotics in the soil can be compensated.

Owner:王德生

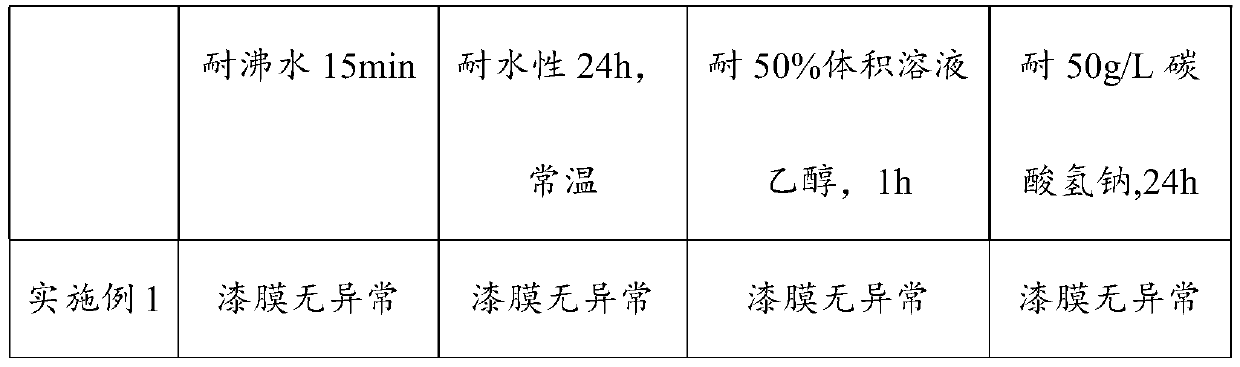

Ultraviolet-curable waterborne polyurethane emulsion as well as preparation method and application thereof

The invention belongs to the technical field of new polymer materials, and particularly relates to an ultraviolet-curable waterborne polyurethane emulsion as well as a preparation method and application thereof. According to the invention, polypropylene carbonate dihydric alcohol, diisocyanate and a reactive monomer are used as main raw materials; a UV-curable double bond group then is introducedso that the acrylate resin and the polyurethane resin are connected through chemical bonds, therefore, organic unification of respective excellent properties of the two resins is effectively achieved,and a film cured by the ultraviolet-curable waterborne polyurethane emulsion is high in hardness and has good solvent resistance, corrosion resistance, scratch resistance and mechanical strength. Moreover, the raw materials of the ultraviolet-curable waterborne polyurethane emulsion do not need an organic solvent, acetone is not required to be used as a solvent to reduce the viscosity of the system during preparation, the reactive monomer can reduce the viscosity of the system, the use of the organic solvent is avoided, the problem of VOC emission is further solved, and the pollution to the environment and the harm to health are reduced.

