Patents

Literature

117results about How to "High spring force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

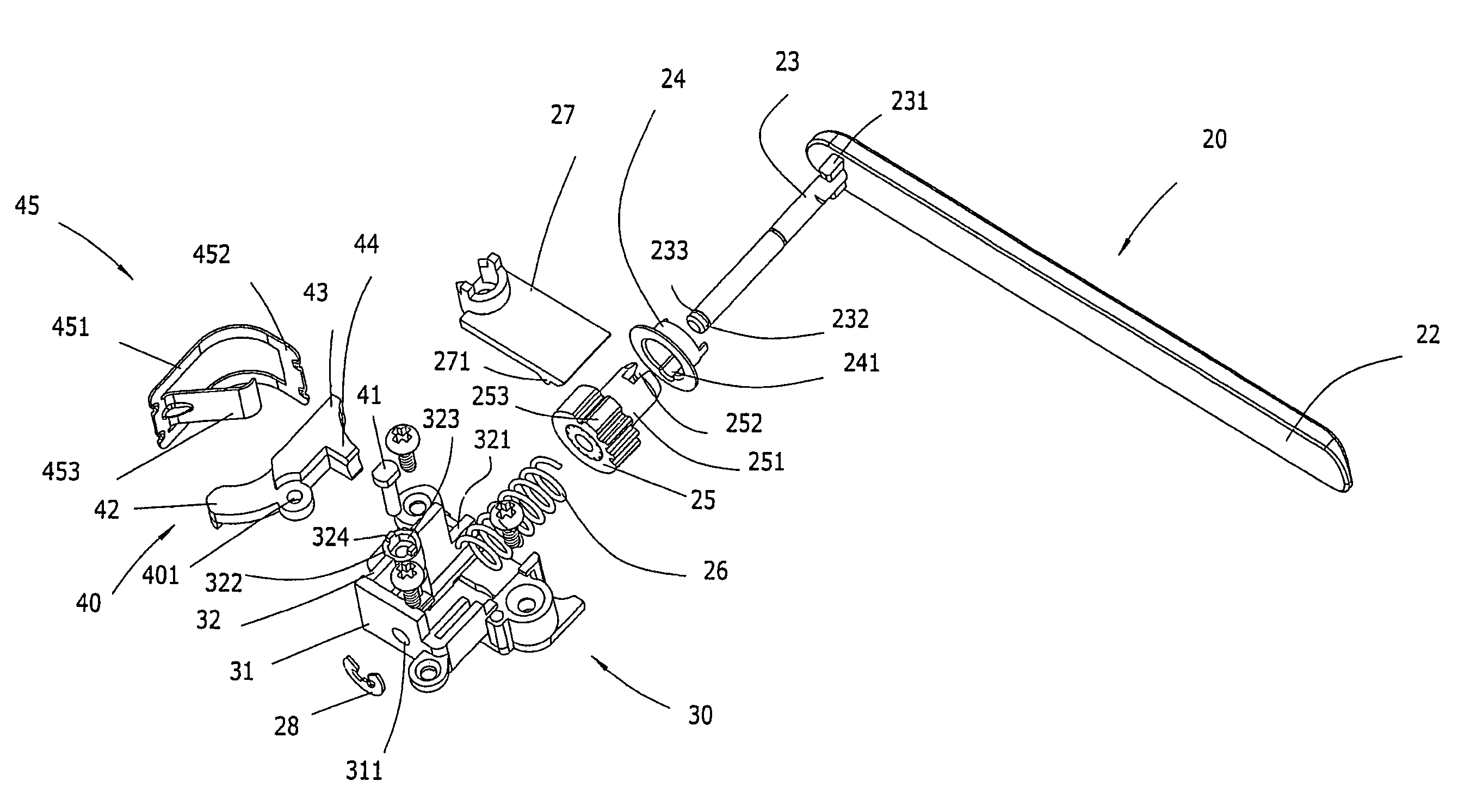

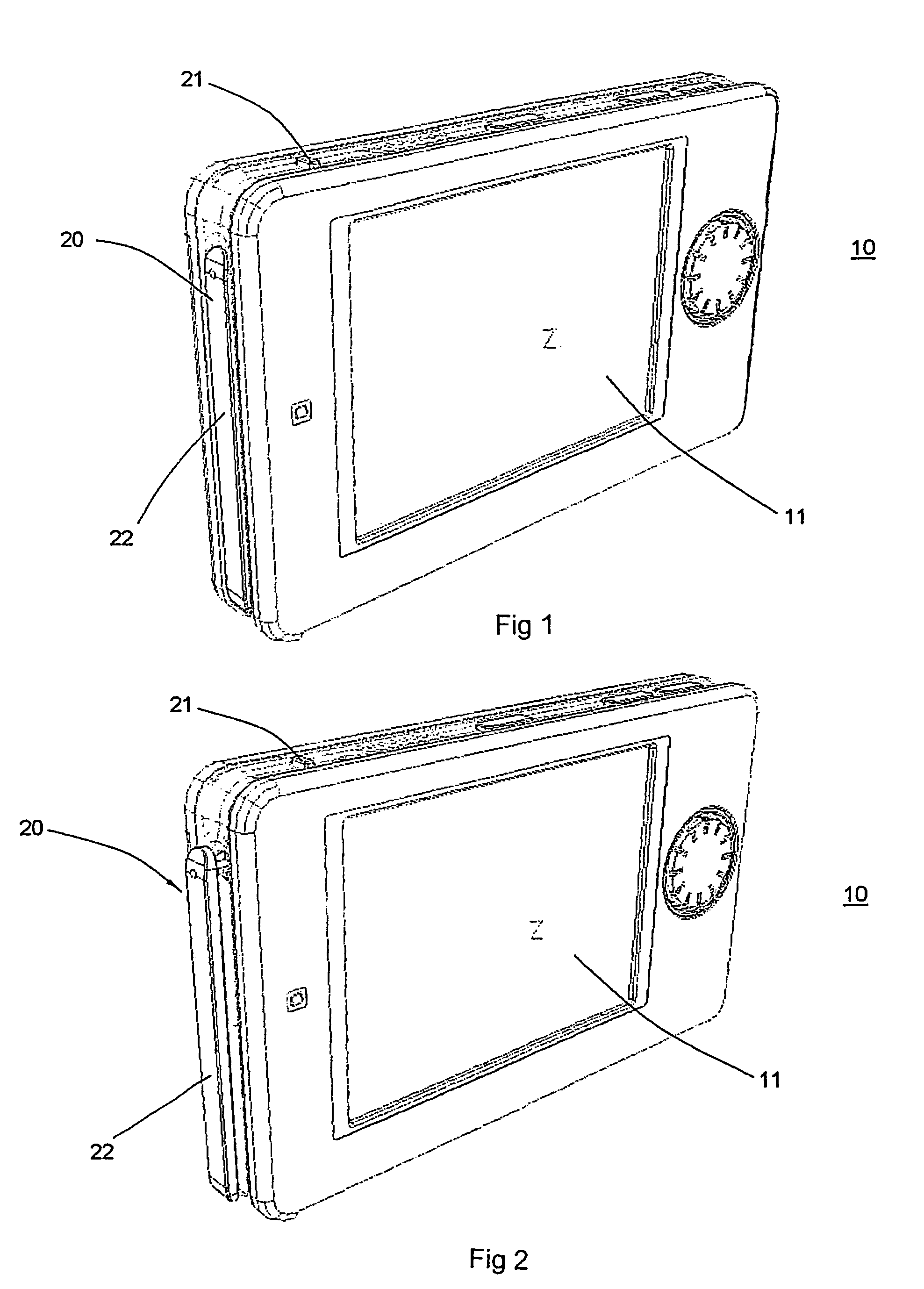

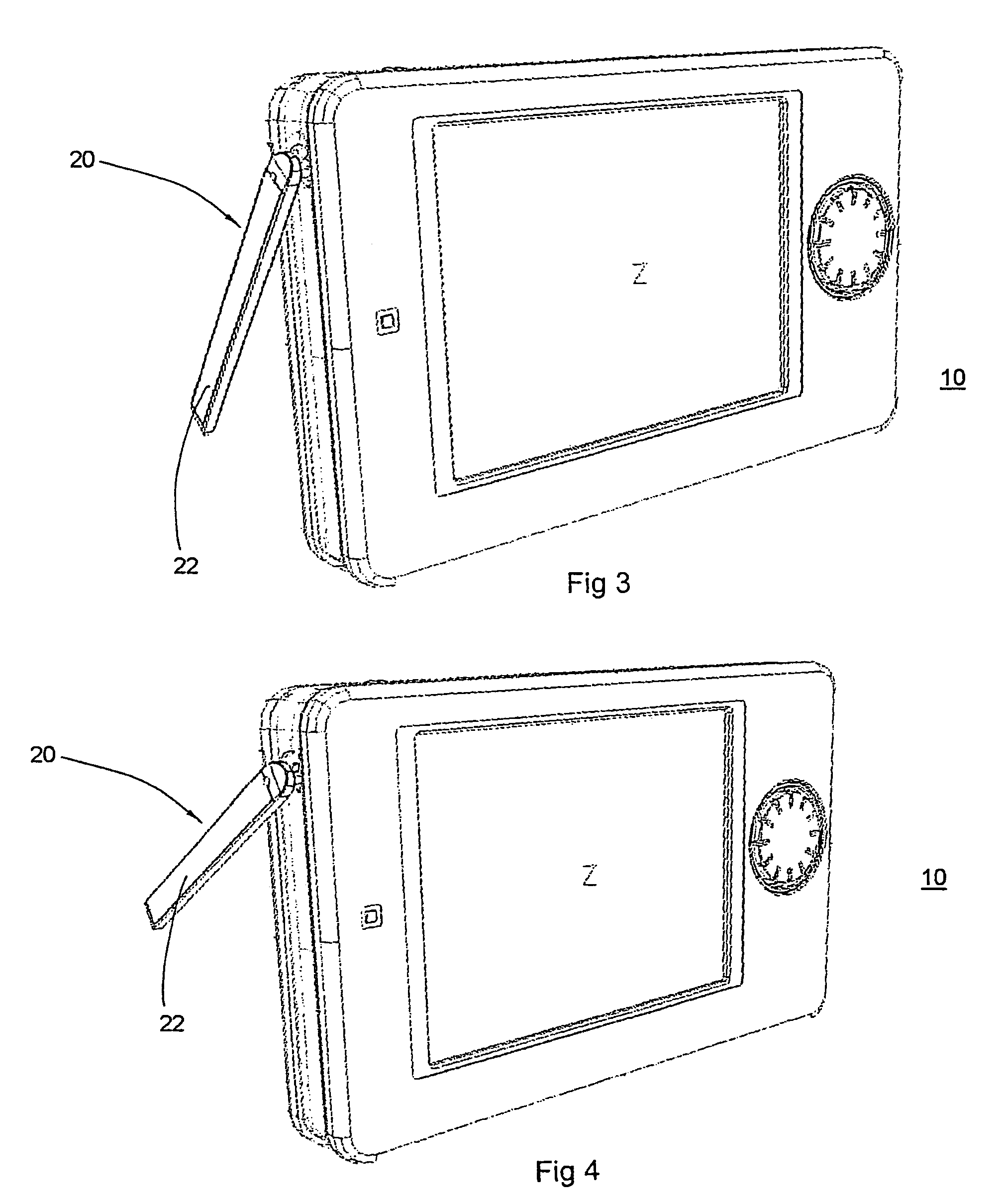

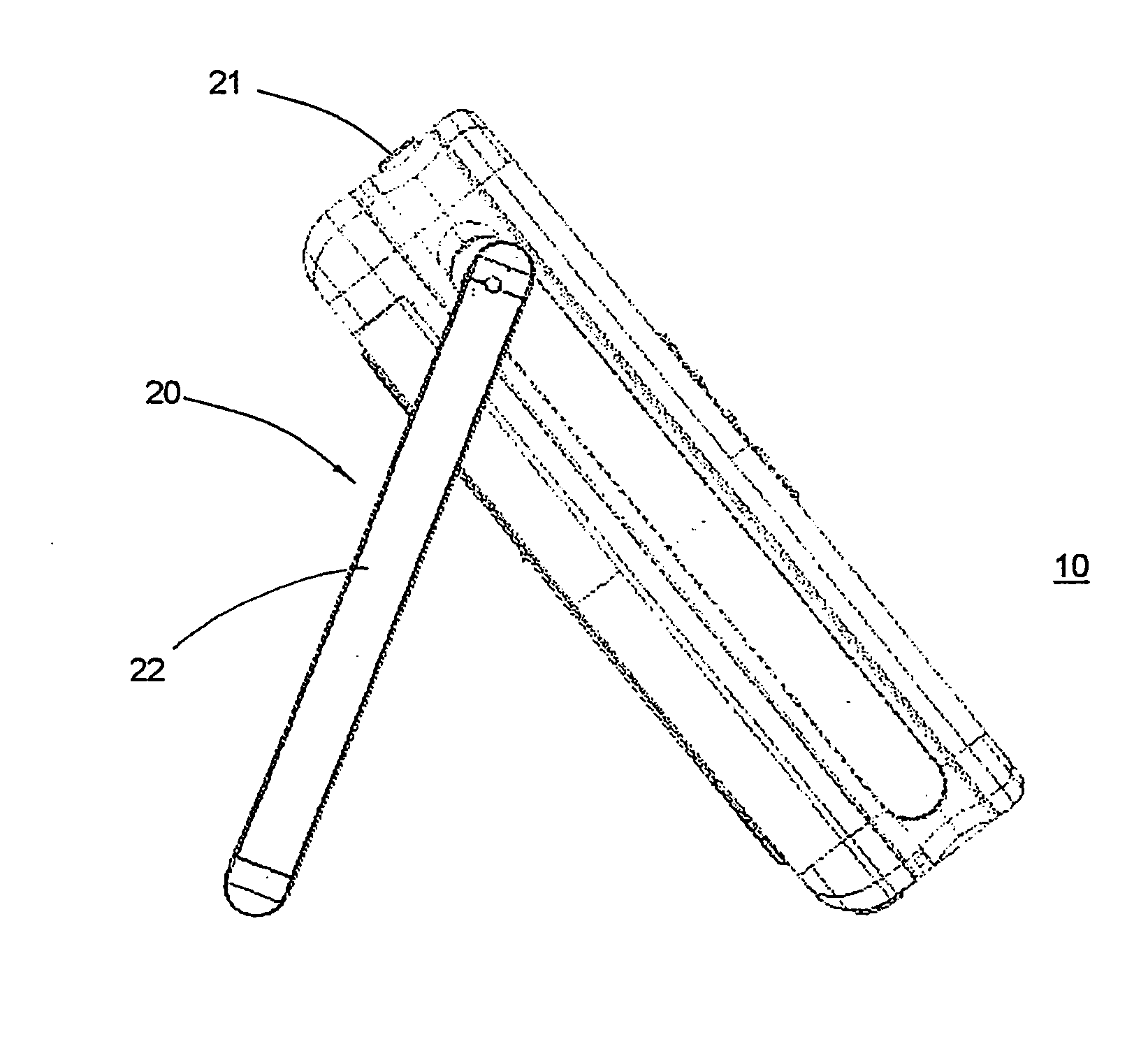

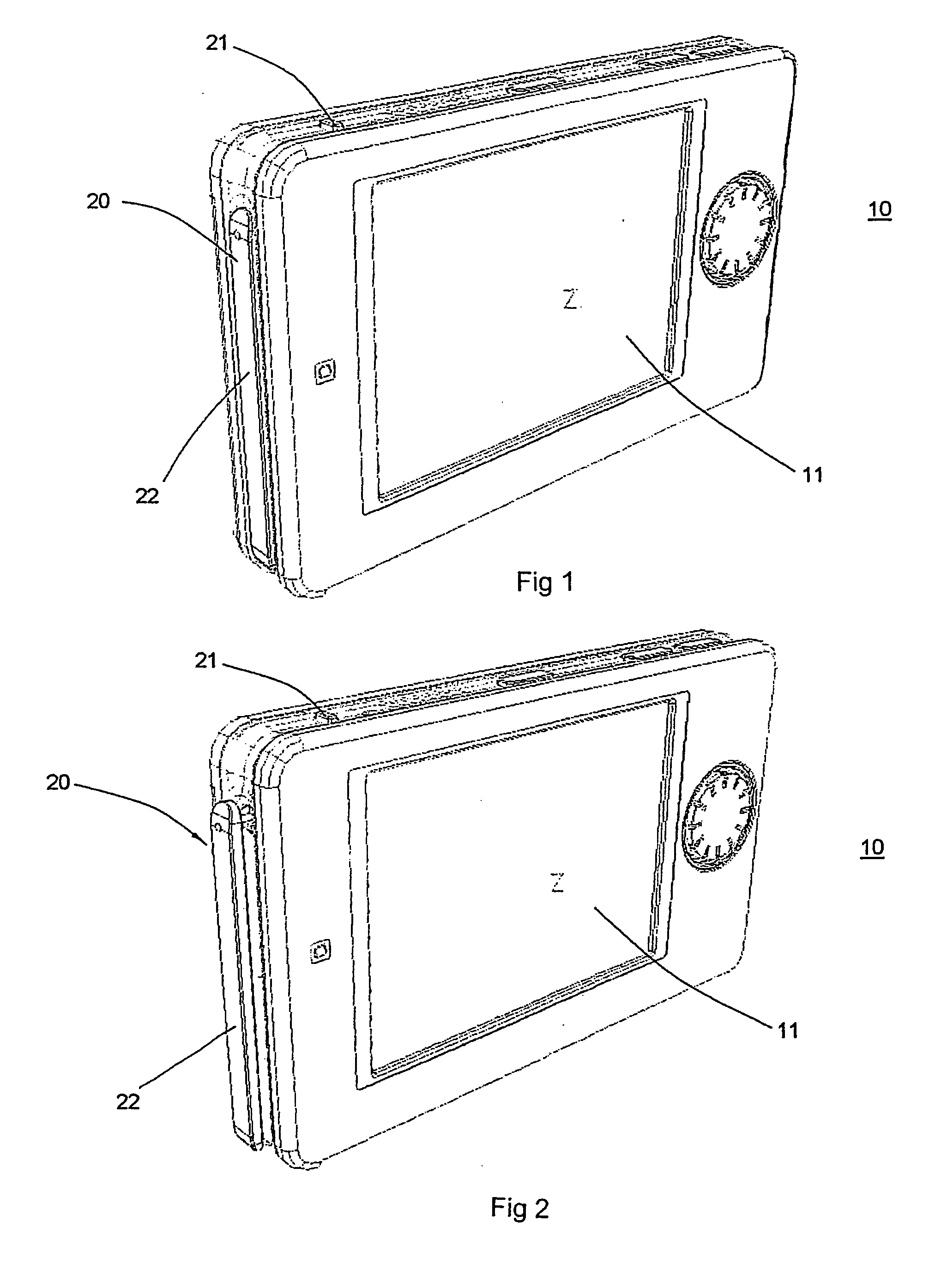

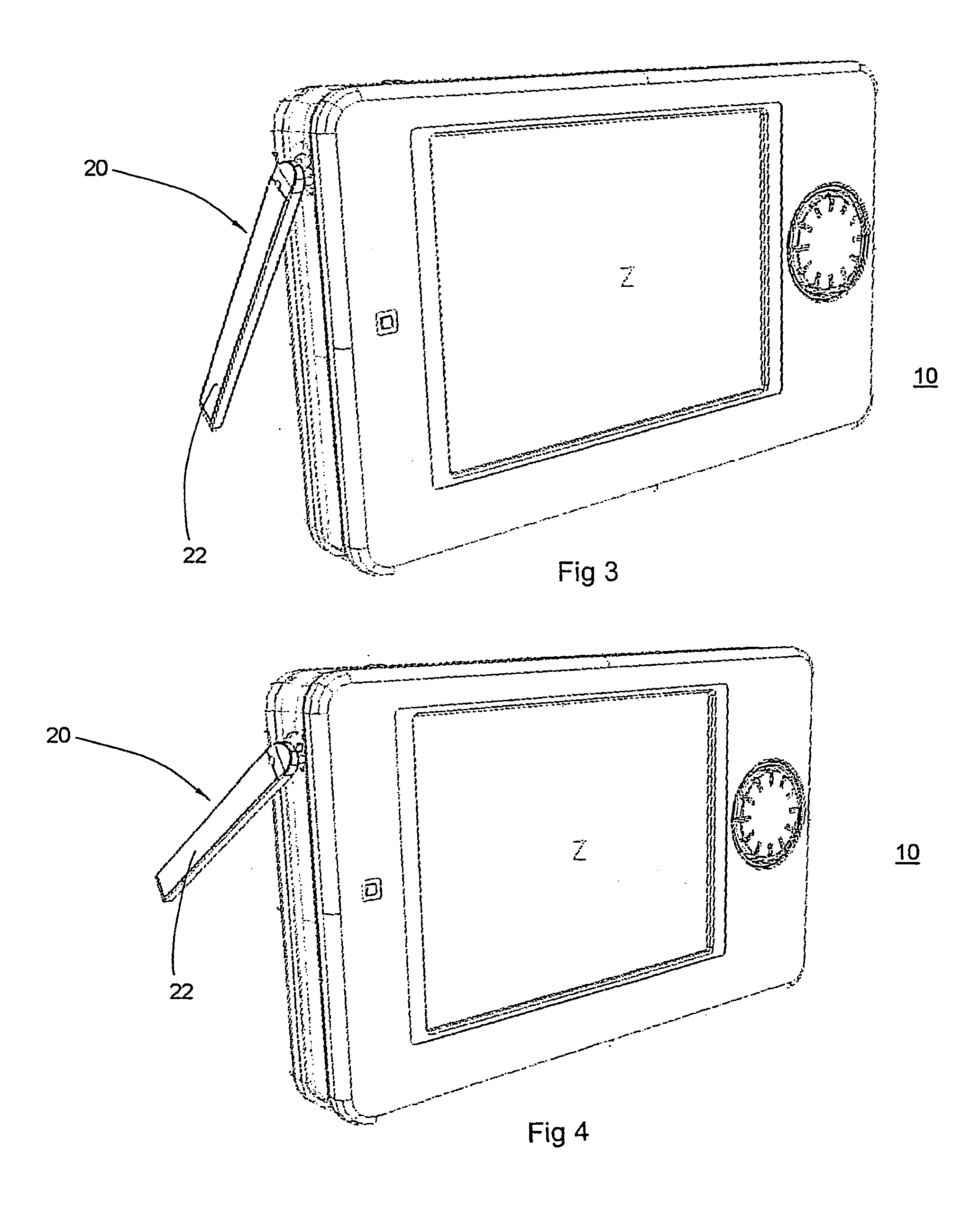

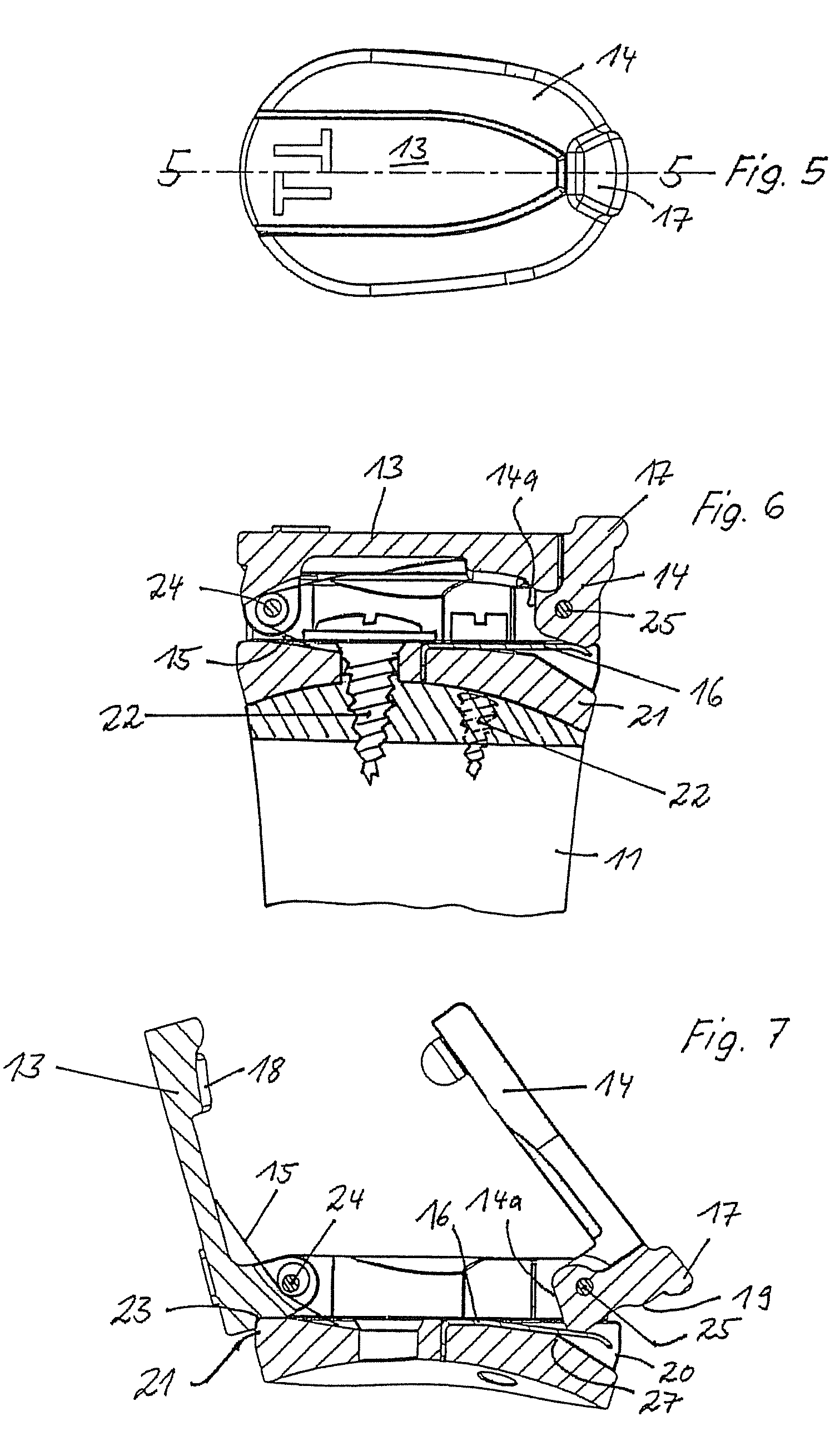

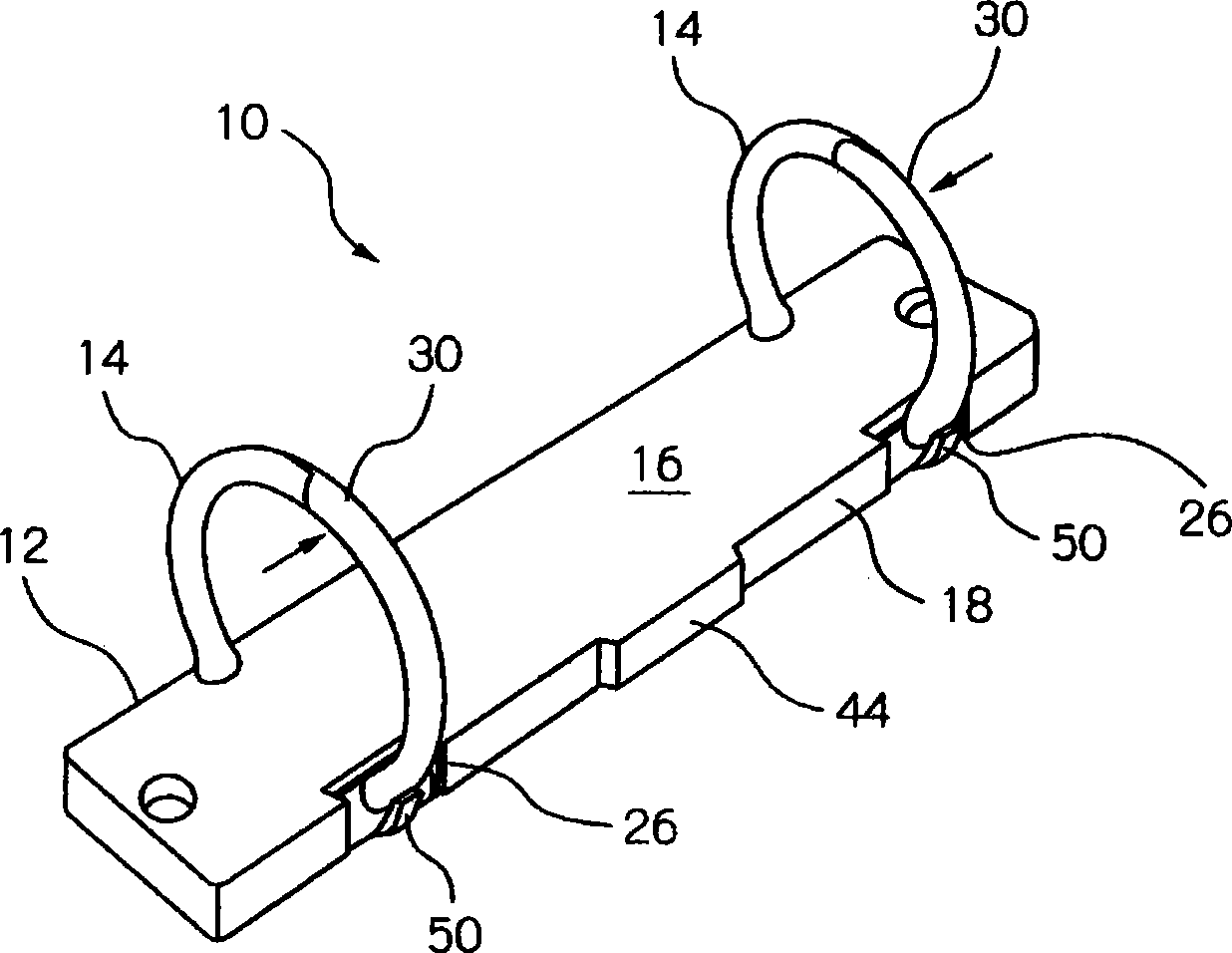

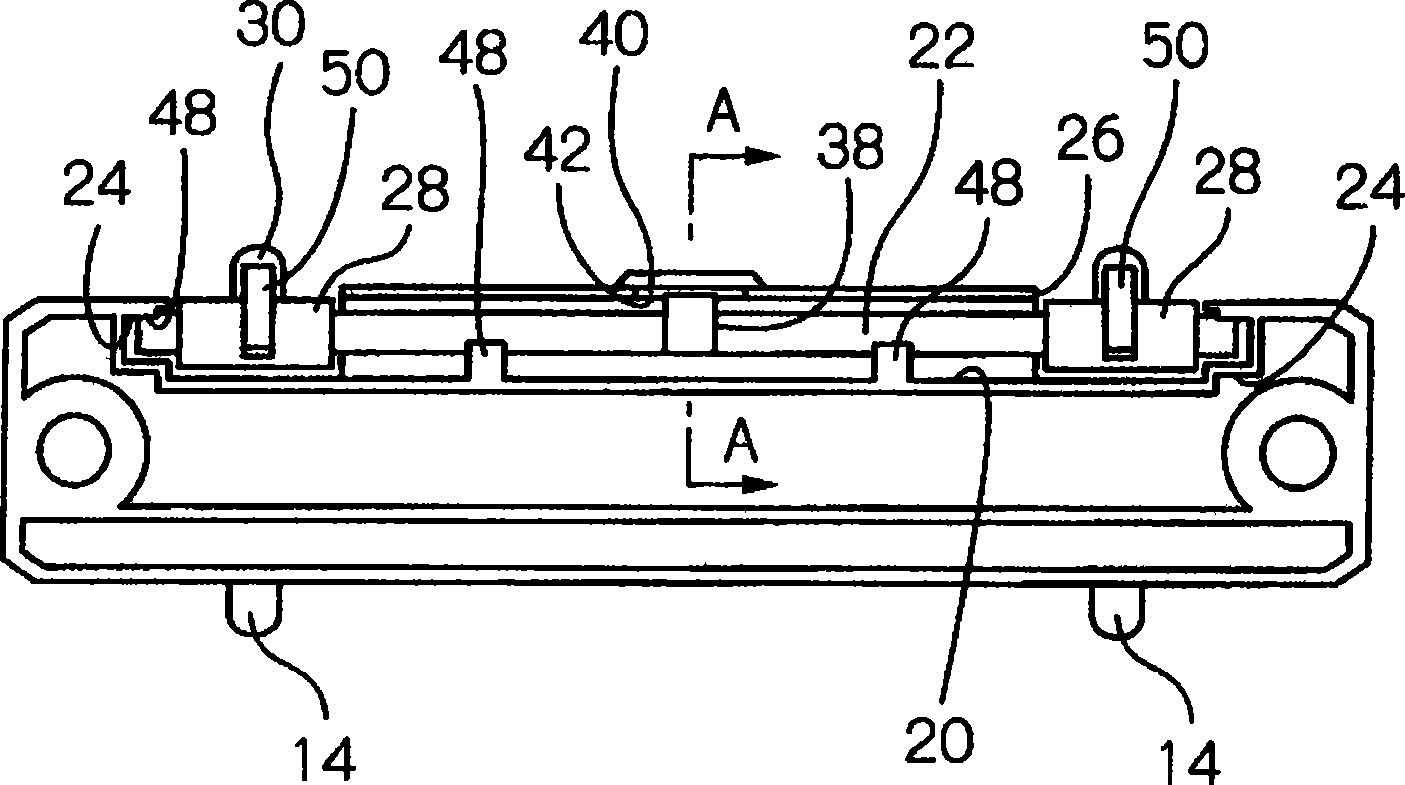

Foot stand assembly with multi-viewing angles

InactiveUS7594638B2Prevent escapeHigh spring forcePortable framesStands/trestlesEngineeringView angle

An auto-eject foot stand assembly with multi-viewing angles for a visual device includes a foot having an axle perpendicular to the foot. The axle rotatably extends in a bracket. A gear is securely provided outside the axle and between the bracket and the foot. A spring is provided between the gear and the bracket. An elasticity plate is engaged with the gear. A locker is pivotally mounted on the bracket and operated by a metal spring plate to lock the gear. When the metal spring plate is pressed, the gear is released from the locker and the foot can be ejected under the elastic force of the spring. By the engagement between the gear and elasticity plate, the foot can be rotated and positioned at various desired viewing angels.

