Patents

Literature

72results about How to "Avoid streaks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

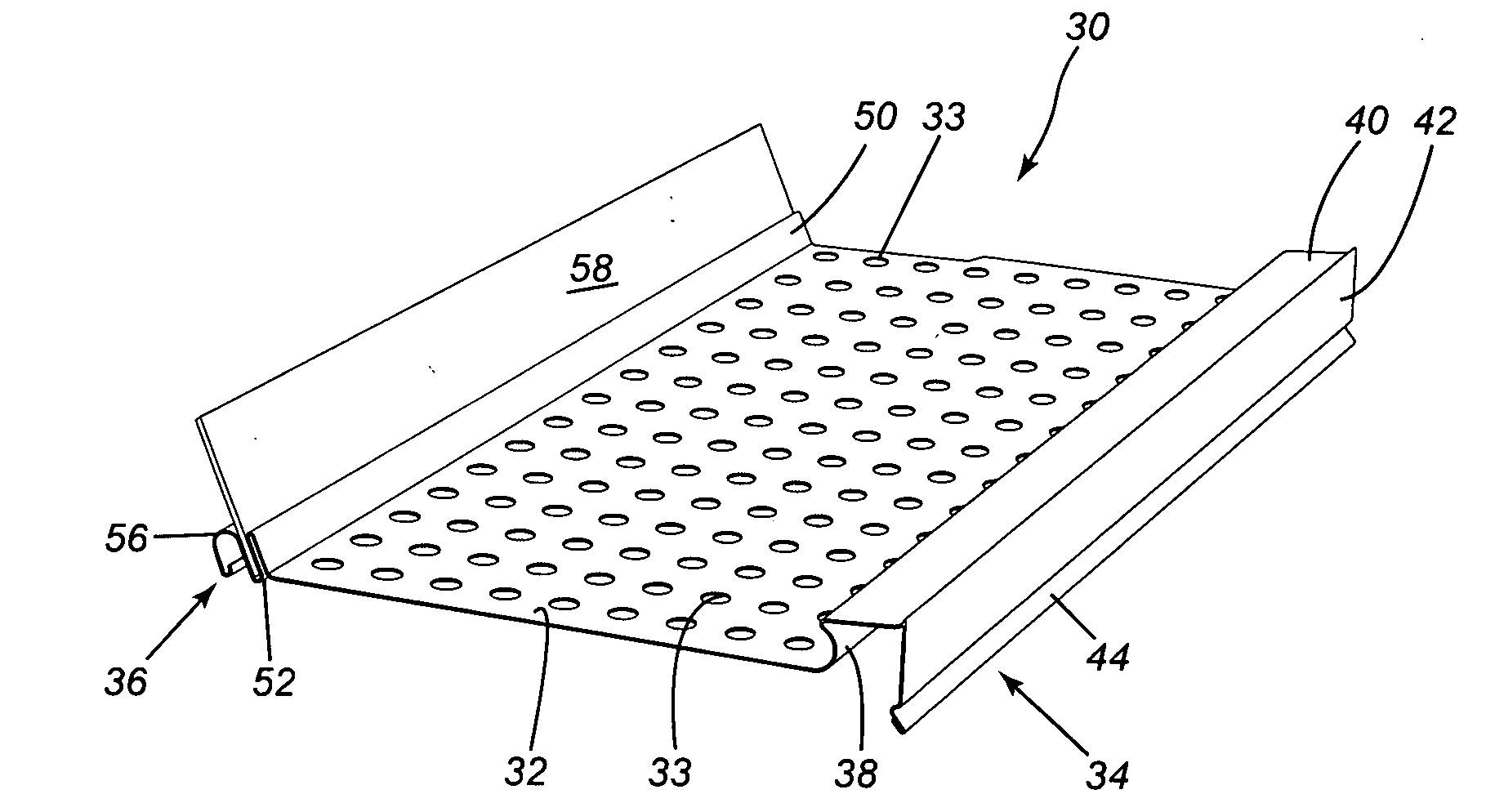

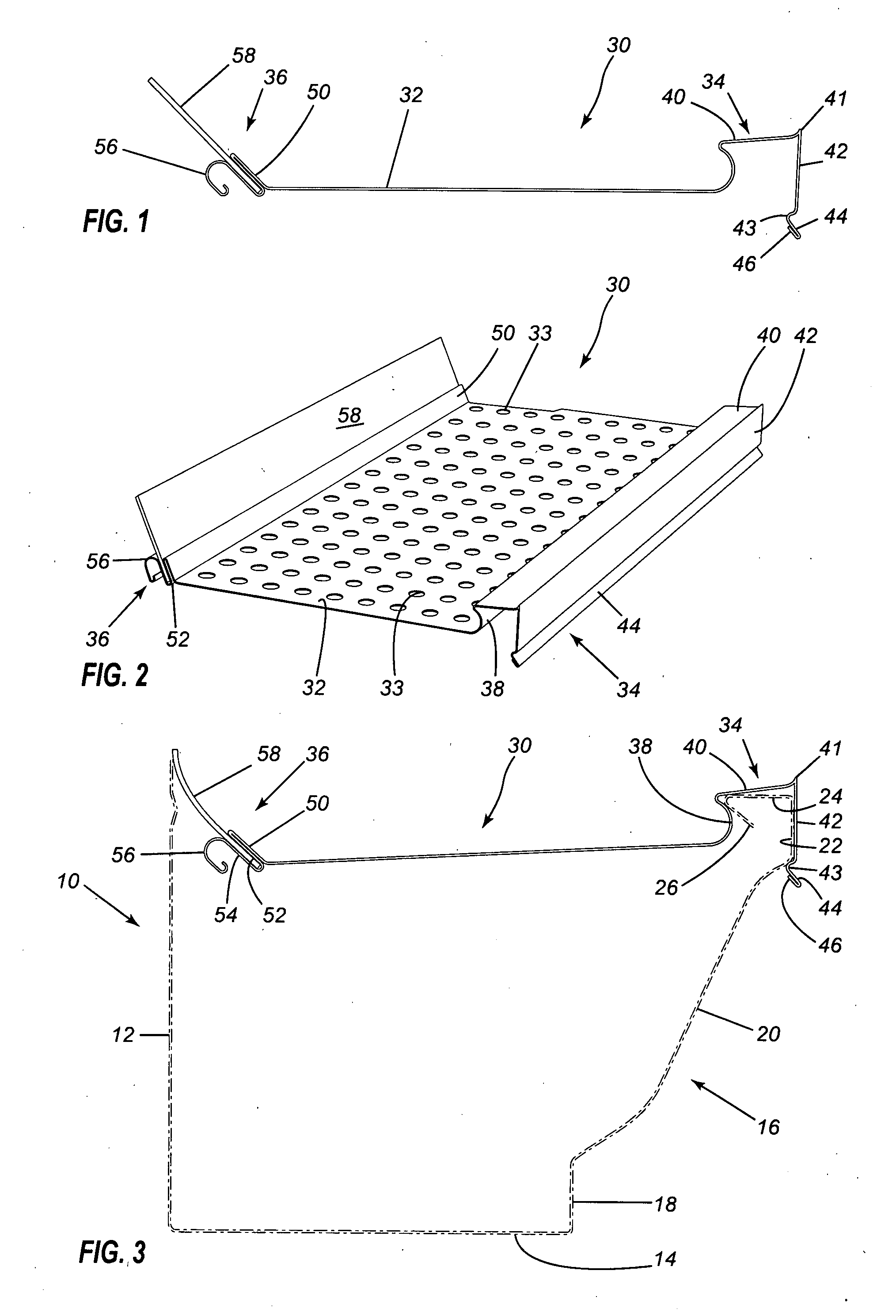

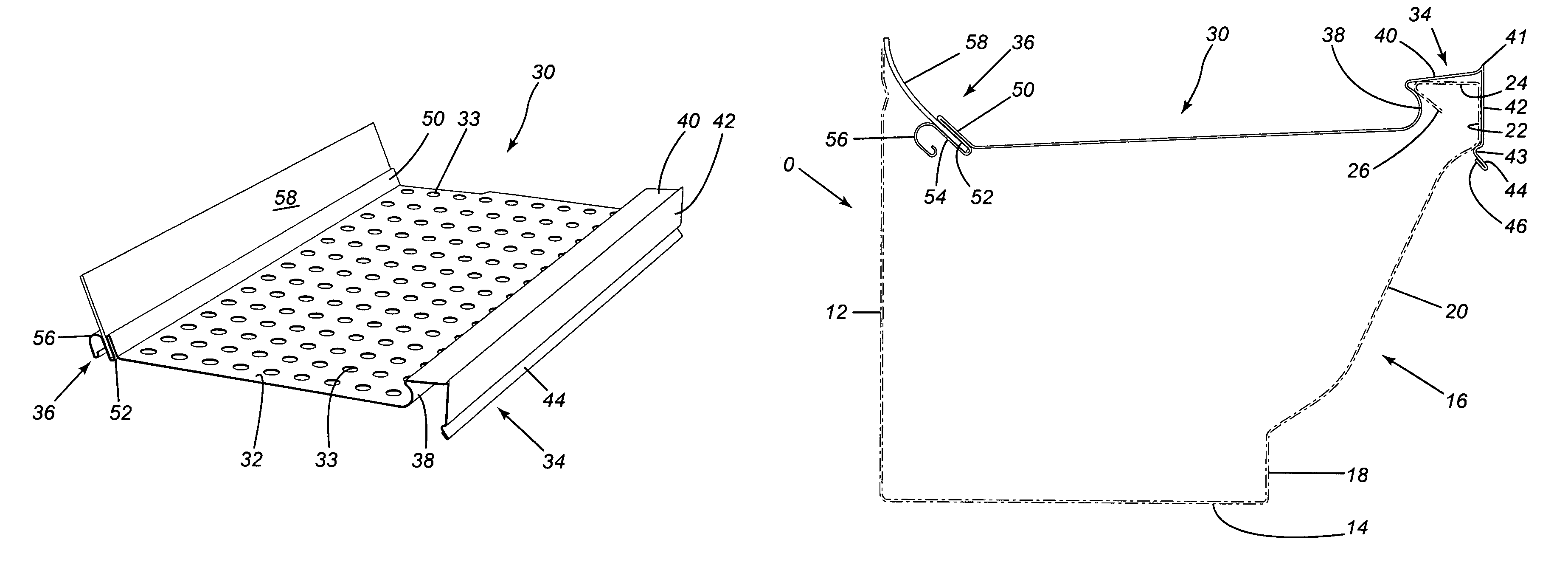

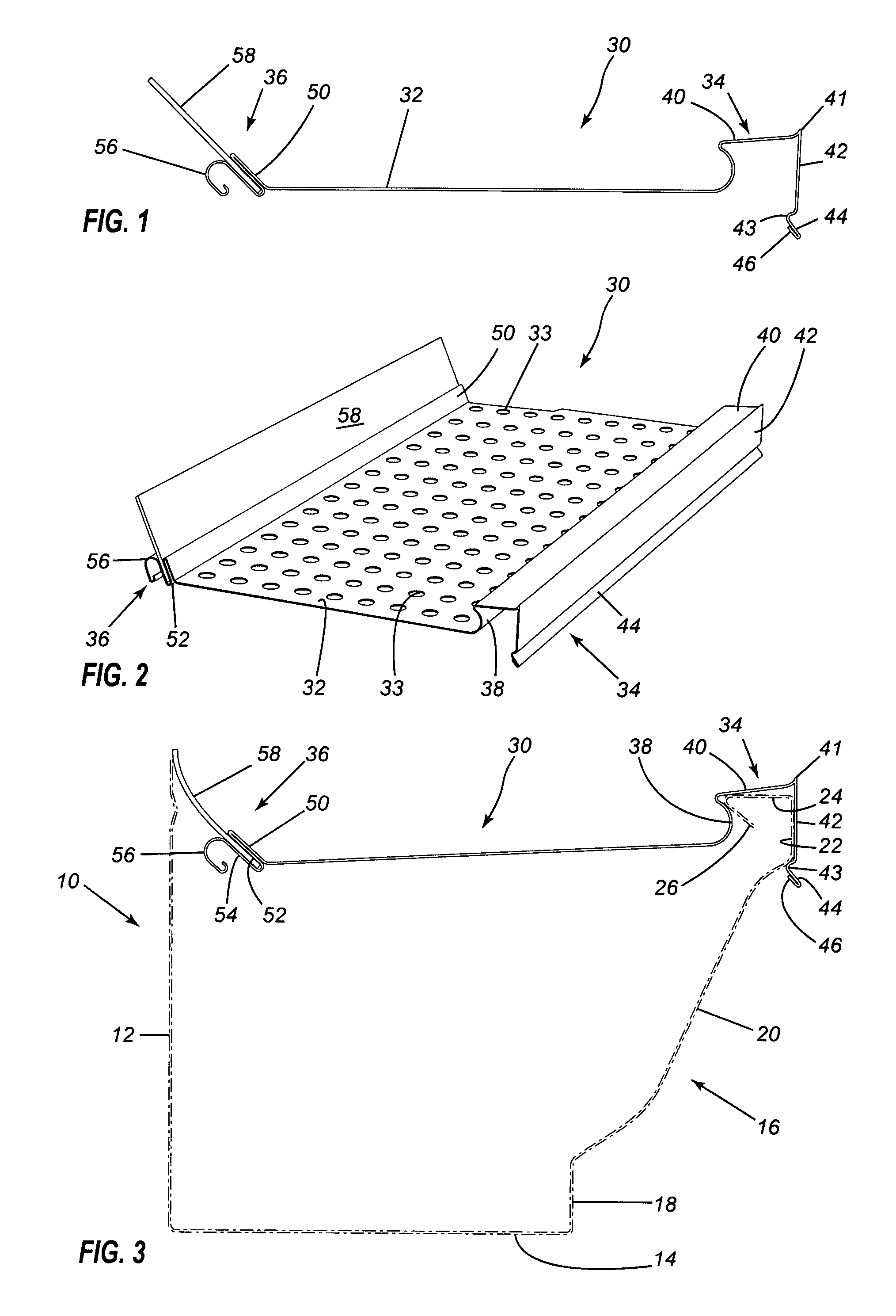

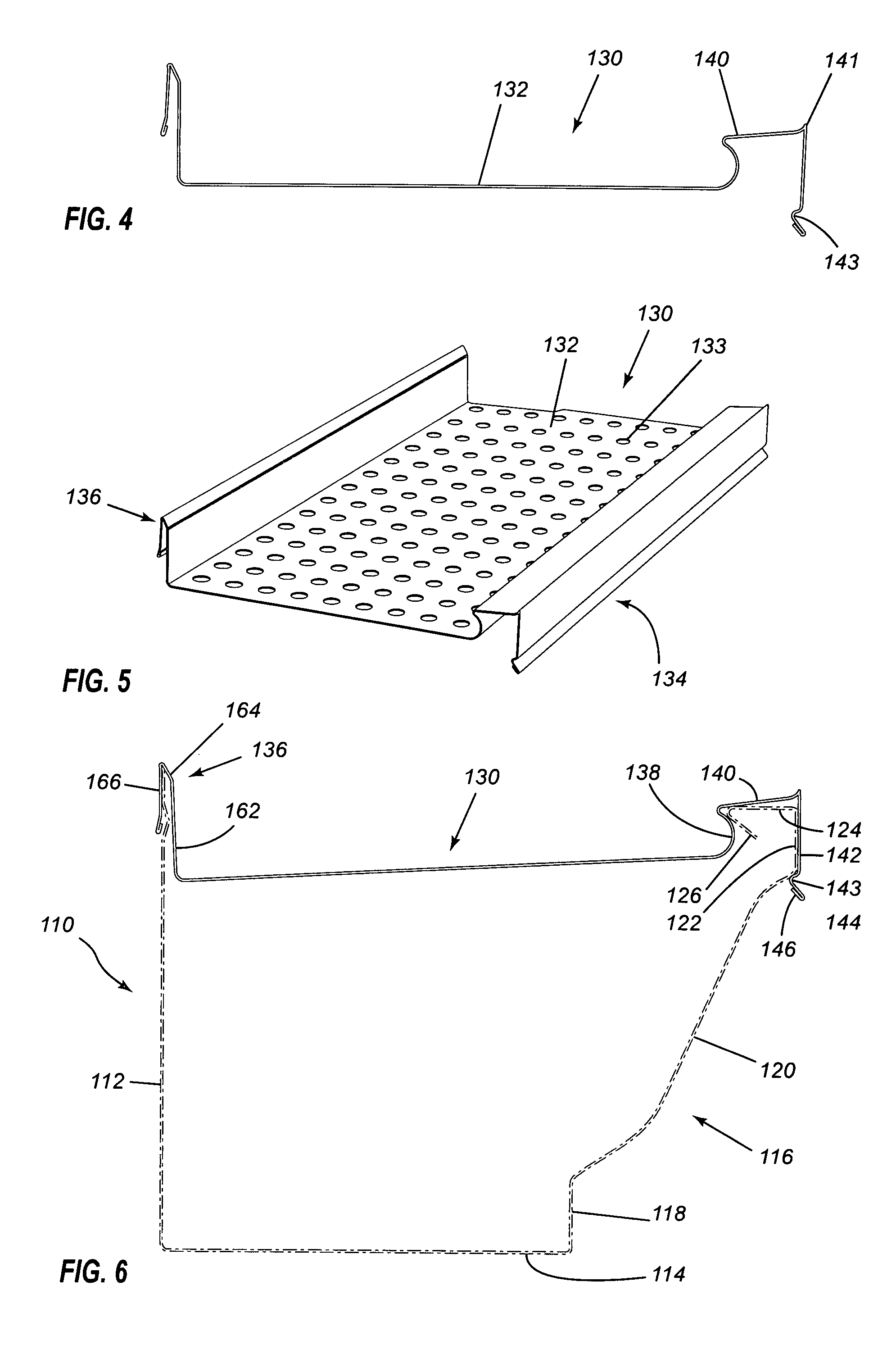

Anti-streak cover for eavestrough

ActiveUS20090108144A1Avoid streaksQuantity minimizationRoof coveringStands/trestlesEngineeringCivil engineering

An eavestrough cover designed to cover the upper front wall portions of a conventional eavestrough and which has a finish to minimize streaking or staining. The eavestrough cover snaps into position on the eavestrough.

