Patents

Literature

534results about How to "Increase preload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

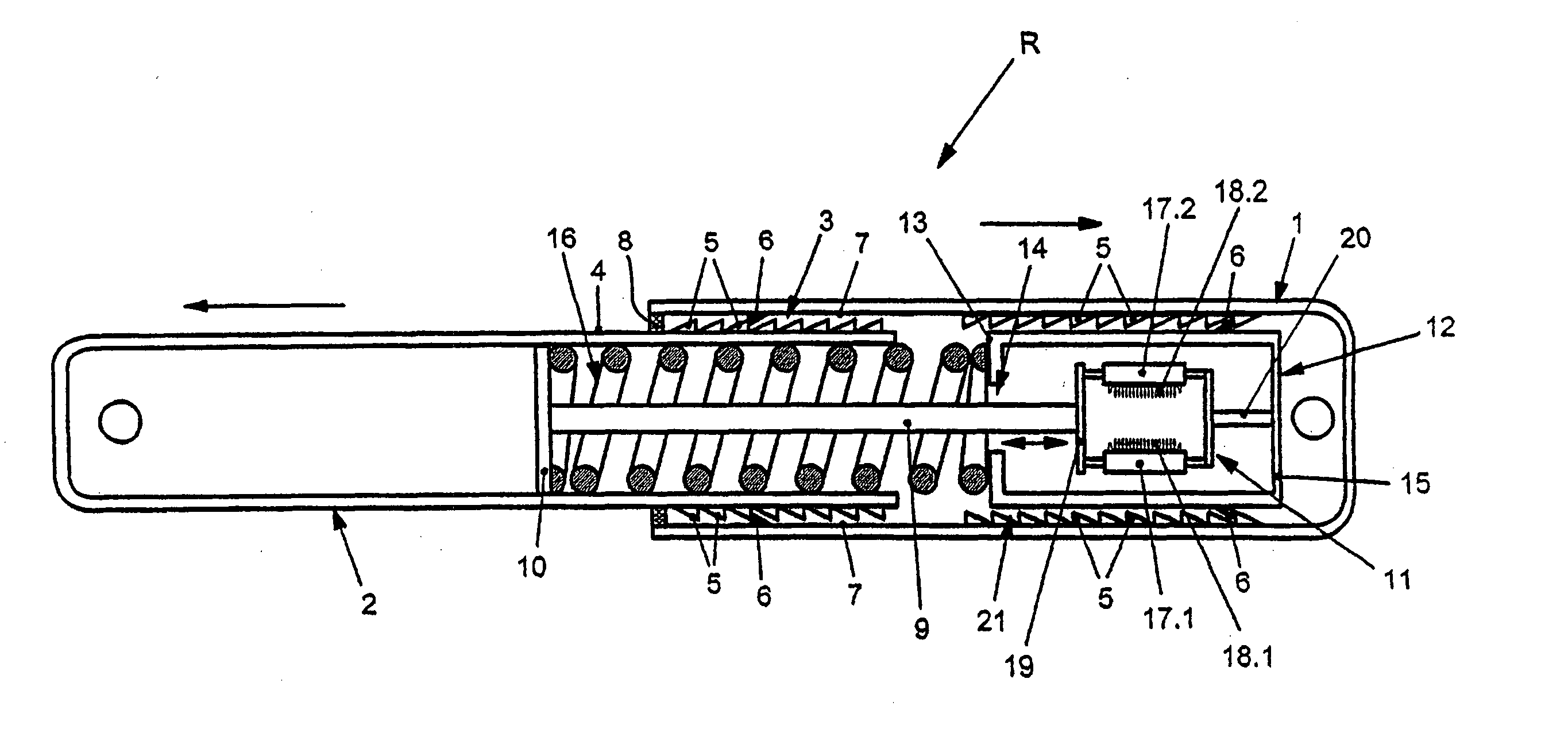

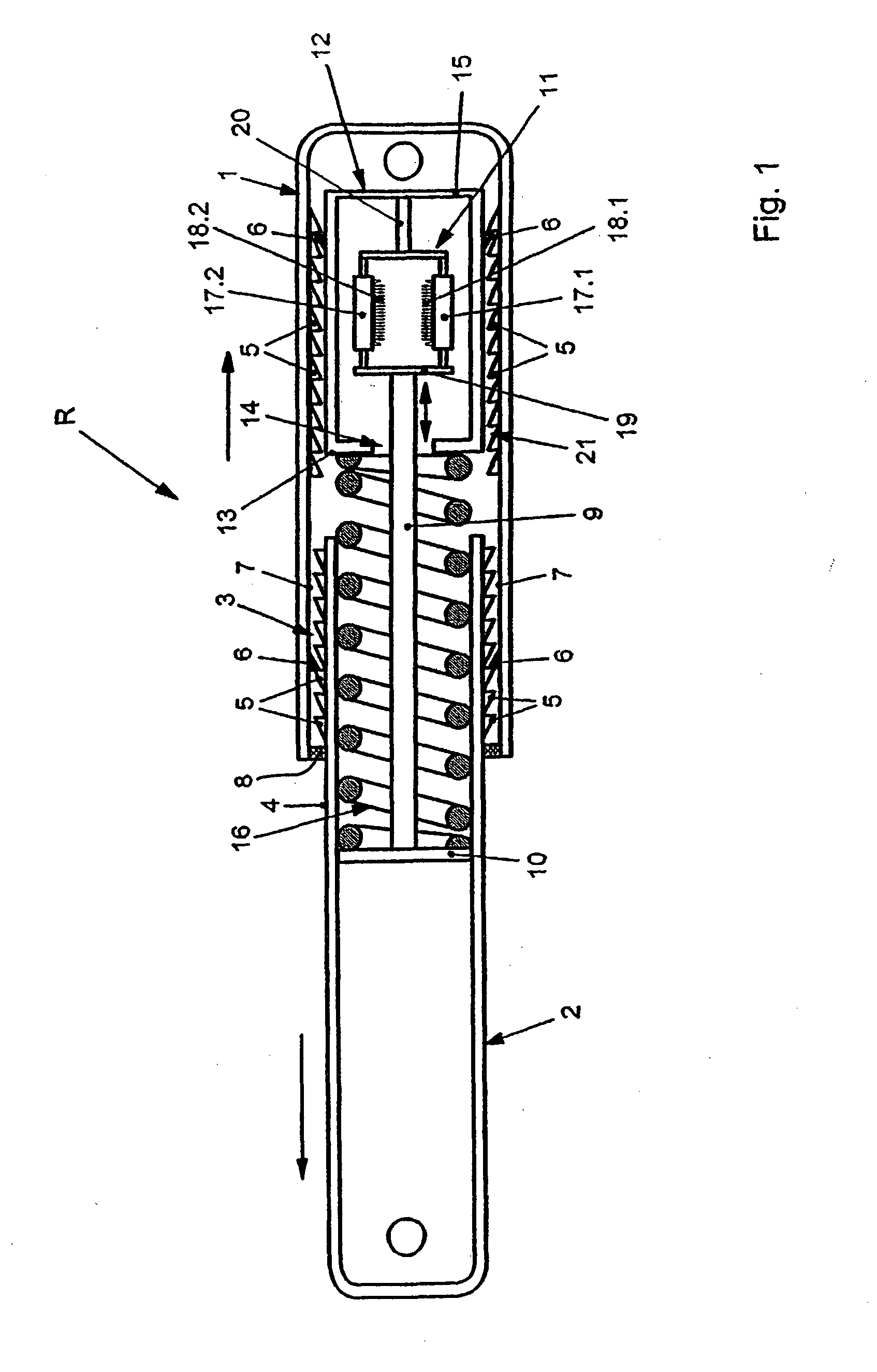

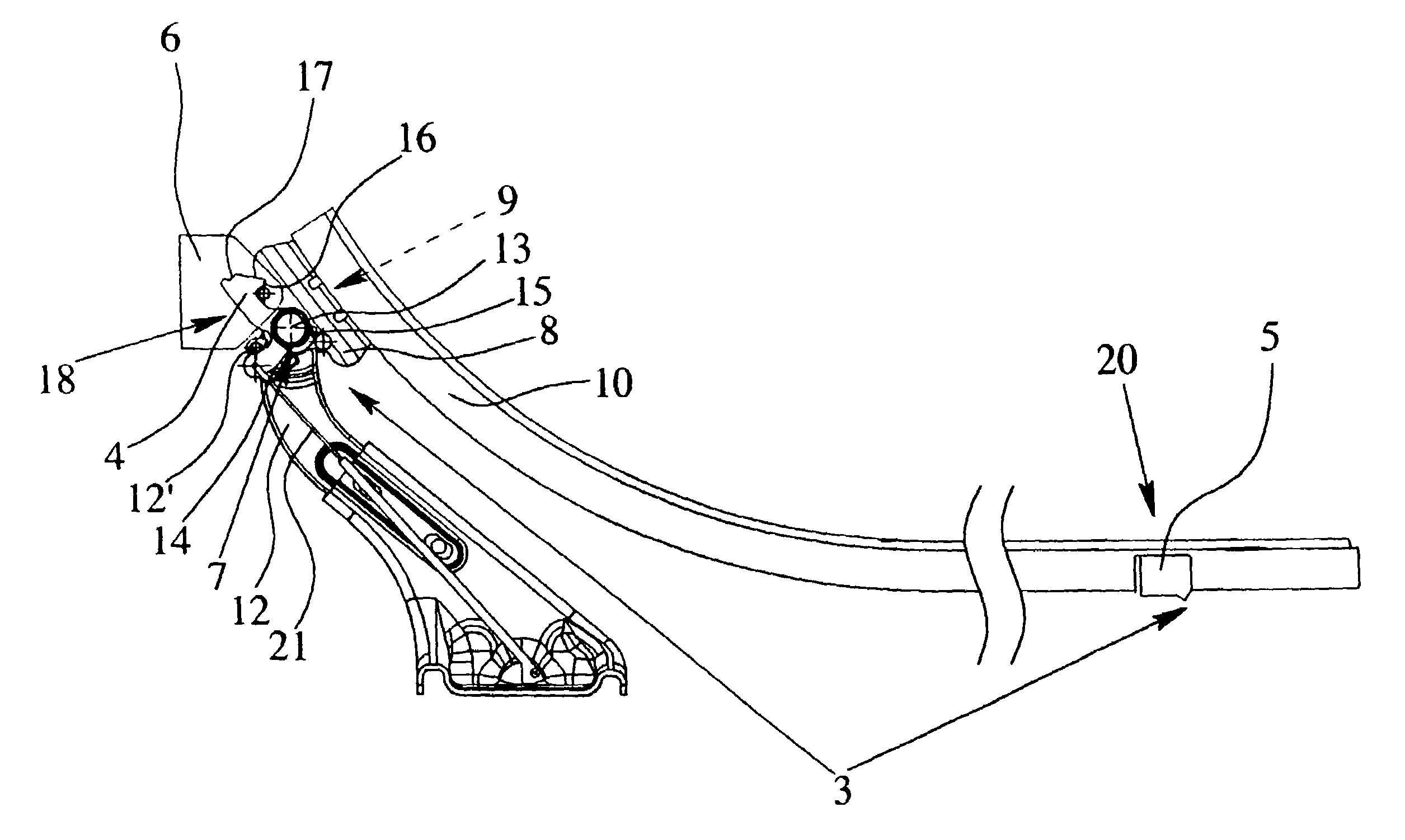

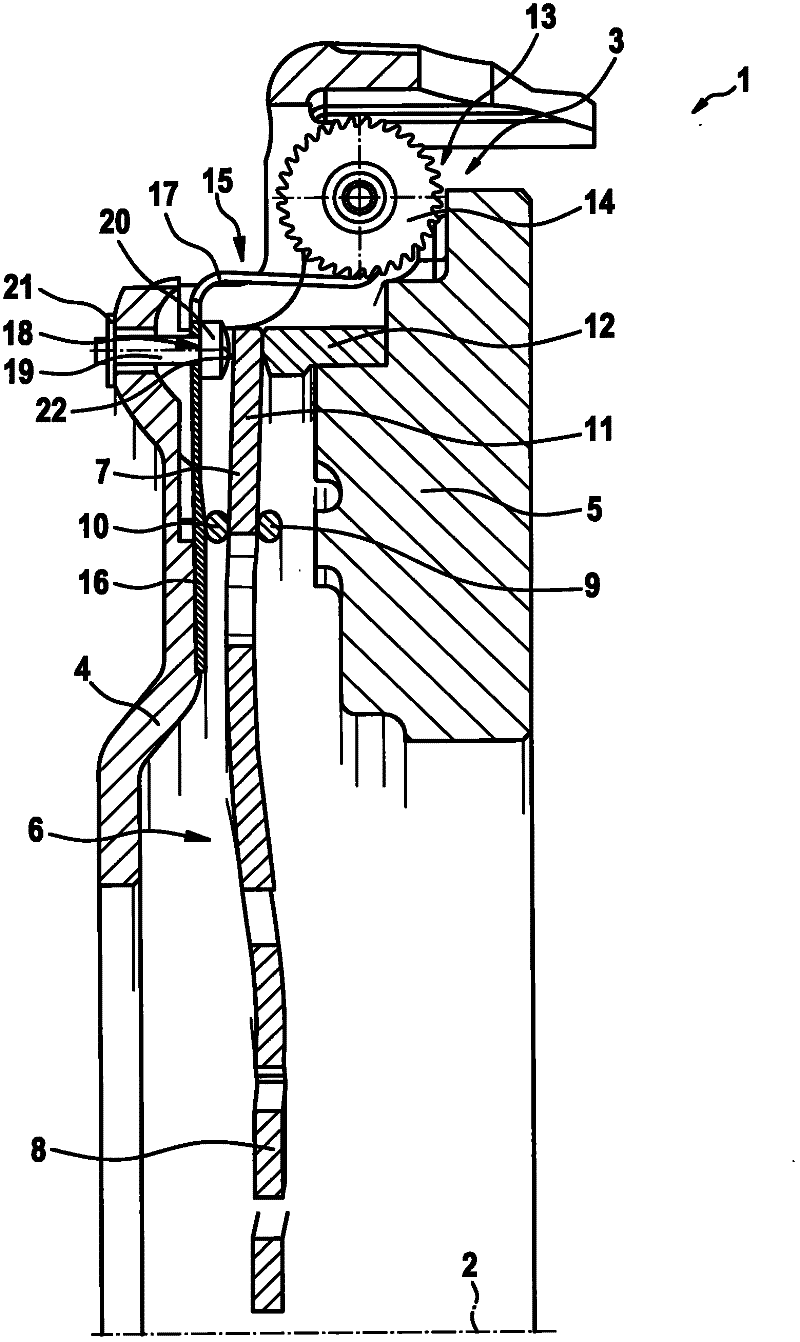

Distraction device

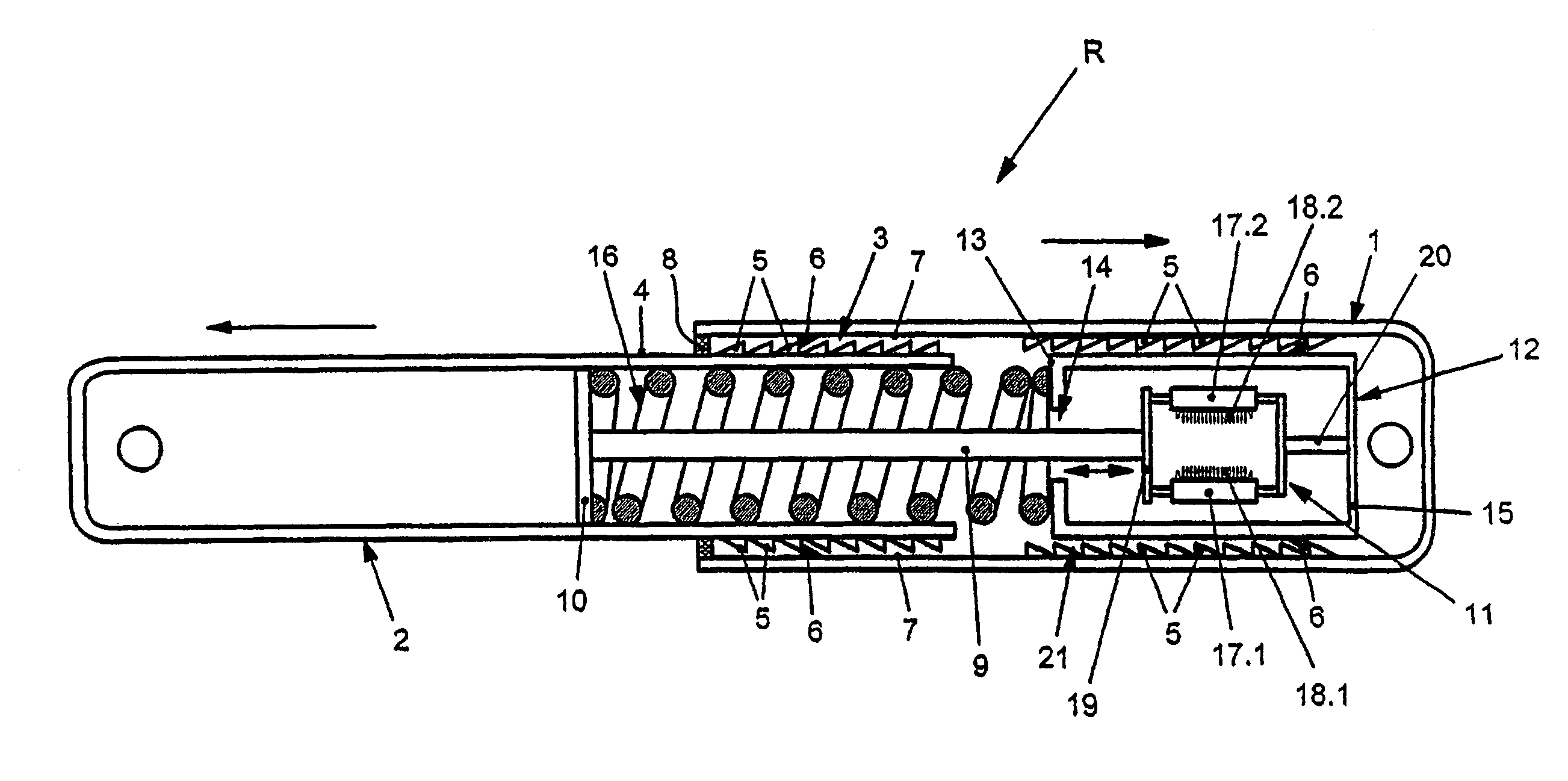

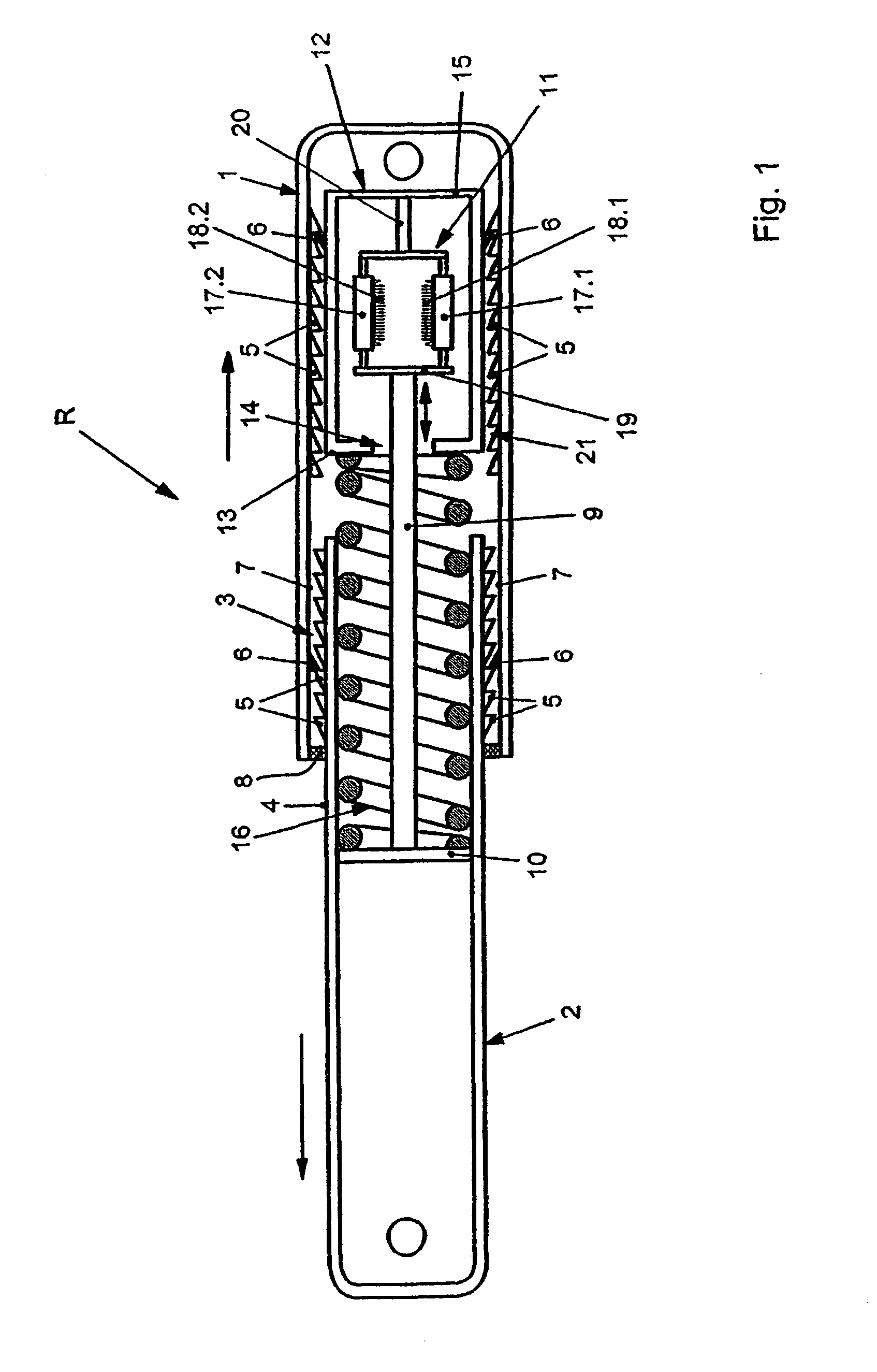

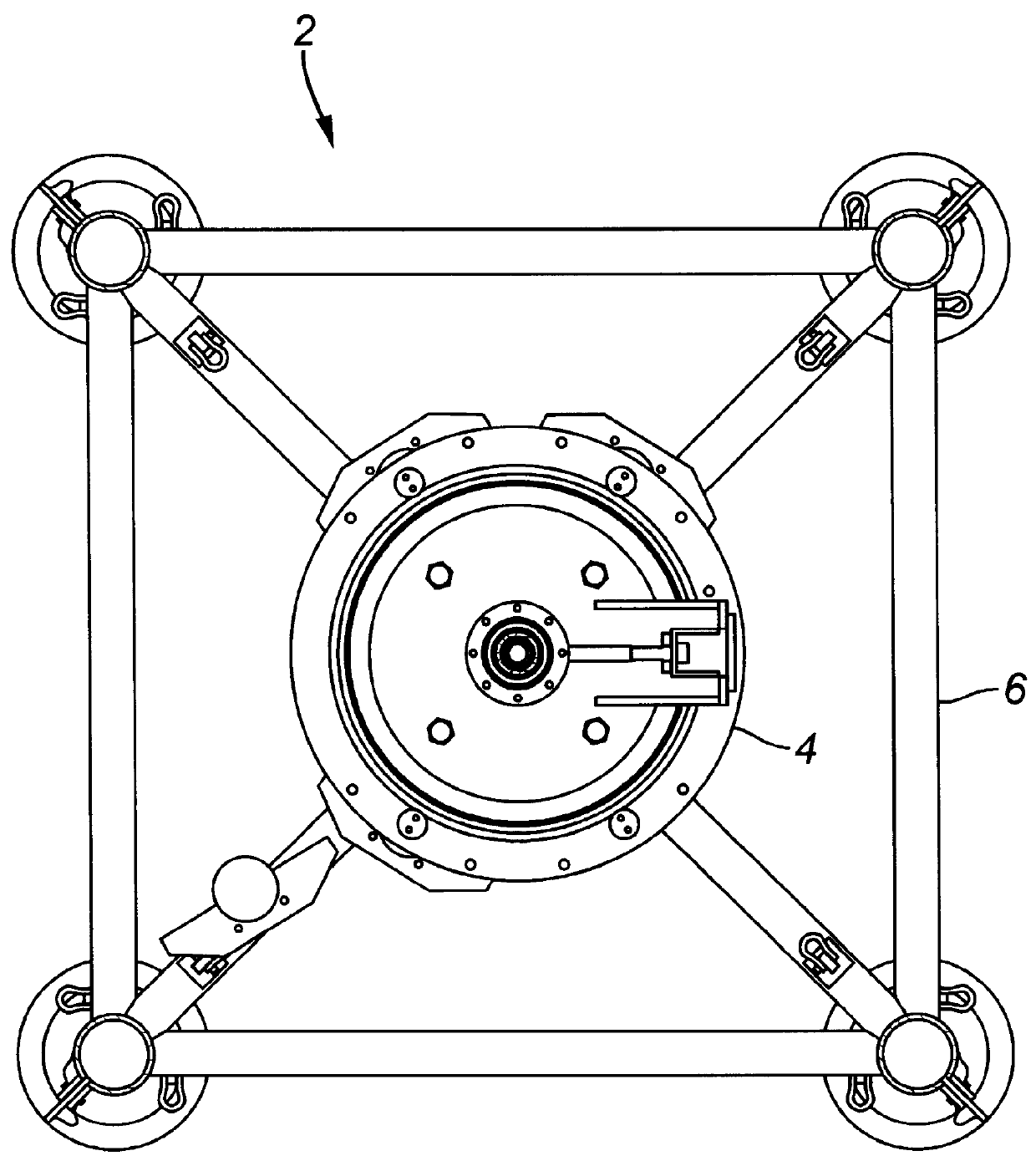

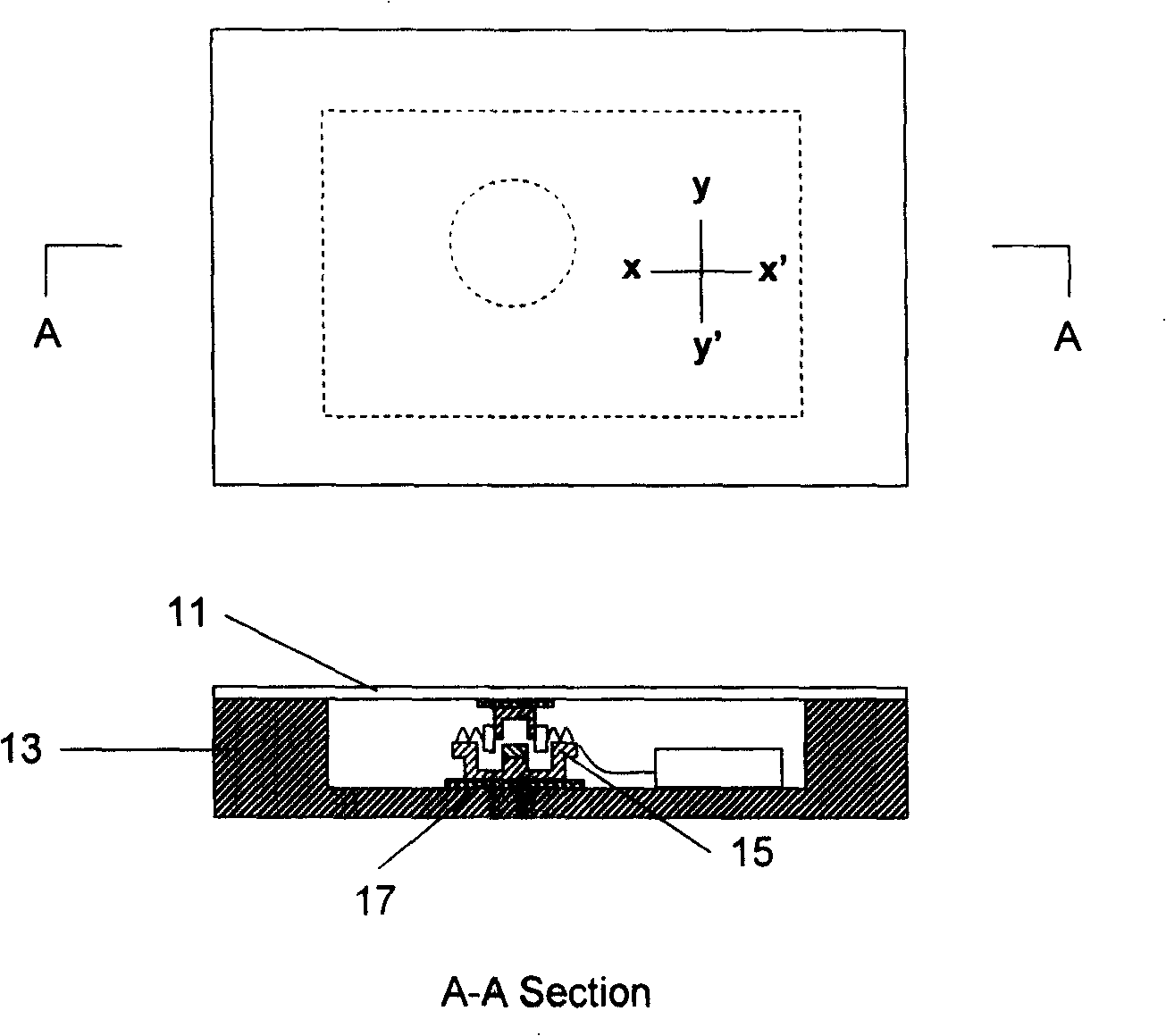

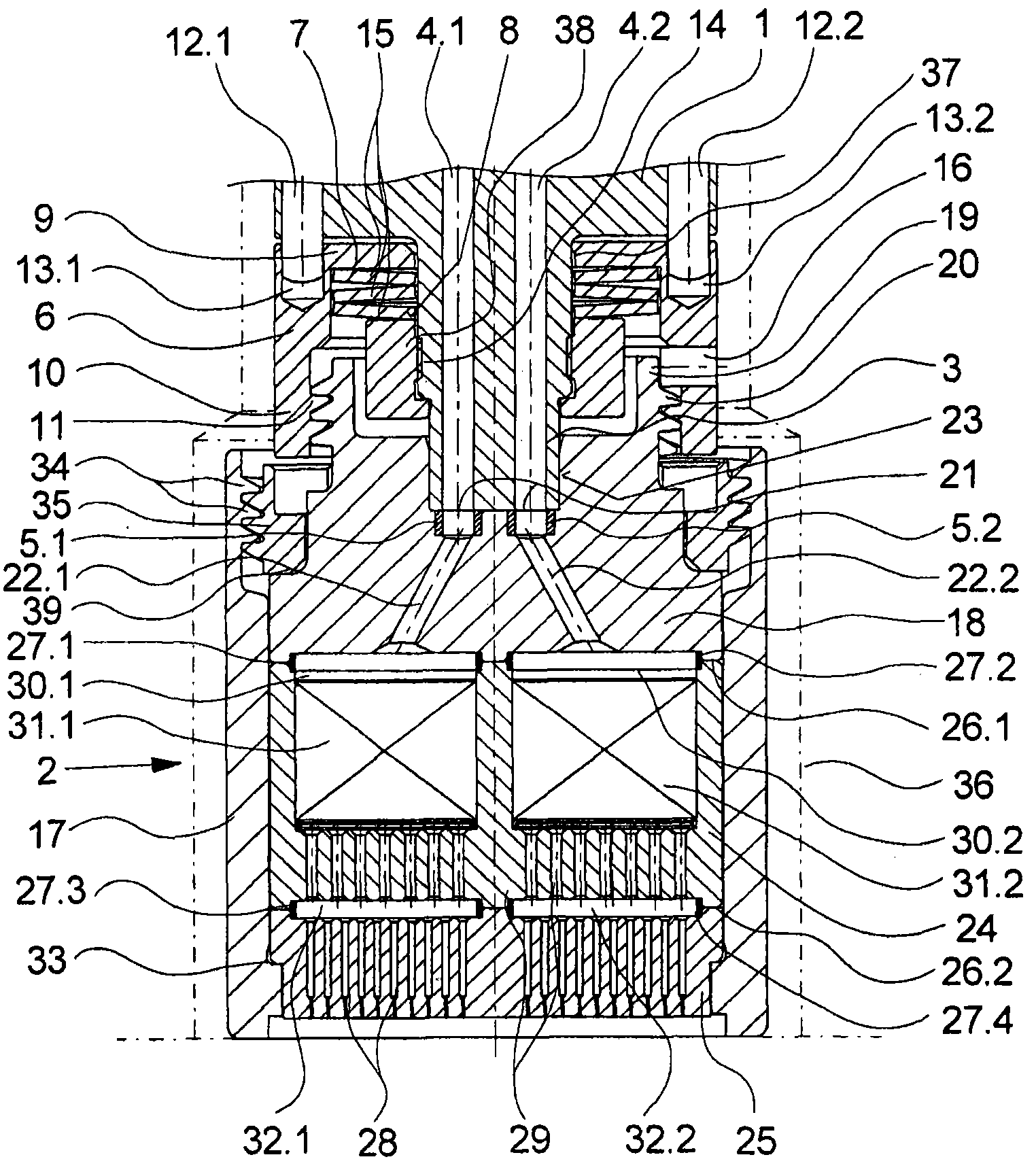

InactiveUS7063706B2High constantSmall overall lengthInternal osteosythesisProsthesisDistractionDetent

A distraction device for moving a one-part or two-part or separated bone apart in order to extend or bridge a bone gap. The device is optionally provided in the form of an intramedullary pin, which can be inserted into a medullary space of a bone and which has at least two elements that can be axially moved in relation to one another. The first element is joined to the second element via at least one detent device for securing a distraction movement, and a pushing module for distracting the first element is assigned to the second element and is joined to the second element in a manner that enables it to be locked.

