Patents

Literature

262results about How to "Solve the lack of cooling capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

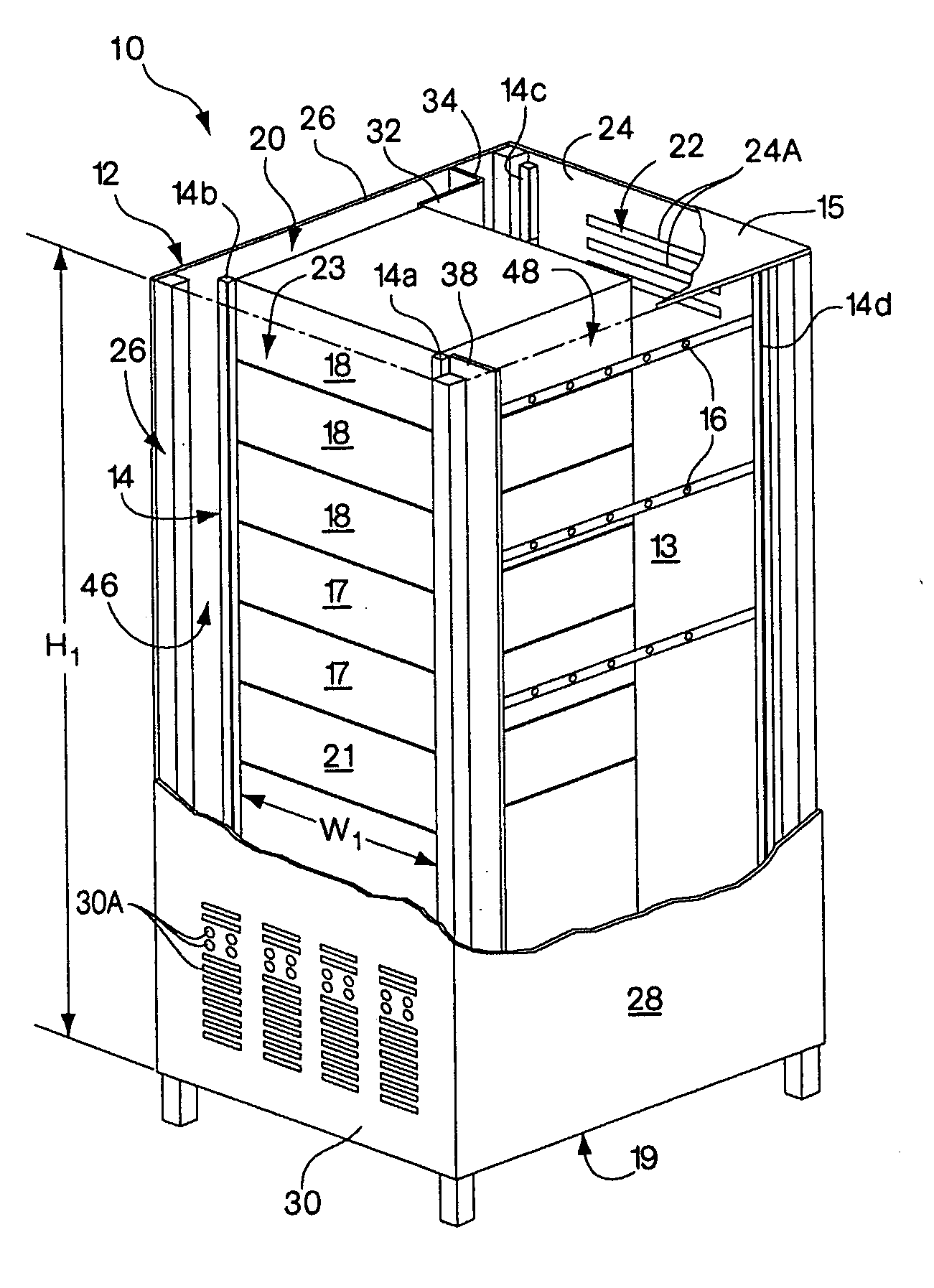

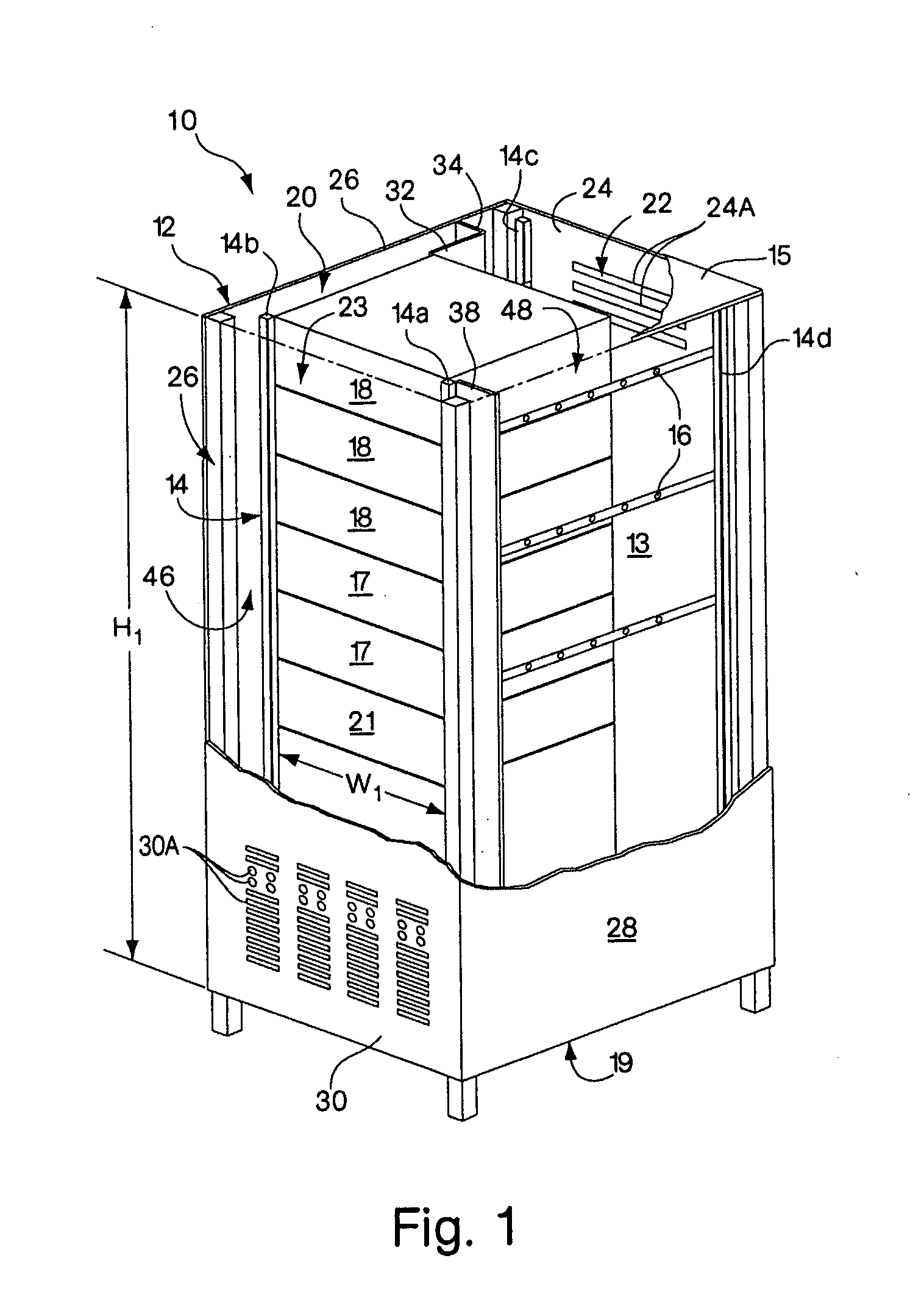

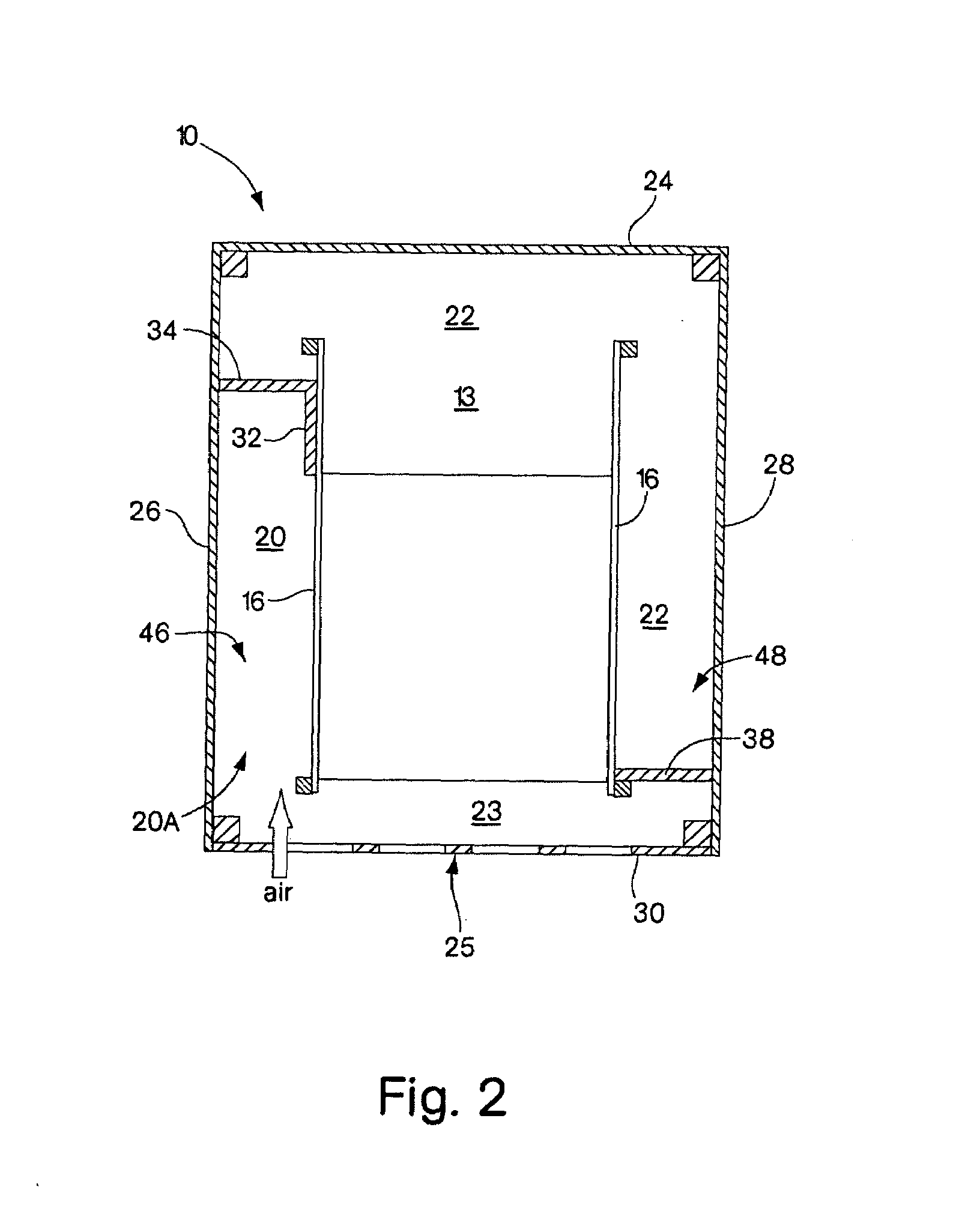

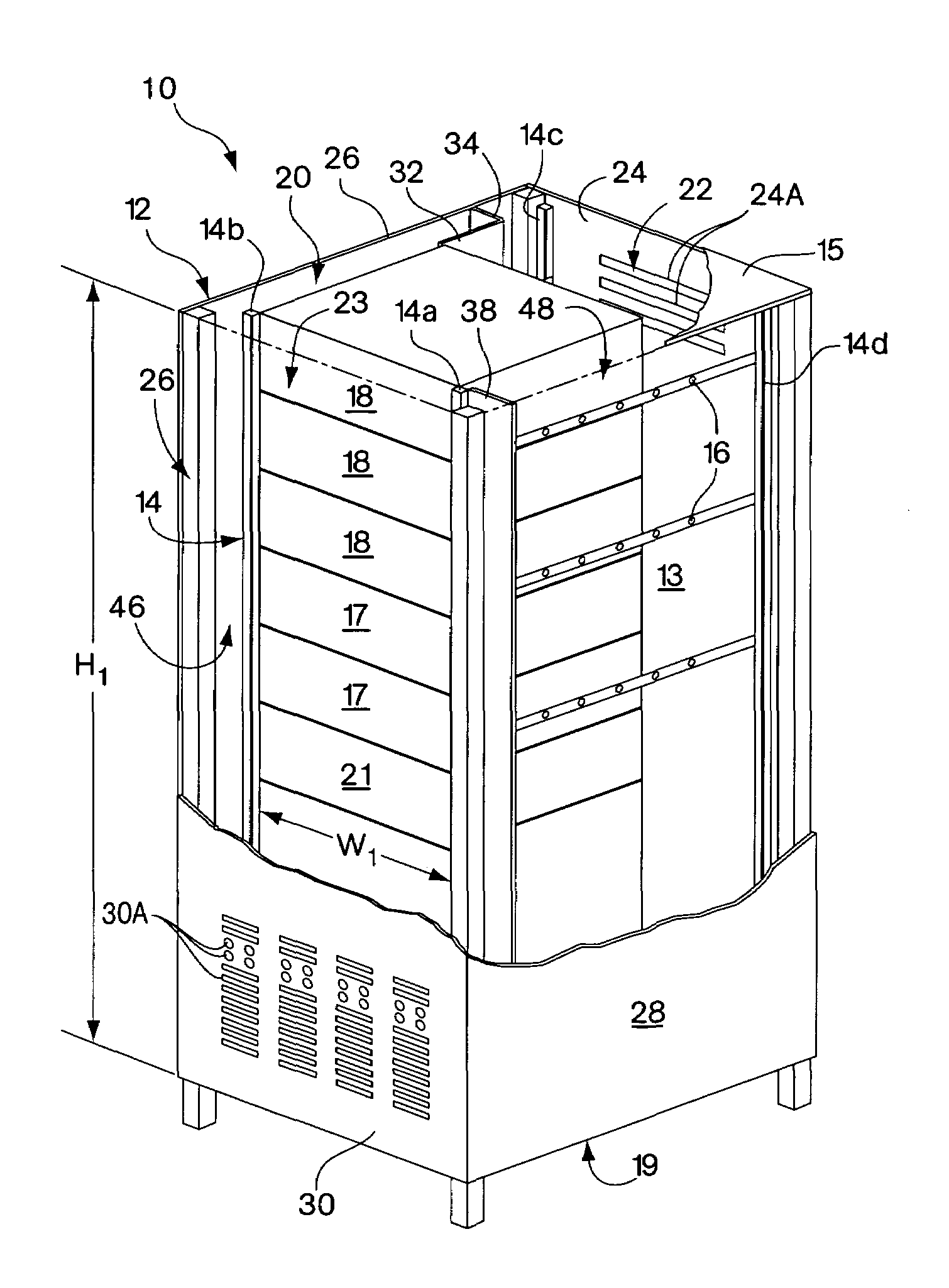

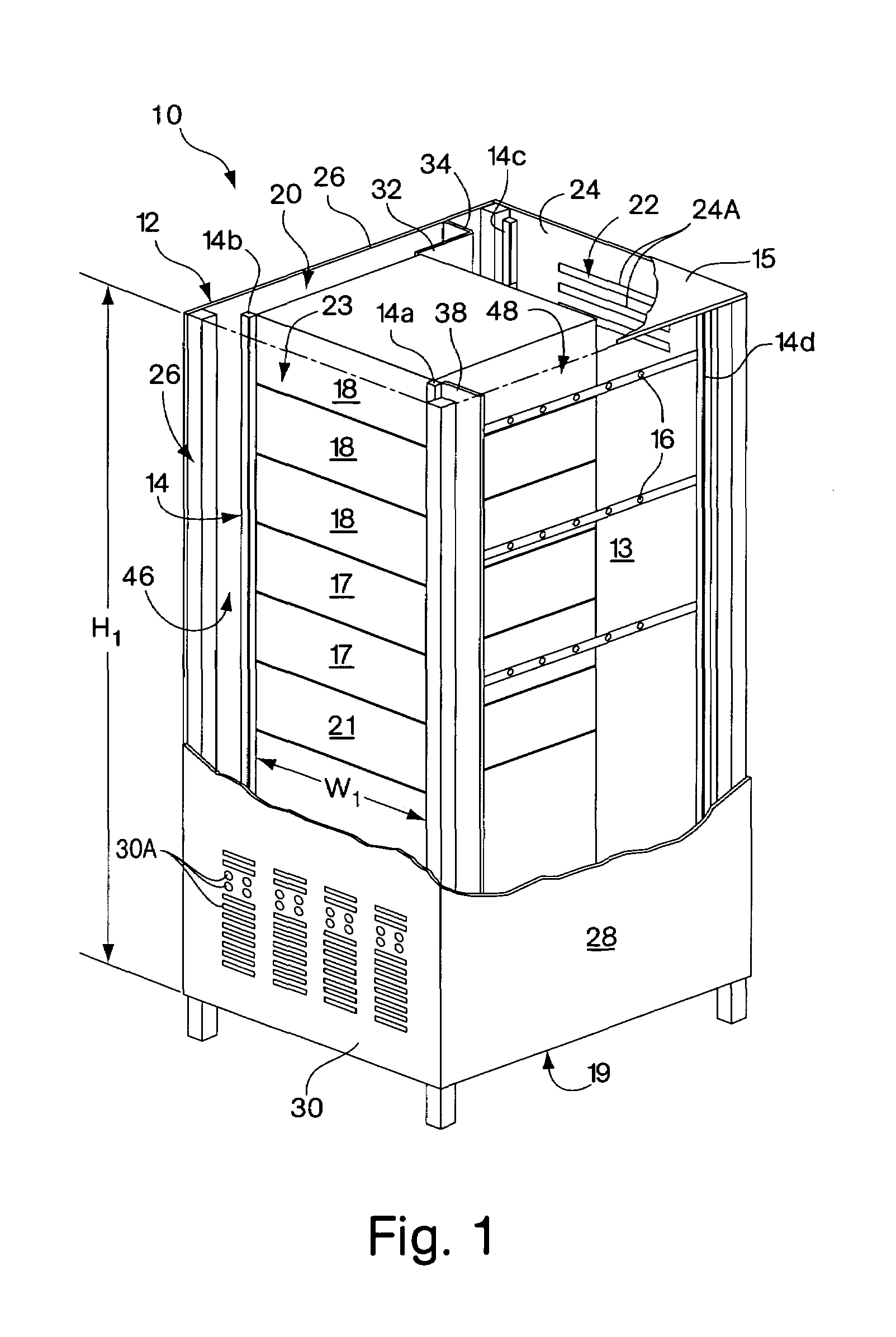

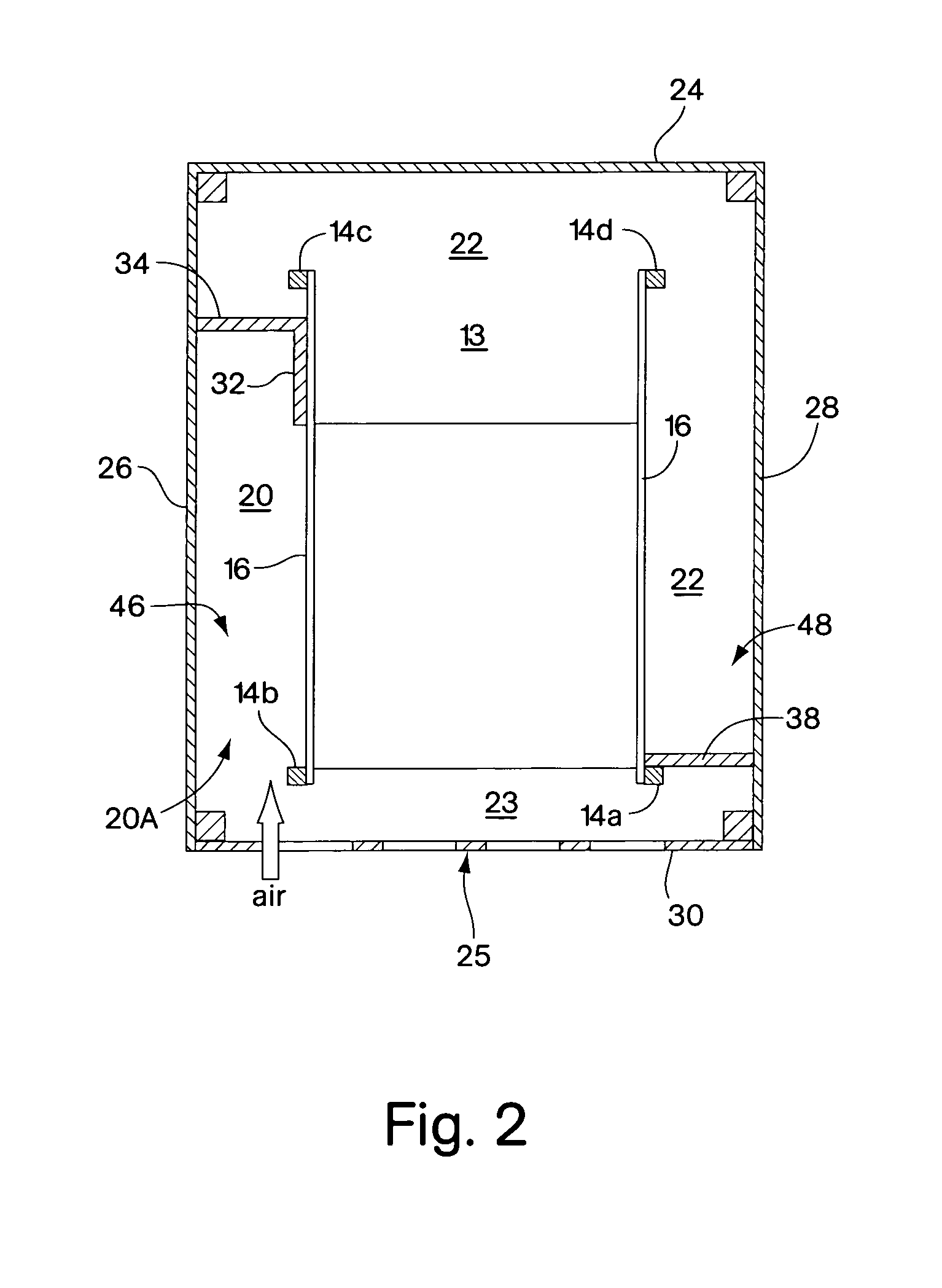

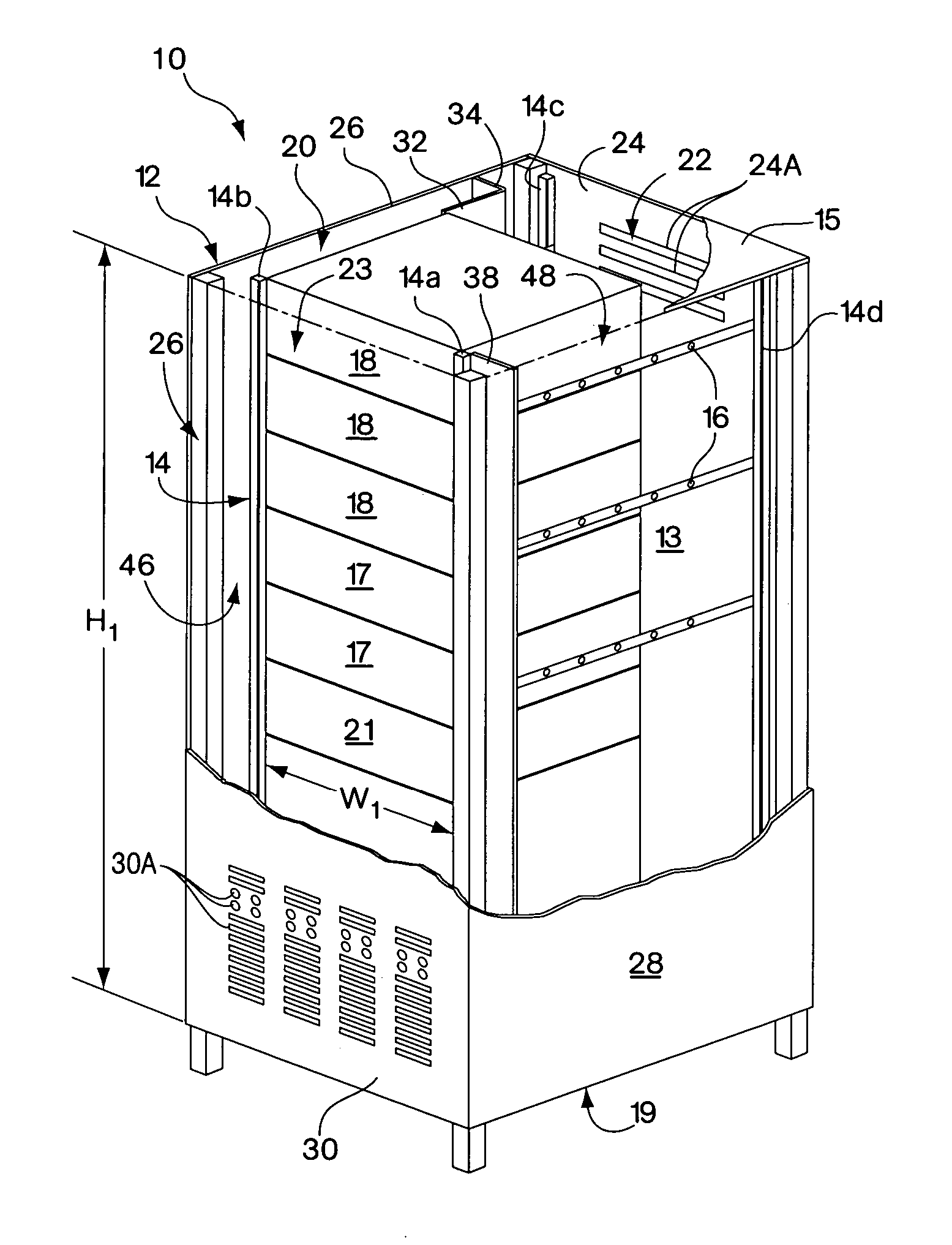

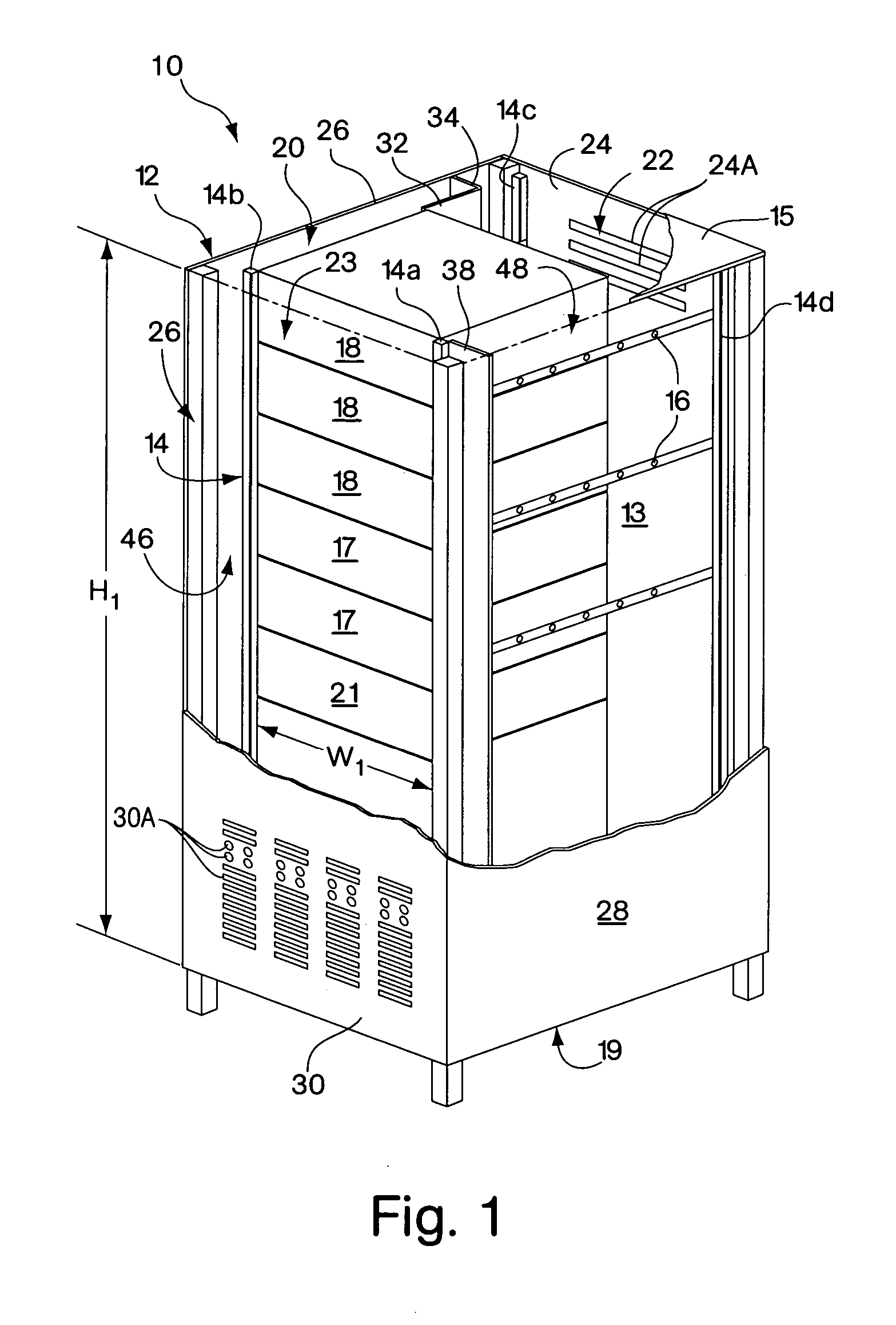

Rack enclosure

ActiveUS7112131B2Avoid overall overheatingPrevent air lossSemiconductor/solid-state device detailsSolid-state devicesData centerTelecommunications equipment

