Patents

Literature

82results about How to "Rapid cooling and solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

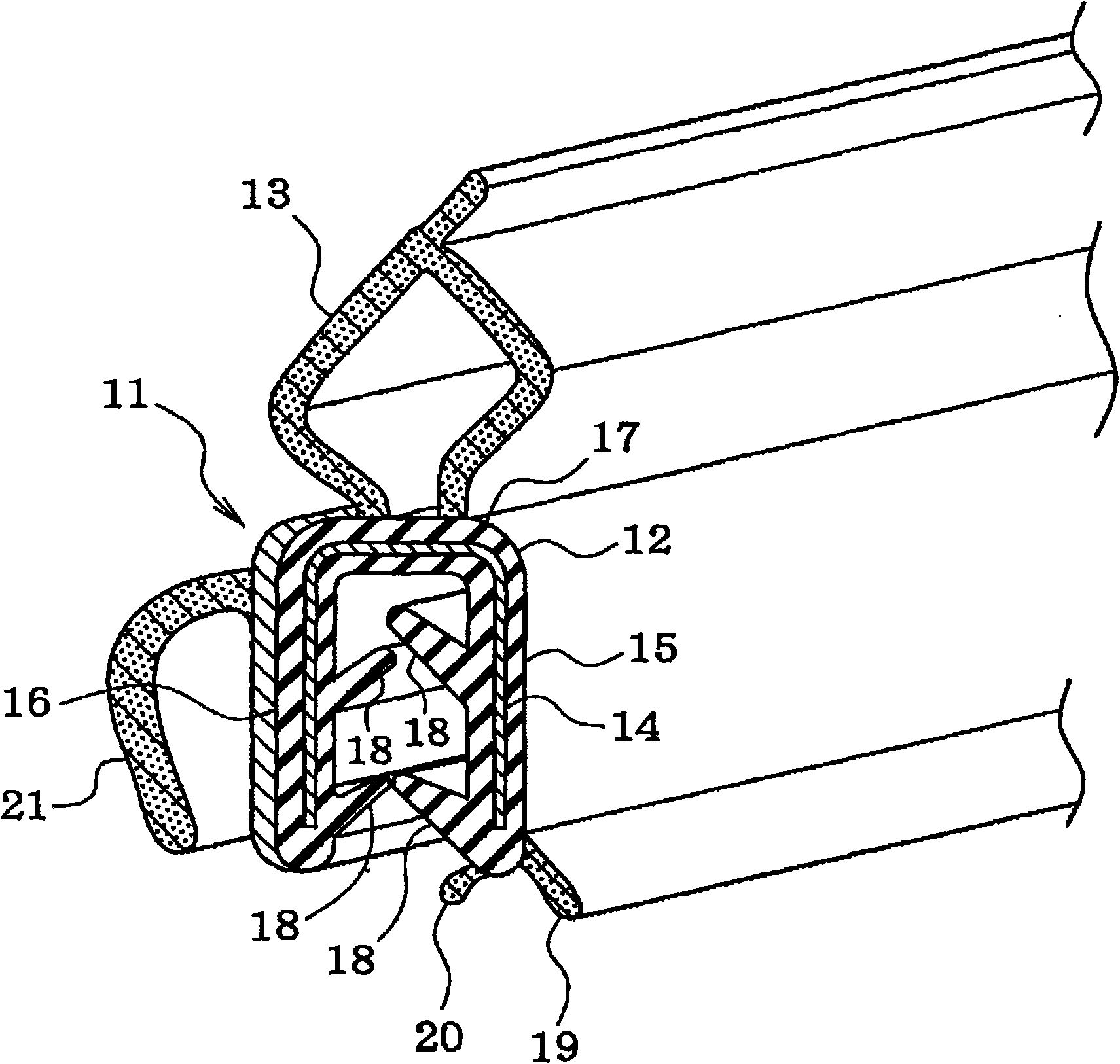

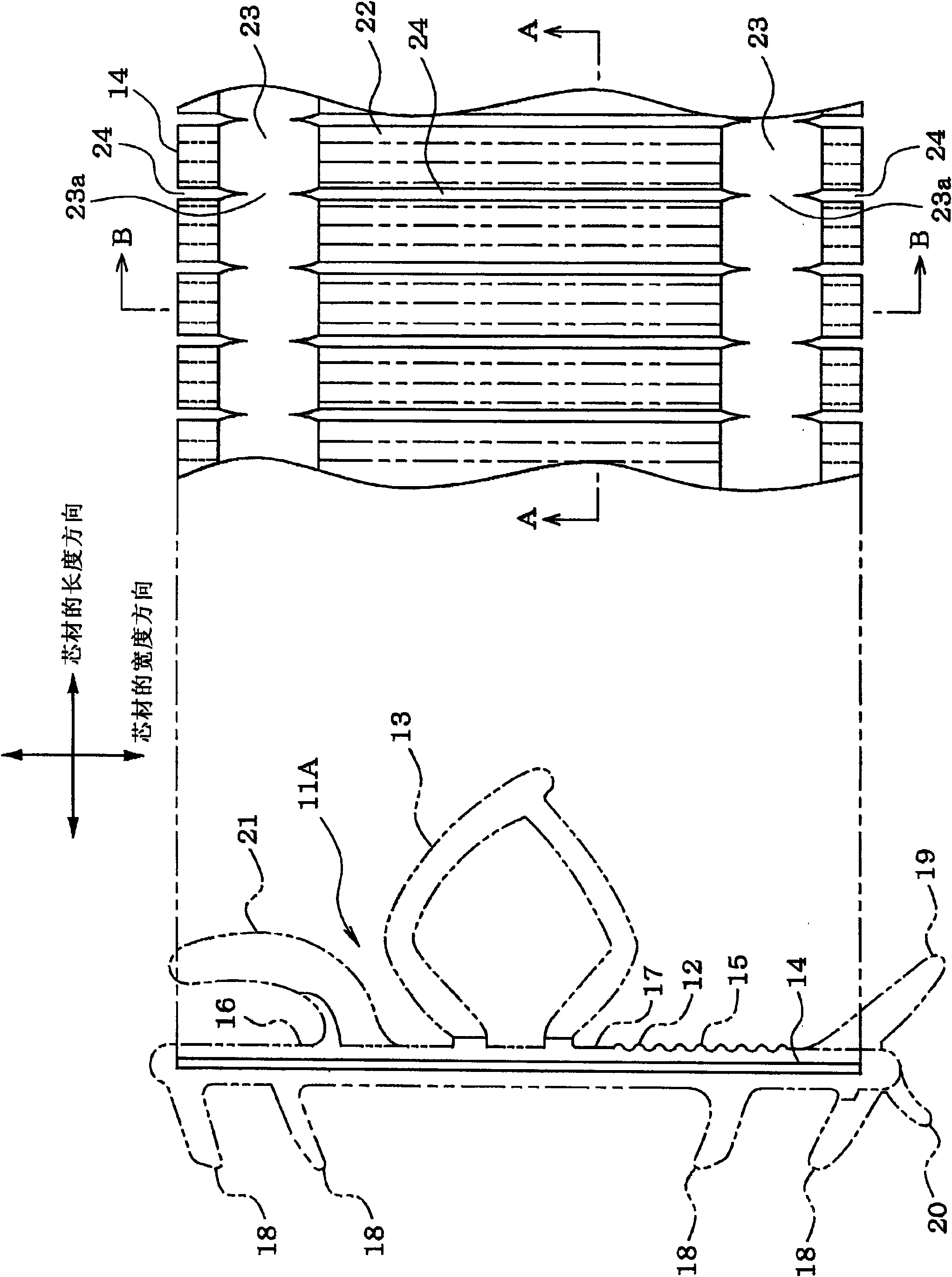

Method of manufacturing core, method of manufacturing trim, and core manufactured by the same

ActiveCN101837764AImprove rigidityGuaranteed rigidityEngine sealsVehicle sealing arrangementsMechanical engineering

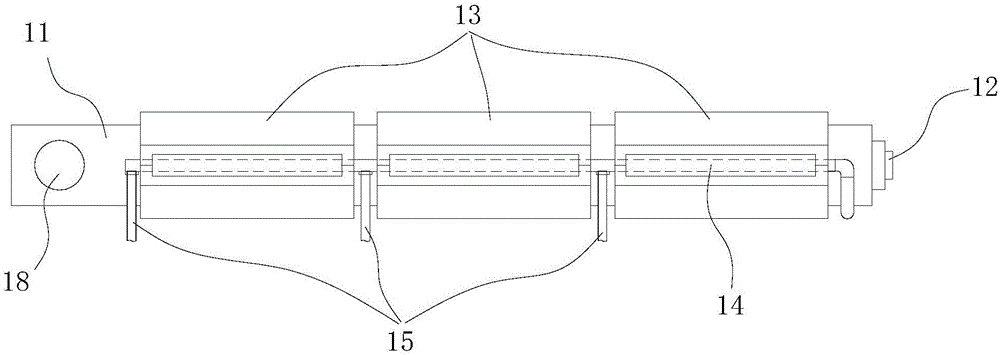

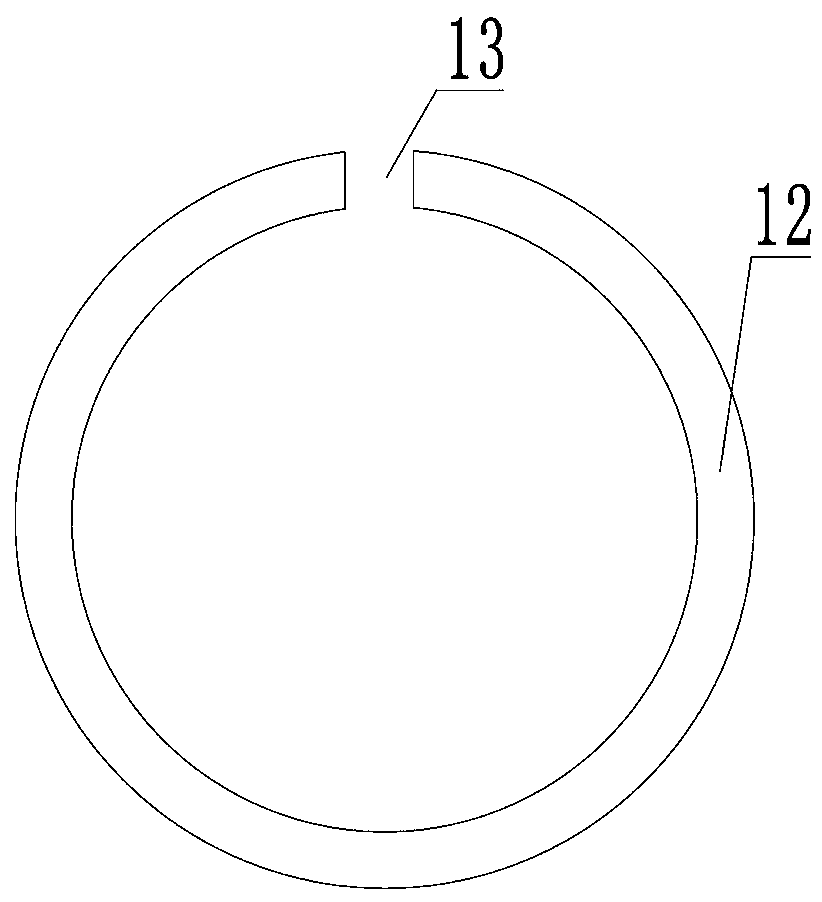

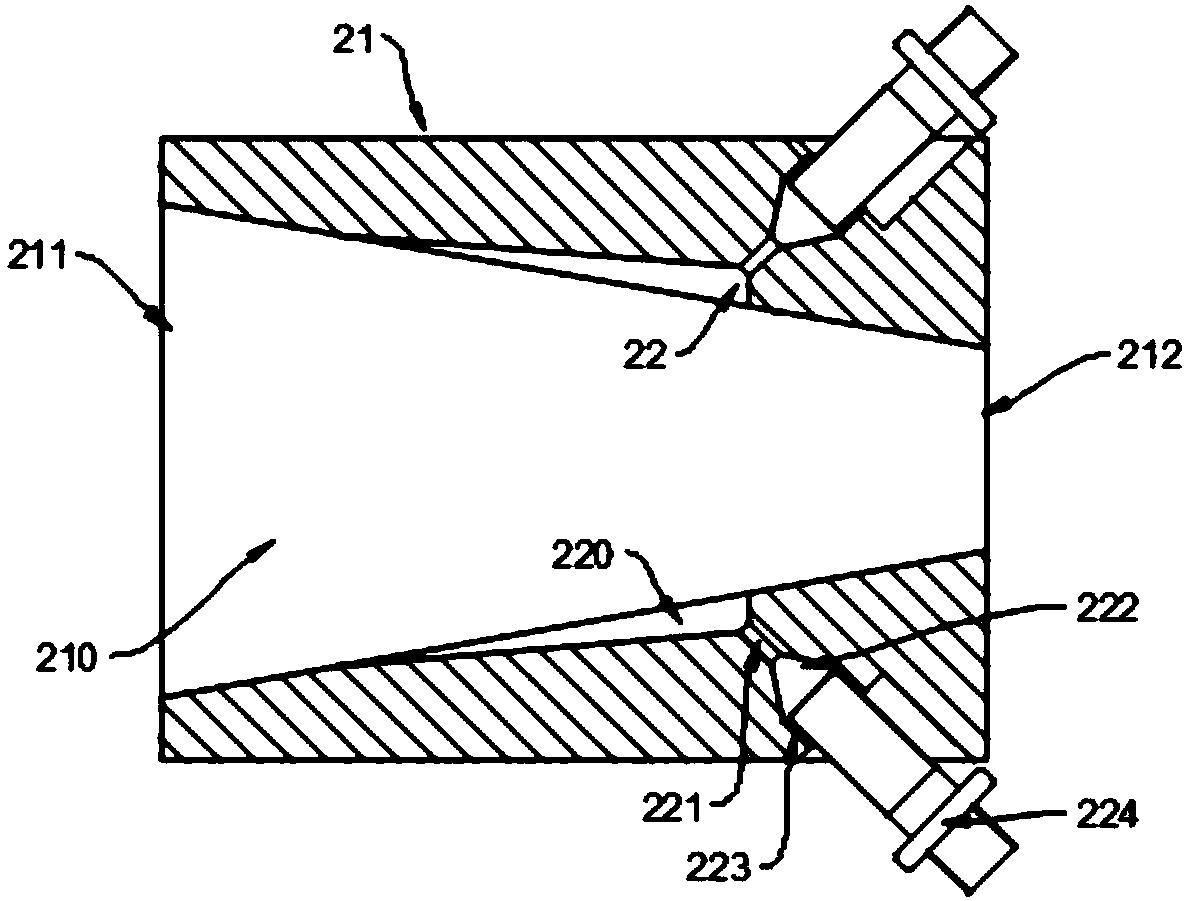

The present invention may make it possible to efficiently form reinforcing deformed portions in a core buried in the trim, and may make it possible to sufficiently secure the rigidity of the core, the rigidity based on reinforcing deformed portions. The method of manufacturing an elongated core which is buried in an elongated trim. A longitudinal direction of the elongated core is a first direction and a width direction of the elongated core is a second direction, the method comprises: the slit forming being performed by supplying an elongated strip-shaped metal plate to between a pair of slitter rollers engaged with each other, forming slits, which extend in the second direction in a state in which the slits are not formed to a portion of the strip-shaped metal plate in the second direction, at predetermined intervals in the first direction so as to form the core pieces between the adjacent slits; and the rolling being performed by supplying the strip-shaped metal plate having the slits formed therein to between a pair of rolling rollers, rolling the portion of the strip-shaped metal plate in which the slits are not formed in the second direction to form a rolled portion extending in the first direction, and expanding the slits in the first direction to form the spaces, and supplying the primary core to between a pair of deformed portion forming rollers engaged with each other such that reinforcing deformed portions extending in the second direction are repetitively formed in the first direction, wherein the convex and concave deformed portions are alternately formed in the first direction, and wherein the convex and concave deformed portions are formed so as to be continuously S-shaped in a cross section along the first direction.

Owner:TOKAI KOGYO CO LTD

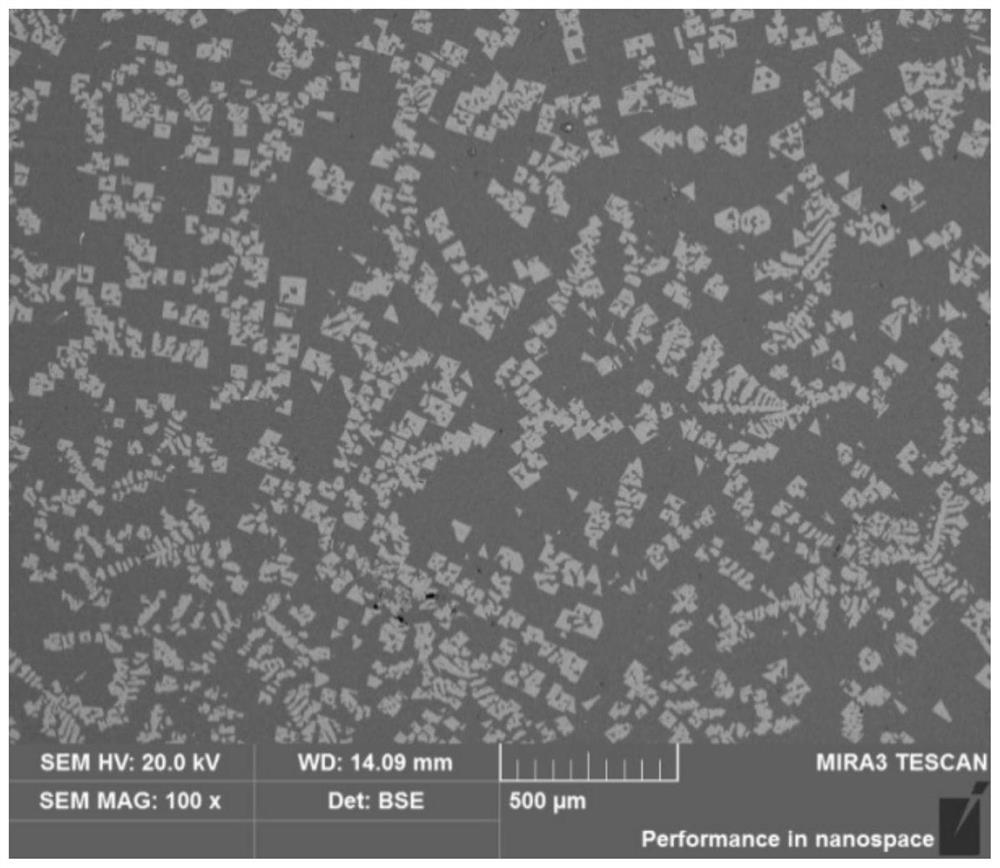

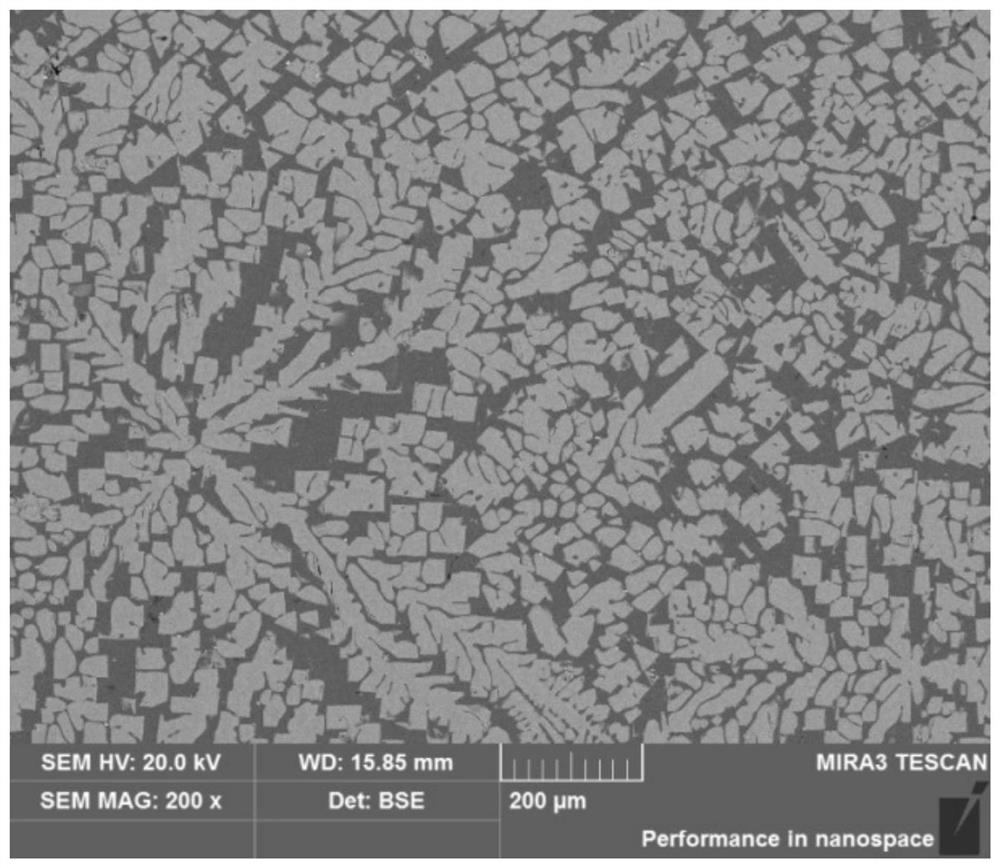

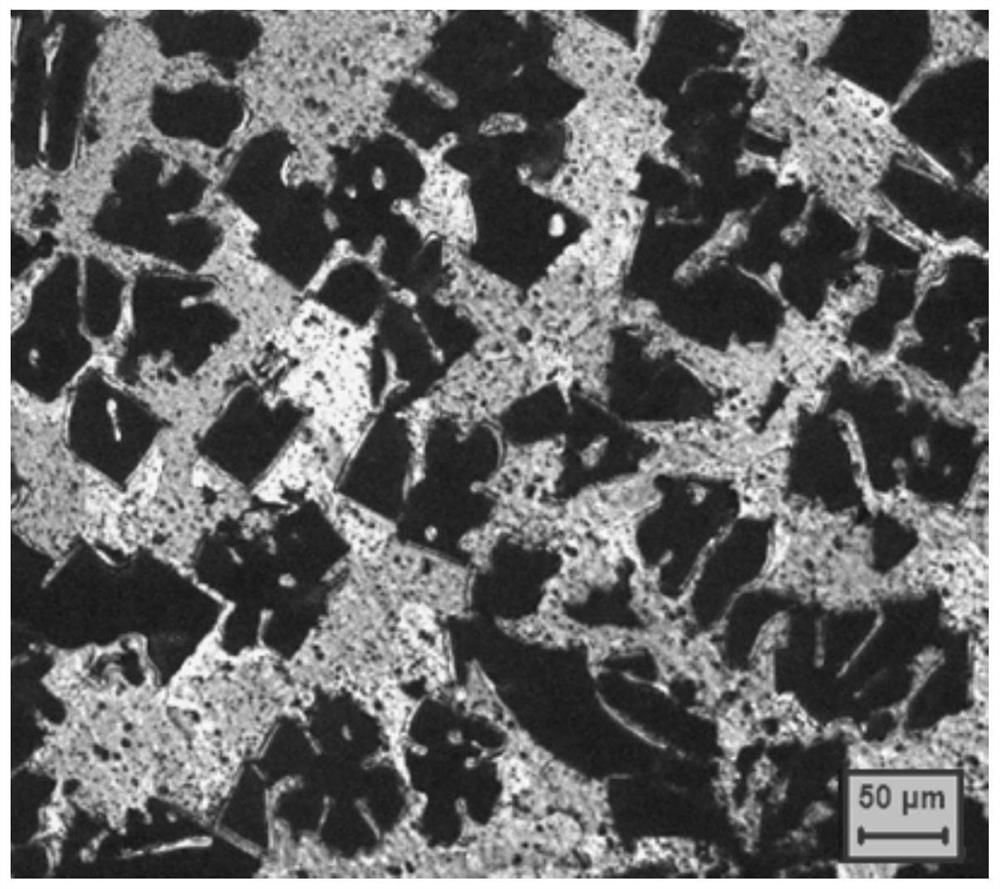

Method for producing shot blasting machine blades by composite shell investment casting using chilled surface coating

