Friction clutch

A friction clutch, clutch housing technology, applied in the direction of friction clutch, clutch, mechanical drive clutch, etc., can solve problems such as unreliable compensation adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

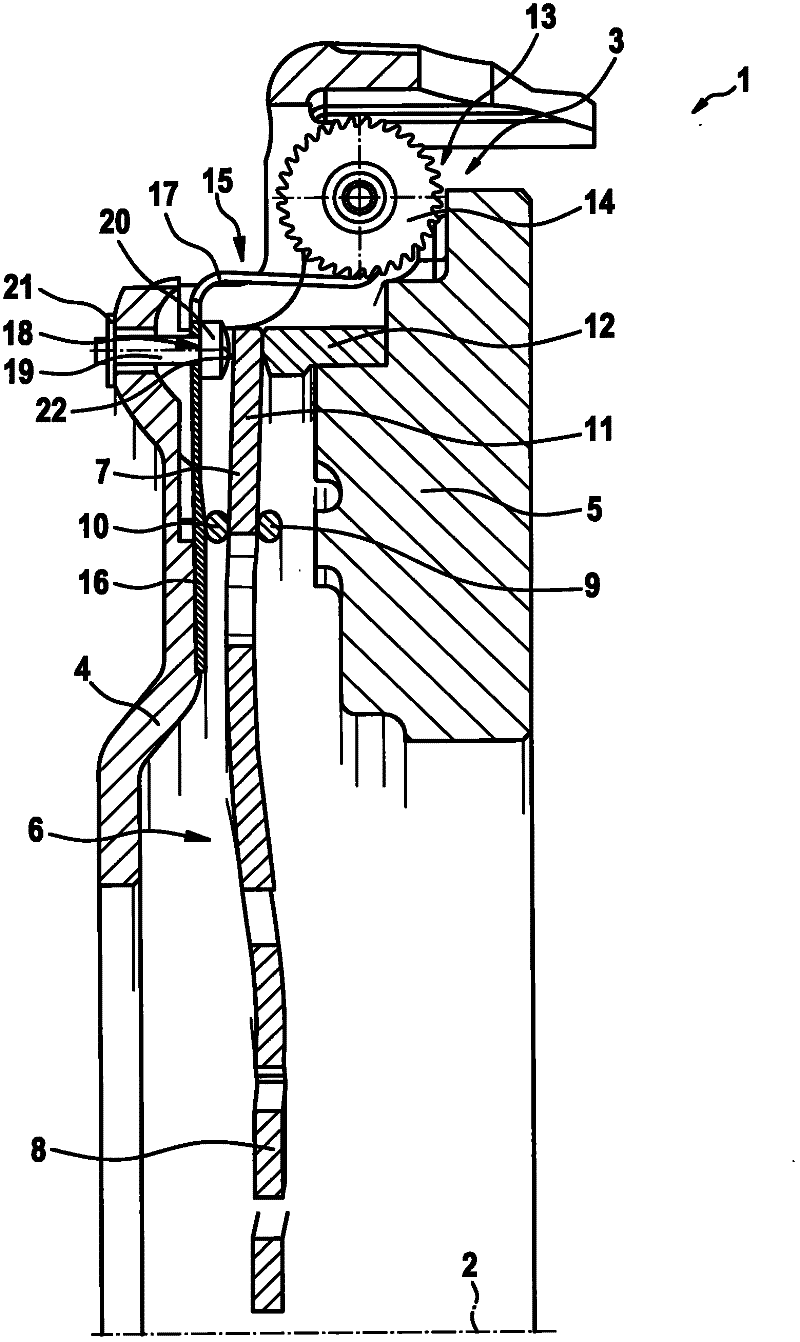

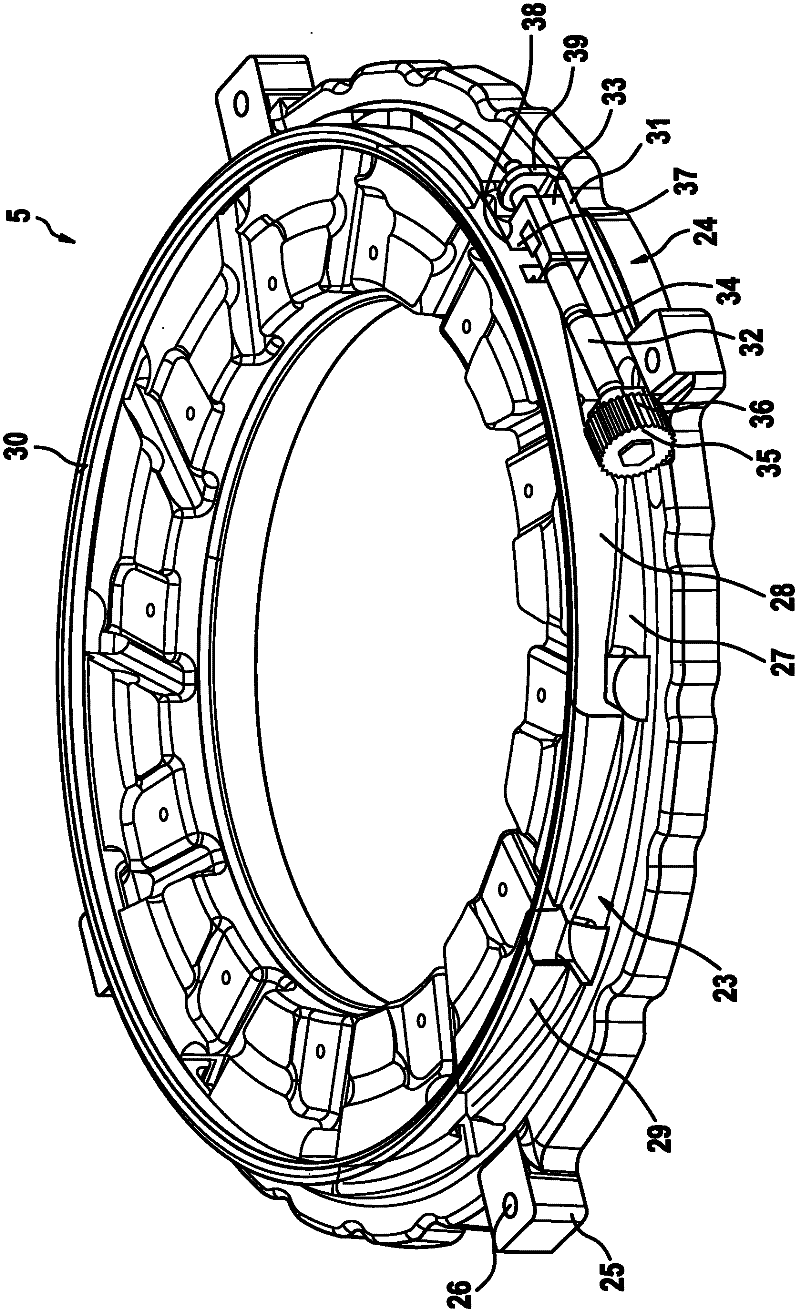

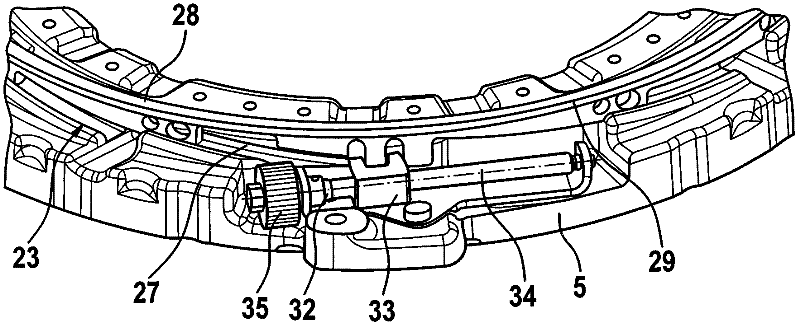

[0030] figure 1 A partial section of an exemplary embodiment of a friction clutch 1 along its axis of rotation 2 is shown, only one half with the compensating adjustment device 3 being shown. The friction clutch 1 is formed by a clutch housing 4 in which a pressure plate 5 is received in a rotationally fixed and axially displaceable manner by means of an energy store, not visible in this section. Furthermore, the lever system 6 is accommodated in the clutch housing 4 as a disk spring 7 which has disk spring tongues 8 radially on the inside, which are axially controlled by a disengaging system not shown. supporting. The illustrated exemplary embodiment is a pressure friction clutch 1 which is disengaged when the Belleville spring tongue 8 is acted upon by pressure. For this purpose, the disk spring 7 is pivotably supported on the clutch housing by means of two wire loops 9 , 10 via a rivet, not shown, which presses the two wire loops 9 , 10 against each other, forming a doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com