Electromagnetic-piezoelectric-mixed-driving-based three-degree-of-freedom spherical motor

A hybrid drive, degree of freedom technology, applied in electrical components, electromechanical devices, etc., can solve problems such as too small output torque, and achieve the effect of increasing output torque and increasing output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings.

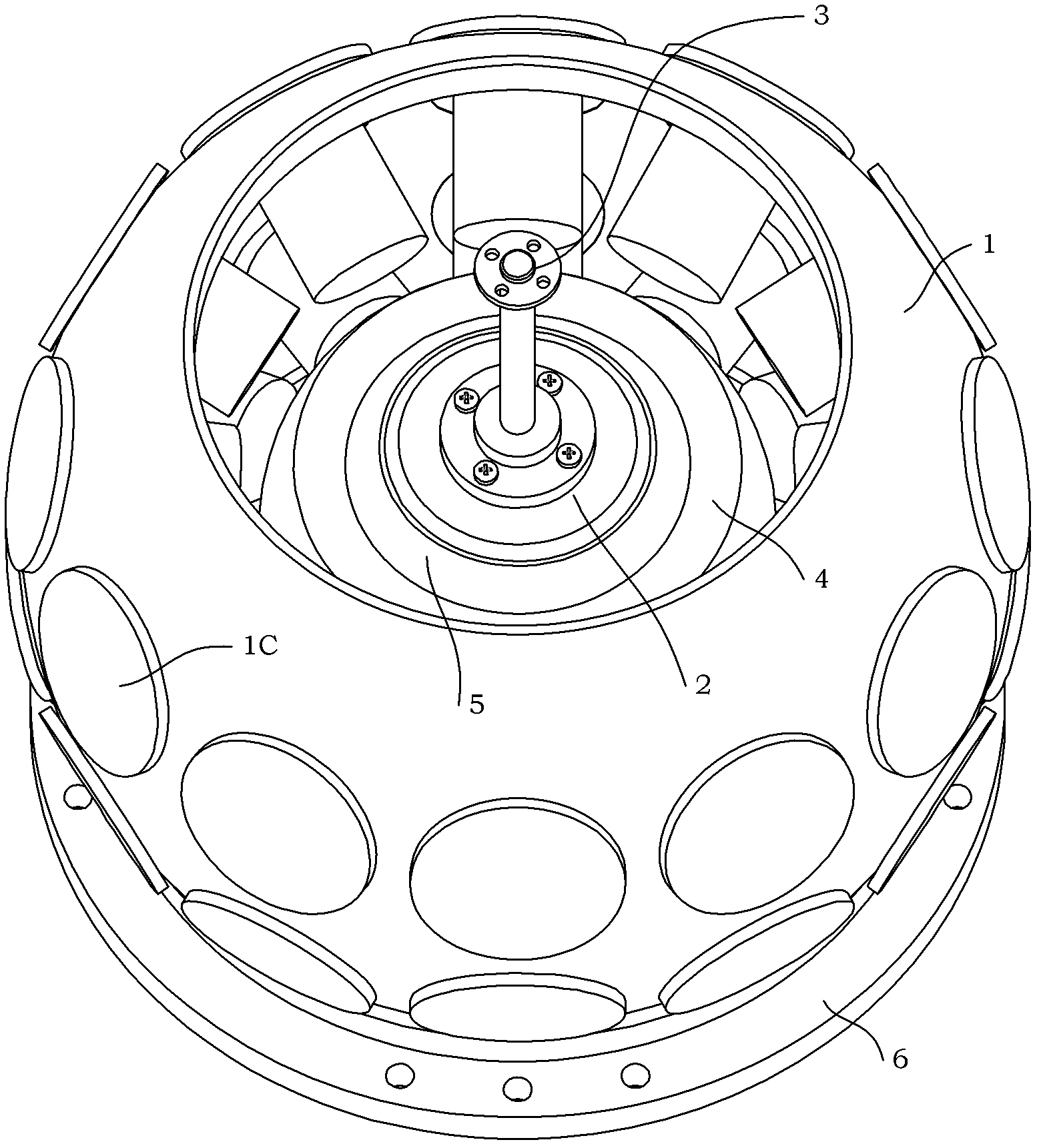

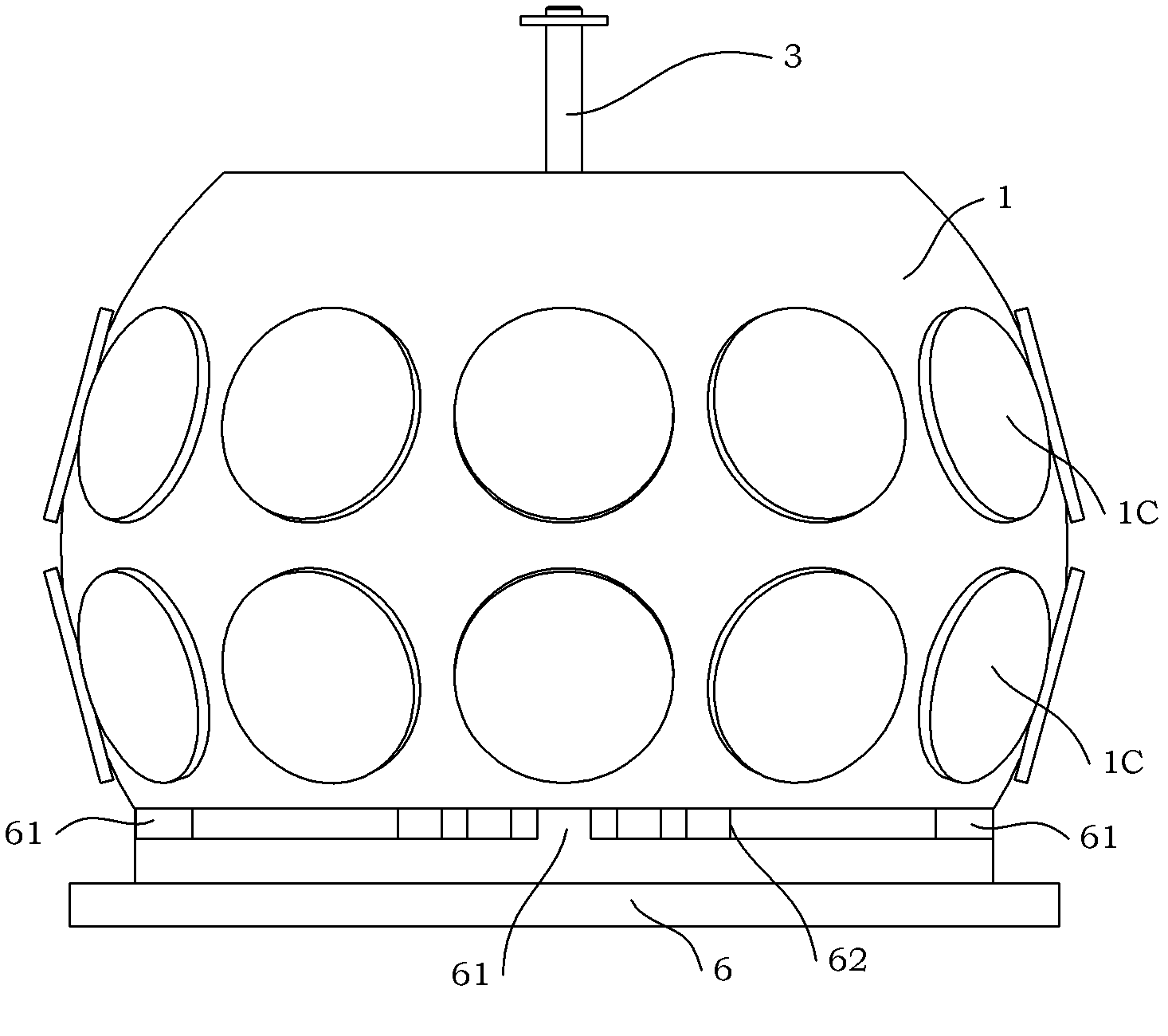