ActiveCN102294435AGrain refinementImprove mechanical propertiesFoundry mouldsFoundry coresWaxSurface layer

The invention, which belongs to the metal wear resistant part and casting technology field, more particularly relates to a method for casting and producing a shot blasting machine blade based on firing mold on a composite shell with utilization of chilled surface layer paint. The method comprises the following steps: manufacture on a wax mould; manufacture on a pouring gate mould; renovation of the wax mould; assembly and welding of the wax mould; dewaxing; and roasting. The method is characterized in that a step of coating paint on a composite shell is added between the step of assembly and welding of the wax mould and the step of dewaxing. The added step comprises particularly the following steps: coating silica solution surface layer paint on surface layer type shell of the composite shell and coating water glass reinforcing layer paint on a back layer shell. According to the shot blasting machine blade produced by the method, a mechanical property of the blade is improved, so thatservice life of the blade is improved; meanwhile, an amorphous glass phase is formed between the shell and the casting surface, so that it is convenient for the amorphous glass phase to be shed from the casting surface during cleaning sand.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

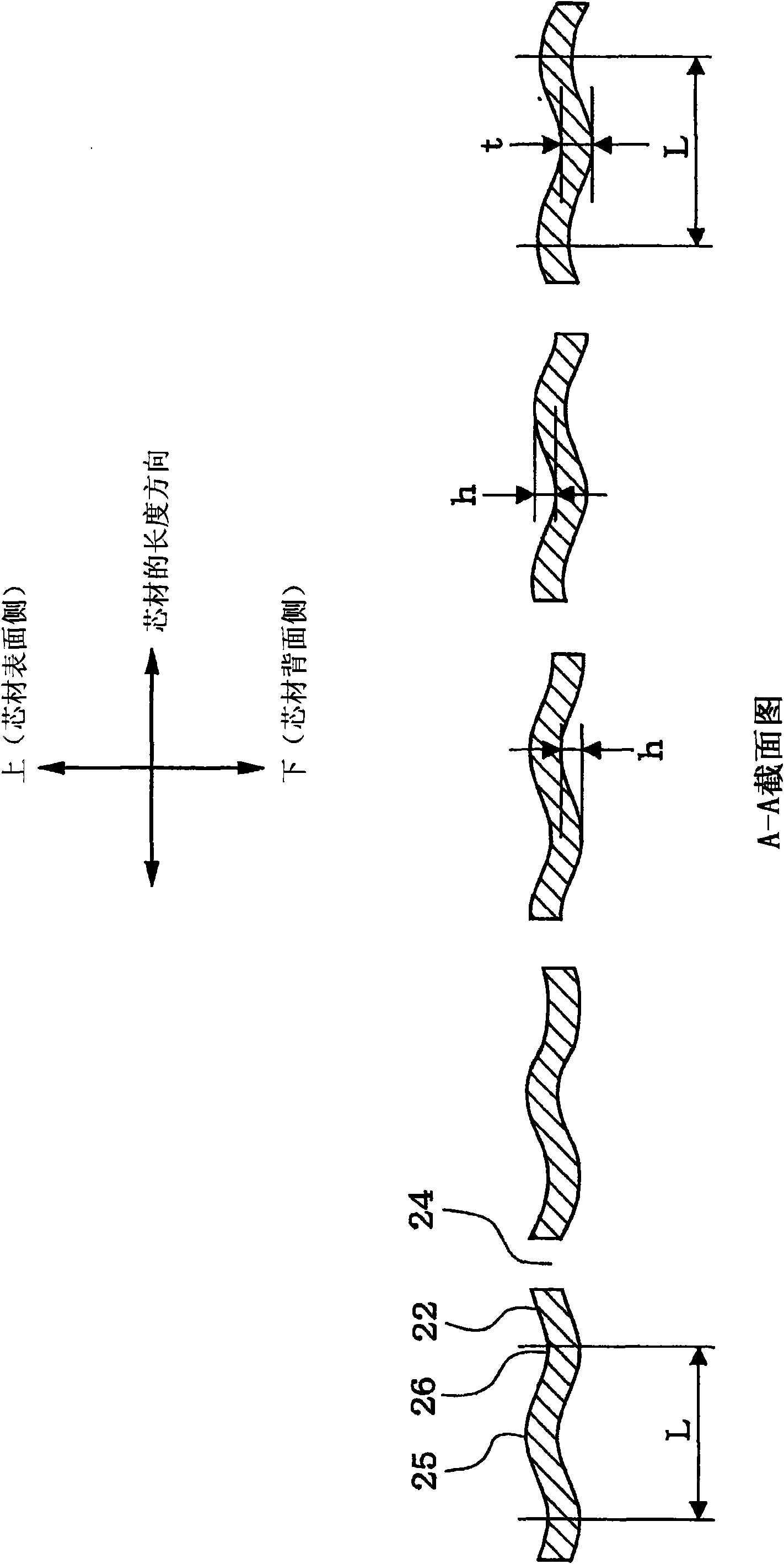

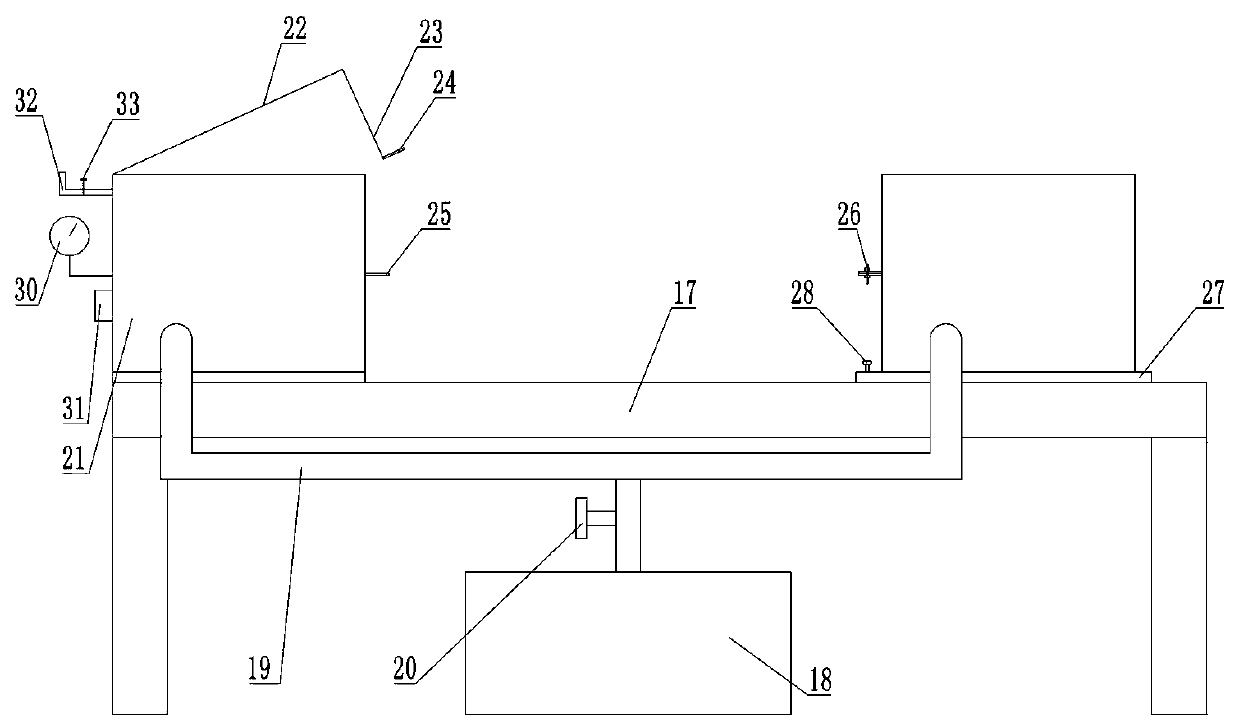

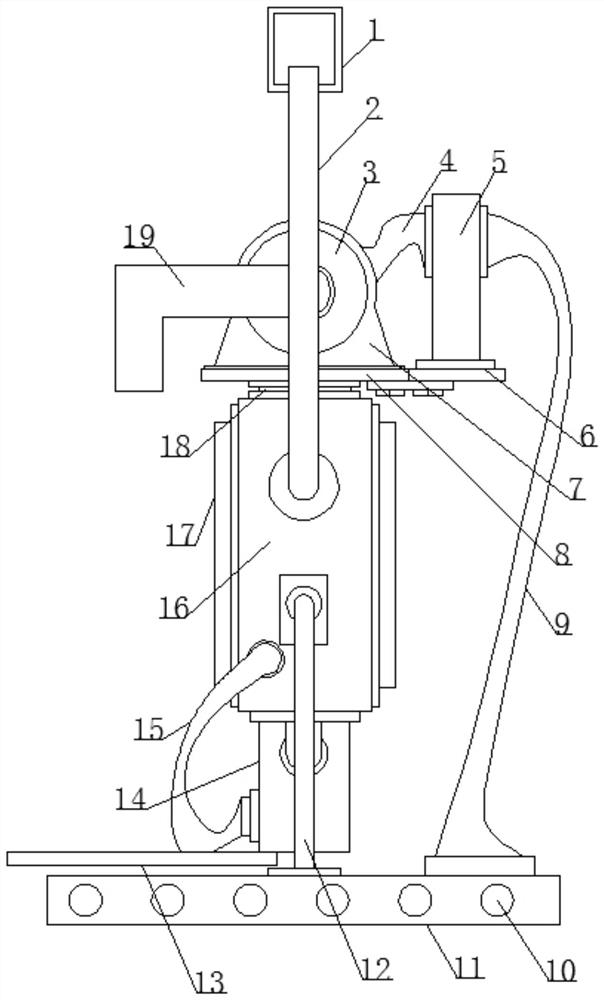

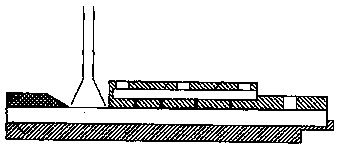

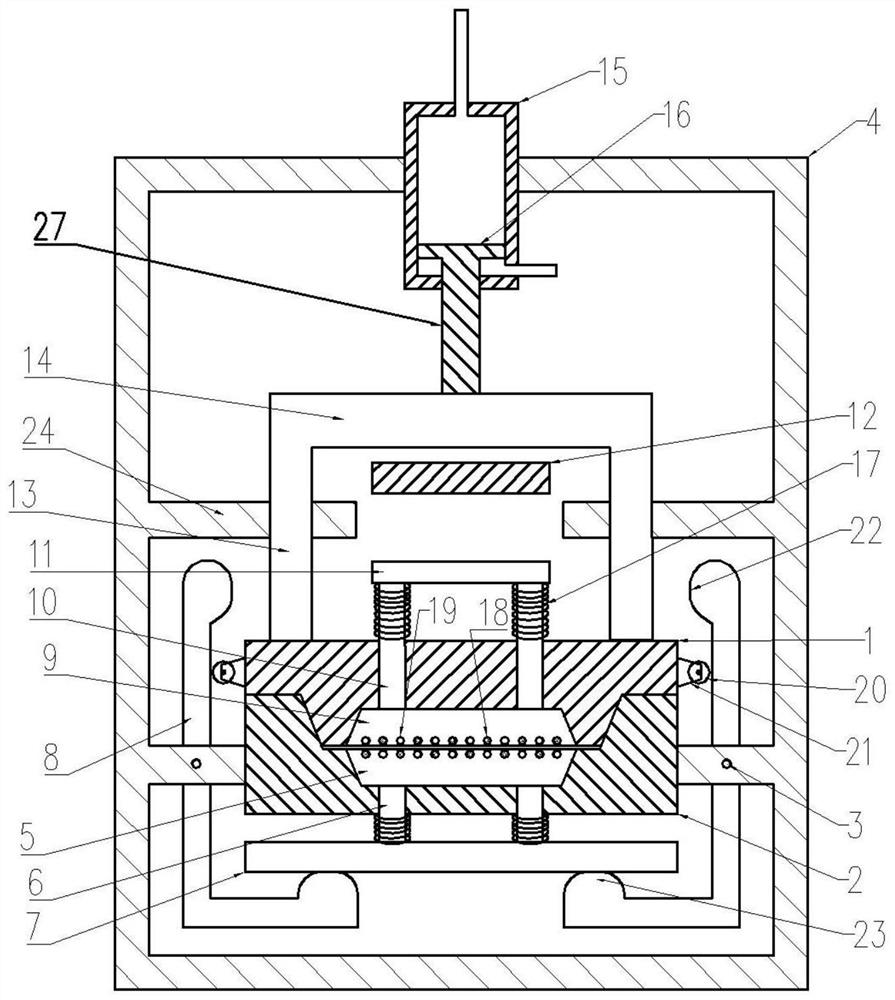

Rapid immersion type metal solidification heat transfer test device and application and application method thereof

InactiveCN106645278ASimple methodSimple test equipmentMaterial heat developmentDirect testGas cylinder

The invention discloses a rapid immersion type metal solidification heat transfer test device and an application method of the device. The test device comprises a mechanical system, a data acquisition system and an atmosphere control system; the mechanical system comprises an induction furnace heated electrically, and an immersion type copper mould controlled by a motor; the data acquisition system comprises a thermocouple located in the copper mould and an external data acquisition card and computer; the atmosphere control system comprises a protective gas hood for accommodating the induction furnace and the copper mould, gas inlet and outlet pipes and a gas cylinder; the mechanical system and key parts of the data acquisition system are both arranged in an atmosphere protection room of the atmosphere control system. The test equipment disclosed by the invention is simple and easy in method, high in accuracy and wide in application range and can be used for carrying out heat transfer testing during a metal rapid solidification process in a laboratory scale, thereby replacing direct testing in industrial production, not affecting the normal production, and further being small in consumption and low in test cost.

Owner:CENT SOUTH UNIV

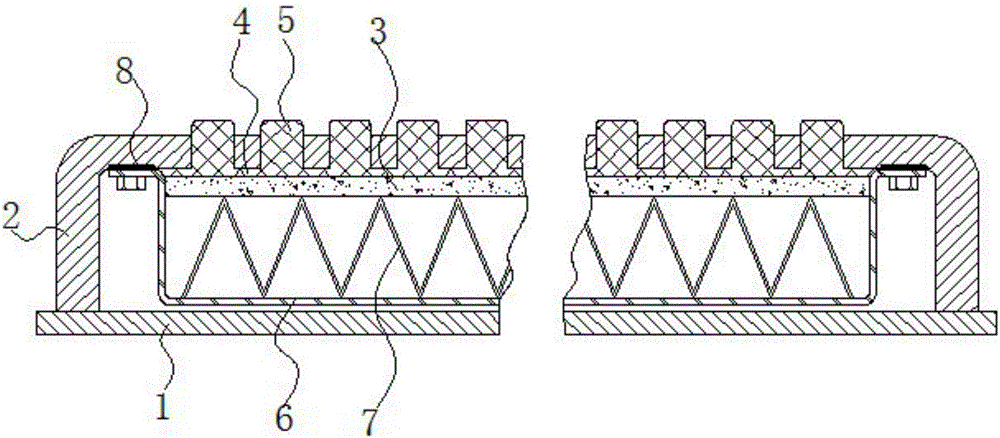

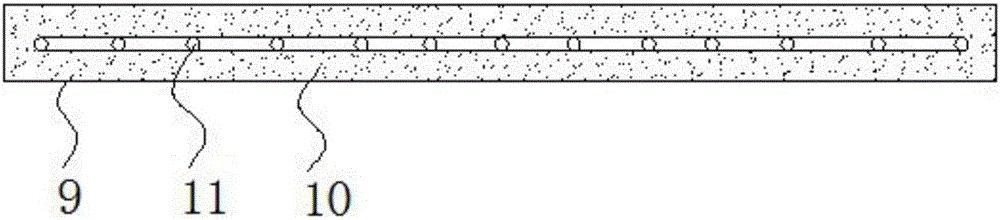

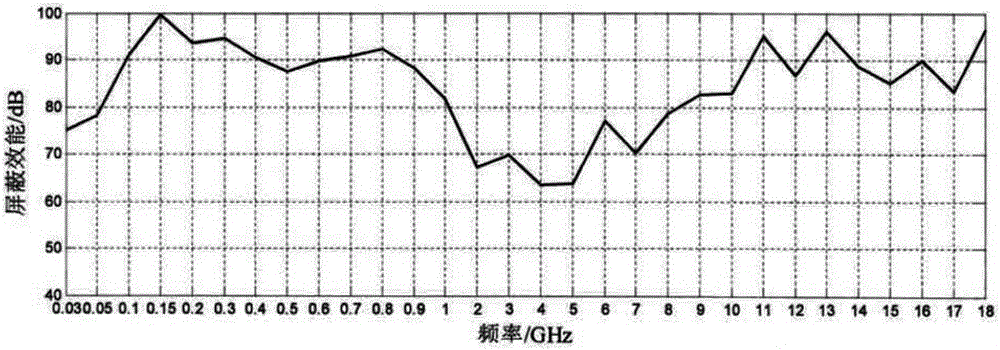

Electromagnetic shielding material preparation method, electromagnetic shielding material product and electromagnetic shielding key terminal

InactiveCN105694470ARapid cooling and solidificationImprove toughnessMagnetic/electric field screeningEmergency protective devicesMaterials preparationFree cooling

The invention discloses a method for preparing an electromagnetic shielding material, which comprises the following steps: 1) preparing the following components in parts by weight: 70-80 parts by weight of silicon rubber; 20-30 parts by polytetrafluoroethylene; 2-3 parts by weight of nano-scale graphite powder; Curing agent ~ 2; heat stabilizer 1 ~ 2; 2) forming a composite rubber mixture uniformly infiltrated with nano-scale graphite particles in a molten state; 3) injecting the composite rubber mixture in step 2) into the mold cavity of the forming mold, and Completely wrap the wire mesh inside; 4) In a negative pressure environment, vibrate the forming mold through a vibrator to remove the internal air bubbles; 5) High pressure and low temperature, rapid cooling and solidification, to obtain a semi-finished electromagnetic shielding material; 6 ) heat and melt the semi-finished electromagnetic shielding material again, and cool and solidify naturally at high pressure and normal temperature to obtain the electromagnetic shielding material. The invention also discloses the electromagnetic shielding material prepared by the method, the corresponding electromagnetic shielding gasket, and the electromagnetic shielding button terminal using the electromagnetic shielding gasket.

Owner:莫镇威

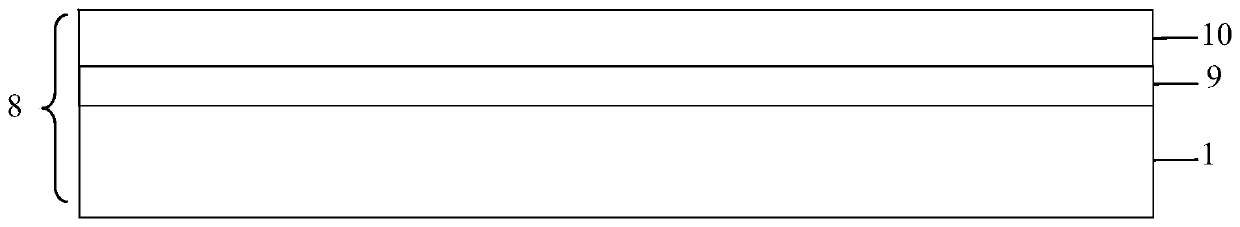

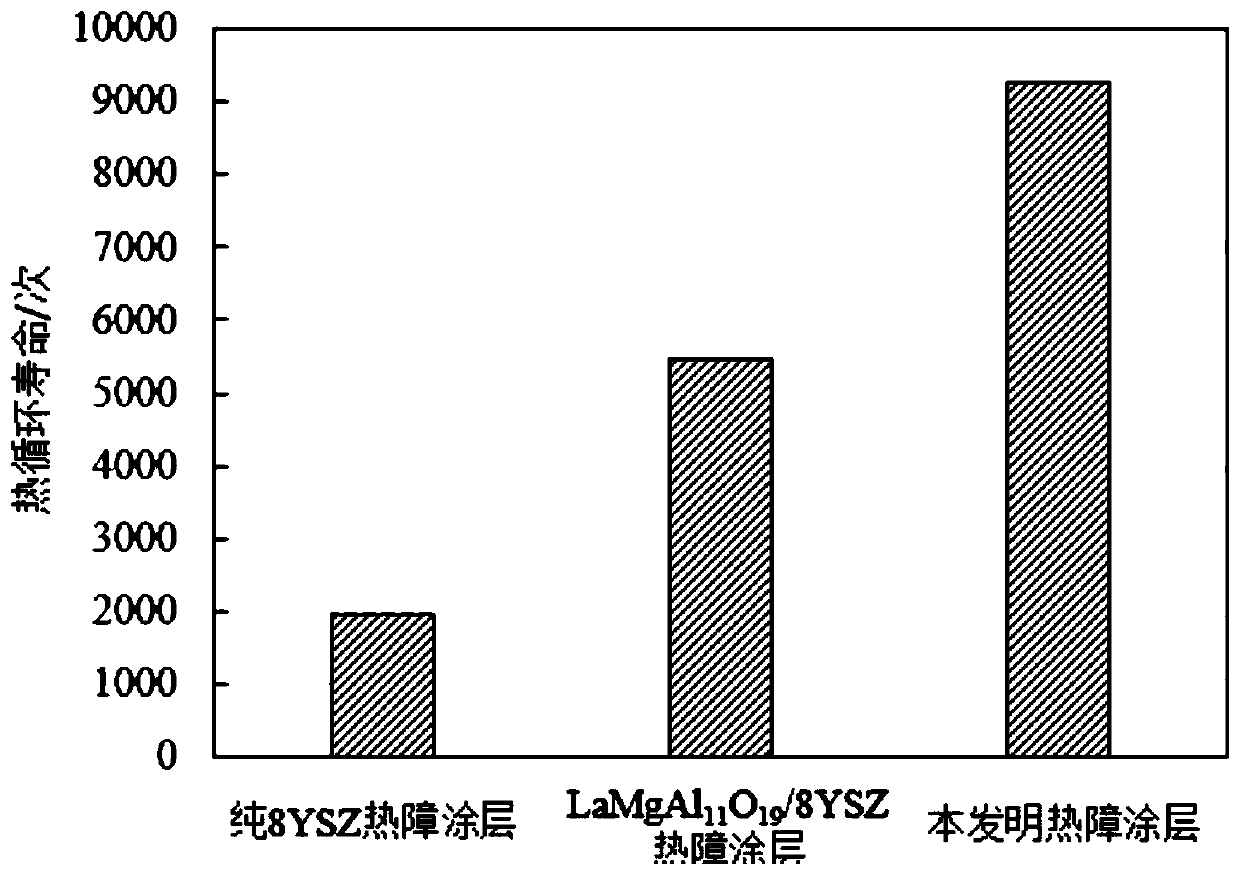

Functional gradient thermal barrier coating and preparation method thereof

PendingCN110205626AHigh crystallinityThickness is easy to controlMetallic material coating processesThermal sprayingAlloy

The invention discloses a functional gradient thermal barrier coating and a preparation method thereof, specifically, a bonding layer and a ceramic layer with components and structures continuously changed are prepared on a part matrix alloy by utilizing a laser near-net forming technology. The thermal barrier coating prepared by the method is not affected by the constraint of a mold, a fixture and a tool in the traditional thermal spraying processing process as well as the size and the geometrical shape complexity degree of parts; and meanwhile, the prepared thermal barrier coating has a columnar grain orientation structure, the coating crystallinity is high, the thickness is controllable, and the bonding strength between the coating and a substrate exceeds 350 MPa. The heat cycle life ofthe functional gradient thermal barrier coating is far higher than that of a traditional pure YSZ and double-ceramic-layer thermal barrier coating, and by using the thermal barrier coating, the inletgas temperature of a gas turbine and the service life of a heat channel part can be effectively prolonged.