Owner:THOMSON LICENSING SA

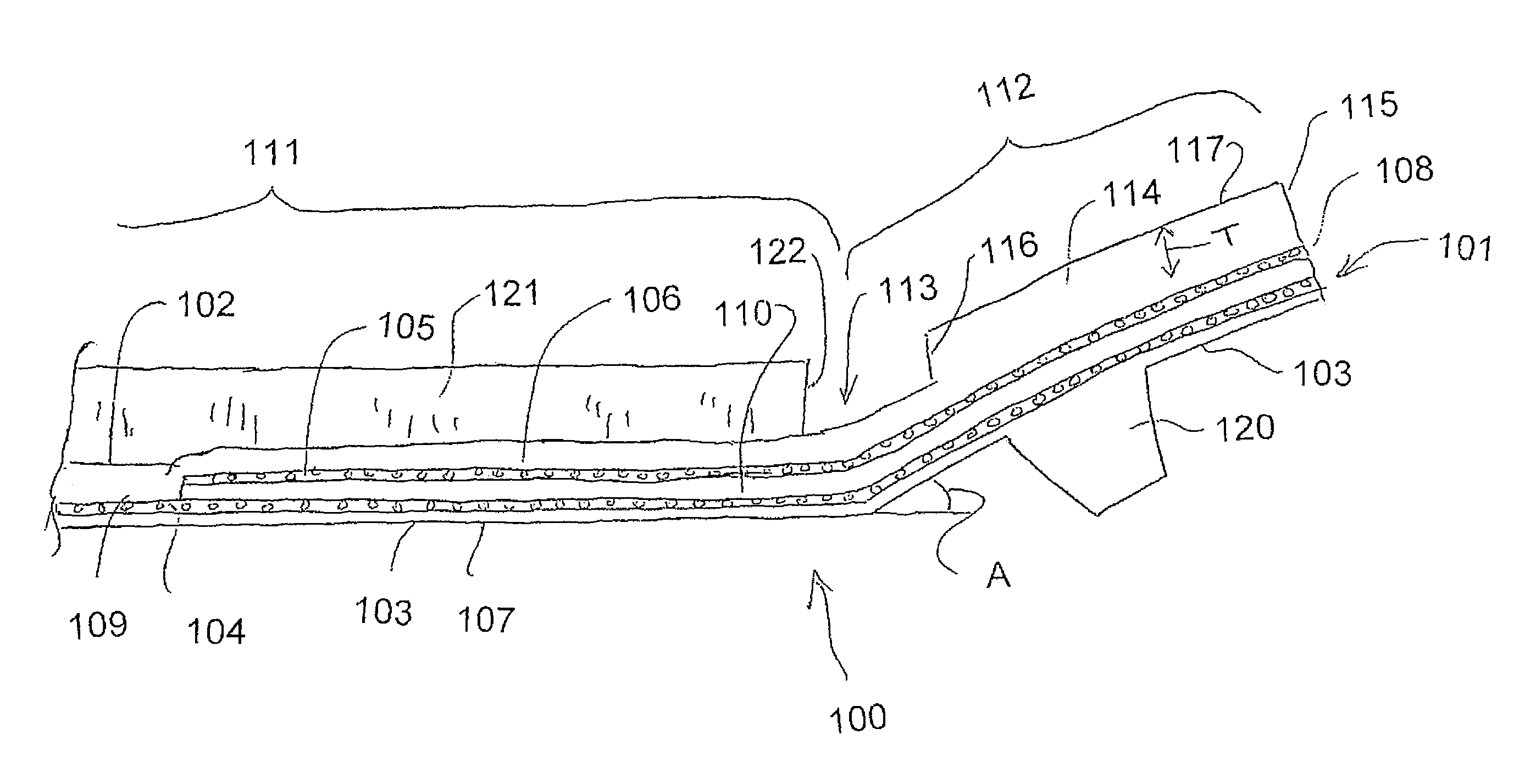

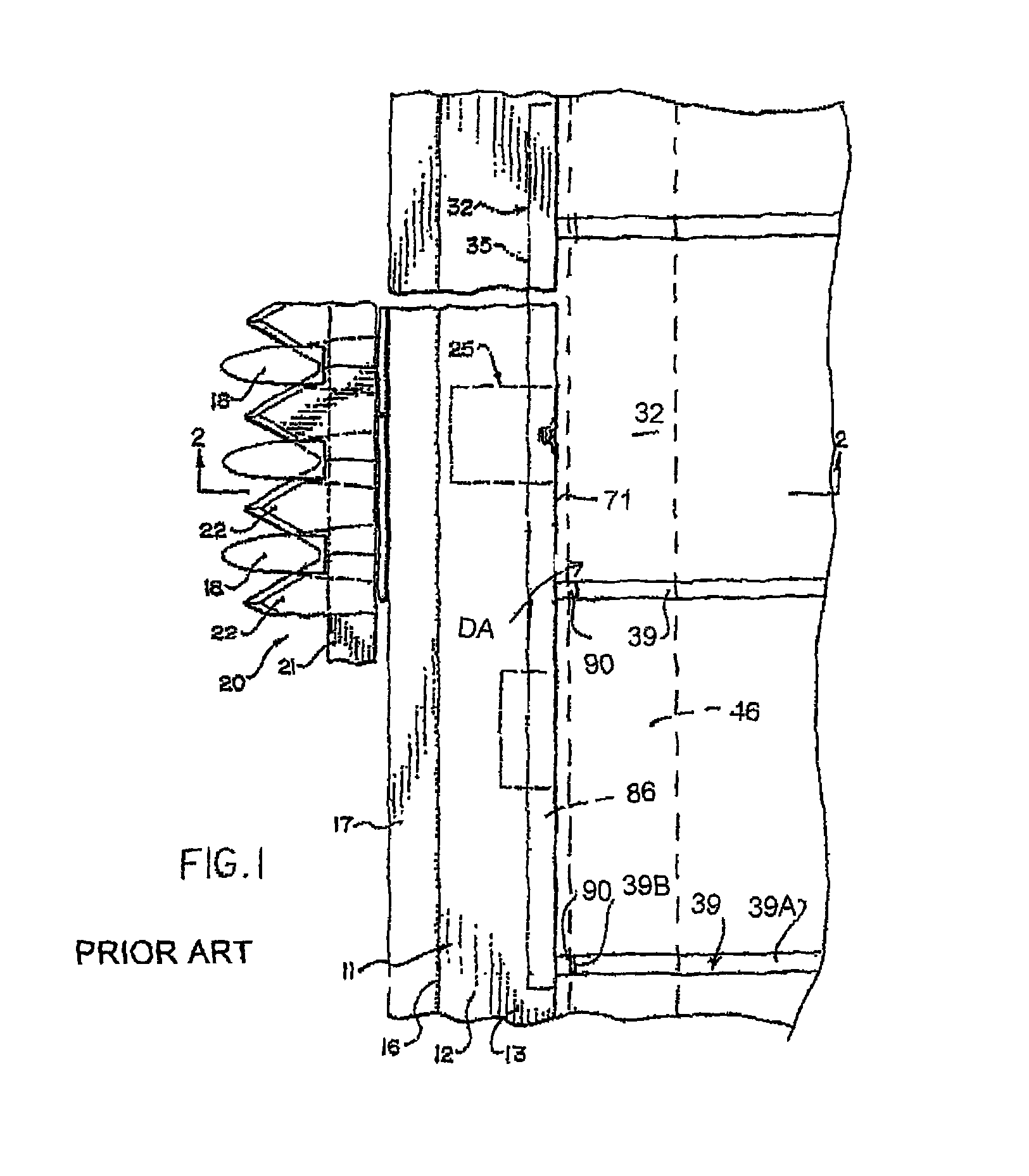

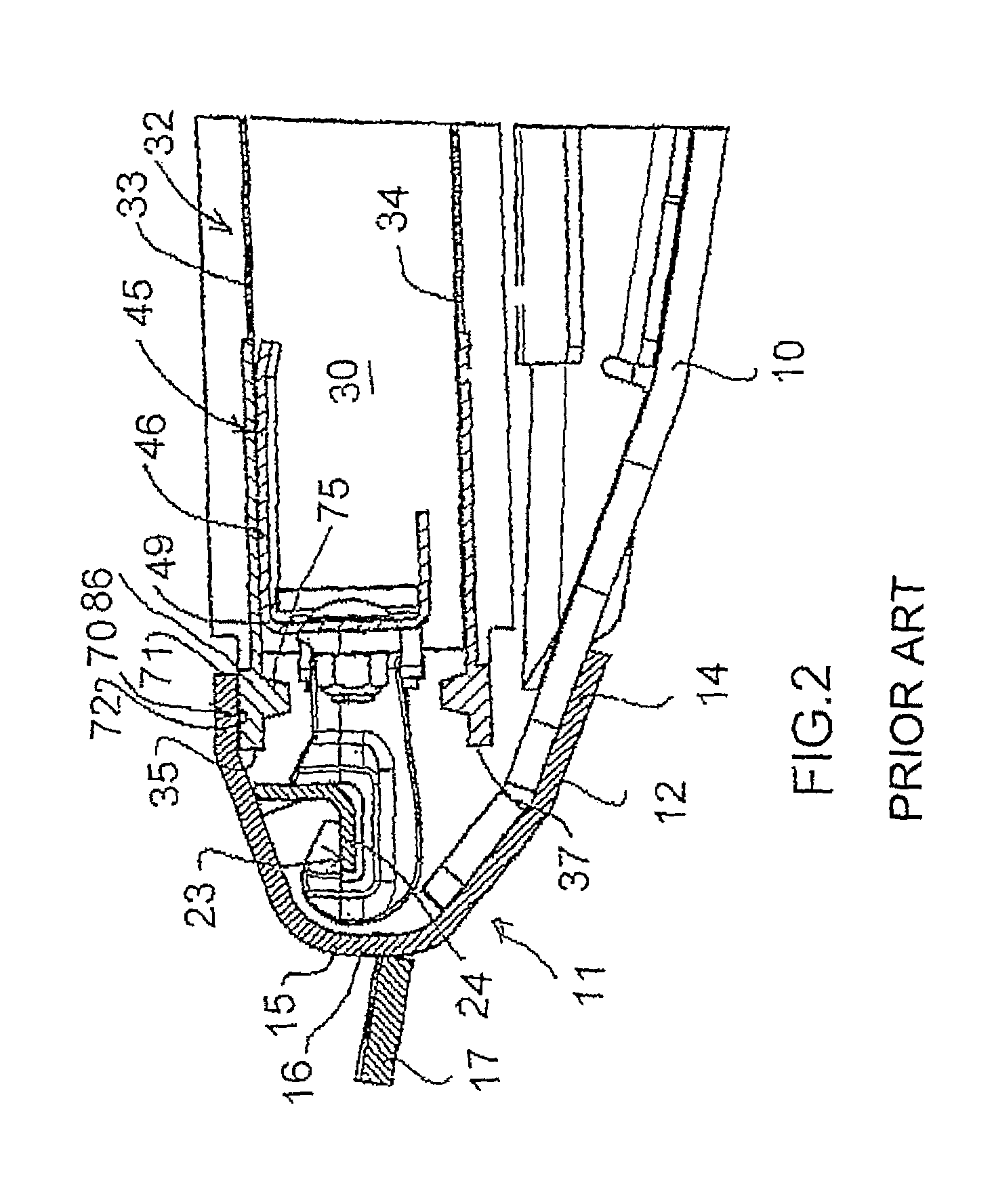

Draper canvas with a shaped edge

A crop harvesting header with a cutter bar and a draper assembly has a draper canvas with an edge portion across a front edge to cooperate with a rearwardly projecting element of the cutter bar extending over the upper run of the draper canvas to engage the upper surface of the edge portion to form a seal to inhibit entry of dirt or crop between the cutter bar and the draper canvas. The edge portion of the canvas is thicker and is canted upwardly at an angle of the order of 10 to 20 degrees. There is also provided a bead on the canvas on the surface opposite the strip within the width of the strip. The arrangement can be symmetrical with a strip at each of the front and rear edges spanned by the slats extending between them.

Owner:MACDON INDS +1

Screwdriver tool

InactiveUS7080582B2Increase the outer diameterClosely arrangedSlip couplingSpannersTorque transmissionSpring force

Owner:WIHA WERKZEUGE

Quick connect assembly

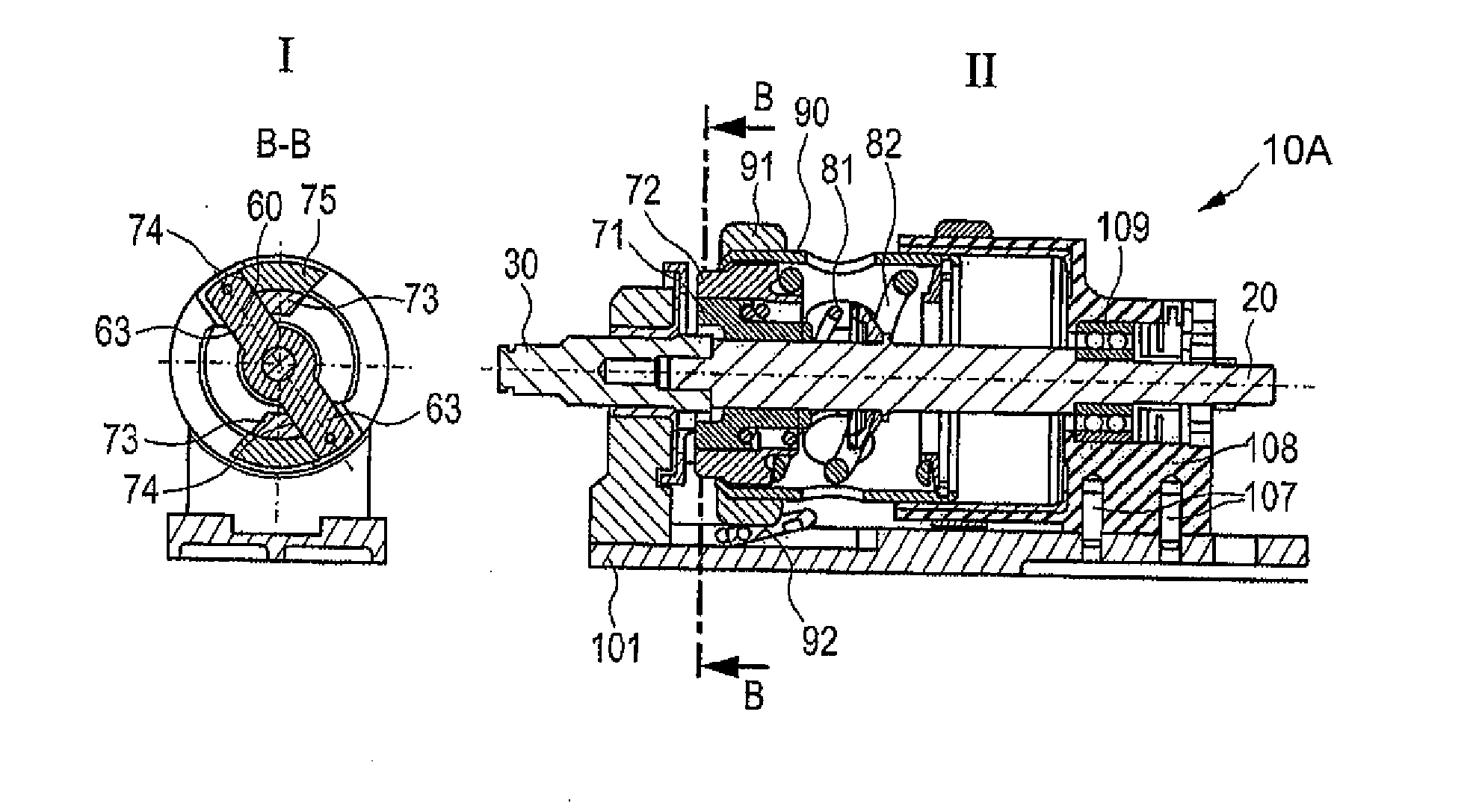

InactiveCN101095268AHigh spring forceFirmly connectedCoupling device detailsEngineeringElectrical connection

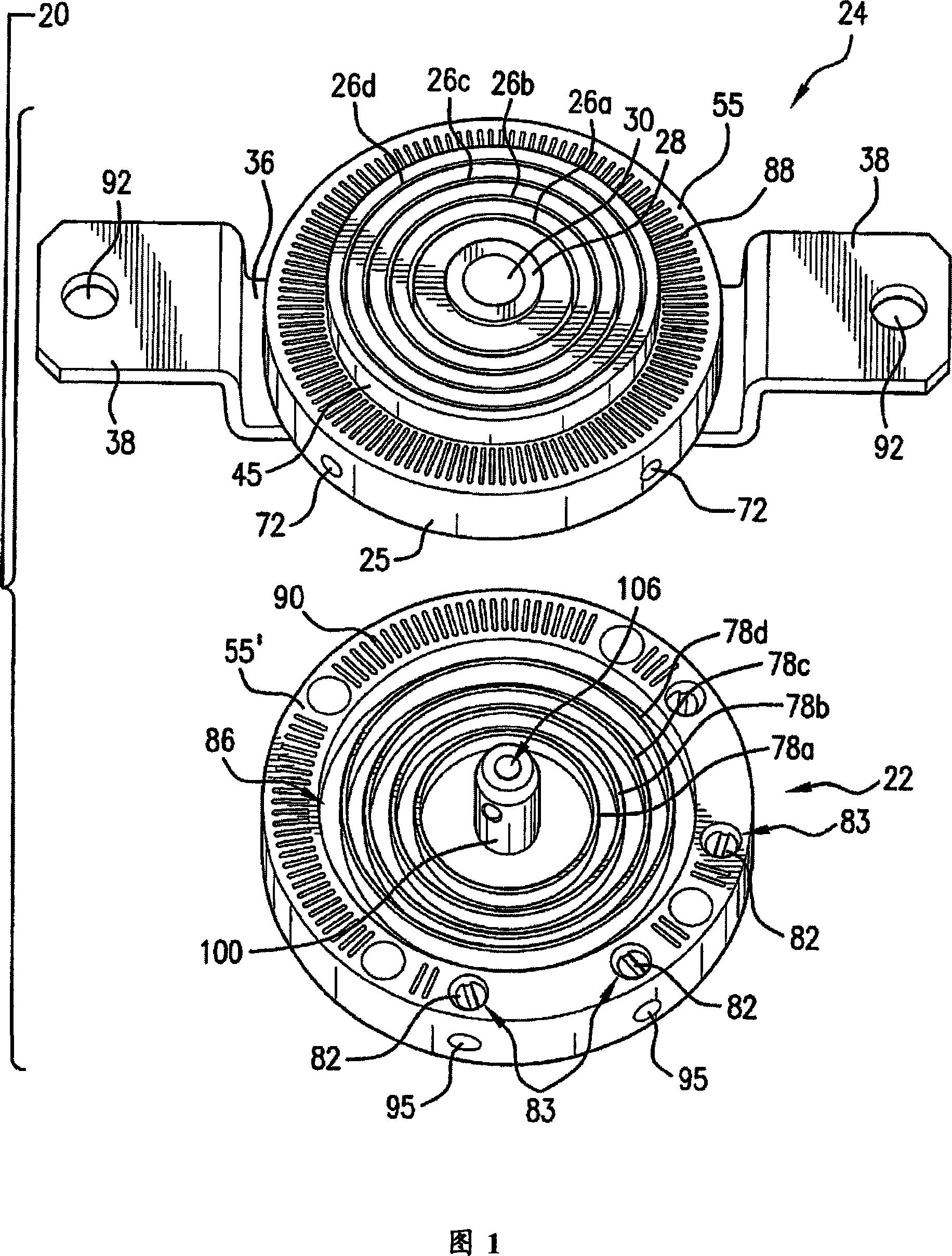

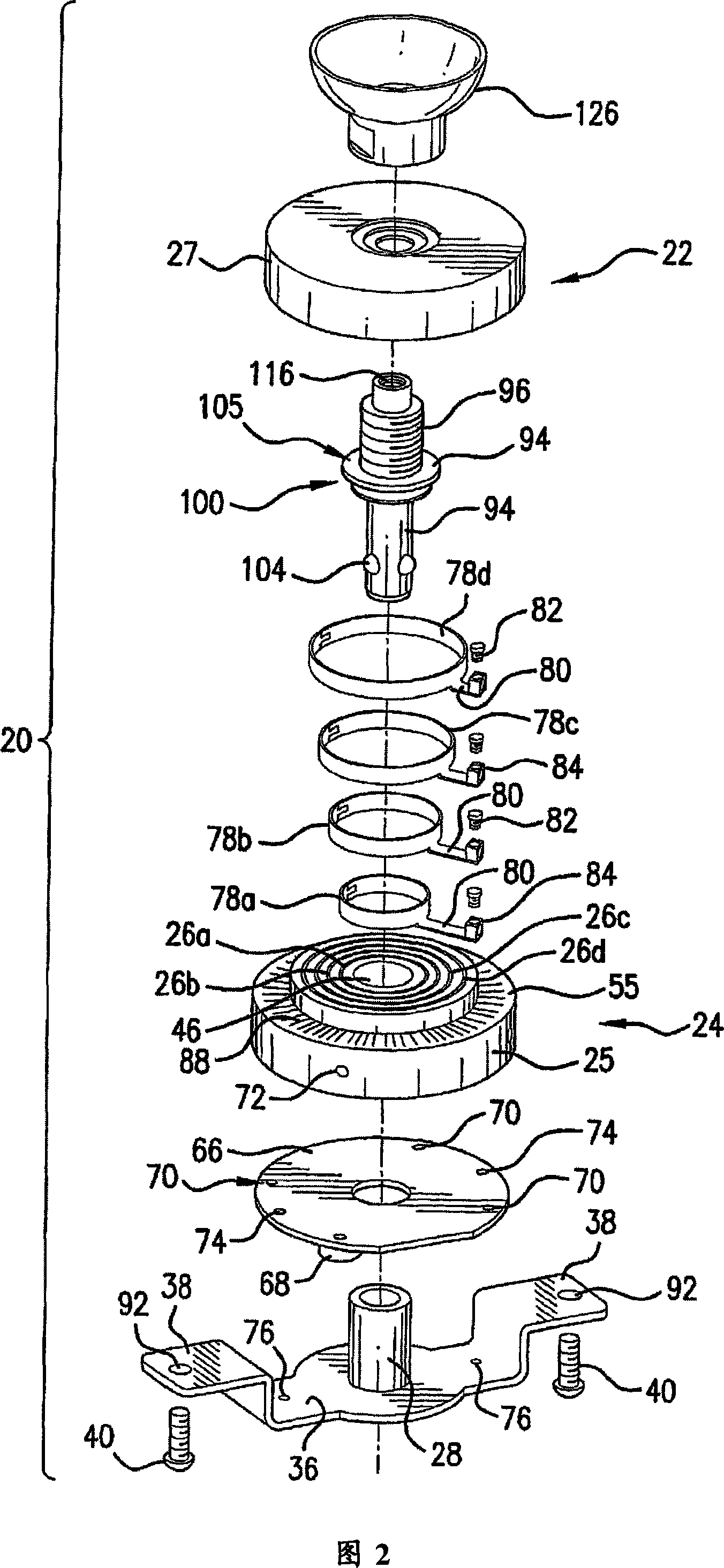

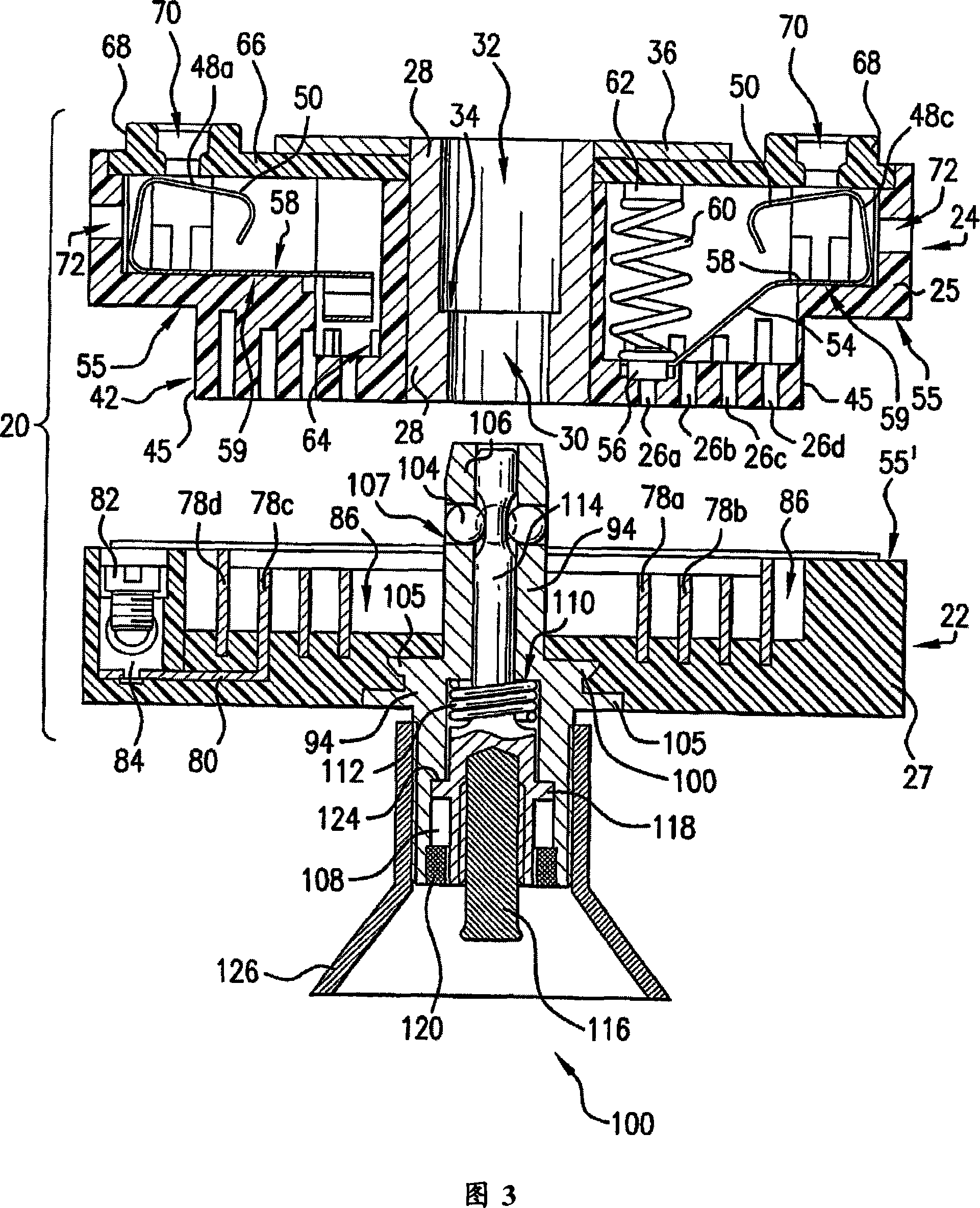

A device for connecting and supporting fixtures, such as electrical fixtures, includes a male plug, a mating female socket and a releasable spindle assembly for both holding the plug in the socket and mechanically mounting the fixture on a supporting surface or an electrical box. The plug is provided with concentric, ring shaped male connectors that are matingly received within similarly shaped female recesses in the socket to create electrical connections and also allow the fixture to be rotated to any of a plurality or mounting orientations. The releasable spindle assembly is controlled by the actuation of a push rod operated by a tool or user's finger.