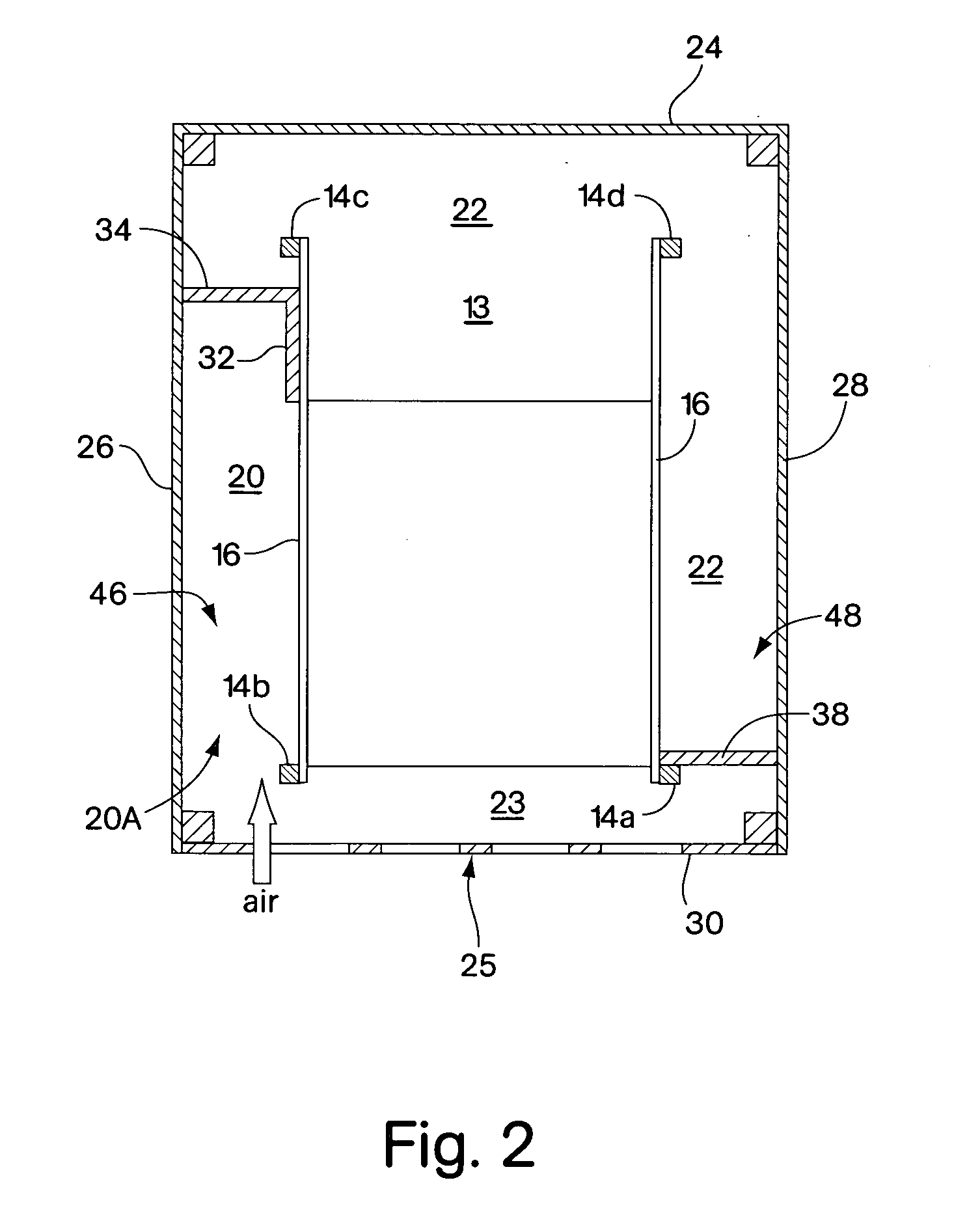

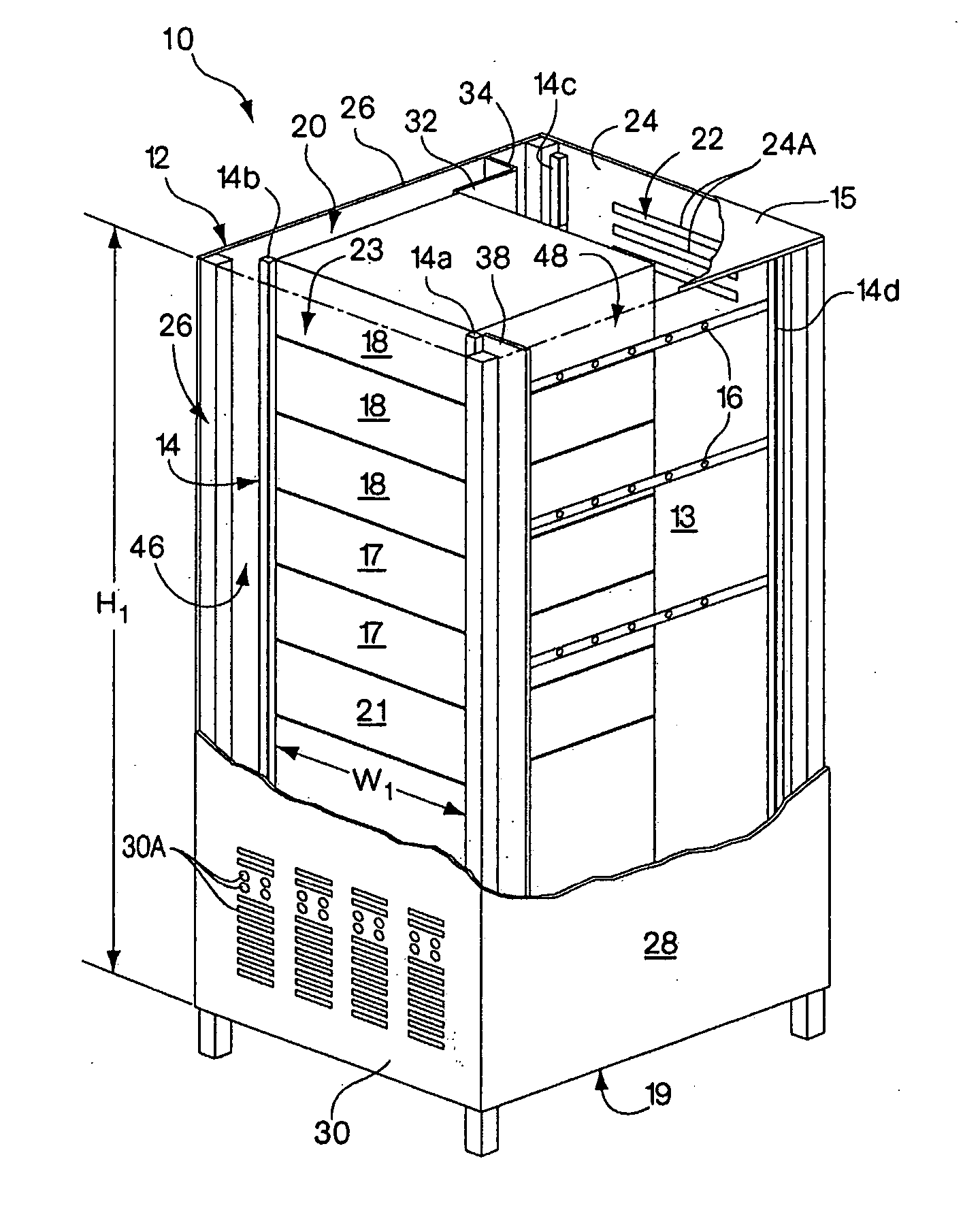

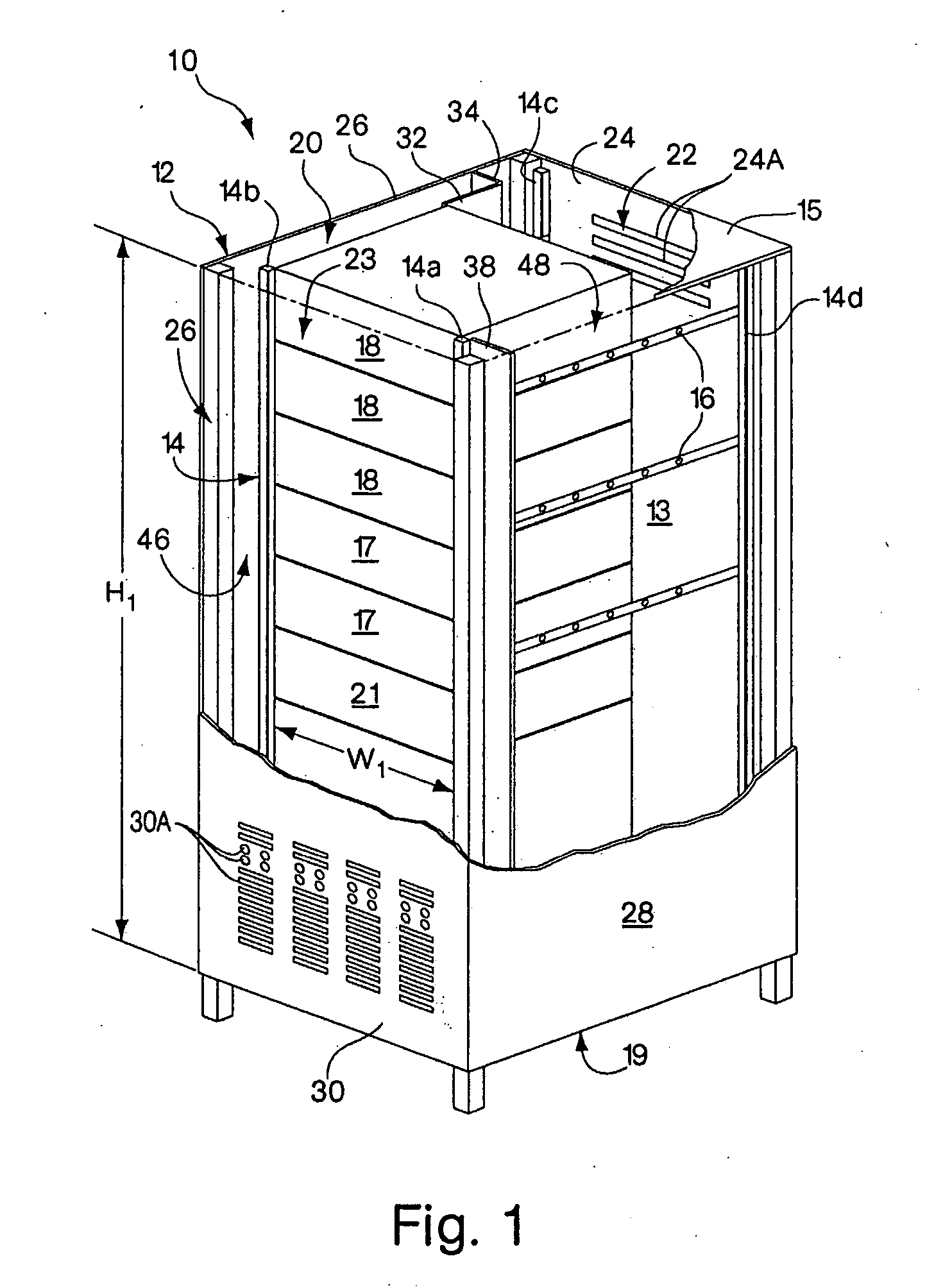

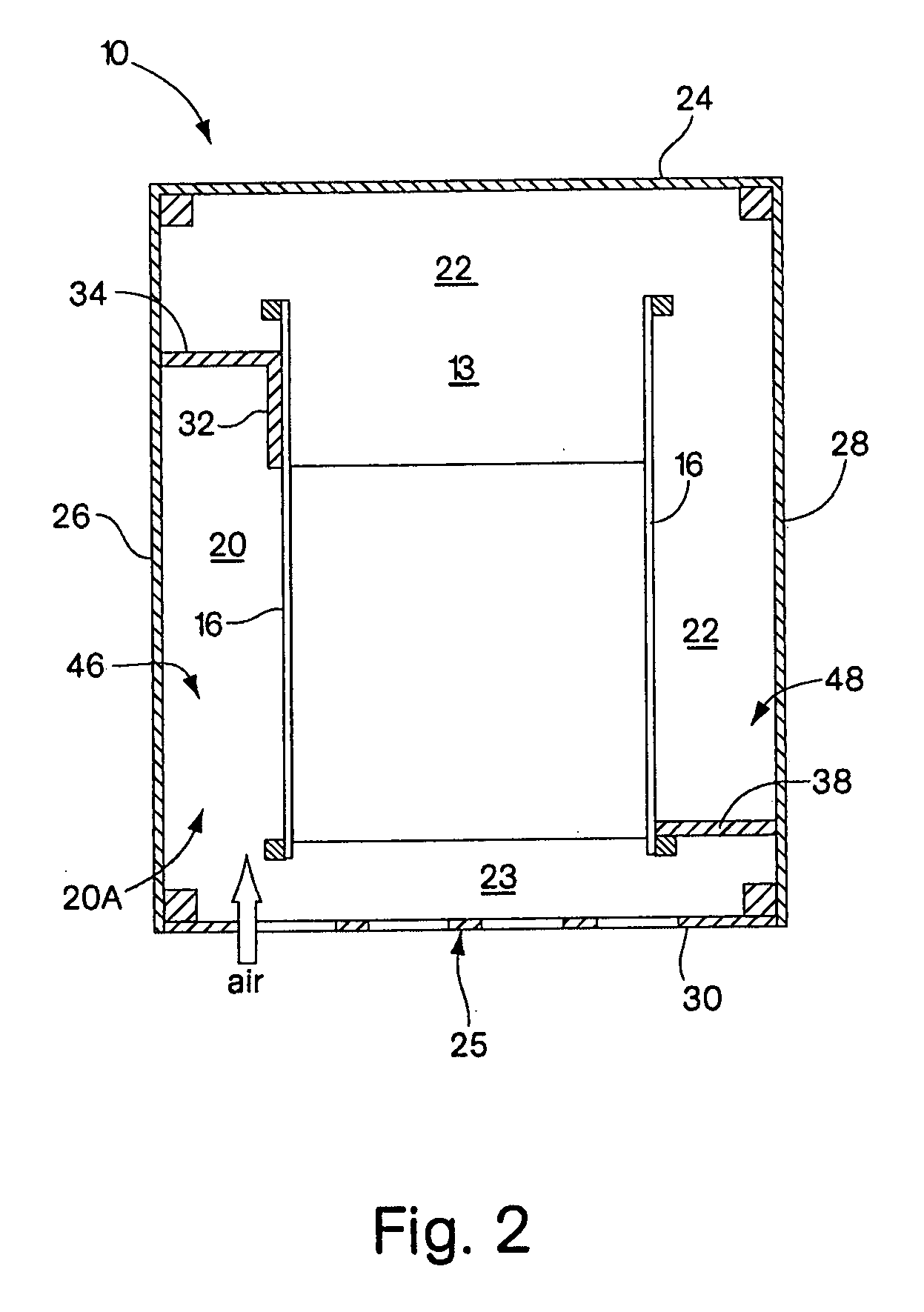

An enclosure is provided for housing electronic equipment that accommodates the different cooling and ventilating requirements of different types of equipment. The enclosure is constructed and arranged to support cooling airflow in a front-to-back configuration through the enclosure and in a side-to-side configuration from one side to an opposite side of the enclosure. The enclosure can thereby provide within a single enclosure means cooling air for components using front-to-back airflow for cooling, such as information technology (IT) equipment, and for components using side-to-side airflow, such as certain types of telecommunications equipment. The enclosure can thereby support a mix of IT and telecommunications equipment, providing flexibility and adaptability in network room and data center configuration. The enclosure is further configured to separate intake air used by equipment for cooling from exhaust air vented by equipment into its interior during operation. As a result, the enclosure promotes sufficient equipment cooling and prevents / minimizes equipment overheating.

Owner:AMERICA POWER CONVERSION CORP

Rack enclosure

ActiveUS7033267B2Improve securityImprove protectionShow cabinetsKitchen cabinetsInformation technologyAirflow

An enclosure is provided for housing electronic equipment that accommodates the different cooling and ventilating requirements of different types of equipment. The enclosure is constructed and arranged to support cooling airflow in a front-to-back configuration through the enclosure and in a side-to-side configuration from one side to an opposite side of the enclosure. The enclosure can thereby provide within a single enclosure means cooling air for components using front-to-back airflow for cooling, such as information technology (IT) equipment, and for components using side-to-side airflow, such as certain types of telecommunications equipment. The enclosure can thereby support a mix of IT and telecommunications equipment, providing flexibility and adaptability in network room and data center configuration. The enclosure is further configured to separate intake air used by equipment for cooling from exhaust air vented by equipment into its interior during operation. As a result, the enclosure promotes sufficient equipment cooling and prevents / minimizes equipment overheating.

Owner:AMERICA POWER CONVERSION CORP

Rack enclosure

InactiveUS20060276121A1Avoid overall overheatingPrevent air lossCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersData centerTelecommunications equipment

Owner:AMERICA POWER CONVERSION CORP

Rack enclosure

InactiveUS20070129000A1Avoid overall overheatingPrevent air lossSemiconductor/solid-state device detailsSolid-state devicesData centerTelecommunications equipment

An enclosure is provided for housing electronic equipment that accommodates the different cooling and ventilating requirements of different types of equipment. The enclosure is constructed and arranged to support cooling airflow in a front-to-back configuration through the enclosure and in a side-to-side configuration from one side to an opposite side of the enclosure. The enclosure can thereby provide within a single enclosure means cooling air for components using front-to-back airflow for cooling, such as information technology (IT) equipment, and for components using side-to-side airflow, such as certain types of telecommunications equipment. The enclosure can thereby support a mix of IT and telecommunications equipment, providing flexibility and adaptability in network room and data center configuration. The enclosure is further configured to separate intake air used by equipment for cooling from exhaust air vented by equipment into its interior during operation. As a result, the enclosure promotes sufficient equipment cooling and prevents / minimizes equipment overheating.

Owner:AMERICA POWER CONVERSION CORP

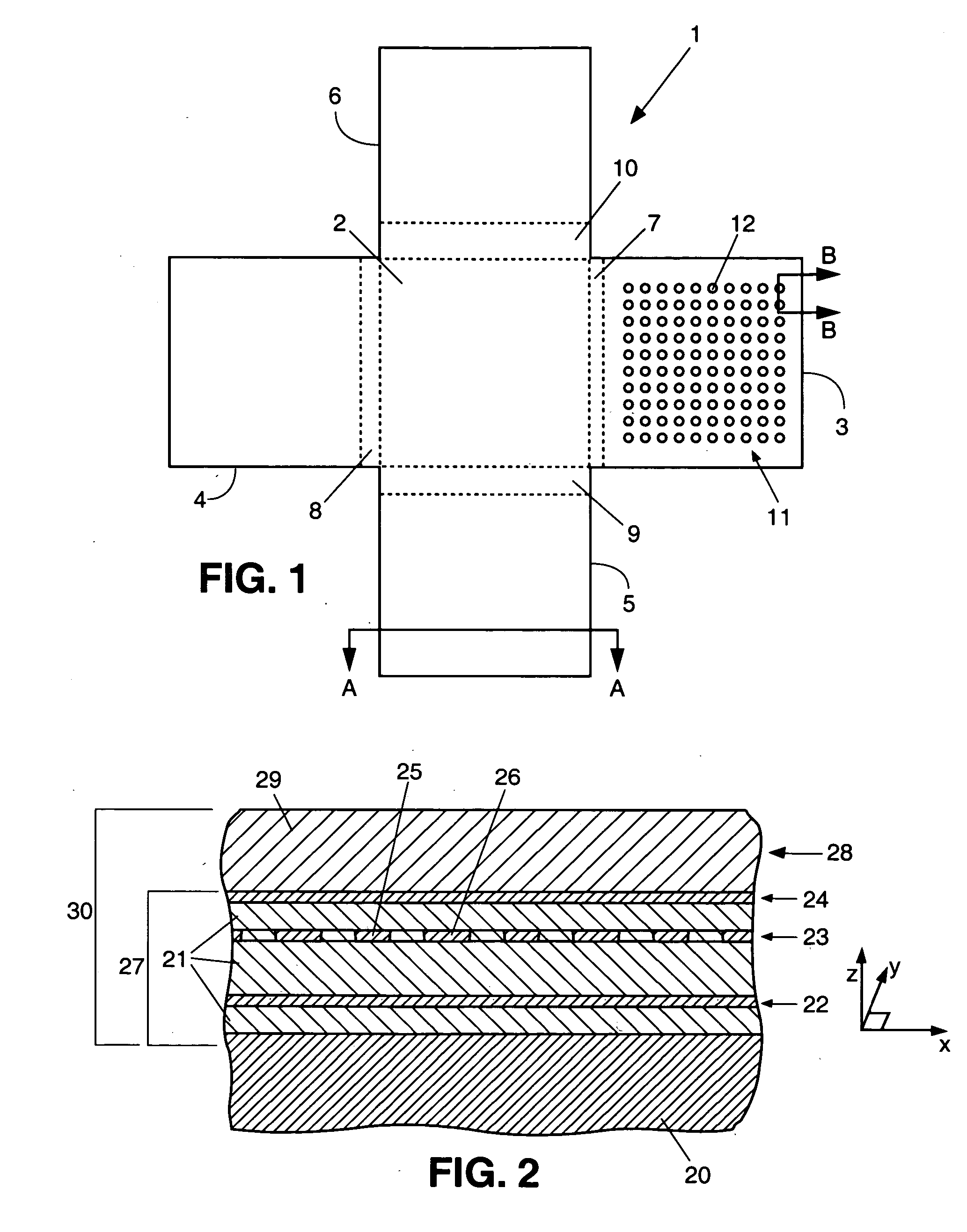

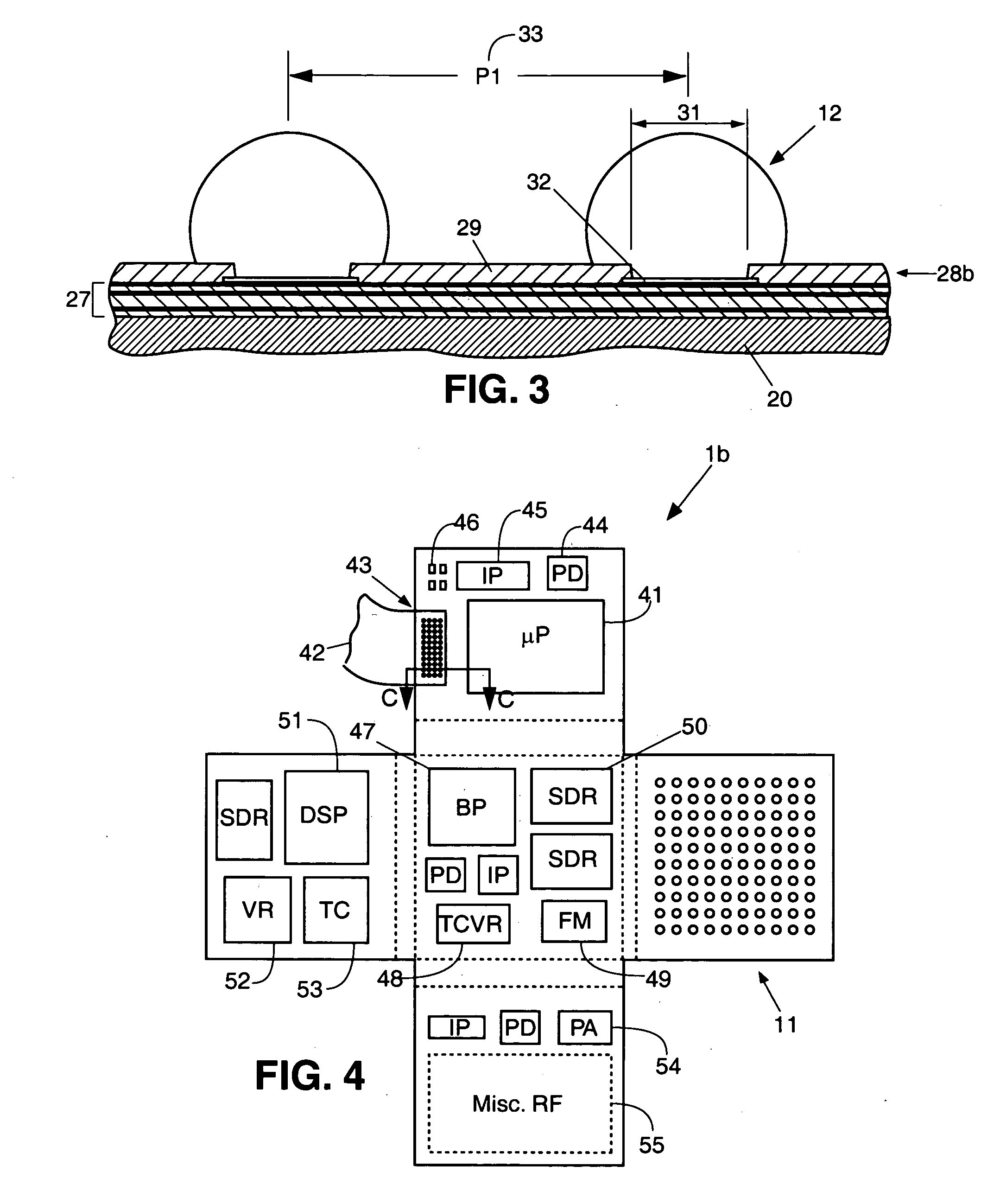

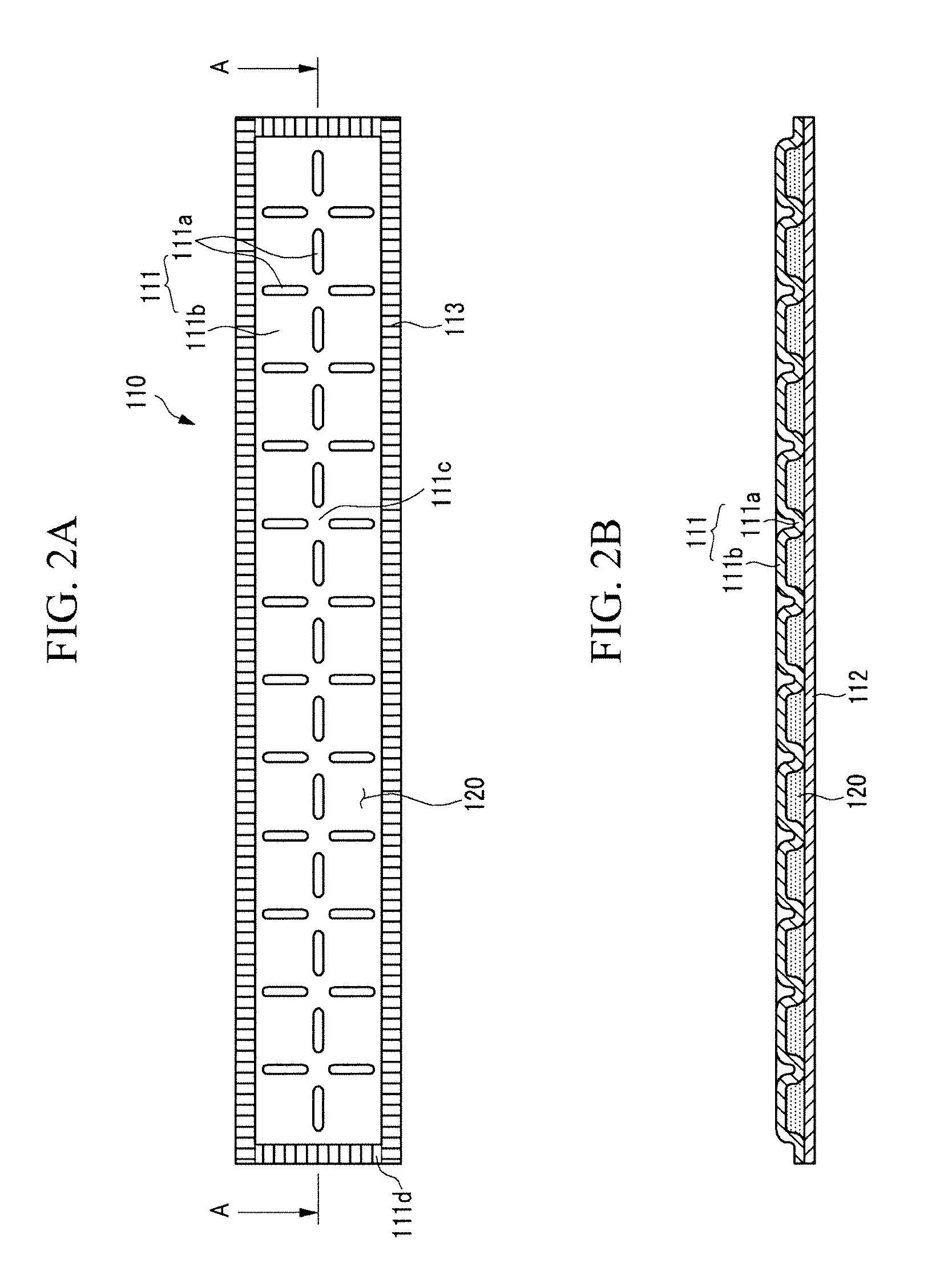

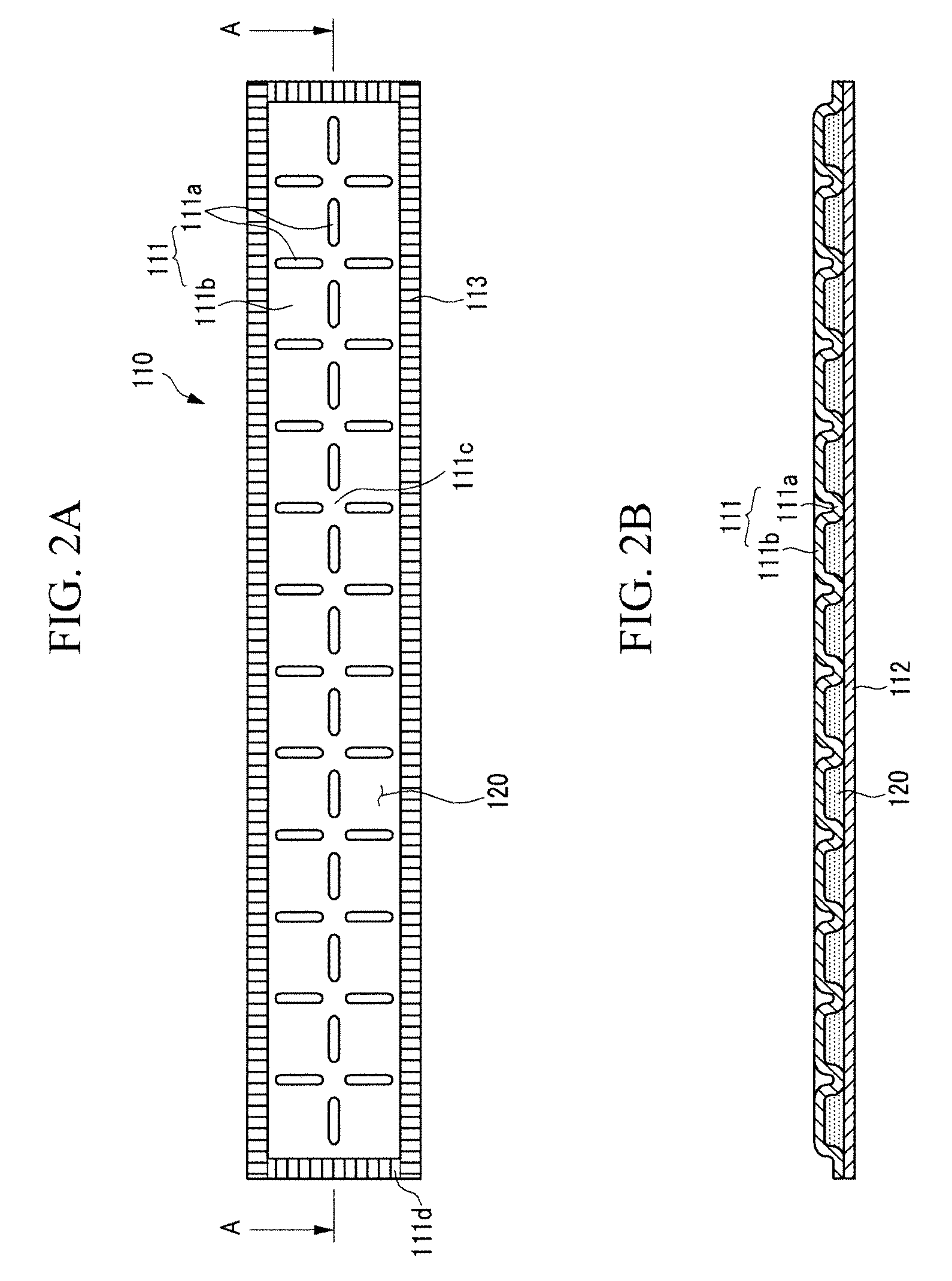

System in package

InactiveUS20050184376A1Improve cooling effectIncrease speedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsCopper conductorBand shape

A system in package (SIP) is fabricated on a sheet of copper foil. An interconnection circuit is fabricated on the foil using copper conductors and a dual damascene structure for each conductive layer. The preferred dielectric material is an amorphous fluorinated polymer called Cytop. Input / output traces of the interconnection circuit terminate in wells filled with solder. Chips are bumped and direct attached by inserting the bumps into the wells. The preferred bumps are gold stud bumps, and the preferred wells contain solder paste to a depth of approximately 15 microns. Imprinting is the preferred method for patterning; it enables 6-micron wide traces, 6-micron diameter vias, and a cost per well of around 0.02 cents. Stripline structures are described for a 4-layer stackup that can support operating frequencies of at least 10 GHz. New methods are proposed for testing the completed assembly and for rework of any chips that prove defective. After the assembly is fully tested and reworked in sheet form the copper foil is folded to form a stacked die package or system in package. 5-high and 9-high stacks are illustrated. The copper foil provides a low impedance thermal path for cooling every chip in the SIP.