Owner:XIAN THERMAL POWER RES INST CO LTD

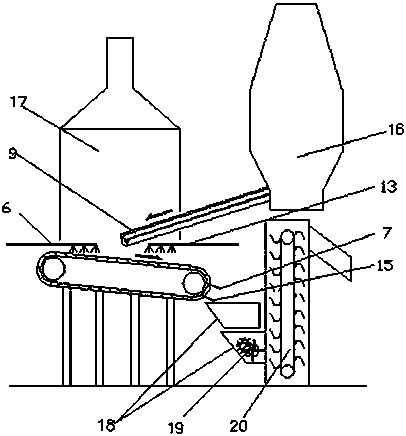

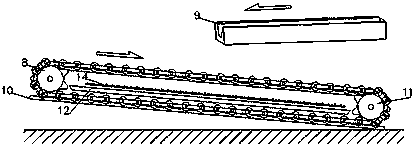

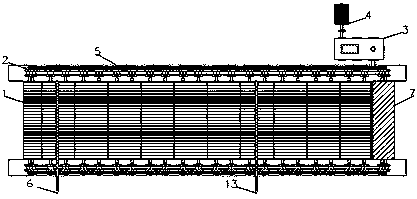

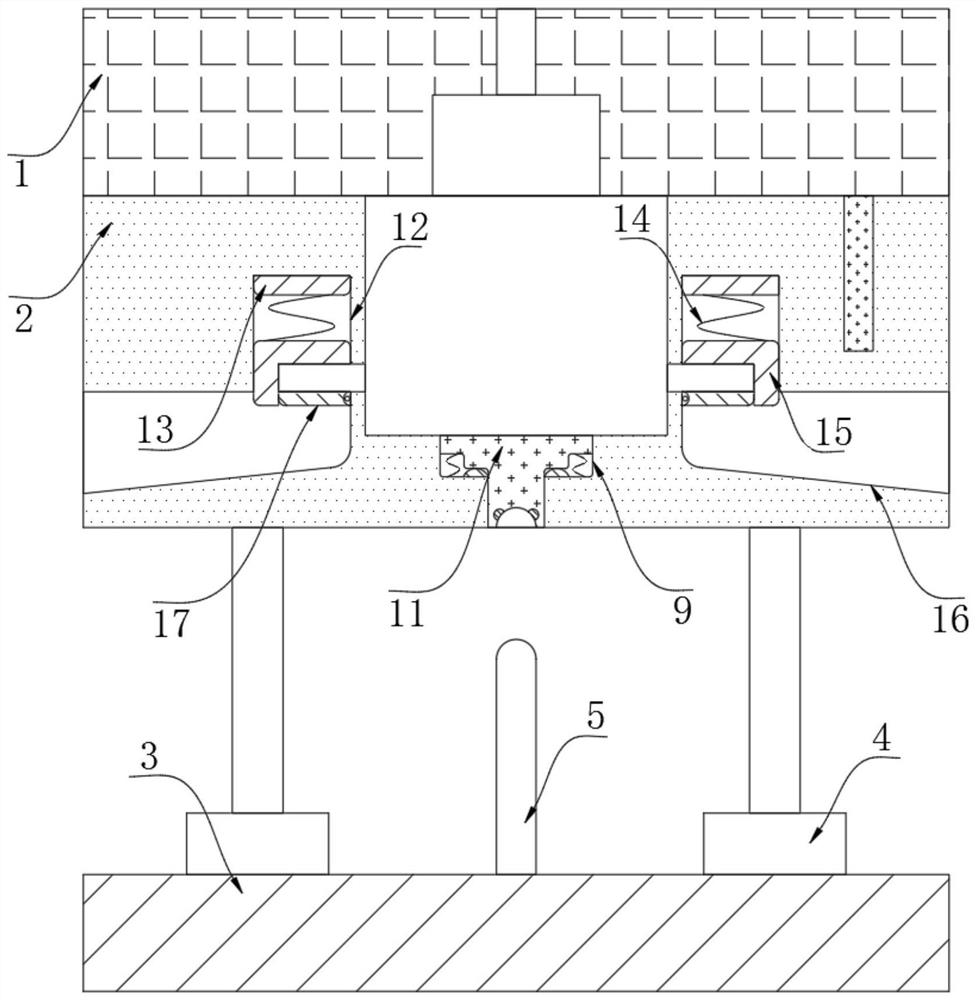

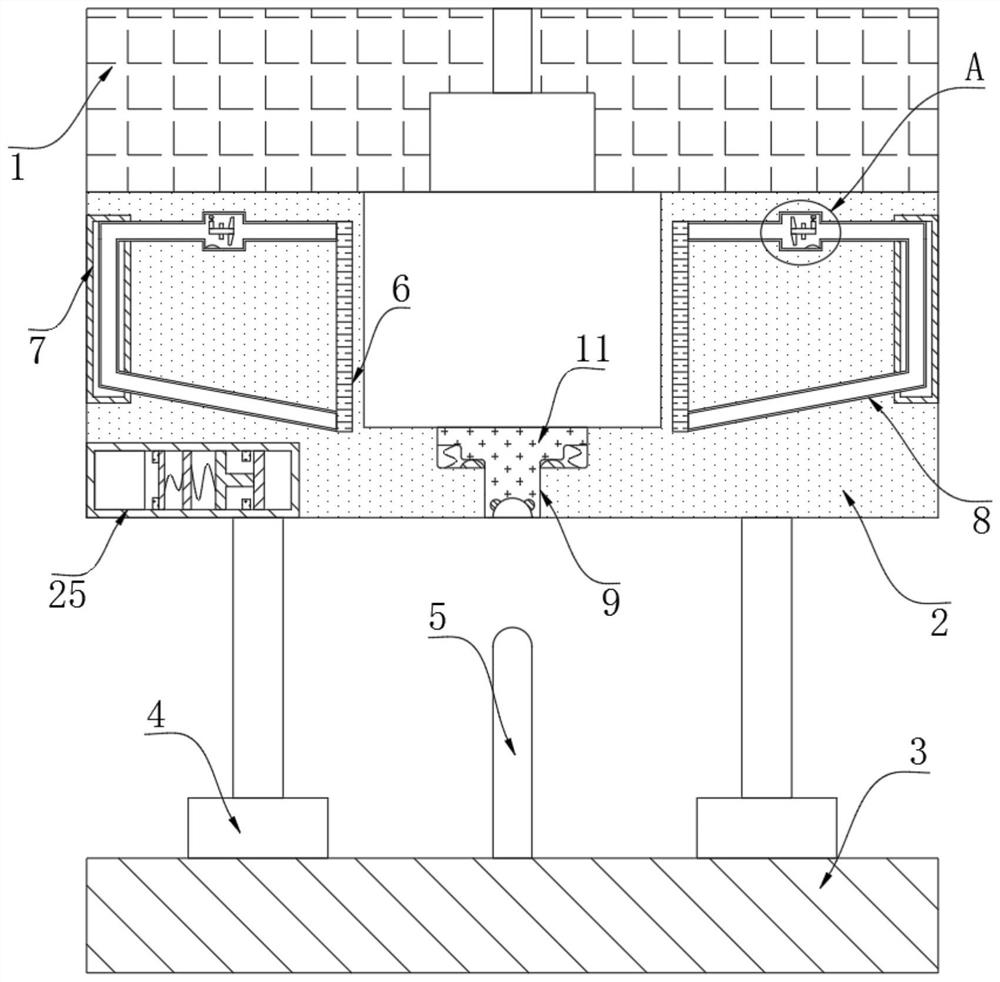

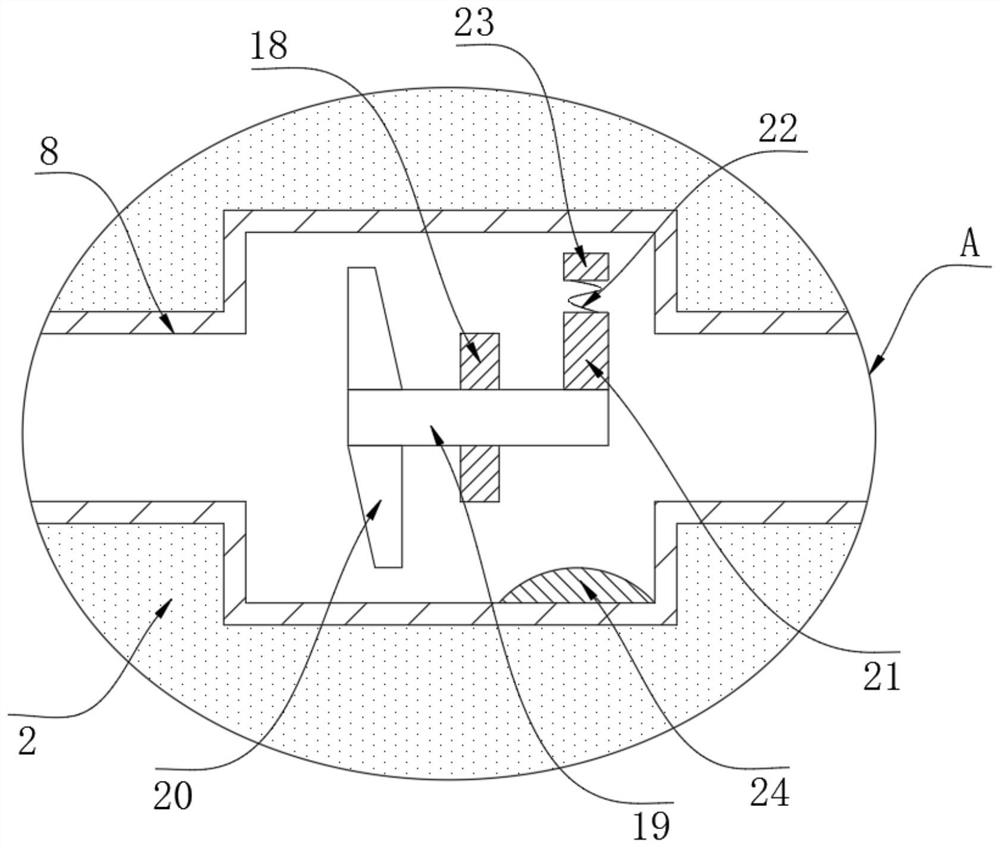

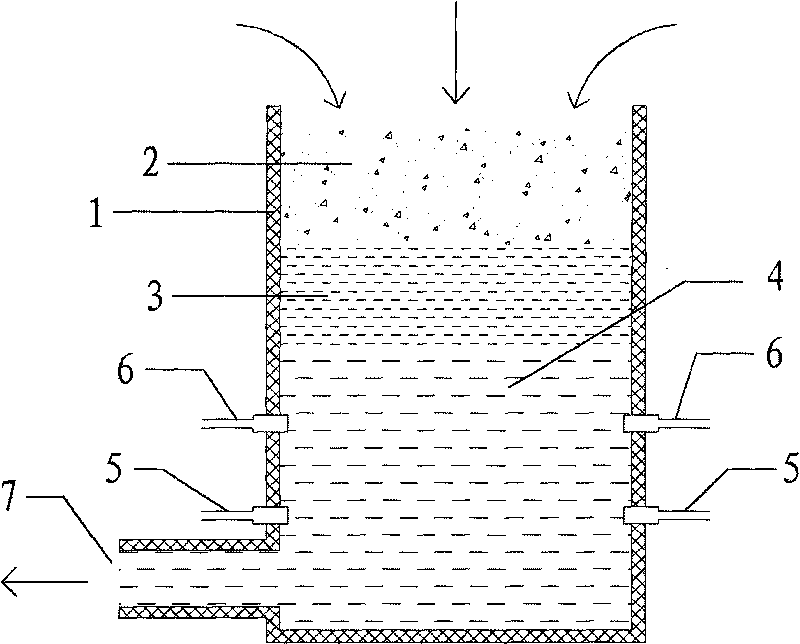

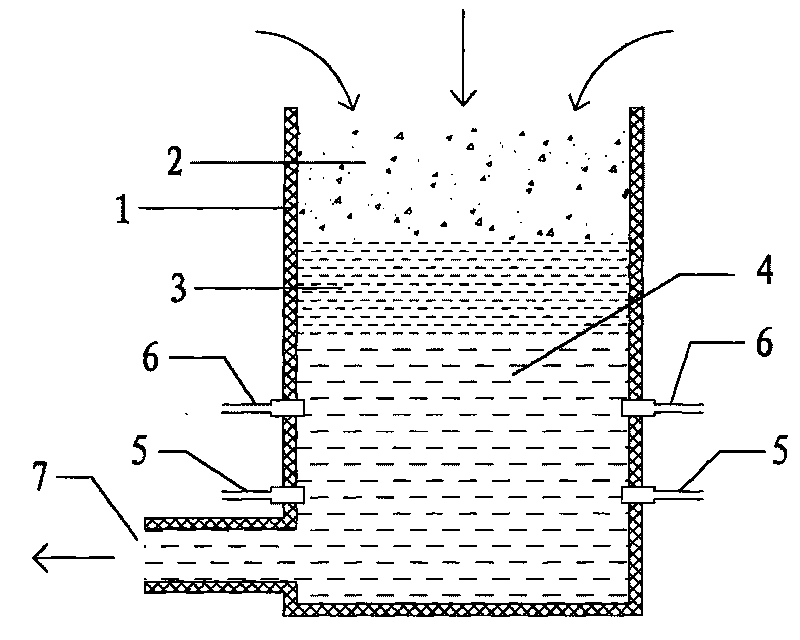

Dry granulation apparatus of blast furnace slag using continuous thin single-layer hot sprinkling and application method thereof

ActiveCN108441590AHighlight the effective effectPromote fragmentationRecycling and recovery technologiesBlast furnace smeltingCrusher

The invention relates to a treatment method of blast furnace slag from blast furnace smelting production, in particular to a dry granulation apparatus of blast furnace slag using continuous thin single-layer hot sprinkling and an application method thereof. The apparatus comprises a grate unit, a cooler, a slag trough, a crusher and a conveying lifter and is characterized in that the grate unit isarranged below the head of the slag trough, the grate unit is mounted at a positive angle of 2-5 degrees relative to a horizontal flowing direction of liquid slag, a condensing column is arranged above the grate unit, a grate plate of the grate unit is composed of a plurality of chain plate groups connected together, a water distributor and an upper cooler are arranged above the grate unit, the crusher is arranged below a head scraper of the grate unit, and a guide plate and the conveying lifter are arranged below a collection channel. Blast furnace slag can be quickly set and can be granulated and loosened via multiple pores, the high temperature is still retained which helps recycle subsequent heat, and the apparatus has the advantages of high efficiency, low energy consumption, and good convenience of arrangement.

