Ultraviolet-curable waterborne polyurethane emulsion as well as preparation method and application thereof

A water-based polyurethane, ultraviolet light technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of low strength, low hardness, easy hydrolysis of ester bonds, poor product performance, etc., to achieve good hardness, wear resistance and scratch resistance. High damage and the effect of reducing the viscosity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

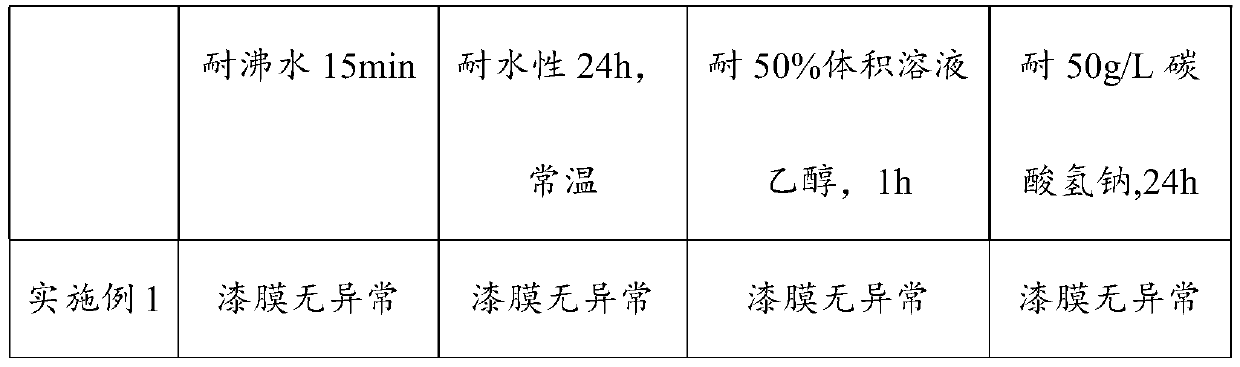

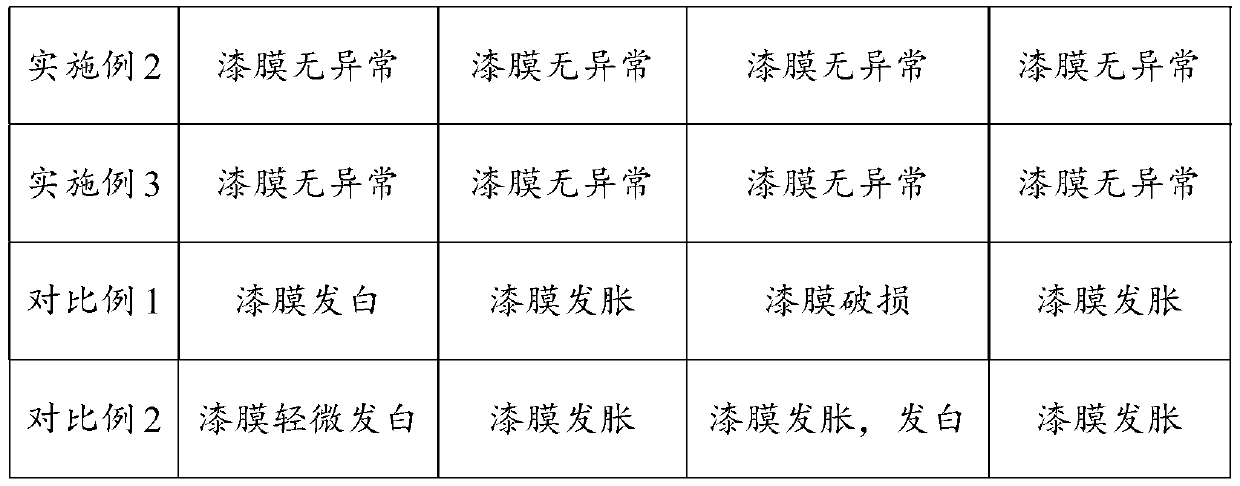

Embodiment 1

[0041]The present embodiment carries out the preparation of UV-curable aqueous polyurethane emulsion, comprising the following steps:

[0042] 1) In terms of parts by mass, take 60 parts of polypropylene carbonate diols with a molecular weight of 2000 and a hydroxyl functionality of 2. After high-temperature vacuum dehydration, add 25 parts of isophorone diisocyanate, 4.5 parts of dimethylol Propionic acid and 0.12 parts of stannous octoate were subjected to the first reaction at 85° C. for 4 hours to obtain an intermediate.

[0043] 2) Lower the temperature to 70°C, add 1.9 parts of chain extender 1,4-butanediol to the intermediate, keep it warm for 0.5 hour for the second reaction, and obtain a polyurethane prepolymer.

[0044] 3) Cool down to 65°C, add 16 parts of reactive monomer hydroxyethyl methacrylate and 0.02 parts of 2,2,6,6-tetramethylpiperidine oxide (TEMPO) to the polyurethane prepolymer, and keep warm 2 hours for the third reaction, lower the temperature to 45°C...

Embodiment 2

[0046] The present embodiment carries out the preparation of UV-curable aqueous polyurethane emulsion, comprising the following steps:

[0047] 1) In terms of parts by mass, take 60 parts of polypropylene carbonate diols with a molecular weight of 2000 and a hydroxyl functionality of 2. After high-temperature vacuum dehydration, add 25 parts of isophorone diisocyanate, 4.5 parts of dimethylol Propionic acid and 0.12 parts of stannous octoate were subjected to the first reaction at 85° C. for 4 hours to obtain an intermediate.

[0048] 2) Lower the temperature to 70°C, add 1.9 parts of chain extender 1,4-butanediol to the intermediate, keep it warm for 0.5 hour for the second reaction, and obtain a polyurethane prepolymer.

[0049] 3) Cool down to 65°C, add 11 parts of reactive monomer dimethacrylate and 0.02 parts of polymerization inhibitor to the polyurethane prepolymer, keep warm for 2 hours for the third reaction, cool down to 45°C, add 3.5 parts Perform the third reactio...

Embodiment 3

[0051] The present embodiment carries out the preparation of UV-curable aqueous polyurethane emulsion, comprising the following steps:

[0052] 1) In terms of parts by mass, take 60 parts of polypropylene carbonate diols with a molecular weight of 2000 and a hydroxyl functionality of 2. After high-temperature vacuum dehydration, add 25 parts of isophorone diisocyanate, 4.5 parts of dimethylol Propionic acid and 0.12 parts of stannous octoate were subjected to the first reaction at 85° C. for 4 hours to obtain an intermediate.

[0053] 2) Lower the temperature to 70°C, add 1.9 parts of chain extender 1,4-butanediol to the intermediate, keep it warm for 0.5 hour for the second reaction, and obtain a polyurethane prepolymer.

[0054] 3) Cool down to 65°C, add 14 parts of reactive monomer pentaerythritol triacrylate and 0.02 parts of polymerization inhibitor to the polyurethane prepolymer, keep warm for 2 hours for the third reaction, cool down to 45°C, add 3.5 parts of neutralize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com