Patents

Literature

299results about How to "Ensure adequate lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

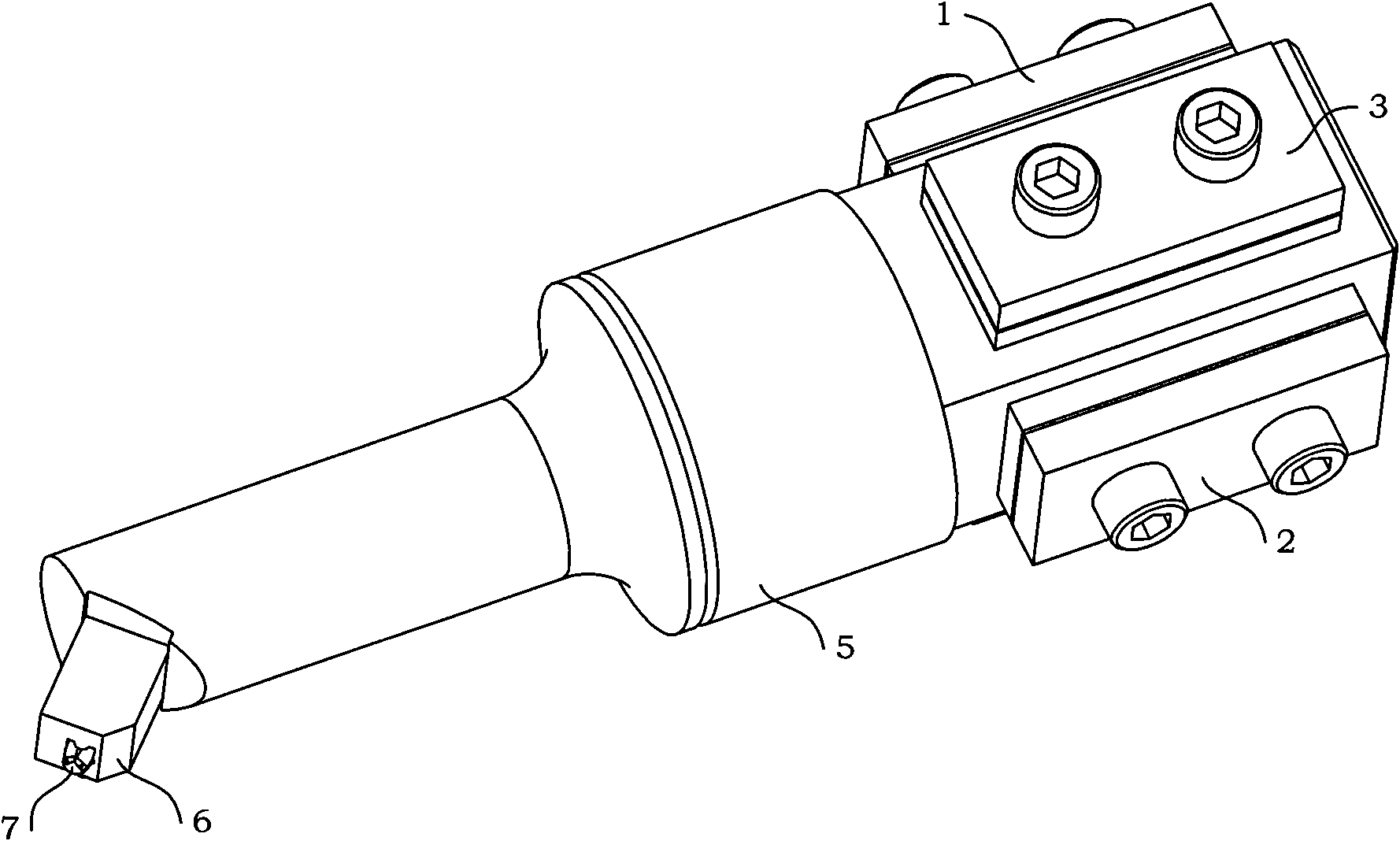

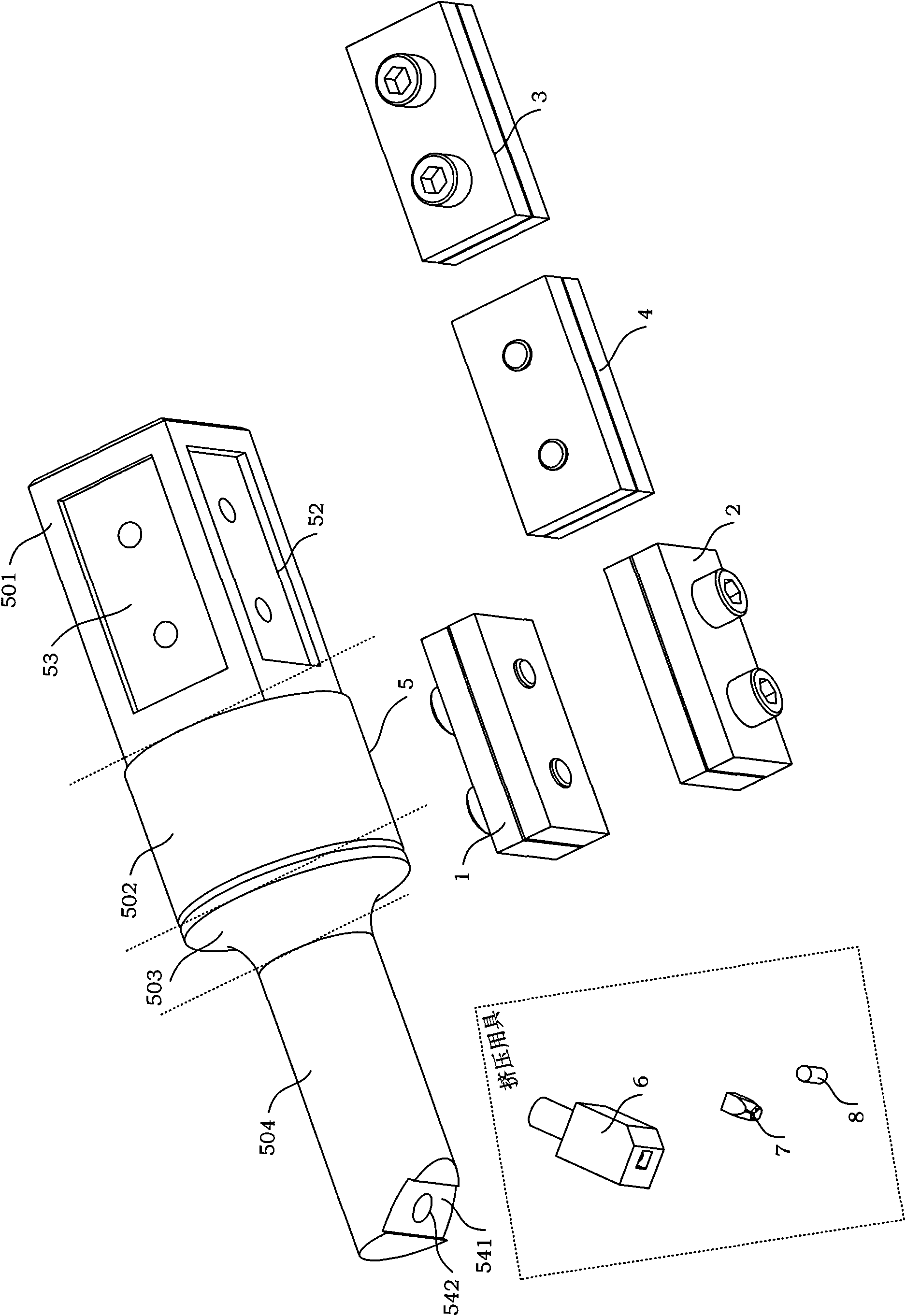

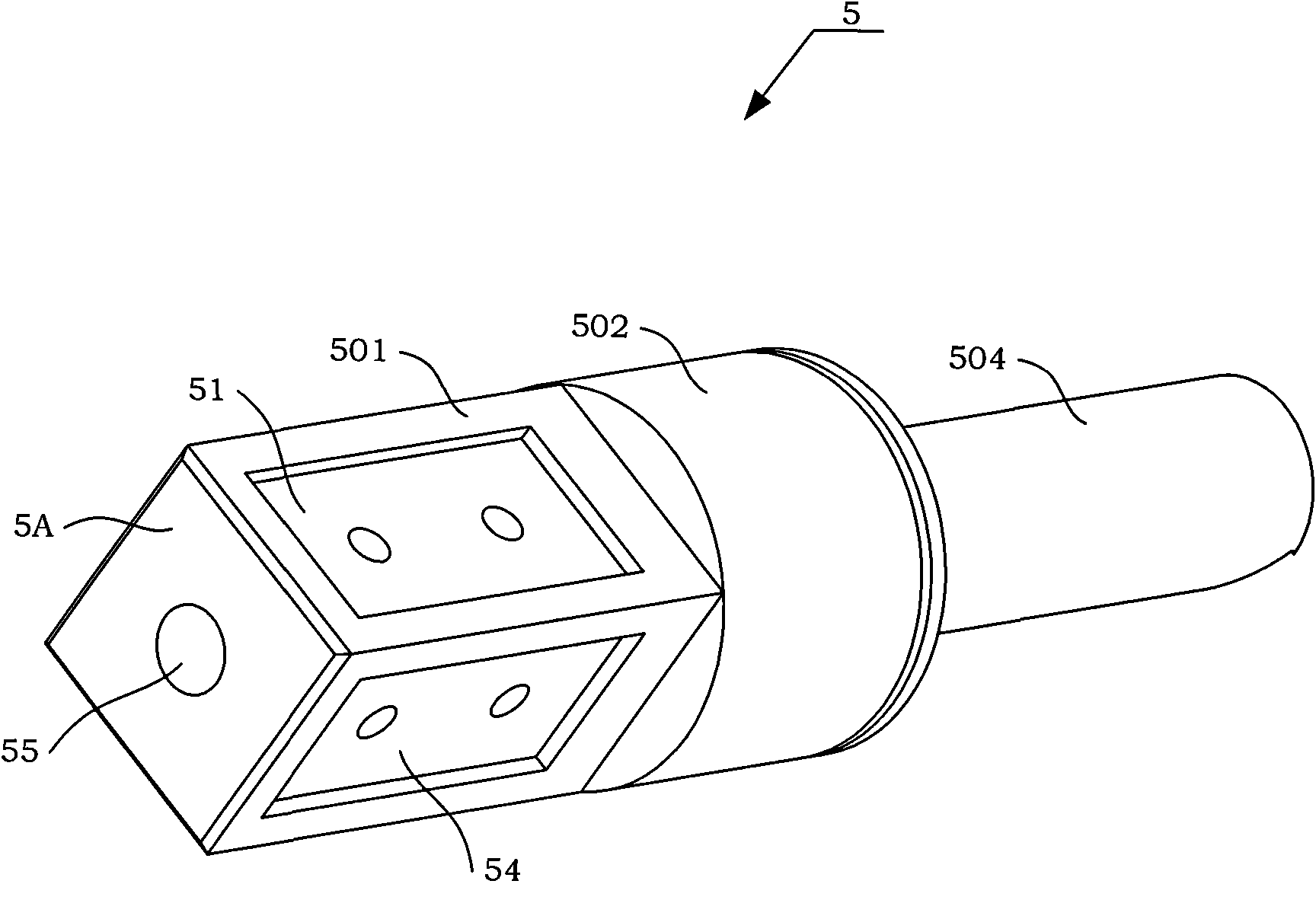

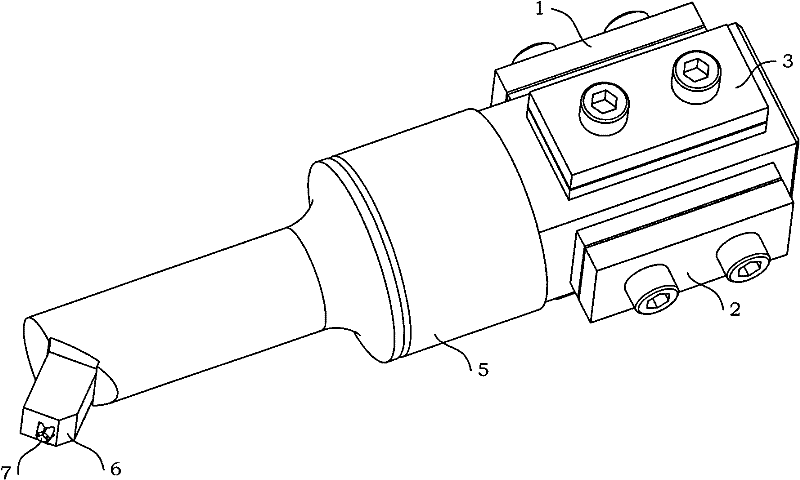

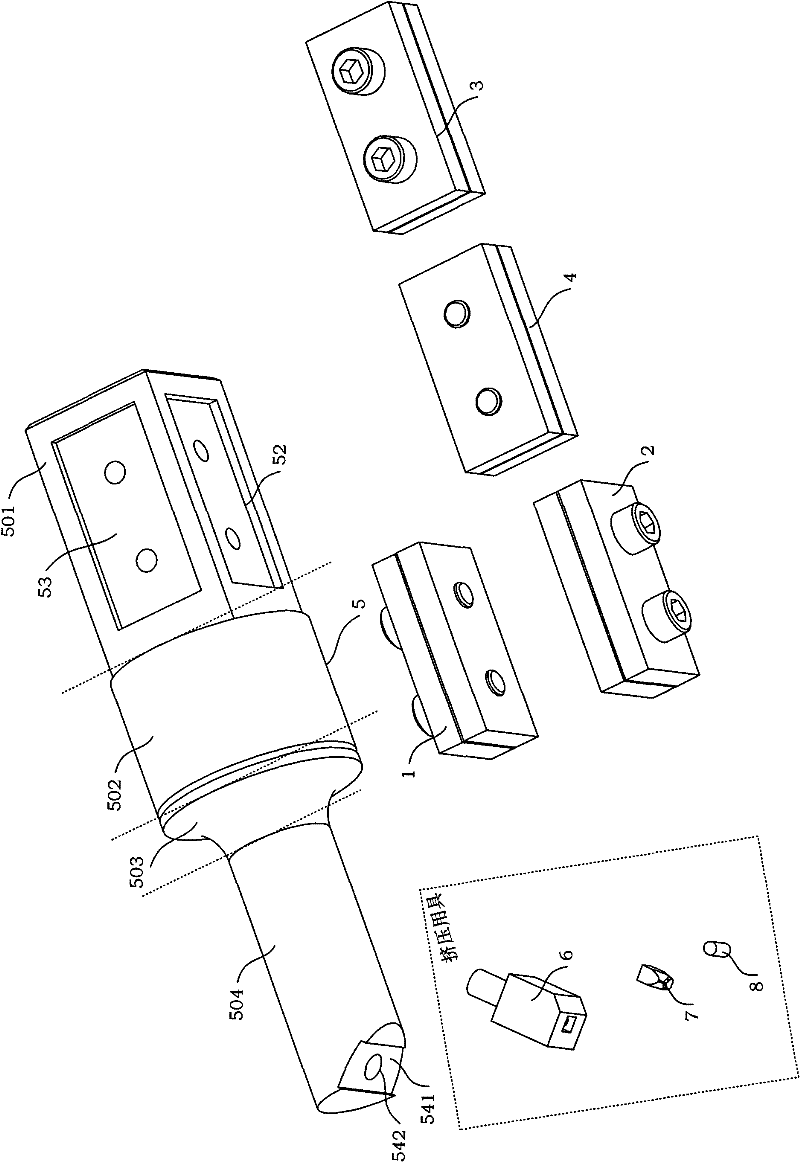

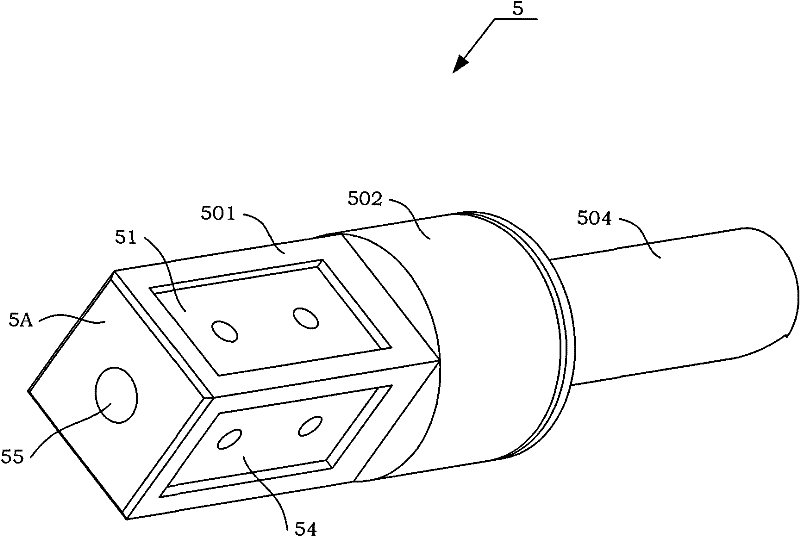

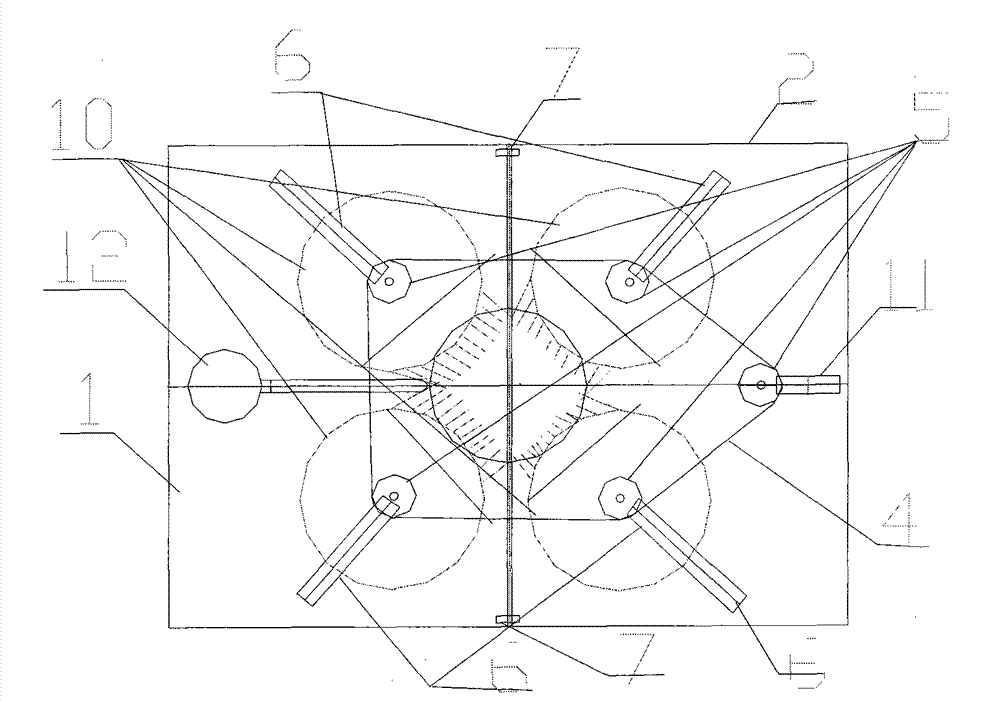

Ultrasonic elliptical vibration extrusion device and vibration extrusion processing method for carrying out surface finishing of part by using same

InactiveCN101942547AReduce volumeLow calorific valueMechanical vibrations separationEllipseTransformer

The invention discloses an ultrasonic elliptical vibration extrusion device and a vibration extrusion processing method for carrying out surface finishing of a part by using the same. The ultrasonic elliptical vibration extrusion device comprises an amplitude transformer, four excitation sources with the same structure and an extrusion tool, wherein the extrusion tool is arranged on the output section of the amplitude transformer; and the four excitation sources are respectively arranged in the four grooves of the excitation section of the amplitude transformer. In the vibration extrusion processing process, an extrusion head makes the ultrasonic vibration in an elliptic orbit relative to the processed surface of the part under the driving of the excitation sources through adjusting an extrusion contact angle between the part and the diamond extrusion head and the processing parameters of ultrasonic elliptical vibration extrusion device. On one hand, the device reduces an extrusion force by utilizing the pulse impact action of the ultrasonic vibration, and thereby, the extrusion process can be applied to thin-wall parts and long and thin parts; on the other hand, the front direct impact is avoided and the sliding friction of the extrusion head and the processed surface of the part is reduced even eliminated by utilizing the separation characteristic and the movement locus characteristic of the elliptical vibration, and thereby, the surface roughness of the processed surface of the part is reduced, and the service life of the extrusion head is prolonged.

