Patents

Literature

441results about How to "Improve rotation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

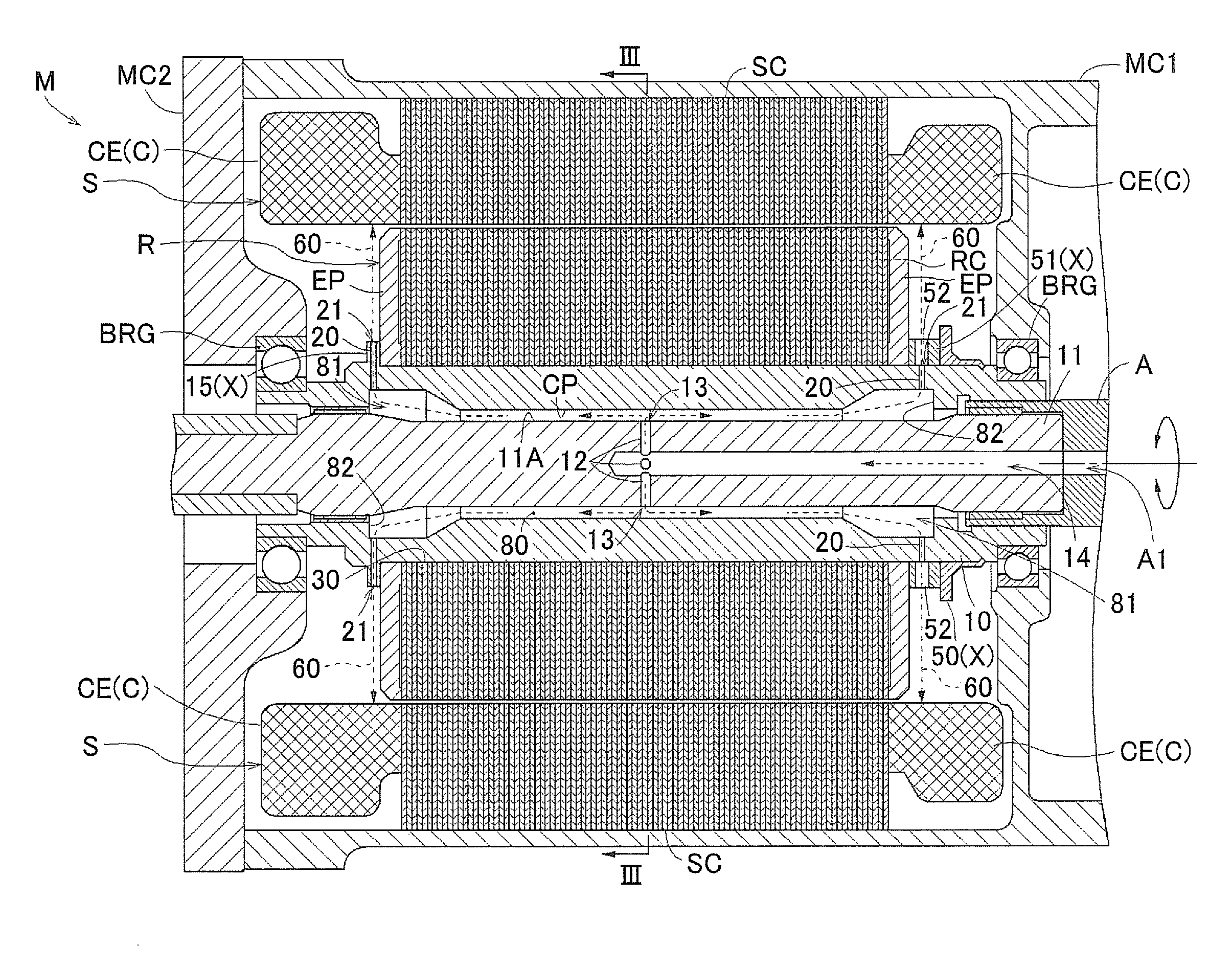

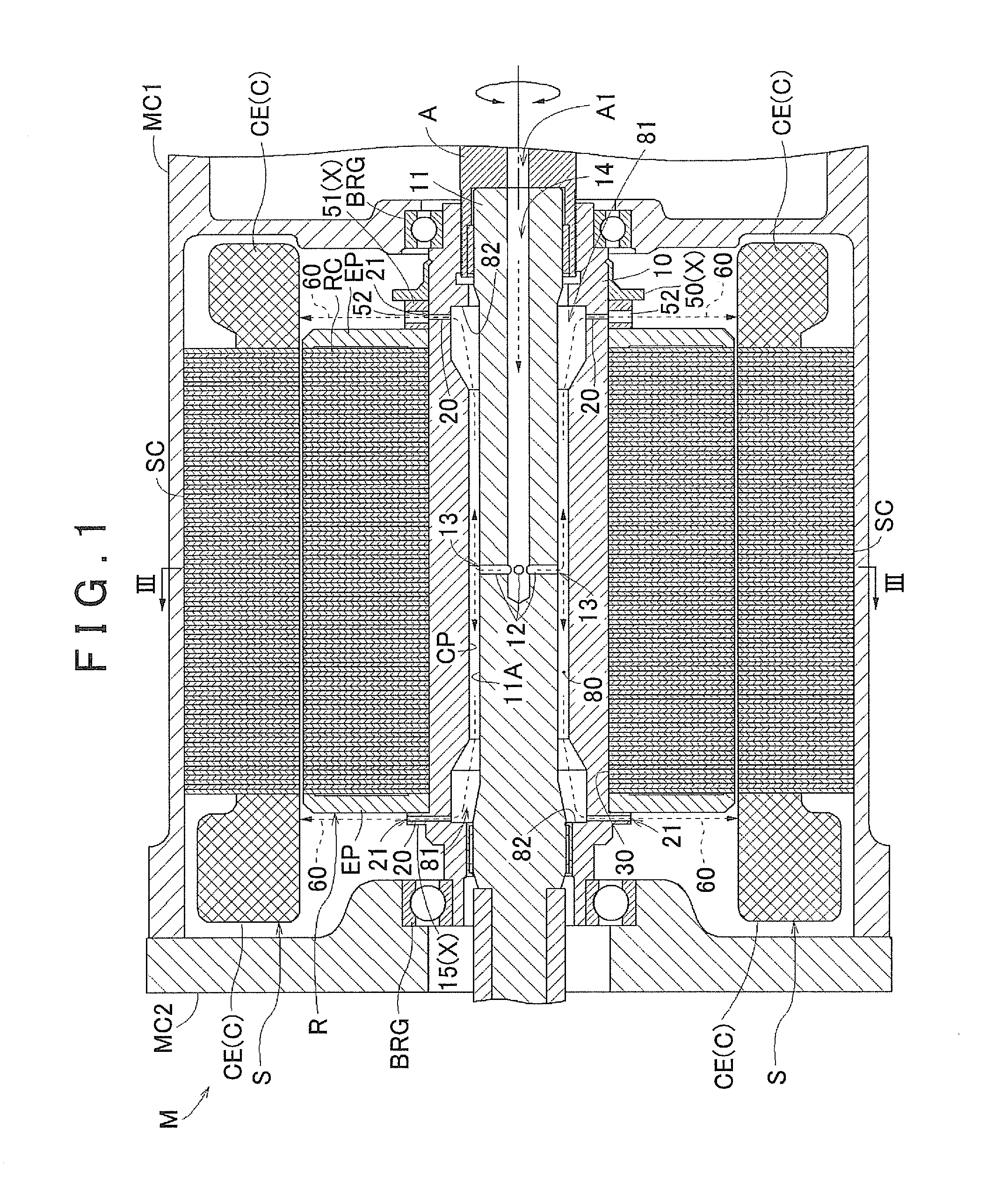

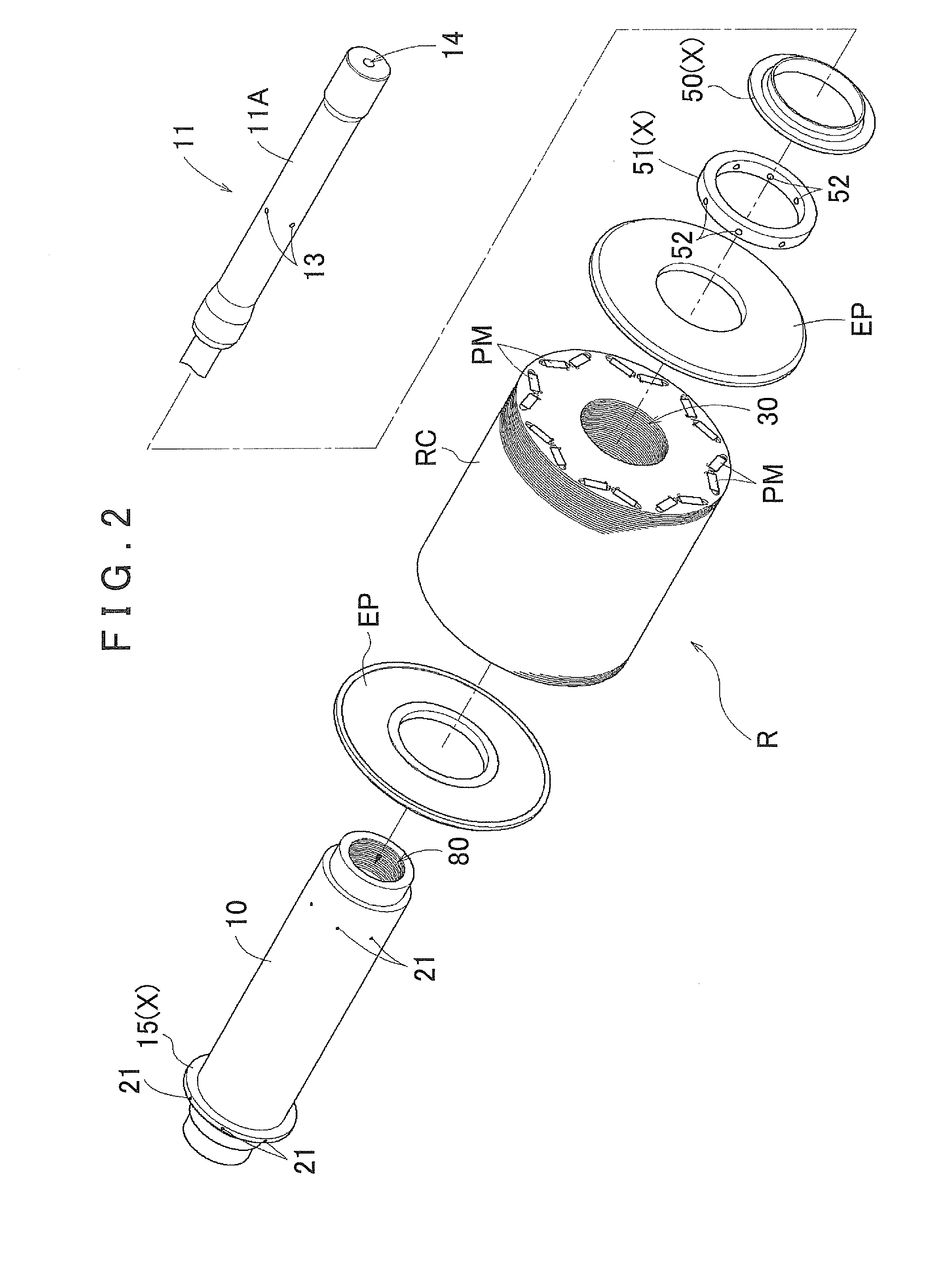

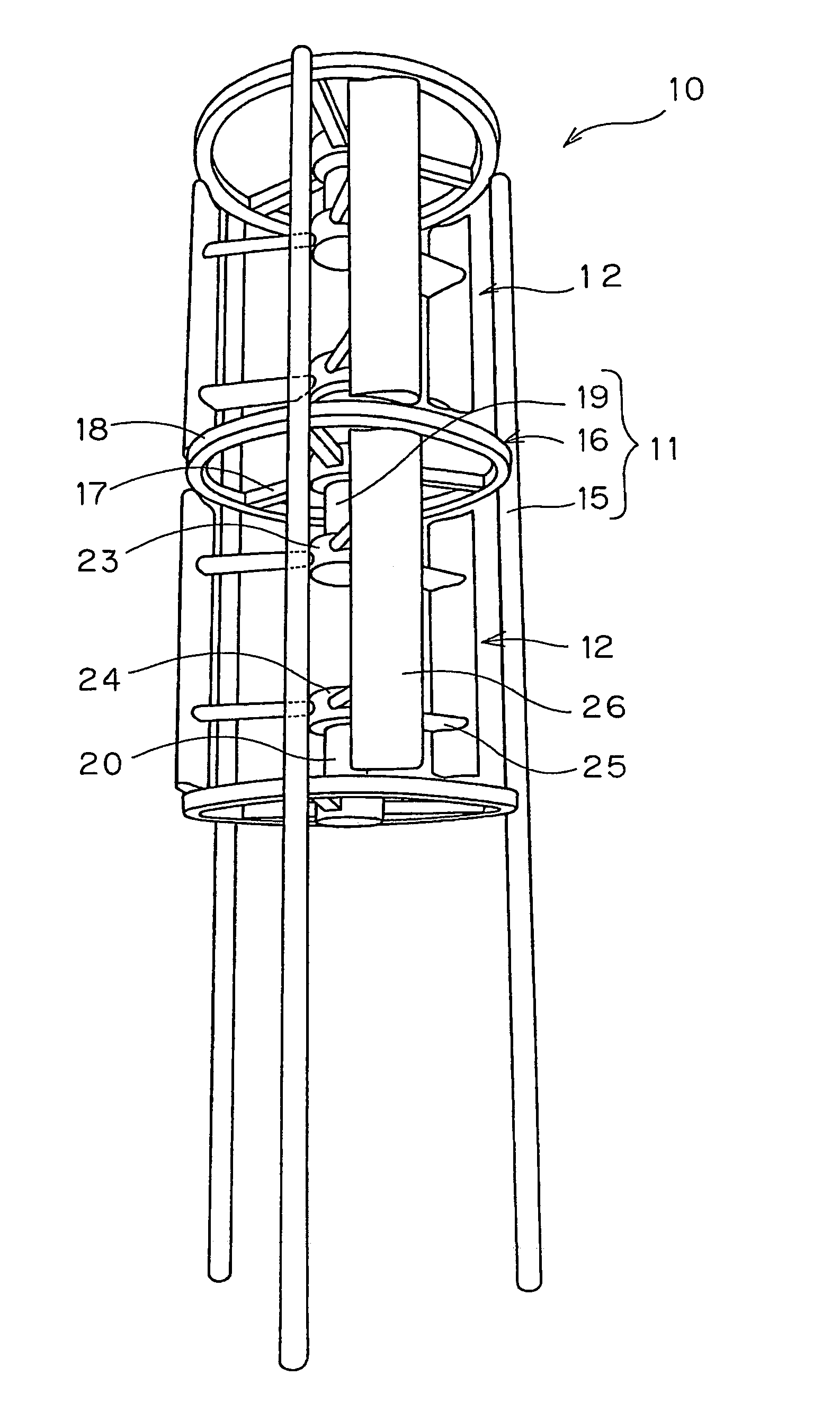

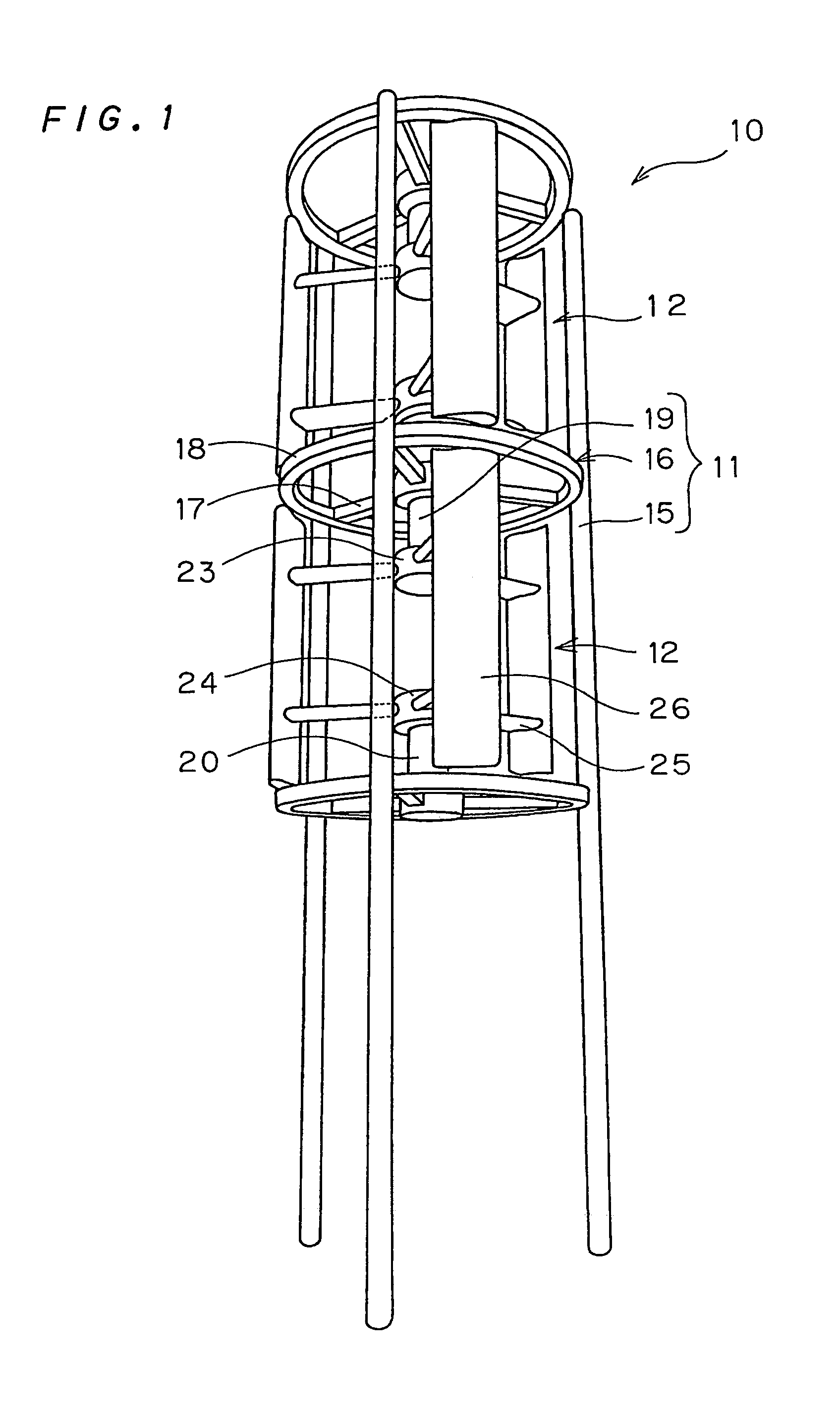

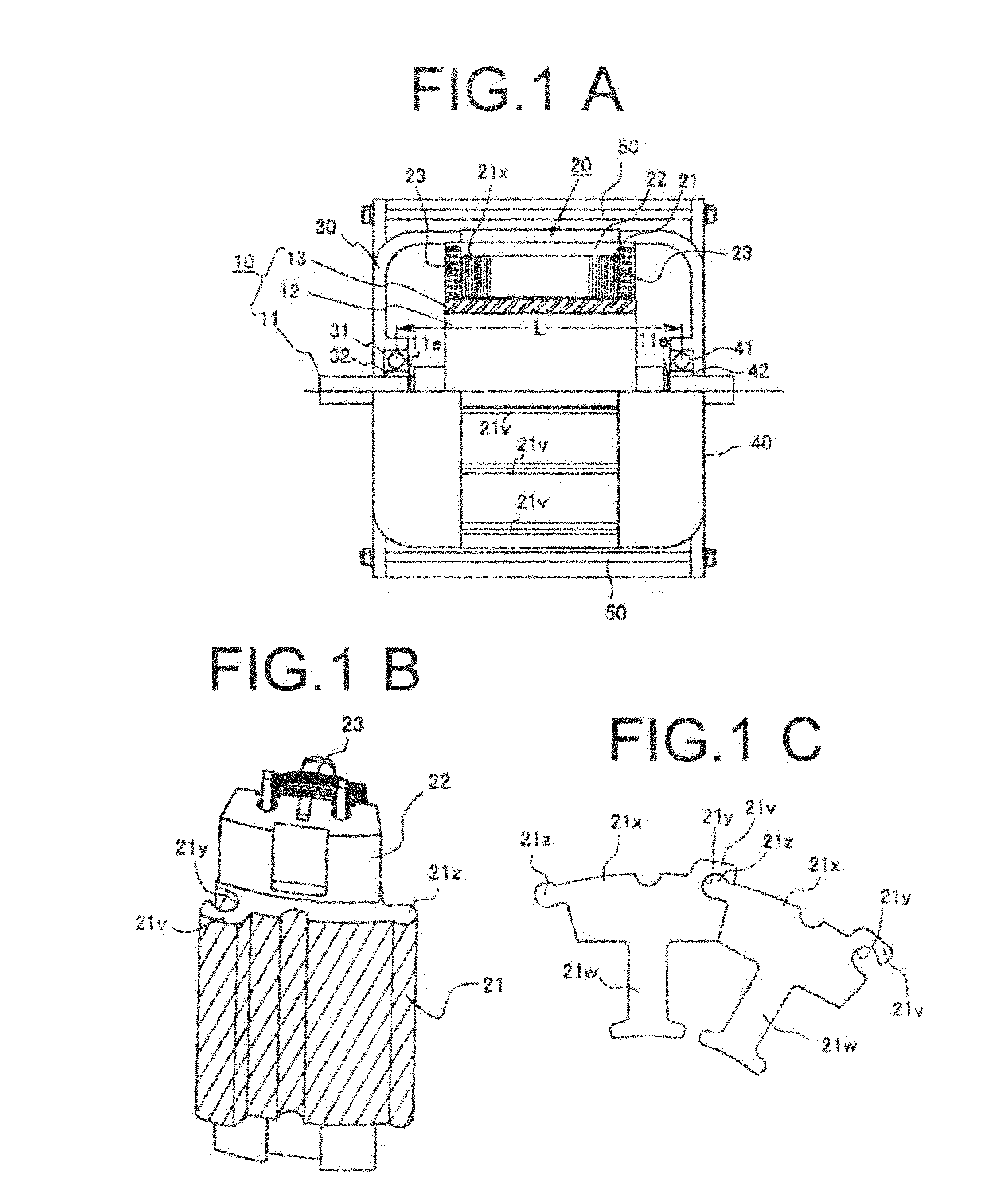

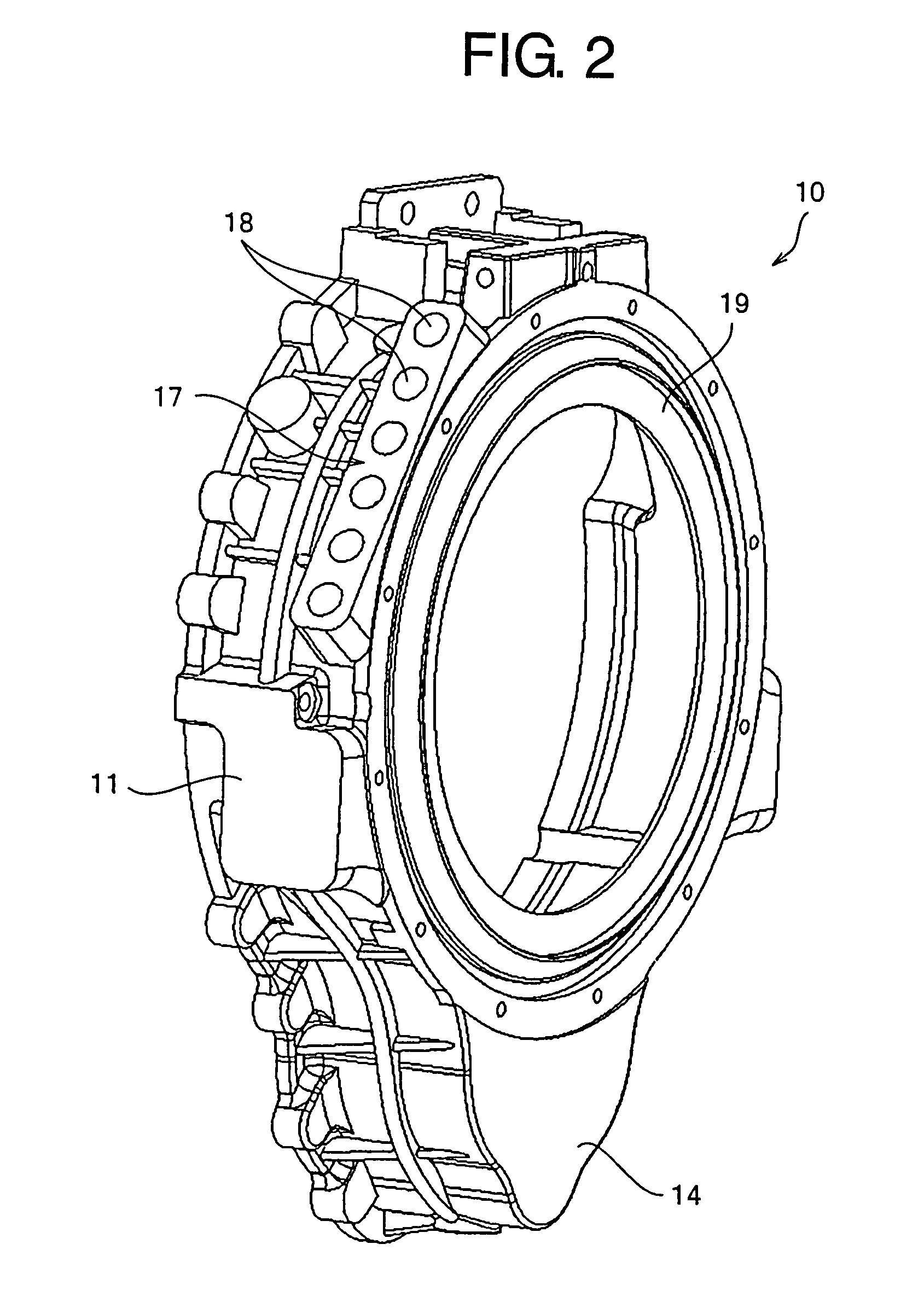

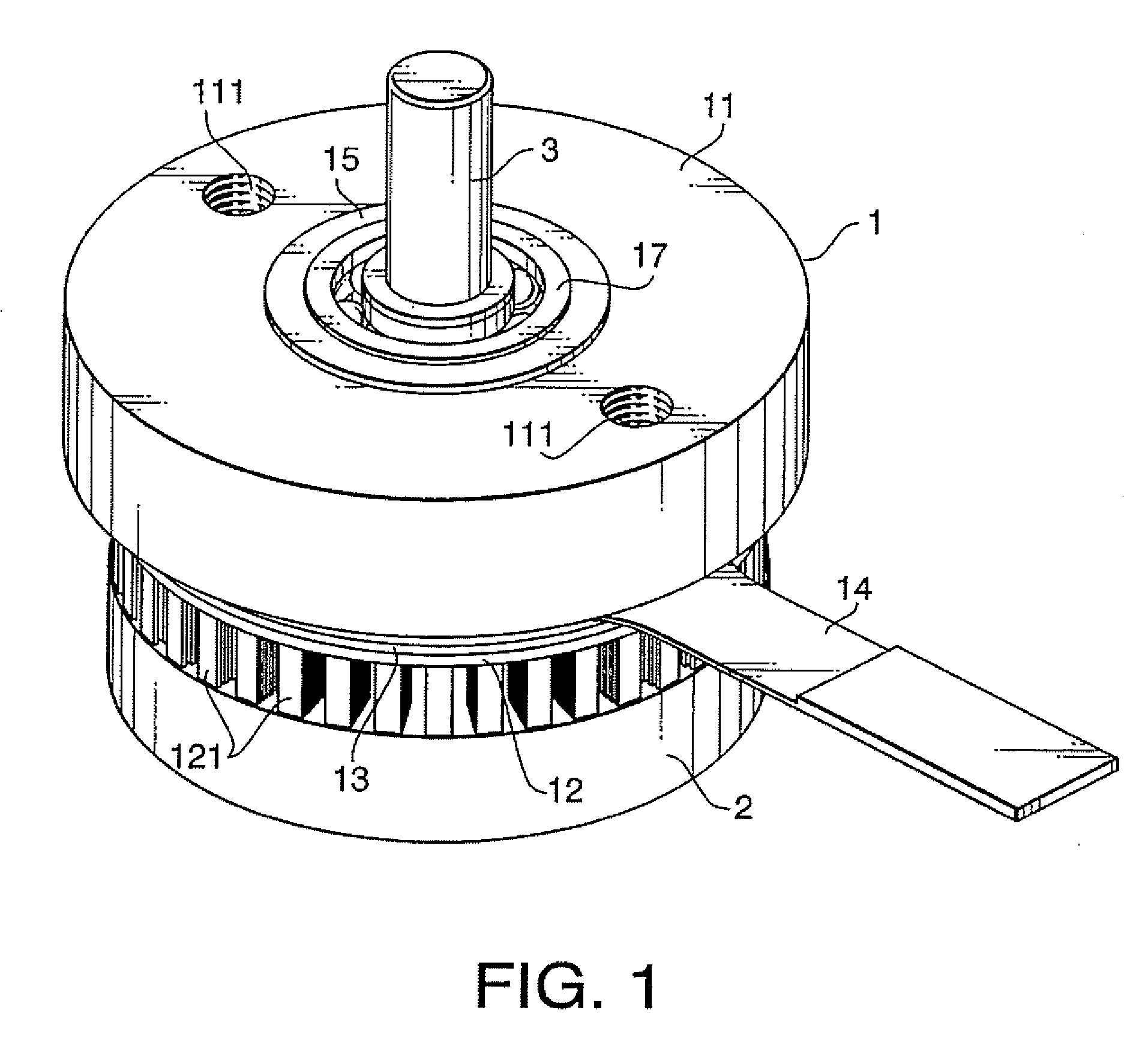

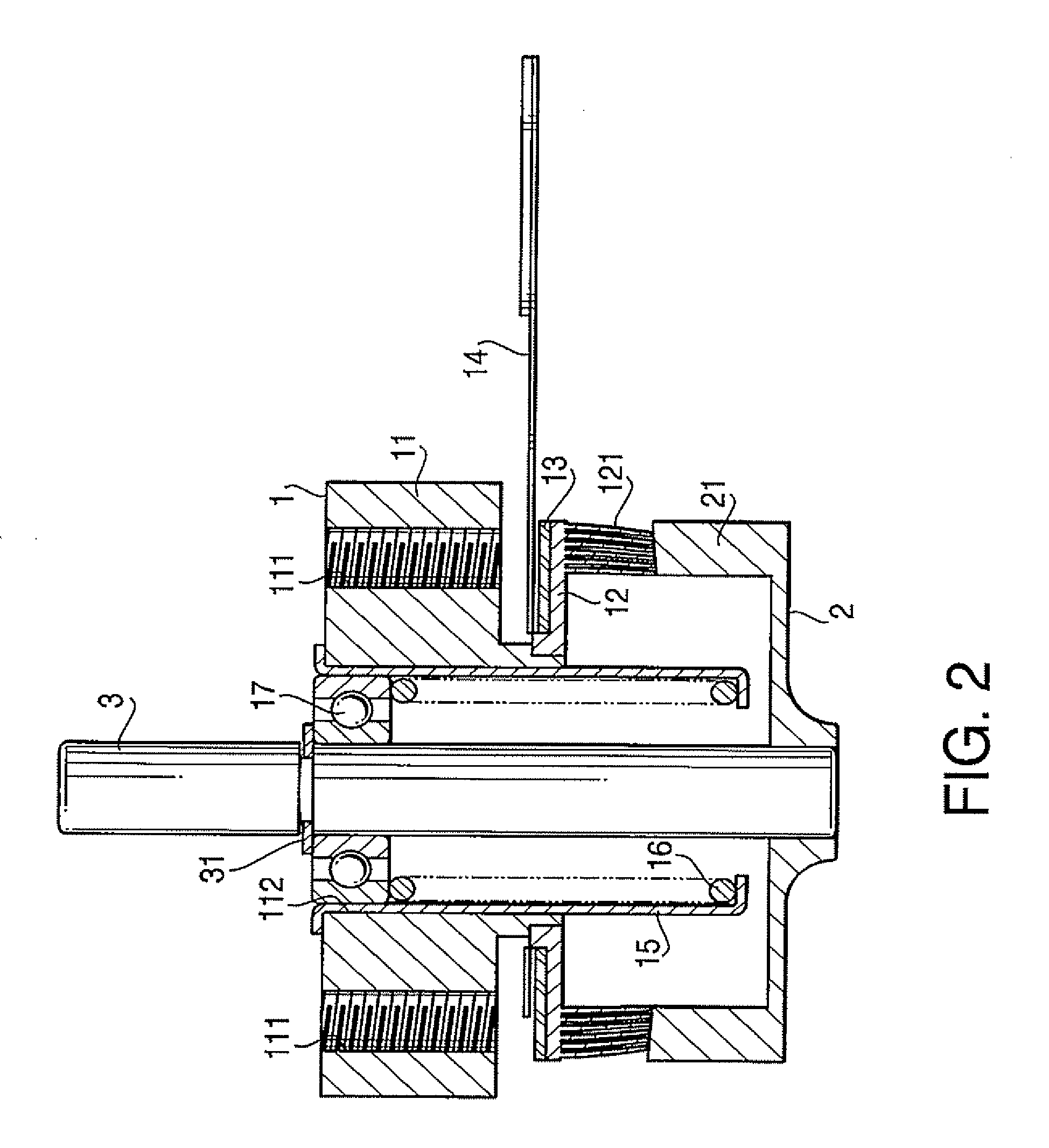

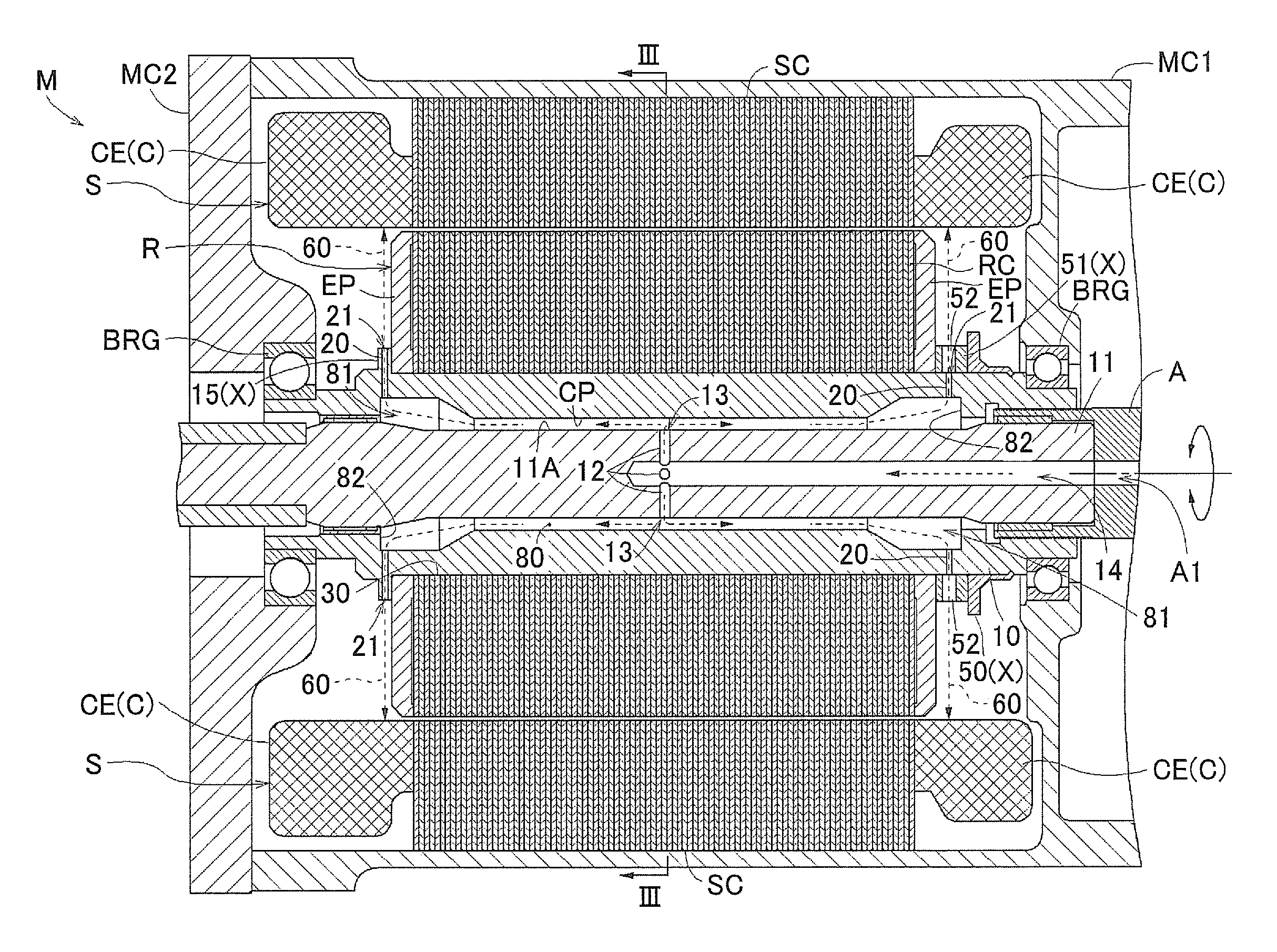

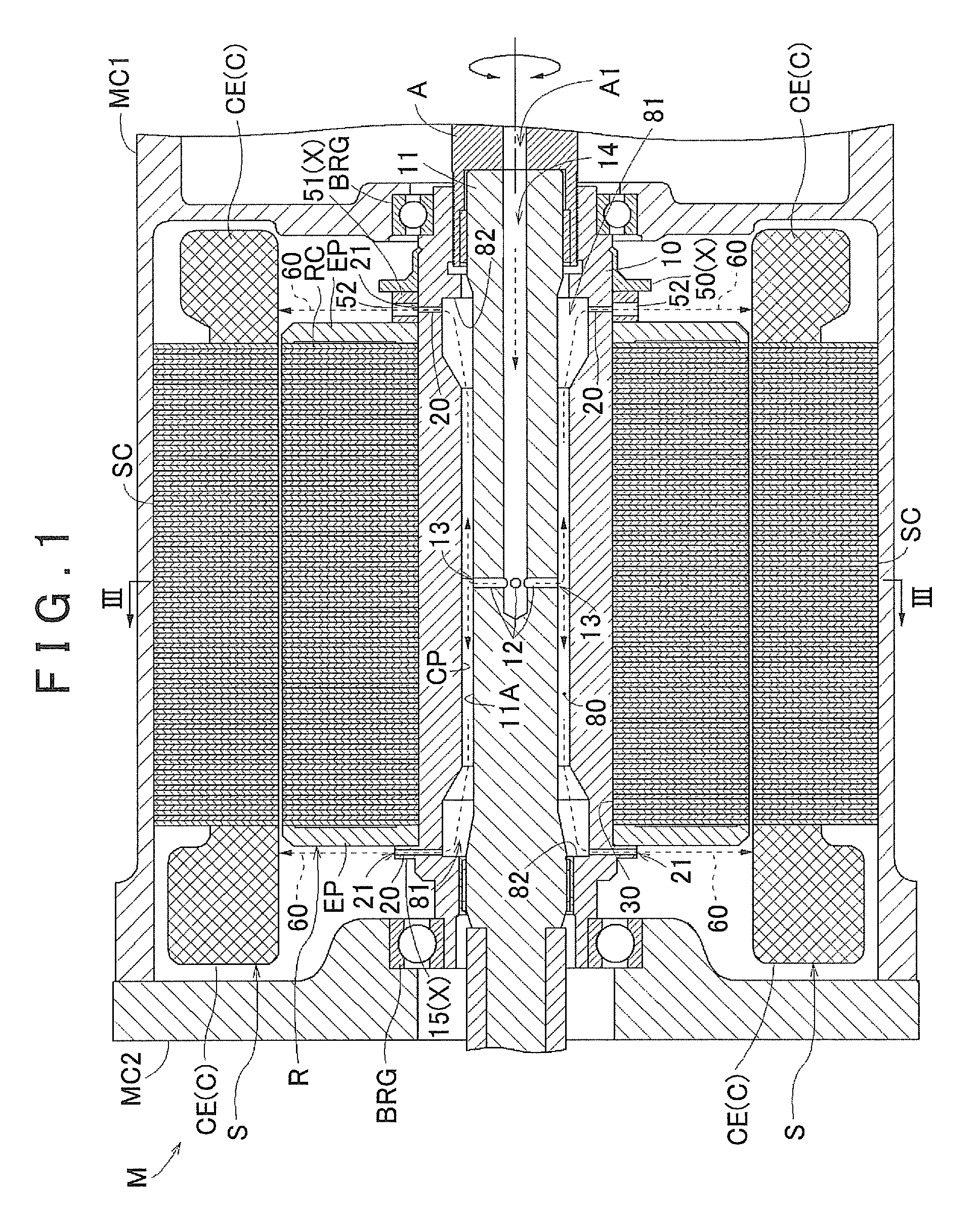

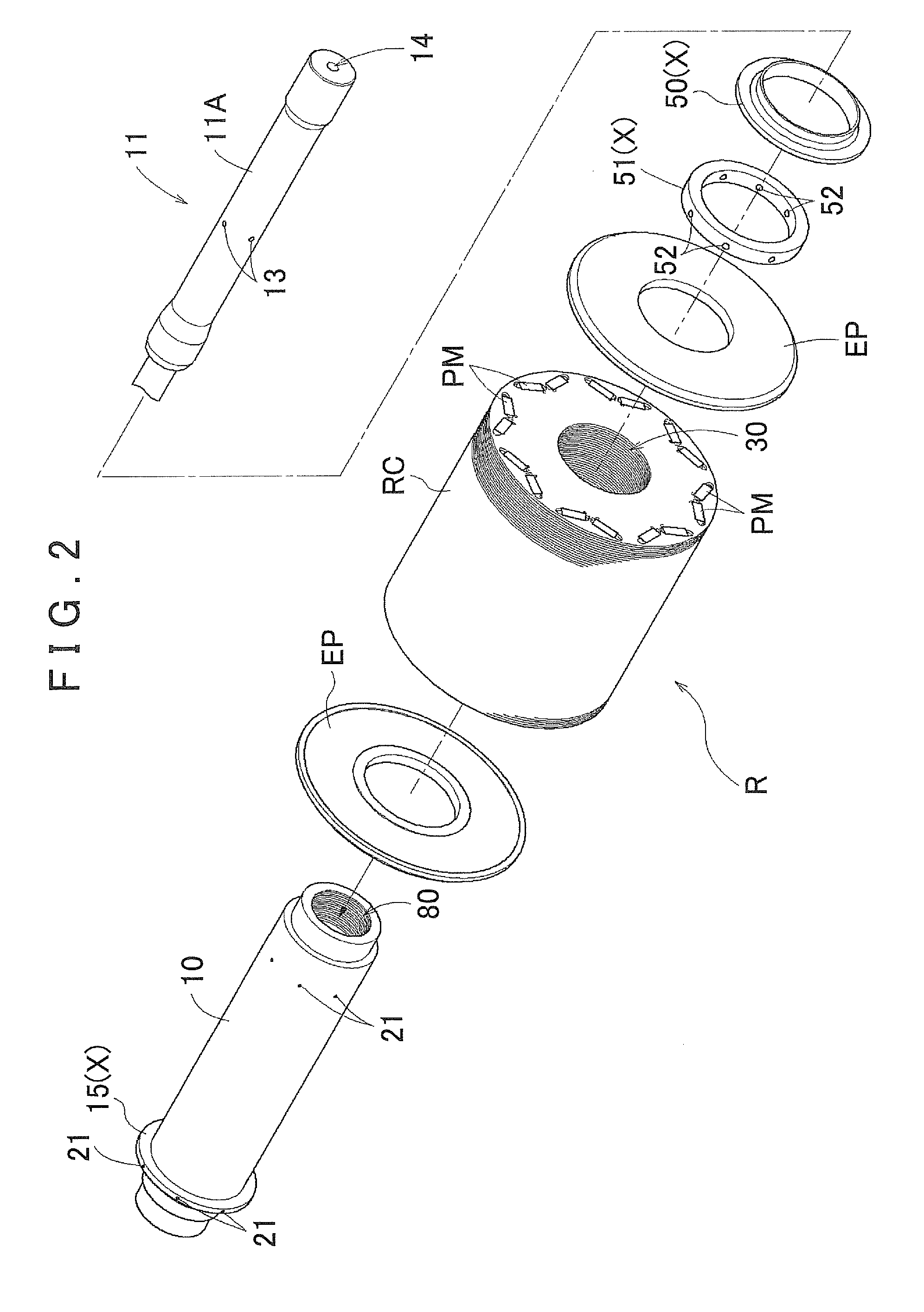

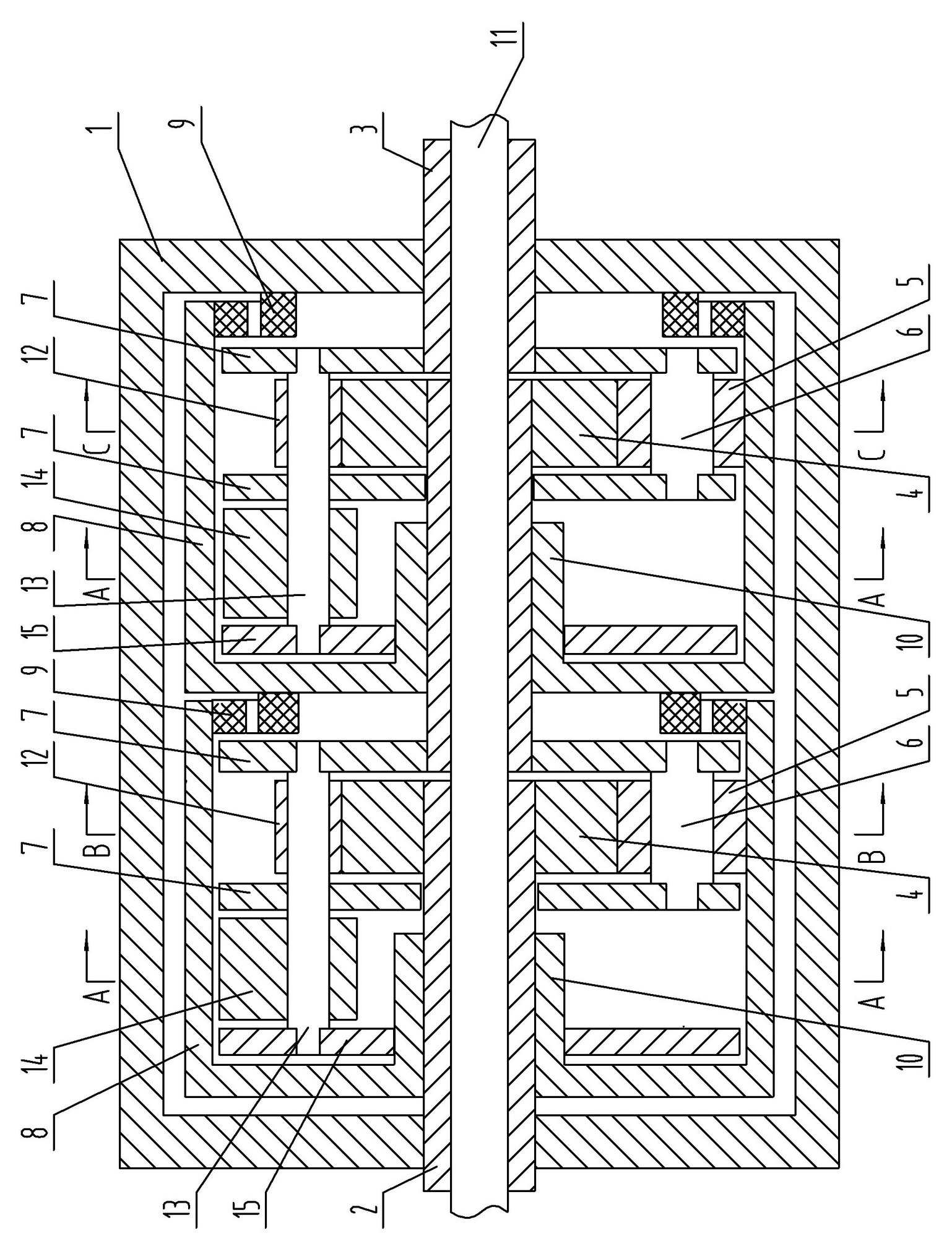

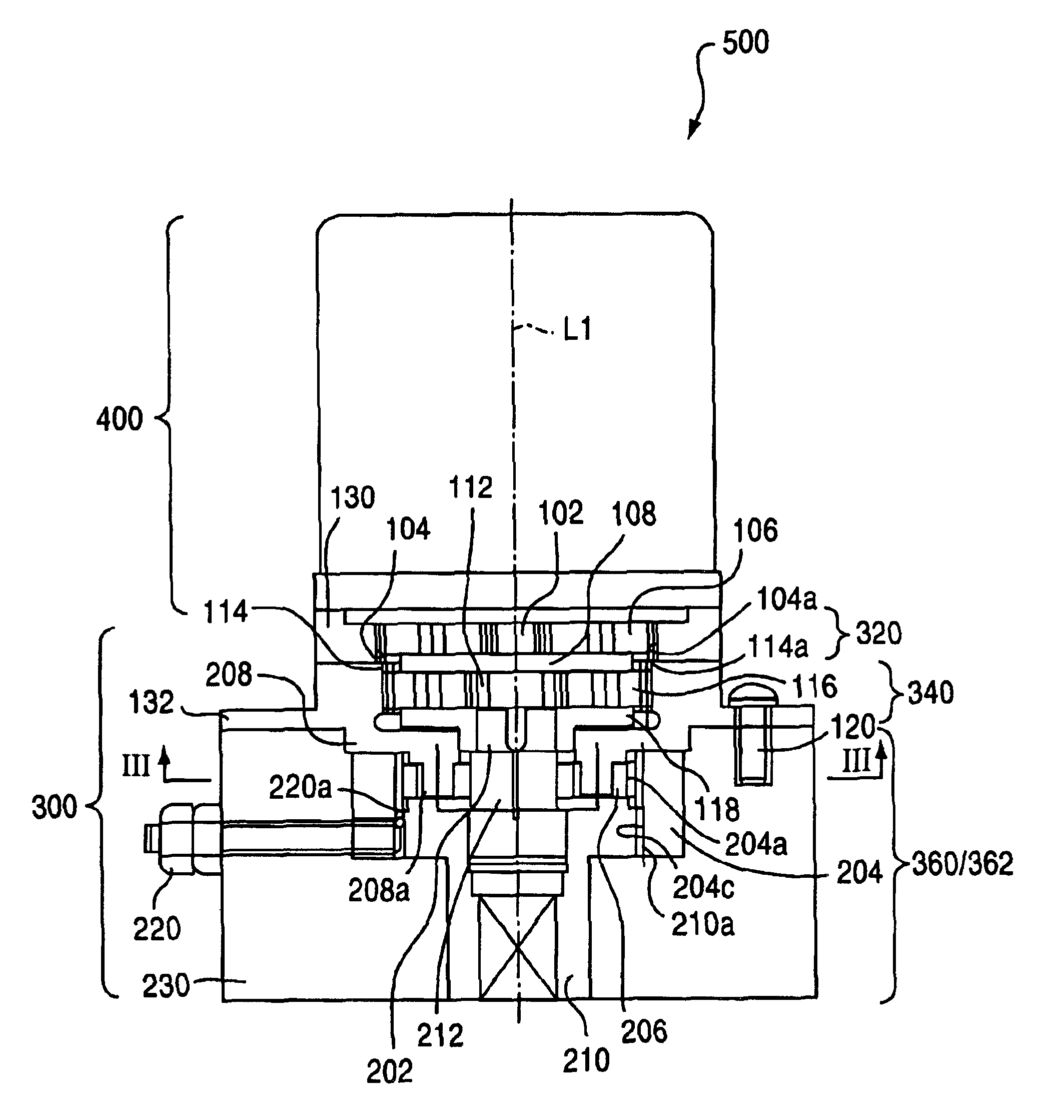

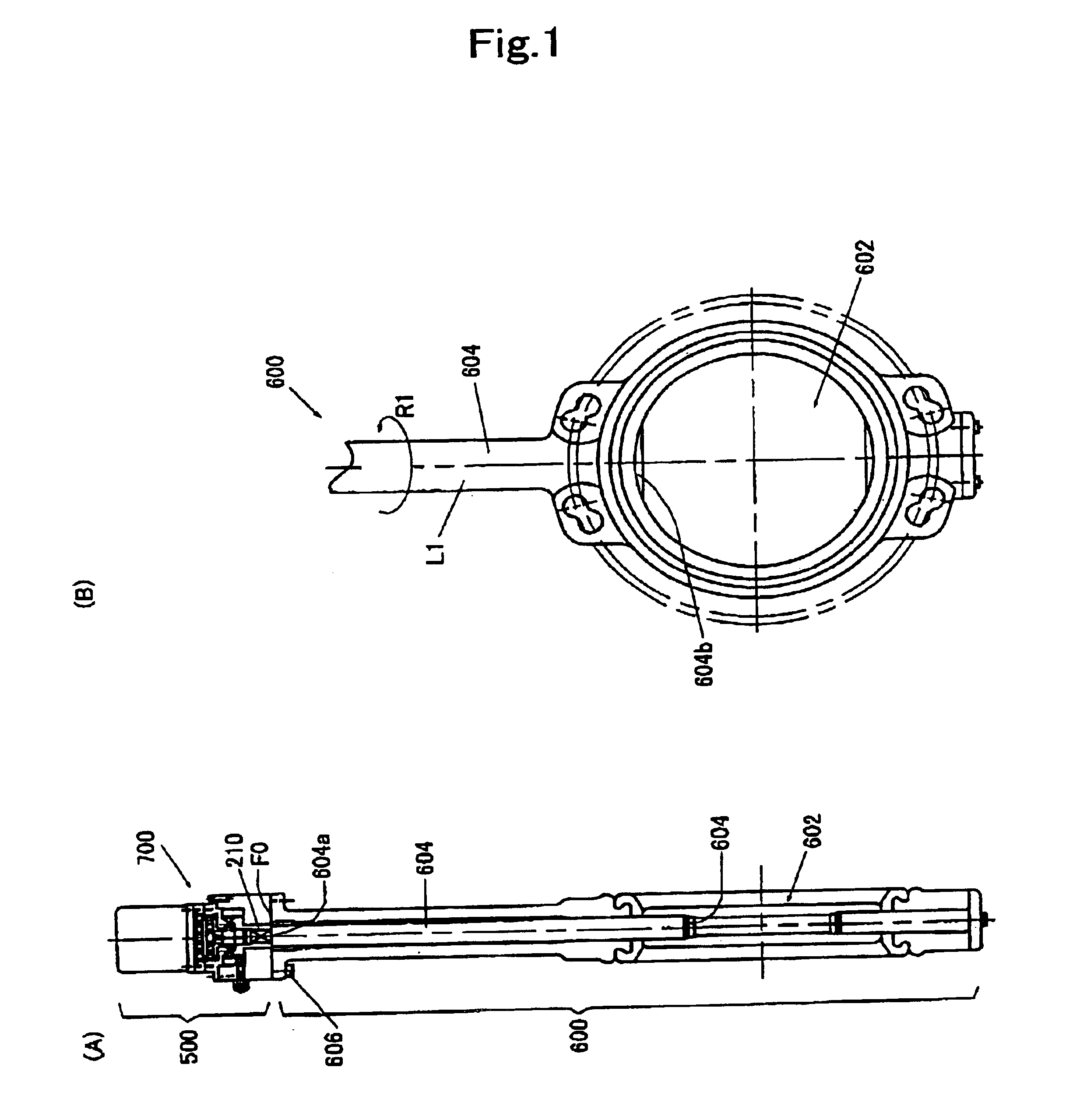

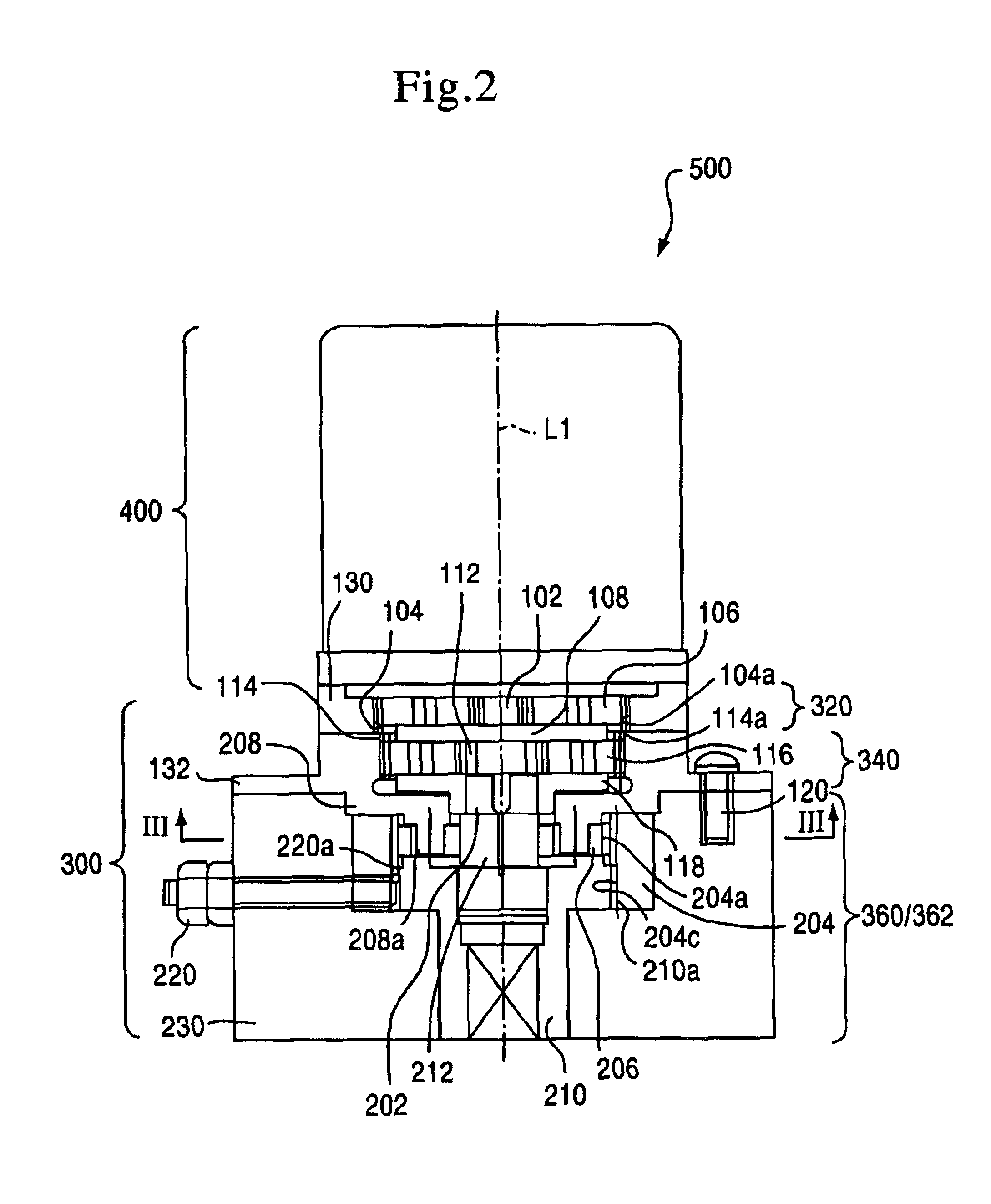

Rotor for rotating electric machine

ActiveUS20120299404A1Inexpensively formedLess energyMagnetic circuit rotating partsCooling/ventillation arrangementElectric machineDynamo

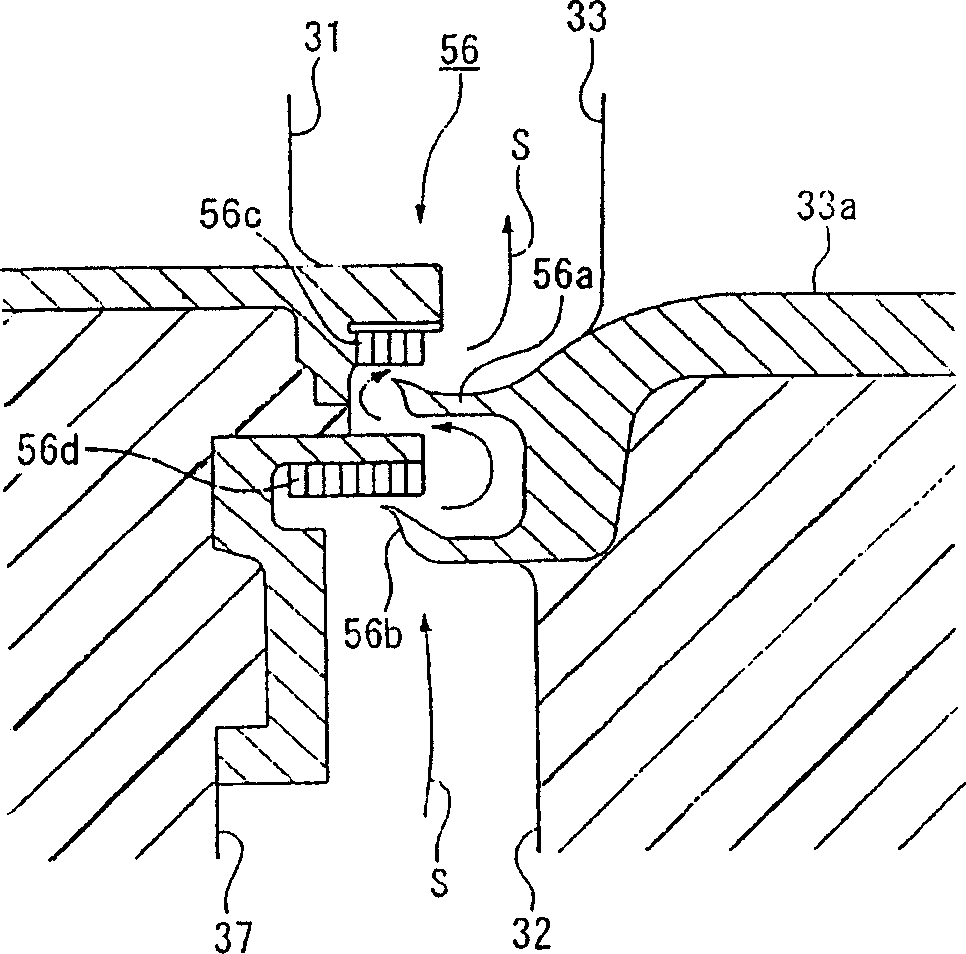

