One-way valve

A one-way valve, valve body technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve problems such as fluid flow failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

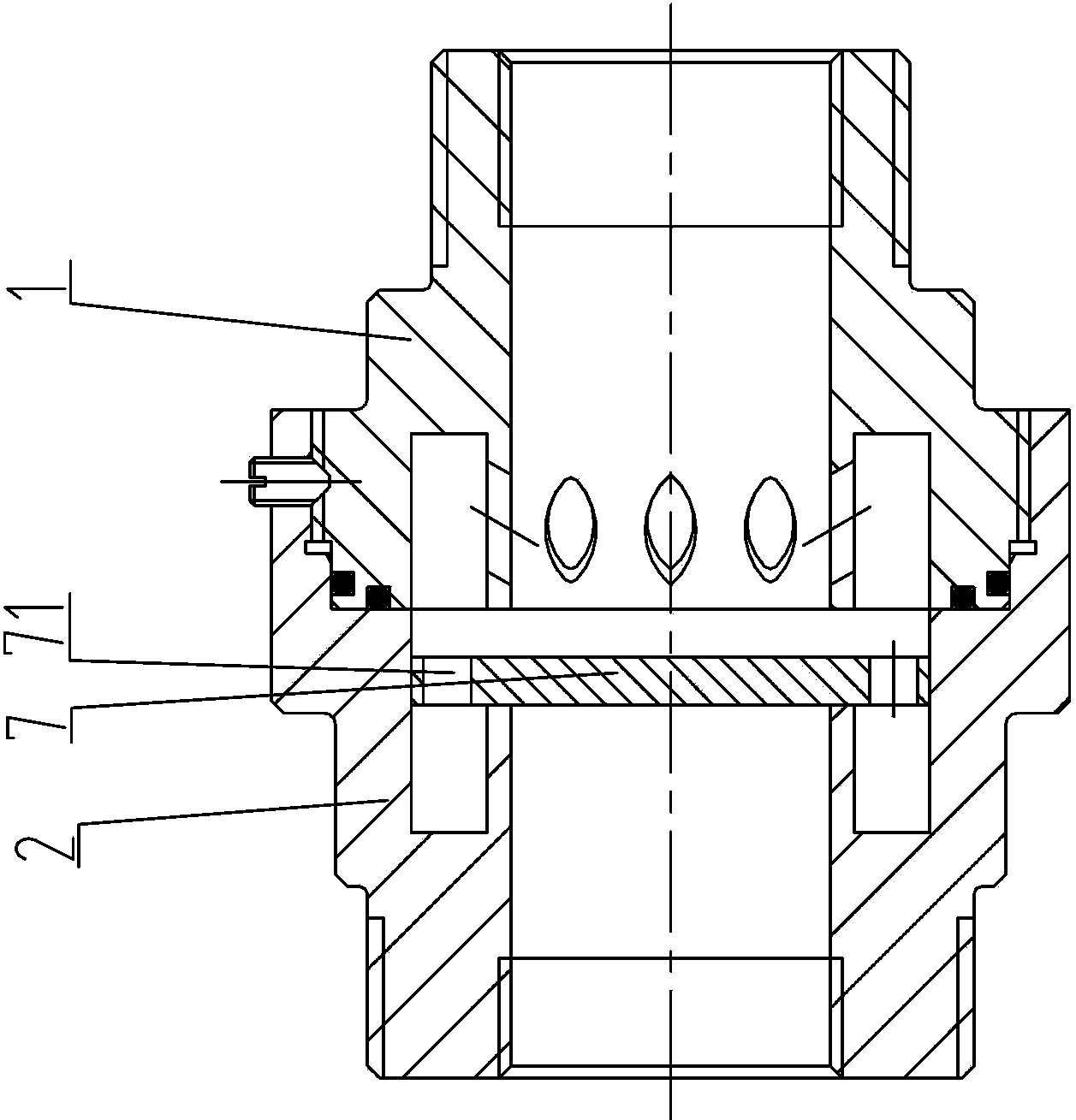

[0020] Such as figure 1 The first type of one-way valve shown includes a first valve body 1 and a second valve body 2, and the first valve body 1 and the second valve body 2 are threadedly connected, of course, they can also be fixedly connected by screws.

