Ultrasonic elliptical vibration extrusion device and vibration extrusion processing method for carrying out surface finishing of part by using same

An extrusion device and elliptical vibration technology are applied in the field of ultrasonic elliptical vibration extrusion device and the field of vibration extrusion processing using it for surface finishing of parts, which can solve the problem of limited life extension of extrusion head, shortening life of extrusion head, extrusion Avoid head impact damage and other problems, to avoid direct frontal impact, reduce surface roughness, and eliminate sliding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

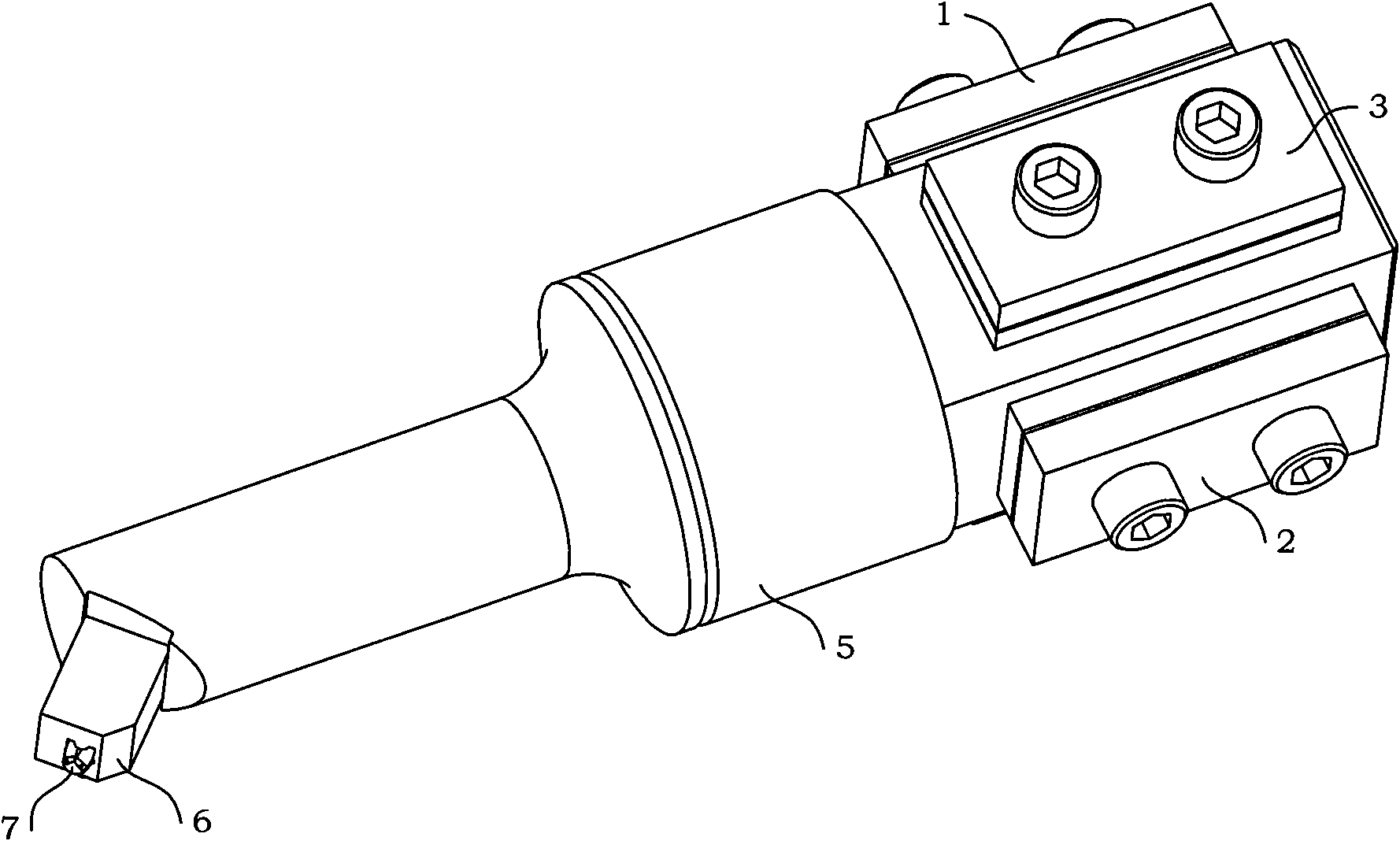

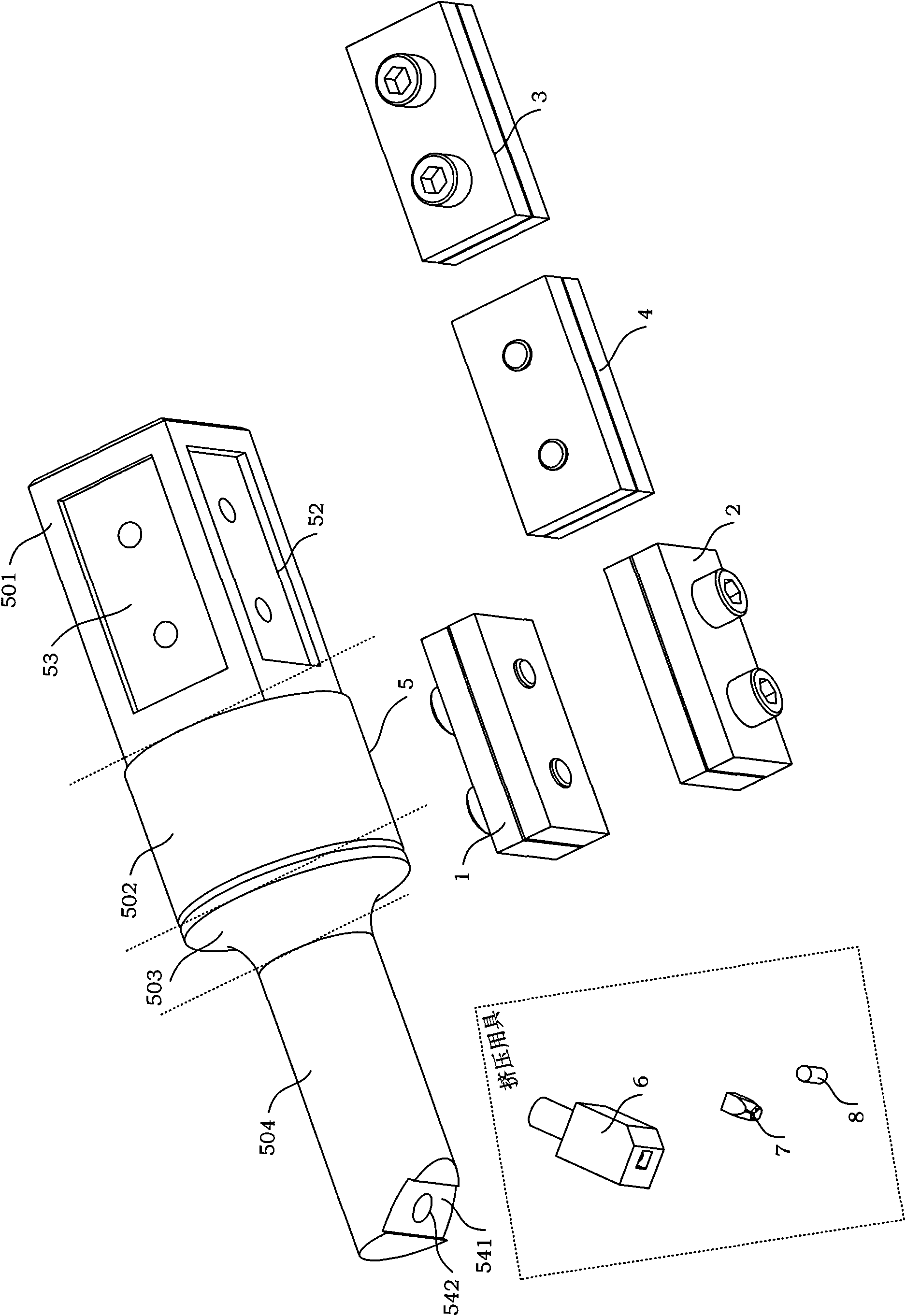

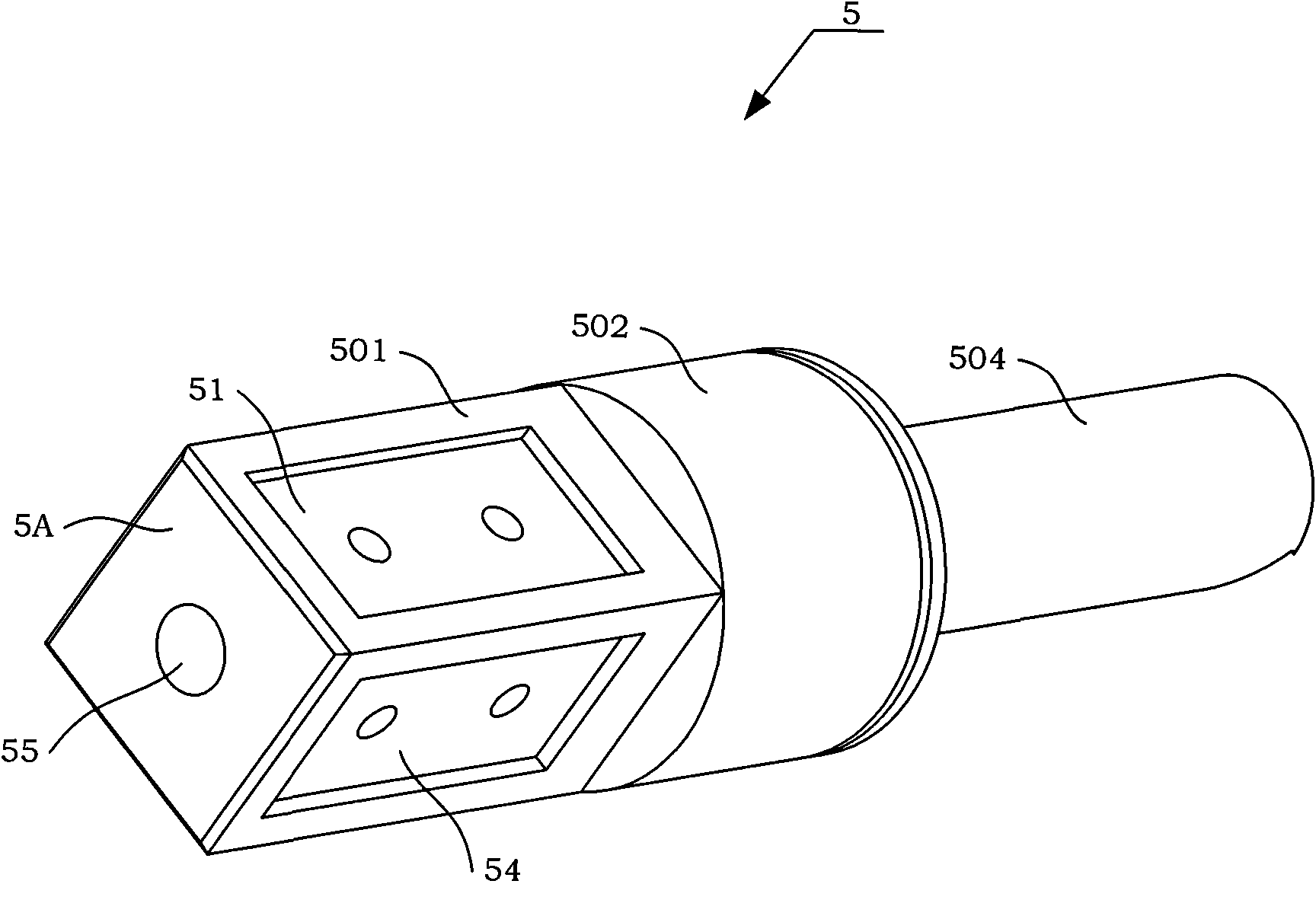

[0027] see figure 1 , Figure 1A As shown, the present invention is a kind of ultrasonic elliptical vibration extrusion device capable of strengthening and smoothing the surface of parts. The device includes a horn 5, four excitation sources with the same structure (A excitation source 1, B excitation source 2, C excitation source 3 and D excitation source 4) and an extrusion tool; Said extrusion tool includes connector 6, diamond 7 and top wire 8, and diamond 7 (hereinafter also referred to as diamond extrusion head) is installed on the connection The through hole at one end of the connecting piece 6 is tightened with the top screw 8 , and the other end of the connecting piece 6 is installed in the positioning groove 541 of the output section 504 of the horn 5 .

[0028] see figure 1 , Figure 1A As shown, the A excitation source 1 includes two ceramic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com