Caron micron tube filling polymer oil-containing friction material for ultrasonic motor and preparation method thereof

A technology of filling polymers and carbon microtubes, applied in chemical instruments and methods, and other chemical processes, can solve the problems of poor elastic properties of friction materials, difficulty in wide-range adjustment, and difficulty in ensuring stable operation of ultrasonic motors with dry friction materials. Achieve the effects of improving elastic modulus and wear resistance, improving restart performance, and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

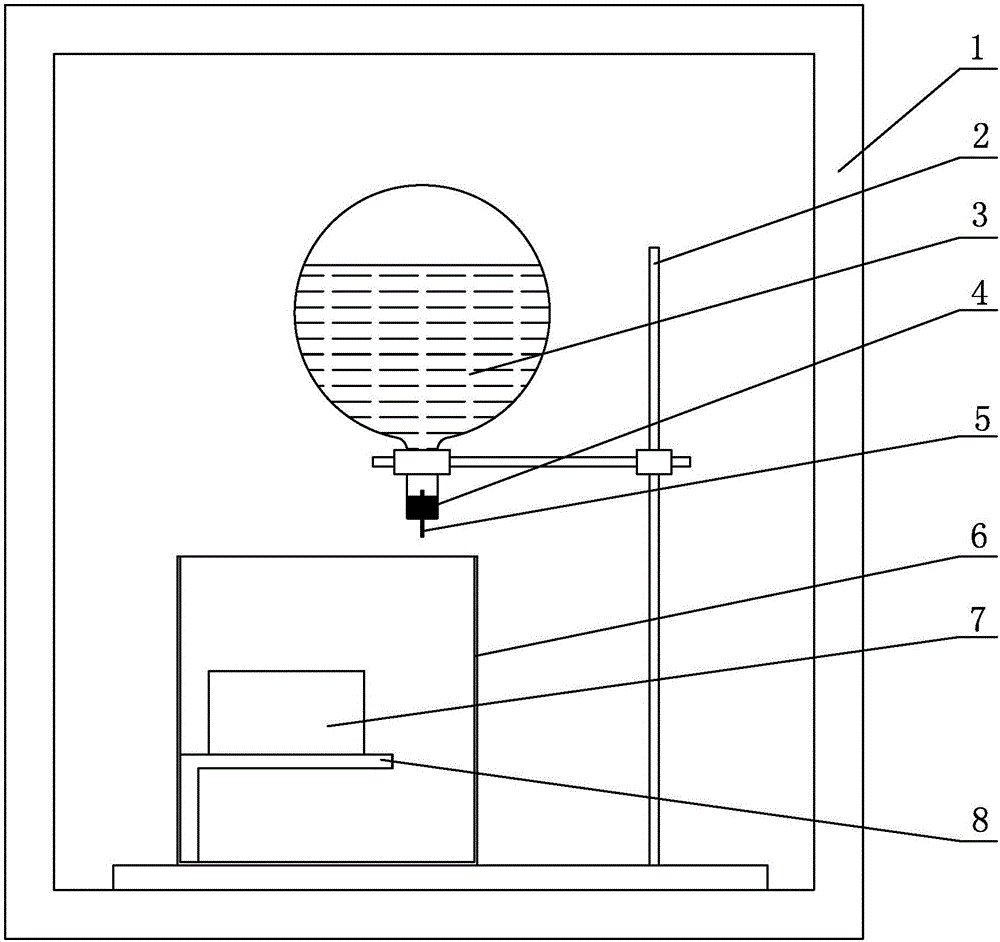

Image

Examples

specific Embodiment approach 1

[0028] Embodiment 1: The carbon microtube-filled polymer oil-containing friction material for the ultrasonic motor of this embodiment includes the following components in terms of mass percentage:

[0029] Polymer matrix: 45%-80%;

[0030] Friction modifier: 10%-30%;

[0031] Carbon microtubes: 1%-30%;

[0032] The polymer matrix is one or a combination of polytetrafluoroethylene, polyphenylene ester, polyimide and bismaleimide;

[0033] The friction modifier is one or a combination of copper powder, nickel powder, copper oxide, molybdenum disulfide, graphite, nano-diamond powder, carbon fiber, glass fiber and rare earth powder.

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment differs from Embodiment 1 in that: the inner diameter of the carbon microtubes is 0.2 μm-5 μm, and the length is 0.1 mm-2 mm. The carbon microtubes with this inner diameter are selected as the oil-containing carrier, which is conducive to the easy entry of nanoparticles / clusters into the pipeline. The carbon microtubes are embedded in the polymer matrix to improve the hardness, impact strength, wear resistance and thermal conductivity of the polymer to meet Design requirements and actual needs. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 to 2 is that the carbon microtube-filled polymer oil-containing friction material for an ultrasonic motor includes the following components in mass percentage: 40%- 55% polytetrafluoroethylene, 5%-20% polyphenylene ester, 1%-5% nano-diamond, 6%-15% rare earth powder, 3%-10% micron or nanoscale copper powder and 5% %-20% carbon microtubes. In this embodiment, adding polyphenylene can increase the hardness, and the others are the same as those in the first to second embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com