Owner:拉恩科亨

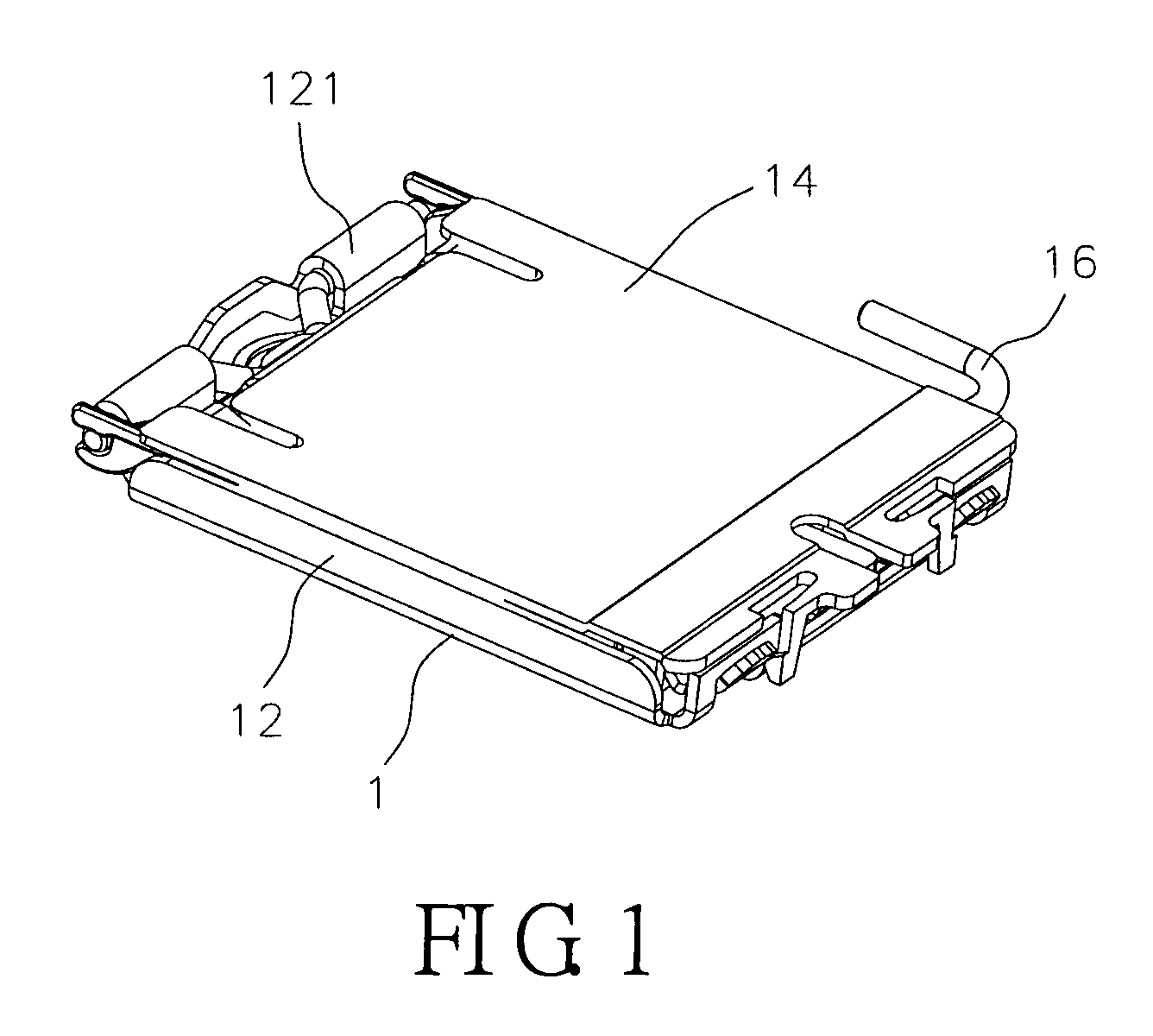

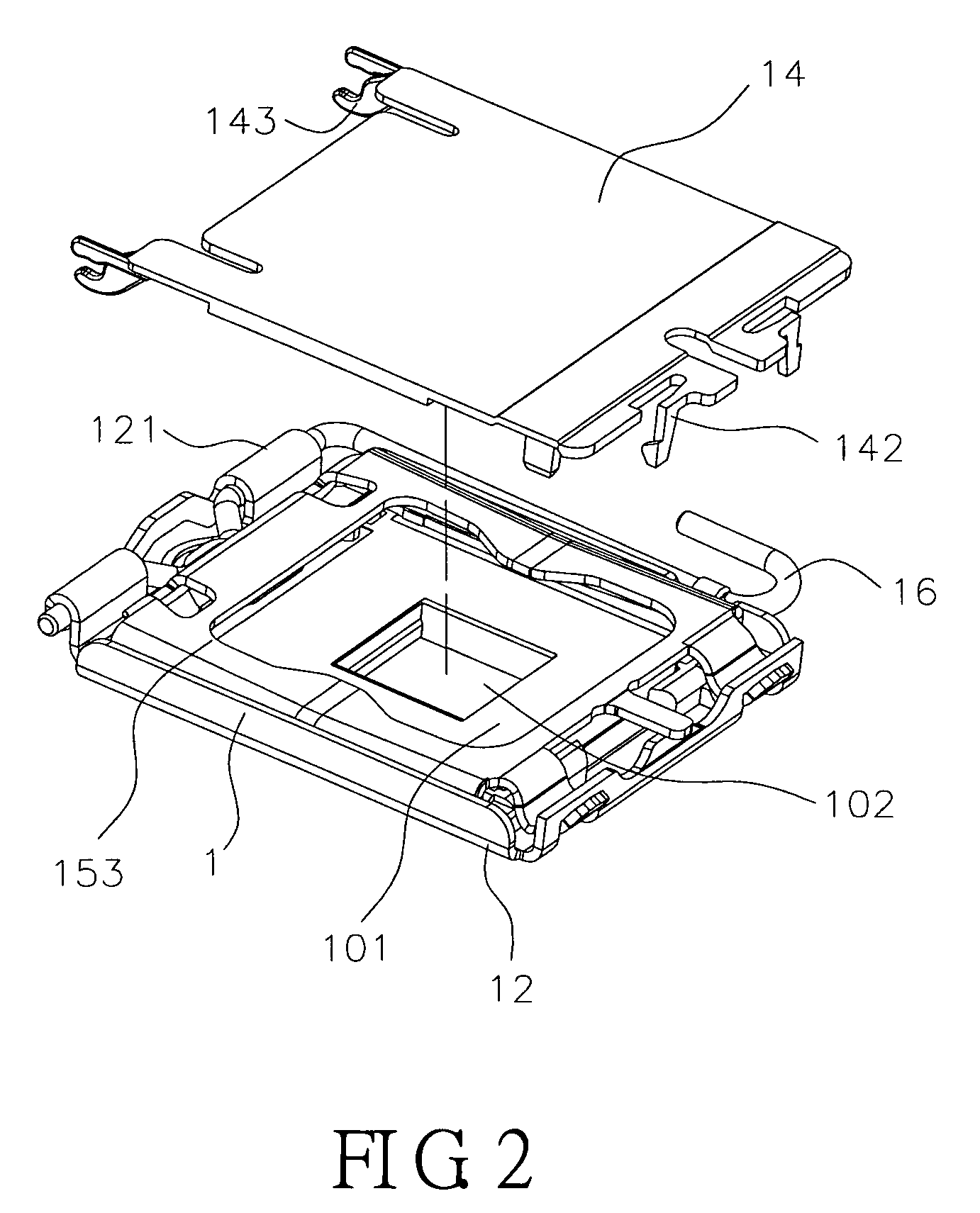

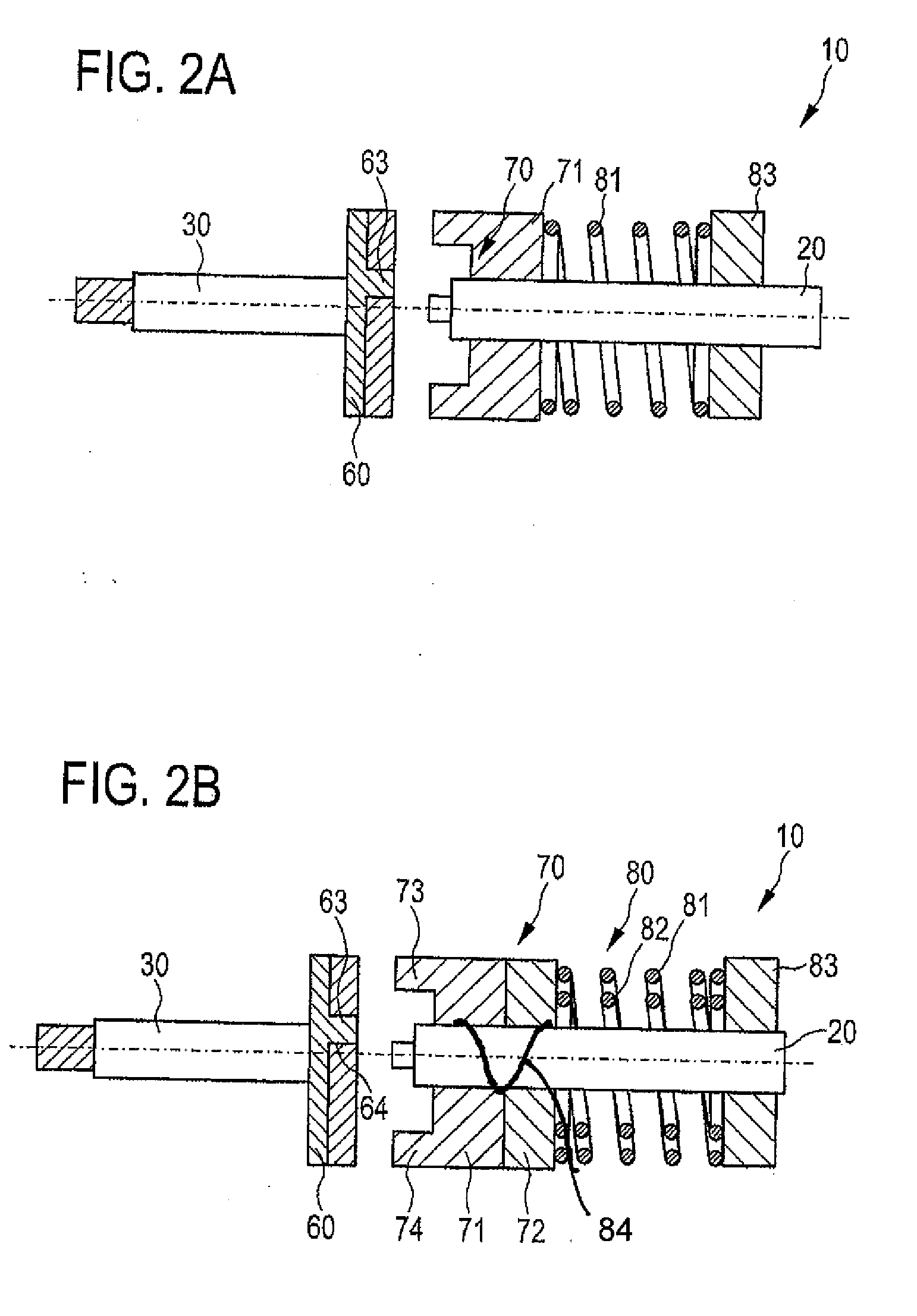

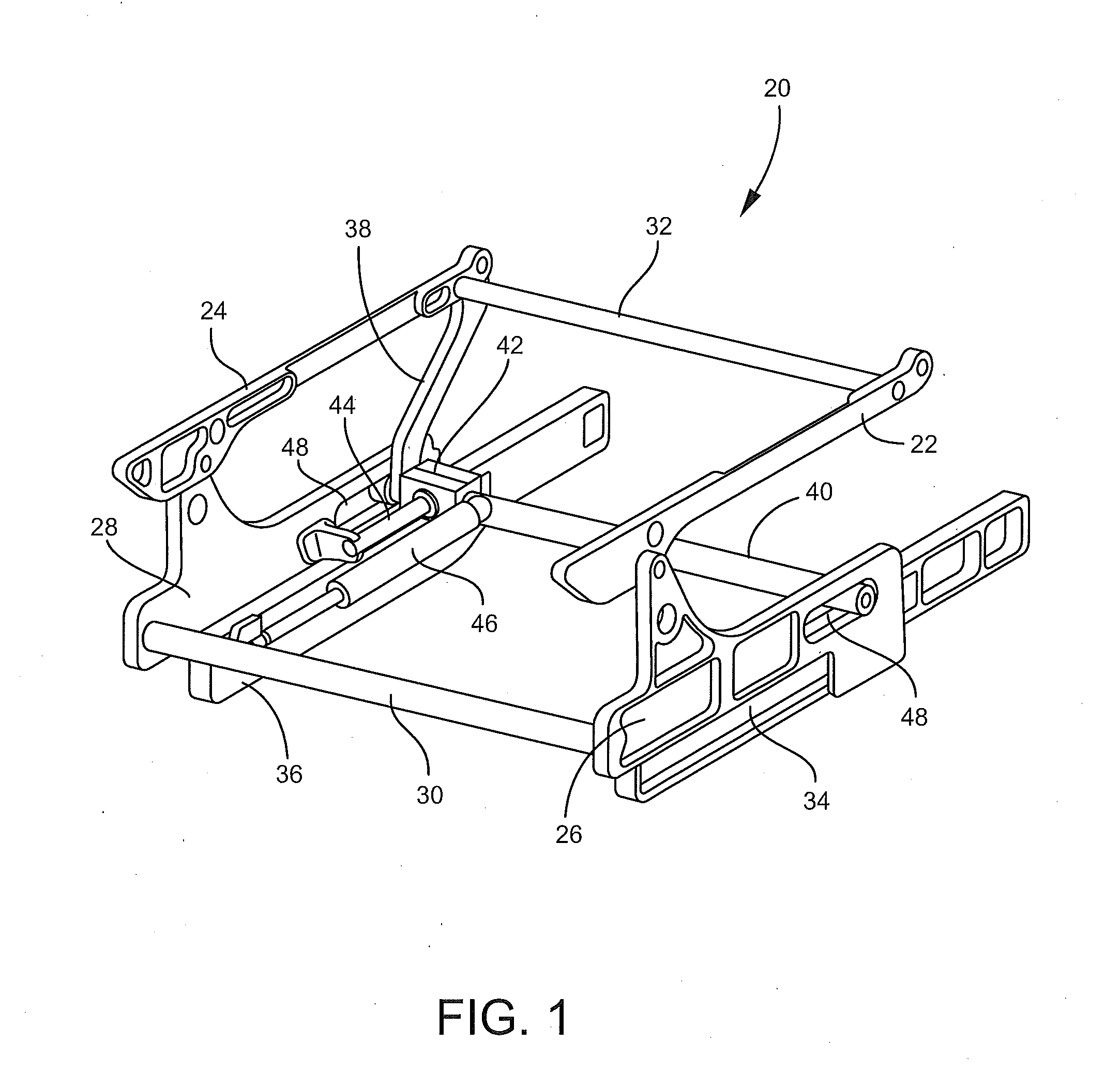

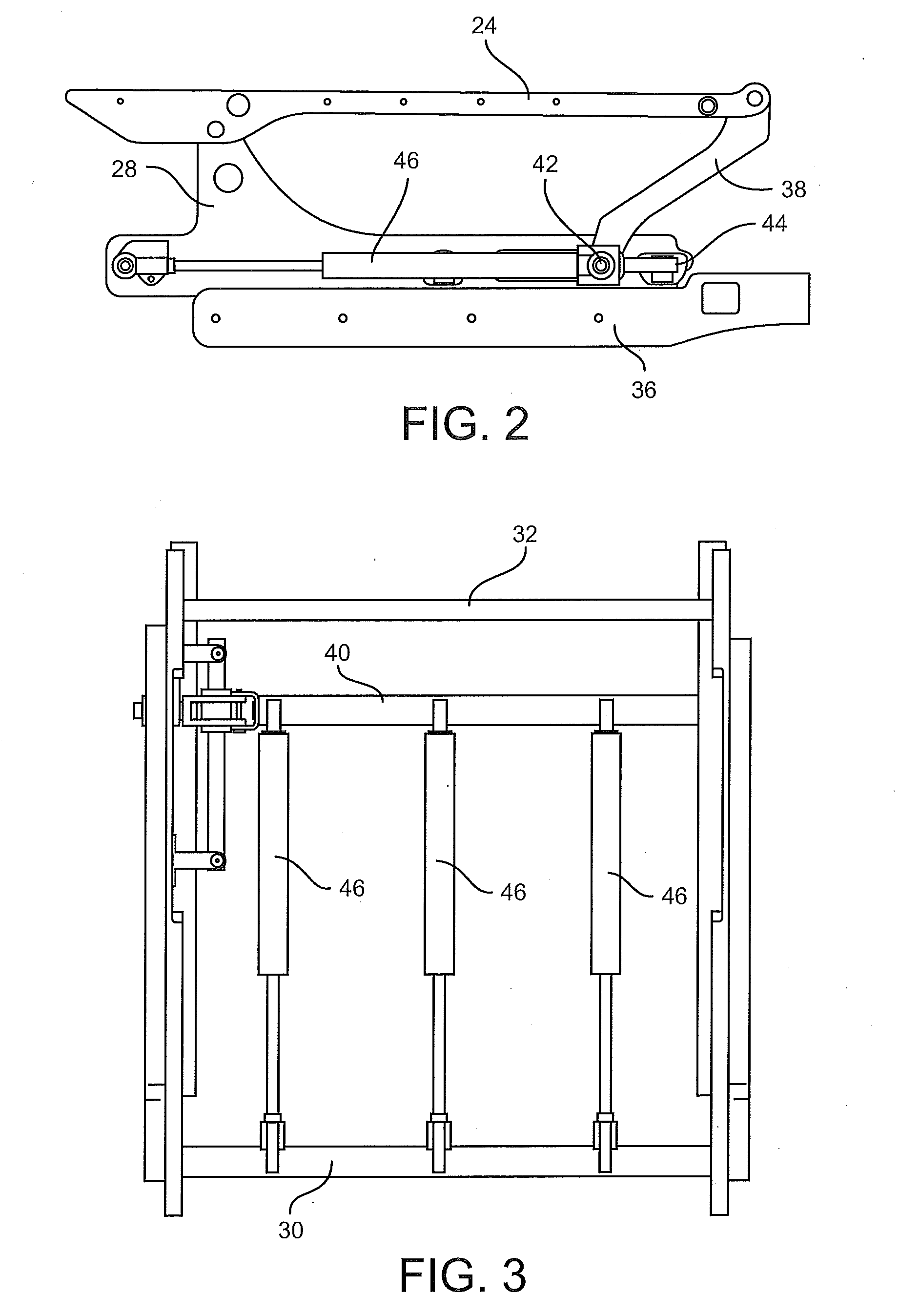

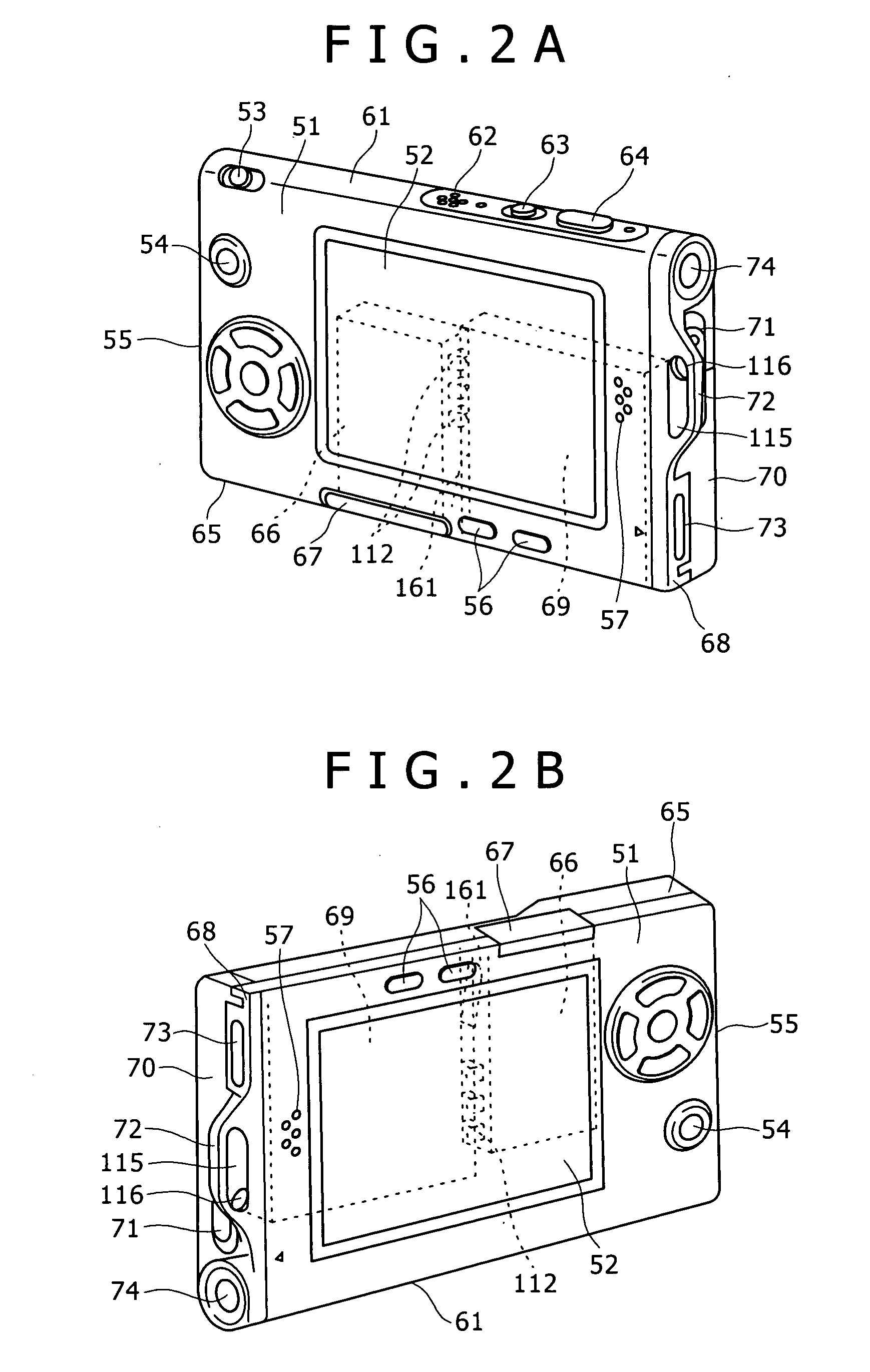

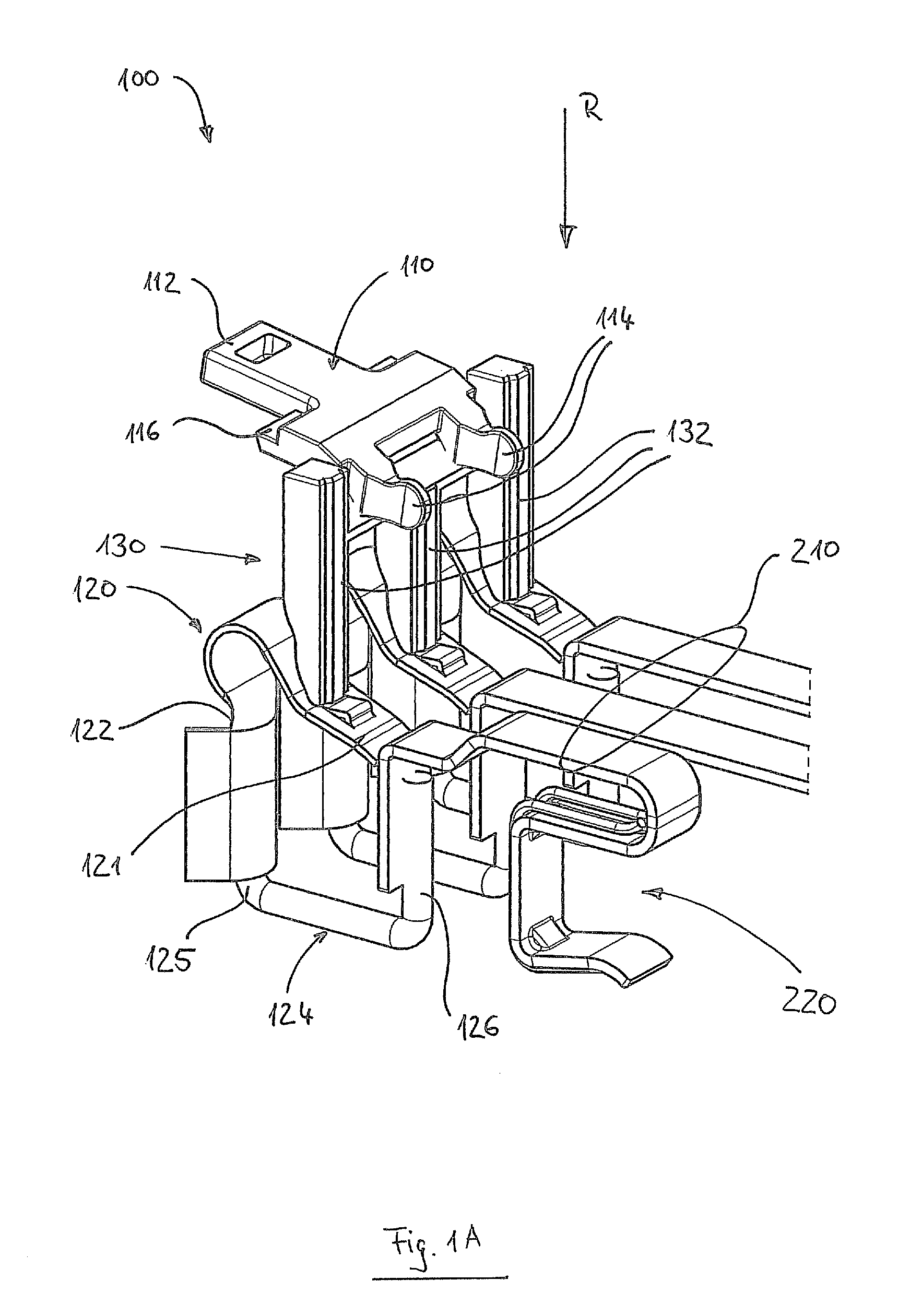

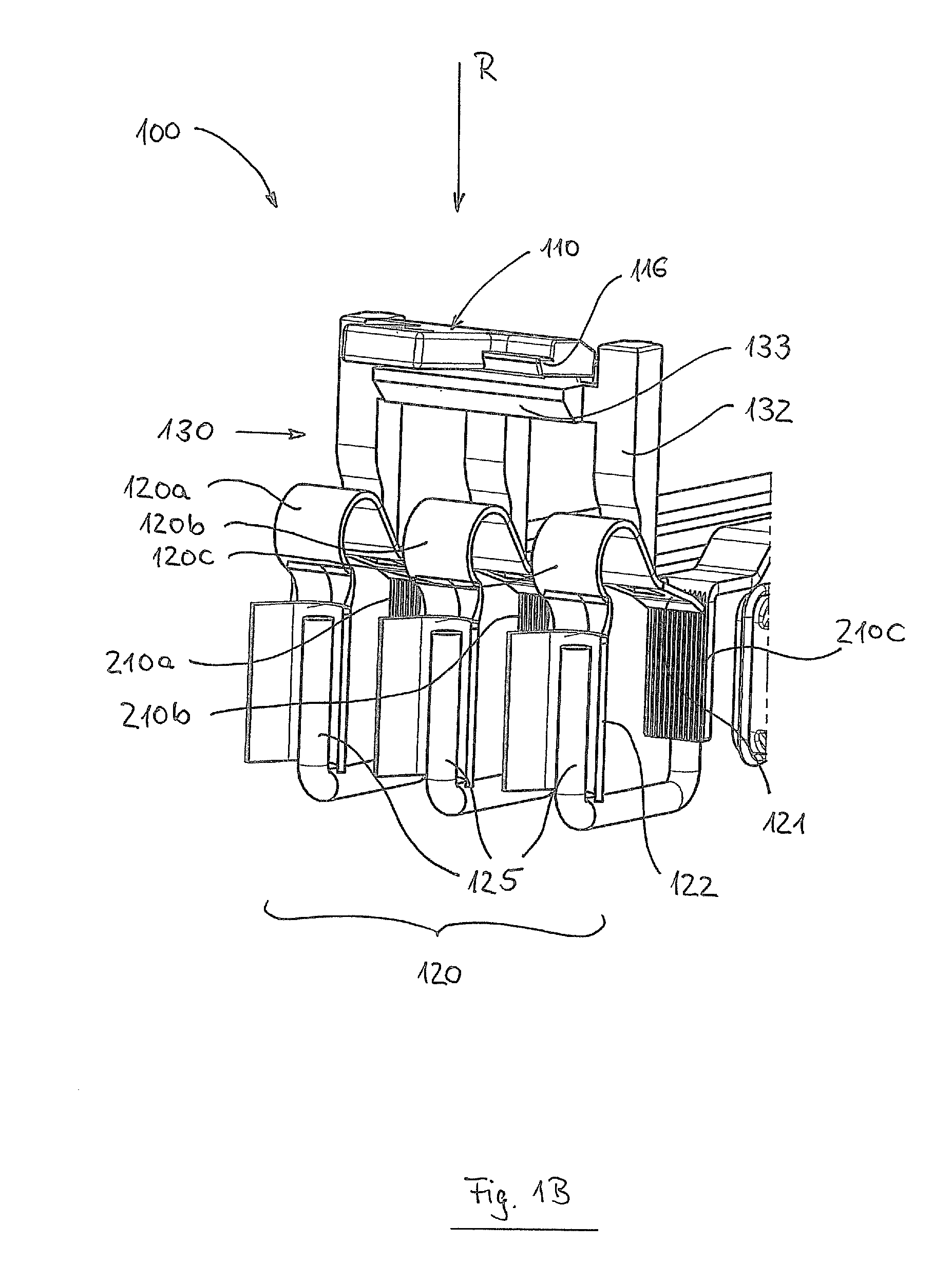

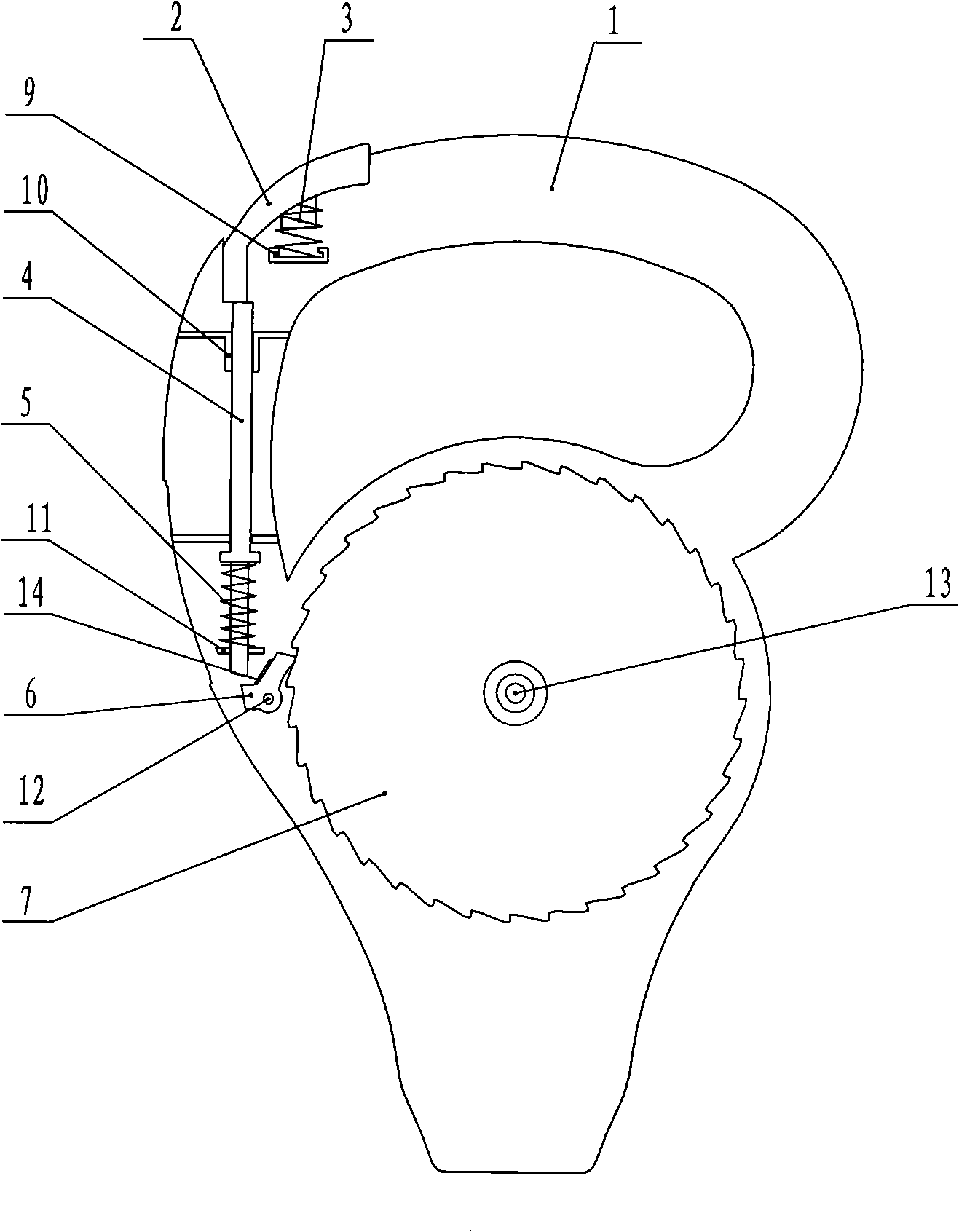

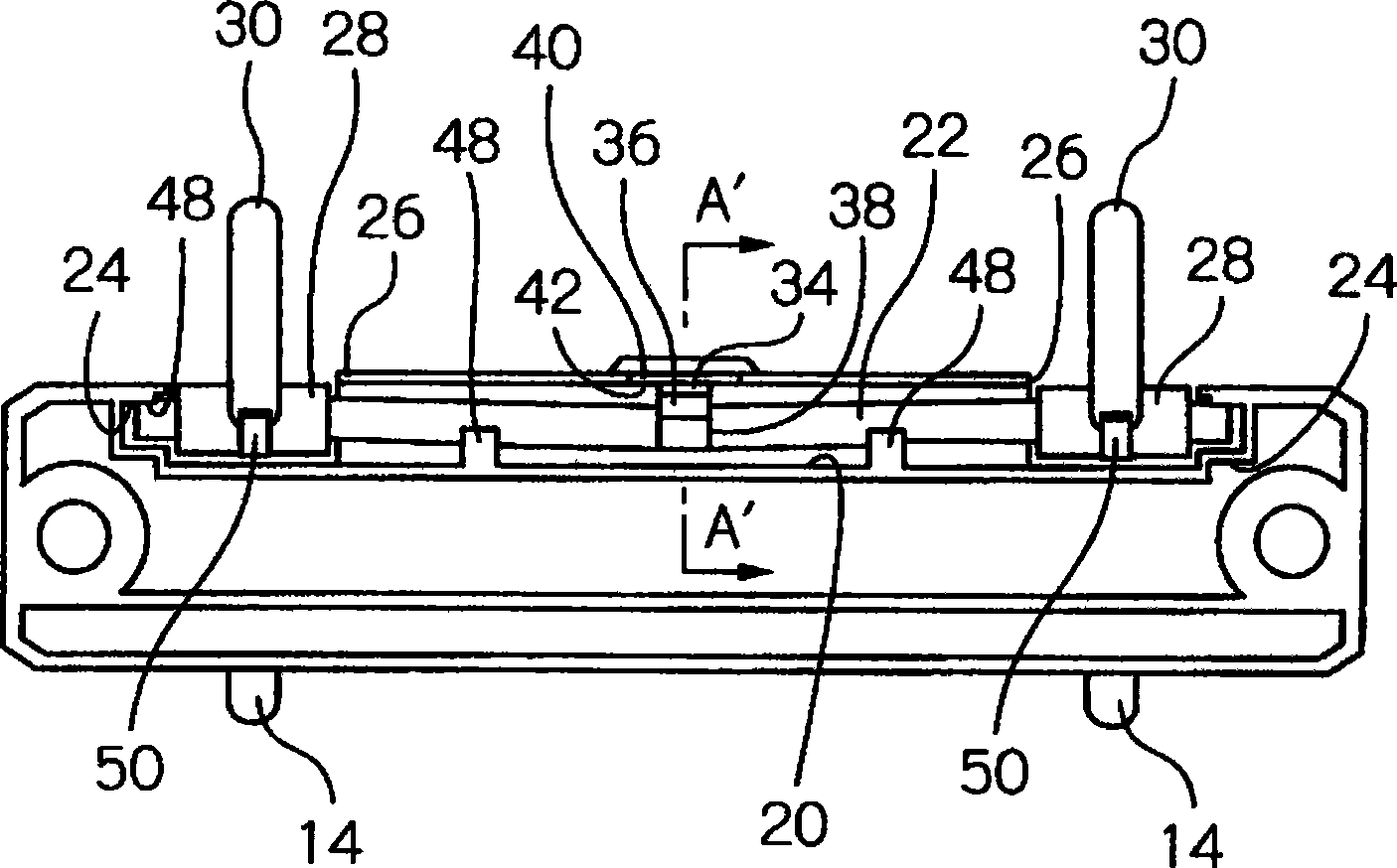

Auto-eject foot stand assembly with multi-viewing angles

InactiveUS20070012856A1Prevent escapeHigh spring forcePortable framesDetails for portable computersEngineeringView angle

An auto-eject foot stand assembly with multi-viewing angles for a visual device includes a foot having an axle perpendicular to the foot. The axle rotatably extends in a bracket. A gear is securely provided outside the axle and between the bracket and the foot. A spring is provided between the gear and the bracket. An elasticity plate is engaged with the gear. A locker is pivotally mounted on the bracket and operated by a metal spring plate to lock the gear. When the metal spring plate is pressed, the gear is released from the locker and the foot can be ejected under the elastic force of the spring. By the engagement between the gear and elasticity plate, the foot can be rotated and positioned at various desired viewing angels.

Owner:THOMSON LICENSING SA

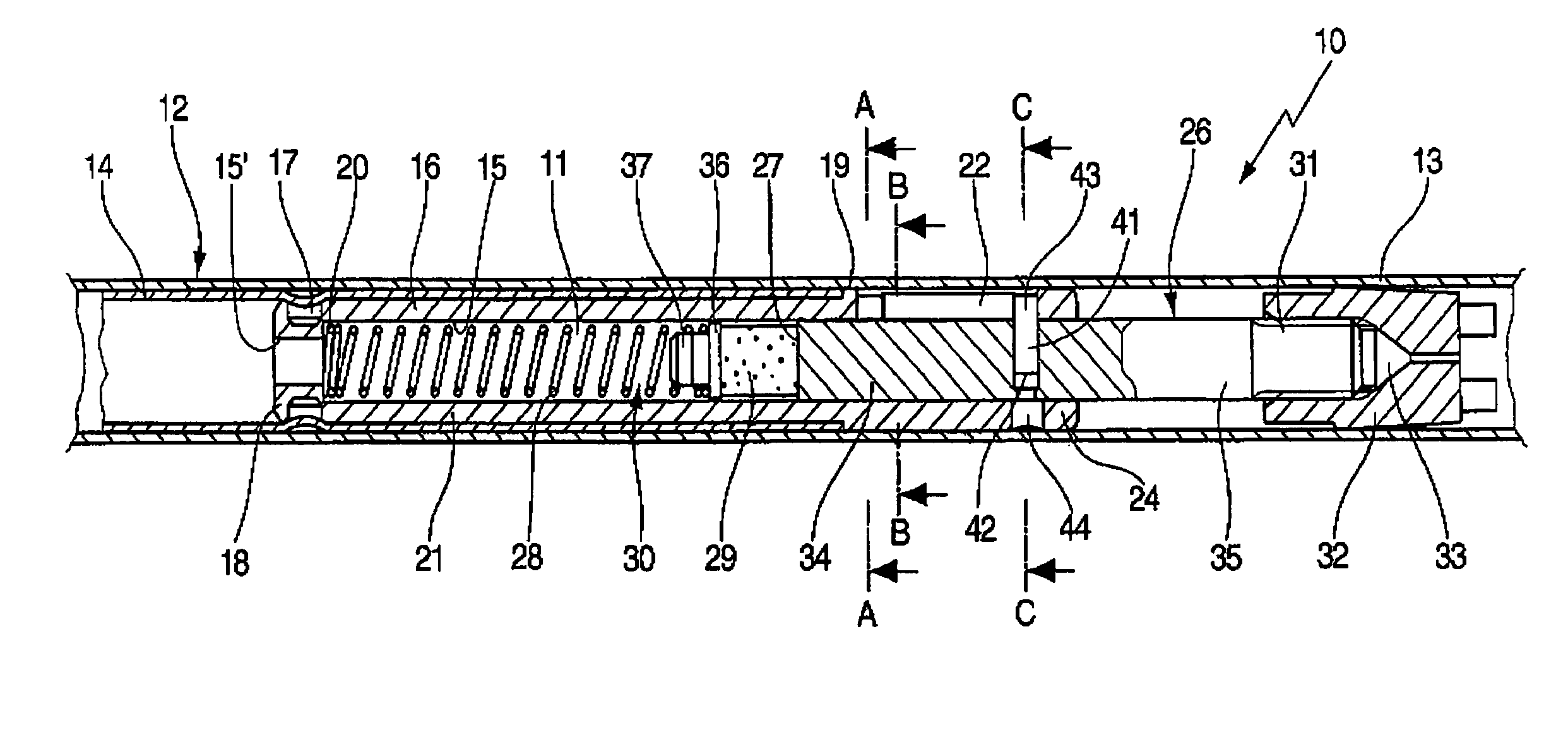

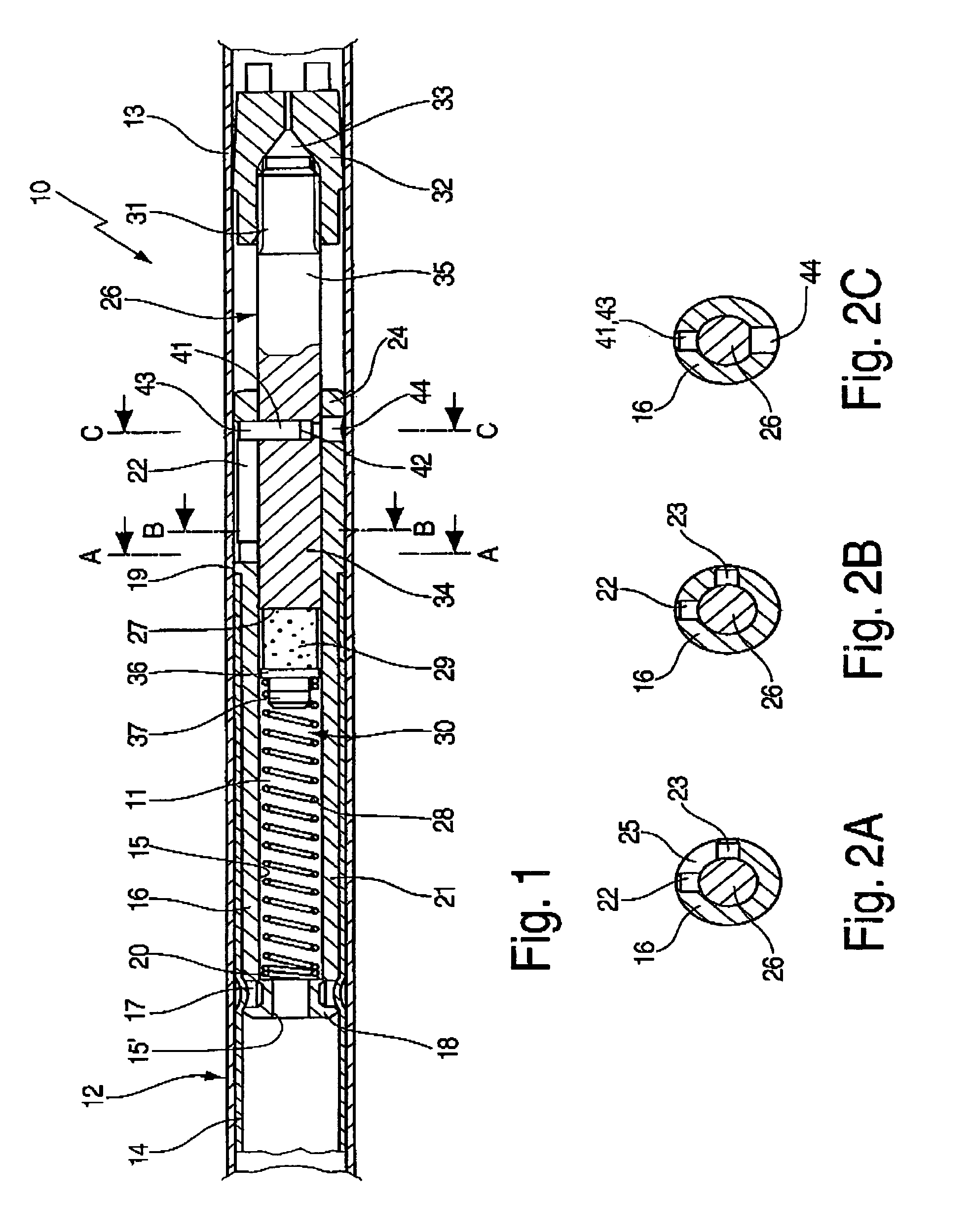

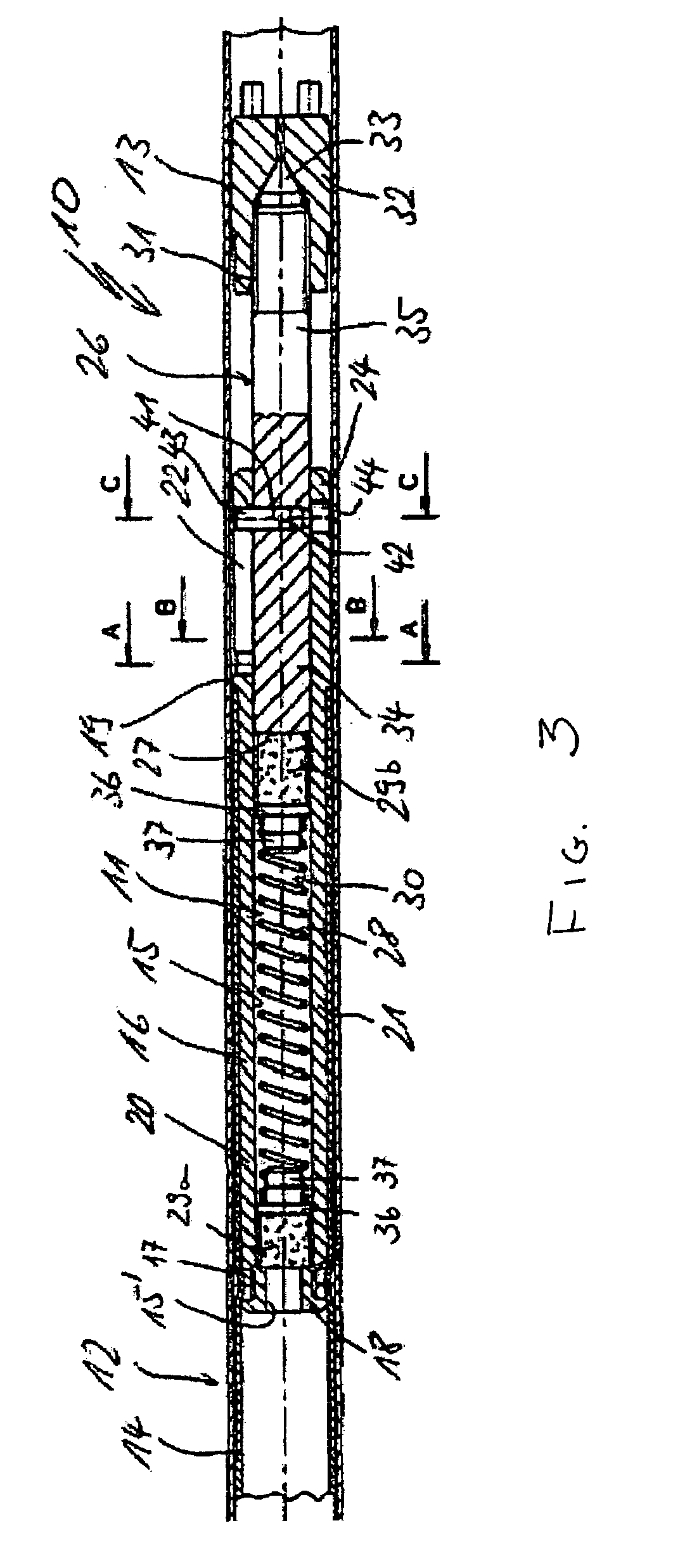

Distraction device

InactiveUS20050010233A1High spring forceHigh constantInternal osteosythesisProsthesisDistractionDetent

A distraction device for moving a one-part or two-part or separated bone apart in order to extend or bridge a bone gap. The device is optionally provided in the form of an intramedullary pin, which can be inserted into a medullary space of a bone and which has at least two elements that can be axially moved in relation to one another. The first element is joined to the second element via at least one detent device for securing a distraction movement, and a pushing module for distracting the first element is assigned to the second element and is joined to the second element in a manner that enables it to be locked.

Owner:WITTENSTEIN GROUP

Tensioner For Flexible Drives

A tensioner in accordance with the present invention employs a spindle and a tensioner arm which are preferably manufactured by a suitable manufacturing process, such as die casting, negating a requirement for machining operations. The biasing spring of the tensioner is wound with wire having a non-circular cross section to increase the spring force of the spring compared to a similar spring wound with wire of circular cross section and, as the tensioner arm is moved away from the flexible drive, the diameter of the biasing spring expands and the coils press a dampening shoe into contact with a wall of the tensioner arm producing a dampening force. The tensioner is simple to assemble and requires a relatively small package volume for the biasing force it can produce.

Owner:LITENS AUTOMOTIVE INC

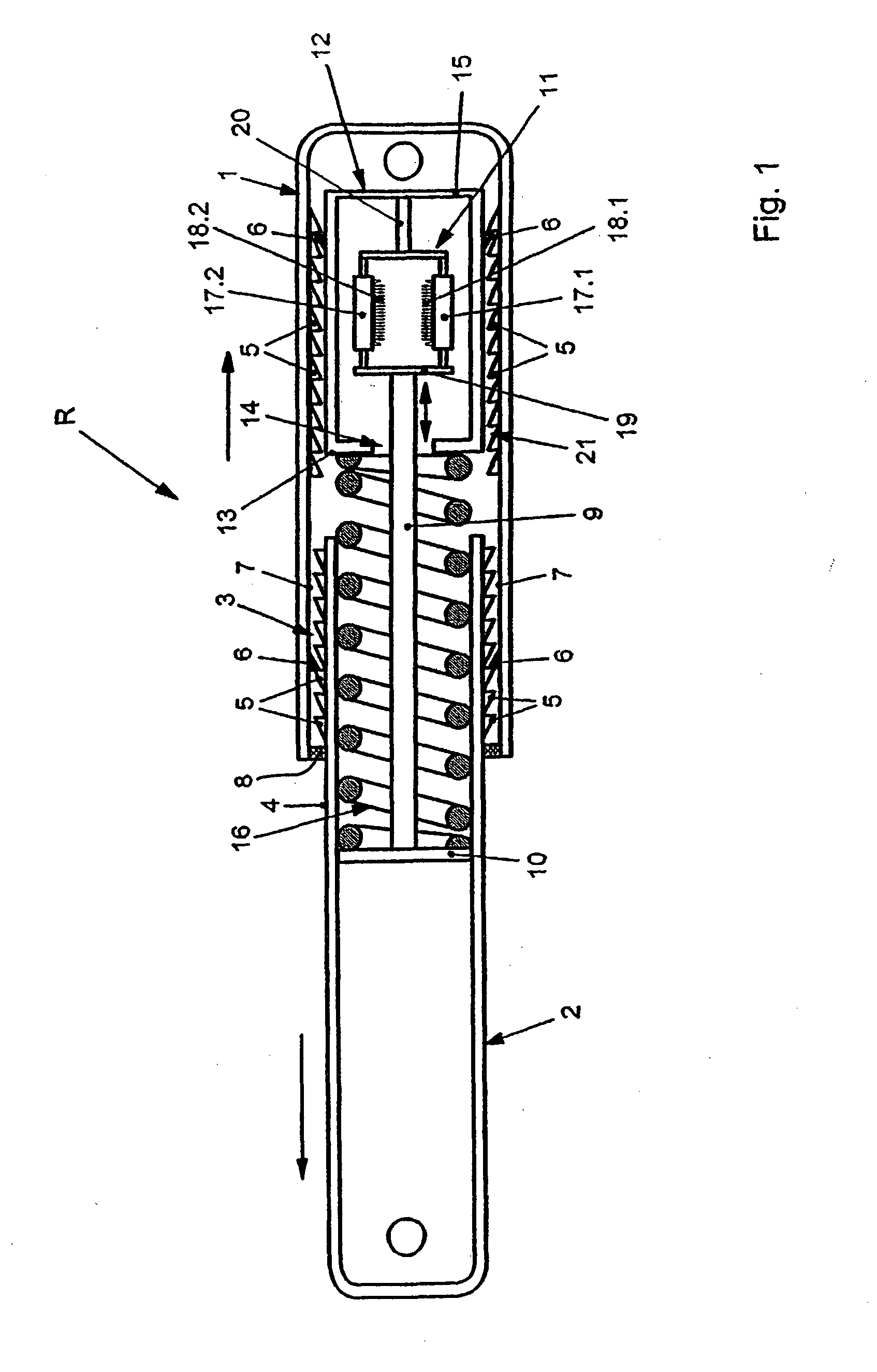

Trekking stick with shock absorber

InactiveUS7229101B2Less jerkySofter and quieter compression effectWalking sticksSnowboard bindingsElastomerEngineering

A stick, such as a trekking stick, ski pole or walking stick, is provided with a shock absorber between a first and a second tubular section of a stick shaft that is equipped with a handle and a stick tip. According to the invention, the shock absorber comprises a guide sleeve, which is held in a rotationally fixed manner in a tubular section and In which a damping rod that is held in an axially fixed manner on the other tubular section Is guided and a compression spring device, operating between the guide sleeve and the damping rod. The aim of the invention is to obtain softer shock absorbing characteristics and resilience characteristics that are less abrupt with minimal kickback. This is achieved by the provision of an elastomer spring in the compression spring device, said spring being located in series with a helical compression spring.

Owner:LEKISPORT

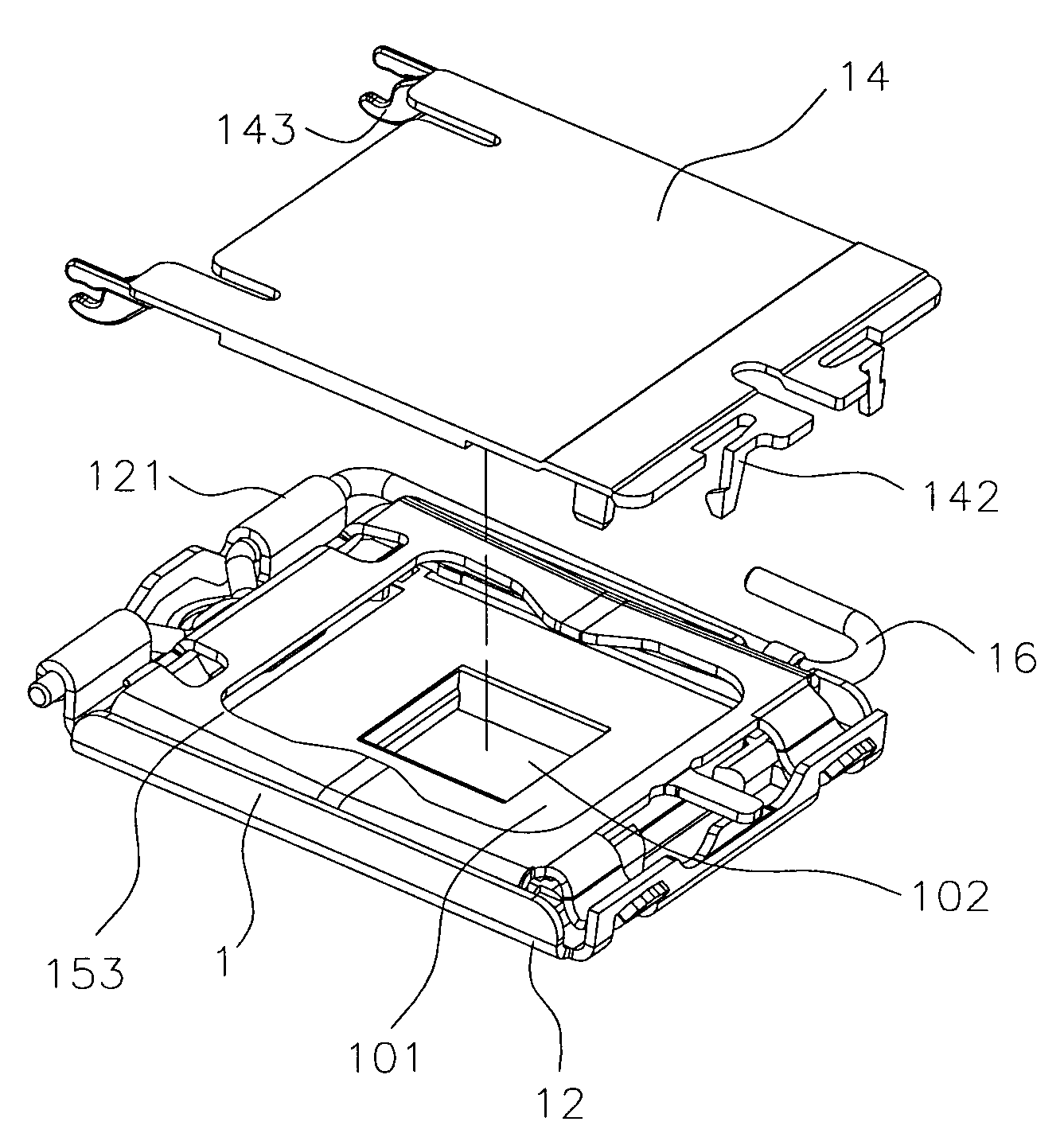

Buckling structure and an electrical connector element using the same

InactiveUS7182620B1Not to damageHigh spring forceEngagement/disengagement of coupling partsTesting/measuring connectorsElectrical connectorMechanical engineering

A buckling structure includes a buckling part having a buckling point. There is a waving point located in the inside of the buckling point. The buckling point rotates with the waving point to be operated between a buckling status and an opening status. An electrical connector element includes an electrical connector and an absorbed cover assembled on the electrical connector. The absorbed cover has a first wedged-hook that can wedge and fasten to the electrical connector. The first wedged-hook includes a buckling part having a buckling point. There is a waving point located in the inside of the buckling point. The buckling point rotates with the waving point to be operated between a buckling status and an opening status.