In a rotor for the dynamo, the interior circumference face of a rotor core main body makes contact in a thermally transmissible manner with a rotor axle, and the rotor axle includes a cooling medium circulation space. The rotor is provided with a cooling medium supply member, which supplies the cooling medium to the cooling medium circulation space. The cooling medium supply member is provided with a cooling medium supply path that extends in the rotor axle direction, and cooling medium supply holes that extend externally in the direction of the rotor diameter. The cooling medium supply holes are provided with supply apertures that open toward the cooling interior circumference face. The rotor axle is provided with cooling medium discharge holes that extend externally in the direction of the rotor diameter. The cooling medium discharge holes are provided with discharge apertures that open externally in the diameter direction.

Owner:AISIN AW CO LTD

Rotor supporting structure of windmill for power generation

Owner:KINPARA SHIRO

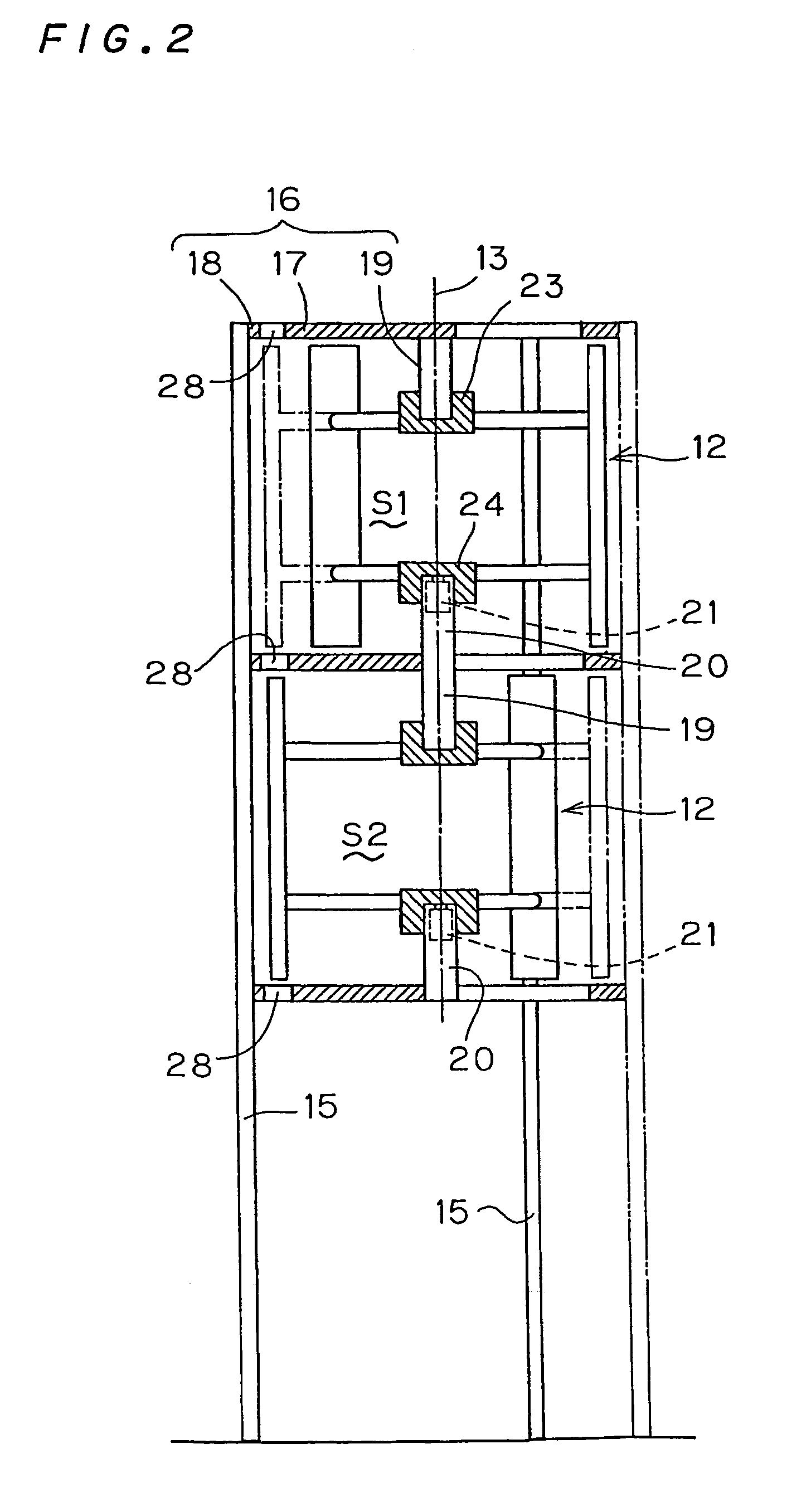

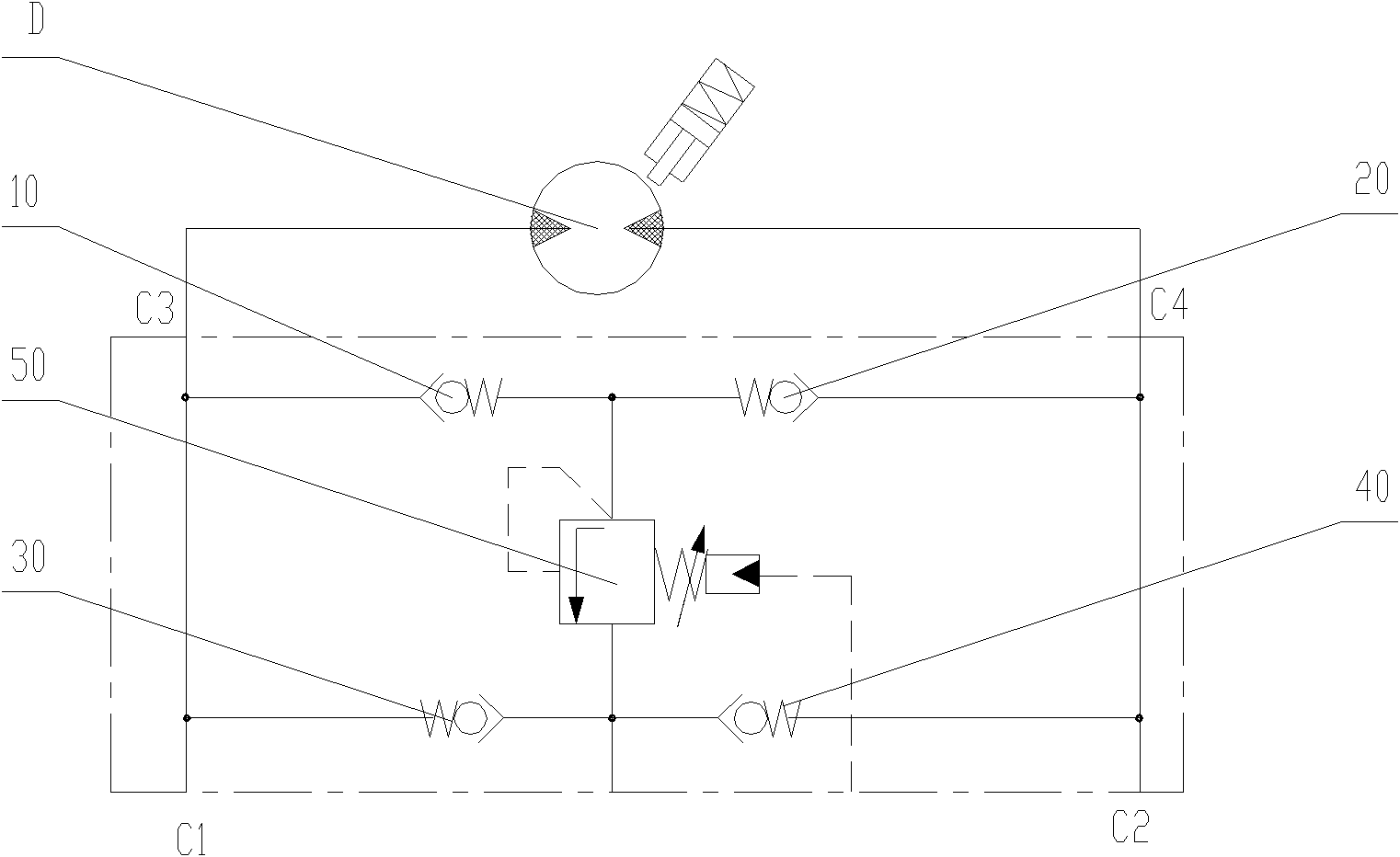

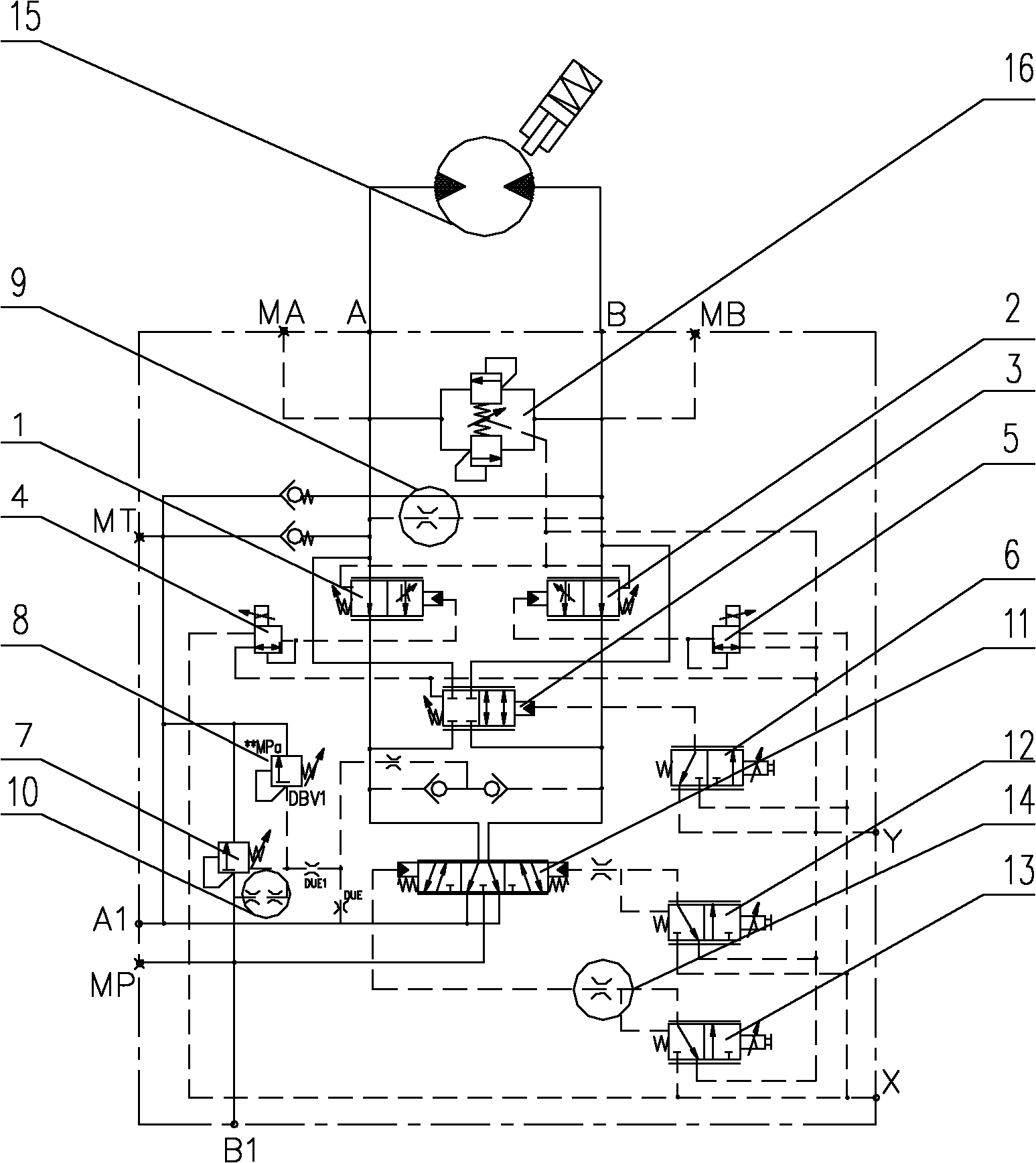

Rotating hydraulic system of crane and rotating buffer valve thereof

ActiveCN102155447AImprove stabilityImprove rotation efficiencyServomotor componentsCranesFuel tankEngineering