Owner:吕艳

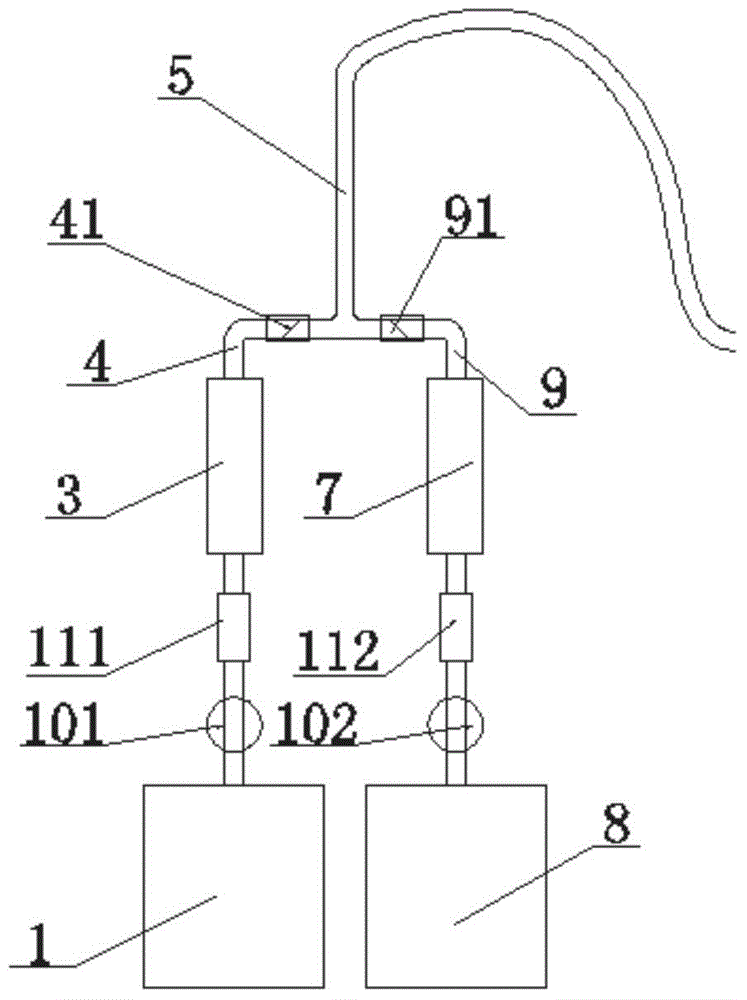

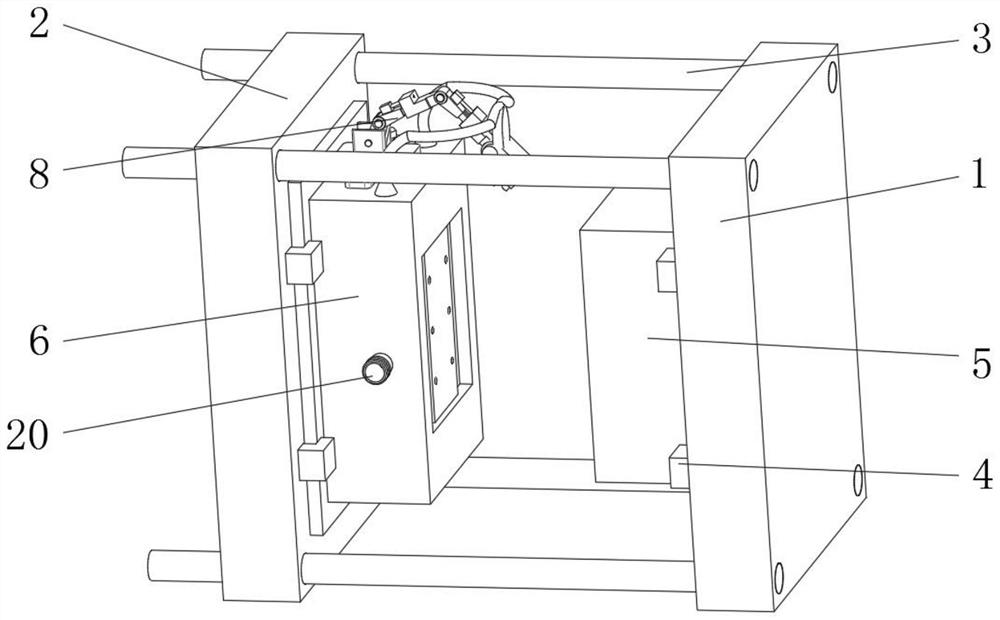

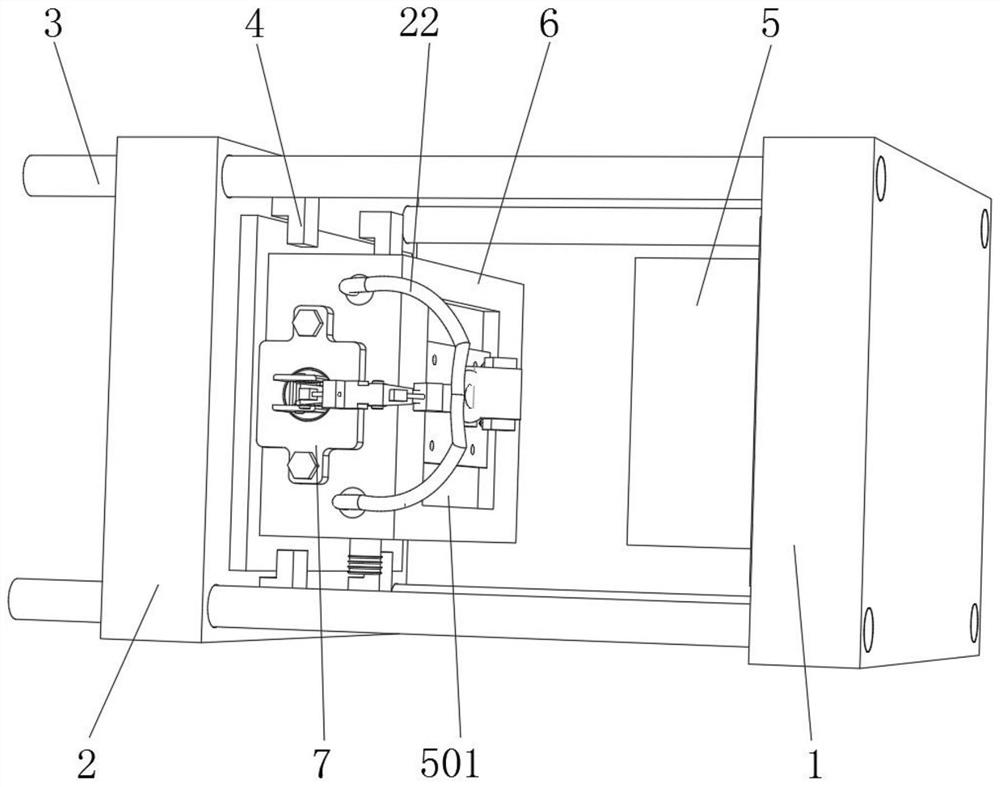

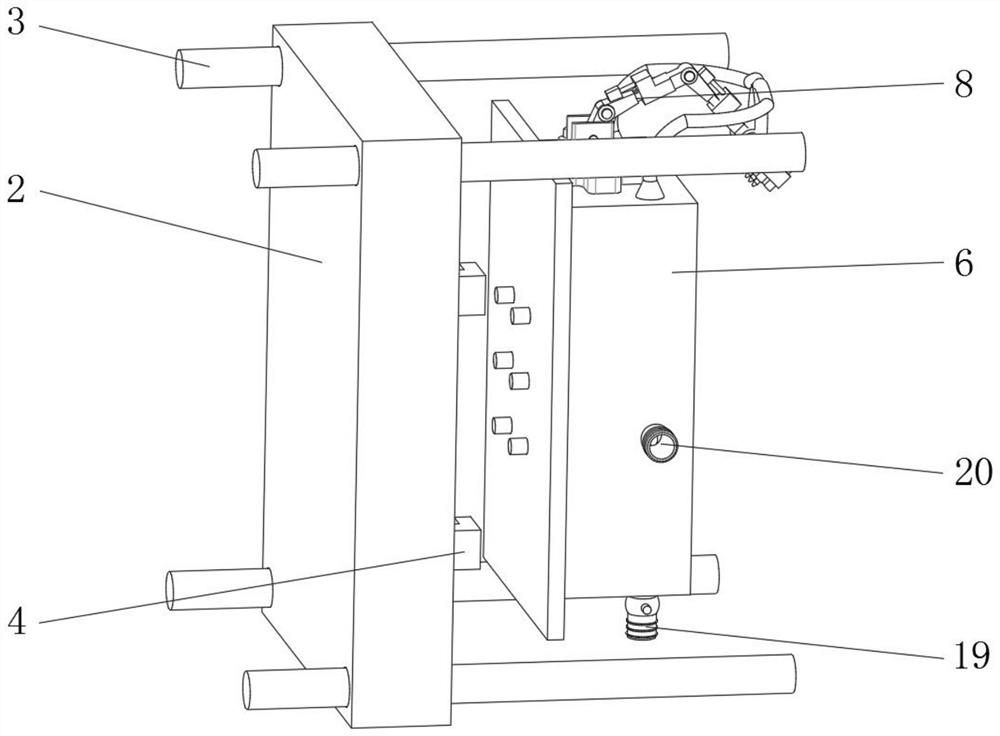

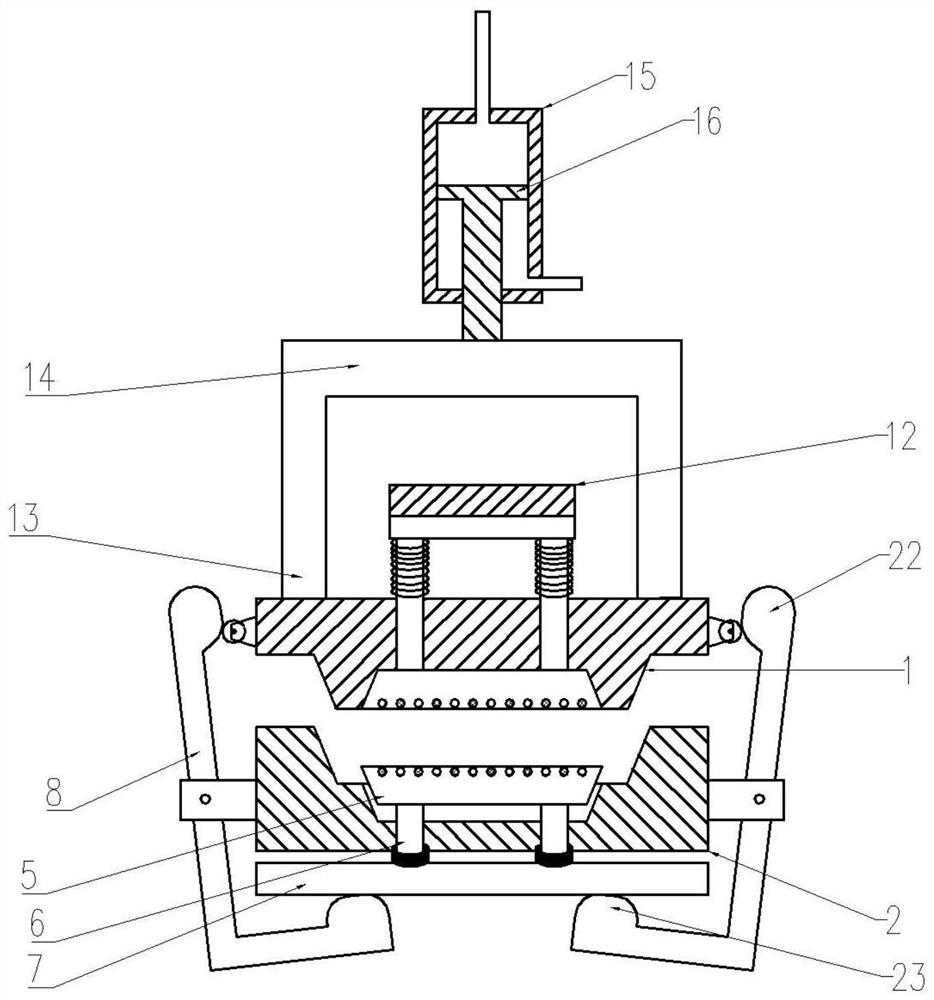

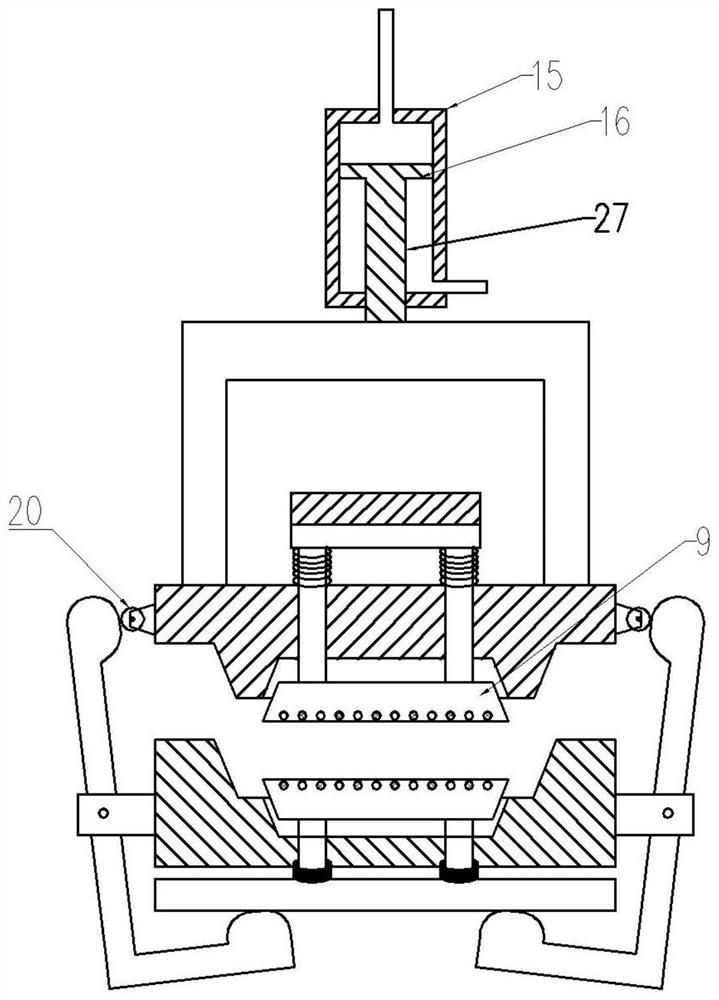

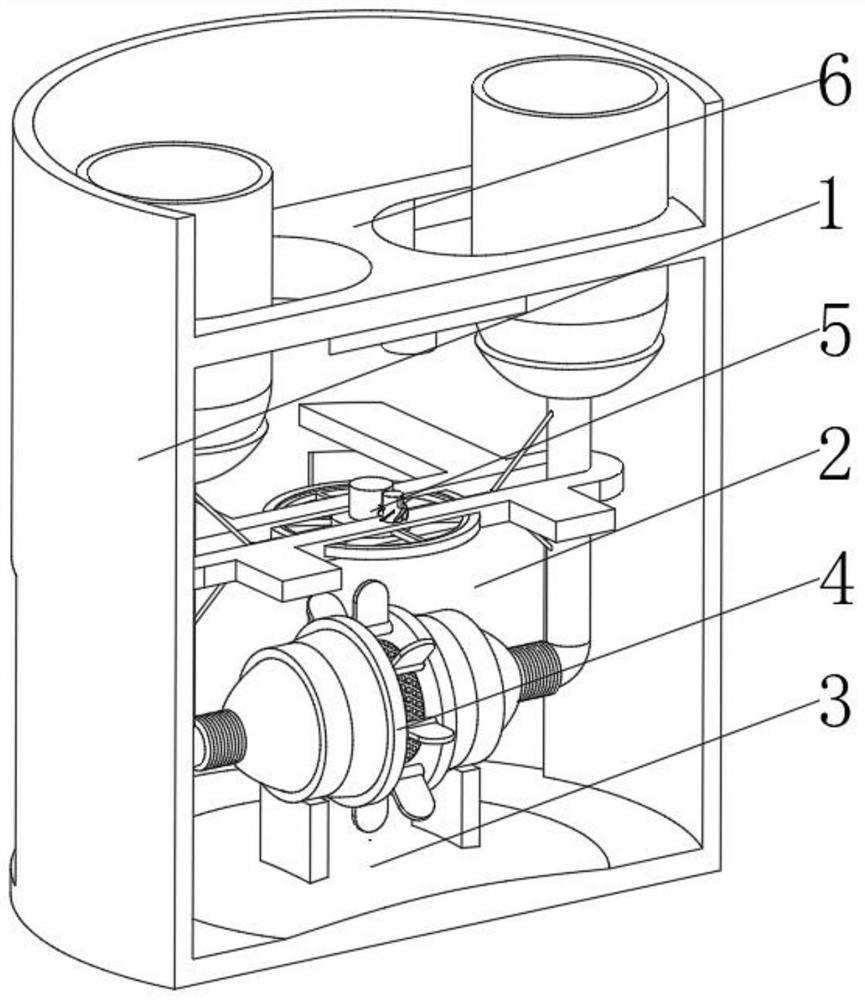

Mold air and water combined cooling system and low-pressure wheel hub mold with same

The invention discloses a mold air and water combined cooling system. The mold air and water combined cooling system comprises an external air pressure source machine, a first pressure gauge, a first flow meter, a first pipe and a main pipe. The external air pressure source machine is connected to one end of the main pipe through the first pipe, the other end of the main pipe comprises at least two or more diversion pipes, the first pipe is provided with the first flow meter, and the diversion pipes are connected to mold hot junction cooling terminals. The mold air and water combined cooling system further comprises an external circulating cooling water machine. The external circulating cooling water machine is connected to a second pipe, the second pipe is connected to the first pipe in parallel and then is connected to the main pipe, a second pressure gauge, and a second solenoid control valve and a second flow meter are arranged on the second pipe sequentially. The first pipe is also provided with a first solenoid control valve. The diversion pipes are in the same number with the mold hot junction cooling terminals and all provided with solenoid control valves. The mold air and water combined cooling system can quickly cool and solidify mold hot junction portions through matched air cooling and water cooling. The invention also discloses a low-pressure wheel hub mold.

Owner:KUNSHAN ZHONGYITE MACHINERY IND

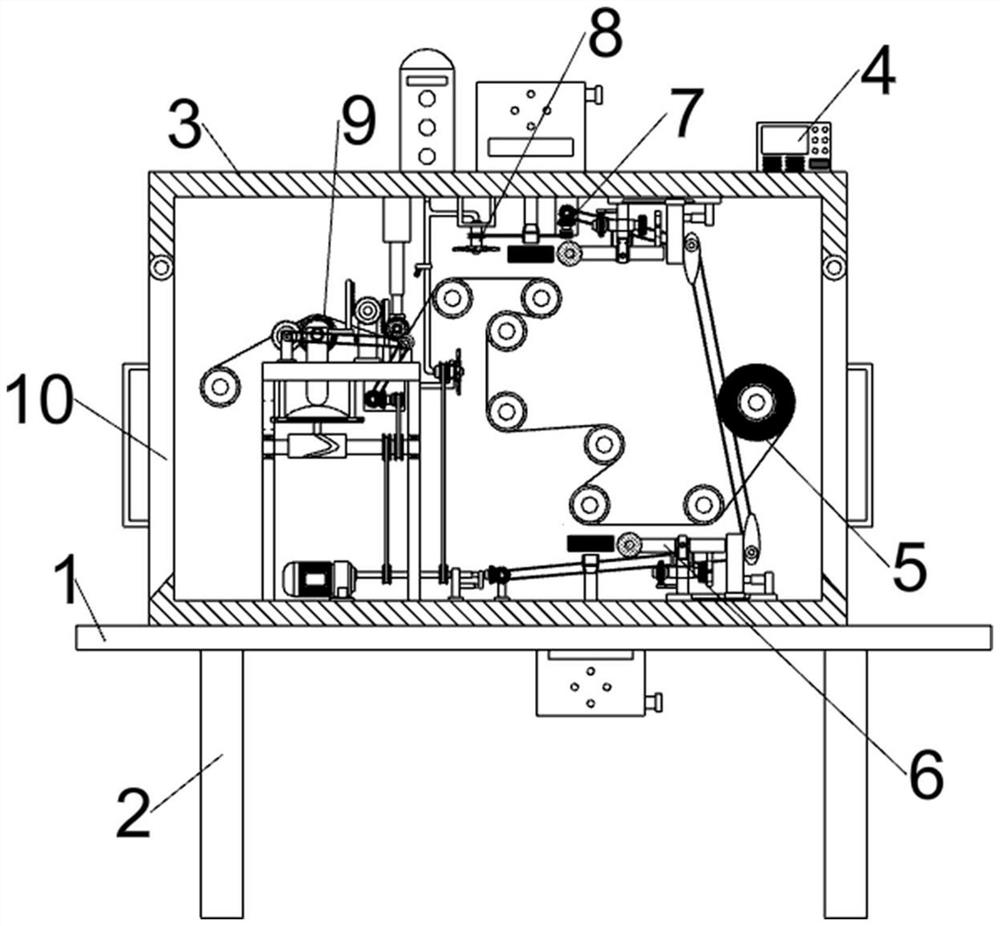

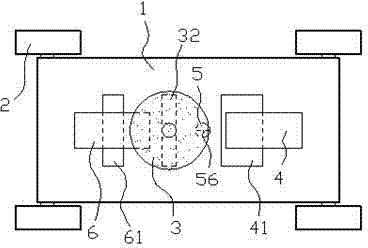

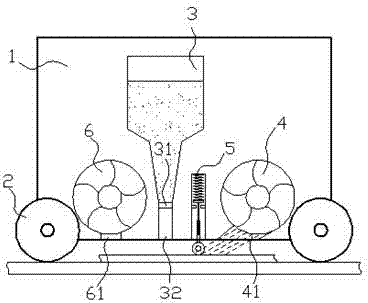

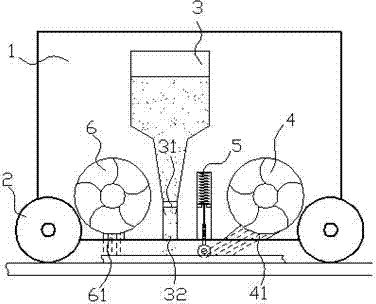

Aluminum plating device

InactiveCN112030132ANot misplacedRapid cooling and solidificationVacuum evaporation coatingSputtering coatingPlastic filmMachine tool

The invention relates to the field of aluminum plating, in particular to an aluminum plating device. The aluminum plating device is provided to solve the technical problem. Based on the technical scheme, the aluminum plating device comprises a conveying roller mechanism, a primary aluminum plating mechanism, a secondary aluminum plating mechanism, a cooling and solidification mechanism, a fastnessdetection mechanism, a communication cabin door and the like, and the lower portion of a working machine tool plate is welded to supporting bottom feet. According to the aluminum plating device, double-sided aluminum plating of a plastic film is achieved, aluminum on the surface of the plastic film is rapidly cooled and solidified after one side of the plastic film is aluminized, then aluminum plating operation is conducted on the other side of the plastic film, and then rapid cooling and solidification are conducted again, so that the plastic film is ensured to be in a tensioned state all the time in the aluminum plating process so as not to be misplaced, meanwhile, aluminum plating on two sides of a conveying roller in the device by means of aluminum steam is avoided, and the effect ofrespectively detecting the fastness of aluminum layers on two surfaces of the plastic film after rapid cooling and solidification is achieved.

Owner:张跃兵

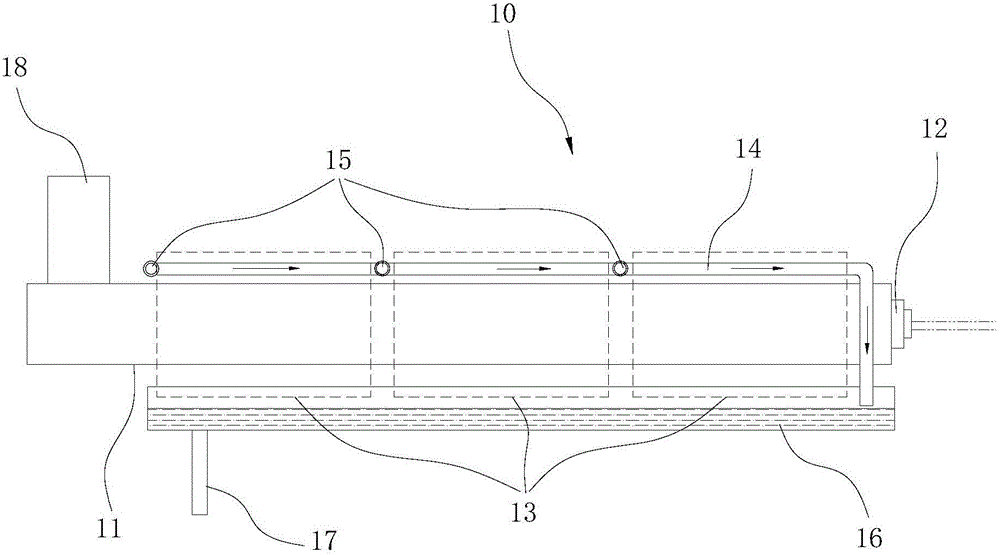

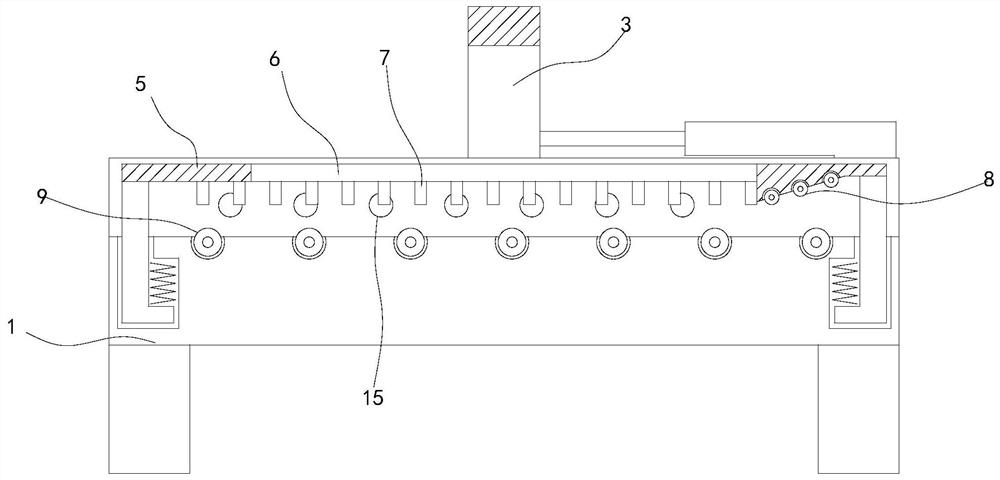

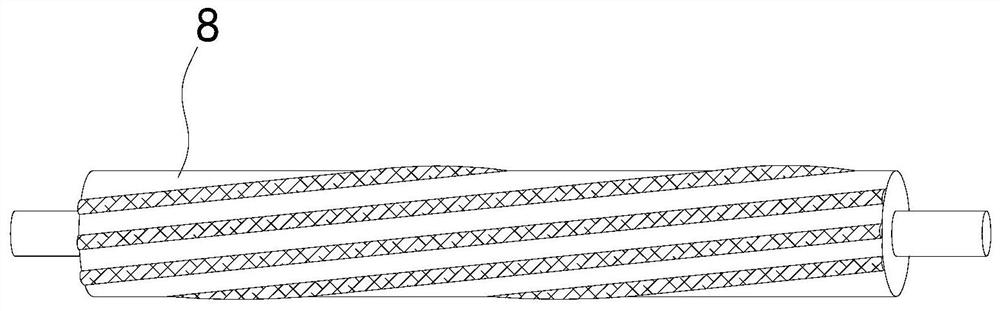

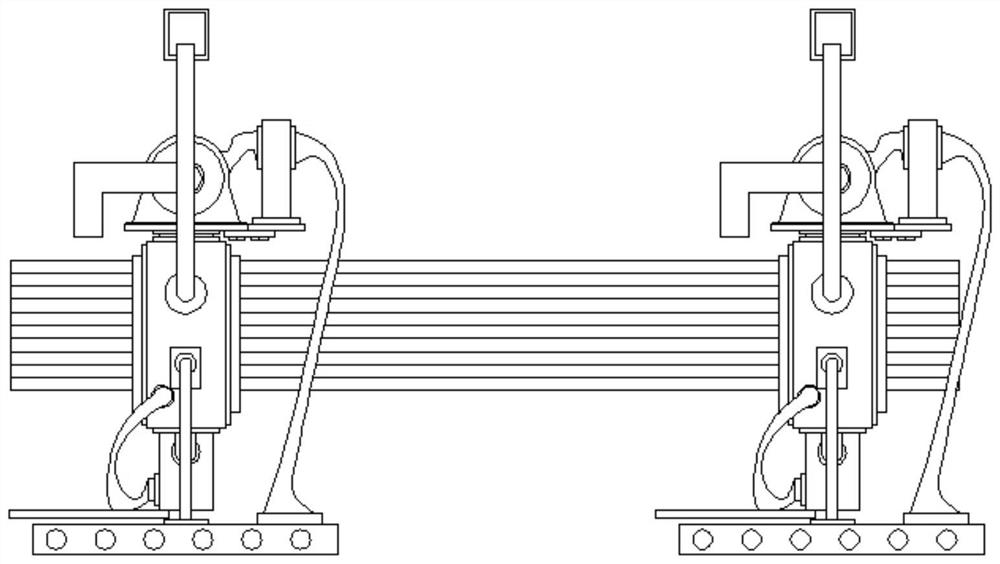

Cooling, conveying and cutting device for eraser strip

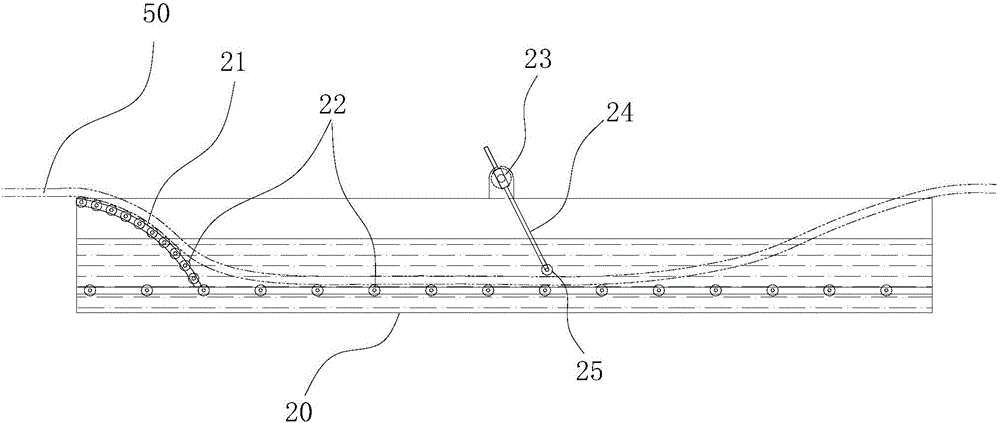

ActiveCN106079367ARapid cooling and solidificationEfficient shearingMetal working apparatusEngineeringMechanical engineering

