Scanning mechanism applied to aerial camera

A scanning mechanism and aerial camera technology, applied in the field of aero-optical remote sensors, can solve the problems of inability to achieve fast, flexible and accurate control, increased inertia of the scanning mechanism, large volume and mass, etc., and achieves fast, flexible and accurate control, simple structure, and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] A scanning mechanism applied to an aerial camera, the scanning mechanism is fixedly connected with the camera main body through a fixing seat;

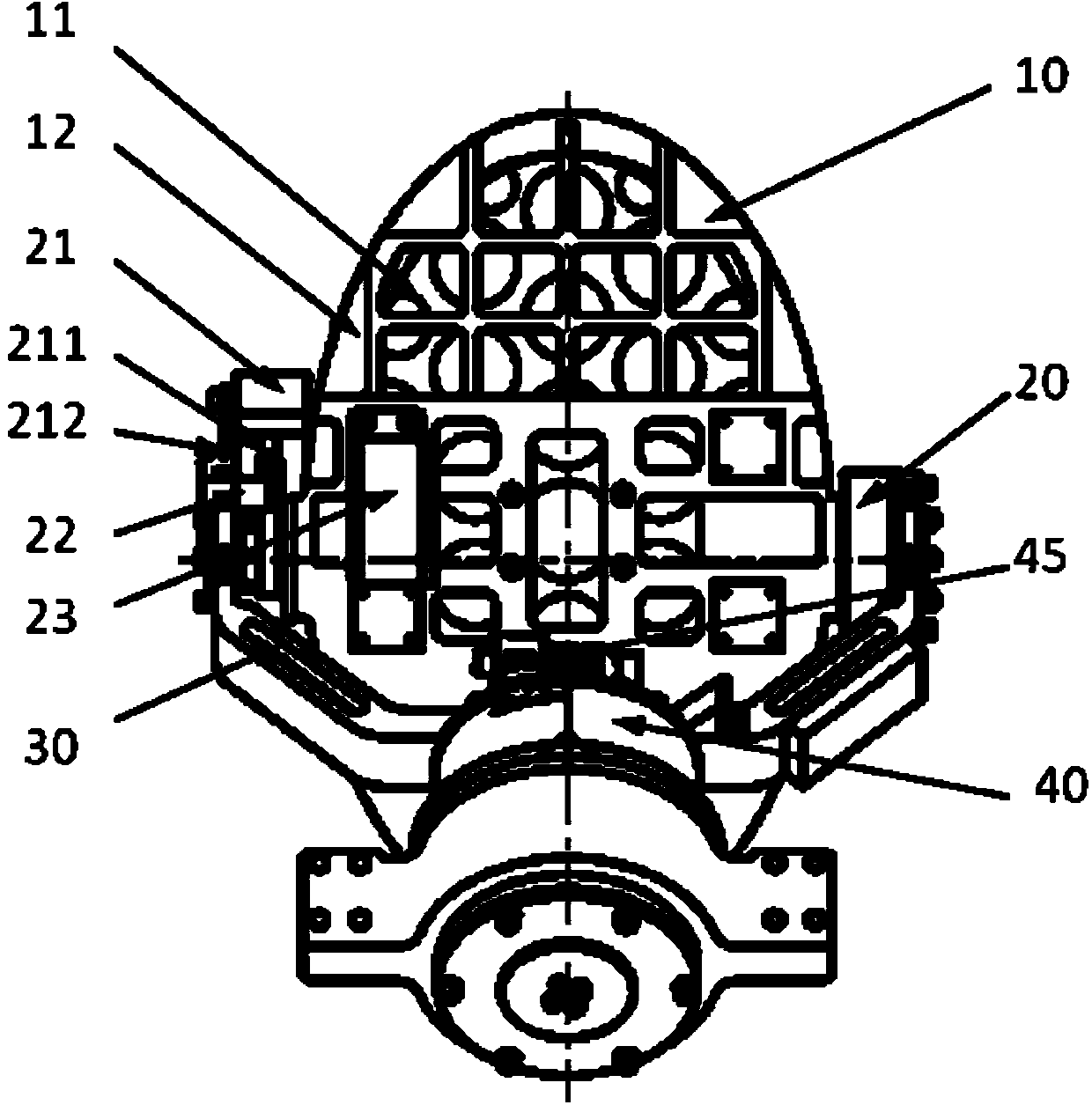

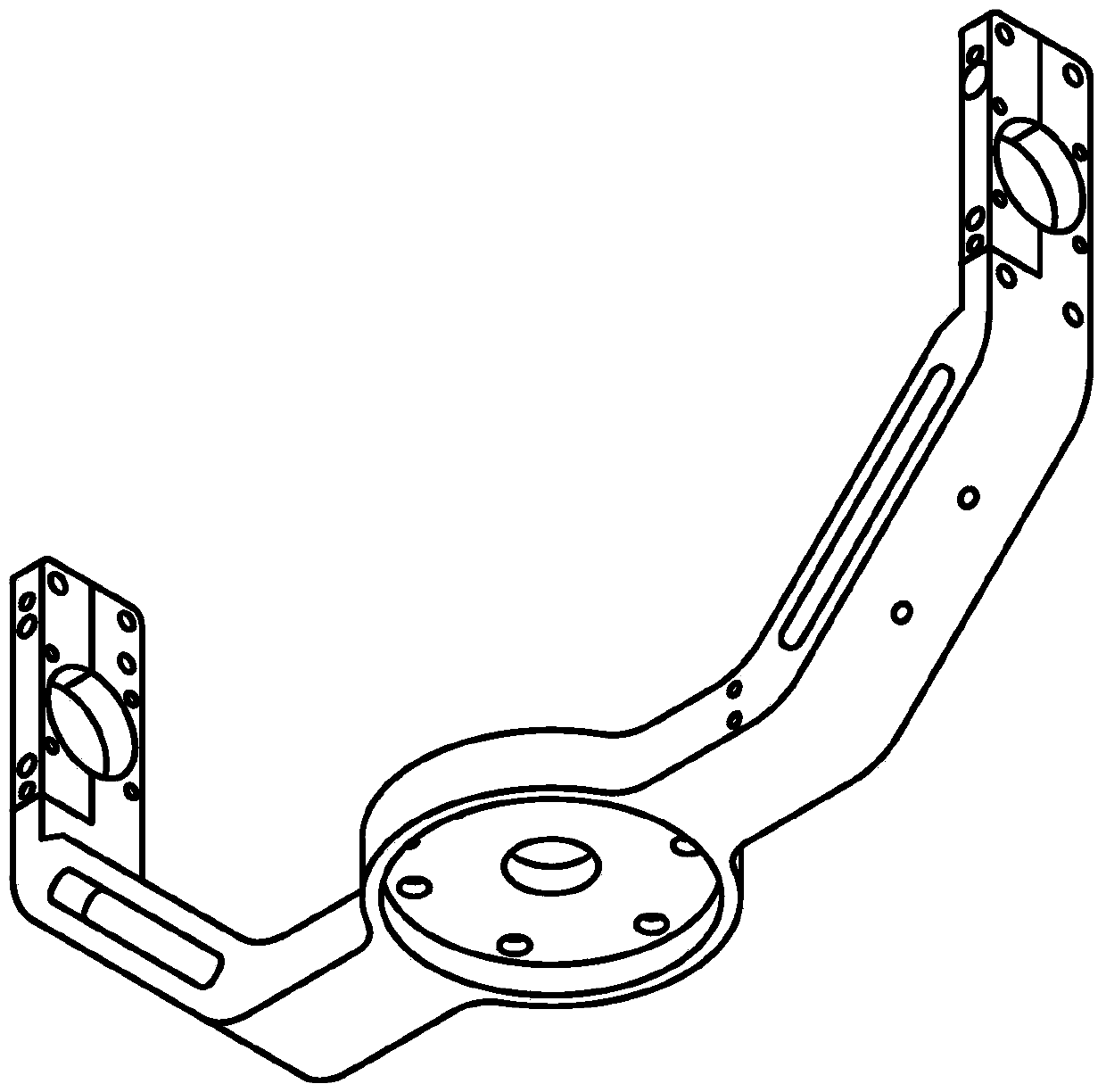

[0032] Such as figure 1 As shown, the scanning mechanism includes a scanning mirror assembly 10, a pitch shaft assembly 20, a U-shaped ring 30 and a roll shaft assembly 40; the scanning mirror assembly 10 is fixedly connected to the pitch shaft assembly 20 through a pitch shaft 28; the pitch shaft The component 20 is flexibly connected to both ends of the U-shaped ring 30; the rolling shaft