Owner:LOTES

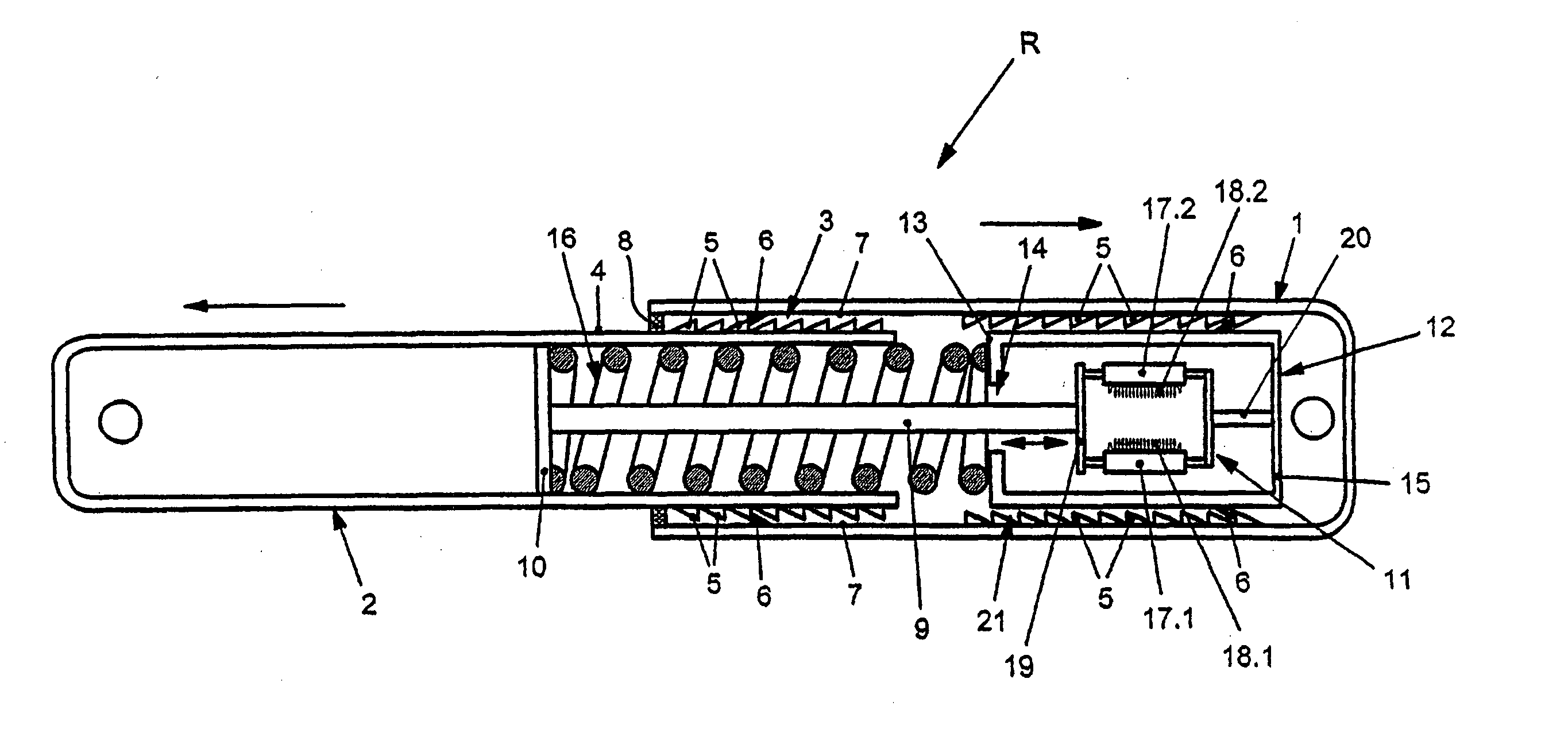

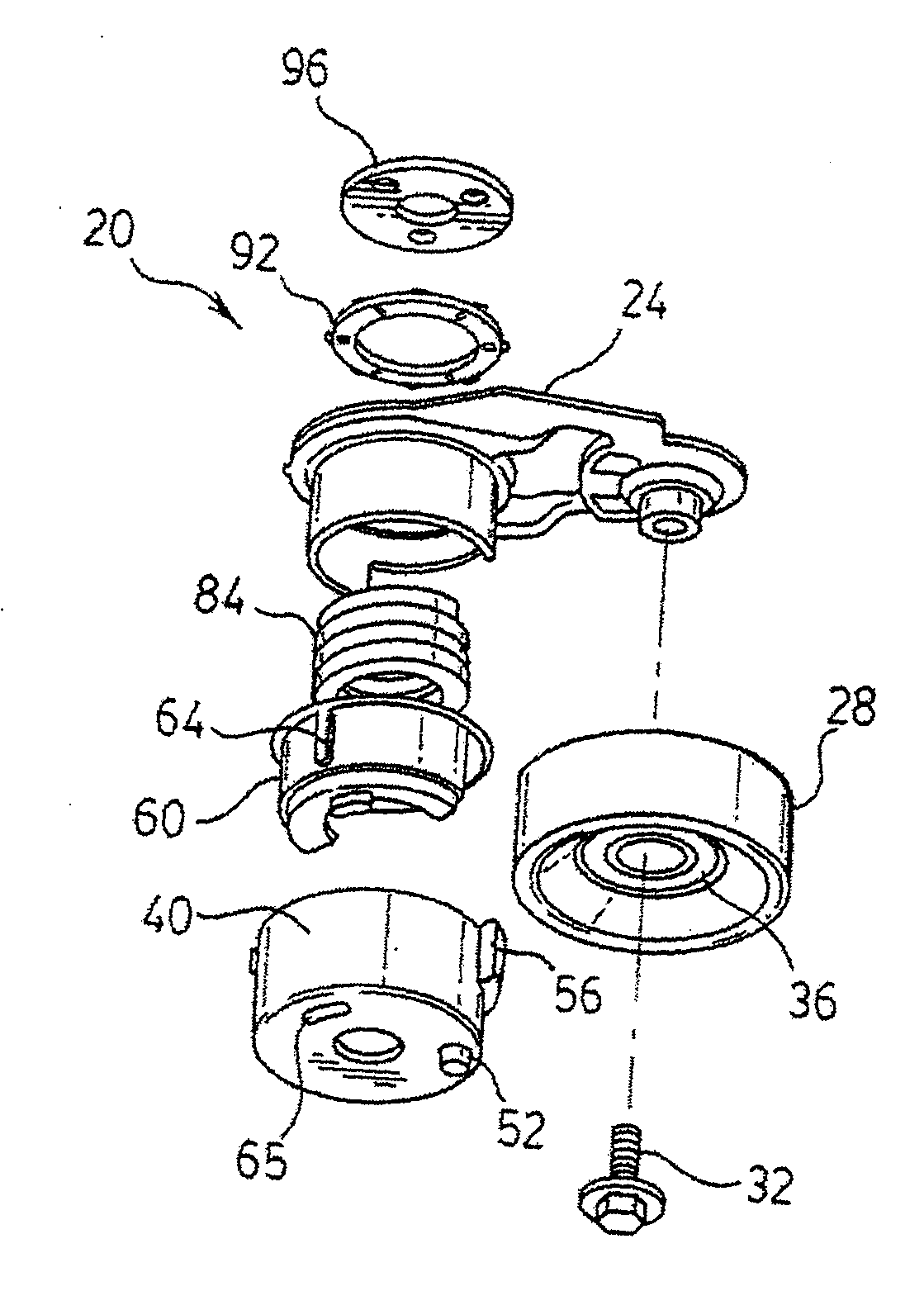

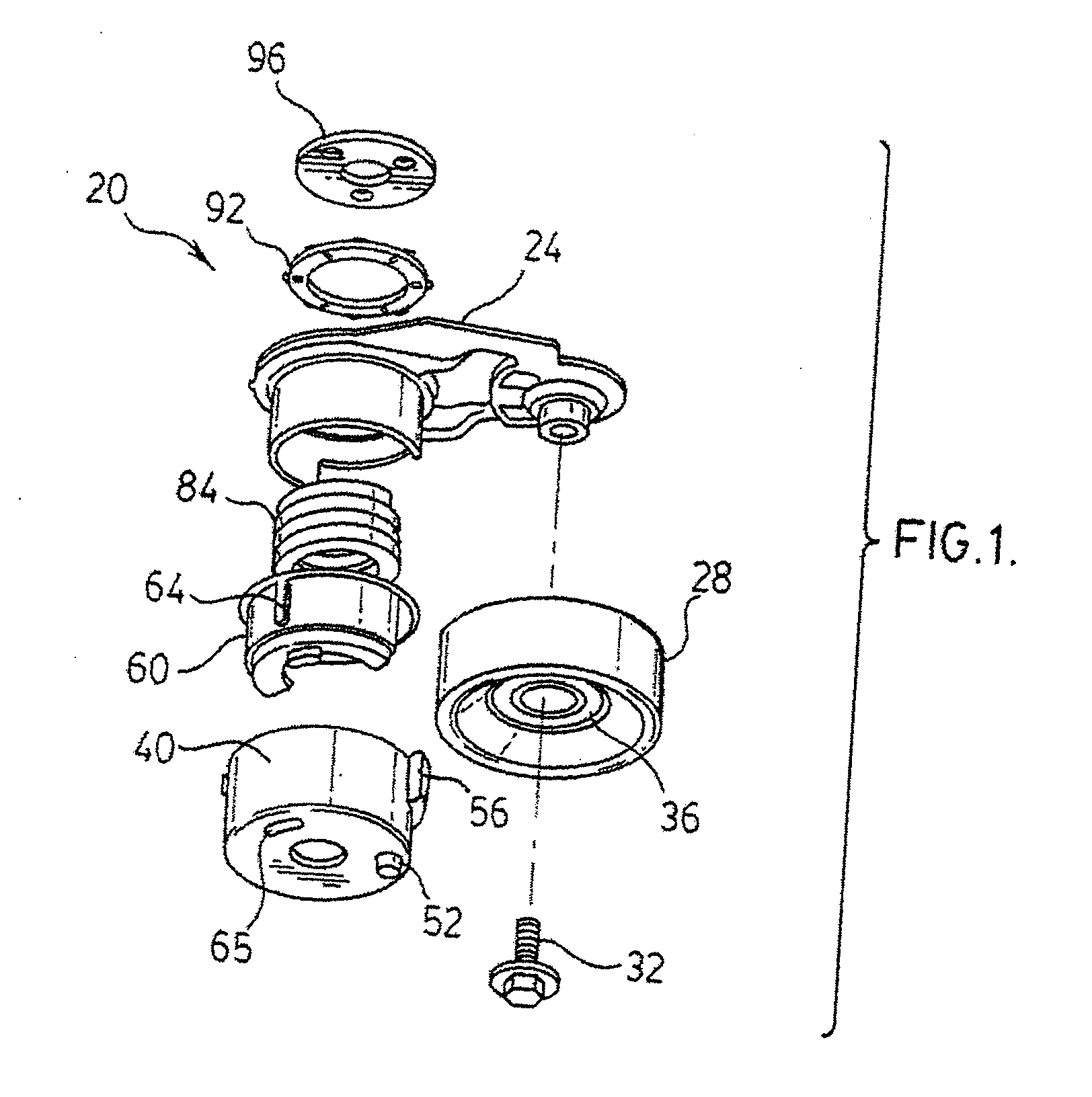

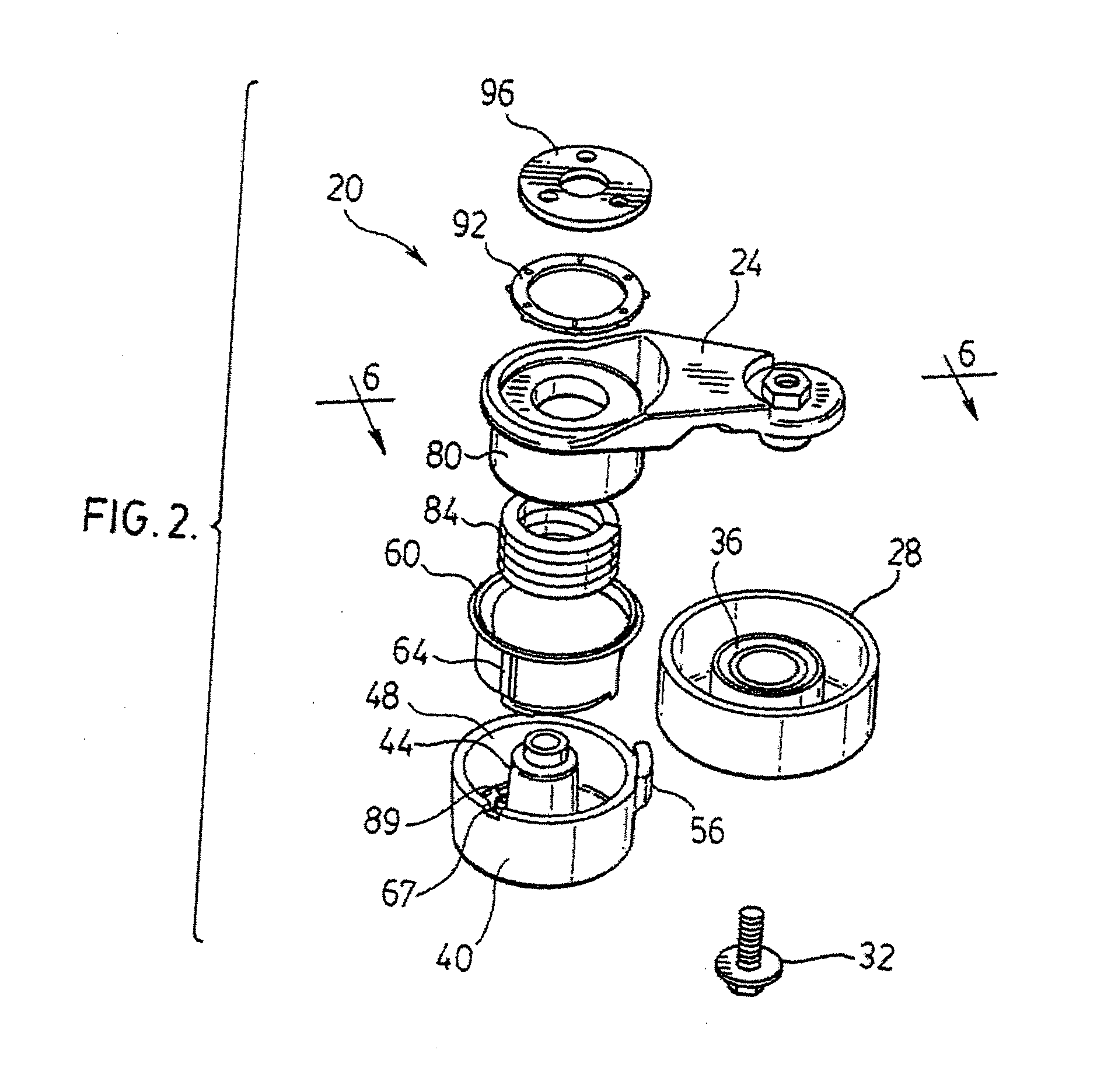

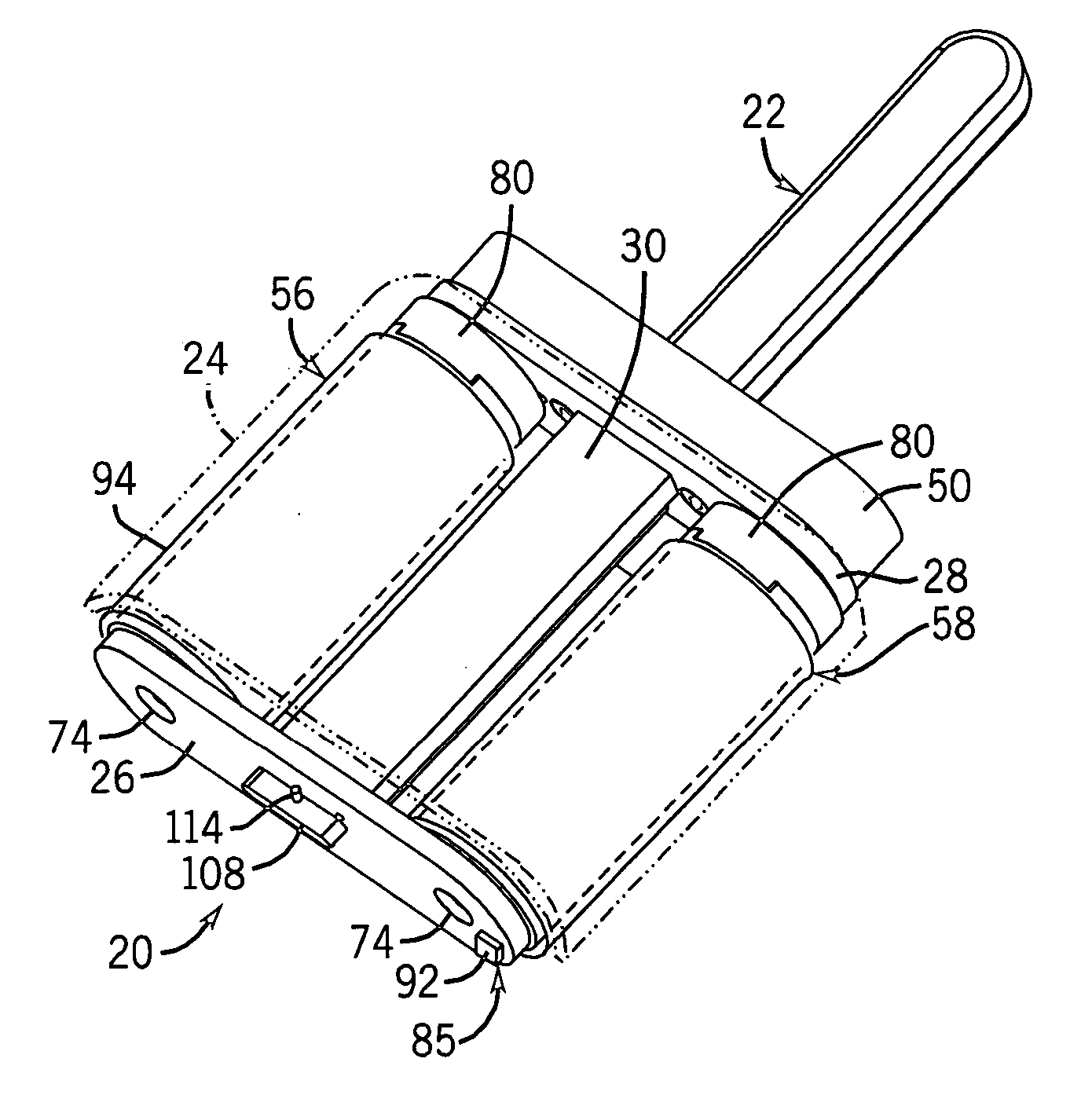

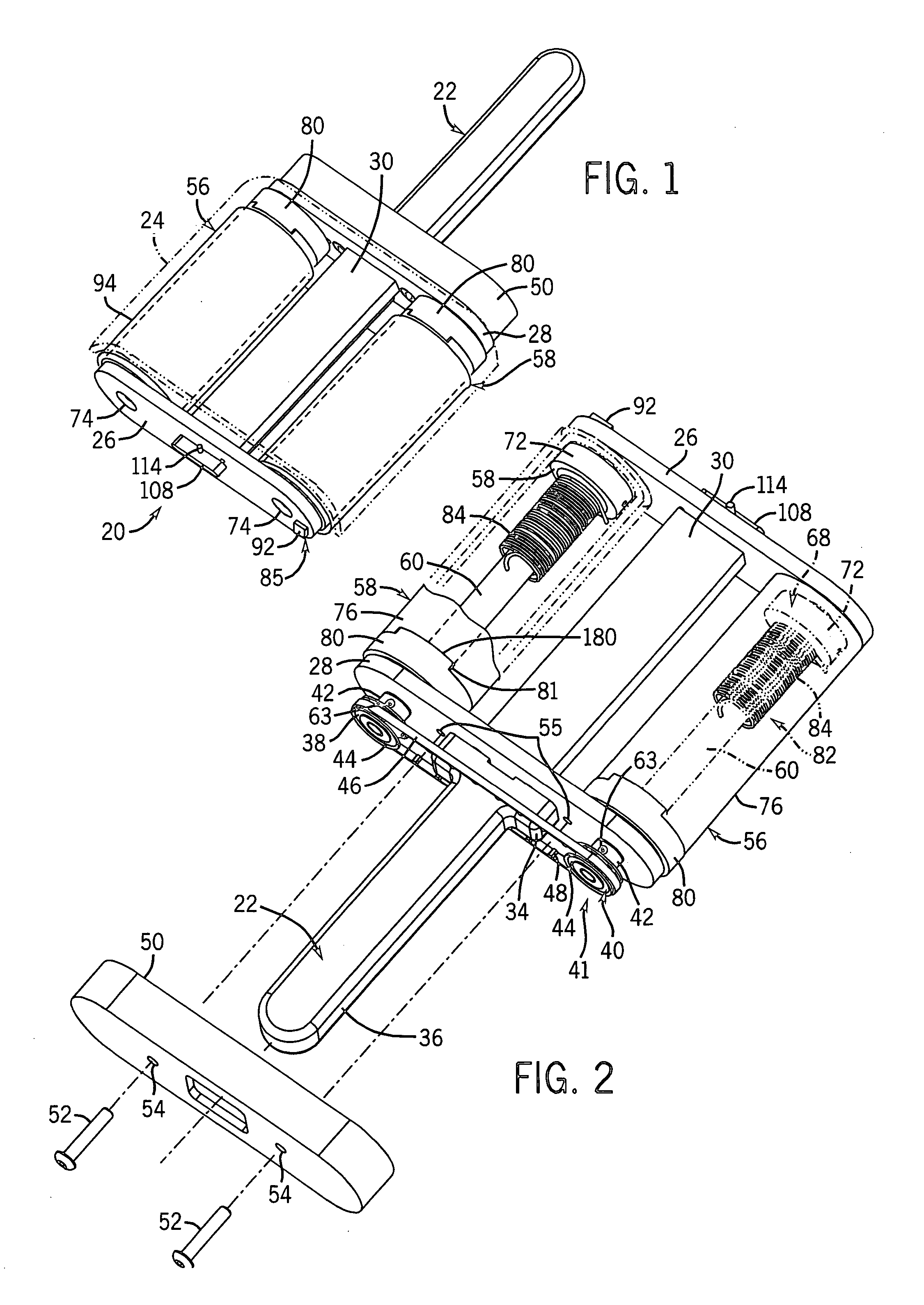

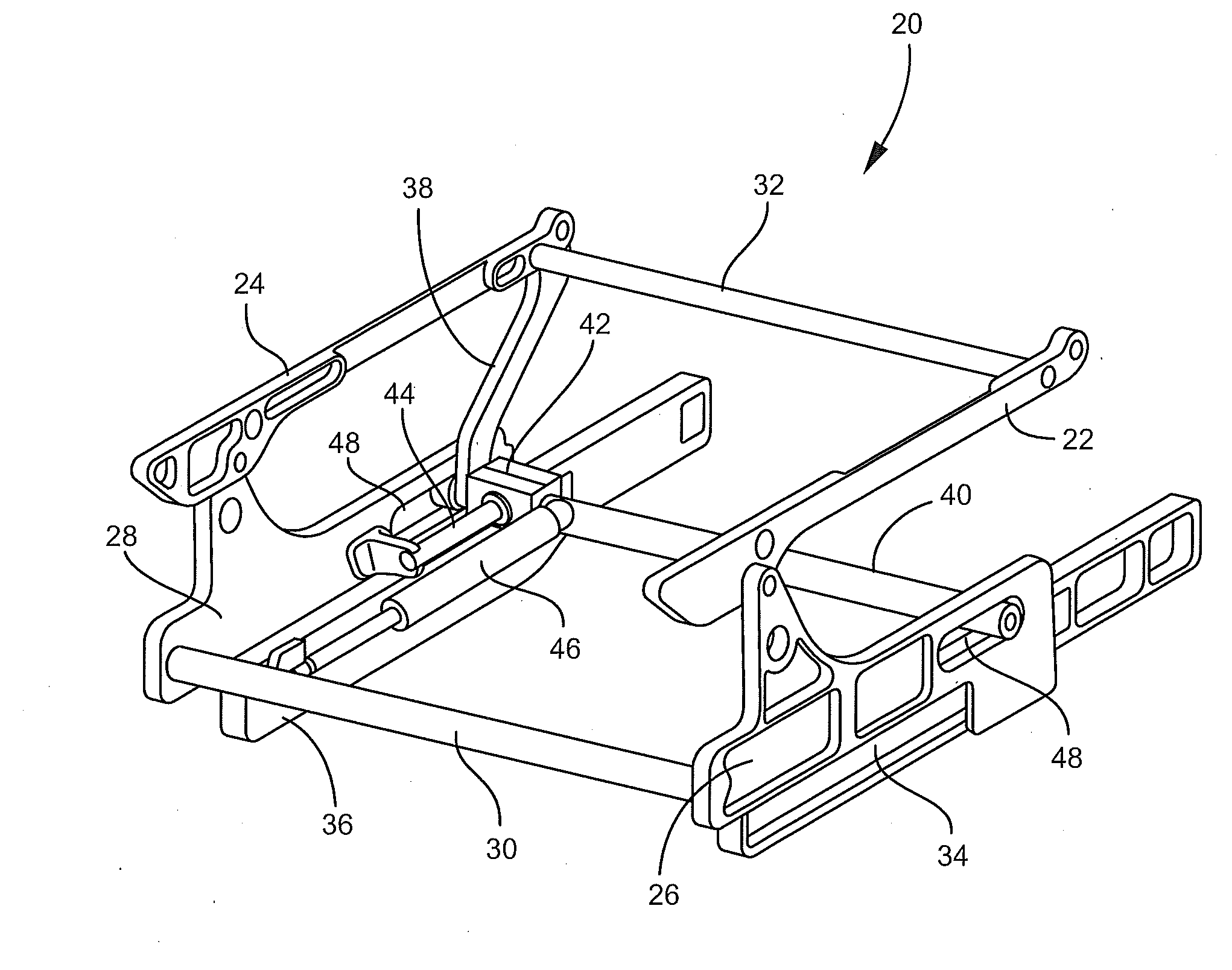

Continuous adhesive roller

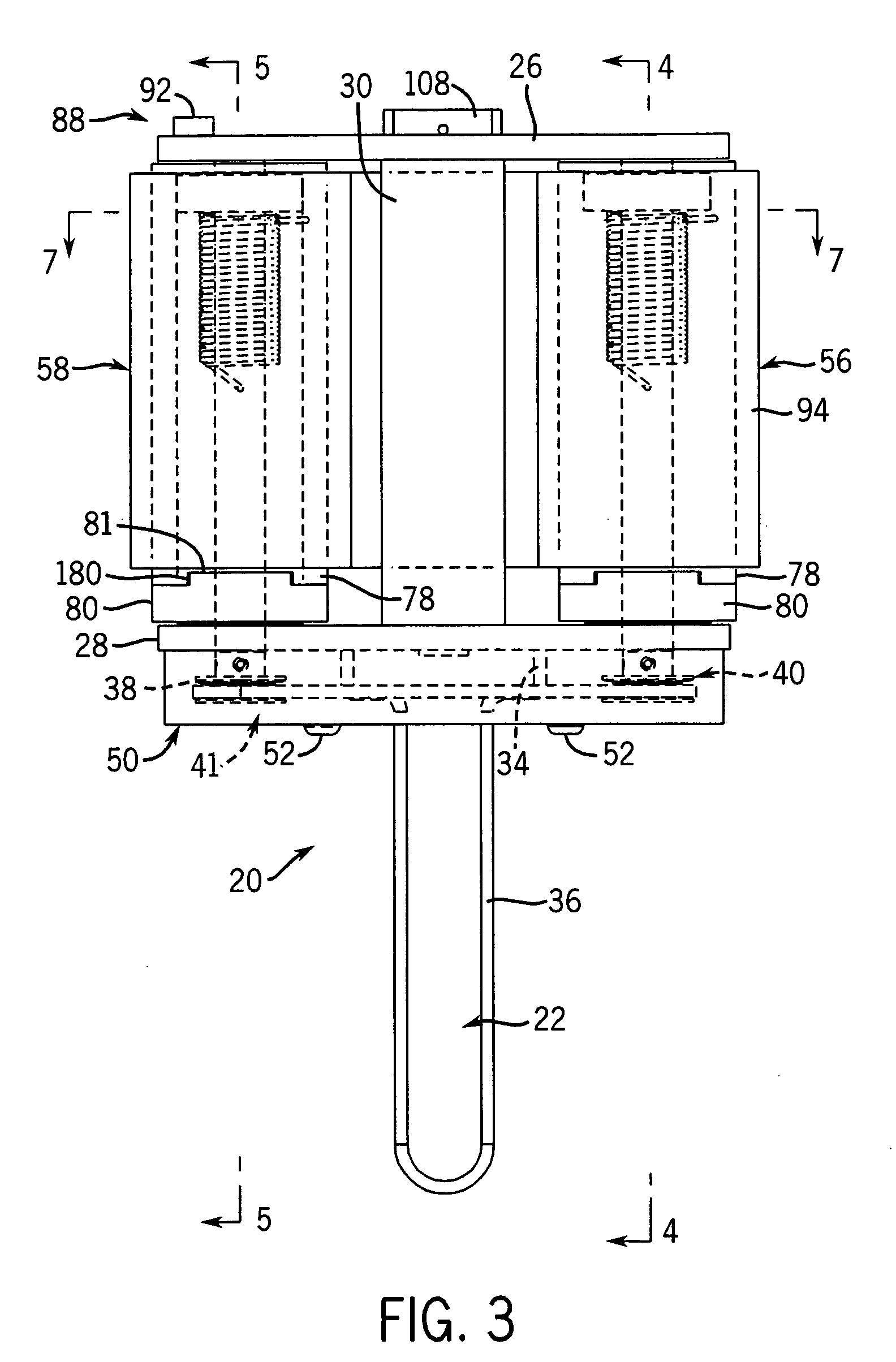

ActiveUS20060254017A1Accurate contactHigh spring forceLiquid surface applicatorsHousehold cleanersEngineeringSheet material

A device (20) for cleaning surfaces is provided utilizing a web (94) of a tackified sheet material movably secured between rollers (56, 58) on the device (20) that enable the web (94) to be moved over the surface in opposite directions. The device (20) includes a supply roller (56) and a take-up roller (58) secured to opposed ends of the web (94) of adhesive sheet material, with at least one roller (56, 58) including a biasing mechanism (82) disposed within the roller (56, 58). The web (94) can be engaged with the surface by passing over a number of idler rollers (98) positioned between the supply roller (56) and take-up roller (58). The biasing mechanism (82) is designed to bias the movement of the web (94) onto the take-up roller (58), such that the mechanism (82) can be selectively operated to advance the web (94) from the supply roller (56) to the take-up roller (58) to expose a clean section of the adhesive sheet material (94). A synchronization mechanism (41) is also connected between the rollers (56, 58) to enable the rollers (56, 58) to rotate in a synchronous manner, regardless of the amount of the web (94) that is positioned on the rollers (56, 58) to continually tension the web (94) a proper amount. The device (20) also is designed to enable the supply roller (56) and take-up roller (58) to be removed as a unit for replacement and disposal after the entire length of the web (94) of adhesive sheet material has been utilized to clean a surface or surfaces. The rollers (56, 58) can be disposed within a housing (50, 202) having a handle (22, 205) thereon to facilitate use of the device (20). The handle (22, 205) can extend from one side of the housing (50) or can be secured to top surface of the housing (202).

Owner:SC JOHNSON & SON INC

Handheld power tool

A handheld power tool, including a tool socket on a drive shaft for purposes of holding a tool, the drive shaft executing a rotating and partially tangentially striking movement using a tangential striking mechanism drivable by a drive. The tangential striking mechanism has an anvil associated with the drive shaft and a hammer associated with the drive, movable with respect to each other so as to strike each other axially when under the effect of the force of at least one first spring, and to strike each other tangentially when the anvil and the hammer are rotated. The hammer has a main mass, and an extra mass that is under the effect of a second spring couplable to the main mass.

Owner:HILTI AG

Door holder

ActiveCN101652526AChange distributionHigh spring forceBuilding braking devicesWing fastenersEngineeringMechanical engineering

Owner:EDSCHA ENG GMBH

Aircraft seat with occupant weight sensing mechanism to adjust tilt-recline force

ActiveUS20150307194A1Assisted drivingHigh spring forceOperating chairsSeating arrangementsGas springEngineering

A weight sensing mechanism for an aircraft seat pan configured to adjust seat pan recline force and including a gas spring arranged between a fixed seat frame member and a movable seat pan member, the gas spring arranged to compress as the seat pan reclines in response to a load on the seat pan, and unloads upon removal of the load on the seat pan to assist in returning the seat pan to upright, and a helper spring positioned forward of and coaxially with the gas spring arranged to deflect under any load on the seat pan. A recline-capable seat pan assembly including a passenger body weight sensing mechanism.

Owner:BE AEROSPACE INCORPORATED

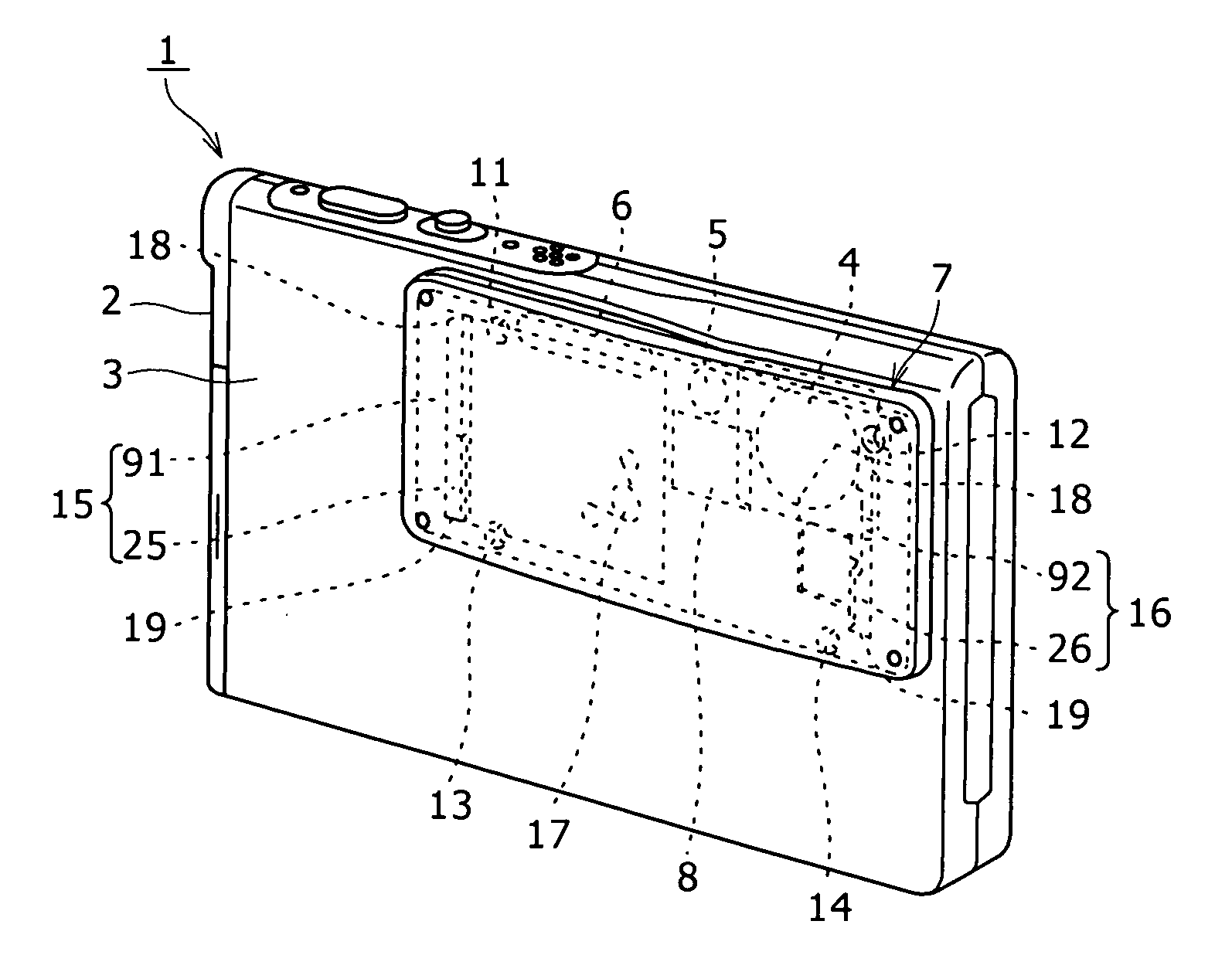

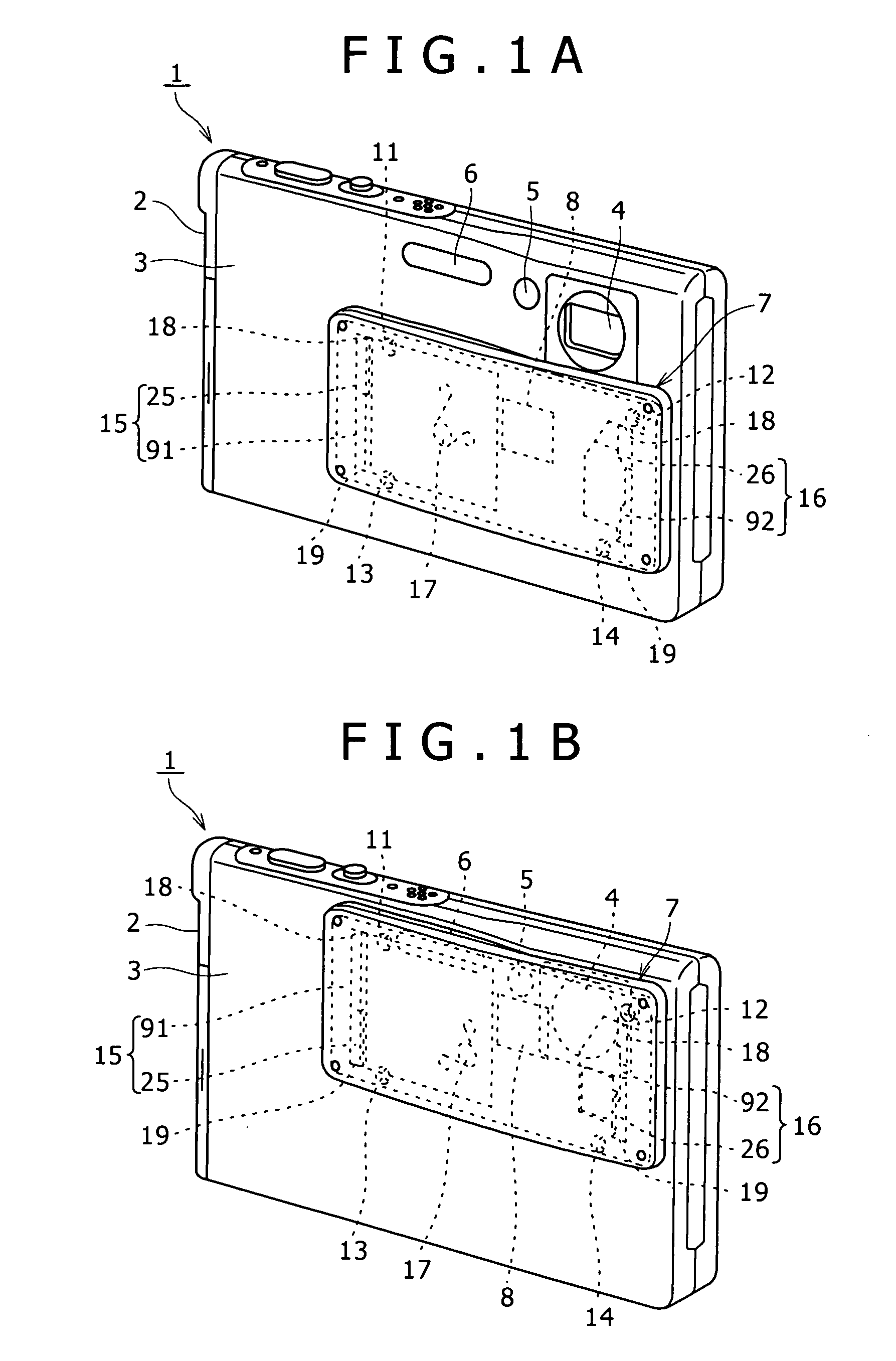

Electronic instrument

InactiveUS20060202659A1High spring forceMinimize heightEngagement/disengagement of coupling partsBatteries circuit arrangementsSpring forceElectronic instrument

Disclosed is an electronic instrument having a housing, a battery accommodating section provided in the housing, and a spring for battery ejection which is pressed by a battery inserted into the battery accommodating section and thus stored in power. In the instrument, the spring for battery ejection includes a spring force generation portion, a first arm portion provided at one end of the spring force generation portion, a second arm portion that is provided at the other end of the spring force generation portion and extends with a certain opening angle with respect to the first arm portion, a first shaft portion provided at an end of the first arm portion, and a second shaft portion provided at an end of the second arm portion. The first shaft portion is mounted in a first bearing portion provided in the housing, and the second shaft portion is slidably mounted in a second bearing portion provided in the housing.