Owner:BEIHANG UNIV

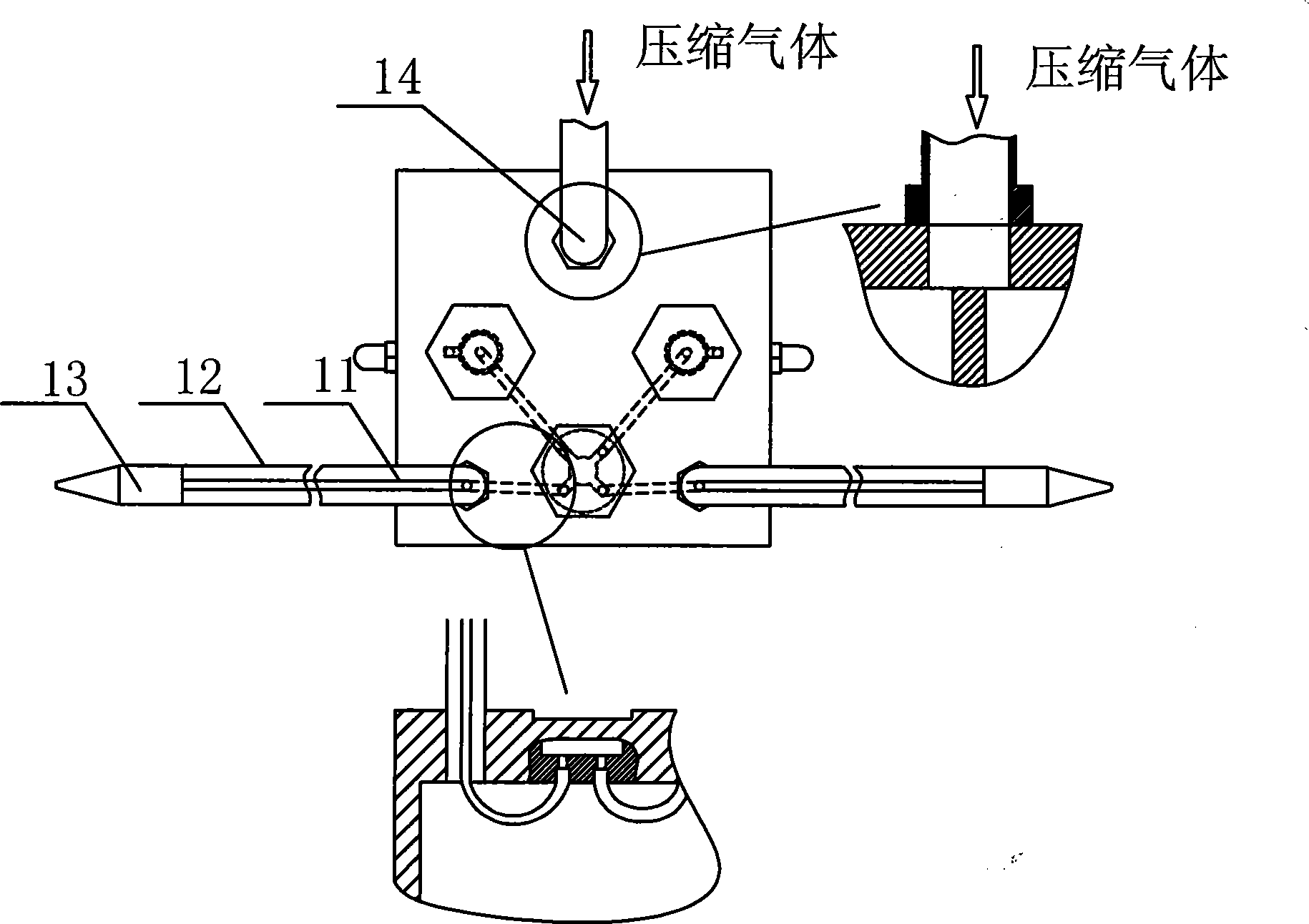

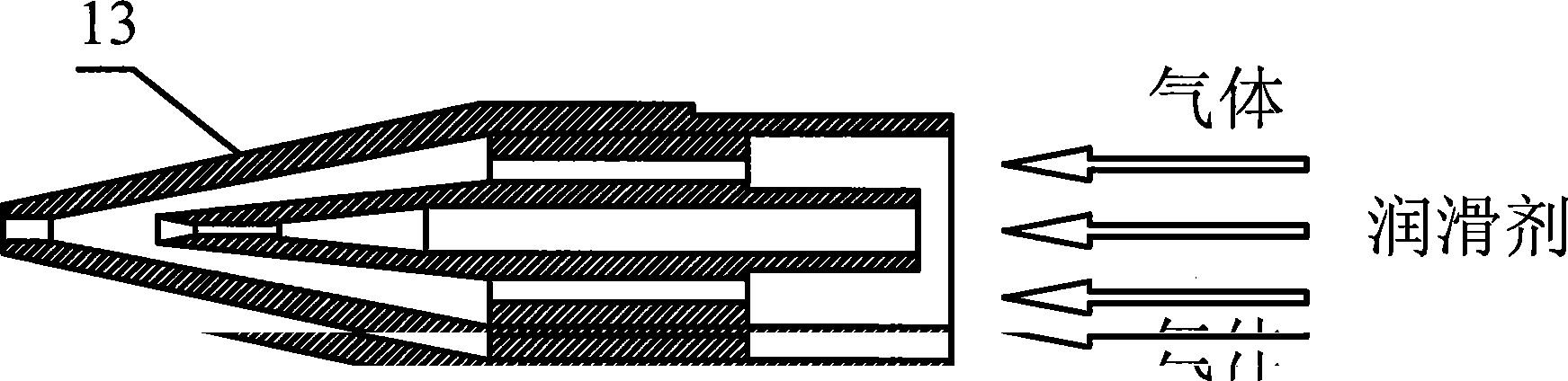

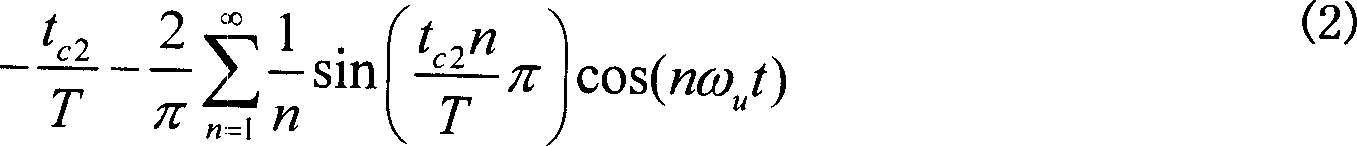

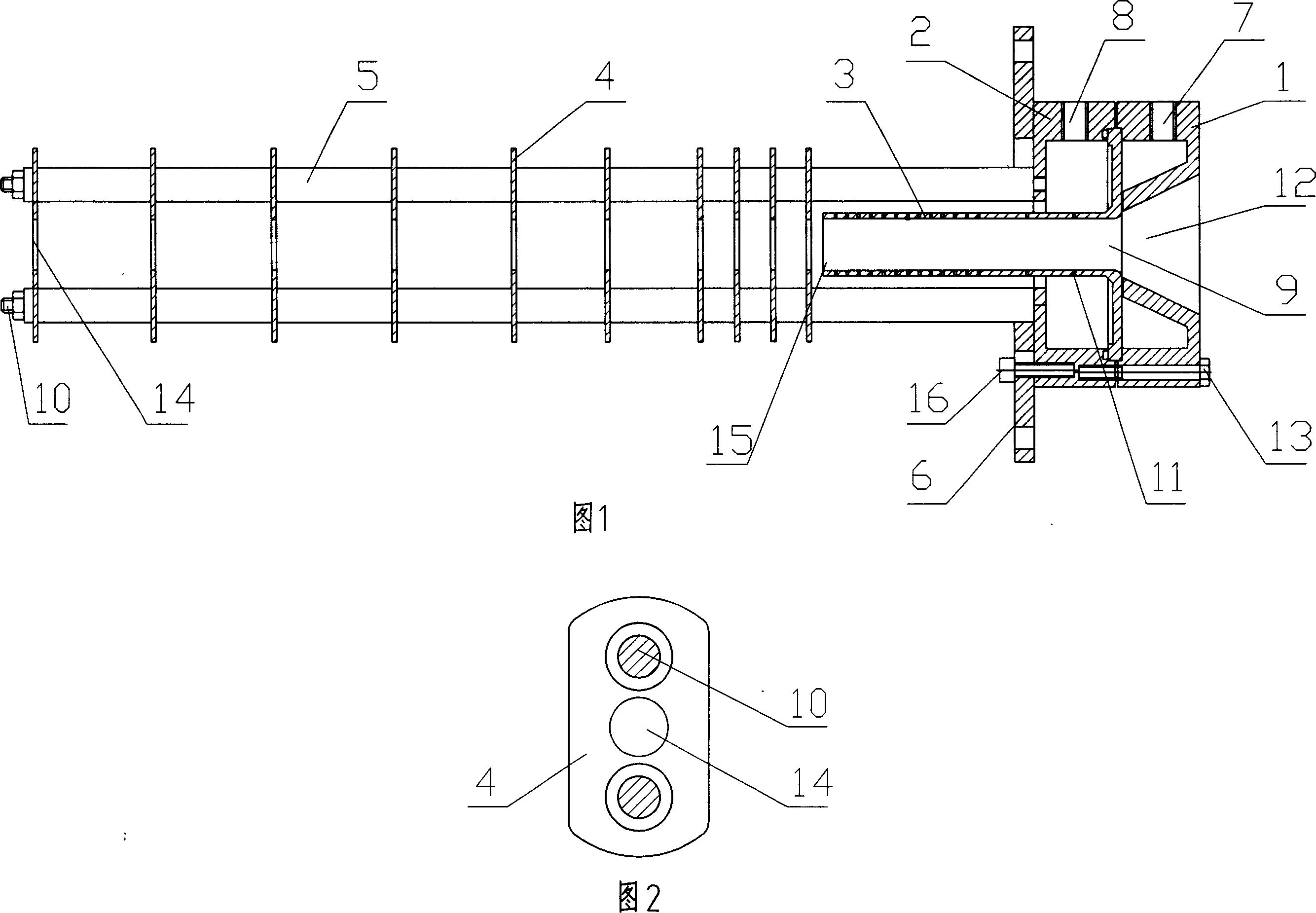

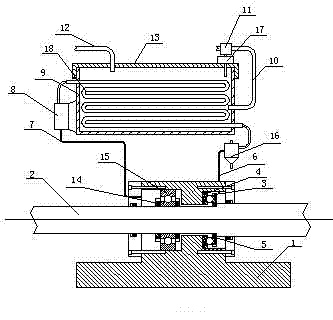

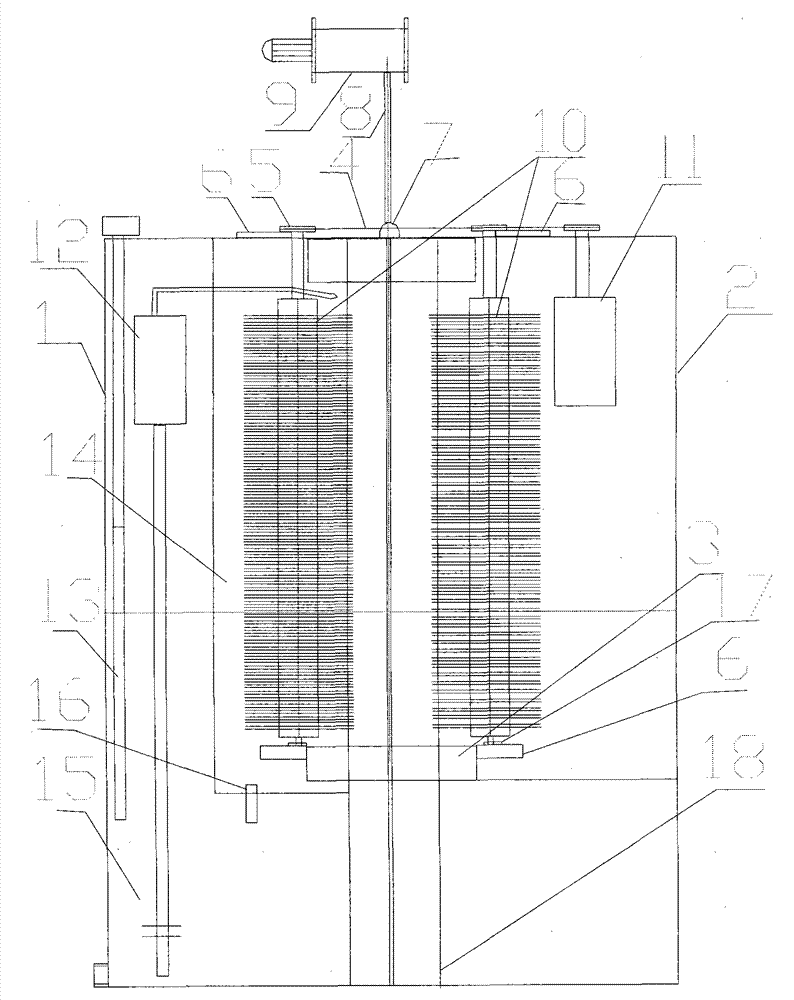

Near dry cutting liquid supply apparatus

InactiveCN101244520ARealize the effect of dust removalLubricating effect is sufficientMaintainance and safety accessoriesResource consumptionLiquid nitrogen cooling

The invention relates to a quasi-dry cutting liquid supply device, which comprises a plurality of chamber walls, a chamber, a partition, an adjusting valve, a hybrid chamber, a drain pipe, a liquid guide pipe, an inner pipe, an outer pipe, an inlet for compressed gas, and a nozzle; wherein, the partition divides the chamber into two sub-chambers for respectively holding different lubricants, which enter the pipeline under the action of the compressed gas, and the quantity of the lubricants can be selected by means of the adjusting valve; the inner pipe and the outer pipe form a double-layer tubular structure, and the nozzle also adopts a double-layer structure. The device can be used as a liquid supply device for oil-less lubrication, low temperature cutting, and liquid nitrogen cooling and process, and can regulate the usage quantity of the lubricants in a reasonable manner. The liquid supply device in the invention has the advantages of simple structure, low costs, less resource consumption, and suitability for mass production. Moreover, by using the nuisance and pollution-free green lubricants, the liquid supply device effectively solves the problems in the prior liquid supply systems, such as large usage of cutting liquid, difficulty in controlling, and severe environmental pollutions.

Owner:BEIHANG UNIV

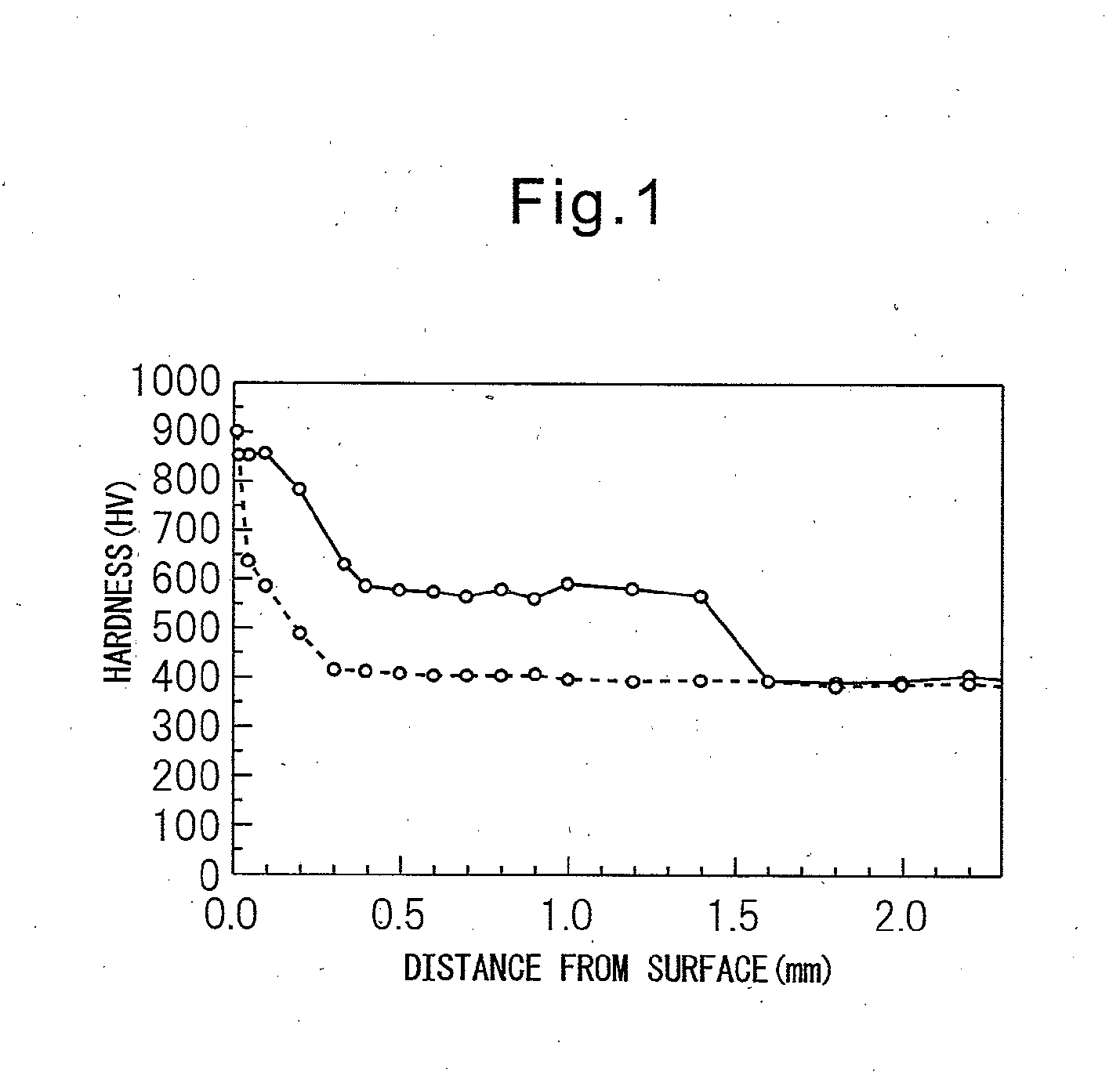

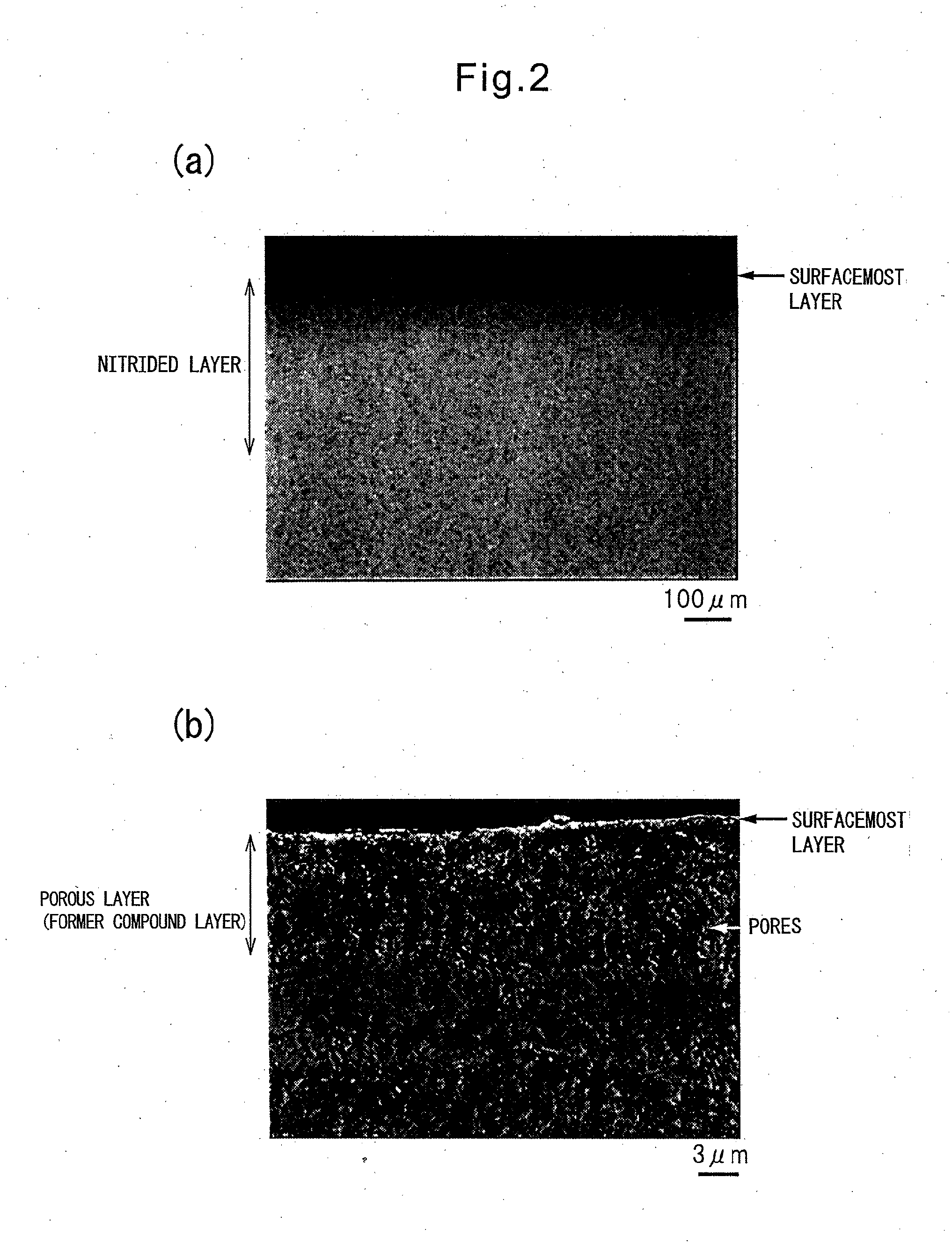

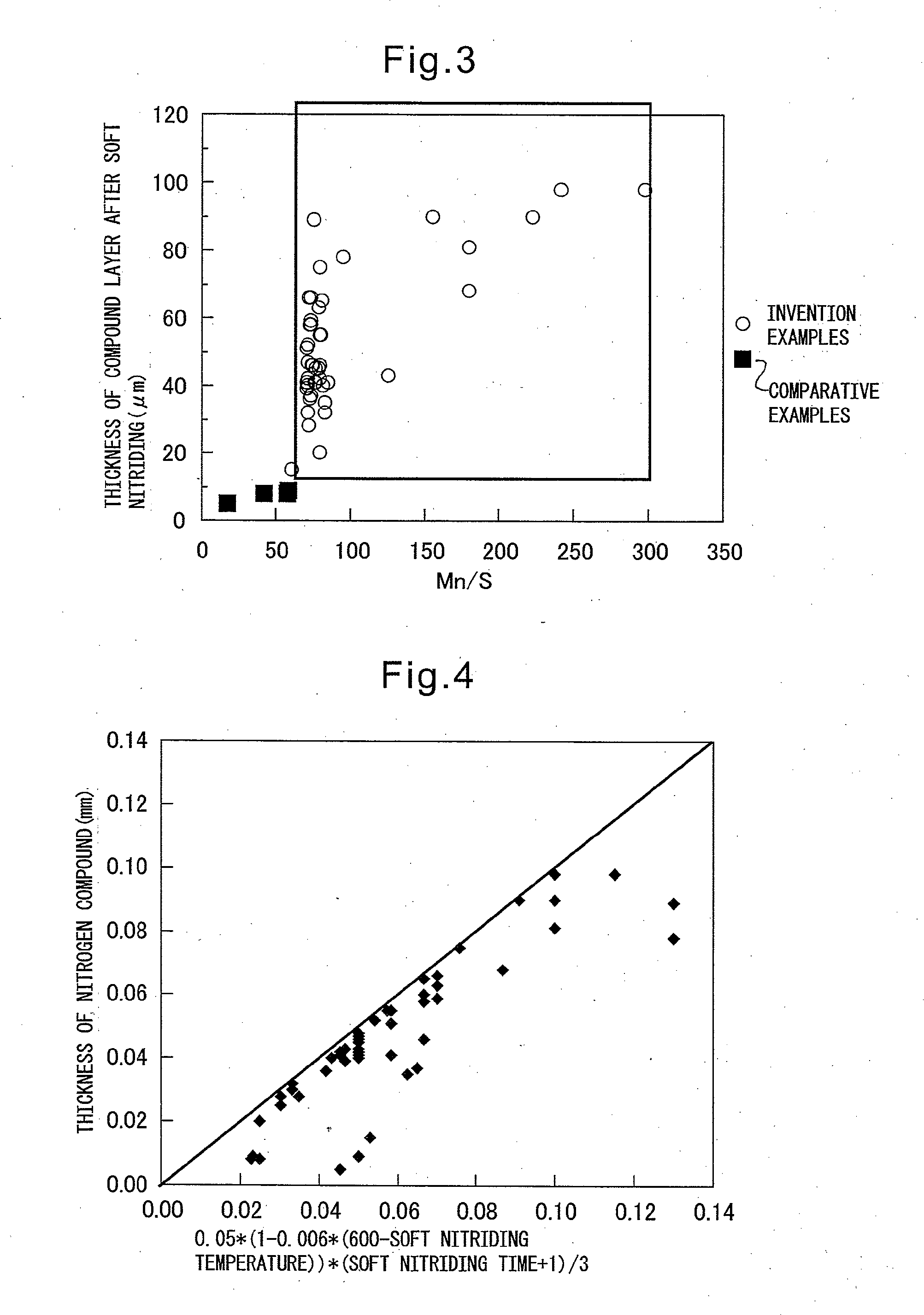

Steel for machine structural purposes for surface hardening use and steel parts for machine structural purposes and method of production of same

InactiveUS20130180626A1Improve corrosion resistanceExcellent in strength resistanceSolid state diffusion coatingIncreasing energy efficiencyMethods of productionImpurity

A steel for surface hardening for machine structural use which is characterized by containing, in terms of mass %, 0.30-0.60% C, 0.02-2.0% Si, 0.35-1.5% Mn, 0.001-0.5% Al, 0.05-2.0% Cr, 0.001-1.0% Sn, 0.0001-0.021% S, 0.0030-0.0055% N, 0.01-2.0% Ni, 0.01-2.0% Cu, up to 0.030% P, and up to 0.005% O, with the remainder comprising Fe and incidental impurities, the contents of Sn, Cu, Ni, Mn, and S satisfying relationships (1) and (2).−0.19≦0.12×Sn+Cu−0.1×Ni≦0.15 (1)60≦Mn / S≦300 (2)