Owner:BROCHU GUY

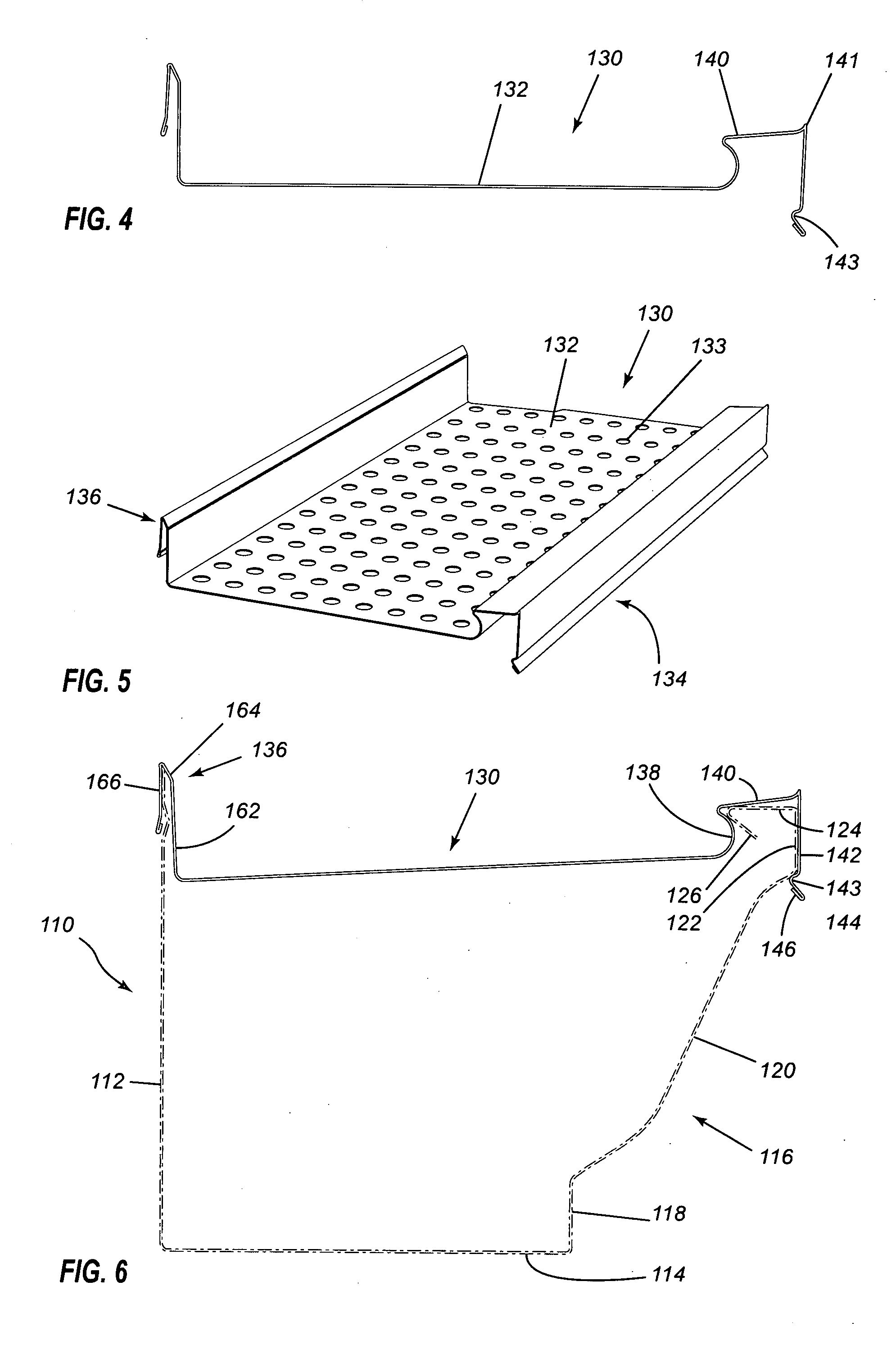

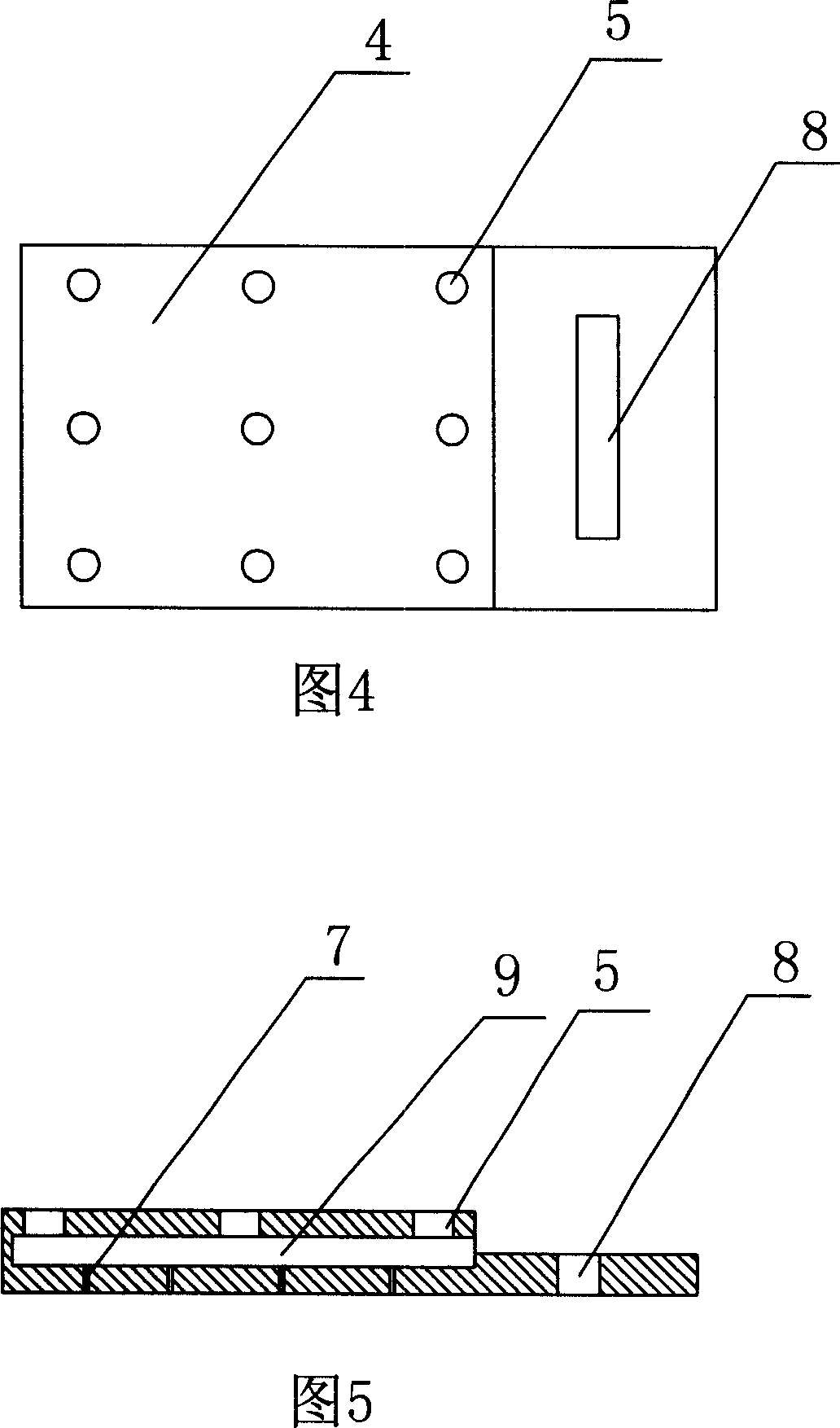

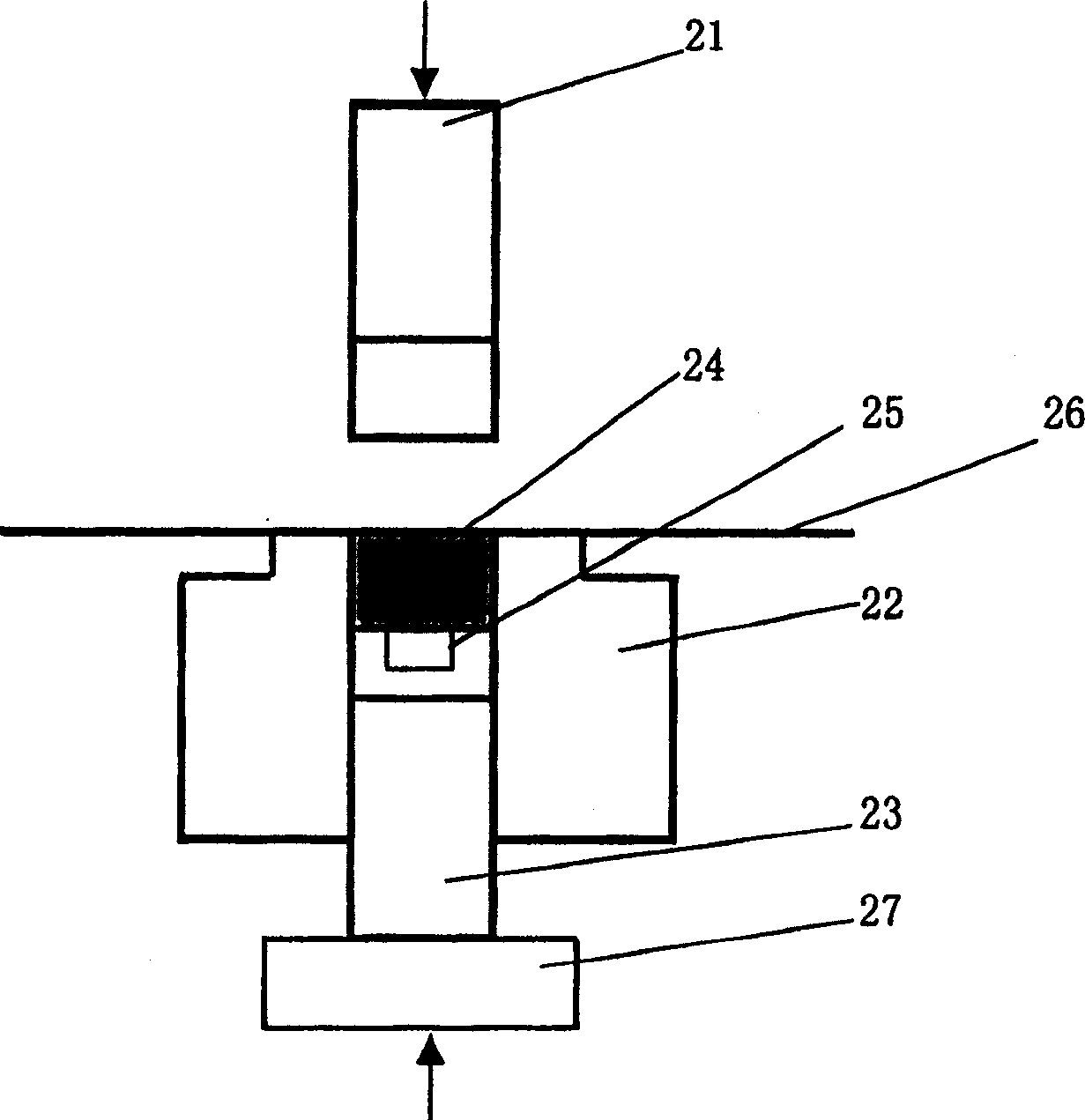

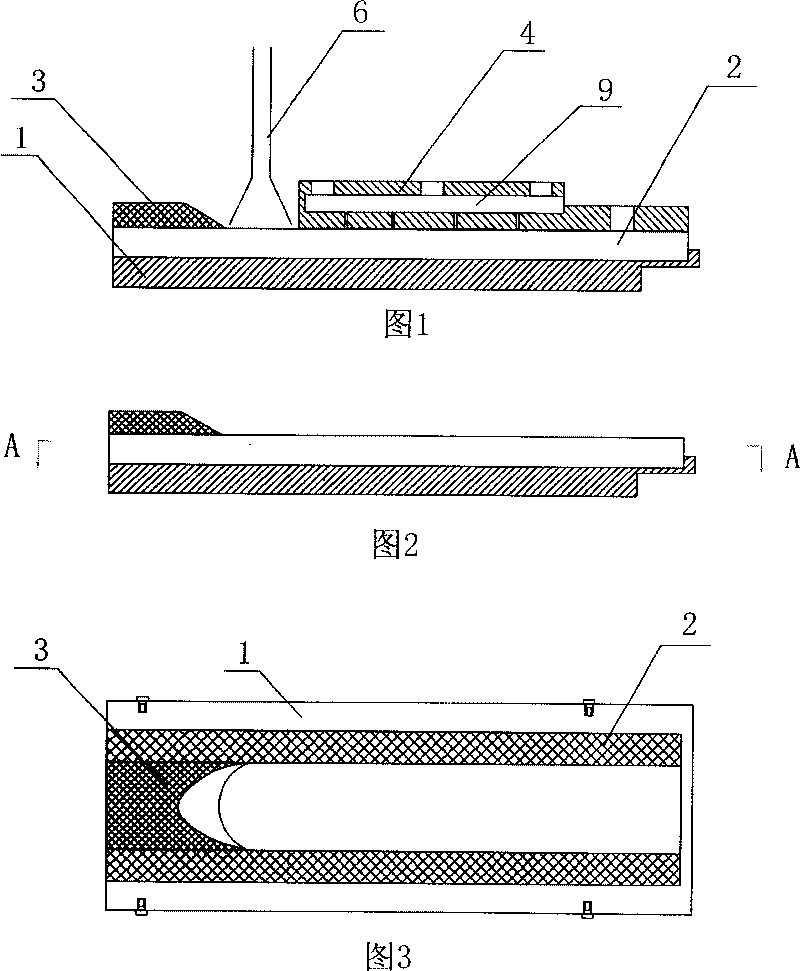

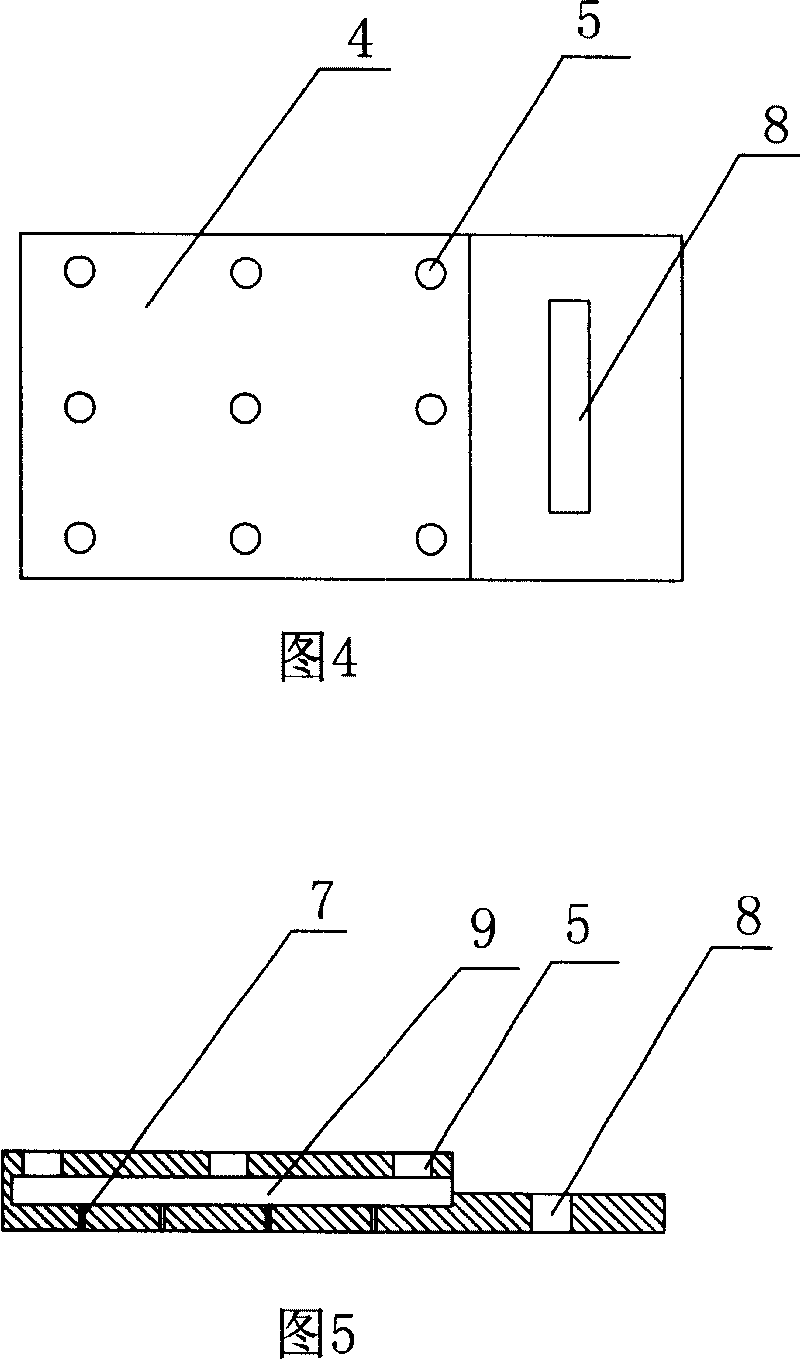

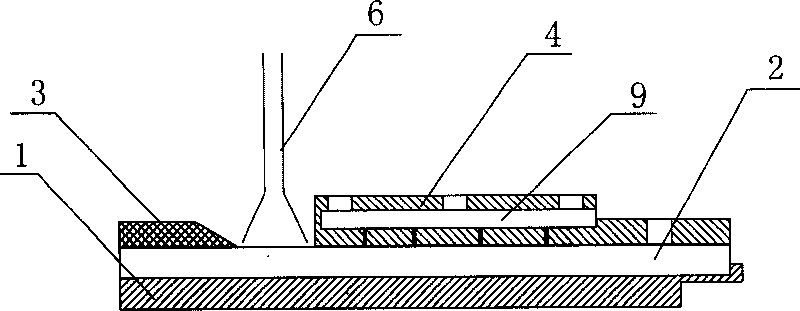

Shaping device of fluorophosphate optical glass and its shaping method

This invention provides a fluorophosphate optical glass molding equipment, including mold. Mold described composed by the end of mold, side die and block, in Mold also provided with cooling flat, air vents are installed on the flat. Fluorophosphate optical glass molding apparatus molding methods includes the following steps: 1) glass fluid flows out of the material tube and flow into Mold; 2) in Mold the glass fluid flow through the upper surface cover the cooling flat, inert gas through the air vents on the cooling flat blow to glass solution surface, so as soon as cool glass liquid for molding. The invention set cooling flat on the mold, through air vents blowing inert gas, so as soon as cooling liquid glass, to avoid the glass at high temperatures causing the volatile stripes, ensuring the quality of products; In addition, the invention uses graphite mold to avoid corrosion.

Owner:CDGM OPTICAL GLASS

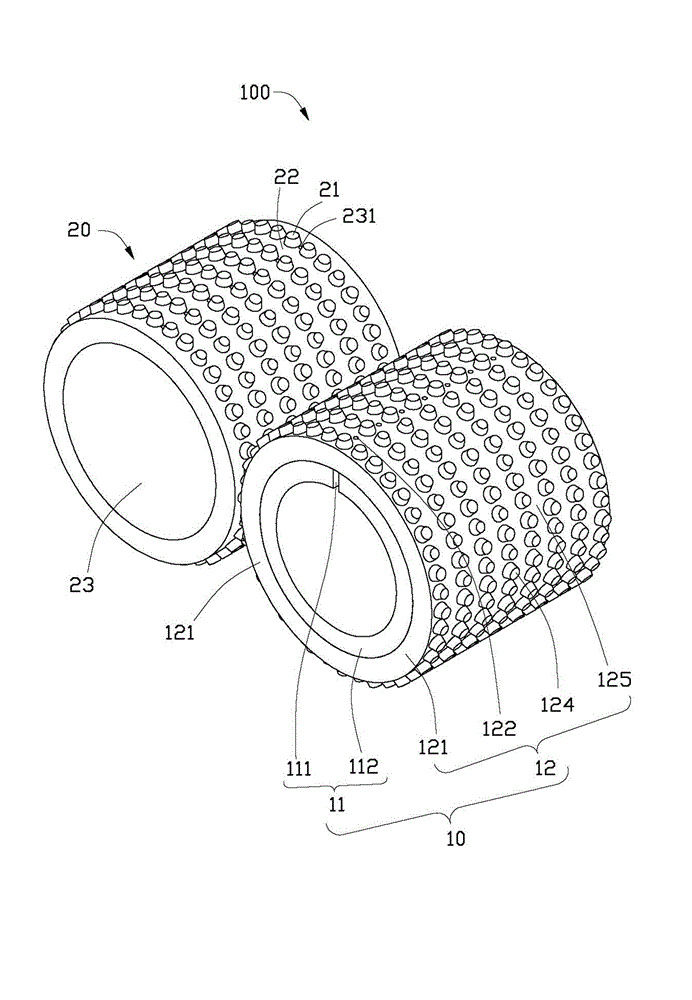

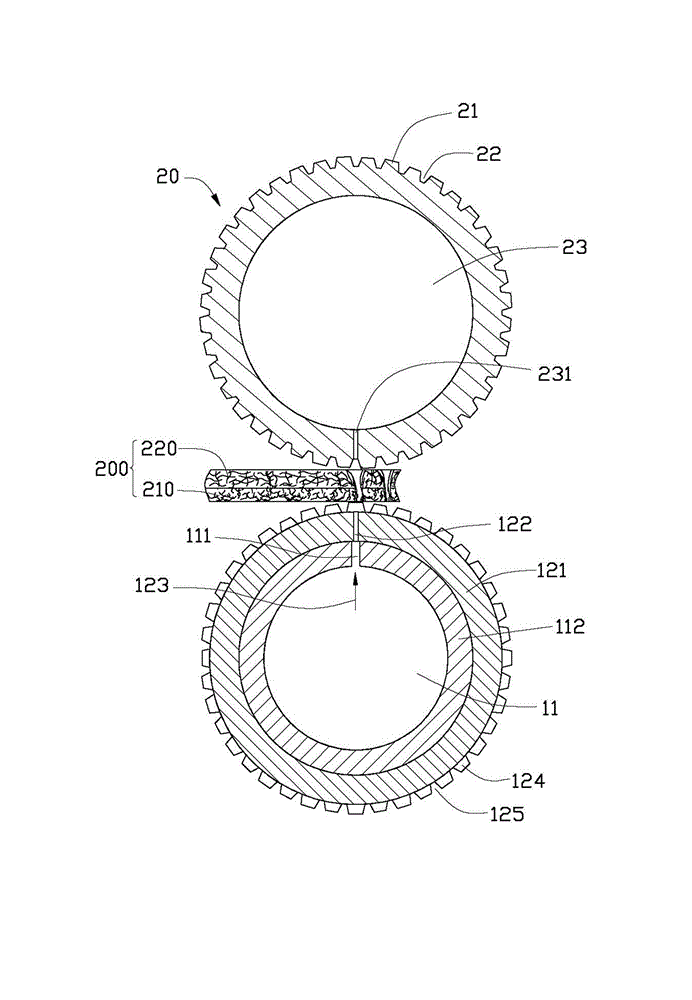

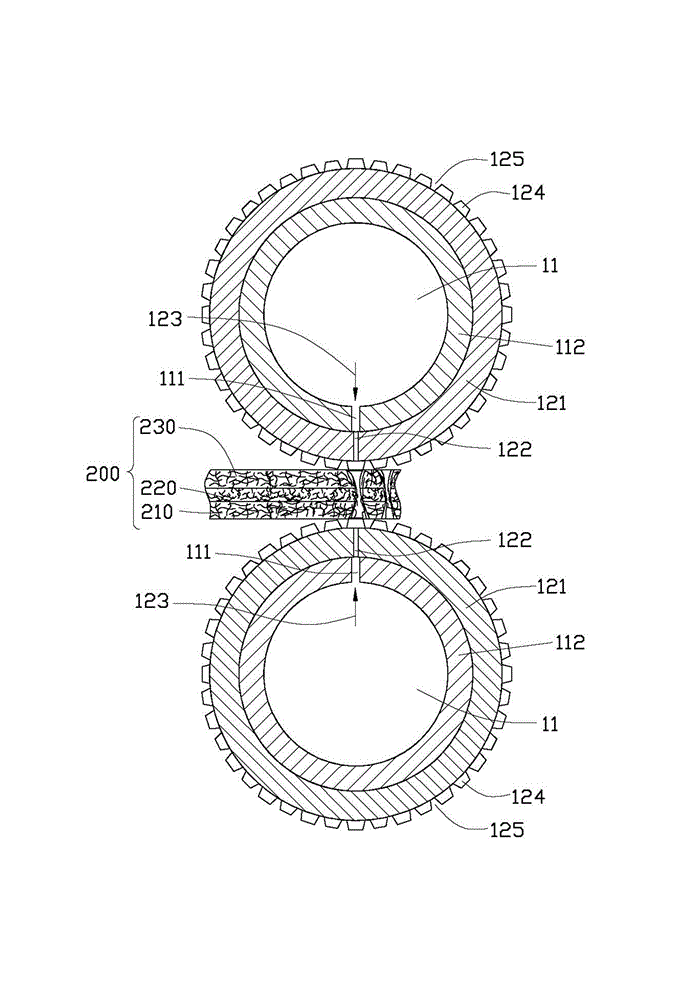

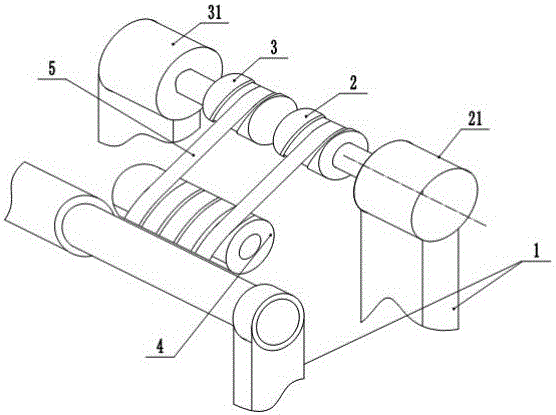

Embossing device and embossing process, composite non-woven fabric absorber, production device and process thereof

InactiveCN102747578AControl softnessControl fluff performancePattern makingNon-woven fabricsInjection portNonwoven fabric

The present invention relates to an embossing device, which comprises a first embossing roller and a second embossing roller, wherein the two embossing rollers are mutually cooperated, and the surface of at least one of the two embossing rollers is provided with embossing patterns. The first embossing roller further comprises a first hot air source and a first housing sleeved around the first hot air source, wherein the first hot air source has a first air outlet for outputting hot air gas to the outside. The first housing is provided with a first injection port corresponding to the first air outlet. When the first injection port rotates and reaches a position coinciding with the first air outlet, the hot air provided by the first hot air source is injected from the first ejection port to form at least a bunch of hot air jet. The present invention further relates to a process for carrying out embossing by using the embossing device, a composite non-woven fabric absorber production device comprising the embossing device, a composite non-woven fabric absorber production process and composite non-woven fabric absorber products.

Owner:GOLD HONG YE PAPER

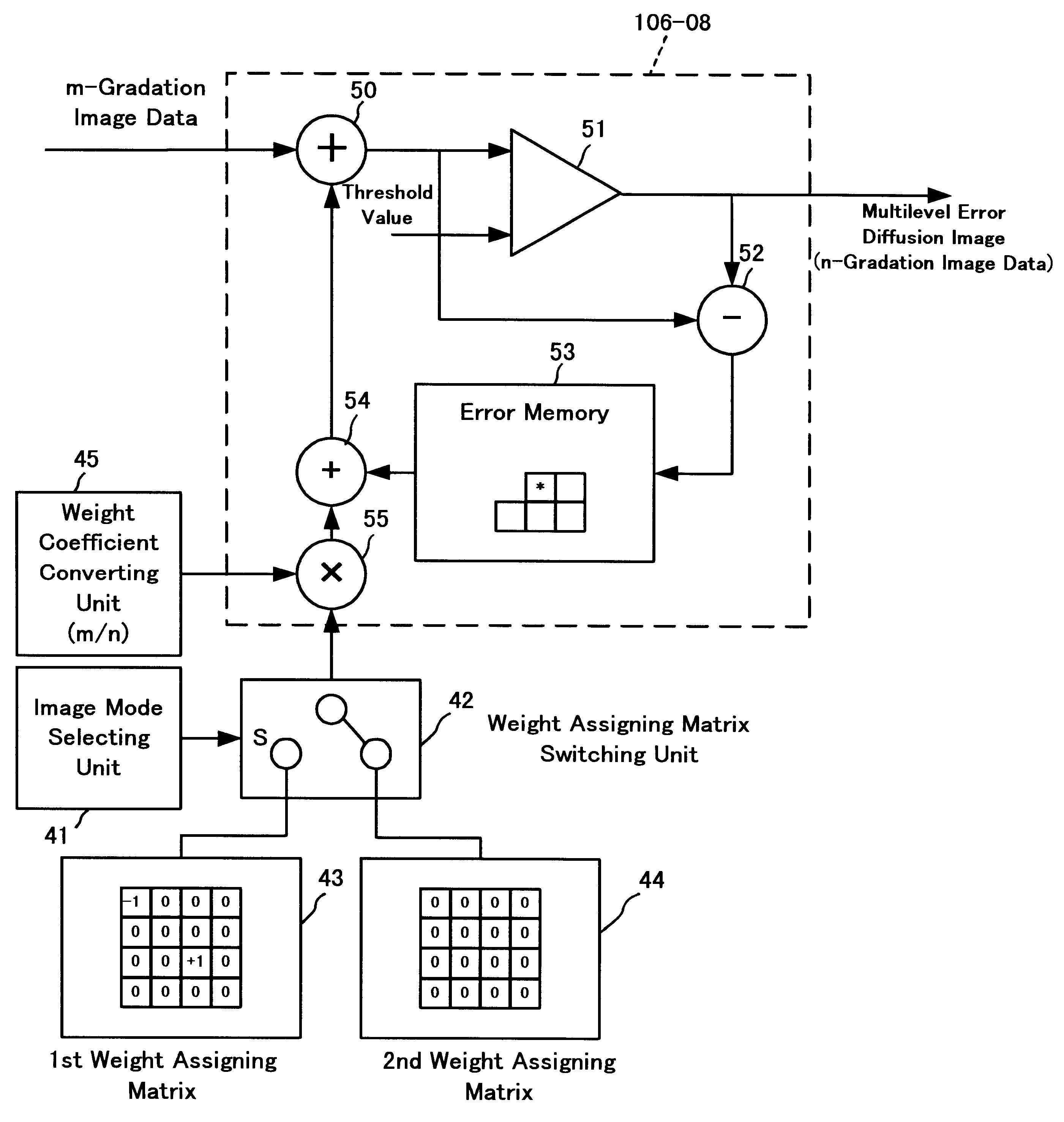

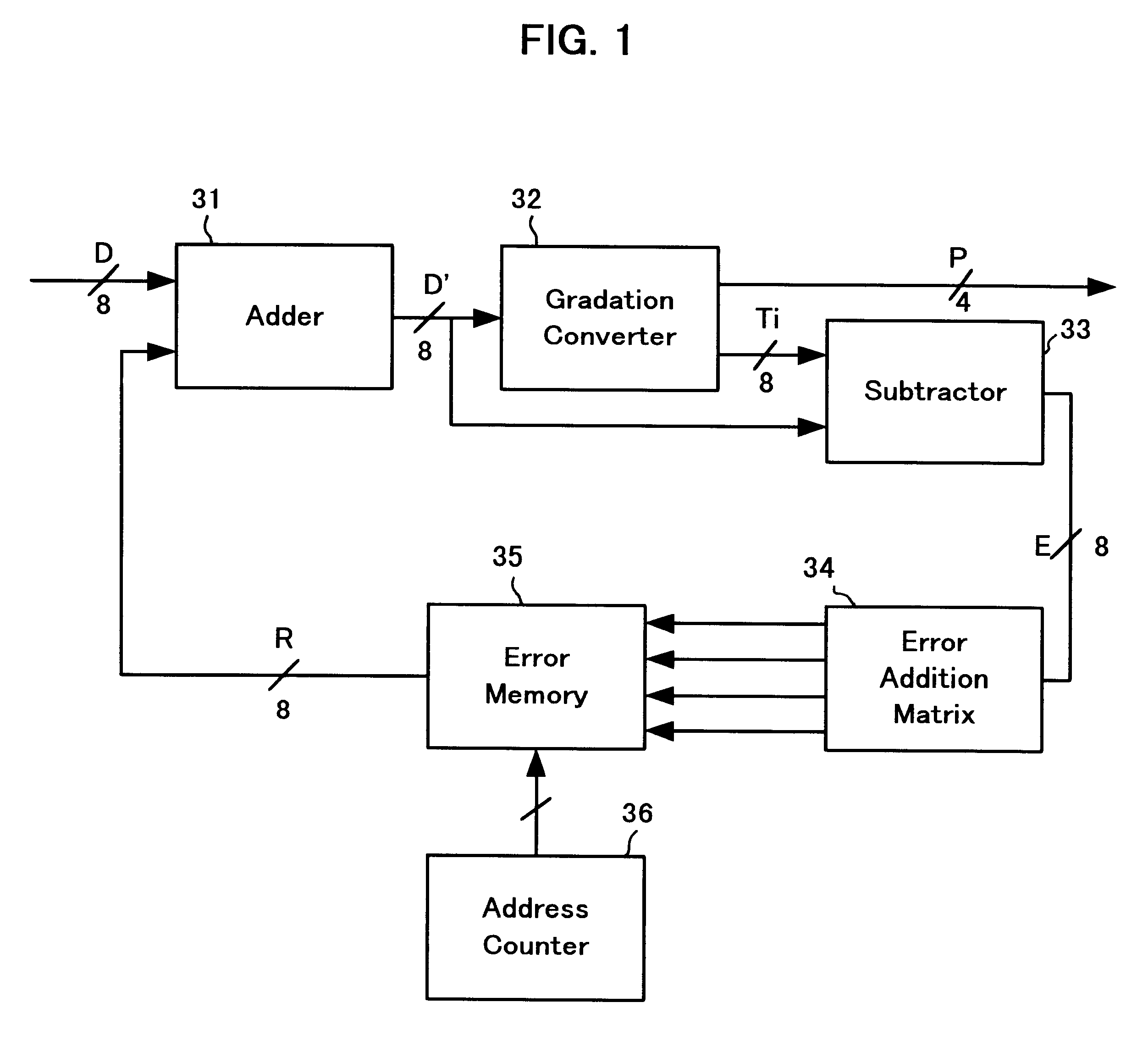

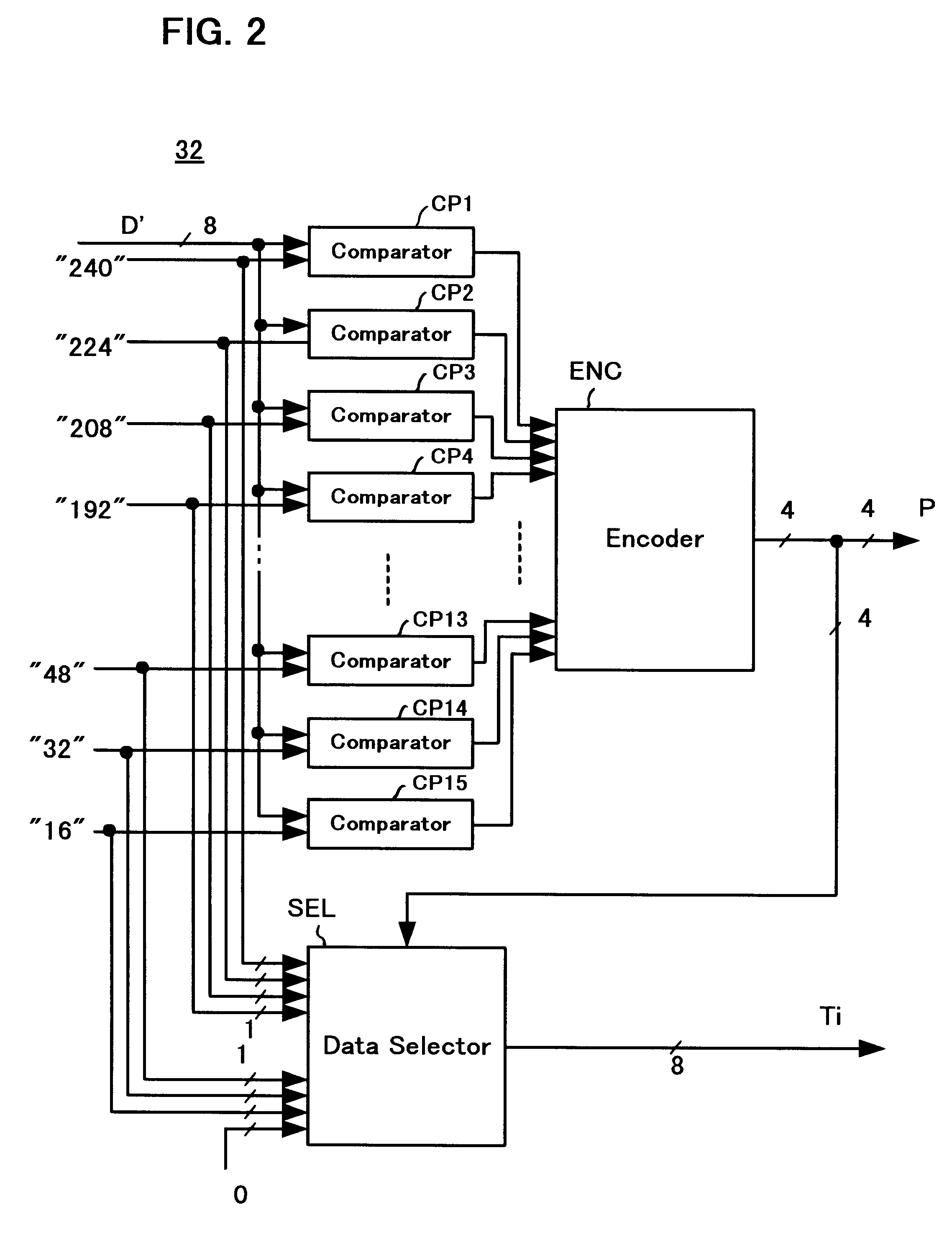

Image processor and image processing method handling multilevel image data

InactiveUS6292268B1Preventing Image Quality DeteriorationReduce in quantityImage enhancementCharacter and pattern recognitionPattern recognitionImaging processing

An image processor converts pixel data represented with m gradations into pixel data represented with n gradations by using the error diffusion method. The m and n are both given integers and satisfy 2<n<m. Not only the error but also a weight assigning value is added to pixel data to be converted. The weight assigning value is determined according to the values of m and n.