Owner:SONY CORP

Friction coupling

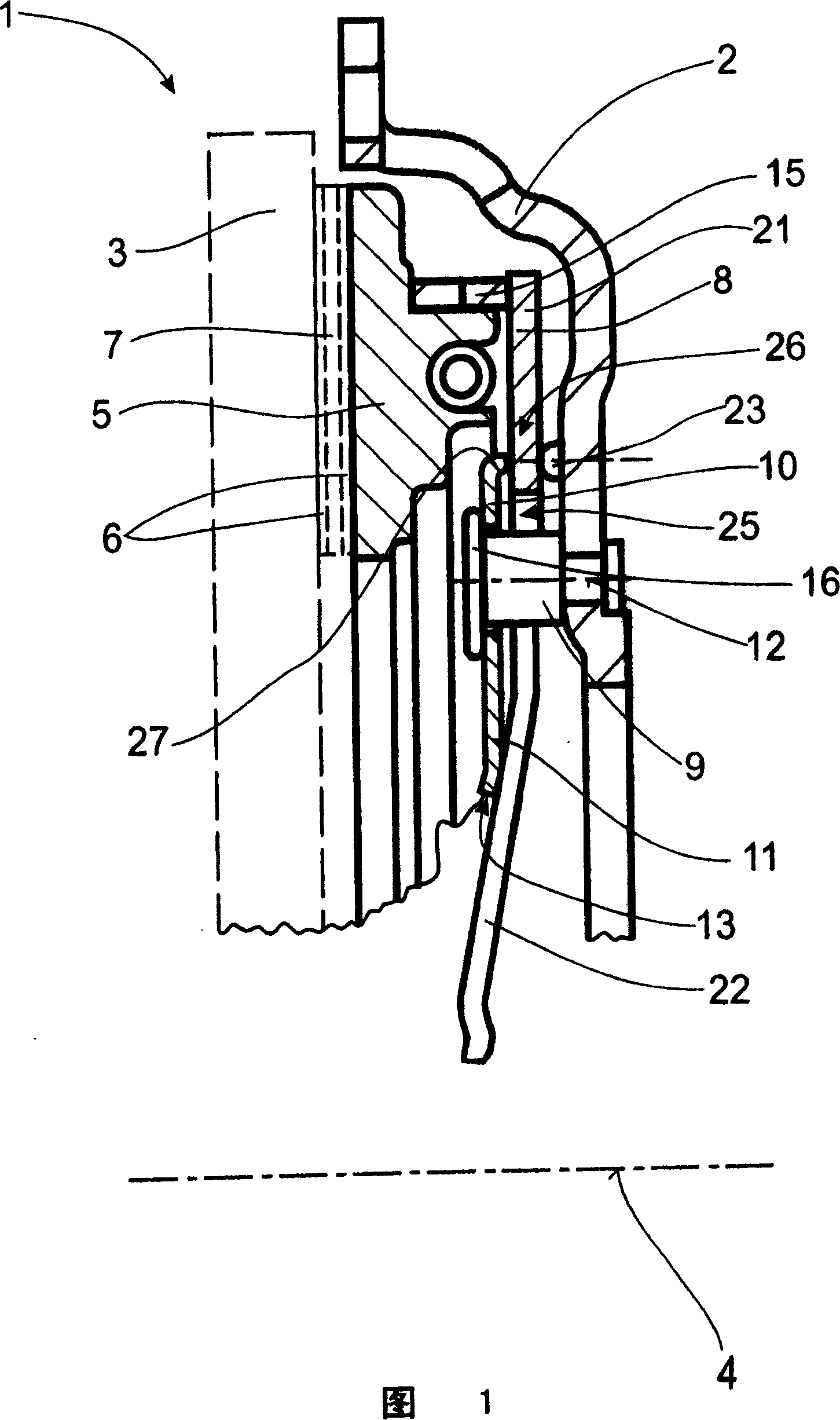

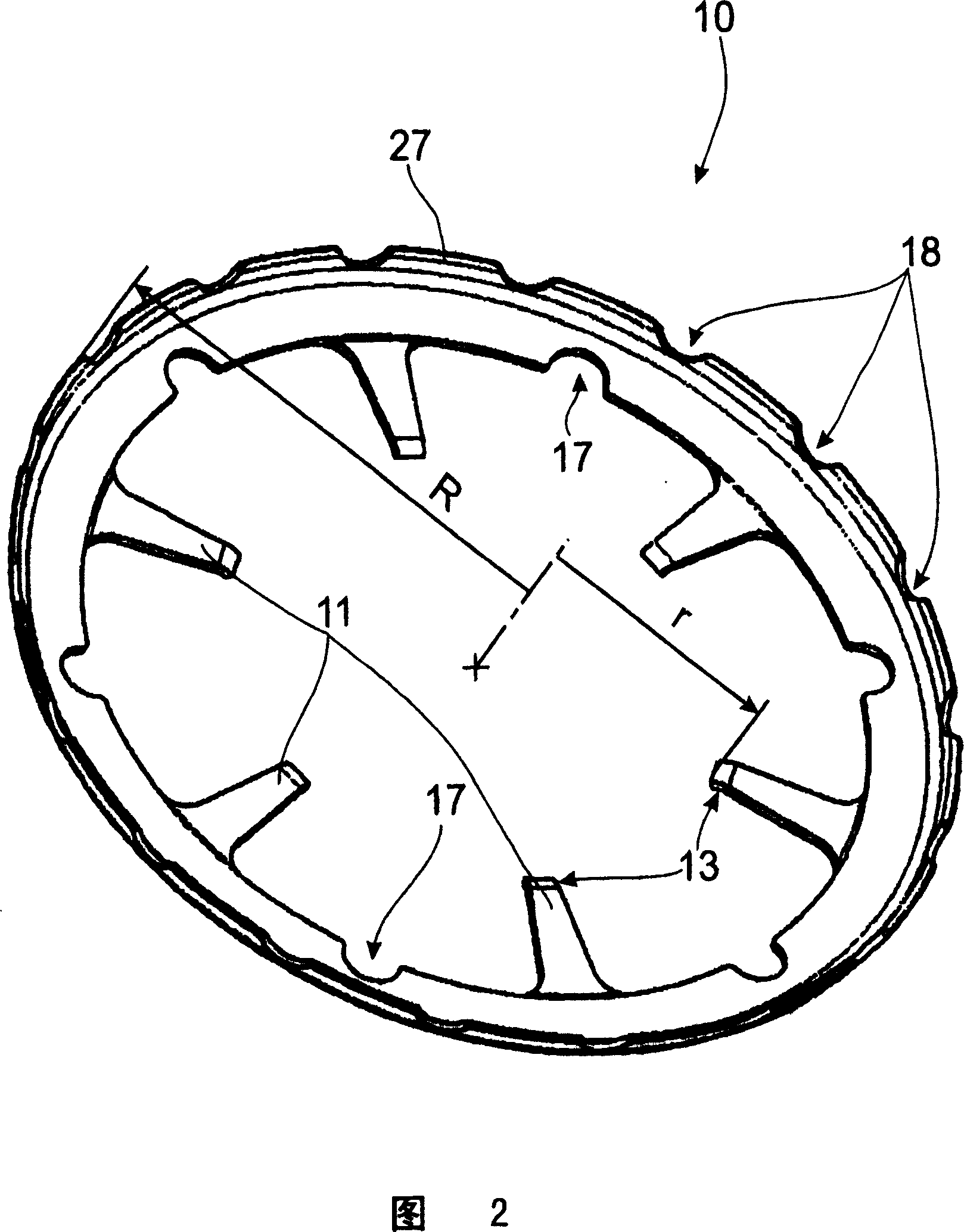

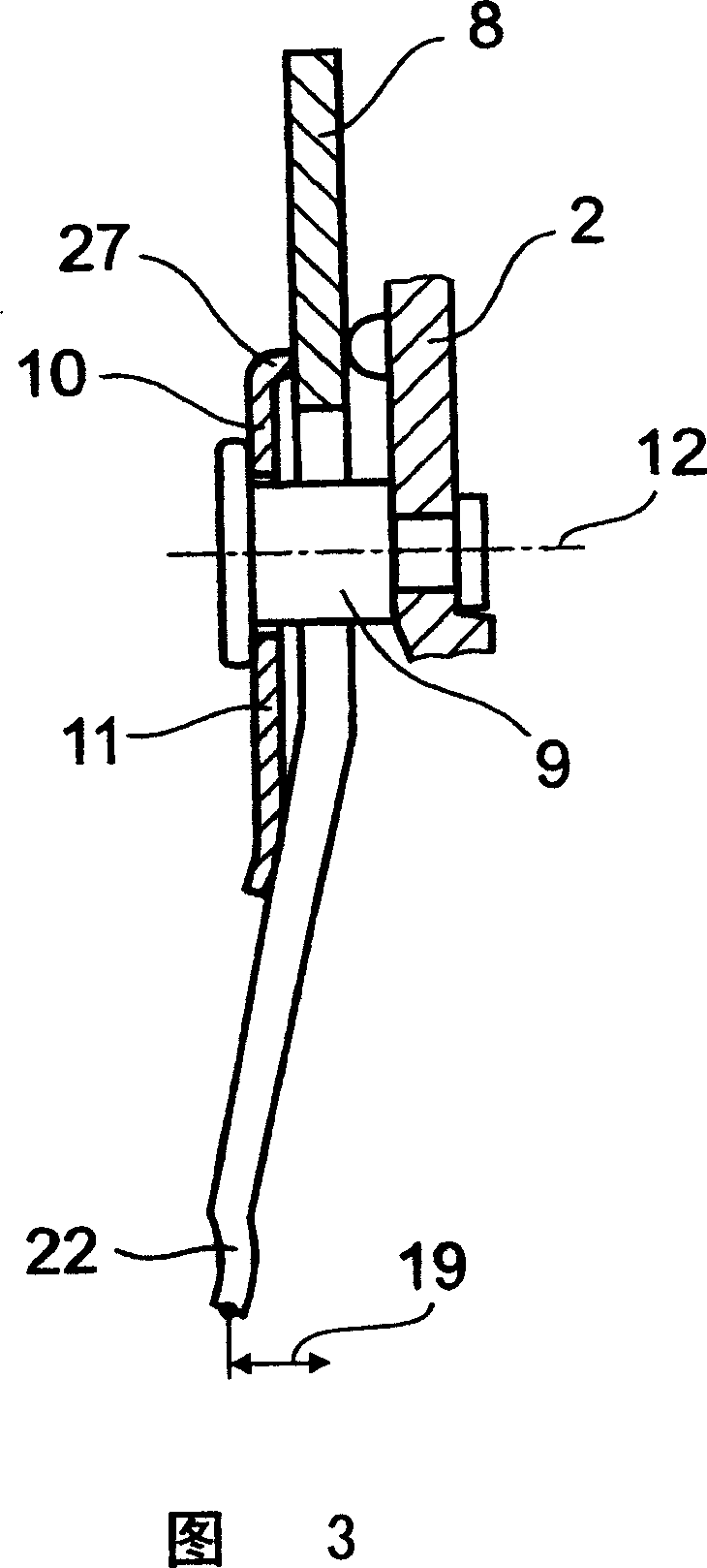

Friction clutch, with a housing; a pressure plate that is not relatively rotatable but axially displaceable in the housing; a clutch plate with at least one friction lining between the pressure plate and the friction surface of the flywheel; a diaphragm spring, It has an actuating tongue formed on it, the diaphragm spring can act on the pressure plate with a pressing force that loads the lining lining and is supported on a bearing area formed on the housing; , directly or indirectly positions the diaphragm spring relative to the housing, passes through the passage region of the actuating tongue and is mounted radially inwardly, wherein a support element with a bearing section is provided, the diaphragm spring during disengagement Supported on this support section, wherein the support element is fixed by the holding element relative to the diaphragm spring and bears against the diaphragm spring with the support section under pretension and has a projection extending radially inwardly of the holding element , these protrusions are supported on the operating tongue.

Owner:ZF FRIEDRICHSHAFEN AG

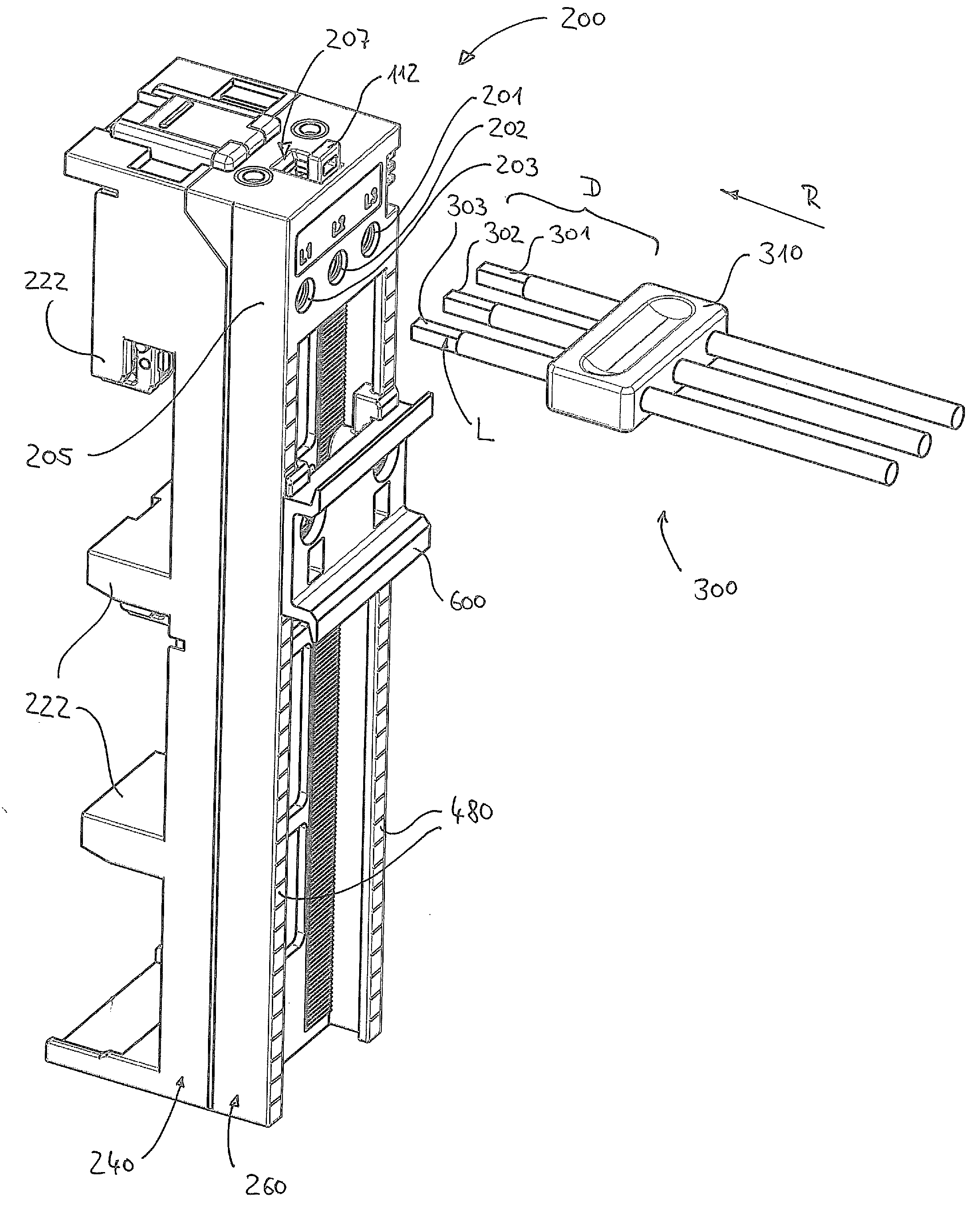

Adapter For Contacting Bus Bars

InactiveUS20150093925A1Simple pulling-outConvenient lengthEngagement/disengagement of coupling partsBus-bar/wiring layoutsBusbarSpring force

An adapter for contacting busbars with a multi-pole connecting cable is disclosed with at least two contact connections for at least two busbars; a housing having holding means; and a cable-connecting device that is secured in the housing by the holding means. The cable-connecting device has: a lever switch; a spring-terminal structure; and a connecting structure. The lever switch has a fulcrum onto which a leverage acts when the lever switch is actuated. The spring-terminal structure provides a spring force for establishing an electrical contact between one of the plurality of poles and one of the at least two contact connections by the spring force after inserting the connecting cable. The connecting structure is arranged between the lever switch and the spring-terminal structure and is designed for transferring the leverage from the lever switch to the spring-terminal structure and to tension the spring-terminal structure counter to the spring force.