The invention discloses a rotating buffer valve which comprises a first back pressure valve, a second back pressure valve and a buffer reversing valve, at the moment of the start and stop of the rotation, hydraulic oil only can enter a rotating motor through a passageway which is provided with the back pressure valve, and then flows to an oil tank; and when in a steady rotating process, the hydraulic oil enters the rotating motor from the buffer reversing valve, then flows back the buffer reversing valve from the rotating motor, and further flows back an oil back tank. At the moment of the start and stop of the rotation, the hydraulic oil only can flow from the first back pressure valve and the second back pressure valve, thus the flow rate and pressure of the hydraulic oil can be controlled effectively, instant system high pressure caused by the instant start and stop of the rotation can be eliminated, the stability of rotation can be improved, and the aim of buffer can be achieved; and during the rotating process, the hydraulic oil can directly enter the rotating motor to work from the buffer reversing valve, thus the rotating efficiency can be improved. The invention also provides a rotating hydraulic system of a crane of the rotating buffer valve.

Owner:XUZHOU HEAVY MASCH CO LTD

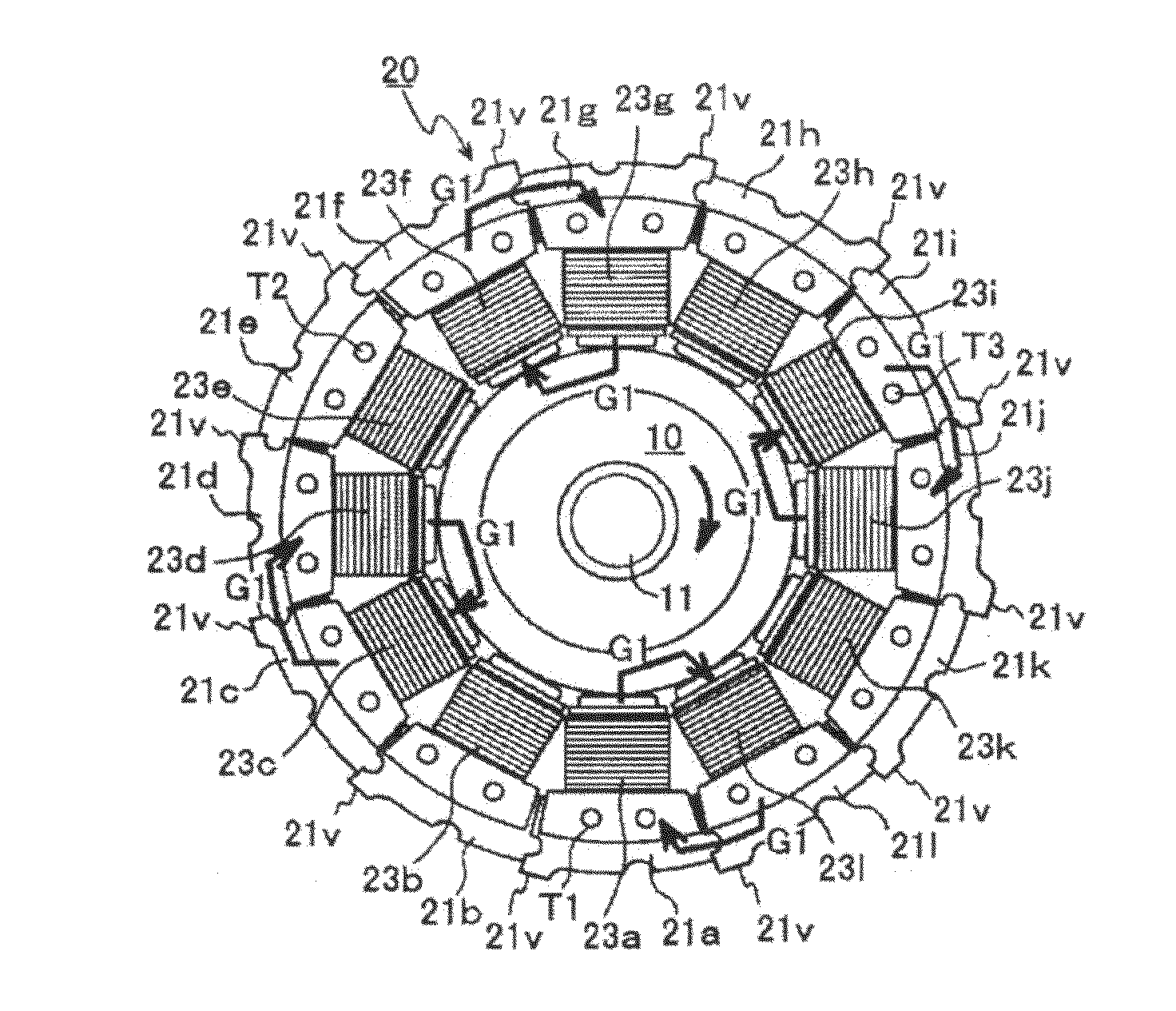

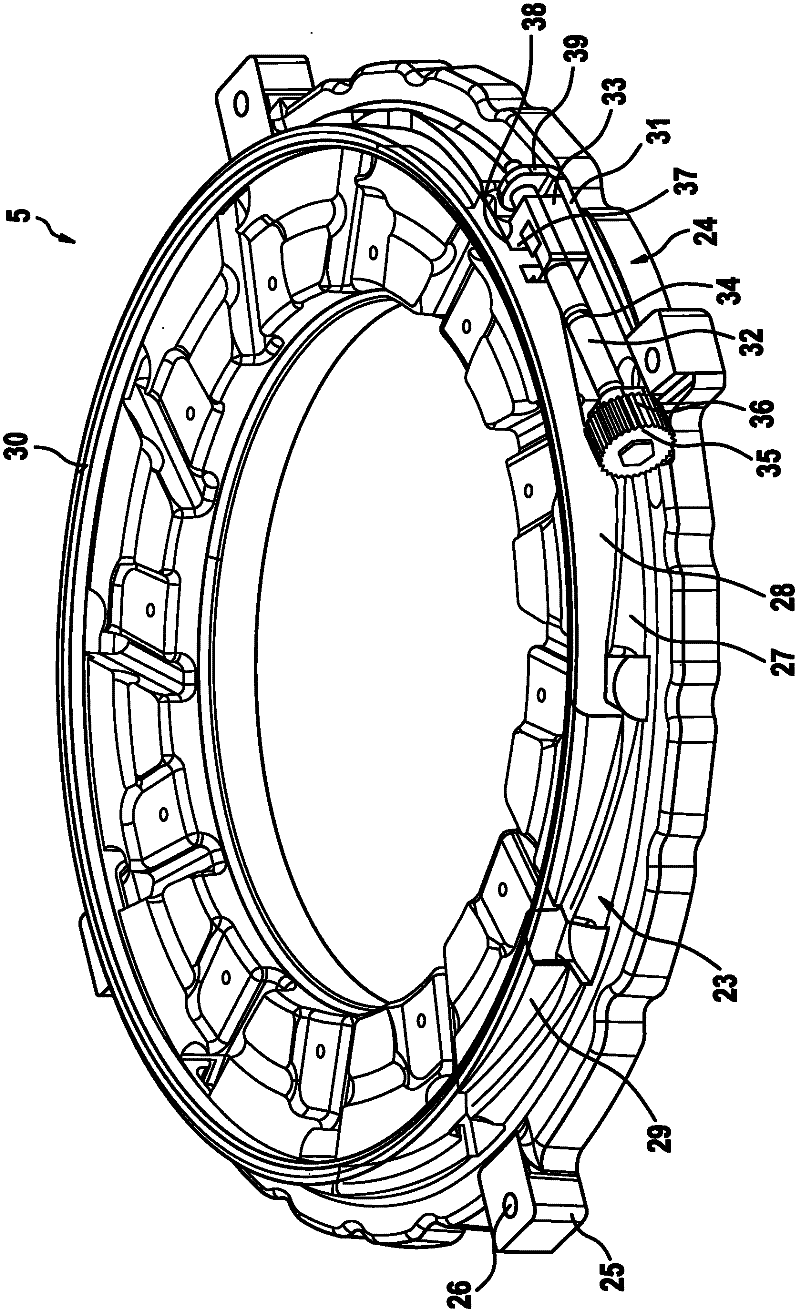

Stator structure and rotating electrical machine using the same

InactiveUS20100237726A1Eliminate fearEasy to fixMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic reluctanceInstability

The invention provides a rotating electrical machine provided with stable rotation characteristics for enabling each core to be reliably fixed in arranging a plurality of cores annularly around the rotor even when the dimensional error occurs in manufacturing accuracy of each core, causing each division core itself to enhance the cooling property, and resolving instability of magnetic reluctance between division cores, where the rotating electrical machine has a plurality of stator cores obtained by laminating electromagnetic steel plates, winding coils wound around the stator cores via insulators, a pair of first and second bracket members that hold the plurality of stator cores from the front and back in the rotary shaft direction of the magnet rotor, and a fastening member that couples the first and second bracket members, in the first bracket member is formed a first contact surface for striking one end face of each of the stator cores to regulate so as to arrange the plurality of stator cores annularly, in the second bracket is formed a second contact surface for striking the other end faces of the stator cores to regulate, the first contact surface constitutes a reference plane to align one end faces of the plurality of stator cores on the same plane, the second contact surface is formed of a deformation surface deformable to follow the other end faces of the plurality of stator cores, and at least one of the pair of first and second brackets is formed of a ring-shaped magnetic material for magnetically coupling between the division cores.

Owner:NISCA KK

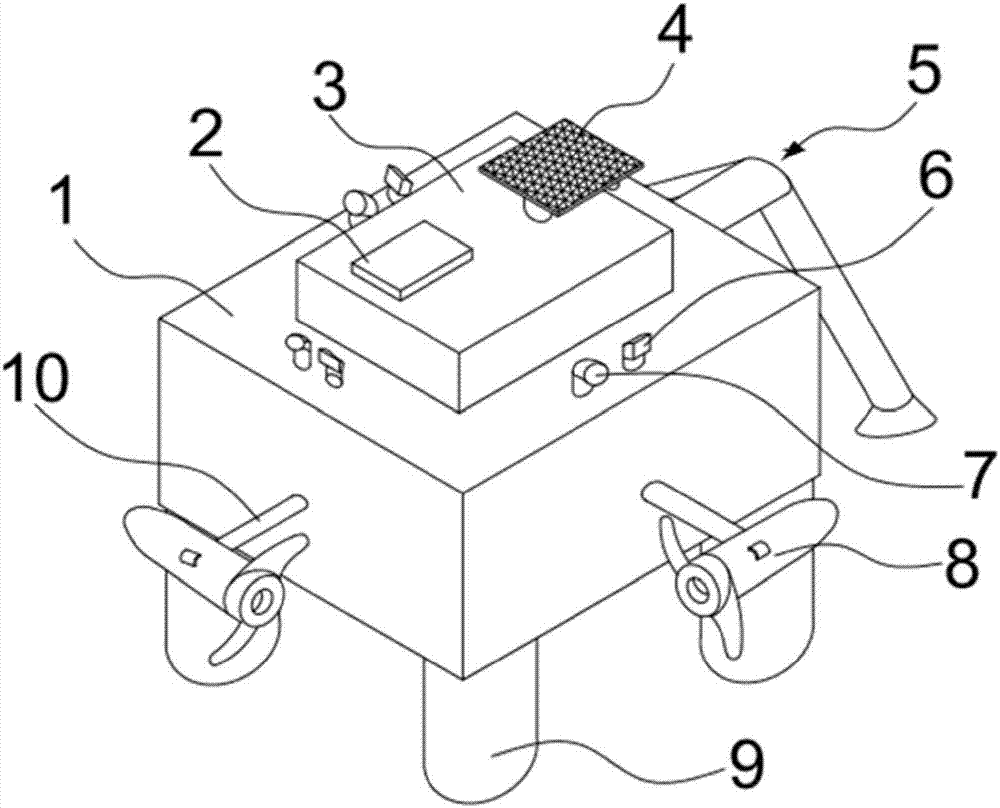

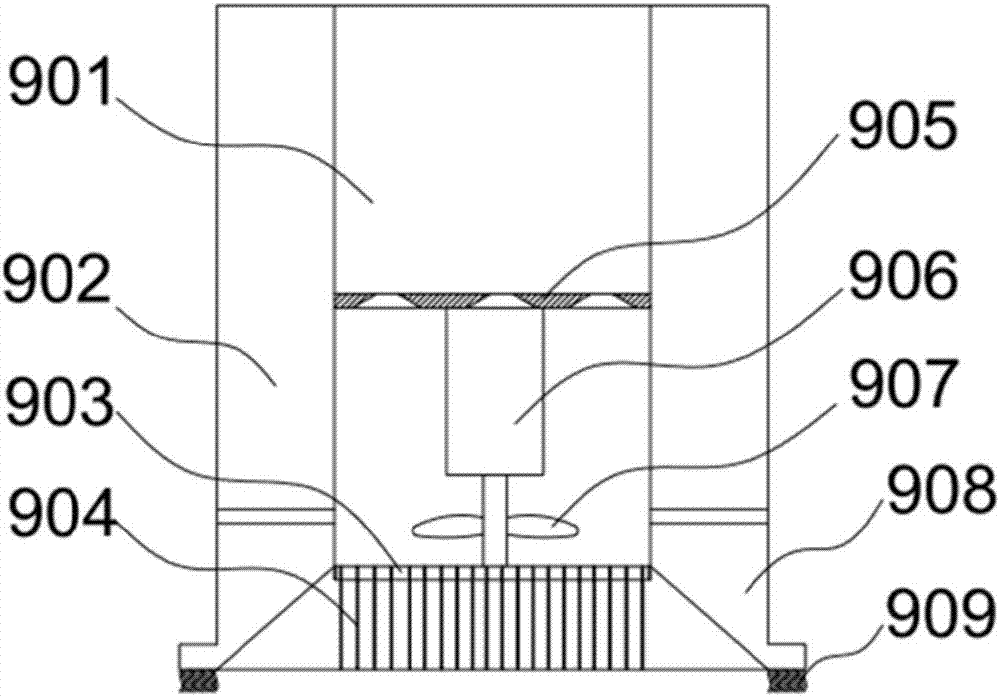

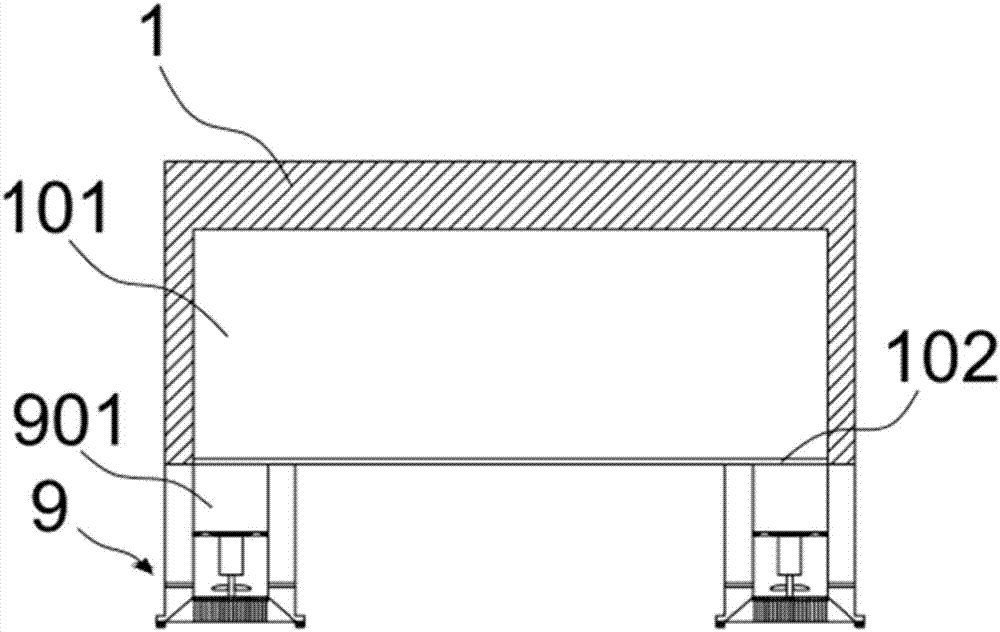

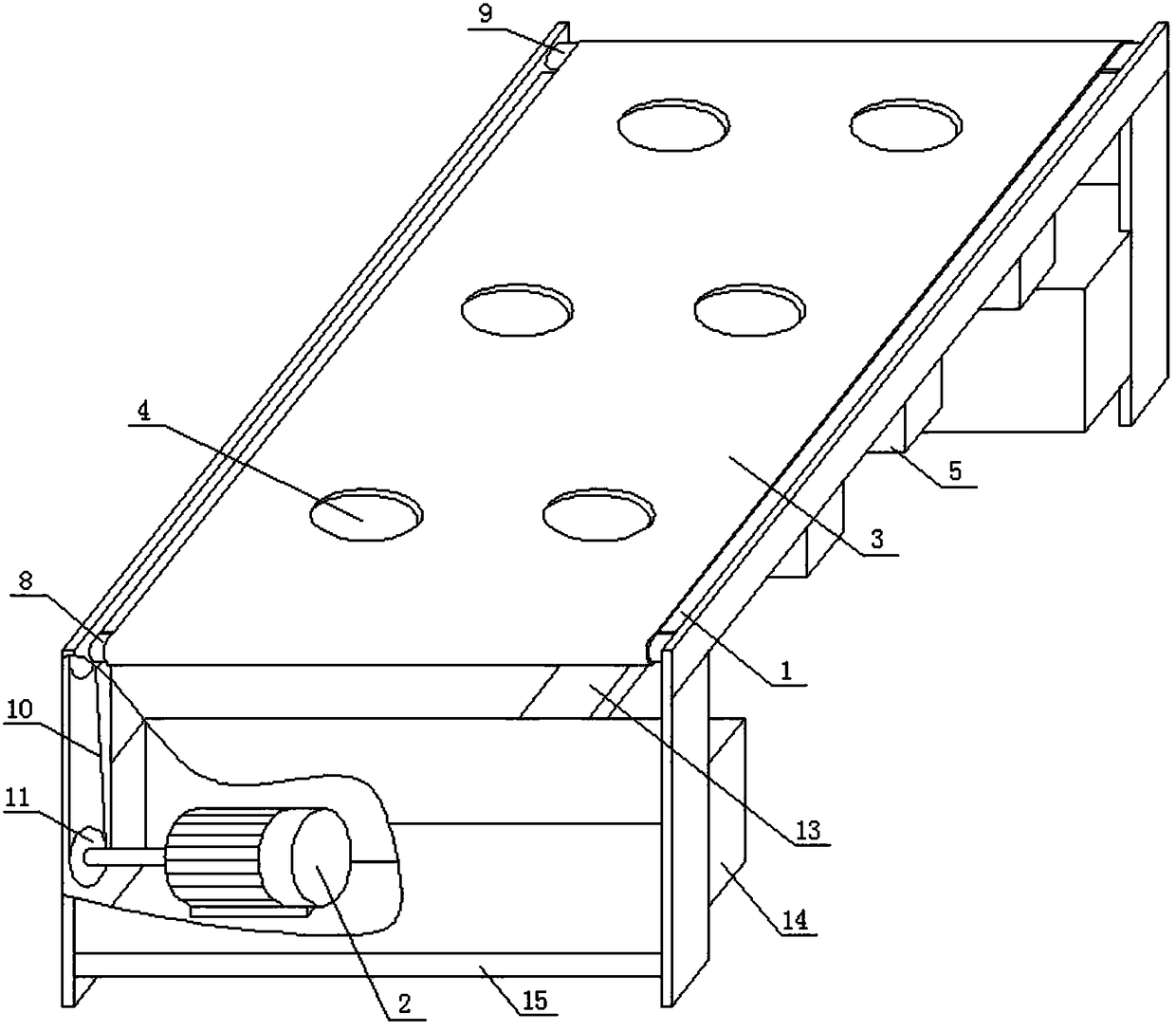

Robot to clear underwater hull attachments

ActiveCN107985526AIncrease buoyancyImprove rotation efficiencyVessel cleaningHullsMarine engineeringCoating

The invention discloses a robot to clear underwater hull attachments and belongs to the technical field of vessel washing. The robot comprises a frame, the frame is rectangular, the lateral side of athruster that is provided with blades which are hollow, a partition is arranged in each blade, support strips evenly distributed are connected between upper and lower surfaces of each partition and the inner wall of the inside of the corresponding blade, four cleaners are distributed evenly at the bottom of the frame, a battery is arranged in the middle of the surface of the frame, a control panelis connected to the surface of the battery, the surface of the battery is also connected with a solar receiving board through a telescopic rod, each side of the frame of the frame is provided with acamera and a probe lamp, and one face of the frame is also connected with an attracting device. The robot of the invention can clear hull attachments and wipe off coating, has good stability in water,and has great underwater operating capacity and long battery life.

Owner:ZHEJIANG OCEAN UNIV

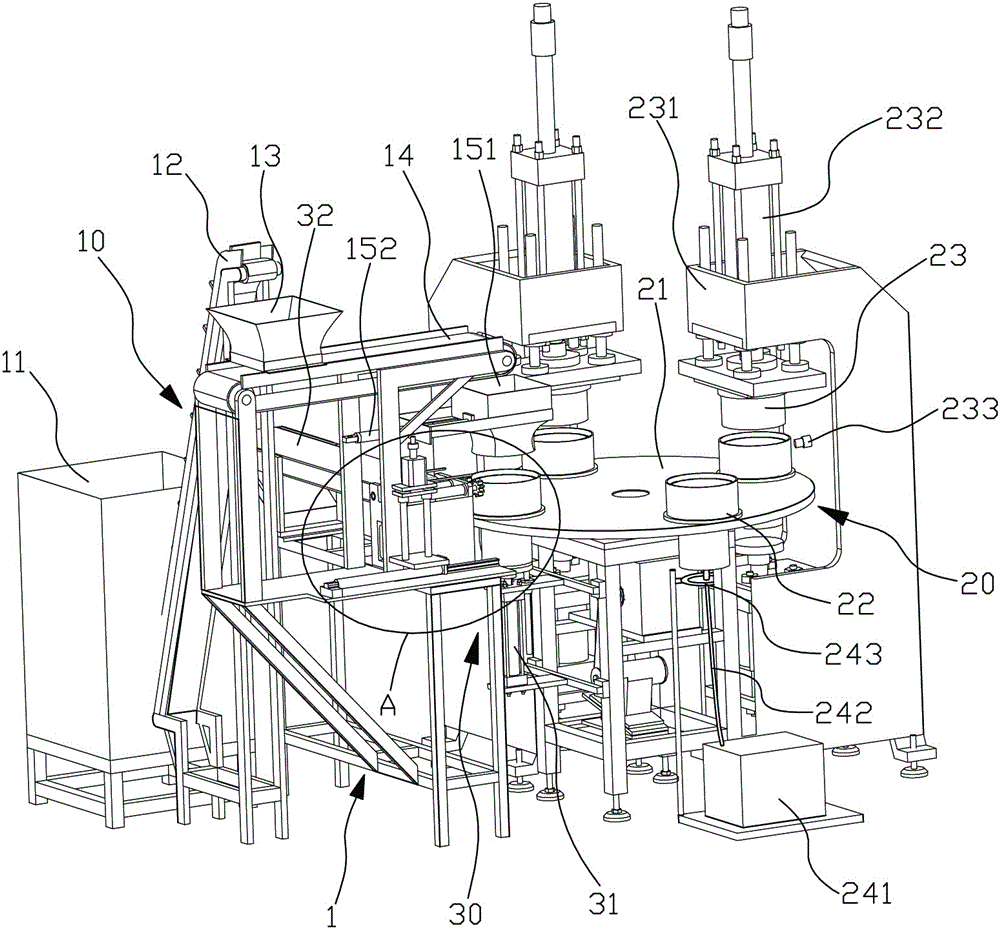

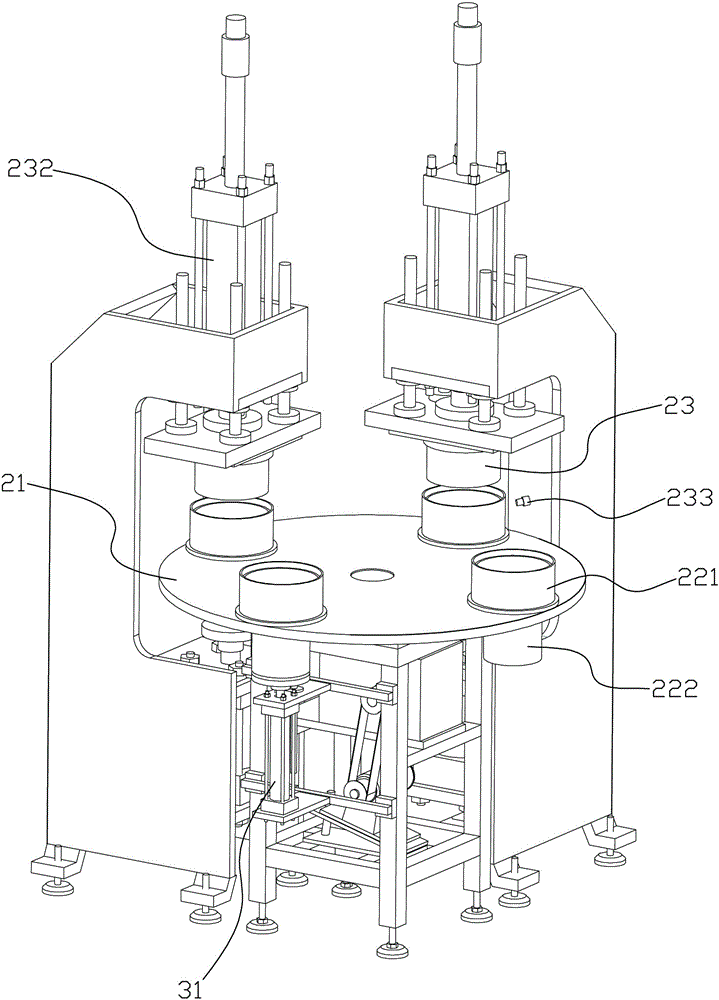

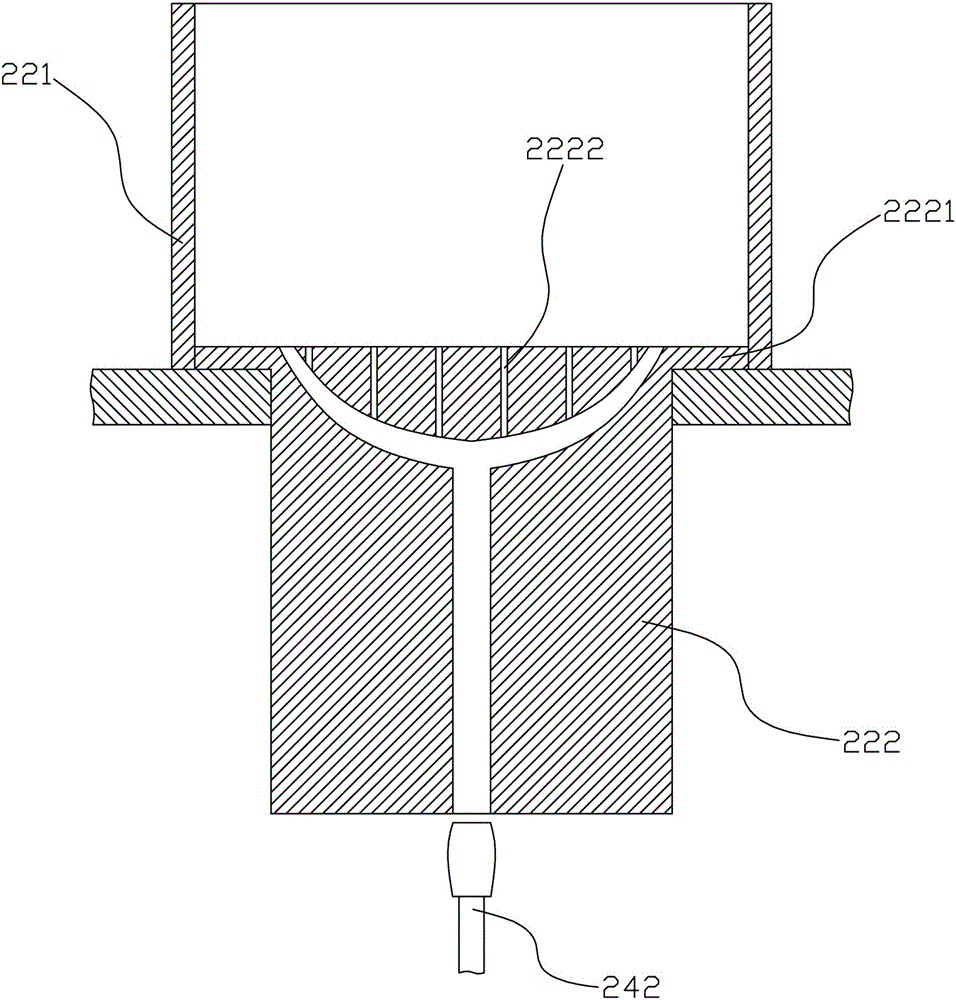

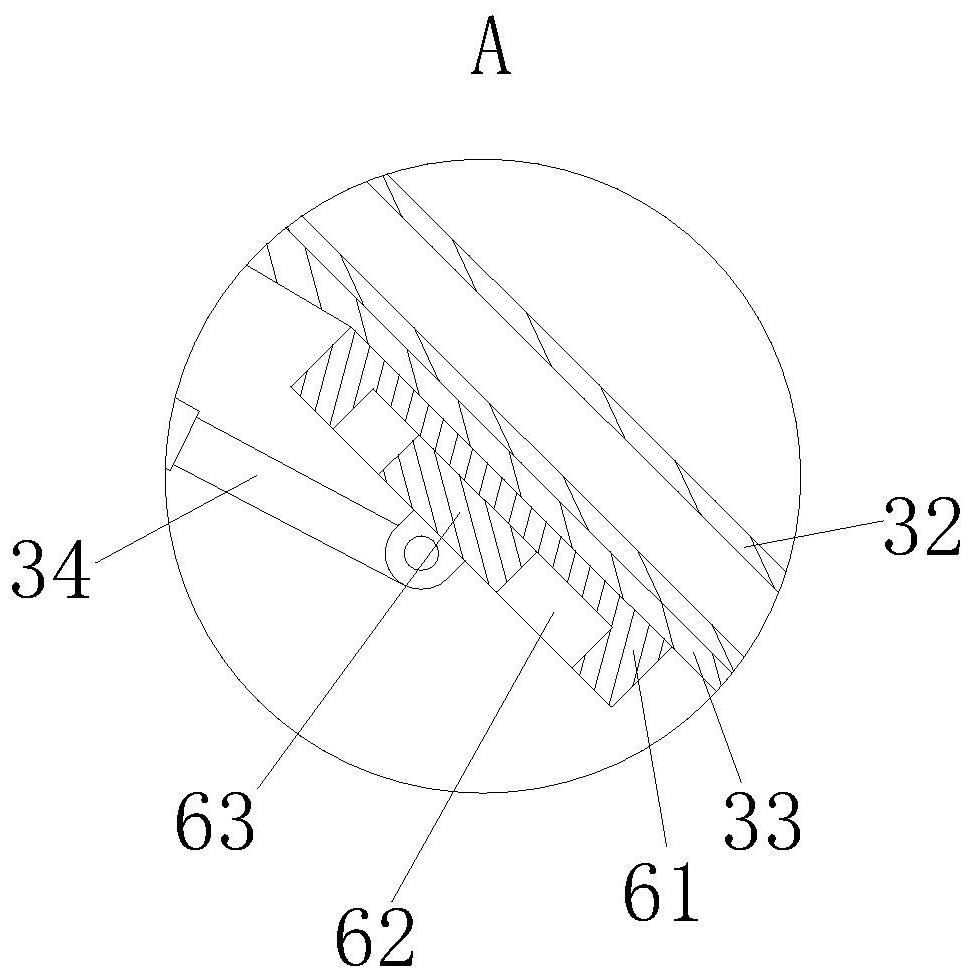

Automatic tea pressing equipment

ActiveCN105053291AImprove rotation efficiencyHigh degree of automationPre-extraction tea treatmentFood shapingManipulatorMoisture

The invention provides automatic tea pressing equipment. The equipment comprises a main engine rack, wherein a feed device, a press device and a discharge device are arranged on the main engine rack; the press device comprises a turntable, and a plurality of lower molds are arranged on the turntable at intervals; an air supply mechanism is arranged on the side face of the turntable and is used for supplying moisture to a through hole; at least one upper mold which is positioned right above the lower molds is arranged on the side face of the turntable; a tea accommodating cavity is formed between the upper mold and the lower molds; a tea pressing air / oil cylinder is fixedly connected with the top of the upper mold; and the discharge device comprises a jacking air / oil cylinder which enables a mold core to move up and down, a molded tea conveyor and a mechanical arm mechanism which is used for transferring molded tea from the mold core to the molded tea conveyor. The automatic tea pressing equipment has a high automatic degree, and can be used for improving the efficiency and quality of tea press molding. Moreover, the maintenance rate of the equipment is greatly reduced.