Owner:WITTENSTEIN GROUP

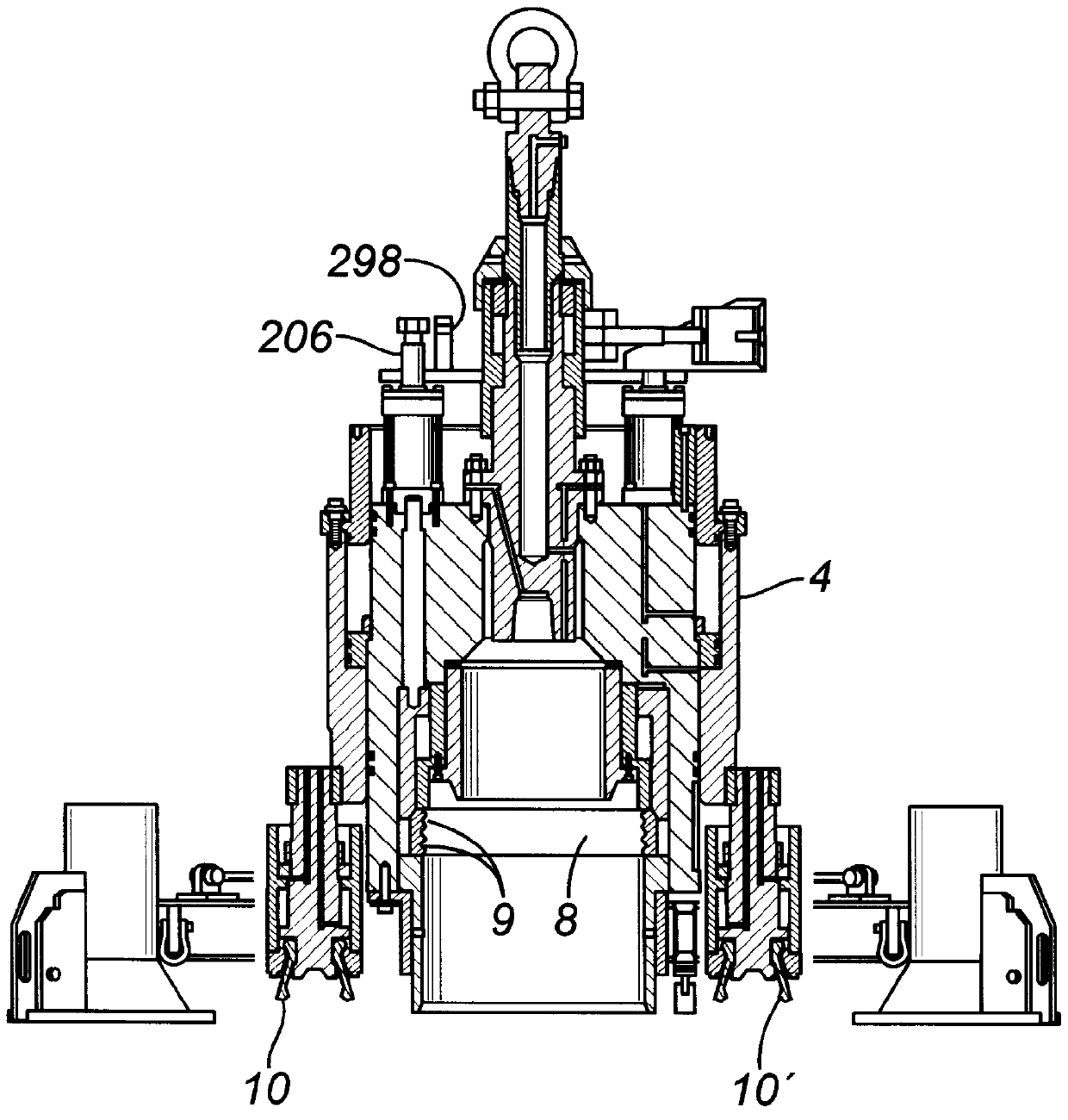

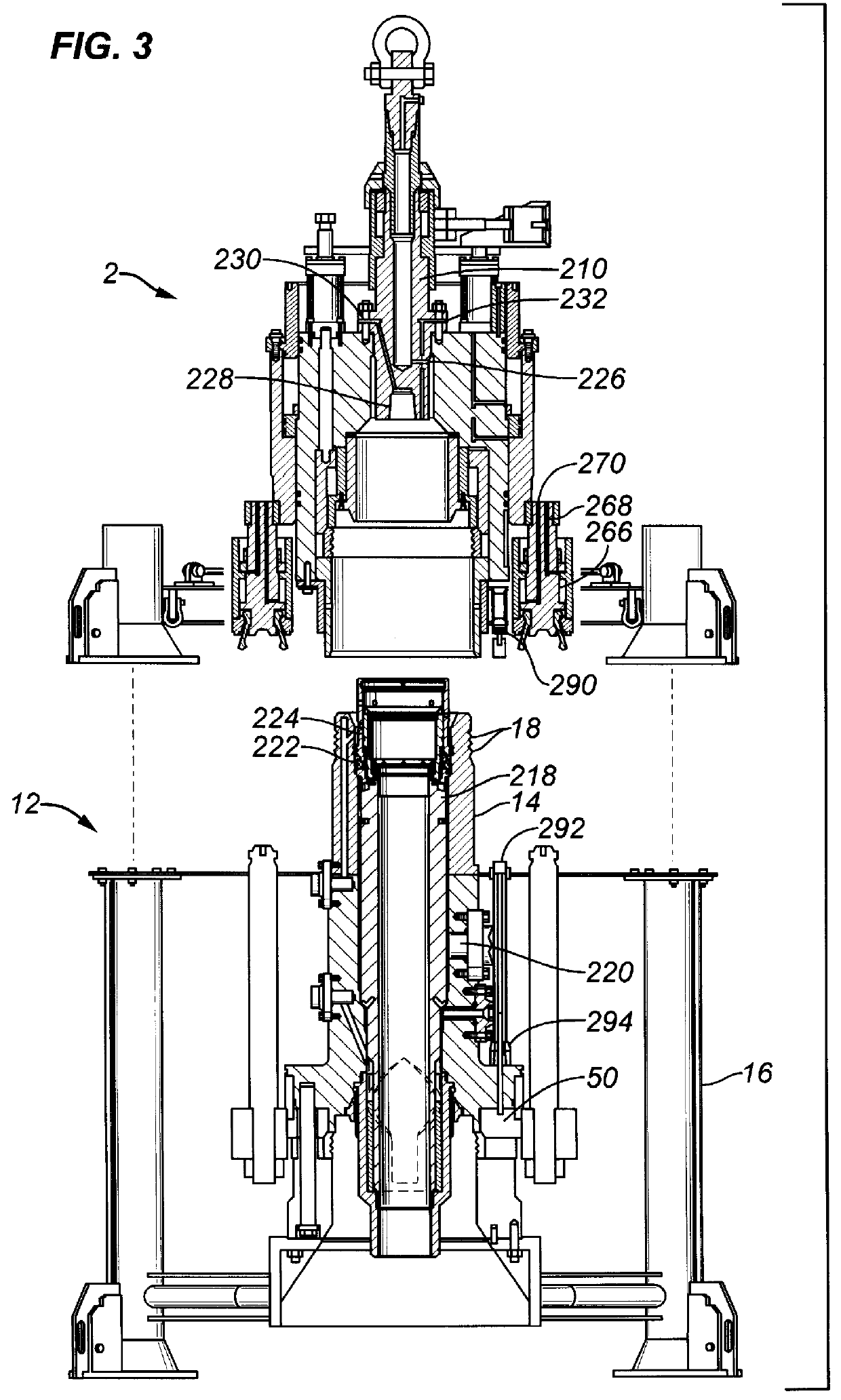

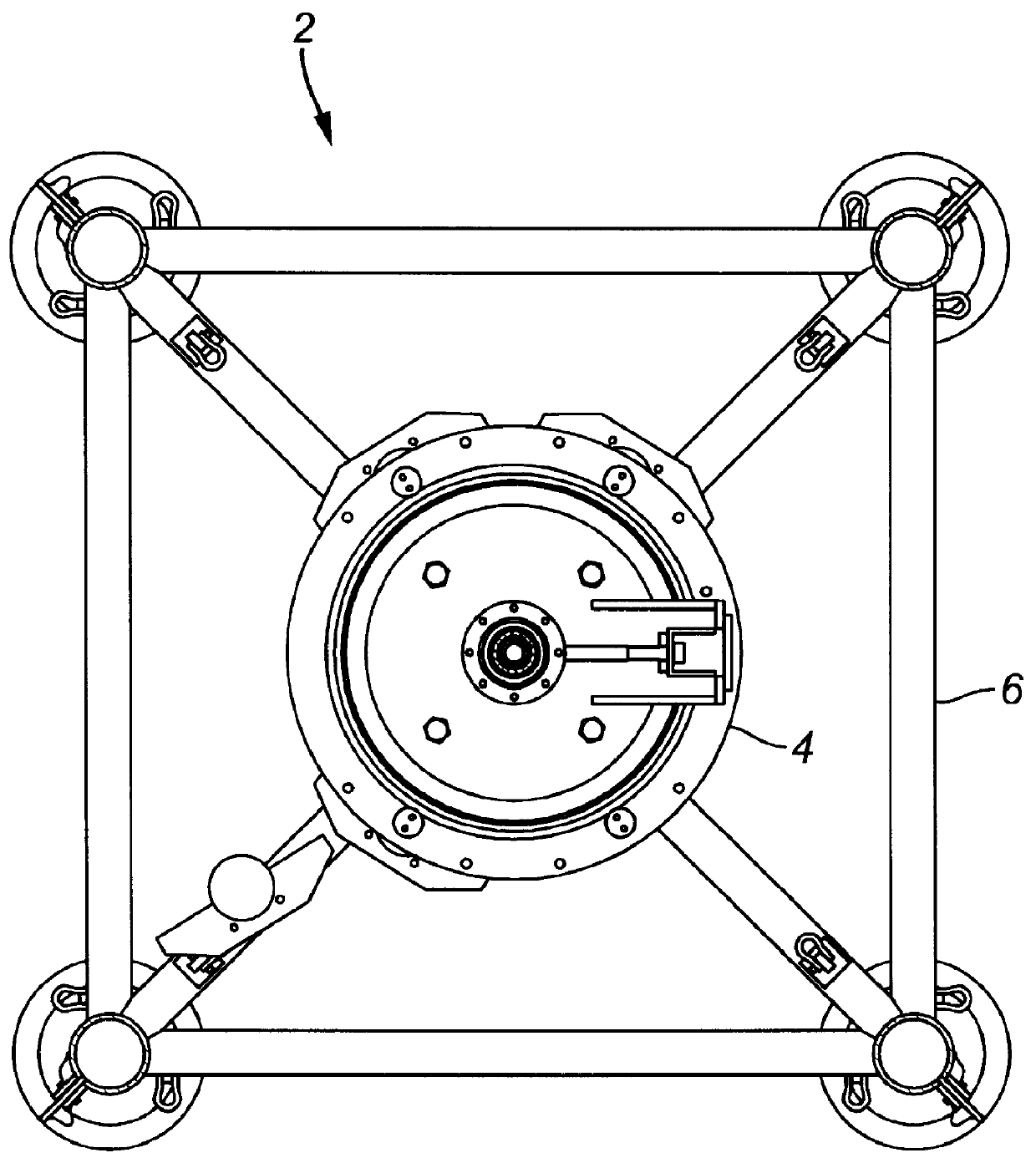

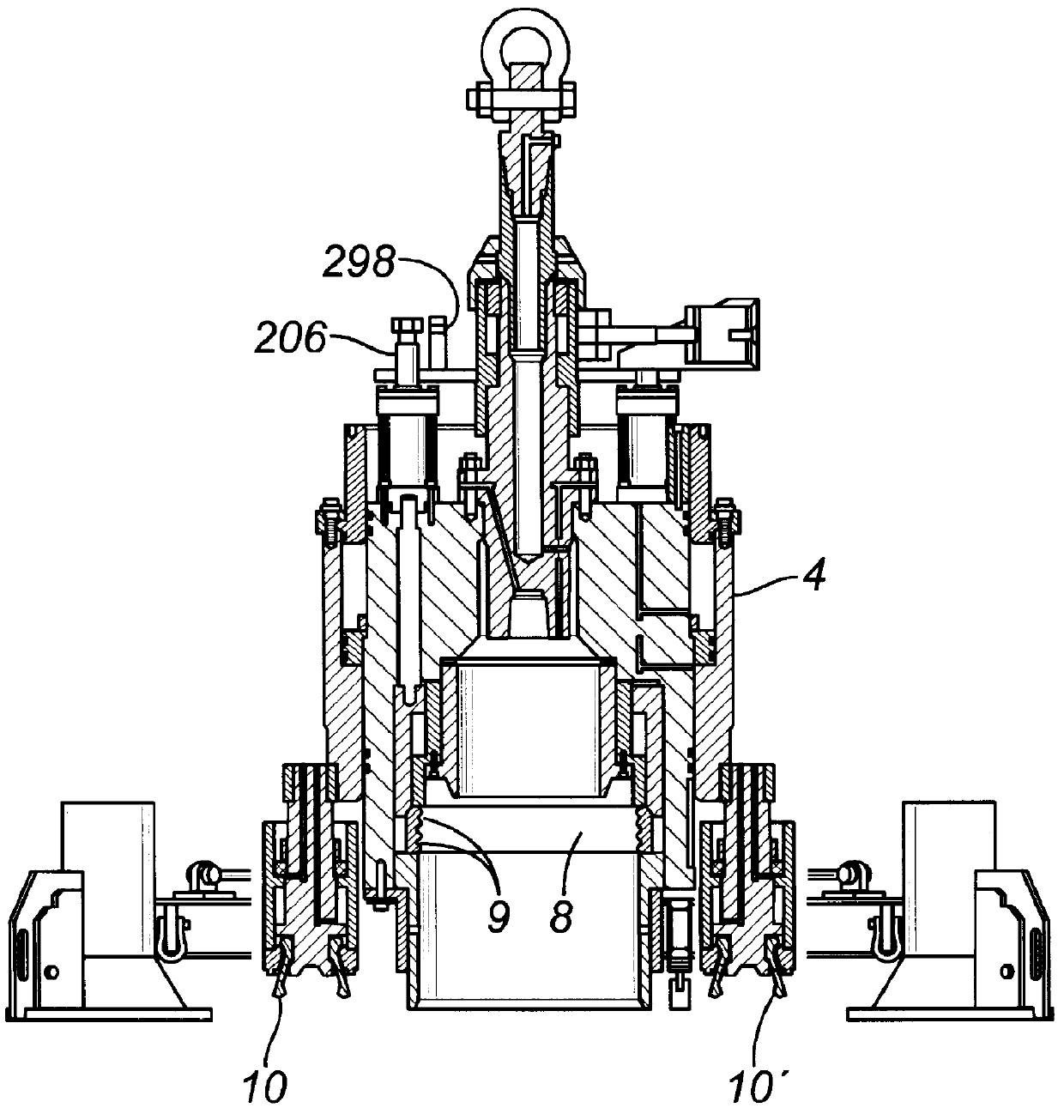

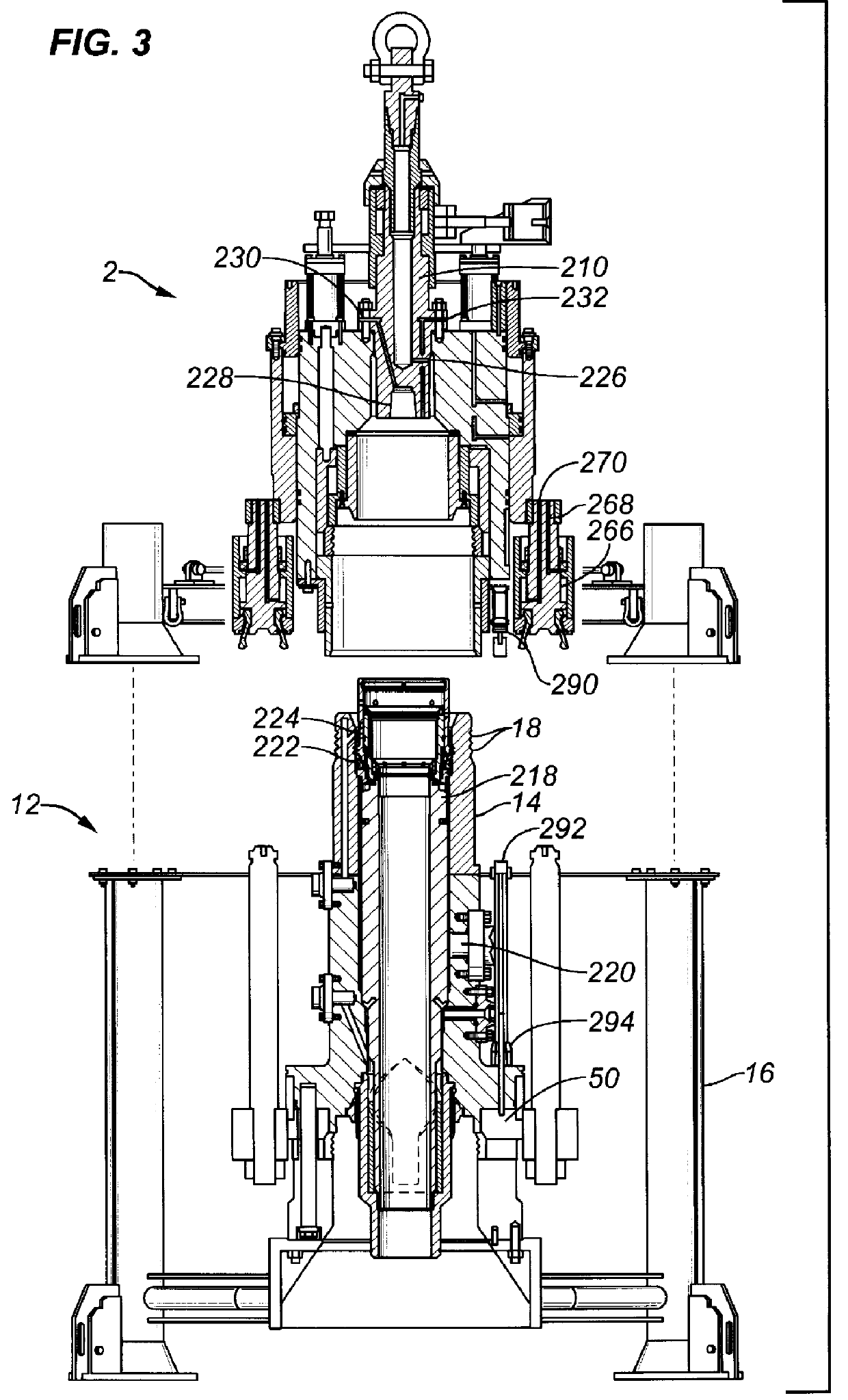

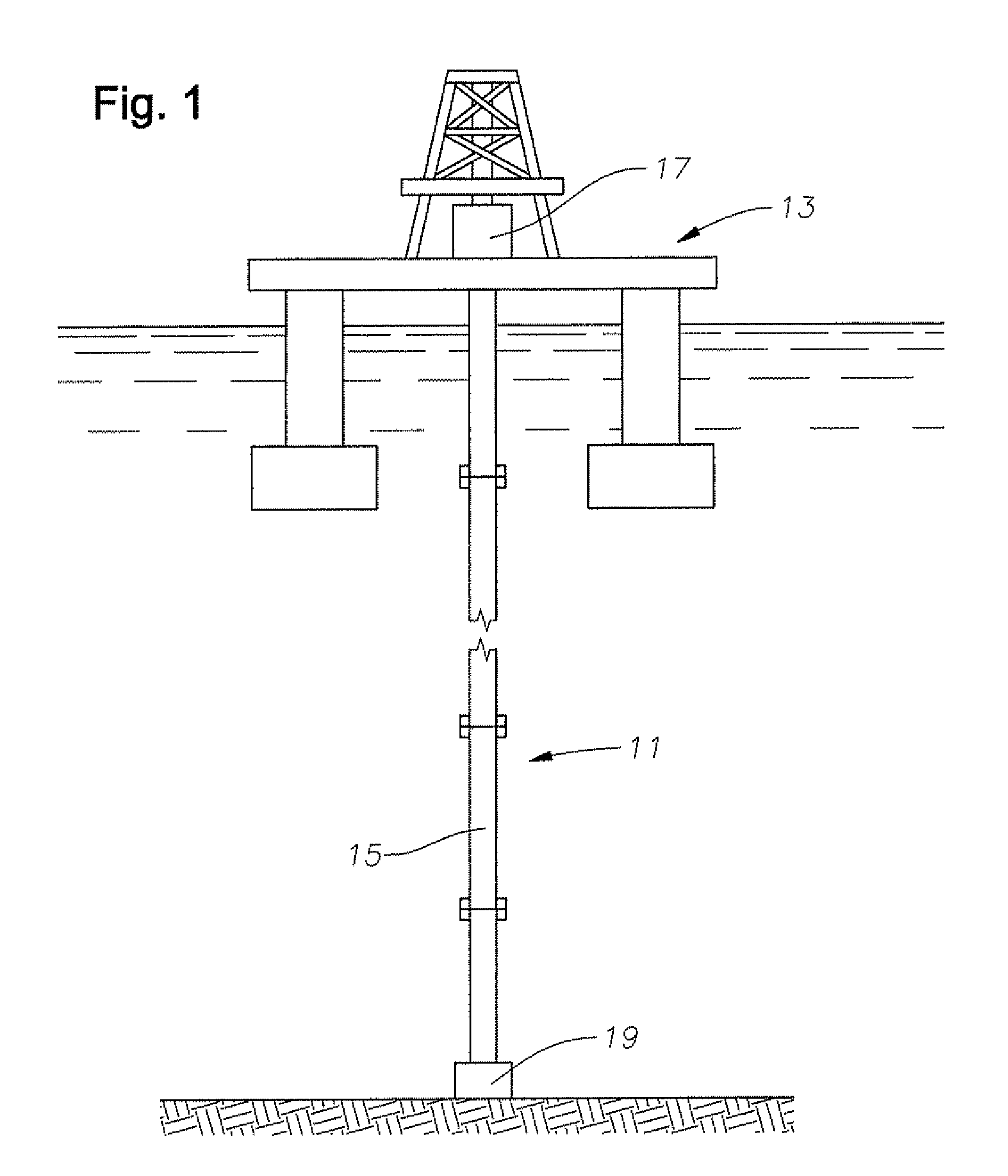

Tree running tool with actuator for latch

InactiveUS6142233AEffected very efficiently and quicklyReduce forceFluid removalUnderwater drillingActuatorPiston

A tree running tool is provided which has a means for actuating a latch for latching a side valve tree to a wellhead. Also disclosed is a tree running tool having an external axially movable actuator, preferably in the form of a sliding piston sleeve which is capable of exerting great forces. Also disclosed is a tree running tool having an external connector unit for connecting the tree running tool to a side valve tree. The connector unit is preferably mounted to the sliding piston sleeve and is for axially mechanically connecting the tree running tool to a linkage extending upwardly from the side valve tree.

Owner:AKER SOLUTIONS AS

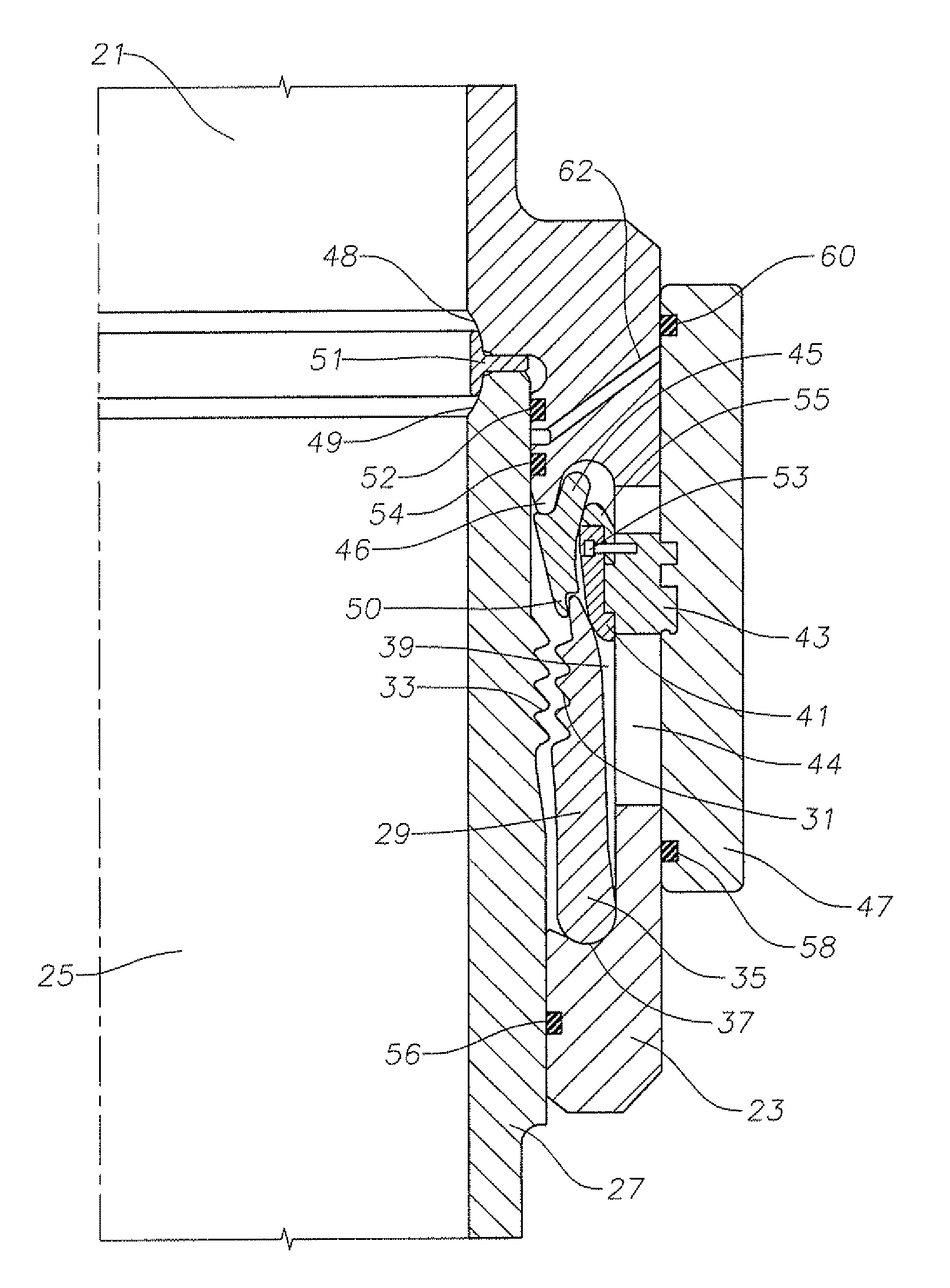

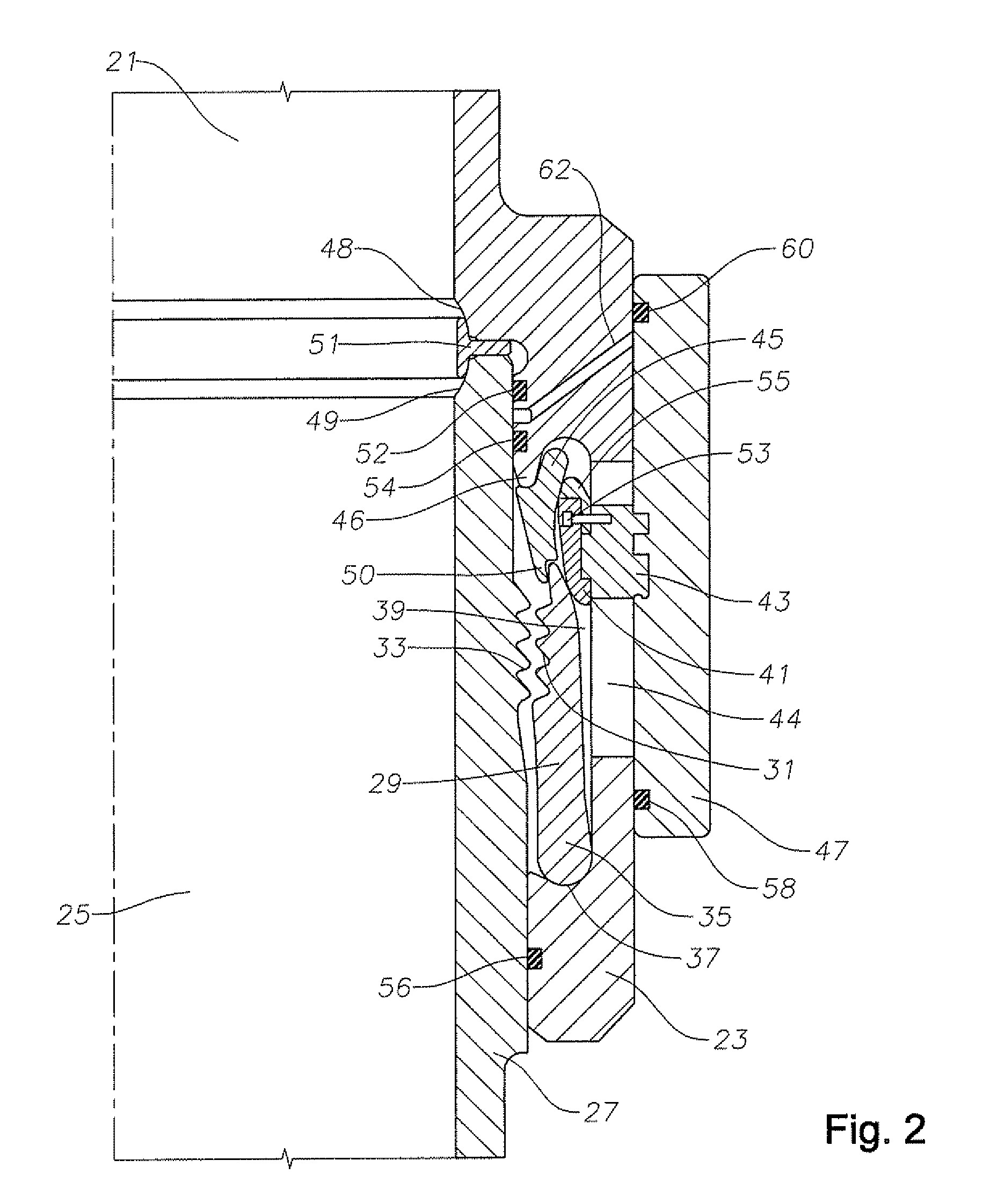

Tree running tool with emergency release

InactiveUS6062312AEffected very efficiently and quicklyReduce forceFluid removalUnderwater drillingEngineeringFlange

In accordance with certain preferred aspects of the present invention, there is provided tree running tool with a mechanical mechanism for unlatching the tree running tool from a side valve tree. The tree running tool is formed from a tool body, a stem, a telescoping element, a retractable spacer, a means for moving the spacer, and a means for attaching the telescoping element to a lift device. The tool body has an upper end, a lower end, and a longitudinal axis. The stem is fixedly attached to the upper end of the tool body and extends axially therefrom. The stem has a lower end attached to the tool body and a generally annular flange at a position spaced apart from the tool body. The telescoping element is positioned alongside the stem. The telescoping element has a generally annular flange at a position between the generally annular flange of the stem and the tool body. The retractable spacer is movable from an engaged position between the generally annular flange of the stem and the generally annular flange of the telescoping element, in which the spacer spaces the generally annular flange of the stem apart from the generally annular flange of the telescoping element, to a retracted position in which a void is formed between the generally annular flange of the stem and the generally annular flange of the sleeve. The means for moving the spacer is mounted to the tool body and the spacer for moving the spacer from the engaged position to the retracted position. The means for attaching the telescoping element to a lift device is mounted to the telescoping element.

Owner:AKER SOLUTIONS AS

Rapid makeup drilling riser

ActiveUS7686087B2Avoid passingRapid make-upSleeve/socket jointsDrilling rodsWell drillingEngineering

A connector for connecting sections of drilling riser pipe wherein a first riser contains a pin assembly with an external first grooved profile and a second riser contains a housing assembly. An internal split pivoting latch segment assembly carried by the housing assembly contains a second grooved profile adapted to mate to the first grooved profile and a split actuation ring movably carried by the housing assembly forces the second grooved profile of the latch segment assembly into engagement with the first grooved profile of the pin assembly. A plurality of retraction links engage an upper edge of the latch segment assembly to disengage the second grooved profile of the latch segment assembly from the first grooved profile of the pin assembly if the risers are to be disconnected.