Owner:NIPPON STEEL & SUMITOMO METAL CORP

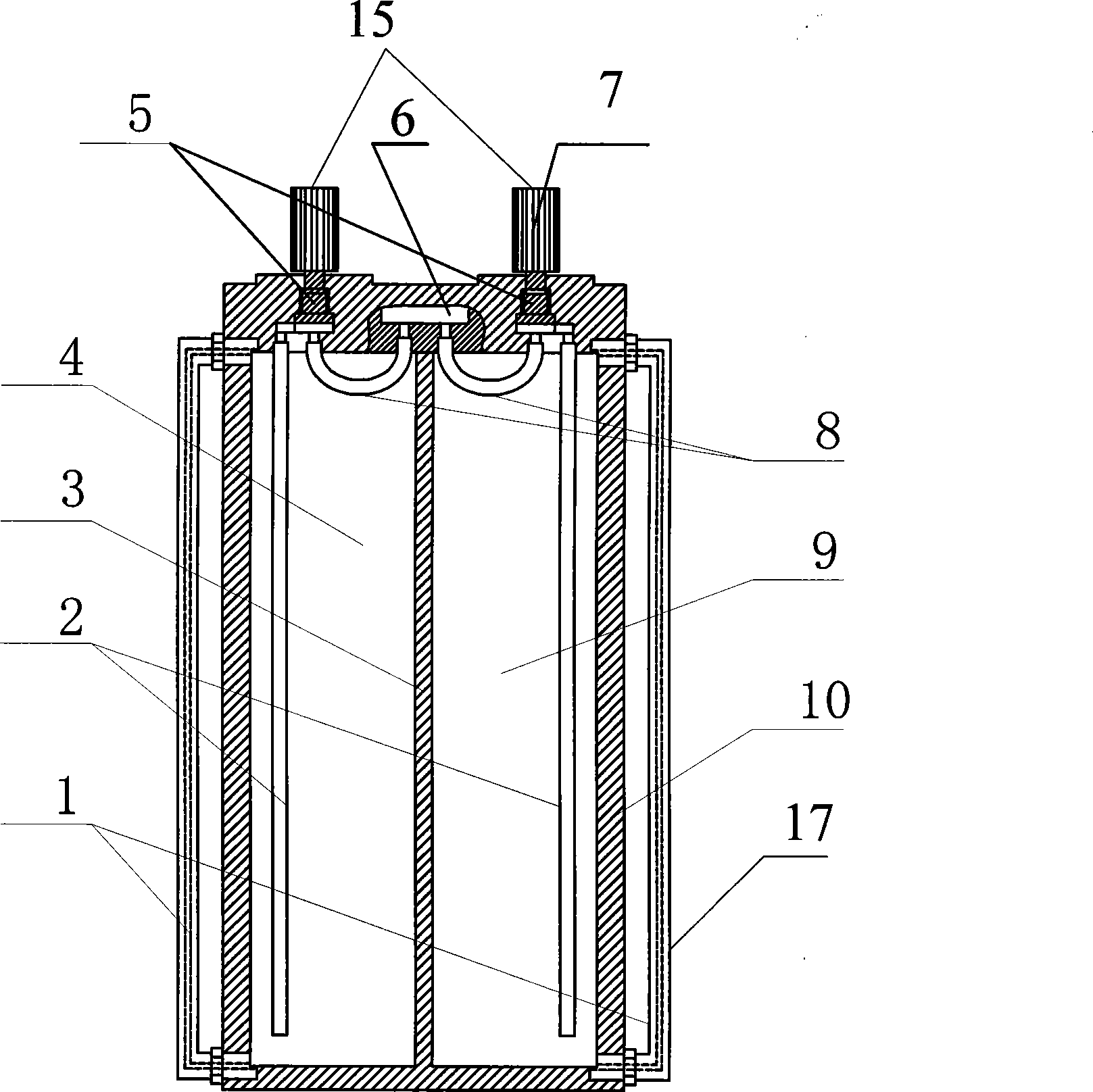

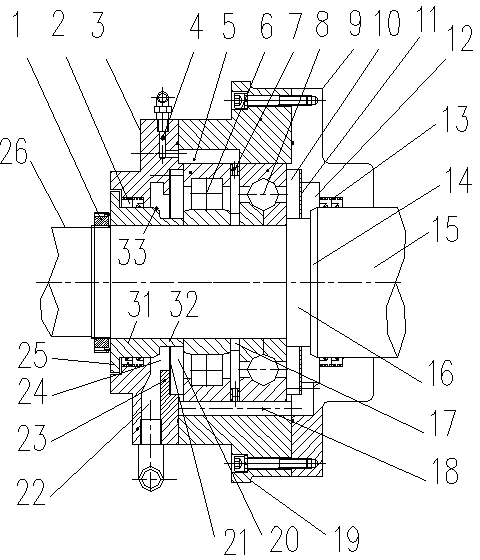

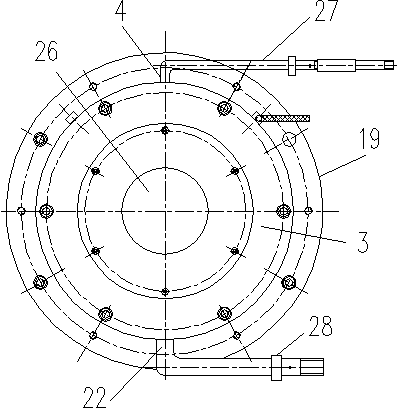

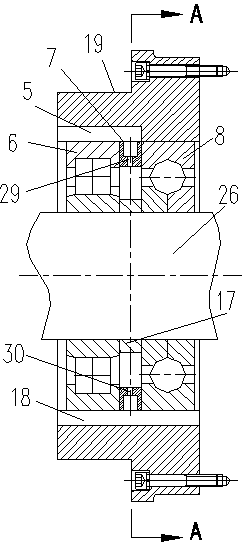

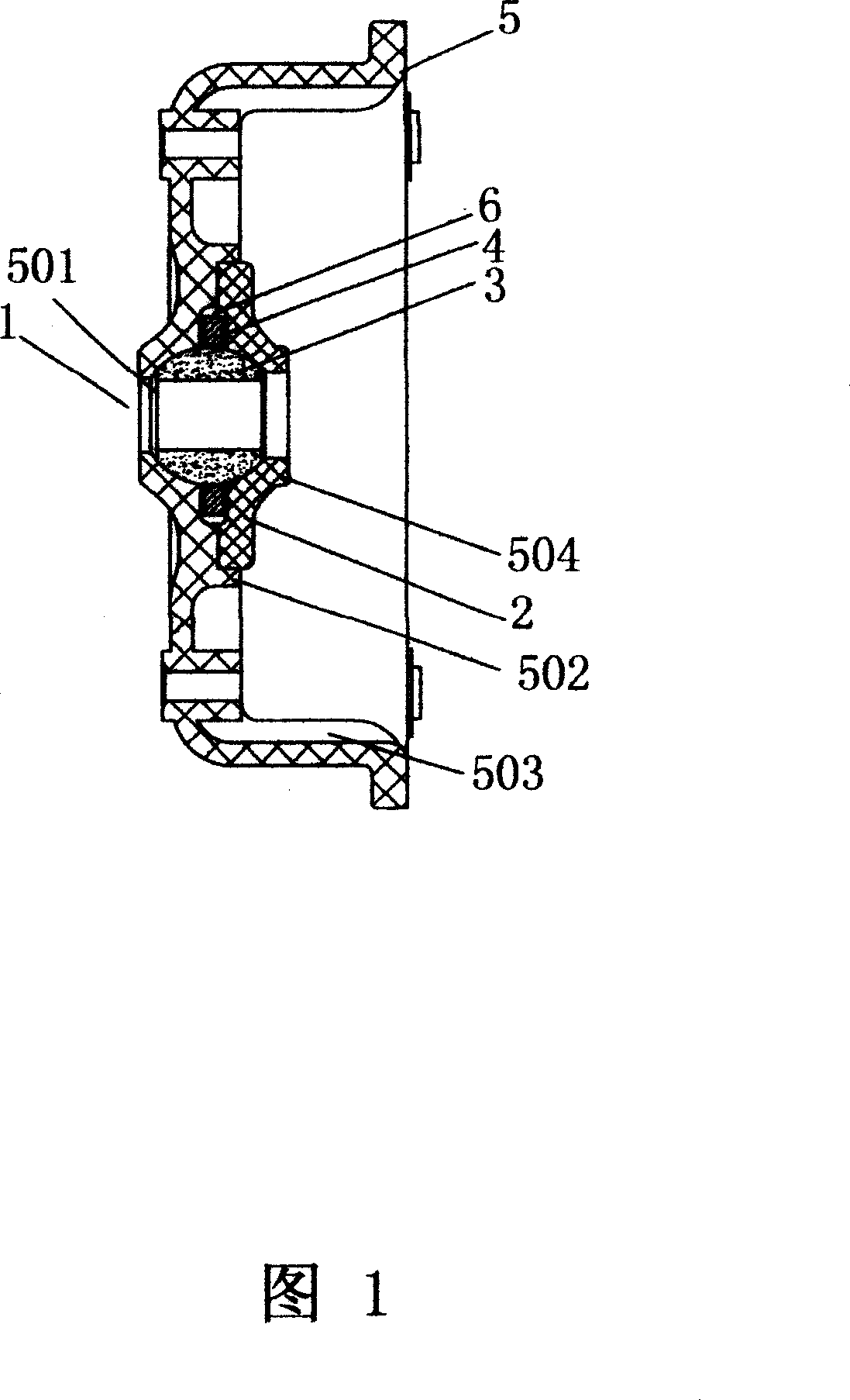

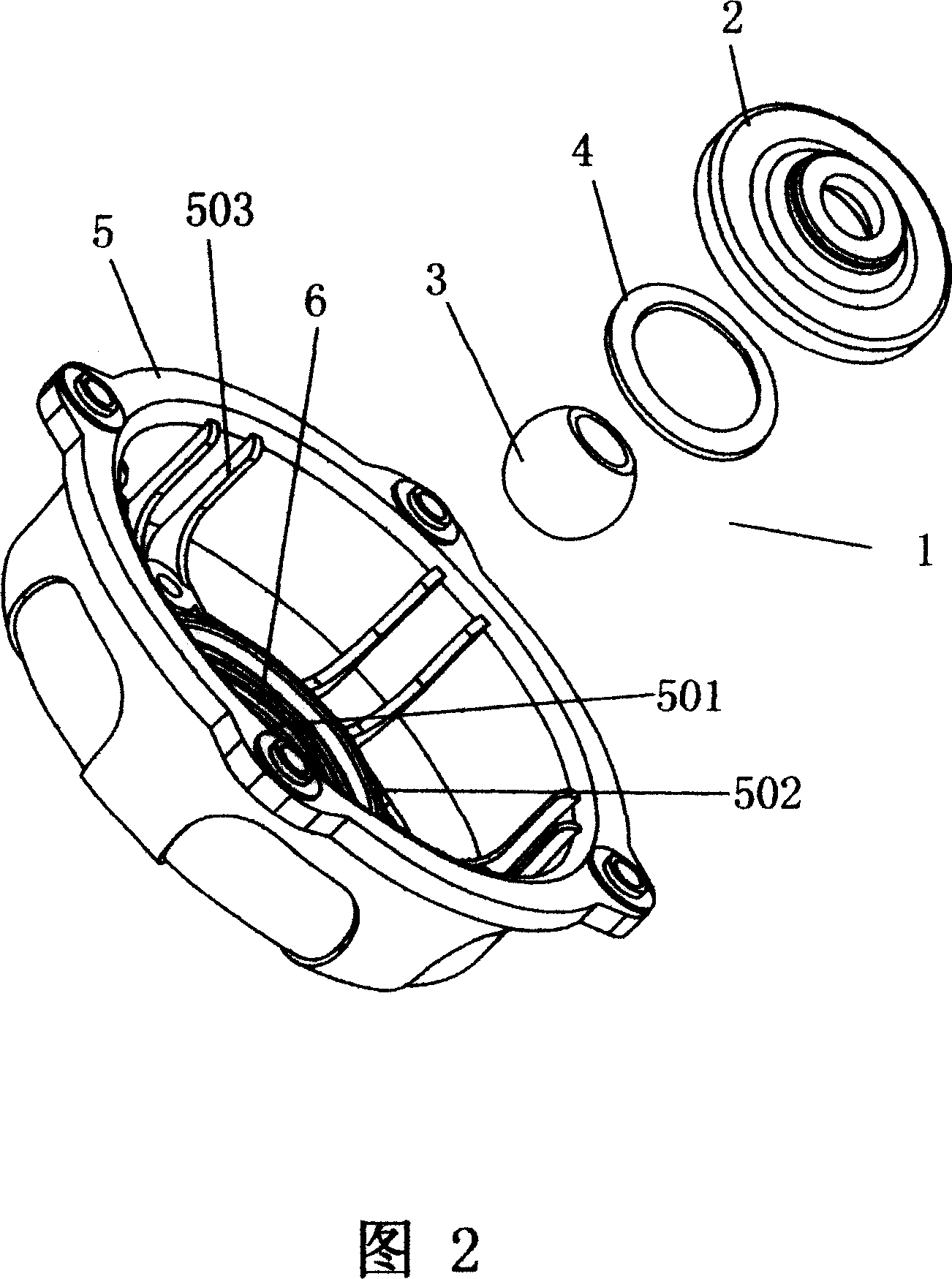

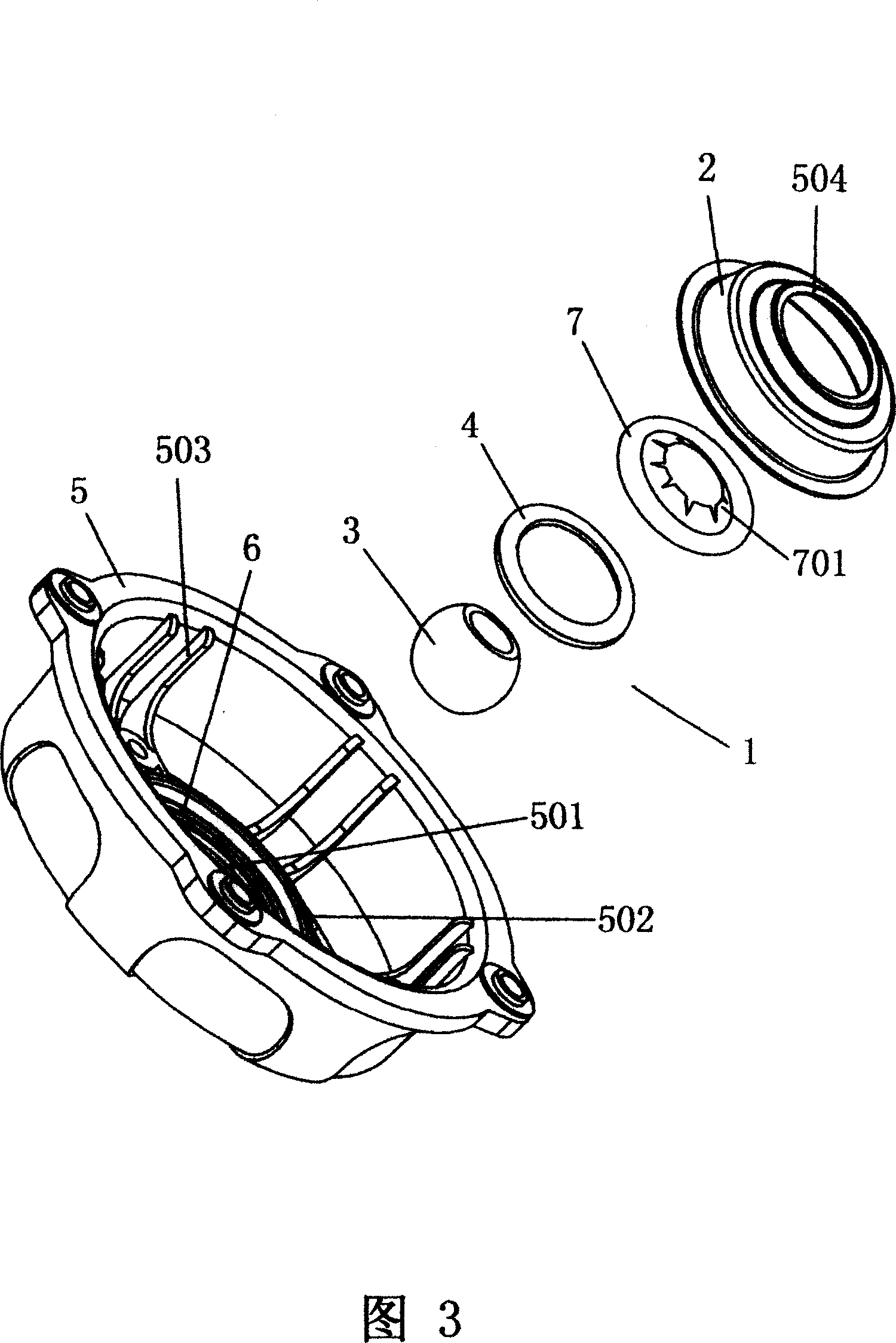

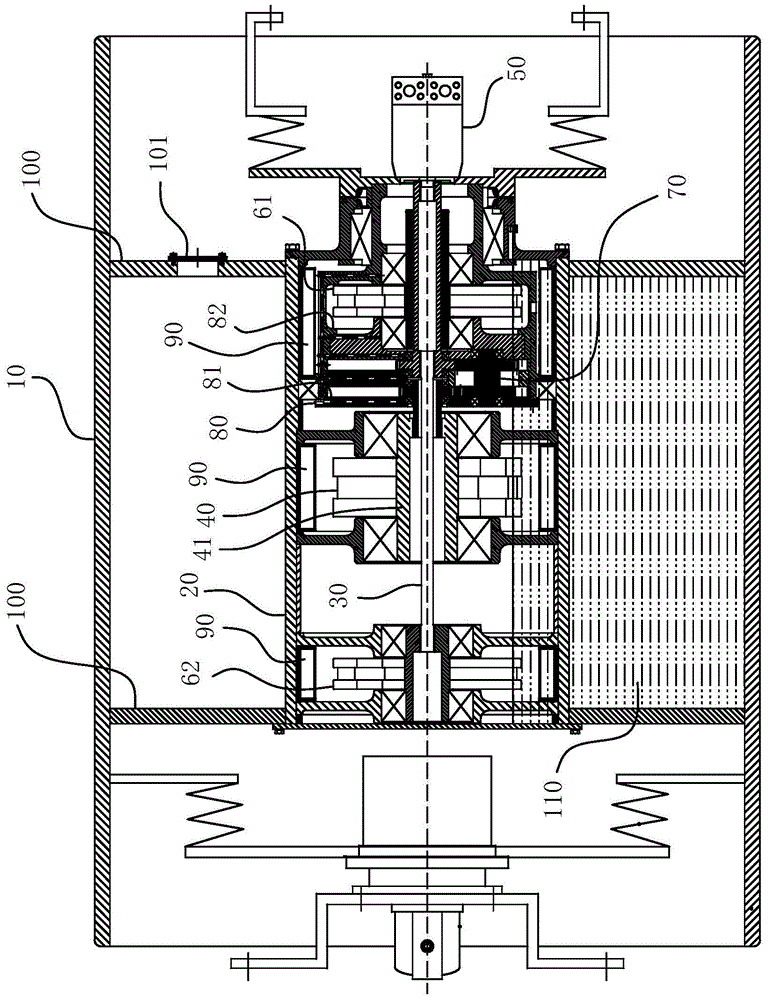

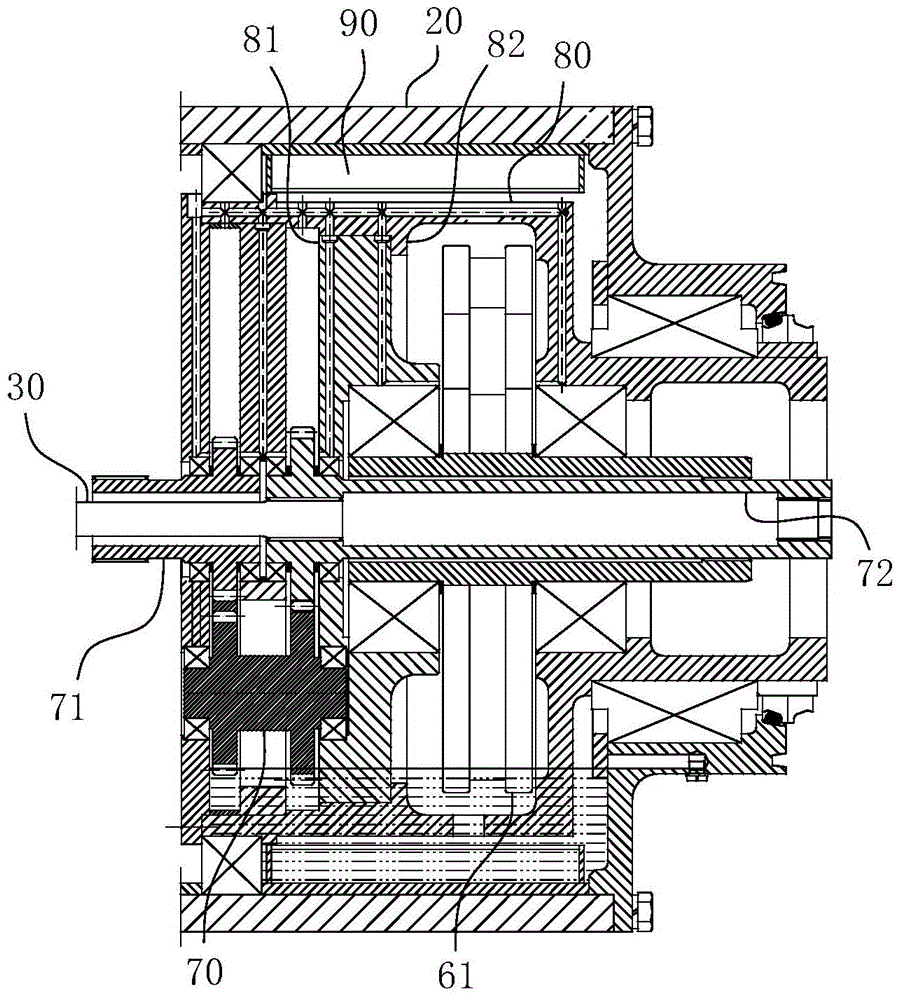

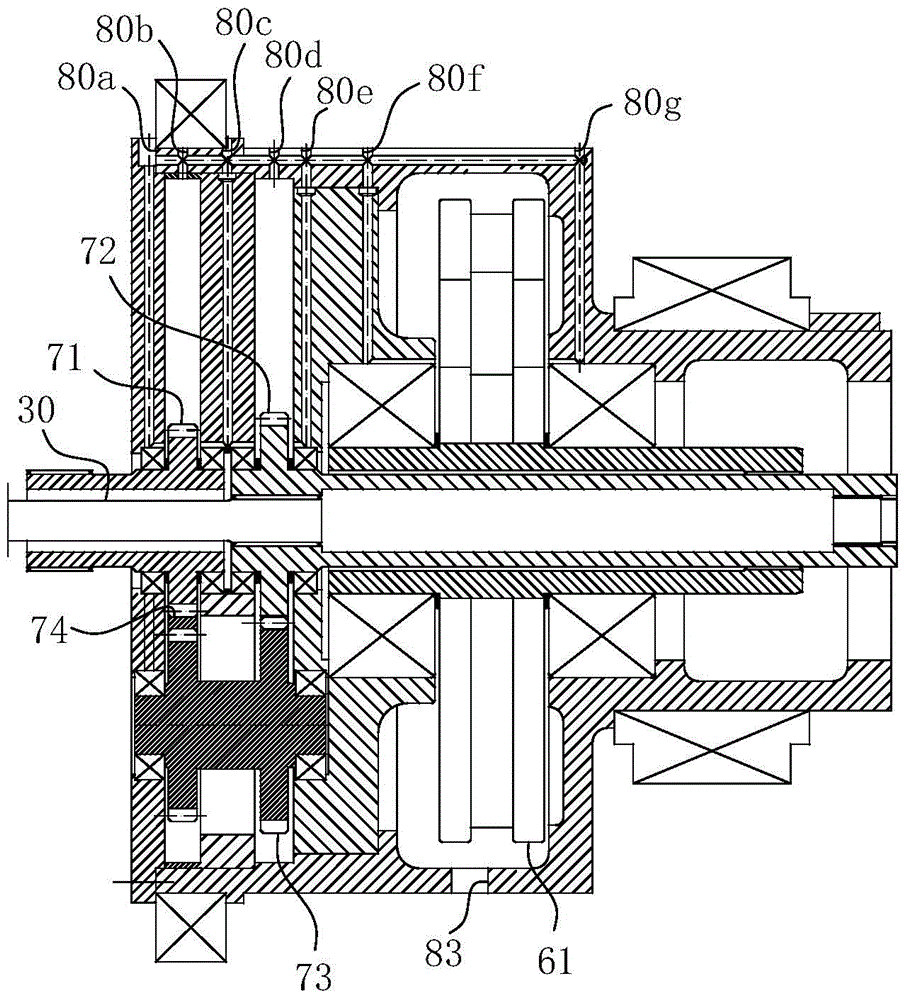

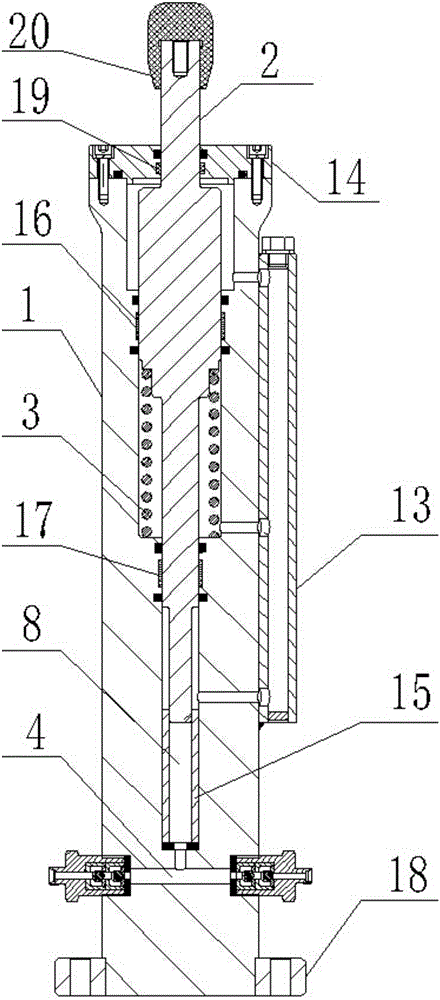

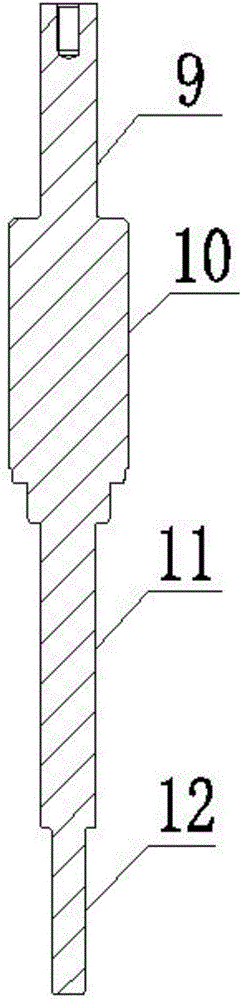

Thin oil lubrication bearing device of motor for coal mine main ventilator

ActiveCN103730976AEnsure adequate lubricationImprove the lubrication effectSupports/enclosures/casingsInlet channelReturn channel