Owner:SALMON TECH

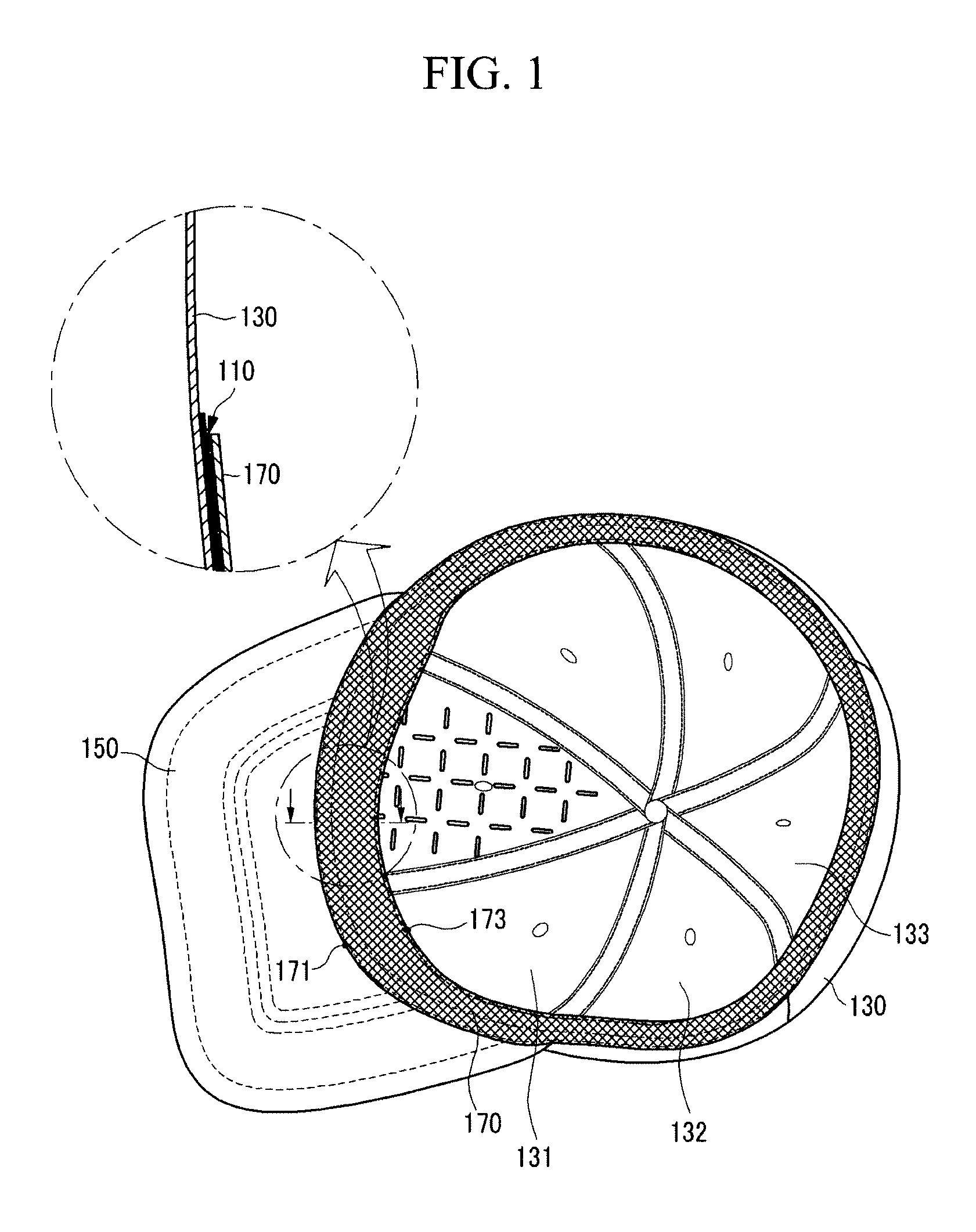

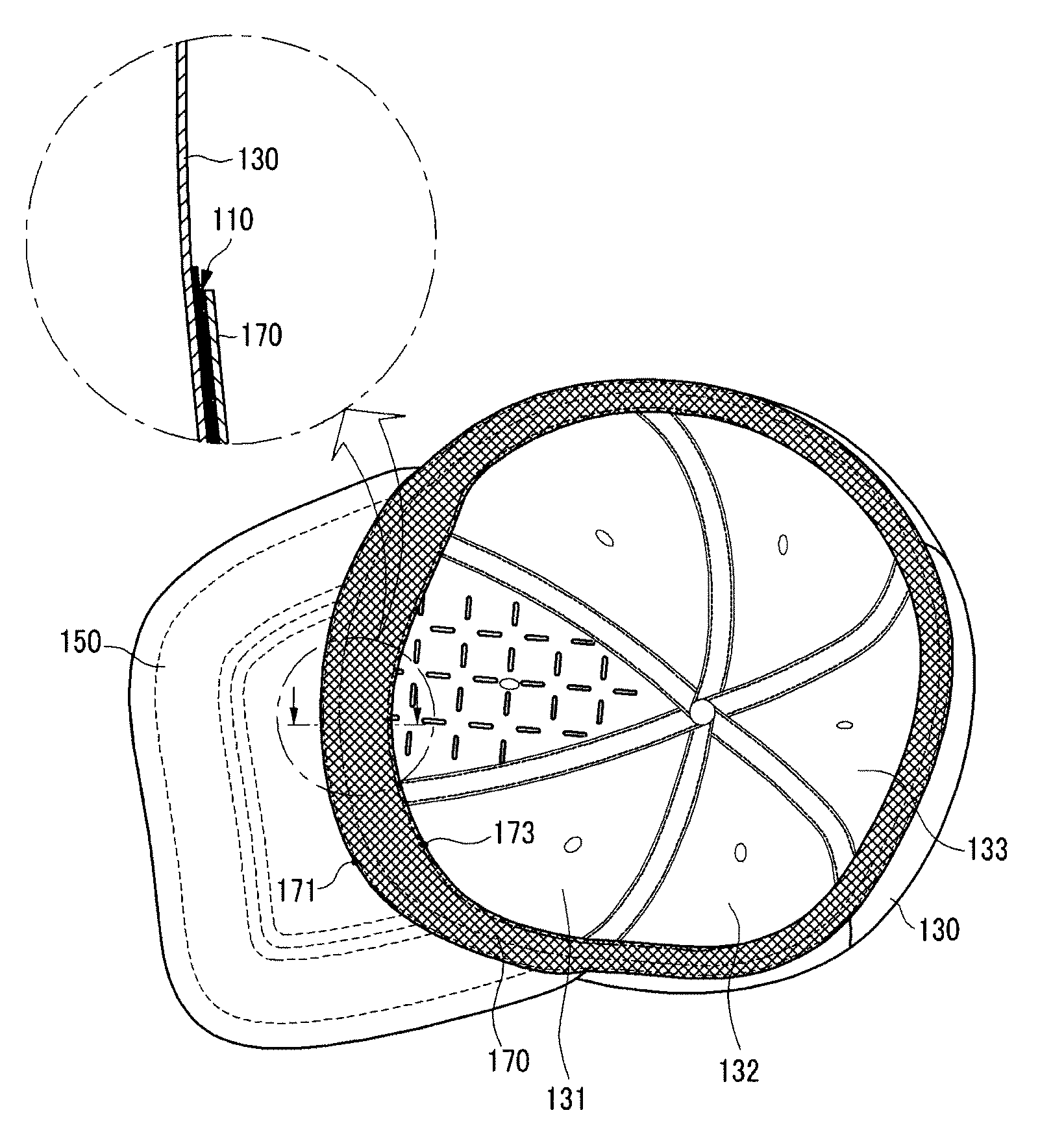

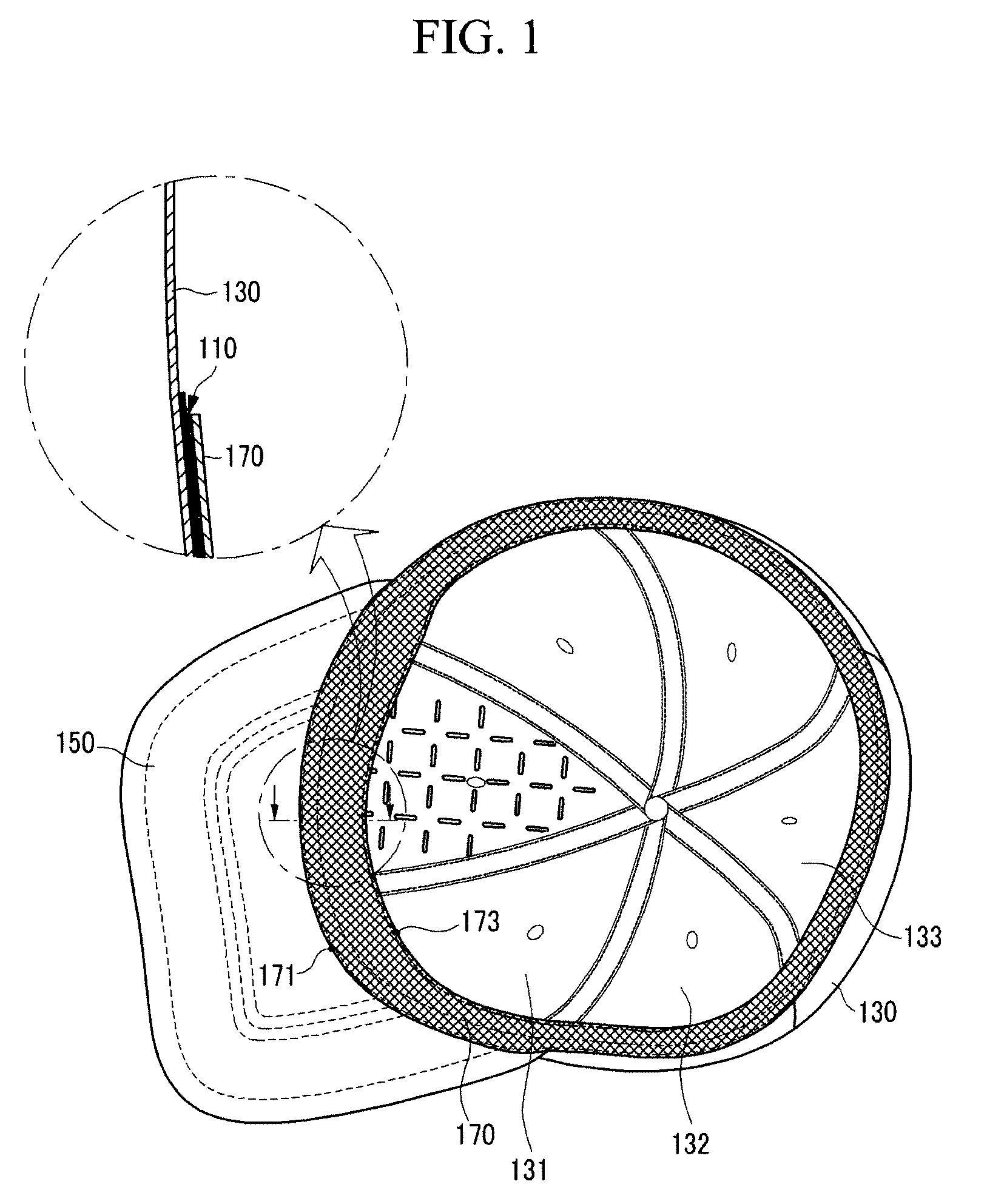

Flexile Plated Cooling Pack of Headwear and Method for Making the Same

ActiveUS20100083421A1Easy to carryEasy to keepHeat storage plantsHeat-exchange elementsCooling effectEngineering

The present invention relates to a flexible plated cooling pack for headwear and a method for making the same that is capable of providing a sufficient cooling effect with a small amount of coolant, not causing worry about leakage of the coolant, and providing a cushion effect without a volume variance regardless of many uses, as well as the cooling effect.The flexible plated cooling pack has an inner and outer synthetic resin film sheet bonded each other and a coolant filled therein, wherein the outer synthetic resin film sheet has a shape respectively corresponding to a piece of the crown portion and a sweatband and the coolant is always maintained in at least a gel state. The flexible plated cooling pack may be disposed in an inner portion of the crown portion and the sweatband of the headwear or may be inserted in a pocket formed at an inner portion of the crown portion and the sweatband of the headwear.

Owner:YUPOONG

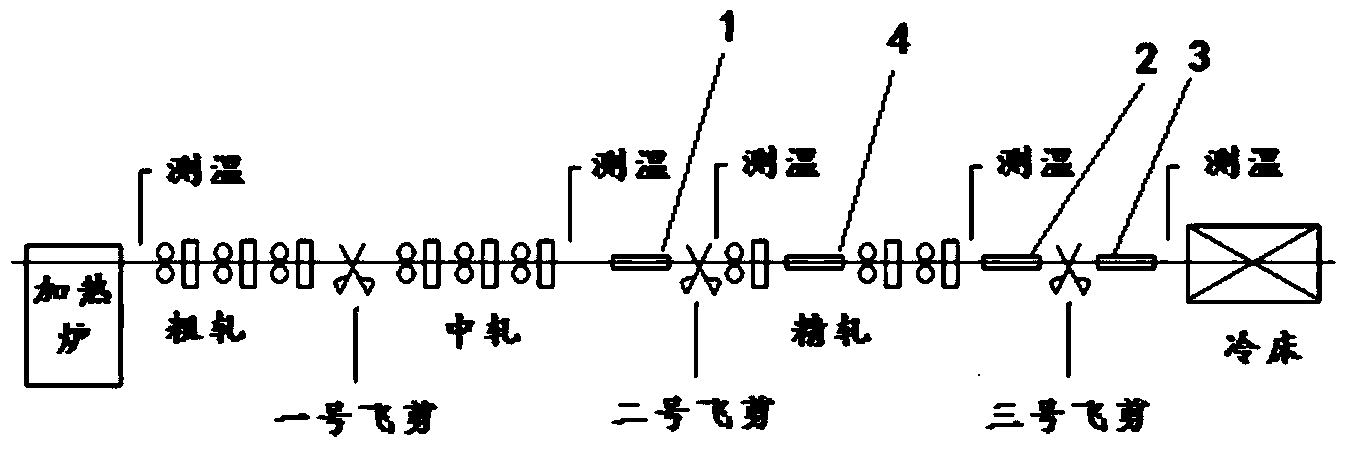

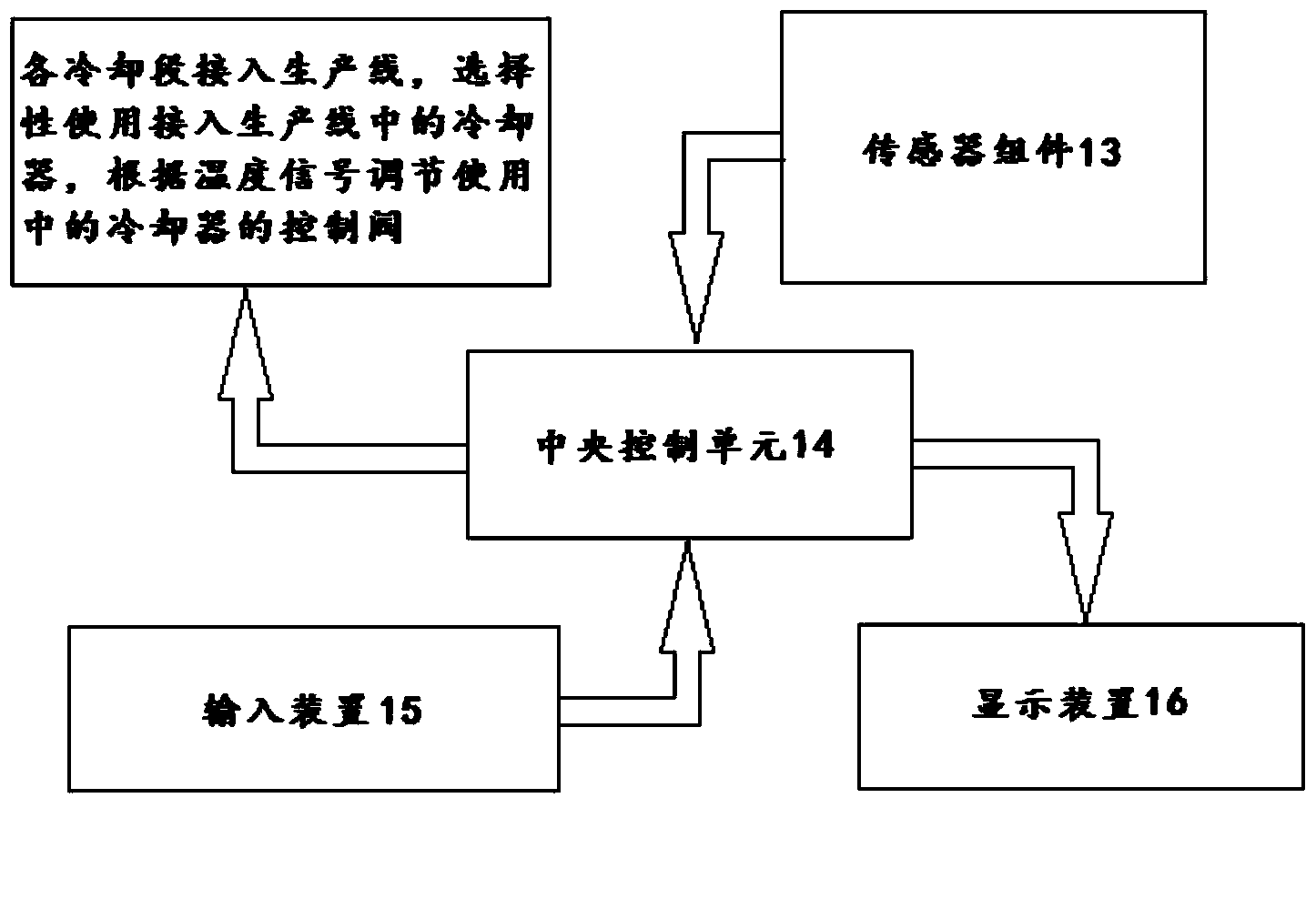

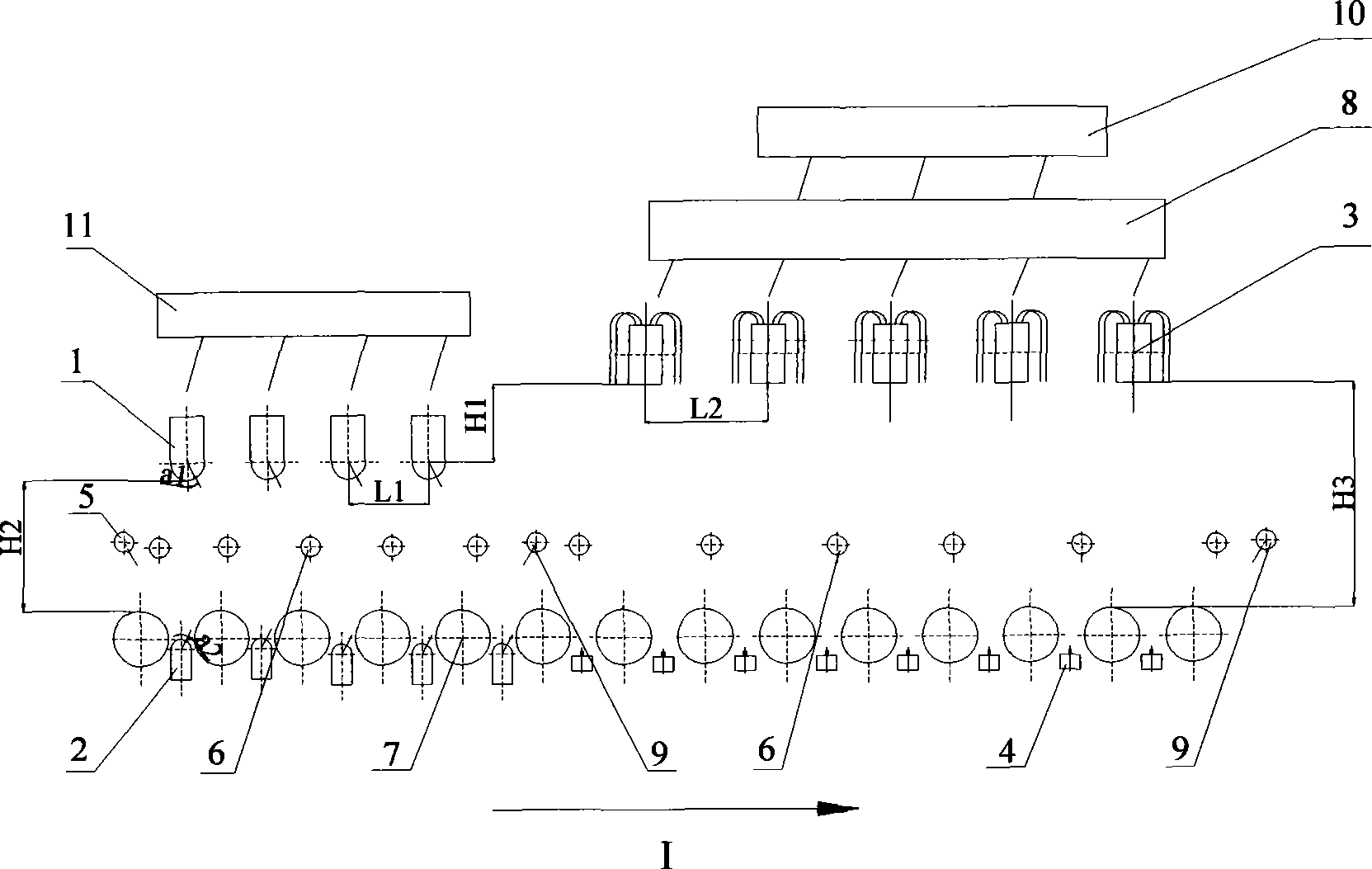

Controlled rolling and controlled cooling system for bars

ActiveCN103551403APrevent "overcooling"Large temperature difference in the axial directionTemperature control deviceWork treatment devicesProduction lineEngineering

A controlled rolling and controlled cooling system for bars comprises a first cooling section at the position of an outlet of an intermediate mill group, a machine cooling section of a finishing mill group, a second cooling section between the finishing mill group and a third flying shear, a third cooling section between the third flying shear and a cooling bed, a sensor module and a central control unit. The first cooling section, the second cooling section and the third cooling section respectively comprise one or a plurality of cooling lines arranged on a horizontal moving trolley and a bypass roll table, one cooling line or the bypass roll table can be selectively connected to a production line by horizontally moving the horizontal moving trolley, and every production line comprises one or a plurality of series connection coolers. Every cooler is connected to a water supply main pipe through one water supply branched pipe, control valves are arranged in the water supply branched pipes, and the coolers connected to the production lines are selected and used by opening and closing of the control valves. According to the controlled rolling and controlled cooling system, a plurality of cooling sections can be selected flexibly, the coolers in every cooling section can also be selectively used simultaneously, and accordingly the system not only is good in applicability, but also improves bar finished product performances.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

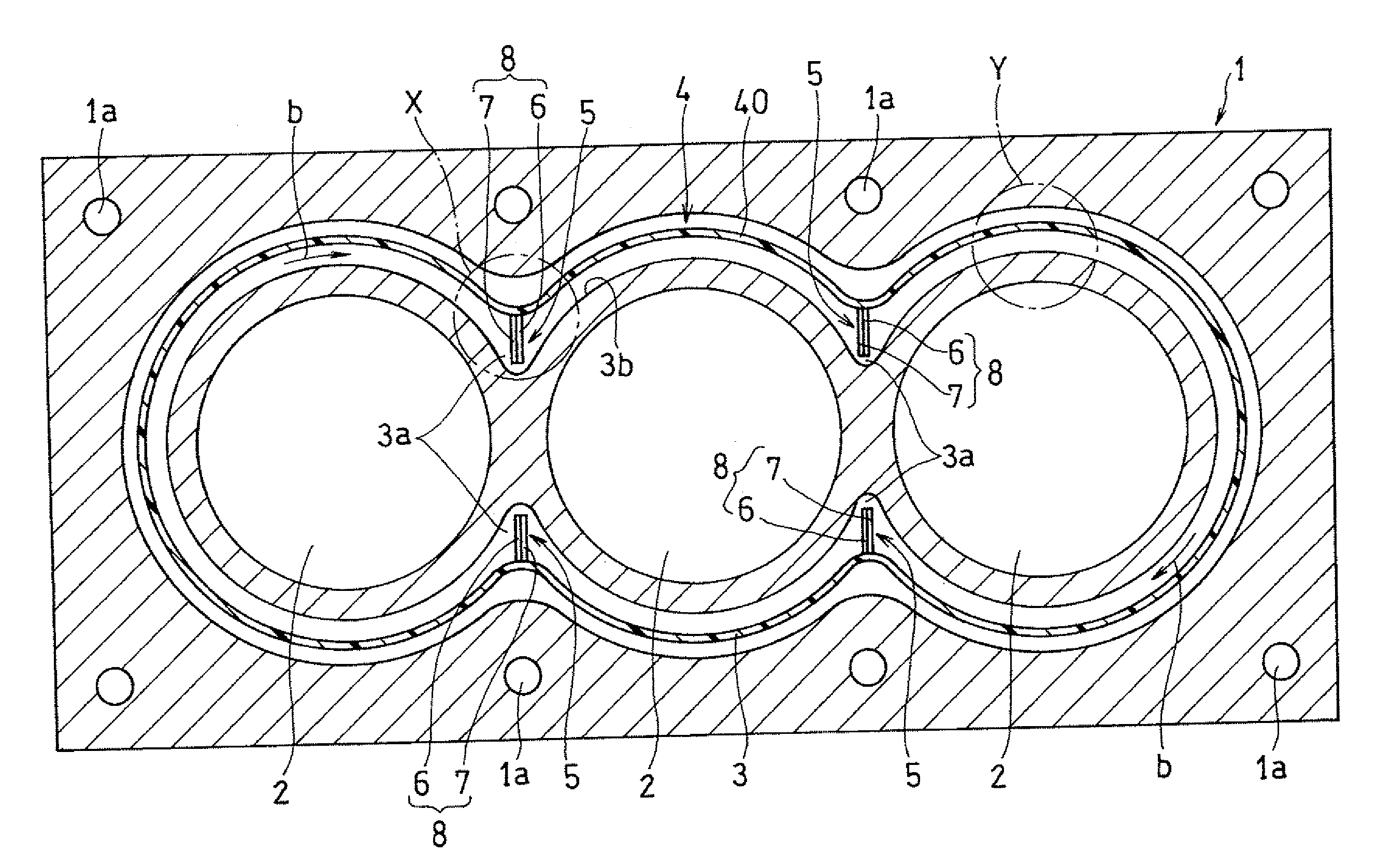

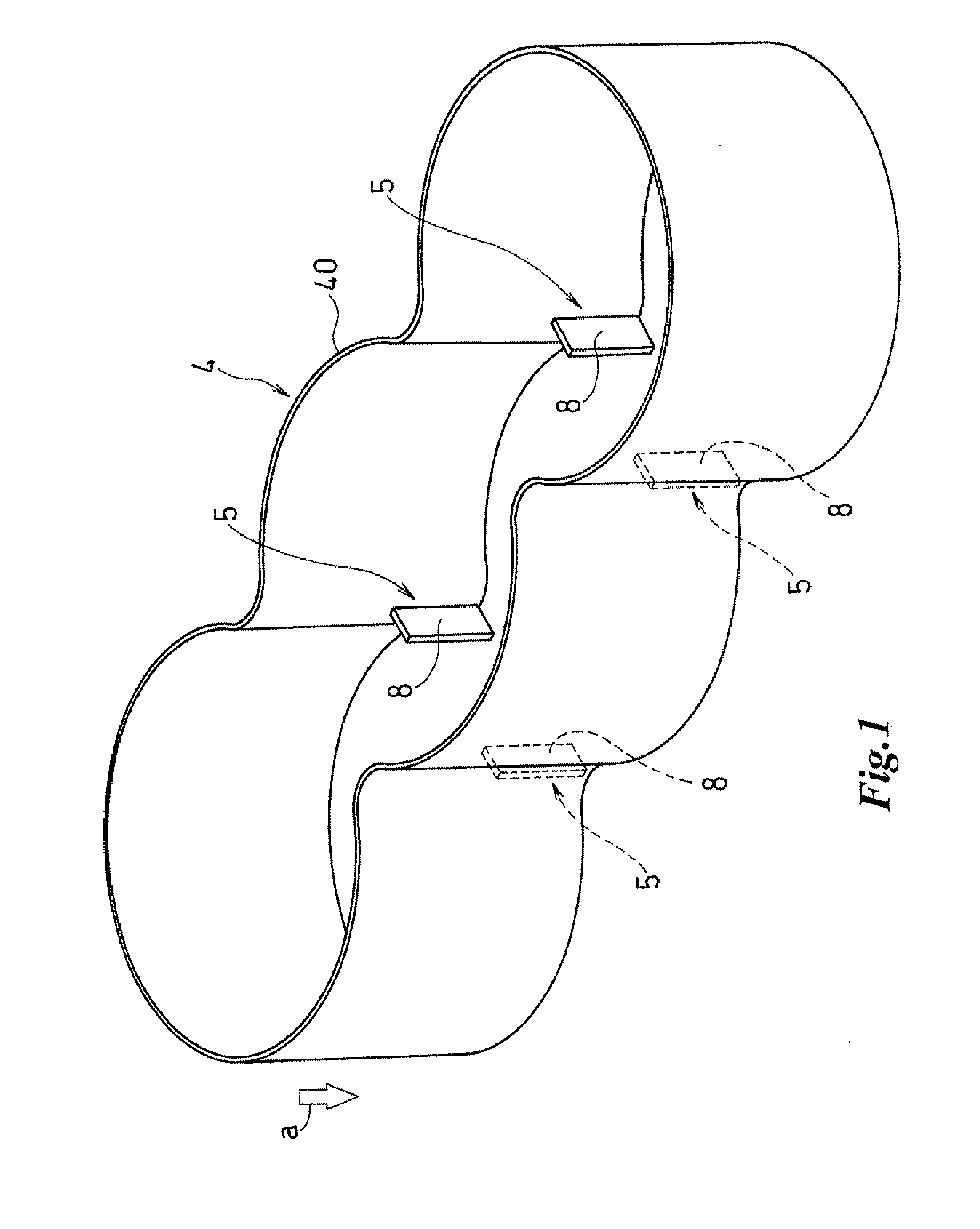

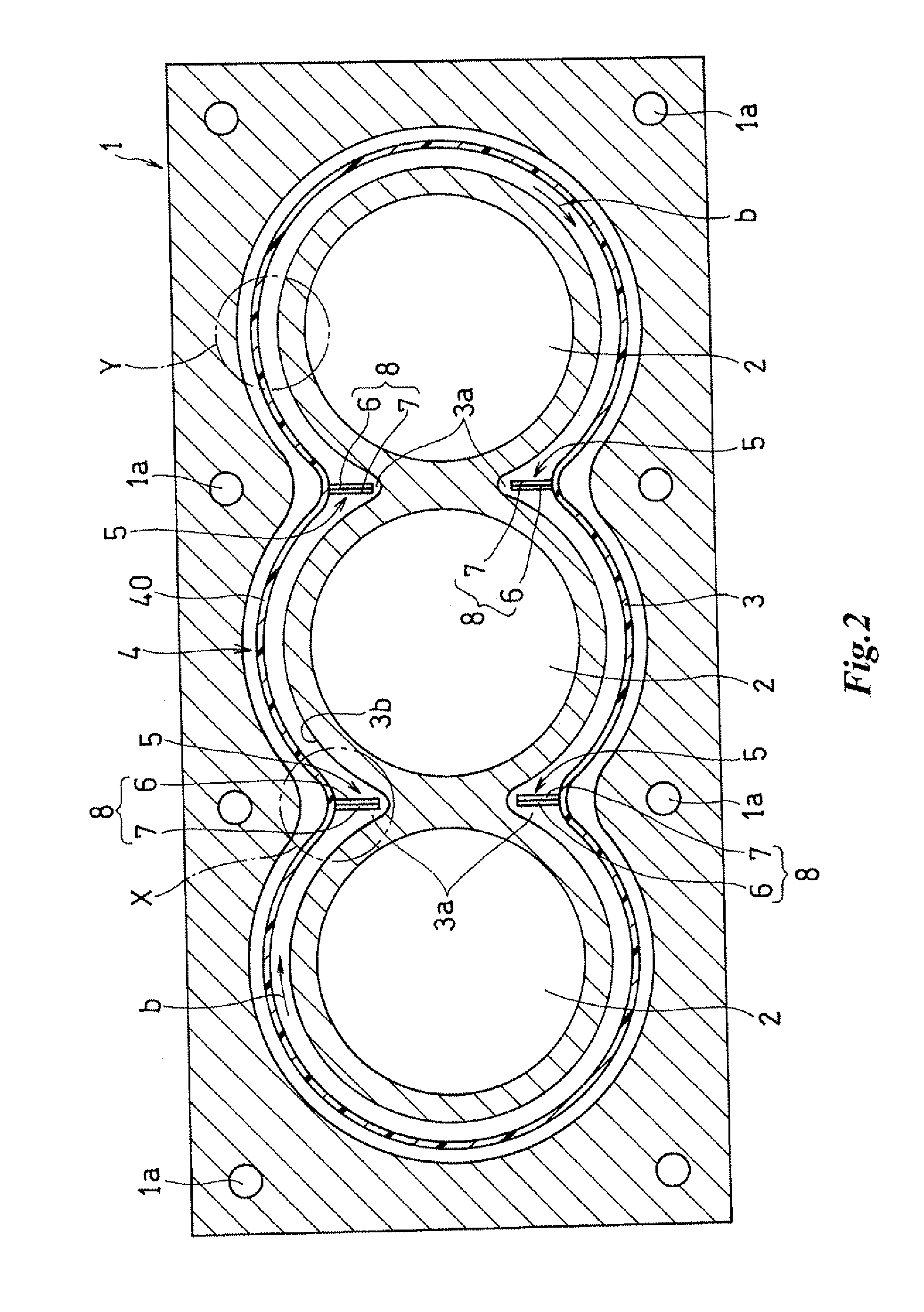

Water Jacket Spacer

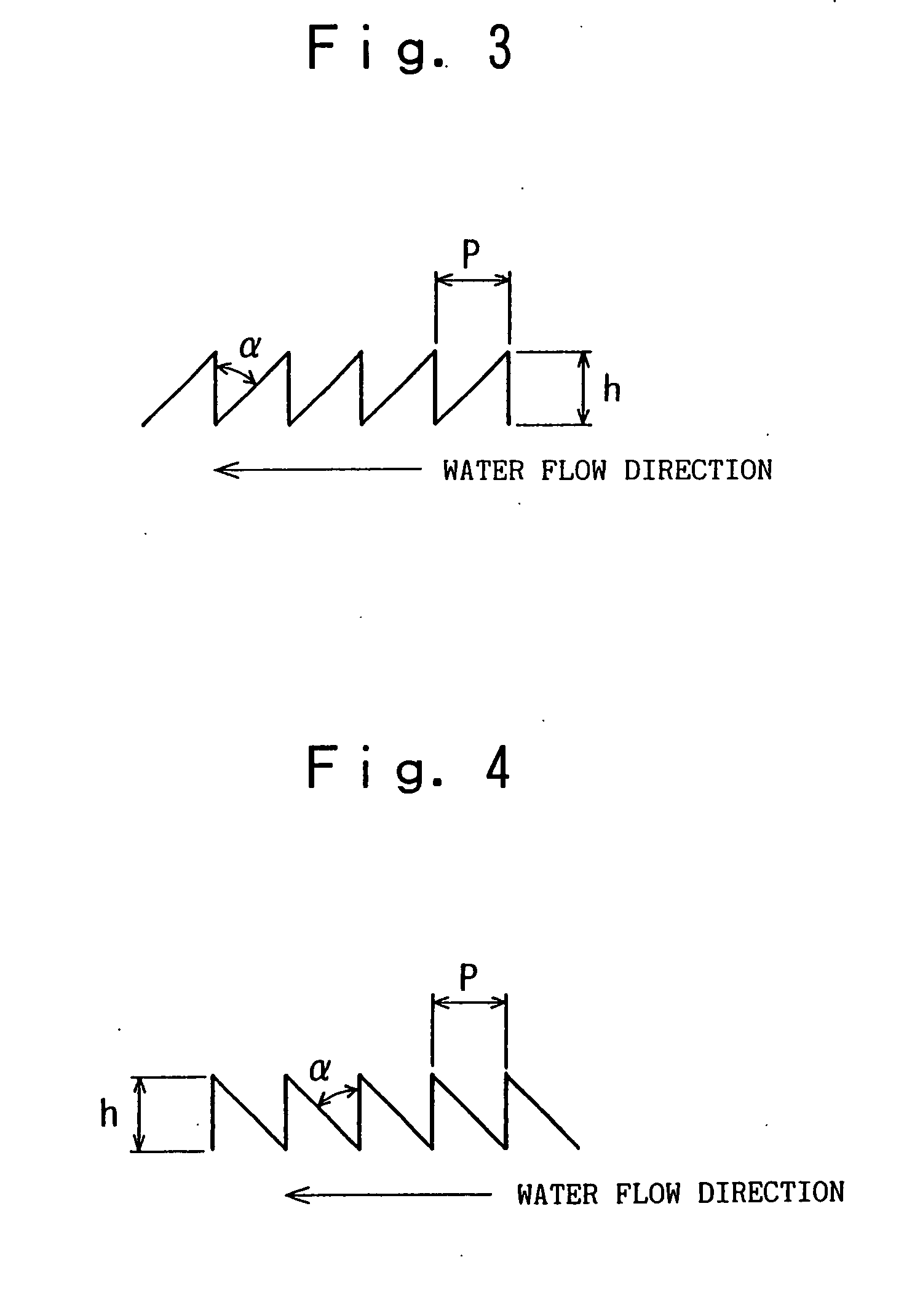

InactiveUS20120132157A1Guaranteed smooth assemblySimple processLiquid coolingCylinder headsElastomerWater flow

A water jacket spacer has a spacer body molded in conformity to the shape of the water jacket and a regulating member whose one side is fixed to the spacer body. The regulating member is composed of a first member which is not water-swellable and is elastically deformable and a second member made of water-swellable elastomer which is integrally fixed to the first member. The regulating member lies in a state not-contacting an opposed wall of the water jacket when inserted into the water jacket together with the spacer body, whereas it blocks a part of cooling water flowing through the water jacket by deforming such that a side of the regulating member not fixed to the spacer body faces toward the opposed wall of the water jacket when the second member swells by absorbing cooling water flown into the water jacket and thereby the first member is elastically deformed.