Owner:VETCO GRAY

Capsule and system for preparing a beverage by centrifugation in a beverage production device

InactiveUS20120301581A1Light structureSolve the lack of resistanceReady-for-oven doughsBeverage vesselsBiomedical engineeringSubstance use

Owner:NESTEC SA

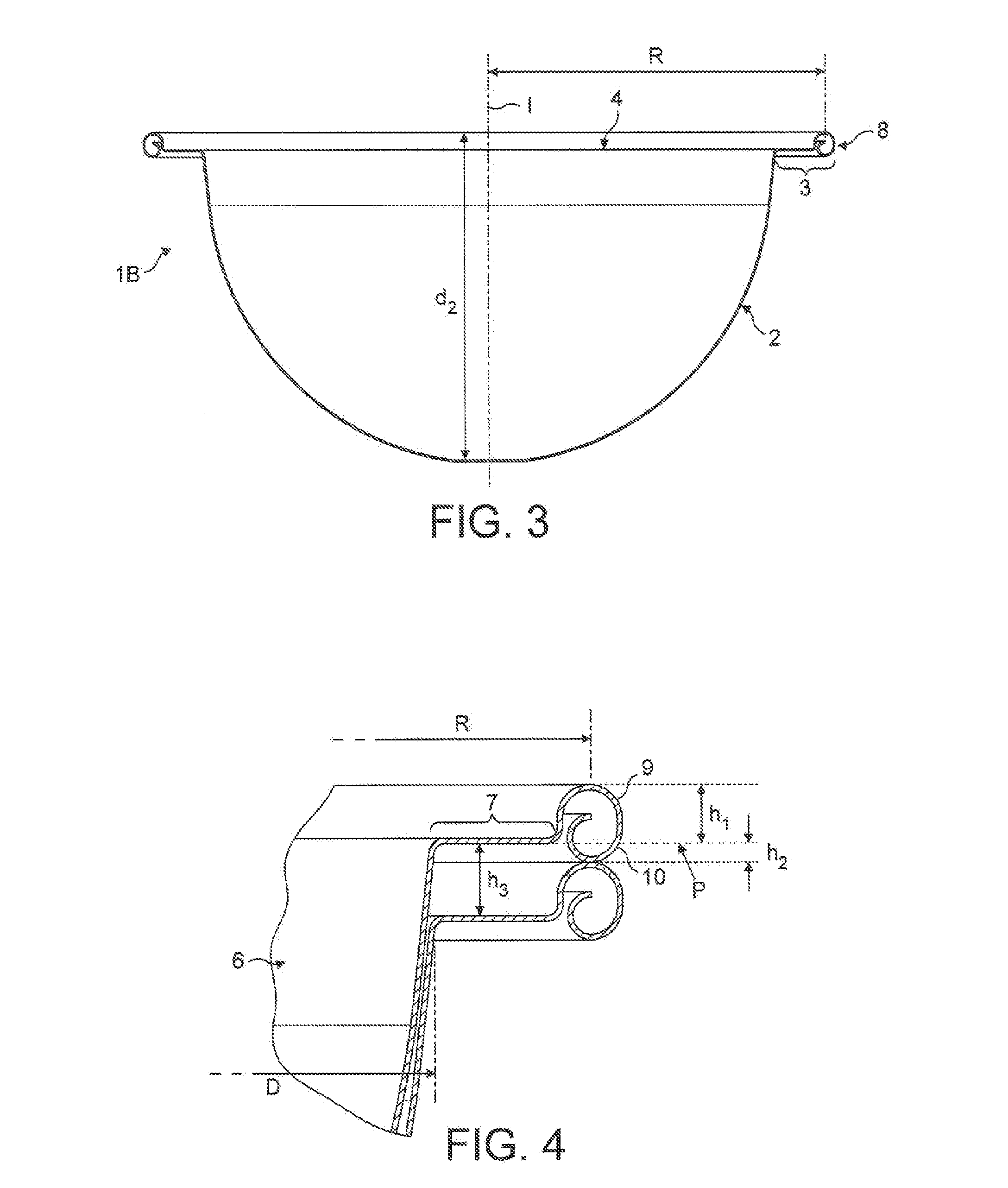

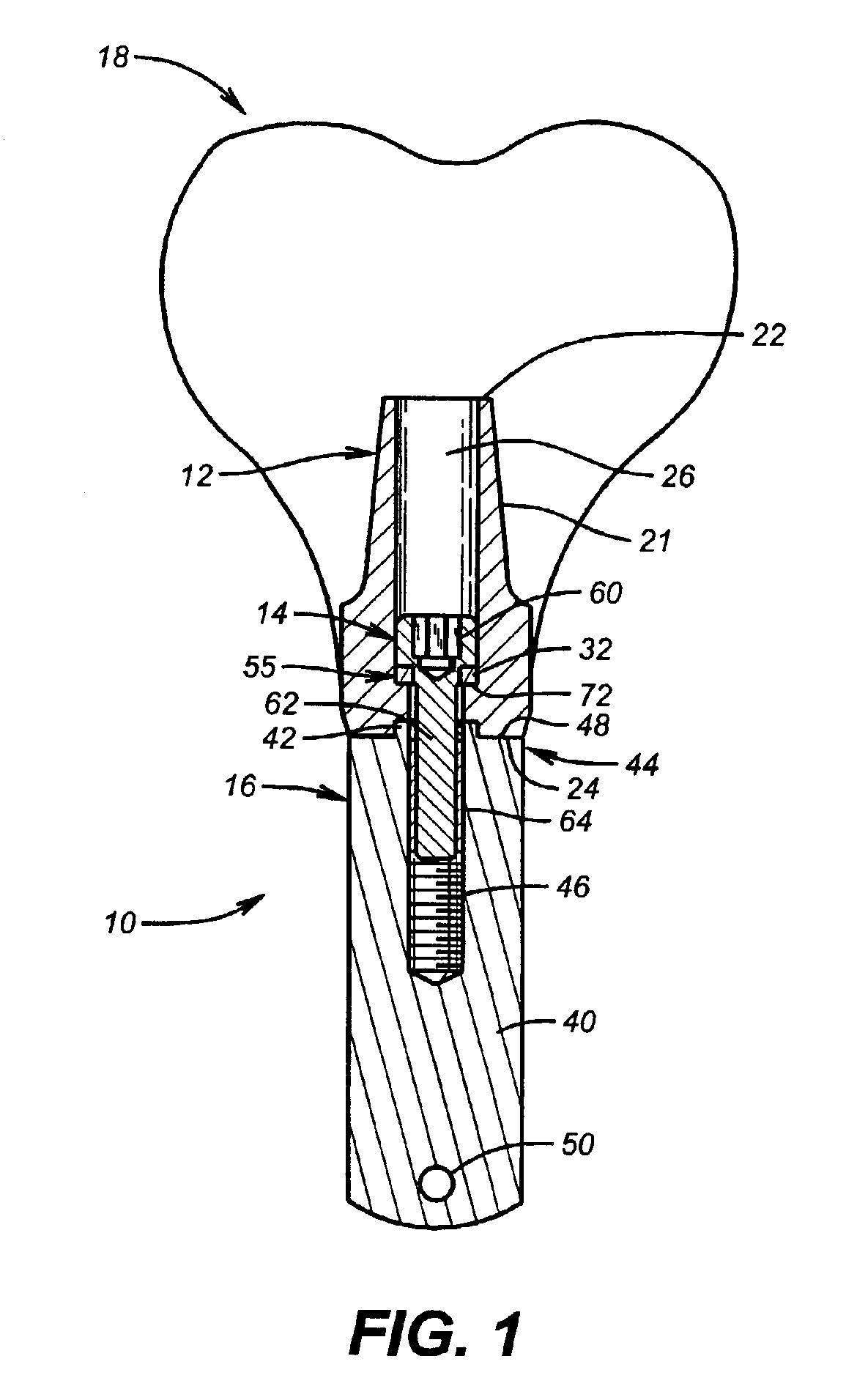

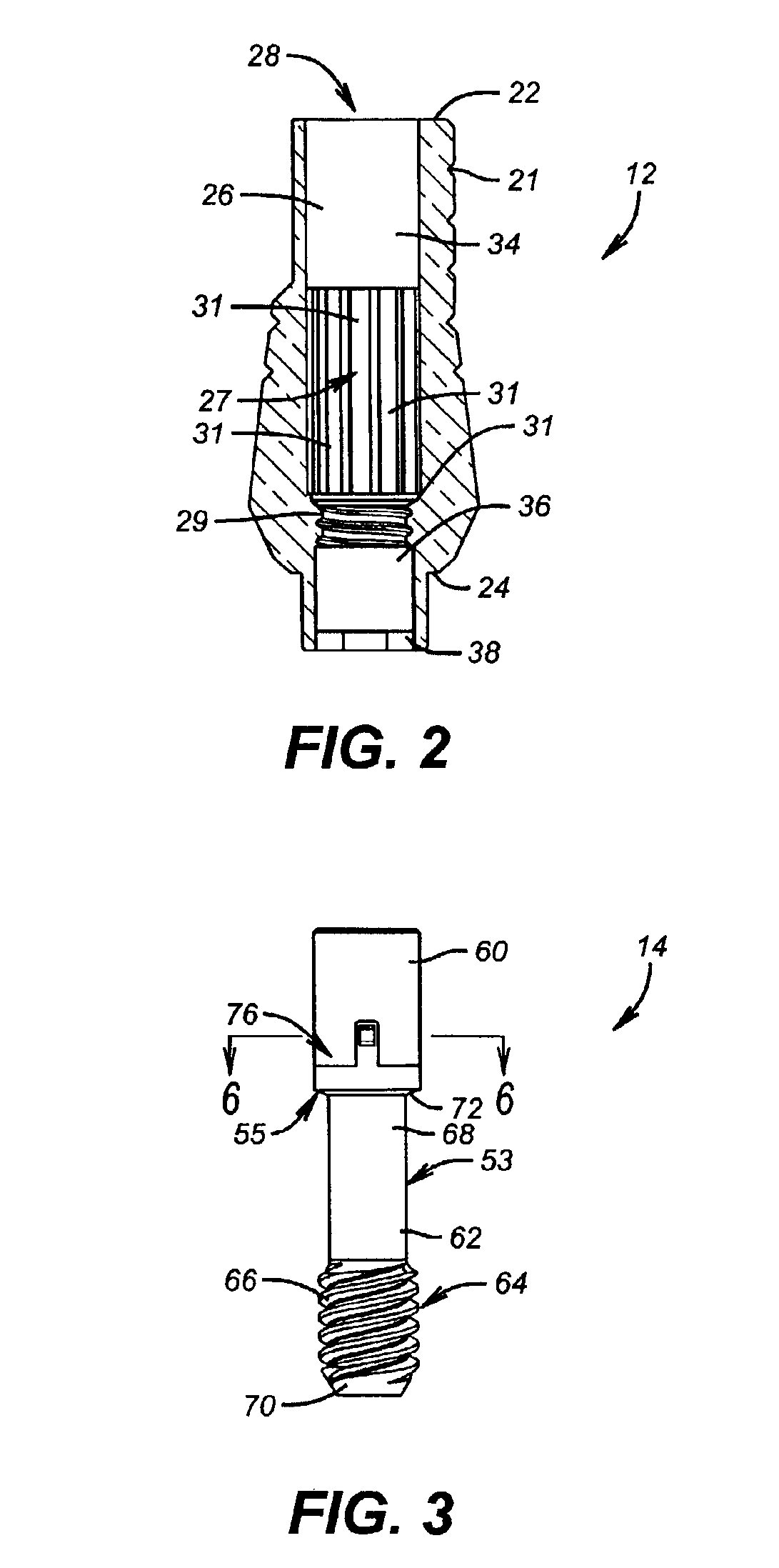

Abutment screw with gold spring-washer

InactiveUS6932606B2Safe and reliableImprove stabilityDental implantsFastening prosthesisProsthesisEngineering

A dental retaining screw used to secure dental components, such as abutments, copings, and prosthesis to dental implants. The screw has a body formed from titanium and a spring-washer formed from gold. The spring-washer is adapted to prevent the screw from loosening or losing preload once tightened to the implant. The spring-washer includes an annular body with a plurality of flexible legs extending from the annular body; the legs prevent the screw from coming loose during shipping or while attached to an abutment.

Owner:ZIMMER DENTAL INC

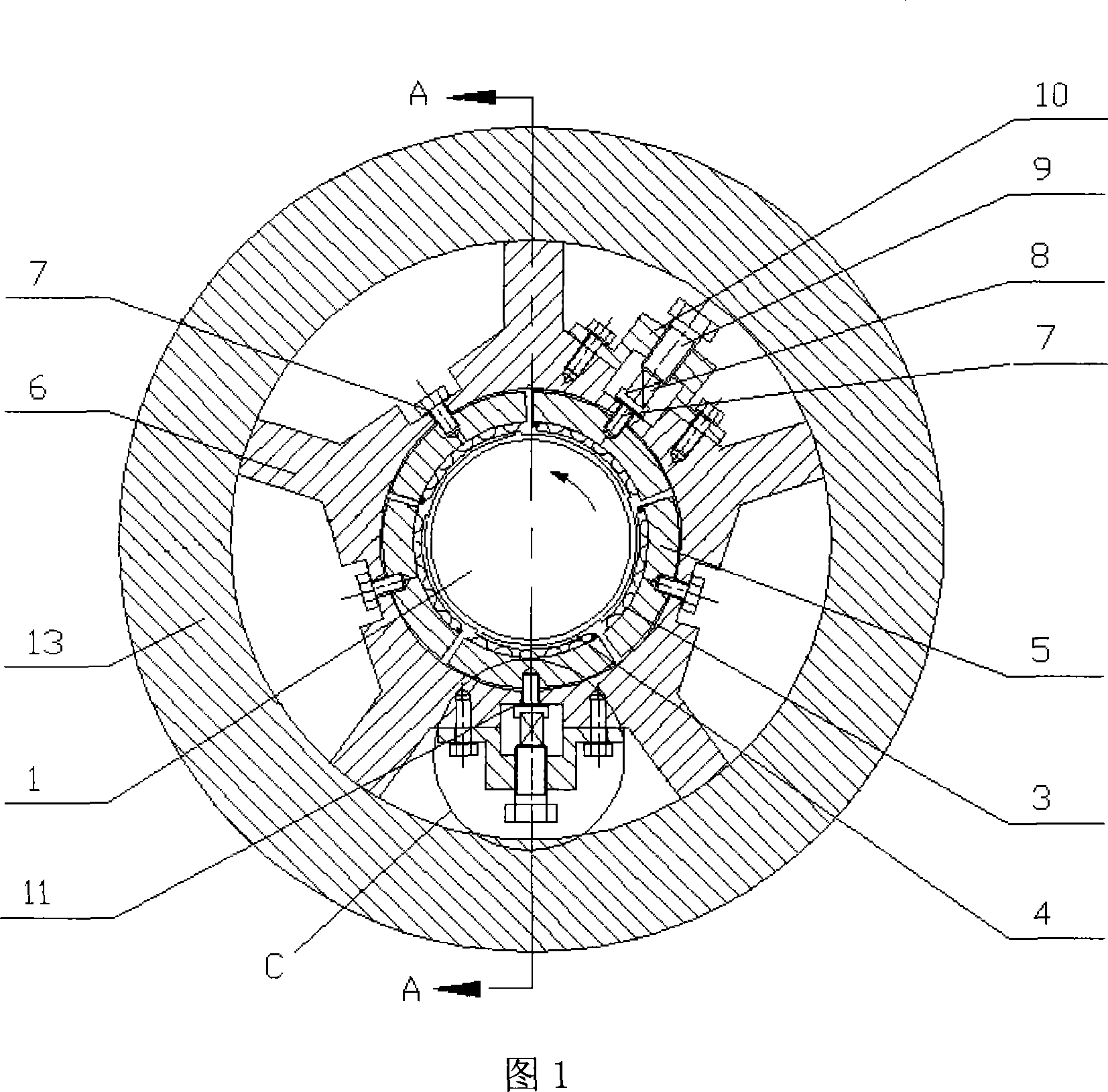

Dynamical pressure gas elasticity foil tablet bearing with stability self-adaptive control function

InactiveCN101225853ARealize micro-displacement control requirementsImprove displacement control accuracyNon-rotating vibration suppressionBearingsDisplacement controlEngineering

The invention relates to a dynamic gas elastic foil bearing with stability and adaptive control functions, comprising a bearing casing, a plurality of bearing pads, an elastic foil, and a piezoelectric ceramics micro displacement actuator. The dynamic gas elastic foil bearing is characterized in that the bearing pads are uniformly distributed along the inner wall of the bearing casing; the bearing pads are welded with a bottom bump foil and one end of a top foil; the other end of the top foil is lapped over an adjacent top foil, wherein the piezoelectric ceramics micro displacement actuator with one end fixed on a set screw and the other end arranged on a jig is connected with two bearing pads; the piezoelectric ceramics micro displacement actuator is connected with a feedback controller PID; an input of the feedback controller PID is connected with an eddy current displacement sensor. The dynamic gas elastic foil bearing with stability and adaptive control functions has the advantages of strengthened equivalent rigidity and equivalent damping of the elastic foil, restrained vibration of rotor system, improved bearing capacity and stability of the bearing, reduced size and structure, increased control precision of displacement, and quickened response speed.

Owner:XI AN JIAOTONG UNIV

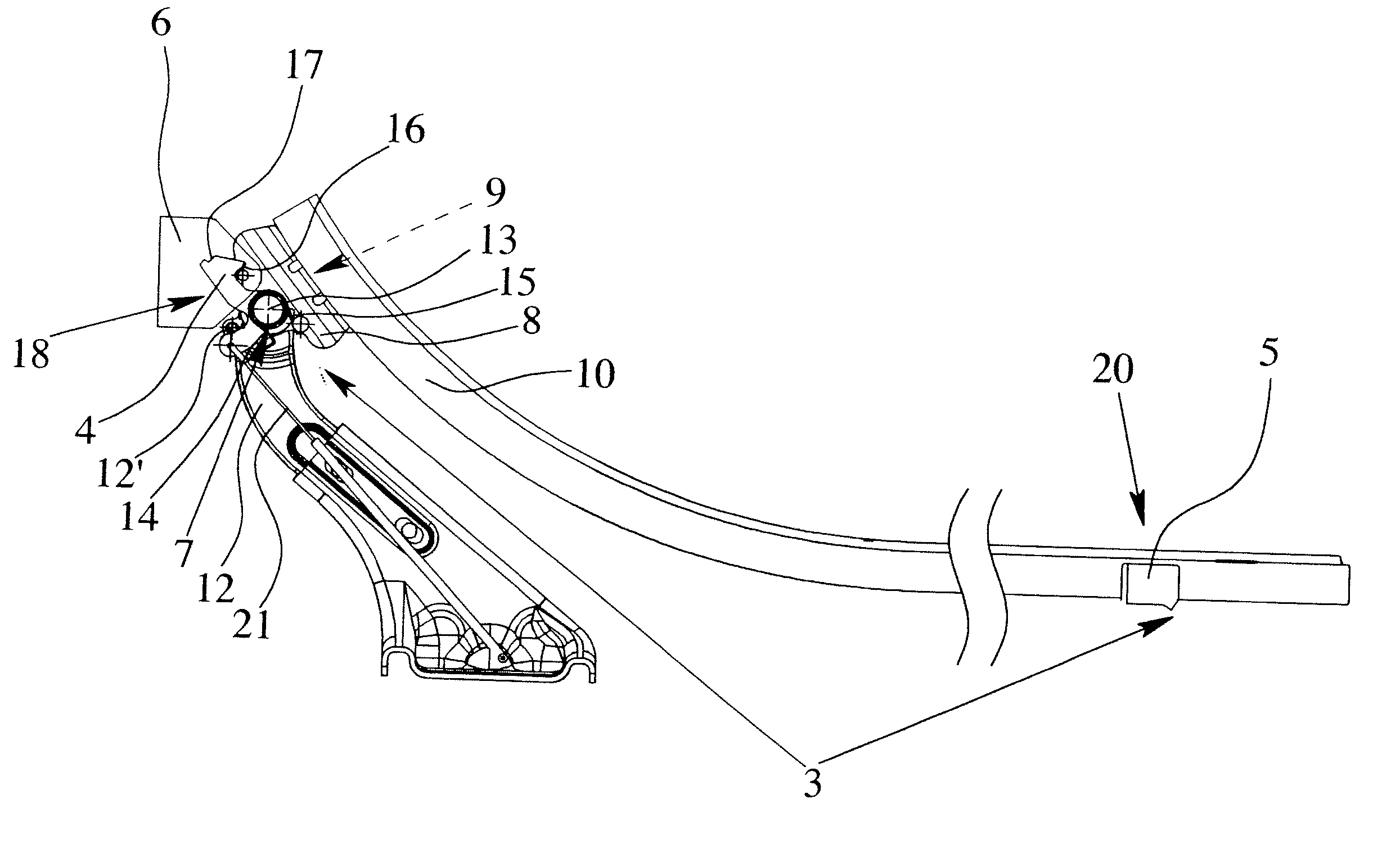

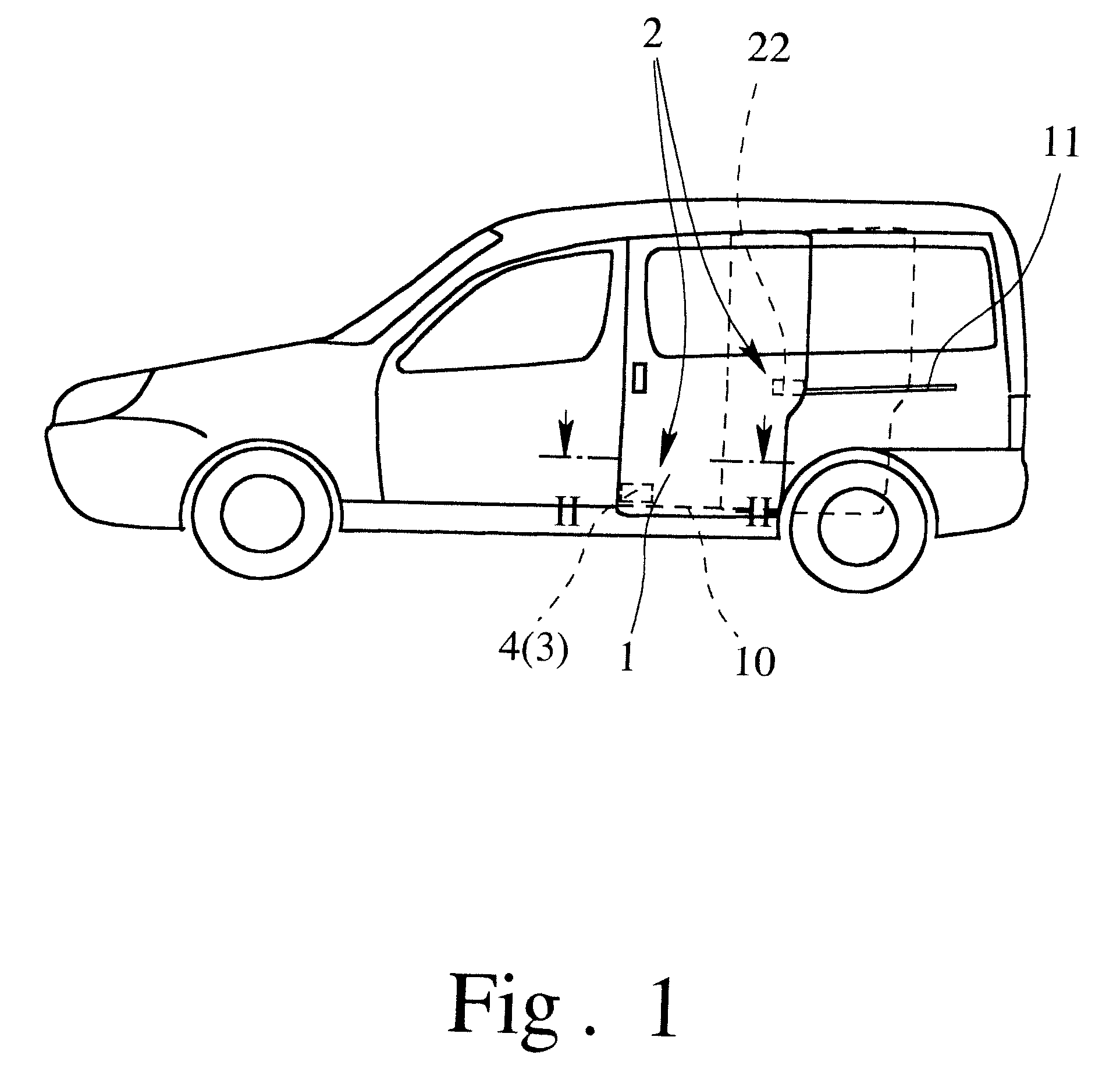

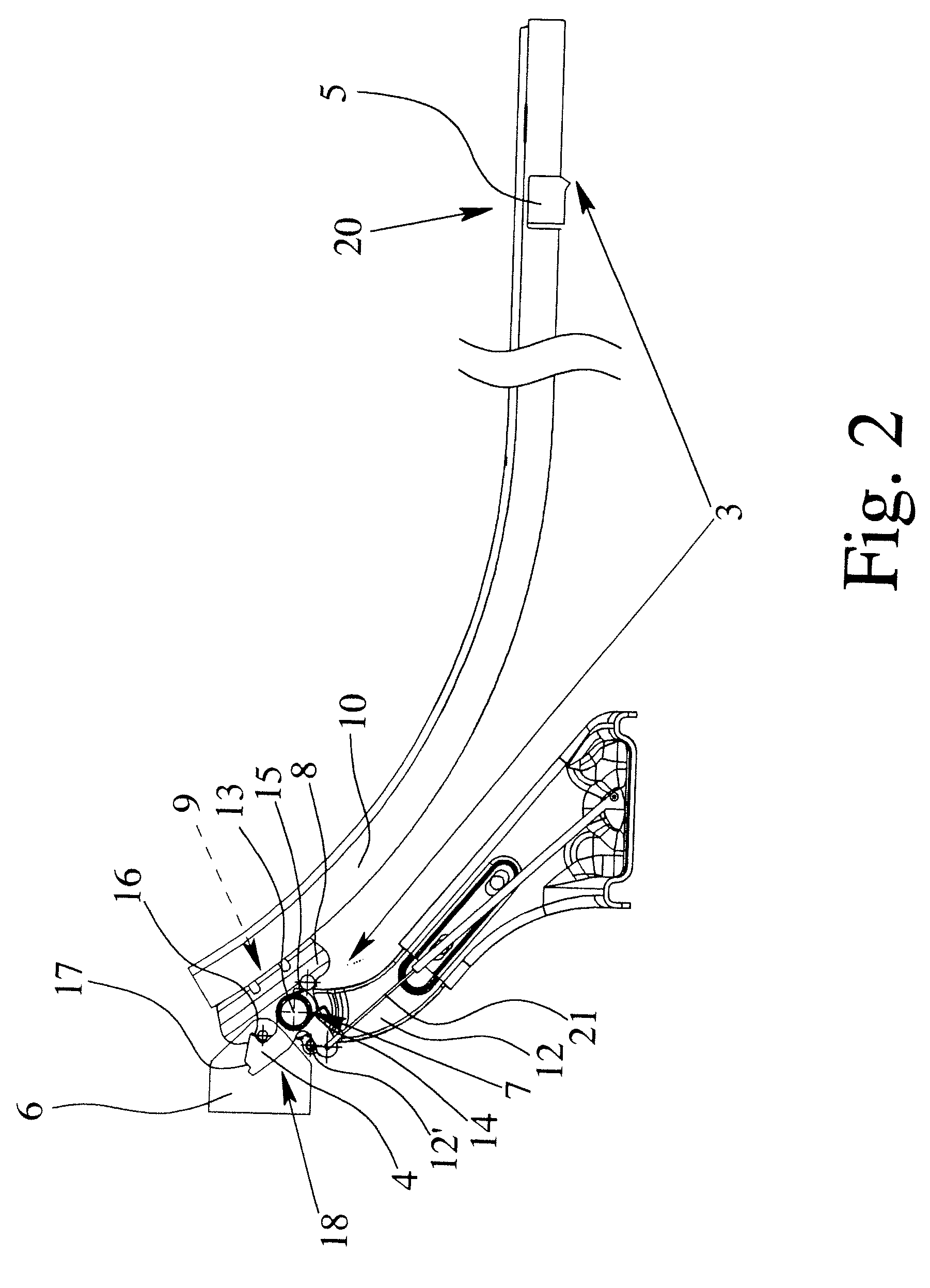

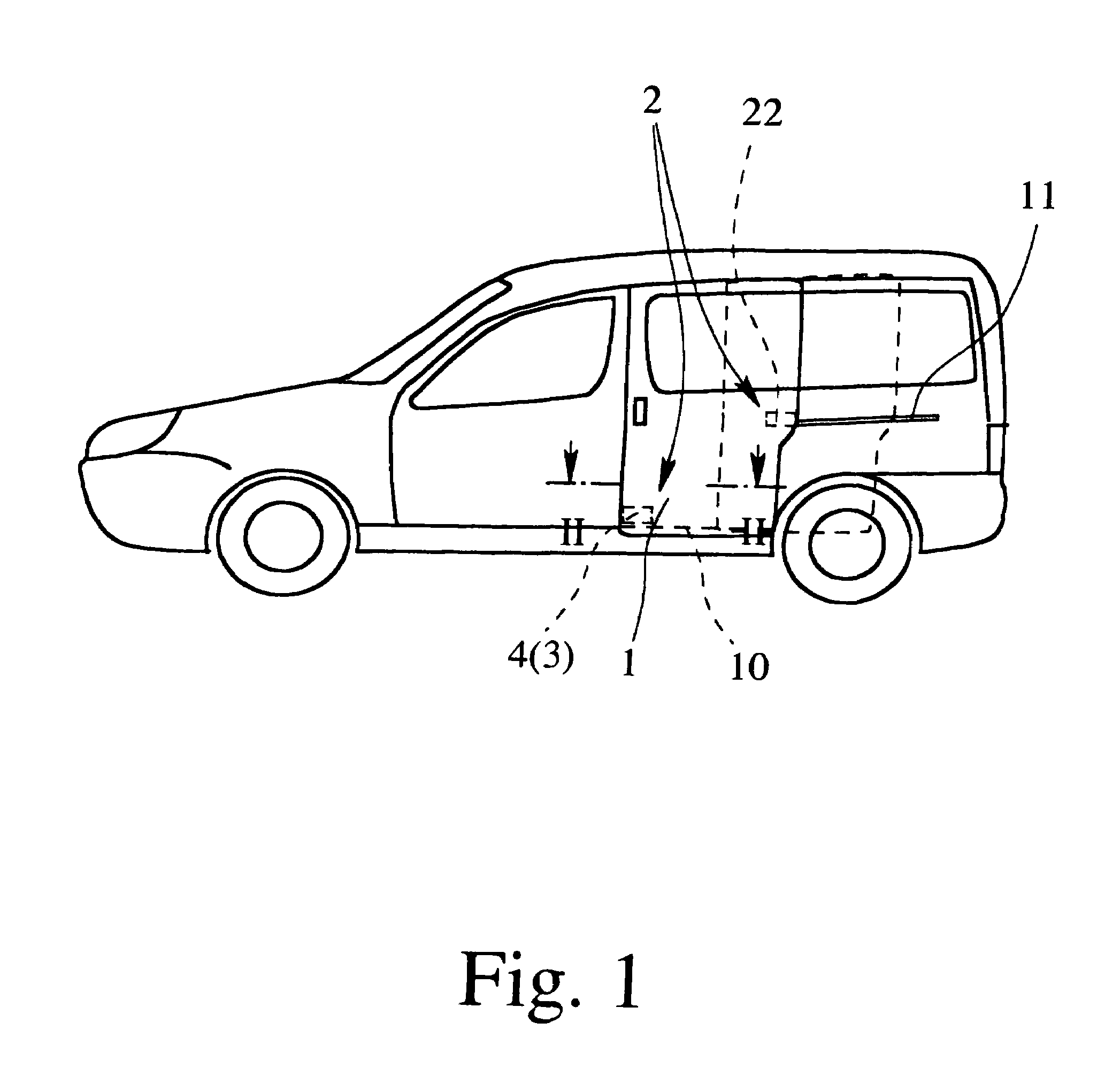

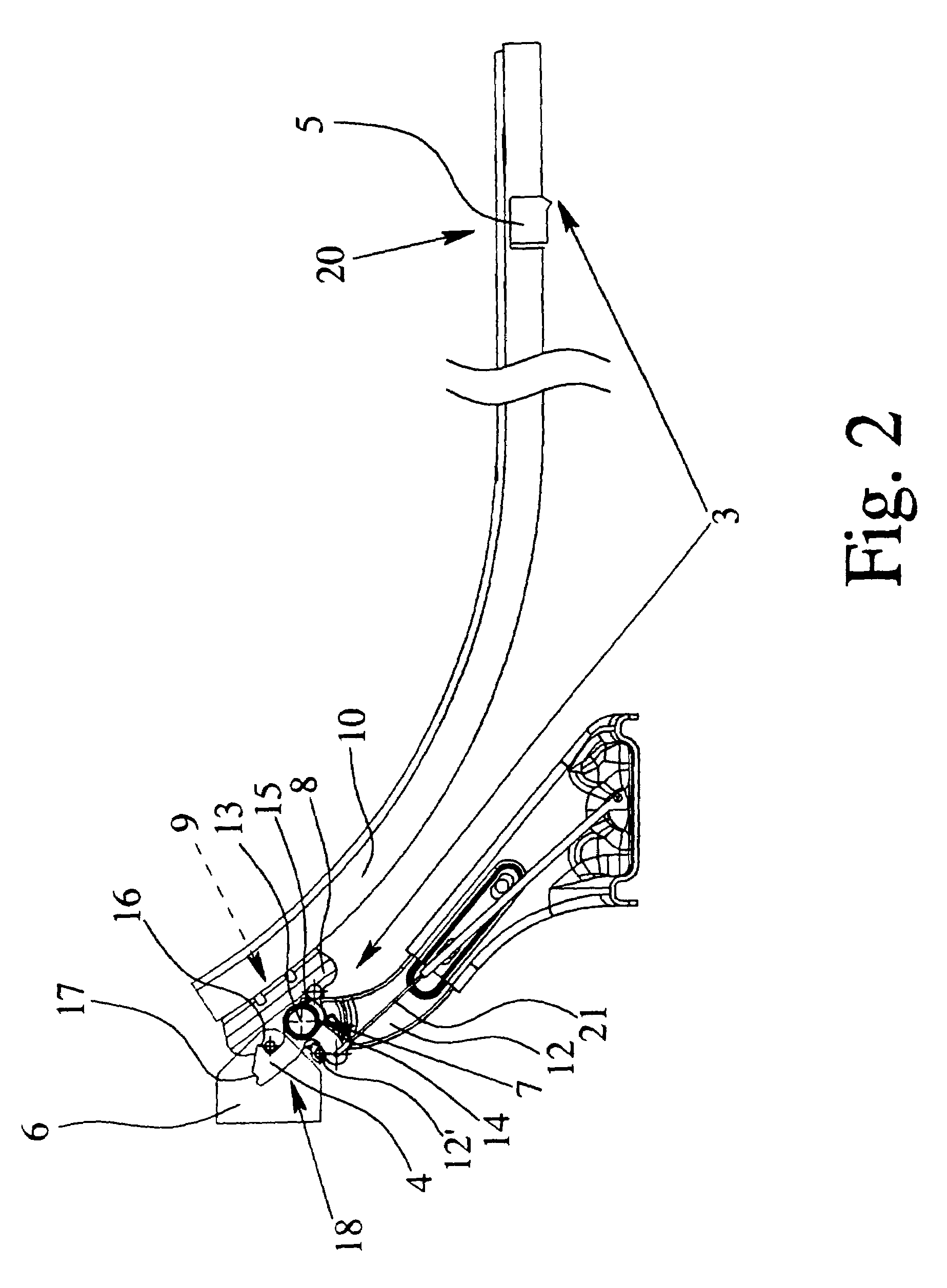

Sliding door arrangement for a motor vehicle

InactiveUS20070096504A1Improve the level ofExcellent ease of useVehicle locksMan-operated mechanismEngineeringMotorized vehicle