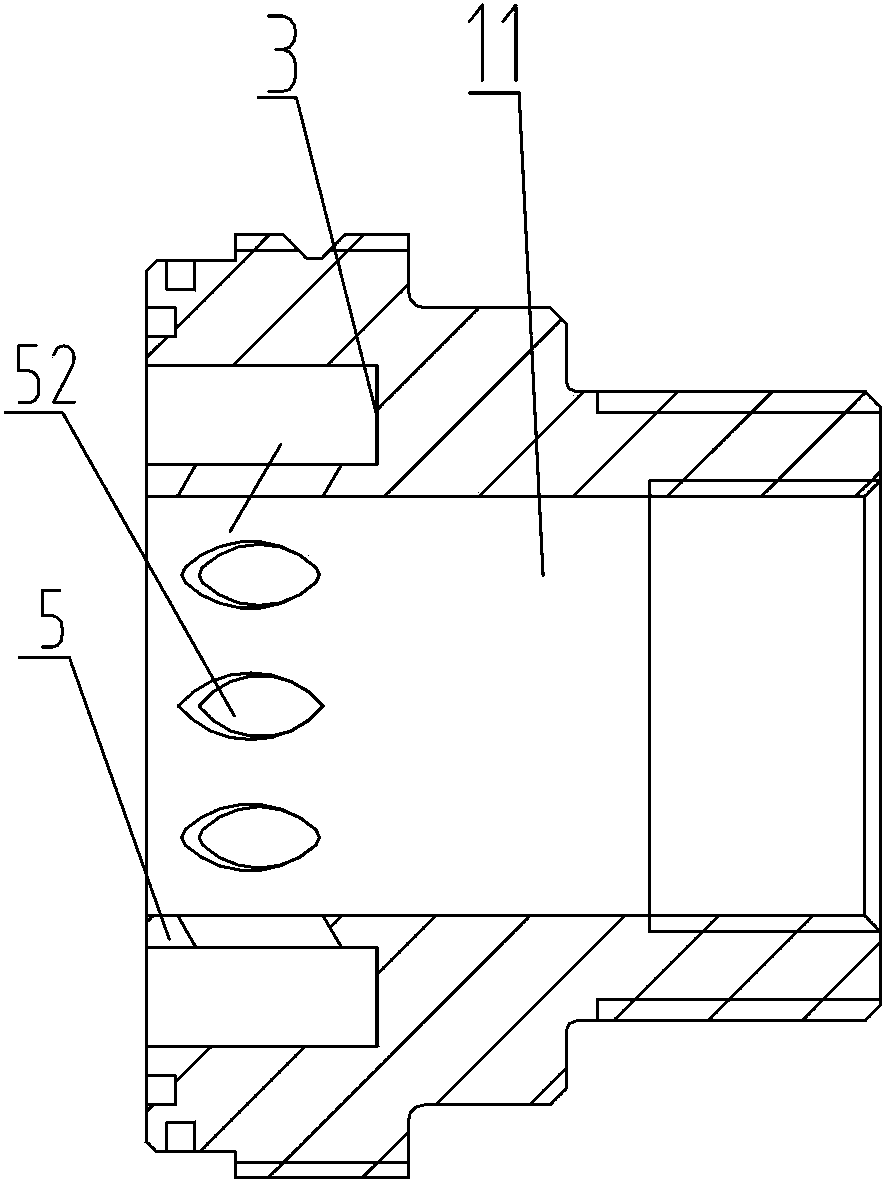

[0021] Such as figure 2 As shown, the center of the first valve body 1 is opened with a first shaft hole 11 whose diameter gradually increases toward the junction of the first valve body 1 and the second valve body 2 , and the first shaft hole 11 is in the shape of two steps. The first stepped surface 3 of the first shaft hole 11 is provided with a first pipe body 5 which is integrally cast thereon and protrudes toward the junction of the first valve body 1 and the second valve body 2 . Several second through holes 52 are arranged on the outer peripheral surface of the first pipe body 5 .

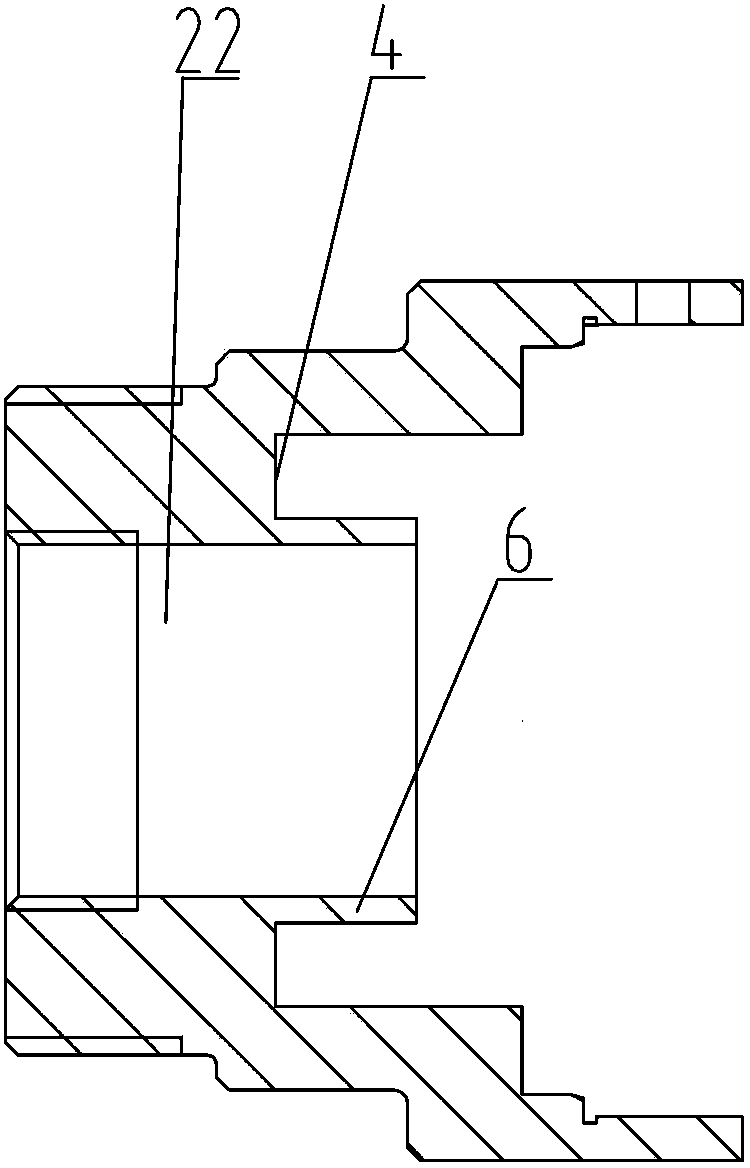

[0022] Such as image 3 As shown, the center of the second valve body 2 is opened with a second shaft hole 22 whose diameter gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com