Owner:UCHIYAMA MFG

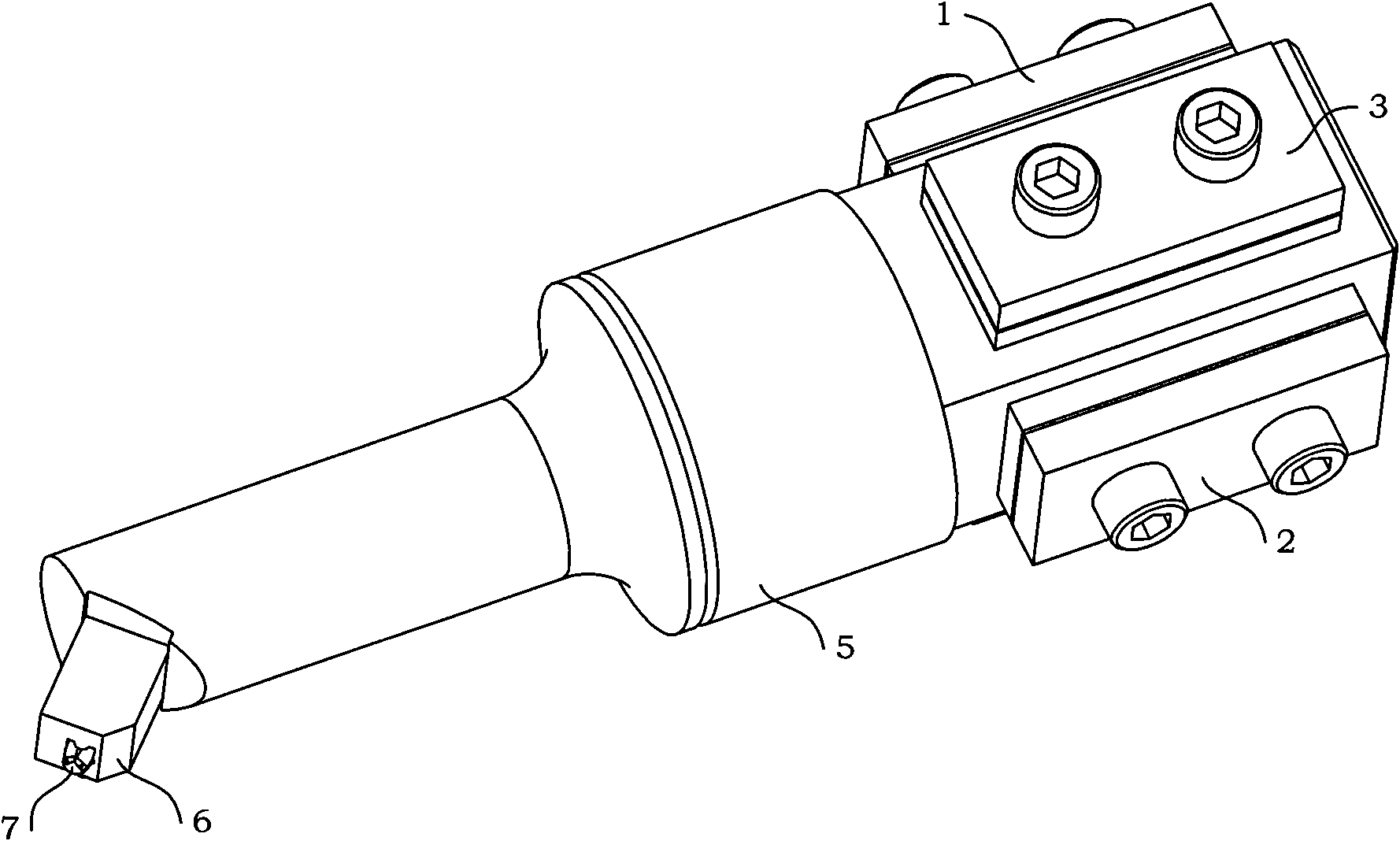

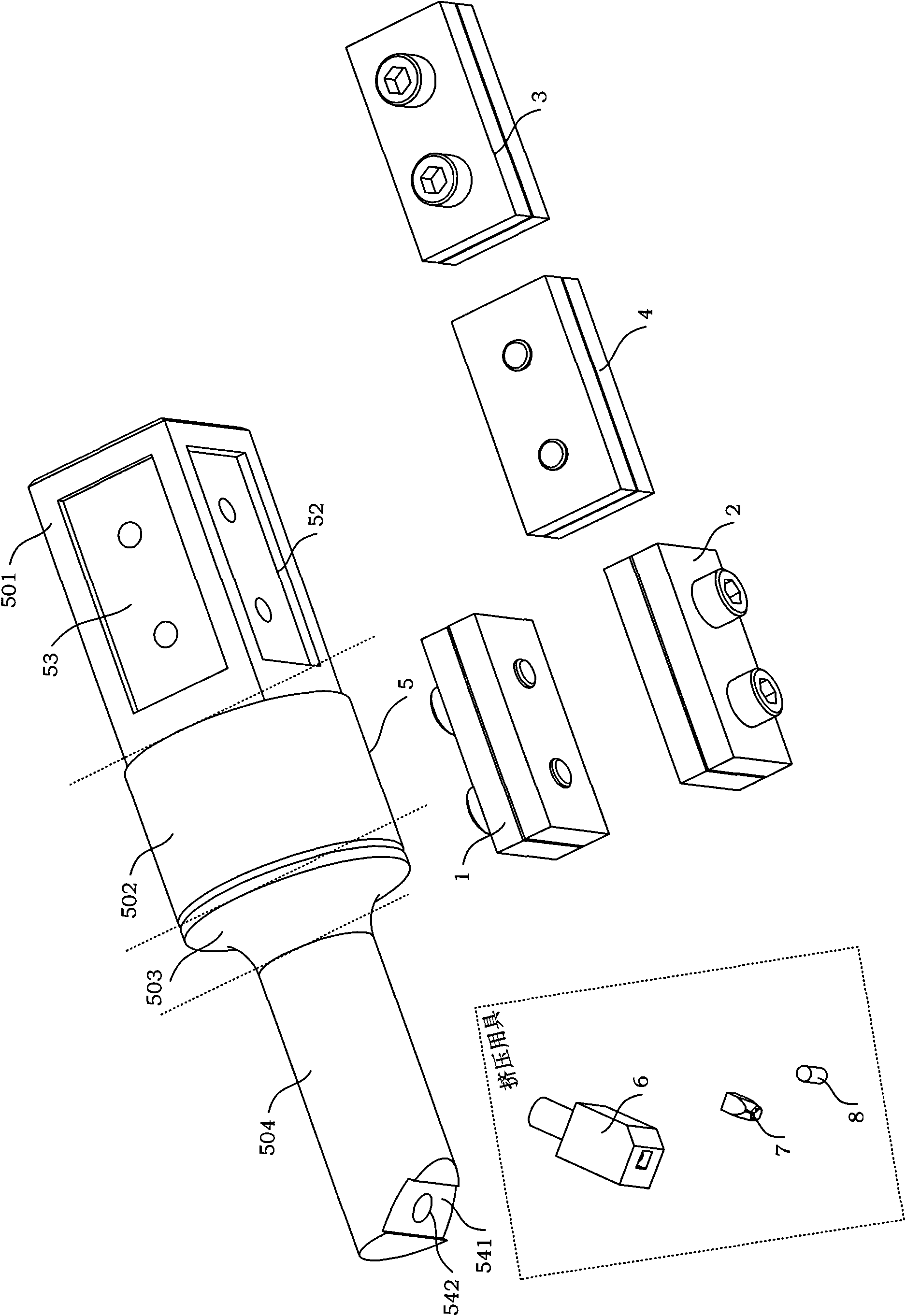

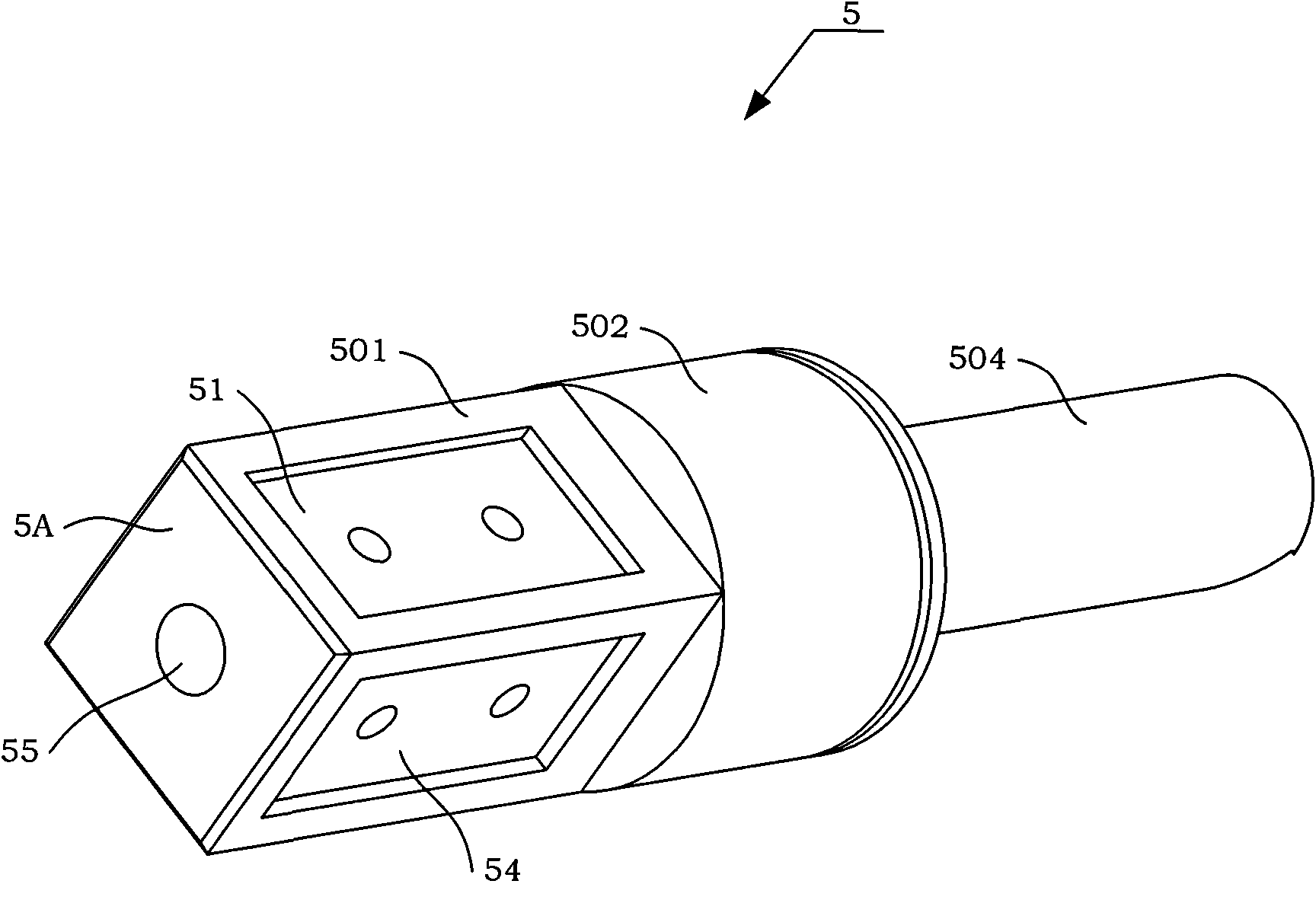

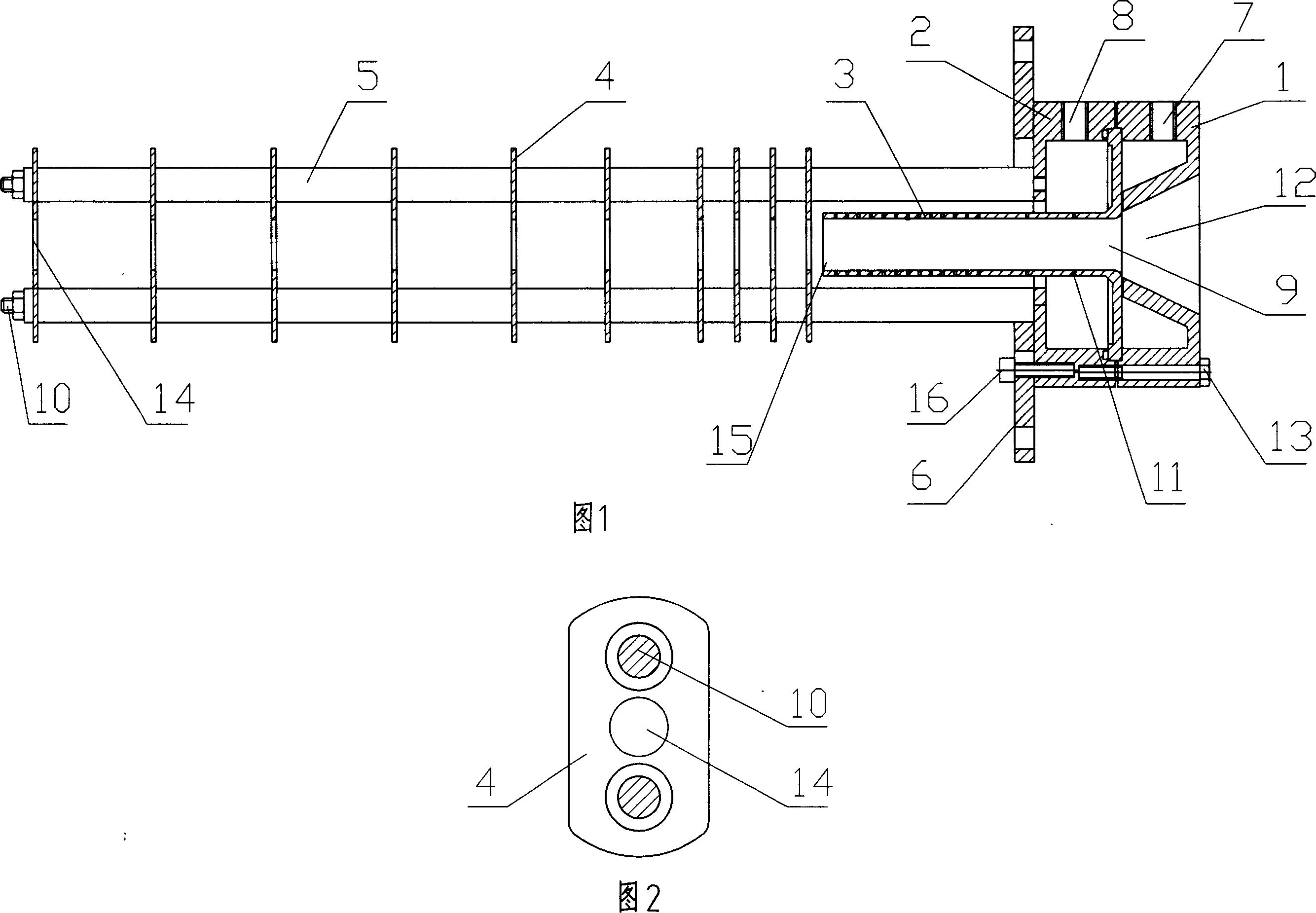

Ultrasonic elliptical vibration extrusion device and vibration extrusion processing method for carrying out surface finishing of part by using same

InactiveCN101942547AReduce volumeLow calorific valueMechanical vibrations separationEllipseTransformer

The invention discloses an ultrasonic elliptical vibration extrusion device and a vibration extrusion processing method for carrying out surface finishing of a part by using the same. The ultrasonic elliptical vibration extrusion device comprises an amplitude transformer, four excitation sources with the same structure and an extrusion tool, wherein the extrusion tool is arranged on the output section of the amplitude transformer; and the four excitation sources are respectively arranged in the four grooves of the excitation section of the amplitude transformer. In the vibration extrusion processing process, an extrusion head makes the ultrasonic vibration in an elliptic orbit relative to the processed surface of the part under the driving of the excitation sources through adjusting an extrusion contact angle between the part and the diamond extrusion head and the processing parameters of ultrasonic elliptical vibration extrusion device. On one hand, the device reduces an extrusion force by utilizing the pulse impact action of the ultrasonic vibration, and thereby, the extrusion process can be applied to thin-wall parts and long and thin parts; on the other hand, the front direct impact is avoided and the sliding friction of the extrusion head and the processed surface of the part is reduced even eliminated by utilizing the separation characteristic and the movement locus characteristic of the elliptical vibration, and thereby, the surface roughness of the processed surface of the part is reduced, and the service life of the extrusion head is prolonged.

Owner:BEIHANG UNIV

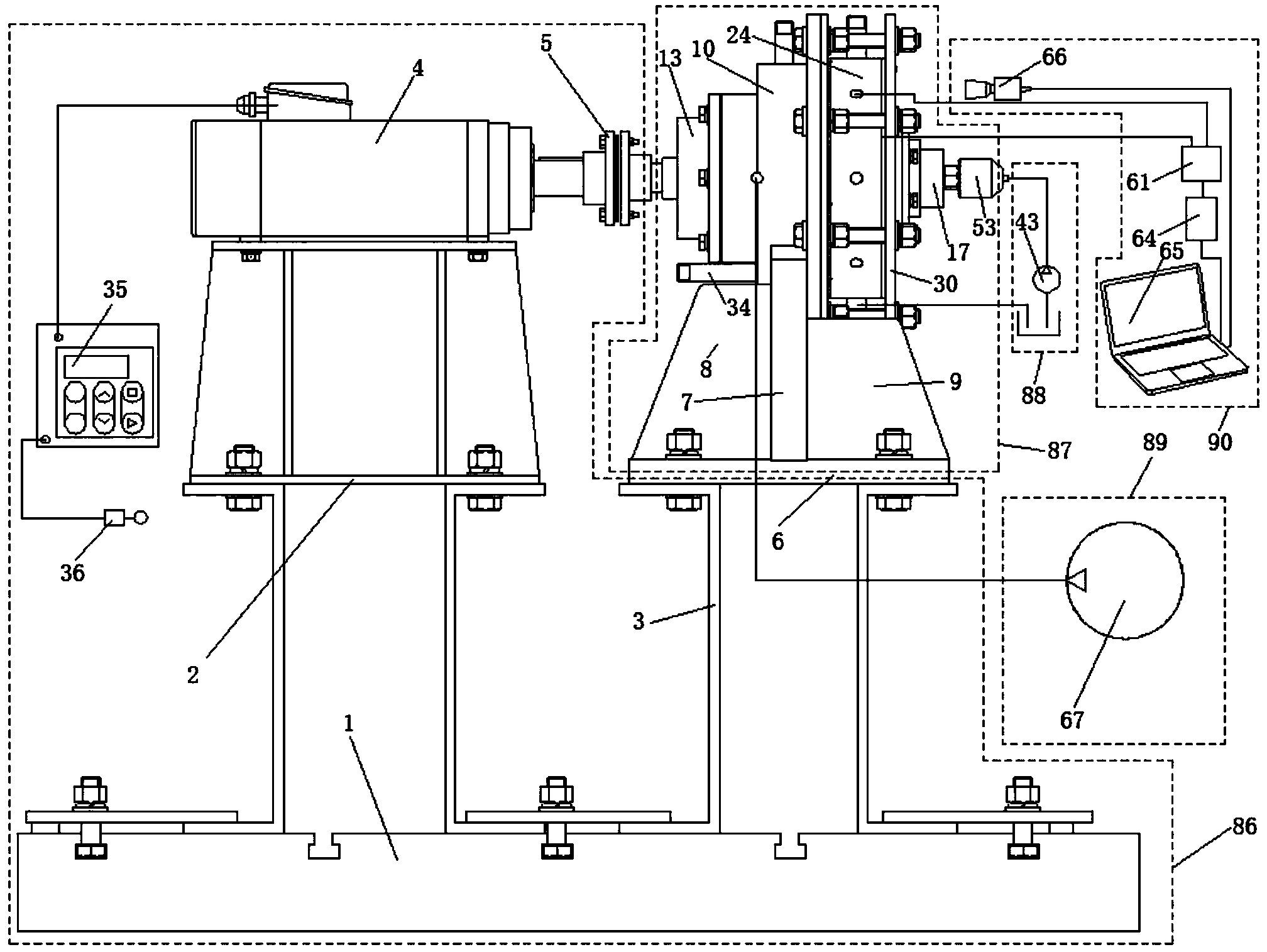

Bearing chamber oil and gas two-phase flow and heat exchange testing device

InactiveCN104034506AReduce distractionsWill not polluteMachine part testingAerodynamic testingFuel tankAxial distance

The invention provides a bearing chamber oil and gas two-phase flow and heat exchange testing device. The structure that a testing bearing and a shaft are directly arranged in a sleeved mode is designed. An oil transportation hole or groove is designed in the inner ring of the testing beaming or the inner ring of the shaft. A testing beaming lubricating structure is simplified under the circumstance that under-ring lubrication of the testing beaming is guaranteed. An electric heating type chamber body heating structure is designed, and the structure of the electric heating type chamber body heating structure is simplified compared with a tap water heating and cooling method, so that cost is reduced. Bearing chamber geometric structures of different sizes can be realized through replacement of axial distance rings of different sizes and radial distance rings of different sizes, and the cost of manufacturing a chamber body is reduced. An oil scavenger pump is additionally arranged so that oil can return smoothly, and the lubricating oil does not accumulate in a chamber. An exhaust vent is connected with an oil return tank through an oil way, so that the situation that oil mist is exhausted from an exhaust pipe and pollutes the environment is avoided, and waste of the lubricating oil is avoided. A high-speed camera is arranged to shoot oil and gas conditions inside the bearing chamber, so that oil and gas condition images and pressure and temperature signals are recorded on a computer synchronously.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

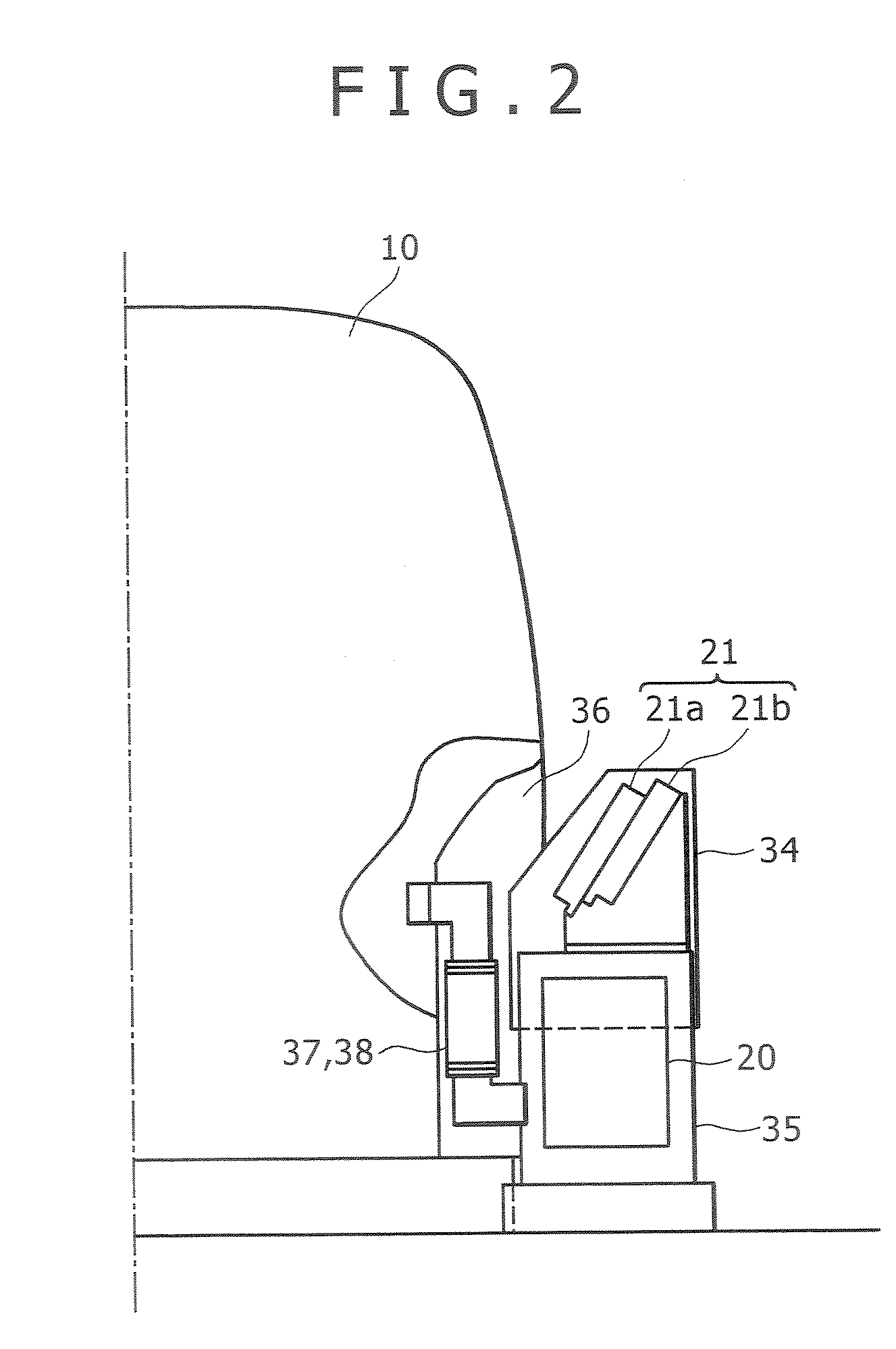

Construction machine

InactiveUS20070090650A1Maintain performanceCostGas pressure propulsion mountingPropulsion using engine-driven generatorsHydraulic pumpEngine power

An inverter / converter as a kind of hybrid unit is composed of a body and a casing covering the body and is disposed in an engine room. An air intake port and an air discharge port each provided with a fan are formed in the casing to configure an internal air cooling device for introducing air present outside the engine room into the casing, allowing the air to flow through the interior of the casing and then discharging it from the air discharge port. A power divider for distributing engine power to a hydraulic pump and a generator-motor is disposed on one of right and left sides of an engine in a rear portion of an upper rotating body. Further, an electric power storage device and the inverter / converter are disposed right and left in parallel behind a cabin and in front of the engine, and a partition wall which defines the engine room is configured by casings of the electric power storage device, the inverter / converter and the power divider.

Owner:KOBELCO CONSTR MASCH CO LTD

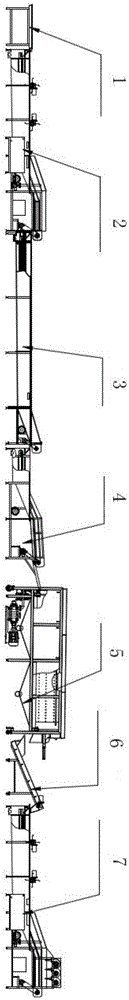

Automatic rhizome peeling and washing assembly line and method

ActiveCN105124725APeeling SatisfactionMeet cleaningVegetable peelingFood treatmentAssembly lineProcess engineering

The invention discloses an automatic rhizome peeling and washing assembly line. According to a material processing flow, the assembly line comprises an unpacking platform, a wind remover bubble washer, a cooking machine, a cooling machine, a roller peeling machine, a belt conveyor, a bubble washer and a control cabinet in sequence, wherein the unpacking platform, the wind remover bubble washer, the cooking machine, the cooling machine, the roller peeling machine, the belt conveyor and the bubble washer are connected with the control cabinet. The invention also discloses an automatic rhizome peeling and washing method. The assembly line and the method have the beneficial effects that according to peeling and washing design of rhizomatic Chinese herbal medicine materials and subsidiary agricultural products, the assembly line and the method comprise material washing, material cooking, material cooling, material peeling and secondary washing, are automatic in control of the whole process and satisfy peeling and washing of different materials; and the whole assembly line saves time and labor and is energy-saving and efficient.

Owner:HANGZHOU FUYANG KANGHUA PHARMA MACHINERY CO LTD

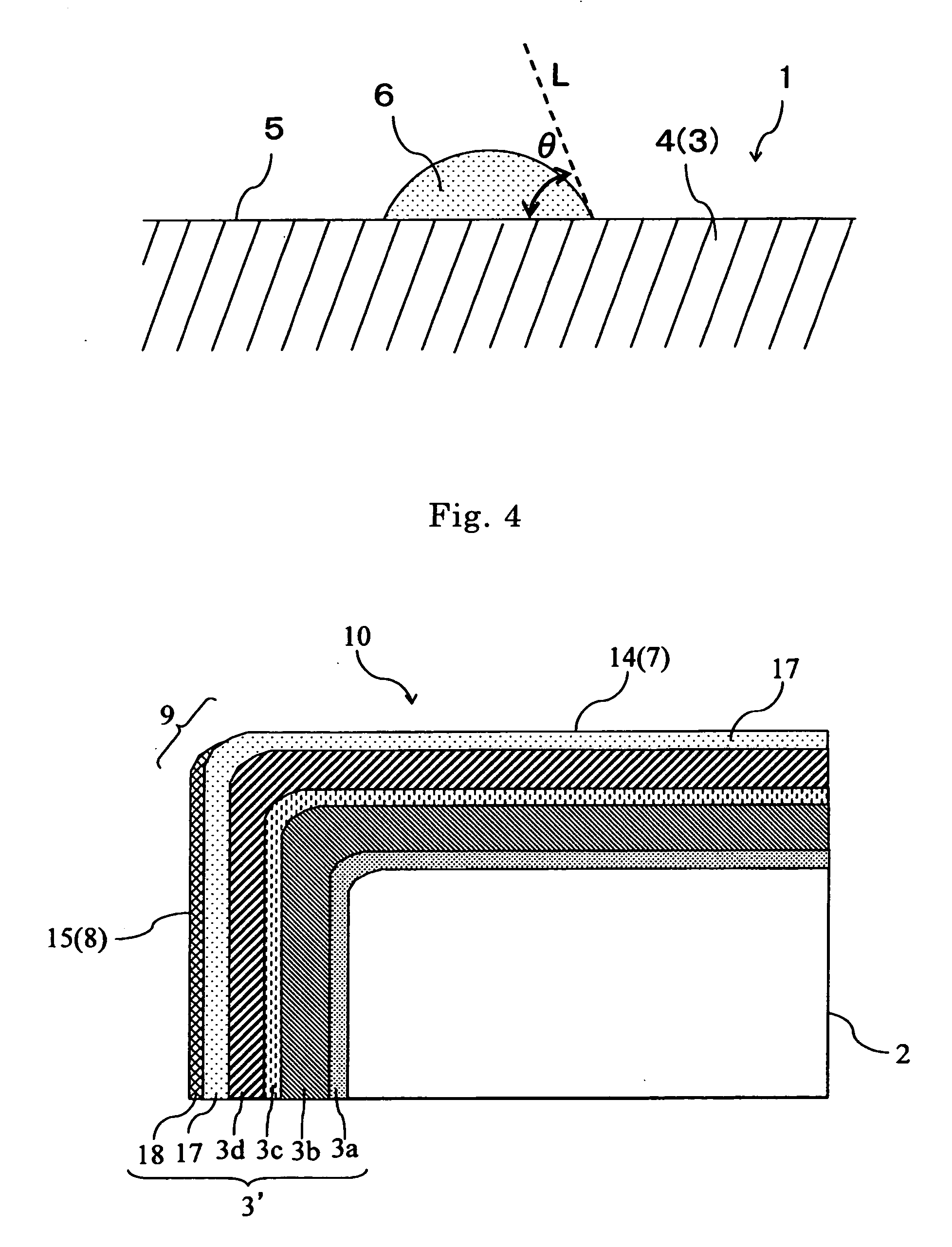

Surface coated cutting tool

ActiveUS20070166545A1Avoid heat effectsEasy to wearLayered productsWorkpiecesEngineeringWear resistance

A surface coated cutting tool comprises a substrate and a hard layer formed on the surface of the substrate, and a contact angle of water θ on the rake face of the hard layer is in the range of 30 to 80°. A surface coated cutting tool comprises a substrate and a hard layer formed on the surface of the substrate, and a contact angle of water θR on the rake face of the hard layer and a contact angle of water θF on the flank face of the hard layer have a relation of θR<θF. Thereby, excellent resistance to wear and fracture can be shown, leading to a excellent surface coated cutting tool.

