Thermo roll

A technology of heated and heat transfer agent, used in textiles and papermaking, calendering, papermaking, etc., can solve the problems of high cost of powder metallurgy technology and few suppliers of large parts, avoid streaks, machining operations Simple, low-volume effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following description, the same reference numerals refer to the same components. It should be noted that the drawings are not drawn to scale in all cases and that they mainly serve the purpose of illustrating embodiments of the invention.

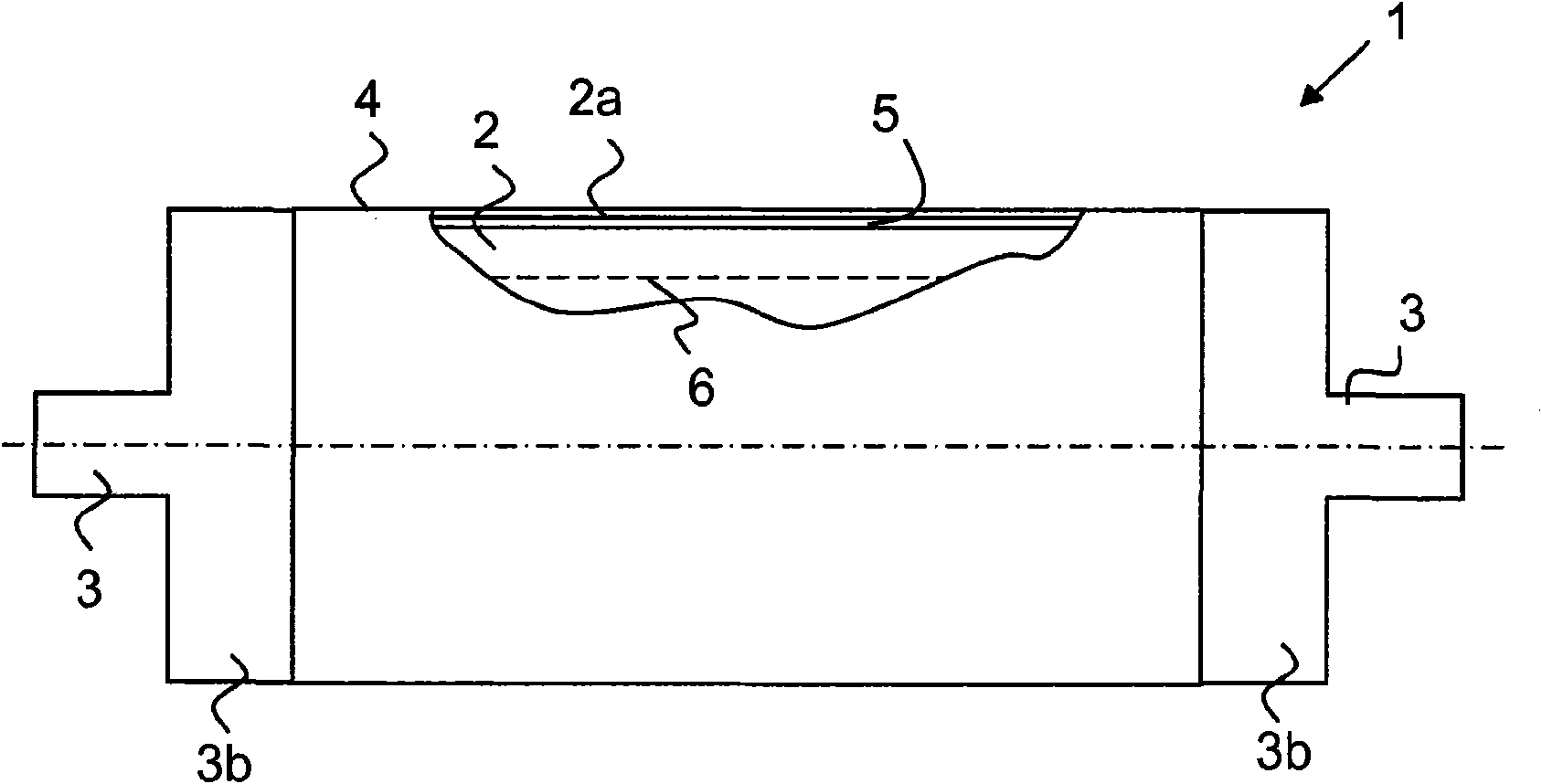

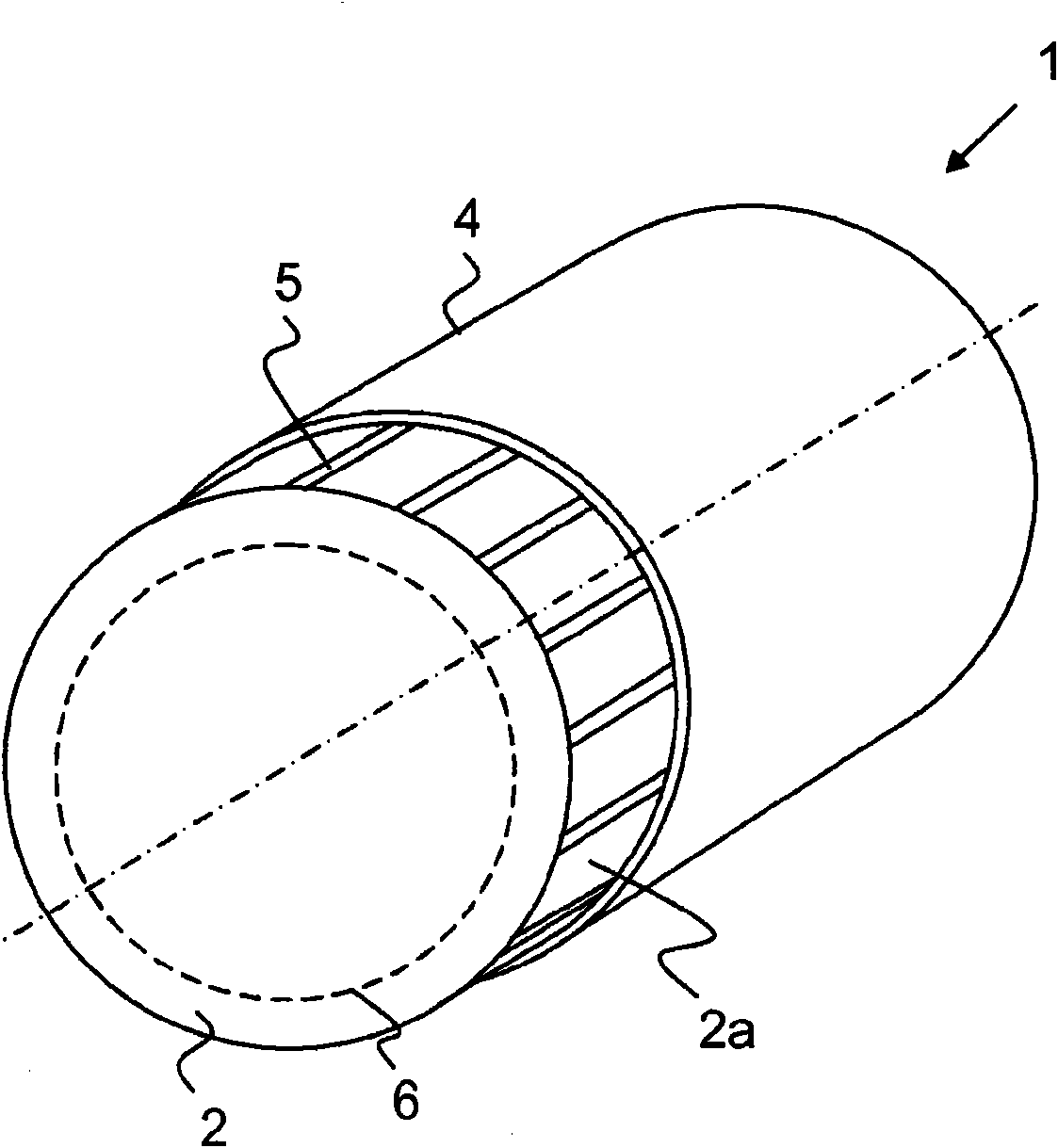

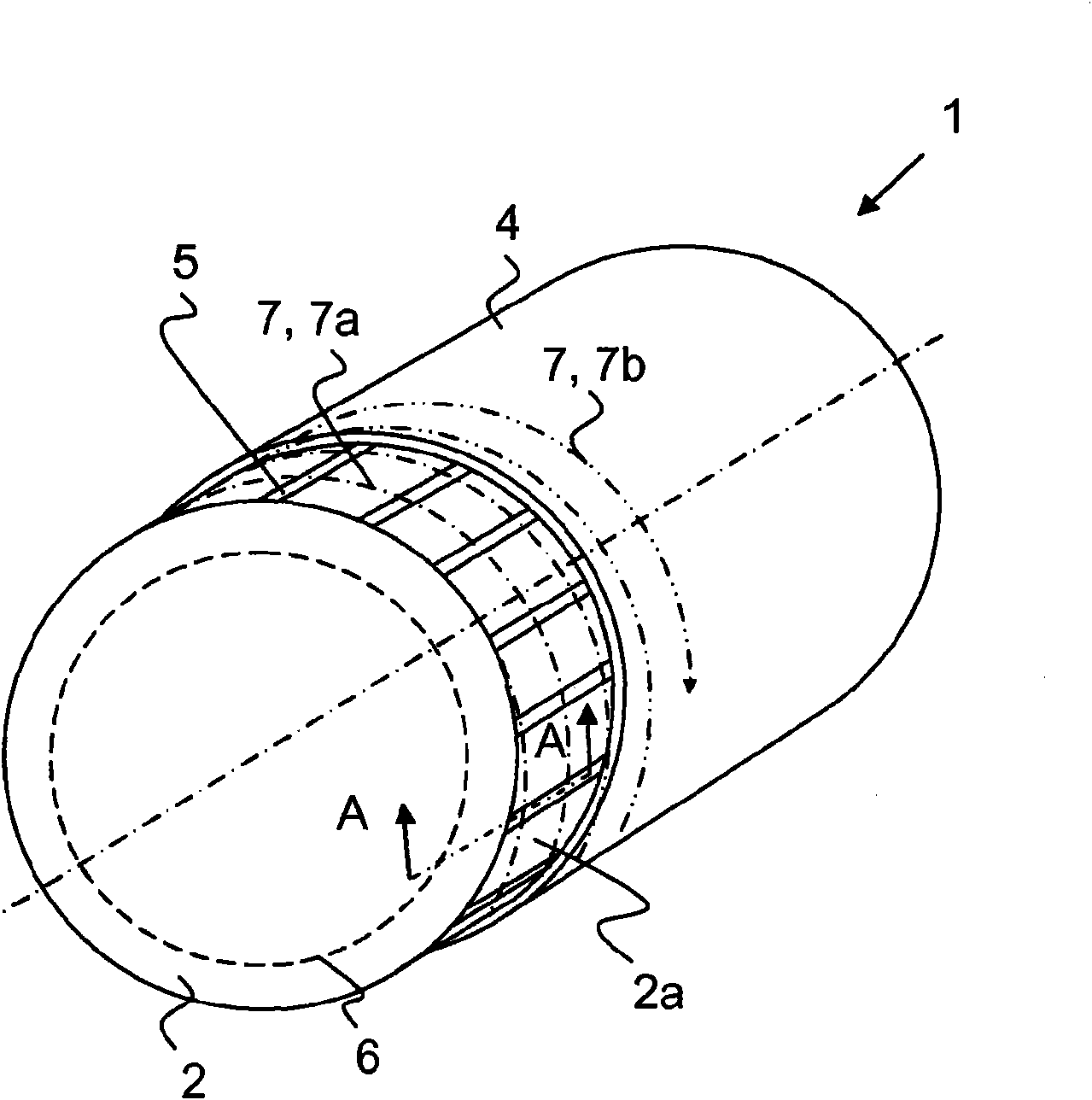

[0037] figure 1 and figure 2 Shows a heated and / or cooled roll according to an embodiment of the invention, namely a thermo roll 1 provided with a thin outer layer 4, for example of steel, and an inner shaft 2 inside the outer layer, the inner The surface of the shaft 2 has flow grooves for constituting flow channels 5 for the heat transfer agent.

[0038] The heat roller 1 includes an inner shaft 2 and a shaft end 3; the shaft end 3 is fastened to the end of the inner shaft 2 to carry a load. exist figure 1 In the example shown, at least one shaft end 3 fastened to the inner shaft 2 comprises at least one flow channel for introducing and / or leading out a heat transfer medium. The thermo roll 1 preferably comprises an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com