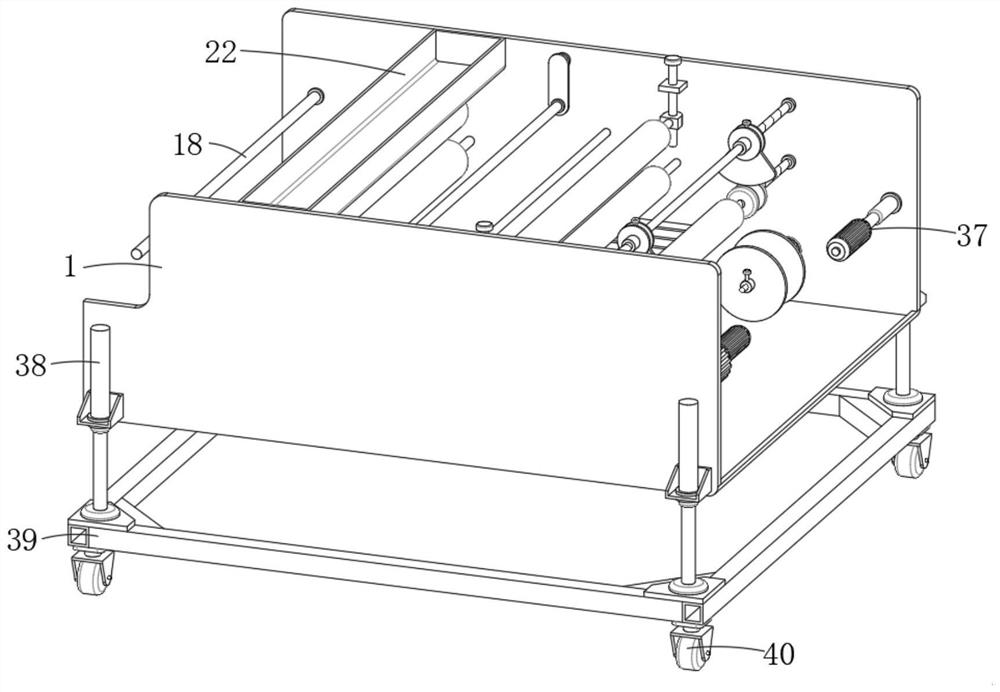

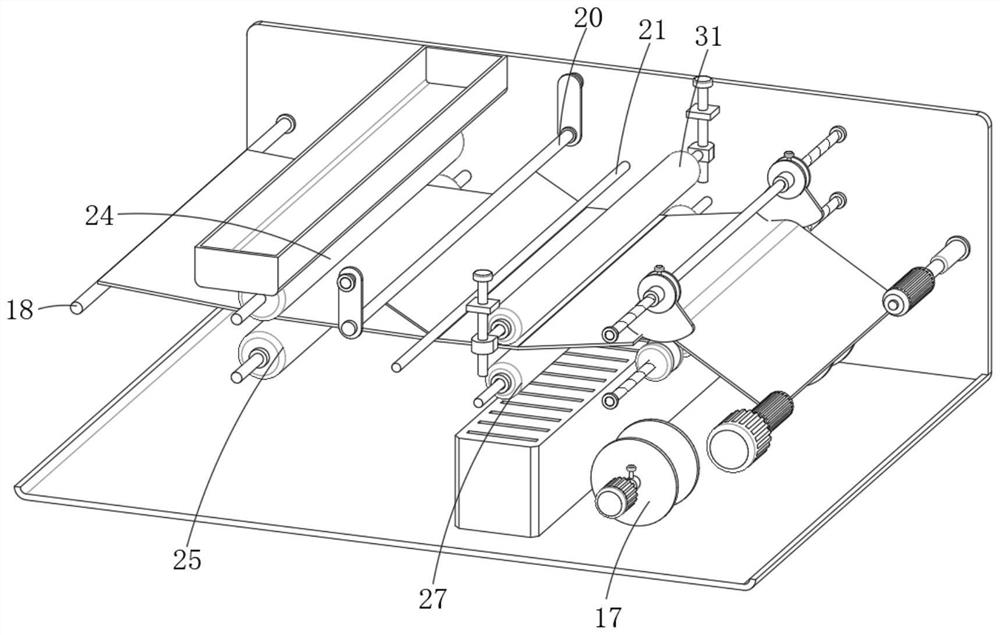

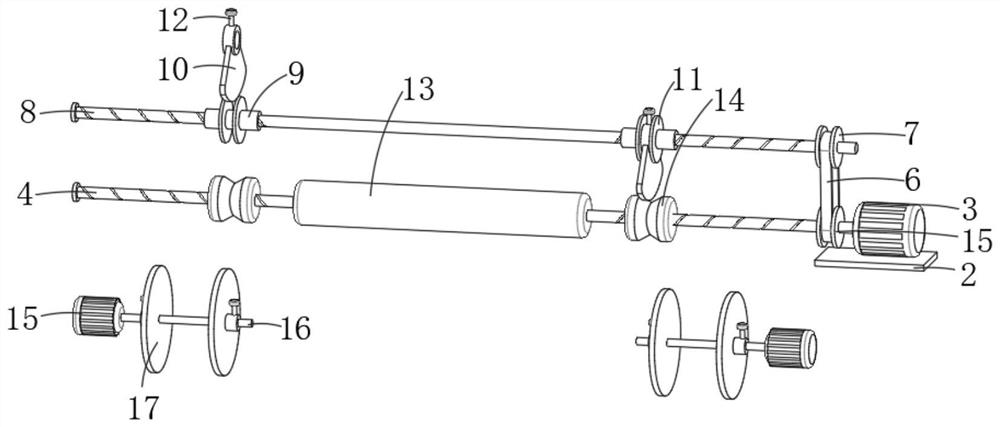

The invention belongs to the field of eraser production and processing and particularly relates to a cooling, conveying and cutting device for an eraser strip. The cooling, conveying and cutting device comprises a cooling water tank and a cutting device body, wherein the cooling water tank is arranged along an extrusion opening of an extruder in an extension mode and filled with cooling water; the eraser strip extruded by the extruder enters the cooling water tank, so that cooling and hardening of the eraser strip are accelerated; after being cooled in the cooling water tank, the eraser strip enters the cutting device body; the cutting device body comprises a fodder chopper and an intermittent feeding mechanism; the fodder chopper moves back and forth in the vertical direction and is matched with a workbench to do a shearing action for cutting the eraser strip; and the intermittent feeding mechanism can convey the eraser strip to the position below the fodder chopper in an intermittent mode, specifically, when the fodder chopper is lifted, the eraser strip is fed forwards, and when the fodder chopper falls, the eraser strip is stopped being fed. According to the cooling, conveying and cutting device for the eraser strip, the extruded eraser strip can be rapidly cooled and cured through the cooling water tank, and deformation is prevented; and the eraser strip can be efficiently sheared through the cutting device body, so that breaking or stacking of the eraser strip is prevented.

Owner:宿州市超晟文具有限公司

Method for quickly measuring tensile mechanical properties of rocks

ActiveCN110031311AIncrease bonding surfaceHigh bonding strengthDomestic cooling apparatusLighting and heating apparatusTest efficiencyRock sample

The invention provides a method for quickly measuring tensile mechanical properties of rocks. The method comprises the following steps: step (1), manufacturing a rock sample; step (2), enabling the two ends of the rock sample to be bonded with clamping sleeves in clamping assemblies respectively by using super glue, and rapidly cooling and curing the super glue between the two ends of the rock sample and the clamping sleeves through a rapid condensing device; step (3), after the two ends of the rock sample are firmly bonded with the clamping sleeves, taking out the rock sample from the rapid condensing device, and assembling the clamping sleeves at the two ends of the rock sample and the rest components in the clamping assembly, fixedly installing the clamping assemblies at the two ends ofthe rock sample on a tensile testing machine, and starting to measure the tensile mechanical property of the rock sample; step (4), after stretching is finished, taking down the rock sample and the clamping assemblies, and rapidly splitting the rock sample and the clamping assemblies; step (5), repeating the above steps (1) to (4), and continuing to measure the tensile mechanical properties of several rock samples; and step (6), ending the test. The method for quickly measuring the tensile mechanical properties of the rocks provided by the invention is convenient and rapid to assemble and disassemble and capable of improving the test efficiency.

Owner:GUIZHOU UNIV OF ENG SCI

Automatic demolding ejection type slide-free injection mold

The invention discloses an automatic demolding ejection type slide-free injection mold. The automatic demolding ejection type slide-free injection mold comprises a fixed mold, a movable mold and a base, wherein the upper end of the base is connected with the bottom of the movable mold through a plurality of telescopic rods; an ejection rod is fixed at the upper end of the base; a plurality of groups of cooling mechanisms are arranged on the side wall of the movable mold; each cooling mechanism comprises a cooling cavity formed in the side wall of the movable mold and a heat dissipation box embedded in the side wall of the movable mold; a heat dissipation pipe communicating with the interior of the cooling cavity is arranged on the side wall of the heat dissipation box in a penetrating andinserting mode; and one-way valves are arranged at the two ends of the heat dissipation pipe. The automatic demolding ejection type slide-free injection mold has the advantages that a pressing block and a supporting plate are arranged, so that the pressing block and the supporting plate form a reserved space in a receding groove; and after cooling, an embedded material connected with a workpiece is reserved in the space, in the downward moving process of the movable mold, the embedded material and the pressing block are kept in a comprehensive abutting state, so that the workpiece can smoothlymove downwards along with the movable mold and is separated from the fixed mold, the mold opening action is completed, and the arrangement of an existing embedded block and a slide is replaced.

Owner:宁波合盛电子商务有限公司

Disposable lunchbox extrusion forming device

PendingCN109397597ARapid coolingRapid cooling and solidificationDomestic articlesWater storageClamp connection

The invention discloses a disposable lunchbox extrusion forming device. The disposable lunchbox extrusion forming device includes a support plate, a mould box is in clamped connection with the upper surface of the support plate, the bottom of the mould box penetrates through the support plate and is located below a bottom plate, a groove is formed in the upper surface of the support plate and is in a square shape, the groove sleeves the outer surface of the mould box and is communicated with the mould box, and a flow guide groove is formed in the upper surface of the support plate and is located in the right side of the mould box; by arranging a water storage box, condensate water is contained in the water storage box and can submerge the outer surface of the mould box so that water subjected to heat exchange inside the water storage box can enter a water tank through a water outlet pipe, then, the water in the water storage box can always keep in a low-temperature state, the mould boxcan be well cooled, therefore, a lunchbox can be rapidly coagulated and formed, it is unnecessary for workers to waste too much time to wait, and thus the production efficiency of the lunchbox is improved.

Owner:TIANJIN RENYI IND CO LTD

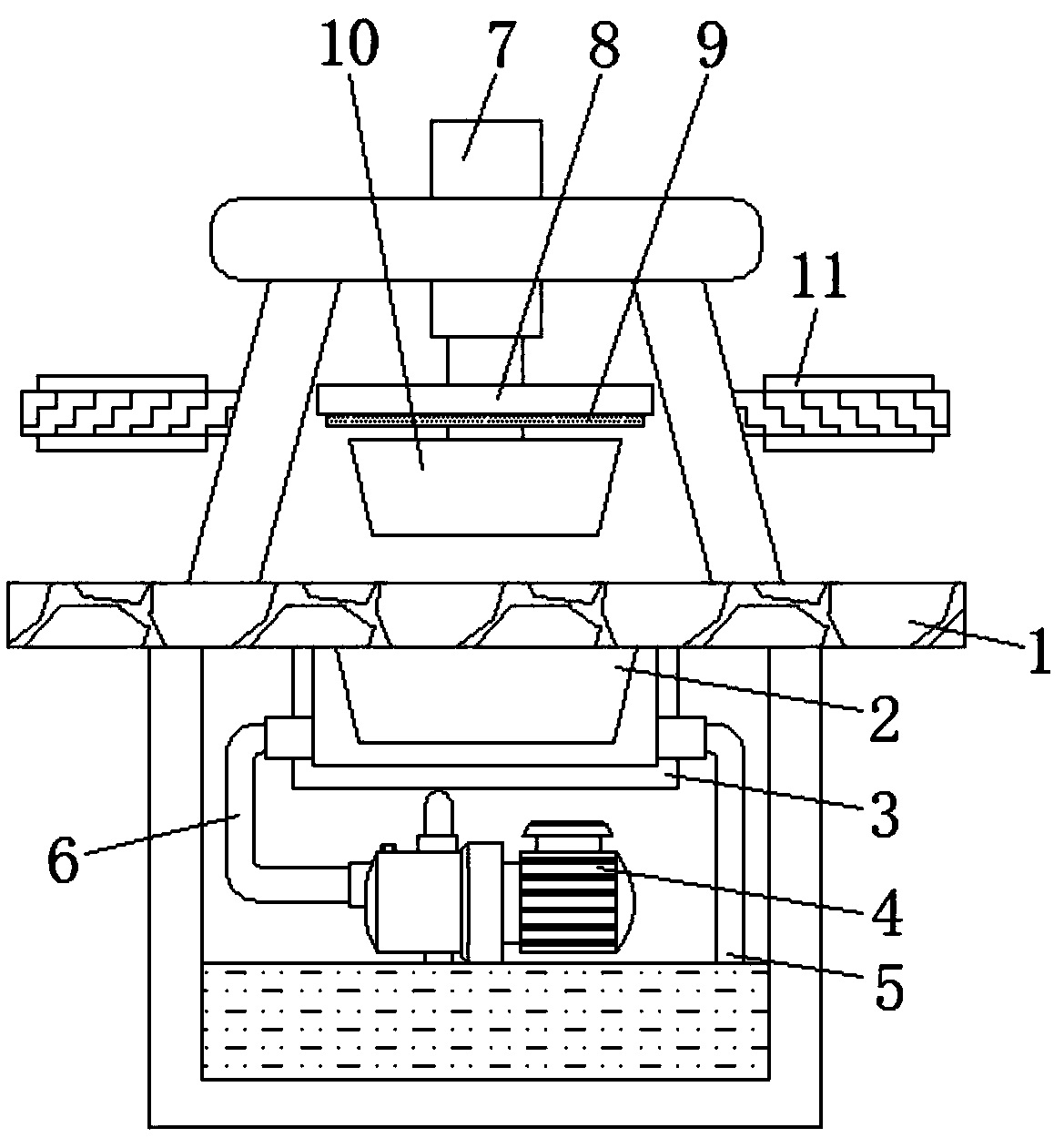

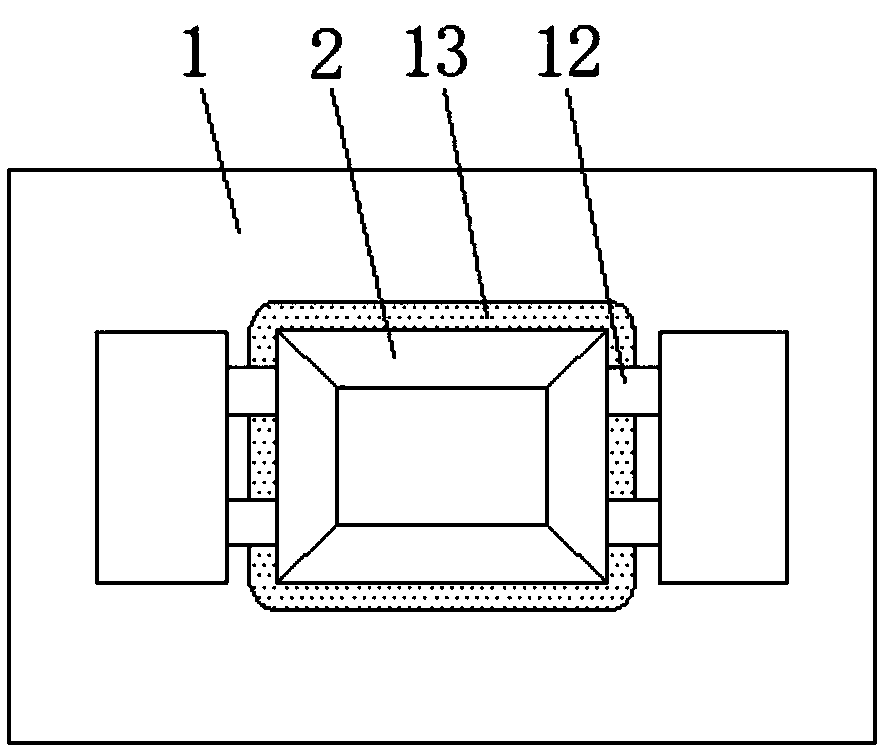

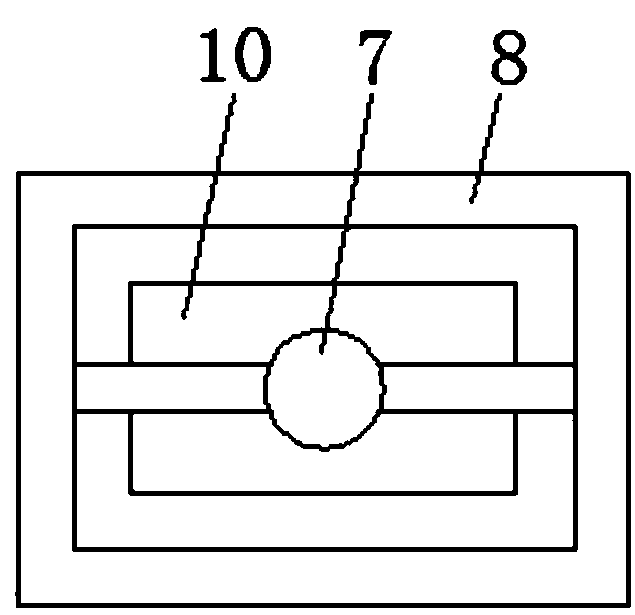

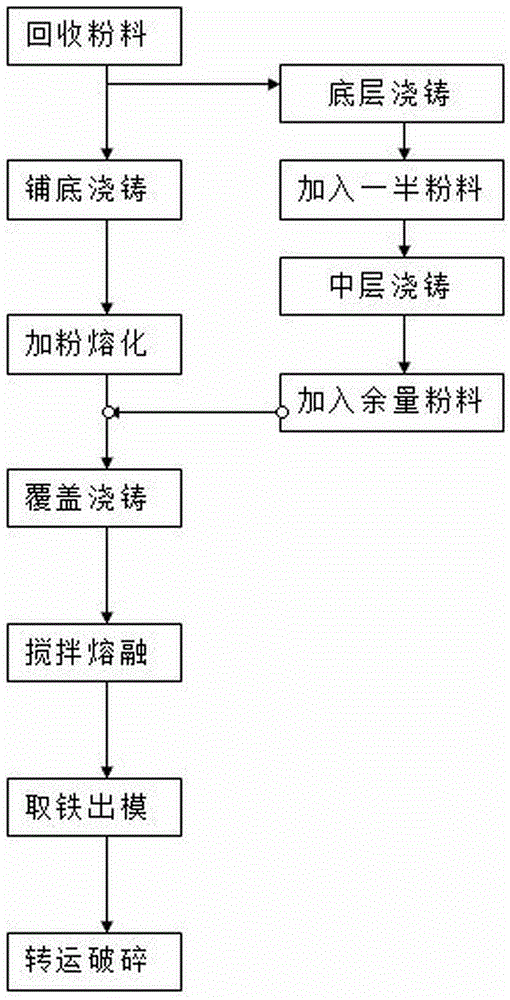

Online fusion production method of manganese-silicon alloy powder

The invention discloses an online fusion production method of a manganese-silicon alloy powder. The method comprises steps of powder recovery, bottom pouring, powder addition and fusing, cover casting, stirring and fusing, iron fetching and mold stripping, transfer and crushing and the like. The method is remarkably characterized in that during the manganese-silicon alloy casting process, molten iron is poured by fractional ''bottom pouring'' and ''cover casting'' and an alloyed powder is added into an ingot mould to carry out heat exchange; and then, the alloyed powder is fused by heat absorption and fused in the molten iron, and an alloy ingot is prepared after condensation. On the precondition of not increasing power consumption, heat of the high-temperature molten iron is utilized to carry out online fusion treatment on the alloyed powder generated by crushing of an ingot. Meanwhile, the time of molten iron condensation and ingot formation can obviously be accelerated, and production operation time can be shortened. The method provided by the invention has obviously effects of enhancing recycling rate of the main element Mn, improving the condition of chemical composition segregation and further raising product quality. When popularized and applied in the manufacturing industry of Mn alloys, the method has social effects of saving energy, reducing emission and protecting the environment as well as great economic benefit.

Owner:四川川投峨眉铁合金(集团)有限责任公司

Angle-adjustable bending device for producing communication equipment products

The invention belongs to the technical field of plastic shell bending and especially relates to an angle-adjustable bending device for producing communication equipment products. The scheme is provided for solving the problems of single bending angles, inconvenience in fixing and high bending damage rate of the present device. The angle-adjustable bending device is characterized by comprising a support platform; a hollow chamber is arranged on the support platform; a support plate is welded on an inner wall on the bottom of the hollow chamber; a pressure sensor is fixed on an outer wall on thetop of the support plate through bolts; the outer wall on the top of the pressure sensor is in contact with the inner wall on the top of the hollow chamber; a bending base is welded on the outer wallon the top of the support platform; different bending slots are formed on the outer wall on the top of the bending base; support pillars are welded on the edges on the two sides of the outer wall onthe top of the bending base. The angle-adjustable bending device provided by the invention is capable of clamping the plastic pieces of the communication equipment, bending the plastic pieces at different bending angles, heating a bending cutter, conveniently forming the plastic pieces, quickly cooling and curing the bent plastic pieces and improving the bending forming degree.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Automatic welding device capable of efficiently replacing filler rods

InactiveCN112975213AReduce the frequency of electrode replacementImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryStructural engineering

The invention relates to the field of automatic welding, in particular to an automatic welding device capable of efficiently replacing filler rods. The device comprises a device main body, a moving frame is movably mounted at the upper end of the device main body, a welding rod is movably mounted at the inner side of the moving frame, and a filler rod replacing device is fixedly mounted at the inner side of the moving frame; and fixing blocks are fixedly installed in the filler rod replacing device at equal intervals along the edge, standby filler rods can be placed between the fixing blocks, after the filler rods at the lower end of the welding rod are used up, the filler rod replacing device can be driven by a motor to rotate, so that the filler rod replacing device uses a driving plate arranged in an annular wavy manner and located at the left side of the filler rod replacing device, rotation in a driving groove of a propelling block is achieved, when the driving block abuts against the driving plate in an attached manner through a spring at one side of a connecting rod, the propelling block can move left and right along the track of the driving plate, and therefore the standby filler rods at the outer side of the propelling block are pushed into welding tongs at the lower end of the welding rod along with rotation of the filler rod replacing device, and replacement is completed. Therefore, the frequency of filler rod replacement through device pause is greatly reduced.