Owner:KYOCERA CORP

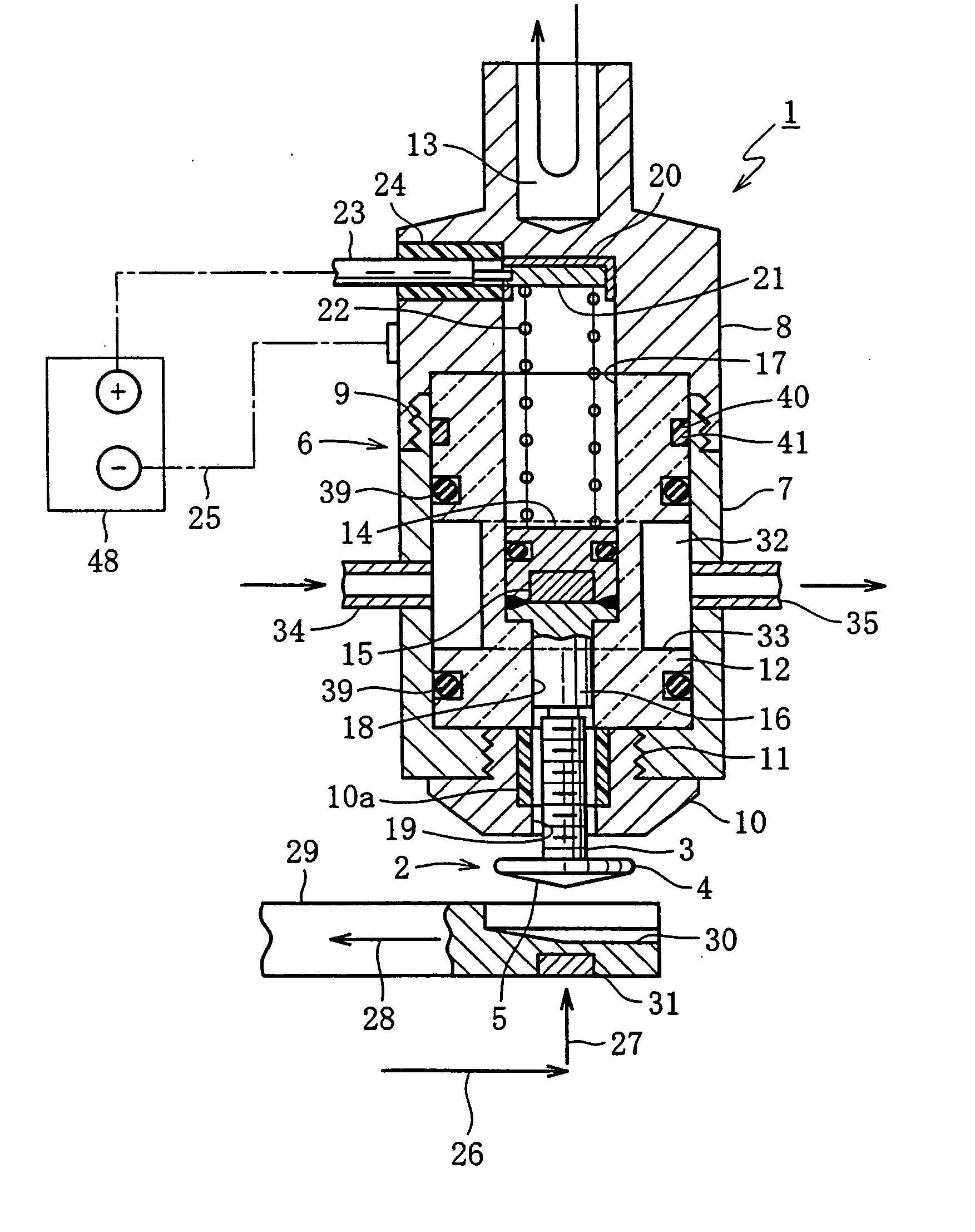

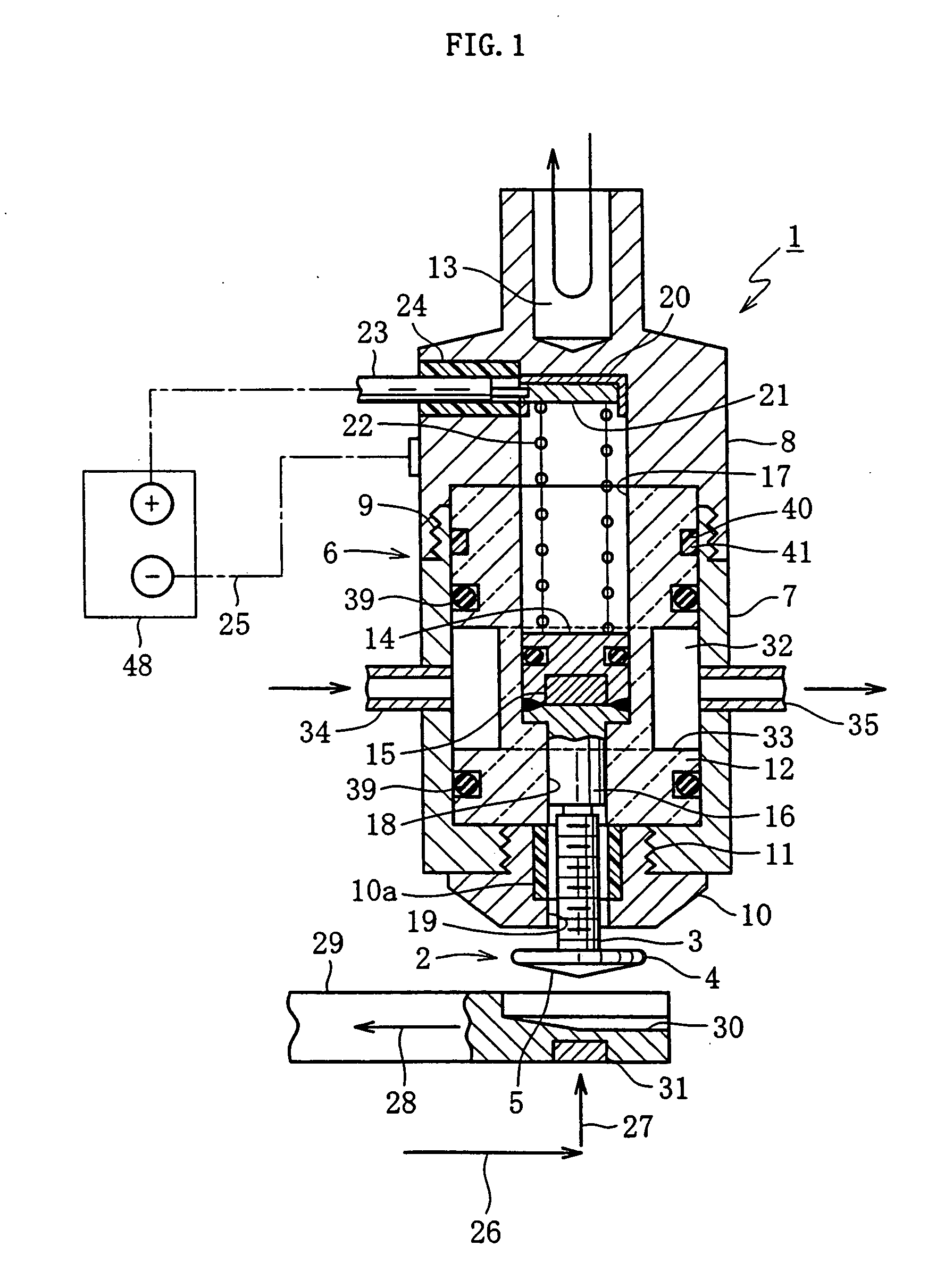

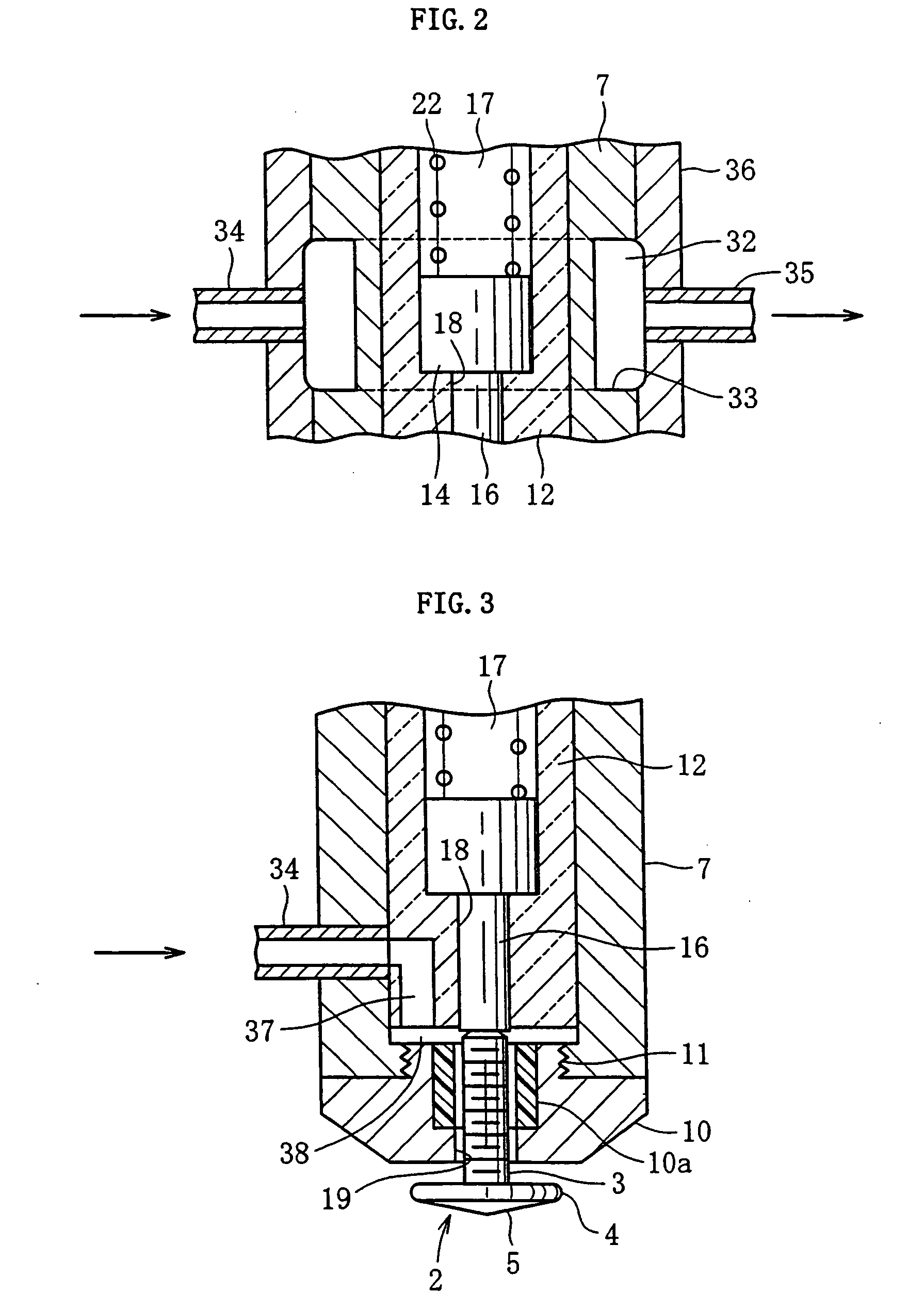

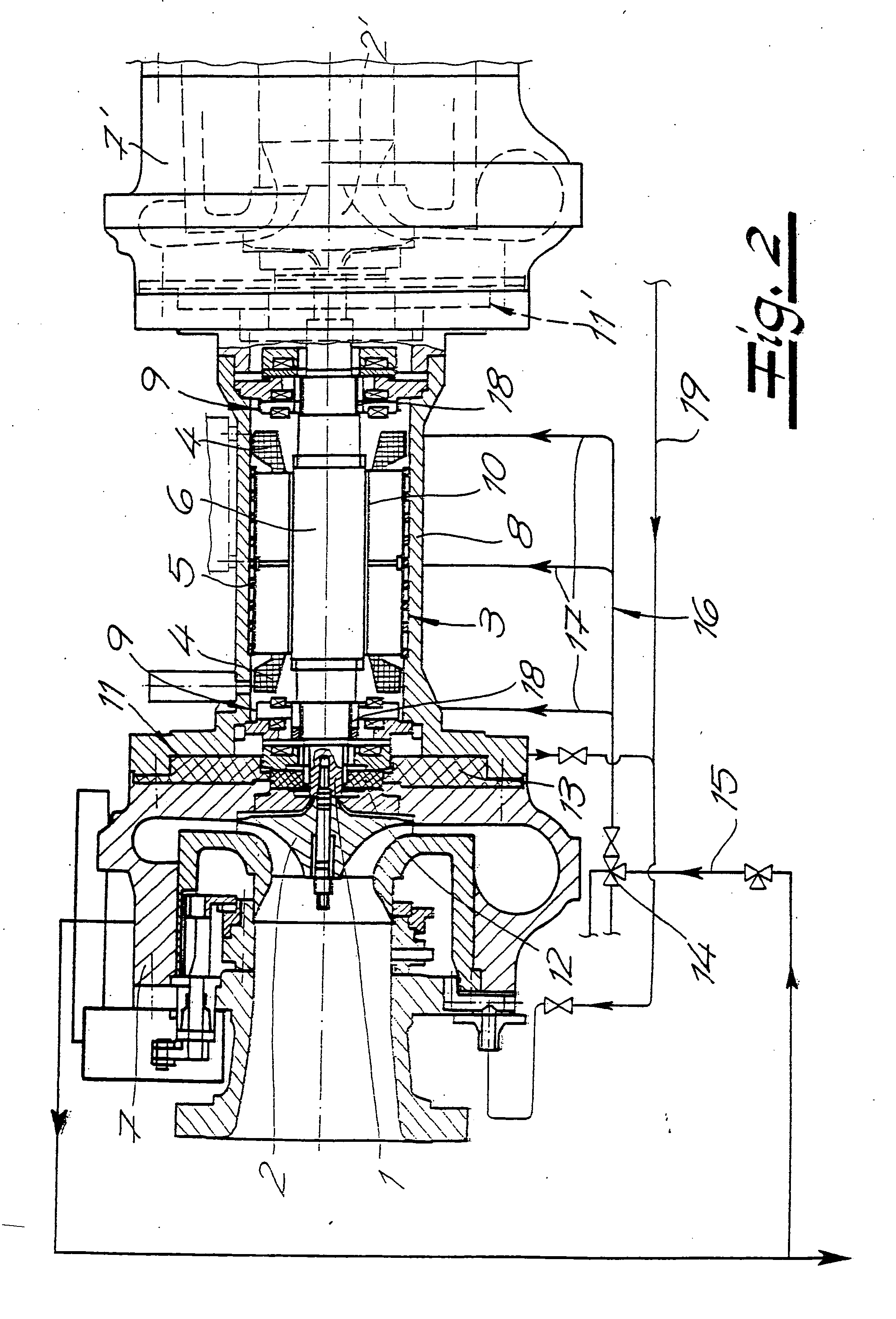

Electrode for projection welding

InactiveUS20050284847A1Cut surfacePrevent thermal degradationWelding/cutting auxillary devicesElectrode supporting devicesBiomedical engineeringWelding

In an electrode for projection welding, an end cover (10) of metal having a through hole (19) is attached to the end of a main body (6) of metal having a cylindrical shape, a guide sleeve (12) of insulation material is disposed in the main body (6), the end of the guide sleeve (12) being formed with a receiving hole (18) for a part (2) in a state in which the receiving hole (18) communicates with the through hole (19) in the end cover (10), and a cooling passage (32) for fluid which cools the guide sleeve (12) is formed.

Owner:KUBUSHIKI KAISHA AOYAMA

Graphite electrode for steelmaking

InactiveUS20060193364A1Improve featuresReduce cooling effectElectric discharge heatingElectric heating for furnacesSteelmakingElectric arc furnace

Owner:TOKAI CARBON CO LTD

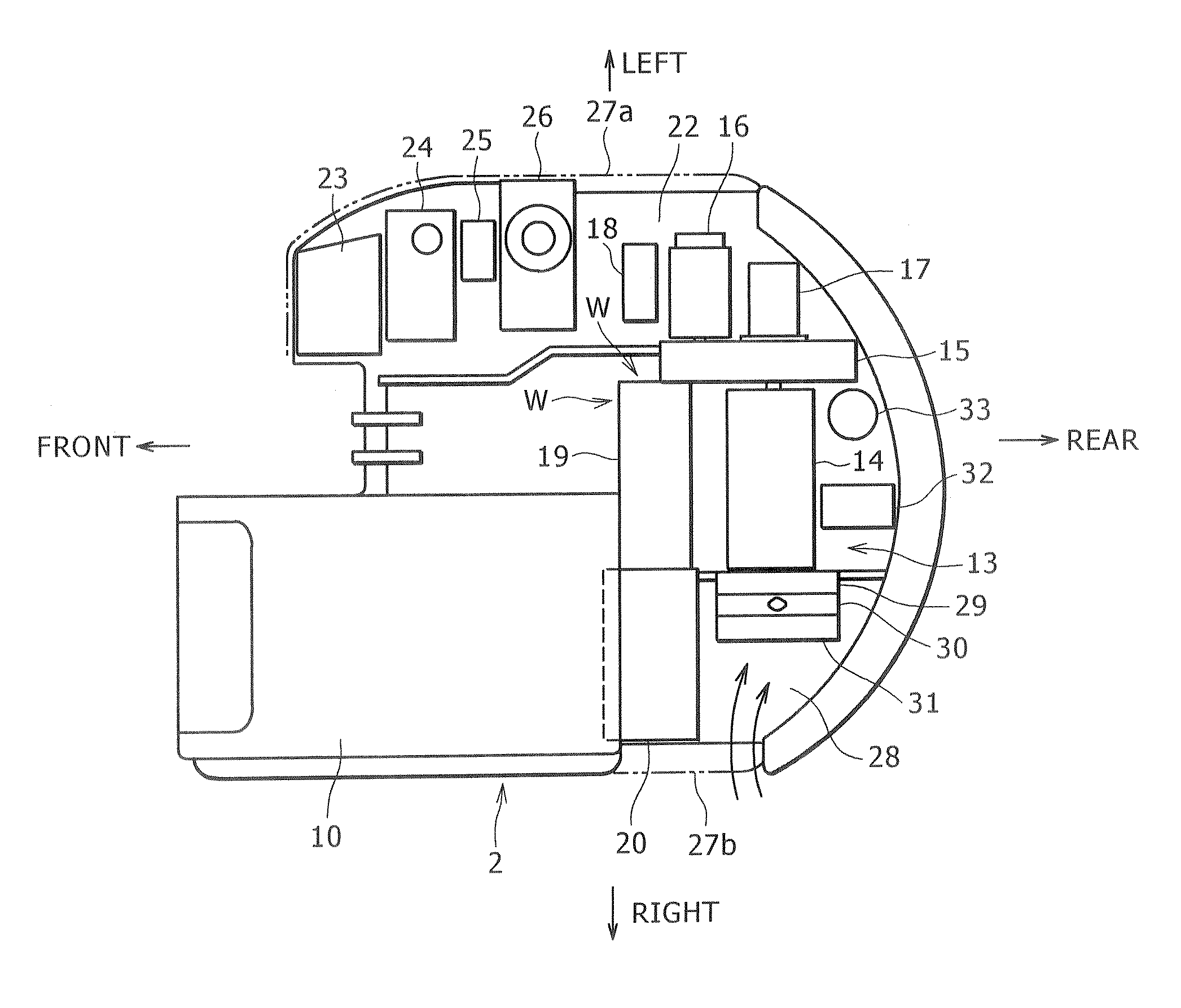

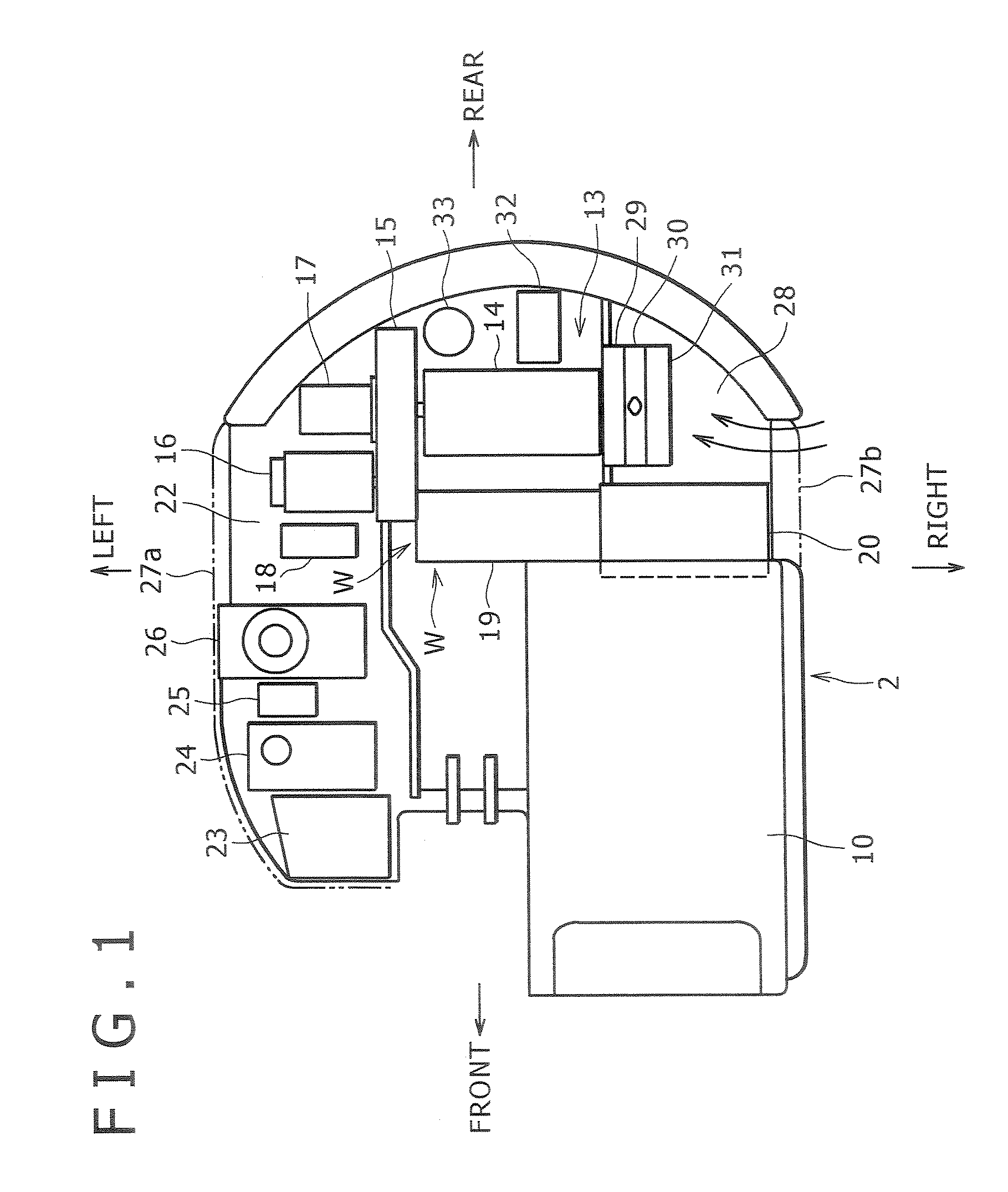

Outdoor unit for air conditioner

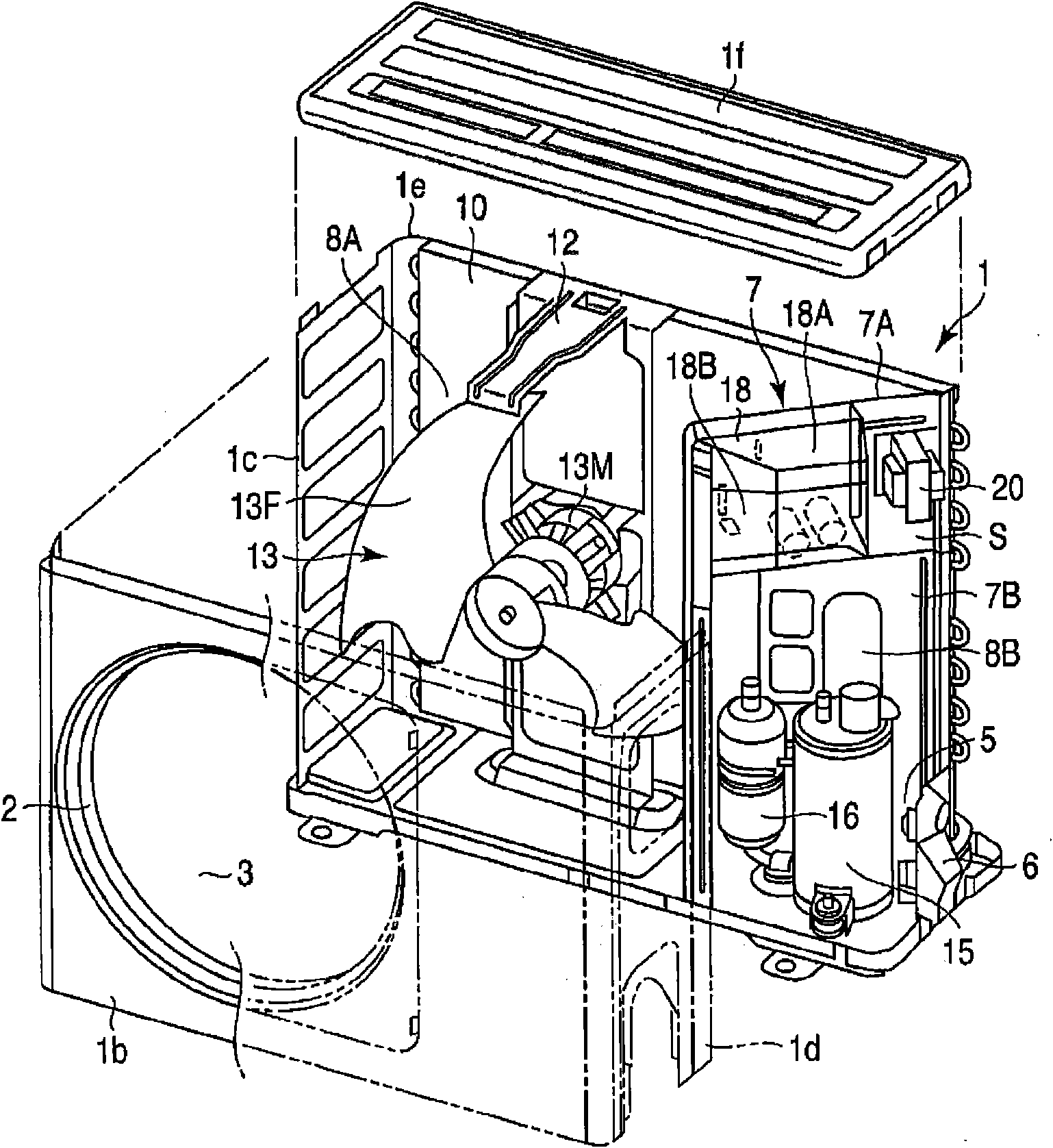

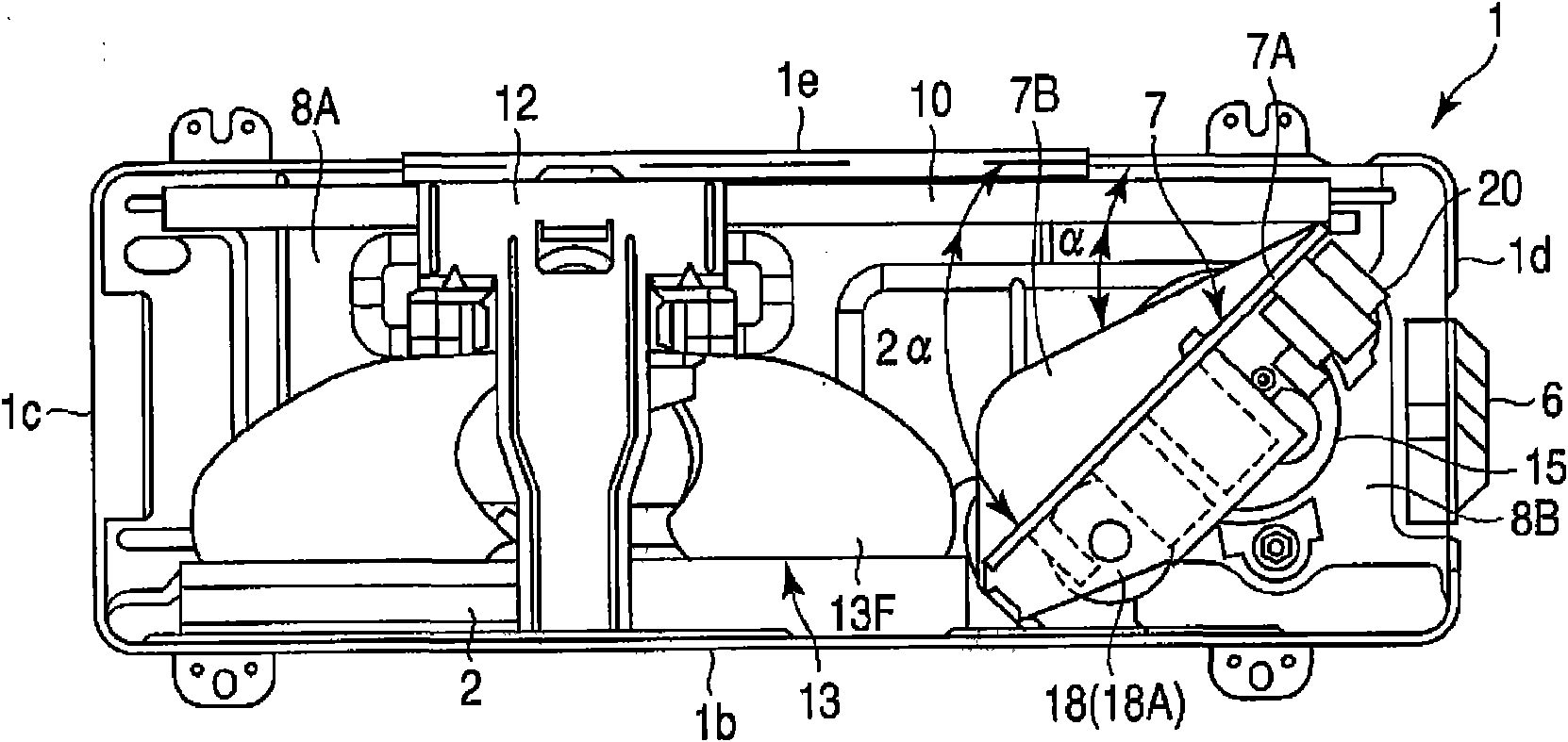

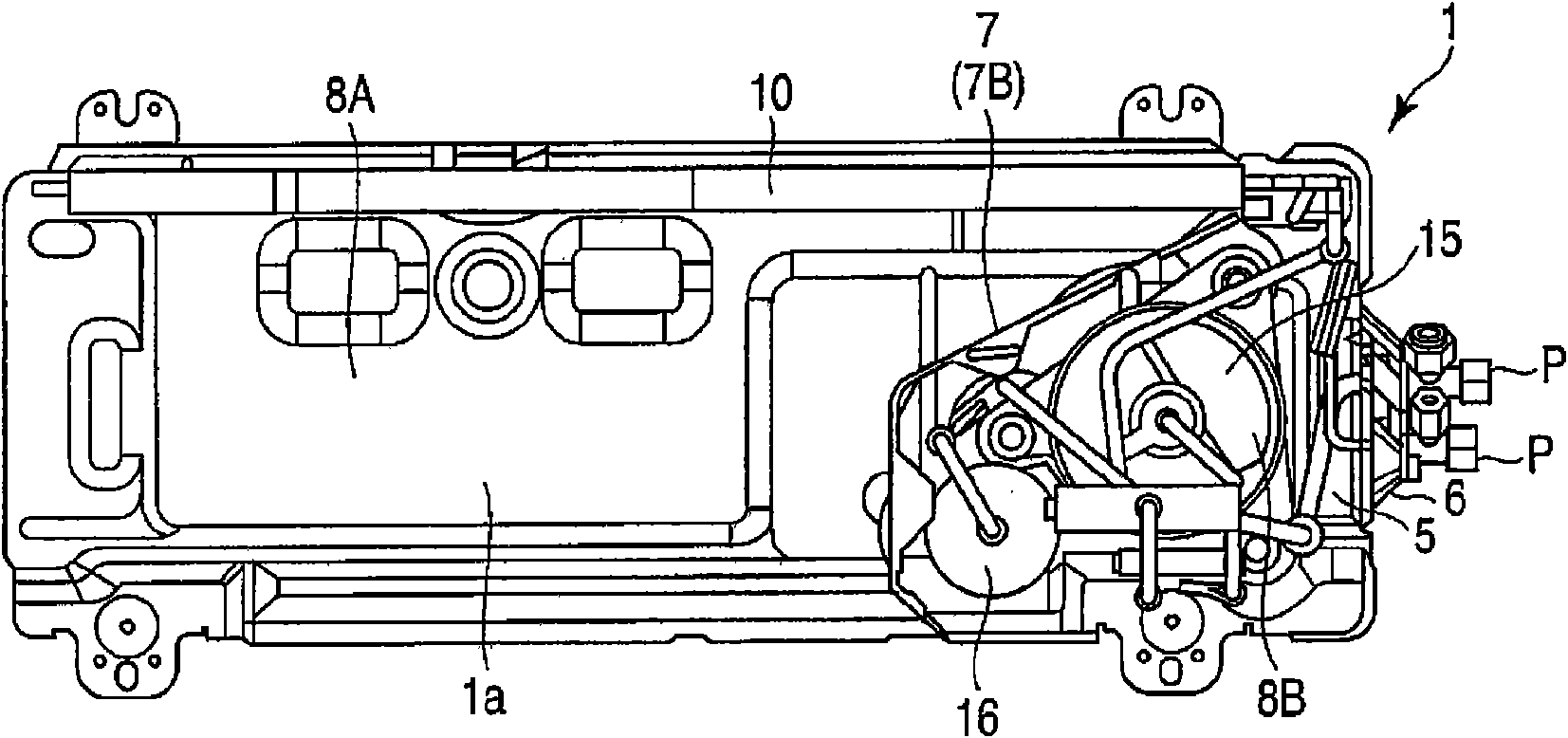

ActiveCN101578488ALow costSolve the lack of cooling capacityLighting and heating apparatusAir conditioning systemsCooling effectHeat exchanger

The inside of an outdoor unit body (1) is partitioned by a partition plate (7) into a heat exchange chamber (8A) for receiving a heat exchanger (10) and an outdoor fan (13) and into a machine chamber (8B) for receiving a compressor (15) and piping (5) or the like. The partition plate (7) is divided by a horizontal plane into an upper partition plate (7A) and a lower partition plate (7B). An electric component mounting surface (S) is provided on that surface of the upper partition plate (7A) which is on the machine chamber (8B) side. On the electric part mounting surface (S) is mounted a control board (22) on which an electric component (D) for controlling drive of electrically driven components such as a fan and a compressor is mounted. The construction improves an installation structure for an electric component box to reduce cost and provides the control board (22) and the electric component (D) with a sufficient cooling effect.