Owner:MINOLTA CO LTD

Froming method of particle, forming method and formed body obtained by the method

InactiveCN1597191AAvoid streaksGuaranteed cleanlinessShaping pressVolumetric Mass DensityMaterials science

Owner:TOTANKAKO

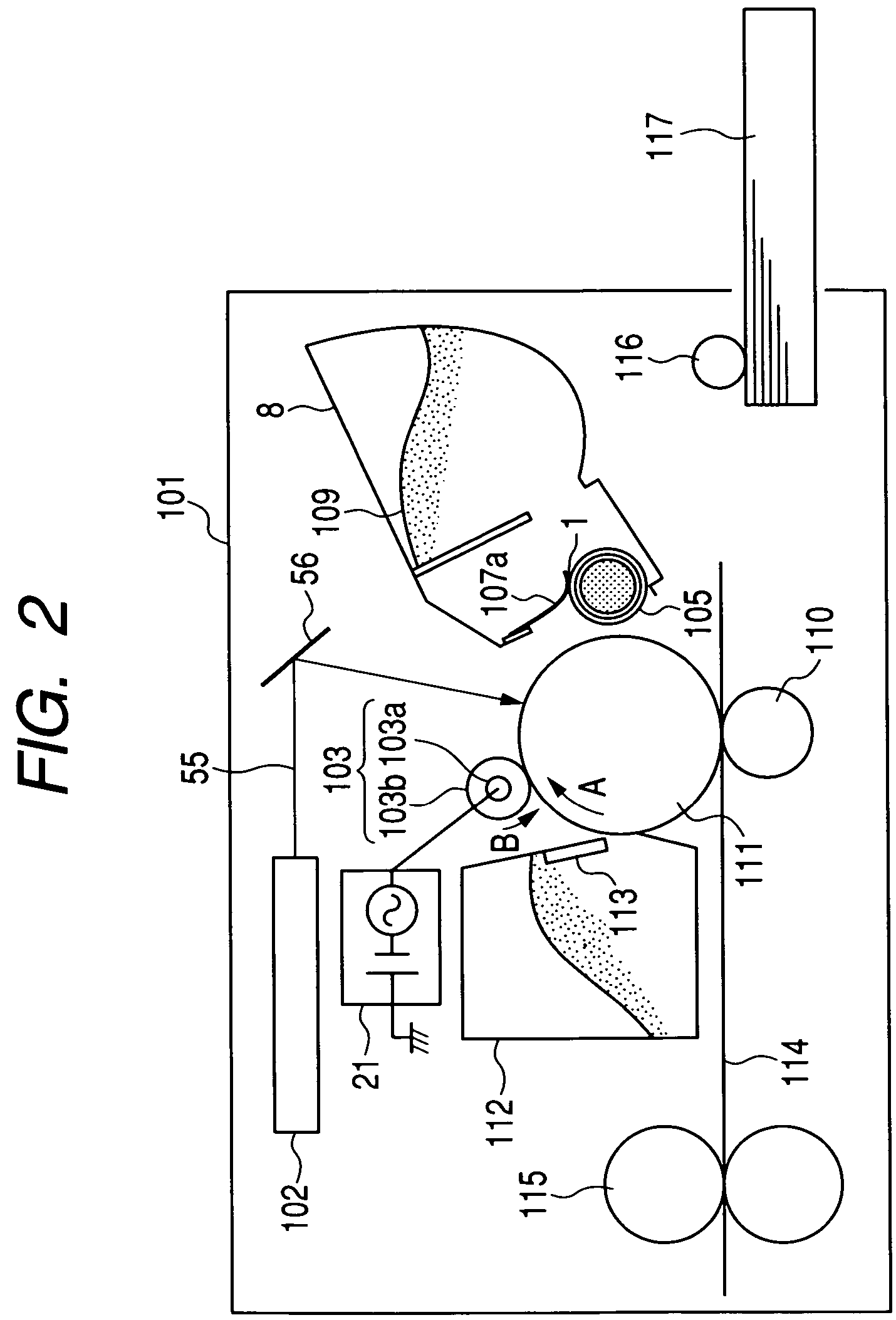

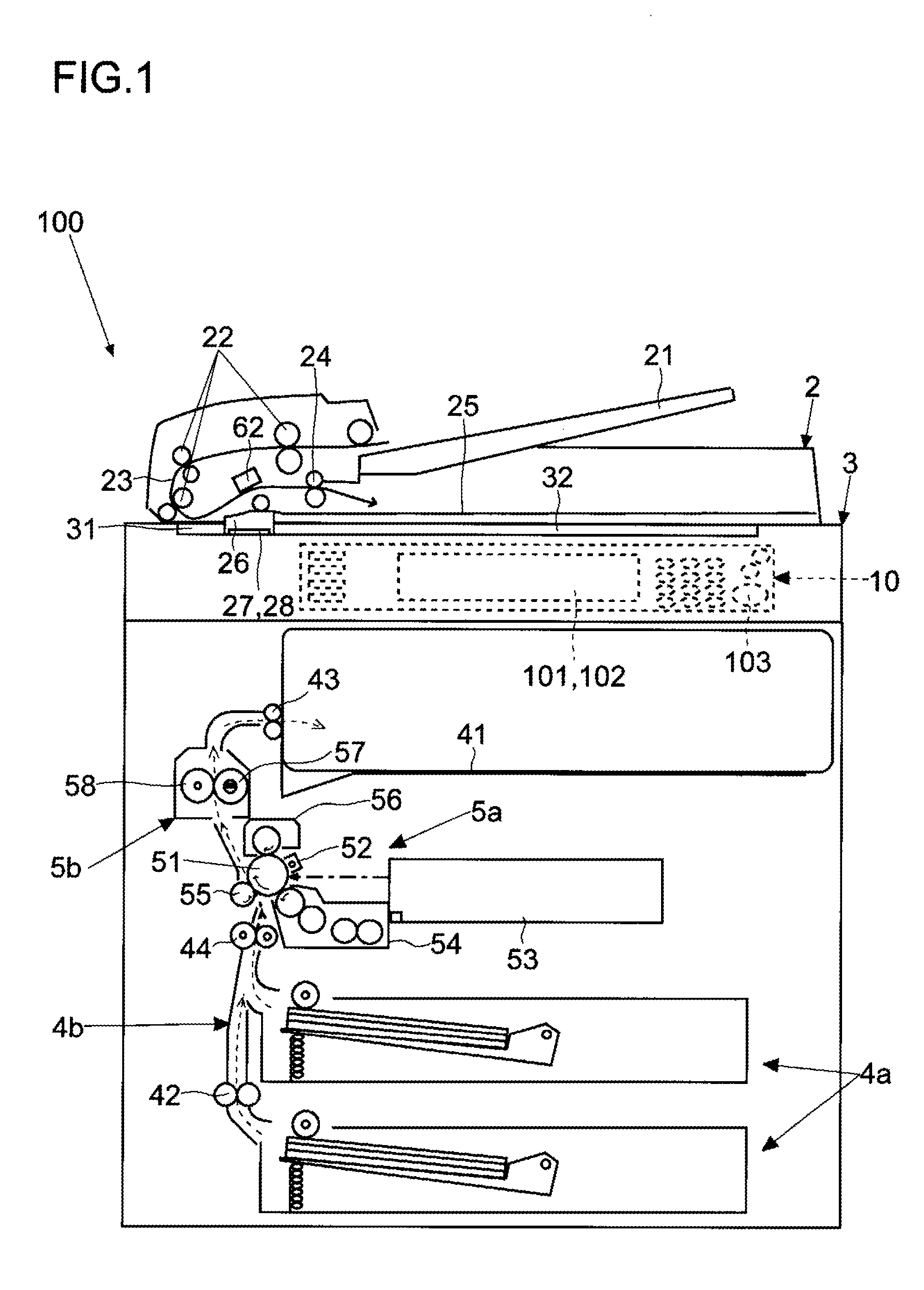

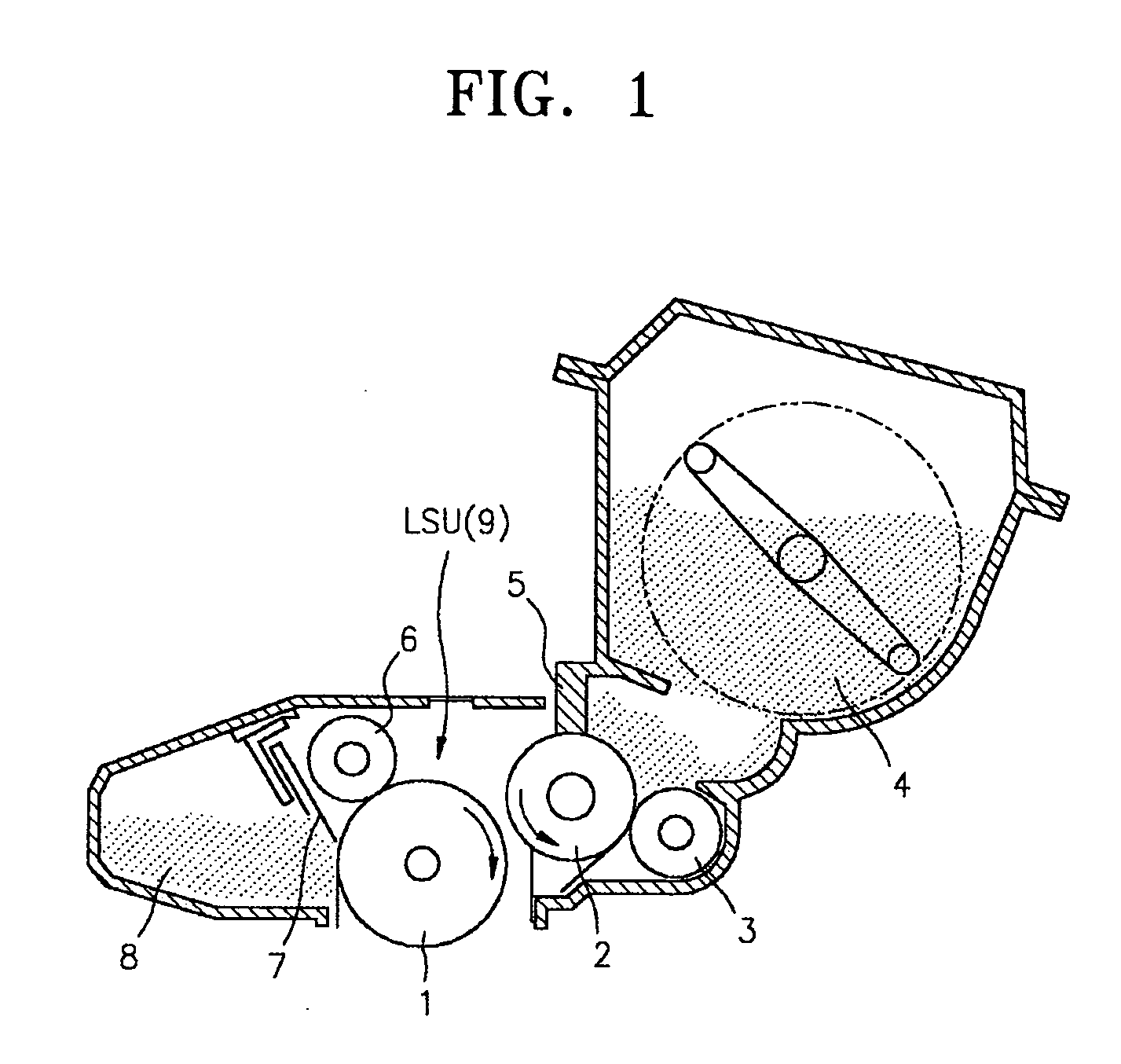

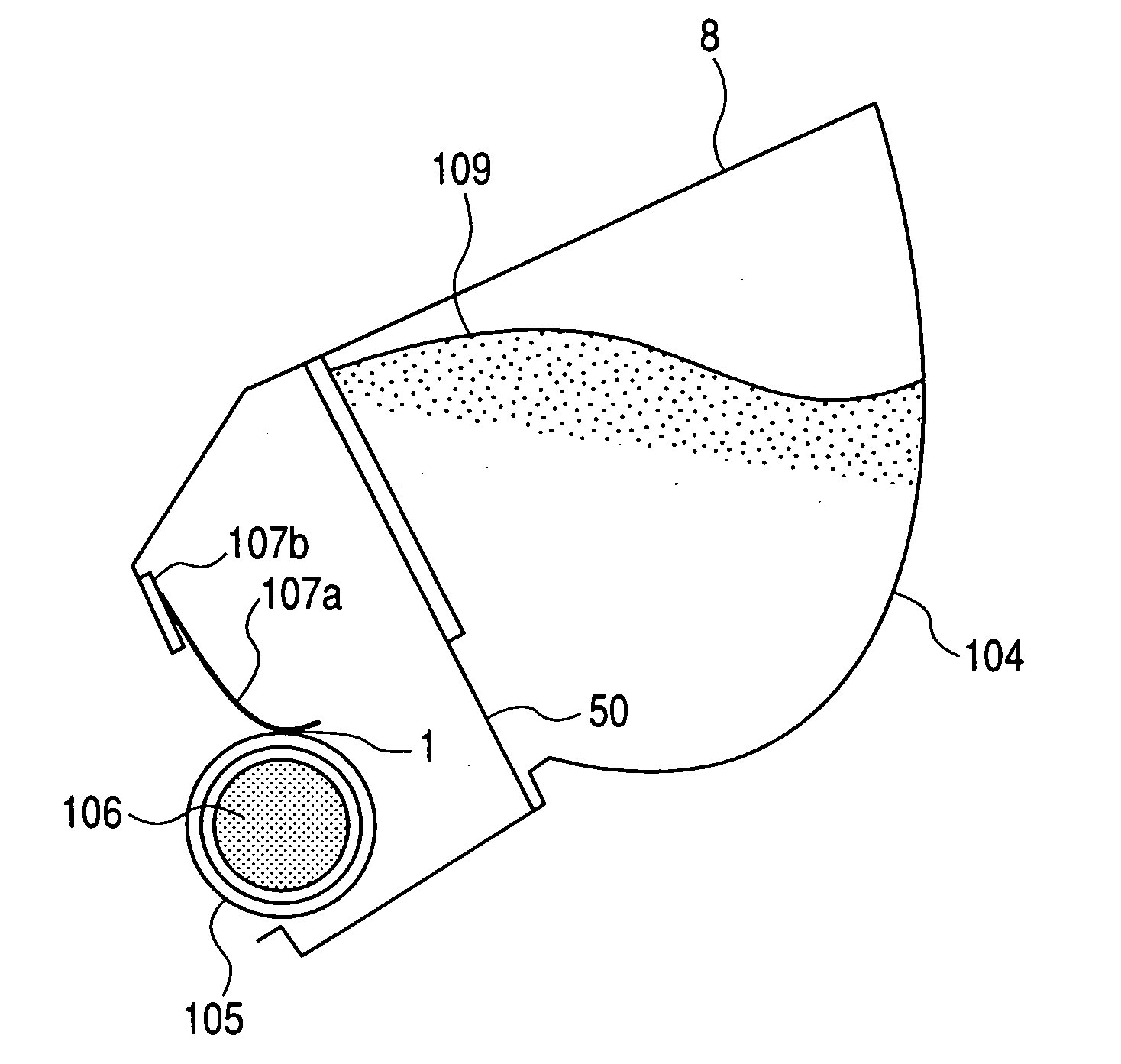

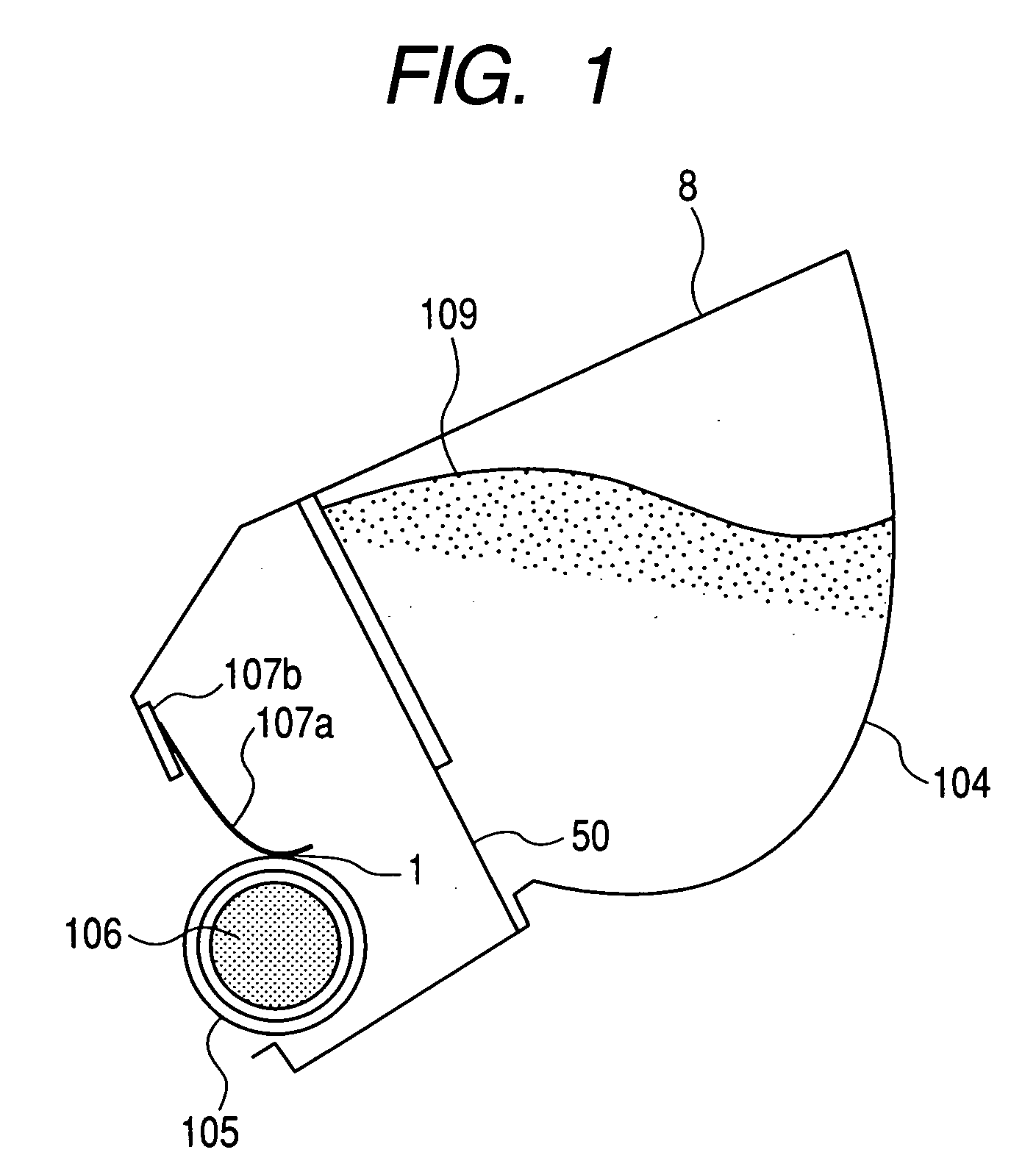

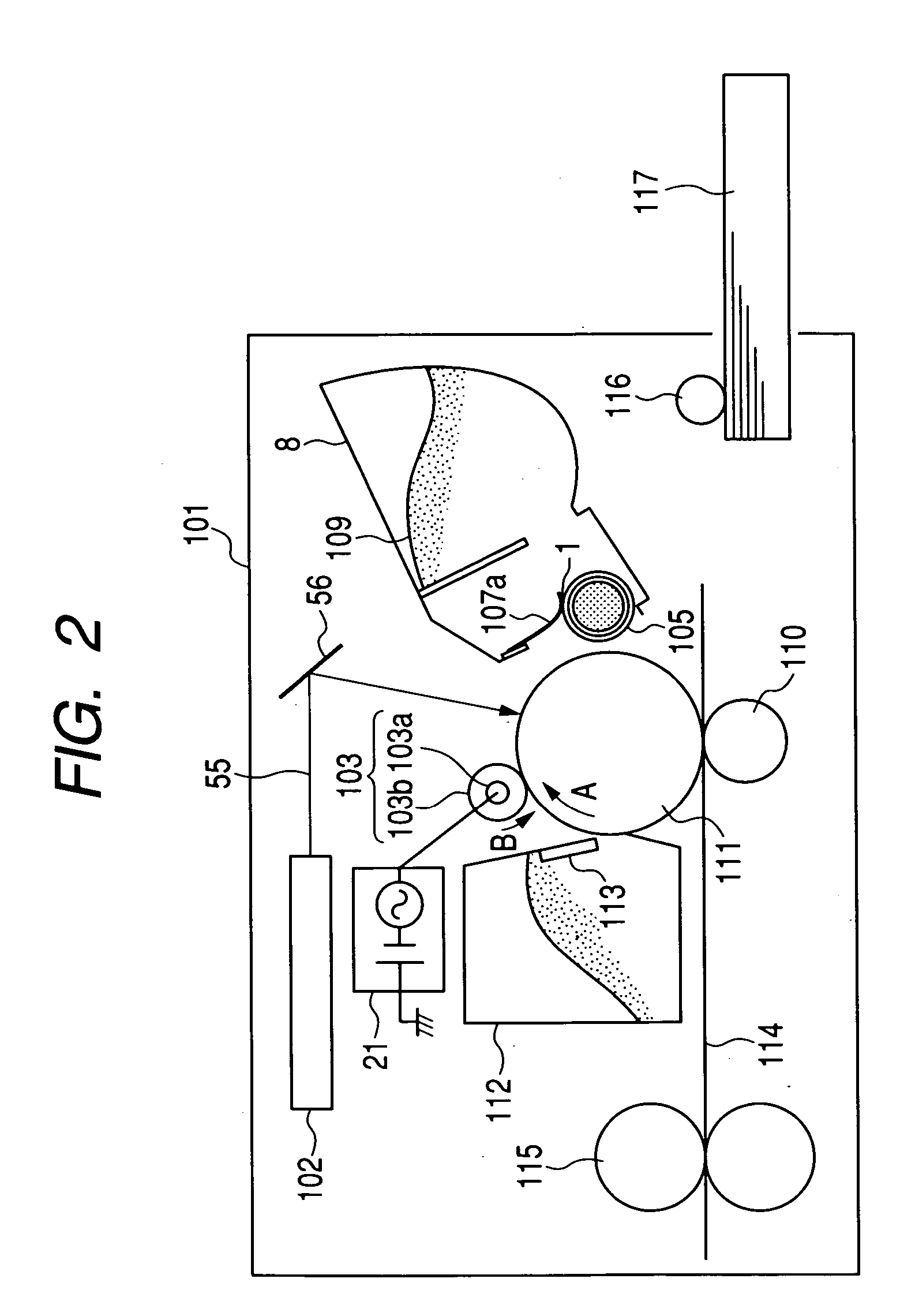

Developing apparatus, cartridge and image forming apparatus

ActiveUS7398040B2Reduce frictional resistanceAvoid layeringElectrographic process apparatusEngineeringLayer thickness

A developing apparatus includes a developer carrying member for carrying a developer thereon and developing an electrostatic image formed on an image bearing member with a developer, a developer layer thickness regulating member provided in contact with the developer carrying member for regulating the thickness of the layer of the developer carried on the developer carrying member, and an electrically conductive particle provided in the portion of contact between the developer carrying member and the developer layer thickness regulating member, in a state in which the developer does not exist between the developer carrying member and the developer layer thickness regulating member.

Owner:CANON KK

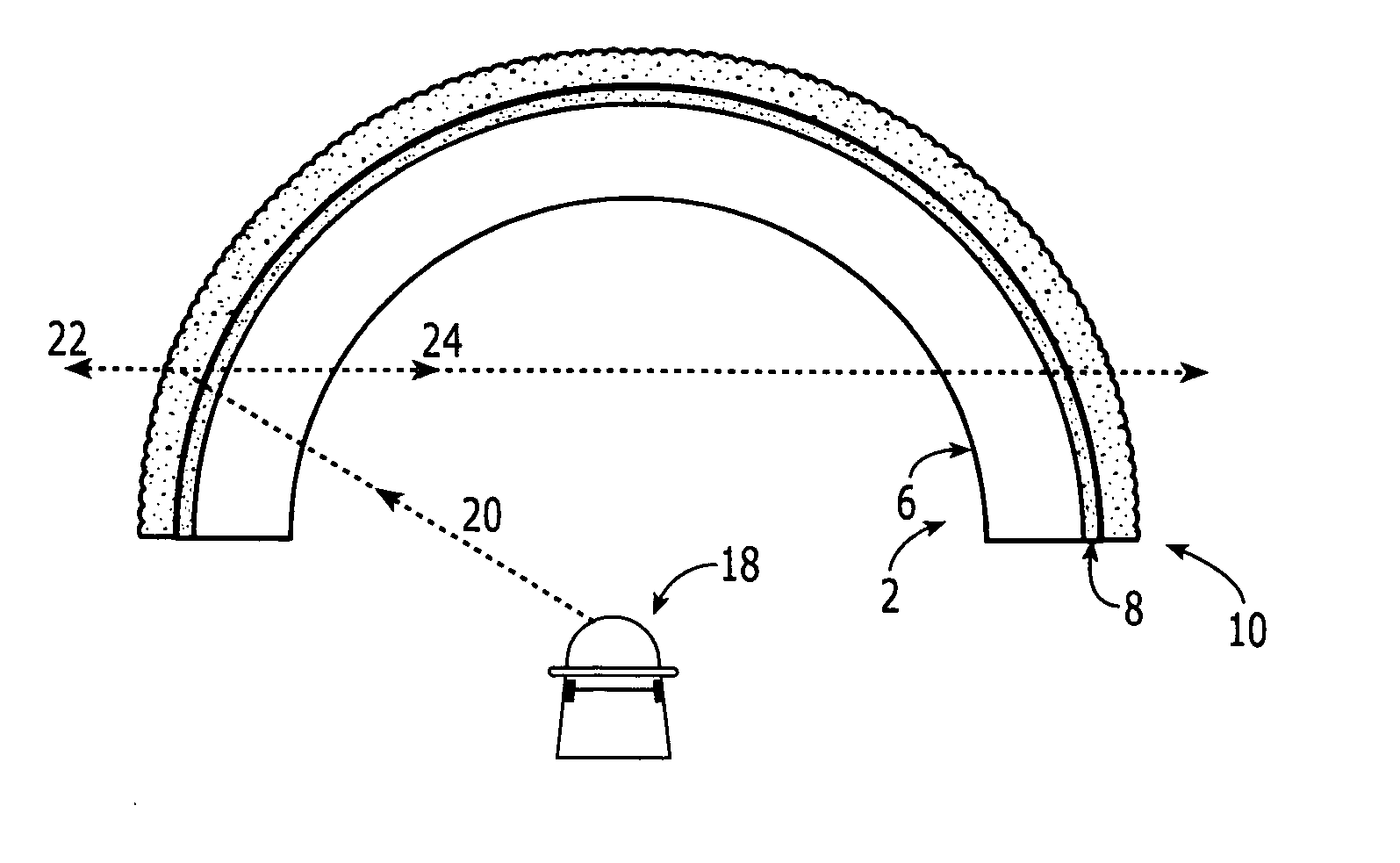

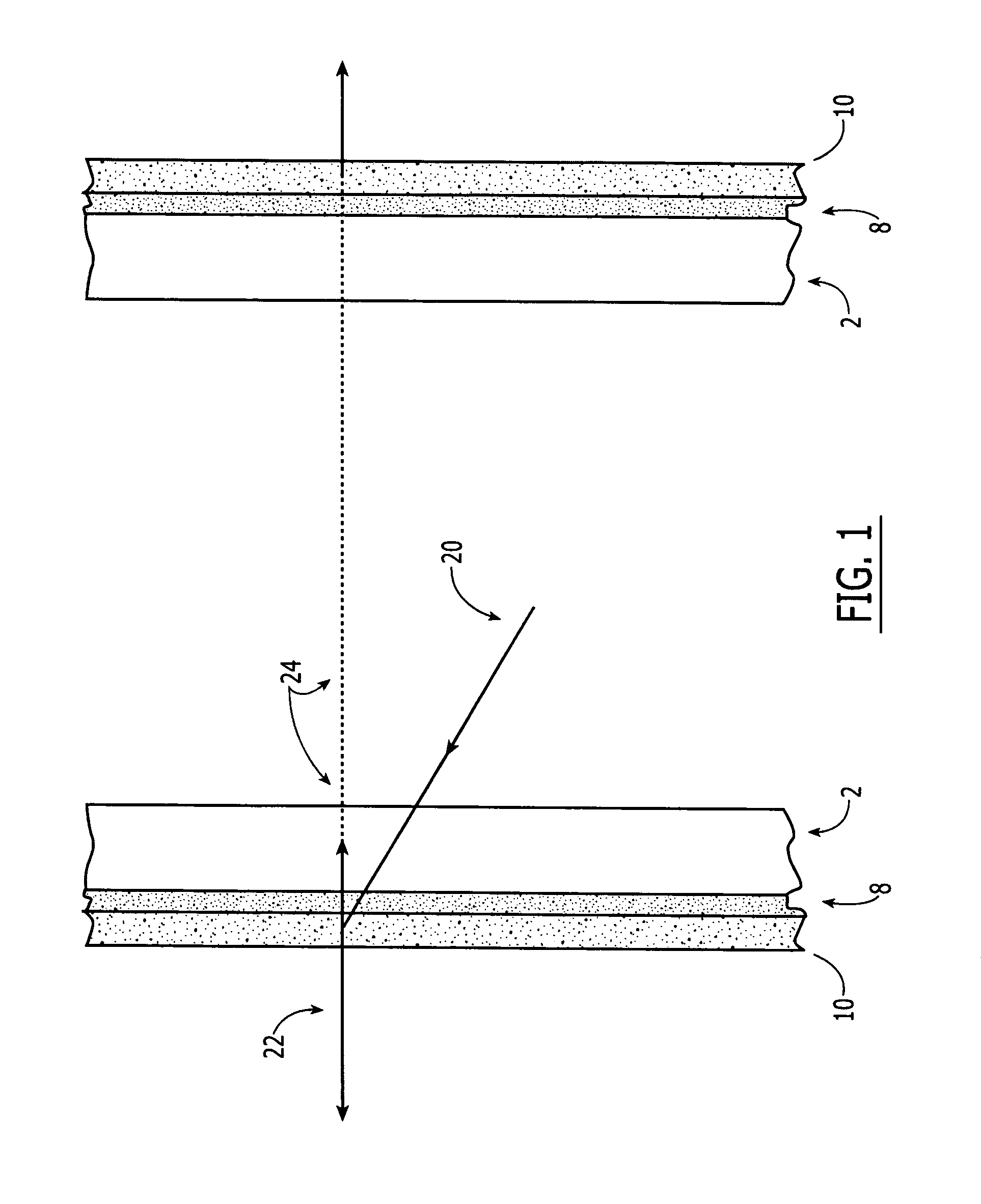

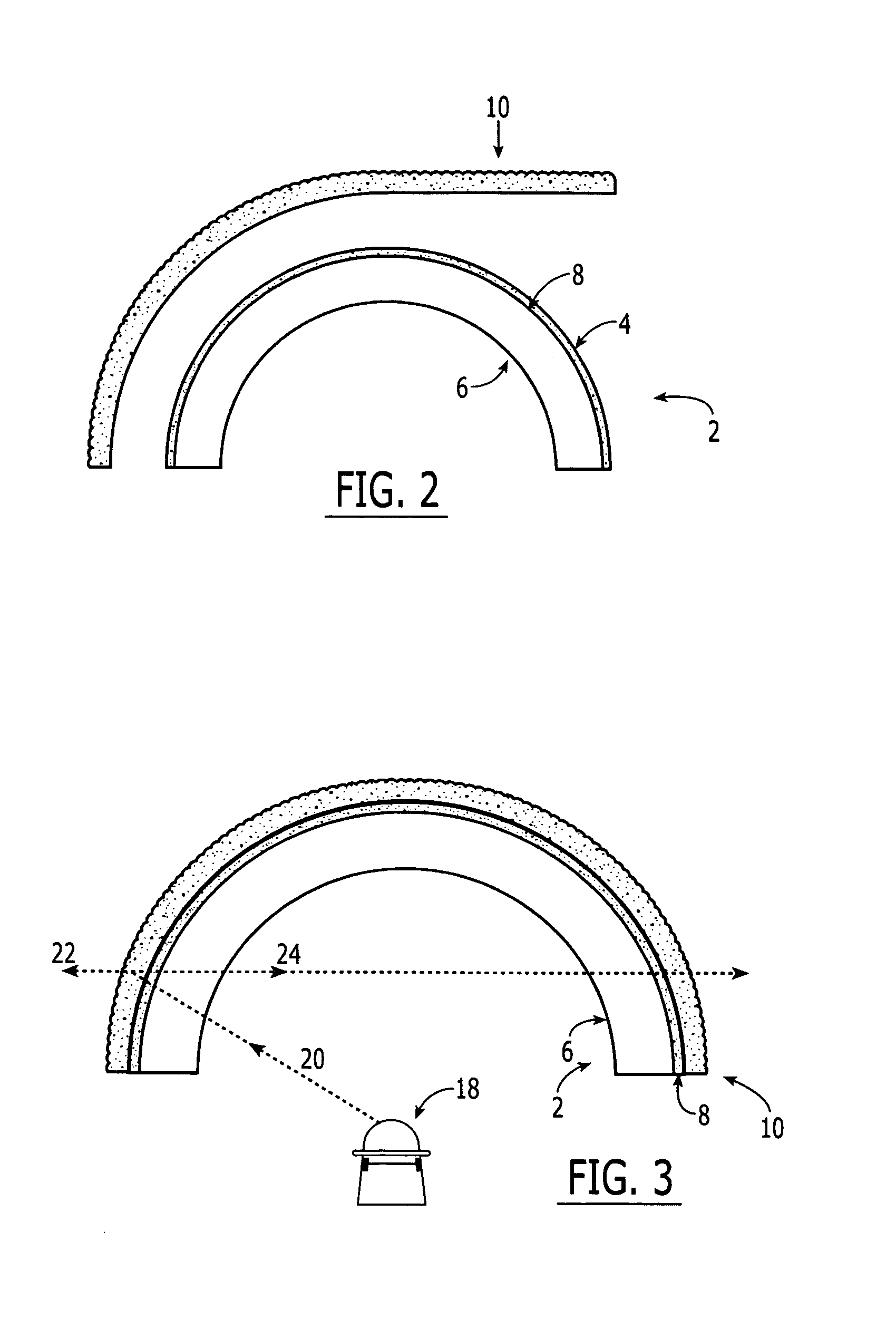

Contrast rear projection screen and method for manufacturing the same

ActiveUS8049960B1Screen contrast can be enhancedDiminishes back-scattered lightProjectorsForward scatterUltrasound attenuation

A three-dimensional rear projection screen that has substantially improved contrast by using a tinted layer disposed between the source of the projected light and the light diffusion layer. This tinted attenuation layer diminishes the back-scattered light more than it diminishes the desired forward-scattered light which makes up the image on the screen. The contrast of the image is thus improved because the reduction of the back-scattered light relative to the forward-scattered light diminishes the degradation of contrast caused by the impingement of spurious light onto opposite portions of the rear projection screen.