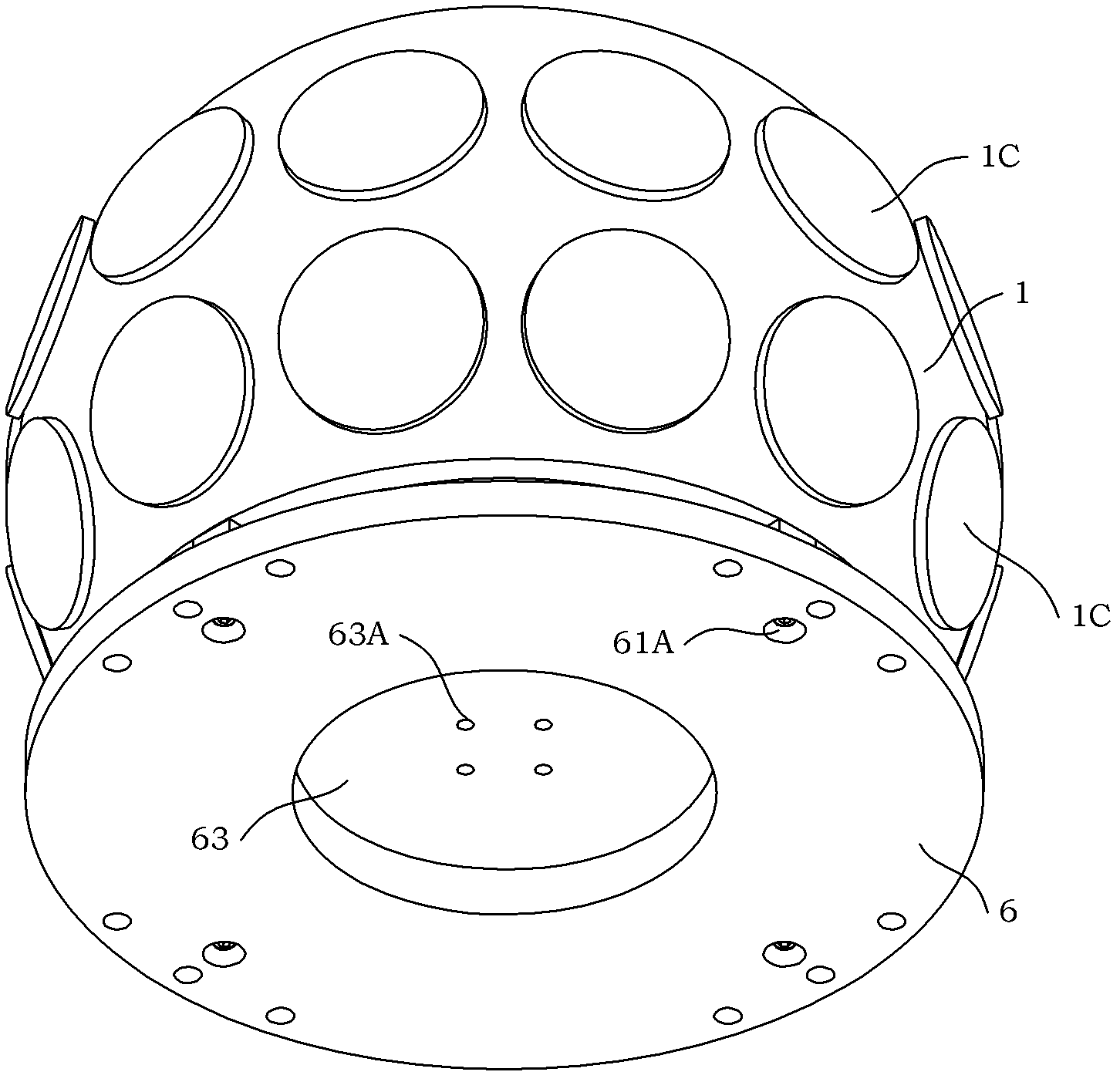

[0037] see figure 1As shown, a three-degree-of-freedom ball motor based on electromagnetic and piezoelectric hybrid drive of the present invention includes a first stator 1, a rotor 2, an output rod 3, a second stator 4, and a rotor protective film 5 , base 6, support cylinder (4 support cylinders), A piezoelectric ceramic driver 7, B piezoelectric ceramic driver 8, C piezoelectric ceramic driver 9, and 24 coils 1C installed on the first stator 1, and 8 magnetic poles 2A installed on the rotor 2;

[0038] The connecting disc 31 of the output rod 3 is installed on the rotor 2, the rotor 2 is coated with a rotor protective film 5, the outer surface of the rotor protective film 5 is the second stator 4, and the outer surface of the second stator 4 is the first stator 1; The second stator 1 is installed on the base 6 through a support cylinder, and the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com