Owner:云南韵和机械科技有限公司 +2

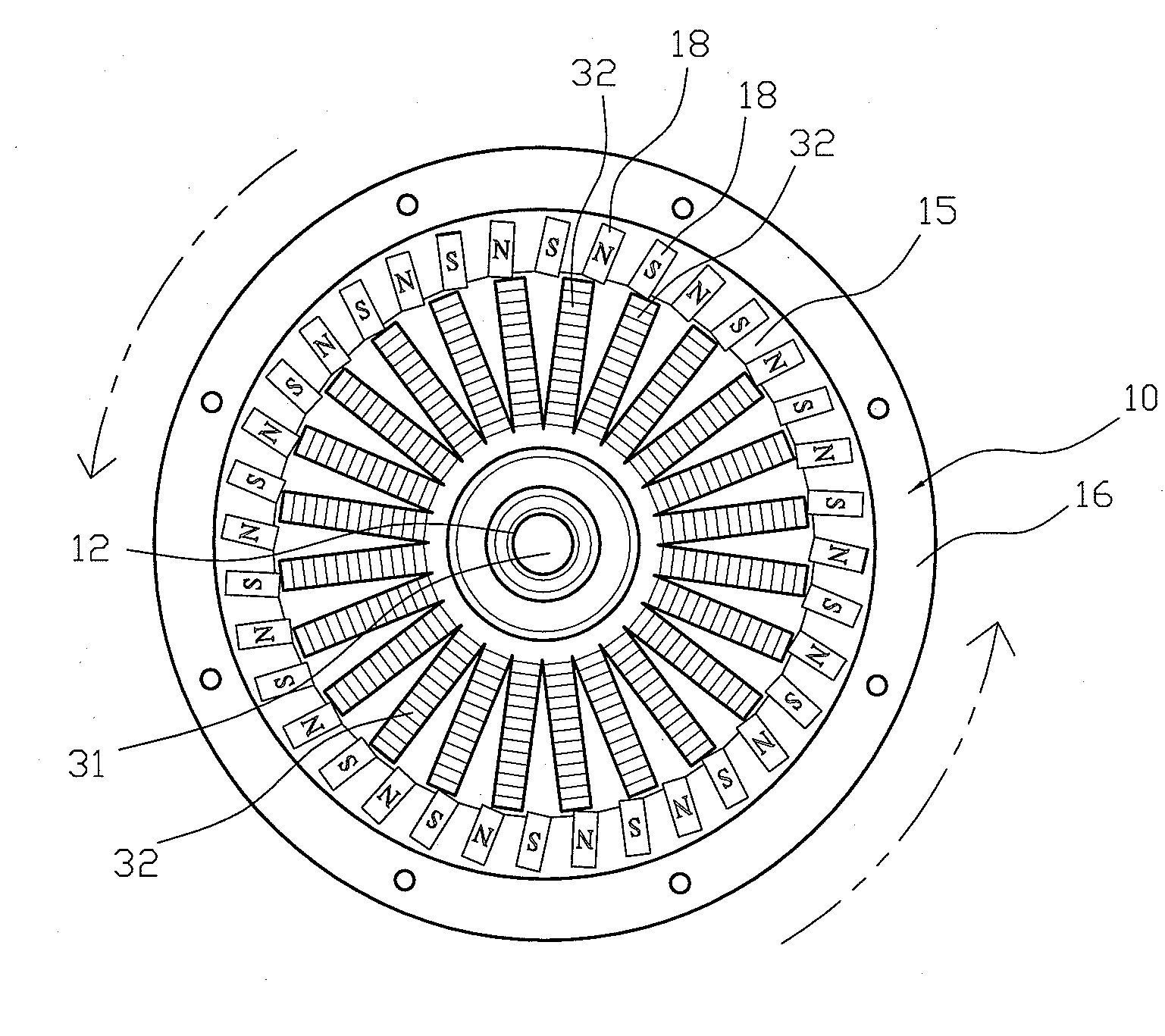

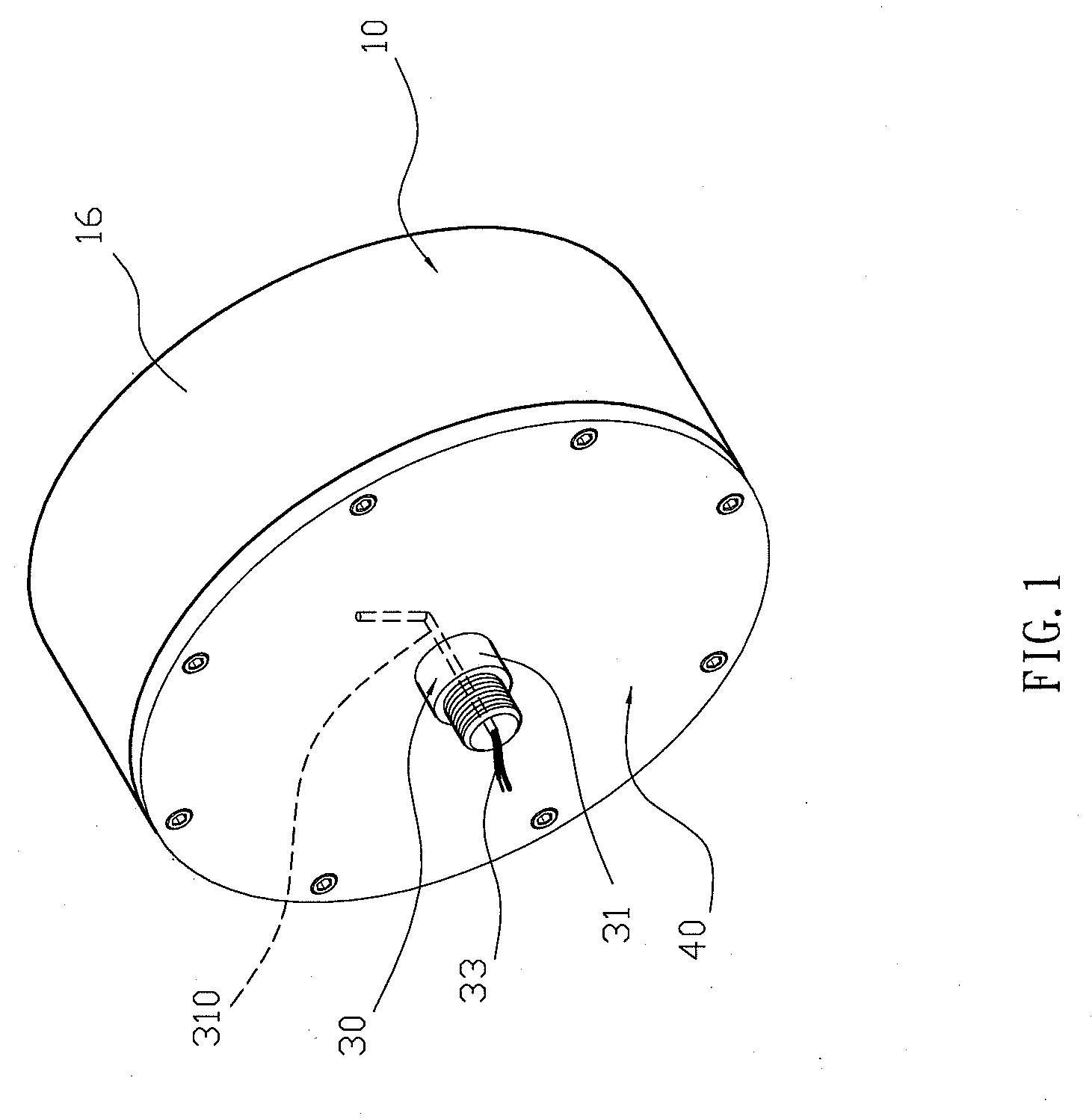

Actuating Device for a Motorized Wheeled Vehicle with an Electric Generating Function

InactiveUS20100052454A1Replenish electric powerImprove rotation efficiencyMagnetic circuit rotating partsElectric machinesMotorized bicycleMagnetic interaction

An actuating device for a motorized bicycle includes a fixed unit and a rotation unit. The fixed unit includes a mandrel and a plurality of coils. The rotation unit includes a rotation member and a plurality of magnets. Each of the magnets is inclined relative to a respective one of the coils so that each of the magnets is closer to any two adjacent coils to promote the magnetic interaction between each of the magnets and any two adjacent coils so as to enhance the rotation efficiency of the rotation unit. When the bicycle is padelled by a rider or traveled on a downward slope, the actuating device has a generating function to produce an electric current so as to replenish the electric power of the bicycle.

Owner:LIN WEI TING

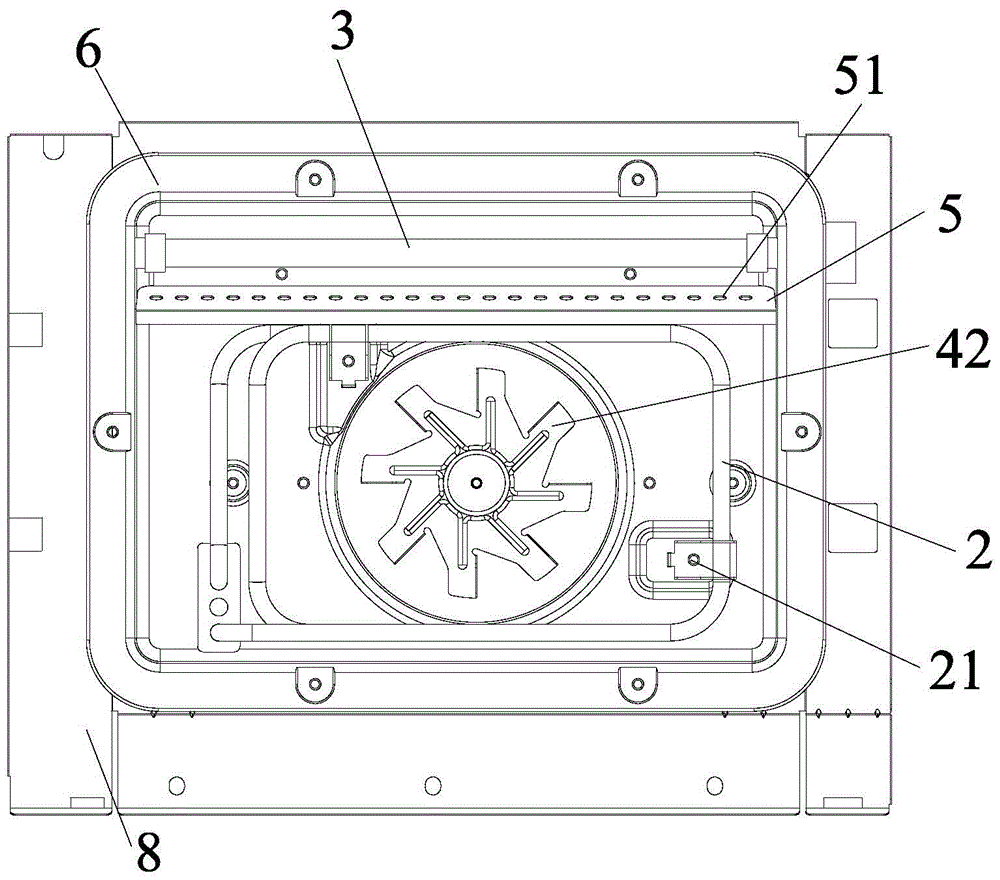

Cooking utensil

InactiveCN105662171AGood cooking effectImprove efficiencyDomestic stoves or rangesLighting and heating apparatusEngineeringAir convection

The invention provides a cooking utensil, which comprises an inner container, a metal heating pipe, a halogen heating pipe and a hot air fan. The inner container has a cooking chamber with one end open. Two air outlets; the metal heating pipe is positioned at the outside of the inner tank; the halogen heating tube is positioned at the outside of the inner tank; the hot air fan includes a hot air motor and a hot fan blade connected with the output shaft of the hot air motor; The air is sucked to the metal heating tube through the air inlet, and after being heated by the metal heating tube, the air flows back to the cooking cavity through the first air outlet, and the light waves emitted by the halogen heating tube can enter the cooking cavity through the second air outlet. In the cooking utensil provided by the present invention, the hot air fan sucks the air in the cooking cavity to the metal heating tube, and the air flows back to the cooking cavity after being heated by the metal heating tube to realize the effect of hot air convection; the light waves emitted by the halogen heating tube heat the food Uniform and high heating efficiency.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

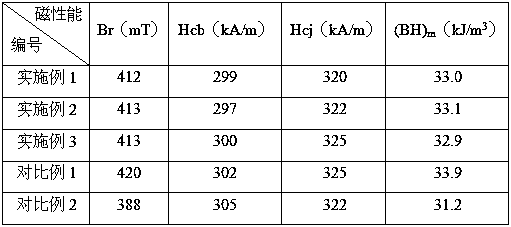

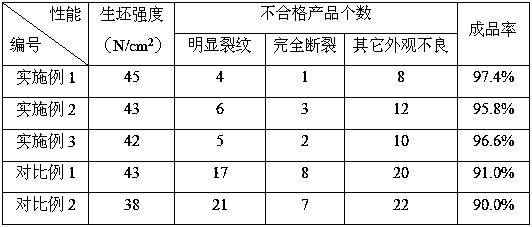

Preparation method of dry process strontium ferrite magnetformed through dry process

ActiveCN108147803AImprove rotation efficiencyHigh green strengthInorganic material magnetismCeramic shaping apparatusGreen bodyMagnetism

The invention discloses a preparation method of a dry process strontium ferrite magnetformed through adry process. The preparation method comprises the following steps: (1) adding water into strontiumferrite powder, adding an additive and performing wet process ball milling to obtain strontium ferrite slurry; (2) performing wet process compression molding on the strontium ferrite magnet slurry obtained in the step (1) in a magnetic field to obtain a strontium ferrite green body; (3) drying and smashing the strontium ferrite green body prepared in the step (2) to obtain oriented magnetic material blocks; (4) adding an amide micro powder additive into the oriented magnetic material blocks obtained in the step (3), and performing dispersion, smashing and sieving to obtain anisotropic powder;(5) performing dry-pressing molding on the anisotropic powder obtained in the step (4) in the magnetic field, performing sintering and grinding to obtain the strontium ferrite magnet. The strontium ferrite magnet green body prepared according to the method is high in strength and high in yield; the dry process strontium ferrite magnet formed through the dry process is high in magnetic performance, and particularly the residual magnetism is up to 98 or more of that of a wet process molded product. The method disclosed by the invention is simple, is low in production cost, and is high in production efficiency.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

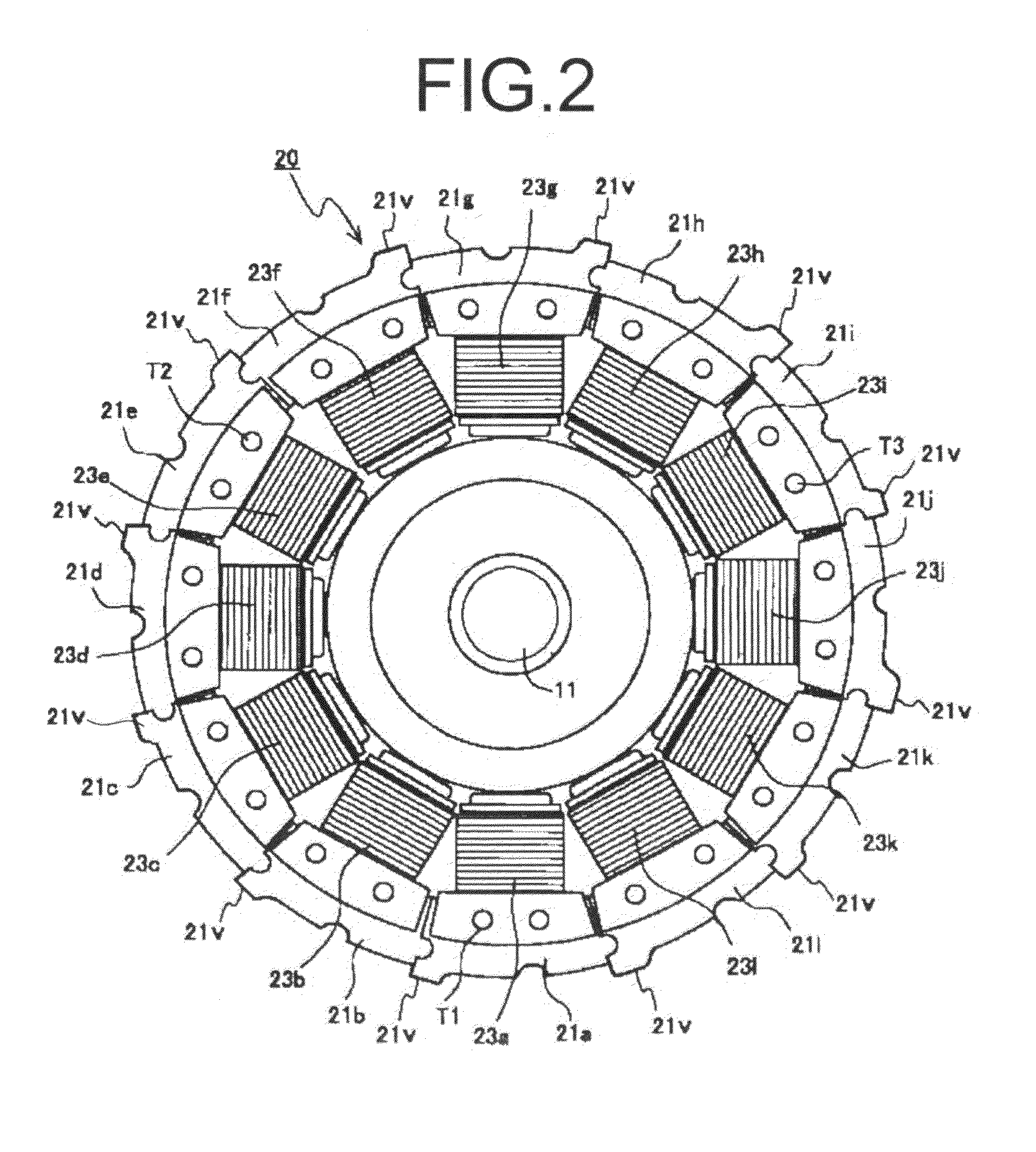

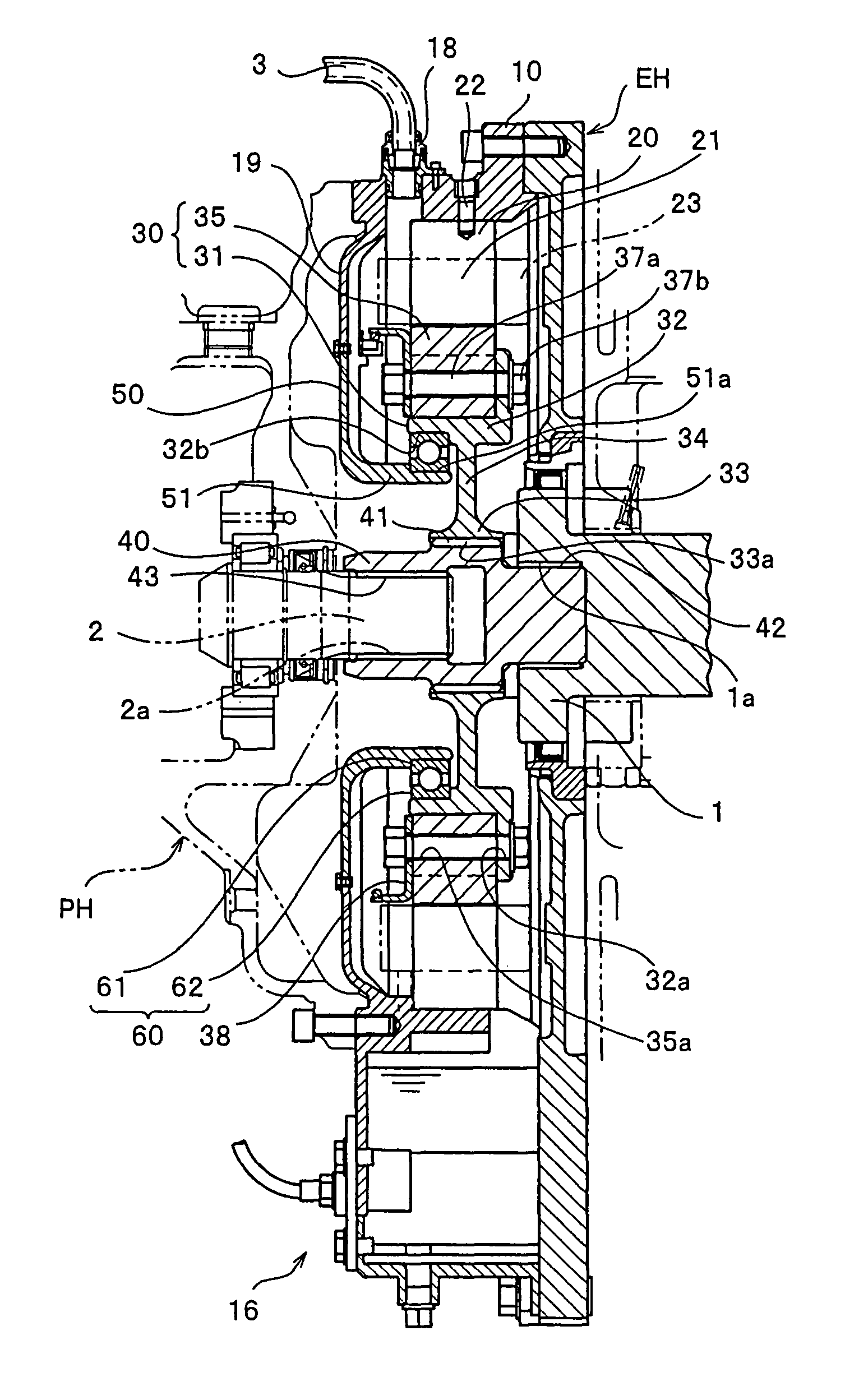

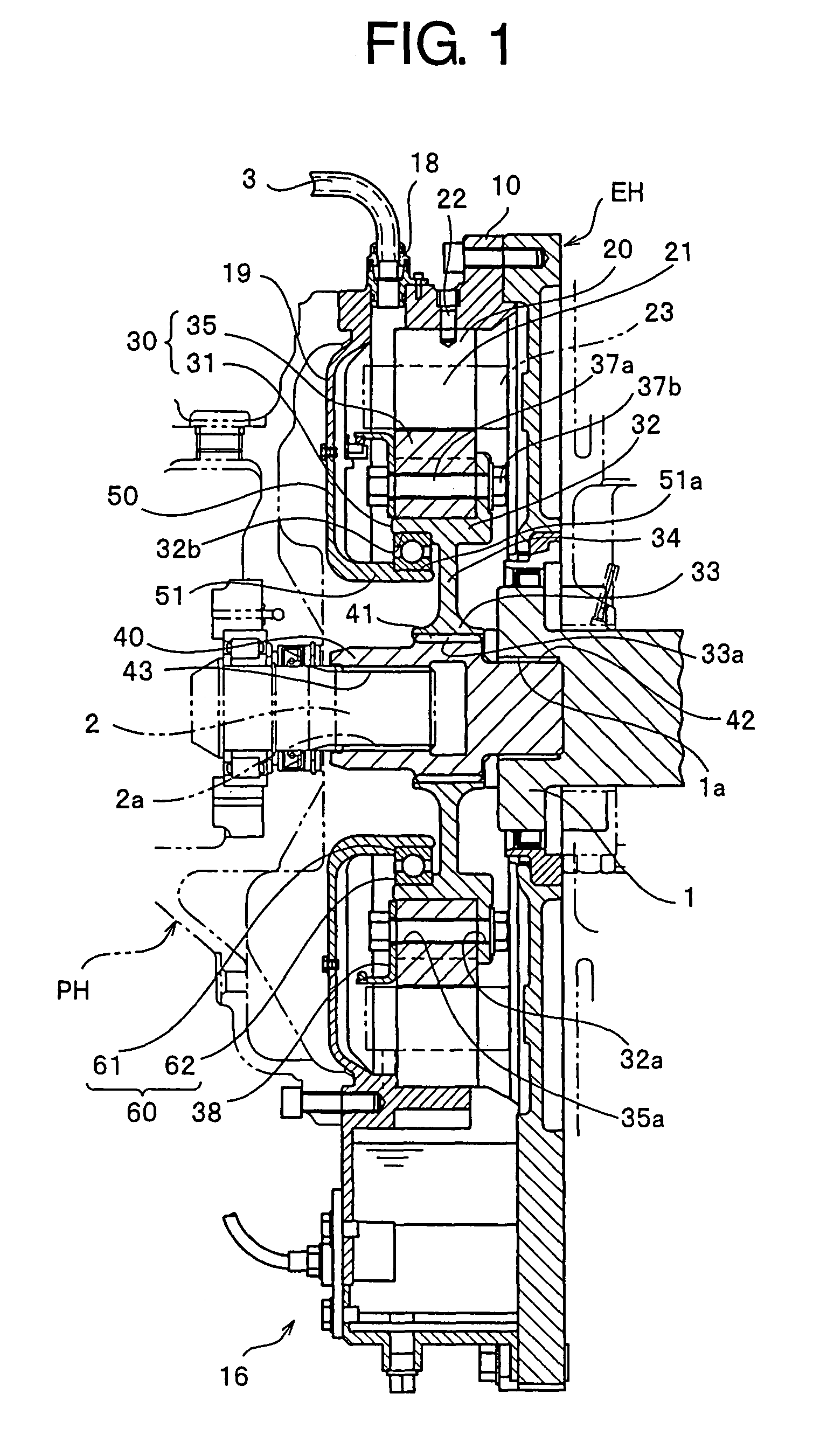

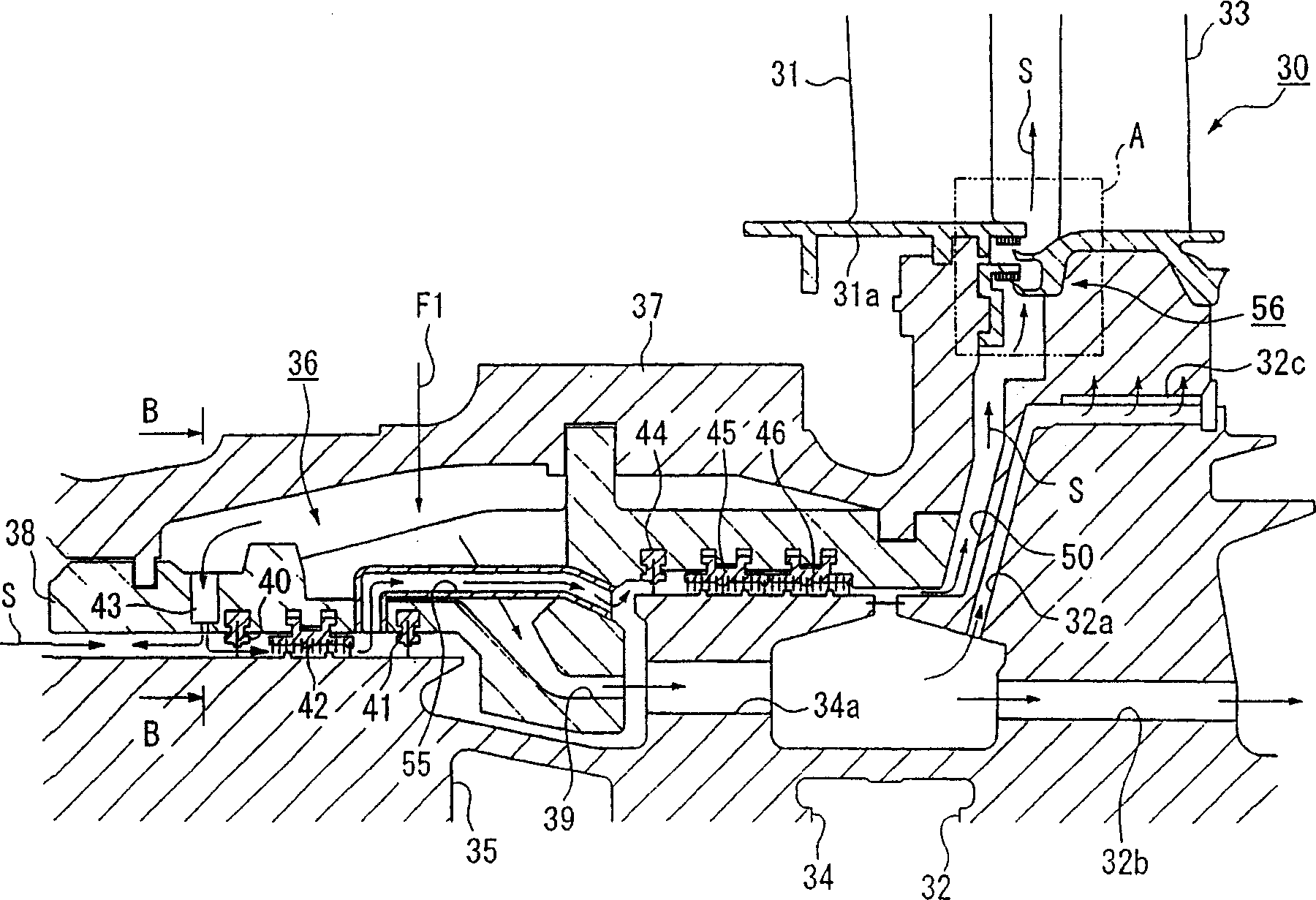

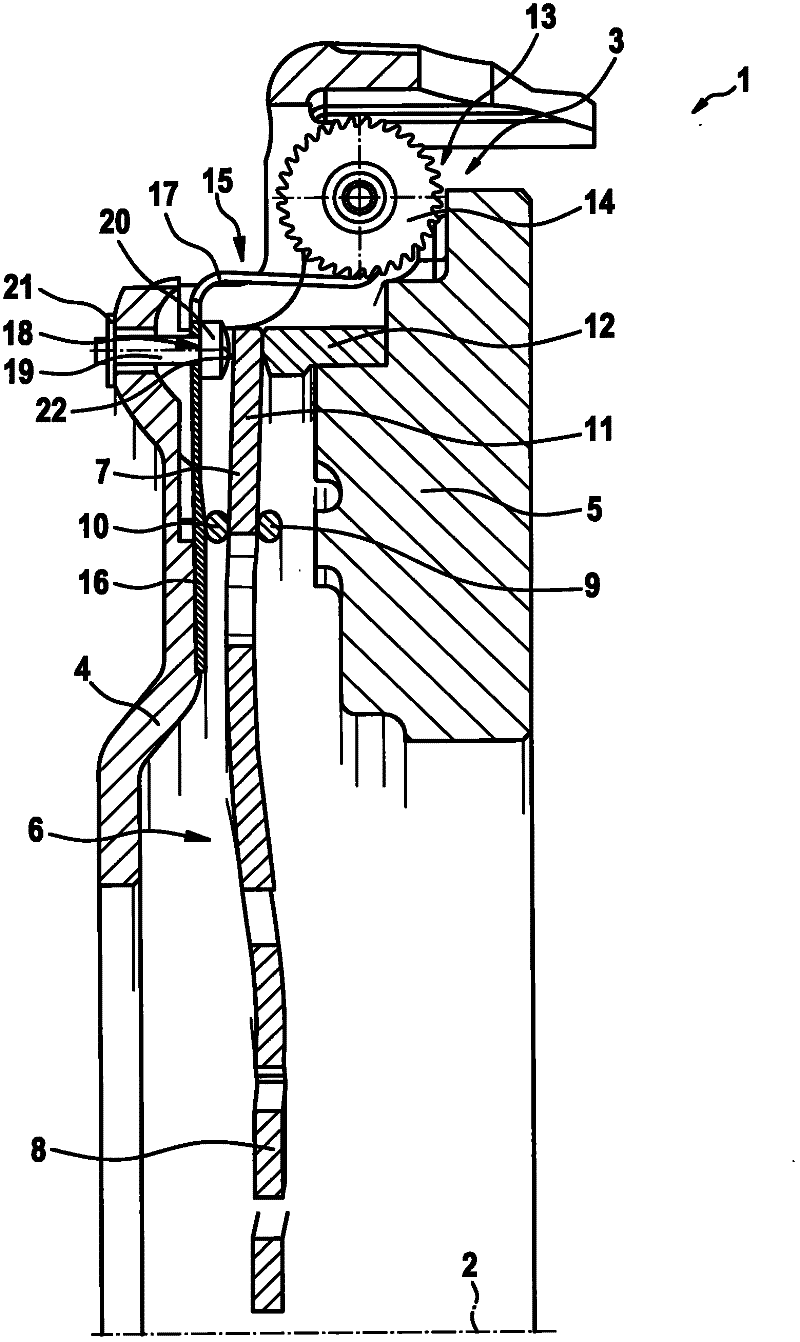

Generator/motor mounted as an auxiliary power unit of an engine

InactiveUS8084908B2Easy to processEfficiency of of deterioratedDynamo-electric brakes/clutchesWindingsAuxiliary power unitCrankshaft

A generator / motor includes a ring-shaped stator core (20) fixed to a motor housing (10), and a motor rotor (30). The motor rotor (30) includes a ring-shaped rotor yoke (35) which rotates in cooperation with the crankshaft (1) and which is opposed to an inner peripheral surface of the stator core (20) with a predetermined gap therebetween. The motor rotor (30) also includes a rotor flange (31) which fixes and supports the rotor yoke (35) at its outer peripheral surface. The rotor flange (31) is rotatably supported by a support member (51a) of the motor housing (10) through a bearing (60). A cylindrical shaft portion (40) is interposed between the crankshaft (1) and the motor rotor (30), and the crankshaft (1) is spline coupled to the cylindrical shaft portion (40).