The invention discloses a thin oil lubrication bearing device of a motor for a coal mine main ventilator. The thin oil lubrication bearing device comprises a rotating shaft. A bearing front cover, a first bearing, a second bearing and a bearing back cover are arranged on the rotating shaft in sequence. A bearing base is arranged between the bearing front cover and the bearing back cover in a clamping mode. The bearing front cover is arranged on the front side of the first bearing in a covering mode. A front cover cavity is formed in the bearing cover. An outer partitioning ring is clamped between an outer ring annular body of the first bearing and an outer ring annular body of the second bearing. An oil inlet channel and an oil returning channel communicated with the front cover cavity are arranged in the bearing front cover. The bearing base is provided with a middle oil inlet channel and a middle oil returning channel. The outer partitioning ring is provided with a radial oil inlet. The oil inlet channel, the middle oil inlet channel, the oil inlet, an oil returning opening, the middle oil returning channel, the front cover cavity and the oil returning channel are communicated in sequence. The thin oil lubrication bearing device of the motor for the coal mine main ventilator is good in sealing performance, high in operation reliability and capable of providing continuous and sufficient lubrication for a rolling bearing.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

Environment-friendly water-based lubricating grease and preparation method thereof

InactiveCN103242949AAdequate lubricity and adhesionGood heat transfer and cooling effectThickenersLubricationWater soluble

The invention relates to the field of lubricating grease, and particularly relates to environment-friendly water-based lubricating grease and a preparation method thereof. The water-based lubricating grease comprises the following components in percentage by mass: 65-90% of basic liquid, a mixed base thickening agent, 0.5-3% of extreme-pressure anti-wear additive and 0.02-2% of antirust agent, wherein the basic liquid is a mixture of water-soluble polyether and distilled water, and the mixed base thickening agent is generated by reaction of 1-4% of calcium hydroxide and 0.5-1.5% of sodium hydroxide with 6.5-24.5% of stearic acid. The water-based lubricating grease prepared by the method has the advantages of full lubrication and adhesion, good heat transfer and cooling effect and easy cleaning operation and is particularly suitable for occasions such as metal stamping and extrusion machining, metal rolling, metal wire drawing and metal pipeline machining.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

Method for mounting plastic electric machine casing and bearing device

InactiveCN1949632AHigh shaft positioning accuracyExcellent matching adjustment performanceManufacturing dynamo-electric machinesEngineeringInjection moulding

Owner:罗世明

Grinding liquid used for grinding back surface of storage hard disk magnetic head

InactiveCN1651544AEvenly distributedImprove dispersion stabilityOther chemical processesAntistatic agentPreservative

An abrasing liquid for abrasing the back of magnetic head for hard disc contains proportionally mineral oil containing C11-C13 alkane, oiling agent, superfine monocrystal diamond powder, antioxidizing anticorrosion agent, non-ionic surfactant, defoaming agent, and antistatic agent.

Owner:TSINGHUA UNIV +1

Automatic power type lubricant passage way system for transmission of satellite gears

InactiveCN101539196AFast shuntImprove transmission efficiencyGear lubrication/coolingGear wheelEngineering

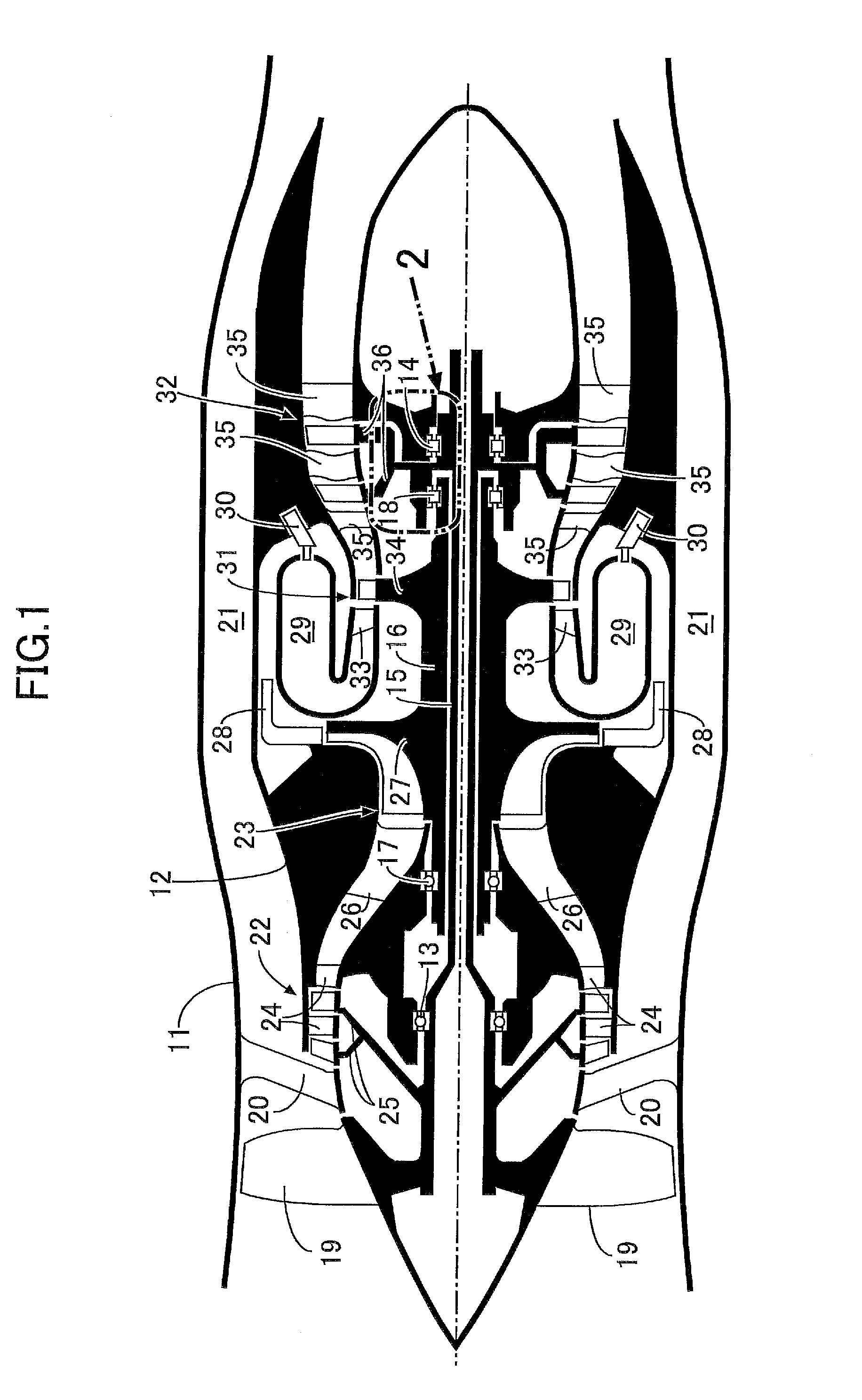

The invention relates to an automatic power type lubricant passage way system for the transmission of satellite gears, which mainly comprises a gear box body, a sun gear, a plurality of satellite gears, a satellite carrier, an outer lubricant pipeline and an inner lubricant pipeline, wherein the outer circle of the satellite carrier is provided with a big gear, the outer wall of the gear box body is provided with a mechanical pump, a lubricant inlet and a lubricant outlet of the mechanical pump are arranged on the outer lubricant pipe, a main shaft of the mechanical pump is sleeved with a small gear, the big gear is meshed with the small gear to drive the mechanical pump to pump lubricant in the gear box body out to supply for a lubricant inlet pipeline through the outer lubricant pipeline. The lubricant passage way system utilizes power generated by the rotation of the satellite carrier to drive the mechanical pump to work, saves the energy and reduces the consumption as well as lowers the cost because the mechanical pump pumps the lubricant in the gear box body out and led the lubricant into the inner lubricant pipeline in the gear box body through the outer lubricant pipeline to safely and durably supply the lubricant for a drive device without external power source, fully lubricates and cools all drive parts and meshing parts, and has little mechanism abrasion and long service life.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

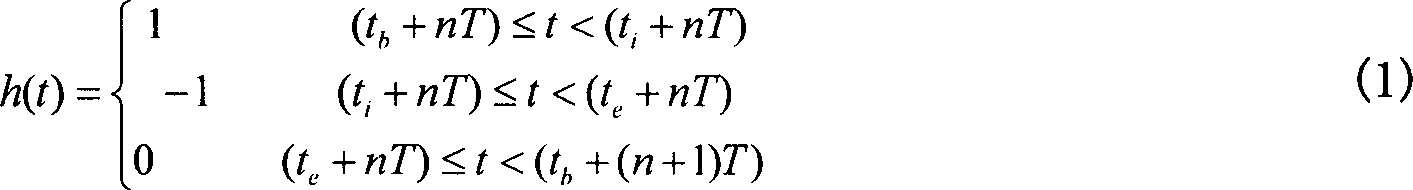

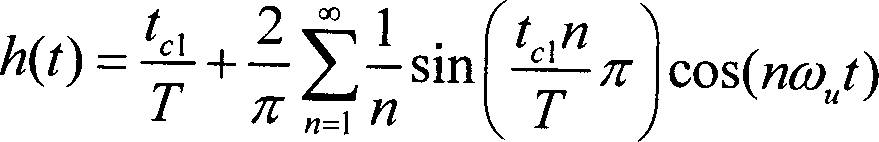

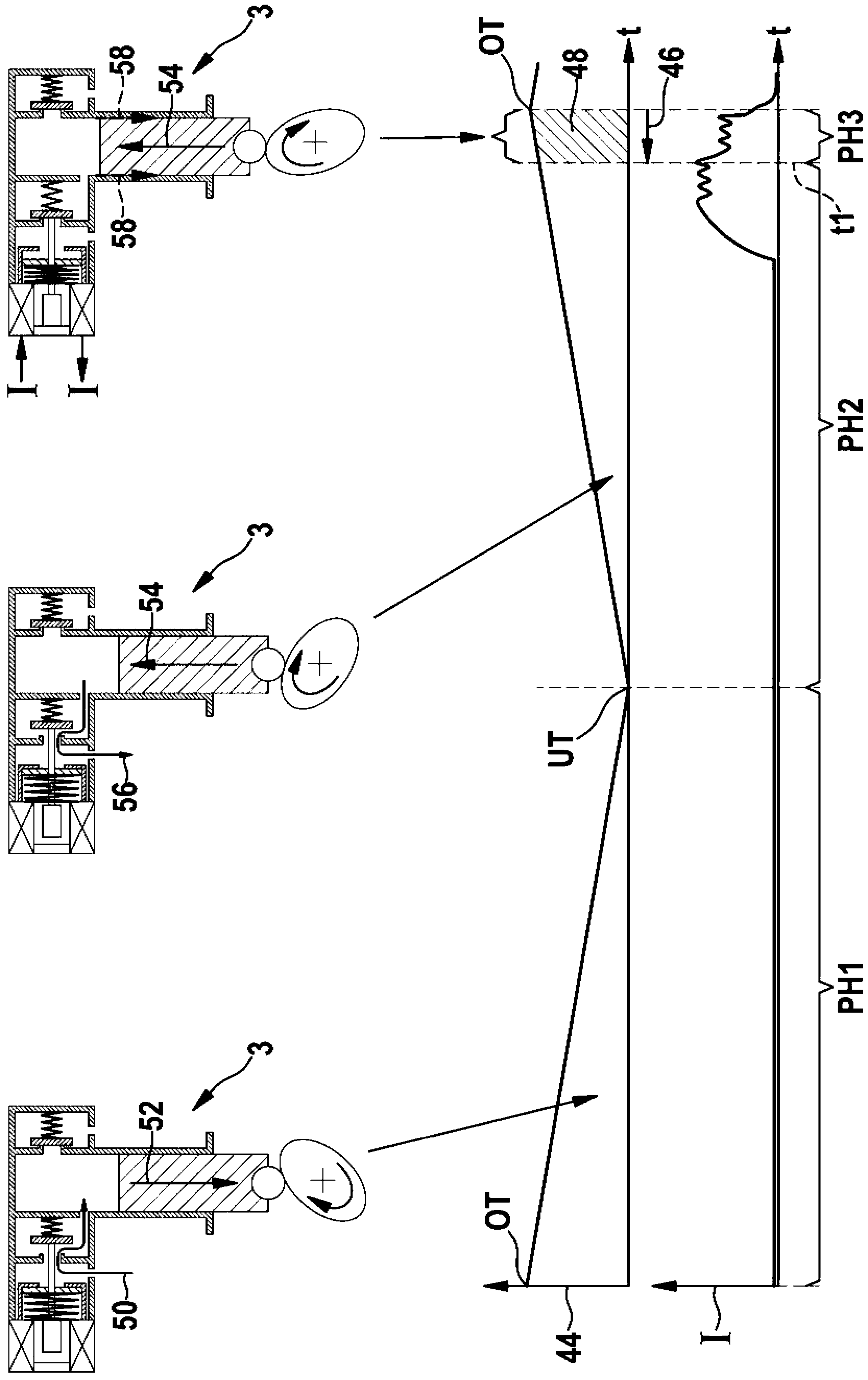

Ultrasonic elliptically vibrating boring process

InactiveCN1672839AEnsure adequate lubricationSolve the lack of cooling capacitySurface finishEllipse

The ultrasonic elliptically vibrating boring process in the field of precise machining technology includes the following steps: 1) adhering two piezoelectric ceramic chips onto two orthogonal surfaces of elliptically vibrating amplitude-varying rod; 2) applying sinusoidal voltage across the chips to make the chips to stretch and contract and the rod to bend and vibrate; 3) strengthening the bending and vibration of the rod; 4) making the boring cutter fixed to the tip of the rod obtain maximum elliptic vibration; 5) synthesizing the horizontal and vertical bending vibrations to obtain the elliptic vibration track in the edge of the boring cutter; and 6) fixing the elliptically vibrating amplitude-varying rod onto the boring rod via the vibration node. The present invention has greatly reduced boring force, reduced boring rod deformation, raised stability of the boring system and raised boring precision and surface smoothness.

Owner:SHANGHAI JIAO TONG UNIV

Water immersion type plastic pipe sizing device

InactiveCN101015952ASolve the lack of cooling capacityEnsure adequate lubricationTubular articlesWater immersionHollow core

The invention discloses a water immersion plastic tube diameter setter, which comprises a hollow fixed disc connected on the side wall of a cooling groove while one side of the hollow fixed disc is mounted with a laminated base. The axial outside of the laminated base is mounted with a water flux adjusting disc whose middle is disposed with a plastic tube inlet, a constant-diameter sheath is mounted between the laminated base and the water flux adjusting disc, while the outlet of the constant-diameter sheath is through the laminated base and the hollow fixed disc and the inlet is relative to plastic tube inlet. The water flux adjusting disc is disposed with a water inlet communicated with the cross between the plastic tube inlet and the inlet of the constant-diameter sheath. The laminated base is parallel mounted with a support rod at same direction with the outlet of the constant-diameter sheath, and the support rod is sheathed with laminated pads whose center is arranged with a tube constant-diameter opening same as the constant-diameter sheath. The inventive tube and device have high cooling speed and two times of improved producing efficiency.

Owner:潍坊凯德塑料机械有限公司

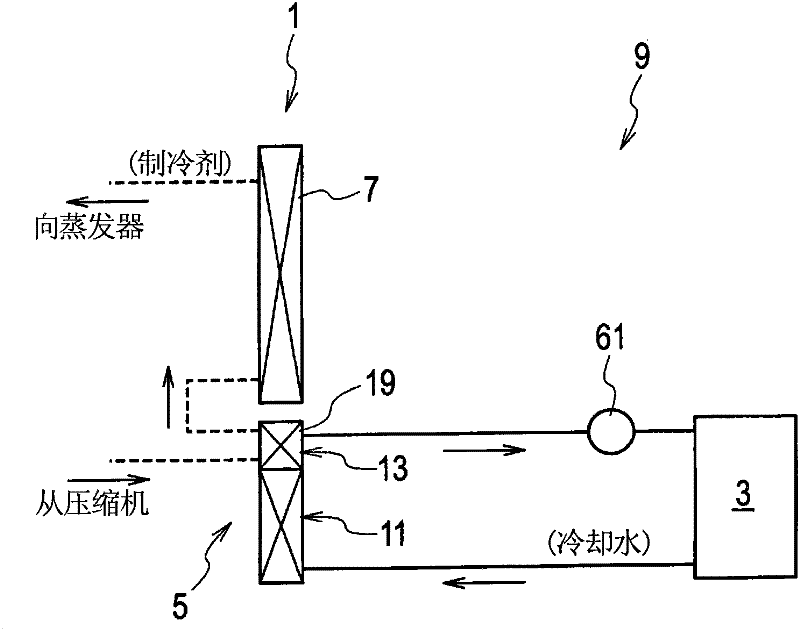

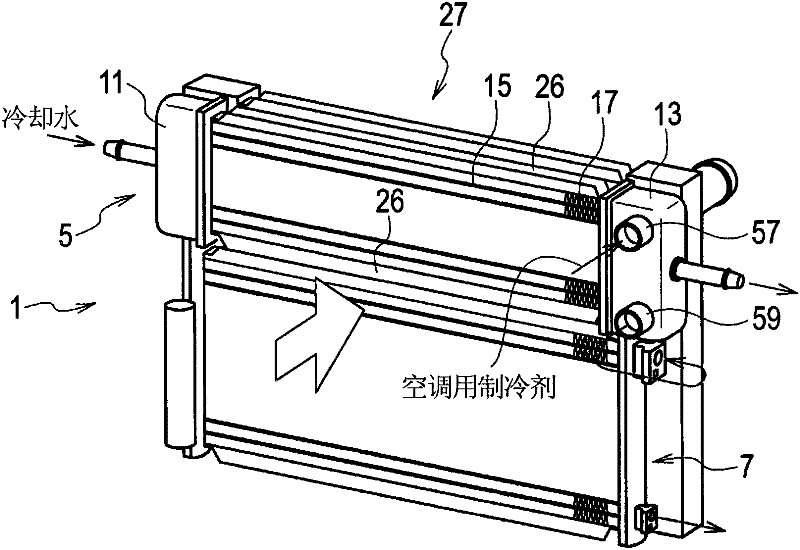

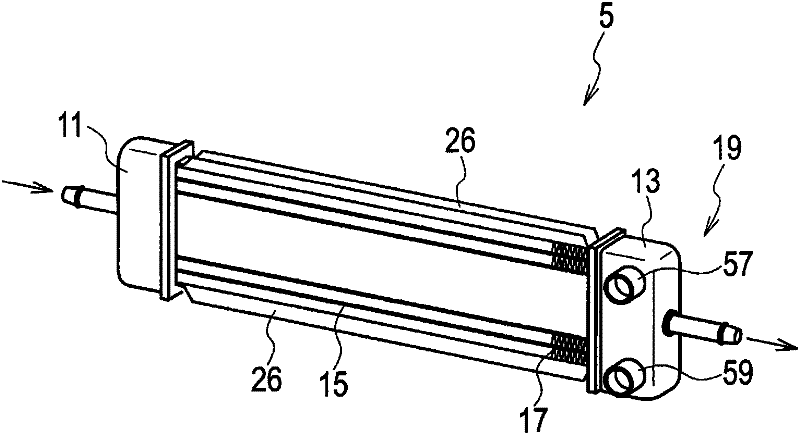

Compound heat exchange unit

InactiveCN102224391AInhibition retentionEnsure adequate lubricationStationary conduit assembliesHeat exchanger casingsCoolant flowWater flow

Disclosed is a compound heat exchange unit equipped with a first air-cooled heat exchange unit (5) that cools cooling water for the heat-generating body of an automobile other than the internal combustion engine and a second air-cooled heat exchanger unit that cools a coolant for vehicle air conditioning. The first air-cooled heat exchange unit comprises an upstream tank into which cooling water flows, a downstream tank from which coolant flows, a flow path member that connects the upstream tank to the downstream tank, radiator fins which are layered alternately with the flow path member, and a water-cooled heat exchange unit that cools the coolant. The water-cooled heat exchange unit is disposed within the downstream tank; at the upper part thereof there is an inlet port into which the coolant flows, and at the lower part thereof there is an outlet port from which the coolant flows. By means of the aforementioned heat exchange unit, it is possible to prevent accumulation of oil mixed with the coolant, heat exchange efficiency can be improved, and reduced size can be achieved.