Owner:KLAUS BRUCHMANN

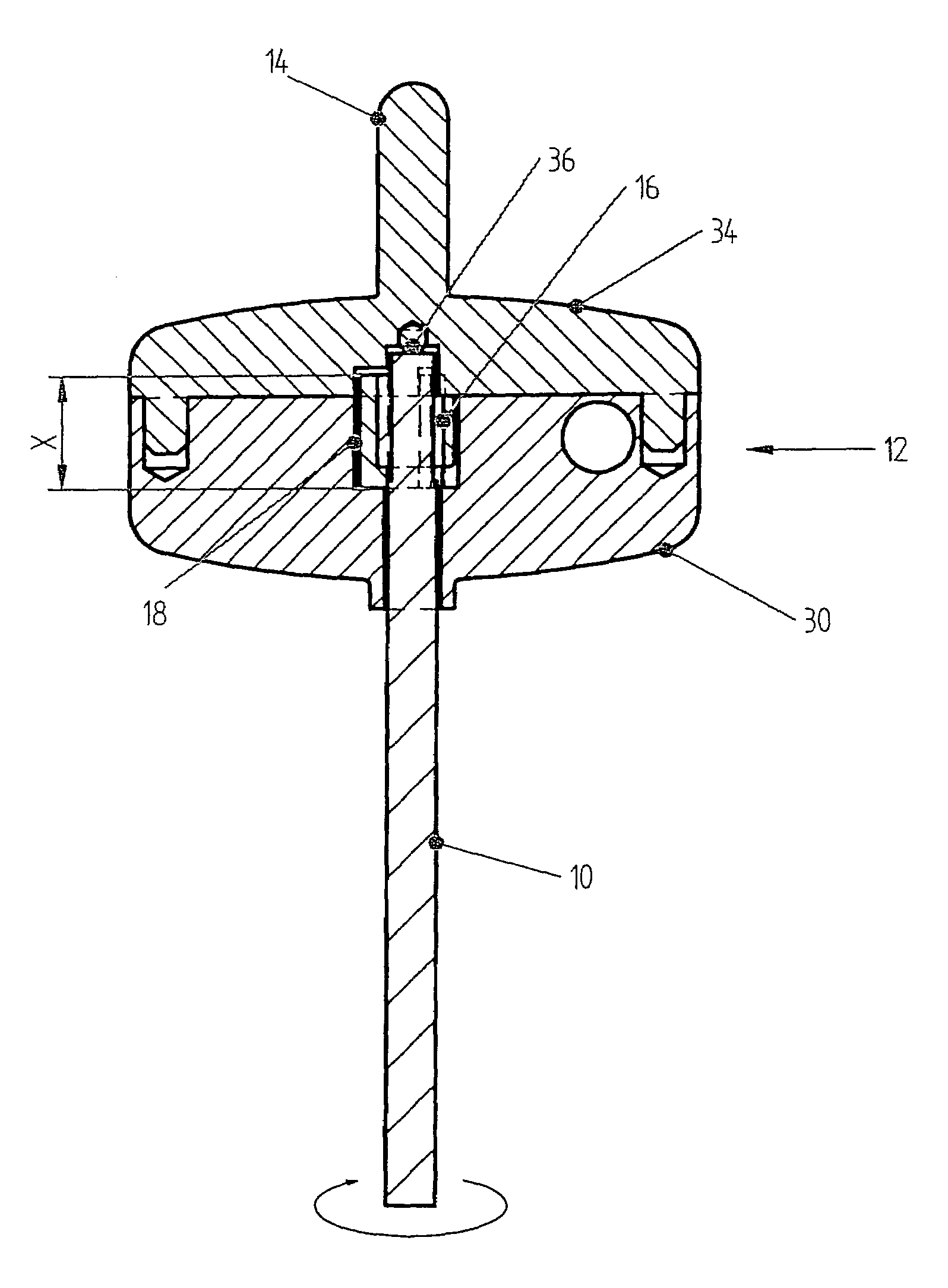

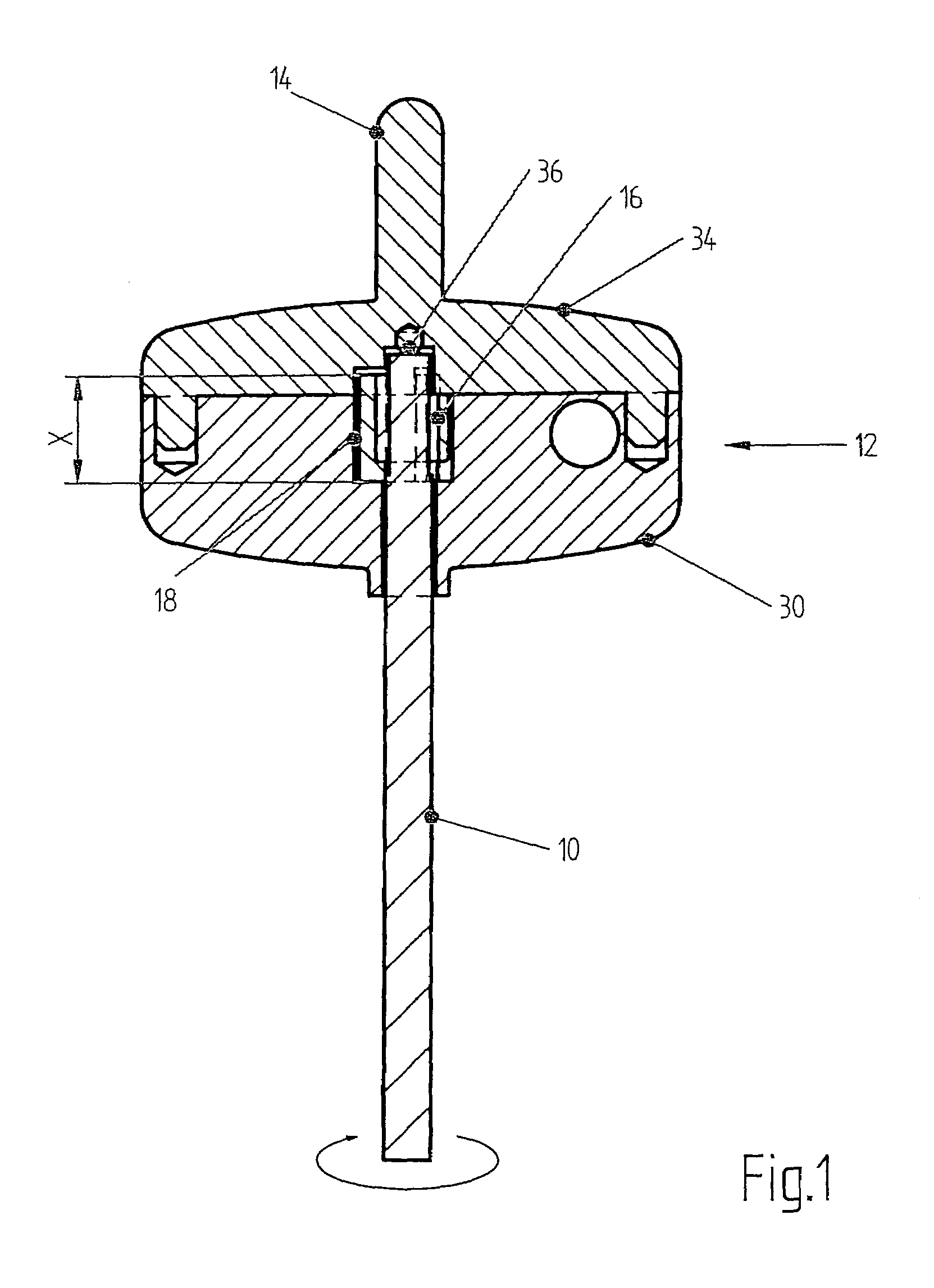

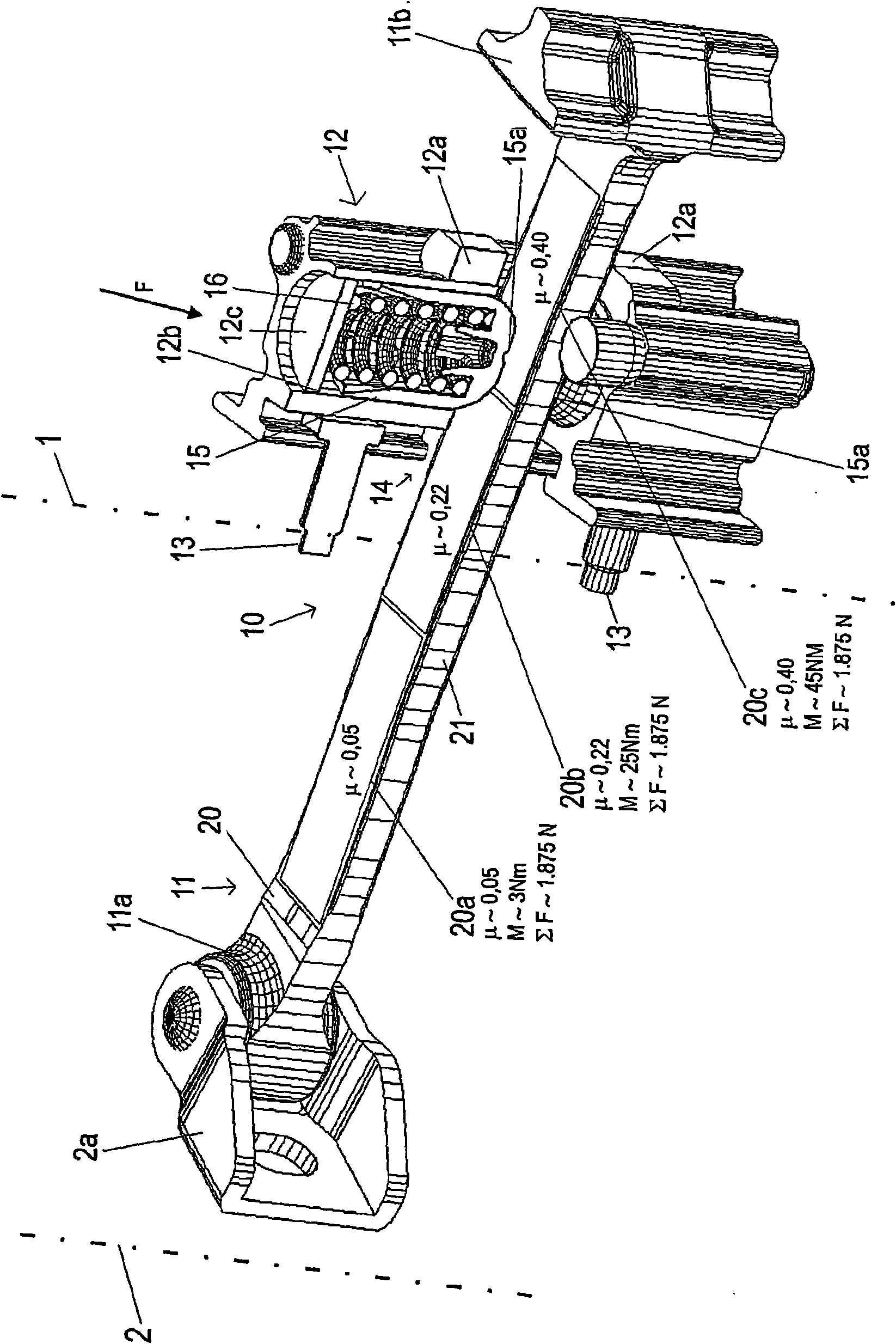

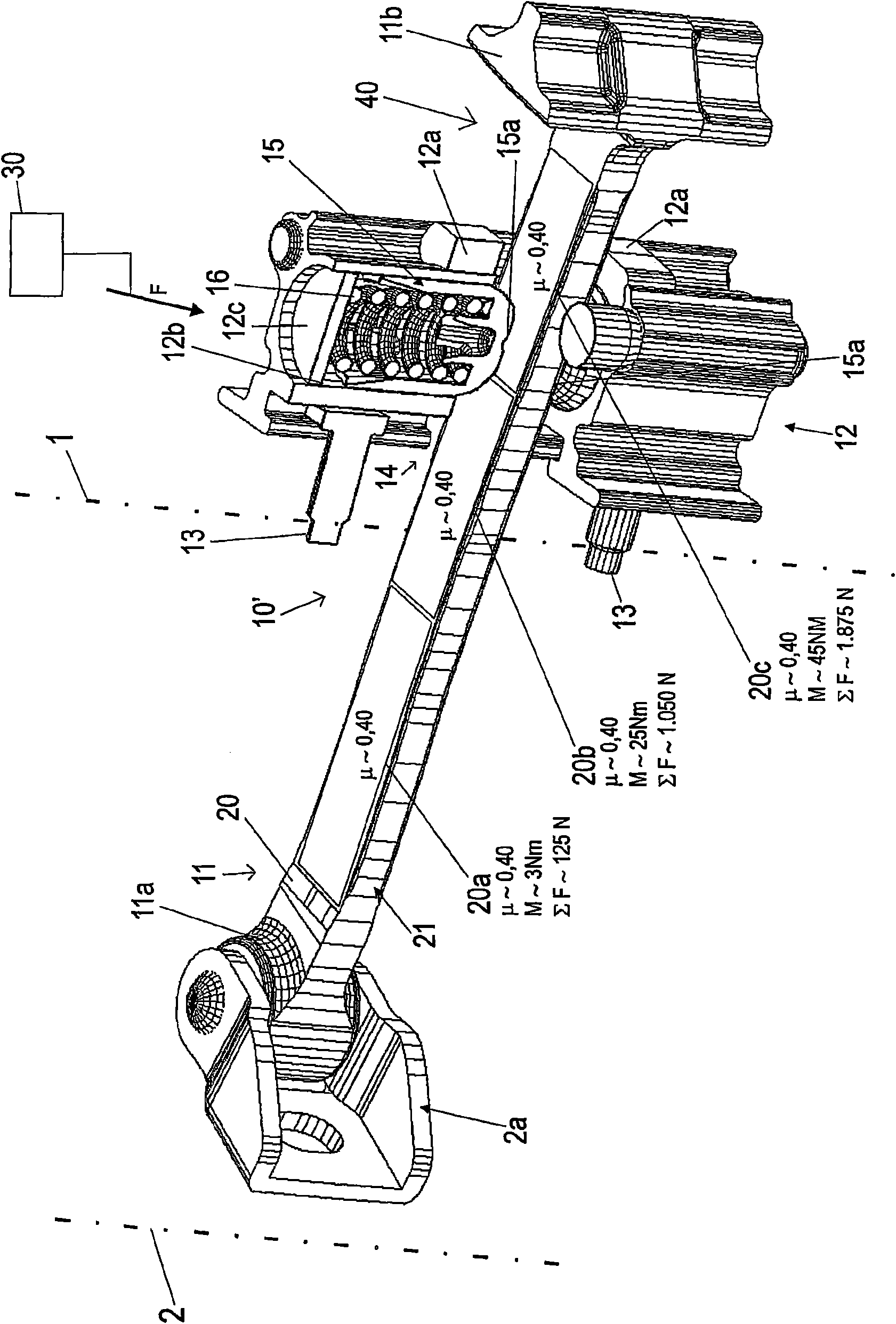

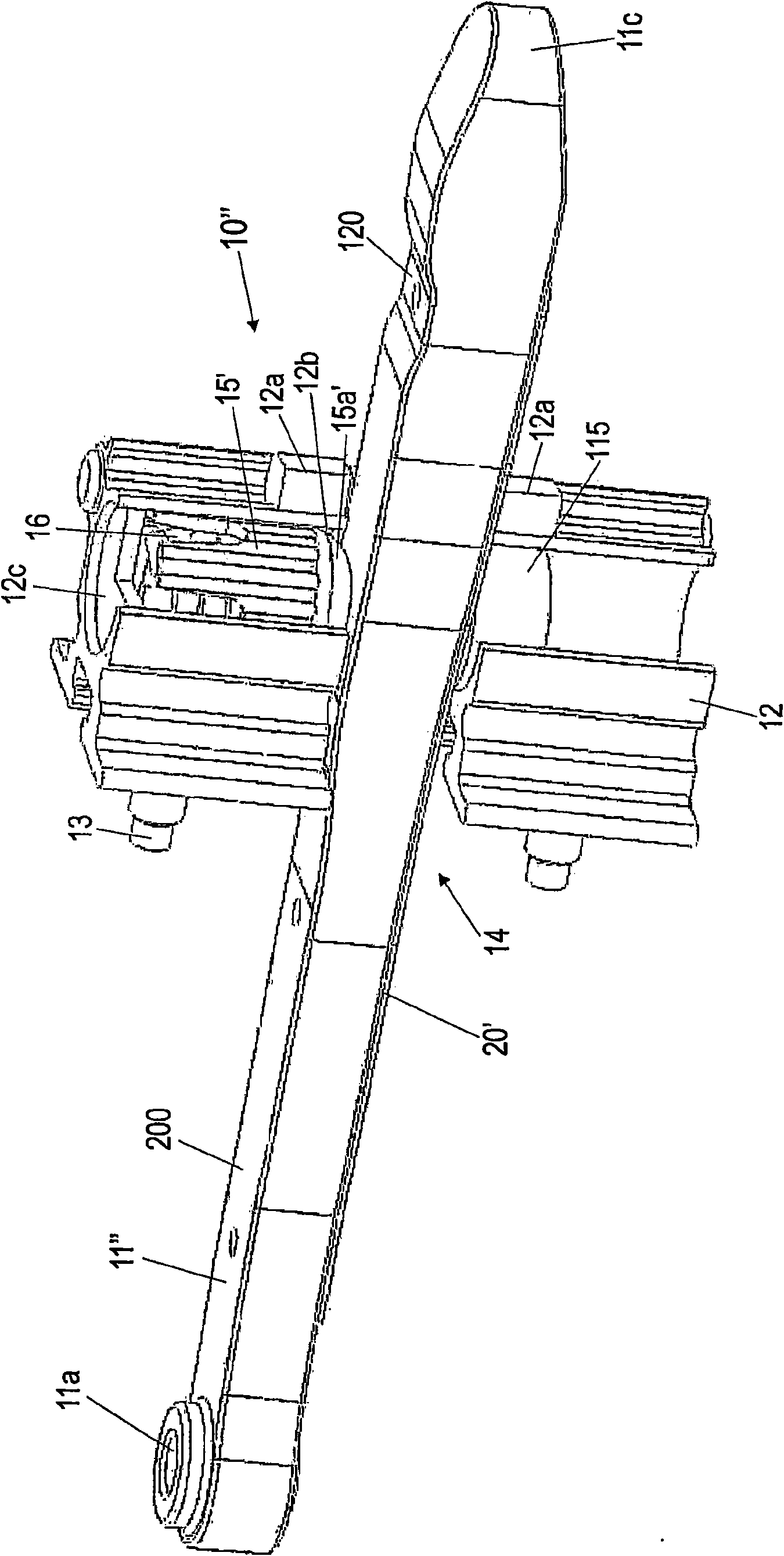

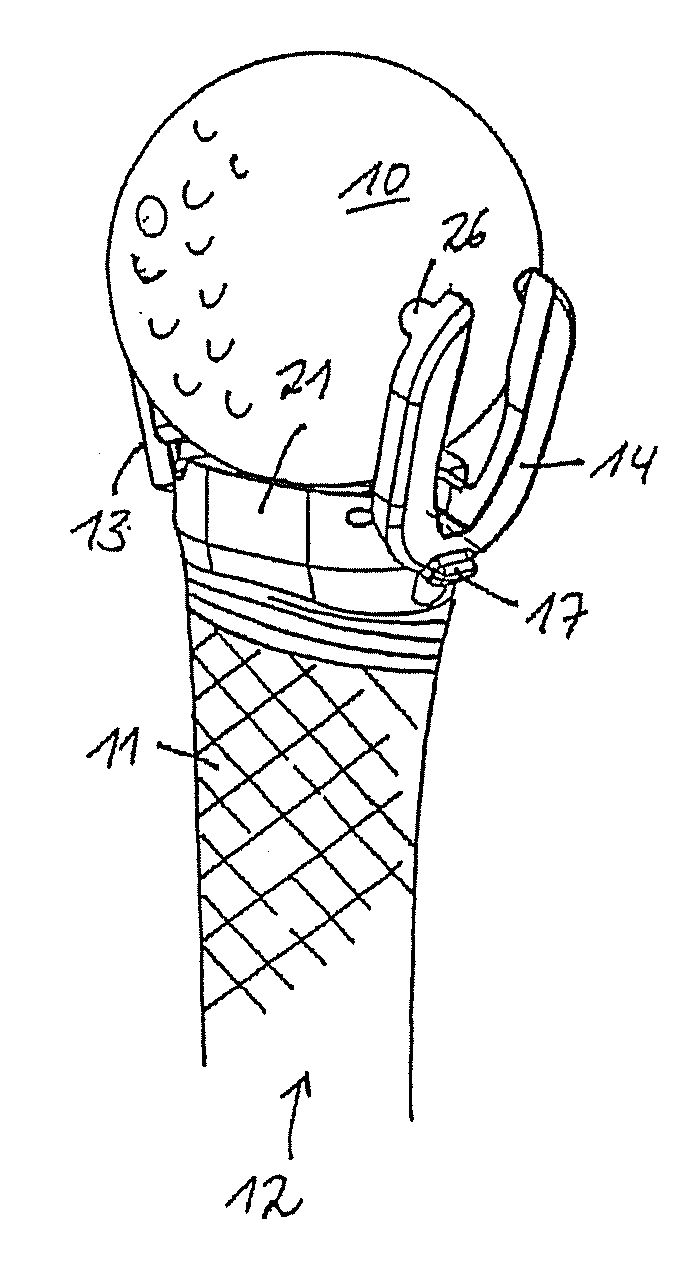

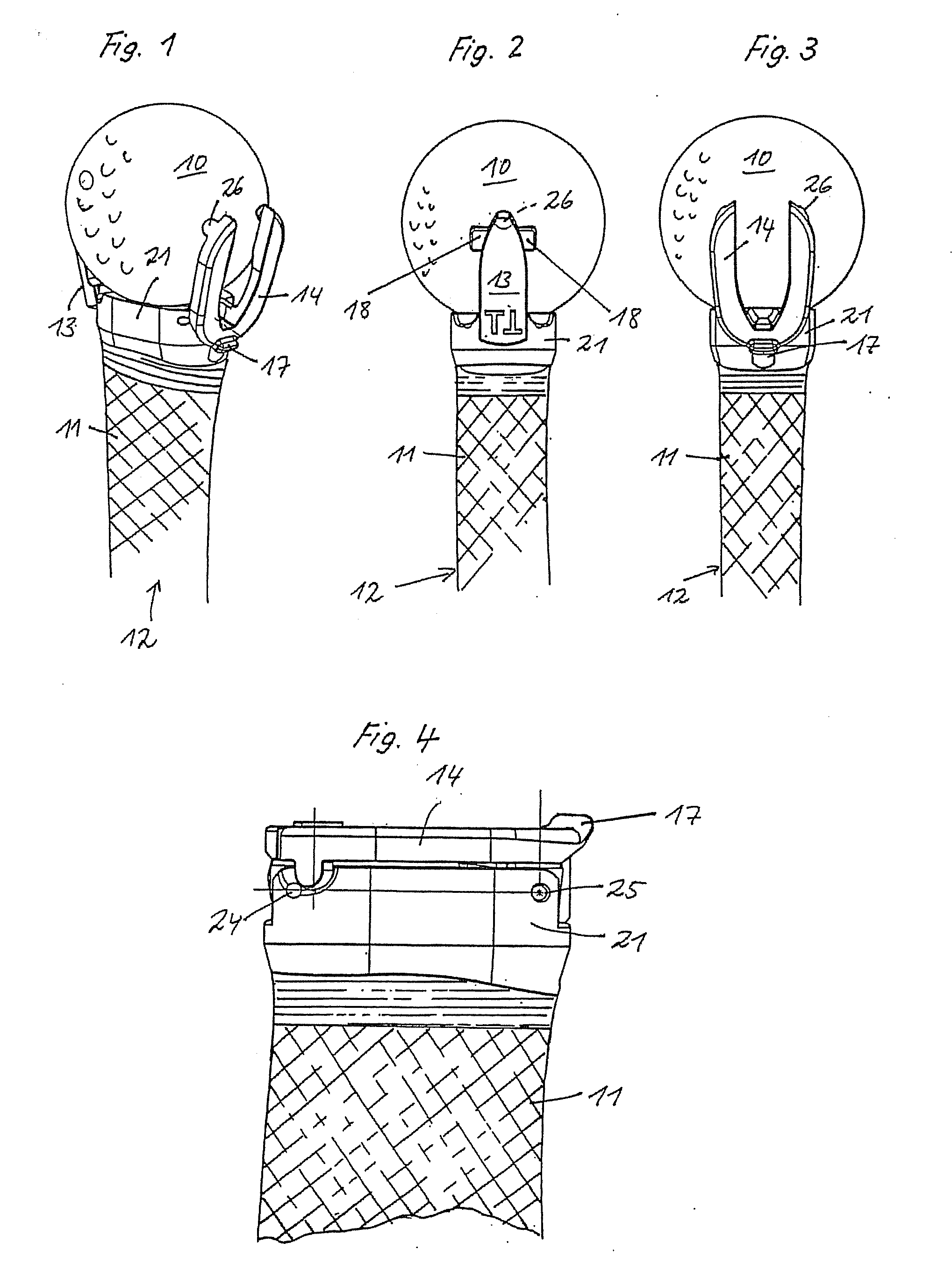

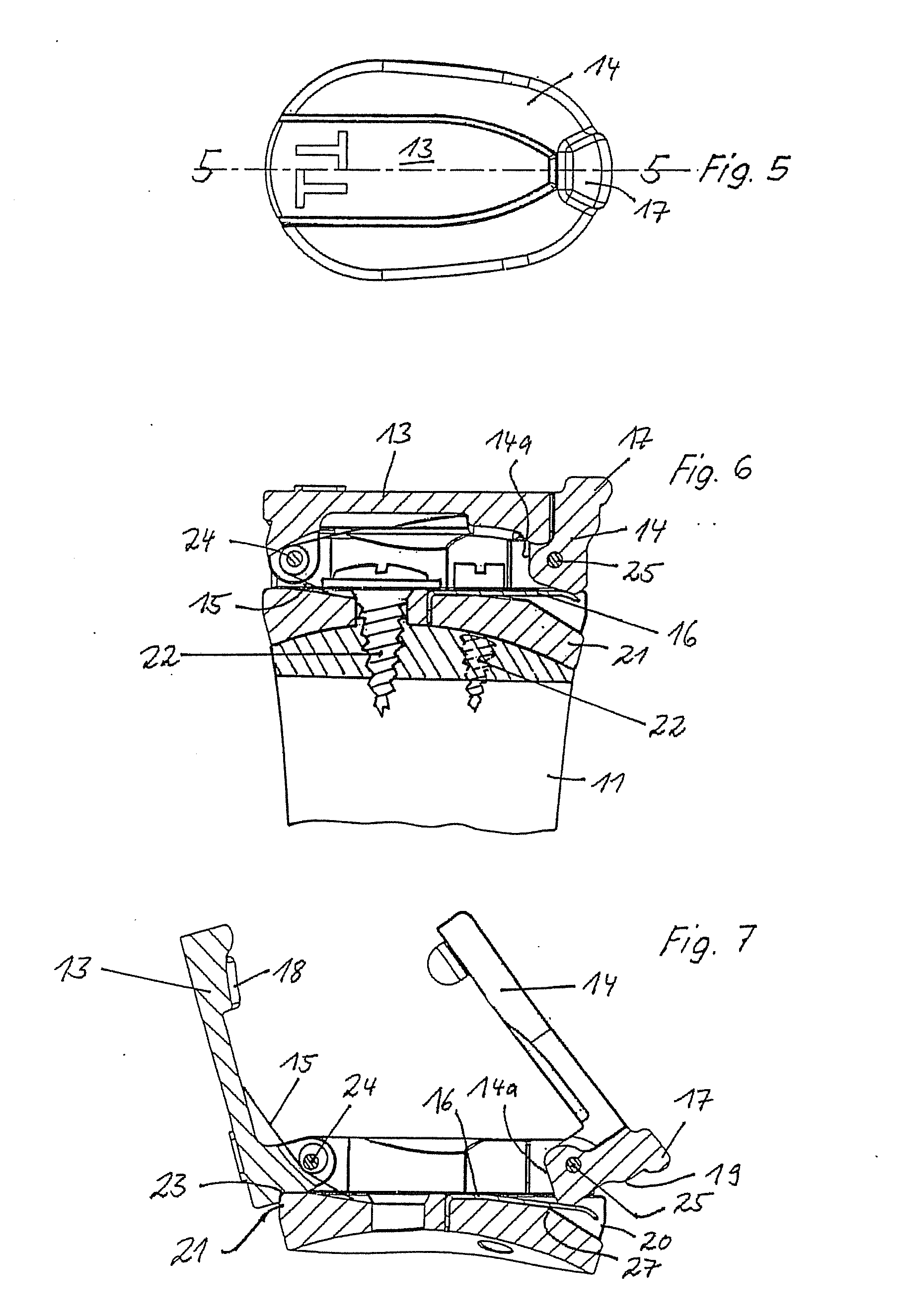

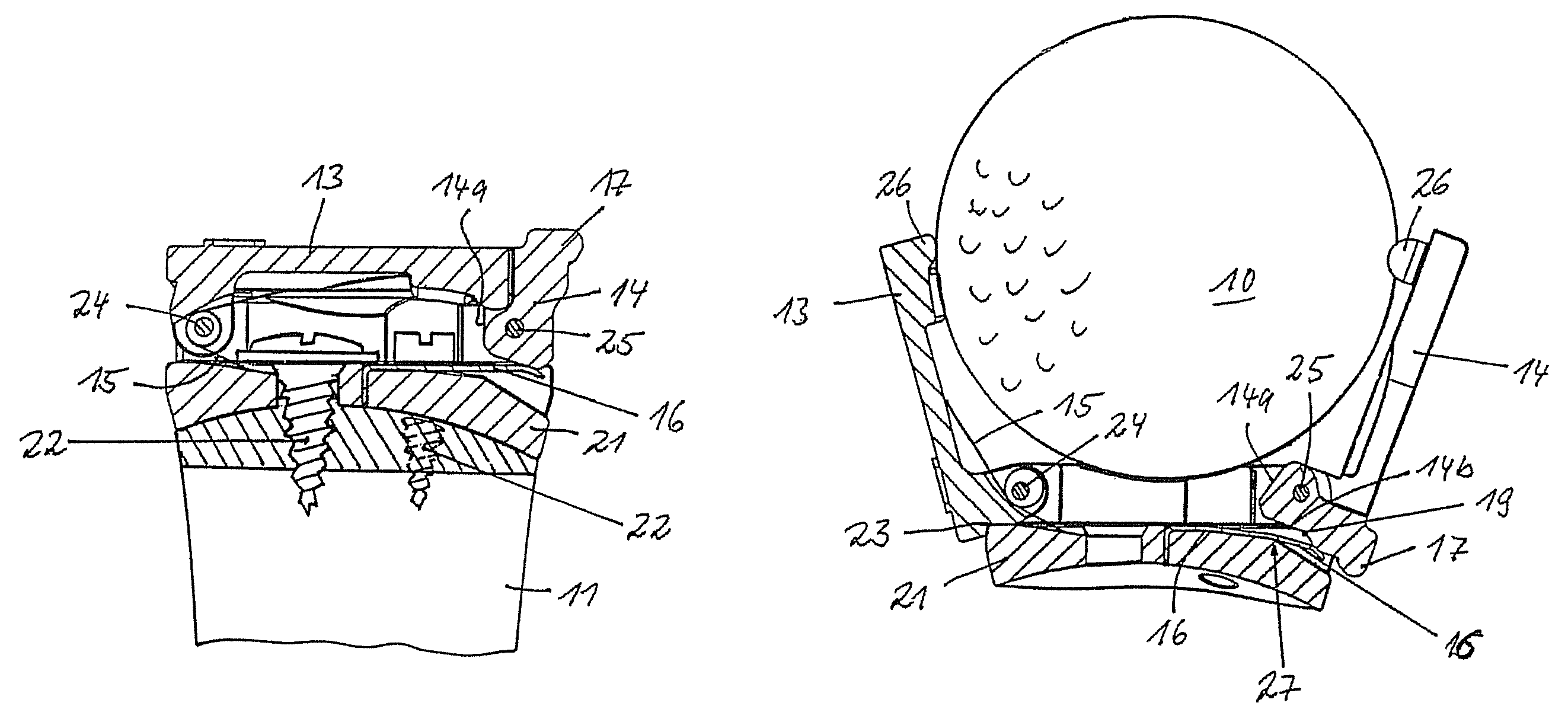

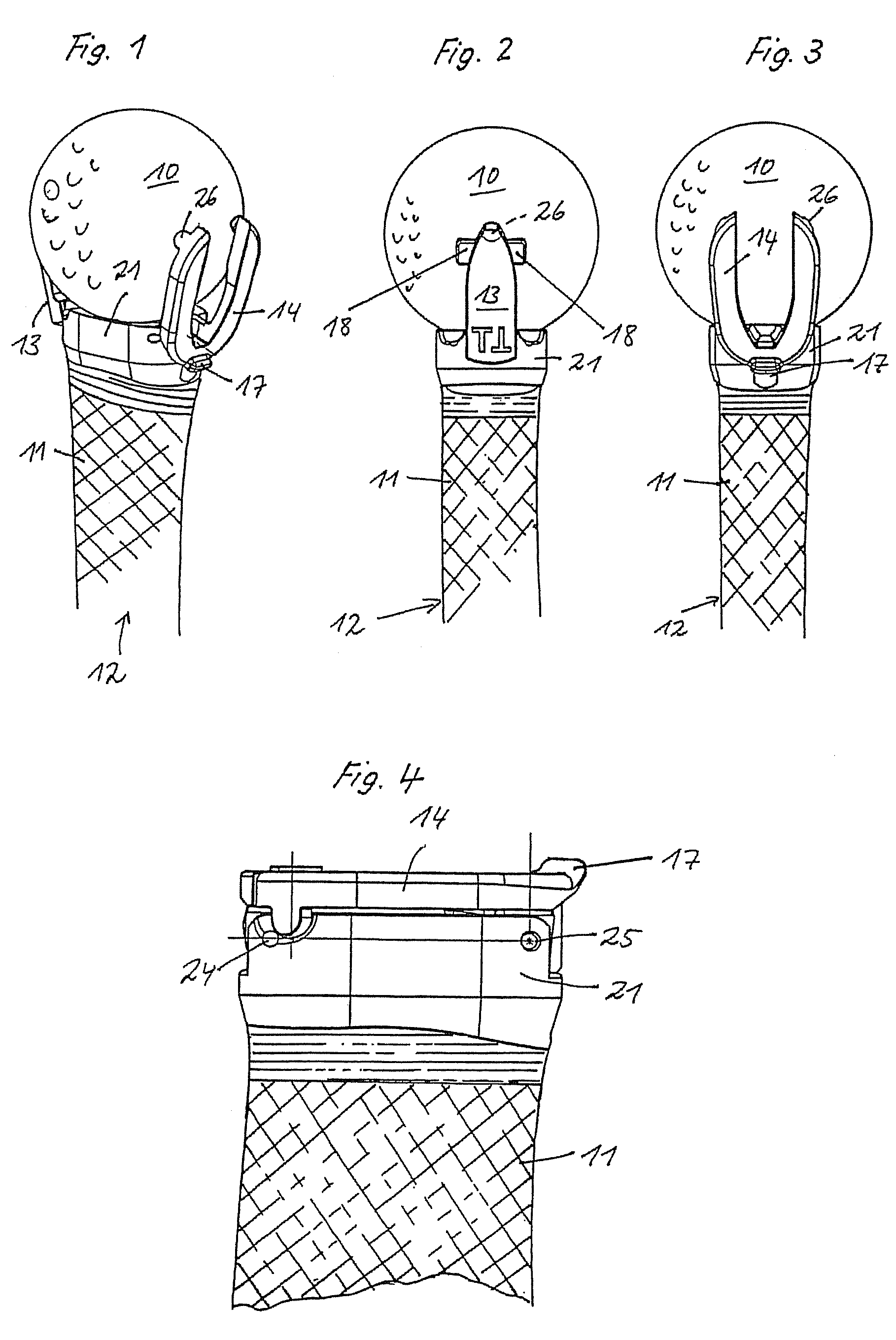

Device for picking up golf balls

ActiveUS20090149270A1Easy to operateHigh spring forceBall sportsGolfing accessoriesRest positionEngineering

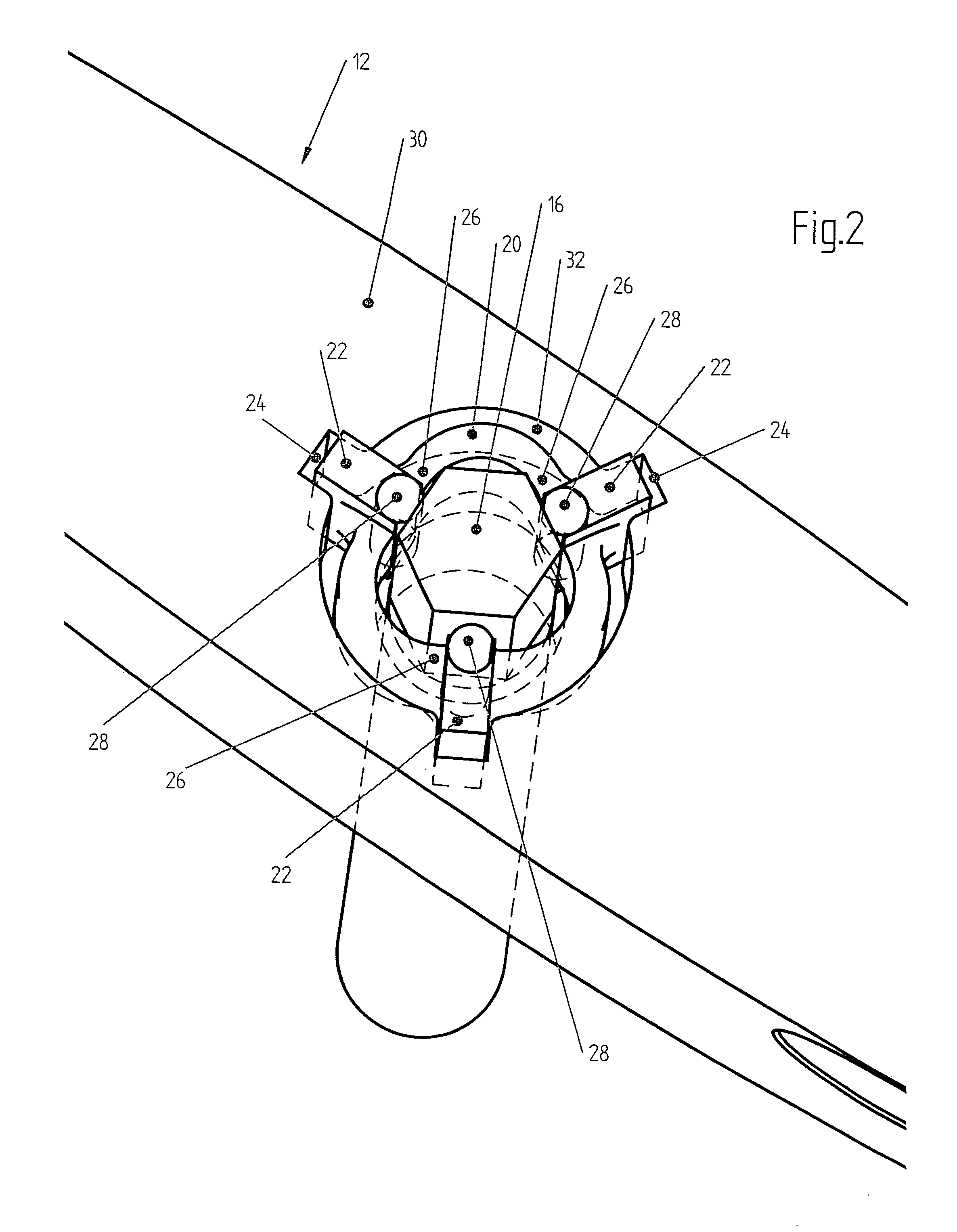

A device for picking up balls or golf balls (10) is disposed in the region of the grip (11) of a club (12). It includes several holding elements, which are displaceable under the effect of at least one resilient element from a rest position on the grip into an actuatable position in which they are capable of picking up the golf ball. By the holding element being at least two gripping arms (13, 14), which are fitted into each other in the rest position under the effect of at least one resilient element, a compact device for picking up that is simple to operate is created.

Owner:NICKEL WERNER

Device for picking up golf balls

A device for picking up balls or golf balls (10) is disposed in the region of the grip (11) of a club (12). It includes several holding elements, which are displaceable under the effect of at least one resilient element from a rest position on the grip into an actuatable position in which they are capable of picking up the golf ball. By the holding element being at least two gripping arms (13, 14), which are fitted into each other in the rest position under the effect of at least one resilient element, a compact device for picking up that is simple to operate is created.

Owner:NICKEL WERNER

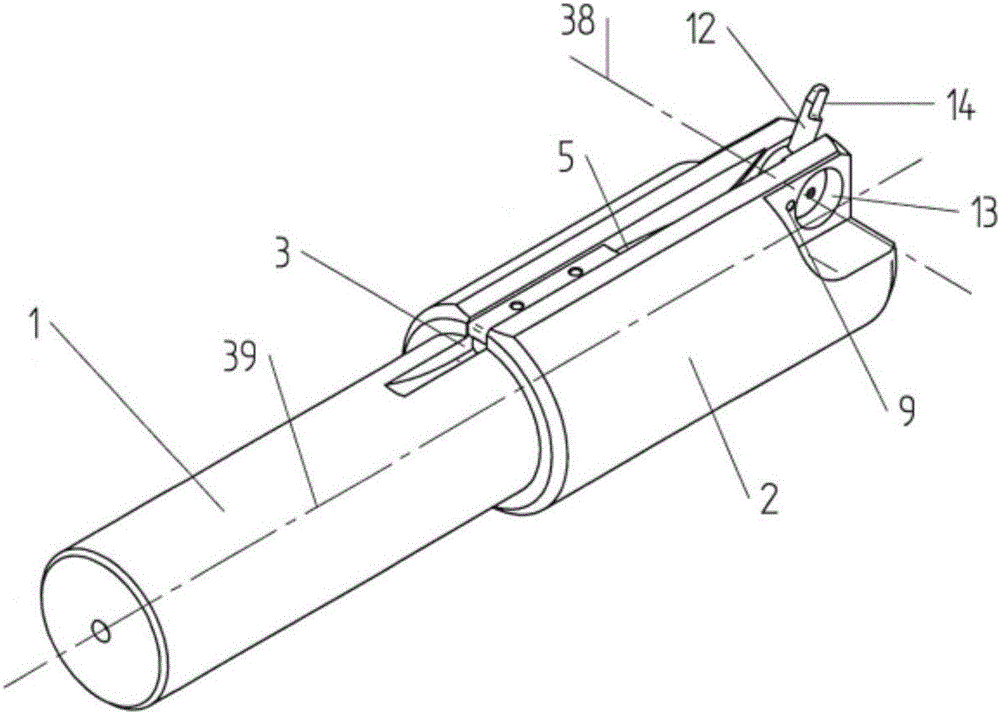

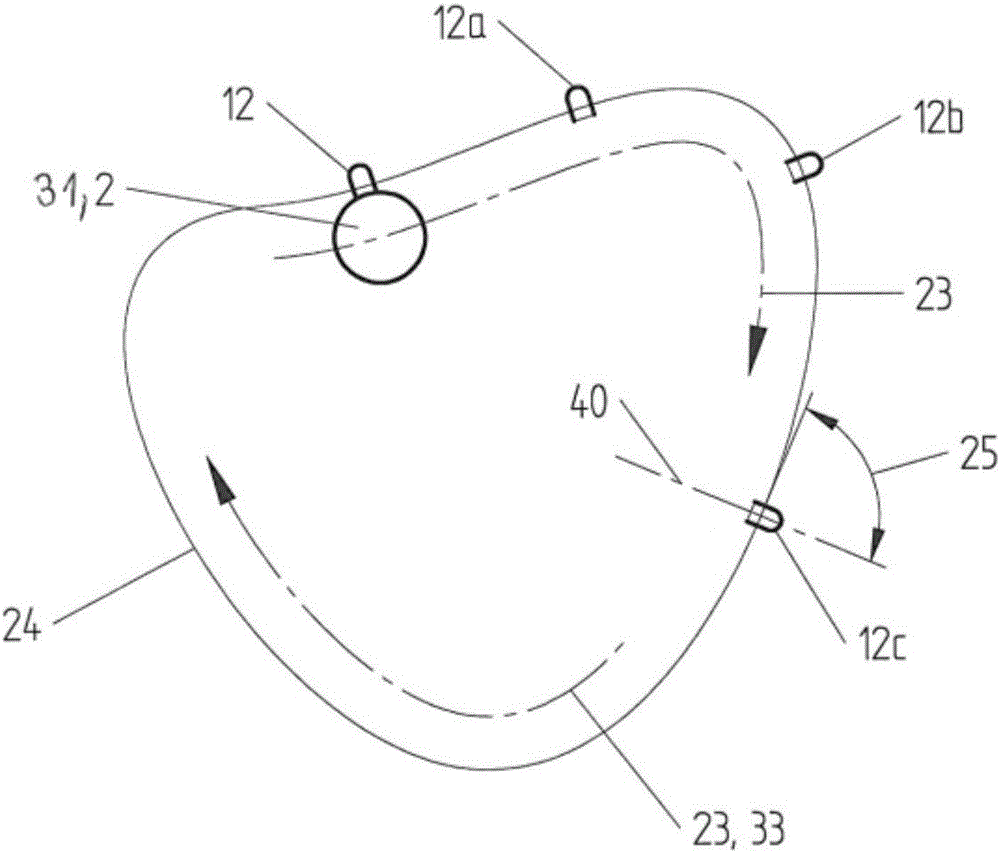

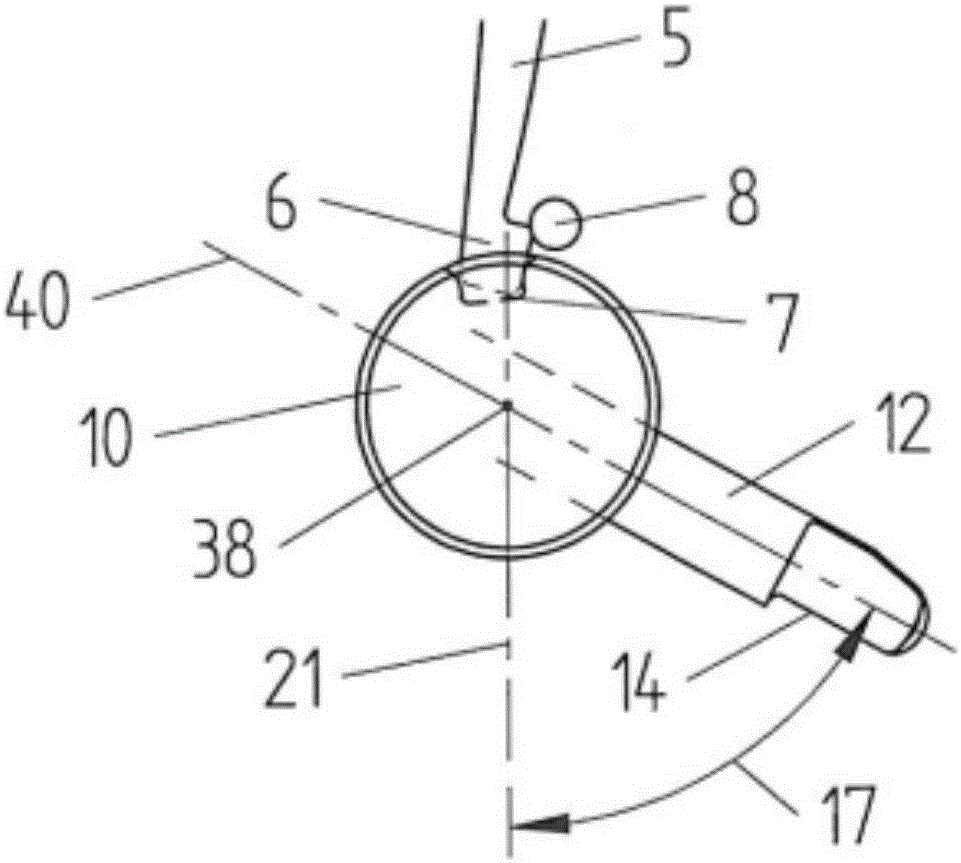

Deburring tool for deburring of nonround contours of workpieces

Deburring tool for deburring of nonround contours on workpieces (22) consisting of a tool shaft (1) for fastening in a path guiding machine (32), which is suitable to guiding the deburring tool (1, 2) by its machine movement (29, 30, 33) along a workpiece contour (24) which is nonround in at least the radial direction, wherein at least one deburring blade (12) having at least one cutting edge (14) is pressed under spring loading against the workpiece contour (24) in chip removing manner and can be moved along the workpiece contour (24).

Owner:HEULE WERKZEUG

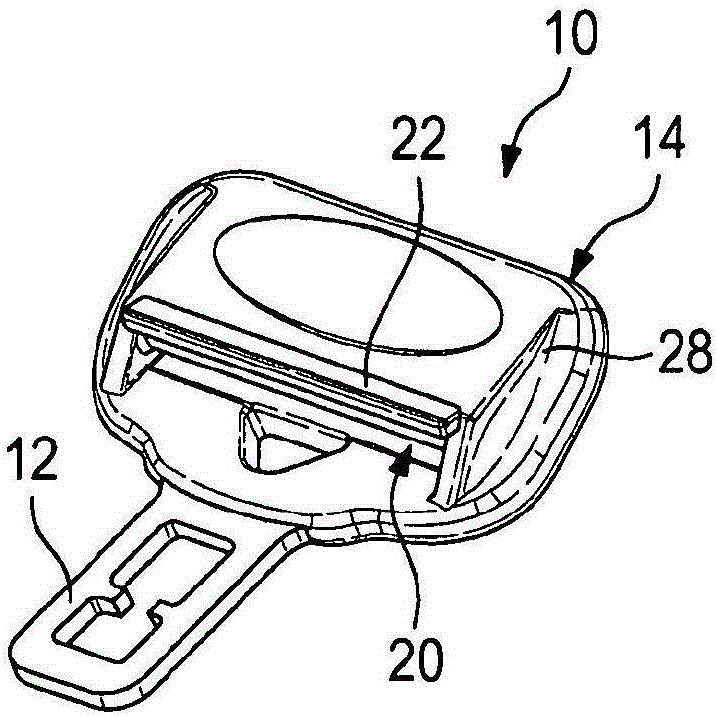

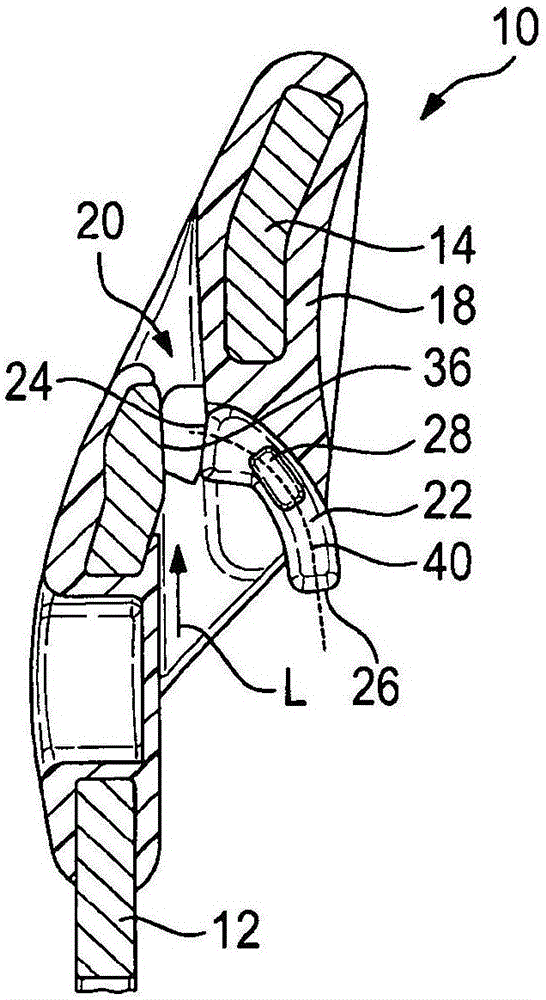

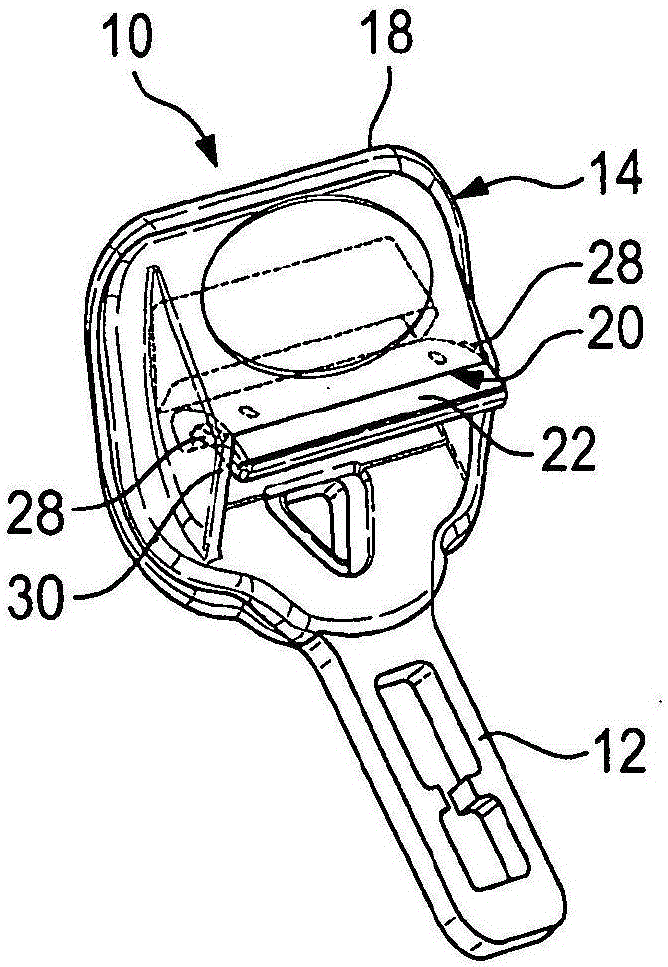

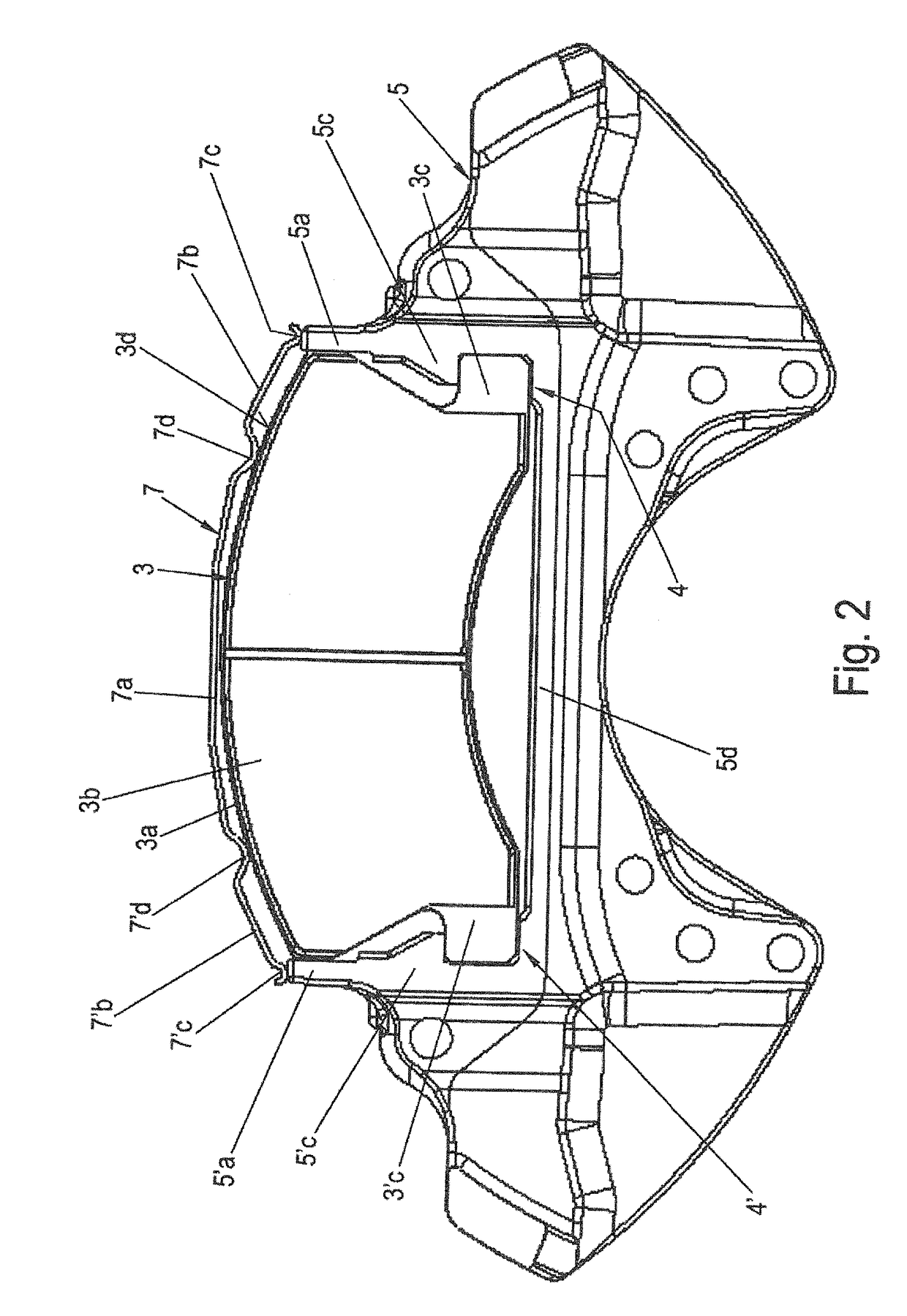

Latch plate and method for producing a latch plate

ActiveCN106455762ASmall sizeLarge clamping surfaceBucklesBelt anchoring devicesMechanical engineering

In a latch plate (10) for a safety belt, having a plug-in portion (12), which can be inserted into a buckle, and a deflection portion (14) for a belt webbing (16), wherein the deflection portion (14) has a belt-webbing channel (20) and a clamping element (22) for the belt webbing (16) and wherein the clamping element (22) is displaceable between a starting position, in which the belt webbing (16) is freely movable, and a blocking position, in which the clamping element (22) is displaced towards a wall (36) of the belt-webbing channel (20) such that the belt webbing (16) is clamped between the clamping element (22) and the wall (36) of the belt-webbing channel (20), wherein the clamping element (22) has a clamping surface (24) which clamps the belt webbing (16) against the wall (36) of the belt-webbing channel (20) in the blocking position, provision is made for the clamping element (22) to be guided along an arcuate guide path (40) which extends substantially perpendicularly to the wall (36) in the region of the blocking position, such that the clamping element (22) is moved towards the wall (36) with the clamping surface (24) in a substantially perpendicular manner in the blocking position. According to the invention, provision is also made of a method for producing such a latch plate (10), said method having the following features of: - providing a deflection portion (14), - positioning the clamping element (22) at the deflection portion (14), and - partially encapsulating the deflection portion (14) and the clamping element (22), wherein the clamping element (22) is fixed to the deflection portion (14).