Owner:LIGON THOMAS R

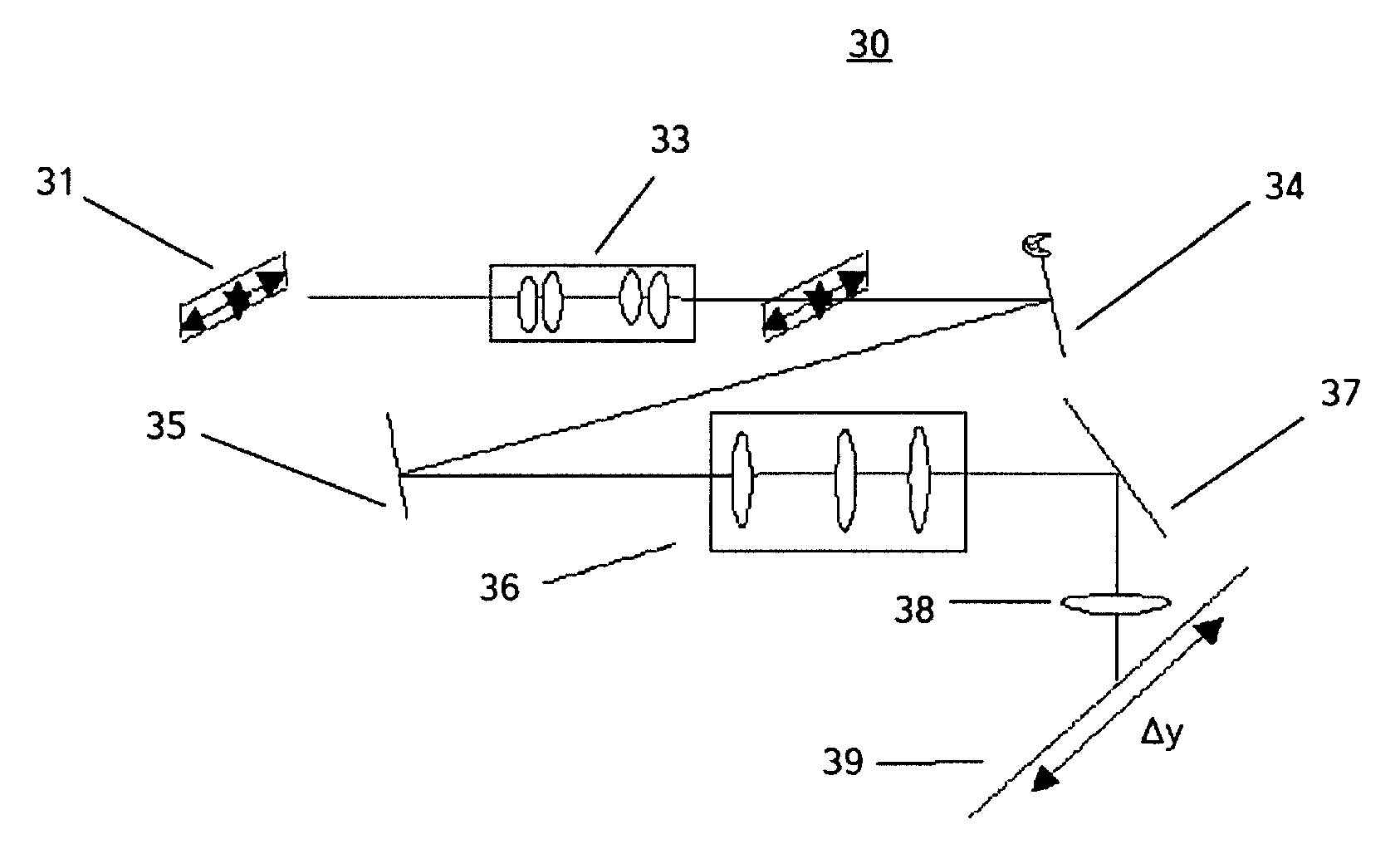

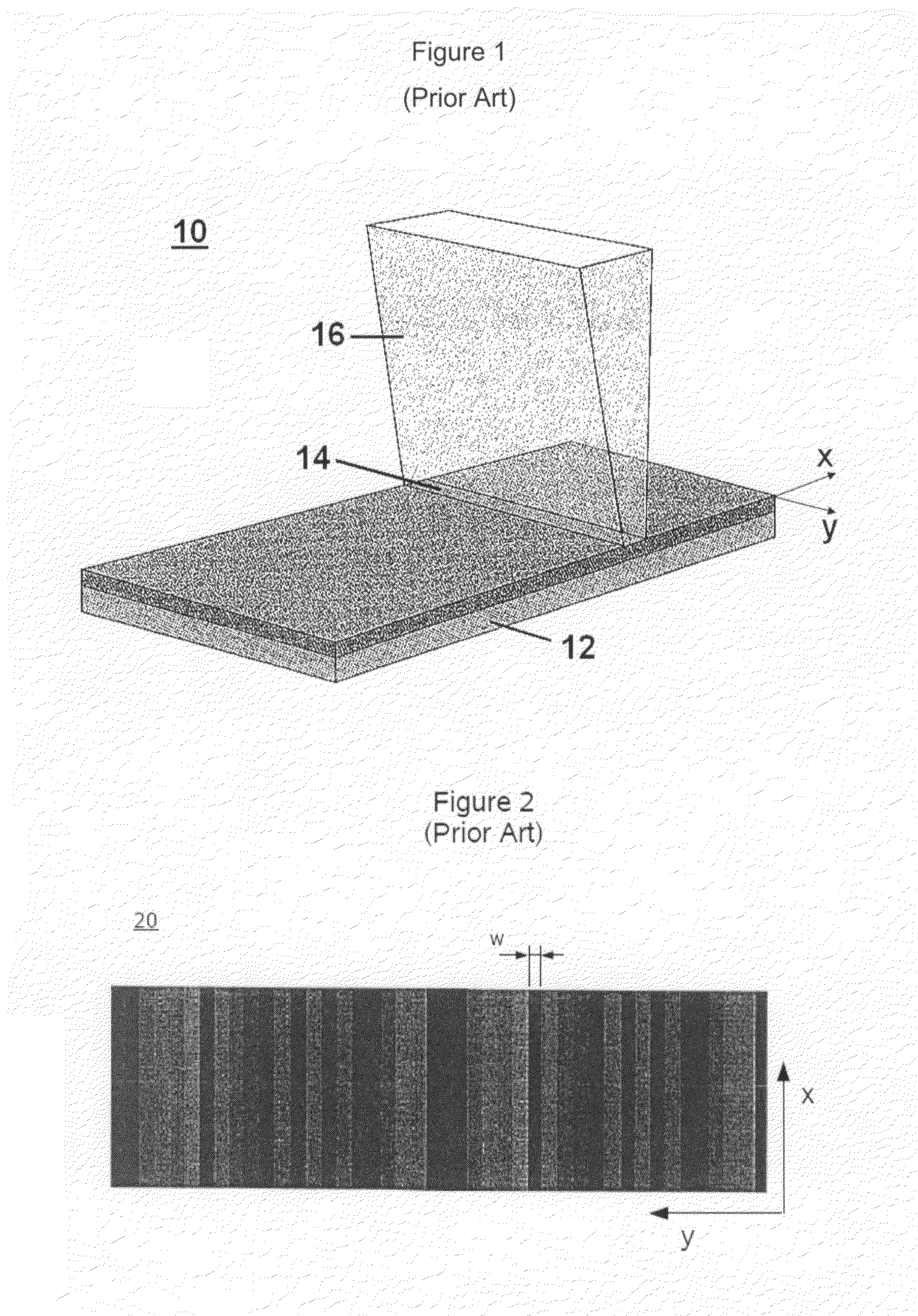

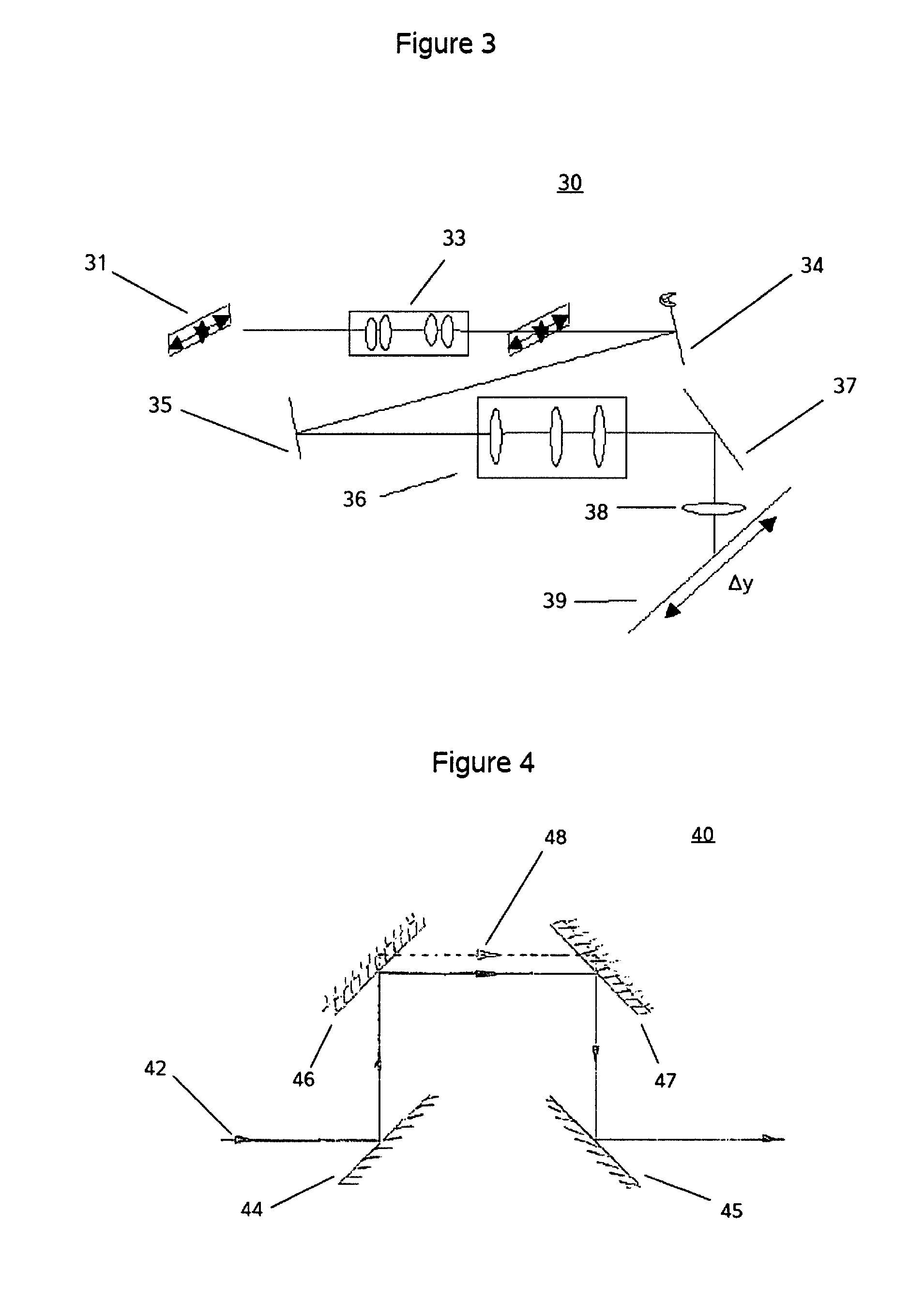

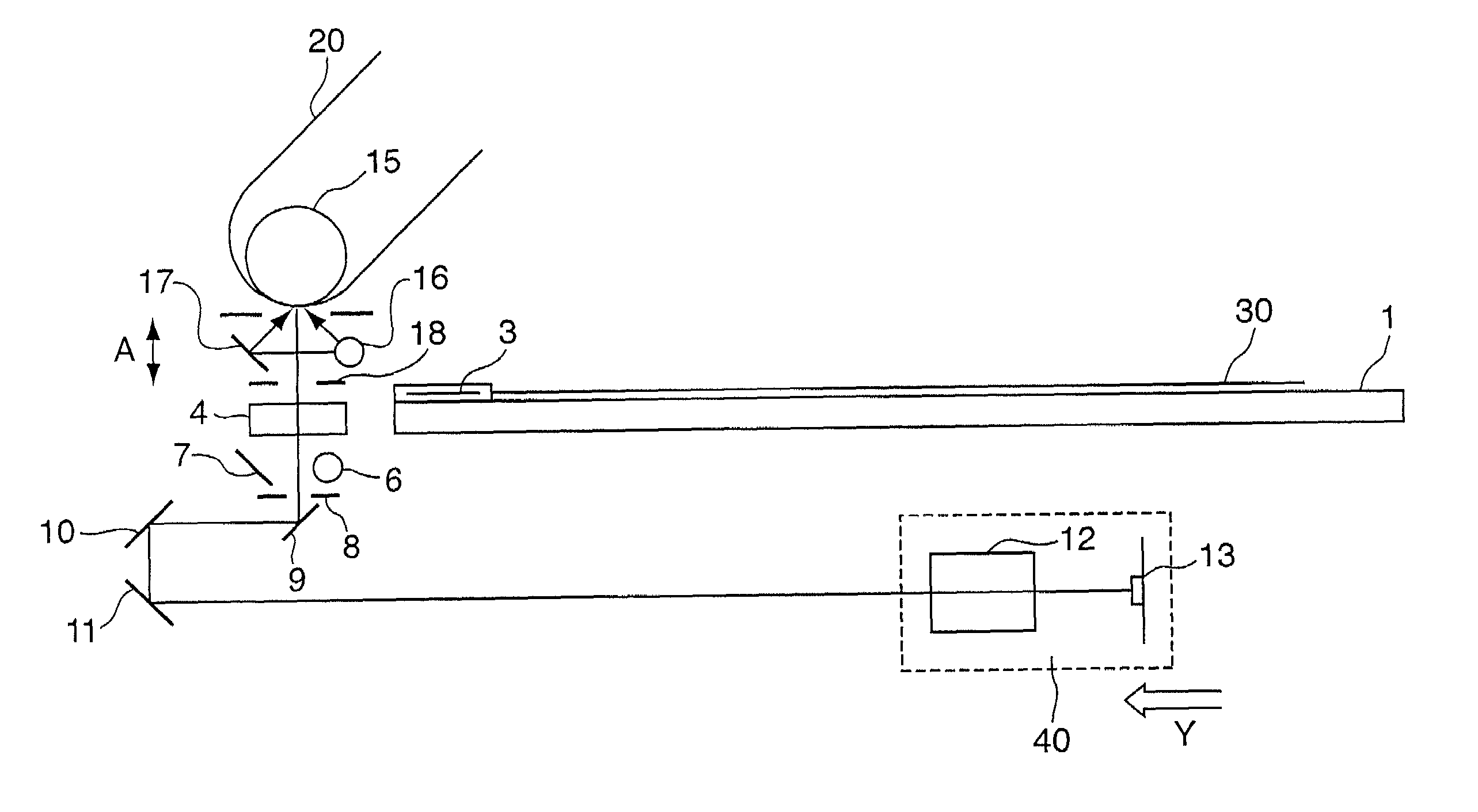

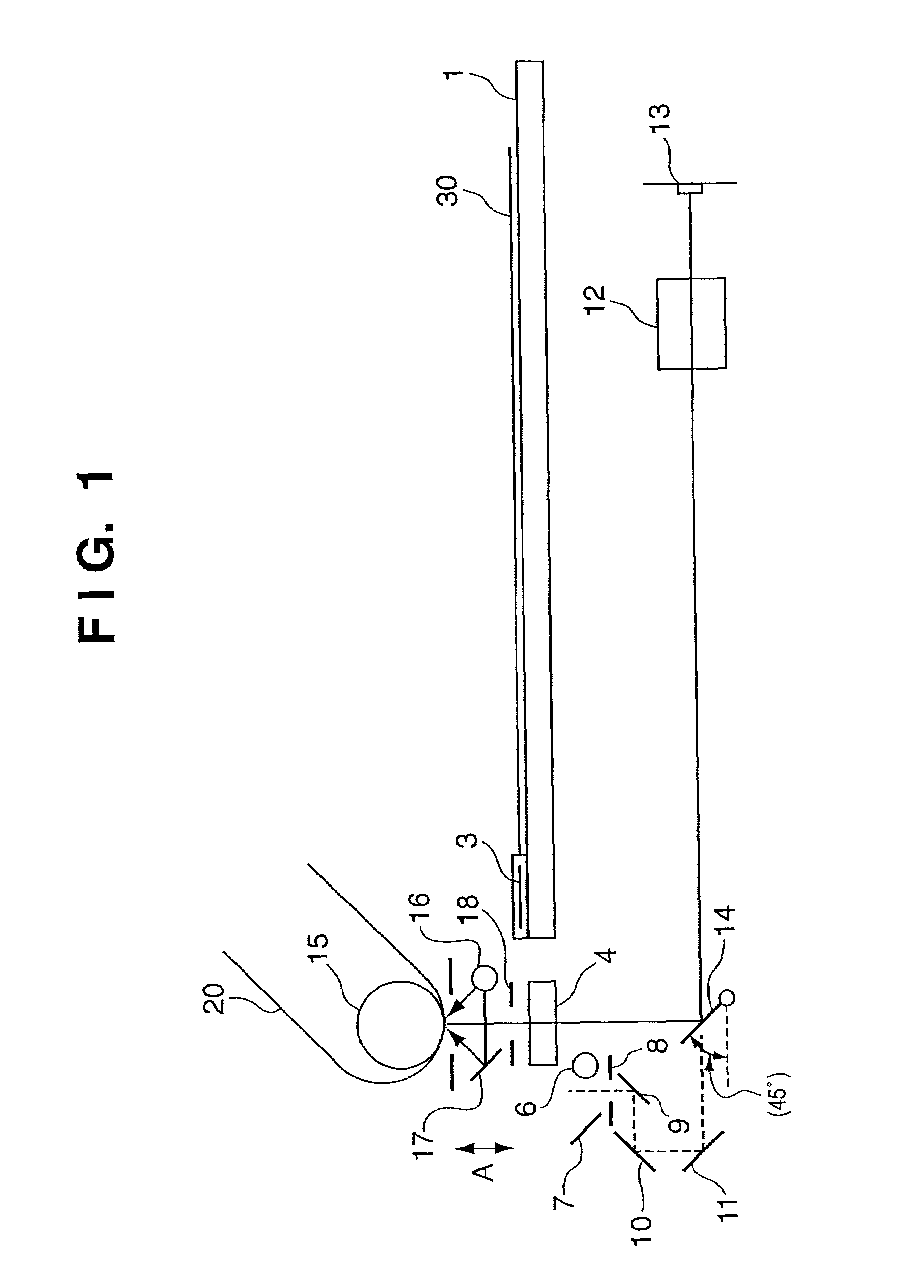

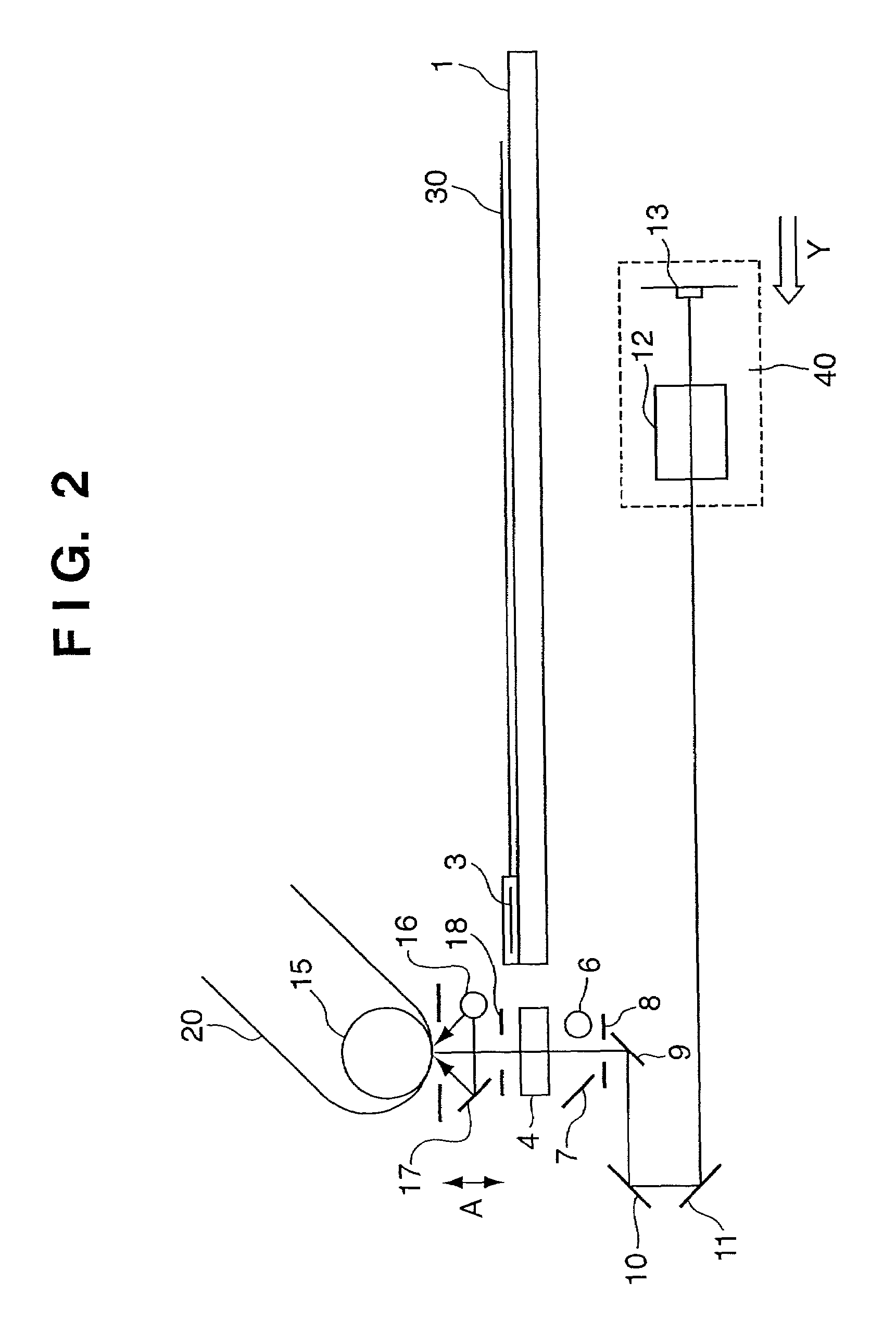

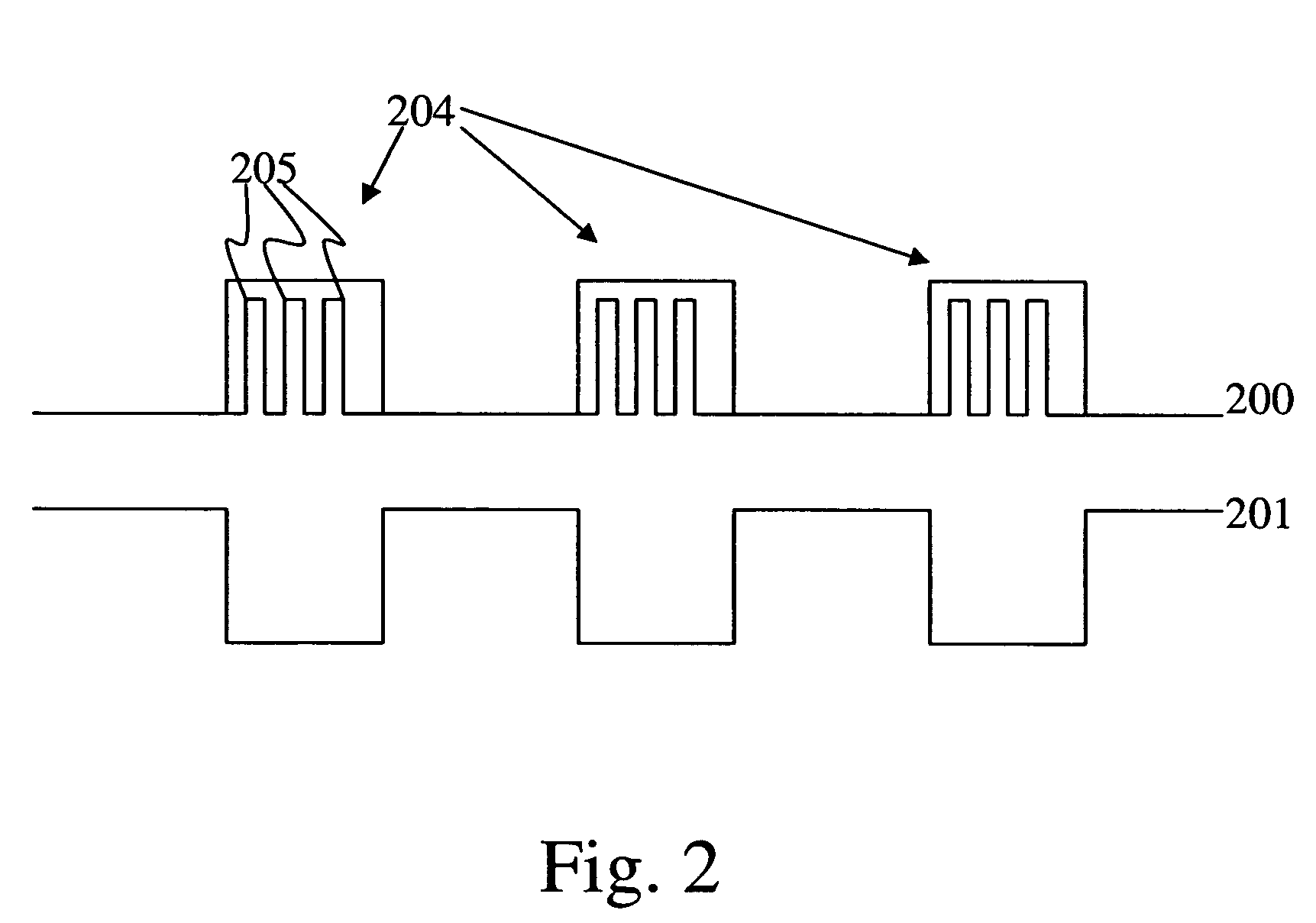

Laser beam micro-smoothing

ActiveUS7723169B2Smoothes out small-scale inhomogeneityAvoid streaksSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsLaser beams

The present invention provides laser beam micro-smoothing for laser annealing systems. Laser beam micro-smoothing comprises shifting a laser beam in the direction perpendicular to the scanning direction (y) of a laser annealing system, while holding the laser beam fixed in the direction of scanning (x). The shifting may be accomplished, for example, with a pair of micro-smoothing mirrors. The shifting smoothes out small-scale inhomogeneities in the profile of the laser beam and prevents microscopic stripes associated with prior art laser annealing systems. Because the shifting occurs only in the direction perpendicular to the scanning direction (y), the laser annealing process in not adversely affected.