Owner:CALSONIC KANSEI CORP

Special anti-bonding low-smoke halogen-free flame-retardant sheath material for GJFJZY type multi-core indoor optical cable

The invention discloses a special anti-bonding low-smoke halogen-free flame-retardant sheath material for a GJFJZY type multi-core indoor optical cable. The sheath material comprises the following components in parts by weight: 5-15 parts of ethylene-vinyl acetate copolymer (EVA), 10-20 parts of polyethylene (PE), 5-10 parts of polypropylene (PP), 55-65 parts of flame retardant, 5-10 parts of compatilizer, 2-3 parts of ultra-high molecular weight silicone, 0.5-1.5 parts of high-melting-point polyethylene wax and 0.3-0.8 part of antioxidant. The PE and the PP having high melting points are used as base materials; a small amount of EVA is further used; the flame retardant is added to achieve the flame-retardant effect; meanwhile, the ultra-high molecular weight silicone is used as internal and external lubricant to improve the material flowability and the powder dispersion effect, the use amount is increased, and the ultra-high molecular weight ensures that no precipitation exists in resin; the high-melting-point polyethylene wax is further used as external lubricant, and the high melting point ensures that sufficient lubrication action exists at high temperature and no precipitation exists on the surface early at low temperature so as to further avoid inactivation, thus realizing that a thin wax layer is formed between a core wire and a sheath layer in the extruding process at about 160 DEG C and serves as an isolating layer; and the core wire and the sheath layer disclosed by the invention have great difference in material, thereby finally ensuring that the both can not be bonded together. Thus, the normal use of a GJFJZY type multi-core optical cable is ensured.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH +1

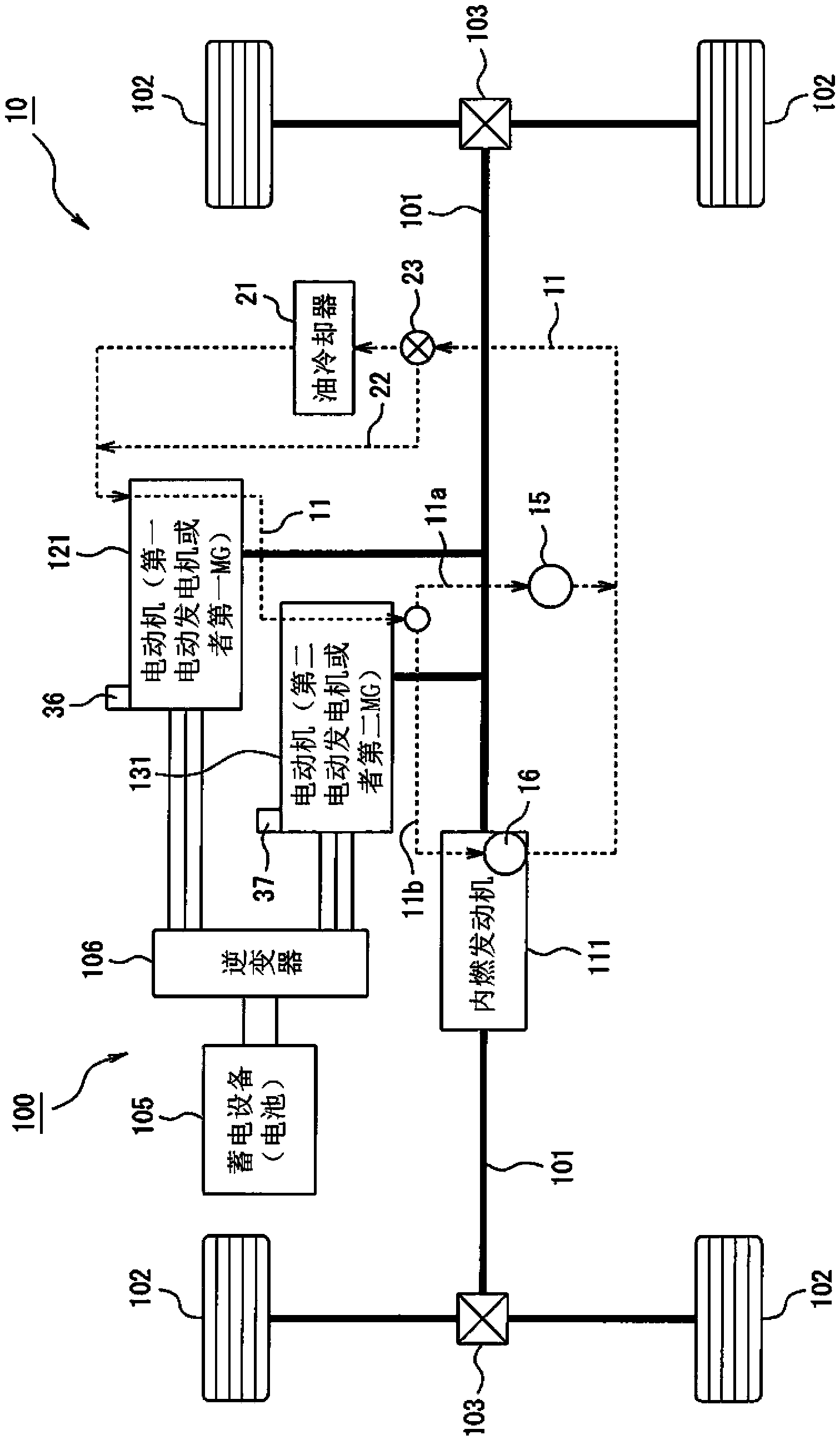

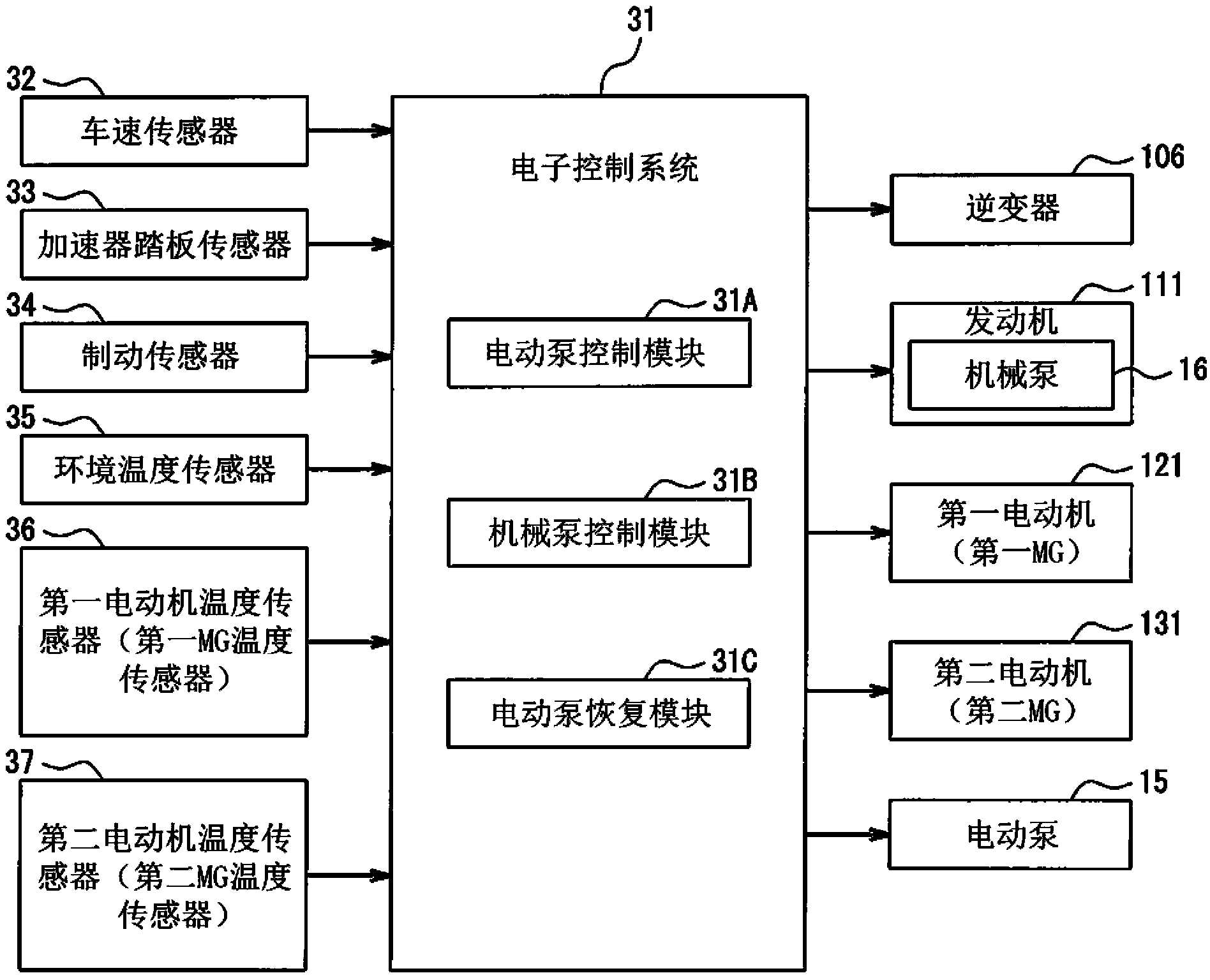

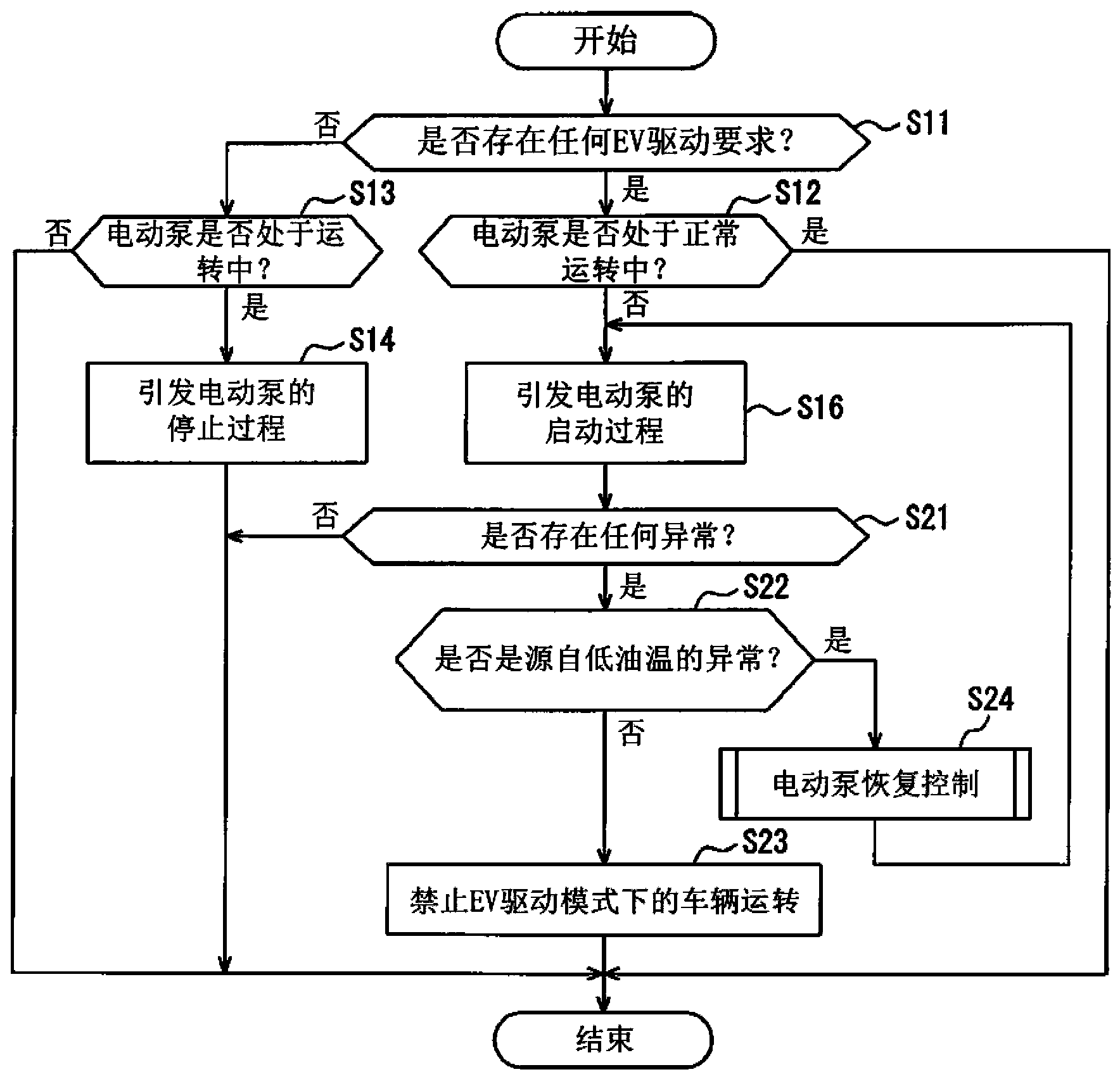

Oil circulation system for electric motor in a hybrid electric vehicle

ActiveCN103448638AEfficient rotationEnsure adequate lubricationPump controlLubricating systemExternal combustion engineInternal combustion engine

An oil circulation system for electric motors in a hybrid electric vehicle having, as a power source, an internal combustion engine is disclosed. Provision is made to start oil circulation under high reliability even though an electric pump cannot circulate lubricant oil through the electric motors due to increased viscosity at low temperatures. The oil circulation system includes the electric pump in fluid communication with an oil flow path for the electric motors;a mechanical pump, in fluid communication with the oil flow path, operable on driving power of the engine;and a controller for control of operation of the electric pump and that of the mechanical pump. The controller utilizes operation of the mechanical pump upon detection of abnormality in operation of the electric pump derived from viscosity of the lubricant oil in order to recover the electric pump.

Owner:SUZUKI MOTOR CORP

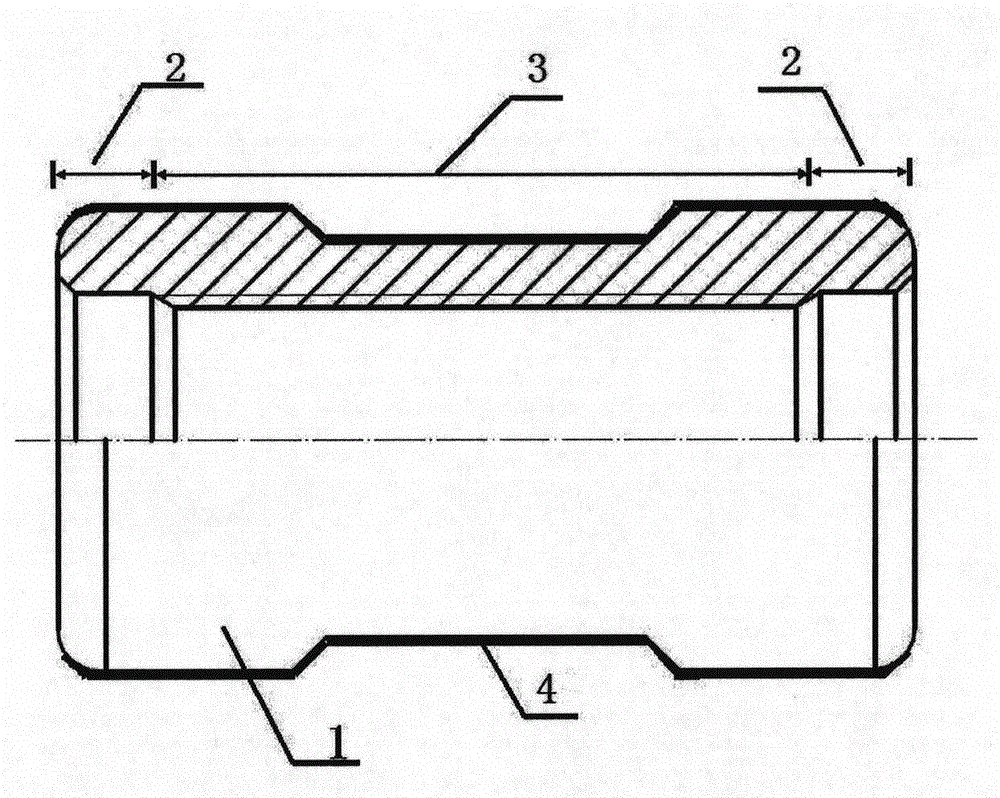

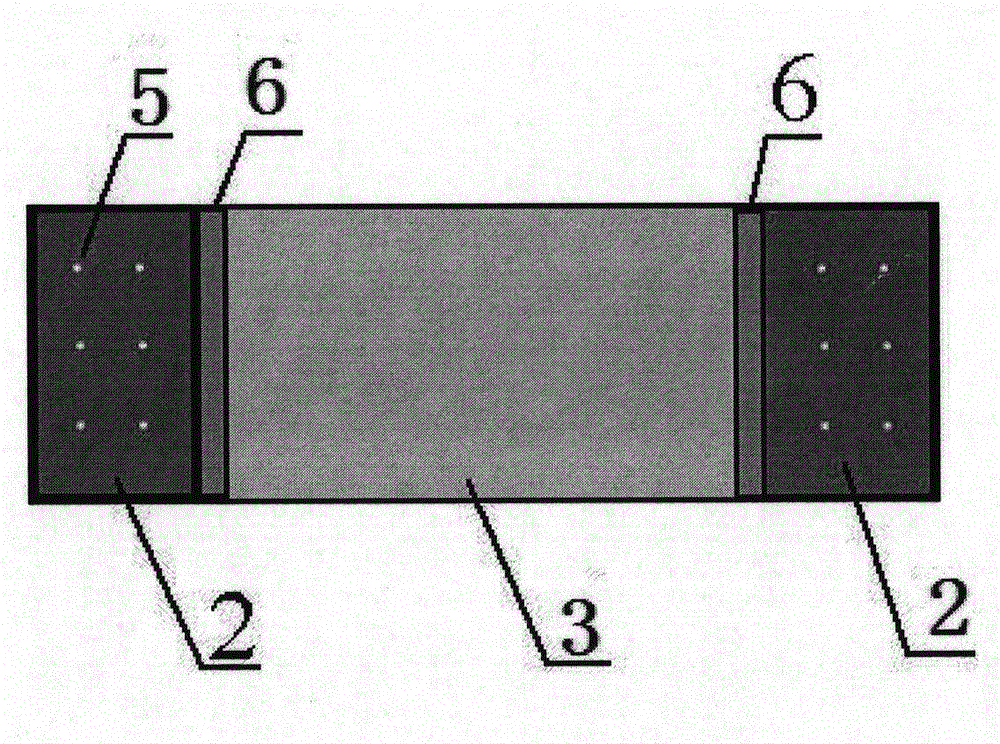

Novel sucker rod coupling and production process thereof

ActiveCN104481420AReduce wearAchieve long-term protectionDrilling rodsDrilling casingsHollow cylinderWrench

The invention relates to the field of oil equipment, particularly to a novel sucker rod coupling and a production process thereof. The novel sucker rod coupling comprises a main body, the main body is a hollow cylinder, the middle of the hollow cylinder is provided with square-neck surfaces matched with a double-edge wrench, the two square-neck surfaces are parallel, and the middle of the main body is provided with an axial internal threaded hole. The novel sucker rod coupling is characterized in that the outer surface of the main body is partially or totally covered with copper-based alloy composite coating, which is composed of, by weight percentage, 10-50% of hard tungsten carbide (WC) particles and 50-90% of copper-based alloy powder. According to the novel sucker rod coupling, the copper-based alloy composite coating and nickel-based alloy coating at both ends of the outer surface of the coupling are connected through transitional sections to ensure continuity and high quality and further to achieve obvious prolonging of the service life and long-term protection on the inner wall of a sucker rod.

Owner:铁岭米勒石油新材料有限公司

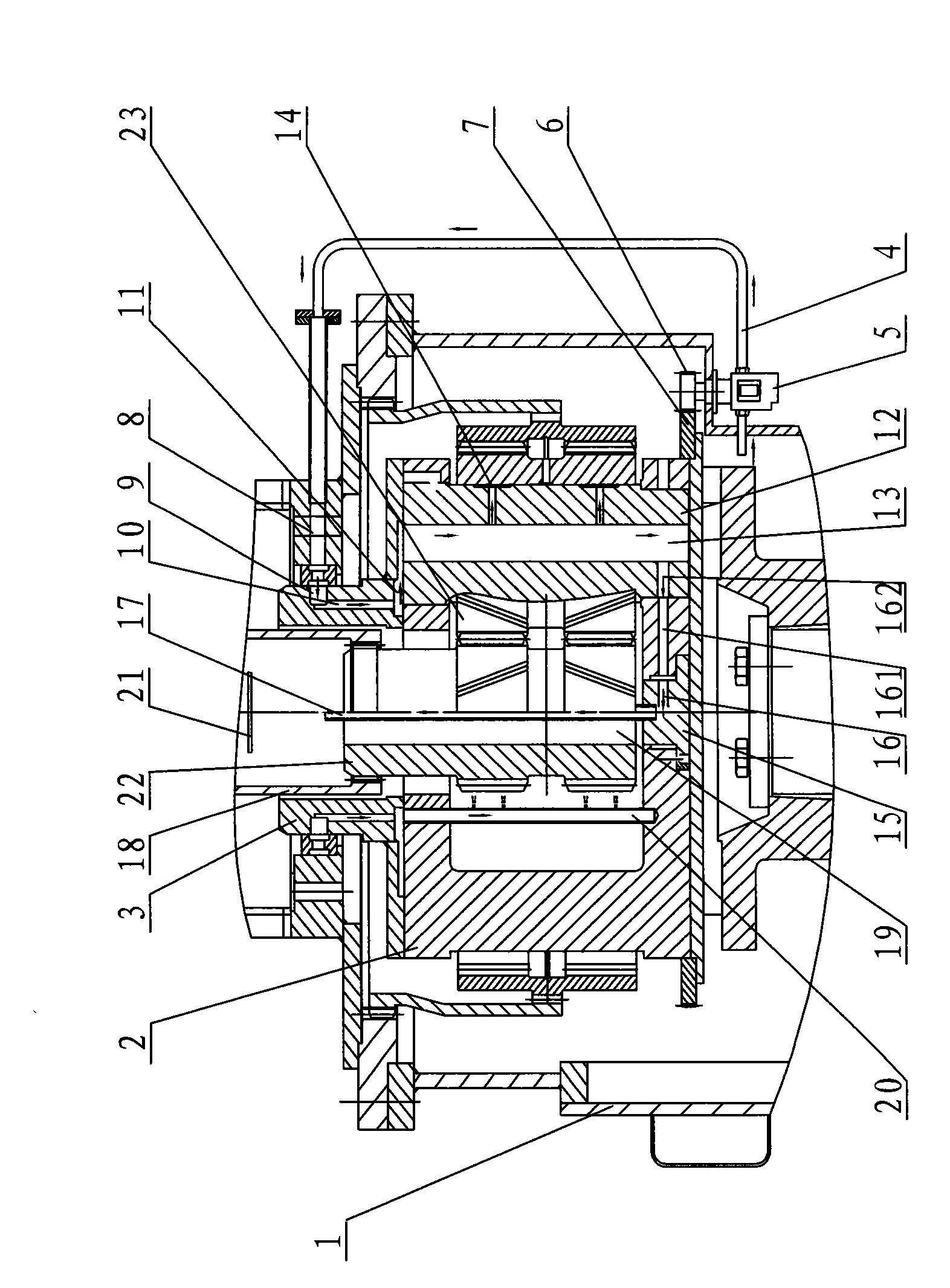

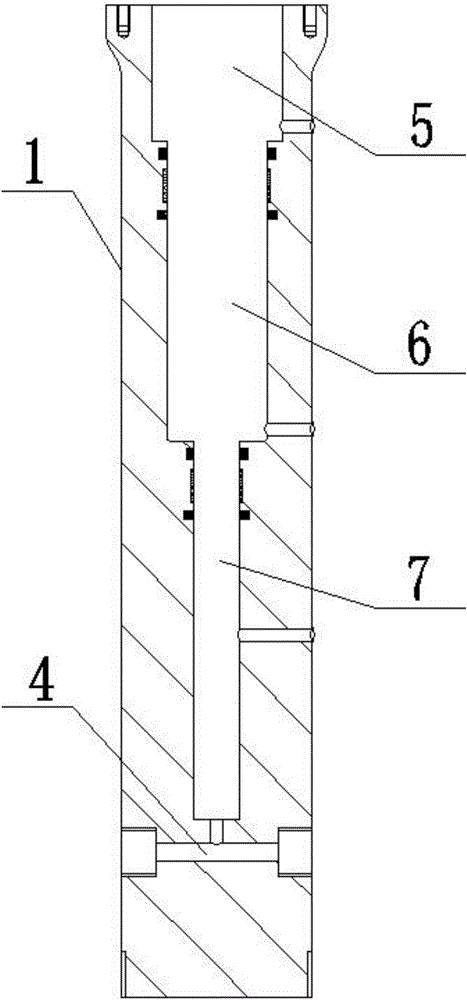

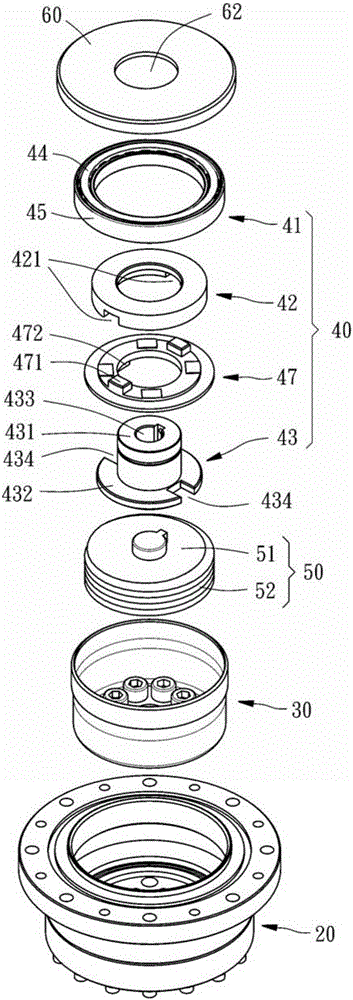

Self-lubricating vertical orientating vibrating wheel structure subjected to counterweight by using liquid