Owner:GUANGDONG UNIV OF TECH

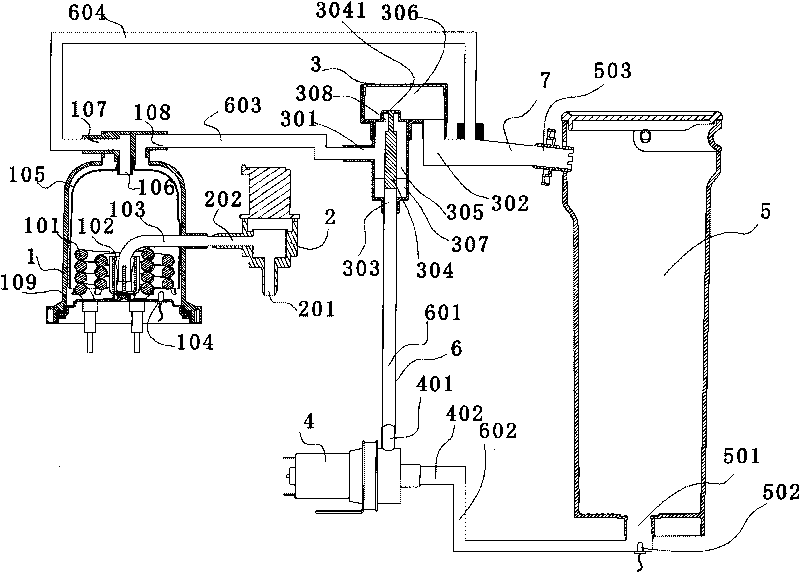

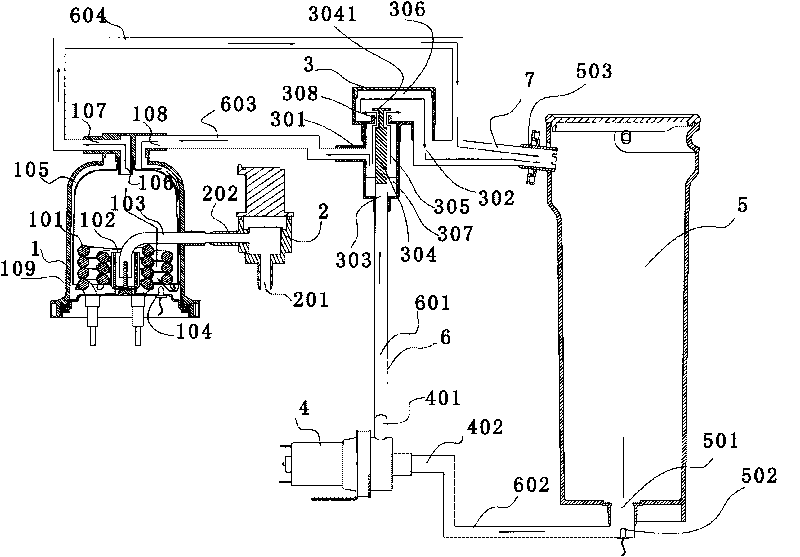

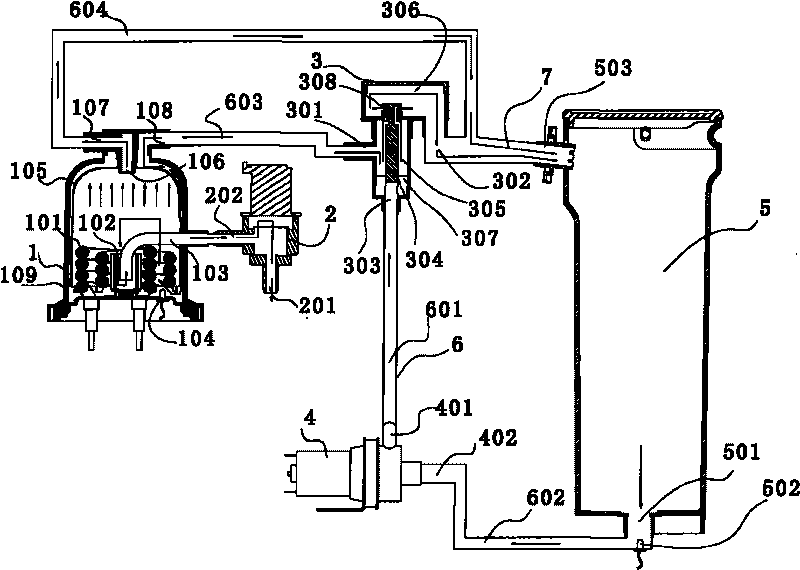

System and method for drying sludge through waste heat of gas turbine

ActiveCN103539333ALower fuel costsSolve the emission problemSludge treatment by de-watering/drying/thickeningSteam useFluidized bed dryingSludge

The invention provides a system and a method for drying sludge through the waste heat of a gas turbine. The gas turbine is connected with a generator; a flue gas outlet of the gas turbine is communicated with a waste heat boiler; a steam outlet of the waste heat boiler is communicated with a steam turbine; the steam turbine is connected with the generator; a steam extraction pipe of the steam turbine is communicated with an inlet of a heated surface pipe of an internal thermal type fluidized bed dryer; an air outlet of an air heater is communicated with an air inlet of the internal thermal type fluidized bed dryer; wet sludge enters the internal thermal type fluidized bed dryer through a wet sludge pipe, flows outside the heated surface pipe, is dried and then is discharged into a dry sludge pipe from a discharging hole. Steam is produced through the flue gas waste heat of the gas turbine to push a steam turbine generator set to generate power, and the waste heat of the steam turbine is taken as a heat source for drying the sludge, so that gradient energy utilization is realized, the heat efficiency is high, and a peculiar smell is not discharged; the fluidization air of the fluidized bed dryer is preheated by hot water, so that the energy utilization rate is further improved, and the environmental problems of groundwater pollution and the like caused by sludge burying and soil utilization are effectively solved.

Owner:凤阳县经济发展投资有限公司

System and method for instantly releasing boiling water from water dispenser

InactiveCN101756638ASolve the large impact of ambient temperatureAddressing Vapor EmissionsBeverage vesselsCentrifugal pumpWater tanks

The invention discloses a system and a method for instantly releasing boiling water from a water dispenser. The system comprises a shell, a water tank, and a heater, a gate valve, a water pump, connecting pipelines, a temperature sensor and a control circuit which are arranged in the shell. The system is also provided with a flow stabilizing device, wherein one water outlet of the flow stabilizing device is connected with a water inlet of the heater through the pipeline; the other water outlet of the flow stabilizing device is connected with a water inlet of the water tank through a three-way device; a water inlet of the flow stabilizing device is connected with a water outlet of the water tank through the pipeline and the water pump; a water vapor outlet of the heater is connected with the water inlet of the water tank through the pipeline and the three-way device; and one end of a water outlet pipeline of the heater is arranged in the heater, and the other end of the water outlet pipeline of the heater extends out of the heater and then is connected with the gate valve. The system adopts the method of arranging the flow stabilizing device, a cheap centrifugal pump and a water supply system preheating water in the water tank to stably supply water, is insusceptible to environment, can enable the boiling water to be instantly released, and has the advantages of simple structure, instantaneity and energy saving.