Owner:BROSE SCHLIESSSYSTEME GMBH & CO KG

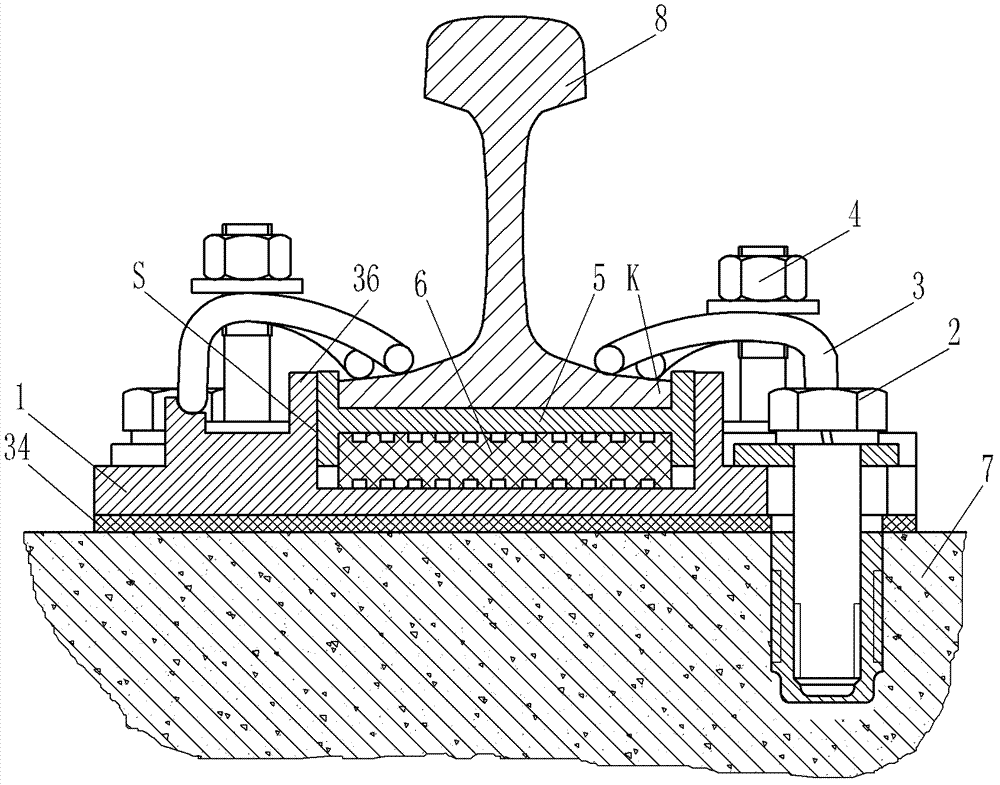

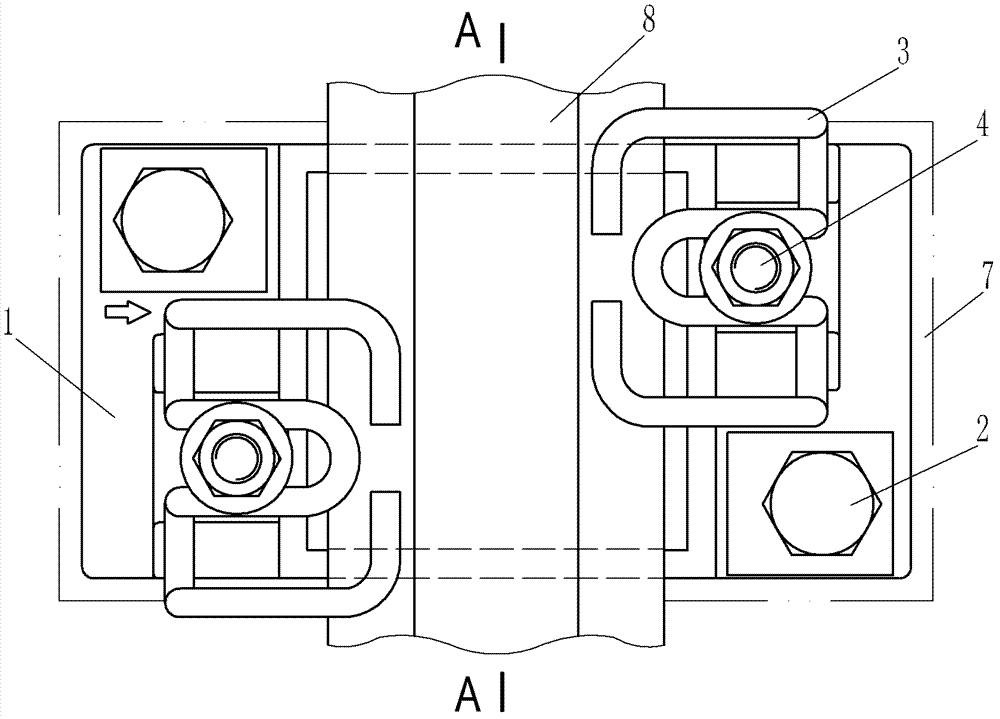

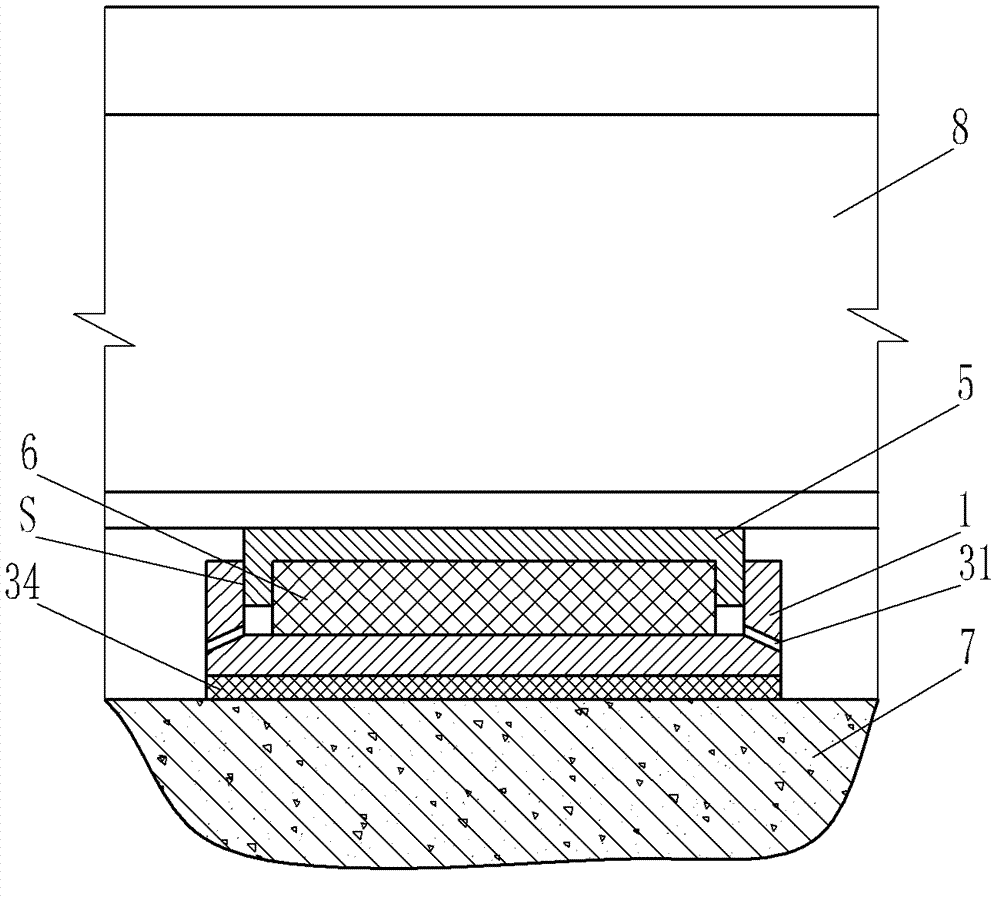

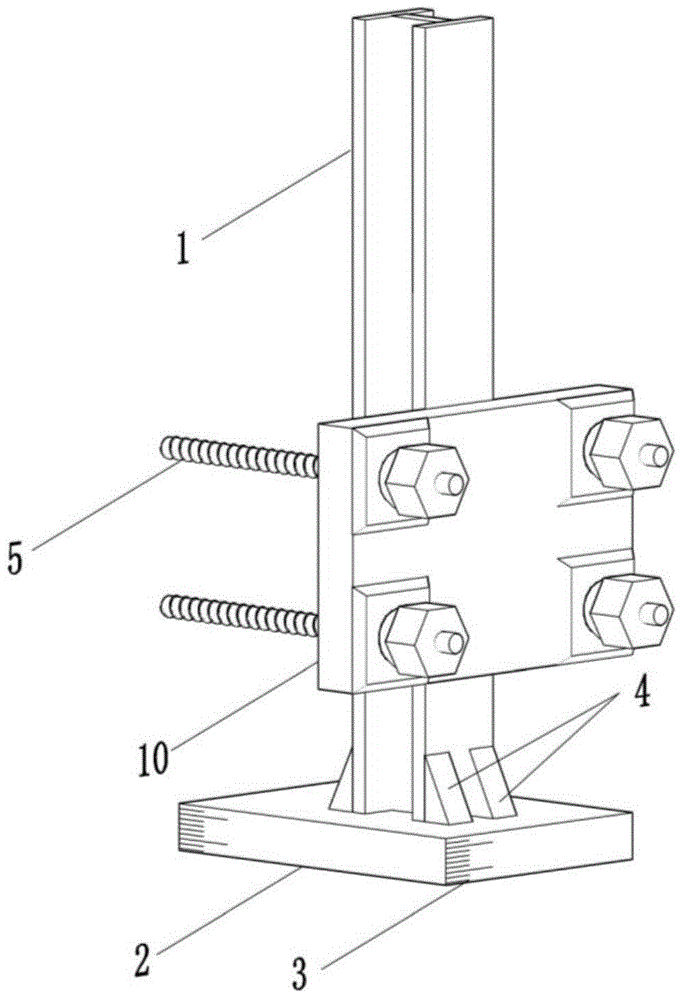

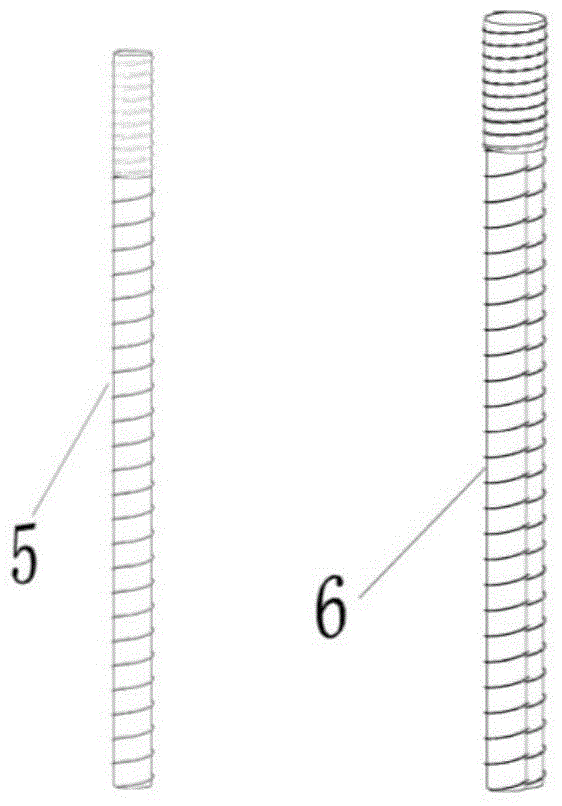

Transverse stiffness-reinforced rail fastener

The invention relates to a transverse stiffness-reinforced rail fastener comprising a base, an anchor bolt, a bar spring and an elastomeric bearing part. The base is fixed on a railway sleeper by the anchor bolt. The transverse stiffness-reinforced rail fastener is characterized by further comprising a guiding element arranged between the base and a steel rail. Interworking guiding surfaces are arranged on the guiding element and the base respectively, the guiding surfaces are all parallel to the steel rail and perpendicularly arranged and the elastomeric bearing part is arranged between the base and the guiding element. The transverse stiffness-reinforced rail fastener can ensure vertical elasticity of the fastener, maintain perfect transverse intensity and effectively prevent the steel rail from occurring deflection and shimmy. The transverse stiffness-reinforced rail fastener can realize effects of reducing vibrate and noise as the traditional rail fastener, can also retard or prevent abrasion of the steel rail so that service life of the steel rail is prolonged greatly. The transverse stiffness-reinforced rail fastener needs small assembling space, is an economic beneficial utility, and is compact in structure, cost effectively and wide in market application prospect.