Owner:KOMATSU LTD

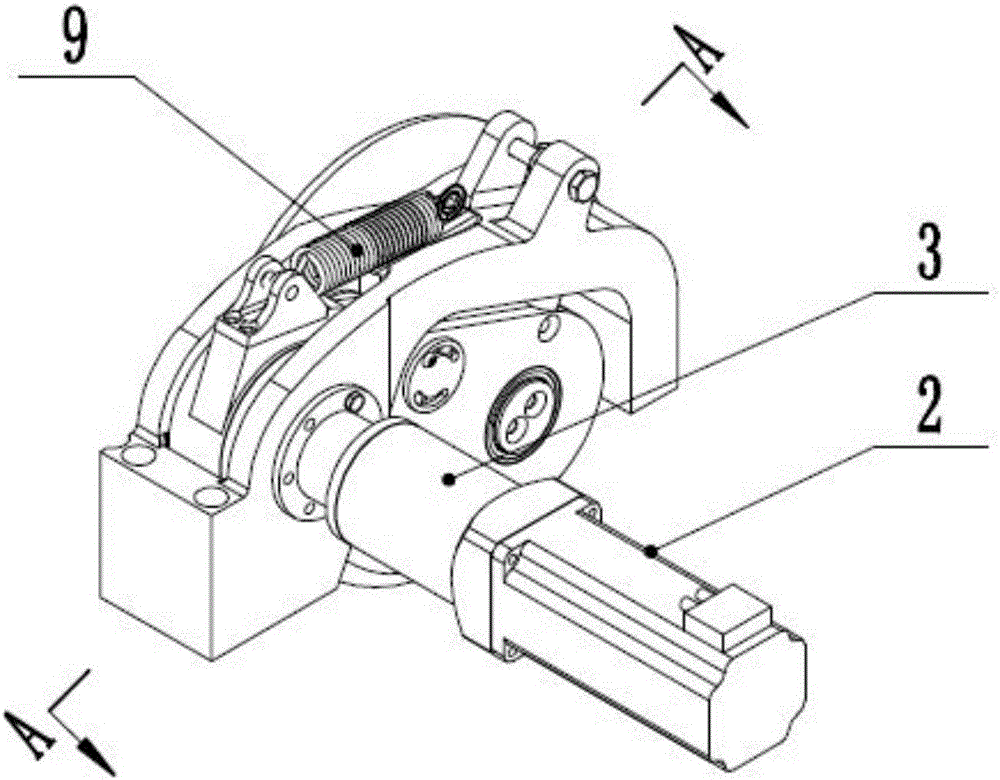

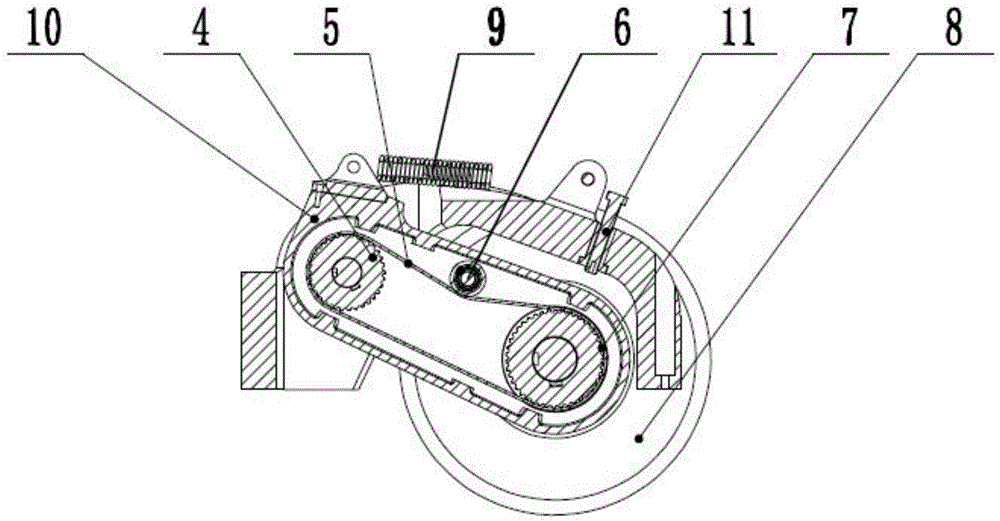

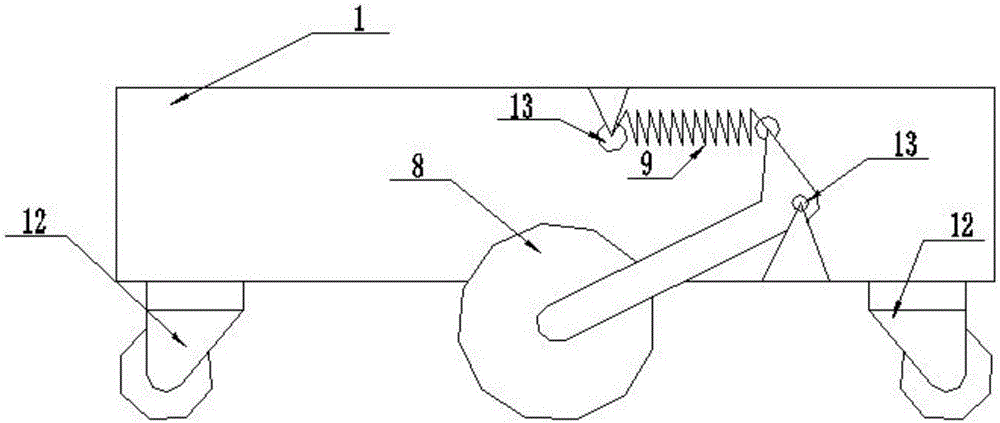

AGV with obstacle crossing function

InactiveCN106275125AEasy to useGuaranteed adhesionResilient suspensionsVehiclesDrive wheelDrive motor

The invention discloses an AGV with an obstacle crossing function. The AGV comprises a vehicle body base, a driving assembly and at least two universal wheels. The driving assembly comprises a driving motor and a driving wheel. The driving motor drives the driving wheel to rotate. The driving wheel and the driving motor are installed on the vehicle body base. The vehicle body base is provided with two hinge fulcrums. Any one hinge fulcrum is movably connected with the driving wheel through a rocker arm. The other end of the rocker arm and the other hinge fulcrum are connected through a tension spring. The at least two universal wheels are installed on the front portion and the rear portion of the vehicle body base correspondingly. The driving wheel and the universal wheels support the whole vehicle body. The AGV is simple in structure and low in cost and has the very good obstacle crossing function.

Owner:武汉萝卜兔科技有限公司

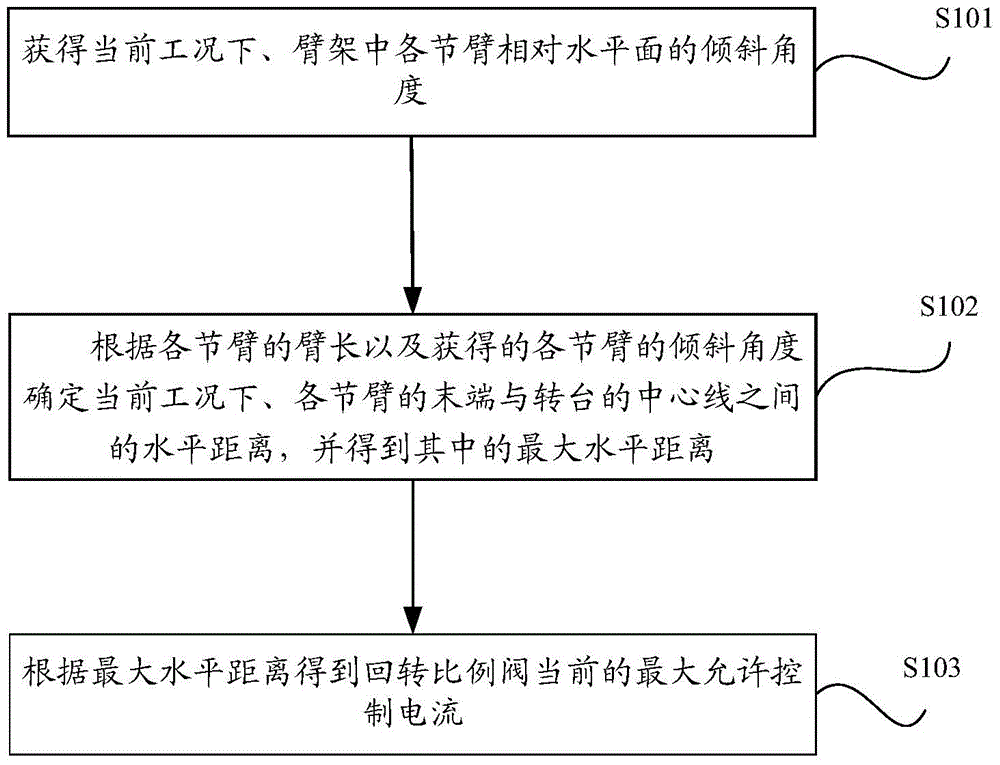

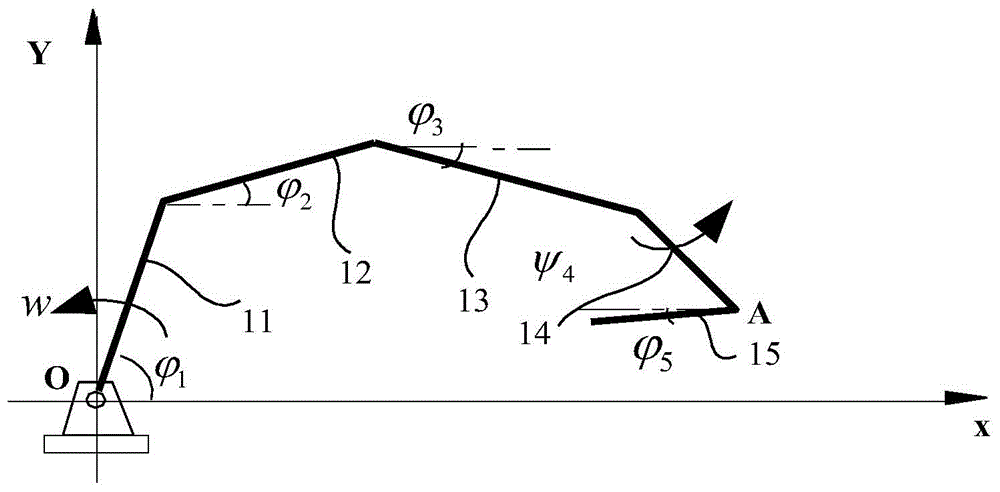

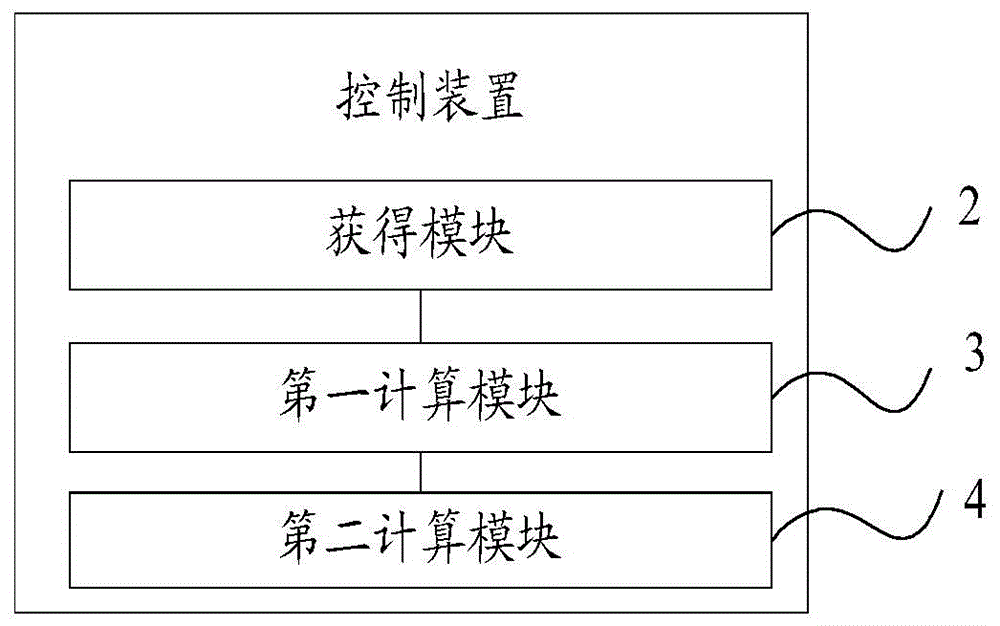

Cantilever crane rotating speed control method, device, system and engineering machinery

ActiveCN105800485AAvoid the phenomenon that the rotation speed is limited too slowlyEnsure safetyLoad-engaging elementsCranesEngineeringCantilever

The invention discloses a cantilever crane rotating speed control method, device, system and engineering machinery. The cantilever crane rotating speed control method, device, system and engineering machinery guarantee cantilever crane rotation safety, improve cantilever crane rotation efficiency and are convenient for operation. The method comprises acquiring inclined angles of arm sections of a cantilever crane relative to the plane under the current work conditions, wherein the inclined angles are angles of the arm sections rotating around a head end hinge joint along an anticlockwise direction and relatively to the plane, determining horizontal distances of the tail ends of the arm sections and the center line of a rotary table under the current work conditions according to lengths of the arm sections and the acquired inclined angles of the arm sections, ensuring the largest horizontal distance and calculating a current maximal admission control current of a rotary proportional valve according to the largest horizontal distance.

Owner:ZOOMLION HEAVY IND CO LTD

Gas turbine pressurizing air supply system

InactiveCN1682012AImprove rotation efficiencySpeed up the flowTurbine/propulsion engine coolingBlade accessoriesGas supplyGas turbines

Owner:MITSUBISHI HITACHIPOWER SYST LTD

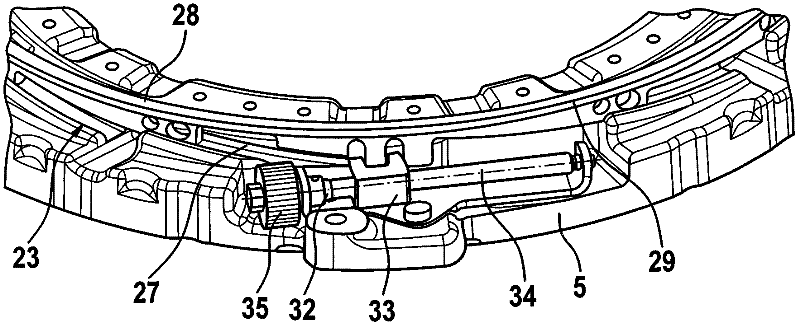

Friction clutch

Disclosed is a friction clutch which comprises a path-controlled adjusting device and in which wear of the friction linings is compensated by compensating a first distance created between a contact plate and a lever system by twisting a ramp system located between the contact plate and the lever system by means of a spindle having a pinion, said first distance being compensated when it is determined that a second predefined distance between a pressure plate and the clutch housing exceeds a predefined value while the lever system applies the maximum force to the pressure plate. The ramp system is twisted while the lever system relieves the pressure from the pressure plate, and the pressure plate is moved by means of the energy stores that are effective between the pressure plate and the clutch housing by having a pawl twist the pinion. In this process, the pawl slides along the pinion during a lifting movement and positively locks therewith when wear has been identified. In order to prevent the pinion from being twisted because of the friction generated between the pawl and the pinion, at least one catch is connected to the pinion.

Owner:SCHAEFFLER TECH AG & CO KG

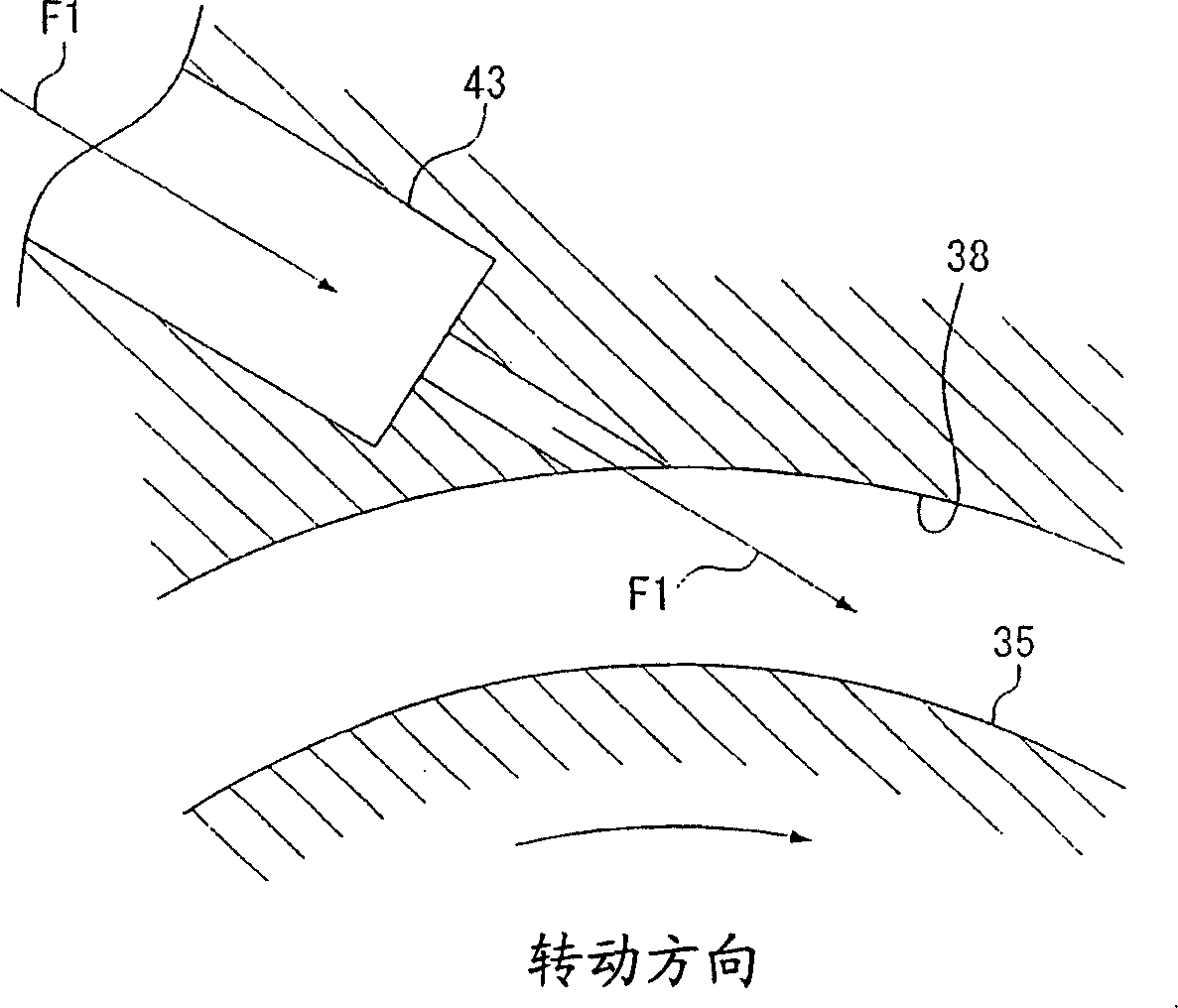

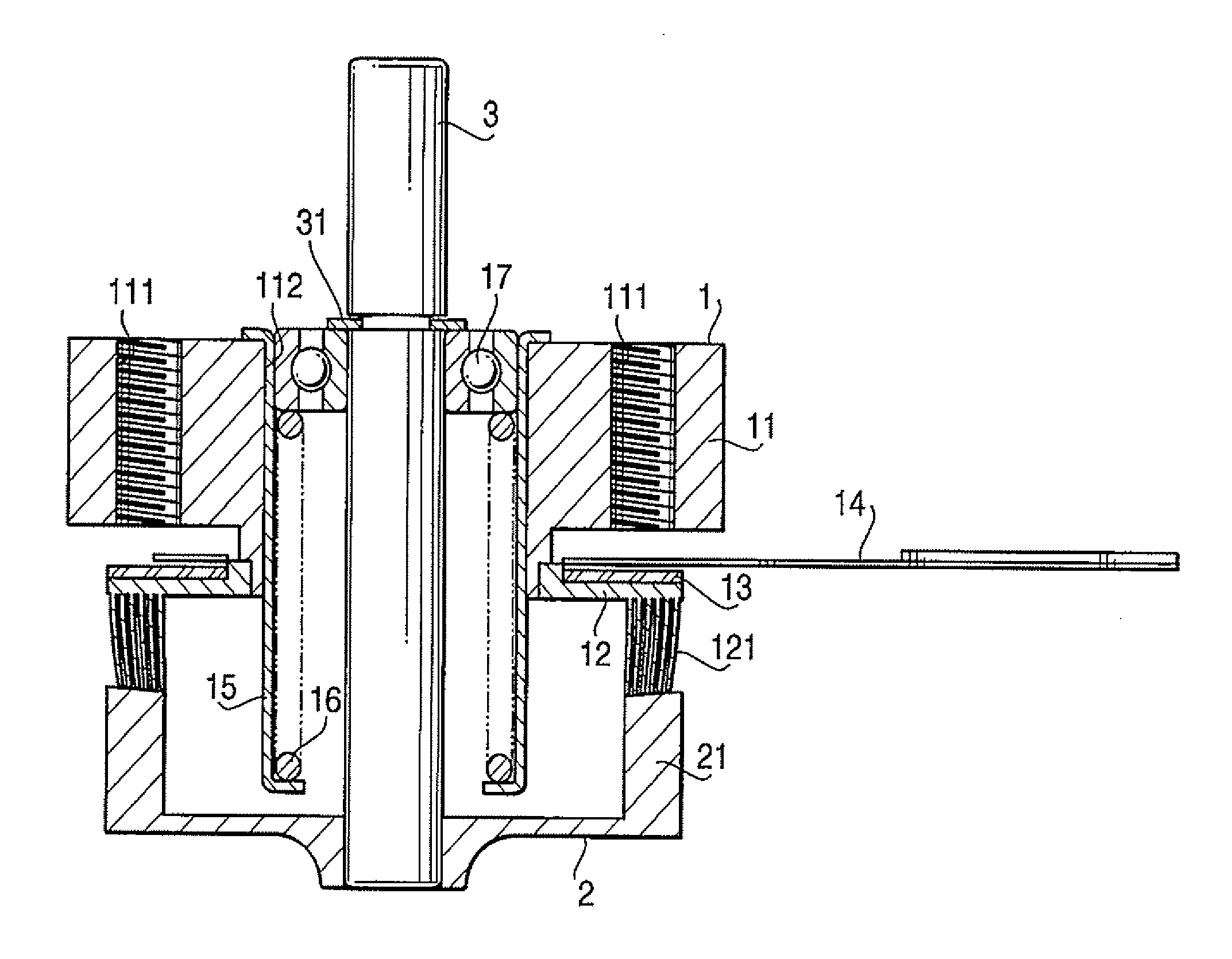

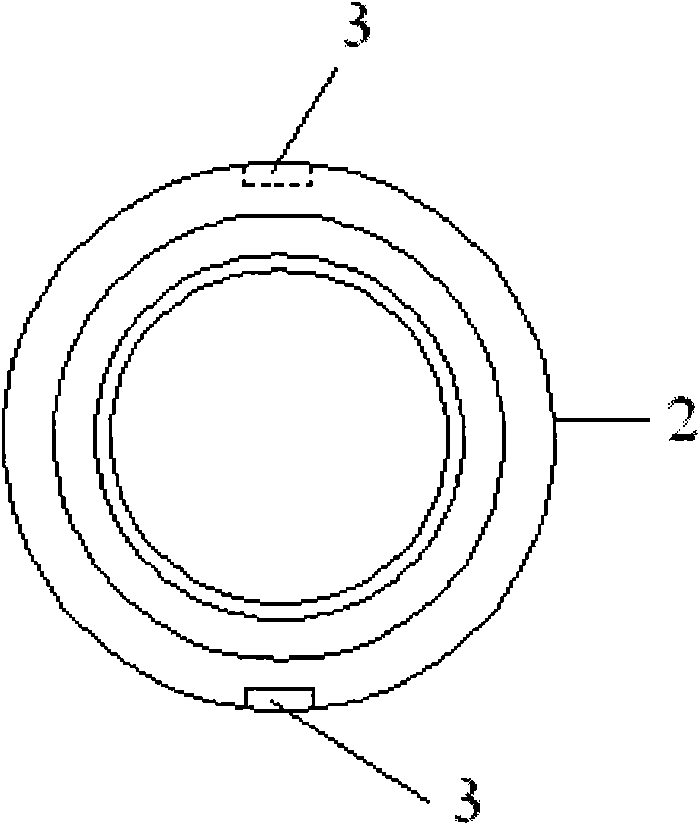

Ultrasonic motor

InactiveUS20070145859A1Improve rotation efficiencyImprove efficiencyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringMechanical engineering

An ultrasonic motor is provided with a circular stator including a piezoelectric element and a comb teeth body with a multitude of comb teeth circumferentially aligned thereon, and a circular rotor supported by a rotating shaft and pressed against the comb teeth body, wherein the comb teeth respectively include, at least in a portion thereof press-contacting the rotor, a plurality of pin-shaped elements radially aligned at a predetermined interval. The pin-shaped element is elastically deformable in a radial direction at least in a tip portion thereof, and has a predetermined rigidity in a circumferential direction.

Owner:RICOH IMAGING COMPANY

Sea power generation device

ActiveCN110671257ALarge displacementReduce swingWind energy with electric storageWind energy with water energyGear wheelEngineering

The invention belongs to the technical field of sea power generation and relates to a sea power generation device which comprises a floating body. A supporting frame is arranged on the floating body.The supporting frame is provided with a wind power generating mechanism which can convert wind energy into electric energy. A plurality of floating cylinders are arranged on the floating body in a surrounding manner. The floating body is provided with a first rotating sleeve. A telescoping mechanism is arranged between the first rotating sleeve and each floating cylinder. A second rotating sleeveis arranged on the supporting frame. A second connecting rod is arranged between a second rotating sleeve and each floating cylinder. An inner gear is fixedly arranged on the second rotating sleeve. The floating body is further provided with a first power generator. An output shaft of the first motor is connected with an inner gear in an engaged manner through a transmission mechanism. The sea power generation device has the advantages that energy sources such as the wind energy and the wave energy can be effectively utilized for power generation, and meanwhile, the stability of the floating body is improved.

Owner:ZHEJIANG OCEAN UNIV

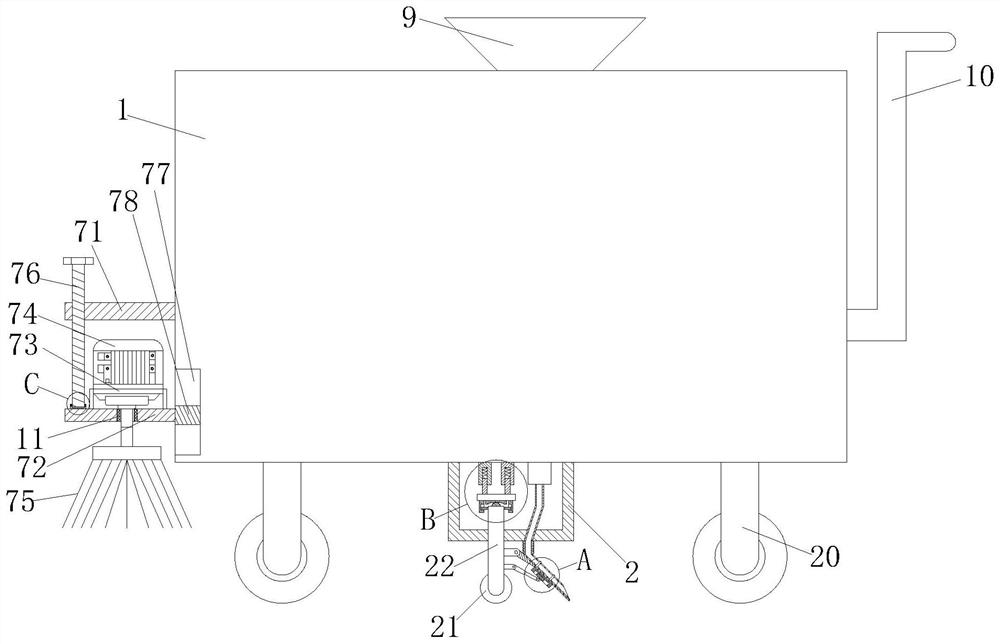

Pavement depression detection device for municipal engineering

InactiveCN113267147AImprove sag detection efficiencyEasy to observeRoad cleaningRoads maintainenceAgricultural engineeringStructural engineering

The invention discloses a pavement depression detection device for municipal engineering. The pavement depression detection device comprises a vehicle body and a detection unit, a working box is fixedly connected to the bottom of the vehicle body; the detection unit is arranged in the working box; the detection unit comprises a positioning mechanism and a marking mechanism; the positioning mechanism comprises a positioning wheel, a supporting rod, an upper contact, a lower contact, a first fixing plate, a damping assembly and a limiting assembly. The positioning wheel is arranged at the bottom of the supporting rod; the top end of the supporting rod penetrates through the inner wall of the working box and is arranged below the first fixing plate. The upper contact is fixedly connected to the bottom of the first fixing plate. By arranging the detection unit, the vehicle body linearly moves on the urban road, and the positioning mechanism is matched with the marking mechanism, so that the vehicle body moves while drawing a straight line by using lime powder, and when the vehicle body encounters a sunken place, an upper contact and a lower contact are disconnected, so that the marking assembly stops drawing the line, and detection personnel can conveniently find the sunken position of the road surface in time; and related data are recorded, so that the pavement depression detection efficiency is improved.

Owner:江苏杜邦建设工程有限公司

Rotor for rotating electric machine

ActiveUS9154006B2Inexpensively formedLess energyMagnetic circuit rotating partsCooling/ventillation arrangementElectric machineEngineering

In a rotor for the dynamo, the interior circumference face of a rotor core main body makes contact in a thermally transmissible manner with a rotor axle, and the rotor axle includes a cooling medium circulation space. The rotor is provided with a cooling medium supply member, which supplies the cooling medium to the cooling medium circulation space. The cooling medium supply member is provided with a cooling medium supply path that extends in the rotor axle direction, and cooling medium supply holes that extend externally in the direction of the rotor diameter. The cooling medium supply holes are provided with supply apertures that open toward the cooling interior circumference face. The rotor axle is provided with cooling medium discharge holes that extend externally in the direction of the rotor diameter. The cooling medium discharge holes are provided with discharge apertures that open externally in the diameter direction.