Owner:新余山海企业服务有限公司

Process for smelting opal glass base material capable of preventing fluorin volatilization

InactiveCN101698564AVolatile will notWon't escapeGlass furnace apparatusShaft furnaceSmelting processRoom temperature

The invention discloses a process for smelting an opal glass base material capable of preventing fluorin volatilization. The process comprises the following steps: adding room-temperature opal glass base material to a certain height from the top of a furnace and then adopting an electrode to heat the base material to a smelting required temperature of 1,400 to 1,500 DEG C inside the lower part of the furnace, thereby realizing high-temperature liquefaction of the basic material at the bottom of the furnace to form a liquefaction layer; forming a solid layer by the upmost material and a semi-melting layer between the solid layer and a liquefied material area; under the pressure of the materials, outputting the liquefied basic material through a sealed discharge port at the lower part of the furnace for further use; during heating, continuously and evenly adding room-temperature basic material in the upper part of the furnace to keep the thickness of the material solid layer inside the furnace at 30 to 80cm; and controlling the power of the electrode and the adding speed of the basic material to ensure that the quantity of the added basic material is equivalent to that of the output liquefied material. The smelting process has the advantages of stable product quality, ideal opalescent effect, no fluoride pollution and high thermal efficiency.

Owner:广东三元玉瓷文化发展股份有限公司

Die-casting die with cooling mechanism and using method of die-casting die

The invention relates to the technical field of die-casting dies, and discloses a die-casting die with a cooling mechanism and a using method of the die-casting die. The die-casting die comprises a fixed die insert and a movable die insert, the fixed die insert and the movable die insert are connected through a guide rod, and fixing pieces are arranged on the opposite circumferential sides of the fixed die insert and the movable die insert. According to the die-casting die with the cooling mechanism, after high-temperature liquid metal is injected into a die groove, a movable die is rapidly heated, cold water in a water storage cavity is rapidly heated and boiled to generate a large amount of steam, the steam is collected in a gas collection chamber, a separation pipe is used for separating water vapor from water, the water vapor is led into the gas collection chamber, the water flows back into the water storage cavity through through holes in a separator and is discharged through a water outlet, cold water is introduced through a water inlet formed above the bottom of the separation pipe all the time, so that part of water vapor in the separation pipe is liquefied into water when being cooled, and the damage to water cooling equipment caused by the fact that the water vapor and the water are discharged through the water outlet after being rapidly formed is avoided.

Owner:尚锟

Fixing device for hoisting reinforcing steel bars for building construction

InactiveCN112897314ABroaden applicationRapid cooling and solidificationLoad-engaging elementsArchitectural engineeringAir pump

For solving the problem that a reinforcing steel bar bundle is prone to loosen during hoisting, the invention discloses a fixing device for hoisting reinforcing steel bars for building construction. The fixing device comprises a lantern ring, wherein a connecting rod is fixedly connected to the top surface of the lantern ring, a second connecting plate is fixedly mounted at the top end of the connecting rod, a supporting frame is welded to the upper surface of the second connecting plate, a material pump is fixedly installed at the top end in the supporting frame, the discharging end of the material pump communicates with a discharging pipe, a first connecting plate is fixedly installed on the right side face of a second connecting plate, a material containing box is fixedly installed on the upper surface of the first connecting plate, a first guide pipe communicates between the material containing box and the material pump, a pull rod is welded to the side face of the lantern ring, a hoisting ring is welded to the top end of the pull rod, an air bag is sleeved with the lantern ring, and an air pump is fixedly installed on the lower end face of the lantern ring. According to the fixing device, gaps between the reinforcing steel bars in the steel bar bundle are filled with wax liquid, then the steel bars are stably bundled through the air bag, the steel bar bundle is stably hoisted, and the steel bar bundle is prevented from loosening.

Owner:冯丹

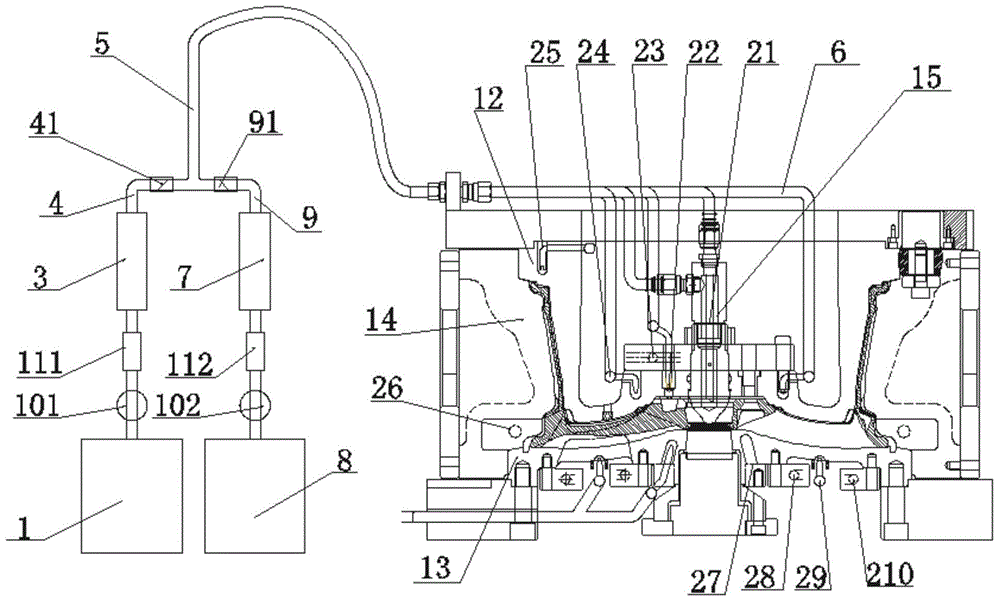

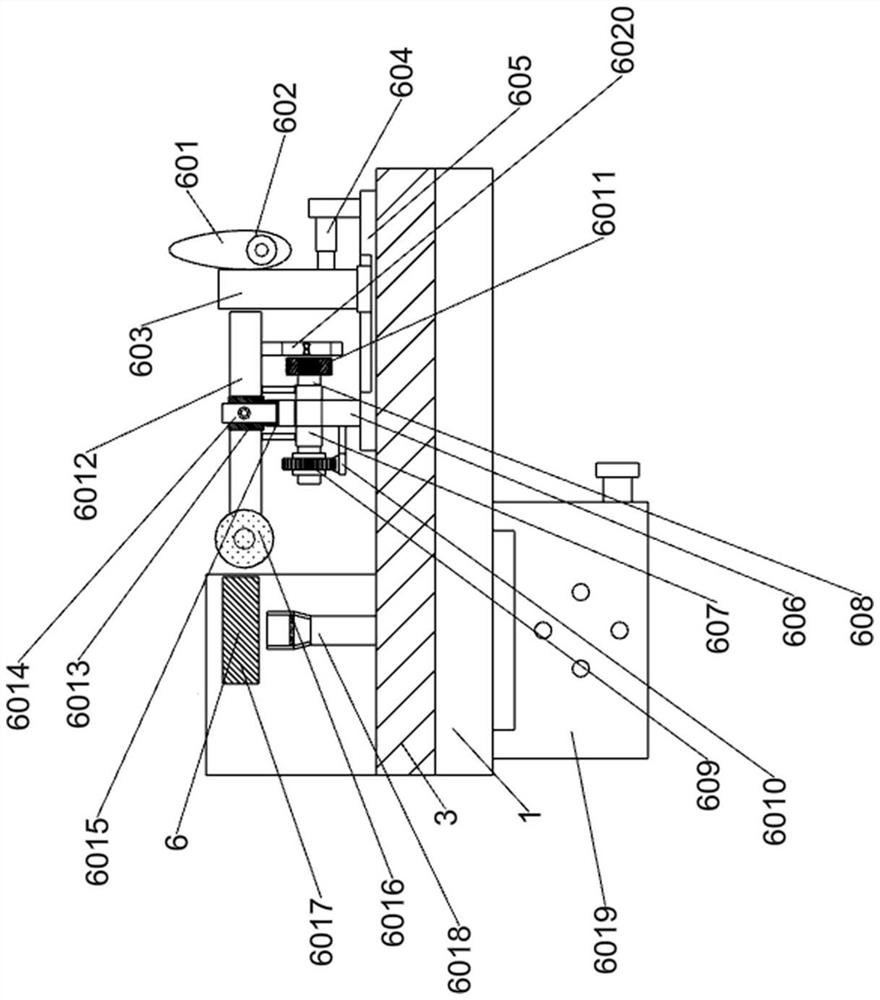

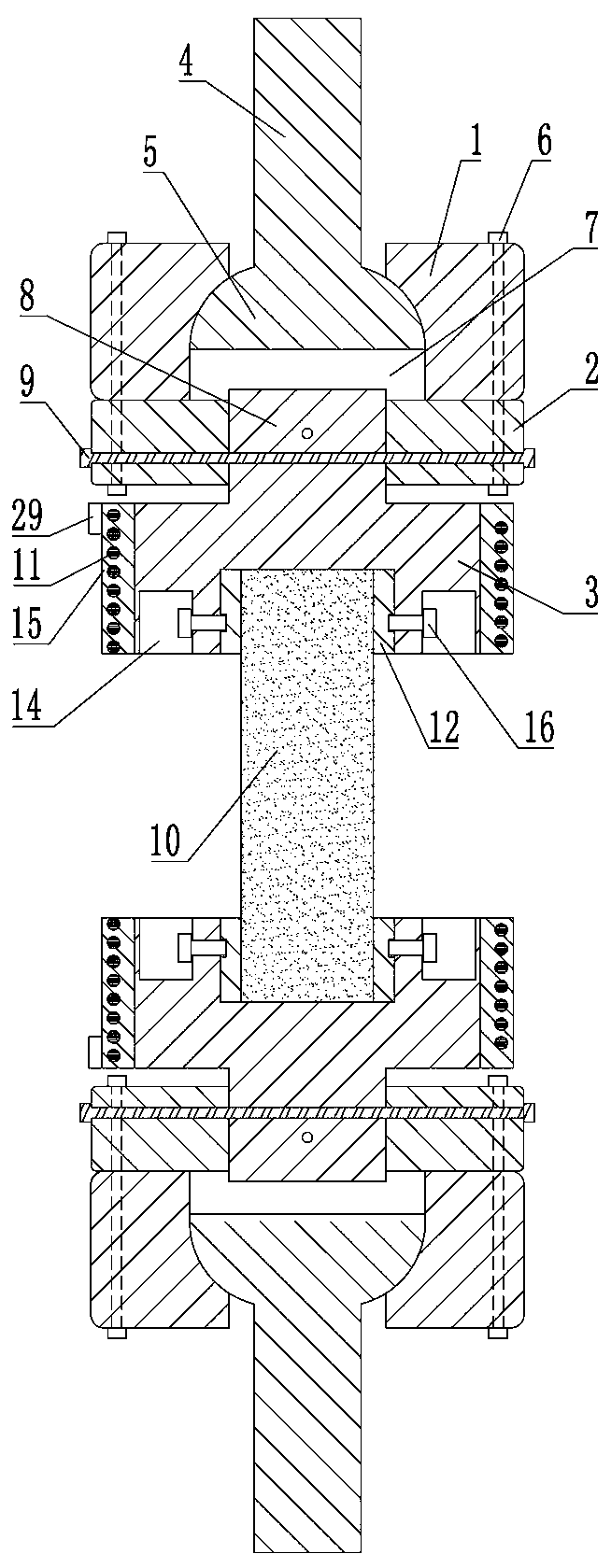

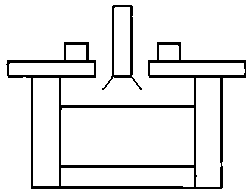

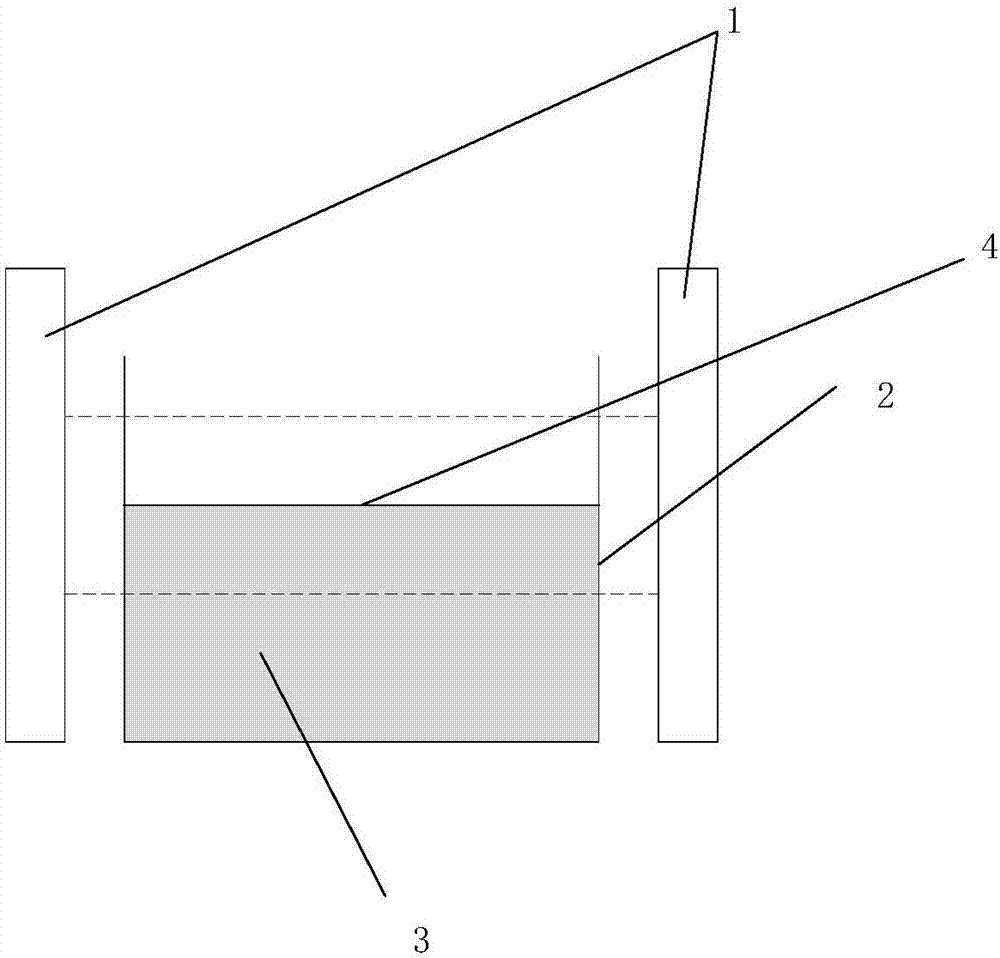

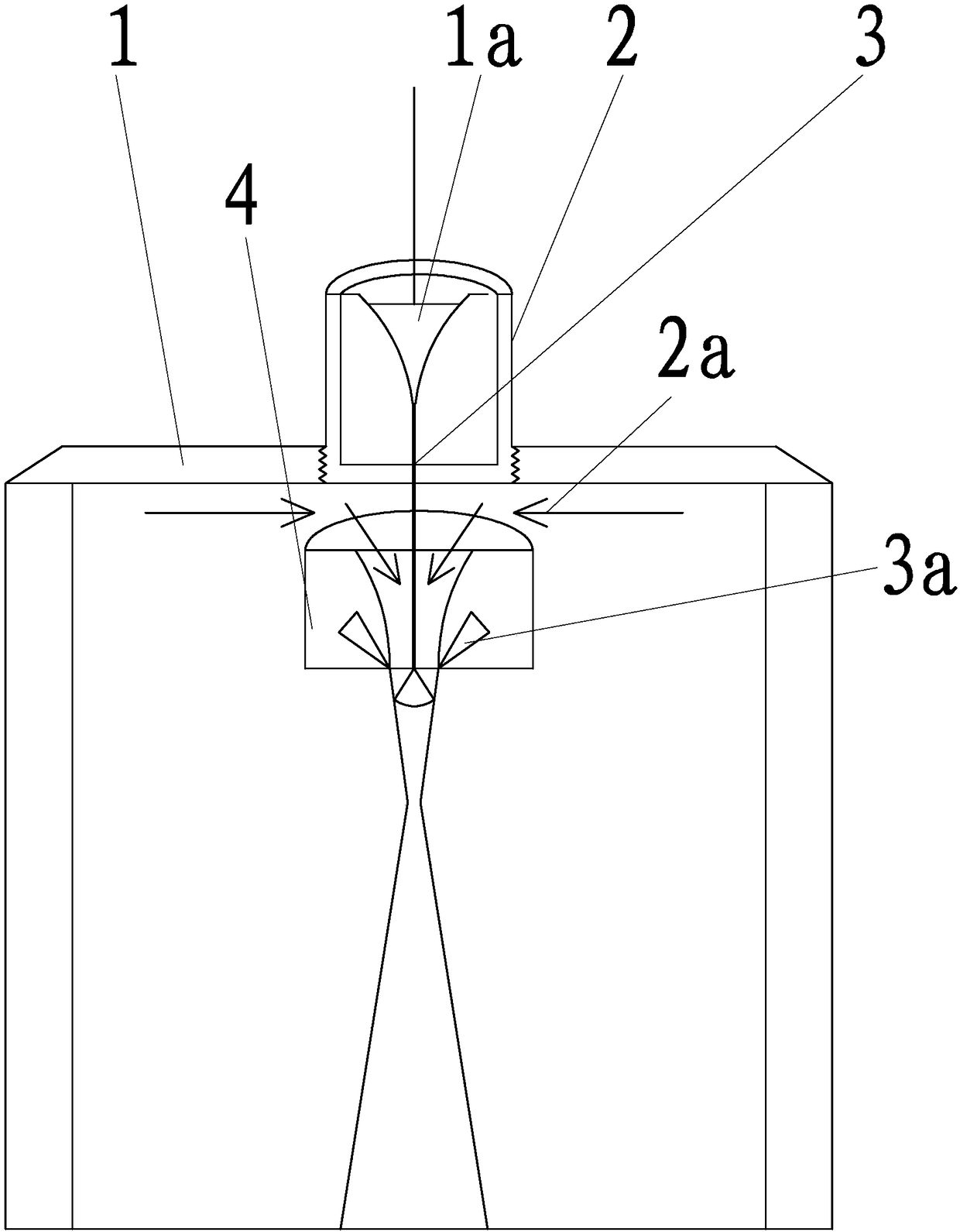

A molding device for optical glass and its production process

ActiveCN103922565BImprove molding qualityRapid cooling and solidificationGlass pressing apparatusOptical glassThermocouple

The present invention relates to a forming device of optical glass and its production technology, which belong to the technical field of optical glass melting. The forming device of optical glass and its production technology solve the problems of poor forming quality, easy generation of surface stripe and crystallization of a strip material of the optical glass with large aperture, the forming device comprises a bottom die, a top die, a heating device, a bottom die cooling channel, a top die cooling channel, a first temperature thermocouple and a second temperature thermocouple; the top die is in an U-shaped groove, the bottom die is a plane base plate, the top die and the bottom die are arranged together to form a glass forming cavity; the top die cooling channel and the second temperature thermocouple are arranged on the upper wall of the top die; the bottom die cooling channel is arranged in the plate of the bottom die; and the heating device and the first temperature thermocouple are arranged in the U-shaped groove at the lower part of the top die. The forming device solves the problems that the forming of the strip material of the optical glass is poor, the thickness is inconsistent, surface stripe and crystallization are easily generated, and has obvious effect for lanthanide optical glass with low viscosity and easy crystallization.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