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH +1

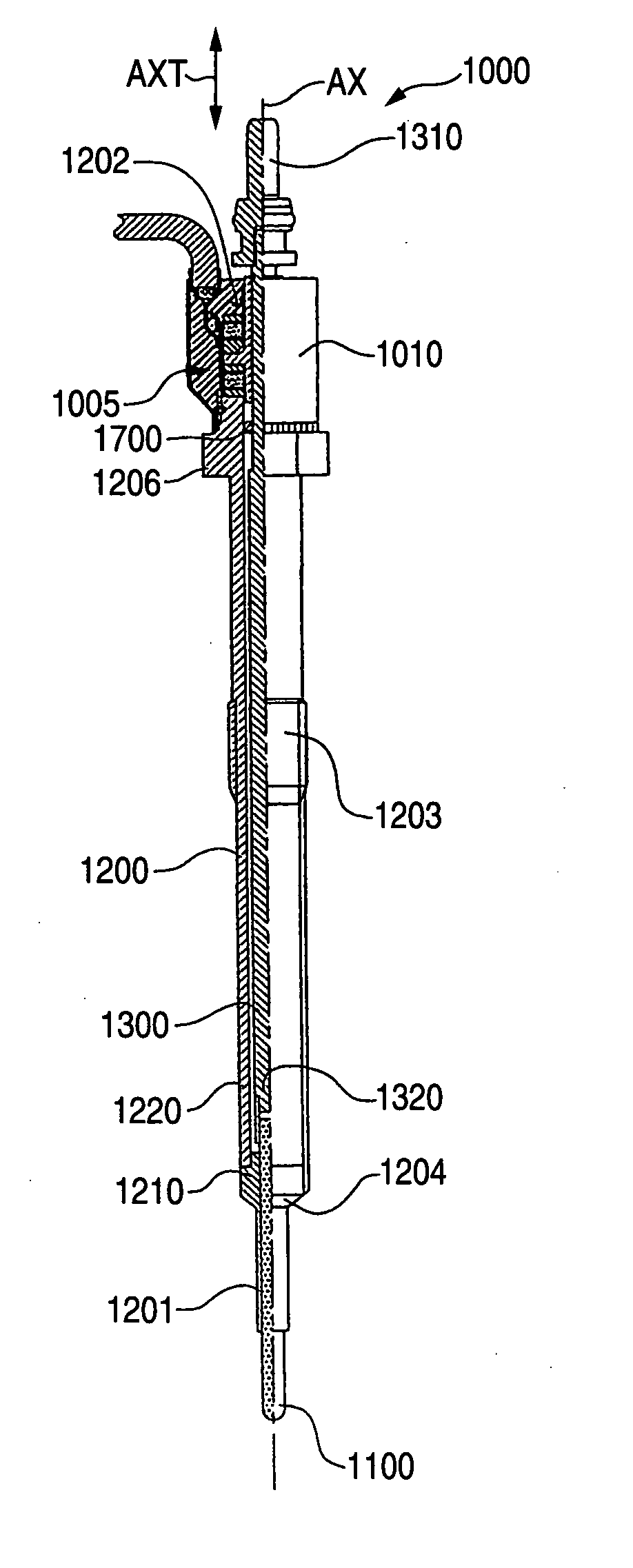

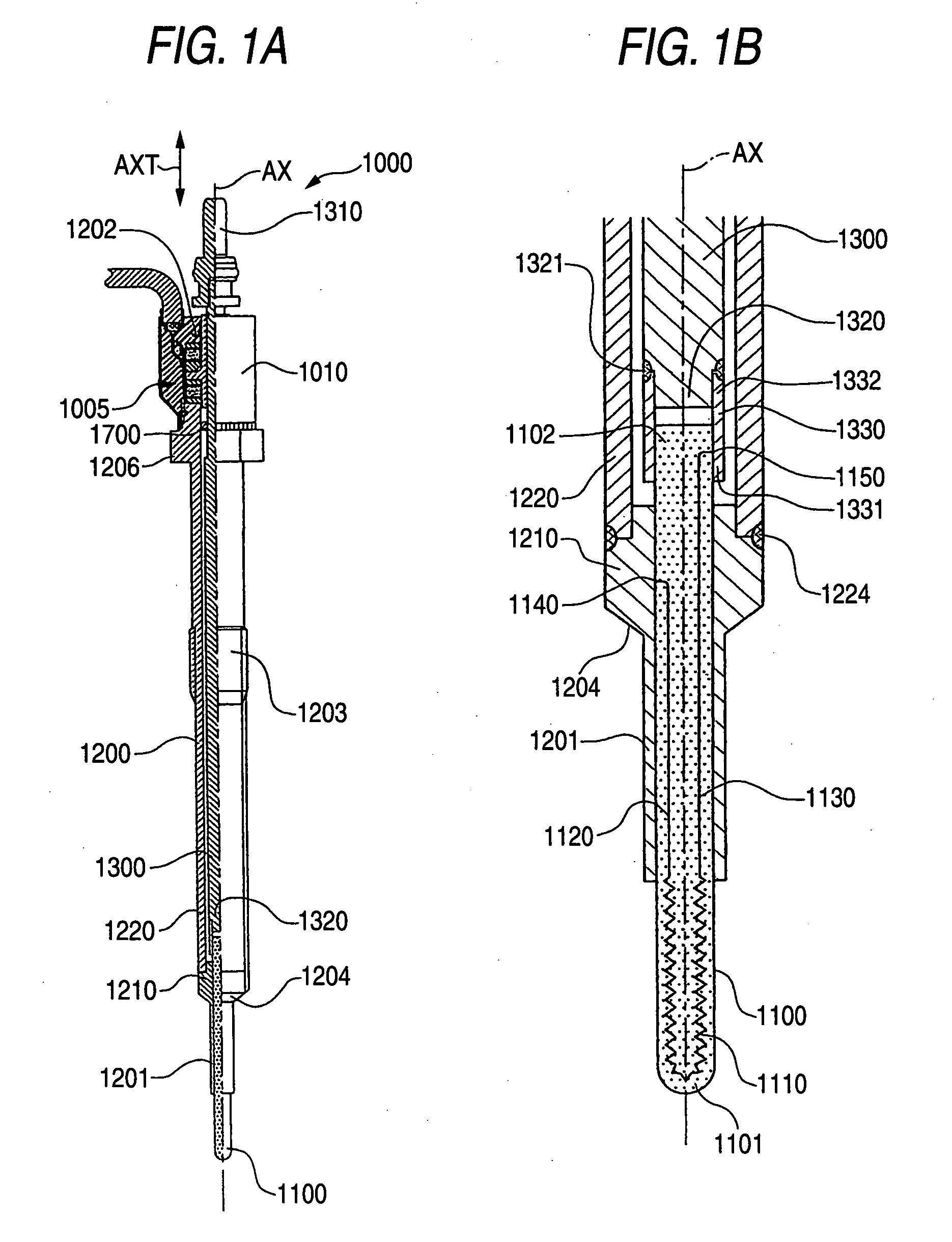

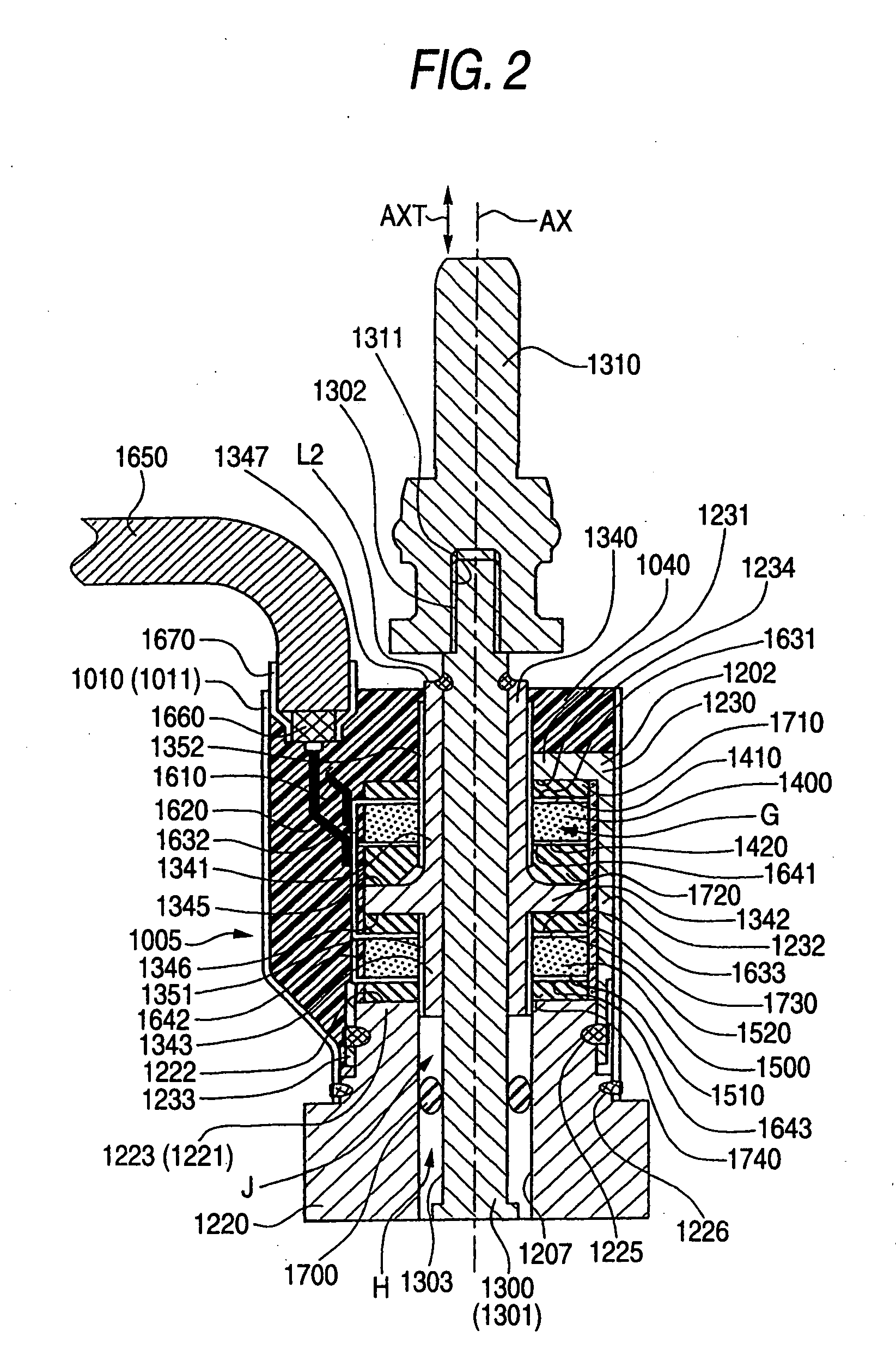

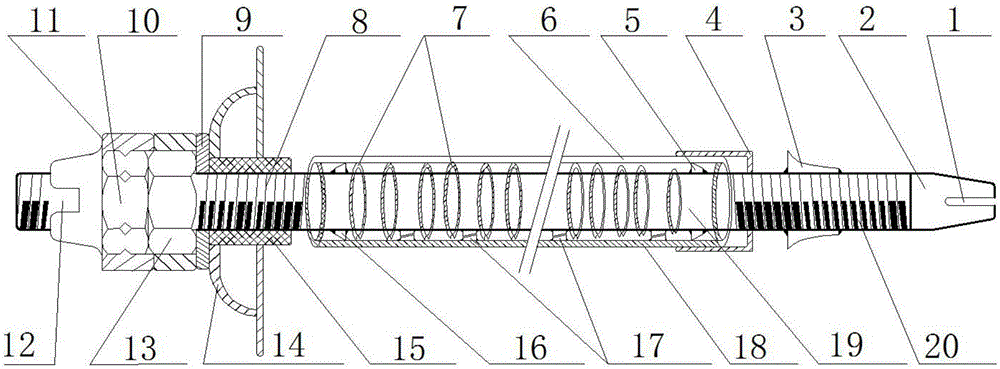

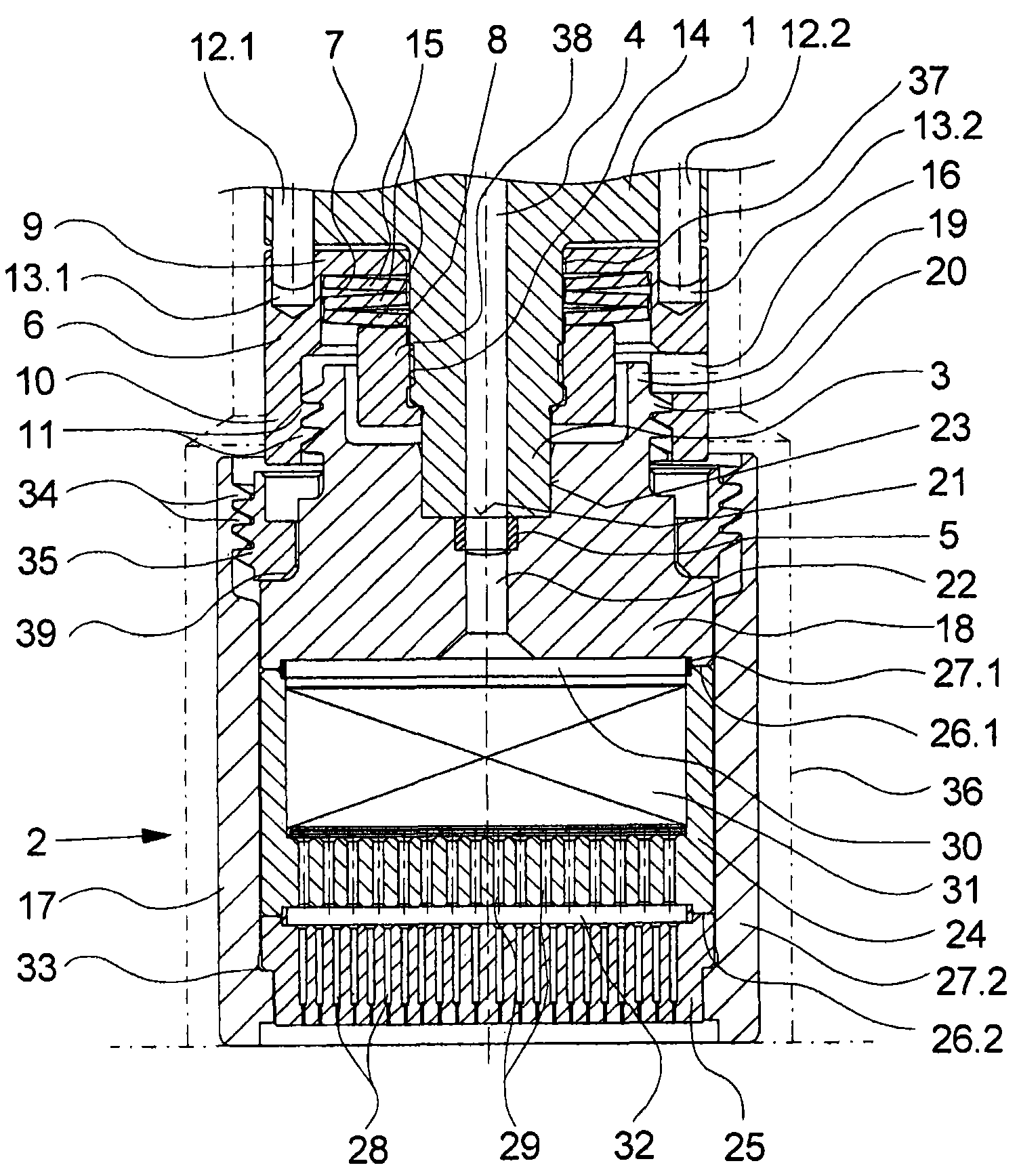

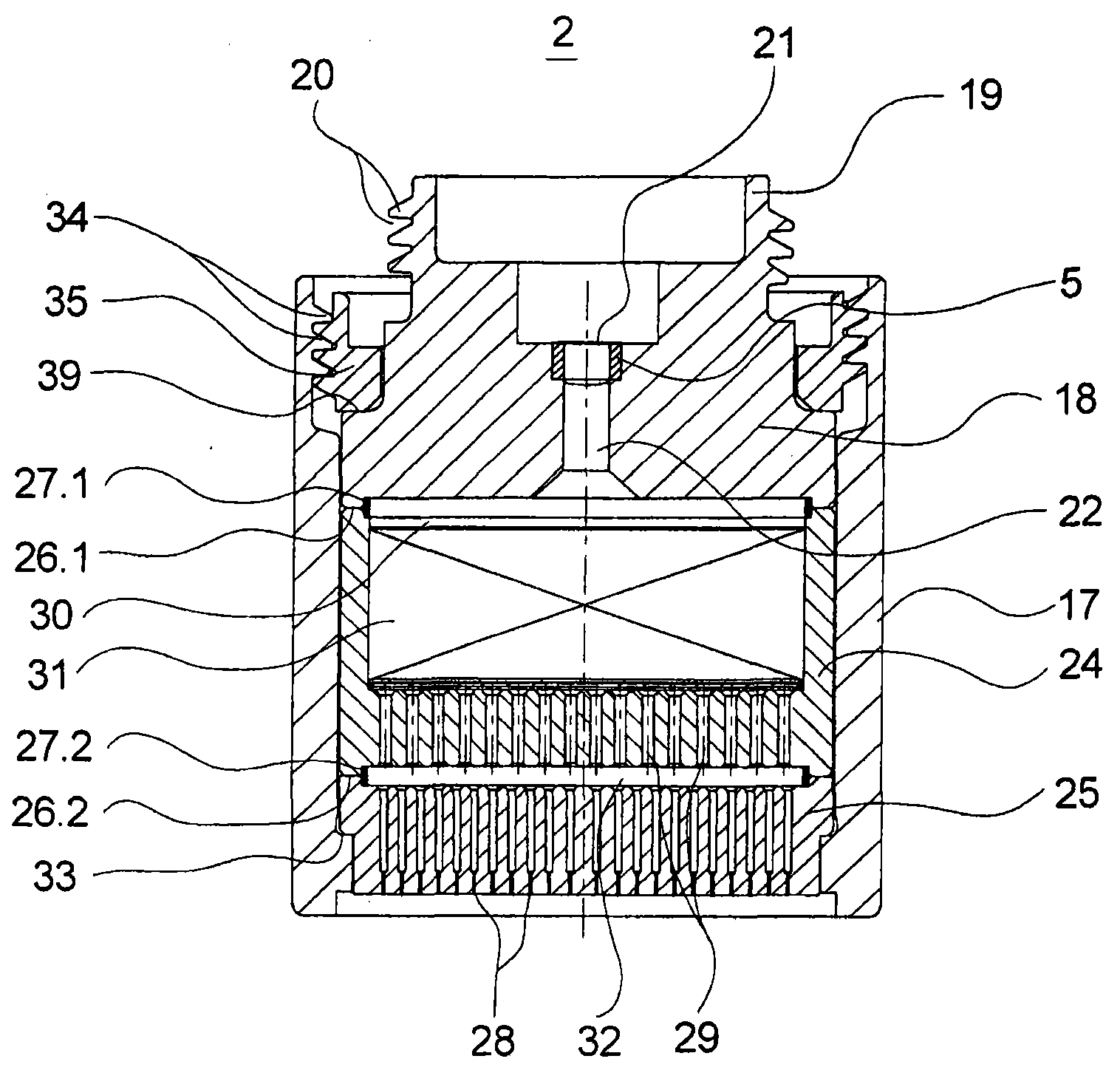

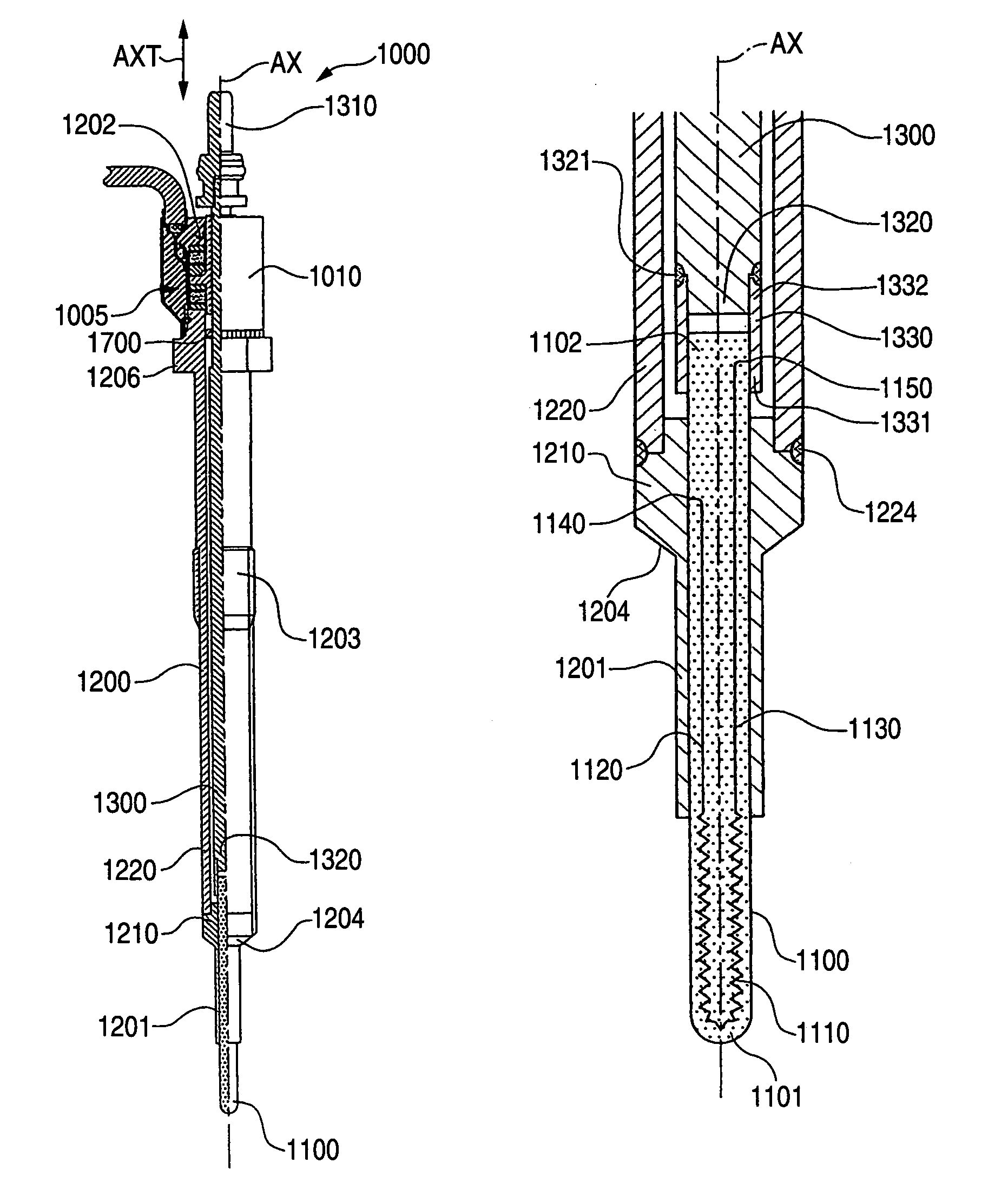

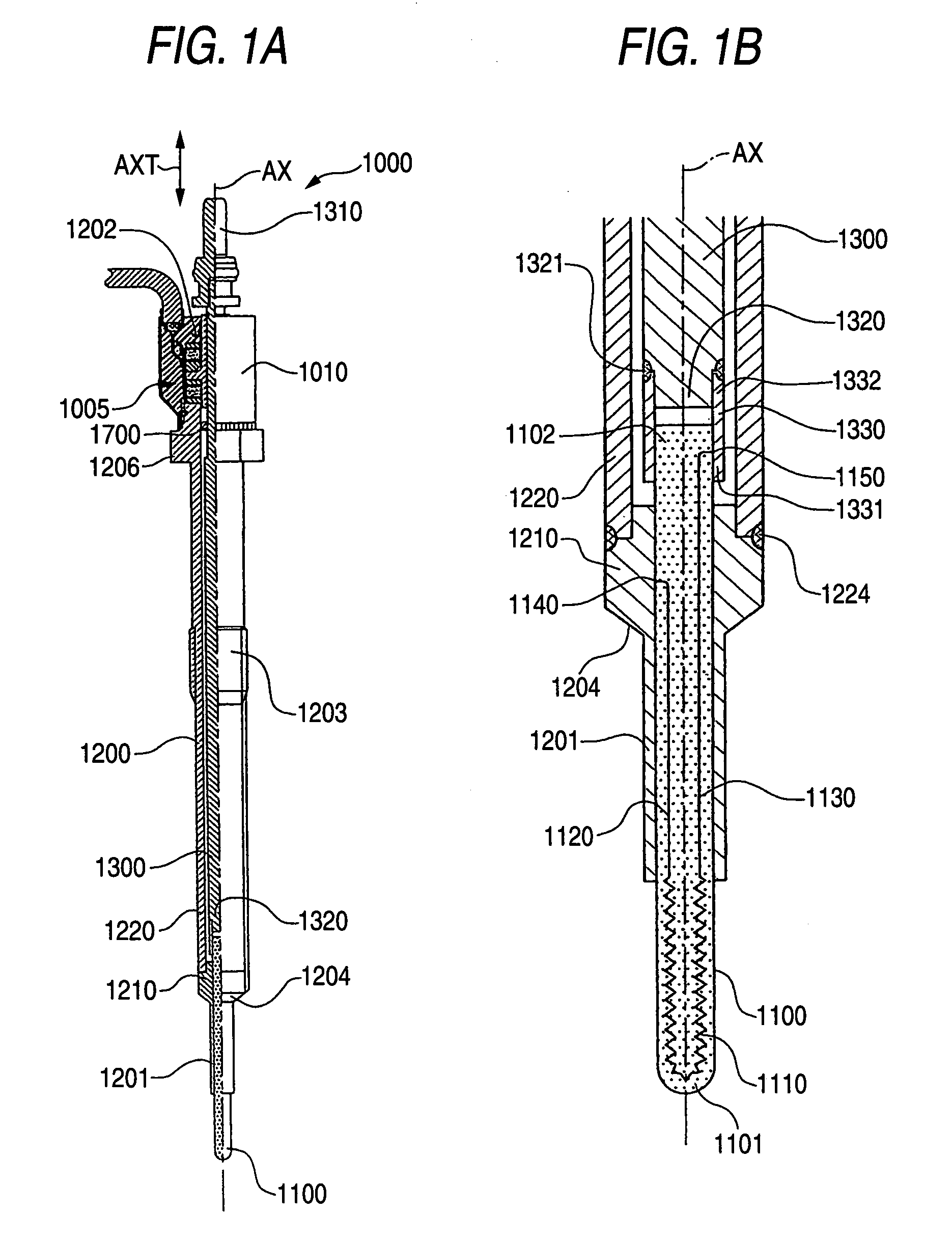

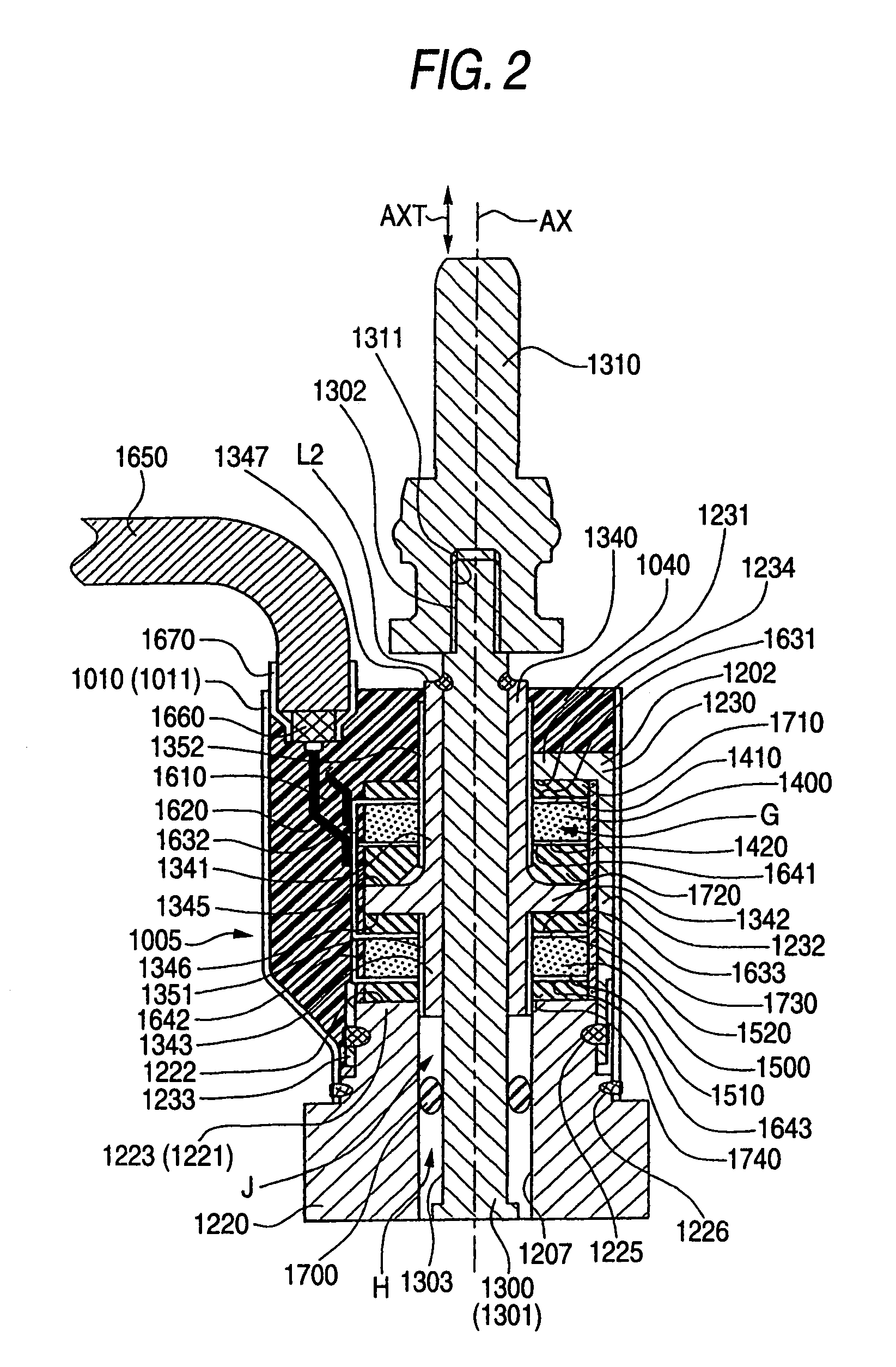

Glow plug with combustion pressure detecting function

InactiveUS20060032472A1Highly strongEasy to handleIncandescent ignitionEngine testingElectricityCombustion

A glow plug comprising: a cylindrical housing; a heater member as defined herein; a conductive center pole as defined herein; a first piezoelectric element as defined herein; and a second piezoelectric element as defined herein, wherein each of said first piezoelectric element and said second piezoelectric element is subjected to a preload for compressing it in said axial direction and is arranged such that, when said center pole is displaced to a root-end side, a load to be applied to one of said first piezoelectric element and said second piezoelectric element for compressing the same in said axial direction increases whereas a load to be applied to the other for compressing the same in said axial direction decreases.

Owner:NGK SPARK PLUG CO LTD

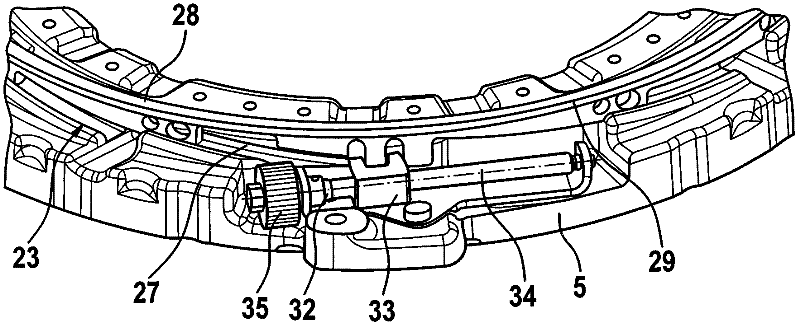

Distraction device

InactiveUS20050010233A1High spring forceHigh constantInternal osteosythesisProsthesisDistractionDetent

A distraction device for moving a one-part or two-part or separated bone apart in order to extend or bridge a bone gap. The device is optionally provided in the form of an intramedullary pin, which can be inserted into a medullary space of a bone and which has at least two elements that can be axially moved in relation to one another. The first element is joined to the second element via at least one detent device for securing a distraction movement, and a pushing module for distracting the first element is assigned to the second element and is joined to the second element in a manner that enables it to be locked.

Owner:WITTENSTEIN GROUP

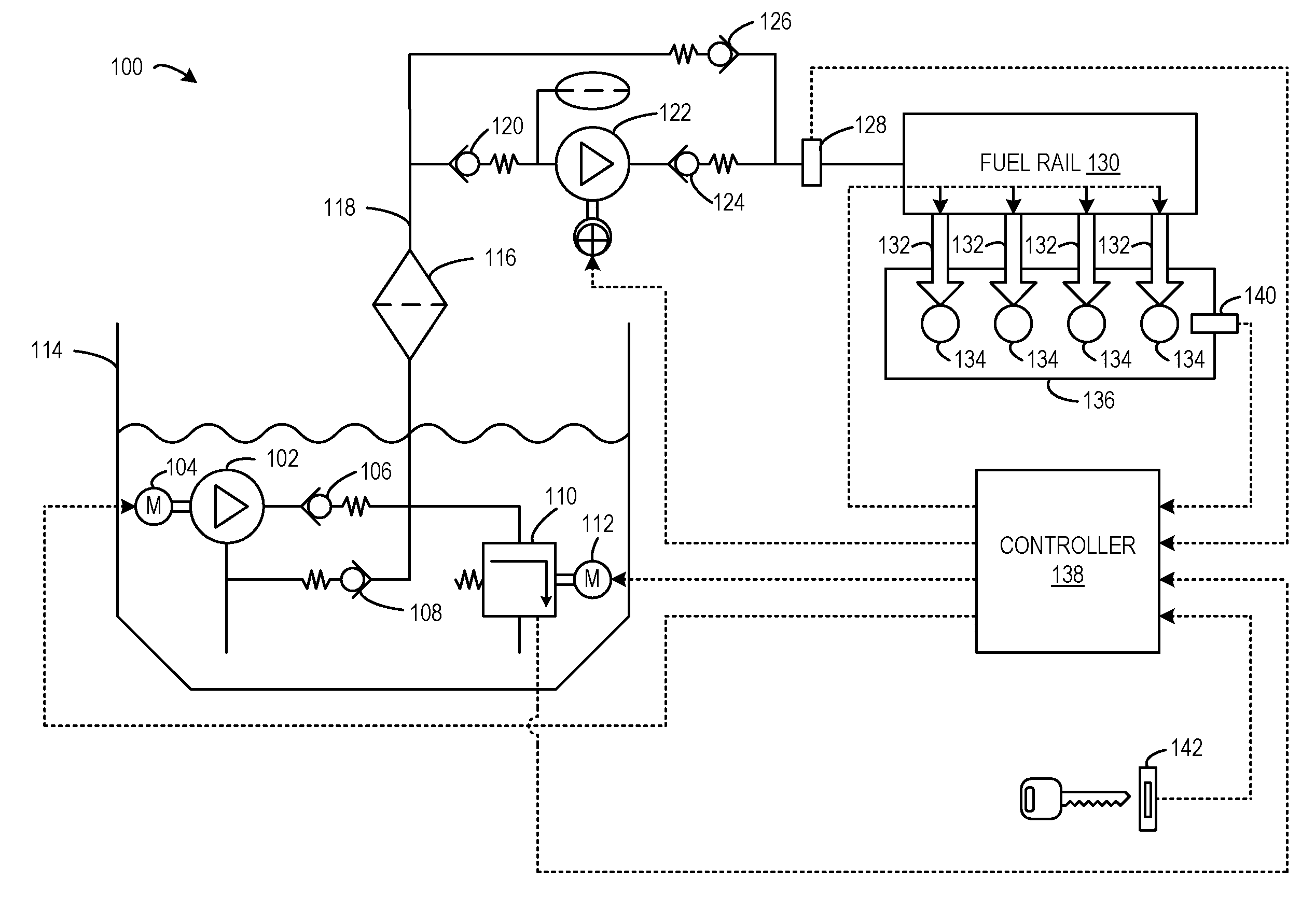

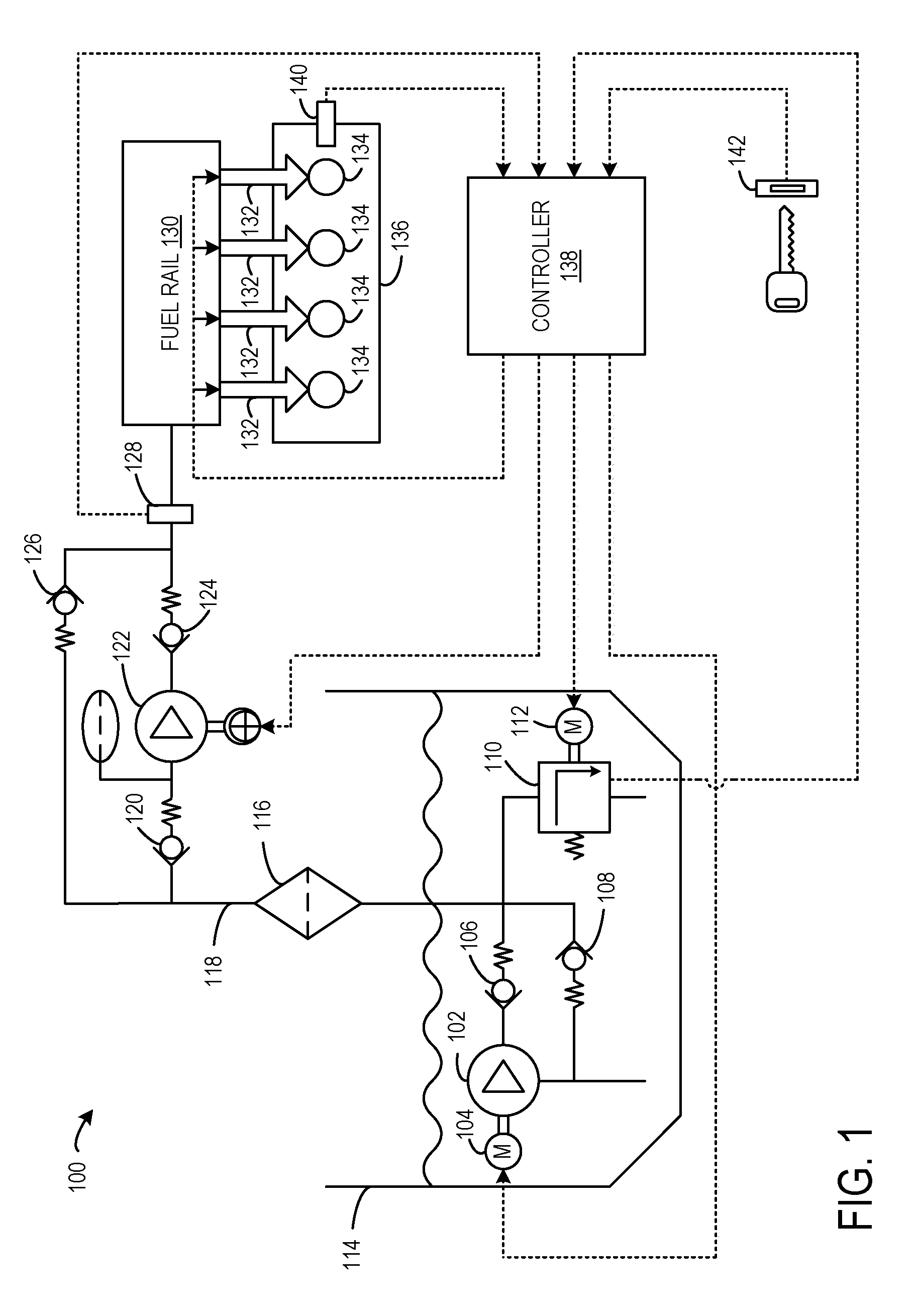

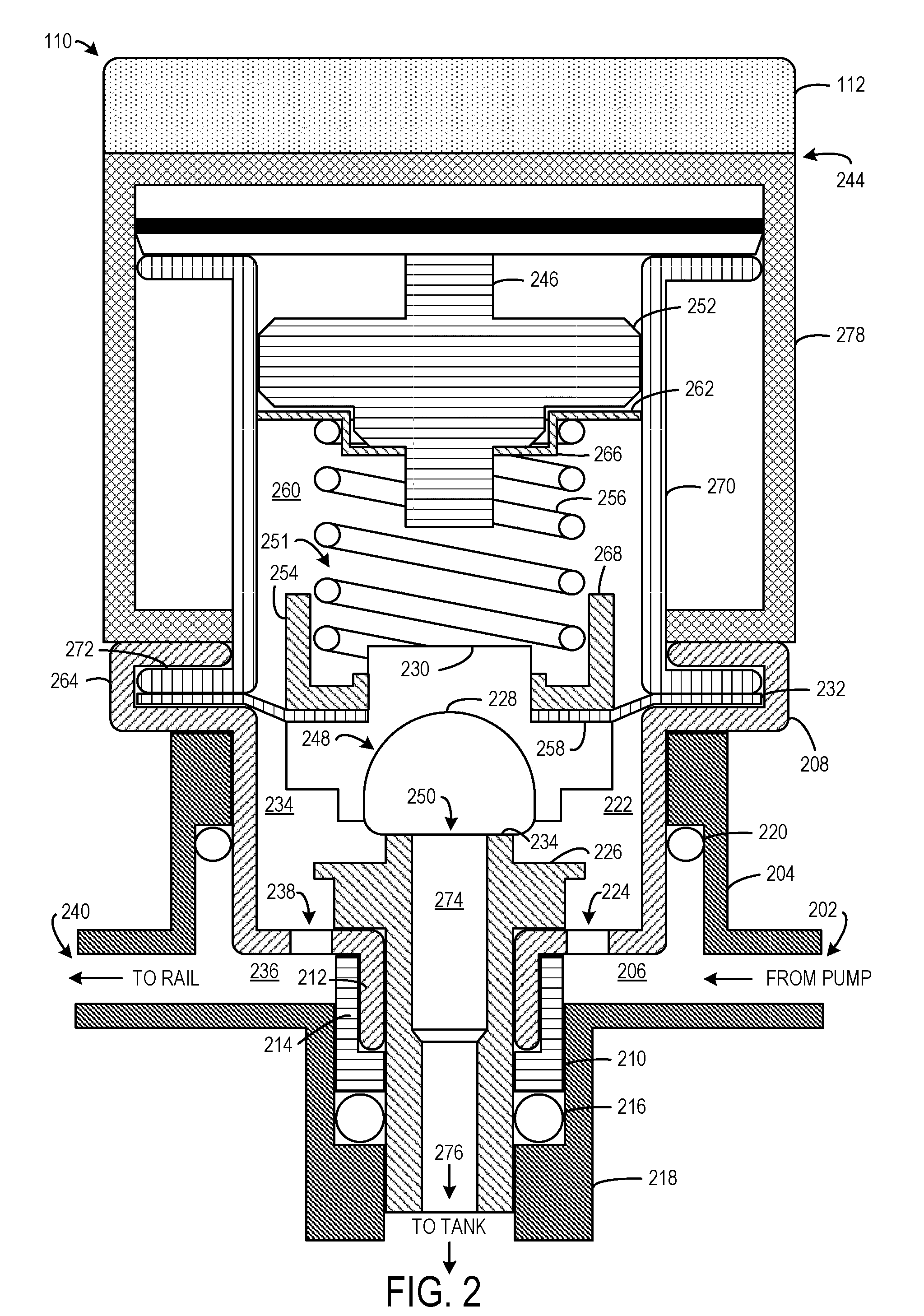

Fuel system with electrically-controllable mechanical pressure regulator

InactiveUS20110000463A1Increase power efficiency and rangeDecrease engine power and efficiencyElectrical controlExhaust apparatusAutomotive engineeringSet point

A method for operating an engine direct injection fuel system is provided. The direct injection fuel system includes a mechanical fuel pressure regulator that has a spring actuatable by an electric motor. The method includes adjusting a preload of the spring by operating the electric motor to adjust a set-point fuel pressure from a first set-point fuel pressure to a second set-point fuel pressure in response to an operating condition, and maintaining the preload of the spring mechanically when the electric motor is not operating.