The invention relates to a self-lubricating vertical orientating vibrating wheel structure subjected to counterweight by using a liquid. The self-lubricating vertical orientating vibrating wheel structure comprises a vibrating wheel, a vibration exciter cylinder, a transmission shaft and a cylinder-shaped gear box, wherein a first forwards-rotating eccentric wheel, a backwards-rotating eccentric wheel and a second forwards-rotating eccentric wheel are sequentially arranged along the axial length direction of the transmission shaft, the backwards-rotating eccentric wheel and the first forwards-rotating eccentric wheel are connected with each other through a change gear set; the cylinder-shaped gear box is provided with a gear cavity and an eccentric wheel cavity corresponding to the change gear set and the first forwards-rotating eccentric wheel; the upper end of the cylinder-shaped gear box is provided with a lubricating flow channel, and the lower end of the cylinder-shaped gear box is provided with a liquid outlet; the vibration exciter cylinder is peripherally provided with oil boxes used for rain falling lubrication corresponding to the inner walls of cylinder cavities positioned on the positions of the cylinder-shaped gear box, the second forwards-rotating eccentric wheel and the backwards-rotating eccentric wheel; and the outer wall of the vibration exciter cylinder, the inner wall of the vibrating wheel and ring plates positioned on two ends of the vibrating wheel are encircled to form a sealing cavity used for filling a counterweight liquid together. The self-lubricating vertical orientating vibrating wheel structure disclosed by the invention achieves the sufficient lubrication effect of various bearings and gears inside equipment and can realize the purposes of counterweight and high-efficiency radiation of the vibrating wheel through the counterweight liquid.

Owner:合肥永安绿地工程机械有限公司

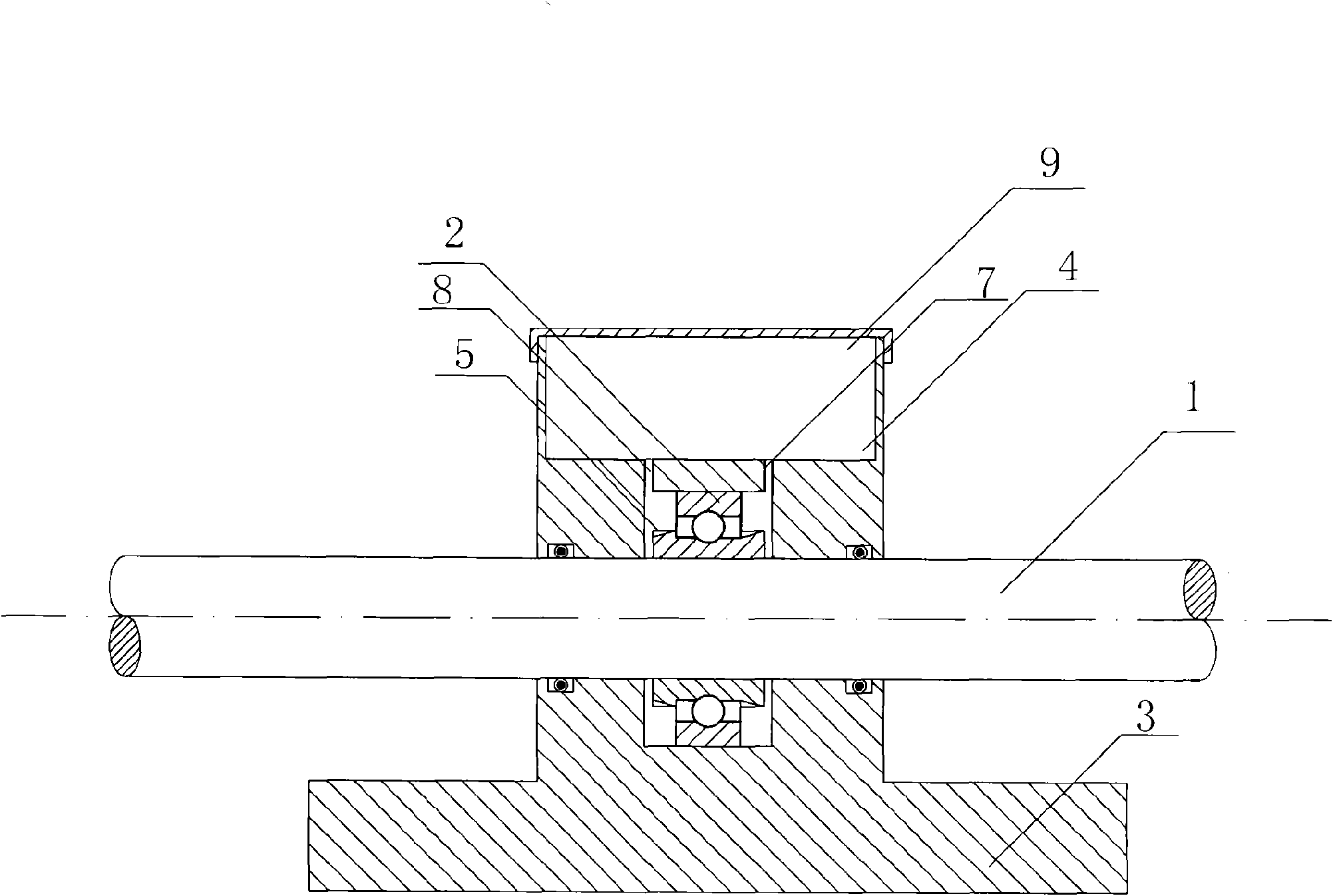

Thrust bearing and lubricating device thereof

InactiveCN103362955AControl swellingReduce bloatBearing componentsLubrication elementsOil canTemperature control

The invention provides a thrust bearing and a lubricating device thereof. The thrust bearing comprises a shaft washer, a housing washer and a rolling body between the shaft washer and the housing washer, and is characterized in that an oil pumping device is arranged on the outer side of the shaft washer. The lubricating device of the thrust bearing comprises a shaft, a radial bearing and a bearing pedestal, and is characterized in that the bearing pedestal is provided with an oil inlet in one side of the bearing and is provided with an oil outlet in the other side of the bearing; the oil inlet and the oil outlet are respectively connected with an oil tube; one end of an oil inlet tube is connected with a cooling device, one end of an oil outlet tube is connected with a magnetic filter, and the cooling device is communicated with the magnetic filter. Therefore, lubricating oil can be continuously supplied to the bearing through the oil pumping device, the temperature of the lubricating oil can be controlled within a certain range through the cooling device, and the lubricating oil passing through a coiled pipe in a water tank is filtered through the magnetic filter, is cooled and then returns inside the bearing pedestal, so that the high temperature of the bearing rotating at high speed can be effectively reduced, the lubricating oil is cleaned through the magnetic filler, the friction force of the bearing is reduced, and the service life of the bearing is prolonged.

Owner:NINGBO ZHENHAI JIEDENG APPL TECH INST

Method for reducing fluid loss during drilling of a hydrocarbon formation using a water-based drilling fluid composition having a multifunctional mud additive

ActiveUS20150210912A1Reduce van der Waals forcesEnsure adequate lubricationFlushingDrilling compositionNanoparticleWell drilling

Embodiments of the invention provide a drilling, drill-in, and completion water-based mud composition containing micro or nanoparticles for use in hydrocarbon drilling. In accordance with at least one embodiment, there is provided a method of drilling a hydrocarbon formation, including contacting the hydrocarbon formation with a water-based drilling mud composition while drilling or completing a well. In accordance with at least one embodiment, the water-based drilling mud composition includes water, the water being present in an amount greater than about 90 wt % of the water-based drilling mud composition to maintain flowability of the water-based drilling mud composition; drilling mud, the drilling mud comprising particles, wherein the particles are selected from the group consisting of microparticles, nanoparticles, and combinations thereof; and a multi-functional mud additive in an amount of 0.8 wt % of the water-based drilling mud composition, the multi-functional mud additive comprising psyllium husk powder, such that the water-based drilling mud composition is operable to keep the particles stabilized and dispersed throughout the drilling mud composition in the absence of a surfactant.

Owner:SAUDI ARABIAN OIL CO

Integrated wellhead continuous dosing device

The invention discloses an integrated wellhead continuous dosing device which comprises a power end and an overflowing end in mutual connection with each other, wherein the power end comprises a cylinder and a plunger; the cylinder is vertically arranged; the plunger is inserted into a chamber of the cylinder; an extending end of the plunger is connected with a power source; a compression spring for resetting the plunger is arranged between the chamber and the plunger; the overflowing end comprises a channel which is respectively in annular communication with the chamber, a drug kit and a wellhead. Compared with the prior art, the integrated wellhead continuous dosing device has the advantages of simple structure, stability and reliability in work, high adaptive capacity to environment, accurate dosage and convenience in maintenance and repairing.

Owner:DONGHAO MECHANICAL & ELECTRONICS

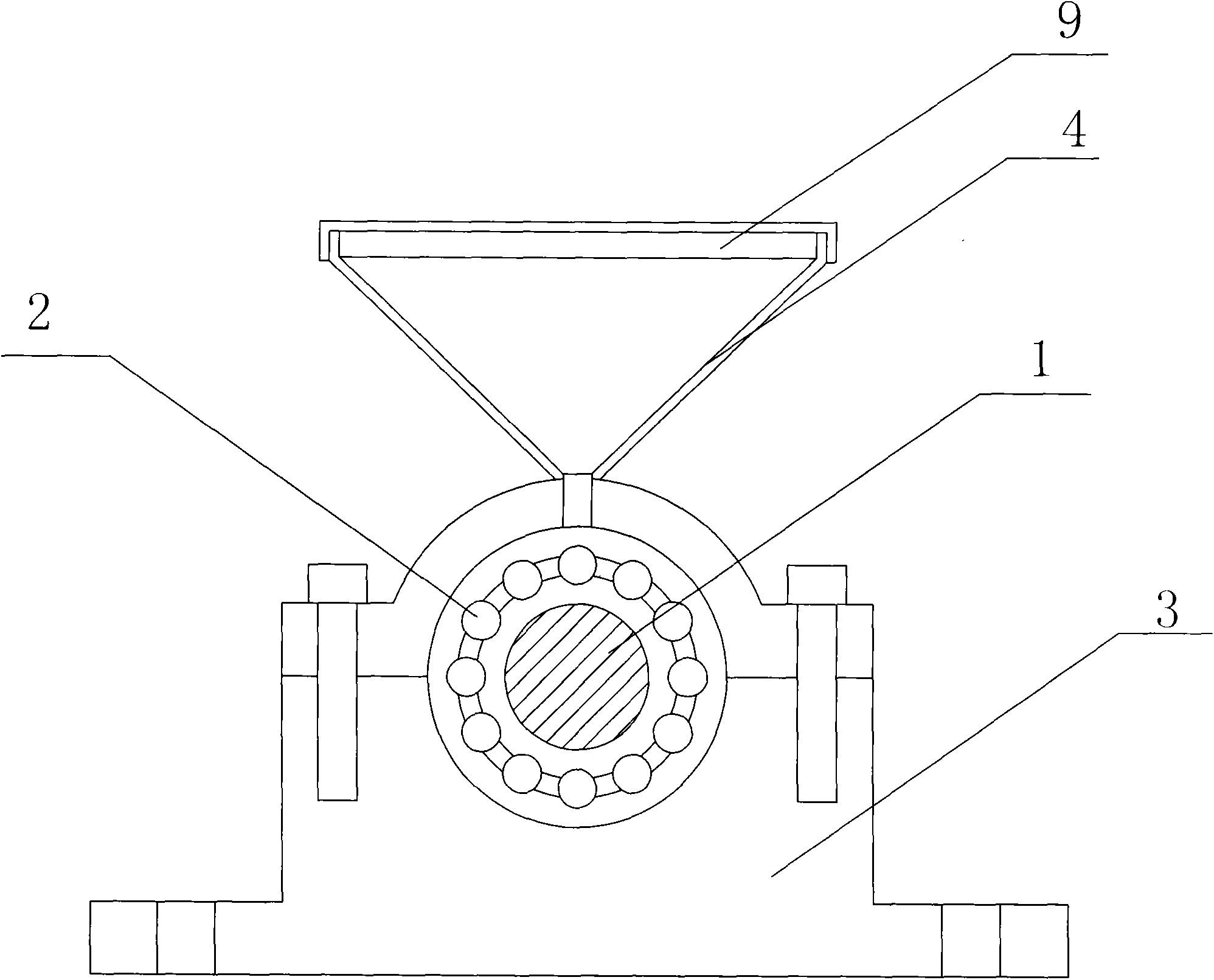

Lubricating device of bearing

InactiveCN101672420AEnsure adequate lubricationReduce high temperatureBearing componentsEngine lubricationOil canFriction reduction

The invention discloses a lubricating device of a bearing which comprises an axle, a bearing, a bearing block and an oil tank, wherein the bearing is arranged on the axle; the lubricating device is characterized in that at least one side of the bearing is provided with an oil suction device along the axle direction; the bearing block is provided with an oil inlet and an oil outlet at one side of the axle provided with a worm gear and at the opposite side respectively; the oil inlet and the oil outlet are respectively connected with the oil tank by an oil pipe; the lubricating device has the advantages that lubricant can be continuously supplied and added again without dismantling an assembled bearing, thus being convenient, saving time, increasing production efficiency and guaranteeing thebearing to be fully lubricated; simultaneously by the rotation of the worm gear, oil can circulate in the whole device, enter the oil tank from an oil inlet pipe and return to the oil tank again froman oil outlet pipe; heat generated by the oil that the oil tank gives off is utilized for reducing high temperature caused by high-speed rotation of the axle, thus reducing friction and prolonging the service life of the axle; moreover the lubricating device has simple structure, convenient operation and is particularly applicable to devices with large bearings.

Owner:海门嘉濠建材贸易有限公司

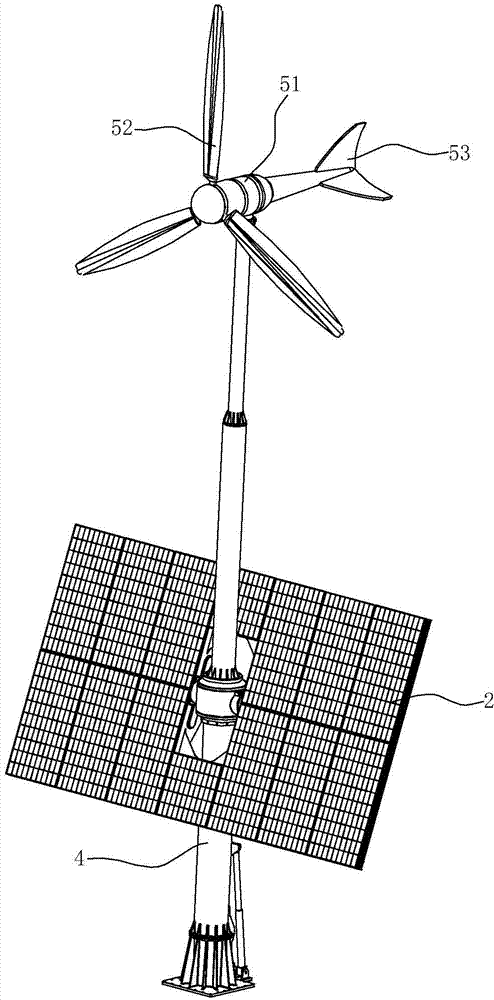

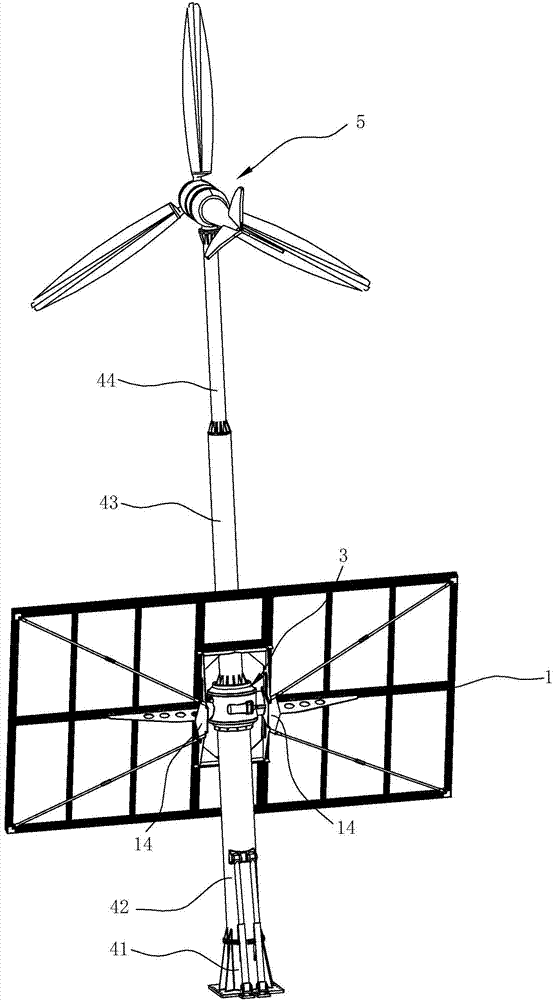

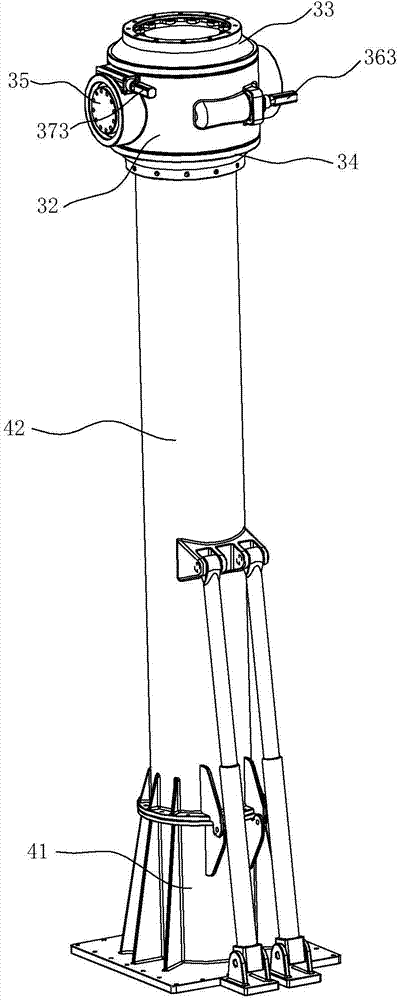

Wind power and solar power combined power generation device

ActiveCN104765383ASave spaceStable forceWind motor with solar radiationPV power plantsElectricityEngineering

The invention discloses a wind power and solar power combined power generation device which comprises a photoelectricity device and a wind power device. The photoelectricity device comprises a solar power support, a solar panel arranged on the solar power support, and a rotating driving device for driving the solar power support to rotate. The wind power device comprises a wind power support, and a wind power generator arranged at the top end of the wind power support, wherein the wind power support comprises a perpendicular stand column. The wind power and solar power combined power generation device is characterized in that the rotating driving device comprises an installation base fixed to the periphery of the stand column, a shell located on the periphery of the installation base, and rotating bearings arranged in the two sides of the shell, the shell is driven by a horizontal driving mechanism and can horizontally rotate relative to the installation base, the rotating bearings are driven by a perpendicular driving mechanism and can perpendicularly rotate in the shell, the rotating bearings are connected to the solar power support, and the stand column penetrates through a central area formed on the solar power support.