Owner:SHENZHEN CRASTAL TECH CO LTD

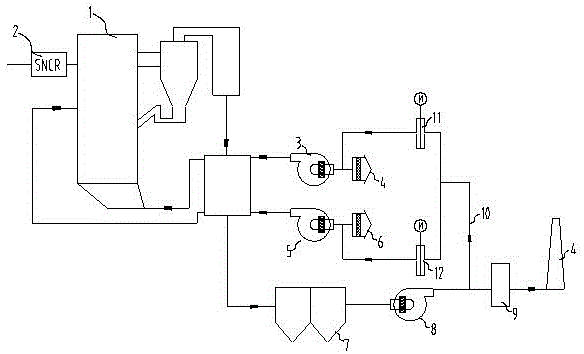

Flue gas recirculation-based wide load-wide coal deep denitrification system for CFB (circulating fluidized bed) boiler

InactiveCN105570883ALower combustion temperatureEmission reductionFluidized bed combustionFluegas recirculationCombustion chamberFlue gas

The invention provides a flue gas recirculation-based wide load-wide coal deep denitrification system for a CFB (circulating fluidized bed) boiler. The system comprises the boiler, an SNCR (selective non-catalytic reduction) system, a primary air blower, a secondary air blower, an induced draft fan, a recirculation flue, a primary air recirculation adjusting valve, a secondary air recirculation adjusting valve and the like. One end of the recirculation flue is connected with an outlet of the induced draft fan, the other end is connected with an inlet of the primary air blower and an inlet of the secondary air blower by the aid of the primary air recirculation adjusting valve and the secondary air recirculation adjusting valve, low-temperature flue gas is led out of the outlet of the induced draft fan, the low-temperature flue gas with the proper flow is sent to different positions of a combustion chamber by the blowers through control by the adjusting valves, distribution of temperature fields in the boiler is optimized by fine controlling content of oxygen of primary air and content of oxygen of secondary air on the basis of SNCR, pollutant emission is reduced, and the CFB boiler can realize low emission of NOx under wide load-wide coal conditions.

Owner:SICHUAN CHUANGUO BOILER

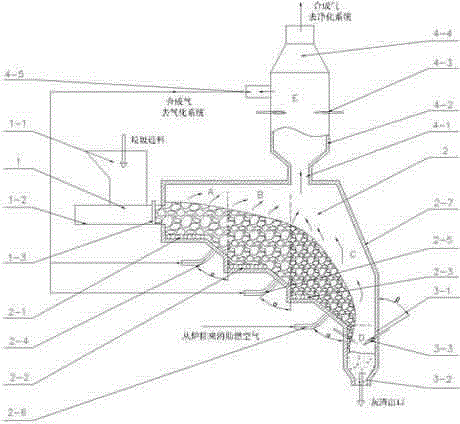

Plasma auxiliary-heating melting and gasifying reactor

ActiveCN104449875ASolve the emission problemFix issues that require reprocessingGasification processes detailsCombustible gas productionOperational costsReaction sequence

The invention relates to a plasma auxiliary-heating melting and gasifying reactor. The plasma auxiliary-heating melting and gasifying reactor comprises a feeder and a reaction chamber, wherein the feeder is connected with the reaction chamber; the reaction chamber sequentially comprises a drying area, a pyrolysis and gasification area, a burn-out area and an ash melting area according to a reaction sequence along a horizontal direction; the drying area is connected with the feeder through a charge port; the bottom of the pyrolysis and gasification area is lower than that of the drying area; the bottom of the burn-out area is lower than that of the pyrolysis and gasification area; the bottom of the ash melting area is lower than that of the burn-out area; the top of the burn-out area is connected with a synthesis gas reforming area through a throat opening; plasma torches are arranged in both the ash melting area and the synthesis gas reforming area. According to the plasma auxiliary-heating melting and gasifying reactor disclosed by the invention, the plasma torches are used as a high-quality external heat source for melting the ash generated after pyrolysis and gasification for household garbage, and the gasified synthesis gas is reformed, thus removing all harmful substances which are possibly generated by the household garbage in pyrolysis and gasification processes, reducing the one-time investment cost and operation cost of garbage plasma gasification, and enabling the synthesis gas to be purer.

Owner:中国东方电气集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com