Owner:TOSHIBA CARRIER CORP

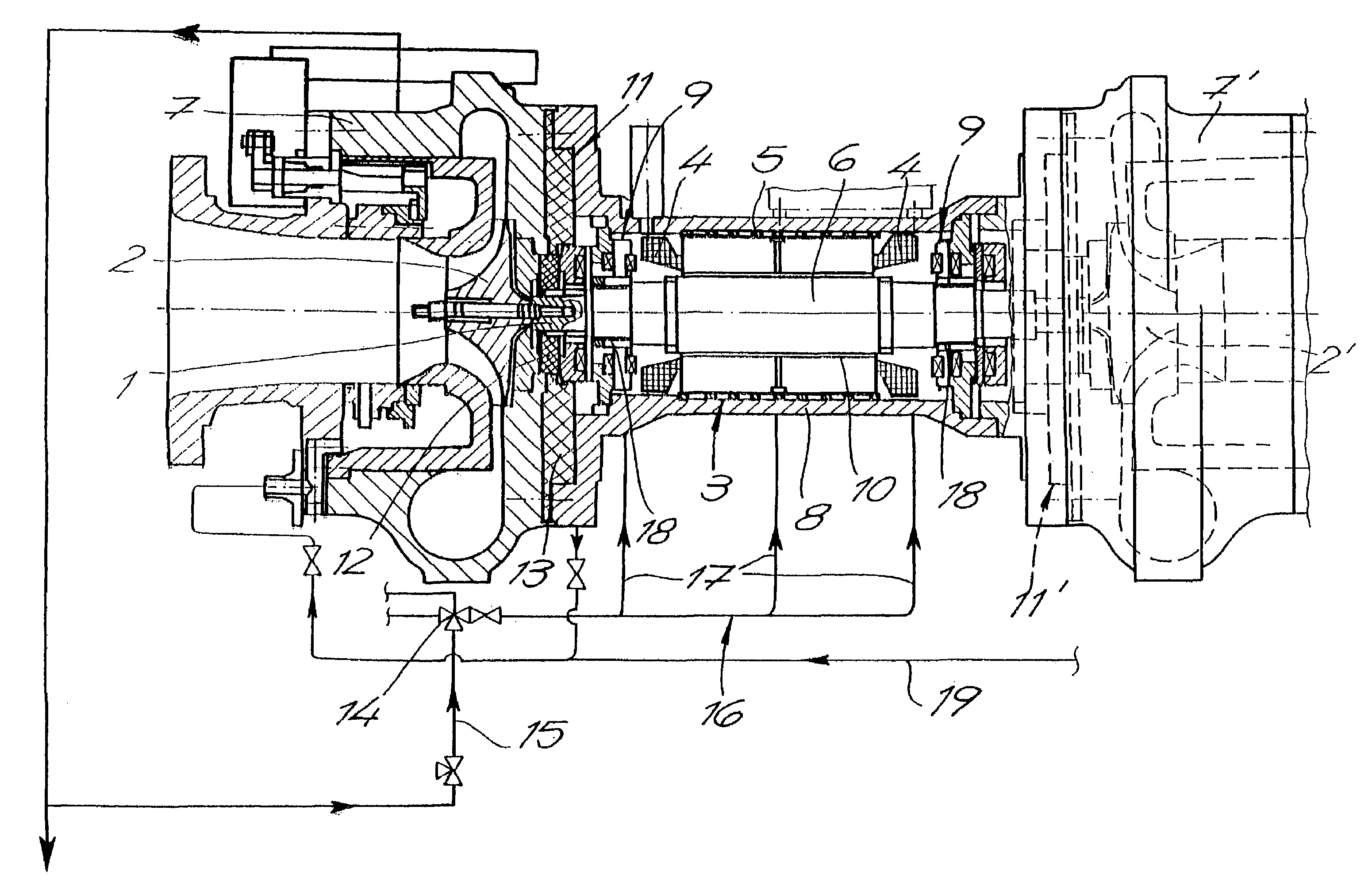

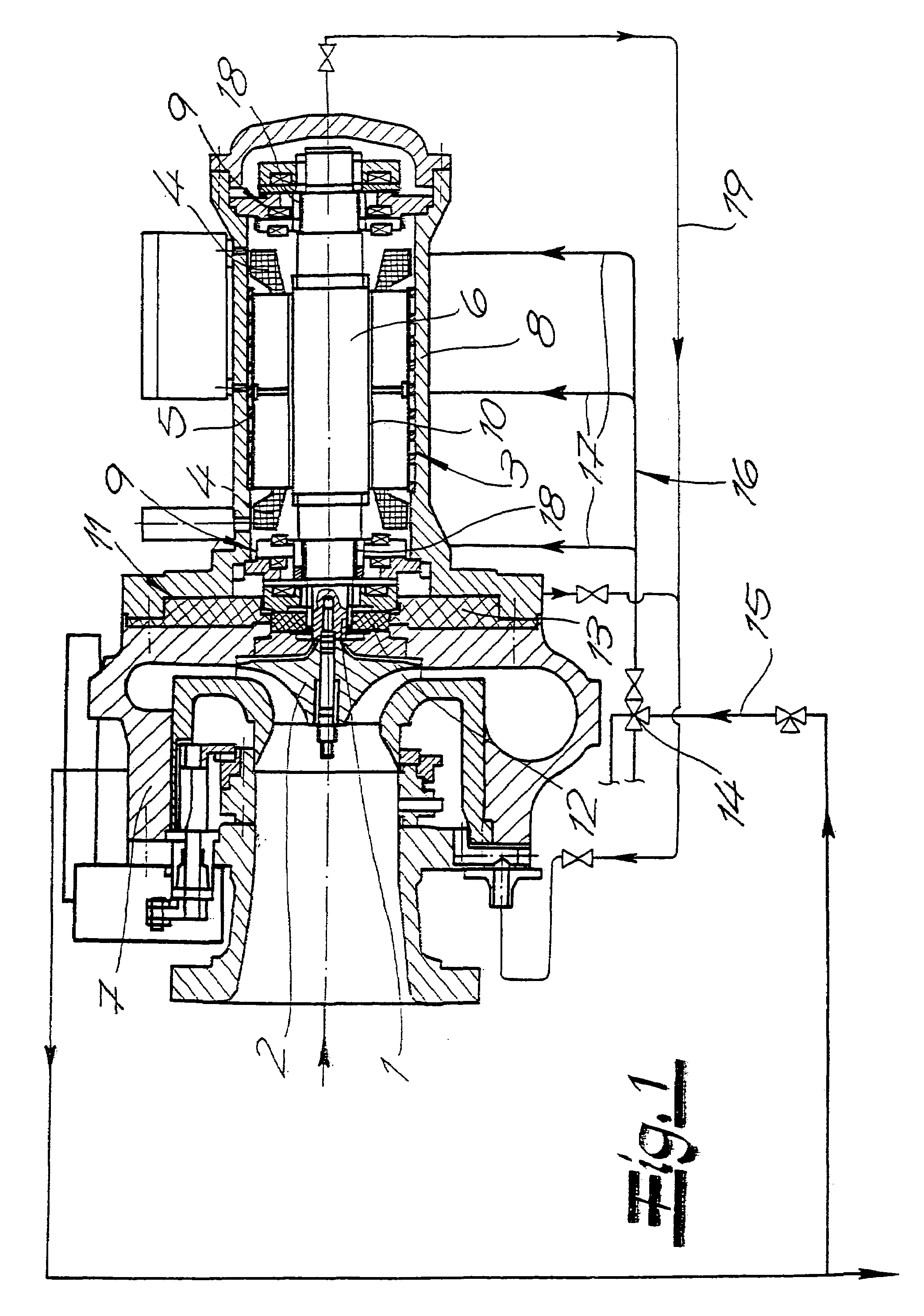

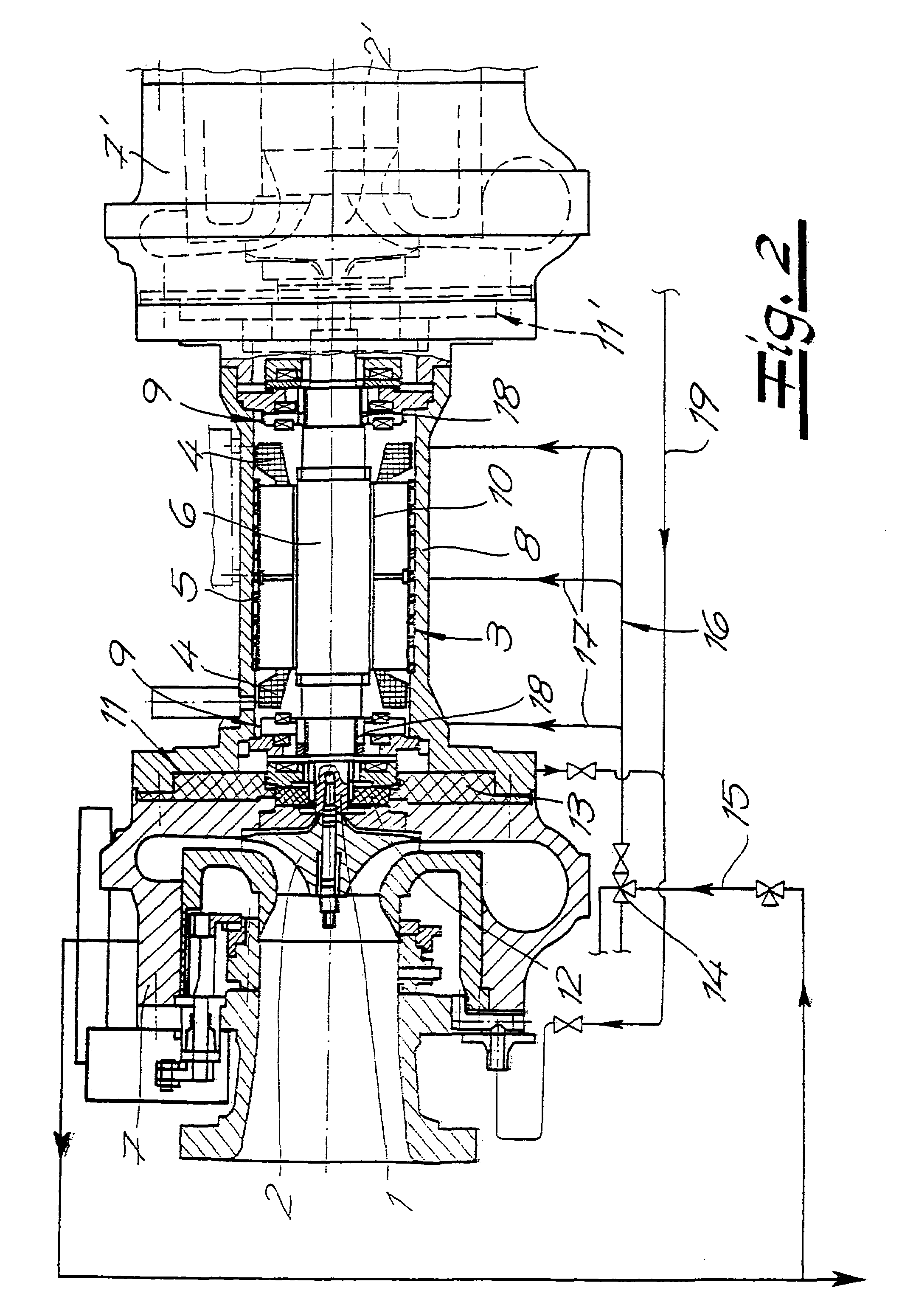

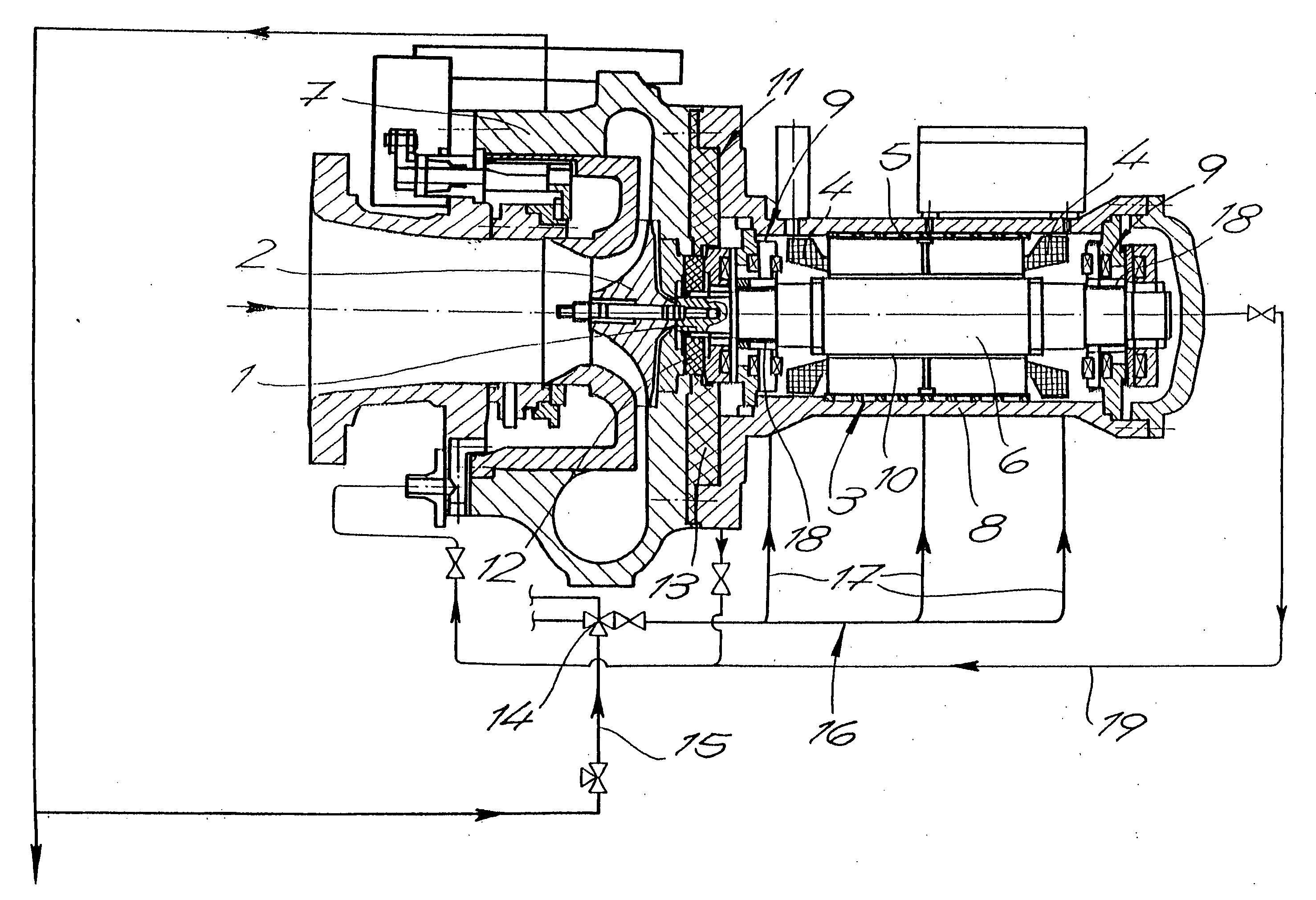

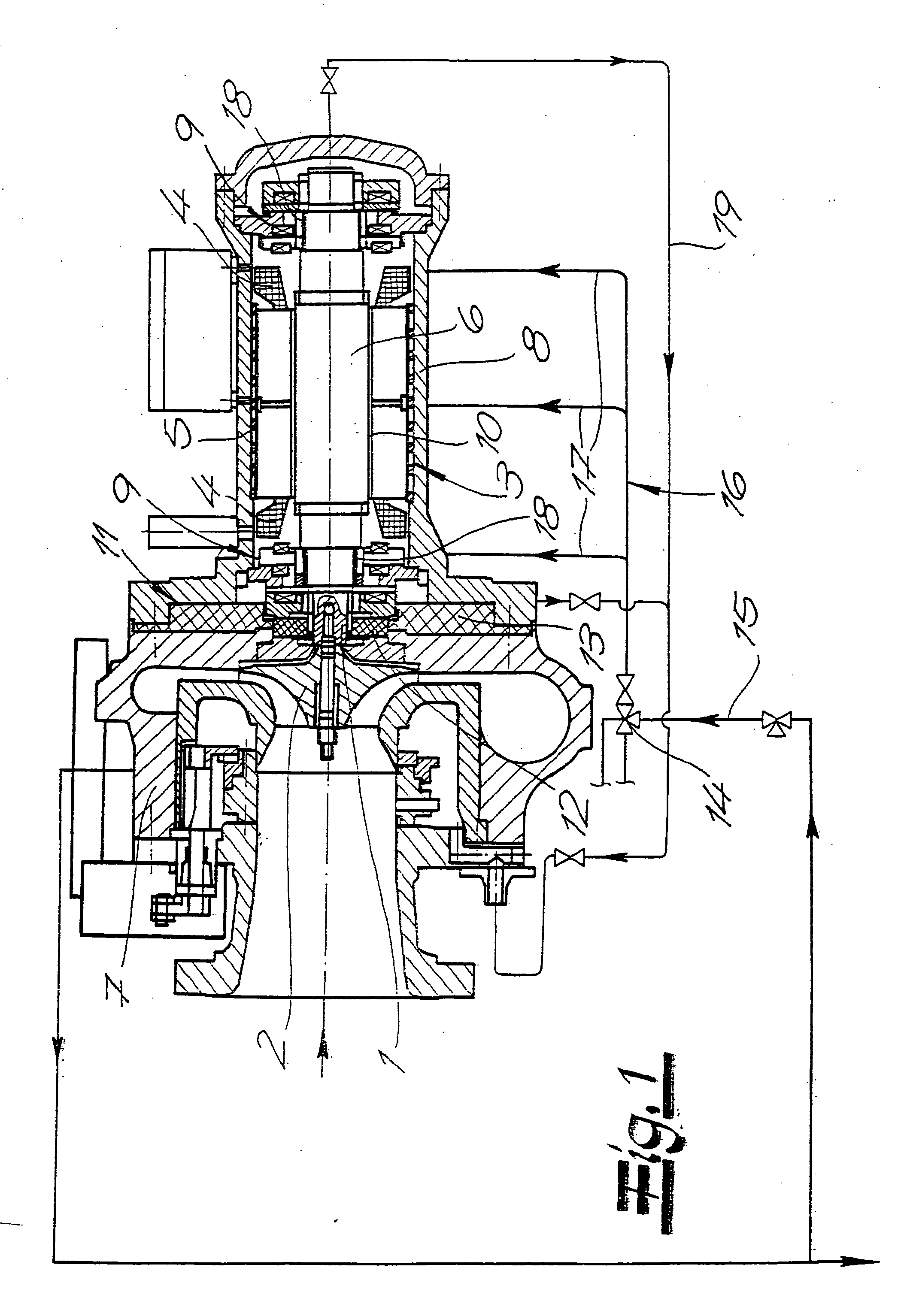

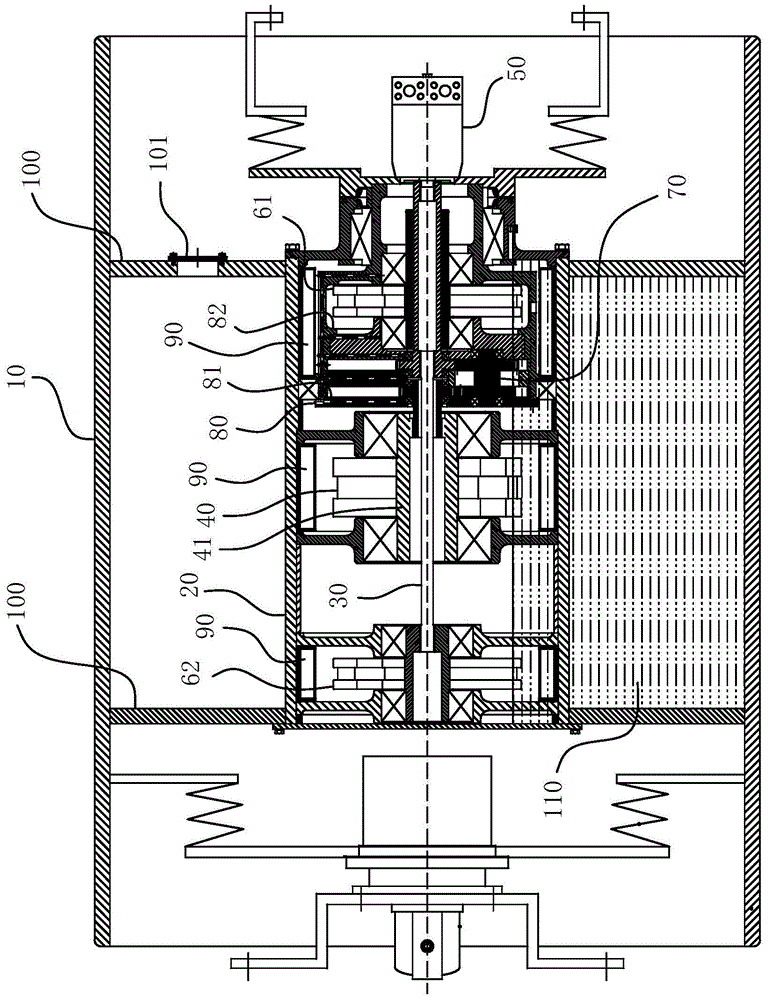

Turbomachine for low-temperature applications

InactiveUS7193341B2Improve cooling effectAccurate measurementPositive displacement pump componentsPiston pumpsLine tubingElectric machine

A turbomachine for low-temperature applications, has a rotor shaft; at least one rotor disk that is arranged in overhung manner at one shaft end of the rotor shaft; an electric machine having a stator having windings, and an electric rotor arranged on the rotor shaft; a stage housing that surrounds the rotor disk and has connections for a cold gas that flows through the stage housing; and a machine housing in which the electric machine and shaft bearings for the rotor shaft are arranged. The machine housing is connected with the stage housing. A partition made of insulating material is arranged between the stage housing and the machine housing, which thermally separates the stage housing from the machine housing. A line provided with a flow-through regulation fitting is connected to the flow path of the cold gas, for branching off an amount-regulated cooling stream, which is passed to the electric machine within the machine housing.