Owner:AISIN AW CO LTD

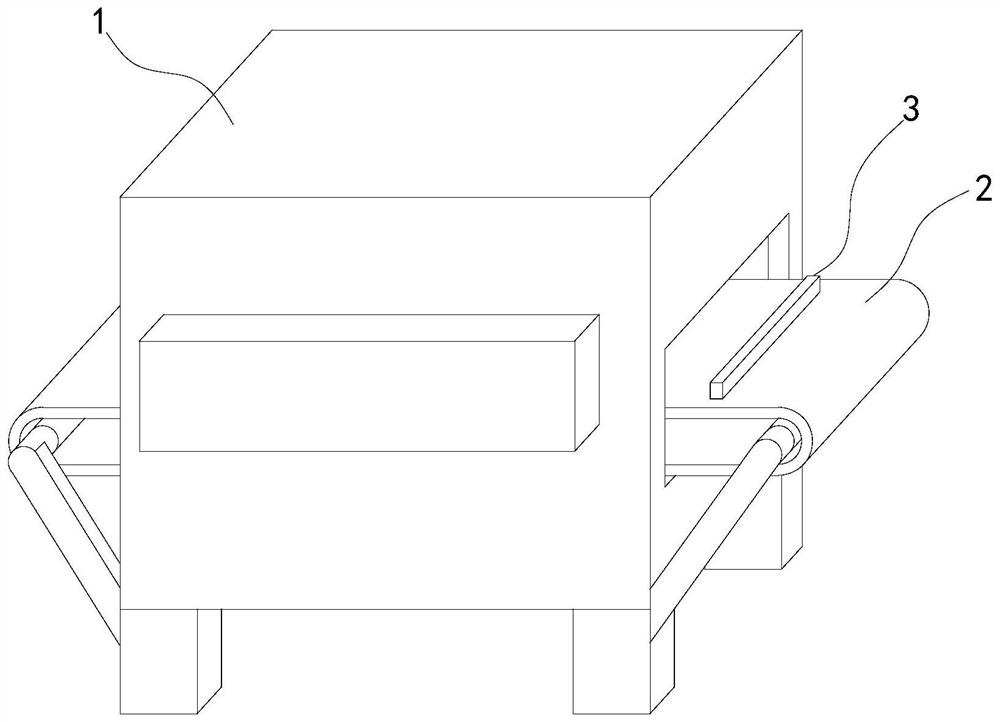

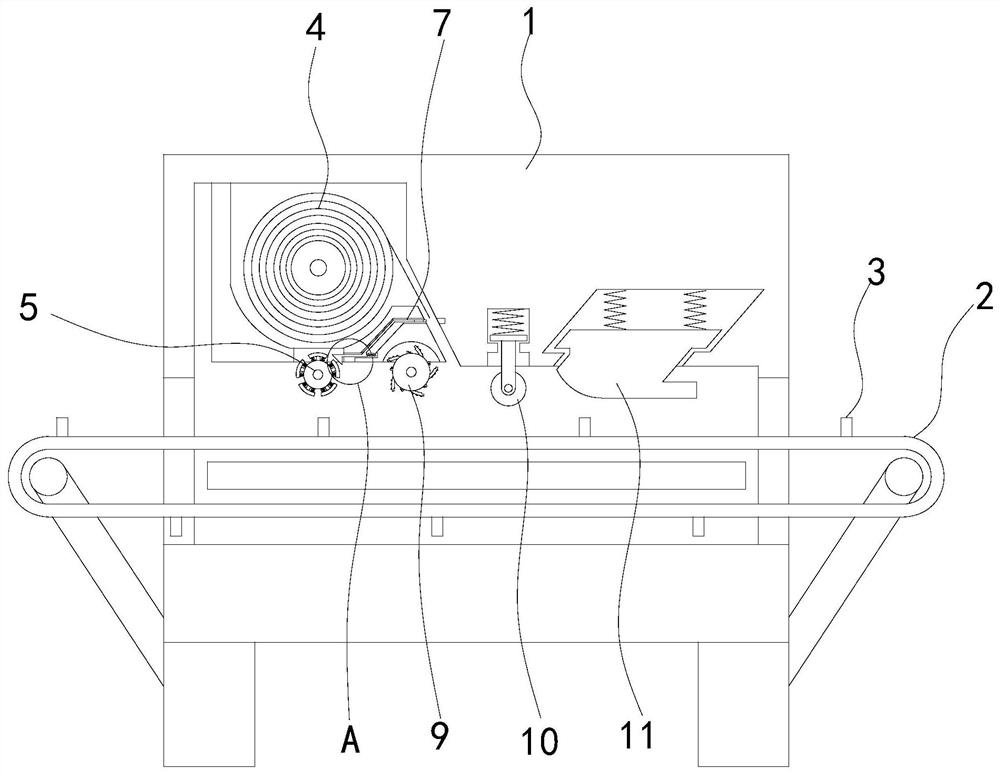

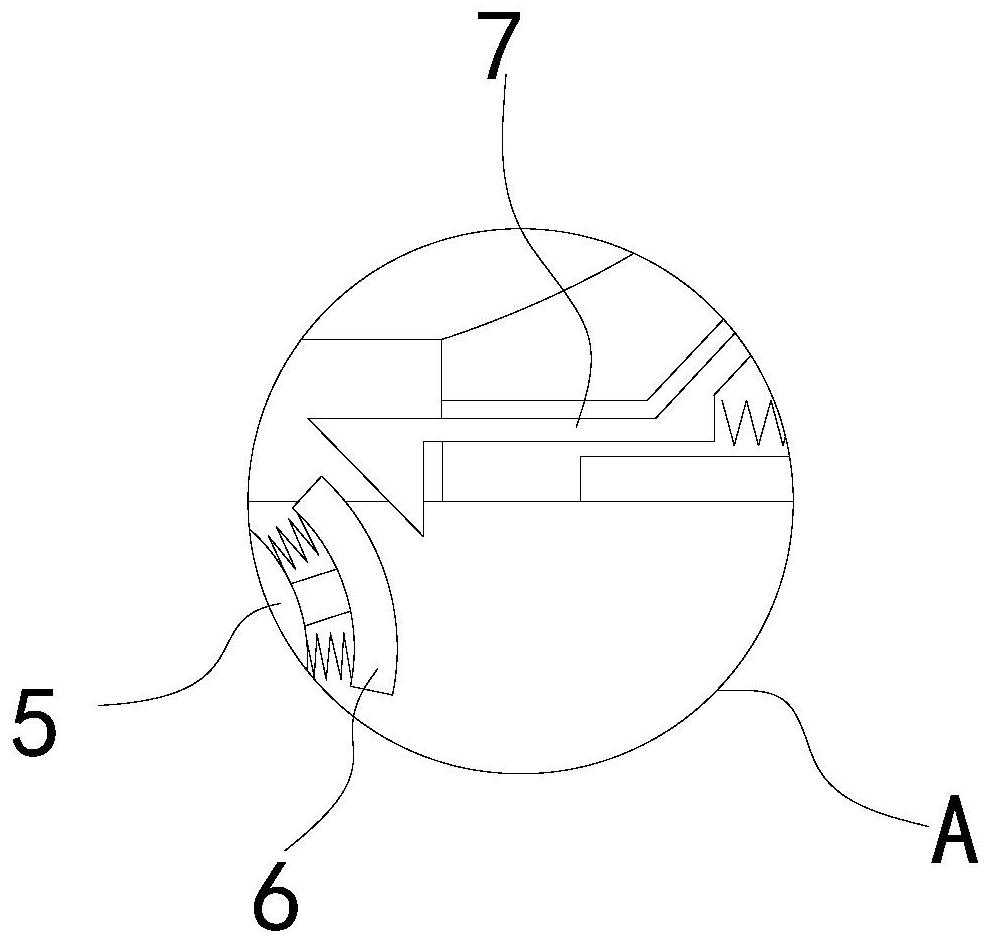

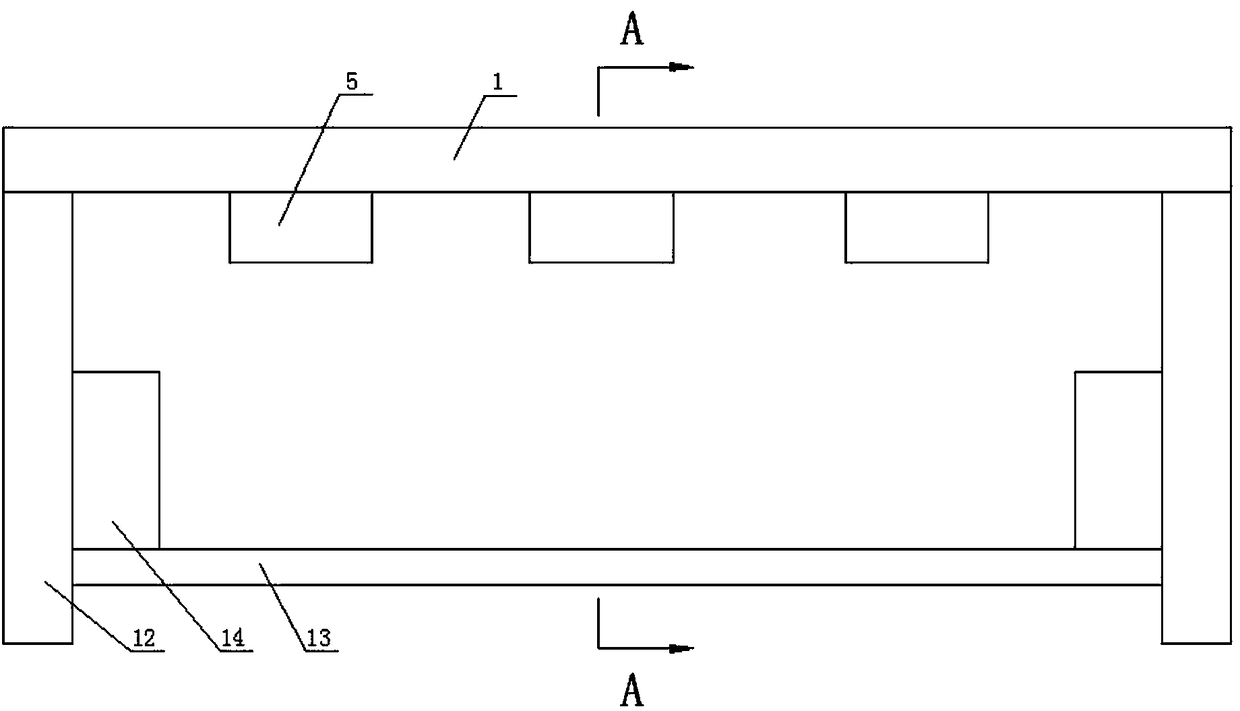

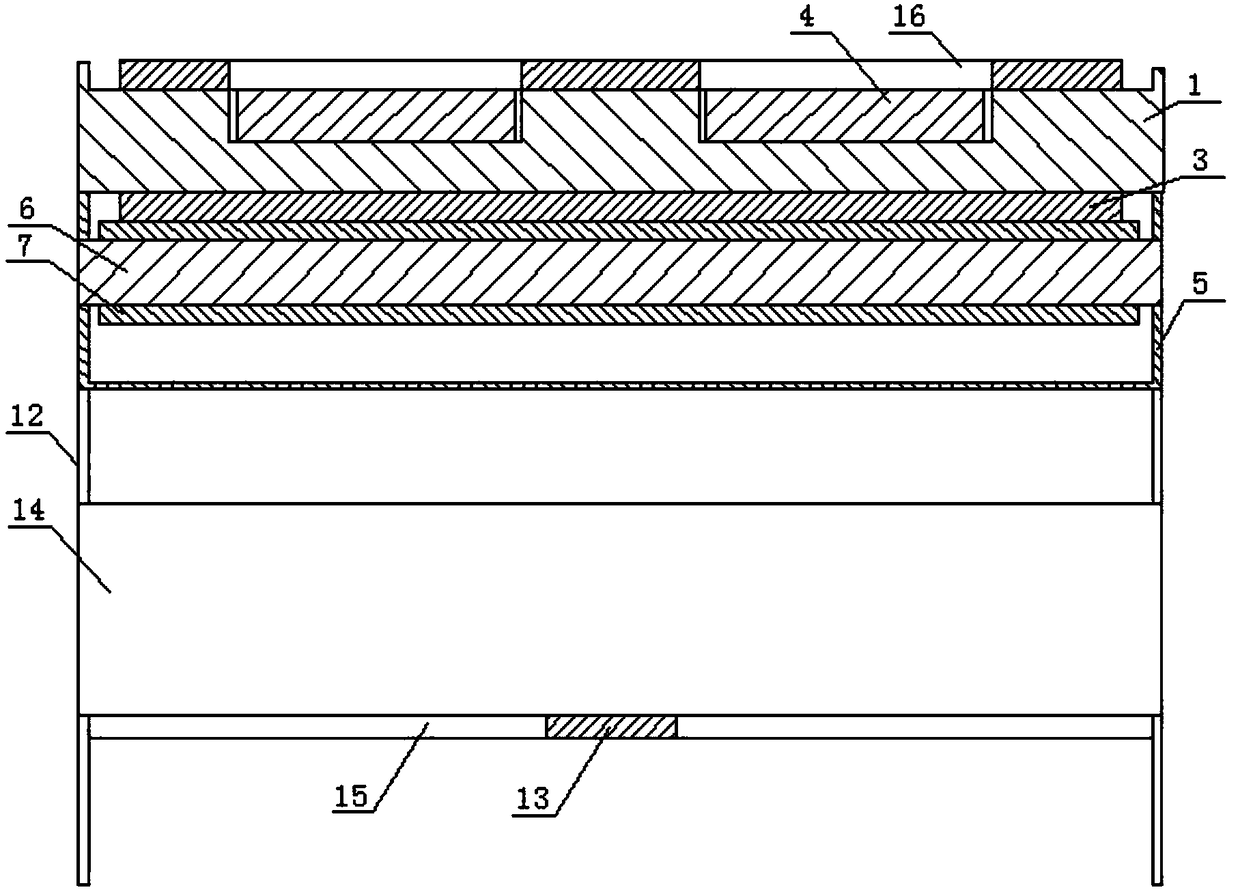

Veneer sticking equipment for wood processing

InactiveCN111702882AReduce consumptionAvoid blockingLiquid surface applicatorsProfiling/shaping machinesStructural engineeringConveyor belt

The invention relates to the field of wood processing equipment, in particular to veneer sticking equipment for wood processing. The equipment comprises a device main body, a conveyor belt is movablyarranged at the lower end of the interior of the device main body, a touch rotating wheel is movably arranged on the left side of the interior of the device main body, a fit plate is movably installedon the outer side of the touch rotating wheel, a gluing rotating wheel is movably arranged on the outer side inside the touch rotating wheel, and a scraping plate is movably installed on the outer side of the gluing rotating wheel. A veneer roll is movably arranged at the upper end of the interior of the device main body, and the touch rotating wheel is arranged under the veneer roll, when wood enters the device main body under the drive of a baffle on the conveyor belt, acting force can be exerted on the touch rotating wheel to drive the touch rotating wheel to move upwards to make contact with the lower end of the veneer roll, and when the wood continues to move, the veneer roll can be driven to rotate clockwise by driving the touch rotating wheel to rotate, so that veneer on the outerside of the veneer roll can move downwards to make contact with the outer side of the wood. Automatic veneer sticking is achieved, and meanwhile energy consumption is saved.

Owner:朱敏宜

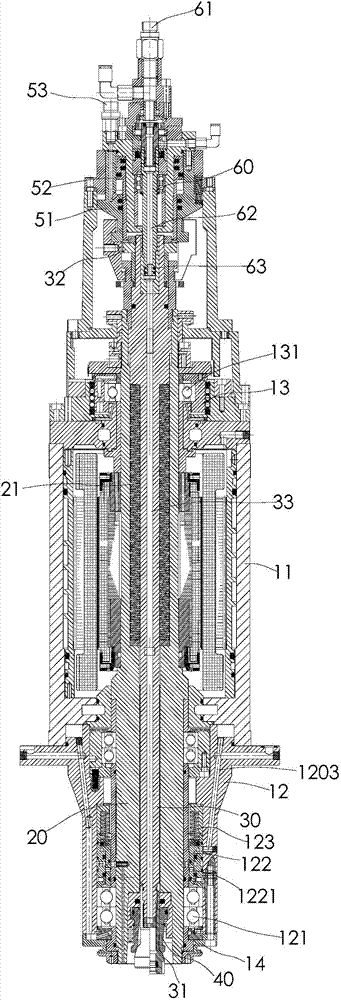

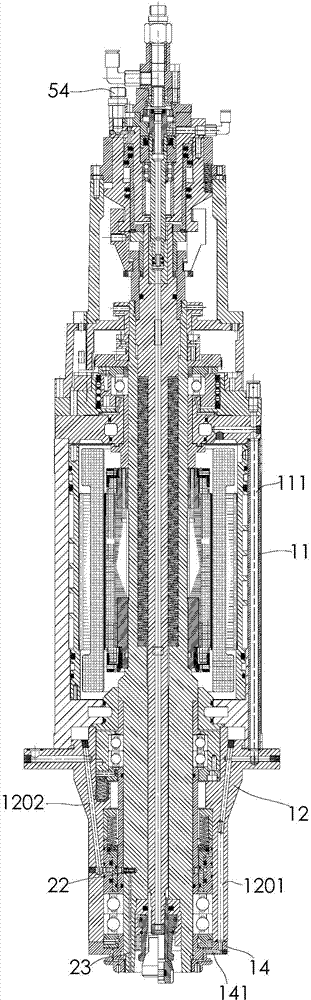

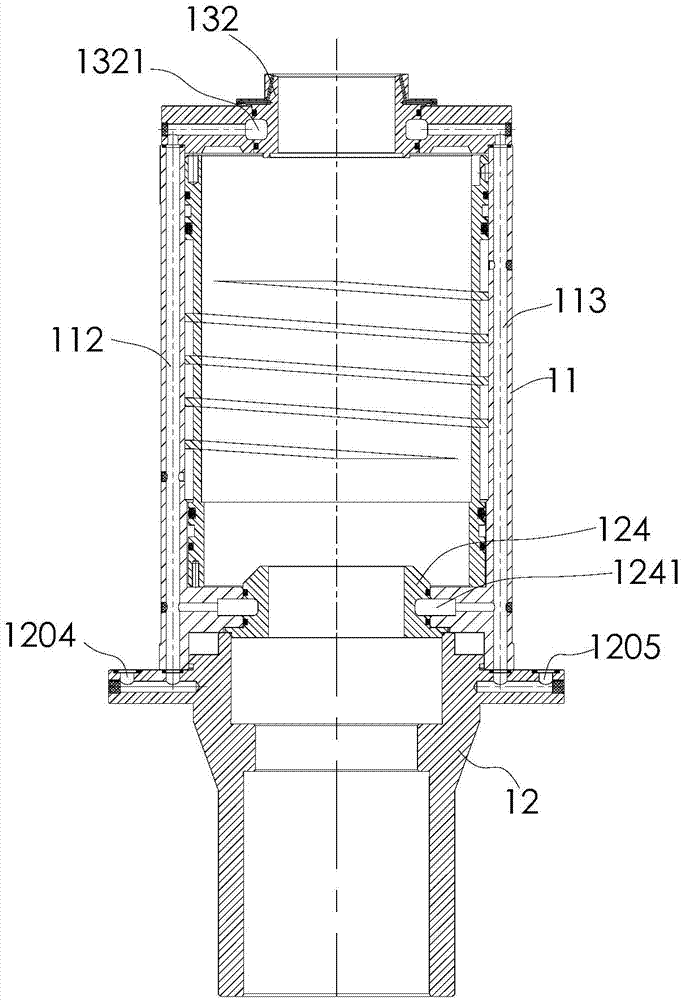

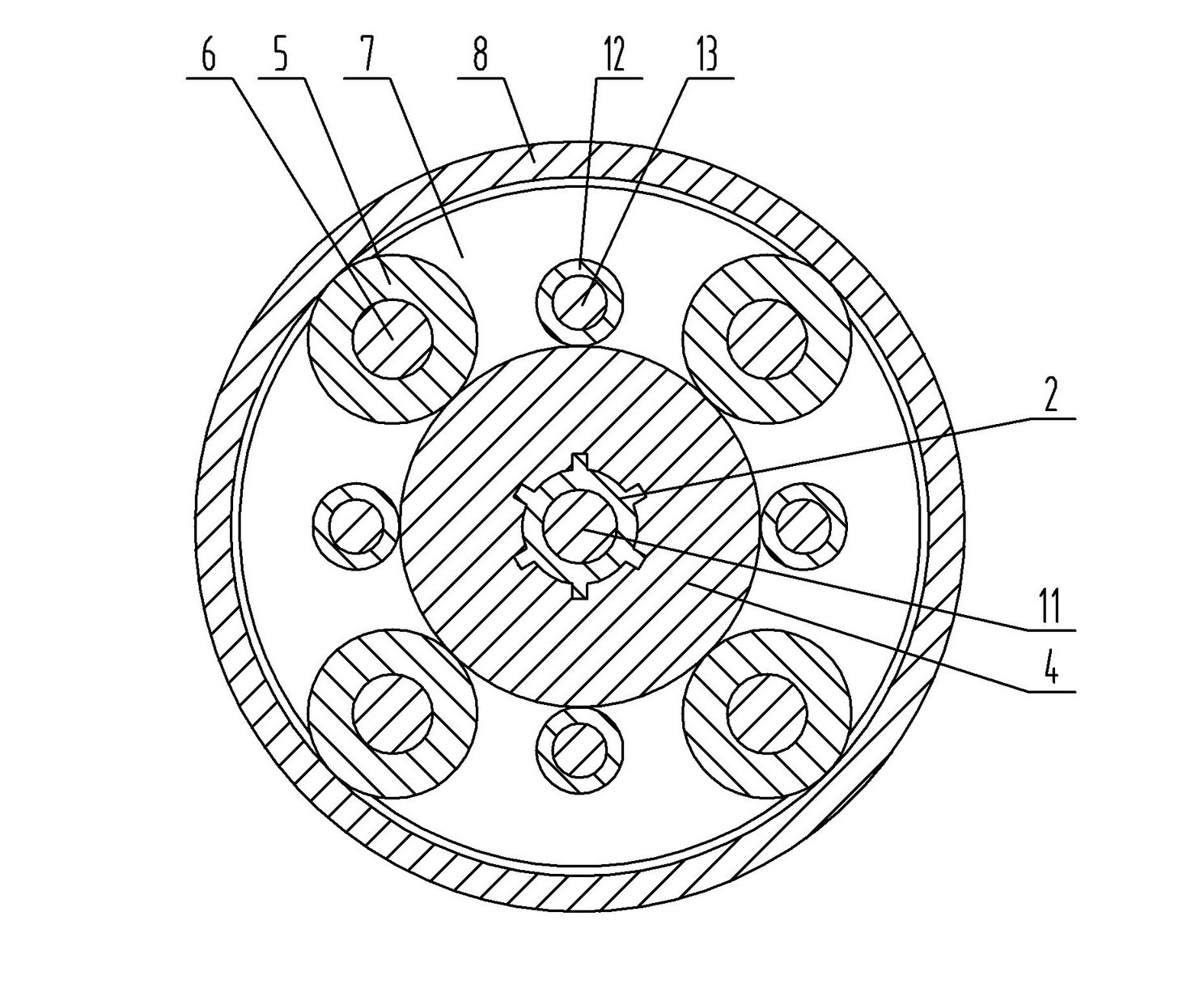

High-power and high-speed electric spindle

ActiveCN103752864AImprove the lubrication effectImprove rotation efficiencyLarge fixed membersDriving apparatusGas lubricationElectricity

The invention discloses a high-power and high-speed electric spindle. The high-power and high-speed electric spindle comprises a body assembly, a spindle core, a pull claw and a pull rod, wherein the body assembly comprises a body, an upper bearing seat component and a lower bearing seat component; the upper end of the spindle core is pivoted with the upper bearing seat component through an upper bearing; the lower end of the spindle core is pivoted with the lower bearing seat component through a lower bearing; the pull claw is mounted on the lower end of the spindle core and connected with a cutter; a lower bearing oil-gas inlet channel and a lower bearing oil-gas outlet channel are formed in the body; an inner side end of the lower bearing oil-gas inlet channel is communicated with a gap between an inner ring and an outer ring of the lower bearing; an inner side end of the lower bearing oil-gas outlet channel is communicated with the gap between the inner ring and the outer ring of the lower bearing; an upper bearing oil-gas inlet channel and an upper bearing oil-gas outlet channel are also formed in the boy; an inner side end of the upper bearing oil-gas inlet channel is communicated with the gap between the inner ring and the outer ring of the upper bearing; and an inner side end of the upper bearing oil-gas outlet channel is communicated with the gap between the inner ring and the outer ring of the upper bearing. According to the high-power and high-speed electric spindle, inner rings and outer rings of the upper bearing, the lower bearing and the middle bearing of the electric spindle are lubricated by using an oil-gas lubrication medium, so that the lubrication effect is improved and the rotation efficiency of the electric spindle center is improved.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