Owner:COHERENT GMBH

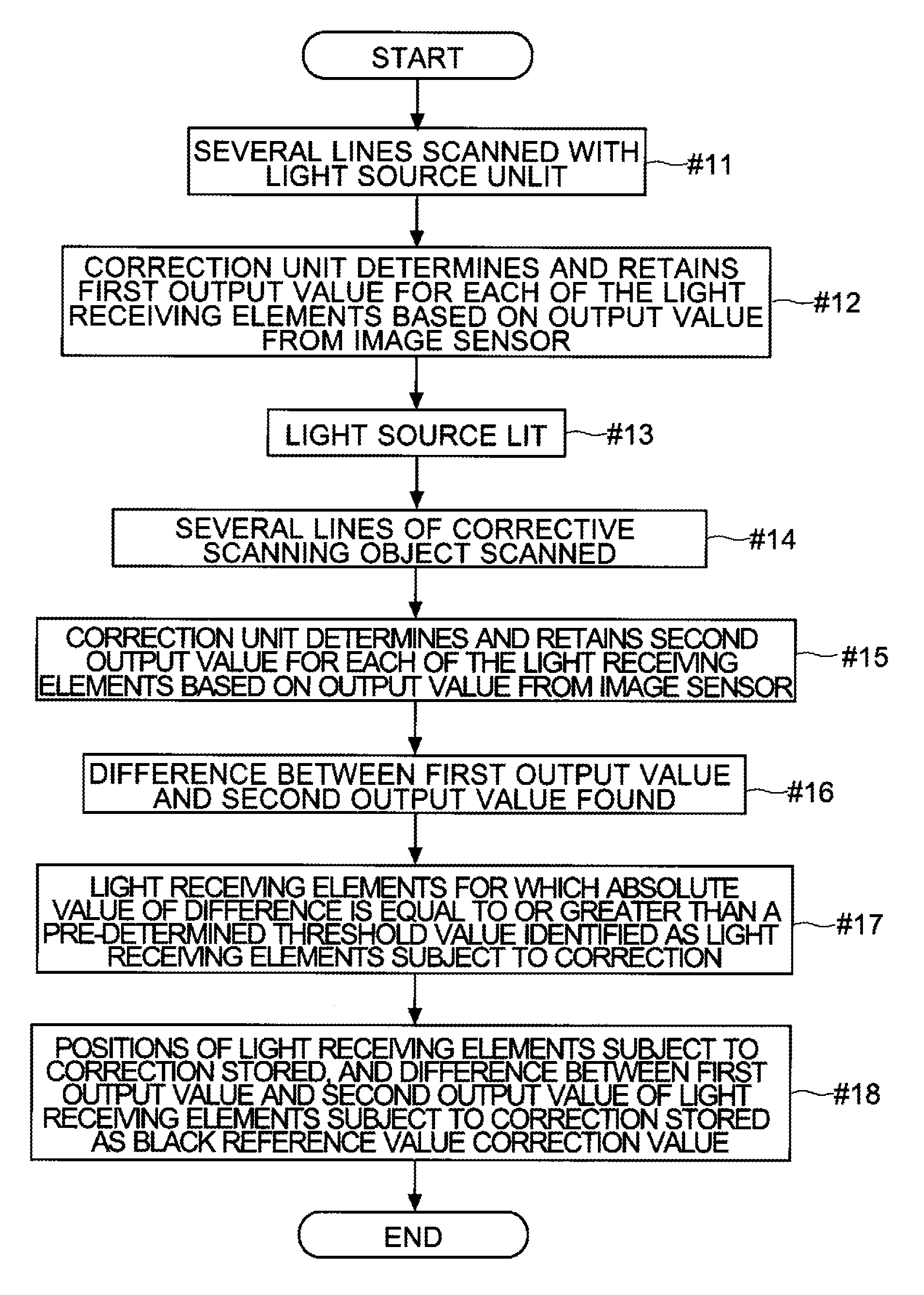

Image scanning device, image forming device, and method for correcting pixel value for pixel corresponding to position of rod lens array joint

InactiveUS20120307325A1Avoid streaksColour-separation/tonal-correctionPictoral communicationImage formationCorrection method

An image scanning device has an image sensor including a plurality of arrayed light receiving elements; a light source for shining light upon a scanning object; a lens unit for guiding reflected light from a scanning object to the image sensor and having a plurality of rod lens arrays, in which a plurality of rod lenses are arrayed, joined together; and a correction unit for generating image data based on the output values from the light receiving elements of the image sensor and correcting the pixel values of pixels in the image data corresponding to a position of a joint section between rod lens arrays so that the pixel values become darker.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Nourishing type eye shadow cream

The invention discloses nutrition type eye shadow which is composed of four components of A, B, C and D. According to parts of the weight, the composition of the A, B, C and D is as follows: component A contains 50-60 parts of deionized water, 2-8 parts of propylene glycol, 0.5-2 parts of tiethanolamine, 0.1-0.3 parts of sodiumhydroxide, 1.5-2 parts of colloidality silicic acid magnalium, and 0.1-0.3 parts of methyl hydroxybenzoate; component B contains 3-5 parts of lanolin, 1-3 parts of myristic acid isopropyl ester, 3-8 parts of white oil, 1-2 parts of olive oil, 4-6 parts of stearic acid, and 6-10 parts of bees wax; component C contains 15-20 parts of talcum powder, 2-4 parts of kaolin, 4-6 parts of titanium dioxide, 3-5 parts of magnesium oxide, and 3-7 parts of white mica powder; and component D contains 0.5-1 parts of essence. The invention has the advantages that the usage is convenient, the effect is convenient and the price is low.

Owner:叶芳

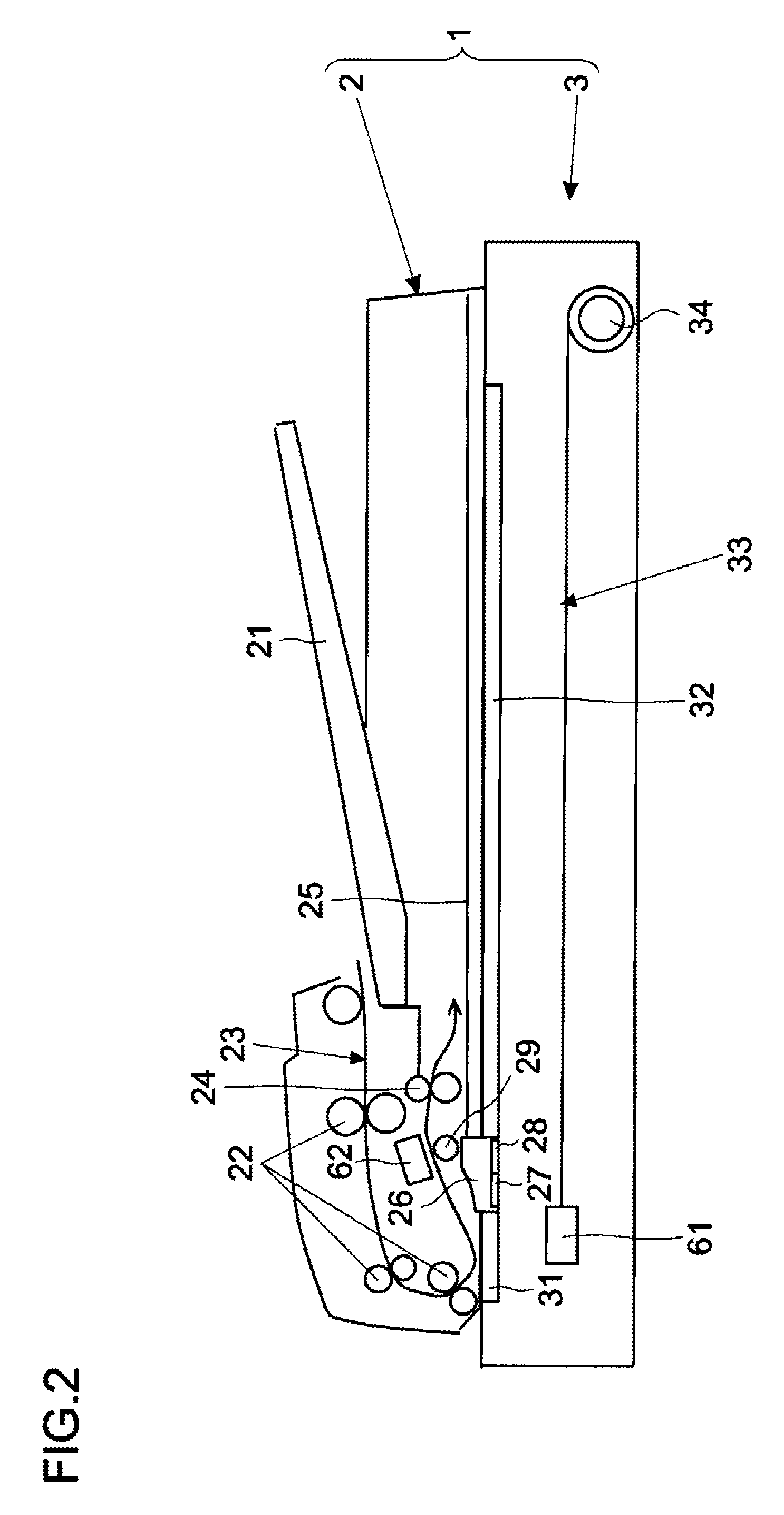

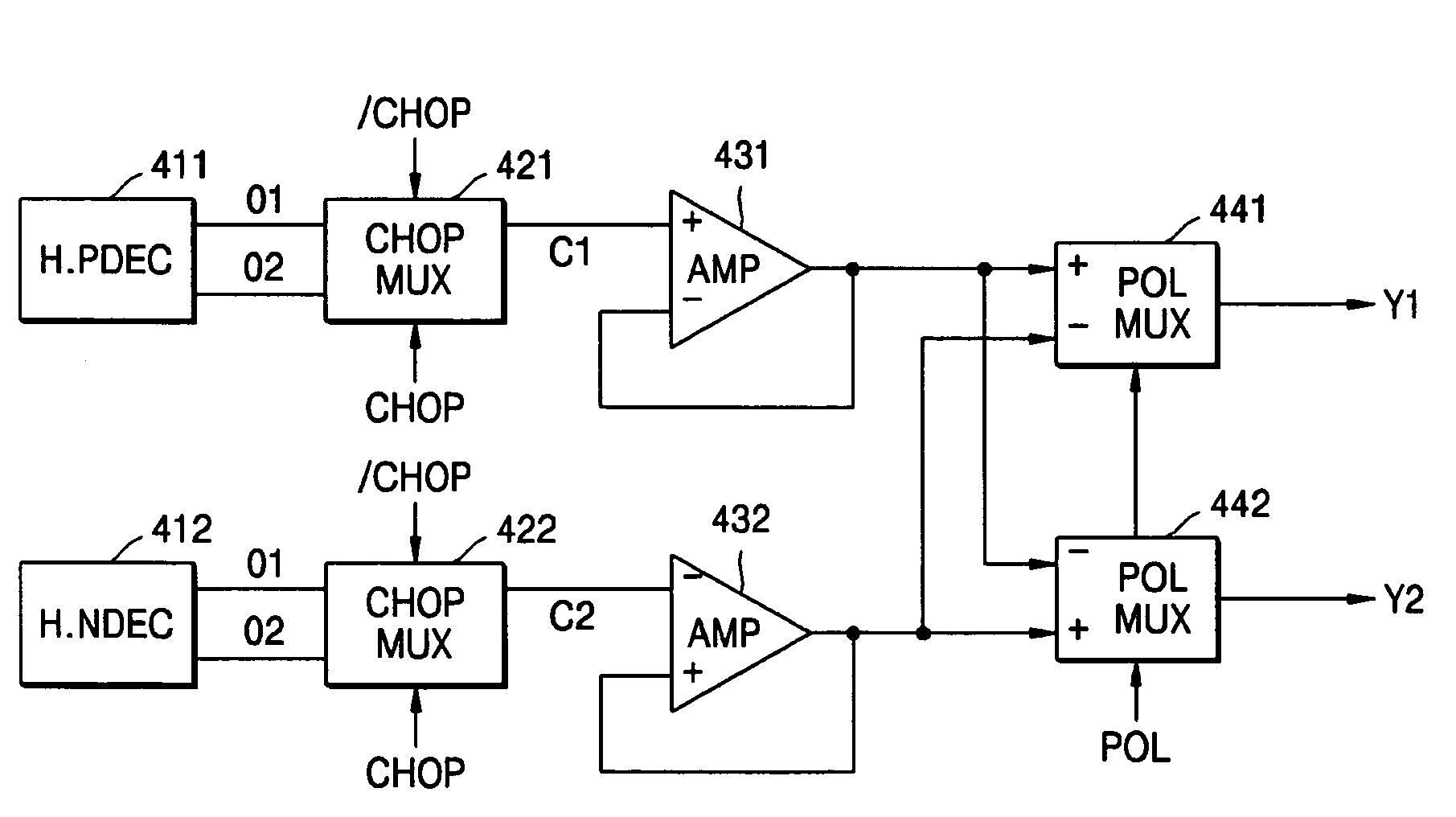

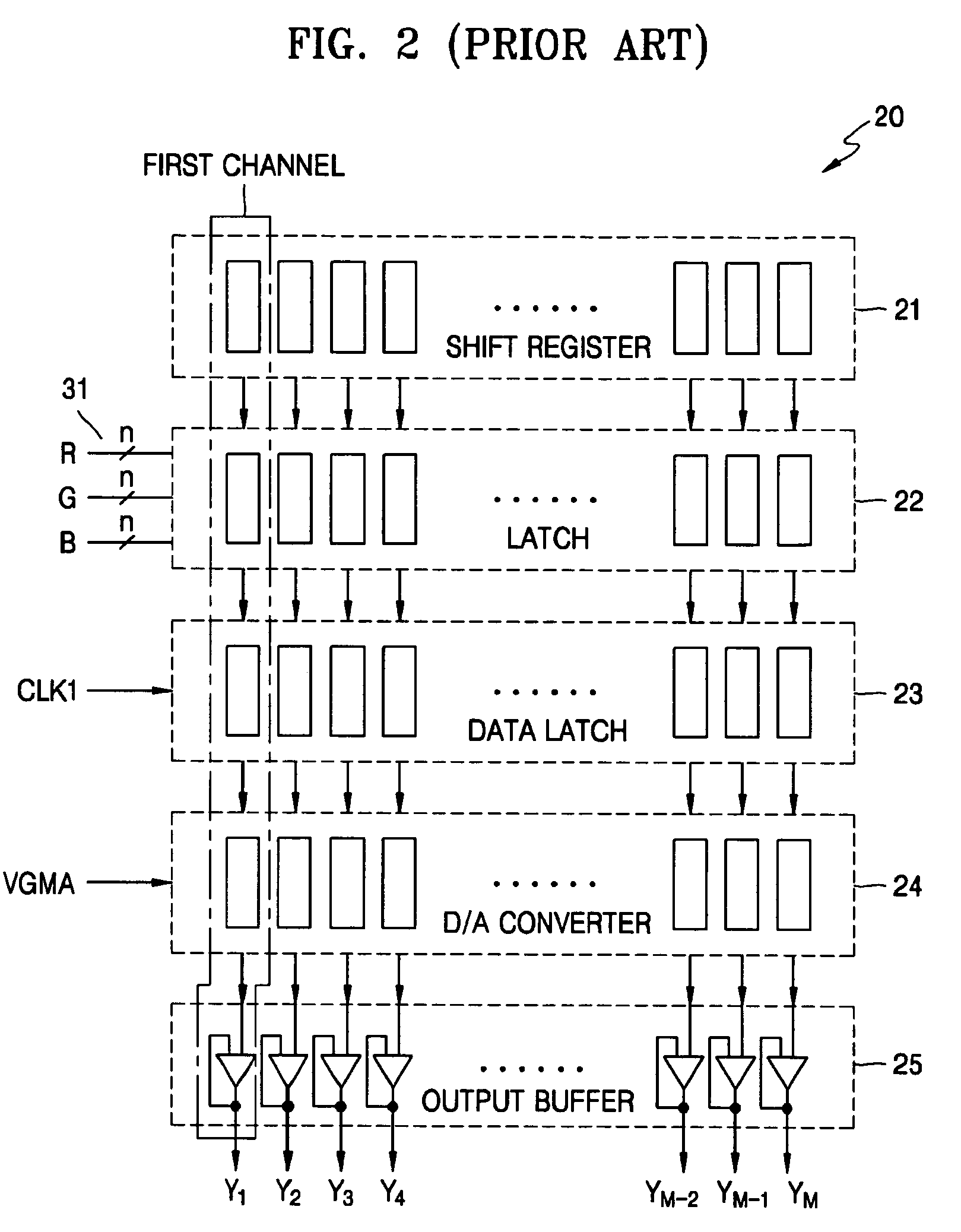

TFT-LCD source driver employing a frame cancellation, a half decoding method and source line driving method

InactiveUS7342567B2Avoid streaksCathode-ray tube indicatorsRemote-control toysDecoding methodsMultiplexer

Provided are a TFT-LCD source driver employing a frame cancellation and half decoding method, and a source line driving method. The TFT-LCD source driver outputs source line driving voltages for every two channels among a plurality of channels. Positive first and second gray scale voltages generated by a positive half decoder and negative first and second gray scale voltages generated by a negative half decoder are selectively transmitted to first and second output buffers through a chopping multiplexer in response to a chopping control signal. Output signals of the first and second output buffers are output to first and second channels through a polarity multiplexer in response to a polarity control signal.

Owner:SAMSUNG ELECTRONICS CO LTD

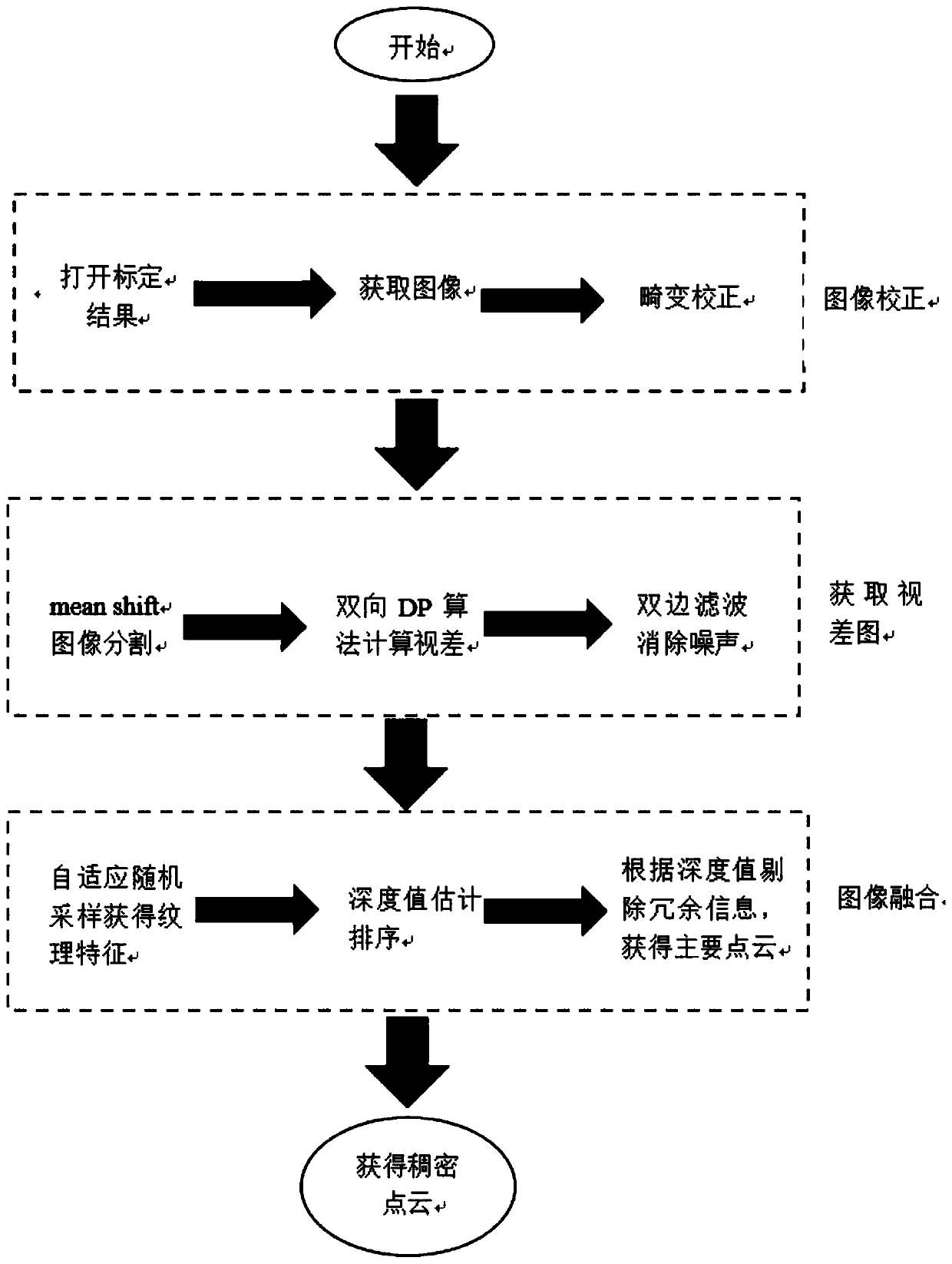

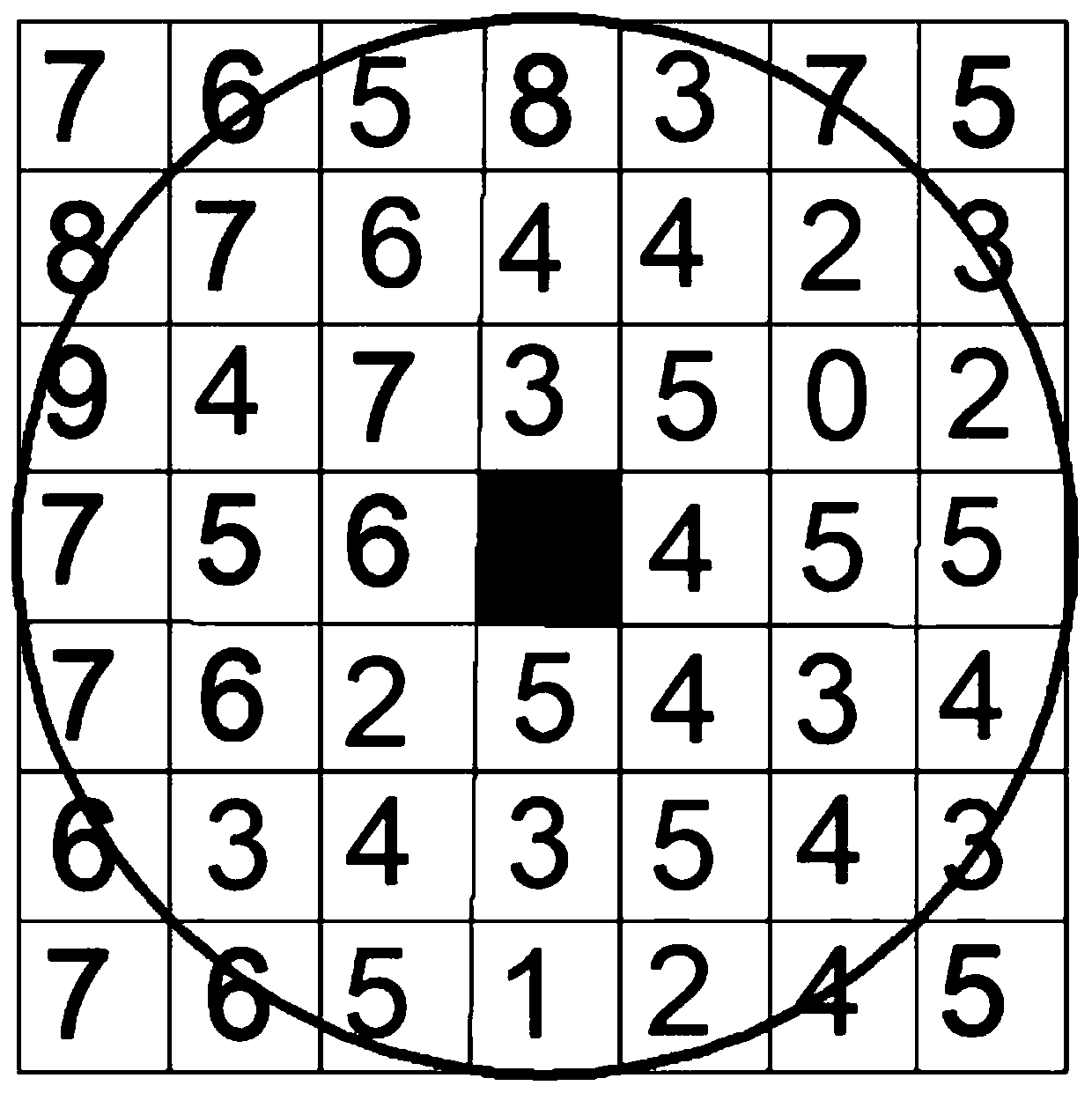

A three-dimensional reconstruction method based on point cloud optimization sampling

InactiveCN109903379AAvoid streaksShorten the search scopeImage enhancementImage analysisParallaxPoint cloud

The invention discloses a three-dimensional reconstruction method based on point cloud optimization sampling and belongs to the field of computer vision. The objective of the invention is to solve theproblem that in the three-dimensional reconstruction process of dense point cloud, under the condition that the main texture characteristics are ensured, the reconstruction speed is low. According tothe method, a mean shift algorithm is mainly utilized to carry out region segmentation on a plurality of corrected images; an improved bidirectional DP algorithm is adopted; sequentially carrying outstereo matching on the same regions after the adjacent images are segmented to obtain a disparity map; secondly, eliminating interference noise of the disparity map by using bilateral filtering to obtain a plurality of dense depth point cloud maps, then obtaining main texture features through self-adaptive random sampling, removing smooth areas, finally calculating depth value estimation of eachpoint cloud, and extracting the main point cloud according to the sequence of the estimation values. According to the method provided by the invention, more obvious texture features can be obtained ata higher calculation speed, and the method has a wide application prospect in natural scene three-dimensional reconstruction.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Toners for electrophotographic imaging apparatus having anti-streaking and anti-filming properties

InactiveUS20050123847A1Avoid streaksToner accumulatingElectrographic process apparatusDevelopersPolyesterStable state

A toner for an electrophotographic imaging apparatus is provided. The toner can stably maintain the charge quantity and charge distribution of the toner in a stable condition, prevent streaking due to the solidification of the toner at a high temperature and humidity, and prevent filming in a developing roller and a toner layer regulator. The toner includes a polyester binder resin having a trimesic acid residue.

Owner:SAMSUNG ELECTRONICS CO LTD

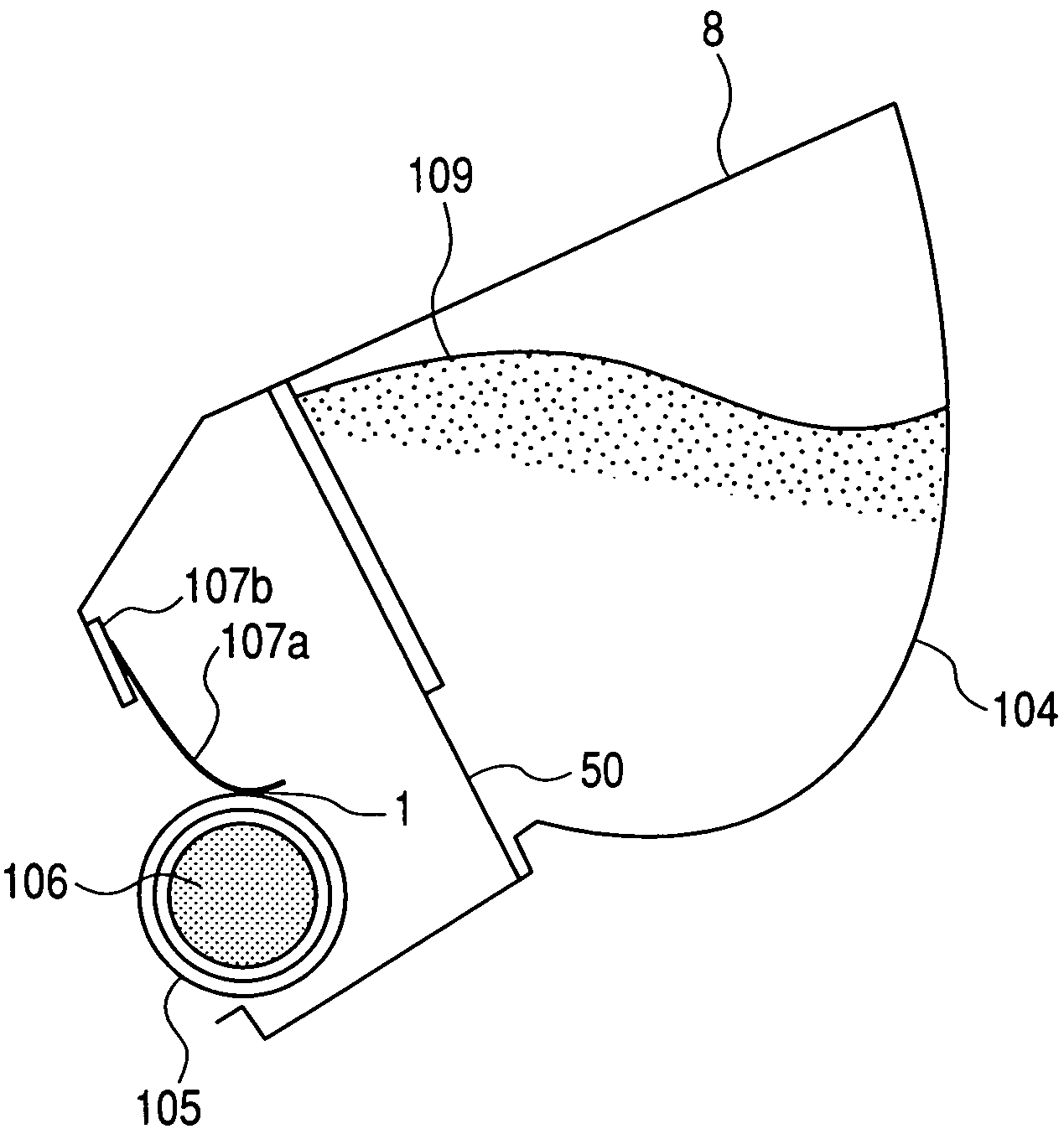

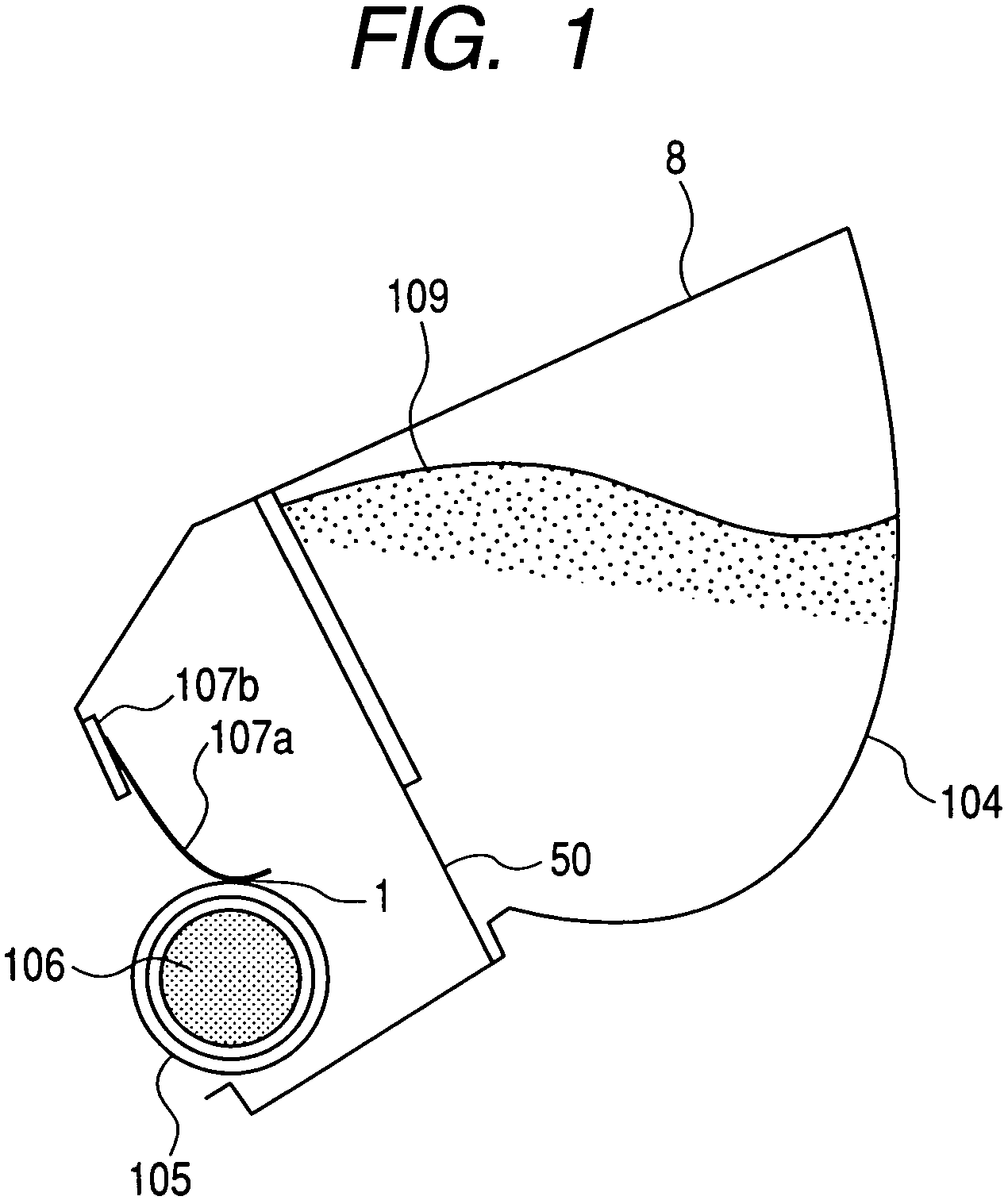

Image reading apparatus

InactiveUS6995878B2Prevent image degradationNot adversely affected by dust or scarPhotographic printingPictoral communicationLine sensorLight beam

The object of this invention is to read an image (scan flow), when an original is being moved, above a scan flow glass member, so as to prevent degradation in image caused by dust or a scar on a scan flow glass. In order to achieve this object, the original which is being moved is illuminated by an illumination system comprised of an illumination light source and reflecting member and different from an illumination system in a reading apparatus body and comprised of an illumination light source and reflecting member. After a reflected light beam passes through a slit and the scan flow glass member, it forms an image on a line sensor, e.g., a CCD, by an imaging lens through a movable mirror. As the original moves at a constant speed, it is read by the line sensor, e.g., a CCD, at a predetermined timing, thereby obtaining image information of the original. The original is located above the scan flow glass member. Even if dust or a scar of about several tens μm is present on the scan flow glass member, it goes out of focus, so it can be prevented from forming an absent point of the line sensor such as a CCD.