Owner:ATLAS COPCO ENERGAS

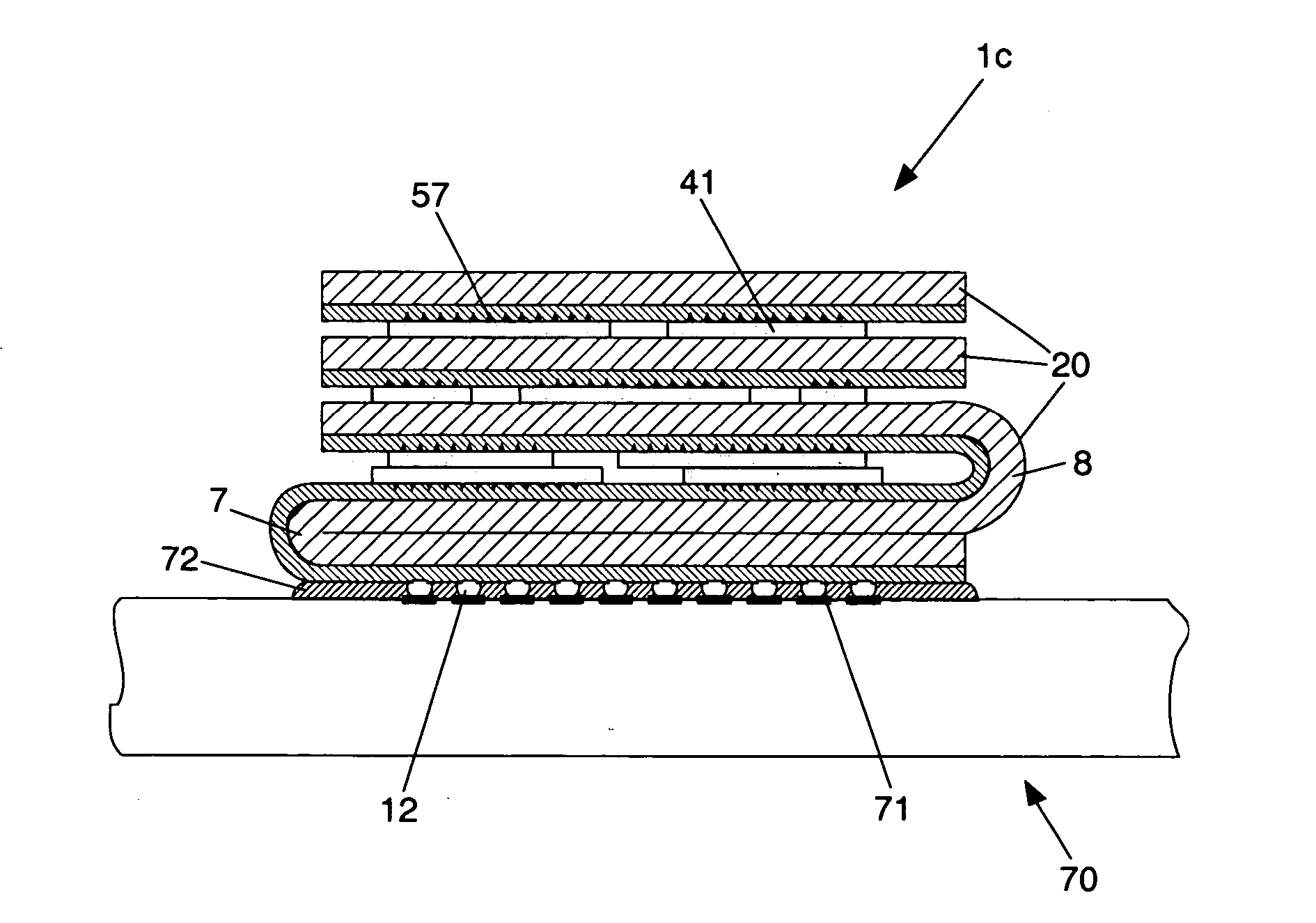

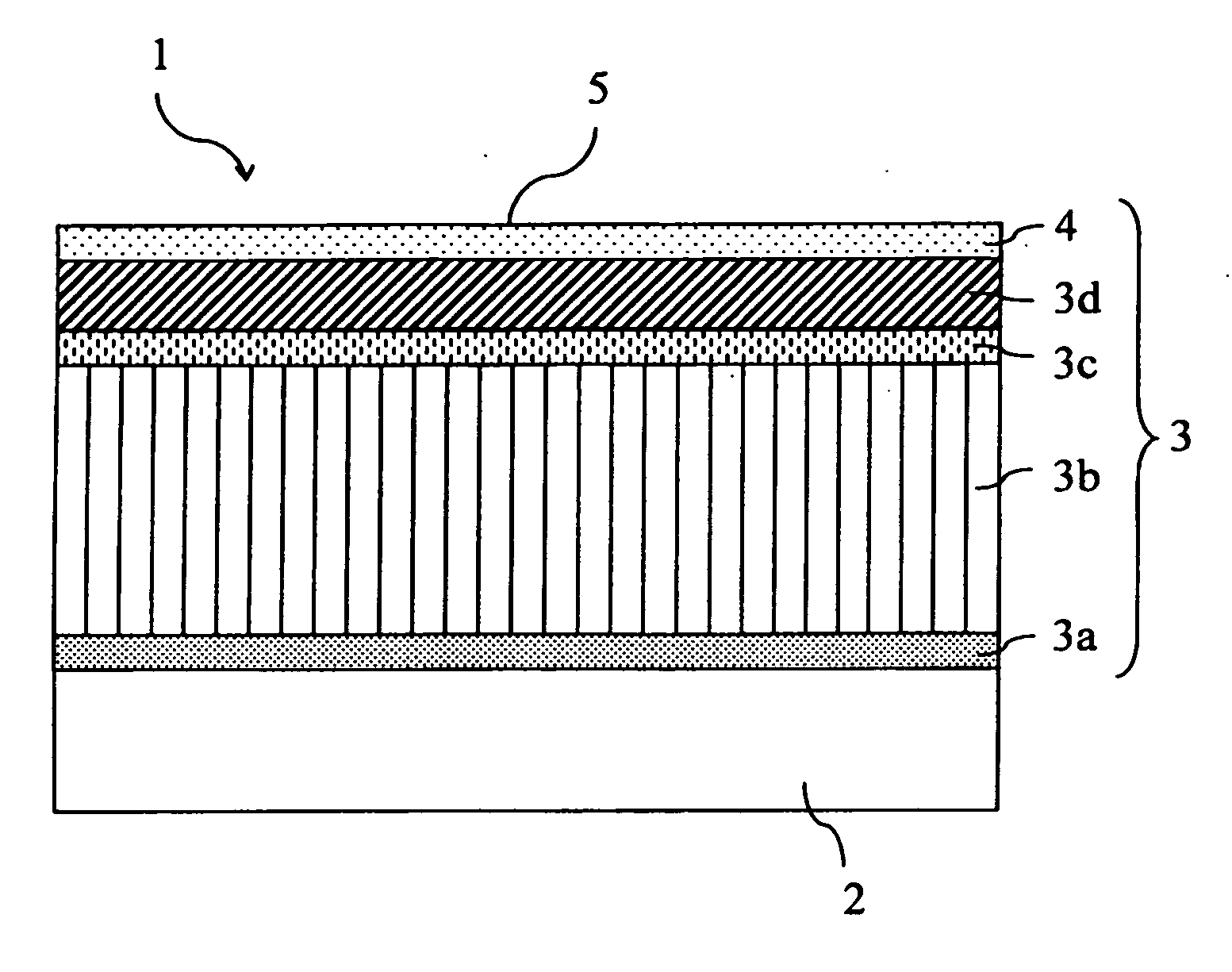

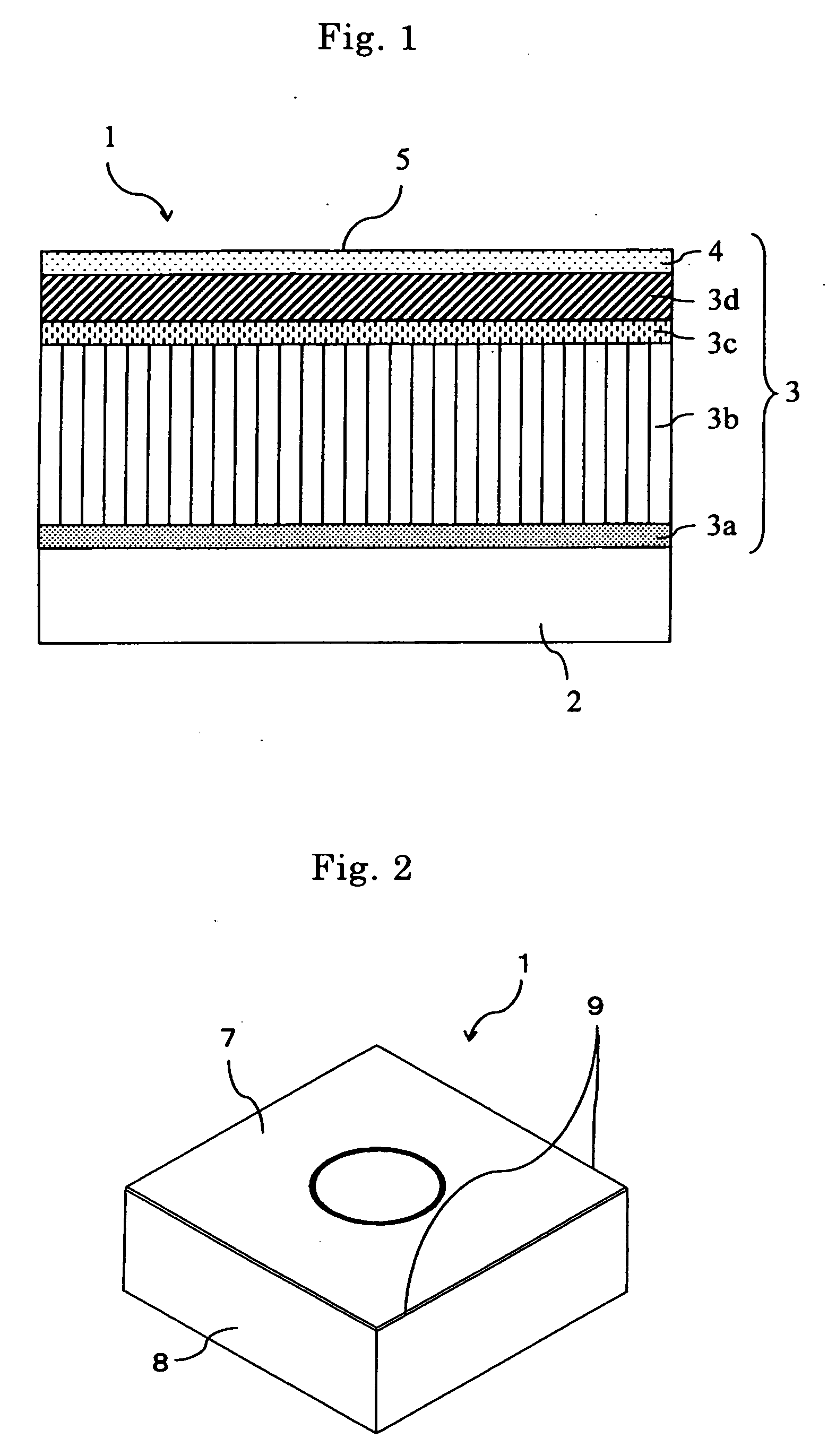

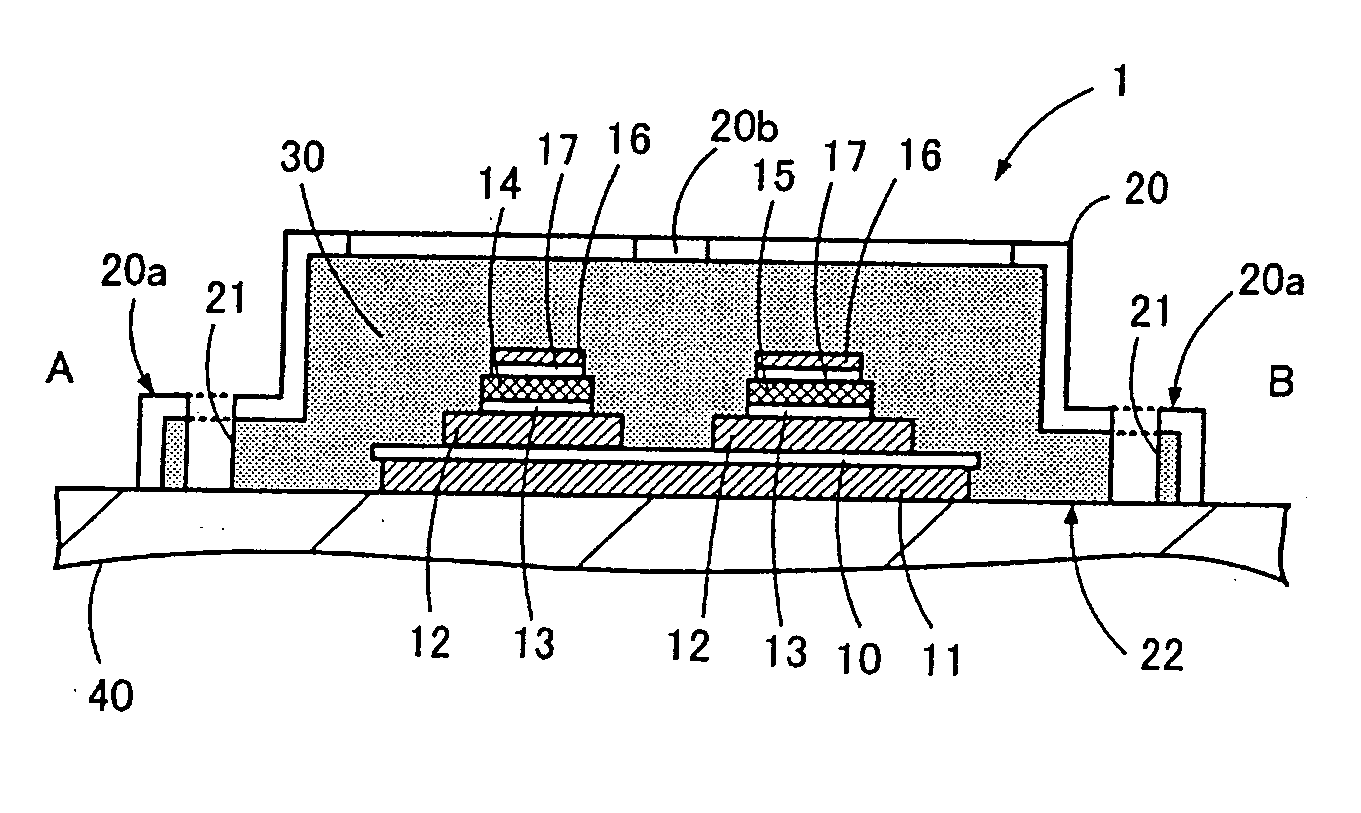

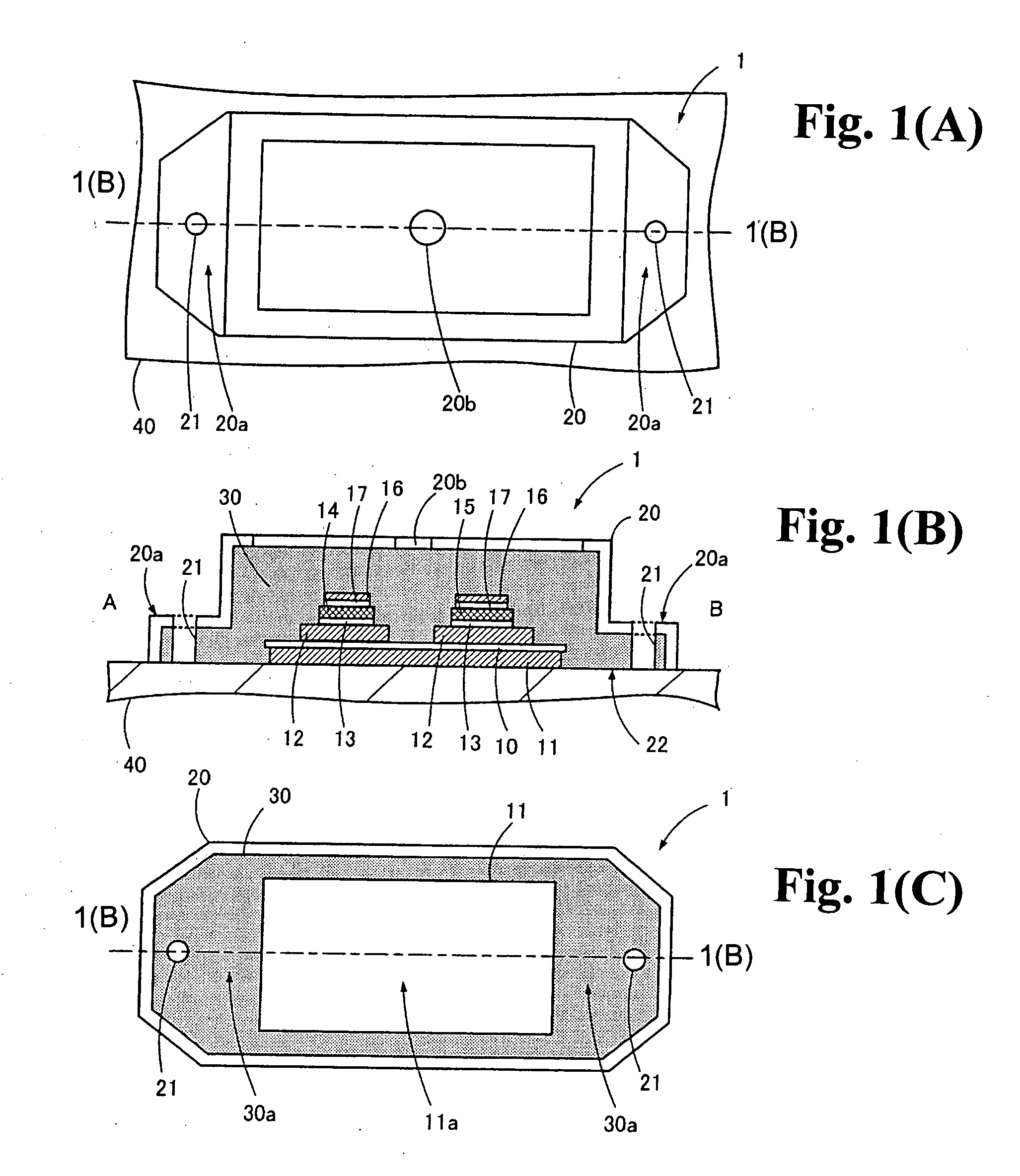

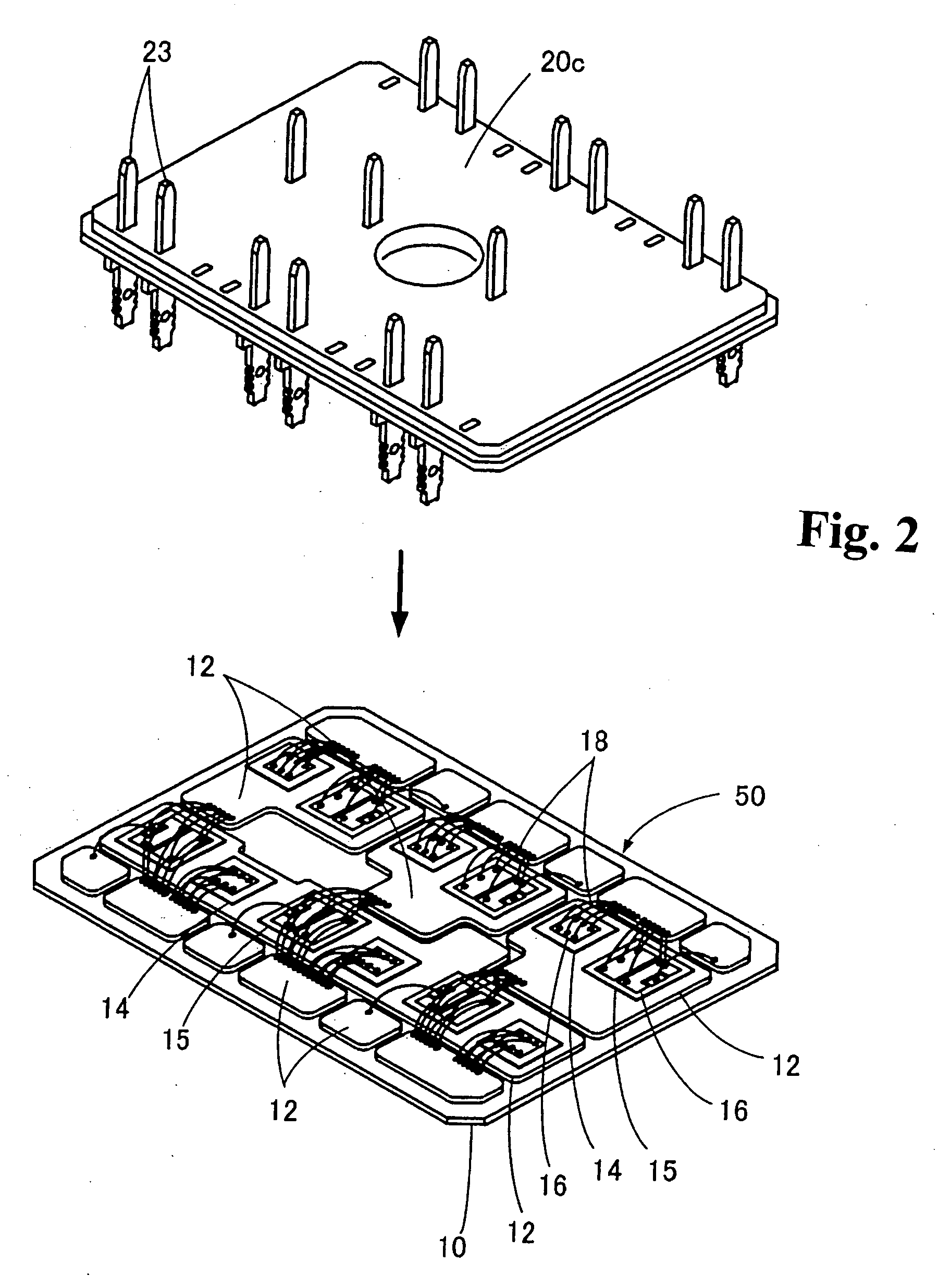

Semiconductor module and method for manufacturing semiconductor module

ActiveUS20080284007A1Light weightSmall sizeSemiconductor/solid-state device detailsSolid-state devicesMetal foilEngineering

A semiconductor module includes a first metal foil; an insulating sheet mounted on a top surface of the first metal foil; at least one second metal foil mounted on a top surface of the insulating sheet; at least one semiconductor device mounted on the second metal foil; and a resin case for surrounding the first metal foil, insulating sheet, second metal foil, and semiconductor device. A bottom end of a peripheral wall of the resin case is located above a bottom surface of the first metal foil. A resin is provided inside the resin case to fill the inside of the resin case. The bottom surface of the first metal foil and the resin form a flat bottom surface so that the flat bottom surface contacts an external mounting member.

Owner:FUJI ELECTRIC CO LTD

Grinding liquid used for grinding back surface of storage hard disk magnetic head

InactiveCN1651544AEvenly distributedImprove dispersion stabilityOther chemical processesAntistatic agentPreservative

An abrasing liquid for abrasing the back of magnetic head for hard disc contains proportionally mineral oil containing C11-C13 alkane, oiling agent, superfine monocrystal diamond powder, antioxidizing anticorrosion agent, non-ionic surfactant, defoaming agent, and antistatic agent.

Owner:TSINGHUA UNIV +1

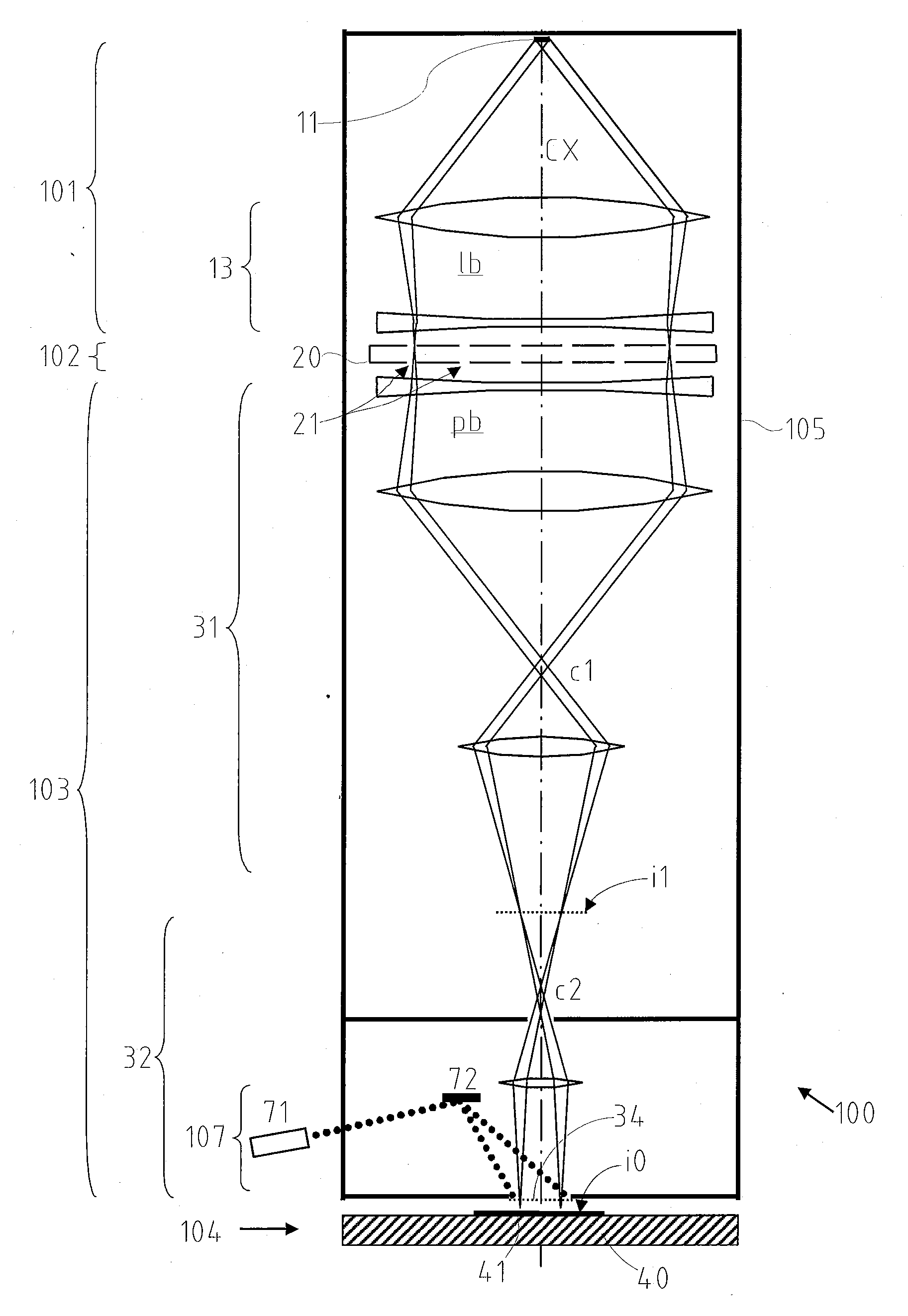

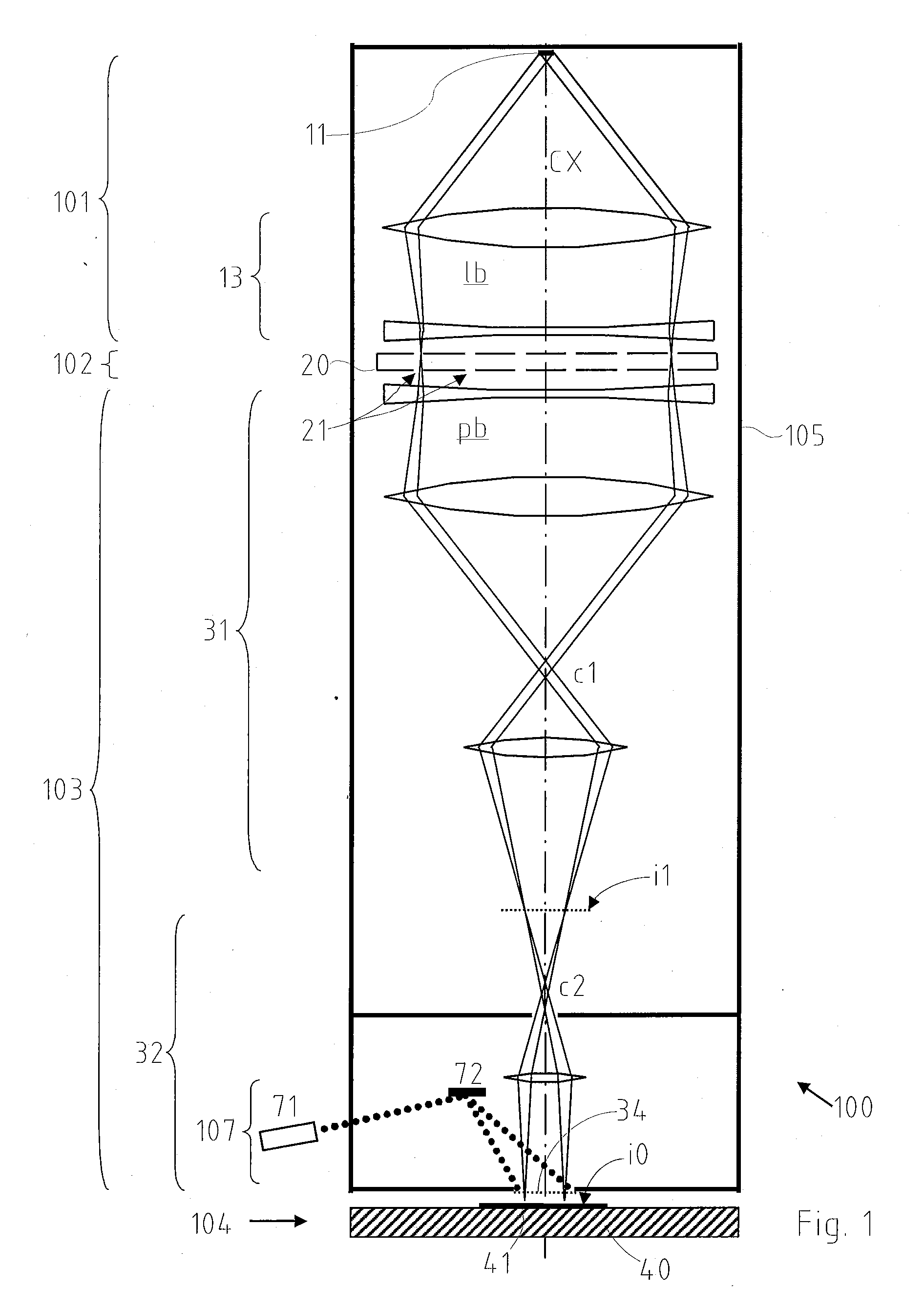

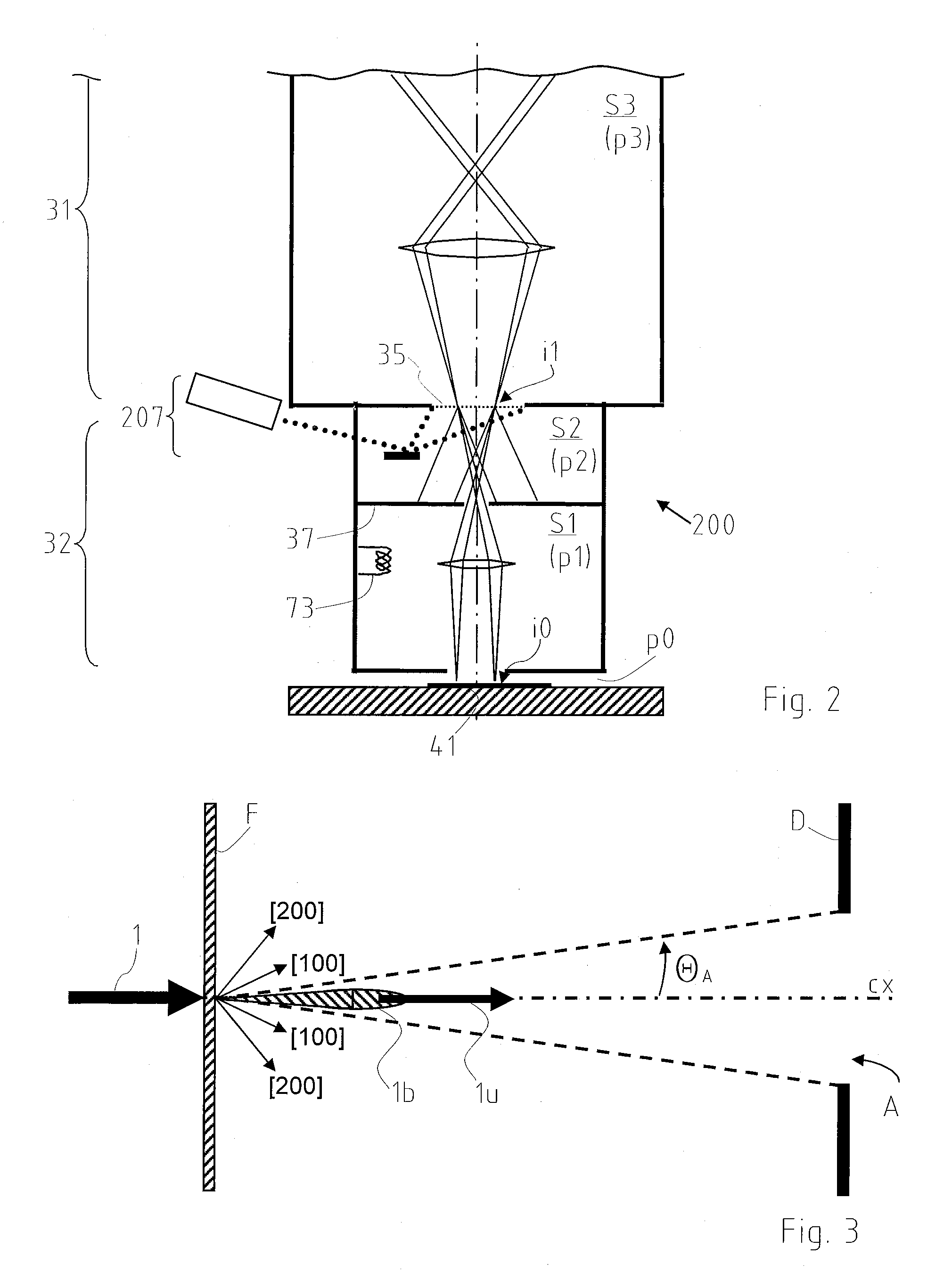

Charged-Particle Exposure Apparatus

ActiveUS20080258084A1High particle puritySevere contaminationElectric discharge tubesNanoinformaticsWide areaParticle beam

A particle-beam projection processing apparatus for irradiating a target, with an illumination system for forming a wide-area illuminating beam of energetic electrically charged particles; a pattern definition means for positioning an aperture pattern in the path of the illuminating beam; and a projection system for projecting the beam thus patterned onto a target to be positioned after the projection system. A foil located across the path of the patterned beam is positioned between the pattern definition means and the position of the target at a location close to an image of the aperture pattern formed by the projection system.

Owner:IMS NANOFABTION

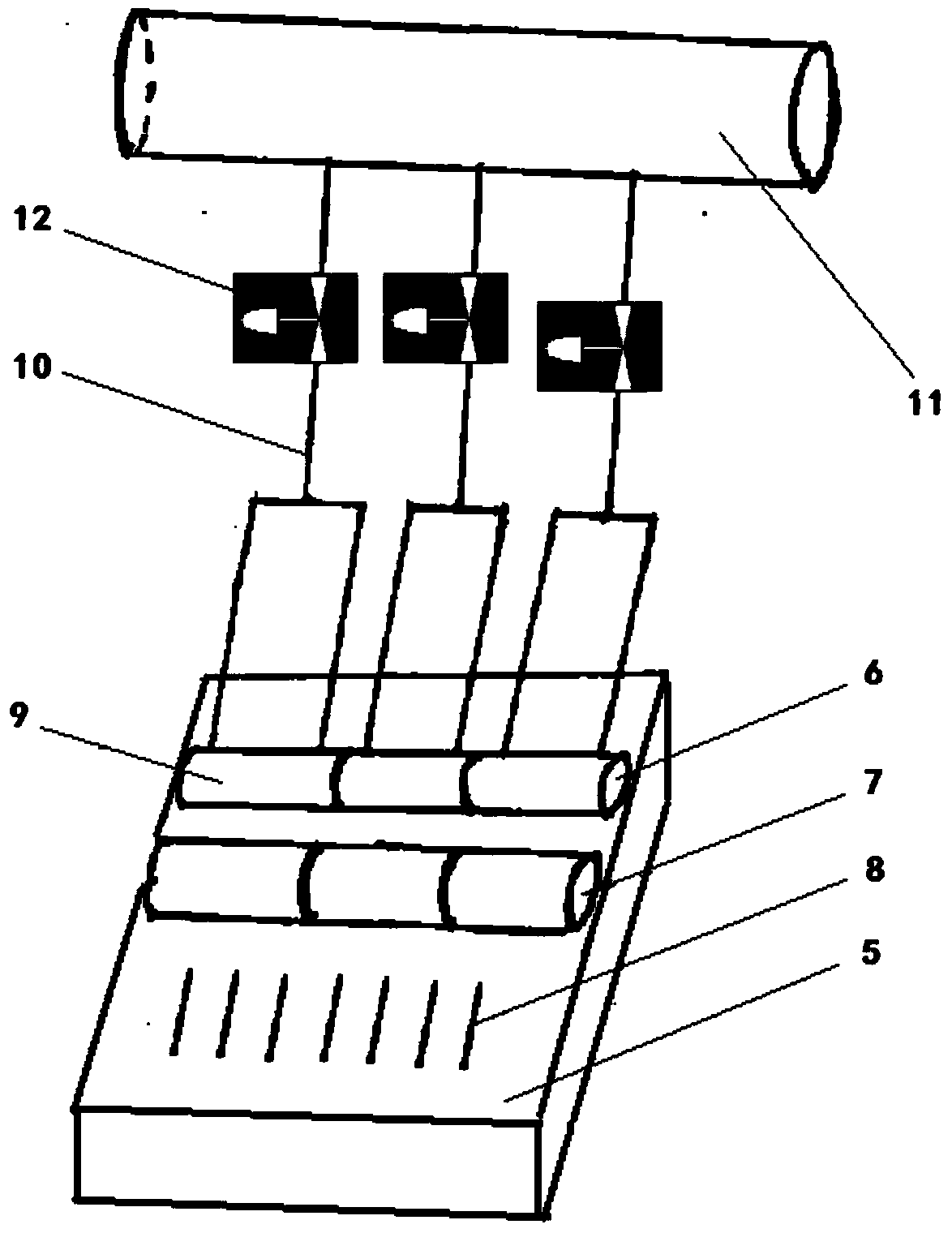

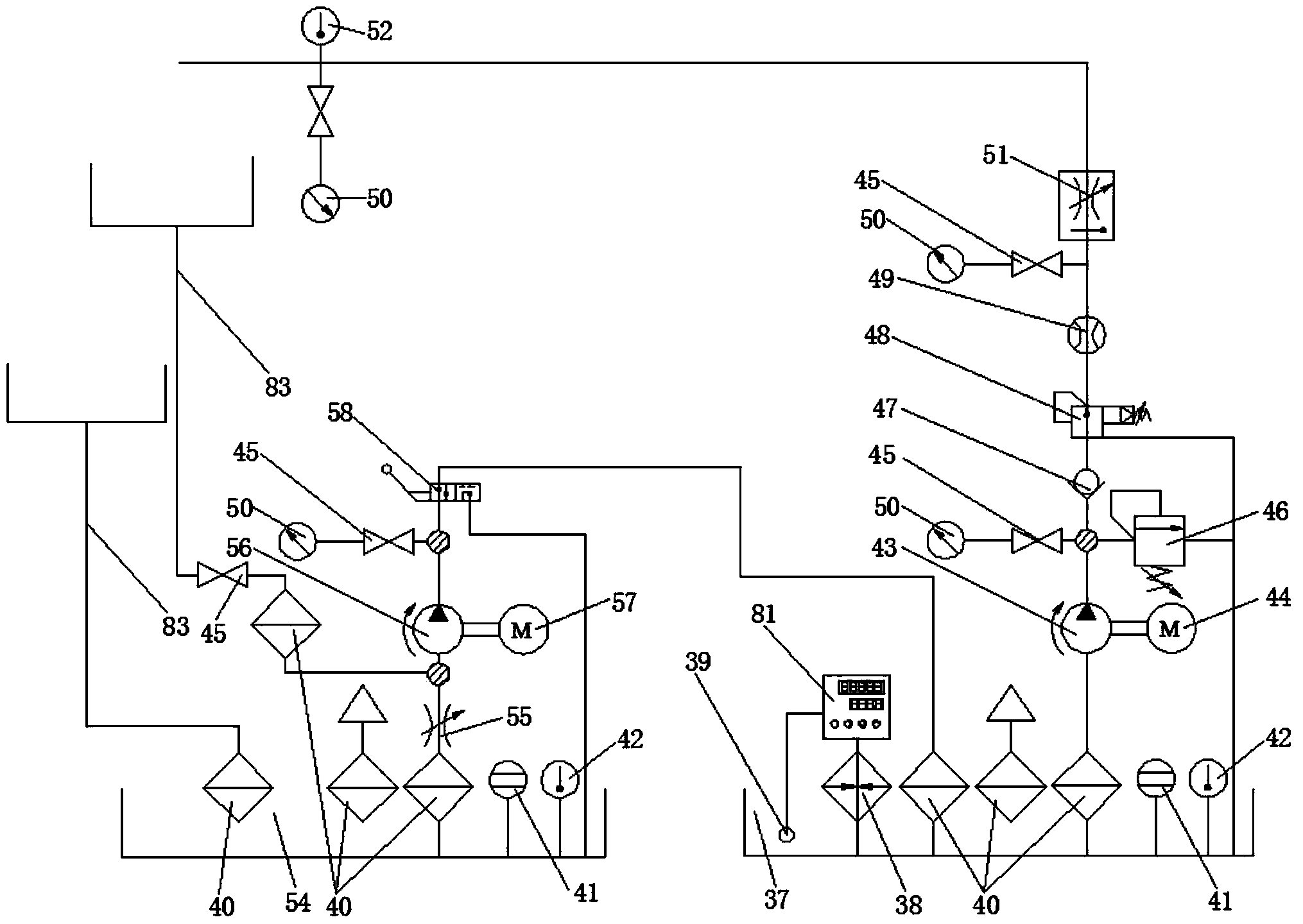

Cooling device used for hot-rolled strip production line

InactiveCN101518788AAchieve high-intensity coolingSolve the lack of cooling capacityWork treatment devicesMetal rolling arrangementsProduction lineUltra fast

The invention discloses a cooling device used for a hot rolled strip production line which comprises a roller way on which hot rolled sheets to be cooled are placed. The cooling device comprises an ultra-fast cooling device and a laminar flow cooling device, wherein the ultra-fast cooling device comprises a plurality of ultra-fast cooling water spraying upper collecting pipes and a plurality of ultra-fast cooling water spraying lower collecting pipes; the ultra-fast cooling water spraying upper collecting pipes are arranged sequentially and are perpendicular to the hot rolled strip production line; the ultra-fast cooling water spraying lower collecting pipes are arranged in the gaps of the roller way; the laminar flow cooling device comprises a high cistern, a shunting and collecting pipe, a laminar flow cooling upper collecting pipe and a laminar flow cooling lower collecting pipe; the high cistern and the shunting and collecting pipe are arranged up and down; and the high cistern, the shunting and collecting pipe, the laminar flow cooling upper collecting pipe and the laminar flow cooling lower collecting pipe are connected with each other through distribution pipes. The cooling device used for the hot rolled strip production line can cool hot rolled sheets quickly and evenly to meet the production demands of special steel grades, is beneficial to form industrial scale and has significant productive practice meaning.