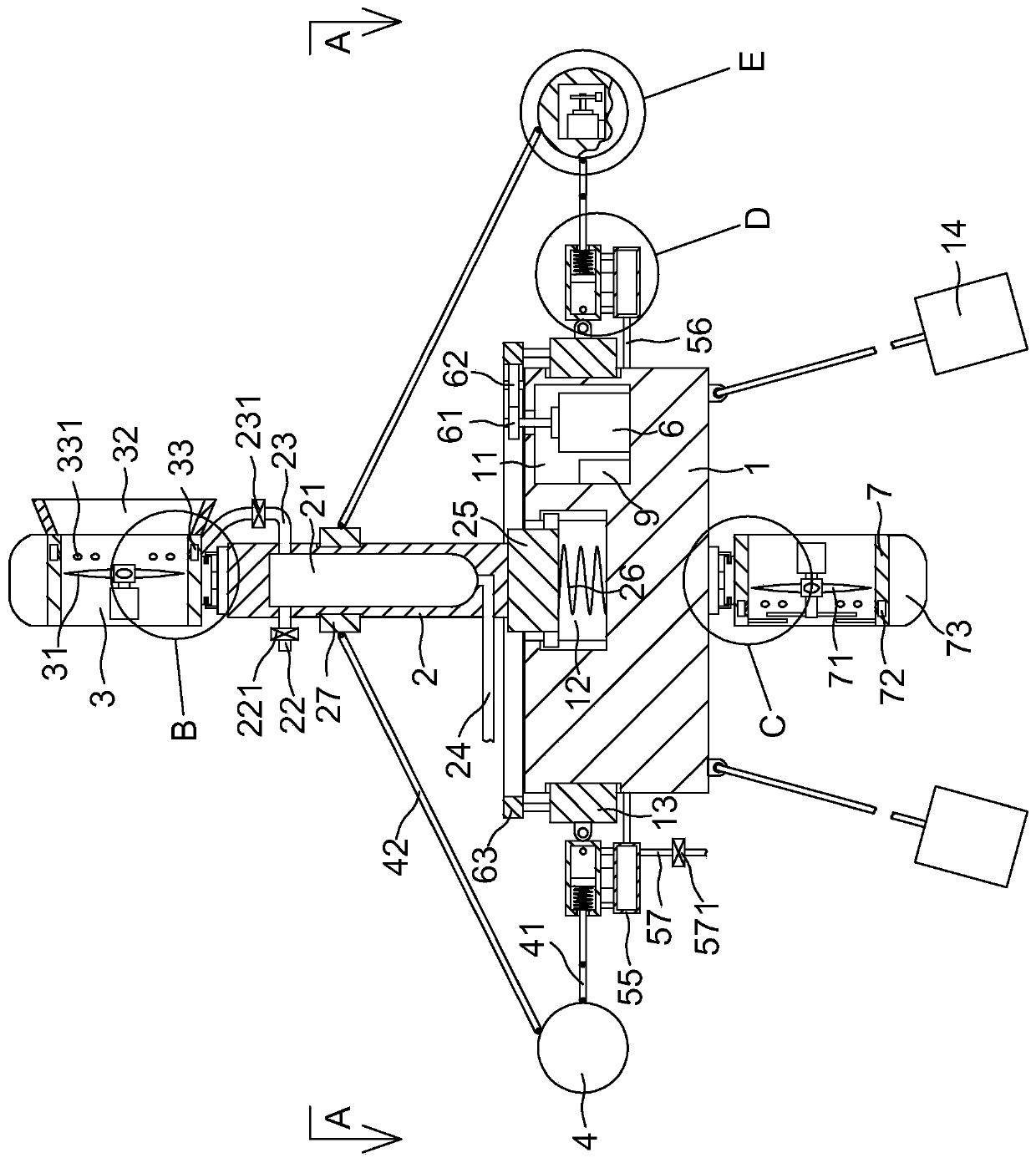

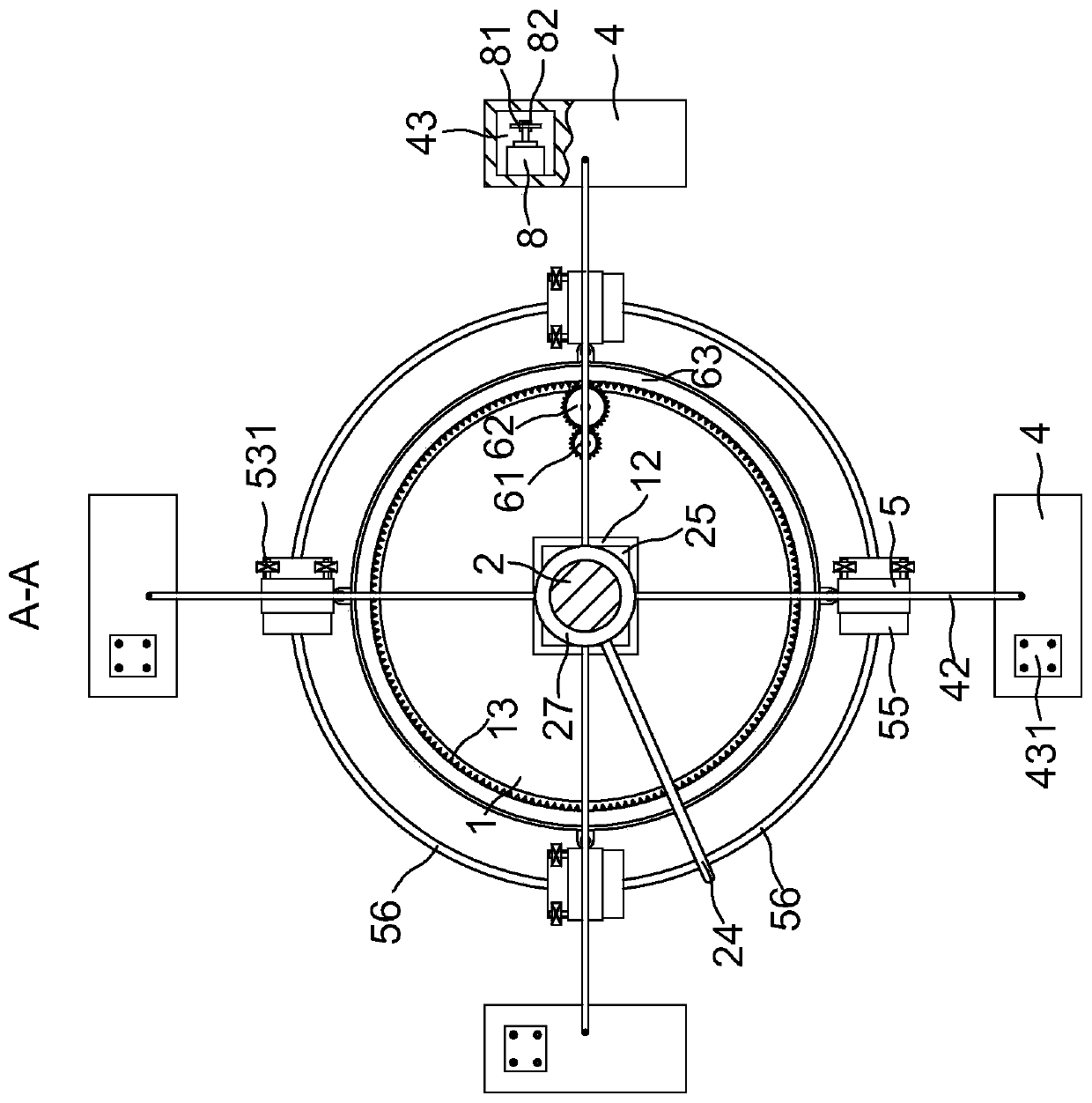

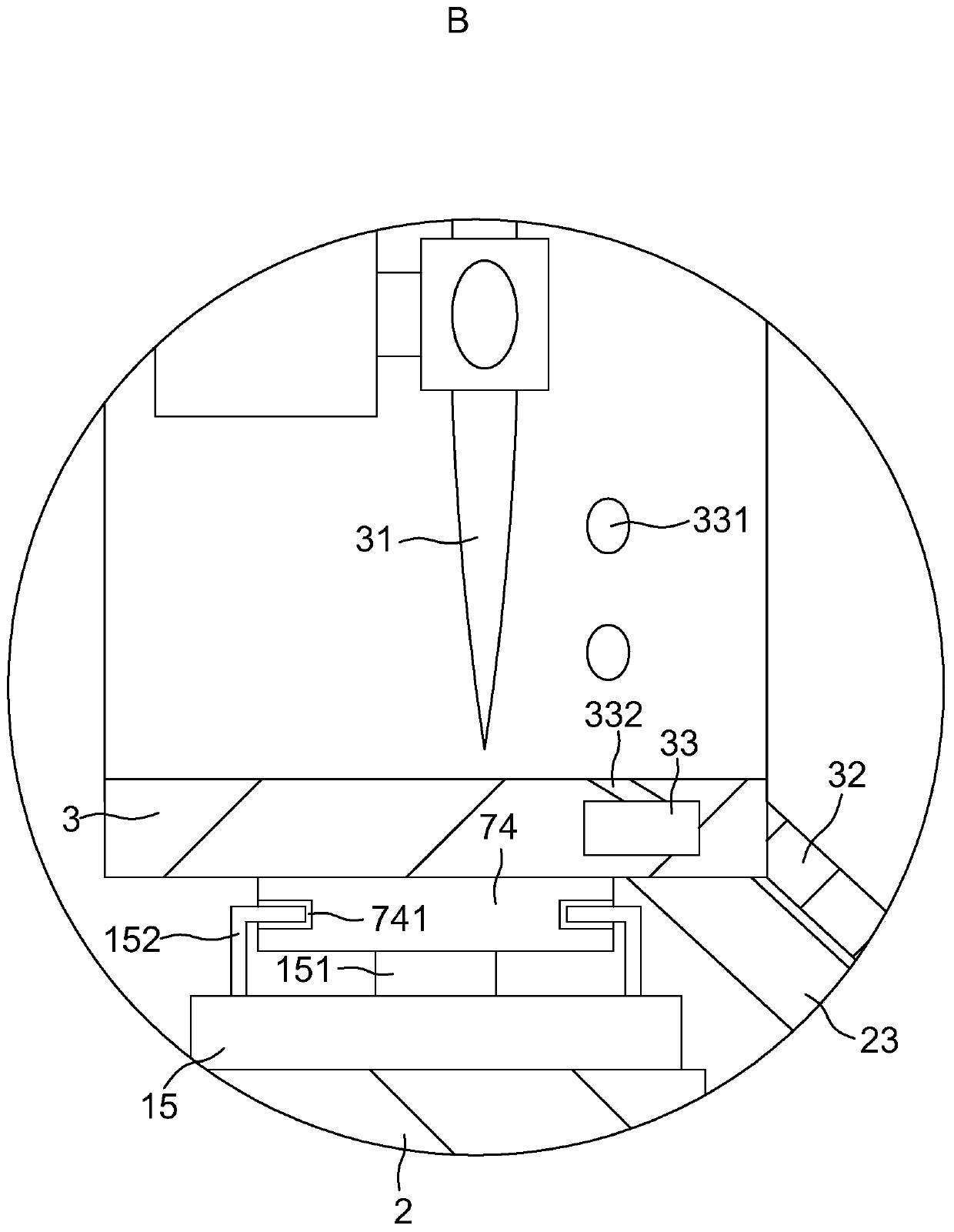

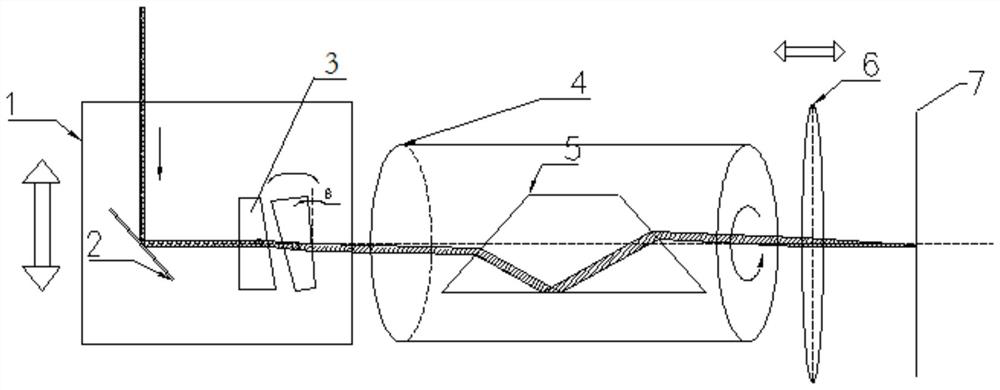

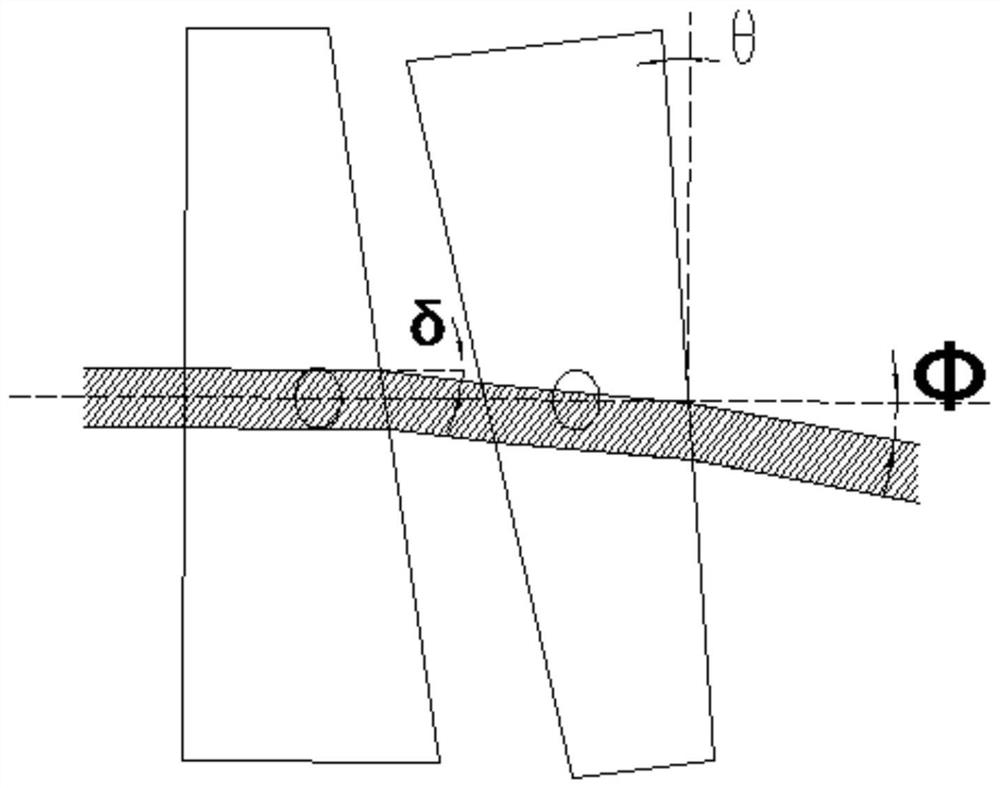

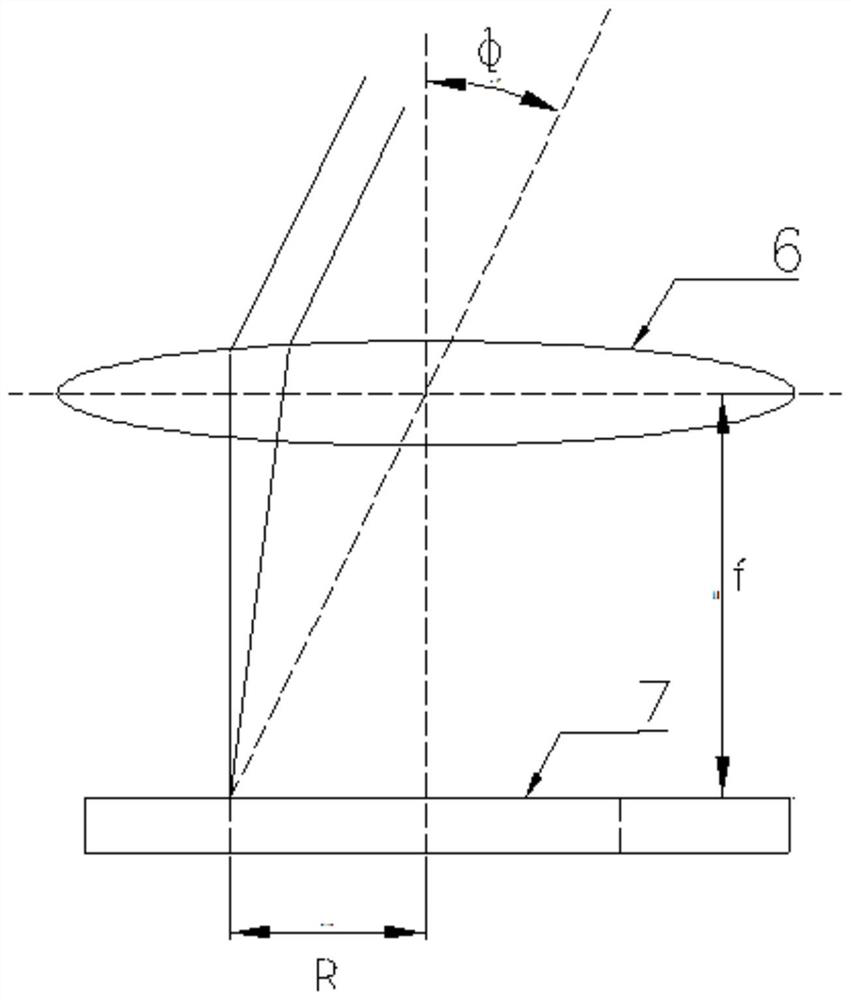

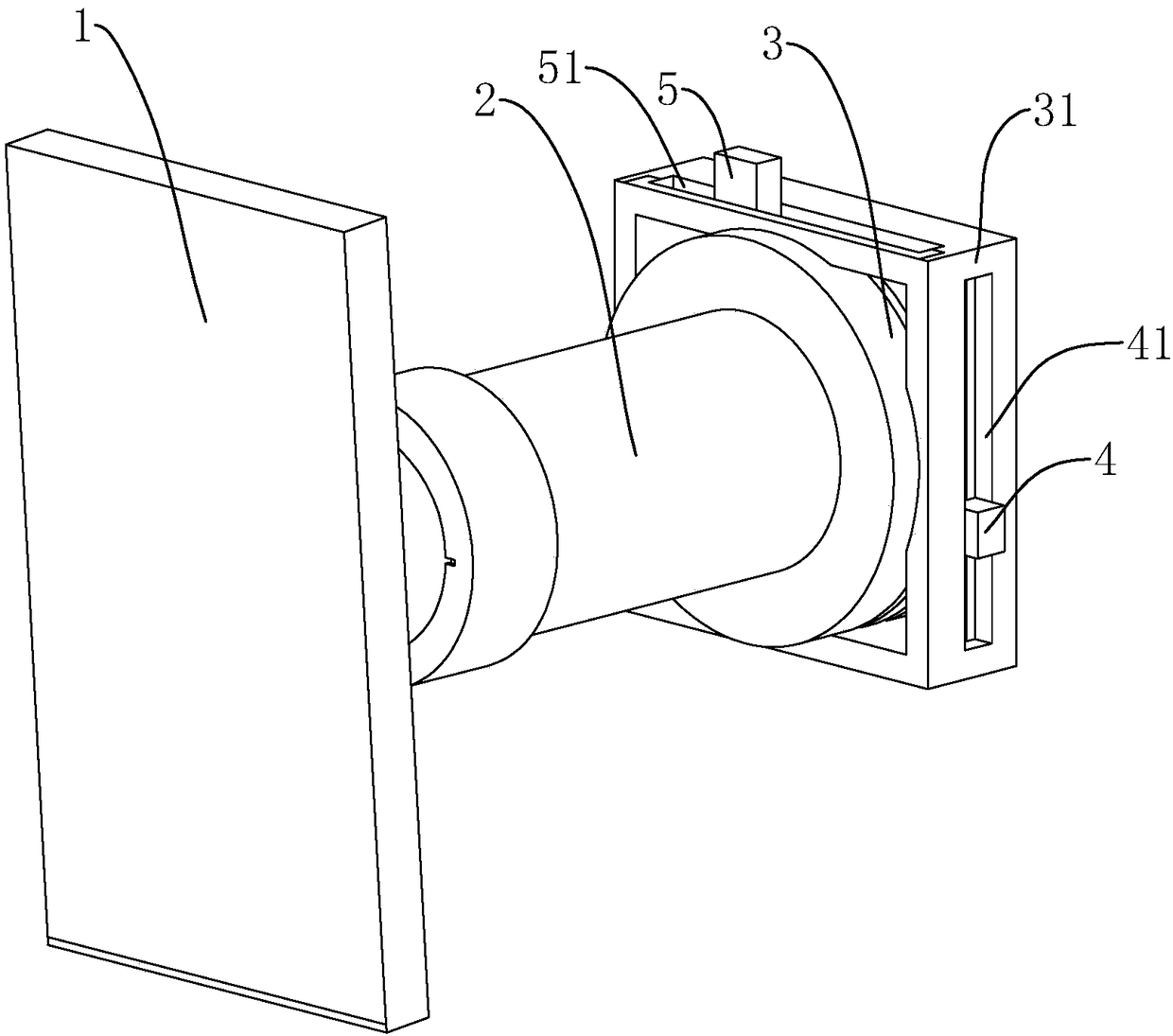

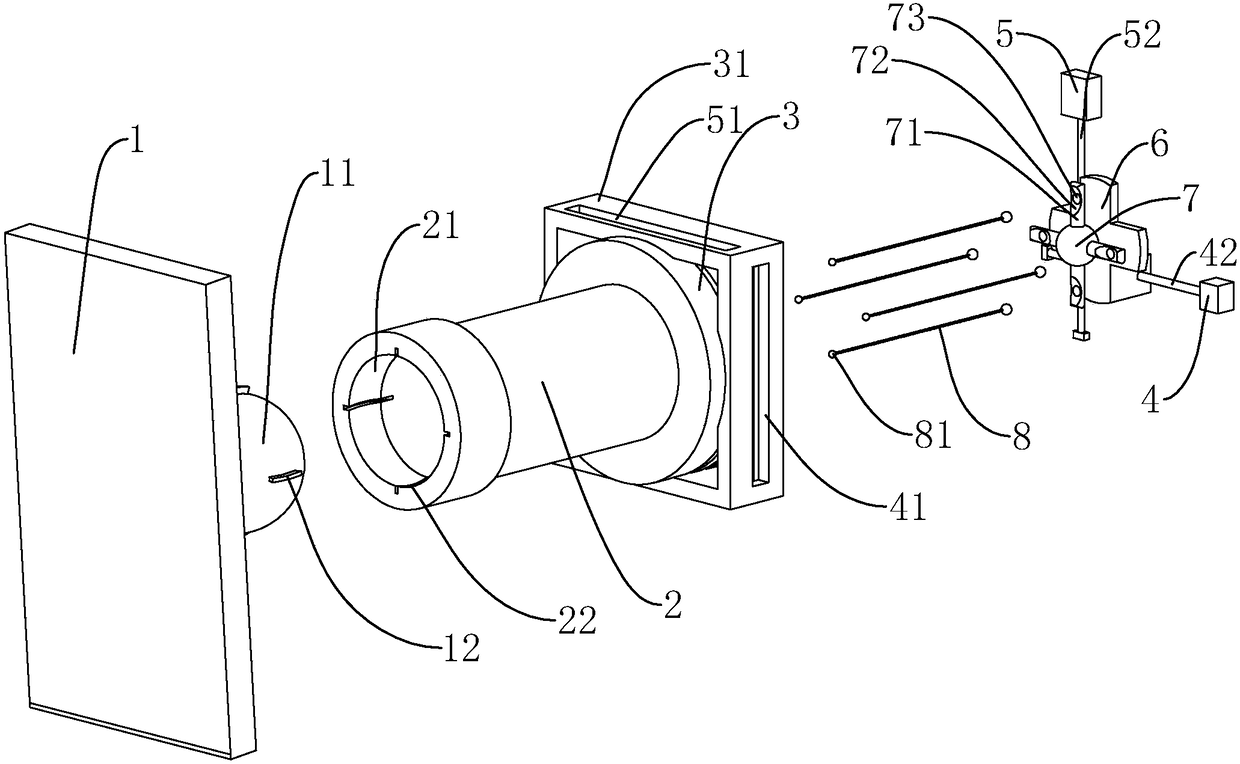

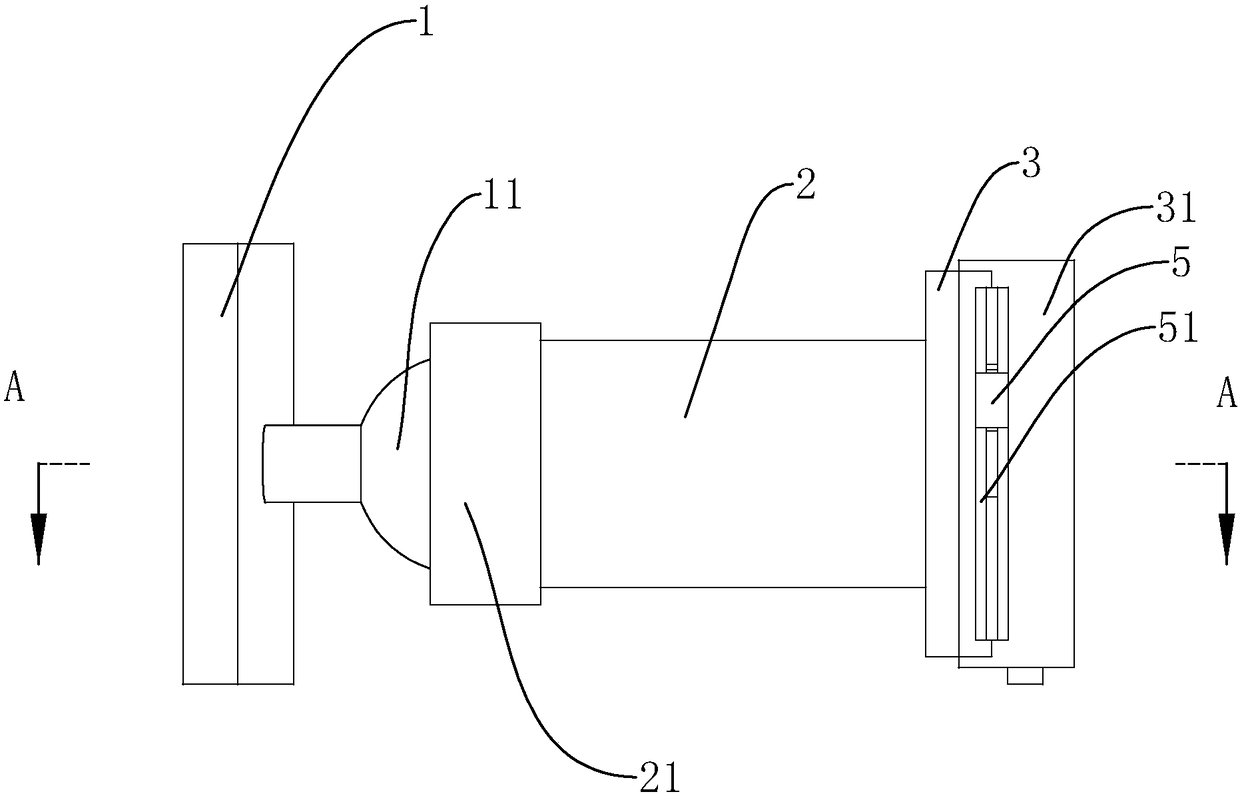

Rotary cutting and punching device based on dove prism

PendingCN112247380AImprove rotation efficiencySimplified installation stepsLaser beam welding apparatusLaser processingLight beam

The invention belongs to the technical field of laser processing, and particularly provides a rotary cutting and punching device based on a dove prism. The rotary cutting and punching device comprisesa supporting plate capable of moving horizontally as a whole, a reflecting mirror, a set of optical wedges arranged in a complementary mode, the dove prism and a focusing lens, wherein the reflectingmirror, the optical wedges, the dove prism and the focusing lens are sequentially arranged in the direction of an optical path. The reflecting mirror and the optical wedge set are fixedly installed on the supporting plate. The dove prism is arranged in a rotatable hollow motor. A processing material is located on the focus of the focusing lens. According to the scheme, the number of adjusting devices is small, the installation steps are simple, and the adjusting steps are relatively simple. Holes with different apertures and different tapers can be punched by simply adjusting the rotating angles of the optical wedges and the overall position of the supporting plate without replacing the devices, and therefore the processing cost is greatly reduced. By means of the dove prism, the efficiency of the rotation of laser beams when the hollow motor works can be improved, the punching efficiency can be doubled compared with other methods, and the overall efficiency is greatly improved.

Owner:武汉先河激光技术有限公司

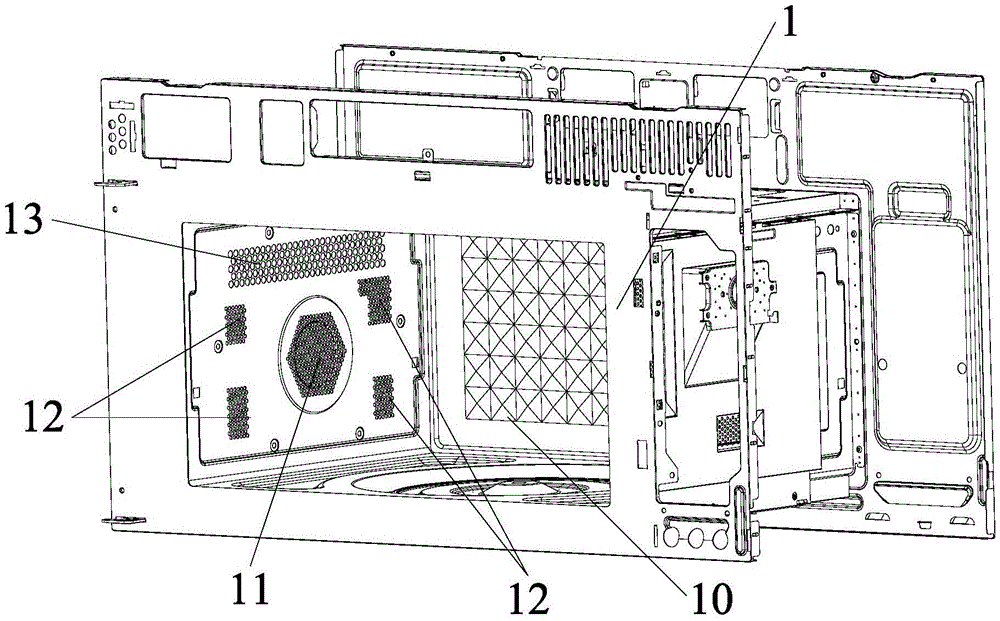

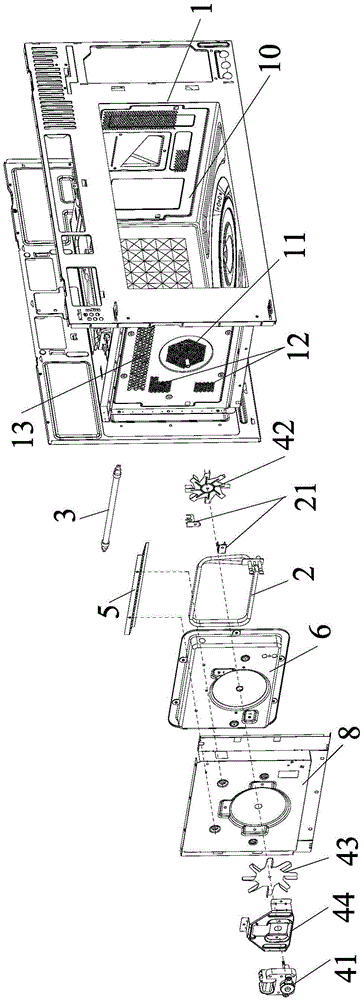

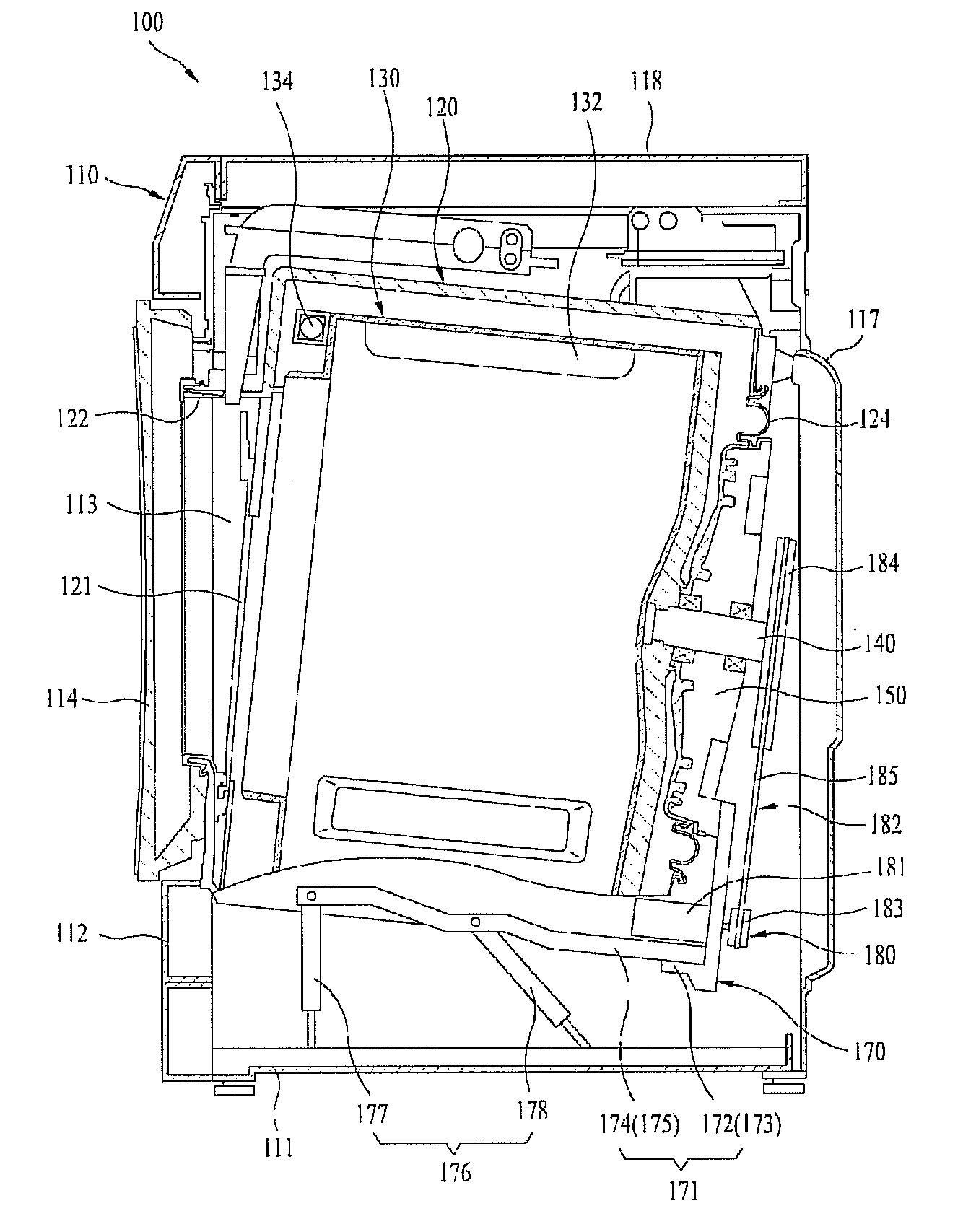

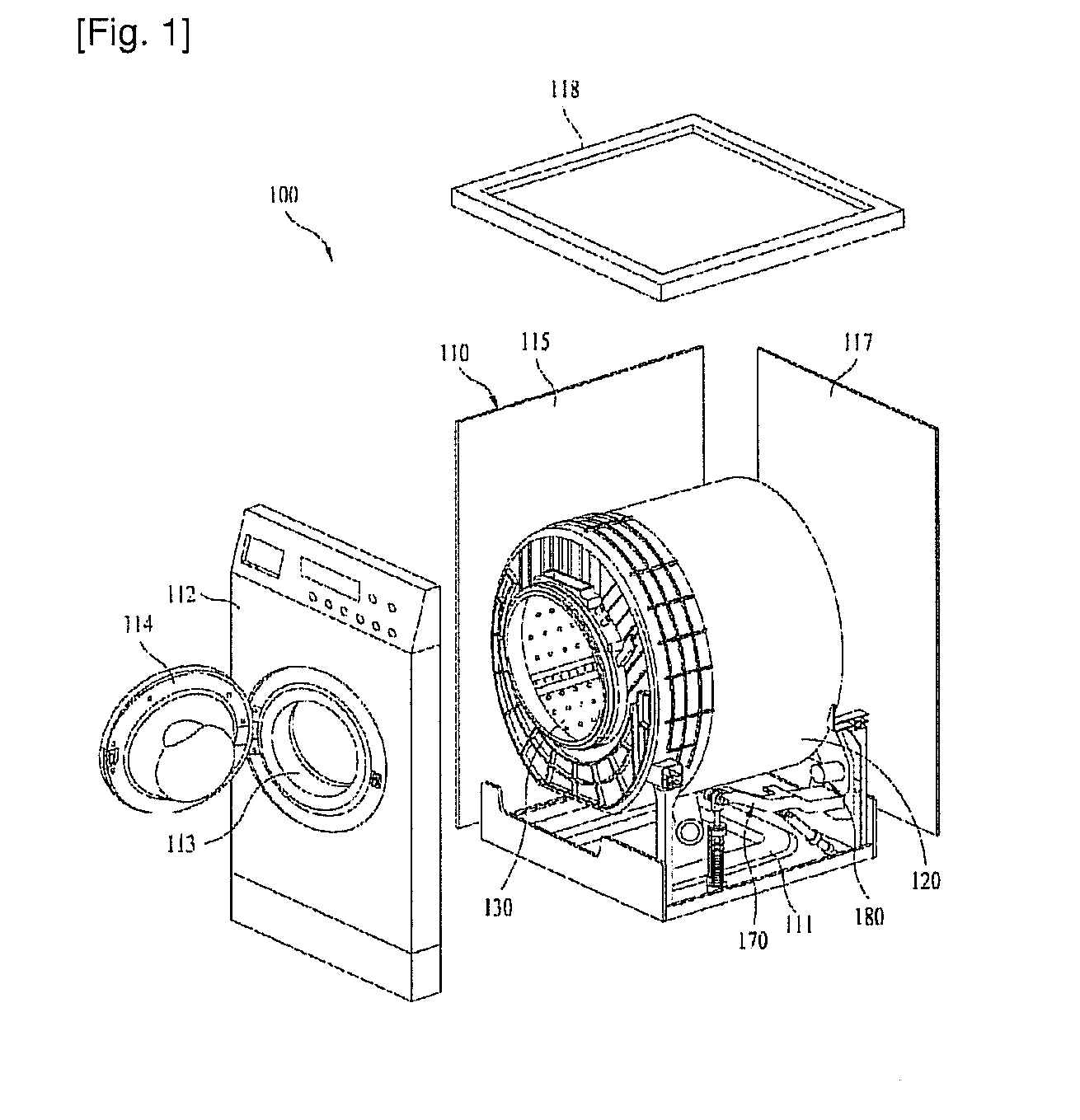

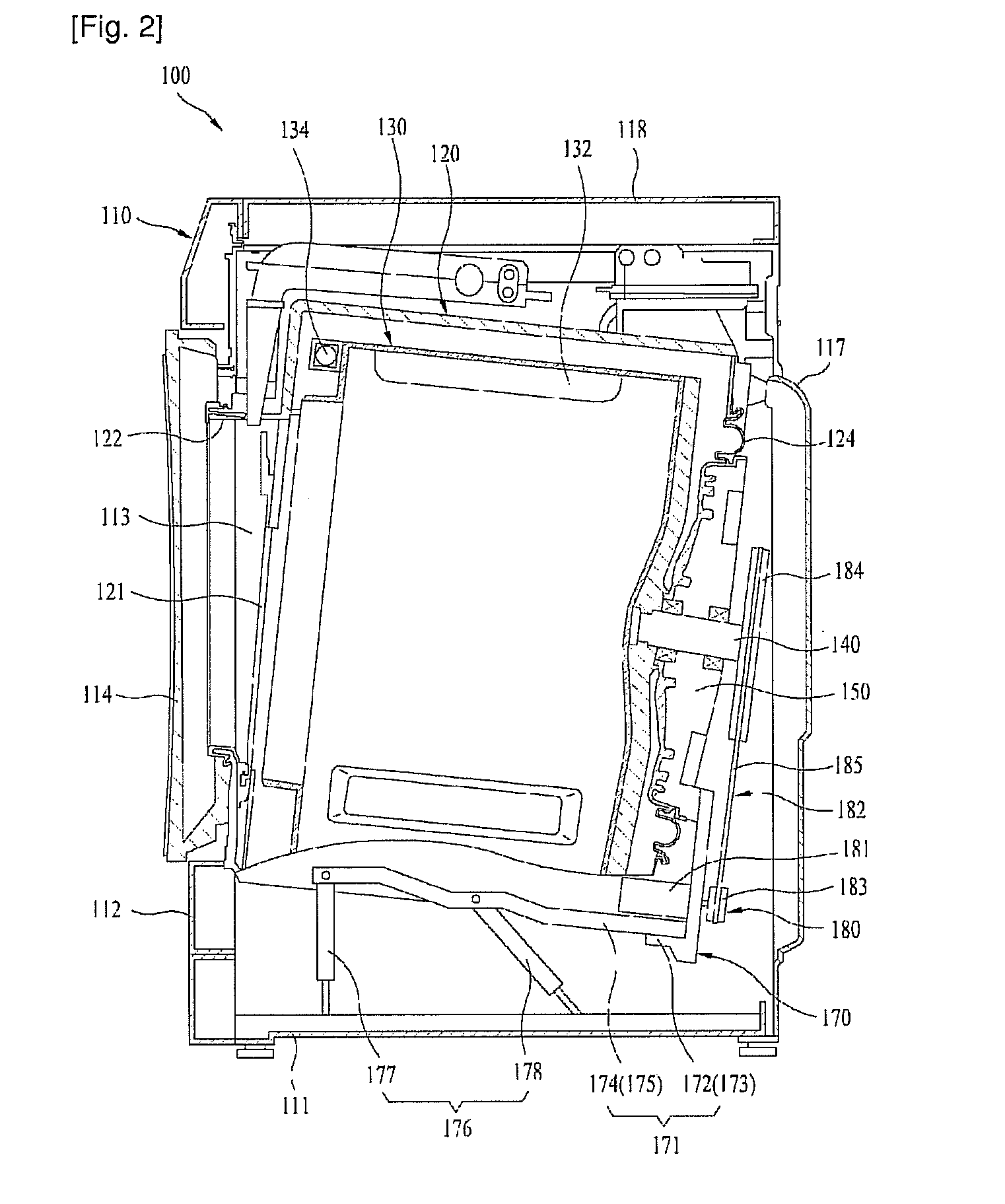

Laundry machine

ActiveUS20110296878A1Improve washing effectIncrease capacityOther washing machinesWashing machine with receptaclesElectric machineryEngineering

The present invention relates to a washing machine (100) including a cabinet (110) having a base (1.11), a tub (120) fixedly secured to an inside of the cabinet (110), a drum (130) rotatable provided in the tub (120), a rotation shaft (140) passed through the tub (120) from a rear of the drum (130), a bearing housing (150) connected to the rotation shaft (140), a suspension assembly (170) for buffering and supporting a structure connected to the bearing housing (150), a driving motor (181) provided to the suspension assembly (170) and a power transmission member (182) for transmission of the rotation force from the driving motor (181) to the rotation shaft (140), thereby permitting to increase a capacity of the washing machine (100) by changing the structure or the washing machine (100) and increase the rotation efficiency of the drum (130) by providing a driving structure which rotates the drum (130) and has an increased capacity by thus effects.

Owner:LG ELECTRONICS INC

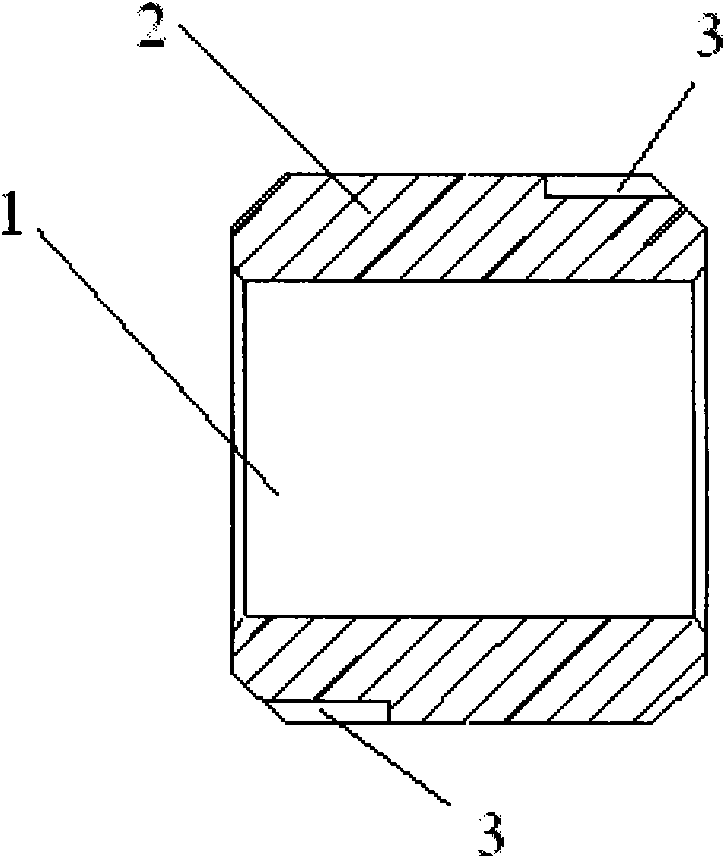

Powder metallurgy oil-free lubricating bearing and method for preparing same

ActiveCN101576122AImprove rotation efficiencyReduce running noiseBearing componentsOil freeMaterials science

The invention discloses a powder metallurgy oil-free lubricating bearing and a method for preparing the same. The powder metallurgy oil-free lubricating bearing comprises a shaft body provided with an axial central hole, and the outer surface of the shaft body is provided with an oil storage tank. The preparation method comprises the following steps: (1) evenly mixing Cu-Sn powder and C powder for forming, wherein the weight portion of all components is that: C is 0.5 to 3.0 portion, Cu is 85 to 93 portions and Sn is 5 to 13 portions; (2) controlling the temperature to between 650 and 730 DEG C, and performing sintering; (3) orderly performing finishing and cleaning; (4) performing vacuum oil immersion; and (5) performing deoiling treatment. The product has high precision and good dimension stability. Because the internal diameter tolerance of the product is controlled at 8u, and the axiality of the product is less than 0.05mm, and the matching gap between the product and the shaft is small, so that the friction contact area is small, the rotating efficiency of a fan is improved, the operating noise of the fan is reduced, and the service life of the fan is prolonged.

