Automobile cable/conduit retainer

A technology for retainers and pipes, which is applied in the direction of pipe brackets, circuits or fluid pipes, pipes/pipe joints/fittings, etc. It can solve the problems of expensive double injection molding and achieve the effect of economical manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

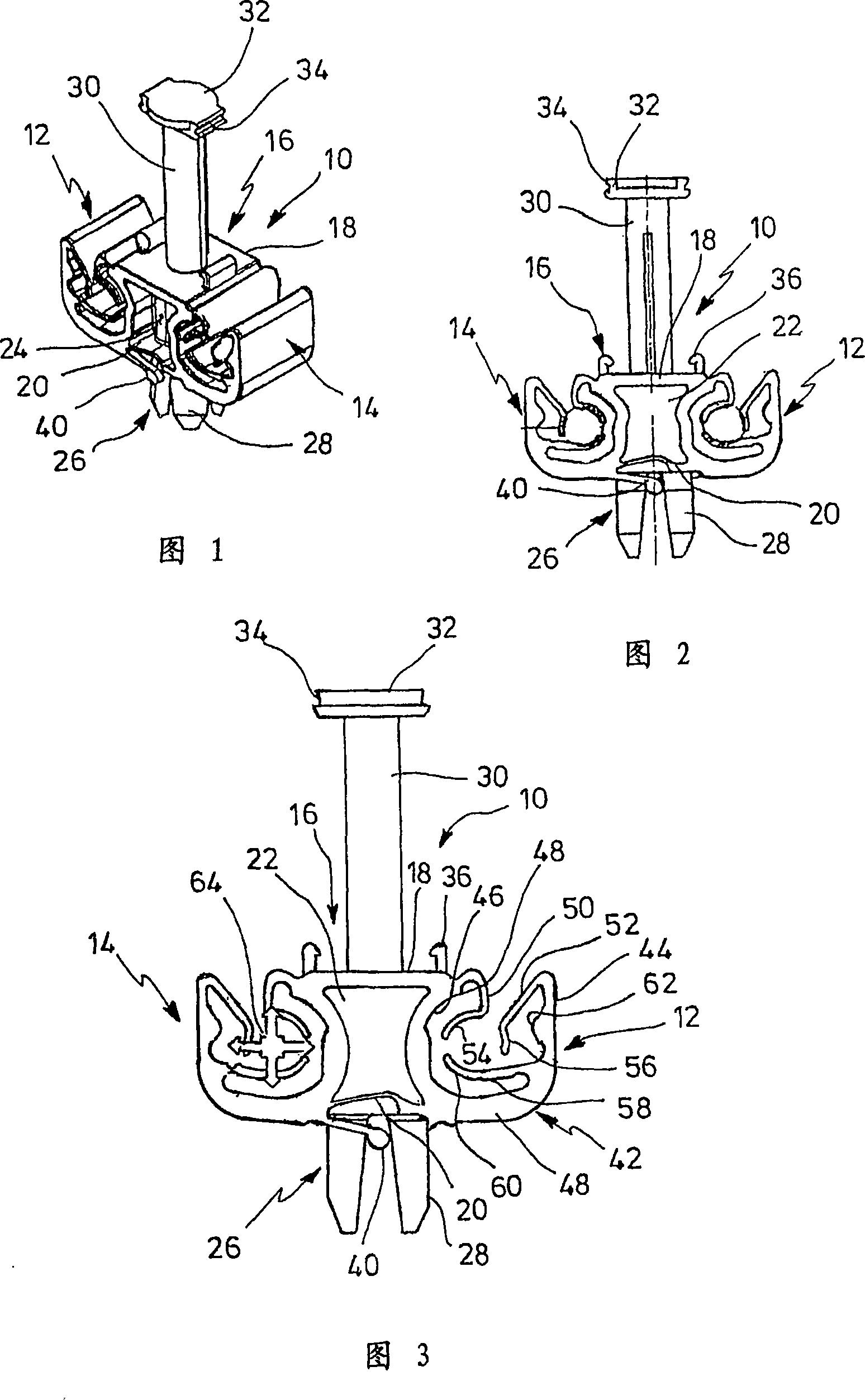

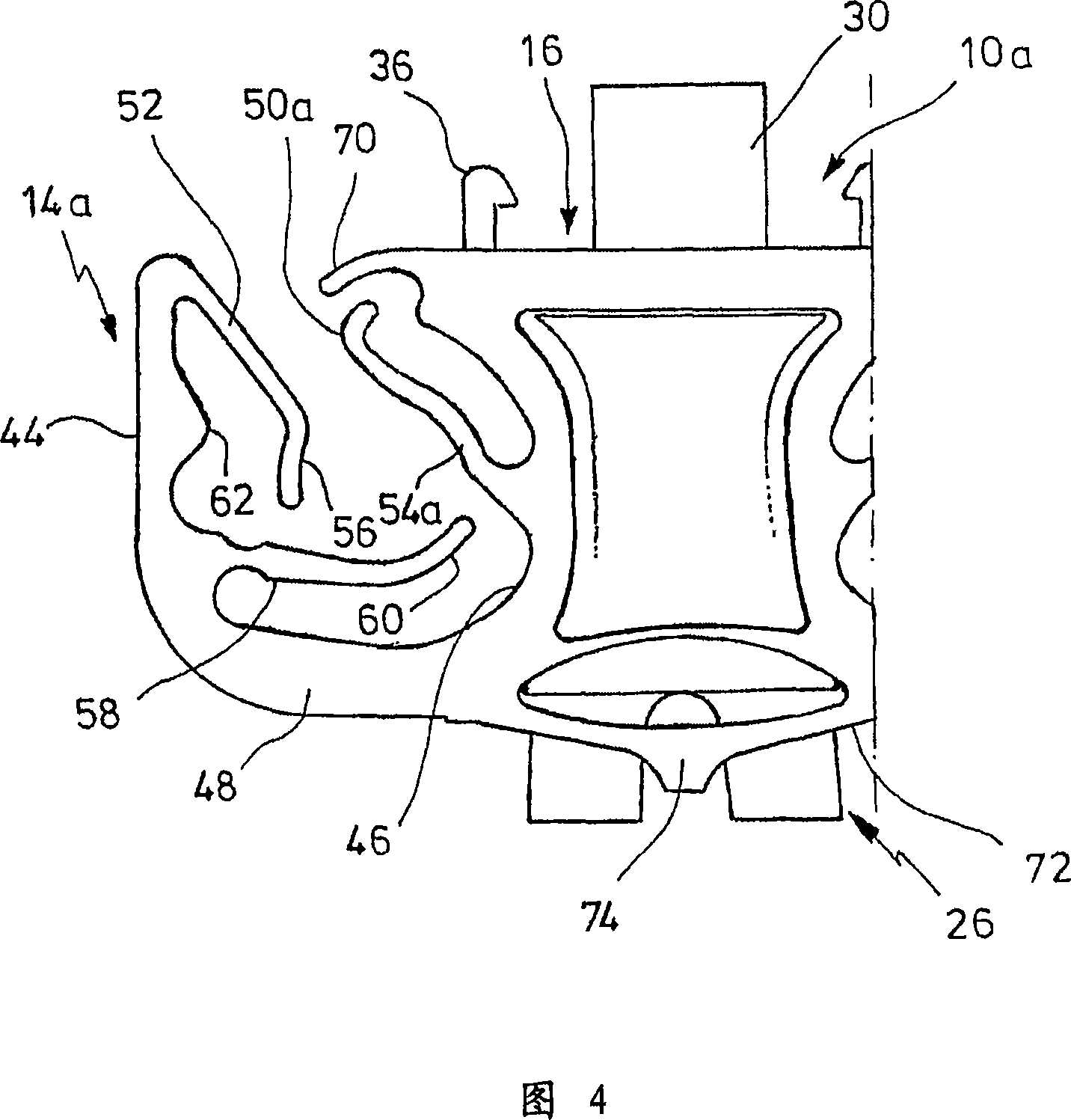

[0020] FIGS. 1 to 3 show a retainer 10 comprising a single body with two retainer portions 12 , 14 designed to receive the two fluid conduits shown in FIG. 2 . The retainer portions 12 , 14 are integral with the fastener portion 16 . The fastener portion 16 includes an upper wall 18 and a lower wall 20 connected by a front wall 22 and a rear opposing wall (not visible). The rear wall is not shown in FIG. 1 . As shown in FIG. 1 , the upper wall 18 and the lower wall 20 are interconnected to each other in the middle by a hollow approximately cylindrical member 24 . The cylindrical member 24 opens downwards into an expansion rivet 26 comprising circumferentially equidistant resilient legs 28 . A cylindrical pin 30 with an elongated flat head 32 is integrally formed in the top side of the wall portion 18 . Each opposite side of the head 32 is fitted with a groove 34 . When installing the fastener part 16 in the hole of the omitted body part, the first expansion rivet 26 will b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com