Owner:TRW AUTOMOTIVE GMBH

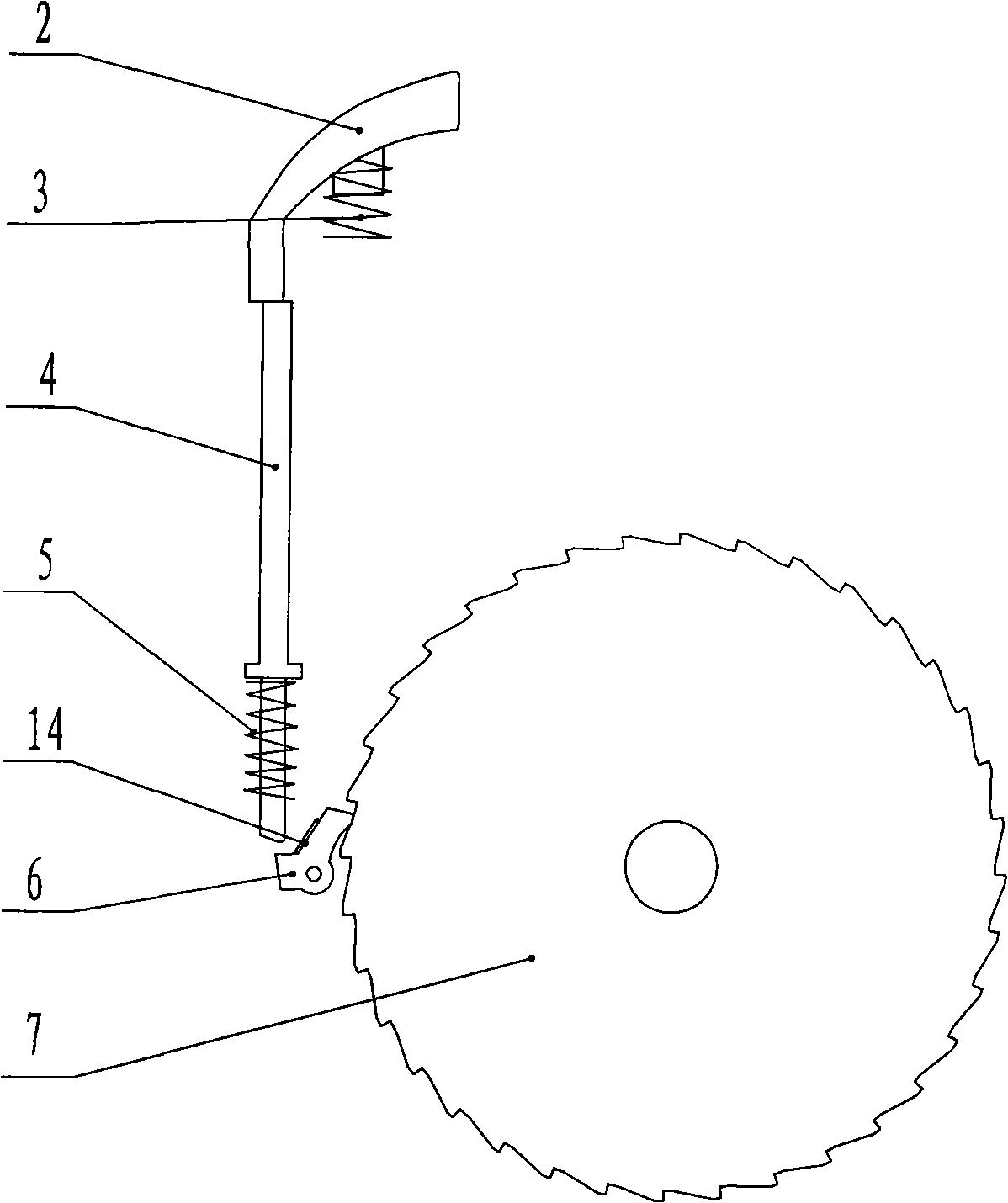

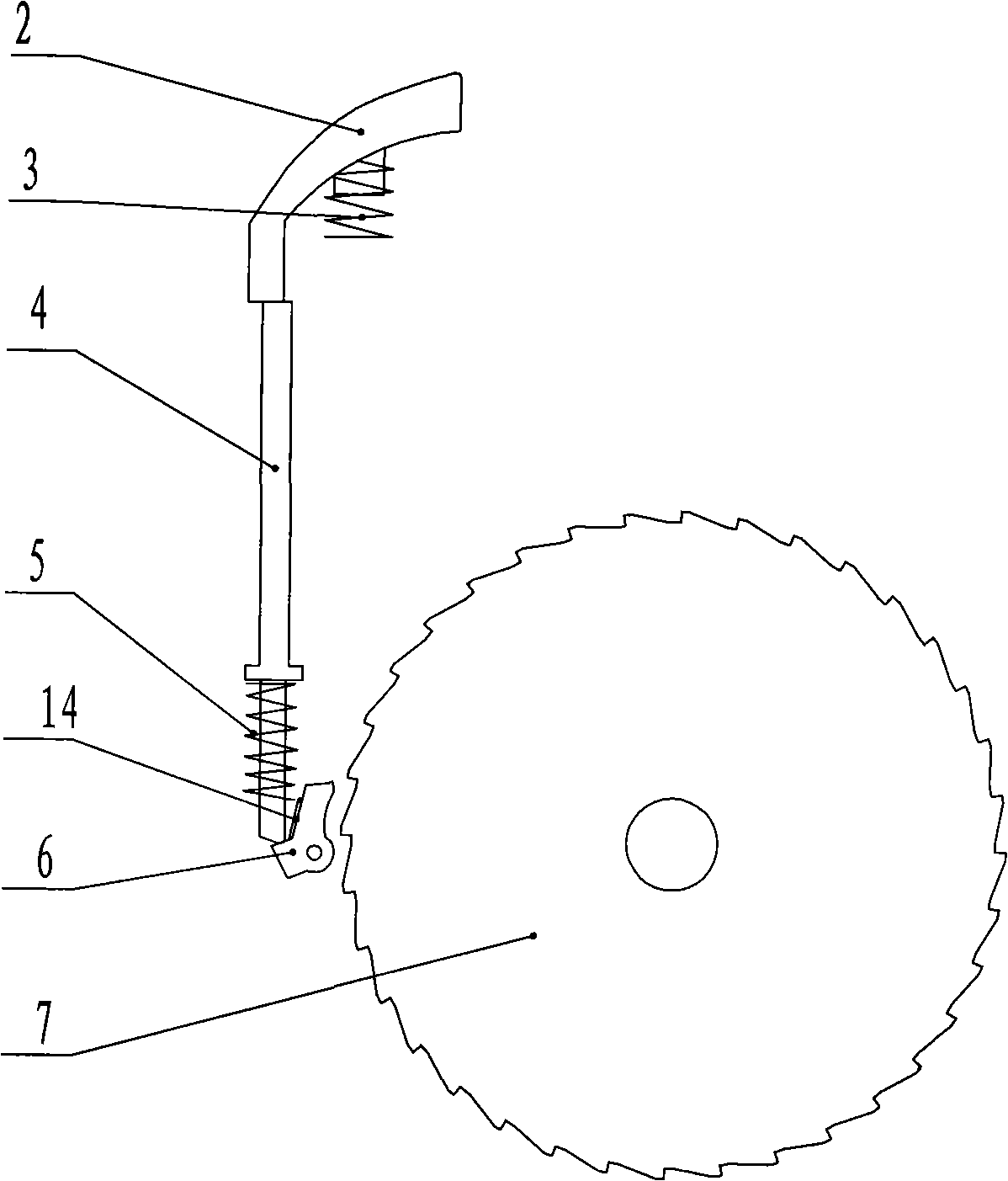

Structure of long ruler push-button

The present invention relates to a caliper button structure, which comprises a button and a caliper shell, and is characterized in that a button hole is formed on the handle part of the caliper shell, and a button is arranged inside the button hole; a small spring is arranged between the button and a supporting part inside the caliper shell; a connection rod is directly or indirectly connected with the button; the connection rod is provided with a compression spring; one end of the compression spring is supported on a fixed part of the caliper shell, and the other end is engaged with a pallet in contradiction way that controls the rotation action of a ratchet wheel disc; the pallet is fixed inside the caliper shell through a pin, and a torsion spring is arranged between the pallet and the caliper shell. The button structure is applicable to the caliper with a frame-typed structure, and has reasonable and simple structure, and is easy to be produced and assembled.

Owner:NINGBO GREAT WALL PRECISION INDAL

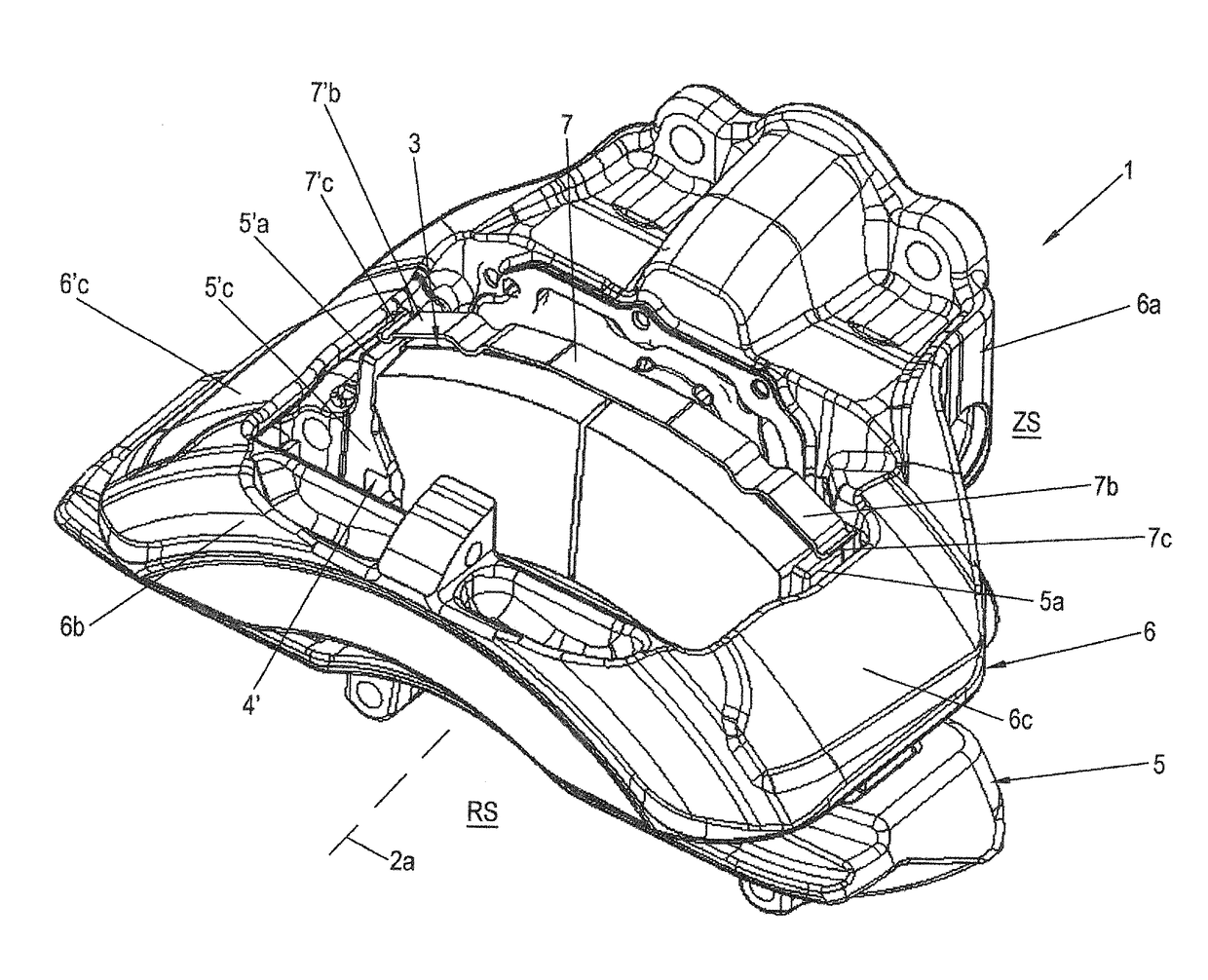

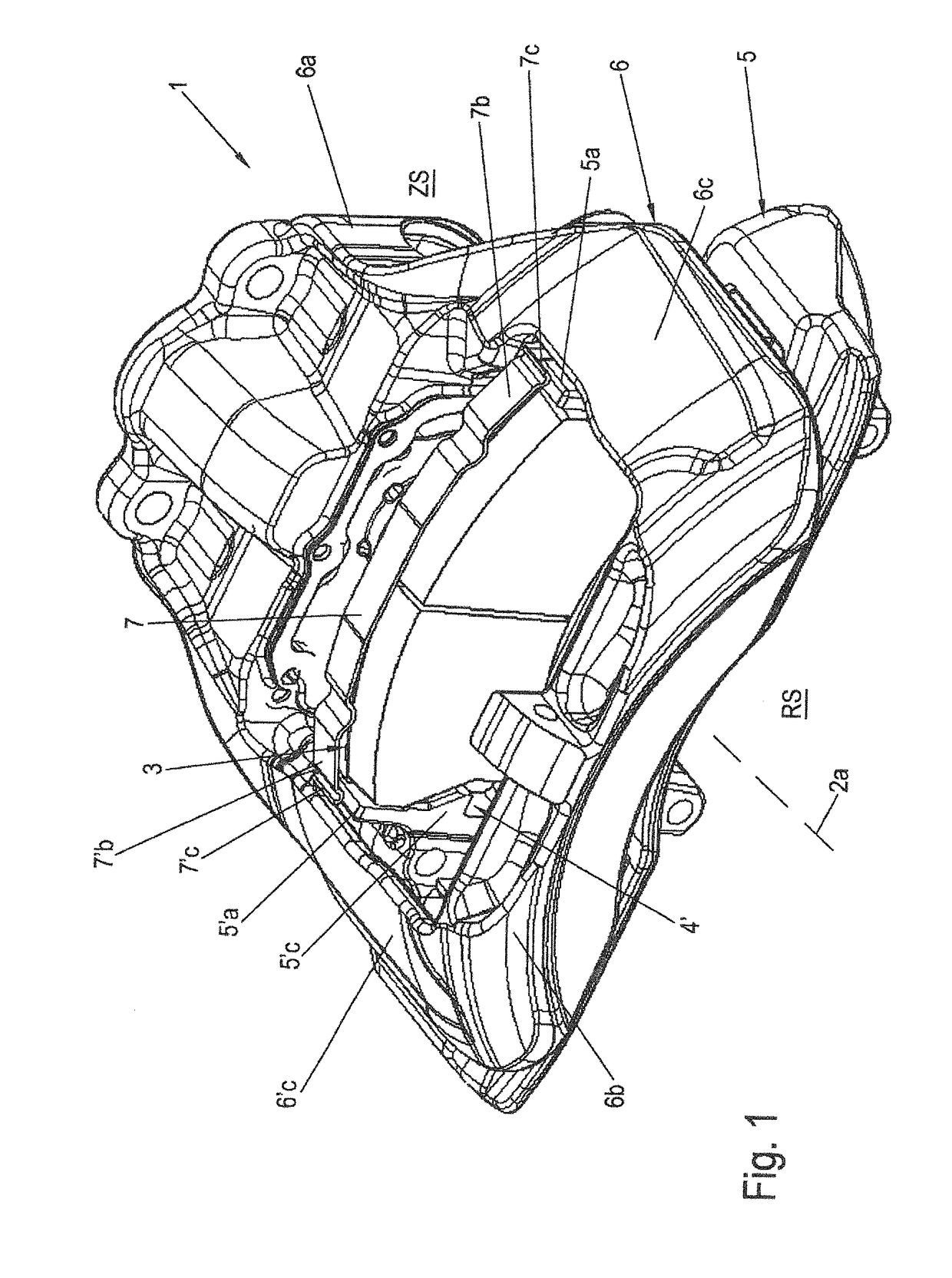

Disc Brake and Brake Pad Set

ActiveUS20170138425A1High spring forcePrevent movementAxially engaging brakesBraking elementsEngineeringCommercial vehicle

A disc brake for a vehicle, in particular for a commercial vehicle, includes a brake carrier which receives at least two brake pads in respective clamping side and rear side pad slots, with the at least one brake pad on the clamping side being held in its pad slot in a form-fitting manner. The at least one brake pad on the clamping side is provided with at least one pad retaining spring which is supported at least on a brake carrier horn of the pad slot of the brake carrier. The at least one clamping spring exerts a tensile force acting radially outward on the brake pad. A brake pad set for the disc brake is also provided.

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK +1

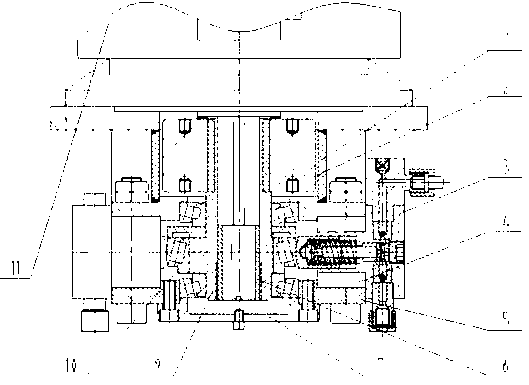

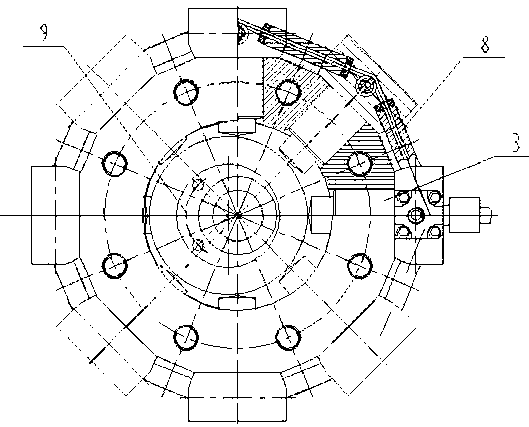

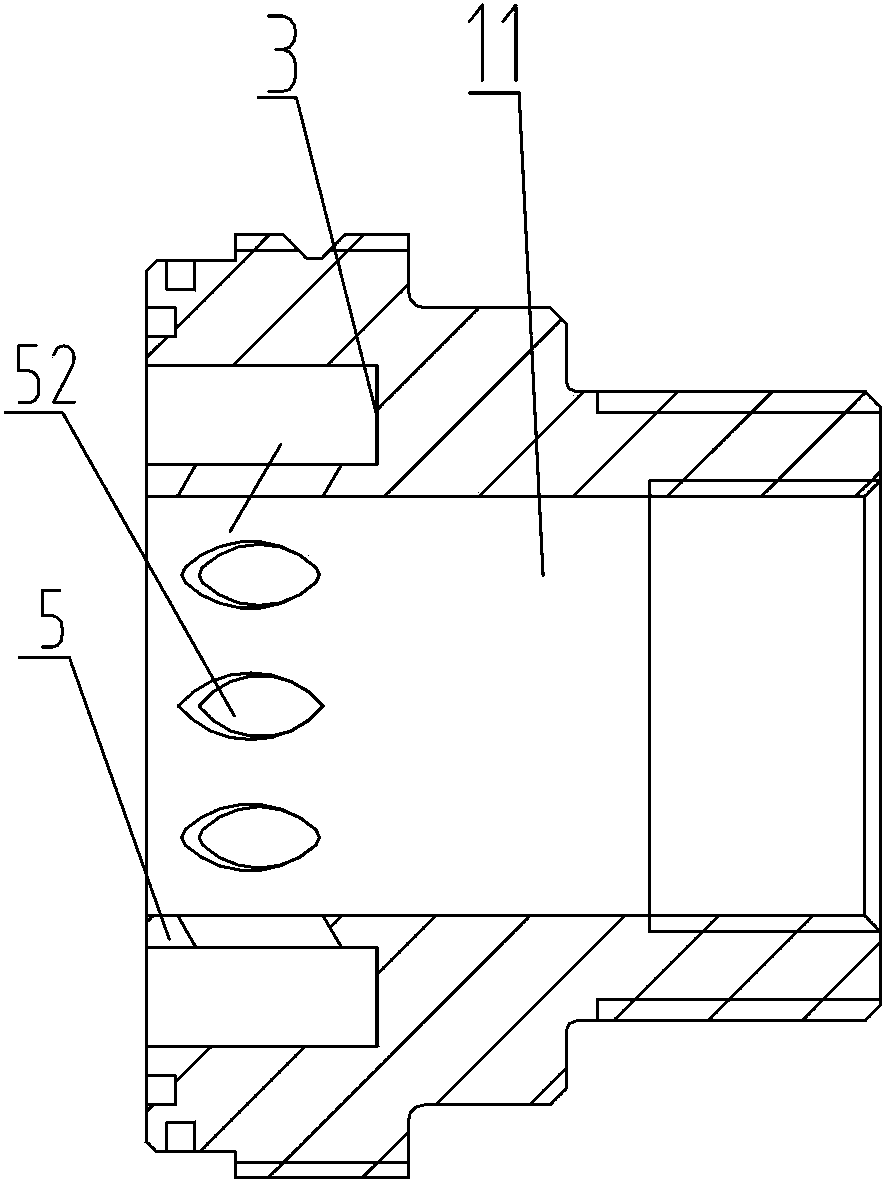

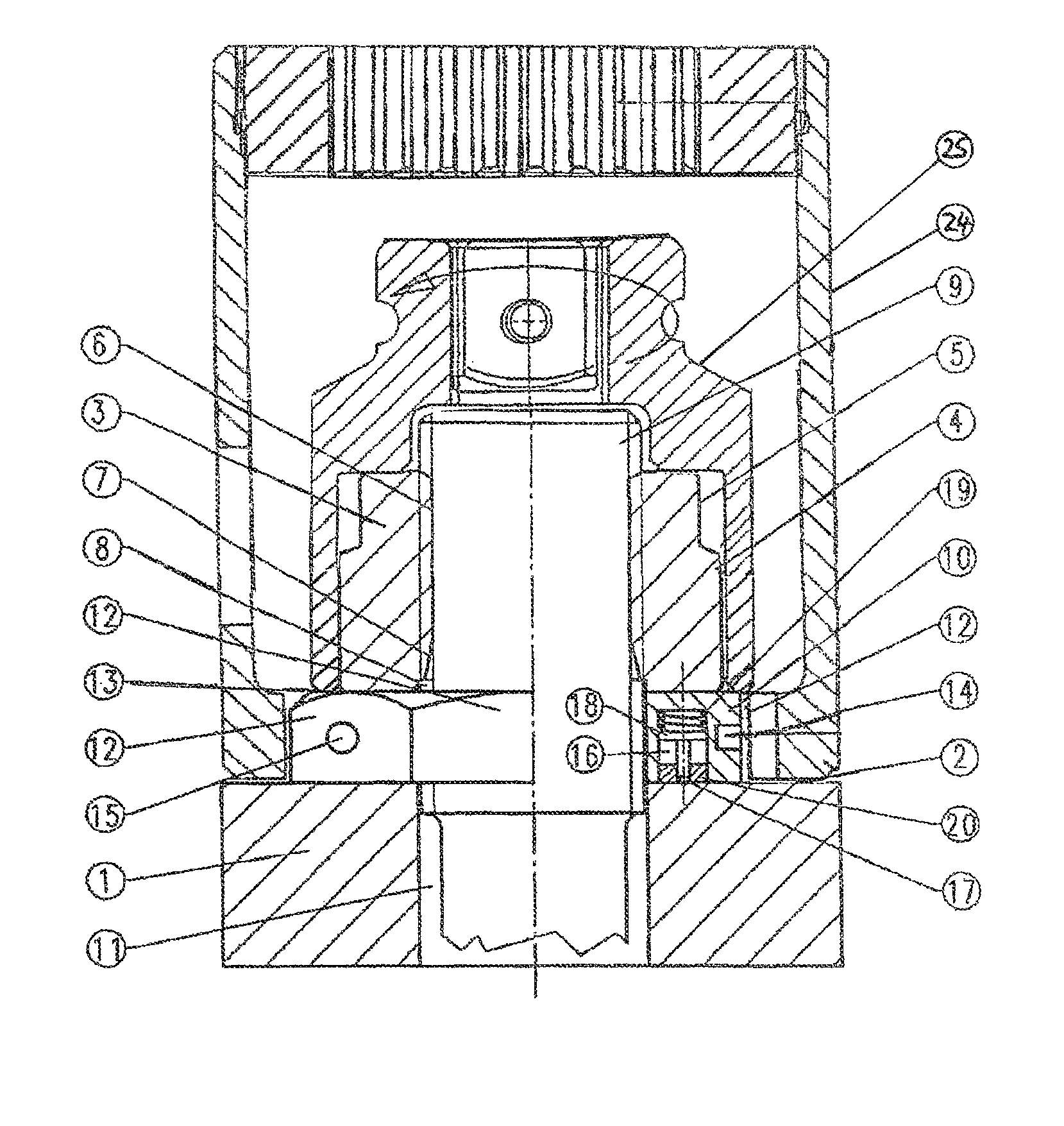

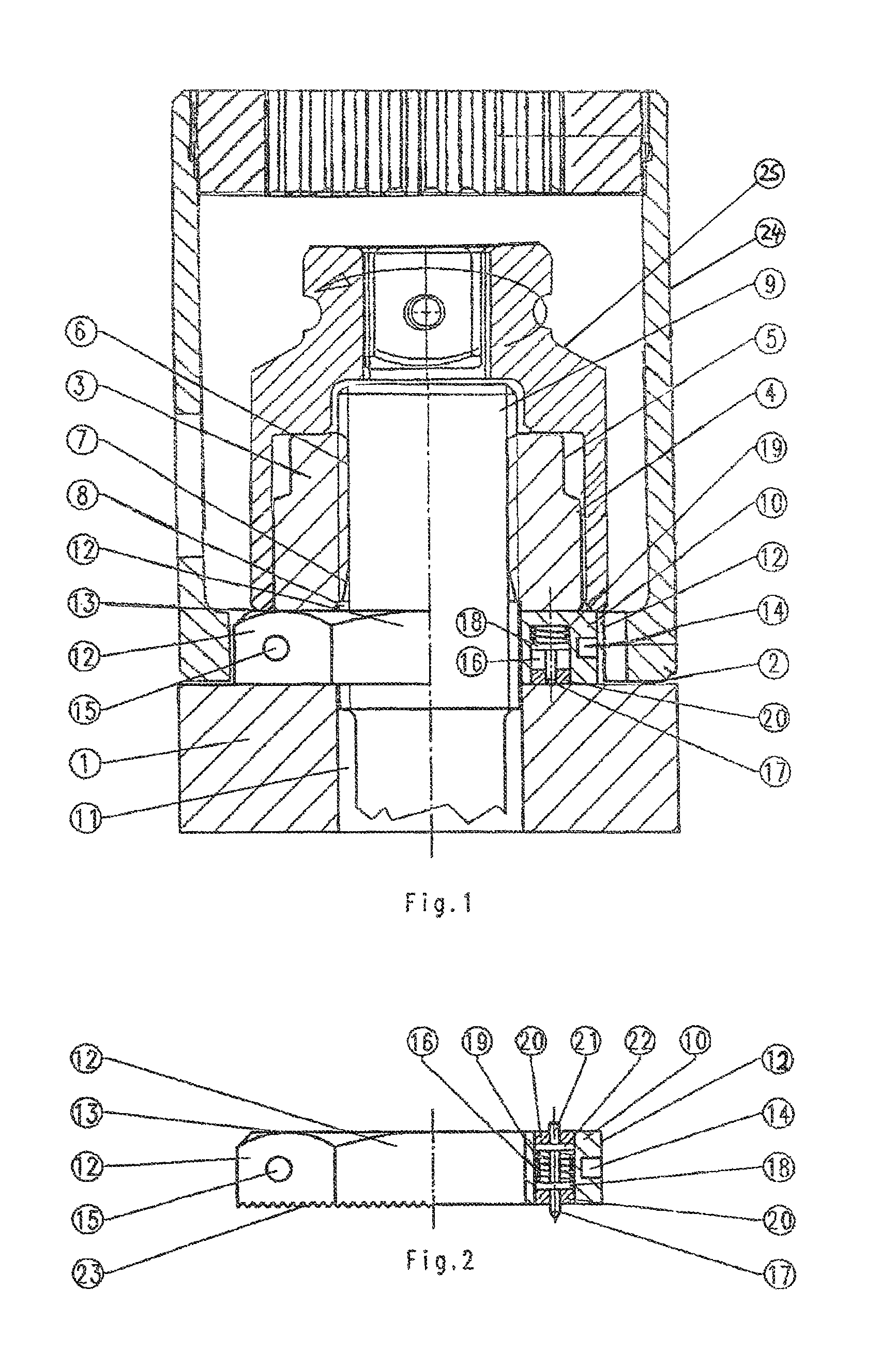

Ultrahigh pressure radial plunger pump

InactiveCN103133291AReduce intermediate linksEnsure adequate lubricationPositive-displacement liquid enginesMulti-cylinder pumpsEngineeringVariable pressure

The invention discloses an ultrahigh pressure radial plunger pump, and belongs to the technical field of hydraulic control. The ultrahigh pressure radial plunger pump comprises a motor which is arranged on a bearing framework, an eccentric shaft is sleeved on an output shaft of the motor, multiple sets of plunger pumps are evenly distributed on the periphery of the eccentric shaft, the multiple sets of plunger pumps with the output shaft of the motor as the center, a conical roller bearing is sleeved on the eccentric shaft, and the outer ring of the conical roller bearing simultaneously contacts with the top ends of the multiple sets of plunger pumps with the output shaft of the motor as the center. The ultrahigh pressure radial plunger pump can achieve variable pressure and variable flow, the multiple plunger pumps can be in parallel connection, oil mass supply of a large-scale hydraulic pressure station is satisfied, sealing performance is good, service life is long, reliability is high, performance cost ratio is high, and the ultrahigh pressure radial plunger pump is suitable for application and popularization.

Owner:SICHUAN SHENGBAO ELECTRICAL TECH

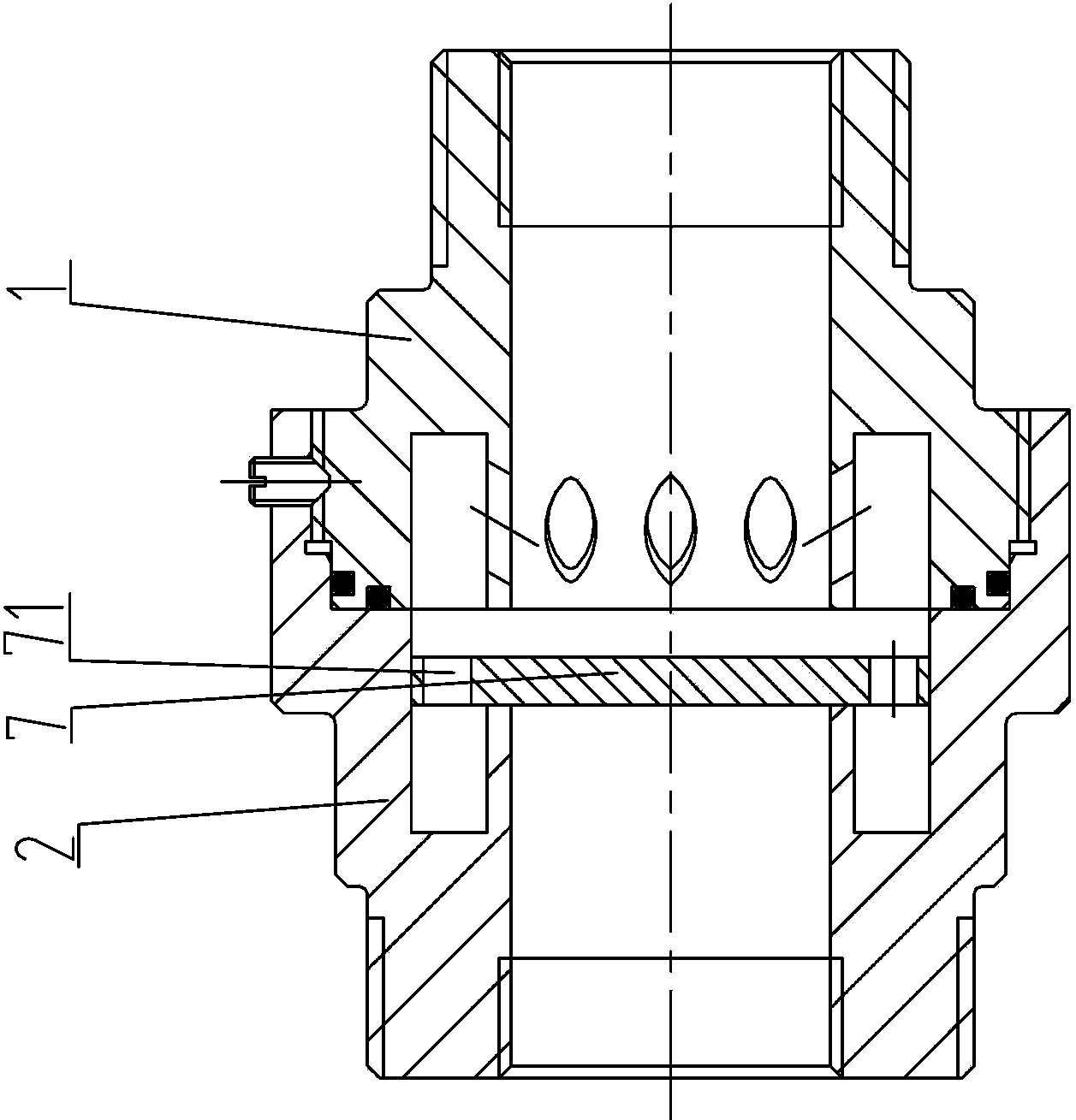

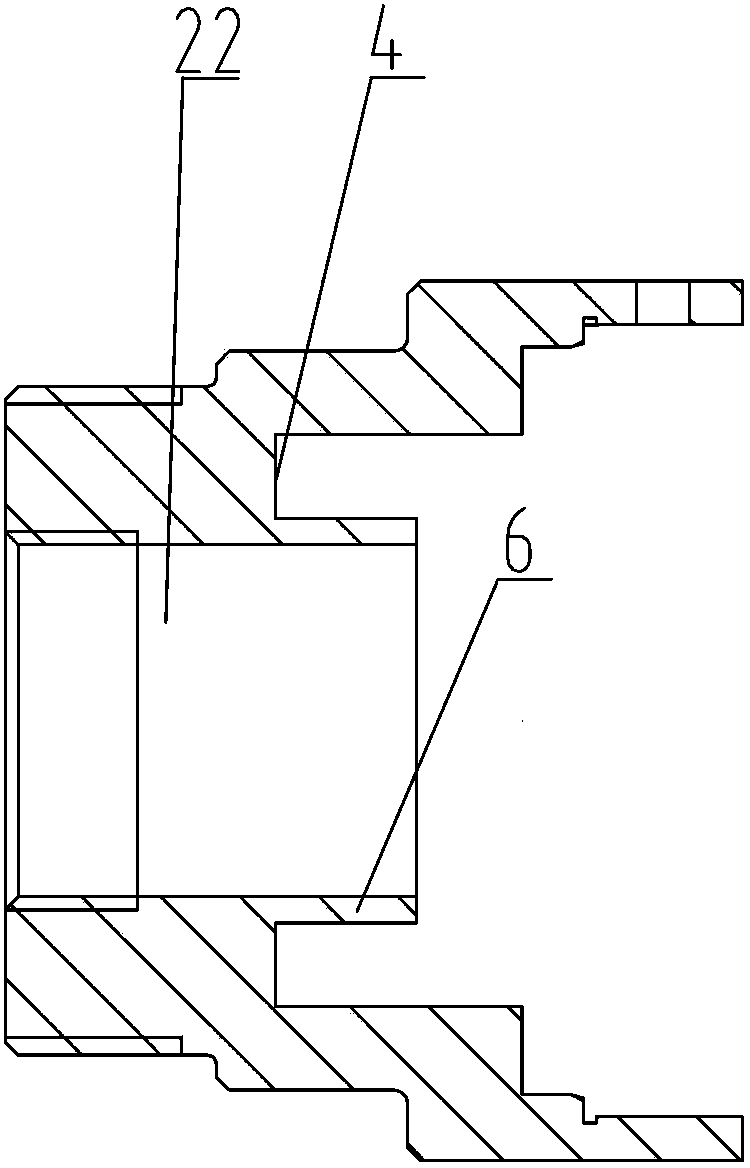

One-way valve

The invention aims to provide a one-way valve. The one-way valve is mainly used for resolving the problem that an existing one-way valve can not be communicated when flowing speed of fluid is overhigh. The one-way valve comprises a first valve body and a second valve body, wherein the center of the first valve body is provided with a first shaft hole in a stair shape, the center of the second valve body is provided with a second shaft hole in a stair shape, the diameter of the first shaft hole and the diameter of the second shaft hole are gradually increased towards the joint of the first valve body and the second valve body, and the diameter of the butt joint of the first shaft hole is equal to that of the butt joint of the second shaft hole. A piston which is in clearance fit with the first shaft hole and the second shaft hole is arranged, the end face of the piston is provided with a plurality of through holes or grooves, the first stair surface of the first shaft hole is provided with a first pipe which is cast to the first shaft hole in an integrated mode, and the outer circumferential surface of the first pipe is provided with a plurality of second through holes; the first through holes or the grooves are located in the end face, between the outer circumferential surface of the first pipe and the inner all of the butt joint of the first shaft hole, of the piston.