Owner:CANON KK

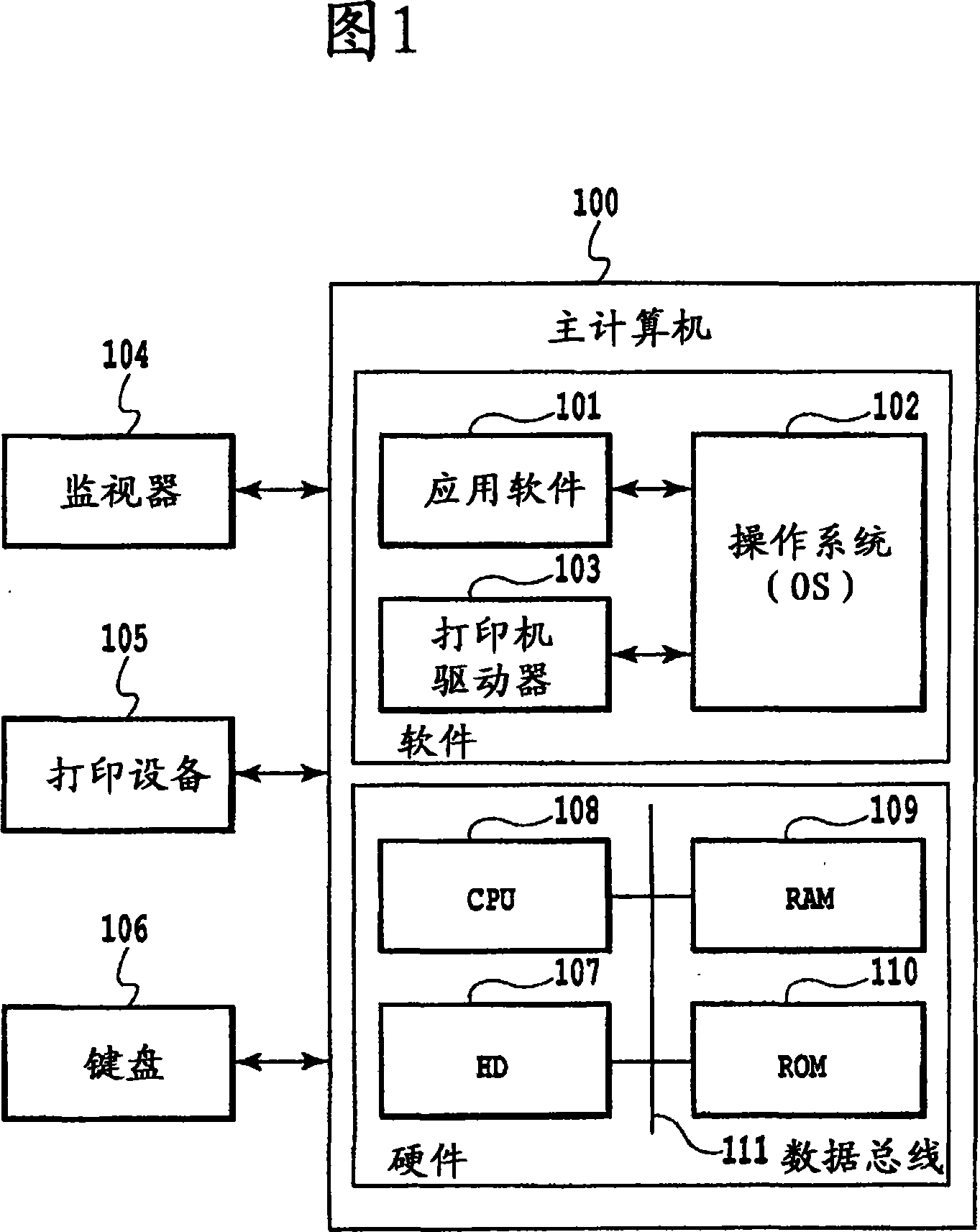

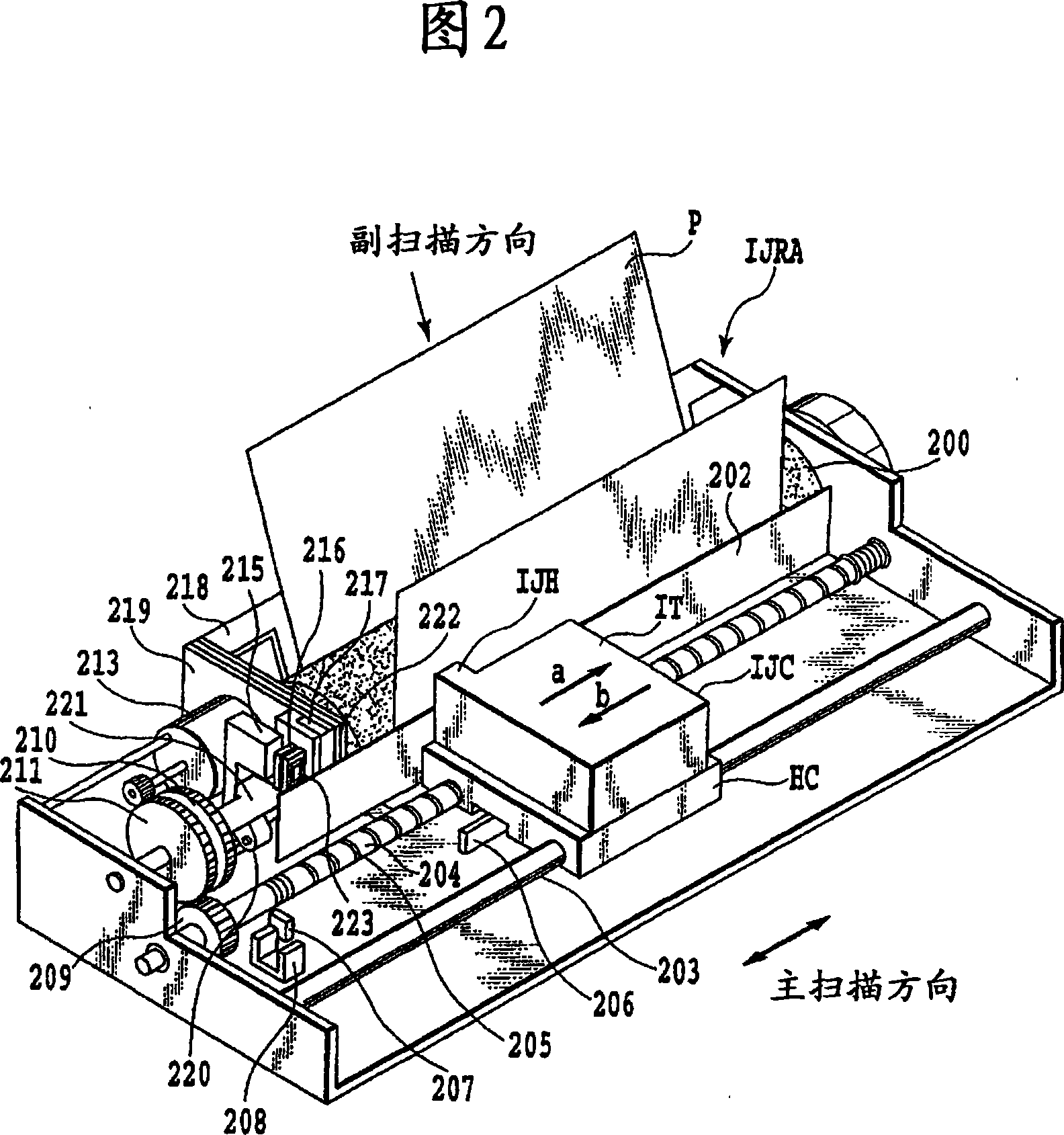

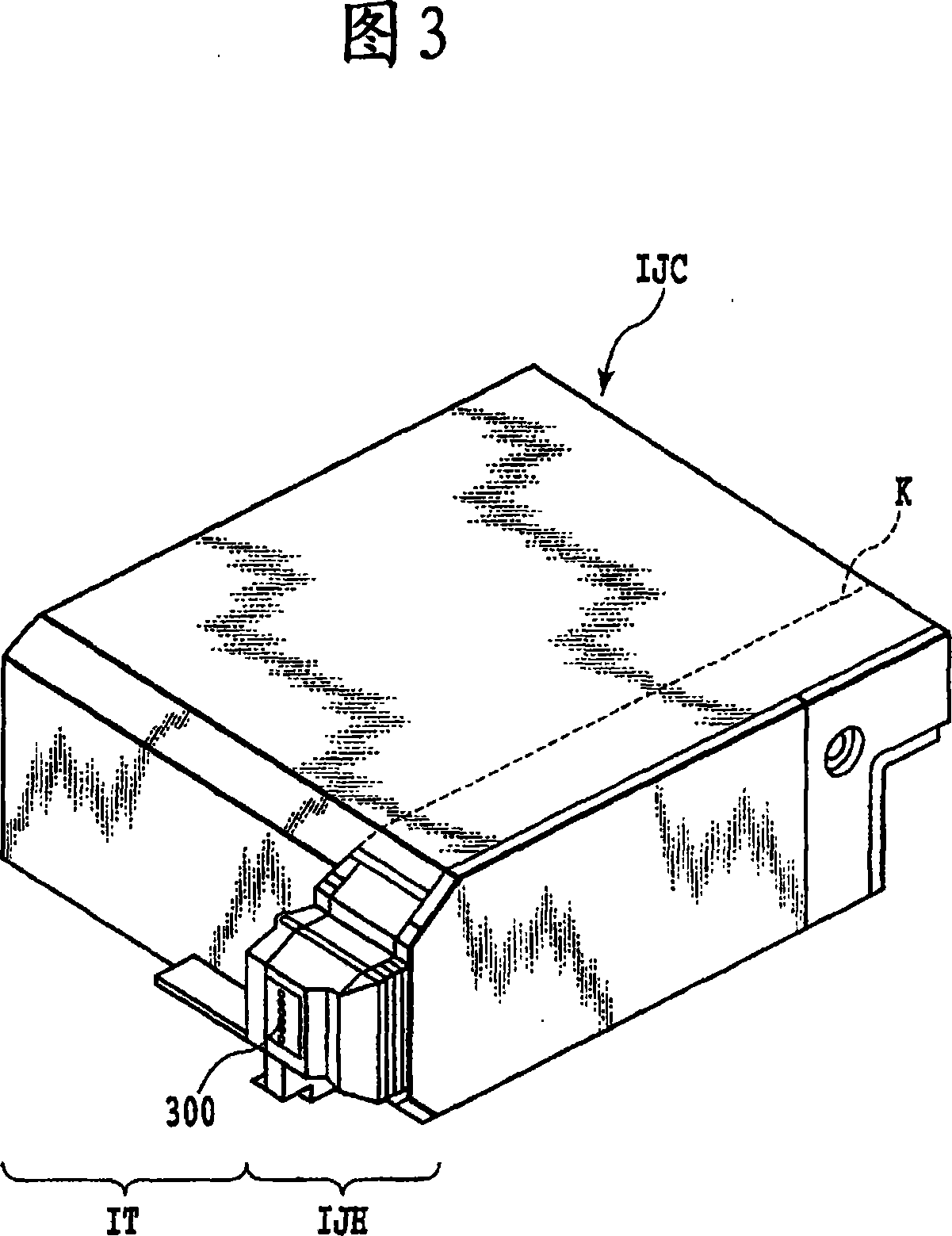

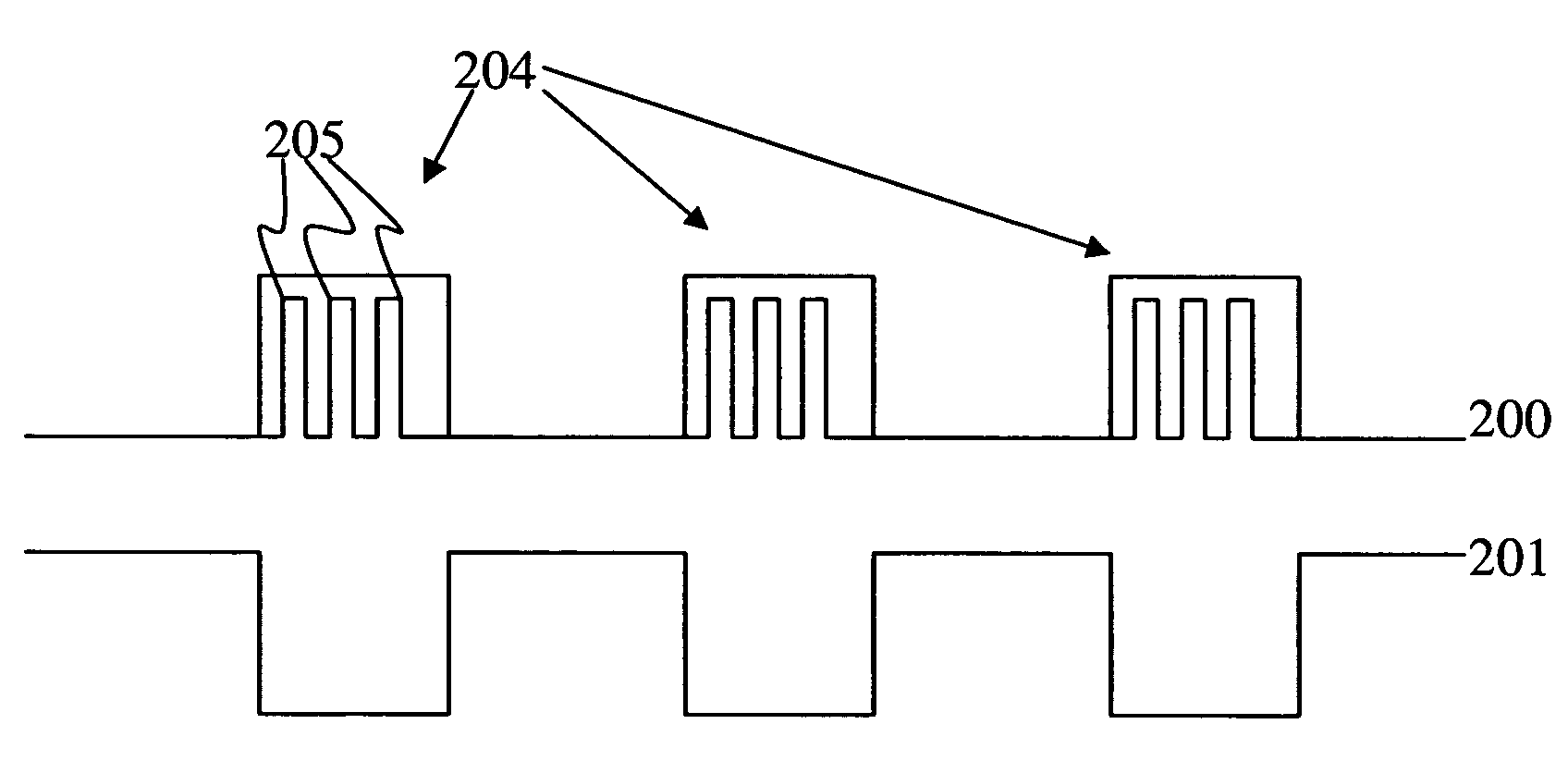

Print controlling apparatus and print controlling method

InactiveCN101078975AAvoid print qualityAvoid streaksDigital output to print unitsData transmissionComputer science

Owner:CANON KK

Exposure time selection in a transmission apparatus with a camera

ActiveUS7664387B2Avoid visible stripeEnabling useTelevision system detailsColor television detailsRolling shutterImaging equipment

A communications apparatus is shown having an imaging device for capturing an image, and a flash for lighting an image to be captured. Also shown is the use of the apparatus. Software for matching a flash performance to other functions of a device is also shown. A radio communications apparatus embodiment is shown that comprises an imaging device including an image sensor and a rolling shutter, and a flash unit. The flash unit is operated at a certain flash frequency, and an exposure time is determined according to the flash frequency so that the image sensor is uniformly exposed by the rolling shutter during the determined exposure time.

Owner:NOKIA TECH OY

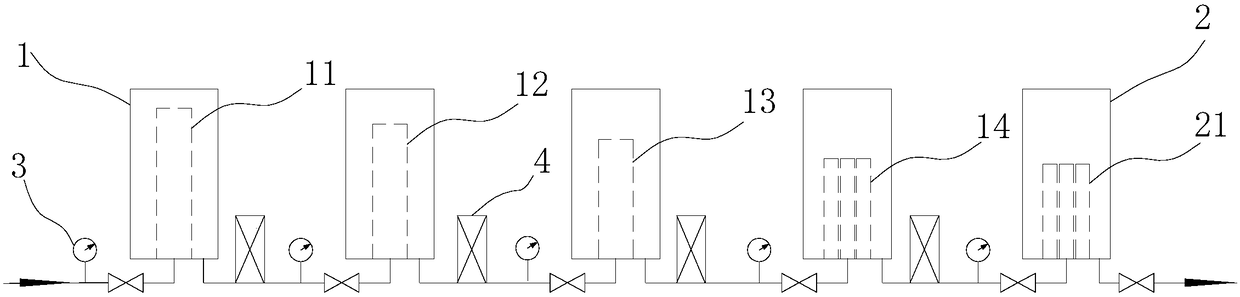

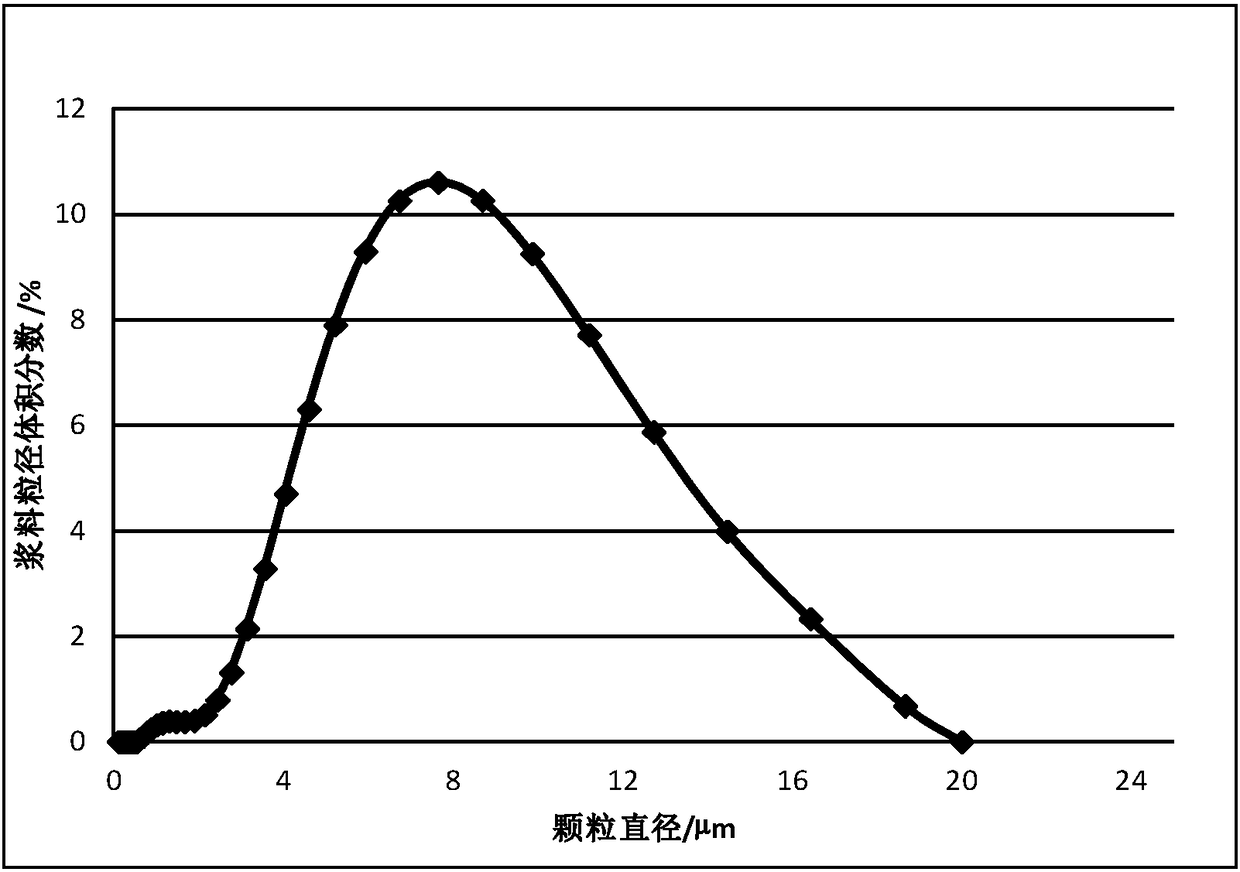

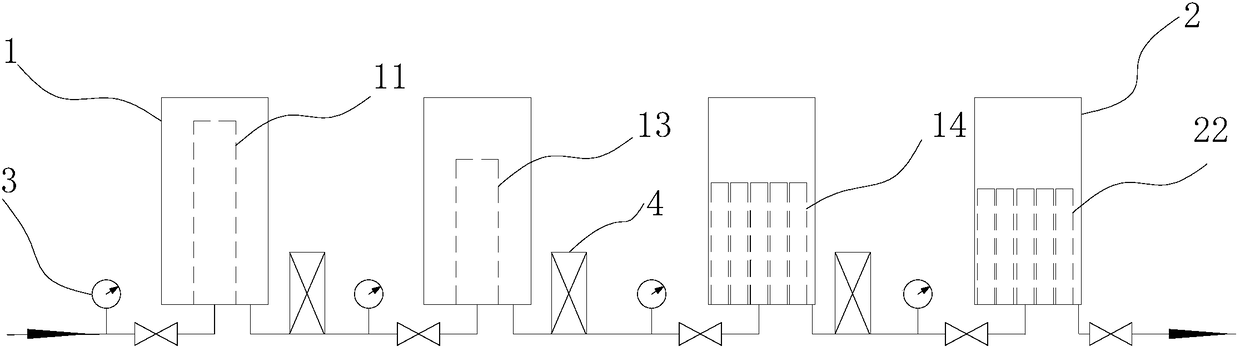

Slurry filtration system used for power lithium ion battery of HEV/PHEV

ActiveCN108392893ALarge amount of filtrationImprove work efficiencyFiltration circuitsSlurry flowLithium electrode

The invention relates to the technical field of production of power lithium ion batteries, and particularly discloses a slurry filtration system used for a power lithium ion battery of HEV / PHEV. The system comprises a slurry flowing pipeline, a plurality of filters connected in series are arranged in the slurry flowing pipeline, the filters are in sequential connection according to a descending order of filter pore sizes, and a slurry flowing direction is formed; and the interior of each filter is provided with one screen or two or more parallel screens, a depth-type filter group is connectedin series with the tail end of the slurry flowing direction, the interior of the depth-type filter group is provided with a plurality of parallel filter elements, and the filter pore size of each filter element is smaller than the filter pore size of the screen. The system provided by the invention filters slurry until the particle size of the slurry is in a suitable range in a classified filtration manner, so that clogging of the screen is effectively avoided, the filtration process has high stability, and requirements for particle miniaturization of the slurry used for the lithium ion battery of the HEV or the HPEV are met; and filter screens with any specifications can adopted for free combination, which is flexible and convenient, and the system is convenient to assemble and disassemble, and convenient for large-scale production.