Owner:NINGBO DAZHI MACHINE TECH CO LTD

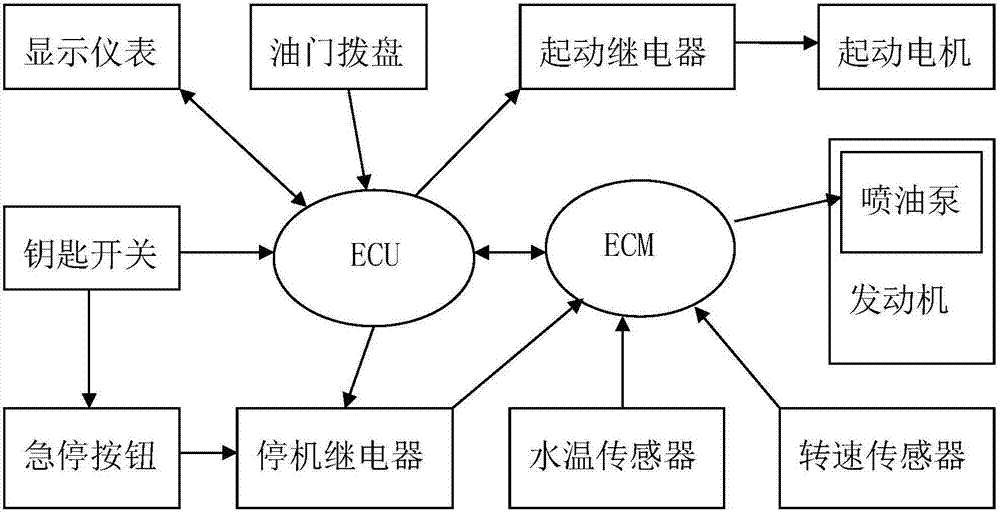

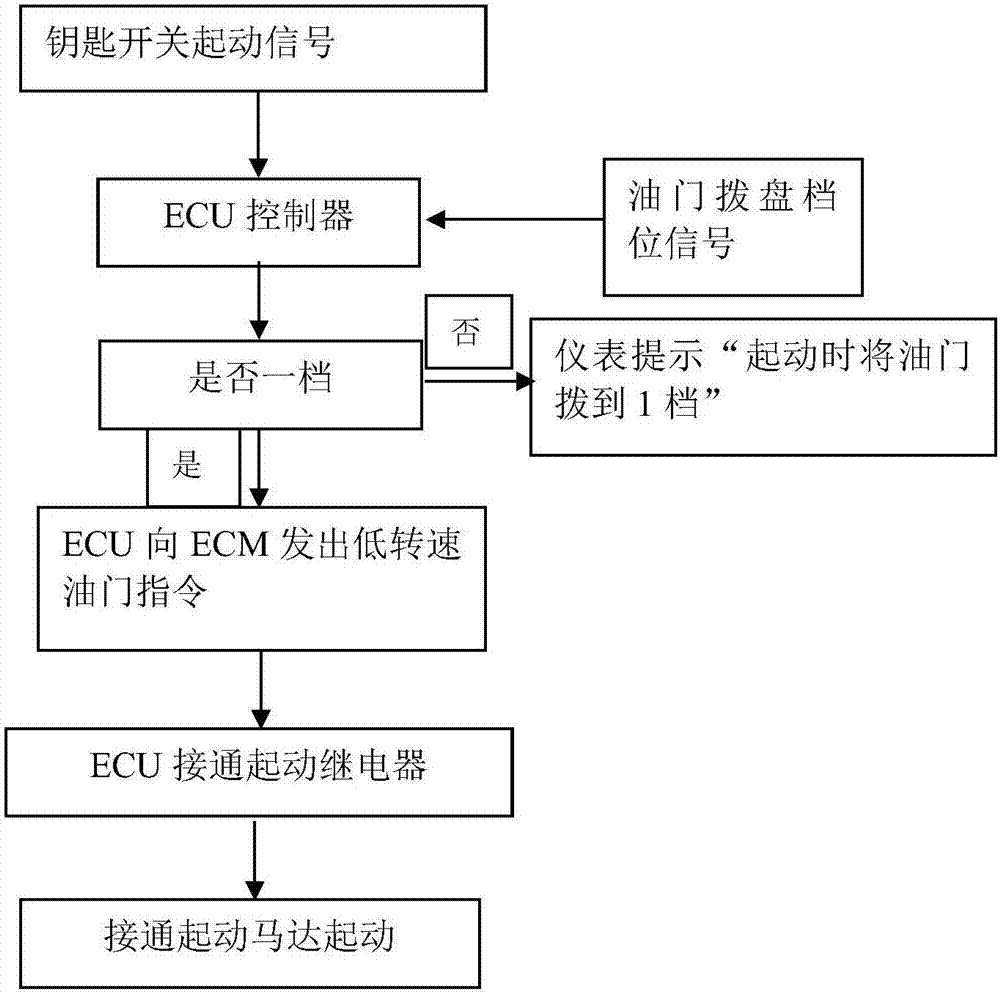

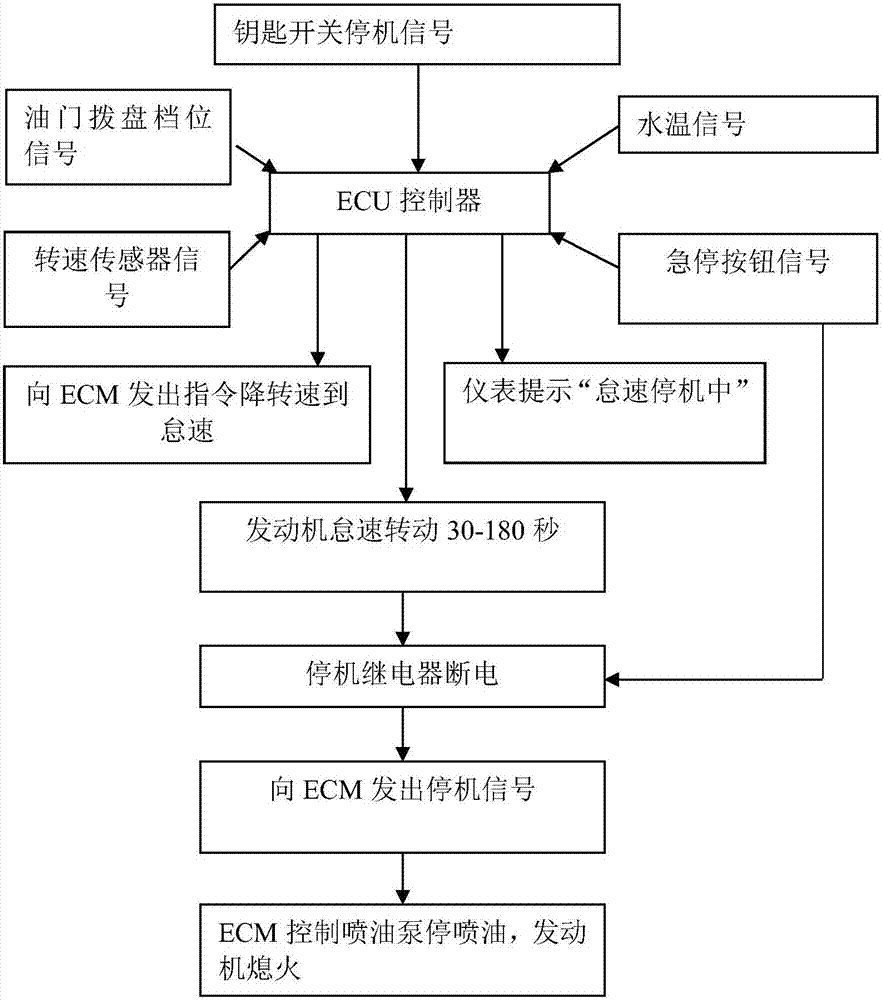

Starting and stopping control system and control method for electronic fuel injection engine of excavator

ActiveCN107461268AReduce the risk of accidentsAvoid damageEngine controllersMachines/enginesControl signalEngineering

Disclosed is a starting and stopping control system for an electronic fuel injection engine of an excavator. The starting and stopping control system comprises an engine, an ECM, an ECU, a display instrument, a key switch, a revolving speed sensor, a water temperature sensor, a throttle dial, a starting relay, a stopping relay and a starting motor. The throttle dial is connected with the ECU. The key switch is connected with the ECU through a wire. The display instrument is connected with the ECU. The ECU is connected with the ECM.A control signal is sent to the ECM. The ECM is connected with the stopping relay, the water temperature sensor and the revolving speed sensor. The engine is connected with the ECM. The starting motor and the starting relay are connected. According to the starting and stopping control system, by controlling starting and stopping of the electronic fuel injection engine of the excavator, accidents such as journal sticking tile burning, piston scraping and piston seizure of the engine caused by poor lubrication and high temperature if the engine is started or stopped at a high throttle position are avoided, and the service life of the engine is prolonged advantageously; in addition, by additionally installing an emergency stopping device, so that stopping can be conducted immediately through an operator in an emergency situation, and accident risks of in the process of operating the excavator are reduced.

Owner:GUIZHOU JONYANG KINETICS

Ultrasonic elliptical vibration extrusion device and vibration extrusion processing method for carrying out surface finishing of part by using same

InactiveCN101942547BReduce volumeSolve the lack of cooling capacityMechanical vibrations separationTransformerSurface roughness

The invention discloses an ultrasonic elliptical vibration extrusion device and a vibration extrusion processing method for carrying out surface finishing of a part by using the same. The ultrasonic elliptical vibration extrusion device comprises an amplitude transformer, four excitation sources with the same structure and an extrusion tool, wherein the extrusion tool is arranged on the output section of the amplitude transformer; and the four excitation sources are respectively arranged in the four grooves of the excitation section of the amplitude transformer. In the vibration extrusion processing process, an extrusion head makes the ultrasonic vibration in an elliptic orbit relative to the processed surface of the part under the driving of the excitation sources through adjusting an extrusion contact angle between the part and the diamond extrusion head and the processing parameters of ultrasonic elliptical vibration extrusion device. On one hand, the device reduces an extrusion force by utilizing the pulse impact action of the ultrasonic vibration, and thereby, the extrusion process can be applied to thin-wall parts and long and thin parts; on the other hand, the front direct impact is avoided and the sliding friction of the extrusion head and the processed surface of the part is reduced even eliminated by utilizing the separation characteristic and the movement locus characteristic of the elliptical vibration, and thereby, the surface roughness of the processed surface of the part is reduced, and the service life of the extrusion head is prolonged.

Owner:BEIHANG UNIV

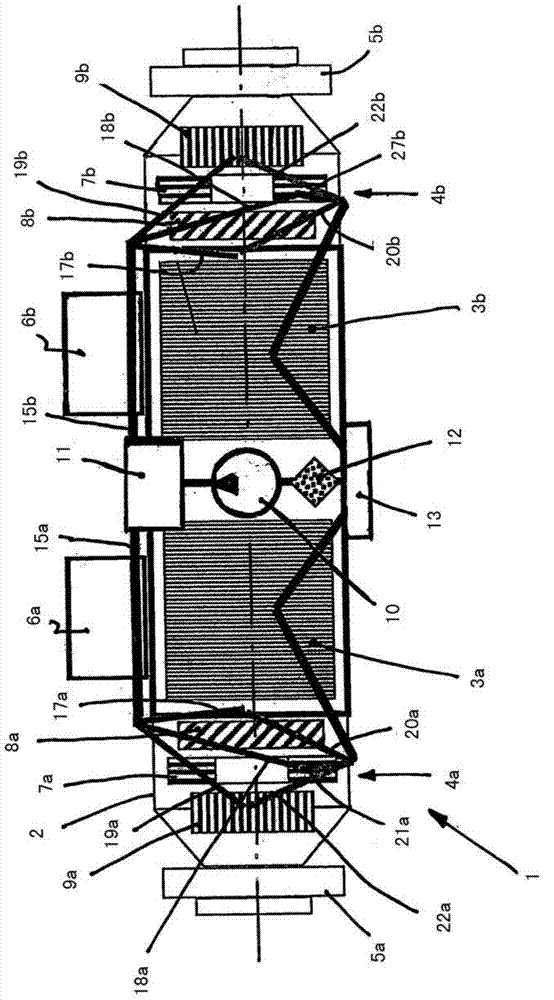

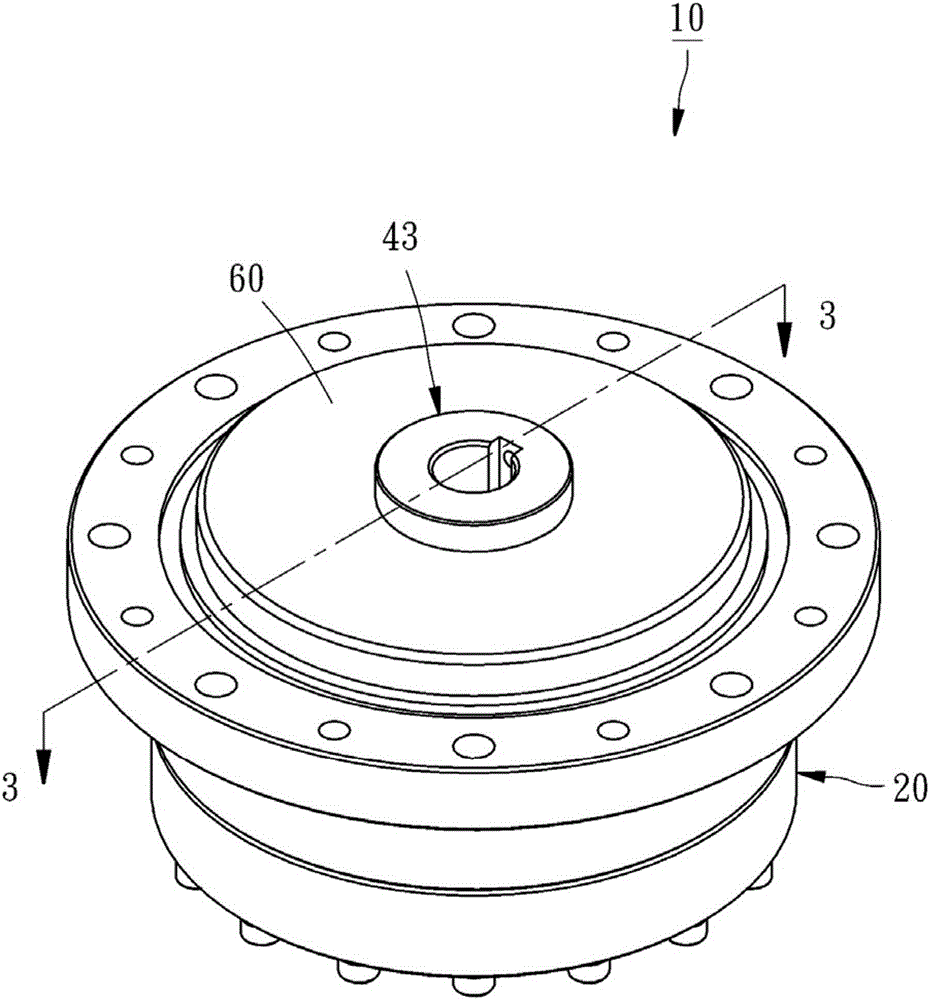

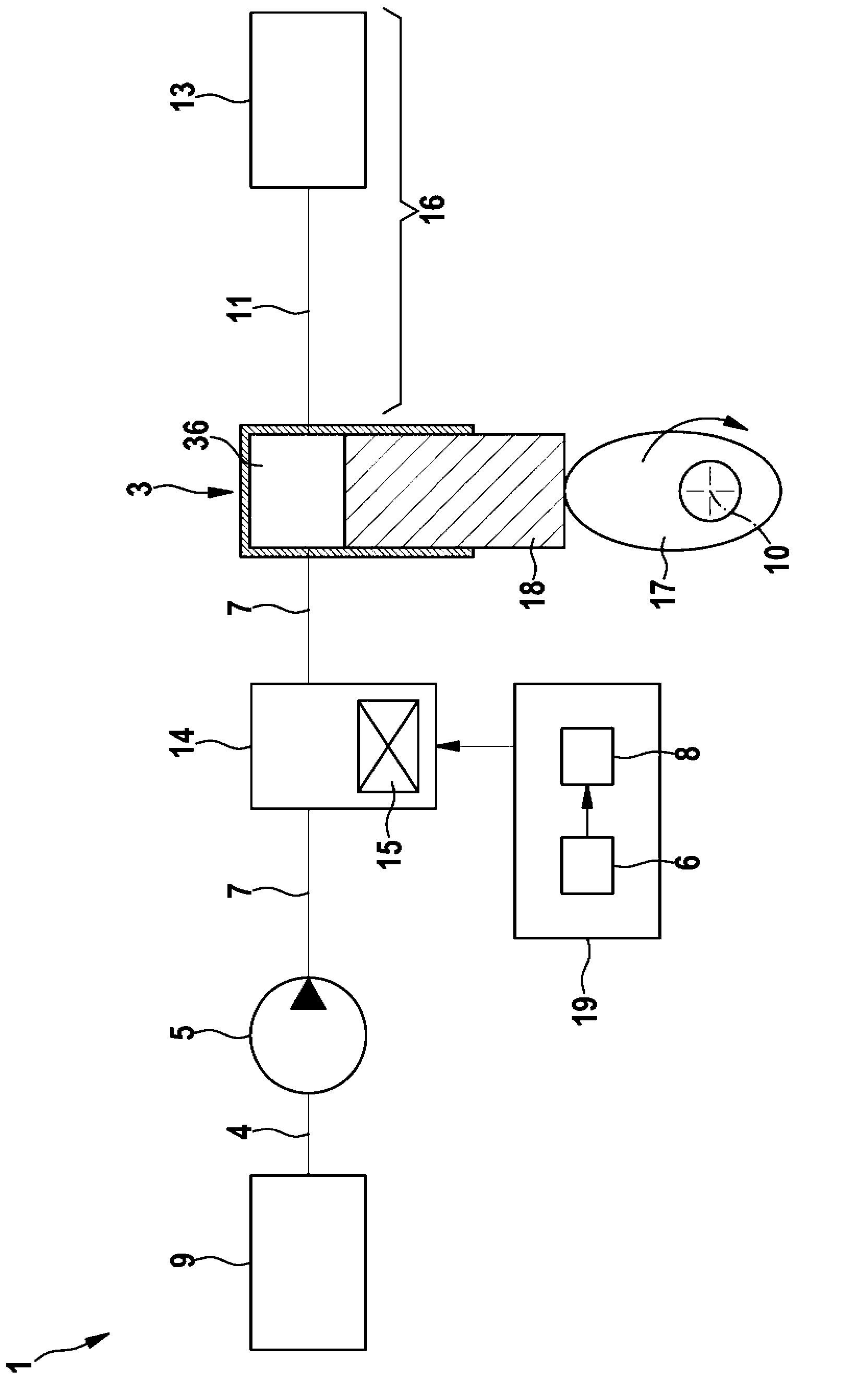

Drive axle for mobile working machine

ActiveCN103863078ALower system temperatureEasy maintenanceAssociation with control/drive circuitsElectric propulsion mountingDrive motorElectric drive

The invention relates to a drive axle (1) for a mobile working machine, especially for a ground conveying machine. The drive axle at least comprises electric drive motors (3a; 3b), power electronic devices (6a; 6b) manipulating the drive motors (3a; 3b), and speed changers (4a; 4b) driven by the drive motors (3a; 3b). The speed changers drive hubs (5a; 5b). A liquid cooling device which is used for the drive motors (3a; 3b), the power electronic device (6a; 6b) and the speed changers (4a; 4b) is equipped with a liquid loop. One or more following parts, a circulating pump (10), a heat exchanger device (11) and a filter (12), of the liquid loop are assembled or attached onto the drive axle (1).

Owner:LINDE MATERIAL HANDLING

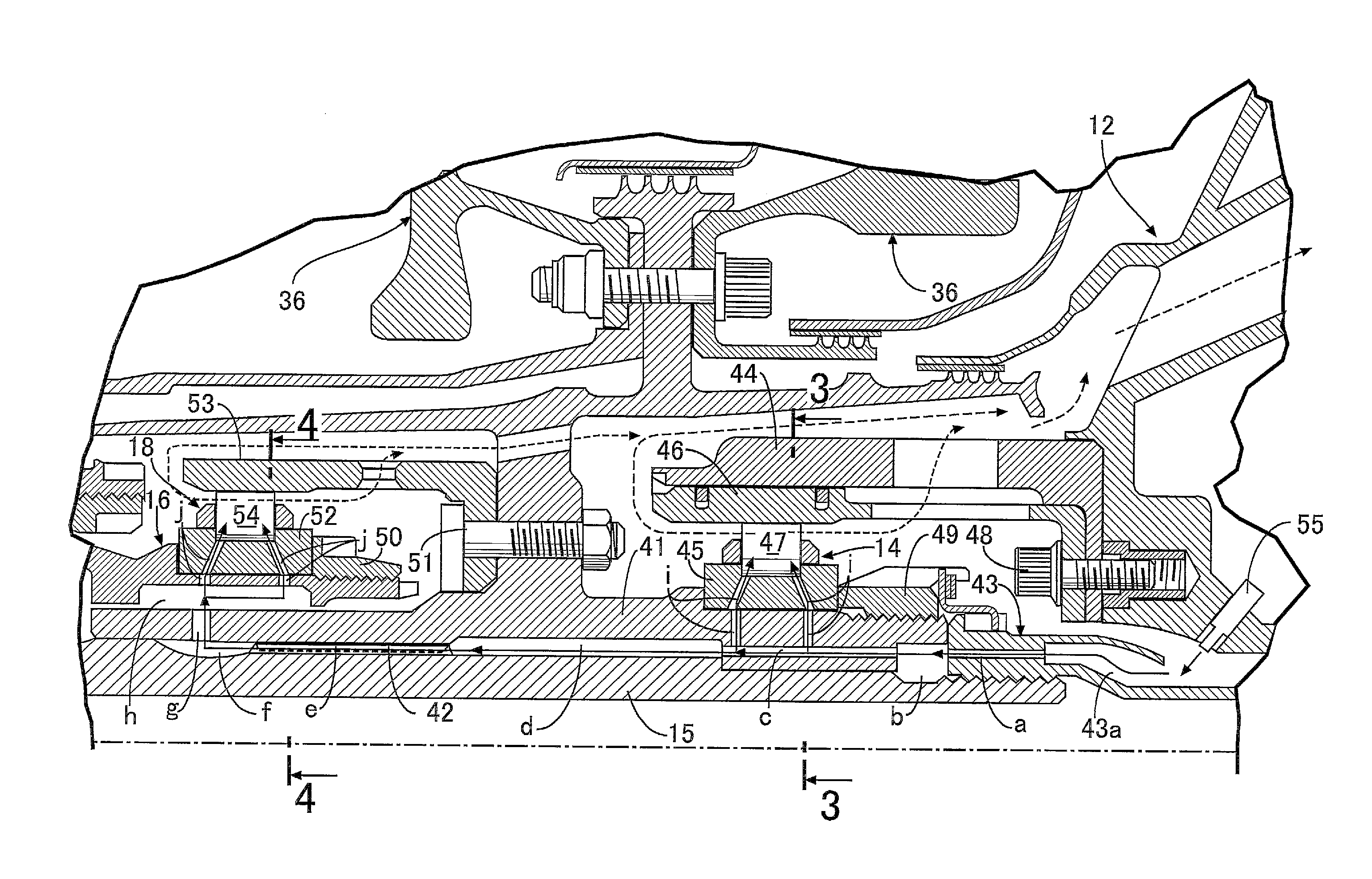

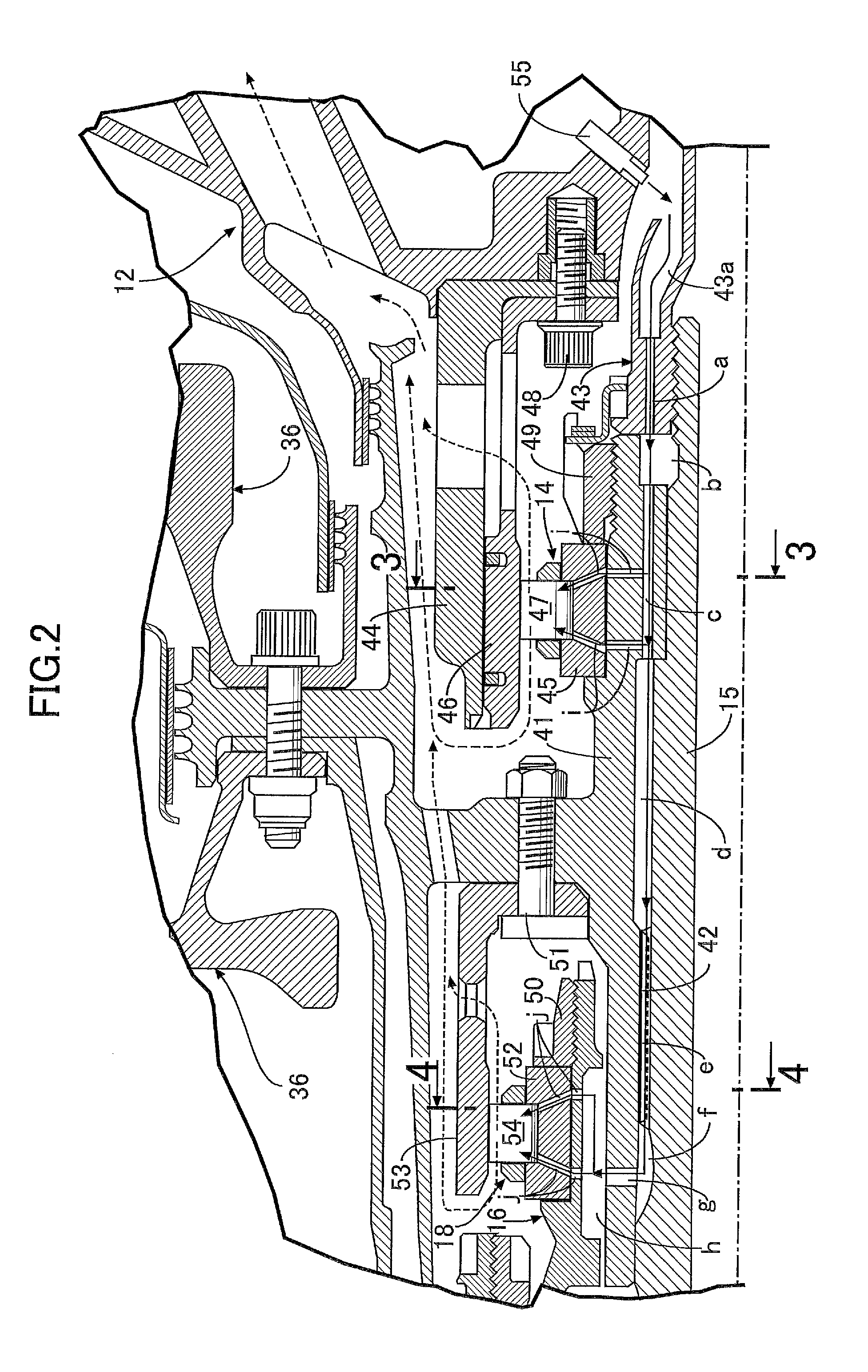

Bearing lubricating structure for gas turbine engine

ActiveUS20150275760A1Easy loadingIncrease oil volumeGas turbine plantsJet propulsion plantsLower limitGas turbines

When A denotes a required oil lower limit amount for one bearing near an oil supply source, and B and C respectively denote a required oil lower limit amount and a safety surplus oil amount for the other bearing away from the source, an amount of oil equal to A+B+C is supplied from the source and a hole diameter and the number of first oil holes are set such that an amount of oil to be supplied to the one bearing is equal to the amount A. Thus, the oil with the amount A can be securely supplied to the one bearing. Also, oil with the sum of the amounts B and C is supplied to the other bearing so that the oil with the amount B can be securely supplied to the other bearing which tends to receive oil insufficiently because of its remoteness from the source.