Owner:中钢集团衡阳机械有限公司

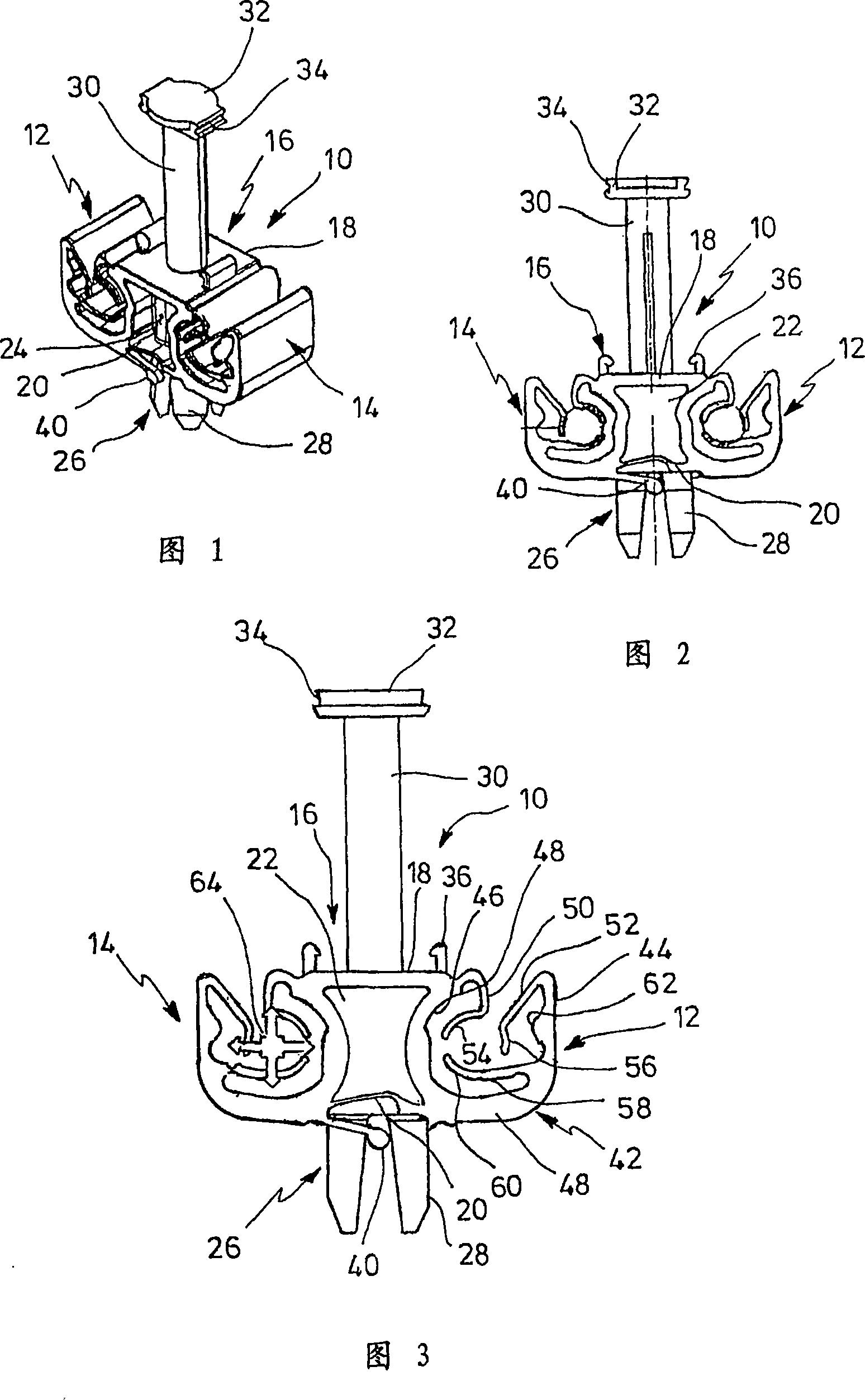

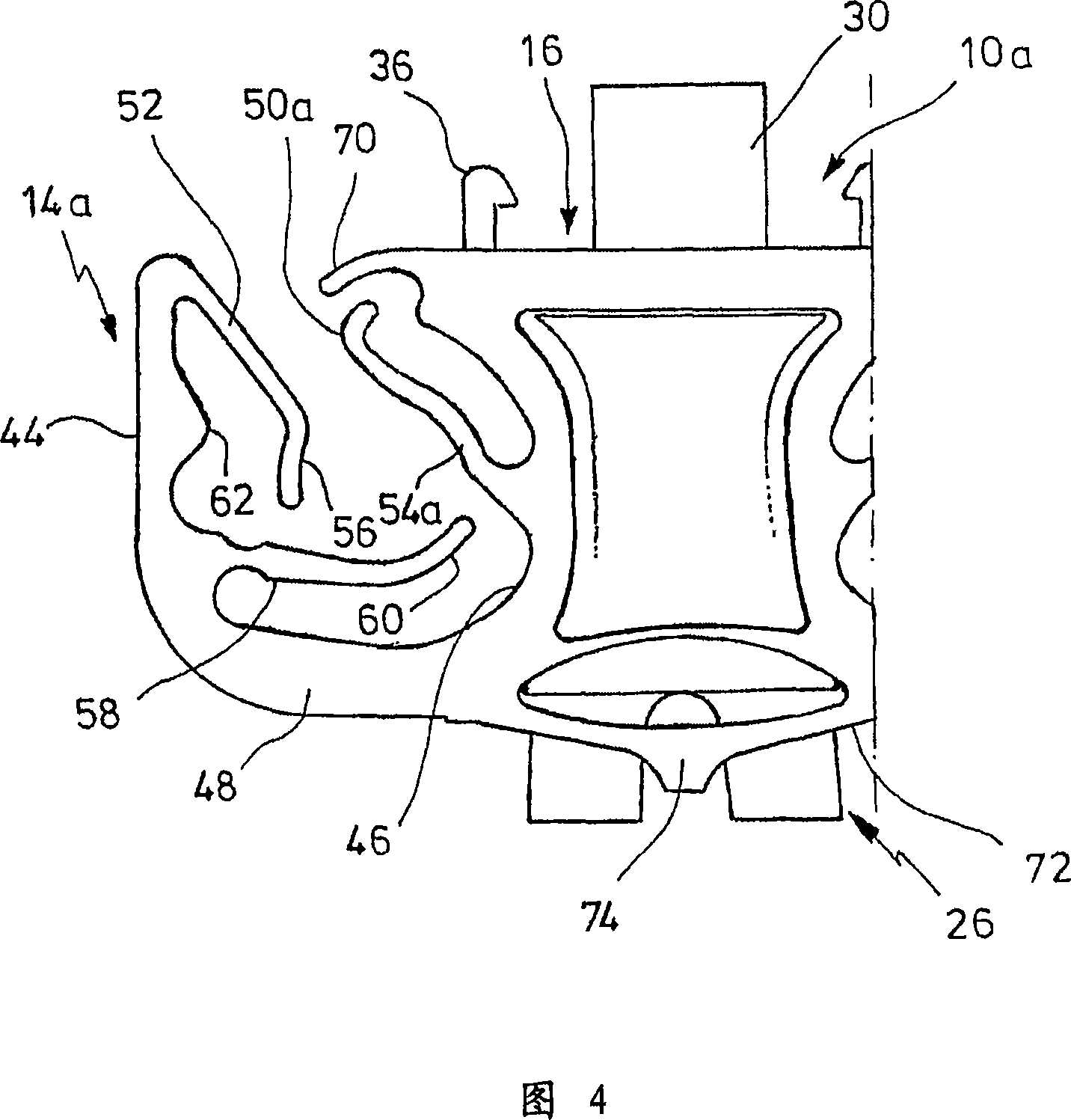

Automobile cable/conduit retainer

ActiveCN101171155AProne to small vibrationsHigh spring forcePipe supportsElectrical apparatusPlastic materialsEngineering

A retainer for a conduit, cable or the like, preferably a fluid conduit in an automobile, includes a retainer body having attaching portions to be mounted to an automobile body part, damping portions for dampening conduit vibrations, an insertion portion that constricts from the outside to the inside, and a receiving portion for the conduit. The retainer body is integrally molded of a plastic material. The receiving portion has three or more engaging portions (54, 56, 60) which are arranged circumferentially of and engage the conduit and which are connected by resilient arms (50, 52, 58) to the retainer body (10, 12, 14) in a manner that, in the event of conduit vibrations, the resilient arms (50, 52, 58) shall yield easily and elastically like leaf springs in all axial and radial directions and shall decouple the vibration-induced forces from the automobile body part.

Owner:ITW AUTOMOTIVE PRODS

Method for effecting a screwed connection

ActiveUS8033000B2Simple configurationAccurate measurementLoad modified fastenersNutsEngineeringScrew thread

A screwed connection has a threaded bolt; a nut; a washer arranged between the nut and a surface of a component to be clamped; a screwing device with a housing, a holding tool connected to the housing, and a tightening tool that engages positively the nut; a measuring element arranged in the washer for measuring a compressive force generated by tightening the screwed connection. The washer has an anti-rotation device oriented toward the surface of the component. The outer periphery of the washer is positive-lockingly engaged by the holding tool. The washer has no positive or frictional connection to the threaded bolt, and the holding tool has no torque supporting action on the threaded bolt or on any other part so that a reaction moment, generated when tightening the nut, is introduced from the housing of the screwing device through the washer into the component to be clamped.

Owner:HOHMANN JORG +1

Loose-leaf binder

ActiveCN101372188APromote engagementAddress manufacturing costsFiling appliancesSheet bindingEngineeringOpening - action

The invention provides a binder integrally made of plastic, performing opening action divided into two stages in rotor ring and preventing the binder from being fallen off, as well as providing a narrow first opening state capable of inserting few binders and wider second opening state capable of inserting a plurality of binders.

Owner:金田克已

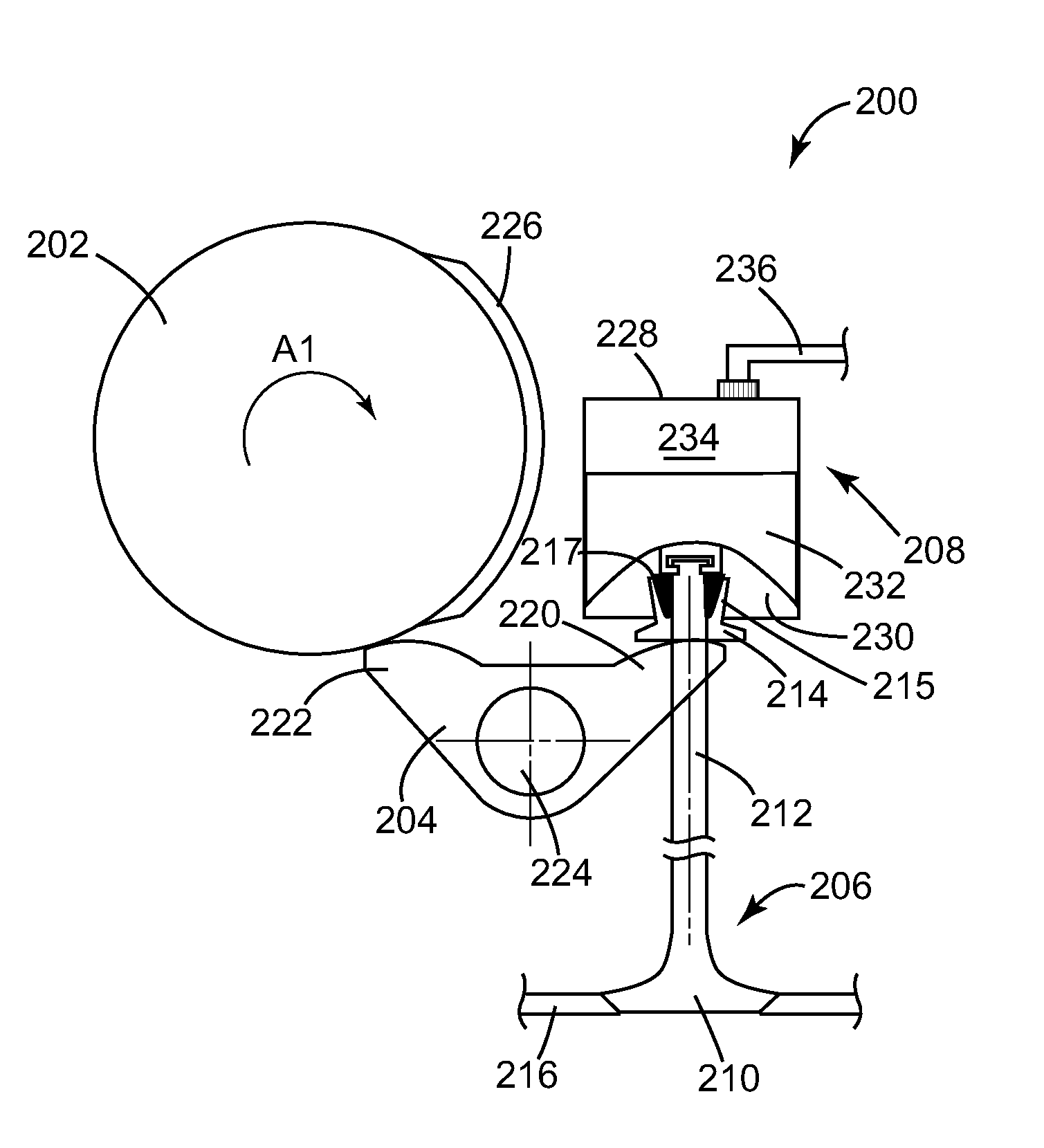

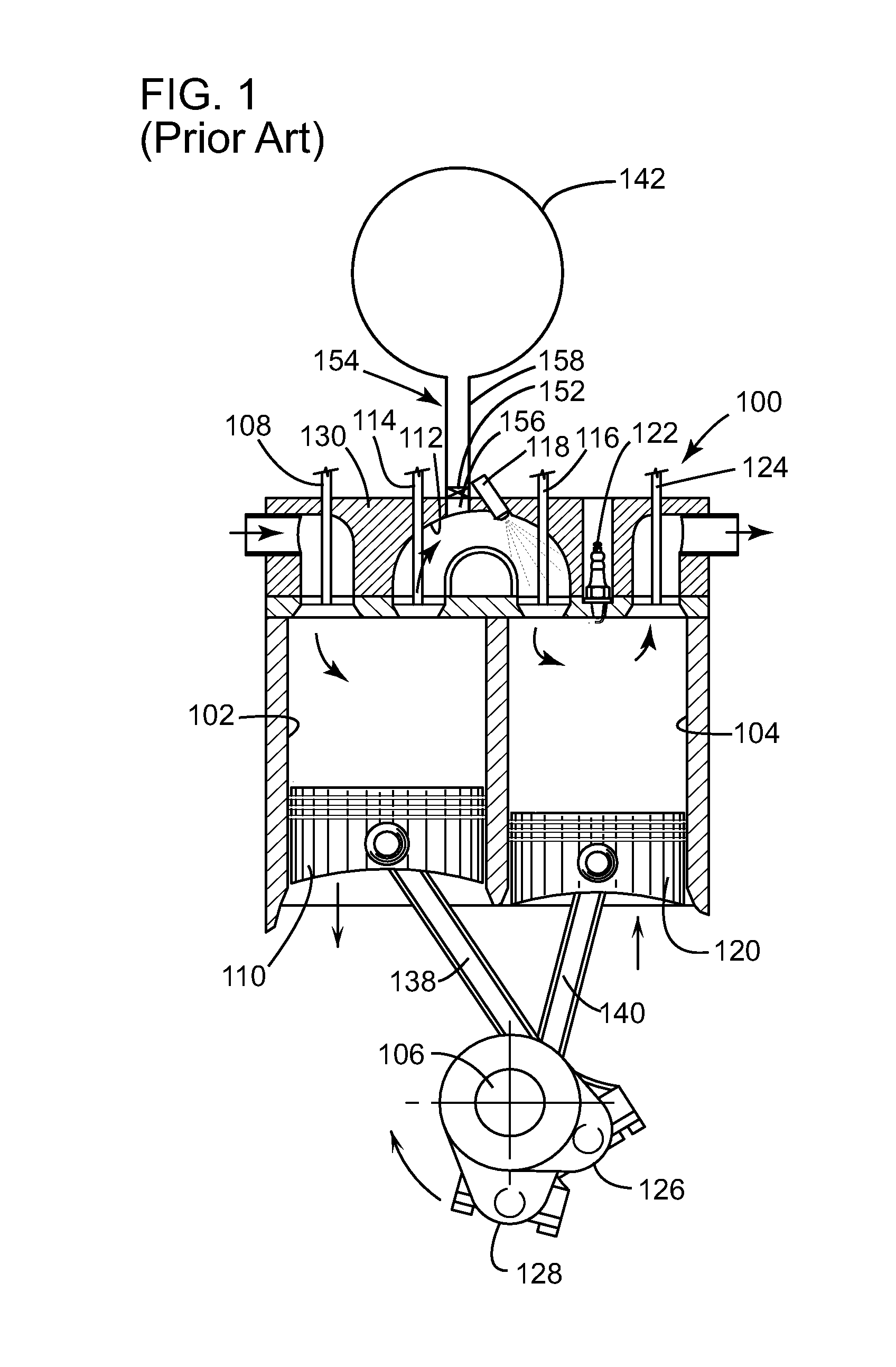

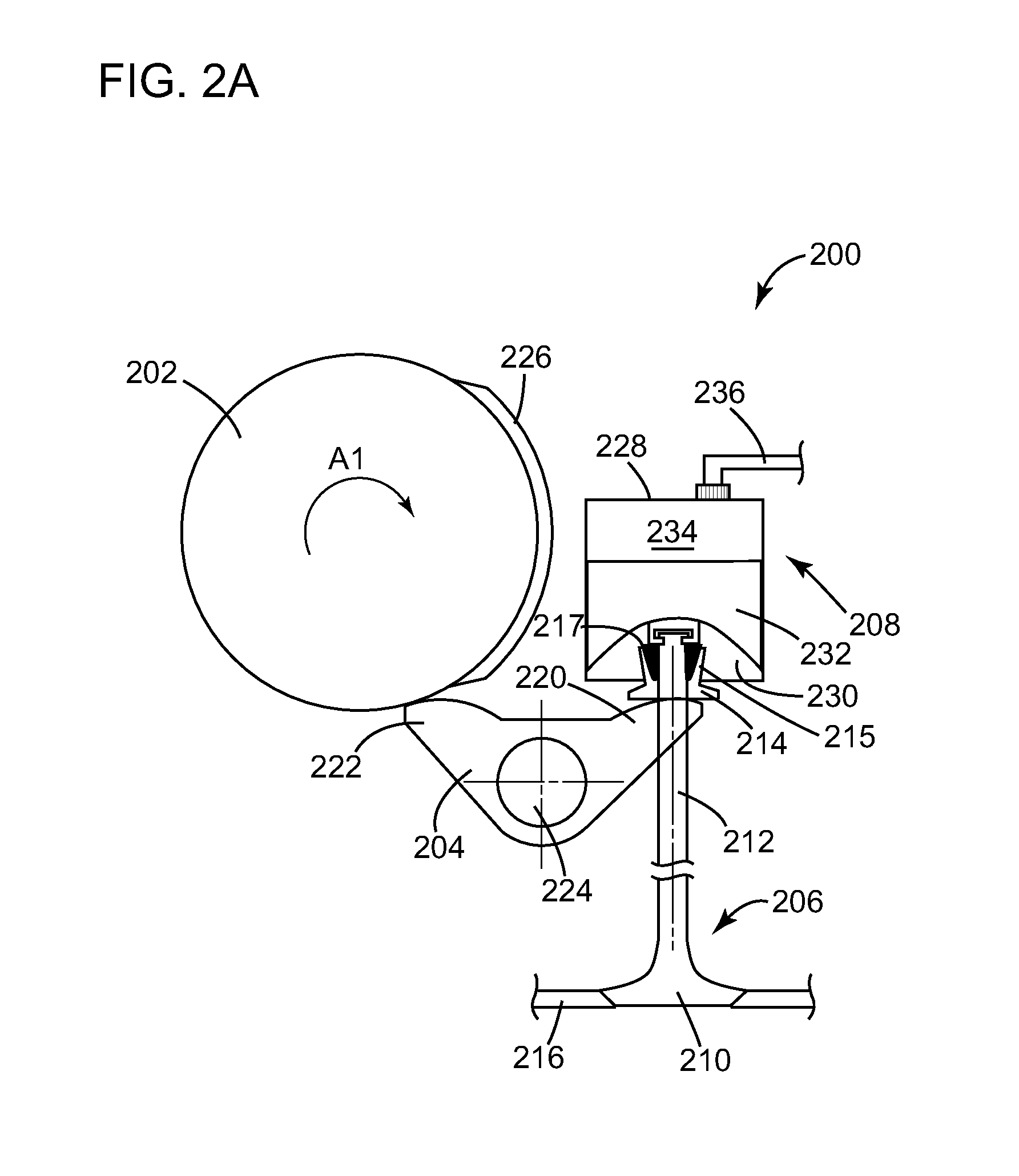

Variable force valve spring

InactiveUS20120192817A1High spring forceReduce spring forceMetal-working apparatusCombustion enginesFluid controlEngine valve

Devices and related methods are disclosed that generally involve variable force valve springs for controlling the motion of an engine valve. The force exerted by the valve spring can be adjusted by altering the pressure at which a fluid is supplied to a fluid chamber thereof, by altering the volume of the fluid chamber, and / or by changing the aggregate surface area over which fluid pressure is coupled to the engine valve. Associated fluid control systems are also disclosed herein, as are various methods for adjusting the force of a valve spring based on a variety of engine parameters, such as engine speed, engine load, and / or a combination thereof.

Owner:SKADERI GRUP LLC

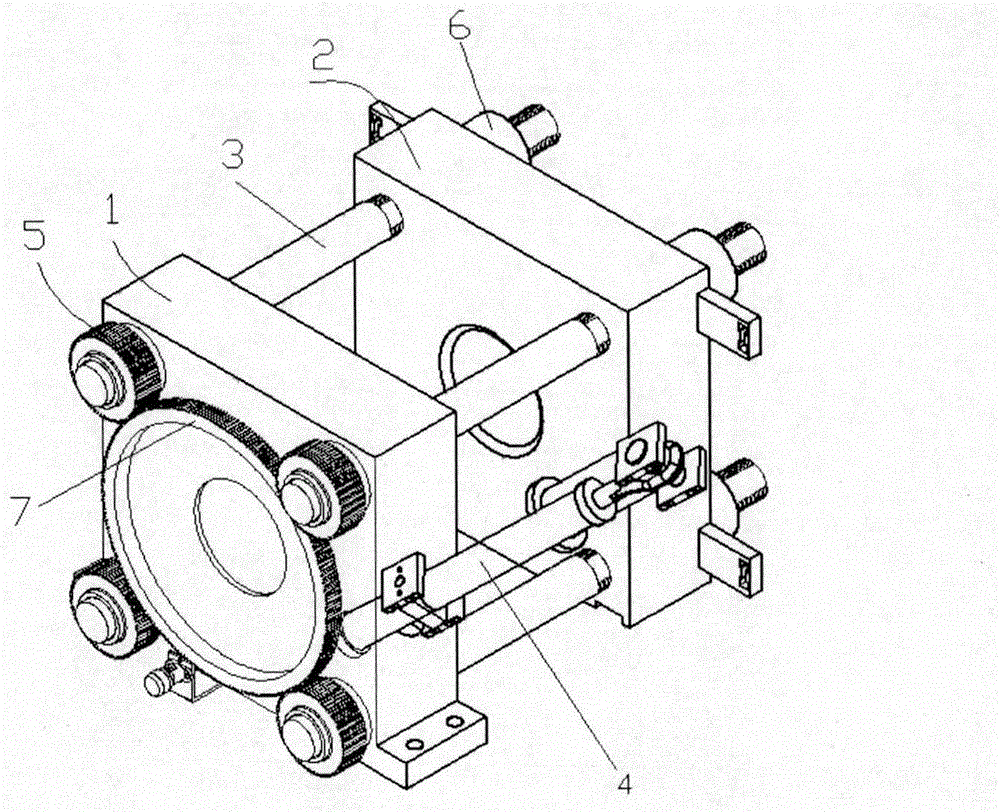

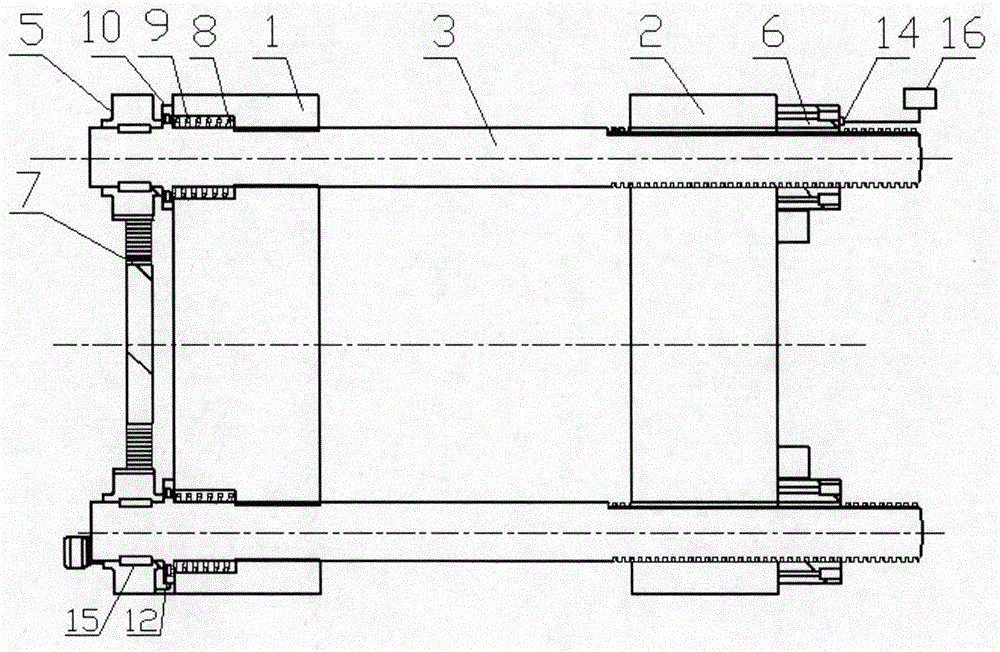

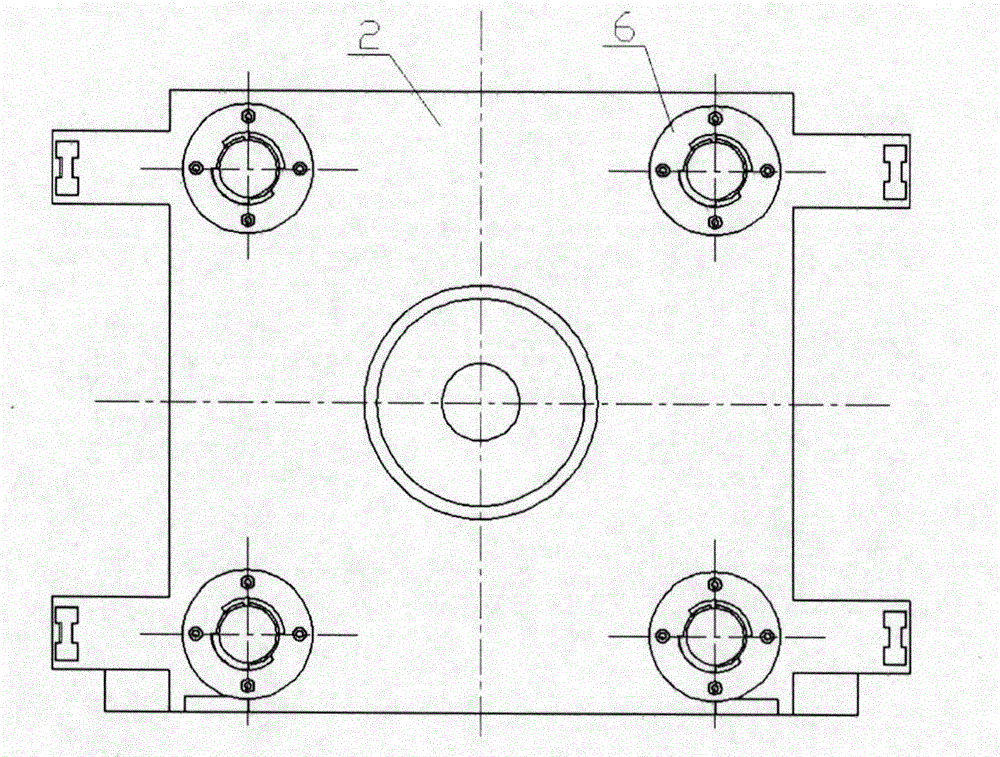

Mold opening and closing method for mold closing device of two-plate type injection molding machine

The invention discloses a mold opening and closing method for a mold closing device of a two-plate type injection molding machine. The mold closing device comprises a fixed mold plate (1), a movable mold plate (2), pull rods (3) and a mold moving oil cylinder (4), wherein the fixed mold plate (1) is arranged at one ends of the pull rods (3), and the other ends of the pull rods (3) are sleeved by the movable mold plate (2); the mold closing device of the injection molding machine further comprises front screw nuts (5), rear screw nuts (6), a large gear ring (7) and a power mechanism for driving the large gear ring (7) to rotate, the front screw nuts (5) are in one-to-one correspondence with the pull rods (3), external threads matched with the rear screw nuts are arranged on the pull rods (3), the rear screw nuts (6) are also in one-to-one correspondence with the pull rods (3) and fixedly connected on the movable mold plate (2), the outer edges of the front screw nuts (5) are set to be like gears, the large gear ring (7) is meshed with each front screw nut (5), and the large gear ring drives the front screw nuts to rotate under the drive of the power mechanism. According to the mold opening and closing method disclosed by the invention, a mold locking oil cylinder is not required, and energy consumption in mold locking is reduced by self-locking of the mechanism.

Owner:TEDERIC MACHINERY

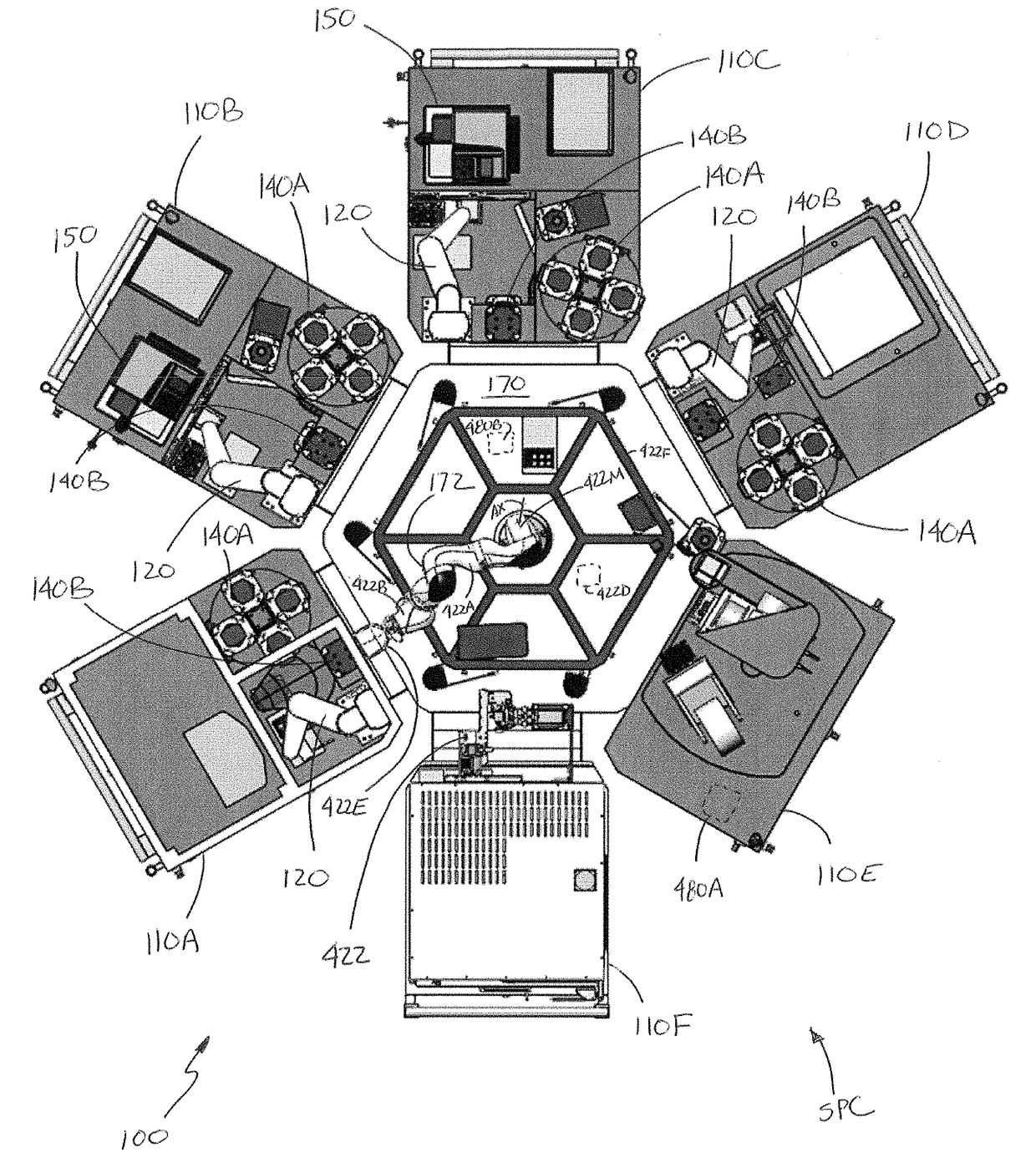

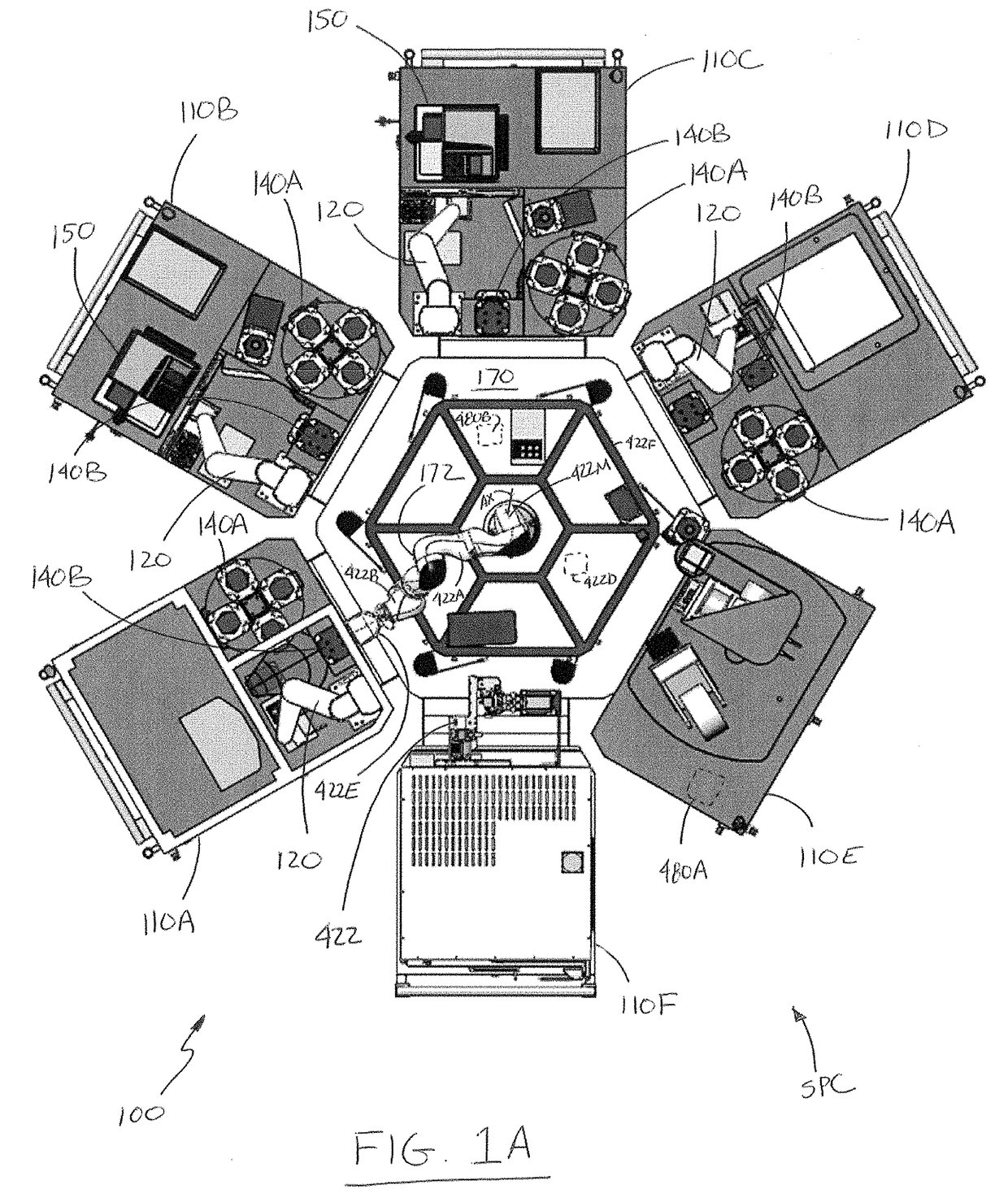

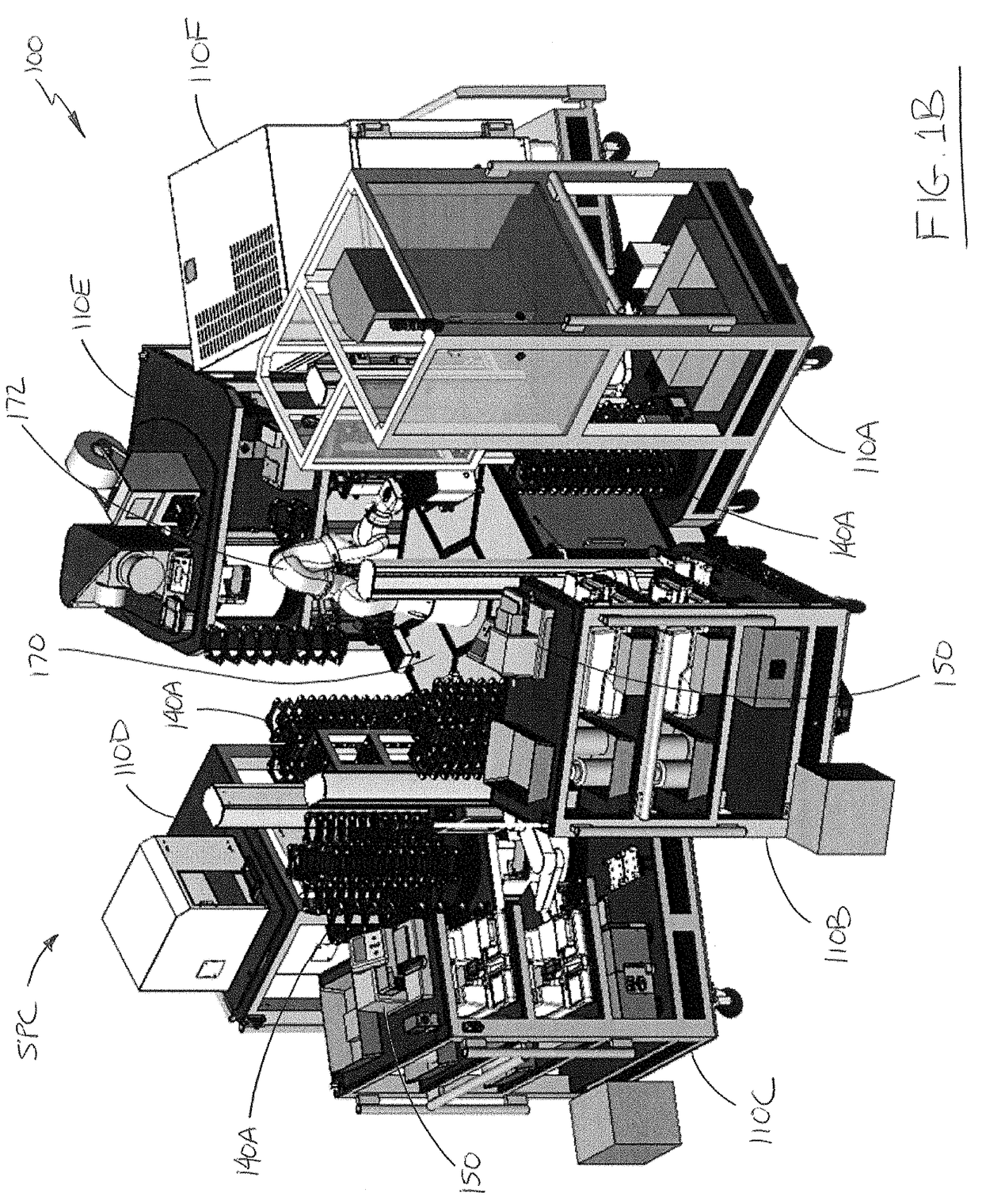

Robotic processing system

A robotic transport system including a drive section connected to a frame, an articulated arm operably coupled to the drive section providing the articulated arm with arm motion in at least one axis of motion moving at least a portion of the articulated arm in a collaborative space, corresponding to the frame, from a first location to another different location in the collaborative space, the articulated arm having an end effector with a workpiece grip having workpiece engagement members engaging and holding a workpiece during workpiece transport, by the arm motion in the at least one axis of motion, wherein at least one of the workpiece engagement members is frangible compliant, having a frangible compliant coupling between a distal portion of the at least one of the workpiece engagement members and a base portion of the end effector from which the at least one of the workpiece engagement members depends.

Owner:HIGHRES BIOSOLUTIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com