Owner:FORD GLOBAL TECH LLC

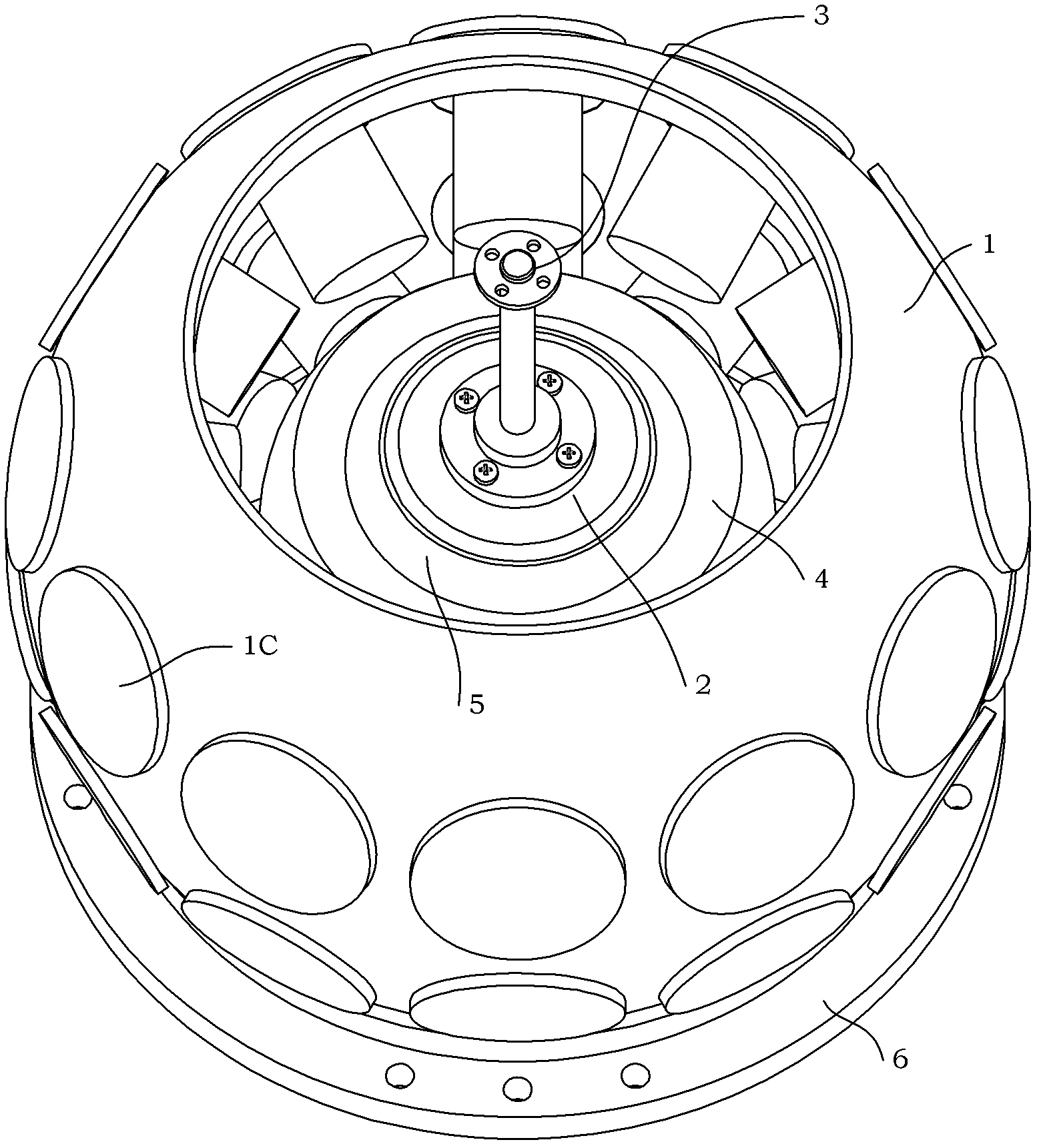

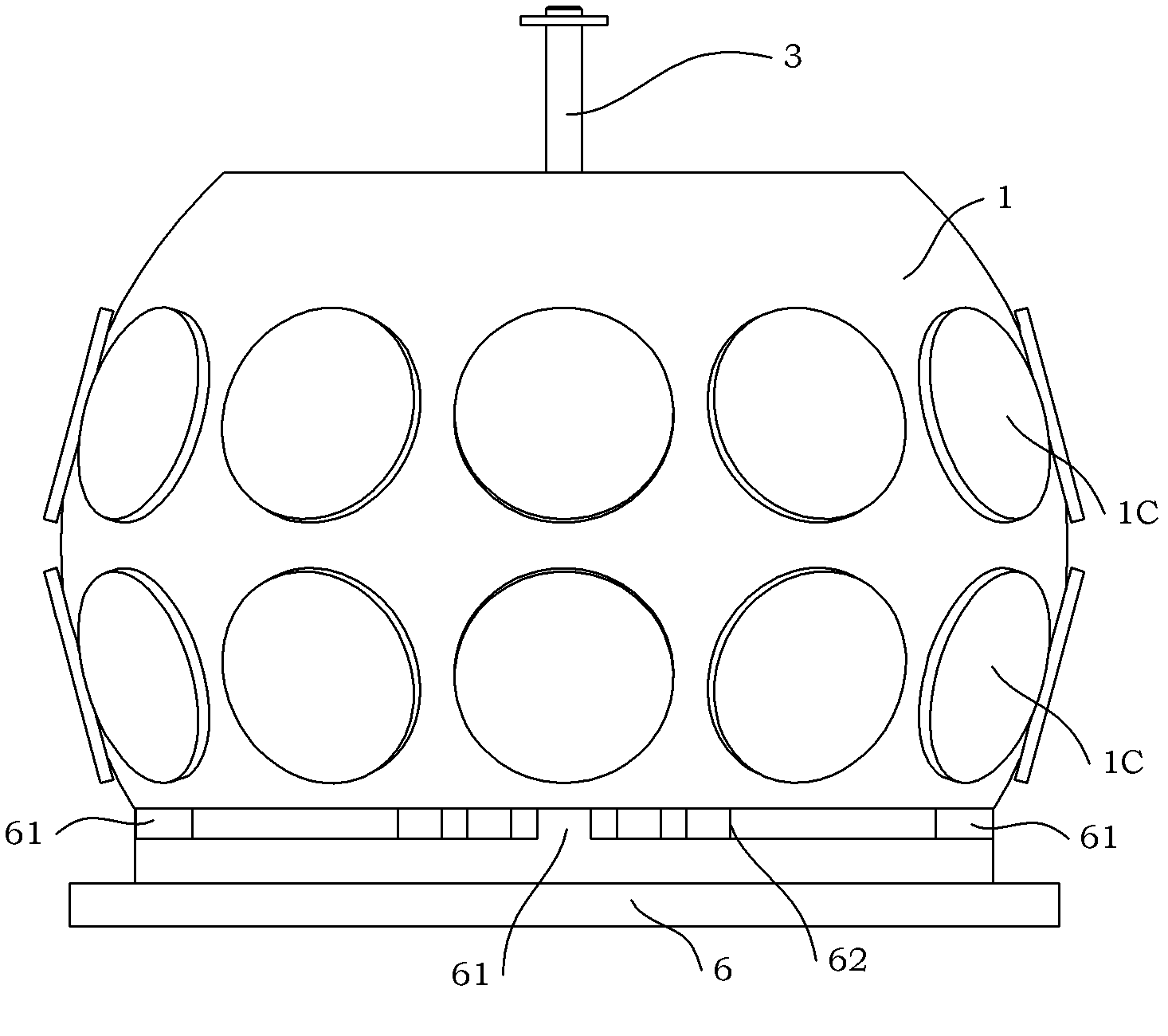

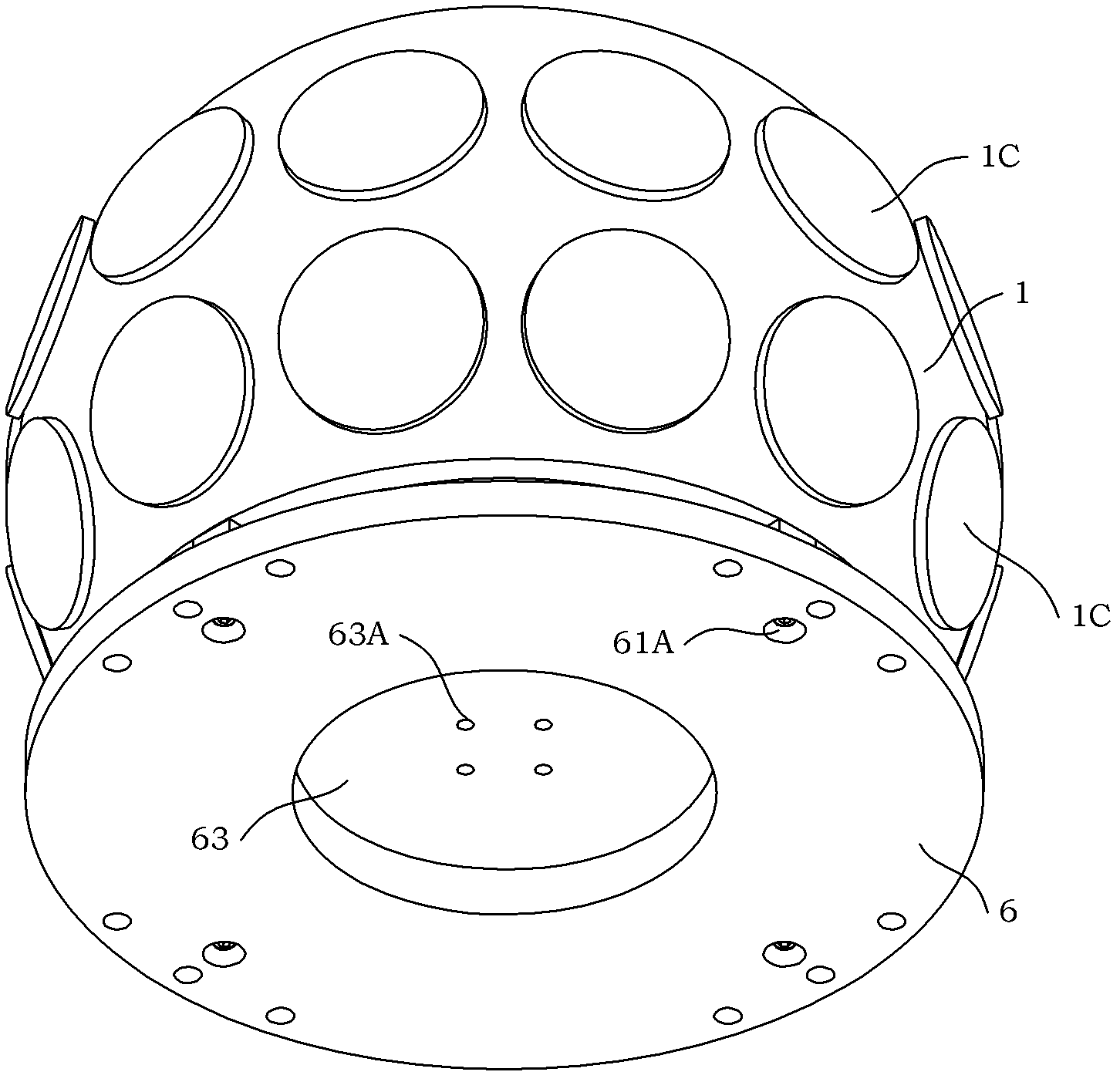

Electromagnetic-piezoelectric-mixed-driving-based three-degree-of-freedom spherical motor

InactiveCN102355103ALarge output torqueIncrease output torqueDynamo-electric machinesElectricityThree degrees of freedom

The invention discloses an electromagnetic-piezoelectric-mixed-driving-based three-degree-of-freedom spherical motor, which comprises a first stator, a rotor, an output link, a second stator, a rotor protection film, a base, a piezoelectric ceramic driver A, a piezoelectric ceramic driver B, a piezoelectric ceramic driver C, 24 coils arranged on the first stator 1 and 8 magnetic poles arranged onthe rotor. A land of the output link is arranged on the rotor. The rotor protection film is coated on the outer surface of the rotor. The second stator is arranged outside the rotor protection film. The first rotor is arranged outside the second stator. The second stator is arranged on the base by support columns. The bottom of the first stator is positioned on L-shaped connecting pieces of the base. The spherical motor provided by the invention adopts a structure with the single rotor and the dual stators; and simultaneously, an electromagnetic driving mode and a piezoelectric ceramic driving mode are fused, compensate for the shortcomings of each other and coact to effectively increase the output torque of the spherical motor.

Owner:BEIHANG UNIV

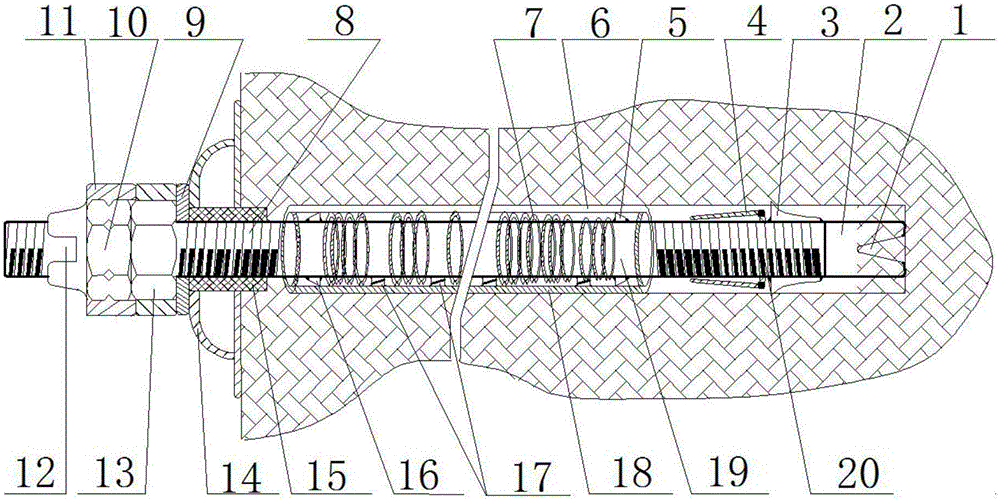

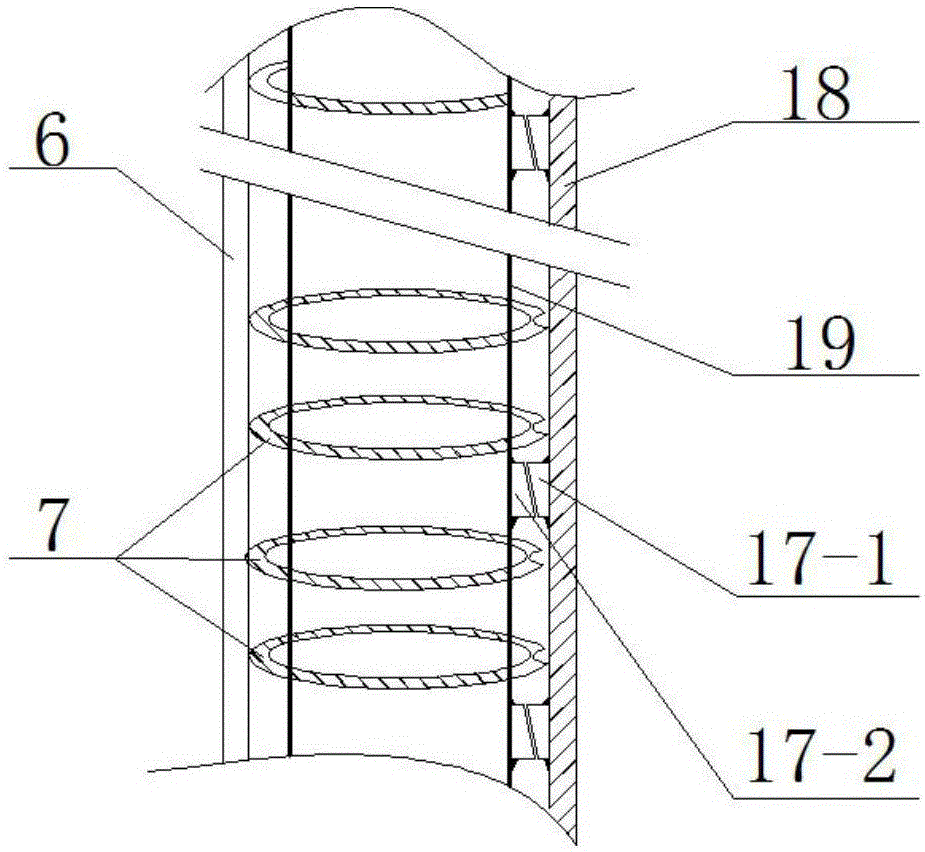

Novel durable magnetization anchor rod

ActiveCN106761868AAvoid violent shakingReduce exposed areaAnchoring boltsEffective actionMagnetization

The invention discloses a novel durable magnetization anchor rod which comprises an anchor rod body, a conical end sleeve, a conical block nut, a claw-shaped elastic anti-expansion outer bushing, a concave spring ring, an elastic magnetization slotting steel pipe, a rubber bushing, an arch tray, an antifriction gasket, an opposite-abutting thickening nut fastening mechanism. The novel durable magnetization anchor rod is characterized in that the conical end sleeve guides the anchor rod body to be drilled into a drill hole, the conical block nut and the deep hole wall of the drill hole form a self-locking structure, the anchor rod body can be pushed axially, the claw-shaped elastic anti-expansion outer bushing is moved to the end of the anchor rod body, the elastic magnetization slotting steel pipe is released, claw teeth are retracted, the concave spring is compressed axially, the elastic magnetization slotting steel pipe is expanded, a wedge block is fitted, the outer wall of the steel pipe and the wall of the drill hole are extruded tightly, and the opposite-abutting thickening nut fastening mechanism compresses the arch tray to exert pretightening force on the anchor rod. On one hand, the anchor rod can stabilize a rock layer by enabling surrounding rock to be in the three-way stress state; on the other hand, the effective action time of the pretightening force of the anchor rod on the surrounding rock can be prolonged, the durability of the anchor rod can be improved, and the supporting efficiency can be improved.

Owner:ANHUI UNIV OF SCI & TECH

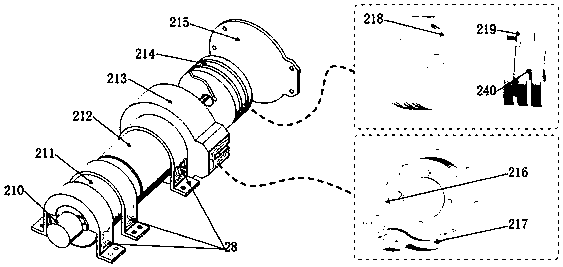

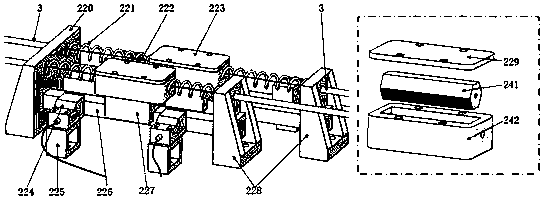

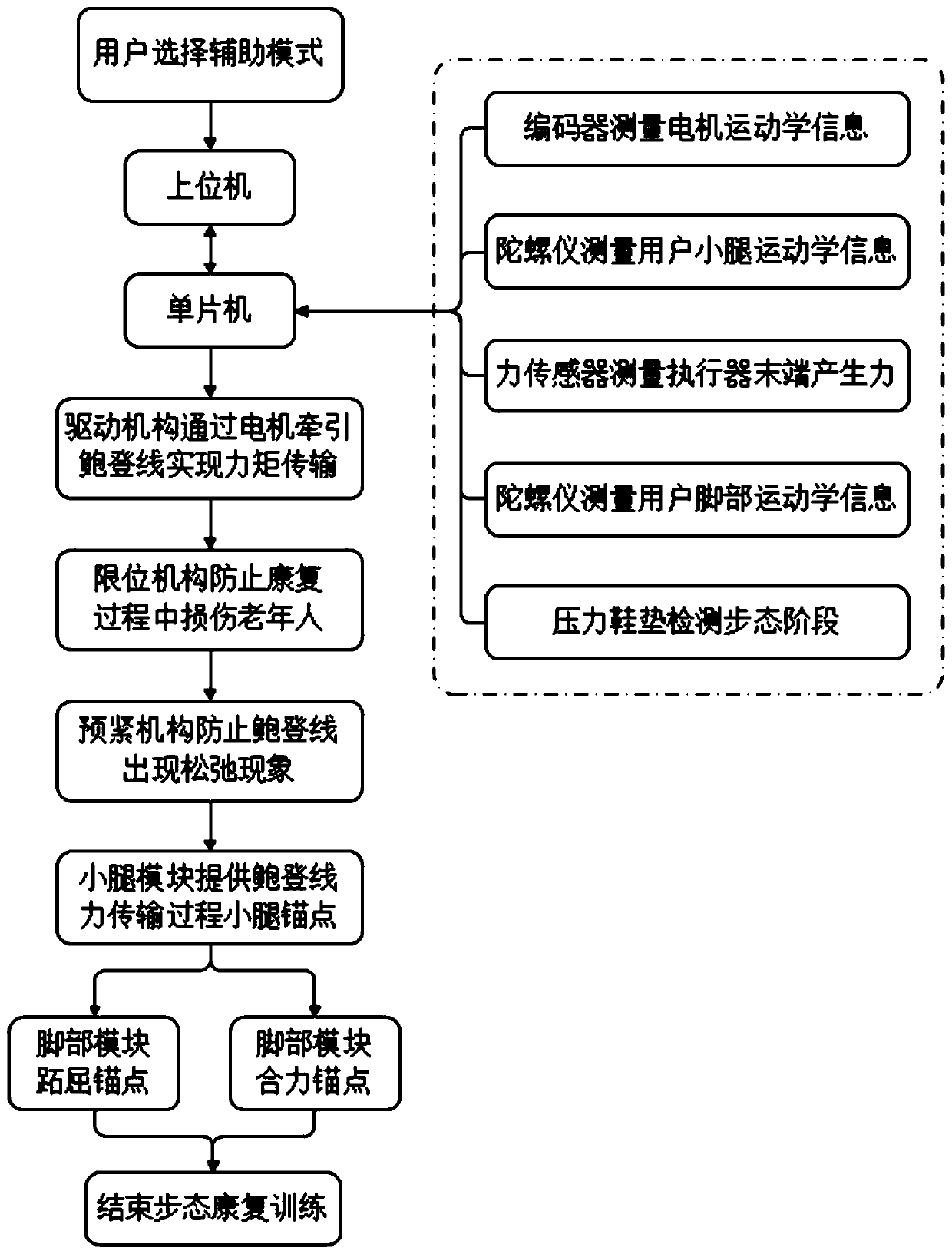

Flexible ankle rehabilitation robot system

ActiveCN110575350AGuaranteed uptimeAvoid injury hazardProgramme-controlled manipulatorDiagnosticsRobotic systemsGyroscope

The invention discloses a flexible ankle rehabilitation robot system. An execution module is connected with a foot module through a Bowden cable and a shank module, and a tension module for measuringtransmission force of the Bowden cable is arranged between the shank module and the foot module; a shank gyroscope is arranged on the shank module, a foot gyroscope and a pressure insole are arrangedon the foot module, a heel pressure sensor and a foot sole pressure sensor are arranged on the pressure insole, and the shank gyroscope and the foot gyroscope are arranged on the front face and the foot face of the shank of a user correspondingly; the pressure insole is located inside the foot module, sends a control instruction towards the execution module through an upper computer and receives sensing feedback information; the execution module transmits torque through the Bowden cable and the shank module to the foot module, so that ankle movement is assisted; and the shank gyroscope and thefoot gyroscope are mutually matched for detecting ankle motion information. The flexible ankle rehabilitation robot system is low in weight and achieves the gait training function for users with abnormal gaits of foot drop and strephenopodia.

Owner:深圳睿瀚医疗科技有限公司

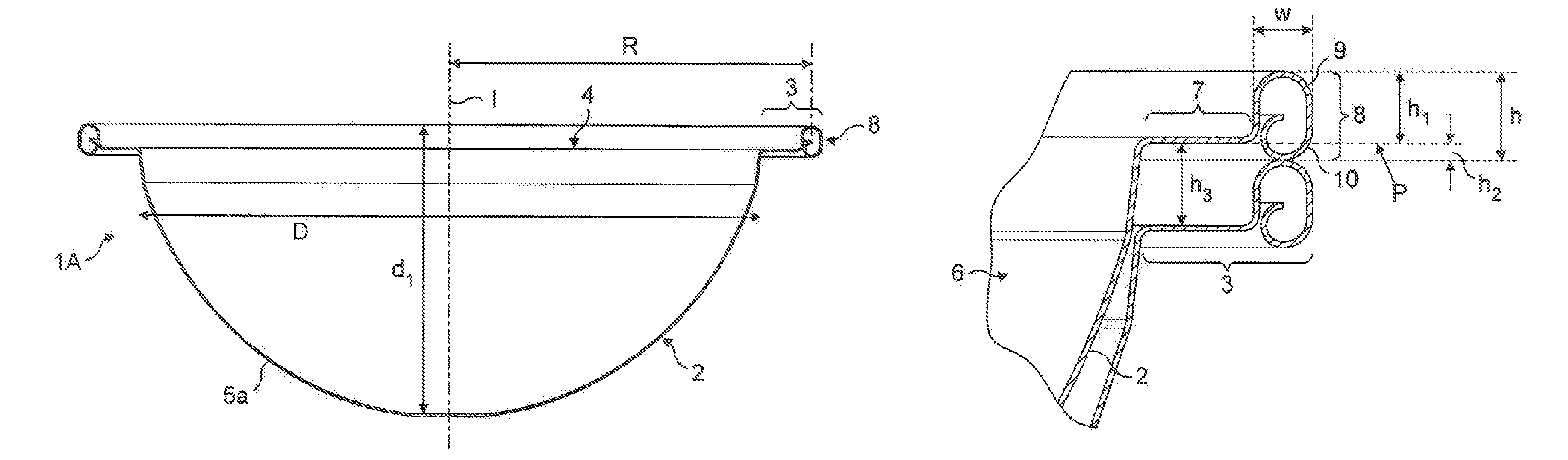

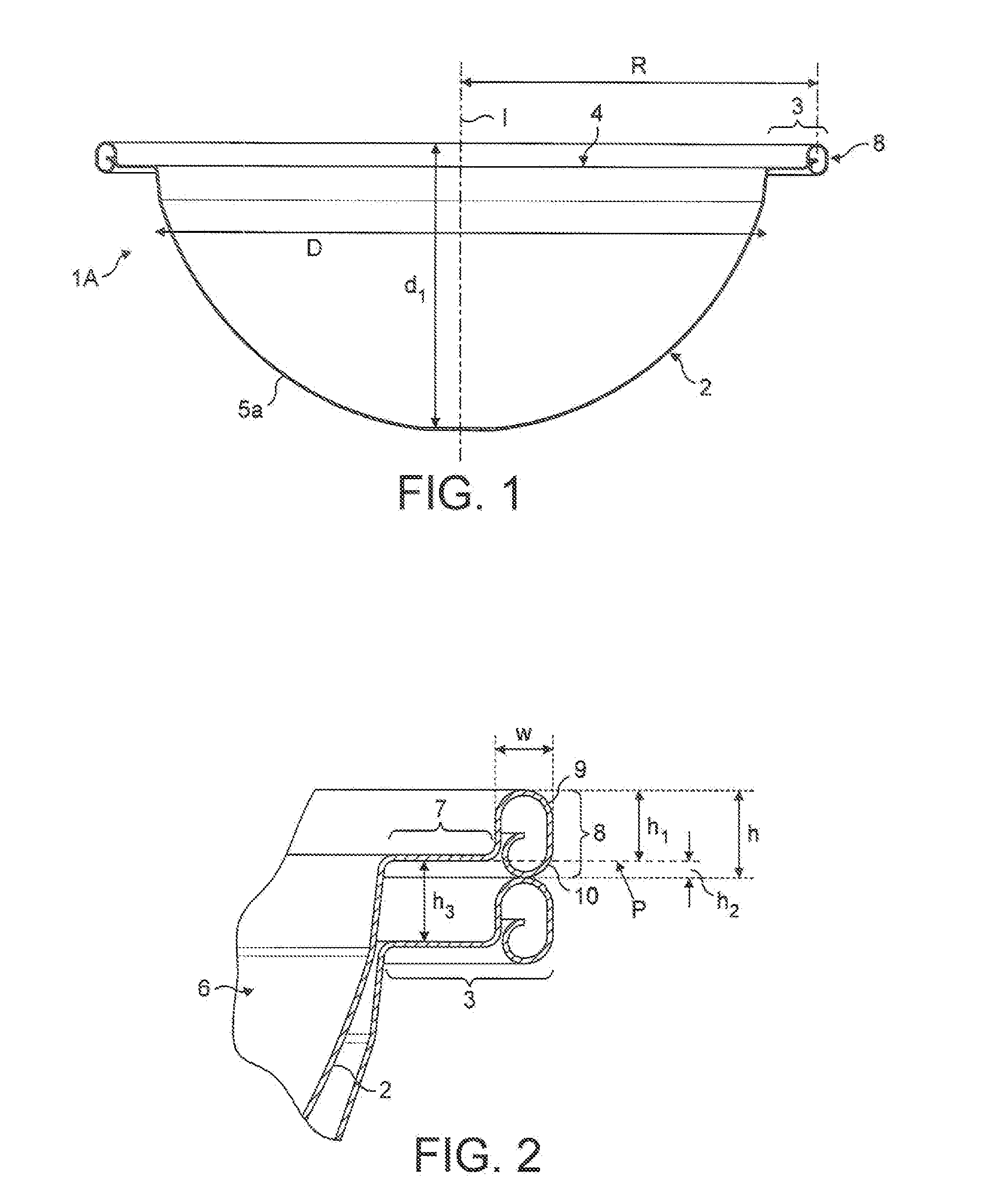

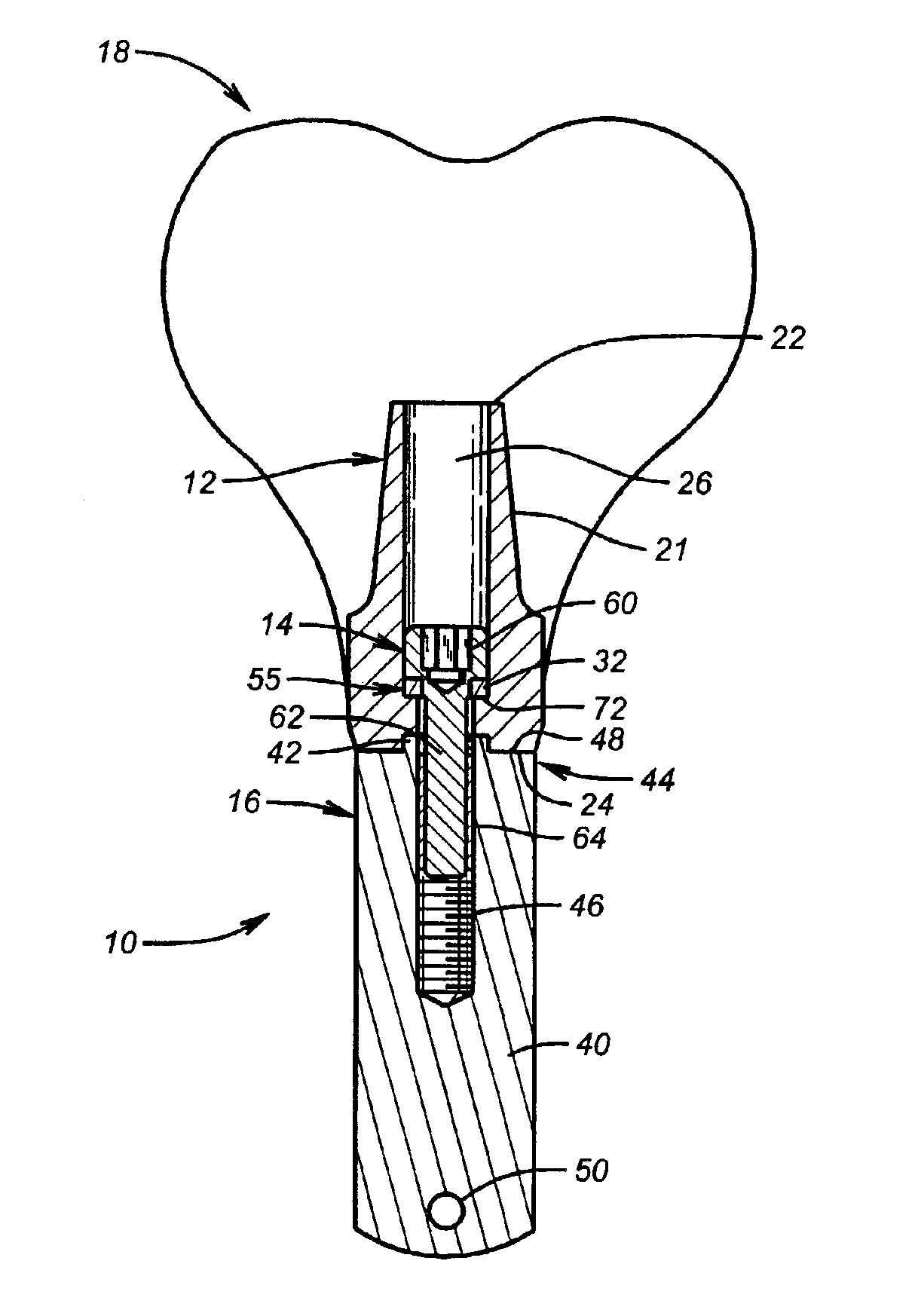

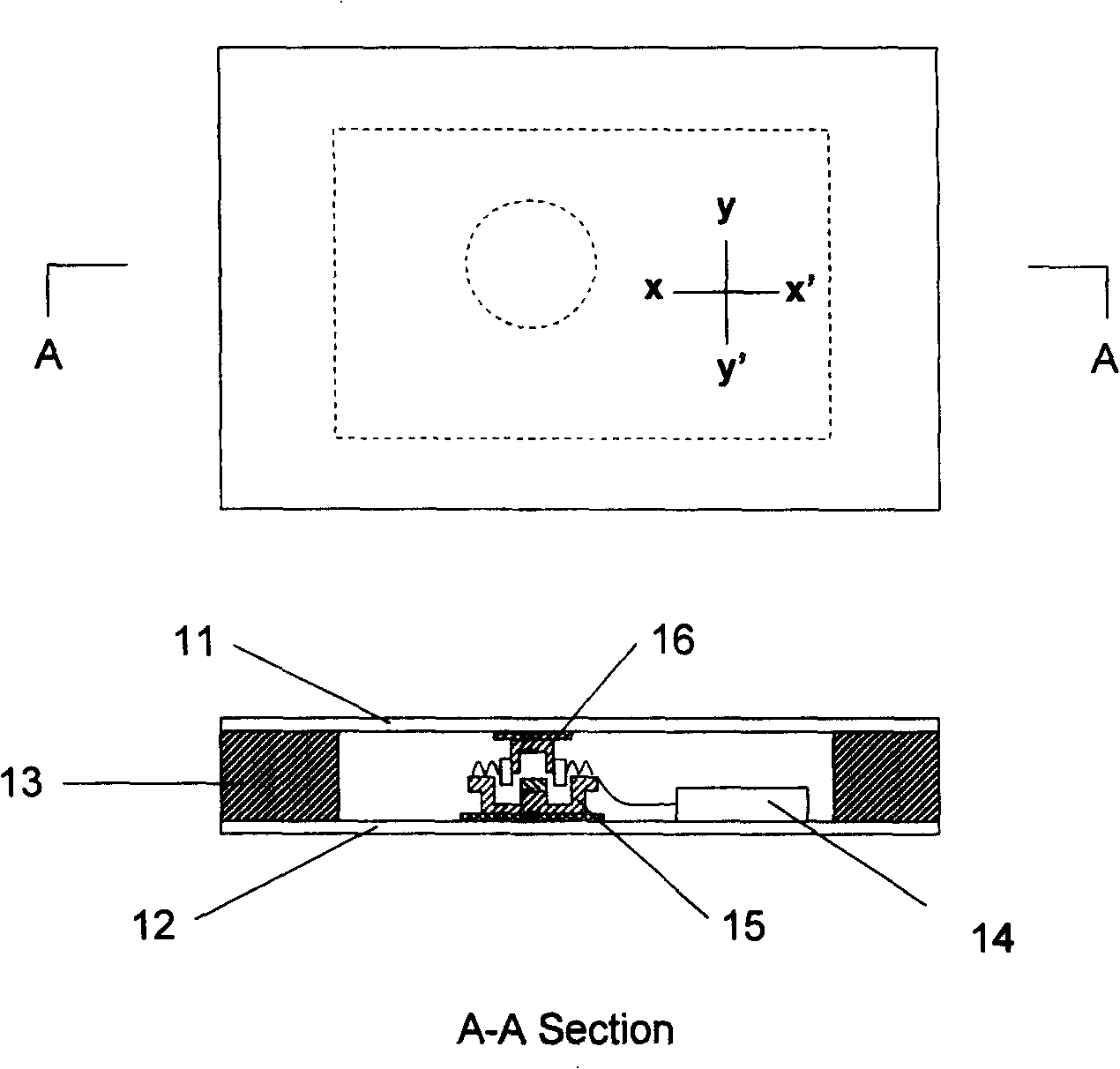

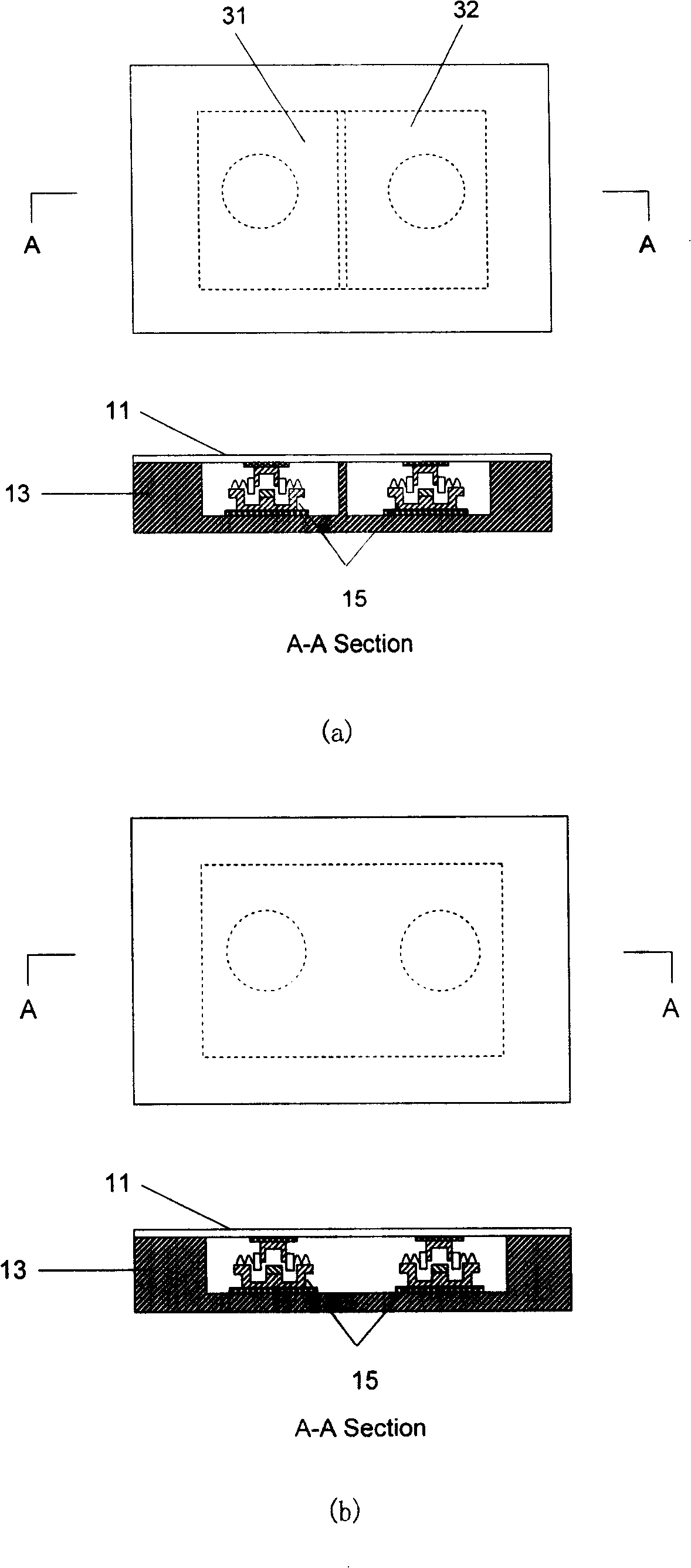

A plane speaker

InactiveCN101262713AMeet the requirements of wide frequency response rangeIncrease preloadTransducer diaphragmsSound energyIntermediate frequency

The invention relates to a speaker, in particular to a flat panel speaker which ensures electric energy is converted to sound energy. The flat panel speaker comprises a diaphragm, a frame and a driver system; the diaphragm is characterized by the flexibility and is stretched by a pretightening force along at least one direction, and then is fixed on the frame and coupled with a drive system, and vibrates to sound after being excited by the drive system. The drive system at least comprises a power amplifier and an executor. The executor can directly connected to the back surface of the diaphragm to excite the diaphragm to sound, and the change of fluid pressures in a cavity at the back of the diaphragm can also be controlled to indirectly excite the diaphragm to vibrate and sound. Output sound pressure and frequency response of the speaker can be modulated by changing the pretightening force and peripheral constraint of the diaphragm; the pretightening force of the diaphragm is improved to enhance the intermediate frequency and high frequency responses of the speaker, reduce the peripheral constraint of the diaphragm and enhance the low frequency response of the speaker.

