Latch plate and method for producing a latch plate

A lock tongue and seat belt lock technology, which is applied in application, transportation, packaging, clothing, etc., can solve problems such as jamming, achieve the effect of improving clamping effect and avoiding point contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

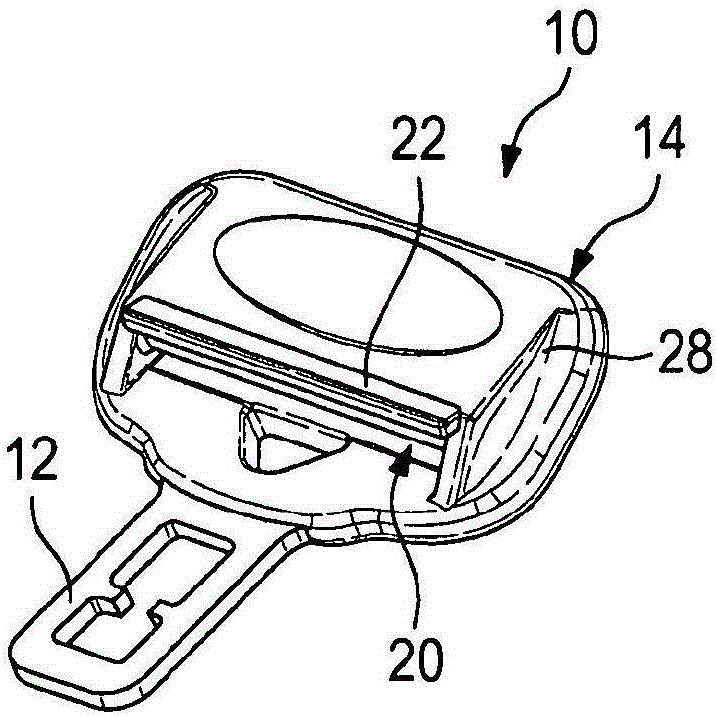

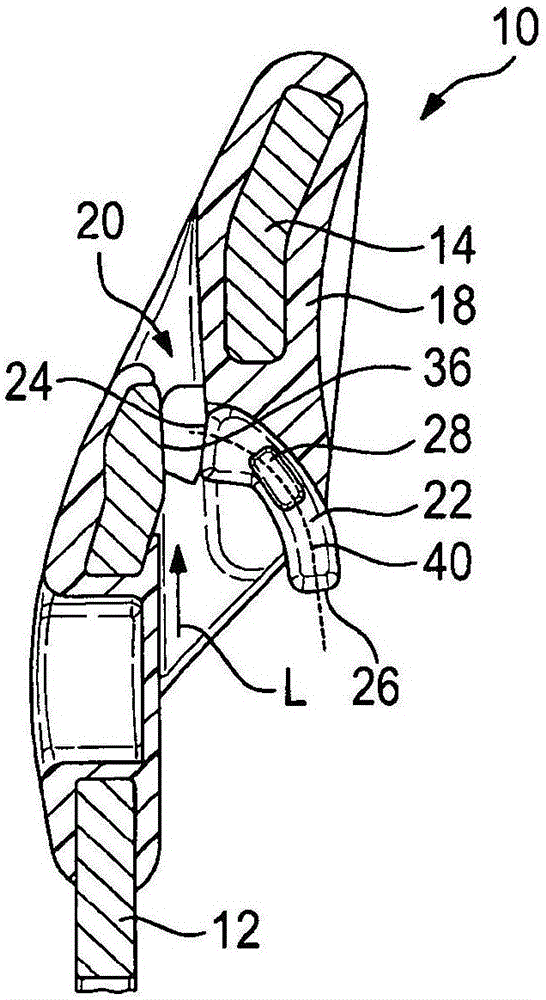

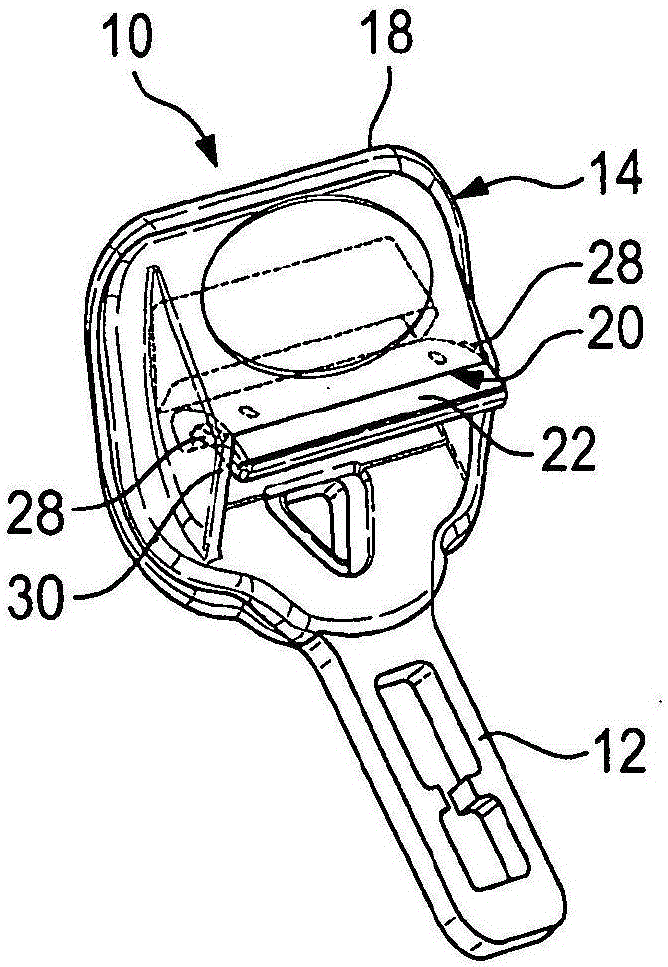

[0041] exist Figures 1 to 4 A tongue 10 for a seat belt in a vehicle is shown in . The bolt 10 has an insertion section 12 , which can be inserted into and locked in the belt lock, and a deflection section 14 which is threaded onto a webbing 16 and can turn the webbing 16 steering (see Figures 5a to 5d ). The deflection section 14 has an injection-molded encapsulation 18 made of plastic, which completely surrounds the deflection section 14 .

[0042] as especially in figure 2 As can be seen in the figure, a webbing channel 20 through which the webbing 16 is guided, as well as a clamping element 22 , the function of which will be explained below, is provided on the deflection section 14 . The clamping element 22 is curved in cross section, circular in this embodiment, and has a clamping surface 24 facing the webbing channel 20 and a deflection surface 26 arranged at the opposite end. Projections 28 are provided laterally on the clamping element 22 , by means of which th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com