Ultrasonic elliptically vibrating boring process

A technology of elliptical vibration and processing method, which is applied in the field of mechanical processing, can solve problems such as the deterioration of grinding surface quality, weak rigidity of boring bar parts, zero thermal deformation of thin-walled deep holes, etc., and achieve the reduction of boring surface roughness and boring accuracy Improvement, tool life improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

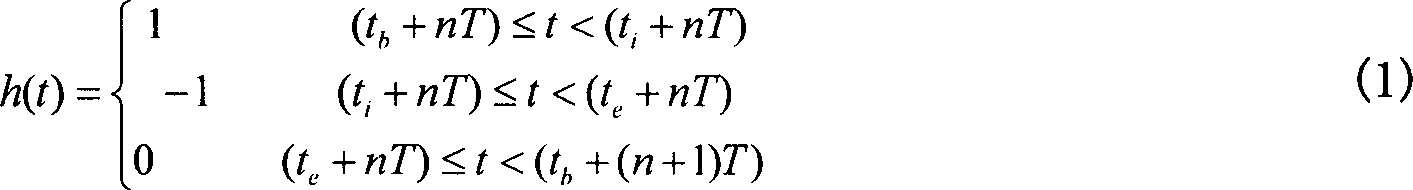

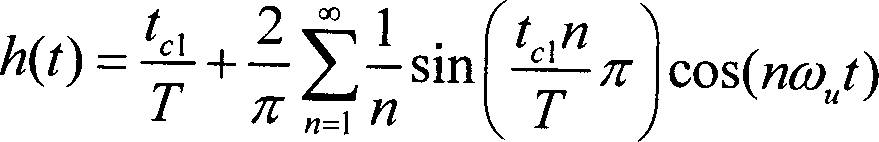

[0032] Combined with the content of the method of the present invention, the following boring processing simulation results are provided. Workpiece material: aluminum (52S). Boring tool material: hard alloy. Tool rake angle: -5°, tool back angle: 12°, leading angle: 65°. Tool nose arc radius: 0.1mm. Vibration conditions: Trajectory circle (radius: 4μm), straight line (amplitude: 4μm), resonance frequency: 18.76 kHz.

[0033] (1) Apply sine wave voltage to the two pieces of piezoelectric ceramics on the horn body, the two pieces of piezoelectric ceramics will expand and contract, the boring tool fixes the end of the elliptical vibration horn, through the elliptical vibration horn, the boring tool The cutting edge reaches the elliptical vibration trajectory with the long axis and short axis of 8 μm. When the boring speed is set to 5m / min, the boring depth is 0.05mm, and the feed rate is 0.025mm / rev, the ultrasonic elliptical vibration boring radial boring The cutting force is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com