Owner:谭红

Spinning device and spinning nozzle assembly used for the spinning device

The present invention relates to a spinning device used for melting a plurality of single filaments.filaments. The spinning device is provided with a nozzle bracket and a detachable spinning nozzle assembly. The spinning nozzle assembly is held to a fusant connector of the nozzle bracket through at least one fusant inlet. For fixing the spinning nozzle assembly, a holding ring which surrounds the fusant connector is provided. The holding ring is connected with the nozzle bracket and is movably held in the axial direction relatively to the fusant connector through the spring component. Hereon, the spinning nozzle assembly and the holding ring are connected so that the fusant inlet is held to the fusant connector under the pre-tightening function caused by the spring component. For realizing enough pre-tightening force, the holding ring has screw thread at a free end, wherein the screw thread cooperates with a corresponding screw thread on the spinning nozzle assembly.

Owner:OERLIKON TEXTILE GMBH & CO KG

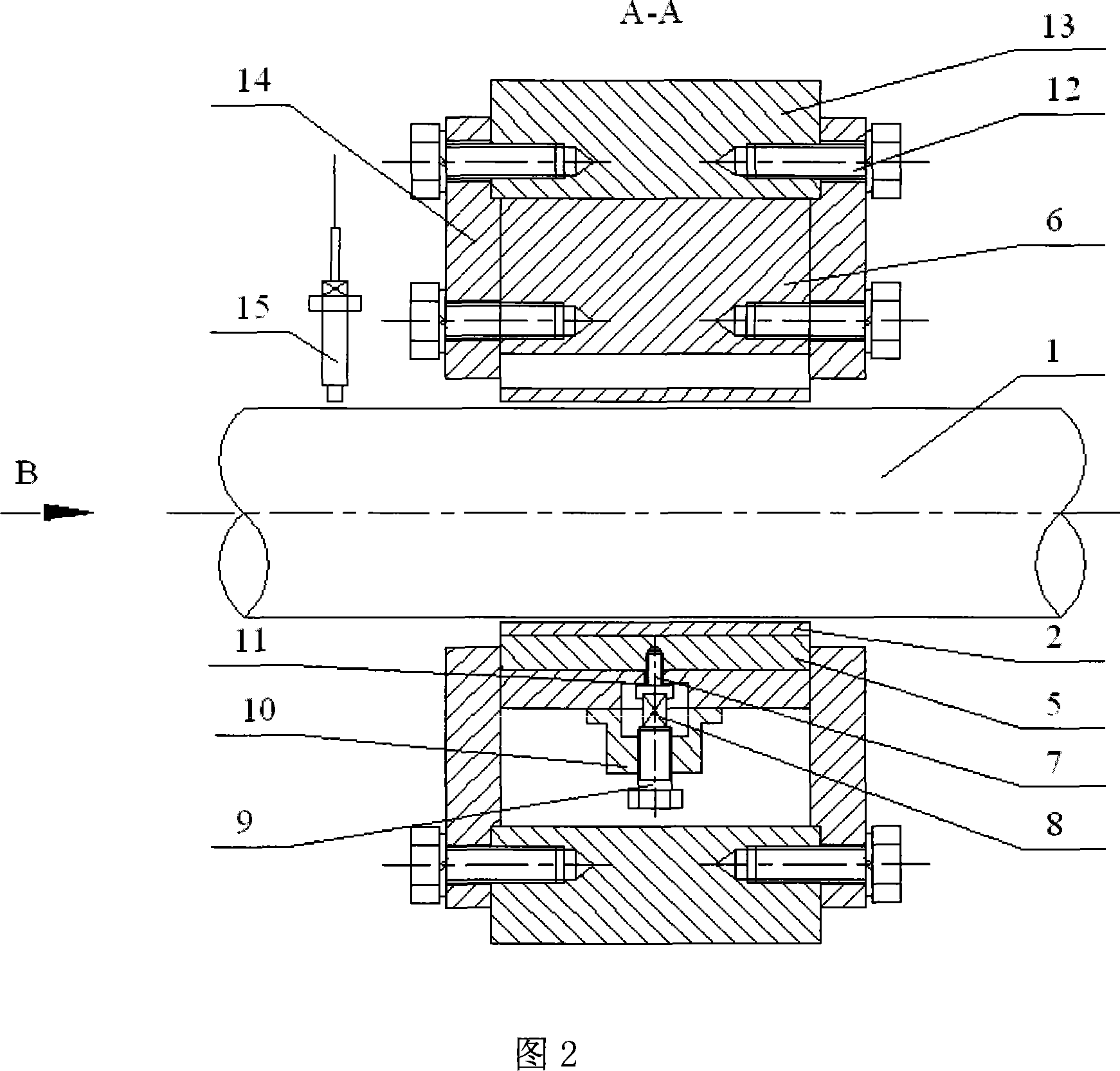

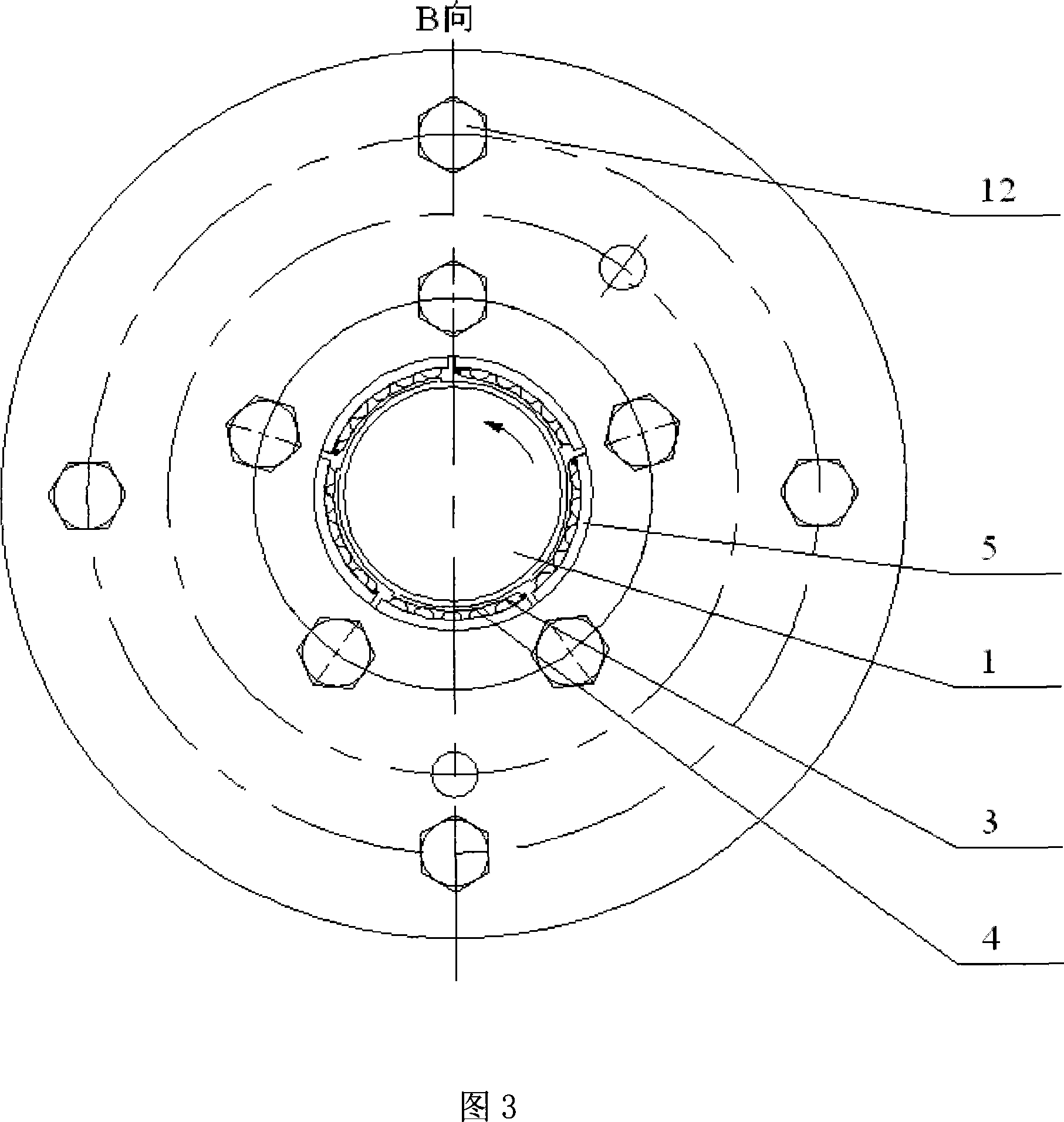

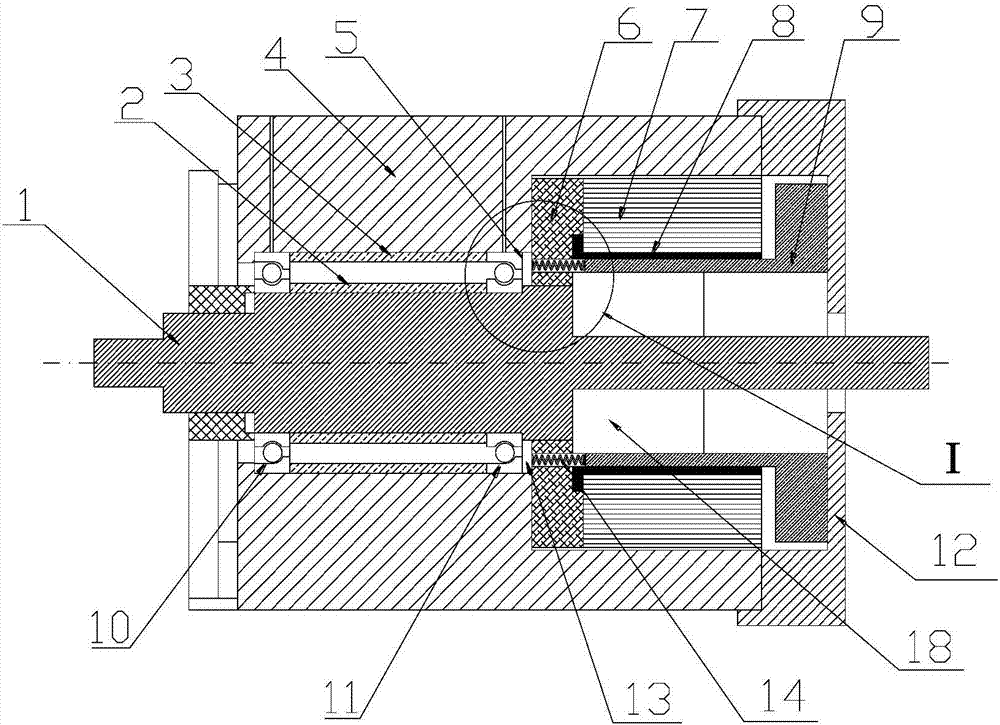

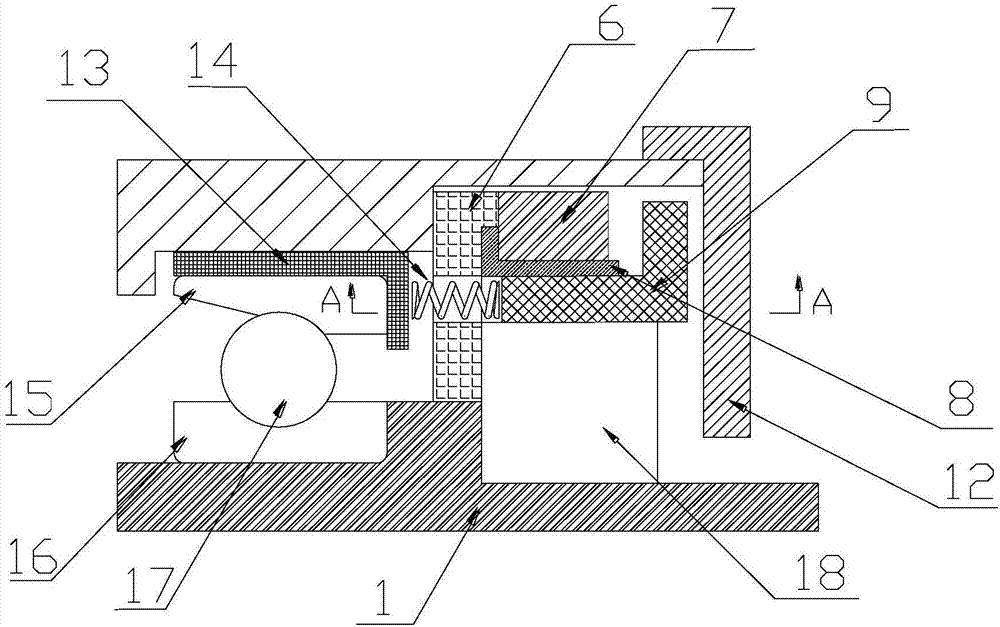

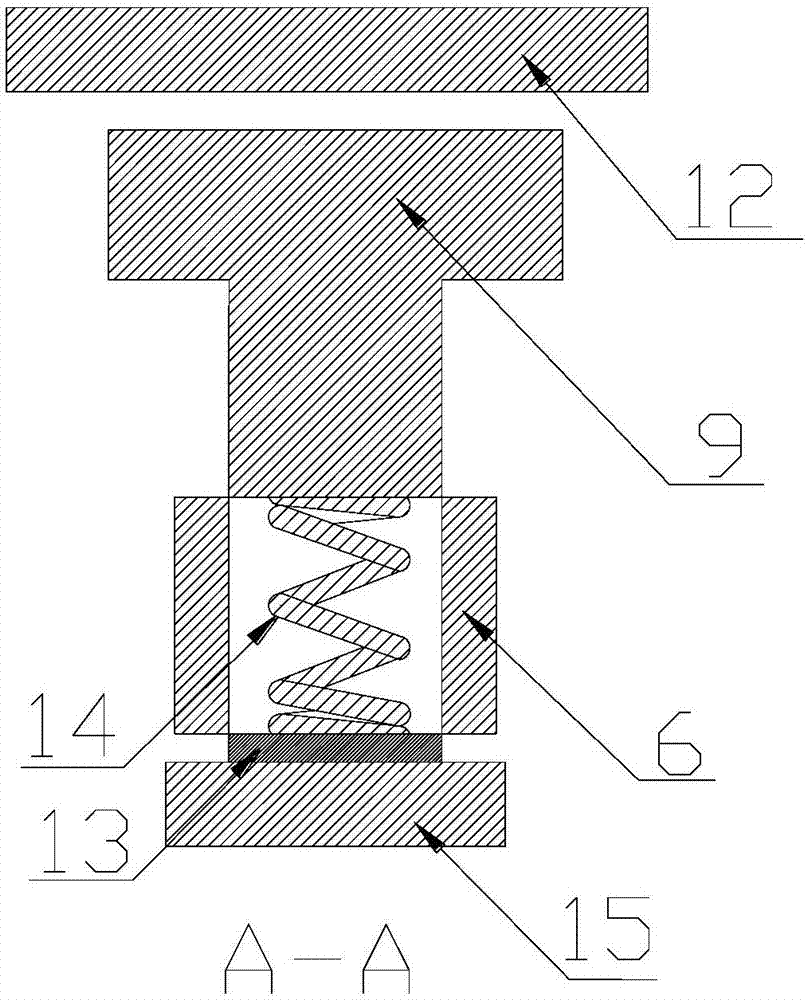

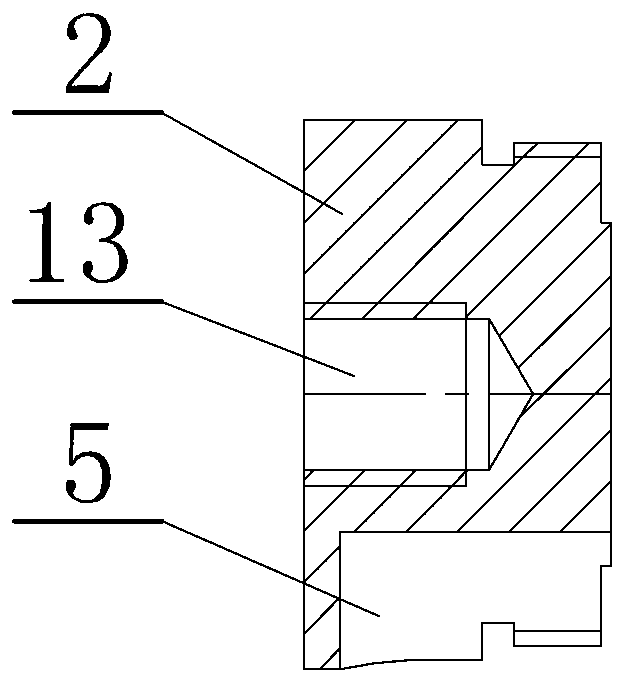

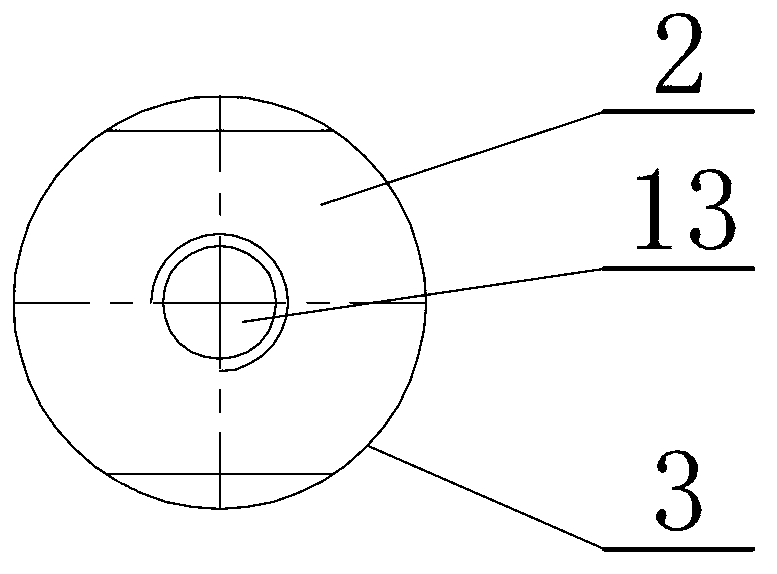

Dynamic adjusting device and method for pre-tensioning force of main shaft bearing of machine tool

PendingCN107262745ADynamically adjustable preloadIncrease preloadGeometric CADLarge fixed membersEngineeringMachine tool

The invention provides a dynamic adjusting device and method for pre-tensioning force of a main shaft bearing of a machine tool. The device comprises a force sensor, a fixed part, an electromagnet, an embedding sleeve, a moving part, an end cover, a spacer, a constant-pressure pre-tensioning spring and a supporting block, wherein the fixed part and the supporting block are connected with the main shaft; the electromagnet is fixedly connected with the embedding sleeve to form a combined body; the embedding sleeve sleeves a main shaft in an embedding manner and is connected with the fixed part; the spacer is mounted on an outer circle of a rear bearing; the moving part is inserted between the supporting block and the embedding sleeve, and two surfaces of the moving part are correspondingly in contact with the supporting block and the embedding sleeve; the constant-pressure pre-tensioning spring passes through a through hole of the fixed part; one end of the constant-pressure pre-tensioning spring is in contact with the spacer, and the other end of the constant-pressure pre-tensioning spring is in contact with the moving part; the end cover is connected with the housing; the force sensor is mounted on the outer circle of the rear bearing and is in contact with the spacer. According to the method, the electromagnetism can be changed by simply controlling the electrifying current of an electromagnet coil, and thus the pre-tensioning force of the bearing can be dynamically adjusted.

Owner:HEBEI UNIV OF TECH

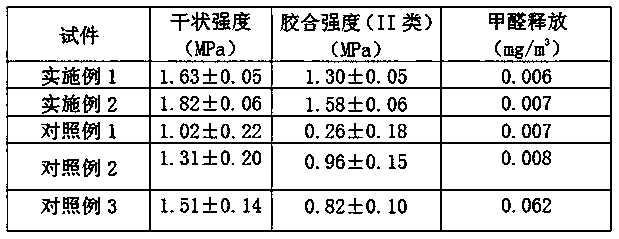

Urea-formaldehyde resin additive, preparing method and application thereof

InactiveCN101585926AIncrease preloadImprove stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesAmmonium compoundsReversible reaction

The present invention an urea-formaldehyde resin additive, a preparing method and an application thereof. The urea-formaldehyde resin additive comprises the following components: ammonium salt, polyhydroxy compound, pH buffering agent and filling agent. The urea-formaldehyde resin additive of the invention contains ammonium compound which reacts with the formaldehyde and generates urotropine. The reaction is reversible reaction and facilitates controlling the speed of polycondensation reaction so that the polycondensation reaction is executed uniformly for obtaining the urea-formaldehyde resin with homogeneous molecular weight distribution and the increase of the stability of the urea-formaldehyde resin is facilitated. The contained pH buffering agent increases the buffer capacity of the urea-formaldehyde resin and facilitates prolonging the pot life of the urea-formaldehyde resin. In the preparing process of urea-formaldehyde resin, the adding of the urea-formaldehyde resin additive can remarkably increase the prepressing performance of the adhesive and shorten the prepressing time. The prepared urea-formaldehyde resin adhesive has the advantages of high stability, greatly prolonged pot life, capacity for totally satisfying the production requirement of the veneer board and effectively increased production efficiency.

Owner:EVERFIRST WISEFUND TECH BEIJING

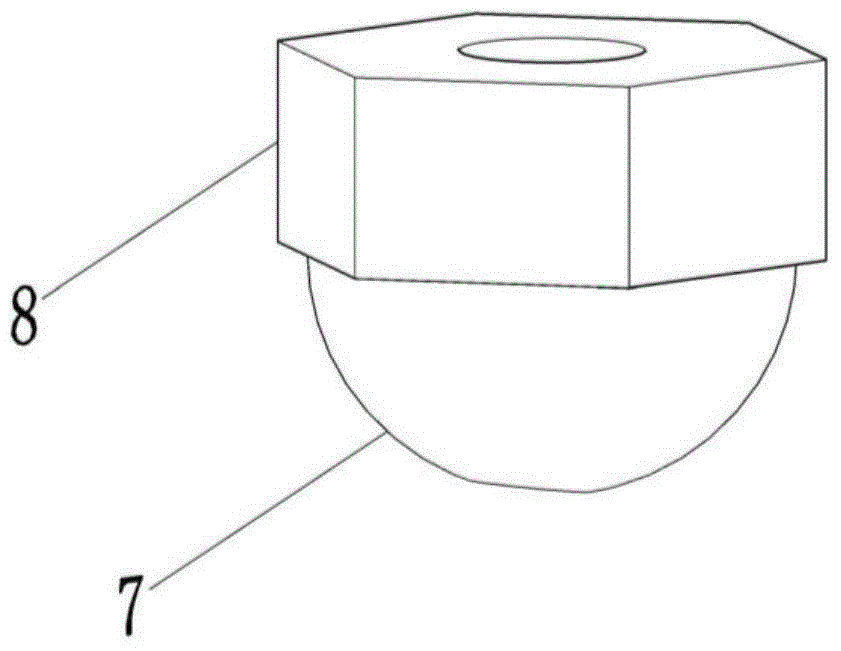

Self-adaptive feet-lock bolt integrated device and application method thereof

The invention provides a self-adaptive feet-lock bolt integrated device applied to the tunnel stepwise excavation process and an application method thereof so that effective control of broke and weak surrounding rock tunnel large deformation is realized. A large-area arch springing bearing plate is arranged at the steel arch springing part so that arch springing bearing area is enlarged and arch springing bearing force is increased; integral settlement of the tunnel is measured by an arch springing bearing plate slide surface scale; feet-lock bolts are self-adaptive to different angles of installation via elastic ball nuts; meanwhile, the size of the applied pre-stress can be reflected by the amount of compression of the elastic rubber ball nuts, and impact energy is absorbed simultaneously so that preliminary supporting of the tunnel is enabled to be more systematical and safer, and preliminary supporting time is shortened by the prefabricated form.

Owner:SHANDONG UNIV

Sliding door arrangement for a motor vehicle

InactiveUS7422268B2Improve the level ofExcellent ease of useVehicle locksMan-operated mechanismMobile vehicleMotor vehicle part

Owner:BROSE SCHLIESSSYSTEME GMBH & CO KG

Tough aldehyde-free soybean meal-based wood adhesive and preparation method thereof

ActiveCN110272716AIncrease crosslink densityImprove water resistance bonding performanceProtein waste adhesivesMacromolecular adhesive additivesDispersed mediaAdhesive

The invention discloses a tough aldehyde-free soybean meal-based wood adhesive and a preparation method thereof. The adhesive comprises, by weight, 30-33 parts of a main agent, 70 parts of dispersed medium water, 3-6 parts of a reinforcing agent, 0.1-0.2 part of a viscosity regulator, 2-4 parts of a crosslinking agent and 0.3-0.6 part of a catalyst. The preparation method comprises the following steps of weighing each component according to the corresponding weight ratio first, adding the crosslinking agent into the dispersed medium water, adding the main agent and the reinforcing agent, and homogenizing and emulsifying the mixture for 20 minutes under the action of an emulsifying force of 0.5 MPa at the pressure of 30 MPa through a high-pressure homogenizer; then, adding the catalyst into the obtained mixture, triggering a reaction at 80 DEG C for 30 minutes, cooling a finished product to 30 DEG C, and then discharging the finished product. The adhesive is likely to form a crosslinking structure, high in crosslinking density and low in reaction temperature; the prepared adhesive is stable in performance, the weak interface layer is obviously reduced, the cost is lowered, the dry / wet strength is high, and the product quality is stably improved.

Owner:山东千森木业集团有限公司

Glow plug with combustion pressure detecting function

InactiveUS7185621B2High sensitivityIncrease preloadInternal-combustion engine testingIncandescent ignitionElectricityCombustion

A glow plug comprising: a cylindrical housing; a heater member as defined herein; a conductive center pole as defined herein; a first piezoelectric element as defined herein; and a second piezoelectric element as defined herein, wherein each of said first piezoelectric element and said second piezoelectric element is subjected to a preload for compressing it in said axial direction and is arranged such that, when said center pole is displaced to a root-end side, a load to be applied to one of said first piezoelectric element and said second piezoelectric element for compressing the same in said axial direction increases whereas a load to be applied to the other for compressing the same in said axial direction decreases.

Owner:NGK SPARK PLUG CO LTD

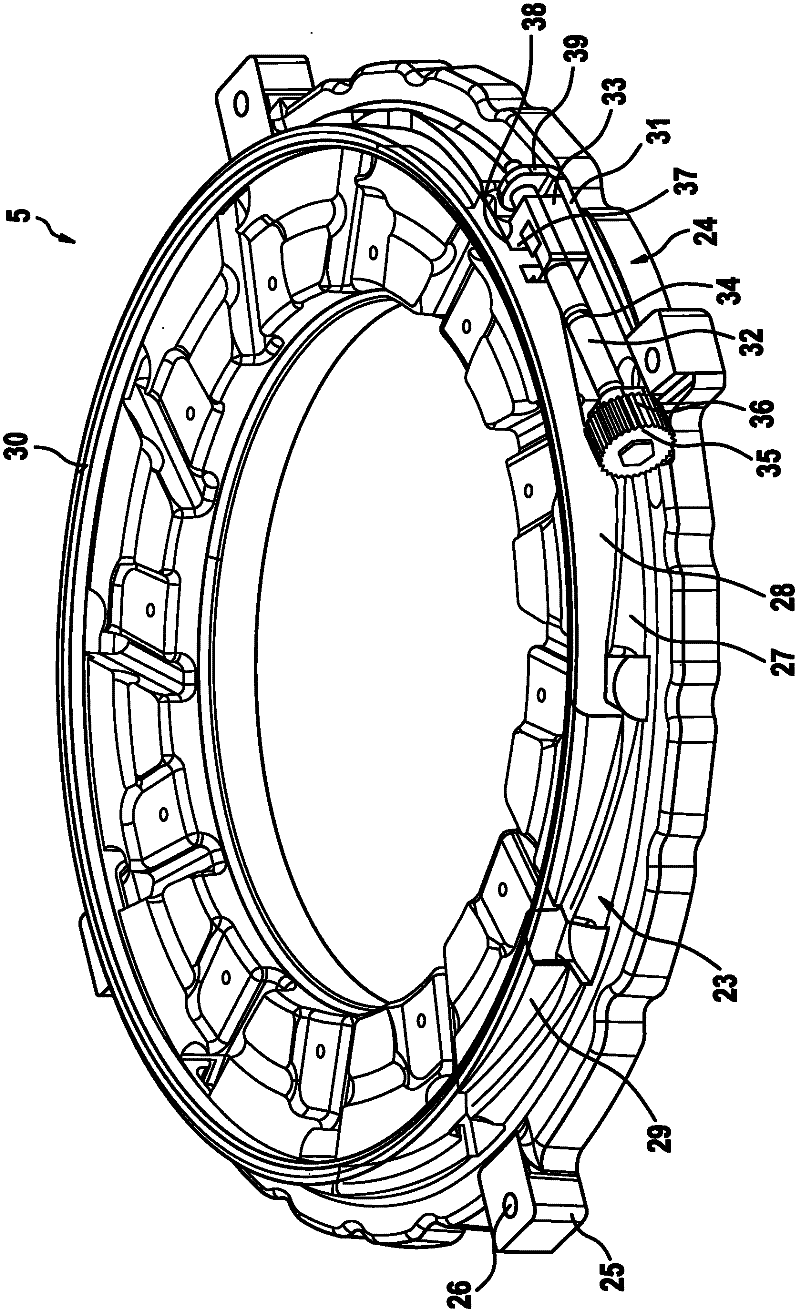

Friction clutch

Disclosed is a friction clutch which comprises a path-controlled adjusting device and in which wear of the friction linings is compensated by compensating a first distance created between a contact plate and a lever system by twisting a ramp system located between the contact plate and the lever system by means of a spindle having a pinion, said first distance being compensated when it is determined that a second predefined distance between a pressure plate and the clutch housing exceeds a predefined value while the lever system applies the maximum force to the pressure plate. The ramp system is twisted while the lever system relieves the pressure from the pressure plate, and the pressure plate is moved by means of the energy stores that are effective between the pressure plate and the clutch housing by having a pawl twist the pinion. In this process, the pawl slides along the pinion during a lifting movement and positively locks therewith when wear has been identified. In order to prevent the pinion from being twisted because of the friction generated between the pawl and the pinion, at least one catch is connected to the pinion.