Owner:扬州保来得科技实业有限公司

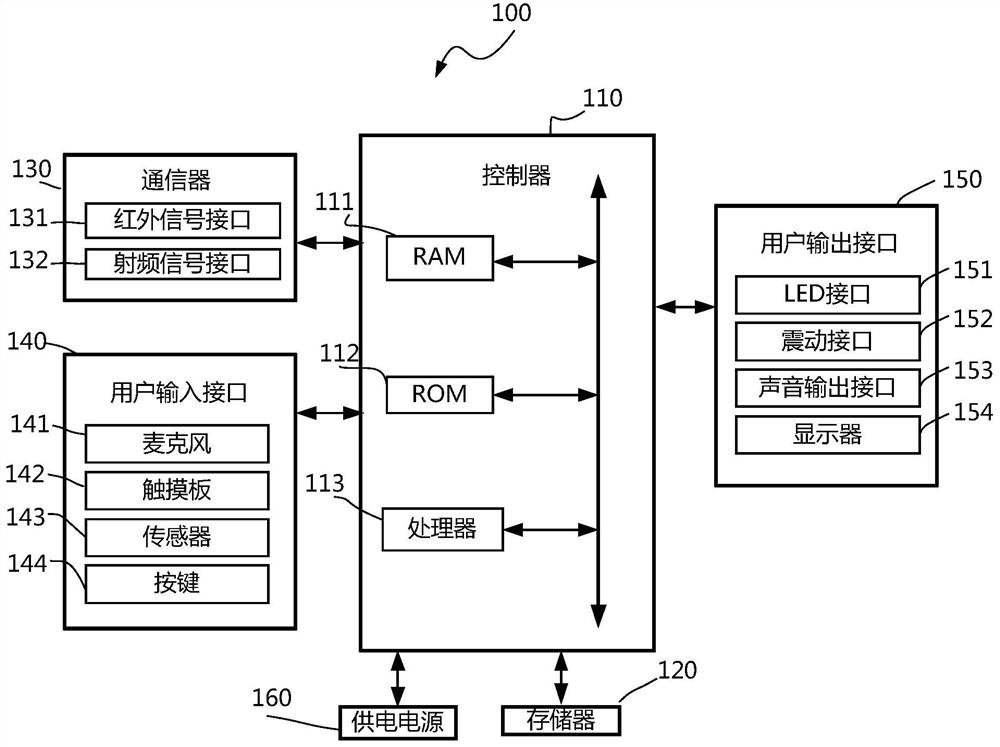

Touch screen rotation control interaction method and display equipment

PendingCN111913608AImprove experienceAvoid interactionInput/output processes for data processingComputer hardwareComputer graphics (images)

The invention discloses a touch screen rotation control interaction method and display equipment, which are used for avoiding complex and stiff interaction, improving the rotation efficiency and interestingness and improving the user experience effect. The method comprises the steps that in response to a screen rotating instruction input by a user, the rotating assembly is controlled to drive thedisplayer to rotate, and the screen rotating instruction is input when the user touches the touch screen through at least two fingers and rotates on the touch screen.

Owner:HISENSE VISUAL TECH CO LTD

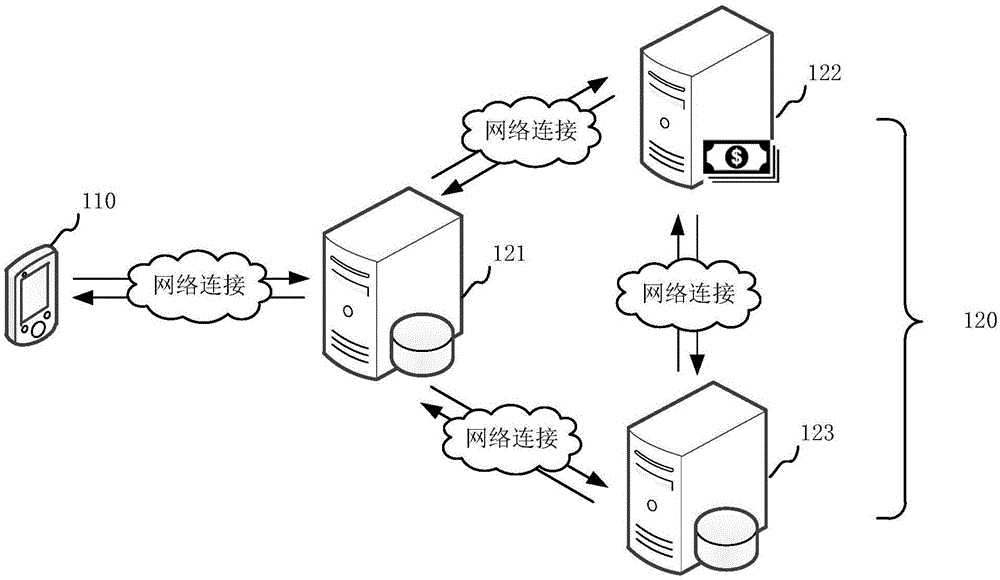

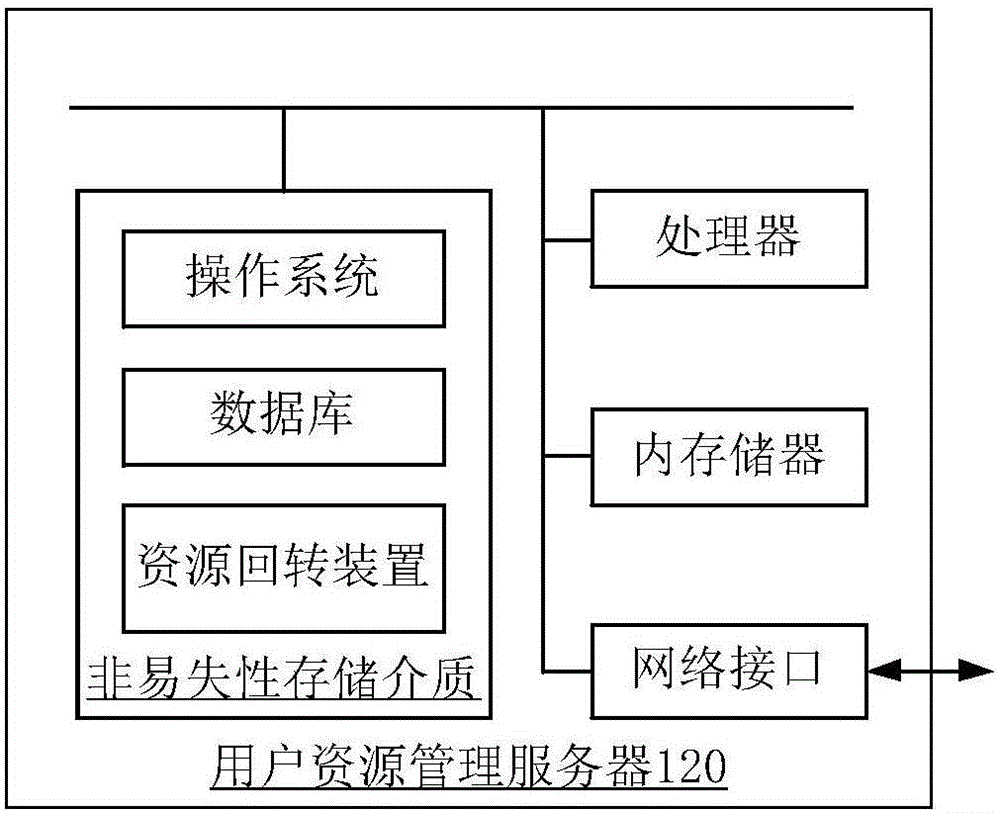

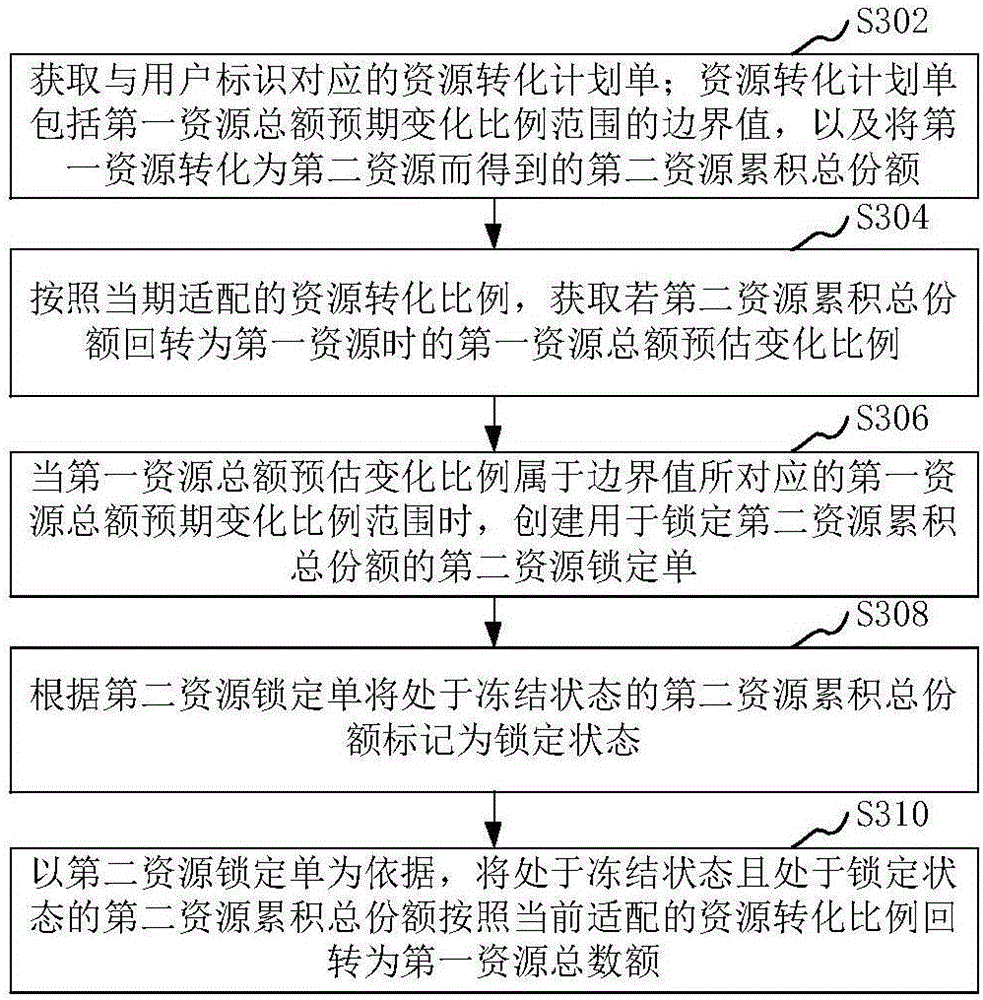

Resource transformation method and device

ActiveCN106656600AImprove rotation efficiencyAvoid the problem of slewing failureData switching networksProgram planningOperating system

The invention relates to a resource transformation method and device. The resource transformation method comprises the steps of obtaining a resource transformation planed order corresponding to a user ID; obtaining a total amount estimated change proportion of a first resource according to a currently adaptive resource transformation proportion if the total accumulated amount of a second resource is transformed into the first resource; when the total amount estimated change proportion of the first resource belongs to a first resource total amount predicted change proportion range corresponding to a border value, establishing a second resource locked order used for locking the total accumulated amount of the second resource; marking the total accumulated amount of the second resource in a frozen state into a locked state based on the second resource locked order; and transforming the total accumulated amount of the second resource in the locked state and the frozen state into the total amount of the first resource according to the currently adaptive resource transformation proportion. The resource transformation method provided by the invention improves the resource transformation efficiency greatly.

Owner:TENCENT TECH (SHENZHEN) CO LTD

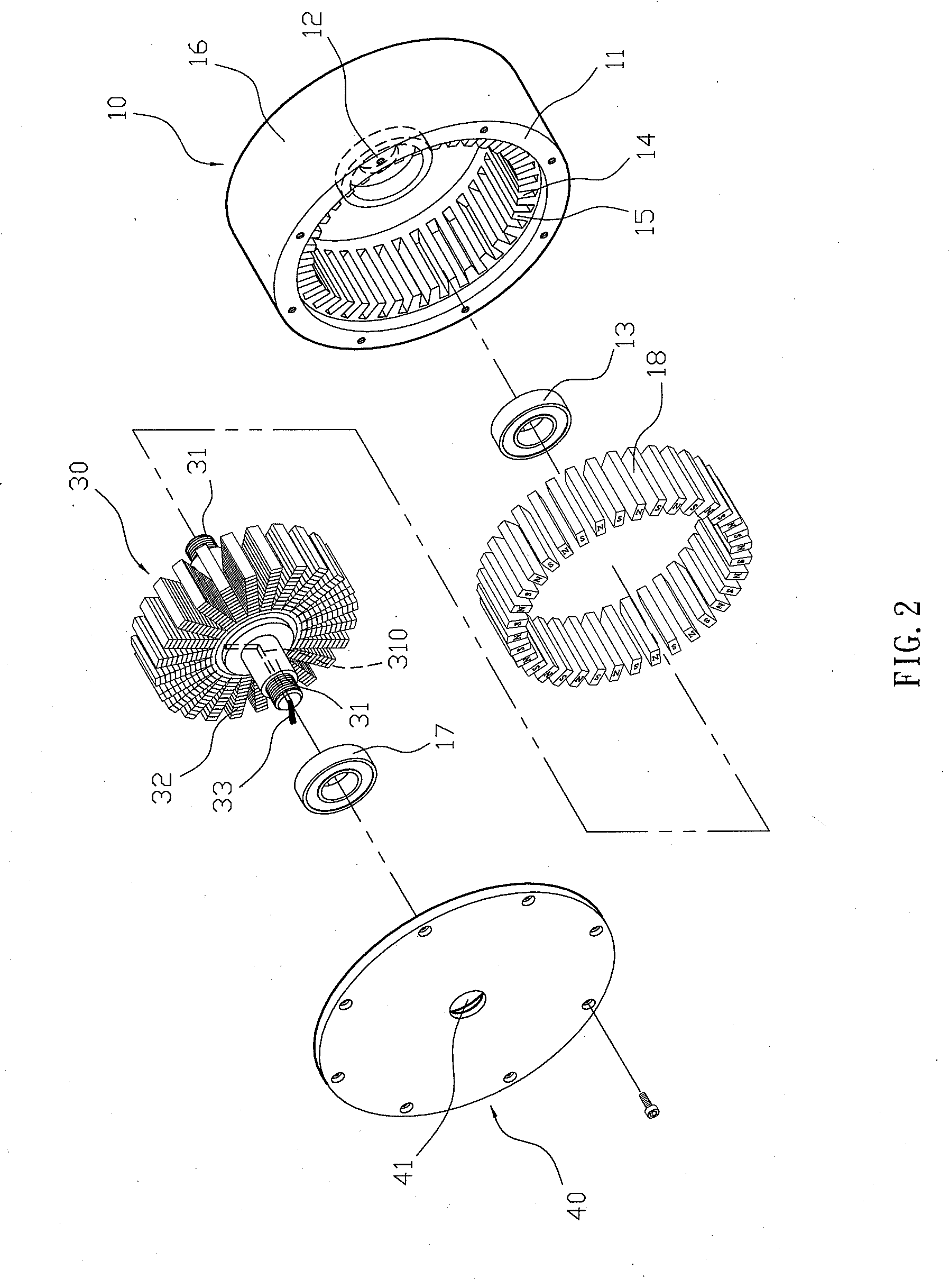

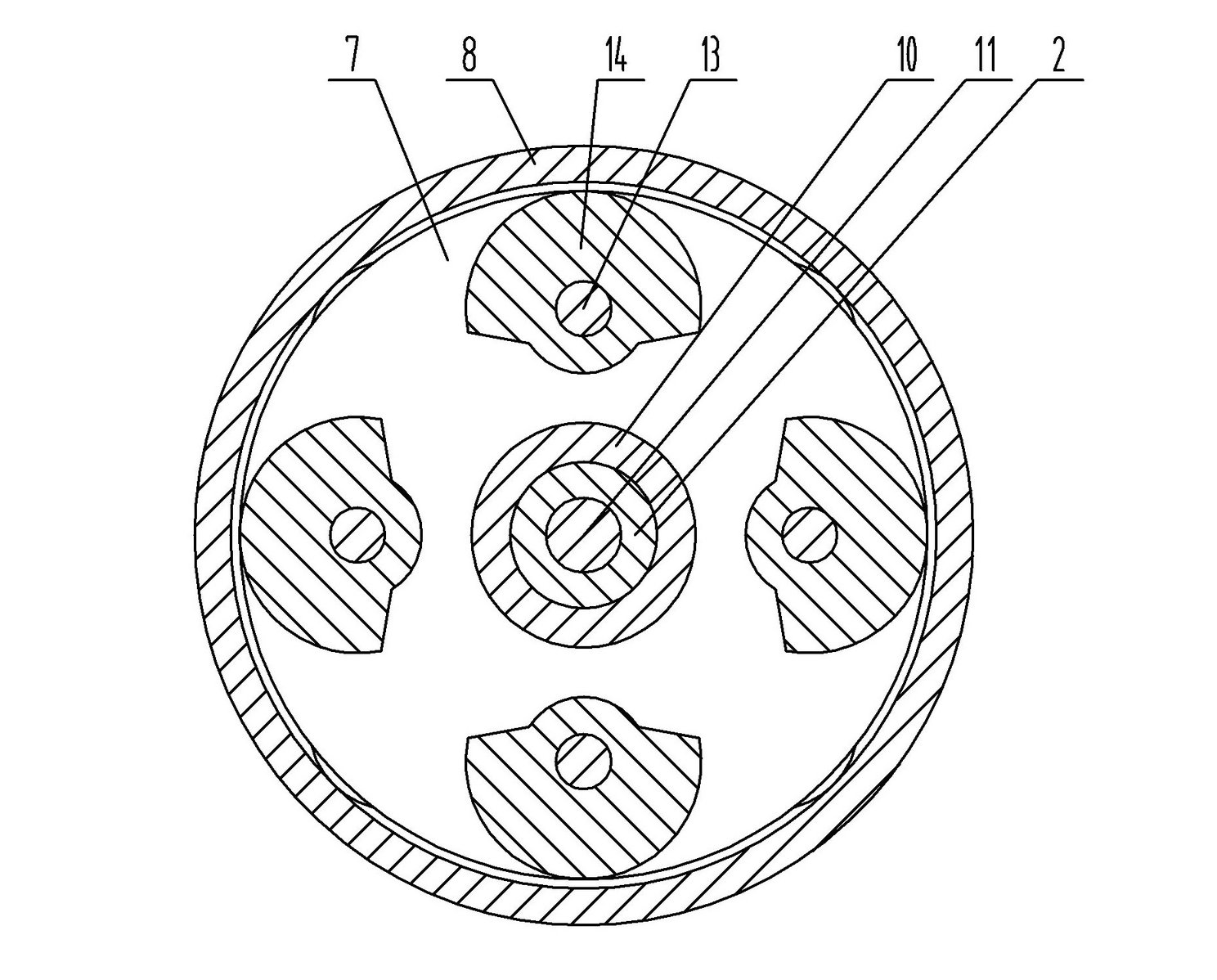

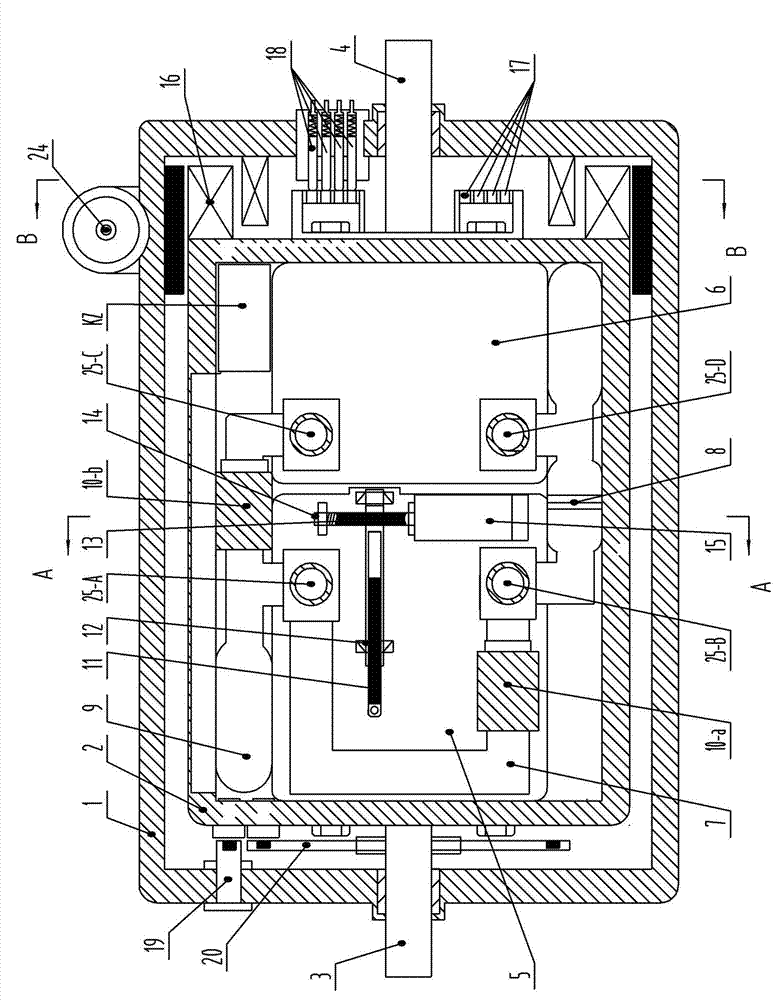

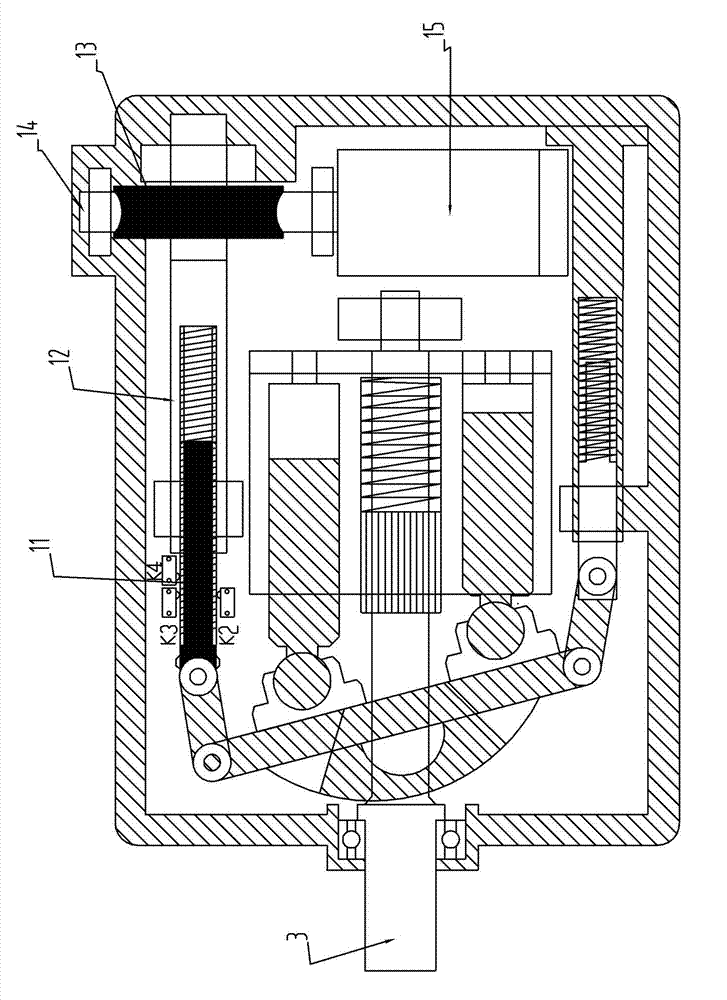

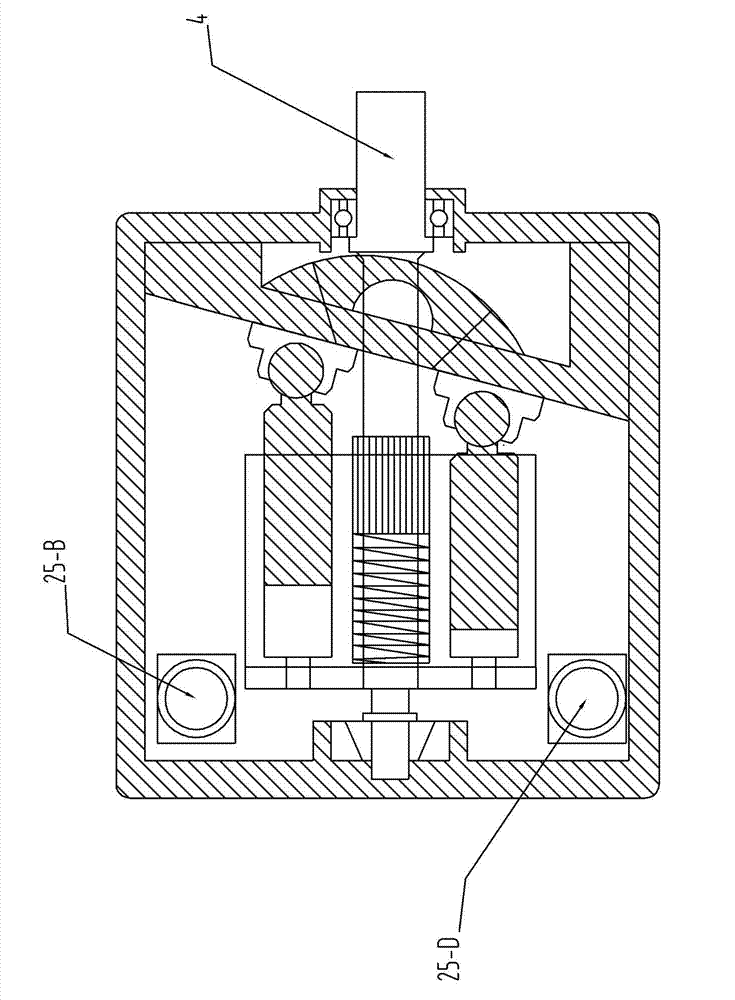

Centrifugal force controlled planet gear stepless transmission

InactiveCN102619939ASimple structureImprove interchangeabilityPortable liftingToothed gearingsGear wheelEngineering

The invention relates to a mechanical transmission, in particular to a planet gear stepless transmission which is used in a transmission system and utilizes centrifugal force to control speed variation and adjust torque. The stepless transmission comprises a housing, at least one stage of transmission unit and overrunning clutches, wherein each transmission unit comprises an input shaft, an output shaft, a large planet gear, a small planet gear, a central gear, a gear ring cylinder, a planet wheel carrier, an eccentric wheel and an eccentric wheel rack; a common intermediate shaft is mounted in the housing; the input shafts and the output shafts of all the stages of the transmission units are sleeved on the intermediate shaft, and are separated from each other; the central gear is fixed on the outer surface of the input shaft; the large planet gear is meshed with the central gear, and is also meshed with corresponding teeth of the gear ring cylinder; the small planet gear is meshed with the central gear; and the overrunning clutches are mounted between each two stages of the transmission units as well as between the gear ring cylinder of the final stage transmission unit and the housing. The planet gear stepless transmission has the advantages that the structure is simple; the manufacturing cost is low; the transmission ratio and the continuous carrying capacity are large; the transmission efficiency is high; the torque can be adjusted automatically according to the variation of loads during the work process; and stepless speed change is realized during operation.

Owner:安徽英杰精工机械股份有限公司

Valve drive unit and series thereof

InactiveUS6918572B2Reduce the burden onLow costOperating means/releasing devices for valvesServomotor componentsGear wheelEngineering

Owner:SUMITOMO HEAVY IND LTD

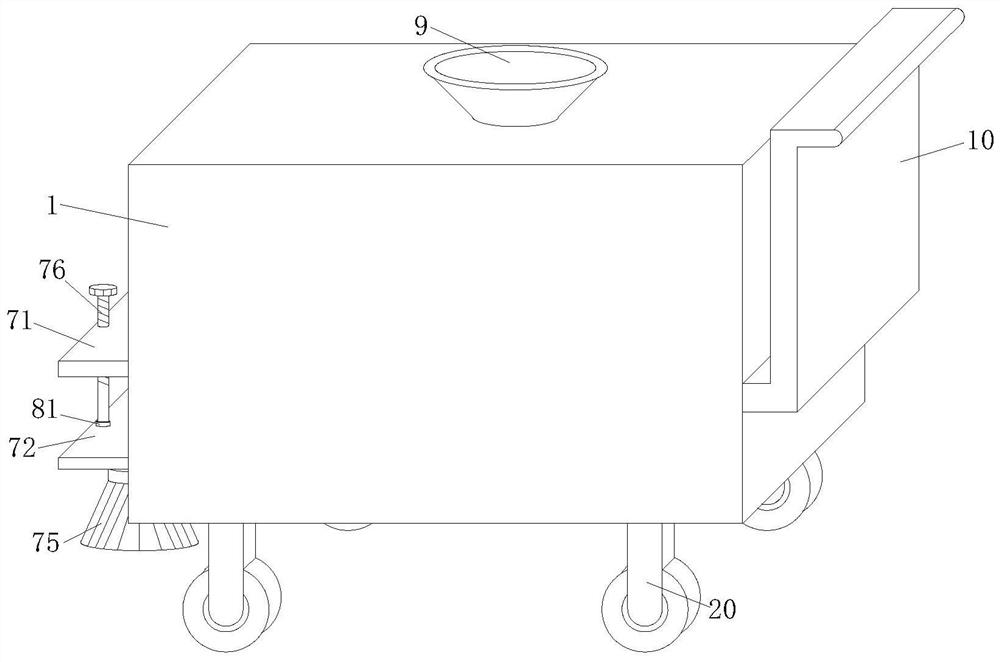

An intelligent dining table and an intelligent dining table system

PendingCN108158222AReduce waiting timeImprove cleaning efficiencyFurniture partsServing tablesControl systemLow demand

The invention relates to an intelligent dining table and an intelligent dining table system. The intelligent dining table comprises a table plate, a support, an annular table cloth sleeving the tableplate, a cleaning device and a control system, wherein the control system comprises a power source for supplying power, a relay, a magnetic proximity switch, a magnet used for changing the on-off state of the magnetic proximity switch and a motor. The intelligent dining table system comprises a bowl collection device, a tableware fetching stand and the intelligent dining table. The dining table can be cleaned wholly automatically to allow different groups of guests to have meals; the intelligent dining table and the intelligent dining table system have the advantages of simple structure, low demand for manual work, high cleaning efficiency and low production cost and can be put into production and use in batches.

Owner:伍贤勇

Hydraulic transmission and automatic control stepless speed regulator

InactiveCN103867681AImprove transmission efficiencyCompact structureGearboxesGearing controlAutomatic controlControl system

The invention discloses a hydraulic transmission and automatic control stepless speed regulator, which comprises an enclosure, a speed regulator component, an overrunning clutch and a speed regulator component brake device, wherein the speed regulator component comprises an inner shell, a speed regulator input shaft and a speed regulator output shaft; a two-way hydraulic variable pump, a constant displacement hydraulic motor, a variable control driving device and a control system are arranged in the inner shell; the two-way hydraulic variable pump is connected in series with the constant displacement hydraulic motor; the two-way hydraulic variable pump, the constant displacement hydraulic motor and two oil passages communicated with the two-way hydraulic variable pump and the constant displacement hydraulic motor form a closed loop; a buffer cavity is connected to each of the two oil passages connected with the two-way hydraulic variable pump and the constant displacement hydraulic motor; in addition, a second hydraulic electromagnetic valve is arranged between an oil port of the two-way hydraulic variable pump and an oil port of the constant displacement hydraulic motor; a first hydraulic electromagnetic valve and the second hydraulic electromagnetic valve are electrically connected with the control system. The hydraulic transmission and automatic control stepless speed regulator is simple and compact in structure, low in manufacturing cost, continuous in transmission ratio, high in bearing capacity, high in transmission efficiency, safe, reliable and long in service life.

Owner:枣庄市九洲快运有限公司

Project supervision and construction management informatization device

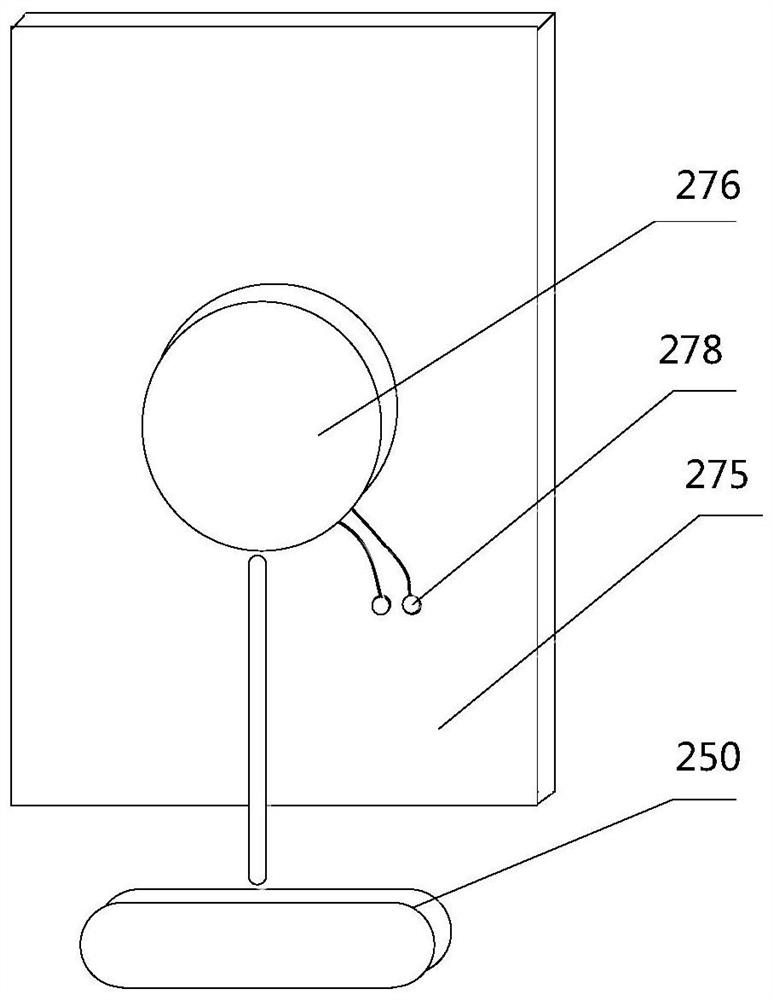

ActiveCN108194796AImprove rotation efficiencyImprove monitoring effectivenessTelevision system detailsColor television detailsInformatizationConstruction management

The invention discloses a project supervision and construction management informatization device. According to the technical scheme, the project supervision and construction management informatizationdevice is characterized in that the project supervision and construction management informatization device comprises a camera screen, a fixing end used for installing and fixing the camera screen anda connecting column connected with the camera screen and the fixing end. One end of the connecting column is provided with a steering end. The steering end is internally and rotatably connected witha steering ball fixedly connected with the camera screen. The end, inserted in the connecting column, of the steering ball is provided with four connecting pieces which are symmetrical in an up-down and left-right mode correspondingly. The end, connected with the fixing end, of the connecting column is internally and rotatably connected with a driving ball. Four connecting supporting arms connected with the corresponding connecting pieces correspondingly are connected with the driving ball in an inserted mode. The end, away from the camera screen, of the driving ball penetrates out of the connecting column and is connected with a moving plate which drives the driving ball to rotate upwards, downwards, leftwards or rightwards. The project supervision and construction management informatization device has the function that during running of the moving plate, the steering ball is driven to rotate upwards, downwards, leftwards or rightwards, and then the camera screen is driven to rotate.

Owner:浙江浙铭建设管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com