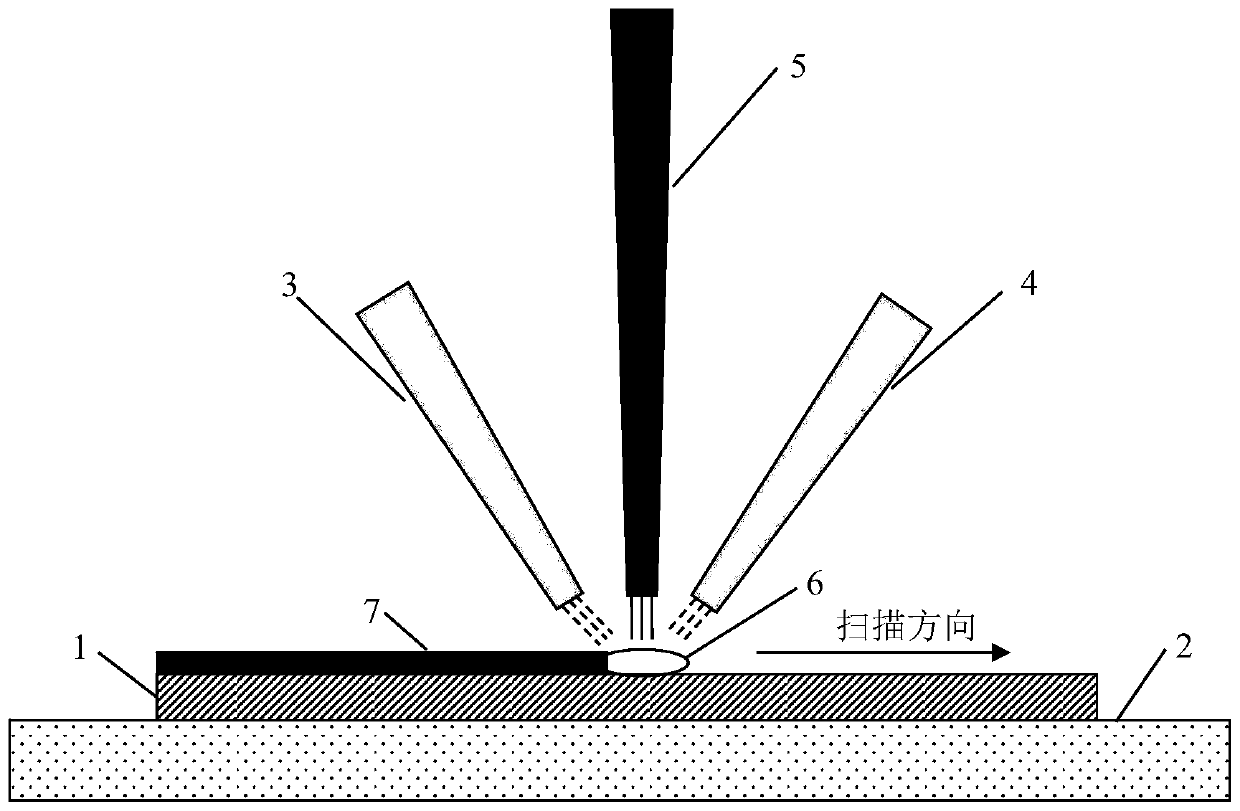

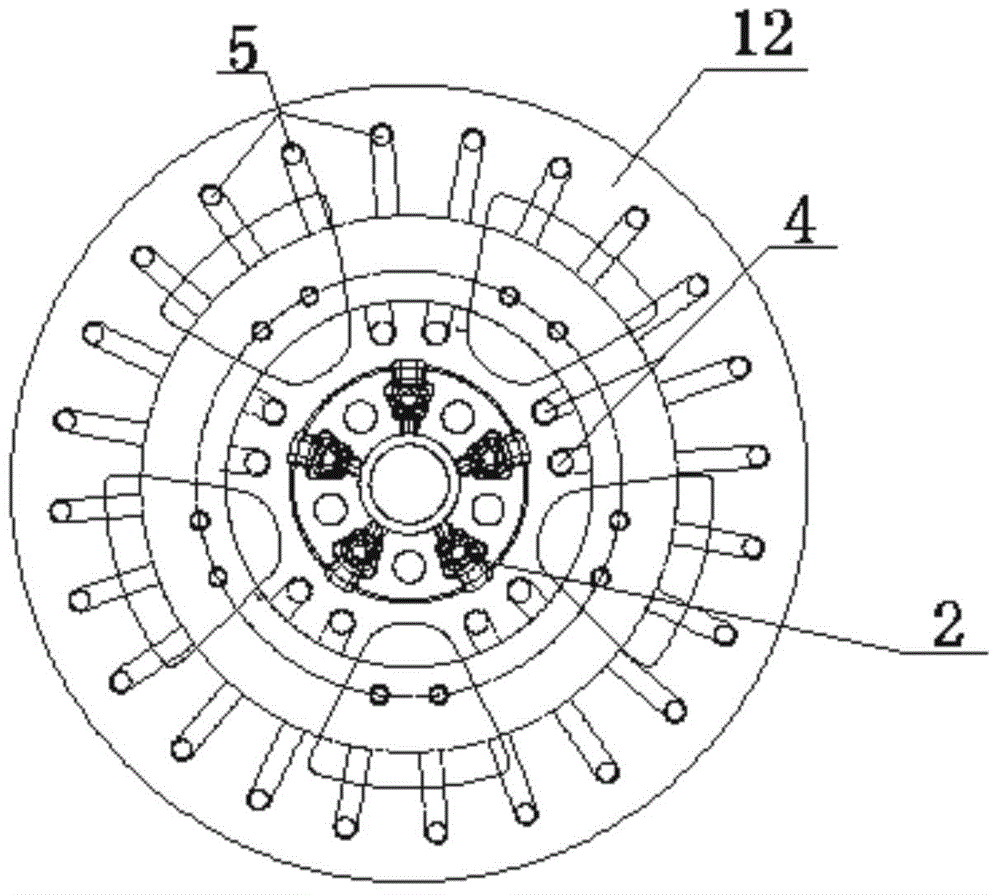

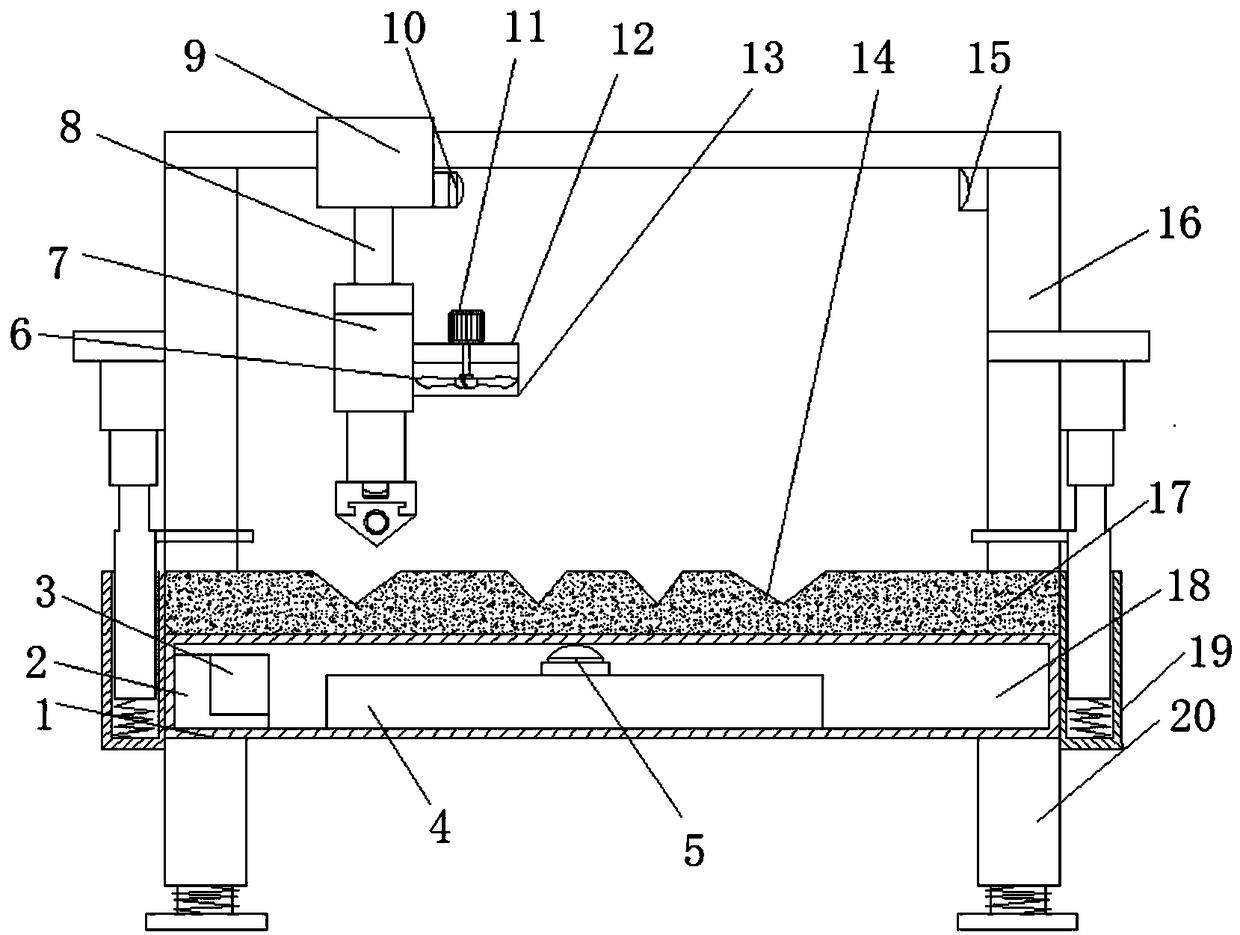

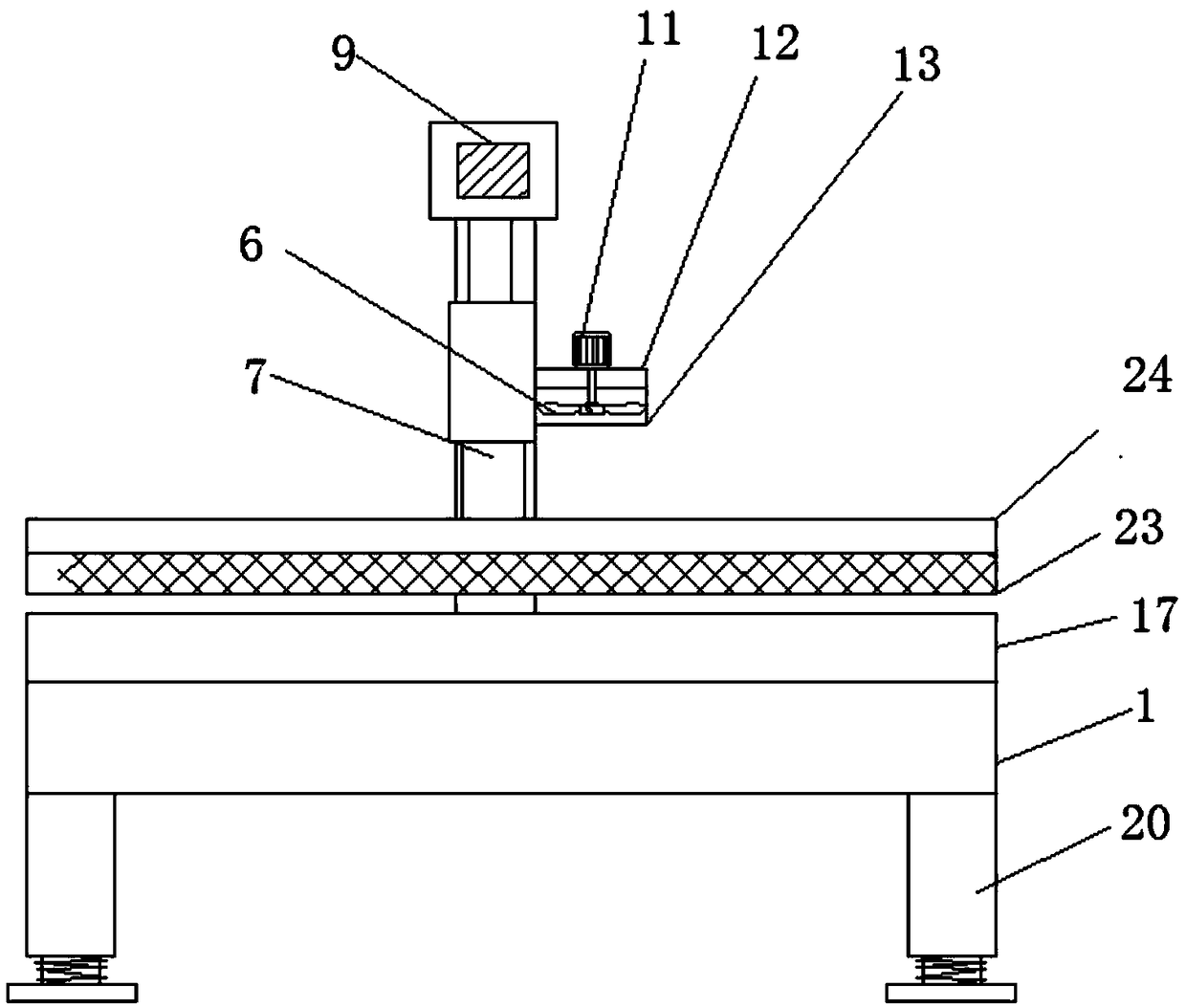

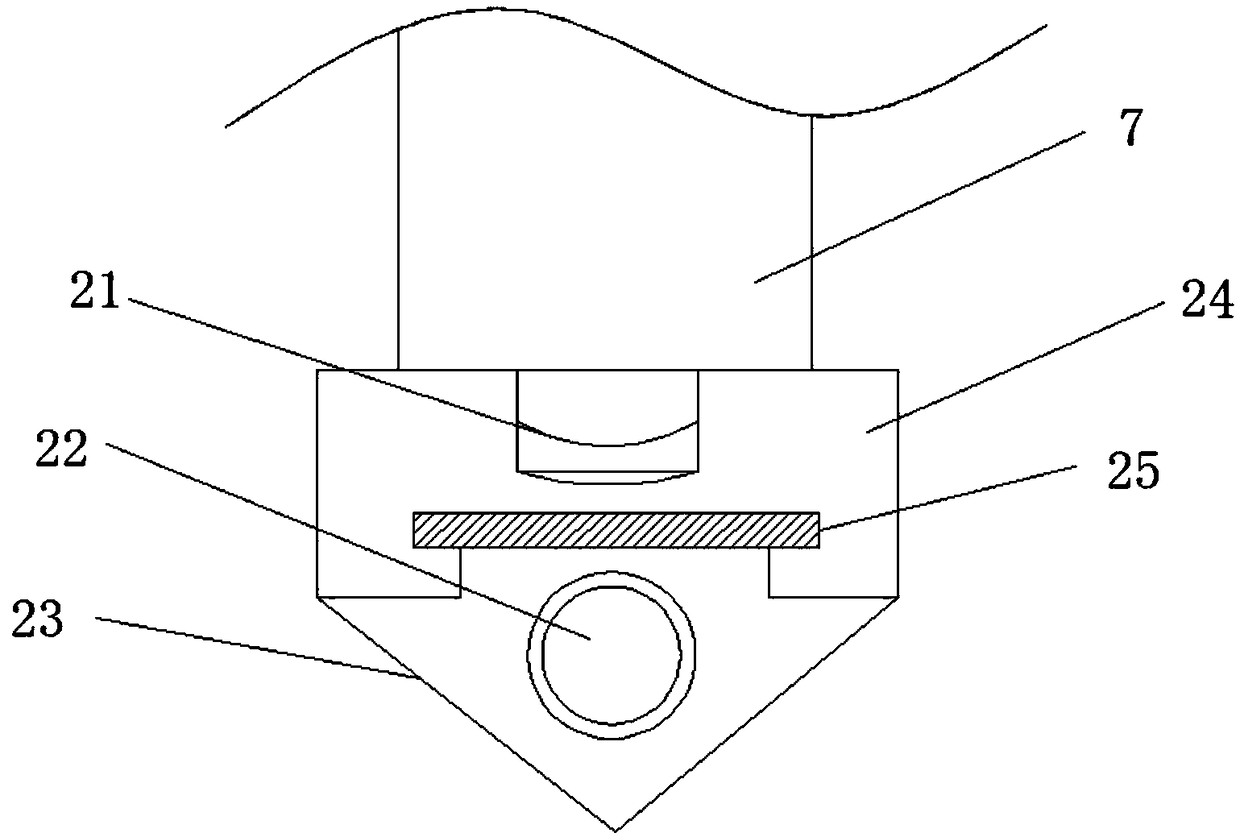

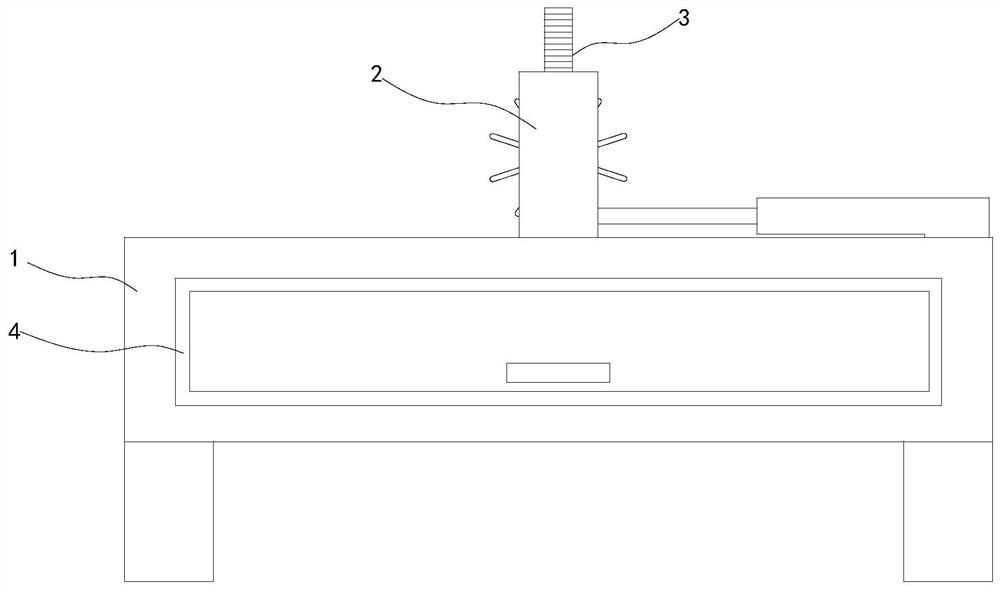

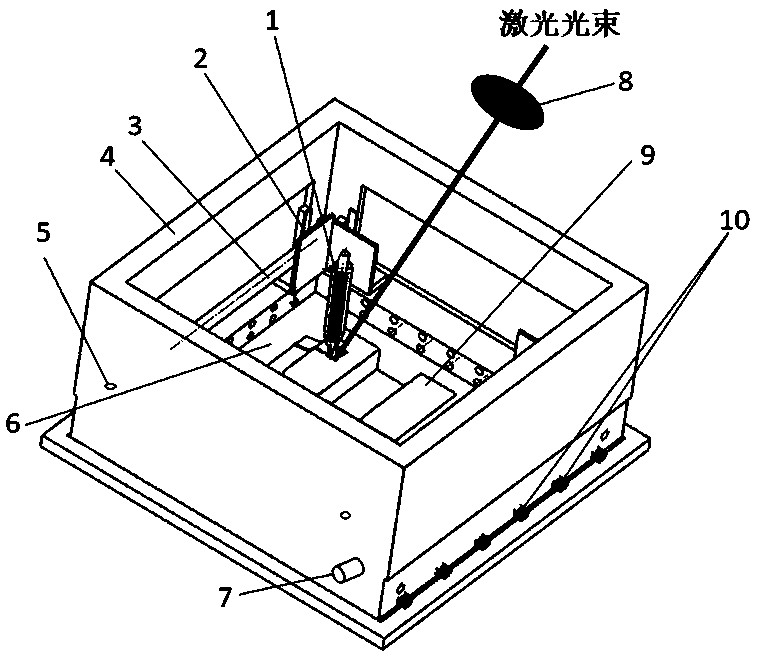

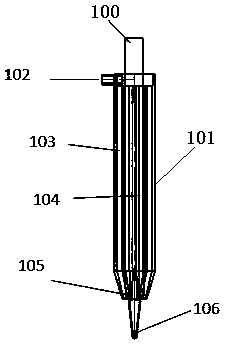

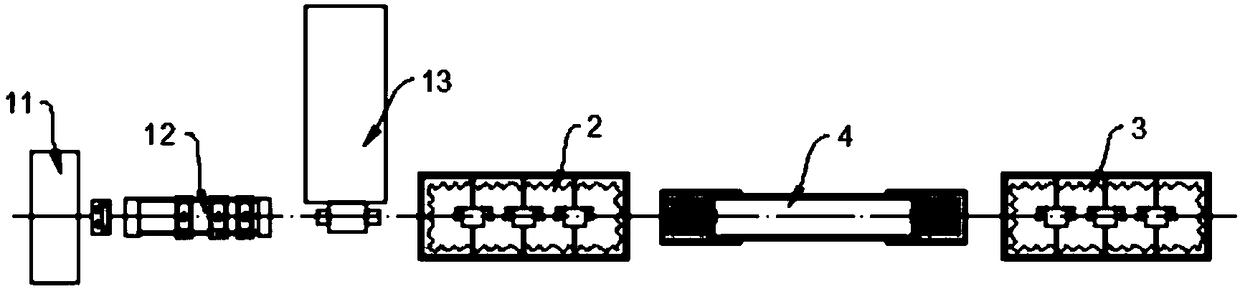

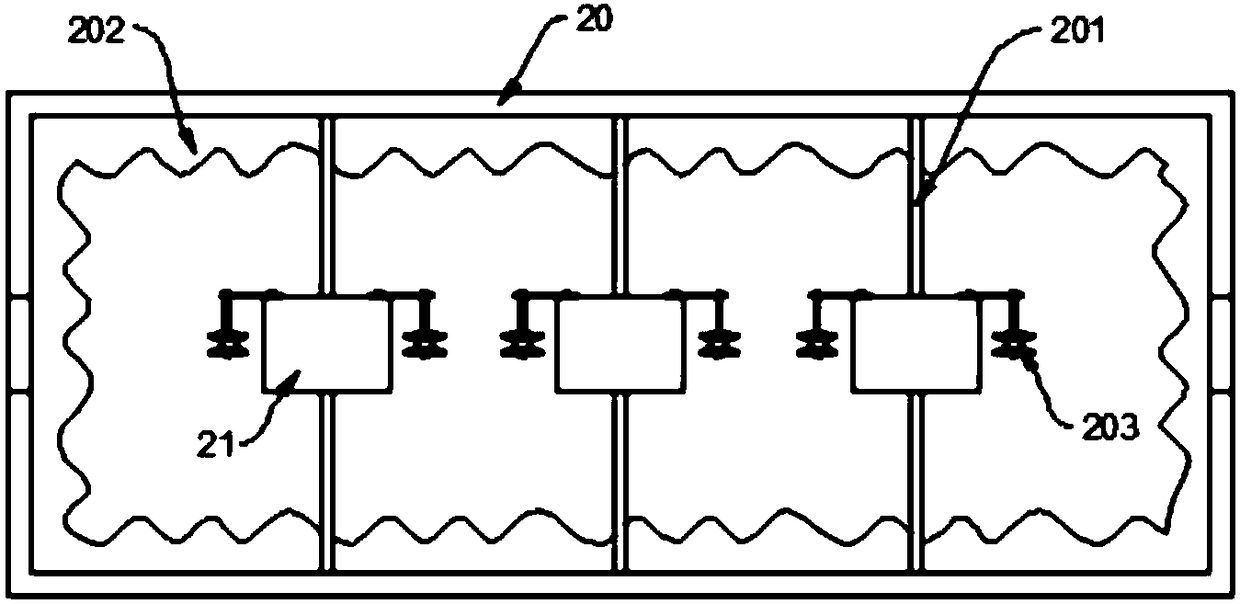

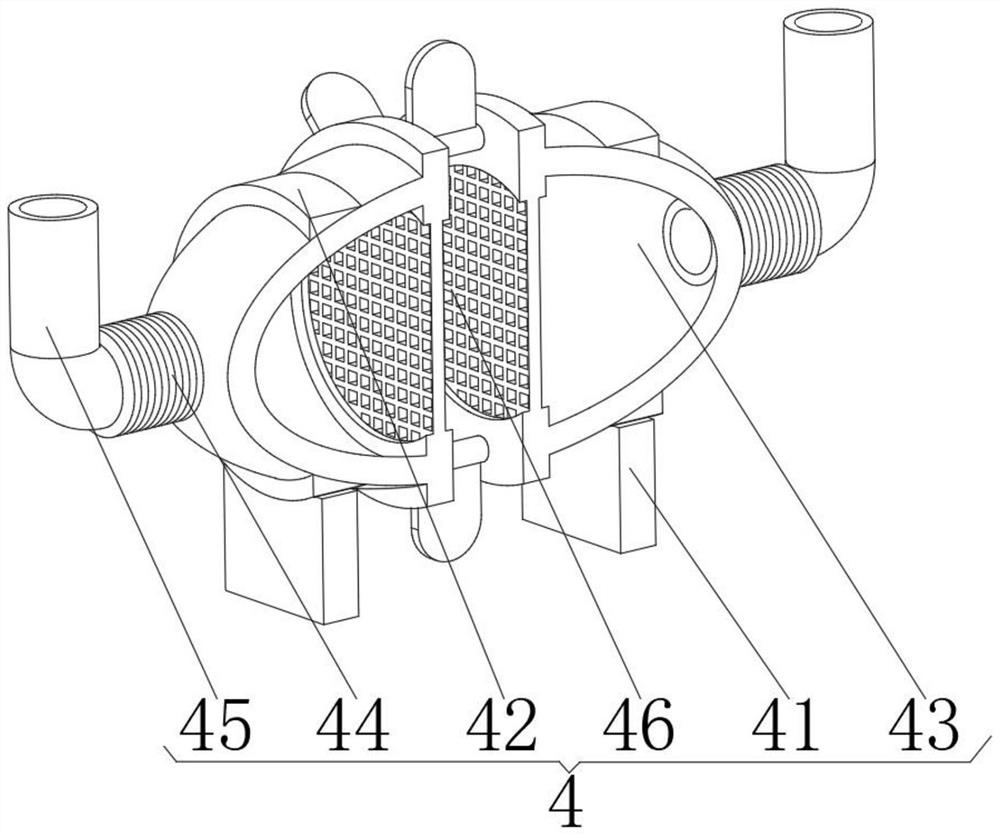

In-situ integrated additive manufacturing device for nano-metal circuit

ActiveCN108112159AEvenly distributedSuitable temperature fieldAdditive manufacturing apparatus3D rigid printed circuitsModular designMetal particle

The invention discloses an in-situ integrated additive manufacturing device for a nano-metal circuit, and the device employs a modular design, achieves the high integration of an additive delivery module of nano-metal, in-situ heating, in-situ laser sintering, in-situ irradiation reduction and gas protection, and achieves the coordinative control. The device can achieve the preparation of a two-dimensional plane circuit, and also can achieve the preparation of a three-dimensional circuit which is complex in complex surface curvature and curvature changes. According to the invention, the forming, in-situ reduction and in-situ sintering of a nano-metal circuit are integrated, thereby solving a problem nano-metal oxidation, and improving the efficiency. The manufacturing shape and size are not limited by a sintering furnace, thereby enlarging the application range of an additive manufacturing method, solving a problem of non-uniform distribution metal particles in a preparation process ofa conventional nano-metall circuit or residual gaps after sintering, improving the circuit compactness and consistency, and finally obtaining a circuit with the good performances.