Owner:SCHAEFFLER TECH AG & CO KG

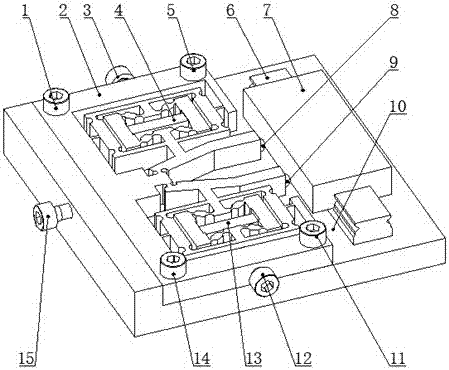

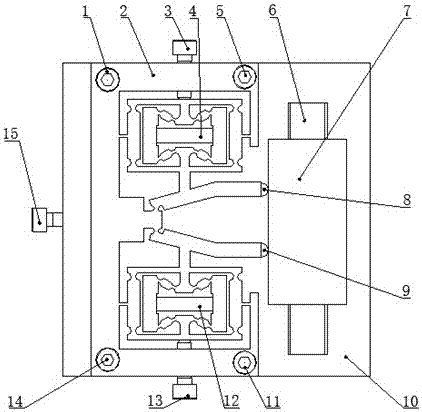

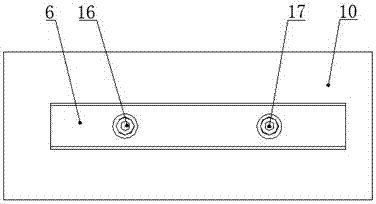

Piezoelectric precision linear driving platform based on stick-slip inertia

ActiveCN107104608ACompact structureSimple structurePiezoelectric/electrostriction/magnetostriction machinesEngineeringMovement control

The invention relates to a piezoelectric precision linear driving platform based on stick-slip inertia, and relates to the precision driving field. The driving platform comprises a driving unit, a motion unit and a pre-tightening unit; the driving unit consists of a piezoelectric stack A, a piezoelectric stack B, a flexible hinge assembly, a replaceable driving contactor A and a replaceable driving contactor B, and is used for providing power source for the motion unit; the motion unit consists of a guide rail and a slide block, so as to provide a displacement output for the driving platform; and, the pre-tightening unit consists of a pre-tightening bolt A, a pre-tightening bolt B and a pre-tightening bolt C, so as to adjust the pre-tightening force between the driving unit and the motion unit. The driving platform is advantaged in compact structure, adjustable speed, big motion displacement, high location precision and strong reliability, and is suitable for the motion control place which has a strict space size requirement, and has a certain requirement to the motion displacement and the location precision.

Owner:JILIN UNIV

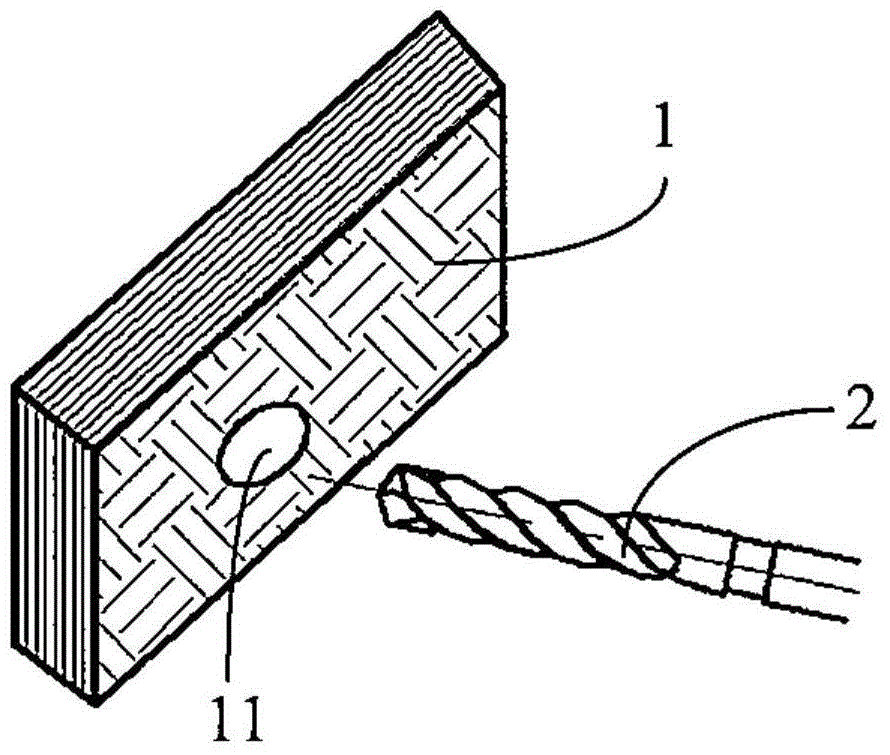

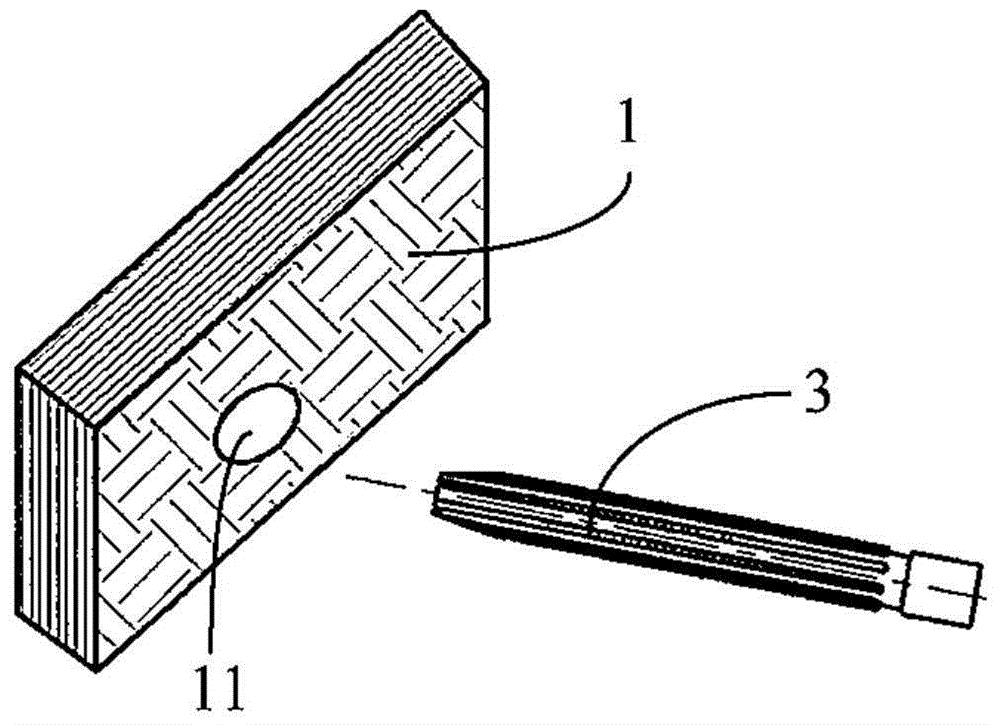

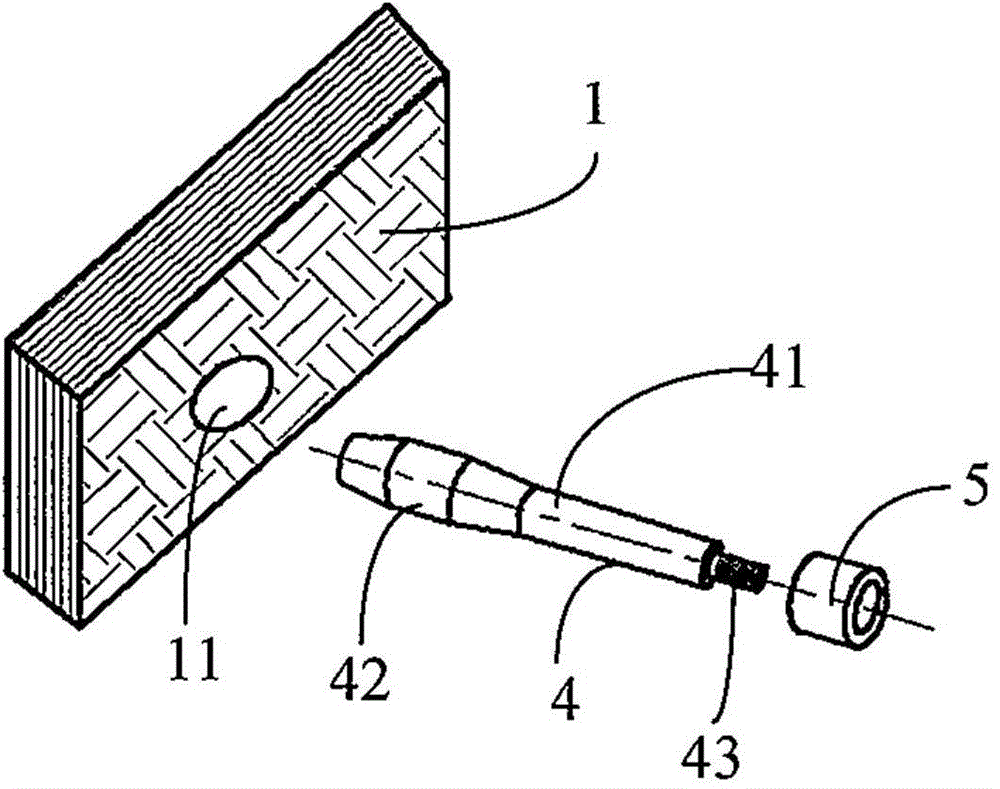

Cold extrusion strengthening method for assembling hole of CFRP composite material laminate

InactiveCN104626726AImprove fatigue lifeEasy maintenanceLamination ancillary operationsLaminationEngineeringAxial force

The invention provides a cold extrusion strengthening method for an assembling hole of a CFRP composite material laminate. The method comprises the following steps: (a) providing a bush, wherein the bush can be assembled in the assembling hole; (b) providing a metal core rod with the taper, and inserting the core rod into the bush; (c) arranging the bush in the assembling hole; (d) applying axial force to the core rod by virtue of extrusion equipment, so that the bush is extruded by the part, with the largest diameter, of the core rod; and (e) removing the core rod, so that the bush is fixedly arranged in the assembling hole. Aiming at the assembling hole of the CFRP composite material laminate, the bush is adopted and is matched with a cold extrusion strengthening process, so that the fatigue life of parts can be effectively prolonged, and the service time of an aircraft is prolonged. Because the bush is fastened in the assembling hole, the wear resistance of the connecting structure is improved, and the detachment of assembling fasteners and the maintenance of the parts can be promoted.

Owner:COMAC +1

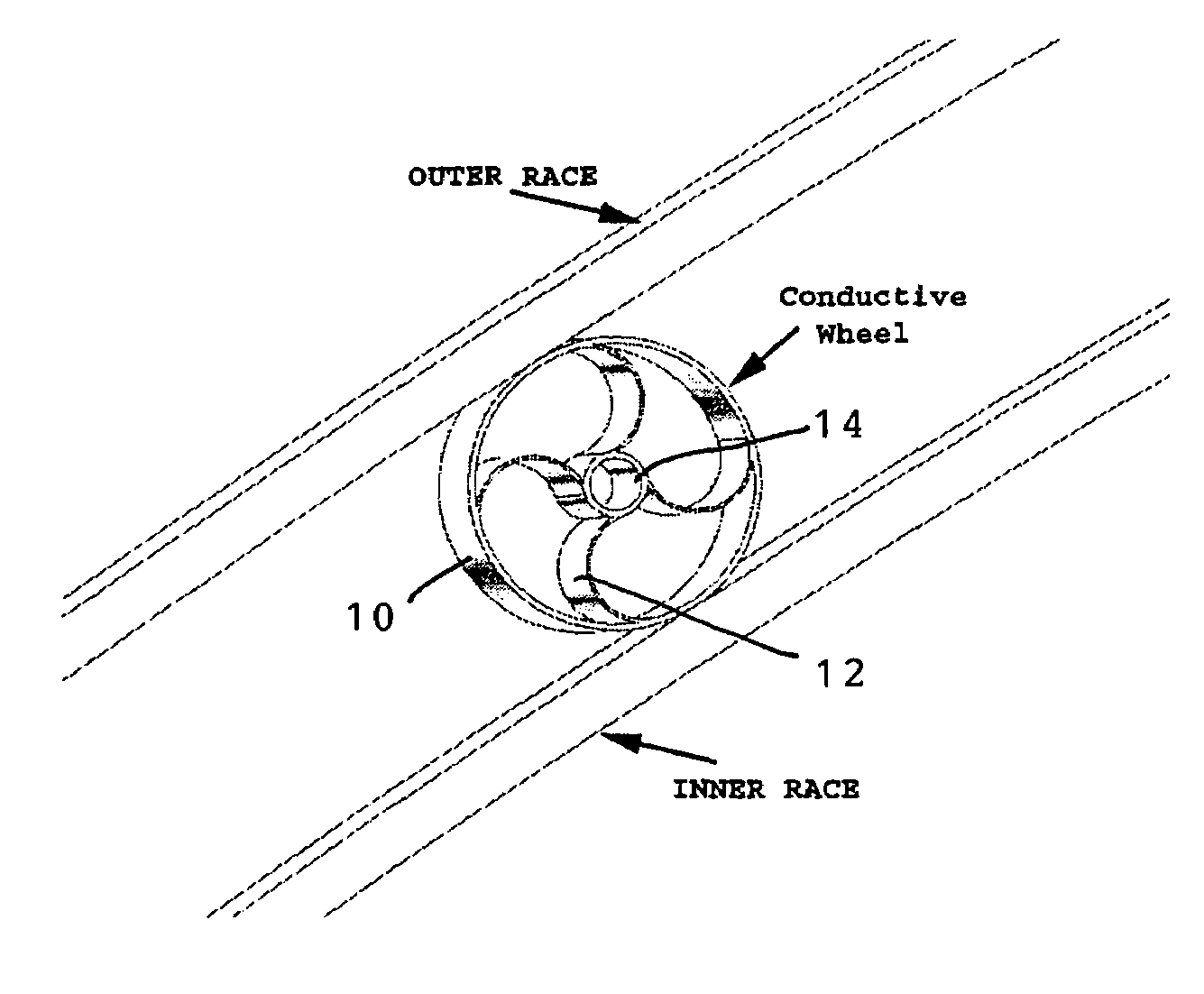

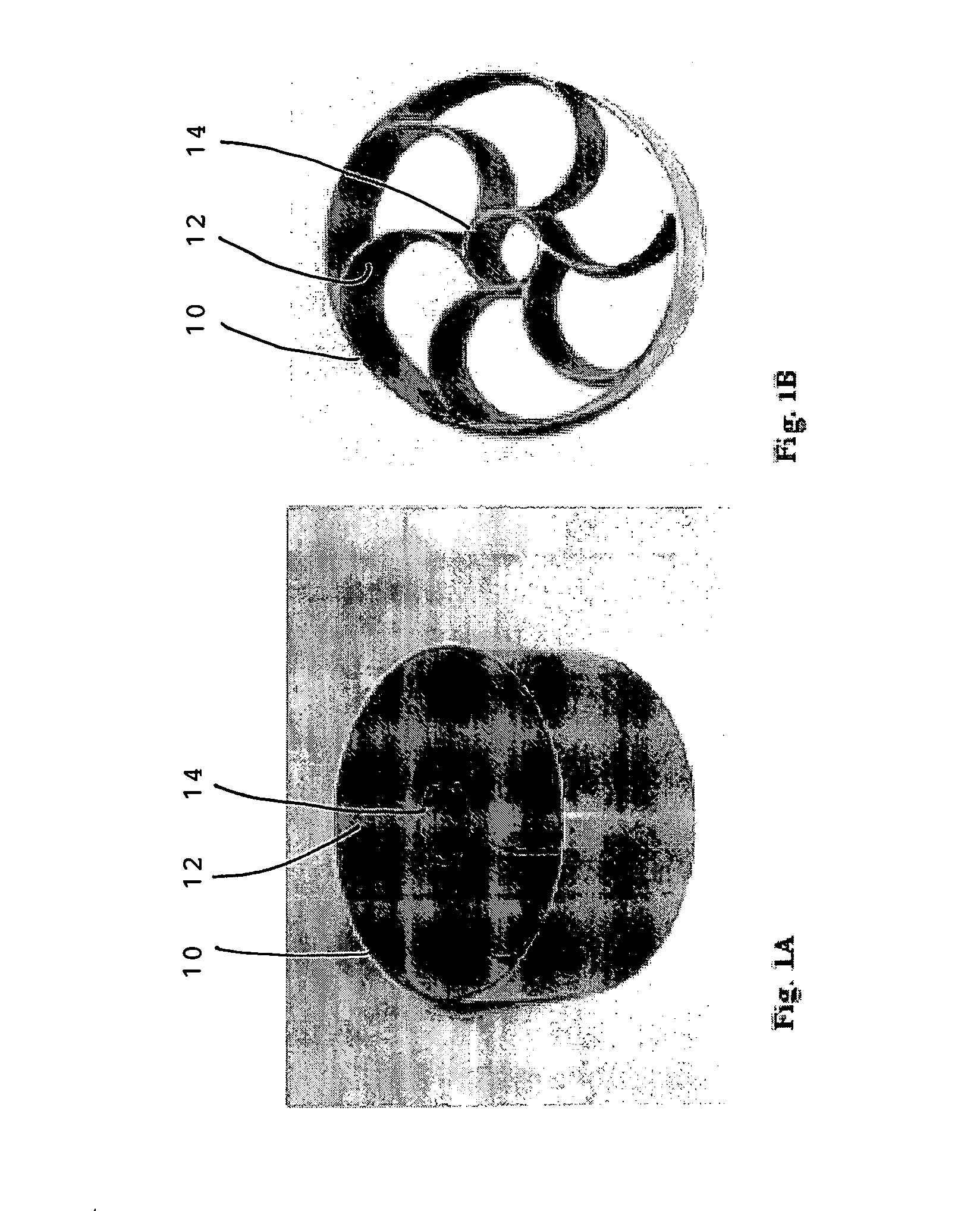

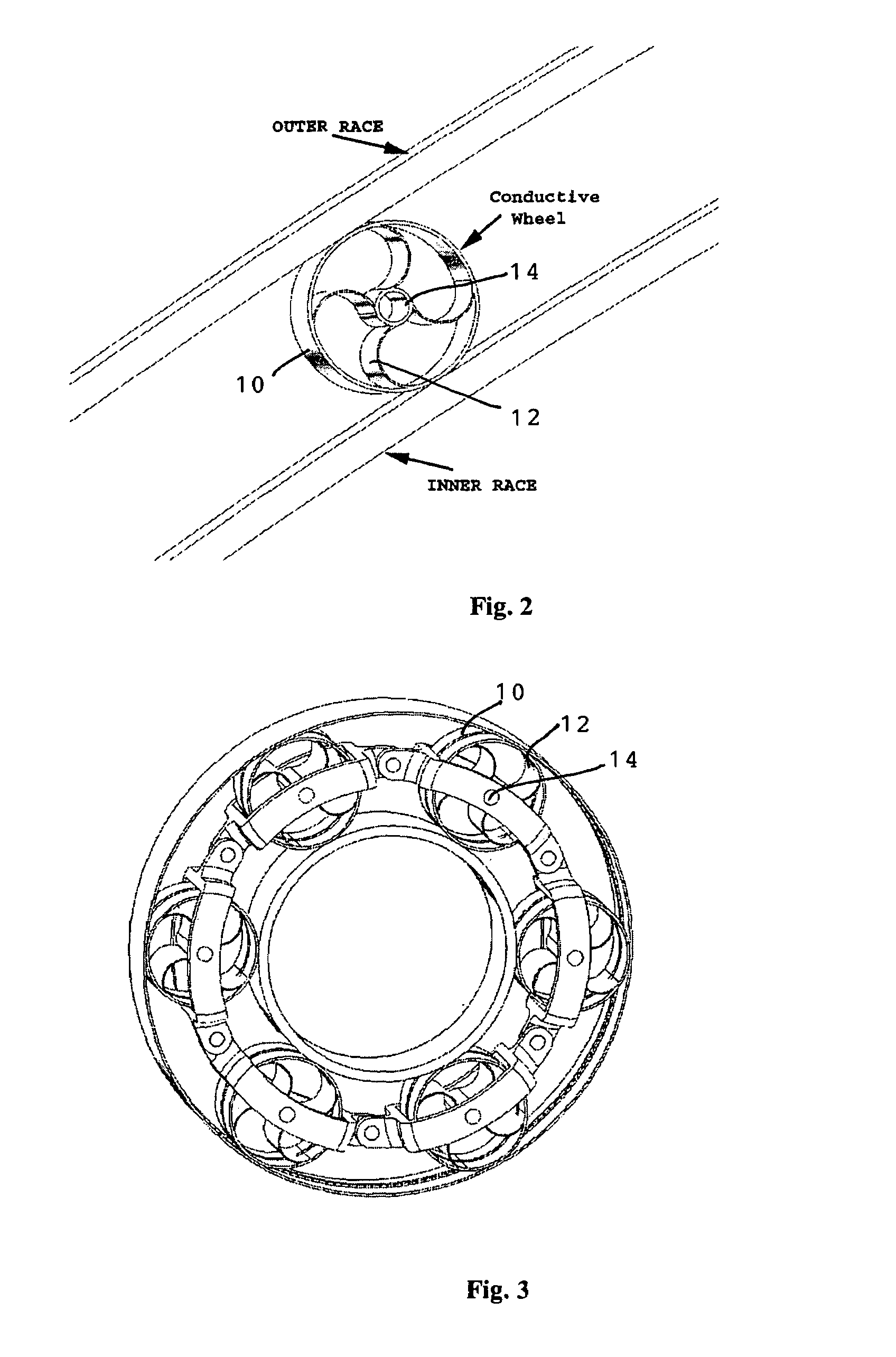

Roll-ring conductive wheel

InactiveUS7215045B1Little wearReduce areaBus-bar/wiring layoutsRotary current collectorConical formsEngineering

A roll-ring conductive wheel is used to conduct electricity between the inner and outer races of rotating or moving parts. The conductive wheel is a thin-walled metal cylinder with a plurality of spokes connecting the outer cylindrical wall to a central hub. The preferred spokes are arcuate and the wheel is made flexible so that it can be compressed to an elliptical shape between the inner and outer conductive races for good electrical contact and to absorb slight deflections or gap variations between the races. The conductive wheel can have other shapes depending on the configuration of moving parts, such as a truncated cone shape for conical or wedge-shaped races.

Owner:HONEYBEE ROBOTICS

MDF(Medium-density fiber)-E1-level urea-formaldehyde resin adhesive

ActiveCN102775946AImprove water resistanceReduce releaseAldehyde/ketone condensation polymer adhesivesFiberStrong acids

The invention provides an MDF (medium density fiber)-E1-level urea-formaldehyde resin adhesive. Formaldehyde and urea are used as main materials; and urea is added by three batches, and the molar ratio of formaldehyde to urea is controlled to be respectively (2.4-3.0) to 1, (1.3-1.5) to 1, and (0.8-1.0) to 1 after each batch of urea is added. The glue preparation process adopts a weak base-medium strong acid-weak base reaction path, and the materials are reacted in three mediums of which the pH is 8.0-8.5, 2.5-3.5 and 8.0-8.5, respectively to finally prepare the MDF-E1-level urea-formaldehyde resin adhesive. By using the MDF-E1-level urea-formaldehyde resin adhesive to prepare an El-level medium-density fiber board, the effect of reducing the formaldehyde emission can be achieved without adding a formaldehyde catching agent or carrying out post ammonia water treatment.

Owner:广西高林林业股份有限公司

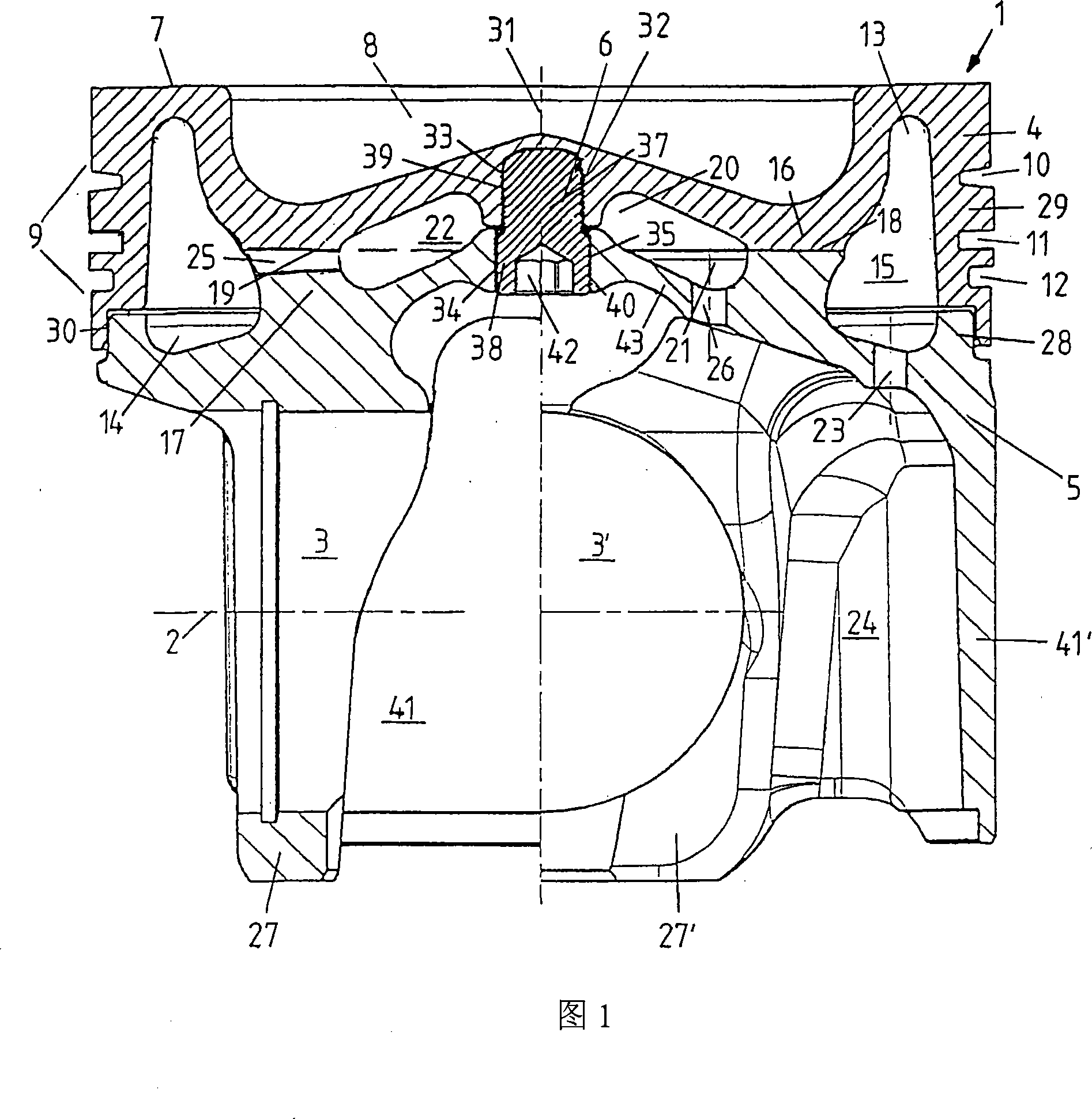

Assembled piston for an internal combustion engine

The invention relates to an assembled piston (1) for an internal combustion engine, said piston consisting of an upper part (4) and a lower part (5) that are interconnected by means of an internal hexagon screw (6) consisting of an upper half (37) and a lower half (38). The upper half (37) of the internal hexagon screw (6) comprises an external thread (39) which is parallel to the external thread (40) of the lower screw half (38) and has a larger lead angle than the same (40). The lead angle resulting from the difference between the lead angles of the two external threads is very small and contributes to a high strength of the screw connection.

Owner:MAHLE GMBH

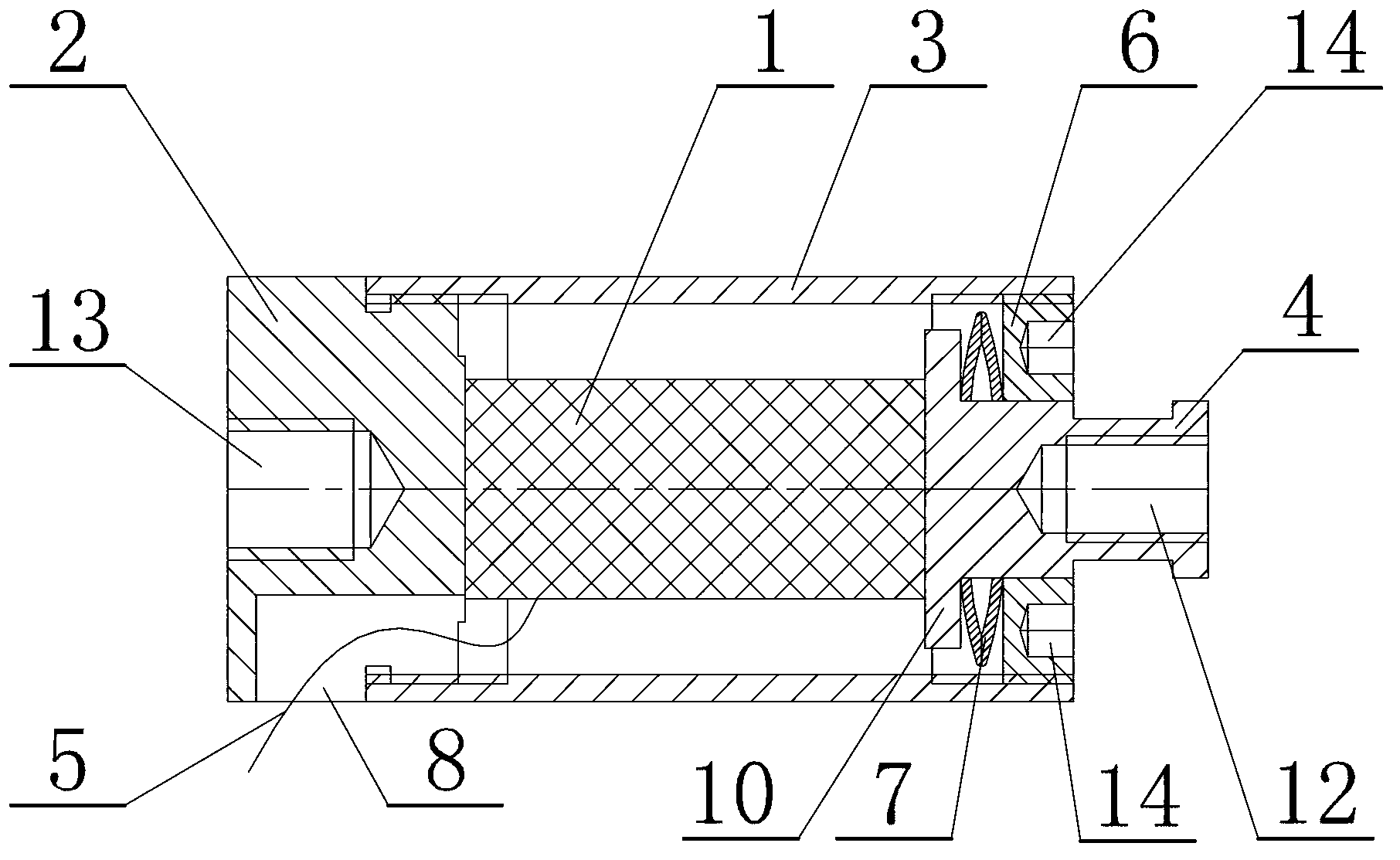

Device and manufacturing method for packing piezoelectric ceramic

ActiveCN102709463AReduce damageIncrease bearing capacity and preloadPiezoelectric/electrostrictive device manufacture/assemblyCeramicMoving parts

A device and a method for packing piezoelectric ceramics relates to a packing device and a manufacturing method. The invention aims to solve the problem that the structures of the piezoelectric ceramics are easy to destroy under the action of external force in the micronano movement process. The piezoelectric ceramics are mounted in an outer shell, and positioned between a base and a moving part; the base is in threaded connection with one end of the outer shell; the inner end surface of the base is fixedly connected with one ends of the piezoelectric ceramics; a base slotting hole is formed in the base; a power line is connected with the piezoelectric ceramics through the base slotting hole; a locknut is in threaded connection with the other end of the outer shell; an axial through hole is formed in the locknut; a shoulder is arranged at the inner end of the moving part; the moving part passes through the axial through hole in the locknut; the shoulder at the inner end of the moving part is close to the other ends of the piezoelectric ceramics; and a disc is arranged between the moving part and the locknut. The manufacturing method comprises the following steps: fixing, assembling, pretightening and solidifying. The piezoelectric ceramics are used in the micronano movement.

Owner:HARBIN CORE TOMORROW SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com