Owner:WANXIANG 123 CO LTD

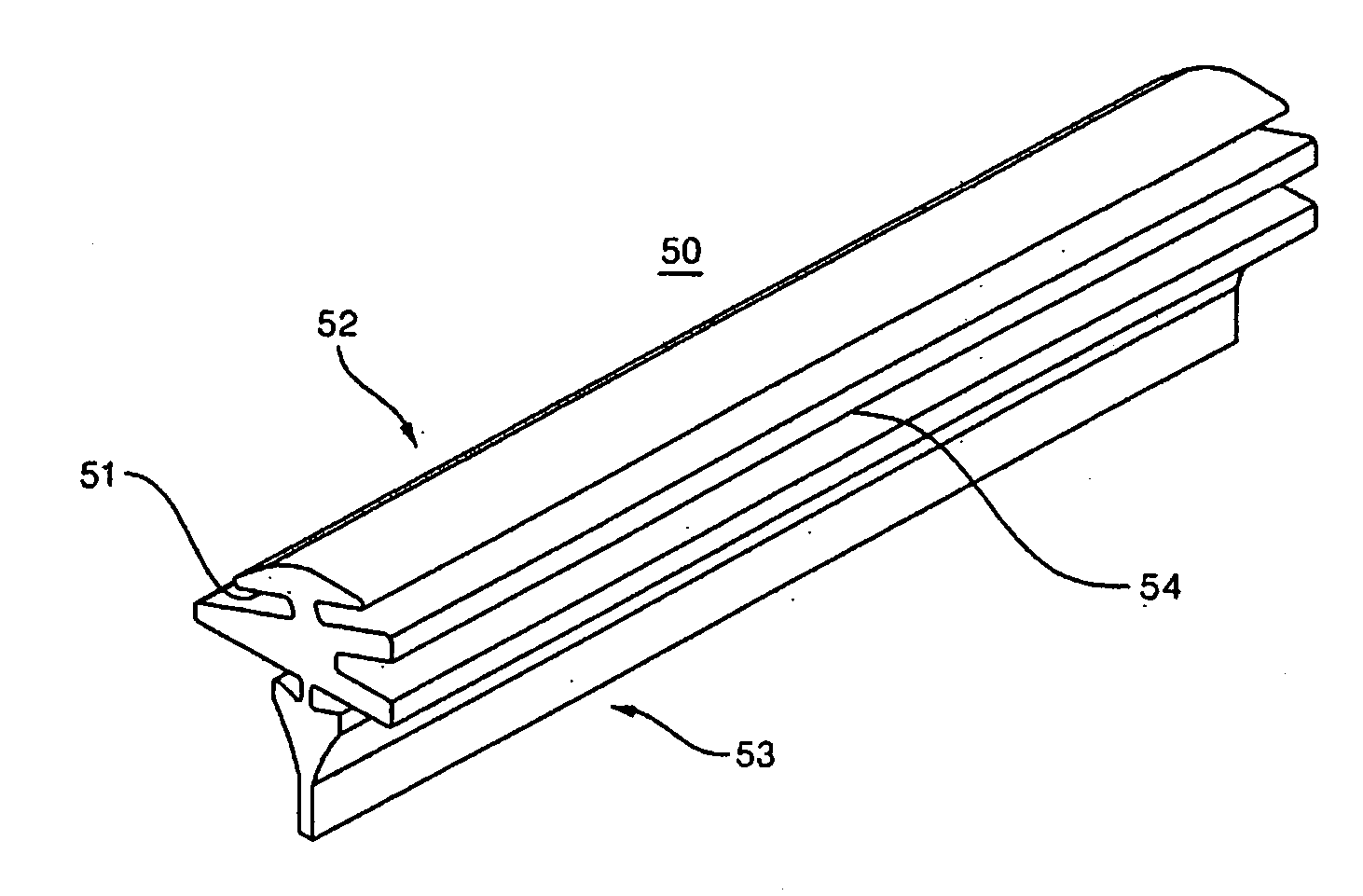

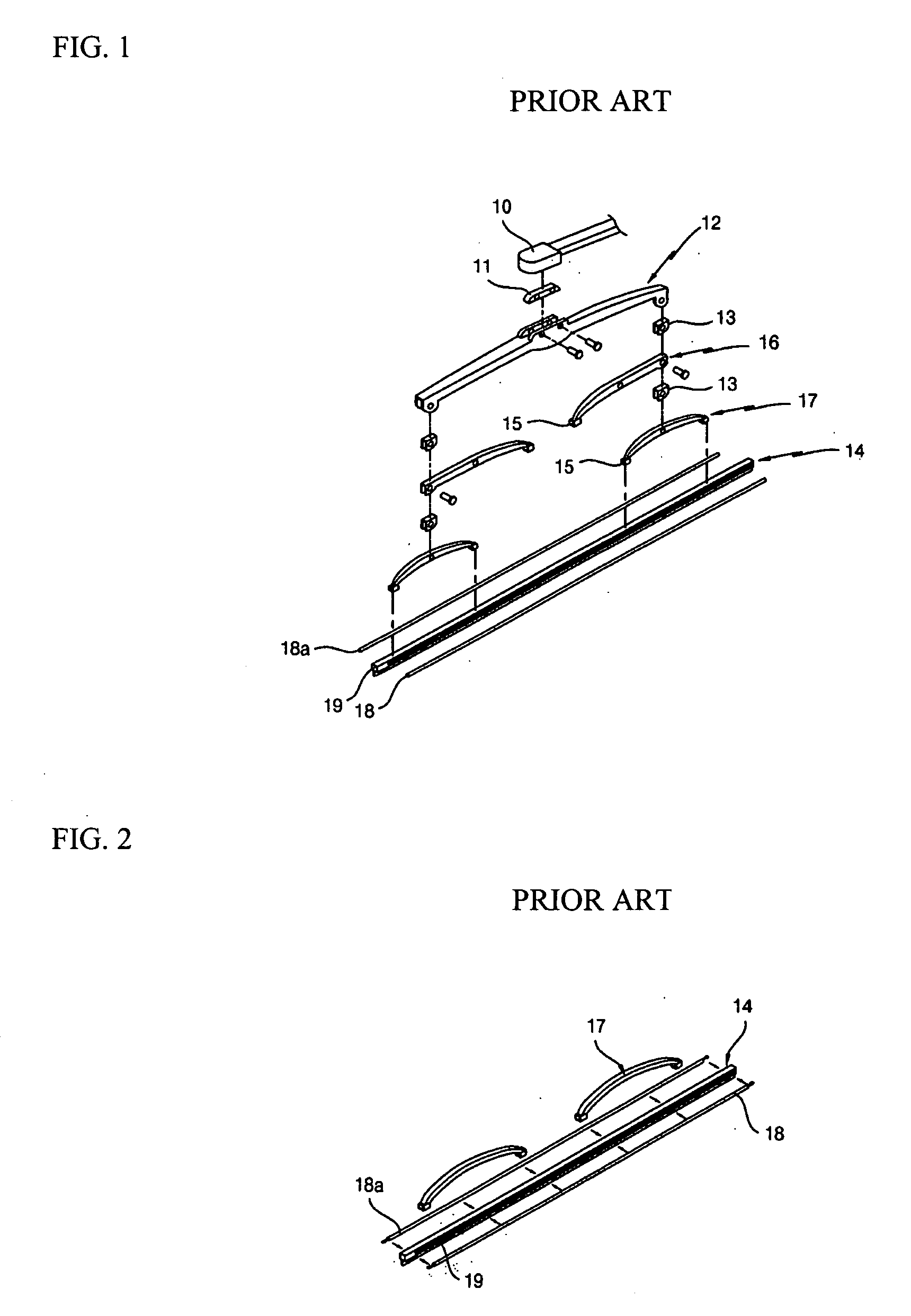

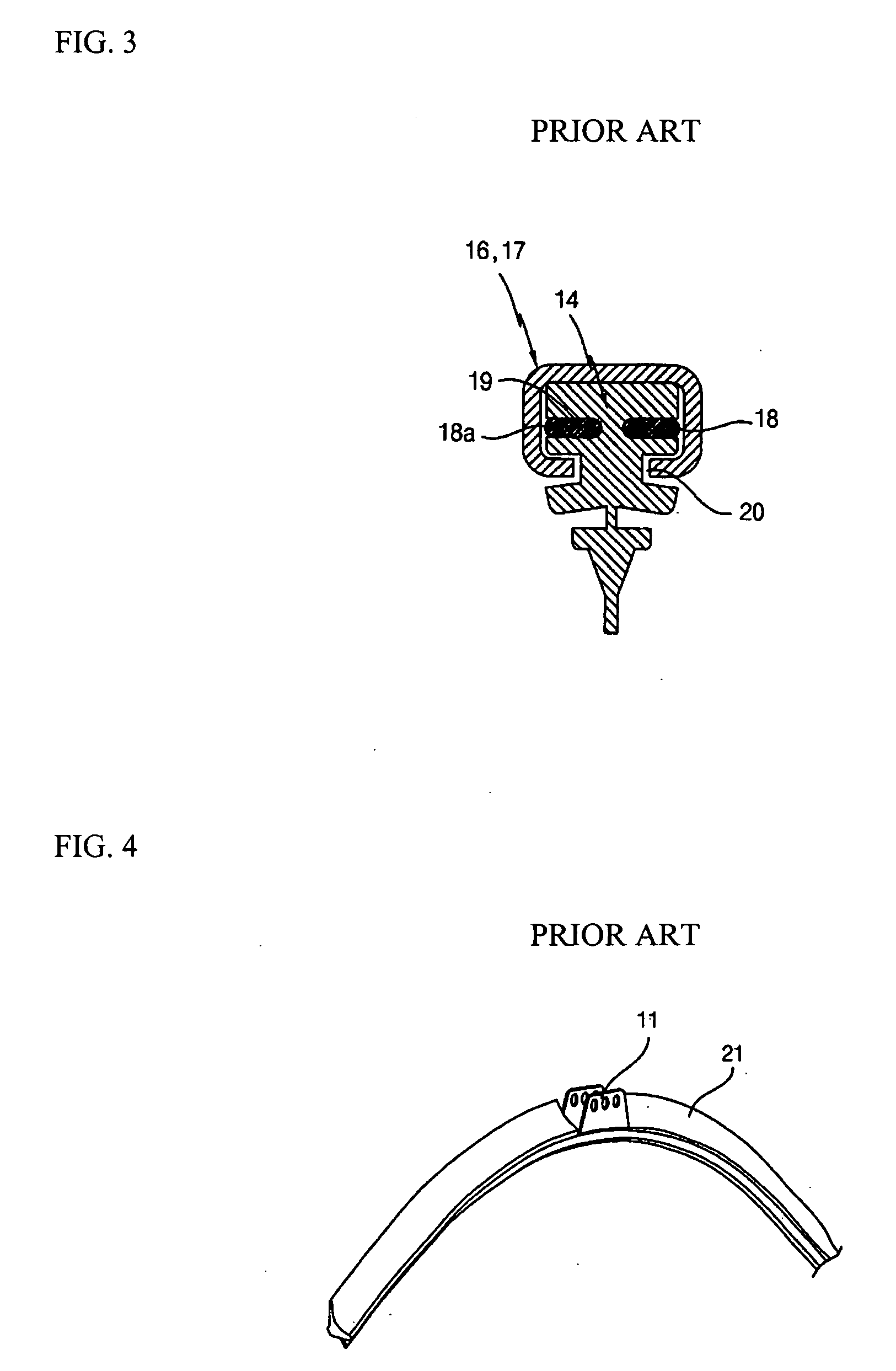

Rubber blade for wiper

InactiveUS20070000084A1Preventing judderAvoid streaksWindow cleanersVehicle cleaningEngineeringKnife blades

Provided is a rubber blade for an automotive wiper capable of autonomously pressing firmly and resting securely against a windshield surface by altering the structure of the rubber blade. The rubber blade has a head portion forming an upper portion of the rubber blade. The head portion includes a pair of mounting slots for mounting the rubber blade along a wiper frame. The pair of mounting slots has a sectional offset angle (θ1), dependant on the disposition of the wiper frame. A central axis in a center between the pair of mounting slots in a sectional view of the blade is offset by an angle (θ3) from a vertical axis (L1). A wiping portion forms a lower portion of the rubber blade for contacting the windshield, and is disposed in the direction of the vertical axis (L1).

Owner:PARK LTD

Anti-streak cover for eavestrough

An eavestrough cover designed to cover the upper front wall portions of a conventional eavestrough and which has a finish to minimize streaking or staining. The eavestrough cover snaps into position on the eavestrough.

Owner:BROCHU GUY

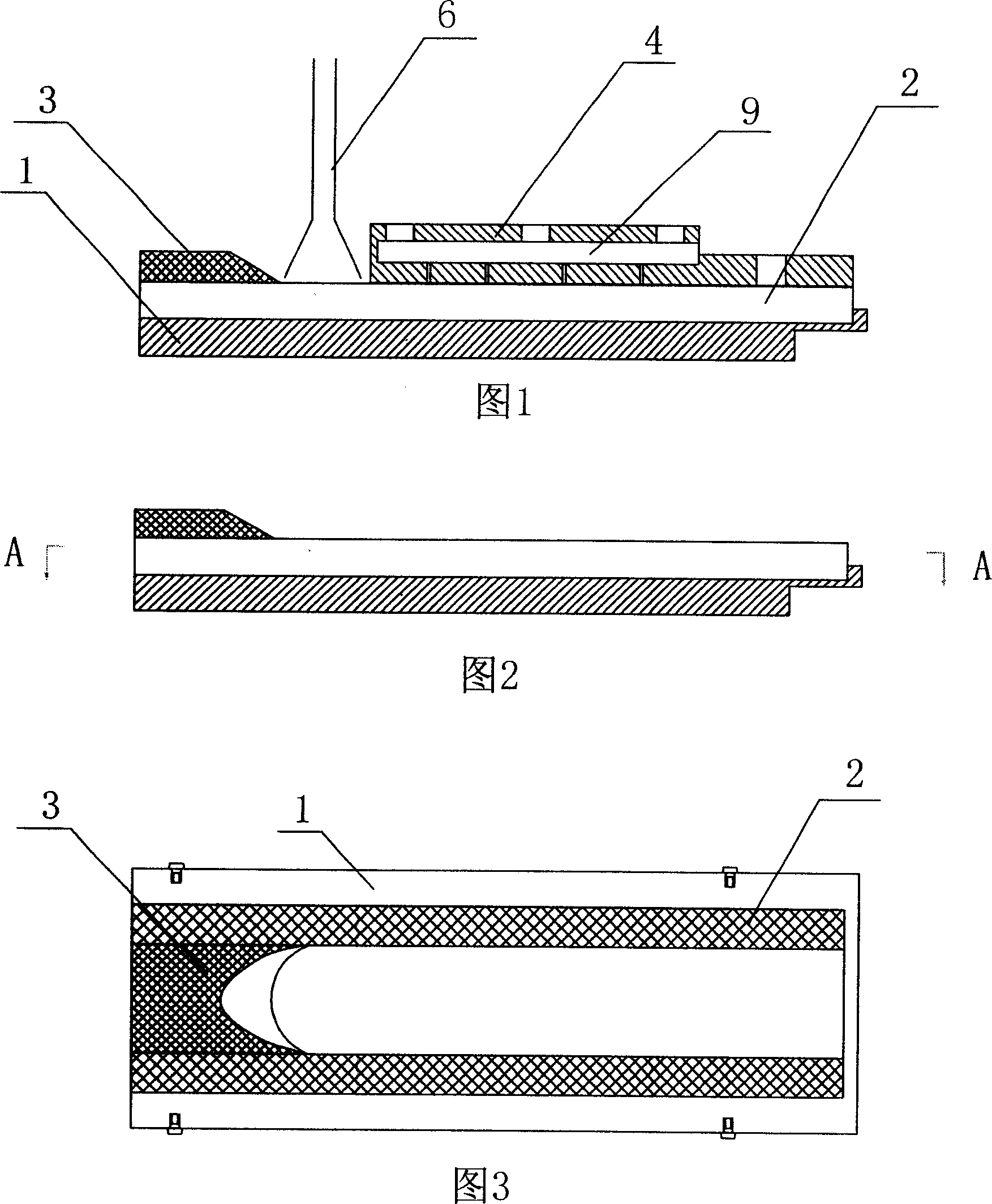

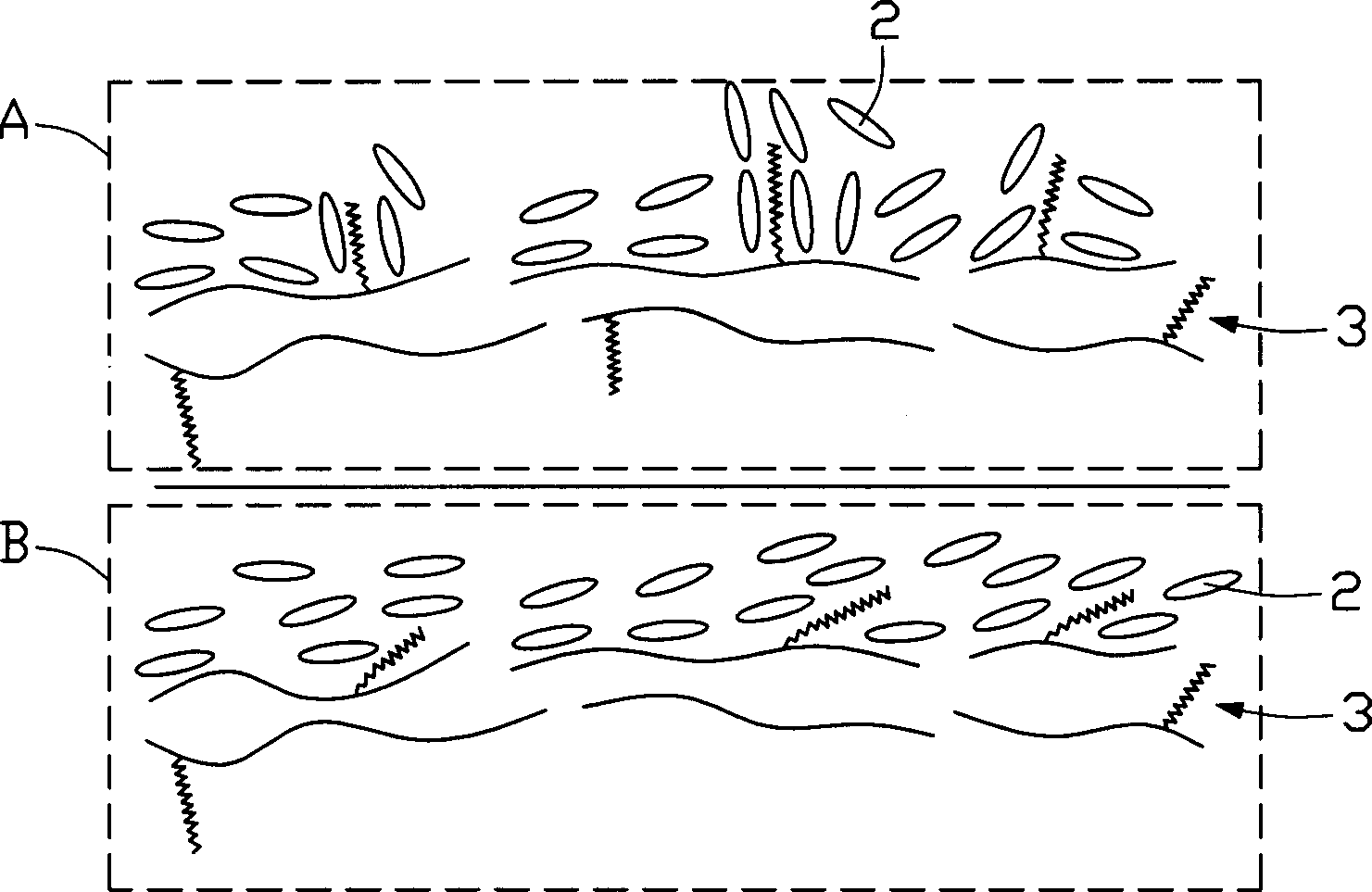

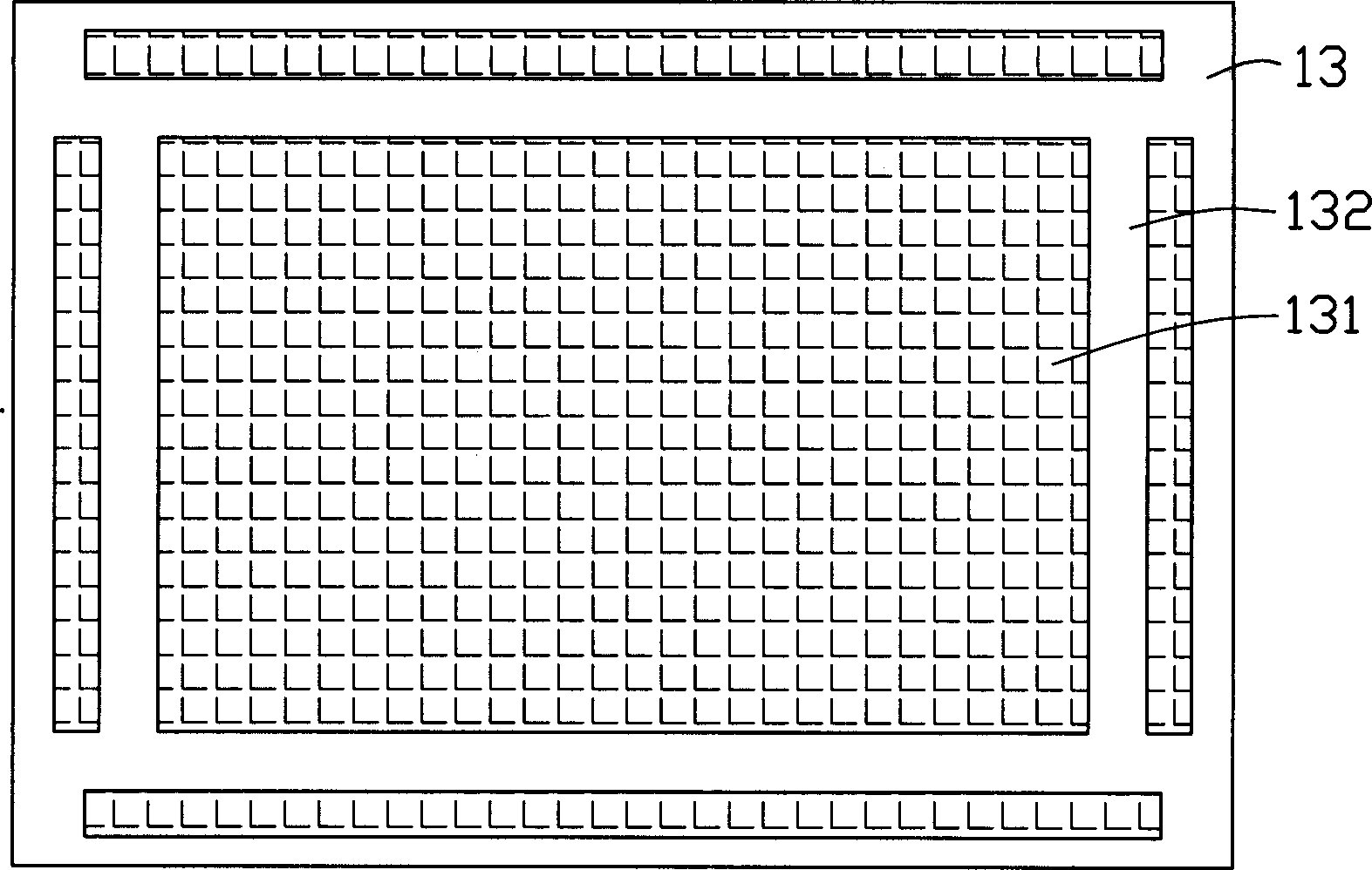

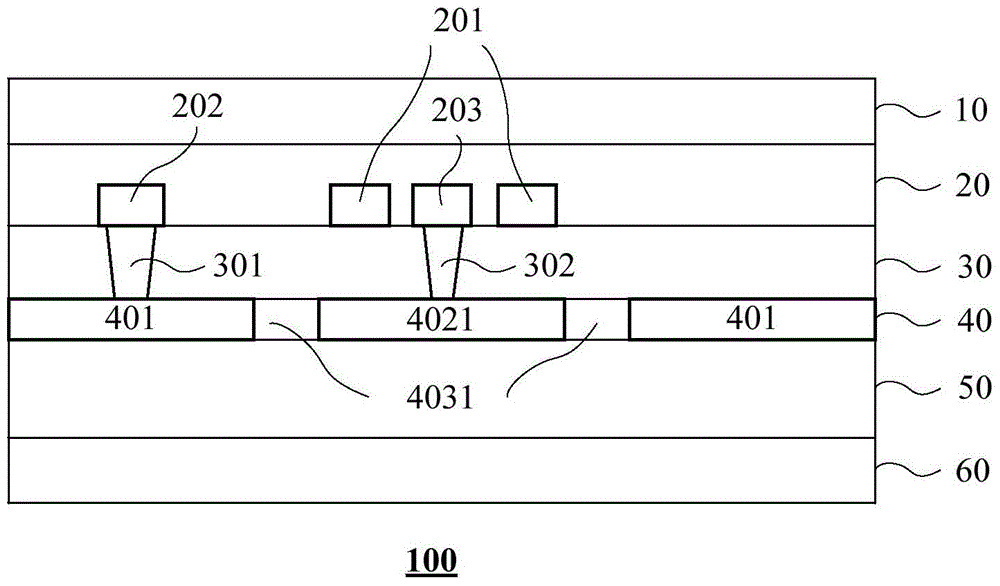

Substrate and LCD device using the same

ActiveCN1834734AGood alignment effectImprove adhesionStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

The invention discloses is a substrate, comprising an active region, an edge region and a frame glue adhesion region between them, where the active region is coated with an aligning film layer, the frame glue adhesion region has fillings with close friction coefficient to that of the aligning film, and the aligning effect is better and the adhesion between the frame glue and the substrate can not be influenced. Besides, the invention provides a LCD using the substrate.

Owner:INNOCOM TECH SHENZHEN +1

Streak-free tire dressing

ActiveUS20130115377A1High glossAvoid streaksPretreated surfacesDyeing processRoom temperatureEvaporation

A tire dressing composition is provided that includes at least one silicone fluid having a viscosity of between 40 and 500,000 centiStokes at room temperature. A fluorinated acrylate polymer is provided in the composition to limit the amount of streaking in a coating formed from the composition upon application to a tire surface. The coating is formed through the evaporation of a solvent in the composition containing the at least one silicone fluid and the fluorinated acrylate polymer. A process is provided for dressing a tire having a previous silicone coating thereon, the process including applying the tire dressing composition and allowing the solvent to evaporate from the composition to form a tire dressing coating. The coating producing an initial gloss of greater than 110 units. A gloss of greater than 110 units is maintained for at least two weeks subsequent to the application under normal vehicle operation conditions.

Owner:ILLINOIS TOOL WORKS INC

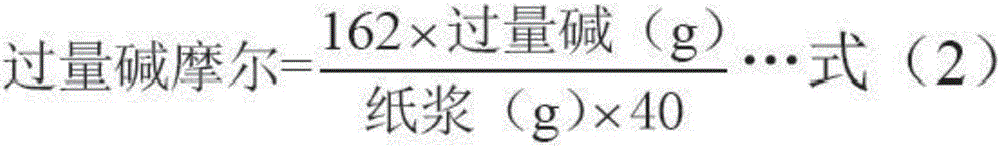

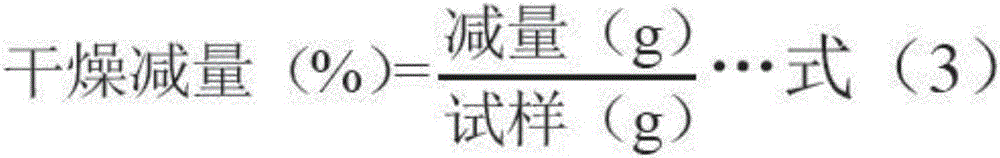

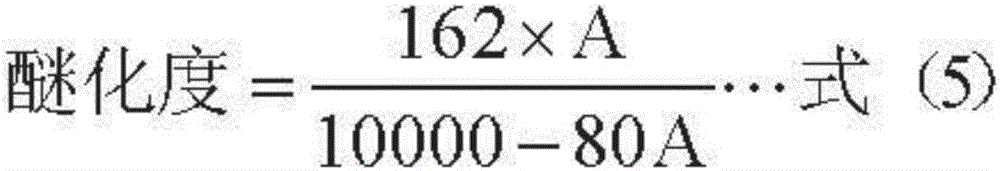

Method for producing carboxymethyl cellulose salt for electrodes of nonaqueous electrolyte secondary batteries, electrode for nonaqueous electrolyte secondary batteries, and nonaqueous electrolyte secondary battery

ActiveCN106573991AAvoid streaksImprove adhesion strengthLi-accumulatorsNon-aqueous electrolyte accumulator electrodesElectrolytic agentCellulose

The purpose of the present invention is to provide a carboxymethyl cellulose salt for electrodes of nonaqueous electrolyte secondary batteries, which is capable of achieving a good balance between prevention of defects such as streaks and pin holes on a coated electrode surface and excellent bonding strength to a collector or excellent bonding strength between active materials. A production method which comprises: (1) an alkali cellulose formation reaction step wherein a mixed solvent that contains an alcohol having 3 or less carbon atoms and water at a mixing ratio (mass ratio) of from 75:25 to 95:5 is used and the alkali concentration relative to water is 25-40% by mass; (2) an etherification reaction step wherein a reaction is carried out in the presence of an excess alkali of 0.2-0.5 mol per unit of an anhydroglucose of the cellulose; (3) a neutralization step wherein an acid is added after the etherification reaction so that the pH of the reaction mixture is adjusted to 6.0-8.0; and (4) a heating step wherein the mixed solvent is removed and an alkali is added after the neutralization step so that the pH of the reaction mixture is adjusted to 8.0-9.0, and subsequently, a heat treatment is carried out at 40-70 DEG C for 30-120 minutes.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Shaping device of fluorophosphate optical glass and its shaping method

This invention provides a fluorophosphate optical glass molding equipment, including mold. Mold described composed by the end of mold, side die and block, in Mold also provided with cooling flat, air vents are installed on the flat. Fluorophosphate optical glass molding apparatus molding methods includes the following steps: 1) glass fluid flows out of the material tube and flow into Mold; 2) in Mold the glass fluid flow through the upper surface cover the cooling flat, inert gas through the air vents on the cooling flat blow to glass solution surface, so as soon as cool glass liquid for molding. The invention set cooling flat on the mold, through air vents blowing inert gas, so as soon as cooling liquid glass, to avoid the glass at high temperatures causing the volatile stripes, ensuringthe quality of products; In addition, the invention uses graphite mold to avoid corrosion.

Owner:CDGM OPTICAL GLASS

Austenitic stainless steel having excellent processability and surface characteristics, and manufacturing method therefor

ActiveCN110225992AEasy to processAvoid defectsFurnace typesHeat treatment furnacesManganeseSS - Stainless steel

An austenitic stainless steel having excellent processability and surface characteristics, and a manufacturing method therefor are disclosed. The disclosed austenitic stainless steel comprises, by wt%, 0.005-0.15% of C, 0.1-1.0% of Si, 0.1-2.0% of Mn, 6.0-10.5% of Ni, 16-20% of Cr, 0.005-0.2% of N, and the balance of Fe and inevitable impurities, and the Ni surface negative segregation thereof defined by the following formula (1) is 0.6-0.9. (CNi-Min) / (CNi-Ave) - formula (1). Here, CNi-Min is the minimum concentration of Ni on the surface and CNi-Ave is the average concentration of Ni on the surface.