Owner:HONDA MOTOR CO LTD

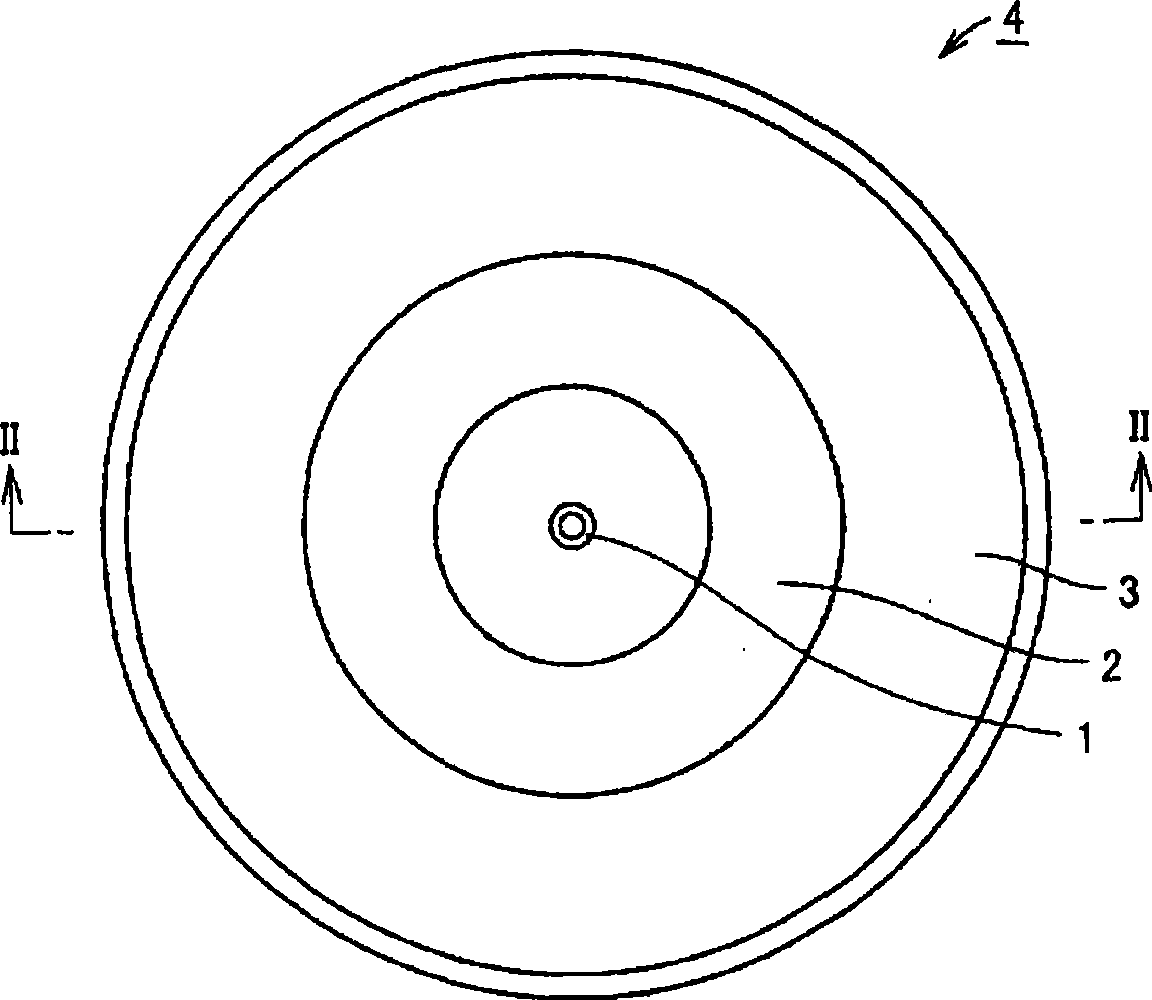

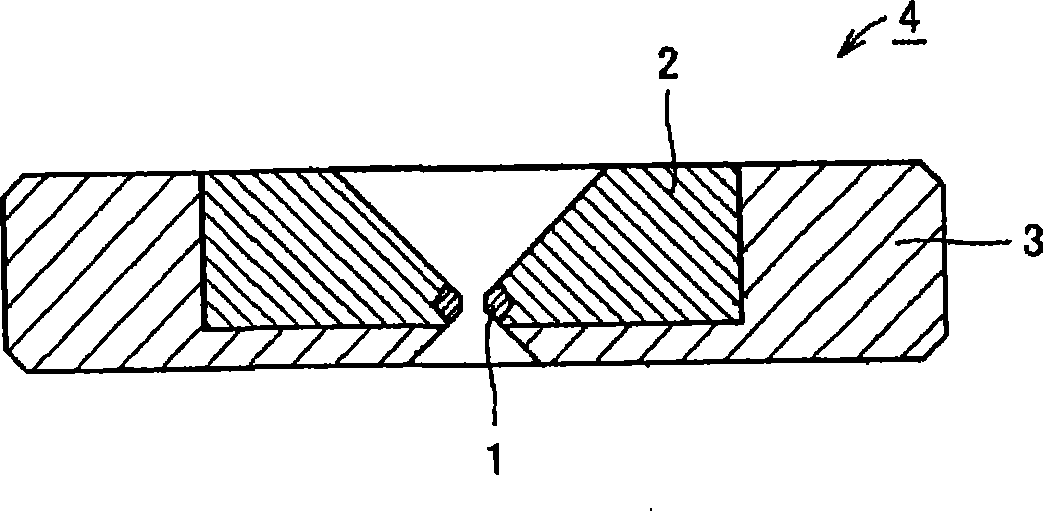

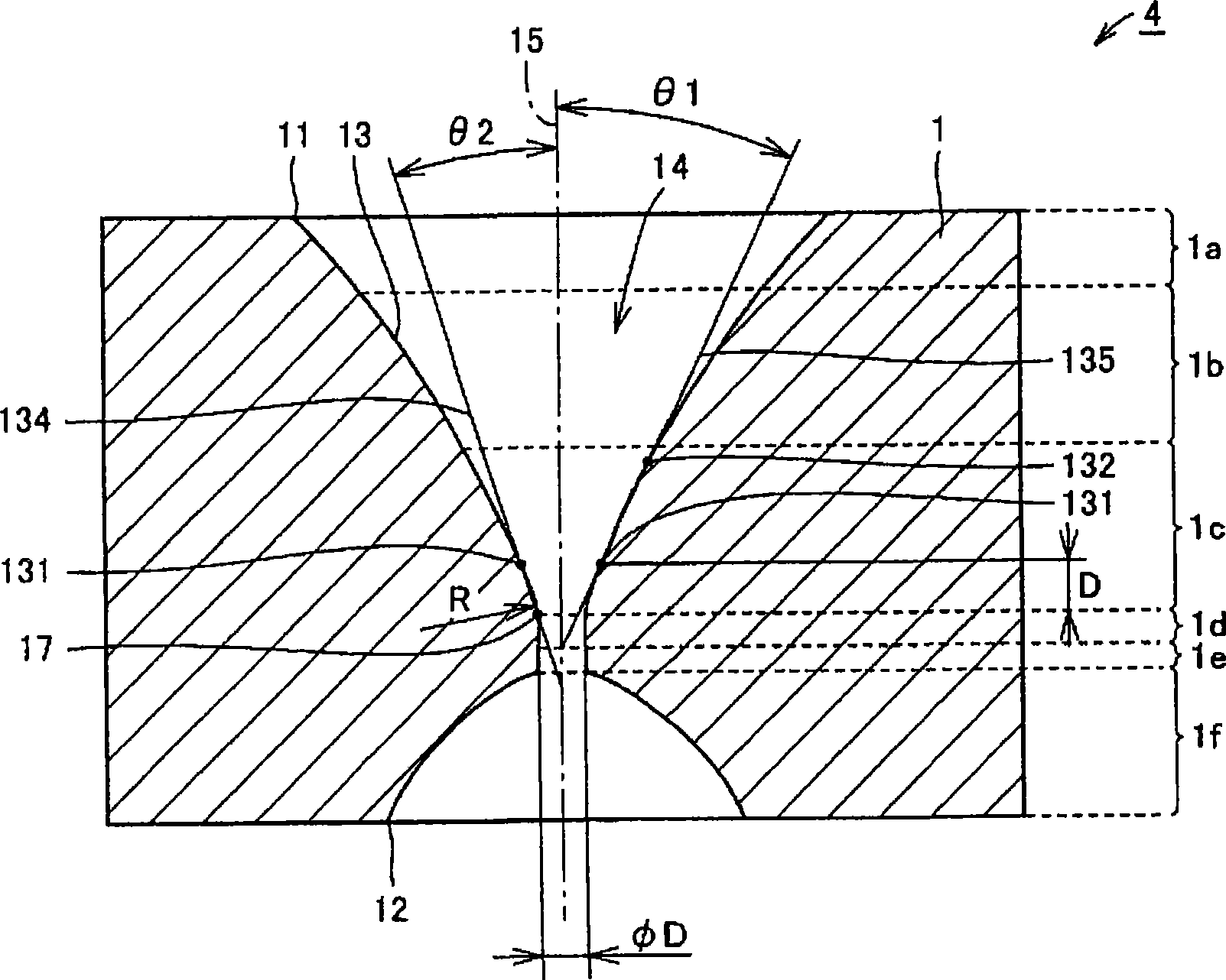

Diamond dice and method for producing wire using diamond dice

InactiveCN101547757AImprove straightnessImprove qualityDrawing diesMechanical engineeringPlane parallel

The present invention discloses a diamond dice that has a bearing region touching a wire inserted via an inlet, a reduction region arranged on the inlet side continuously to the bearing region, and a sidewall defining a hole extending from the inlet to the outlet along the axis so as to penetrate the bearing region and the reduction region. A wire inserted into the hole via the inlet is drawn out from the outlet via the bearing region. Assuming the inside diameter of the hole is D in the bearing region, a line connecting a first point on the sidewall located closer to the inlet side by a length of 1.0D in the axial direction of the hole than the boundary portion between the bearing region and the reduction region, and a second point on the sidewall located closer to the inlet side by a length of 3.0D in the axial direction of the hole than the boundary portion between the bearing region and the reduction region makes an angle Thema 1 of 15-30 degrees with respect to the axial direction on a cross-section appearing when the diamond dice is cut on a plane parallel with the axis and including the axis. The boundary portion between the bearing region and the reduction region has a curved surface.

Owner:ALLIED MATERIAL

Method for manufacturing 2-series aluminum alloy ingot

The application provides a method for manufacturing a 2-series aluminum alloy ingot. The method comprises the following steps: (A) smelting a raw material of the 2-series aluminum alloy ingot; (B) guiding a smelted fusant into a heat-preserving furnace, and refining by adopting a mixed gas, wherein the mixed gas is a mixed gas of nitrogen and chlorine; (C) sequentially carrying out on-line degassing and on-line filtration on the fusant obtained from the step (B); (D) casting the fusant obtained from the step (C) at the casting speed of 48-55 mm / minute, the water flow of 28-35 m<3> / hour.piece and the casting temperature of 715-725 DEG C to obtain the 2-series aluminum alloy ingot. The method provided by the application sequentially carries out the procedures of smelting, refining, the on-line degassing, the on-line filtration and casting in the manufacturing process of the 2-series aluminum alloy ingot and obtains an optimal proportion by regulating casting temperature, a casting cooling water flow and casting speed, thereby greatly enhancing the finished product ratio of the 2-series aluminum alloy ingot.

Owner:SOUTHWEST ALUMINUM GRP

Steel-wire-rope-suspended maintenance machine

InactiveCN103114400AImprove securityFlexible reciprocating motionLiquid surface applicatorsLiquid/gas/vapor article treatmentMotor driveEngineering

The invention relates to the field of suspended maintenance of steel-wire-ropes on a large-scale bridge and hydraulic engineering hoists, and discloses a steel-wire-rope-suspended maintenance machine. The steel-wire-rope-suspended maintenance machine comprises steel wire rope guide wheel oil seals, a chain wheel, a chain wheel adjustment shaft, a locking buckle, a locking buckle hanging rope, a forward-and-reverse-rotation electric winch, hairbrush rolls and the like, and is characterized in that a maintenance machine framework is rectangular-shaped or column-shaped or special-shaped and is formed by connecting the folding locking buckle, a left box and a right box. The left box and the right box are opened. Steel wire ropes are sleeved in two semicircular steel wire rope guide wheel oil seals. When the left box and the right box are closed, the locking buckle locks the steel wire ropes, the steel wire rope guide wheel oil seals and the steel wire ropes rub in a sliding mode, more than two hairbrush rolls are fixedly connected inside the left box and the right box, and a motor drives the hairbrush rolls to tightly contact the steel wire ropes and operates in a rub mode. Accordingly, not only dust, sand and aged old oil can be cleaned but also new oil can be efficiently and evenly covered on the surfaces of the steel wire ropes, and all kinds of defects of prior manual oil coating are overcome. The steel-wire-rope-suspended maintenance machine is reasonable in structural design, and improves operation levels and work efficiency.

Owner:枣庄安澜水利工程有限公司

Preparation method of 7 series aluminum alloy ingots

The application provides a preparation method of 7 series aluminum alloy ingots. The preparation method comprises the following steps: (A) smelting a raw material of the 7 series aluminum alloy ingots; (B) guiding a melt after smelting into a heat preserving furnace, and performing refining by adopting a mixed gas which is a mixed gas of nitrogen and chlorine; (C) sequentially performing online degassing and online filtration on the melt obtained in the step (B); and (D) performing casting on the melt obtained in the step (C) to obtain the 7 series aluminum alloy ingots, wherein the casting speed is 48-55mm / min, the water flow rate is 28-35m<3> / h per each ingot, and the casting temperature is 715-725 DEG C. According to the preparation method provided by the application, during preparation of the 7 series aluminum alloy ingots, the processes of smelting, refining, online degassing, online filtration and casting are performed sequentially, and by matching the casting temperature, the casting cooling water flow and the casting speed, an optimal mixing ratio is obtained, so that rate of finished products of the 7 series aluminum alloy ingots is greatly improved.

Owner:SOUTHWEST ALUMINUM GRP

Helical lubrication type harmonic wave reducer

ActiveCN106481763AEnsure adequate lubricationGear lubrication/coolingFriction gearingsHelical bladeCoupling

The invention discloses a helical lubrication type harmonic wave reducer. The helical lubrication type harmonic wave reducer comprises a rigid inner gear ring, a flexible outer gear cup, a wave generator and a flow turbulence component. The flexible outer gear cup is engaged with the rigid inner gear ring. The wave generator is provided with a bearing, an oval wheel and a coupling, wherein the bearing is arranged in the flexible outer gear cup; the oval wheel is arranged in the bearing; and the coupling is connected with the oval wheel. The flow turbulence component is located in an oil storage space formed between the wave generator and the flexible outer gear cup and provided with a rotating shaft portion and a helical blade arranged on the rotating shaft portion. The flow turbulence component is connected with the coupling of the wave generator through a rotating shaft, therefore when the flow turbulence component is driven by the coupling, lubricating oil can be made to generate convection through the helical blade, and thus the bearing of the wave generator can obtain a good lubrication effect.

Owner:HIWIN TECH

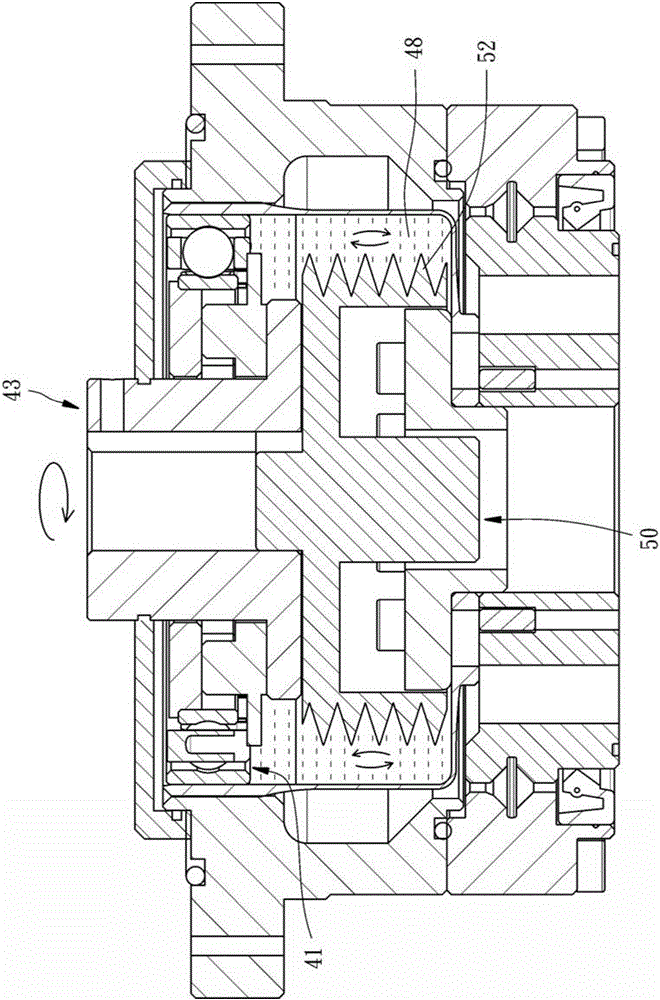

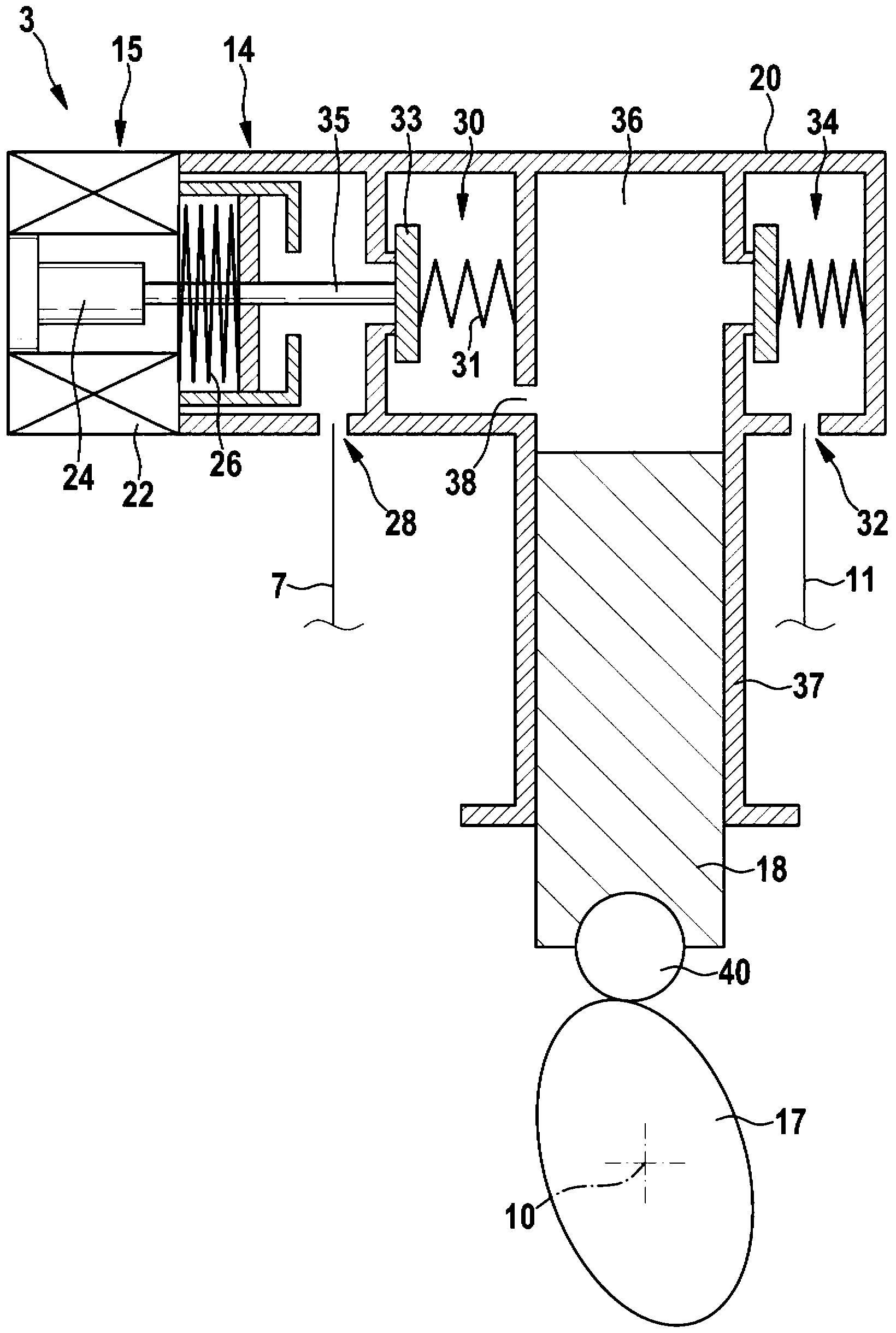

Method for operating a fuel system of an internal combustion engine

ActiveCN103221678AIncreased durabilityImprove the lubrication effectElectrical controlMachines/enginesExternal combustion engineInternal combustion engine

A method for operating a fuel system (1) of an internal combustion engine is described, in which method, in at least a first operating situation, a fuel pump (3) compresses fuel in a delivery space (36) by means of a corresponding setting of a valve device (14) and feeds said fuel into a pressure region (16), and in at least a second operating situation the fuel pump (3) feeds no fuel into the pressure region (16) by means of a corresponding setting of the valve device (14), wherein in the second operating situation the valve device (14) is at least intermittently actuated in such a way that fuel in the delivery space (36) is compressed but is not fed into the pressure region (16).

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com