Automatic welding device capable of efficiently replacing filler rods

An automatic welding and electrode technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low degree of automation, reduced welding efficiency, lack of automatic replacement of welding electrodes, etc., so as to reduce the frequency of electrode replacement and improve welding efficiency. , to ensure the effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

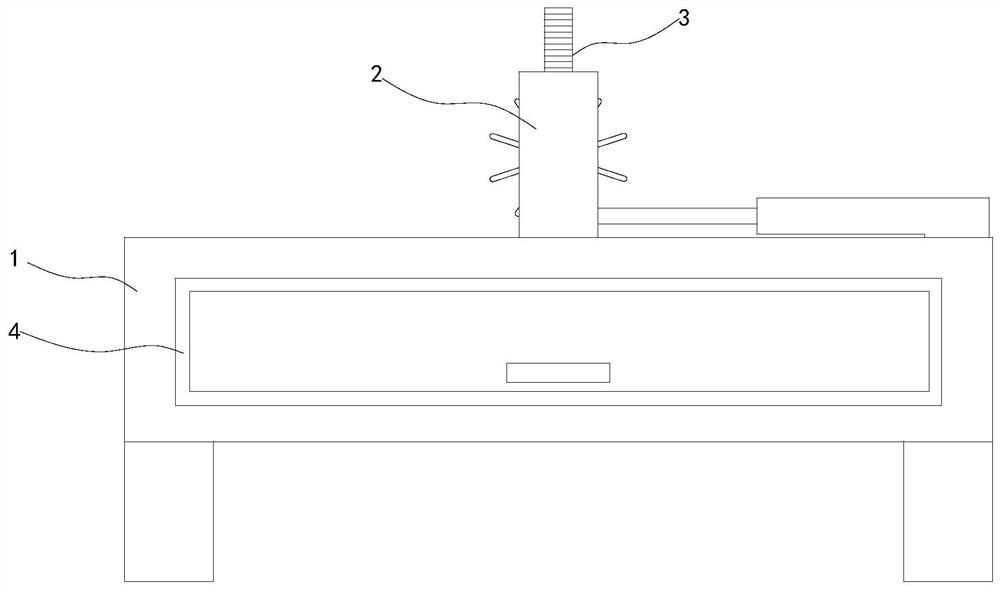

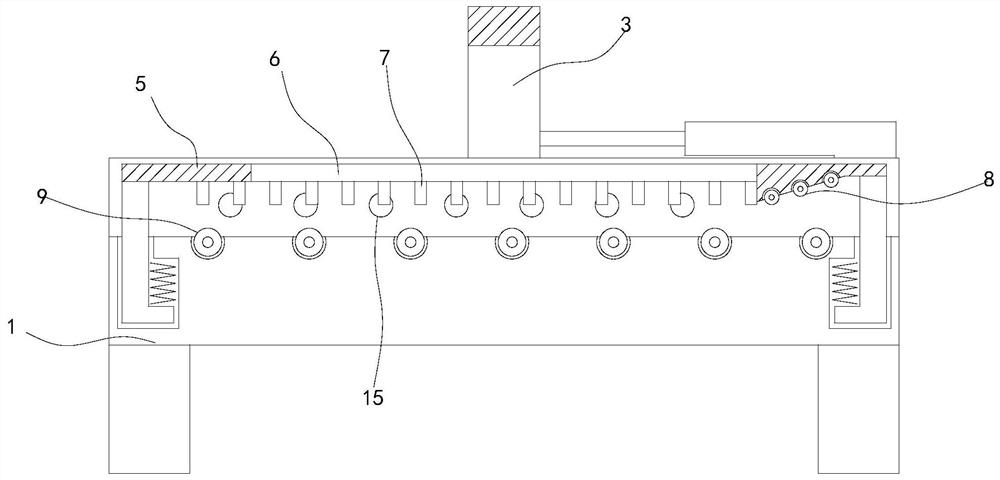

[0033] see Figures 1 to 12 , a schematic plan view and a three-dimensional structure view of an automatic welding device for efficiently replacing electrodes.

[0034] The invention provides an automatic welding device for efficiently replacing welding rods, comprising a device main body 1, a moving frame 2 is movably installed on the upper end of the device main body 1, a welding rod 3 is movably installed on the inner side of the moving frame 2, and an electrode replacement is fixedly installed on the inner side of the moving frame 2 In the device 10 , a fixed plate 5 is movably installed on the upper end of the device main body 1 , and an air injection port 15 is fixedly installed on the side of the device main body 1 opposite to the fixed plate 5 .

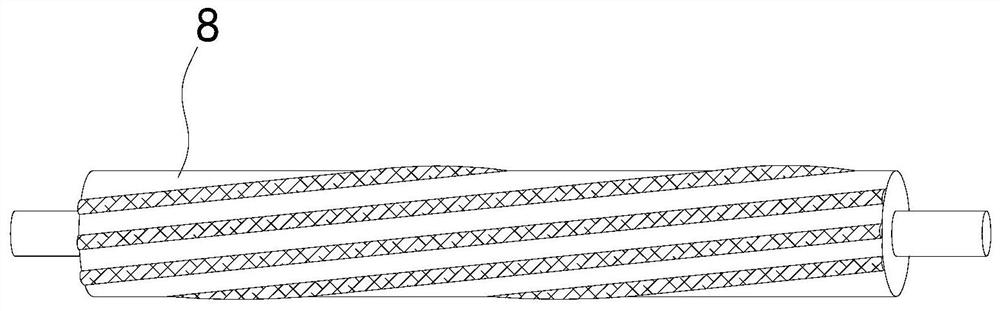

[0035] In specific implementation, the right end of the fixed plate 5 is obliquely arranged, and the rotating rod 8 is fixedly installed, the lower end of the moving frame 2 is embedded in the device main body 1, and the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com