Owner:浦项股份有限公司

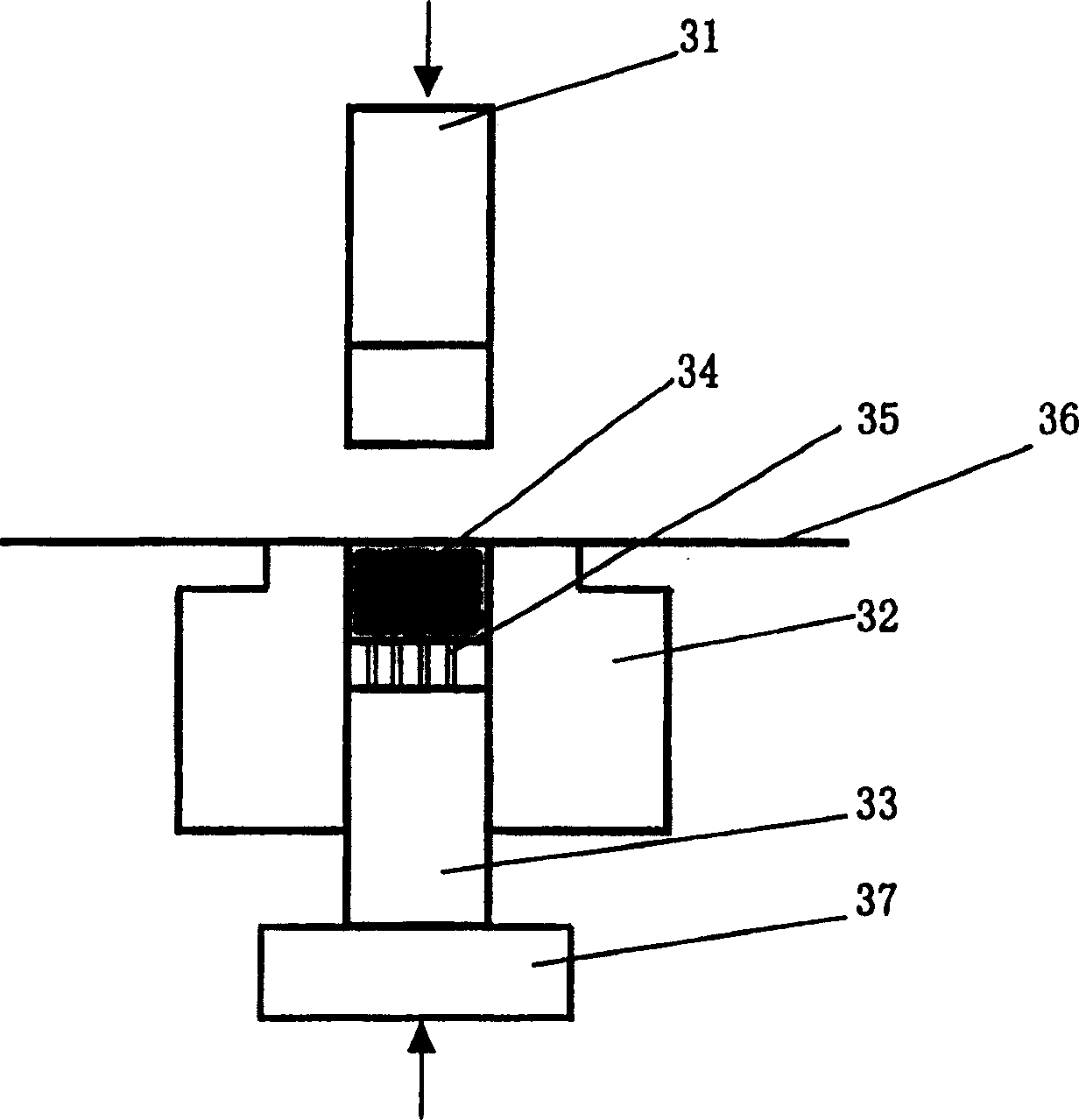

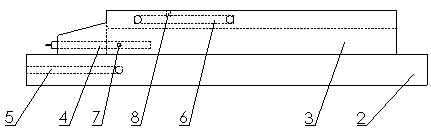

A molding device for optical glass and its production process

ActiveCN103922565BImprove molding qualityRapid cooling and solidificationGlass pressing apparatusOptical glassThermocouple

The present invention relates to a forming device of optical glass and its production technology, which belong to the technical field of optical glass melting. The forming device of optical glass and its production technology solve the problems of poor forming quality, easy generation of surface stripe and crystallization of a strip material of the optical glass with large aperture, the forming device comprises a bottom die, a top die, a heating device, a bottom die cooling channel, a top die cooling channel, a first temperature thermocouple and a second temperature thermocouple; the top die is in an U-shaped groove, the bottom die is a plane base plate, the top die and the bottom die are arranged together to form a glass forming cavity; the top die cooling channel and the second temperature thermocouple are arranged on the upper wall of the top die; the bottom die cooling channel is arranged in the plate of the bottom die; and the heating device and the first temperature thermocouple are arranged in the U-shaped groove at the lower part of the top die. The forming device solves the problems that the forming of the strip material of the optical glass is poor, the thickness is inconsistent, surface stripe and crystallization are easily generated, and has obvious effect for lanthanide optical glass with low viscosity and easy crystallization.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Developing apparatus, cartridge and image forming apparatus

ActiveUS20050180784A1Frictional resistanceReduce frictional resistanceElectrographic process apparatusElectrically conductiveMechanical engineering

A developing apparatus having a developer carrying member for carrying a developer thereon and developing an electrostatic image formed on an image bearing member with a developer, a developer layer thickness regulating member provided in contact with the developer carrying member for regulating the thickness of the layer of the developer carried on the developer carrying member, and an electrically conductive particle provided in the portion of contact between the developer carrying member and the developer layer thickness regulating member, in a state in which the developer does not exist between the developer carrying member and the developer layer thickness regulating member.

Owner:CANON KK

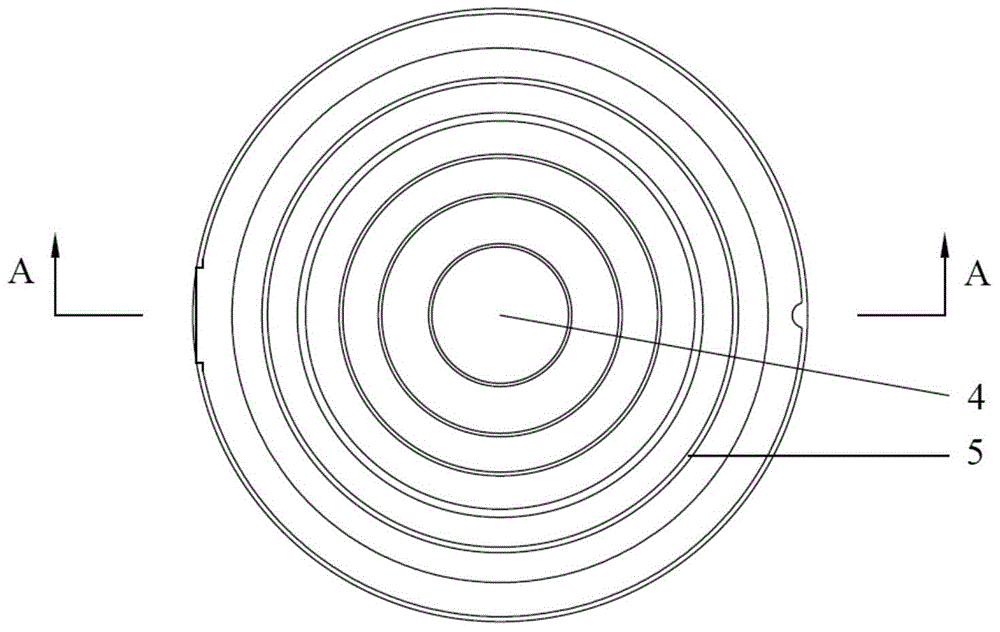

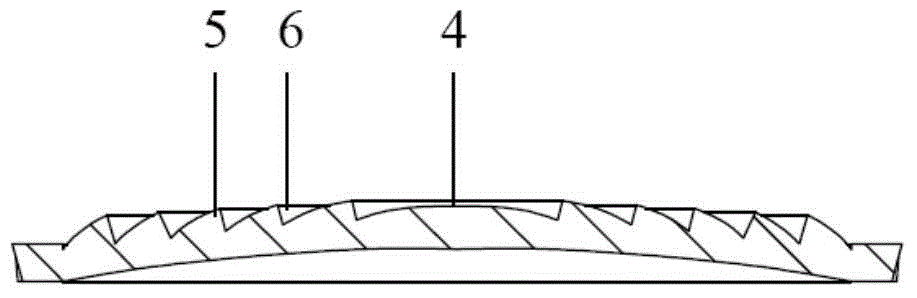

Fresnel lens

InactiveCN105570833APrevent yellow circleAvoid streaksPoint-like light sourceLight fasteningsFresnel lensEngineering

The invention provides a fresnel lens. The fresnel lens comprises an incident face and an emergent face opposite to the incident face. The emergent face is provided with an arc-shaped protruding face. Multiple circles of protruding ridges are arranged outside the arc-shaped protruding face in an enclosure manner. The protruding ridges extend in the direction of a center shaft of the arc-shaped protruding face. The wall faces of the sides, opposite to the arc-shaped protruding face, of the protruding ridges are adjusting faces. The included angle of the intersecting positions of the adjusting faces and the center shaft of the arc-shaped protruding face ranges from 20 degrees to 30 degrees. According to the fresnel lens, the light-emitting angle, ranging from 120 degrees to 140 degrees, of an LED chip can be controlled effectively to obtain even small-angle light applicable angle ranging from 23 degrees to 40 degrees, and the accent lighting design requirement is met.

Owner:FOSHAN NANHAI SHENGLI LIGHTING

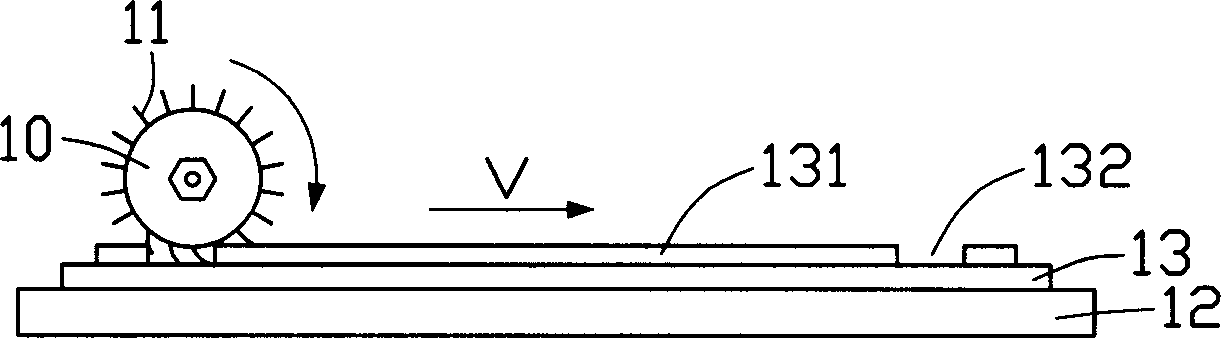

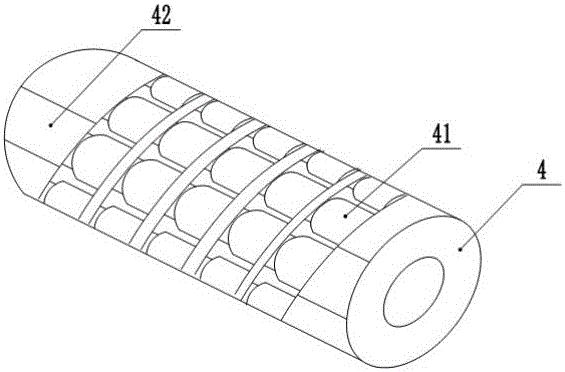

Polishing mechanism used for shaft

ActiveCN106826480AAvoid streaksPolished evenlyBelt grinding machinesGrinding work supportsEngineeringMachine tool

The invention belongs to the field of machine tools for grinding or polishing and specifically discloses a polishing mechanism used for a shaft. The polishing mechanism comprises a clamping device, a rack, abrasive belts, a transmission roller, a first drive roller and a second drive roller. The transmission roller is fixedly connected to the rack, the transmission roller is provided with a spiral strip-shaped slot along the roller surface, and the strip-shaped slot is internally provided with a plurality of rollers which are uniformly distributed along the spiral track; and the abrasive belts are arranged along the spiral strip-shaped slot in the transmission roller and matched with the rollers, one end, stretching out of the transmission roller, of each abrasive belt is wound on the first drive roller, and the other end of the corresponding abrasive belt is wound on the second drive roller. According to the polishing mechanism used for the shaft, through specific structures of the spiral strip-shaped slot in the transmission roller and the rollers, inclined arrangement and continuous transmission of the abrasive belts are achieved, through inclined polishing of the abrasive belts, strip-shaped polishing scratches are avoided, polishing is more uniform, and the polishing effect is better; and through intermittent reverse polishing, oneness of polishing textures on the surface of the shaft is avoided, and polishing is more uniform.

Owner:重庆普莱斯恩机械制造有限公司

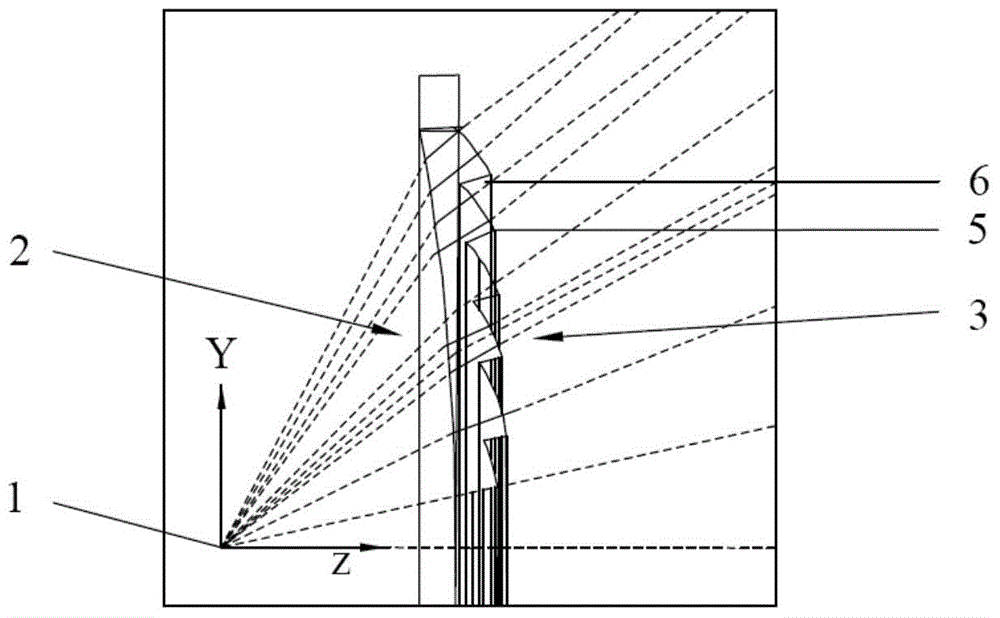

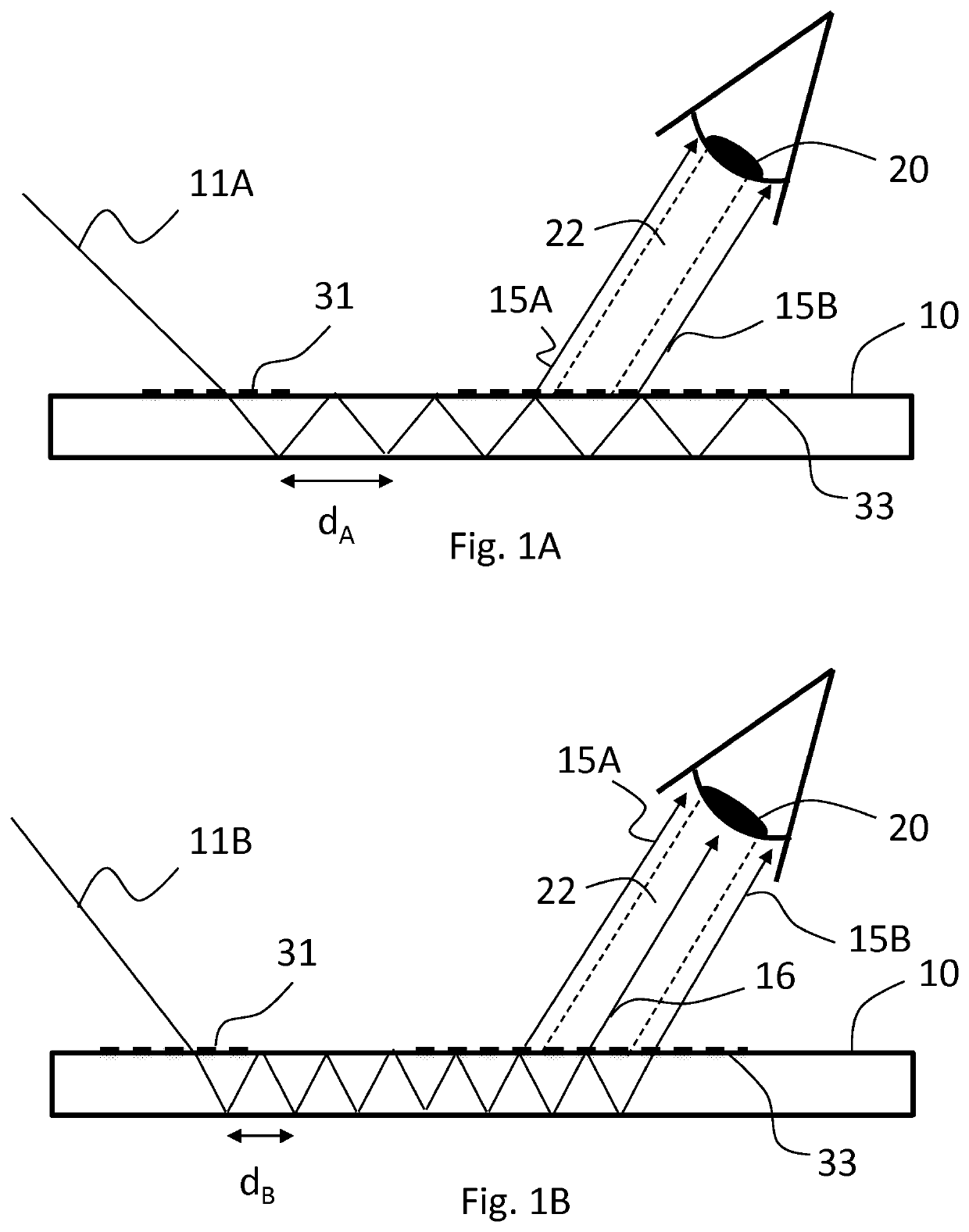

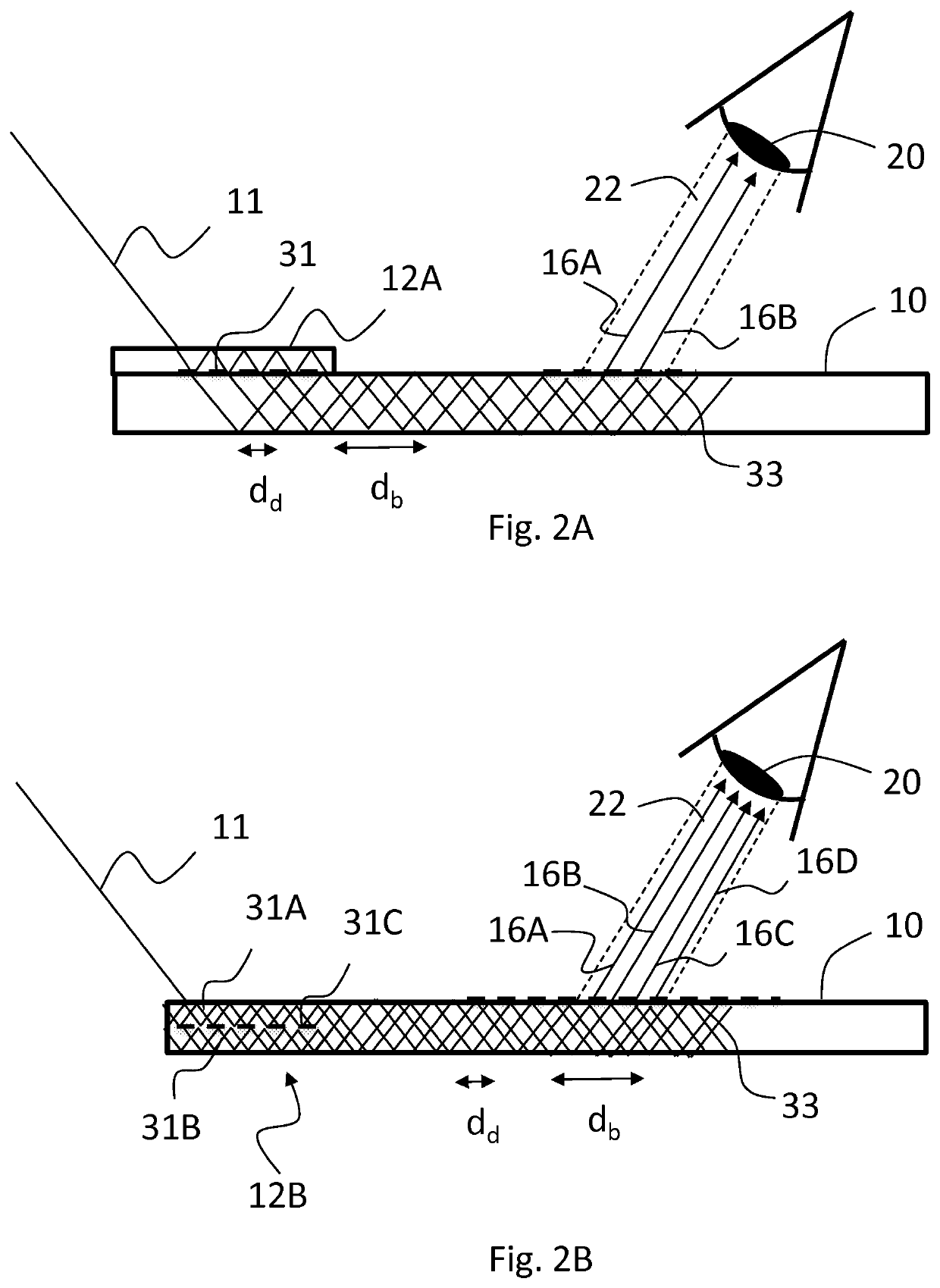

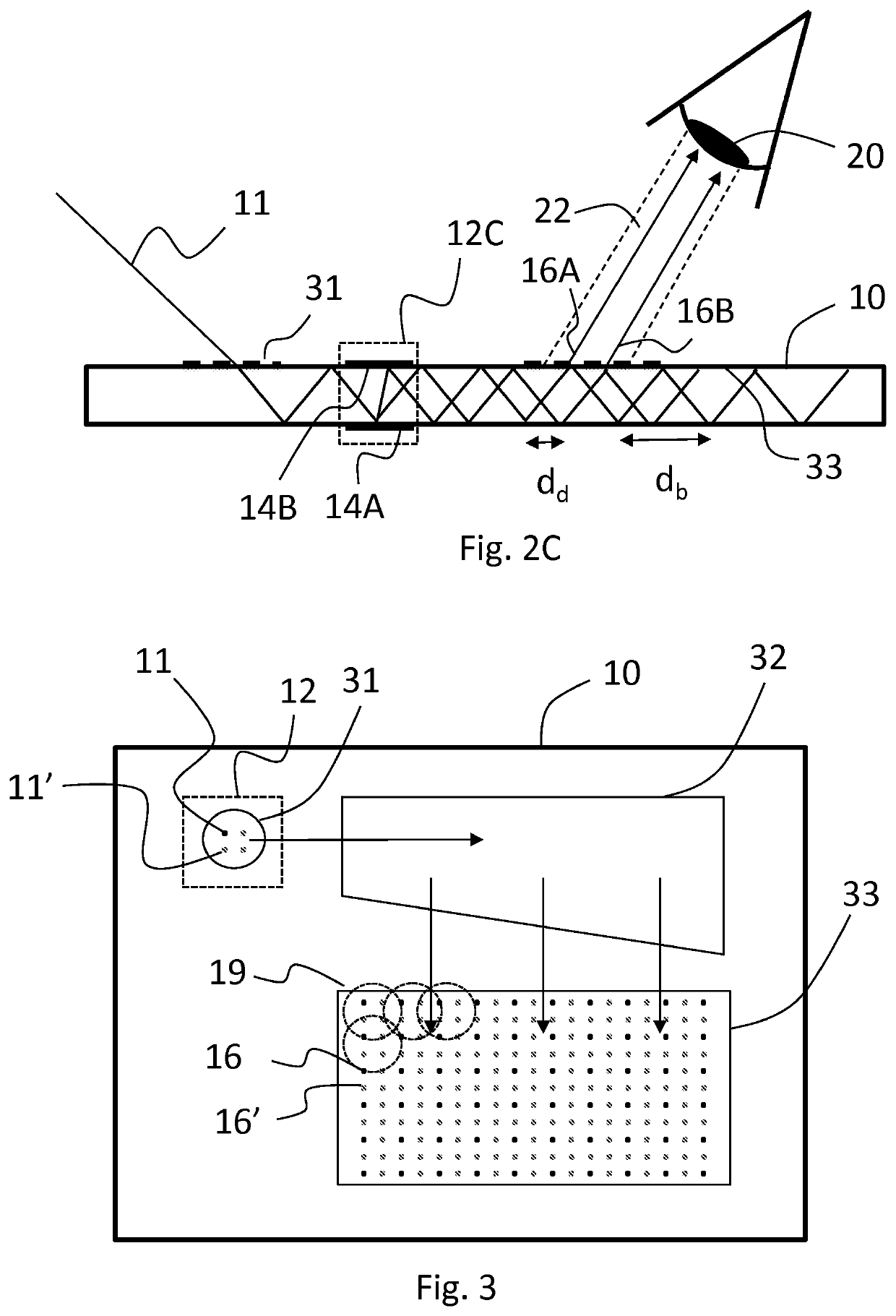

Diffractive waveguide element and diffractive waveguide display

PendingUS20200333615A1Diminishes stripingPrevents stripingMechanical apparatusDiffraction gratingsEngineeringDiffraction optics

A diffractive waveguide element for a personal display device includes a display waveguide extending in a waveguide plane, an in-coupling diffractive optical element arranged onto or into the display waveguide for diffractively coupling light rays into the display waveguide, and an out-coupling diffractive optical element arranged onto or into the display waveguide for coupling the diffractively coupled light rays out of the display waveguide. In addition, there is provided a ray multiplier element optically upstream of the out-coupling diffractive optical element, the ray multiplier element being capable of splitting a light ray incoming to the in-coupling grating into a plurality of parallel rays spatially displaced in the waveguide plane before they enter the out-coupling diffractive optical element. A waveguide display device is also provided.

Owner:DISPELIX OY

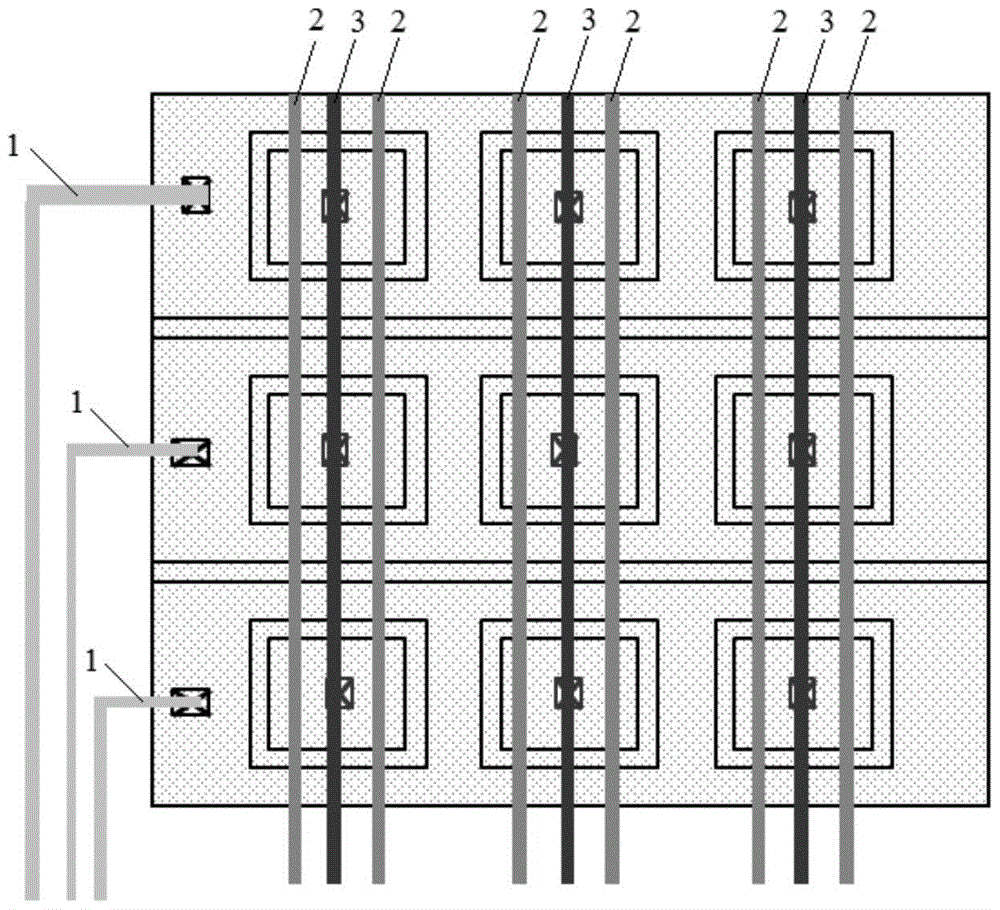

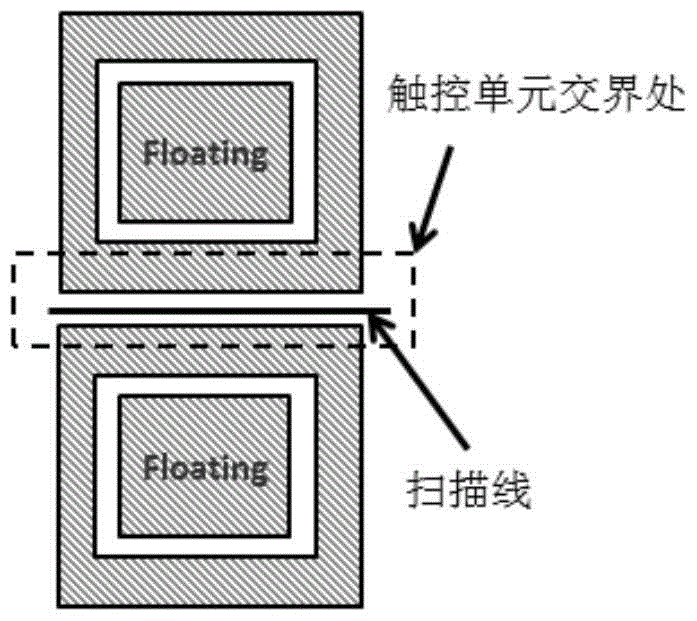

Mutual-capacitance embedded-type touch screen

ActiveCN105677086AAvoid streaksNon-linear opticsInput/output processes for data processingScan lineTouchscreen

A mutual-capacitance embedded-type touch screen is provided. The embedded-type touch screen comprises a touch control unit array formed by a plurality of touch control units. The mutual-capacitance embedded-type touch screen is characterized in that each touch control unit is formed by a pixel electrode layer, a first dielectric layer, a second dielectric layer, a common electrode layer, a third dielectric layer and a thin film transistor array which are stacked in order. The common electrode layer of each touch control unit is divided into a driving area, a first suspension area, a second suspension area, a first shielding area and a second shielding area, the first shielding area and the second shielding area are respectively formed at two sides, which are back to each other, of the driving area, the first suspension area is formed at one side, of the first shielding area, being far from the driving area, and the second suspension area is formed at one side, of the second shielding area, being far from the driving area. With respect to the mutual-capacitance embedded-type touch screen, the capacitance value of a scan line on the juncture of adjacent touch control units is approximate to that of a scan line which is not positioned on the juncture, and the case that obvious stripes occur on the juncture of adjacent touch control units can be effectively avoided.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com