assembly 40 is fixedly connected to the middle of the U-shaped ring 30; the structural diagram of the U-shaped ring 30 is as follows image 3 shown;

[0033] The scanning mirror assembly 10 includes a scanning mirror 11 and a mirror frame 12, and the scanning mirror 11 is fixed in the mirror frame 12 with stress-free glue;

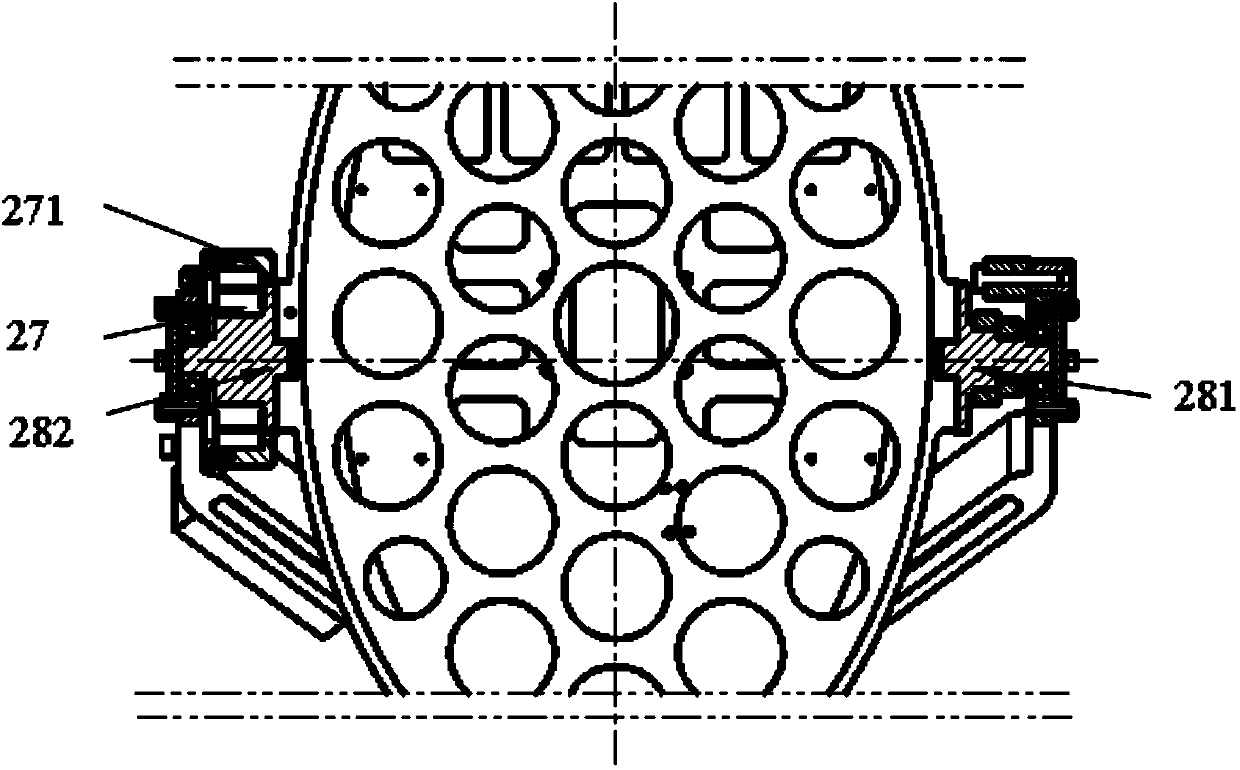

[0034] Such as figure 1 and figure 2 As shown, the pitch shaft assembly 20 includes a pitch shaft 28, a voice coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com