Owner:HARBIN INST OF TECH AT WEIHAI

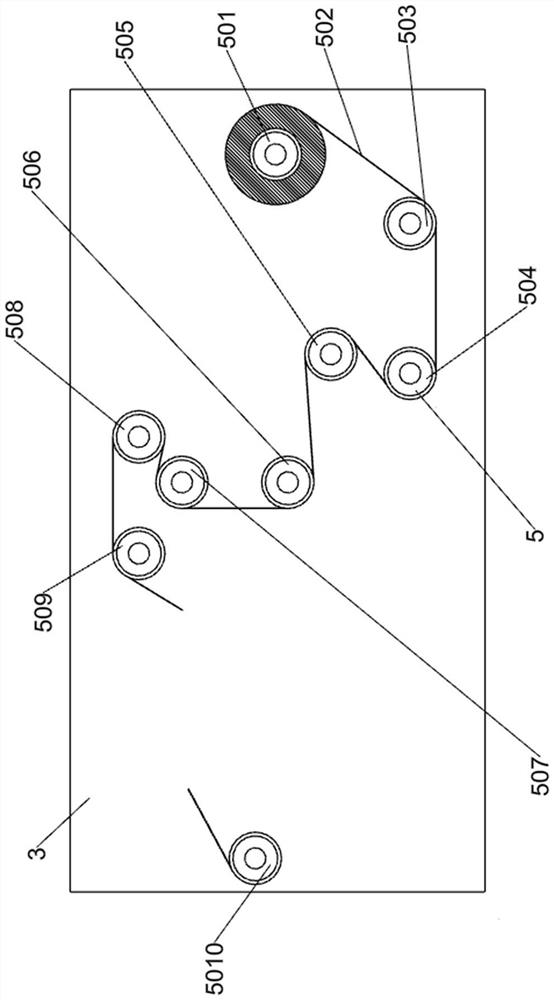

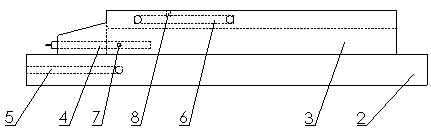

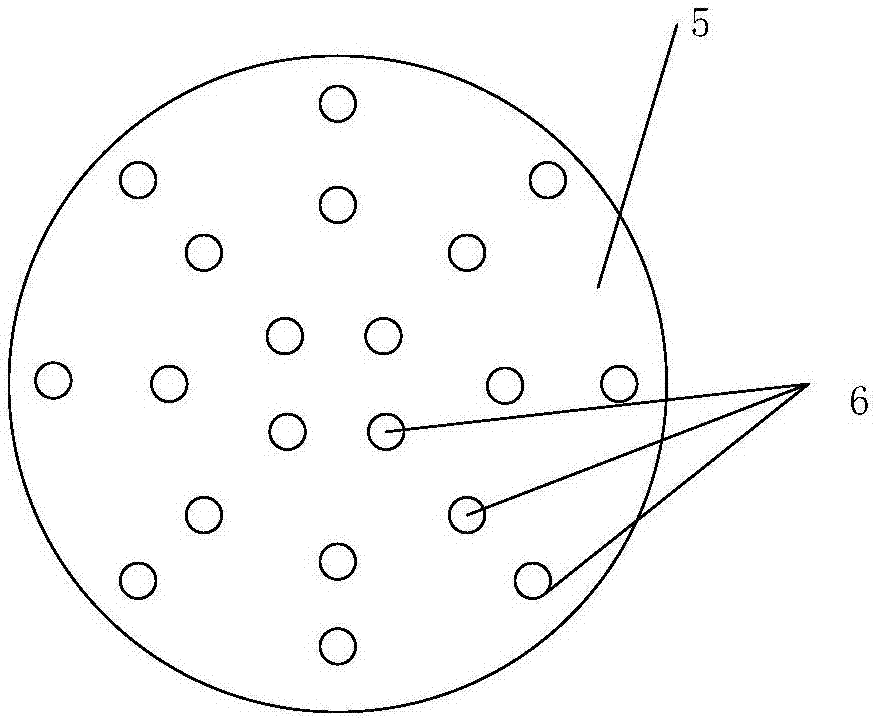

Optical cable production line

PendingCN108544734ARapid cooling and solidificationSmall footprintOptical articlesProduction lineEngineering

An optical cable production line comprises an optical fiber pay-off device, a twisting device, an extruder, a cooling and curing system and a winding device which are arranged in sequence, the coolingand curing system comprises an optical cable rubber coating curing device and a cable rubber coating air cooling device, and the optical cable rubber coating curing device and the optical cable rubber coating air cooling device are sequentially arranged behind the extruder. The optical cable rubber coating curing device comprises an atomizer, the atomizer is provided with a plurality of atomizingnozzles uniformly circumferentially arranged around a curing channel; and the optical cable rubber coating air cooling device comprises a wind distributor, and the wind distributor is provided with aplurality of air cooling nozzles uniformly circumferentially distributed around a cooling channel. An optical cable undergoes water mist cooling curing after being coated with rubber in order to stabilize the performances of the above product, the cooling curing efficiency is high, and a very long cooling water tank is not needed, so the occupied space of the optical cable production line is saved; and high pressure blowing is performed after optical cable rubber coating and curing to rapidly blow away residual water on the surface of the optical cable in the last cooling curing process, so the occupied space is small, and the efficiency is high.

Owner:JIANGSU AOTONG OPTICAL CABLE TECH CO LTD

PVC coiled material laminating machine

PendingCN113911784AReduce wearAvoid damagePretreated surfacesCoatingsPolyvinyl chlorideElectric machinery

The invention provides a PVC (polyvinyl chloride) coiled material laminating machine, and belongs to the technical field of laminating machines. The PVC coiled material laminating machine comprises a support frame, one side of the back of the support frame is fixedly connected with a support plate, the upper surface of the support plate is fixedly connected with a first motor, and an output end of the first motor is fixedly connected with a first screw rod. According to the PVC coiled material laminating machine, by arranging sliding blocks, a cutter, a second lead screw and a cutting groove, the first lead screw rotates, so that the sliding blocks move left and right and get close to each other, the trimming width is adjusted, and the use range is enhanced; the second lead screw rotates to enable the cutting groove and the cutter to move synchronously, so that the trimming widths of the left end and the right end of a coiled material are kept consistent when the coiled material is trimmed, and the trimming smoothness and flatness of the cut coiled material are improved; the cutter is in an arc shape, so that the trimming precision can be further improved, abrasion of the cutter in the trimming process is greatly reduced, and the service life is prolonged; and the cutting groove makes contact with the cutter, so that the cutter is prevented from being damaged.

Owner:FOSHAN WELL PLASTICS

Method for preparing aluminum-scandium alloy with high scandium content

The invention discloses a method for preparing an aluminum-scandium alloy with high scandium content. The method comprises the steps that metal scandium and metal aluminum are weighed according to thescandium content in the aluminum-scandium alloy needing to be prepared; the obtained materials are added into a medium-frequency induction melting furnace, continuously vacuumizing is carried out, and then heating is carried out to 1200-1600 DEG C to melt the metal scandium and the metal aluminum; after complete melting is achieved, alloy liquid is obtained, and heat preservation is carried out for 20-40 min; and high-purity argon is introduced in, the alloy liquid subjected to heat preservation is poured into a water-cooled copper die, circulating water is cooled to 1-15 DEG C by adopting amold circulating water refrigerating system, the cooled circulating water is introduced into the water-cooled copper die to circularly cool the alloy liquid, and cooling and solidifying of the alloy liquid can be completed within 3-8 seconds to obtain an aluminum-scandium alloy cast ingot with scandium content of 5%-99%. According to the method, rapid cooling can be achieved within 3-8 s, the aluminum-scandium alloy with high scandium content which is high in purity, high in compactness, low in segregation, uniform in component and low in cost can be prepared, and the requirement of the current market for the aluminum-scandium alloy with high scandium content is met.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Casting and die baking technology for engine cam shaft

The invention discloses a casting and die baking technology for an engine cam shaft. The technology comprises the steps that firstly, a die is placed in a die box, and then a chilling block is placed to be attached to the cam face of the die; secondly, precoated sand is added to the surface of the die and is leveled; thirdly, the die box is placed in an oven, an oven door is closed, the frequency of an alternating power source is adjusted to 35-55 Hz, baking is conducted for 30-60 s, the alternating power source is turned off, and the die box is naturally cooled to 100 DEG C-150 DEG C in the oven; and fourthly, the die box is taken out of the oven, natural cooling is conducted to the normal temperature, and the die is taken out. By means of the casting and die baking technology, when a model is baked, moulding sand can be heated more evenly, contraction is consistent during cooling, the rejection rate of the model is reduced, and the casting quality of the cam shaft is improved.

Owner:ZHEJIANG BOXING IND & TRADE

Aging-resistant and corrosion-resistant SMC sheet molding compound and molding device thereof

The invention discloses an aging-resistant and corrosion-resistant SMC sheet molding compound and a molding device thereof. The aging-resistant and corrosion-resistant SMC sheet molding compound comprises following raw materials in parts by weight: 70-120 parts of epoxy vinyl ester resin, 2-4 parts of an antioxidant, 8-12 parts of a flexibilizer, 15-30 parts of a low profile agent, 1-5 parts of athickener, 30-50 parts of 15-25mm alkali-free untwisted glass fibers, 8-12 parts of a release agent, 1-4 parts of a curing agent, 5-10 parts of color paste, 2-2.5 parts of a dispersing agent, and 0.5-1.5 parts of active magnesium oxide. The forming device thereof comprises an upper die and a lower die, a first trapezoidal push block and a second trapezoidal push block are respectively arranged inthe upper die and the lower die, an L-shaped transmission rod is rotatably connected to a die arm, and a cross beam is arranged above an upper push plate. According to the aging-resistant and corrosion-resistant SMC sheet molding compound and the molding device thereof, by adopting the vinyl ester resin, the antioxidant and the flexibilizer, the corrosion resistance and the aging resistance are improved, a cooling device is additionally arranged so that the processing efficiency is improved, and the technology of simultaneous demolding of the upper side and the lower side is adopted so that the defect that a processed product is difficult to take out during single-side demolding is overcome, the push blocks are combined with the ejector rod, and the defect that the processed product is easily damaged by ejection during demolding by the push rod is overcome.

Owner:杭州吉圣复合材料有限公司

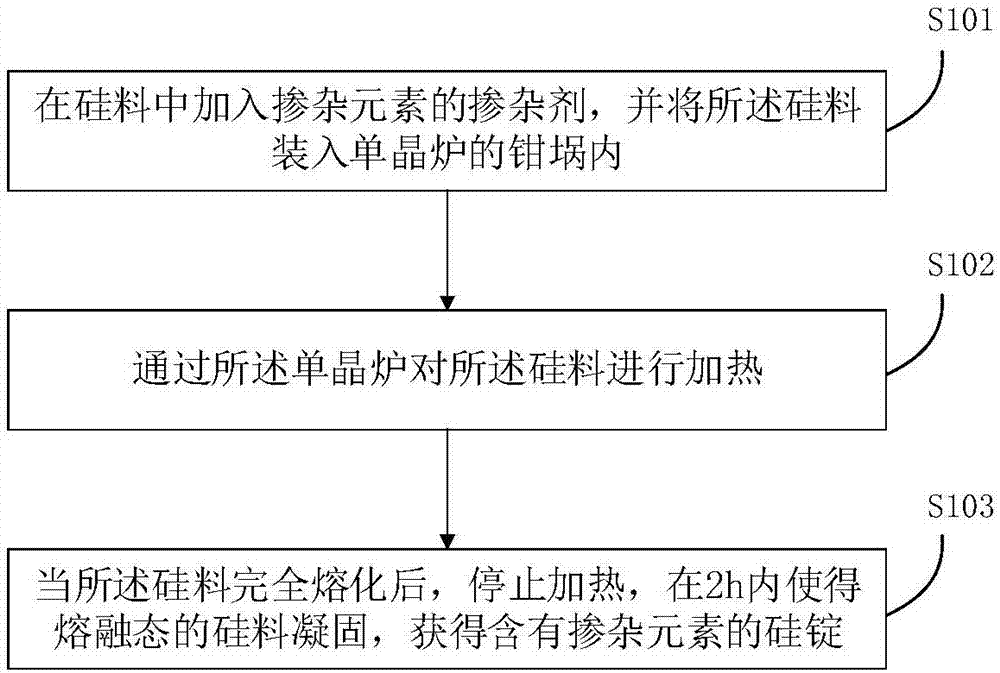

Method for silicon ingot

InactiveCN107488873AUniform resistivitySimple operation processPolycrystalline material growthFrom frozen solutionsDopantCrucible

The invention discloses a method for a silicon ingot. The method comprises the following steps of adding a dopant for doping elements in a silicon material, heating the silicon material in a crucible of a single crystal furnace into a molten state, stopping heating, and cooling the silicon material to enable the silicon material to be solidified within 2h to obtain the doped element-containing silicon ingot. According to the method for the silicon ingot, as the silicon material is solidified within a shorter time, segregation of the doped elements in the silicon material is avoided, and the uniformity of the electrical resistivity of the silicon ingot is ensured; compared with the prior art, the molten-state silicon material does not need to be controlled to acquire the silicon ingot, the operation process is more simple, the production cost is low, the silicon ingot acquired through production has uniform electrical resistivity, and a solar cell prepared by the silicon ingot has better working performance.

Owner:JINKO SOLAR CO LTD +1

Method for protecting converter through slag splashing by using carbon dioxide and nitrogen

ActiveCN113699304ARich splash angleEnlarging the inner area of the furnaceManufacturing convertersProcess efficiency improvementSlagNitrogen gas

The invention provides a method for protecting a converter through slag splashing by using carbon dioxide and nitrogen. The method is suitable for the converter using the slag splashing for protecting the converter to maintain the condition of the converter, specially-made slag splashing materials are added after tapping of the converter, the adding amount is adjusted according to parameters such as the final temperature and molten steel components, the carbon dioxide is completely adopted as slag splashing gas in the early stage of slag splashing, the characteristics of carbon dioxide kinetic energy and carbon reaction heat absorption are utilized to realize rapid thickening of low-viscosity slag in the early stage and continuous change of carbon dioxide and nitrogen in the middle stage, so that the kinetic energy of gas is continuously changed, the splashing angle of slag blocks is enriched, the area in a hearth for slag splashing protection and slag scraping is enlarged, weak parts of single-gas slag splashing are reduced, the heat absorption mechanism of the reaction of carbon dioxide and carbon is utilized in the later period, rapid cooling and solidification of the slag splashing layer are achieved, carbon on the surface of the slag splashing layer is removed, the erosion resistance of the slag splashing layer is improved, maintenance of the converter condition and long-life operation are better facilitated, and good economic benefits and social benefits are achieved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

High magnetic permeability soft magnetic alloy powder, inductance part and preparation method thereof

ActiveCN106205934BReduce power lossHigh Intrinsic Insulation ResistanceTransformers/inductances detailsMagnetic materialsApparent densityInductor

The invention discloses high-magnetoconductivity soft magnetic alloy powder. The alloy consists is prepared from the following components in parts by mass: 25.0 to 80.0 parts of Fe, 3.0 to 8.0 parts of Si, 15 to 55 parts of Ni, 1.0 to 7.0 parts of B and 1.0 to 5.0 parts of P. The invention further discloses an inductance piece prepared from the high-magnetoconductivity soft magnetic alloy powder, a preparation method of the high-magnetoconductivity soft magnetic alloy powder and a preparation method of the inductance piece. By the adoption of the preparation method disclosed by the invention, the soft magnetic alloy powder with various particle sizes can be prepared, and the soft magnetic alloy powder is high in magnetoconductivity, lower in power loss, higher in apparent density, high in tap density, lower in oxygen content, high in product pressing performance and high in magnetic ring density. Due to small oxygen content, few impurities, small carbon content, uniform alloy components and high sphericity degree, the high-magnetoconductivity soft magnetic alloy powder can be widely used as a raw material of a novel sintered inductor.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

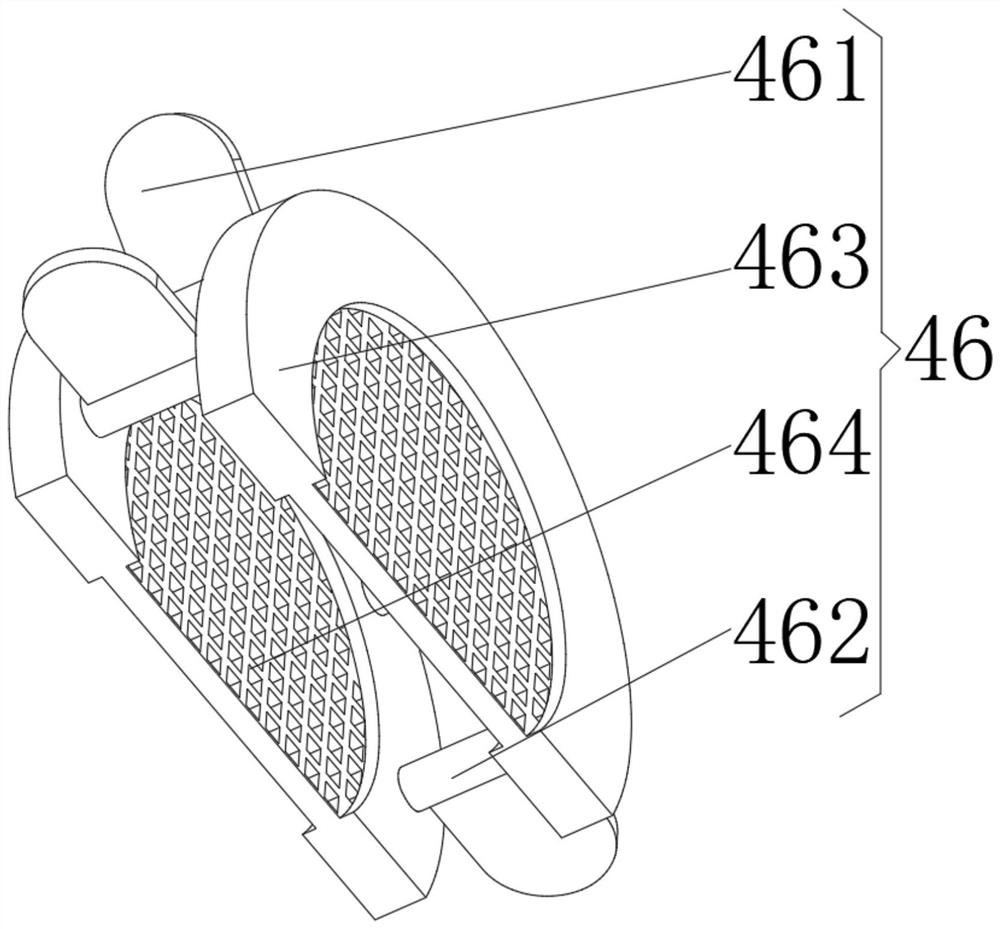

Garbage compression molding, cutting and granulating method

The invention discloses garbage compression molding, cutting and granulating equipment. The garbage compression molding, cutting and granulating equipment specifically comprises a protection box, a granulating device mounted at the top of a material guide table, an adjusting device which is mounted on the inner surface of a barrel-shaped main body and located above the granulating device, and a molding device mounted at the top of the inner surface of the barrel-shaped main body, wherein the granulating device comprises a fixing frame, an elliptical spherical shell mounted on the inner surface of a mounting ring, a spring pipe mounted at the tip end of the elliptical spherical shell, and a hardened pipe mounted at the end, away from the elliptical spherical shell, of the spring pipe. The invention relates to the technical field of granulating. Through the arrangement of the elliptical spherical shell, the accommodating area of the elliptical spherical shell is enlarged, the length of shaped garbage particles is limited, and meanwhile, the surface of the elliptical spherical shell is enlarged, contact with external flowing airflow is facilitated, internal garbage raw materials are preliminarily cooled, adhesion with the granulated and molded garbage is avoided, and the completeness among the molded particles is ensured.

Owner:周建芳

Light-reflective layer adding device for road

ActiveCN104746415AGood softeningRapid cooling and solidificationRoads maintainenceReflective layerMechanical engineering

The invention relates to a light-reflective layer adding device for a road. The device comprises a driving wheel, a shell, a glass bead barrel, a cooling device, a detection device and a heating device, wherein the detection device comprises a sliding barrel; conductive contacts are fixedly mounted on the inner side wall of the sliding barrel; a piston which can transversely move up and down along an axial line of the sliding cylinder is arranged in the sliding barrel and above the conductive contacts; a hard guiding rod coaxial to the sliding barrel is also mounted on the lower surface of the piston and extends out of the bottom of the shell; a detection blade is mounted at the lower end of the hard guiding rod; a heating hole of the heating device faces the lower edge of the detection blade. The device is simple in structure and convenient to operate; by using the device, glass micro-beads can be accurately and uniformly embedded into a melt glue surface so as to form a uniform and firm light-reflective layer.

Owner:佛山市宏润建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com