Owner:TIANJIN DONGDA JINFENG ROLLING TECH

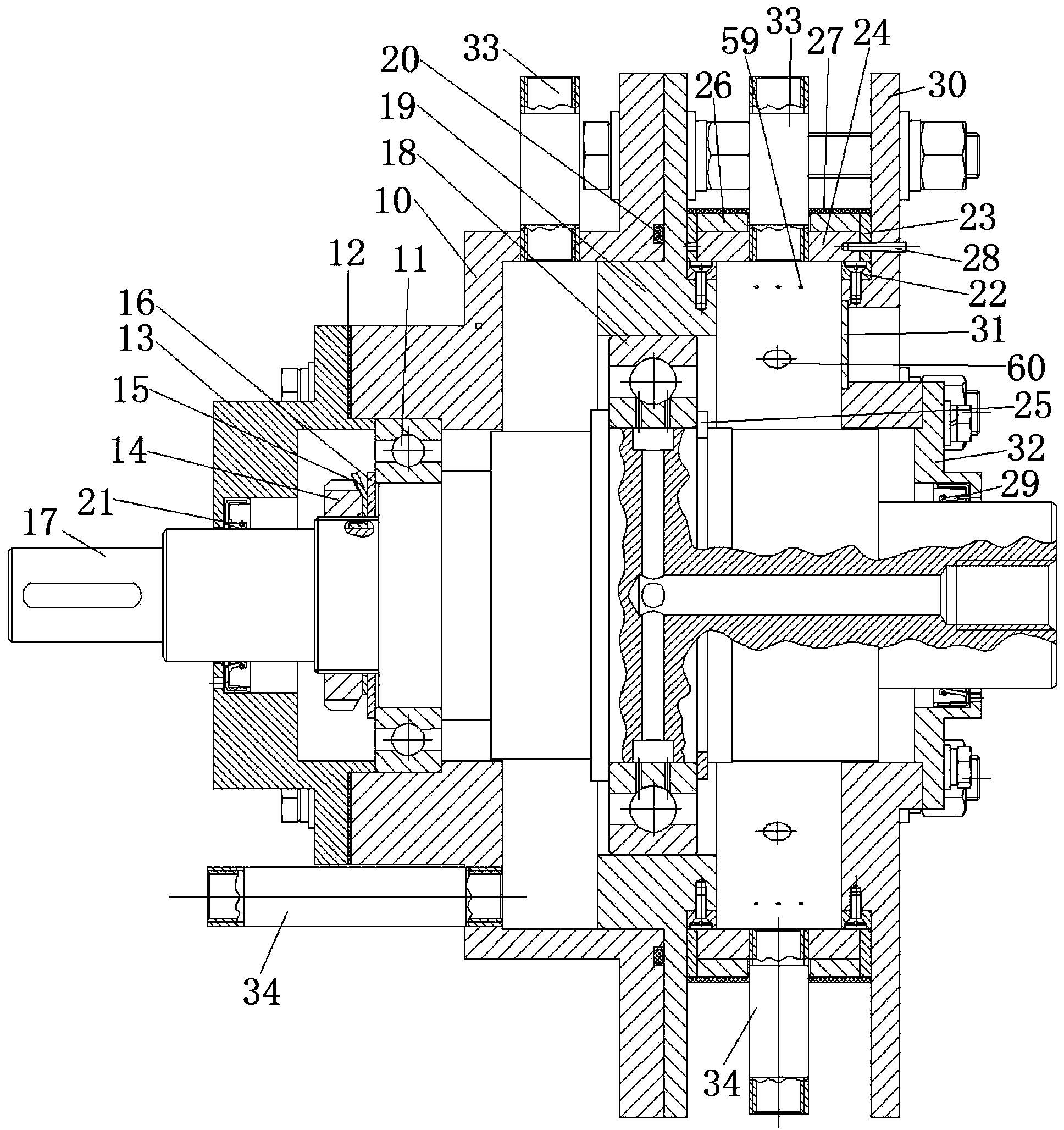

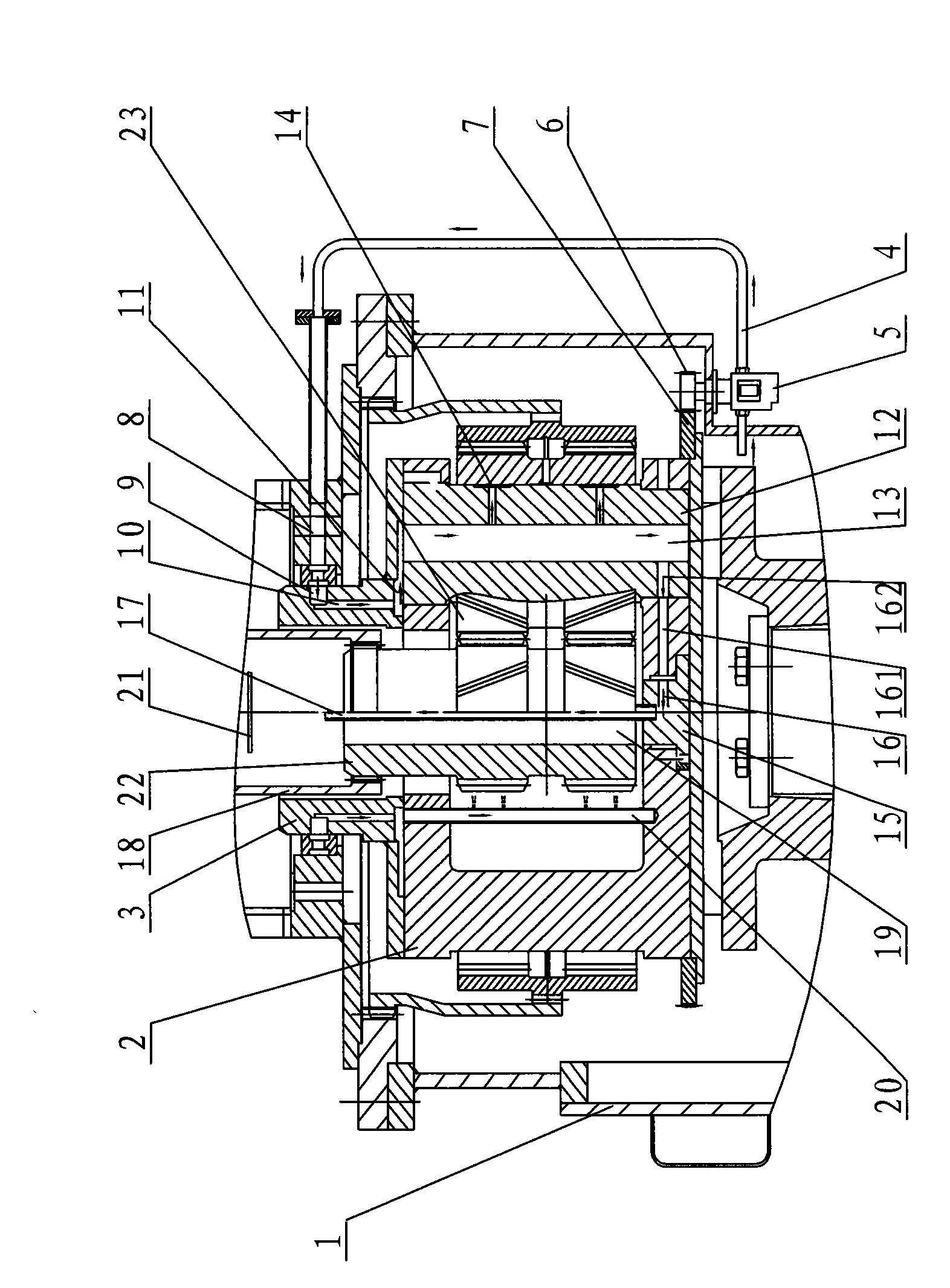

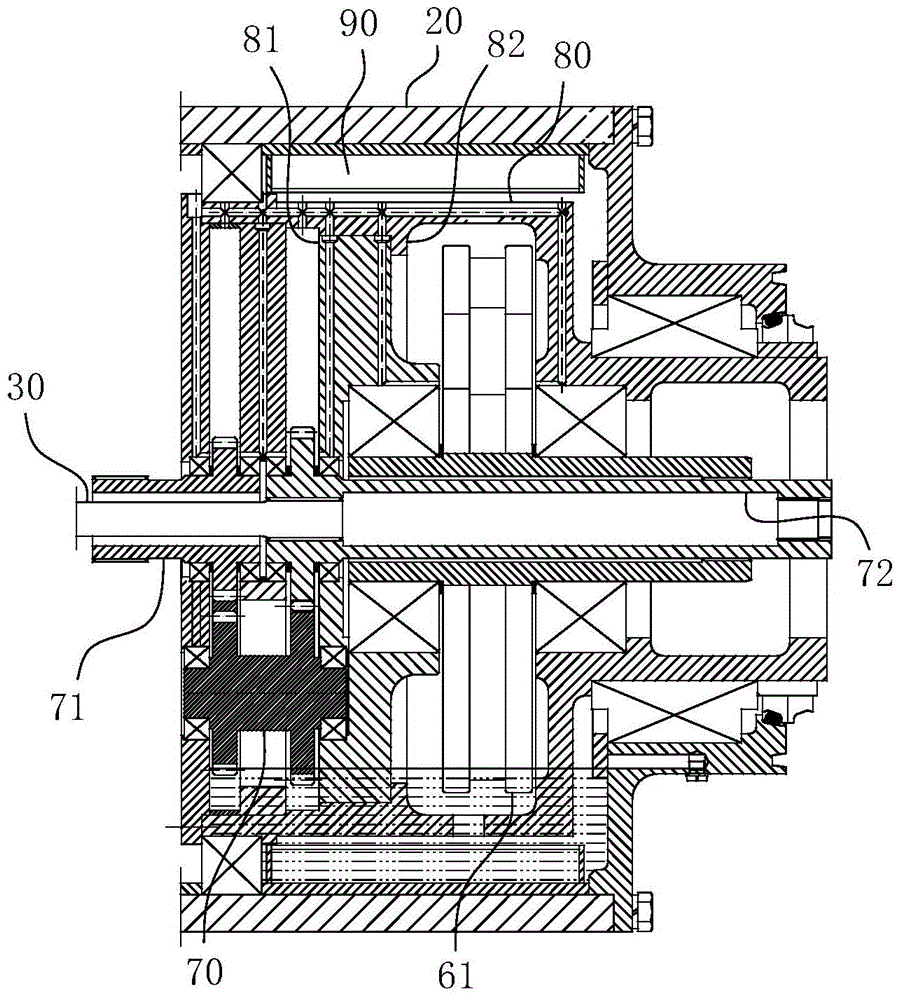

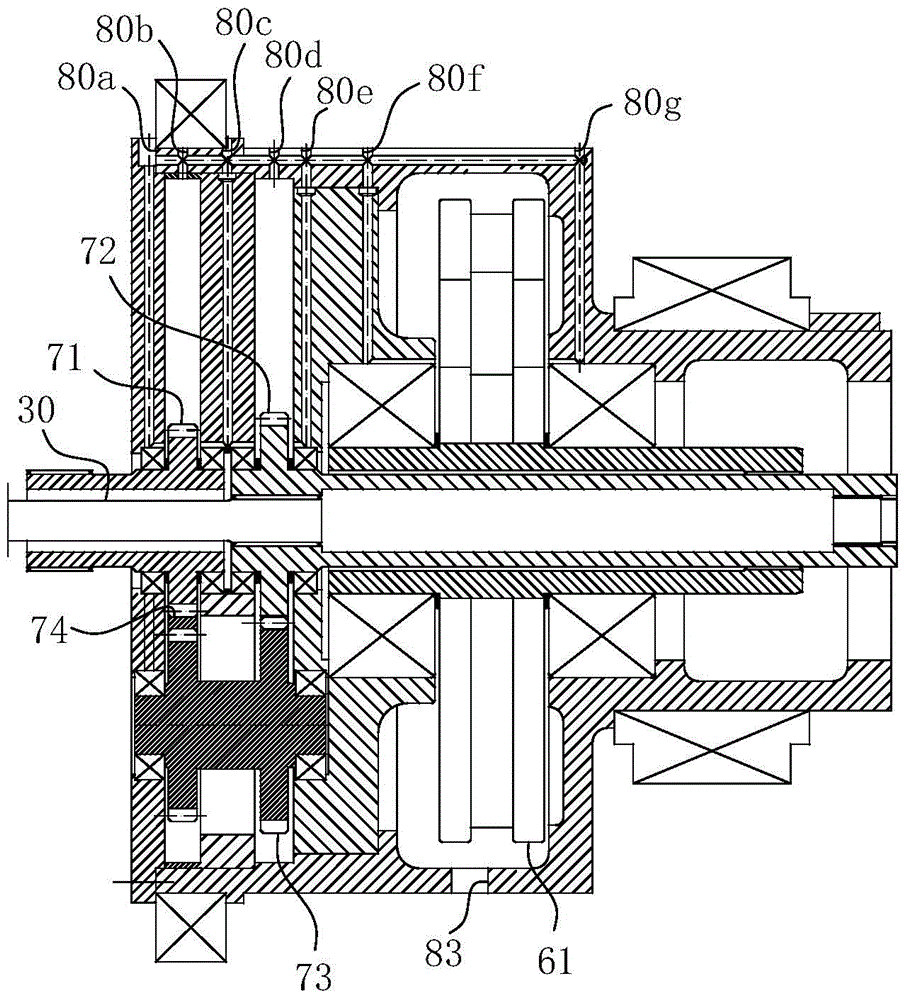

Automatic power type lubricant passage way system for transmission of satellite gears

InactiveCN101539196AFast shuntImprove transmission efficiencyGear lubrication/coolingGear wheelEngineering

The invention relates to an automatic power type lubricant passage way system for the transmission of satellite gears, which mainly comprises a gear box body, a sun gear, a plurality of satellite gears, a satellite carrier, an outer lubricant pipeline and an inner lubricant pipeline, wherein the outer circle of the satellite carrier is provided with a big gear, the outer wall of the gear box body is provided with a mechanical pump, a lubricant inlet and a lubricant outlet of the mechanical pump are arranged on the outer lubricant pipe, a main shaft of the mechanical pump is sleeved with a small gear, the big gear is meshed with the small gear to drive the mechanical pump to pump lubricant in the gear box body out to supply for a lubricant inlet pipeline through the outer lubricant pipeline. The lubricant passage way system utilizes power generated by the rotation of the satellite carrier to drive the mechanical pump to work, saves the energy and reduces the consumption as well as lowers the cost because the mechanical pump pumps the lubricant in the gear box body out and led the lubricant into the inner lubricant pipeline in the gear box body through the outer lubricant pipeline to safely and durably supply the lubricant for a drive device without external power source, fully lubricates and cools all drive parts and meshing parts, and has little mechanism abrasion and long service life.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

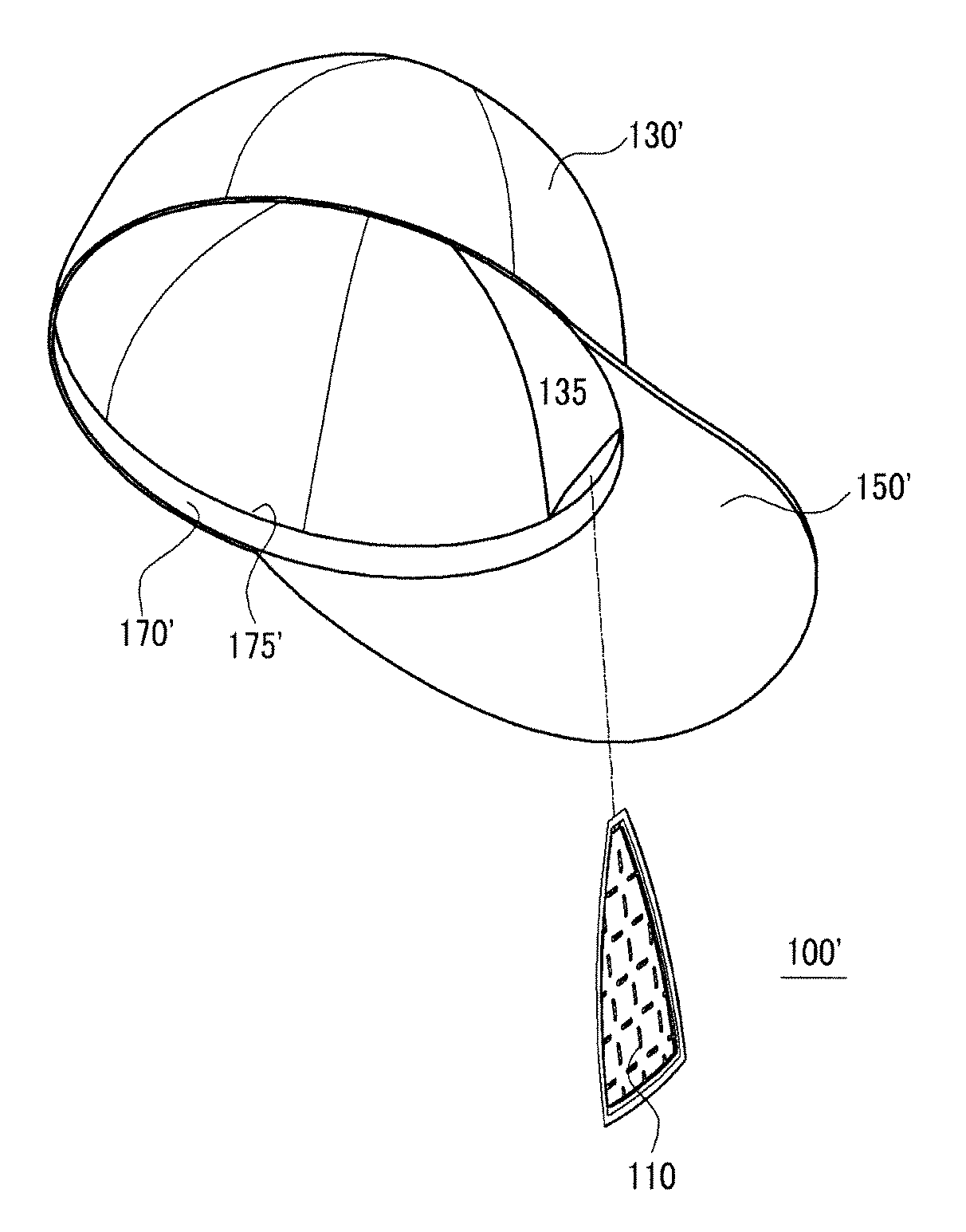

Flexile plated cooling pack of headwear and method for making the same

ActiveUS8166772B2Easy to carryEasy to keepHeat storage plantsHeat-exchange elementsCooling effectEngineering

The present invention relates to a flexible plated cooling pack for headwear and a method for making the same that is capable of providing a sufficient cooling effect with a small amount of coolant, not causing worry about leakage of the coolant, and providing a cushion effect without a volume variance regardless of many uses, as well as the cooling effect.The flexible plated cooling pack has an inner and outer synthetic resin film sheet bonded each other and a coolant filled therein, wherein the outer synthetic resin film sheet has a shape respectively corresponding to a piece of the crown portion and a sweatband and the coolant is always maintained in at least a gel state. The flexible plated cooling pack may be disposed in an inner portion of the crown portion and the sweatband of the headwear or may be inserted in a pocket formed at an inner portion of the crown portion and the sweatband of the headwear.

Owner:YUPOONG

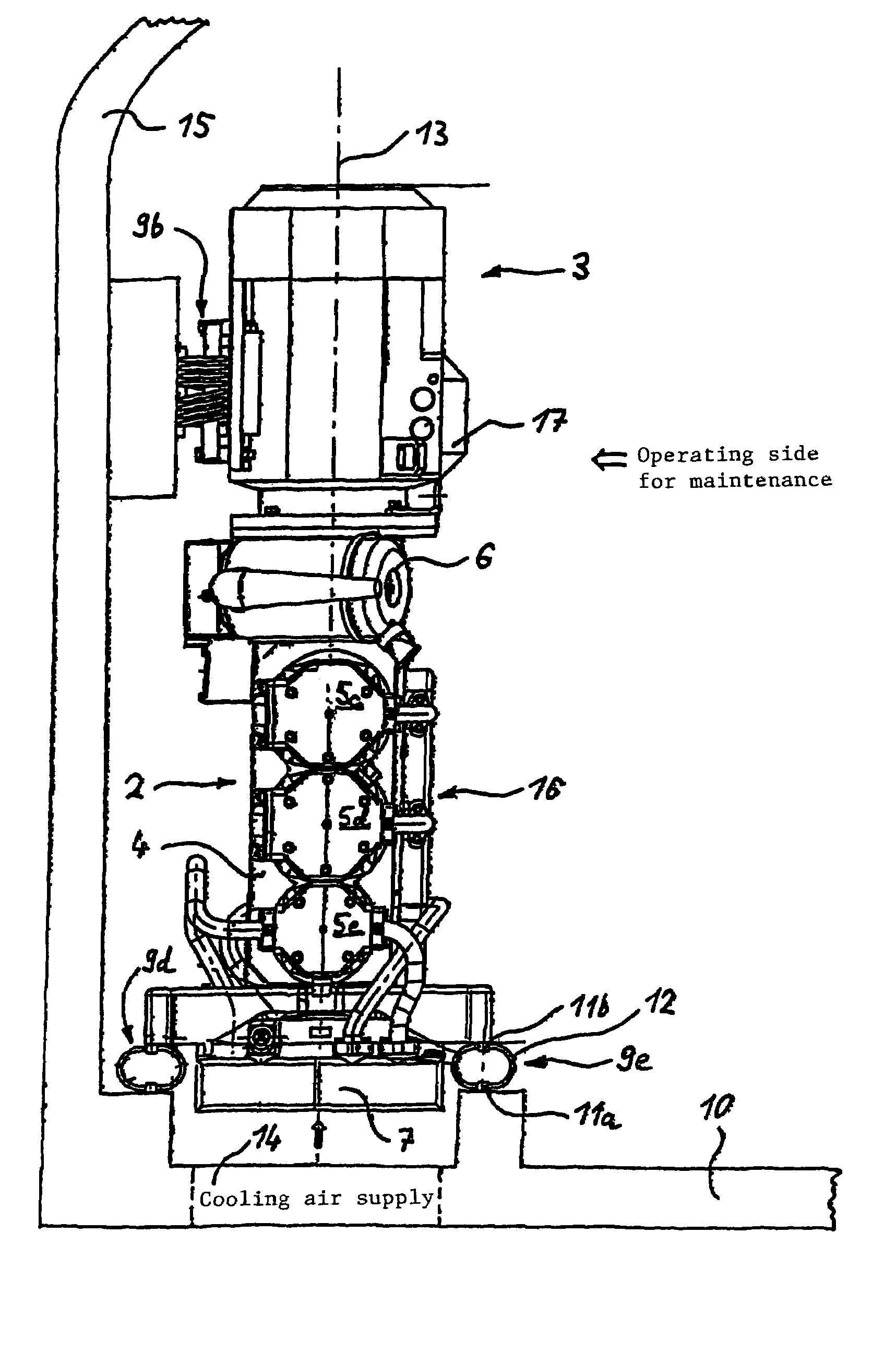

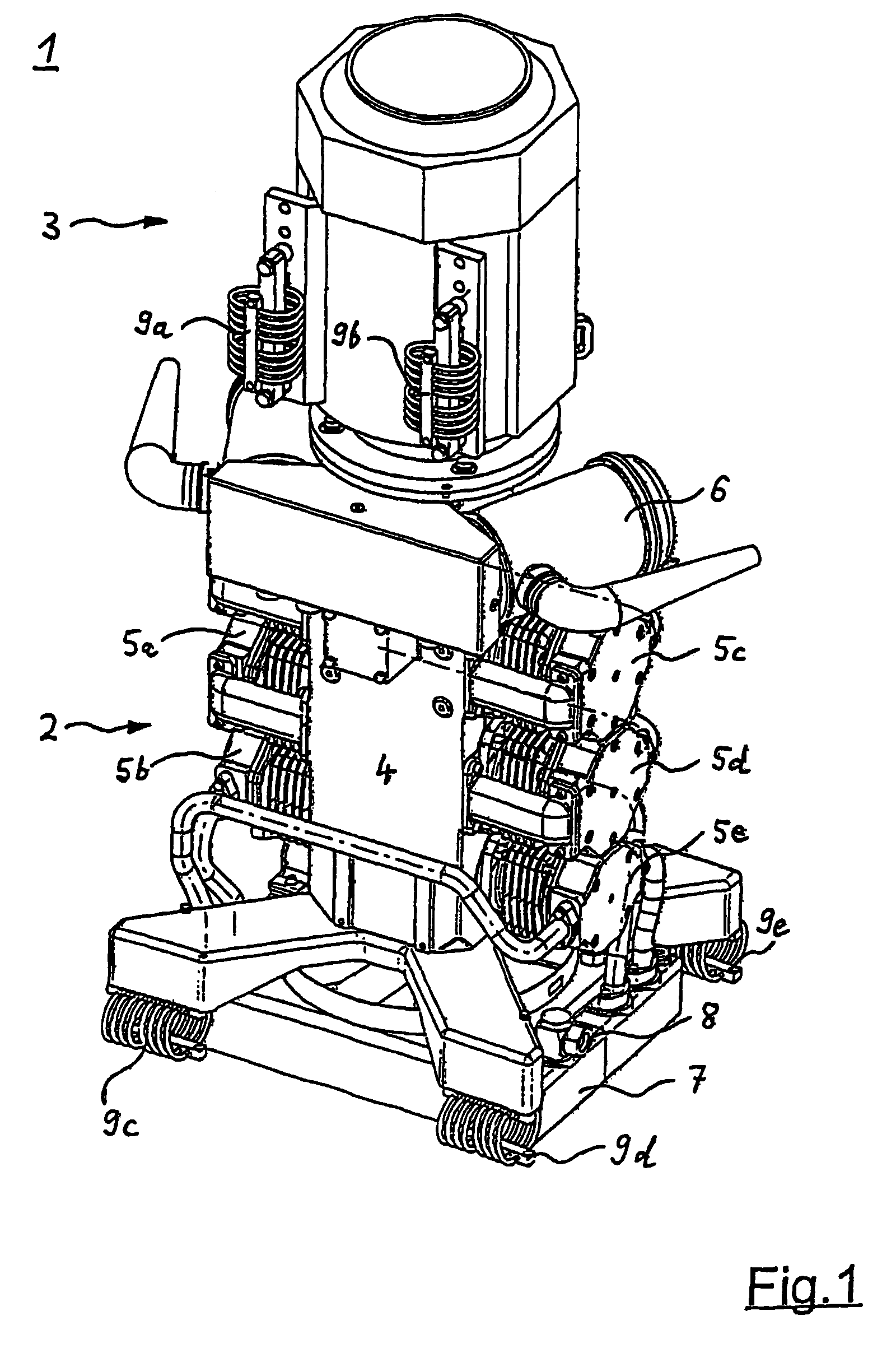

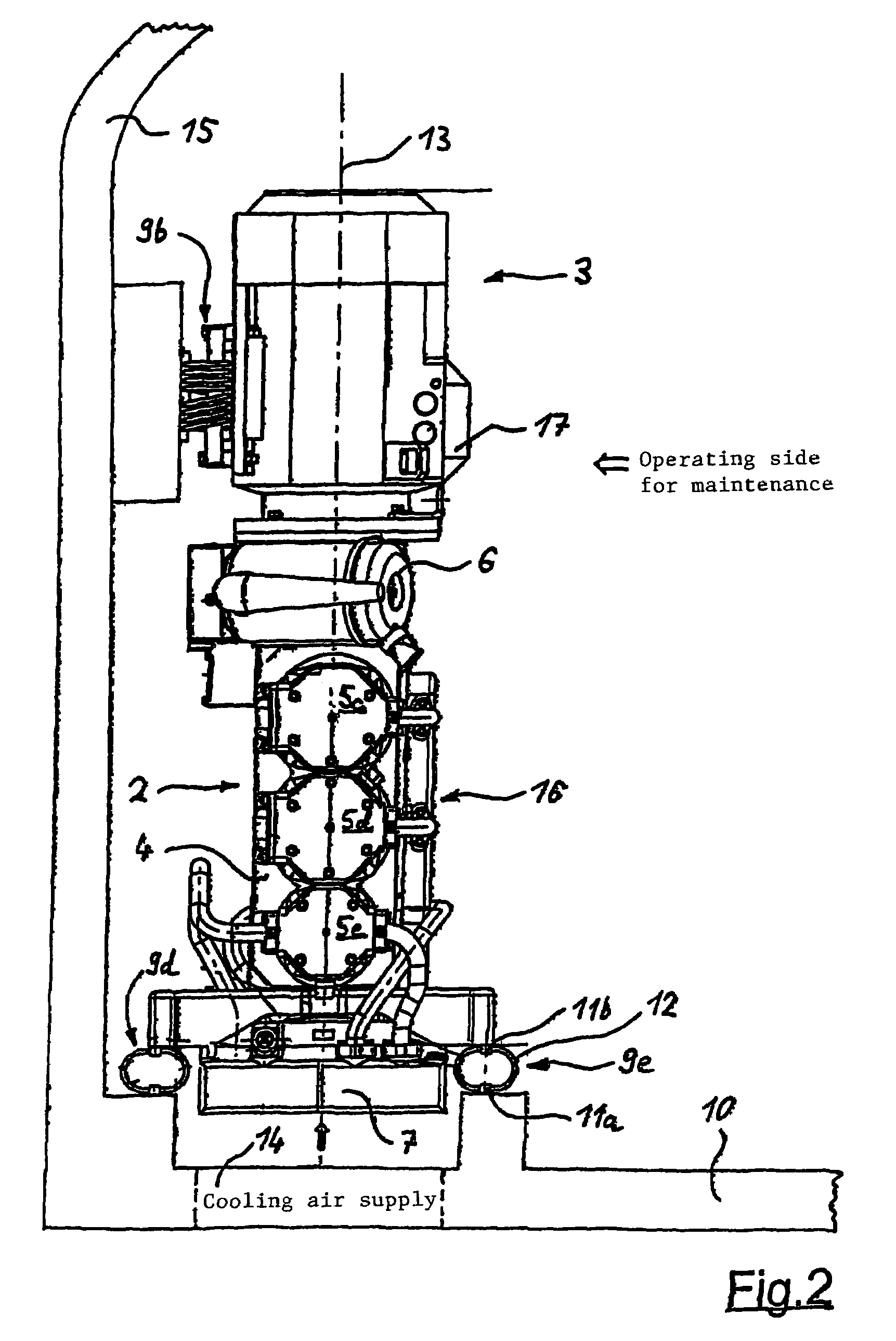

Structure of an oil-free compressor on a vehicle

InactiveUS7059841B2Solve the lack of cooling capacityEasy maintenancePositive displacement pump componentsSteam locomotivesOil freeCooling Units

An arrangement of an oil-free compressor apparatus on a rail vehicle for supplying compressed air to pneumatic units assigned to the rail vehicle. The arrangement includes an oil-free compressor and a cooler unit connected with the compressor. The arrangement also includes a rail vehicle having a floor with at least one opening. The compressor is fastened on at least one side to the vehicle floor such that a main axis of rotation of the compressor is arranged essentially vertical with respect to the vehicle floor. The cooler unit interacts with the at least one opening that is configured to take in cooling air to cool the compressor.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

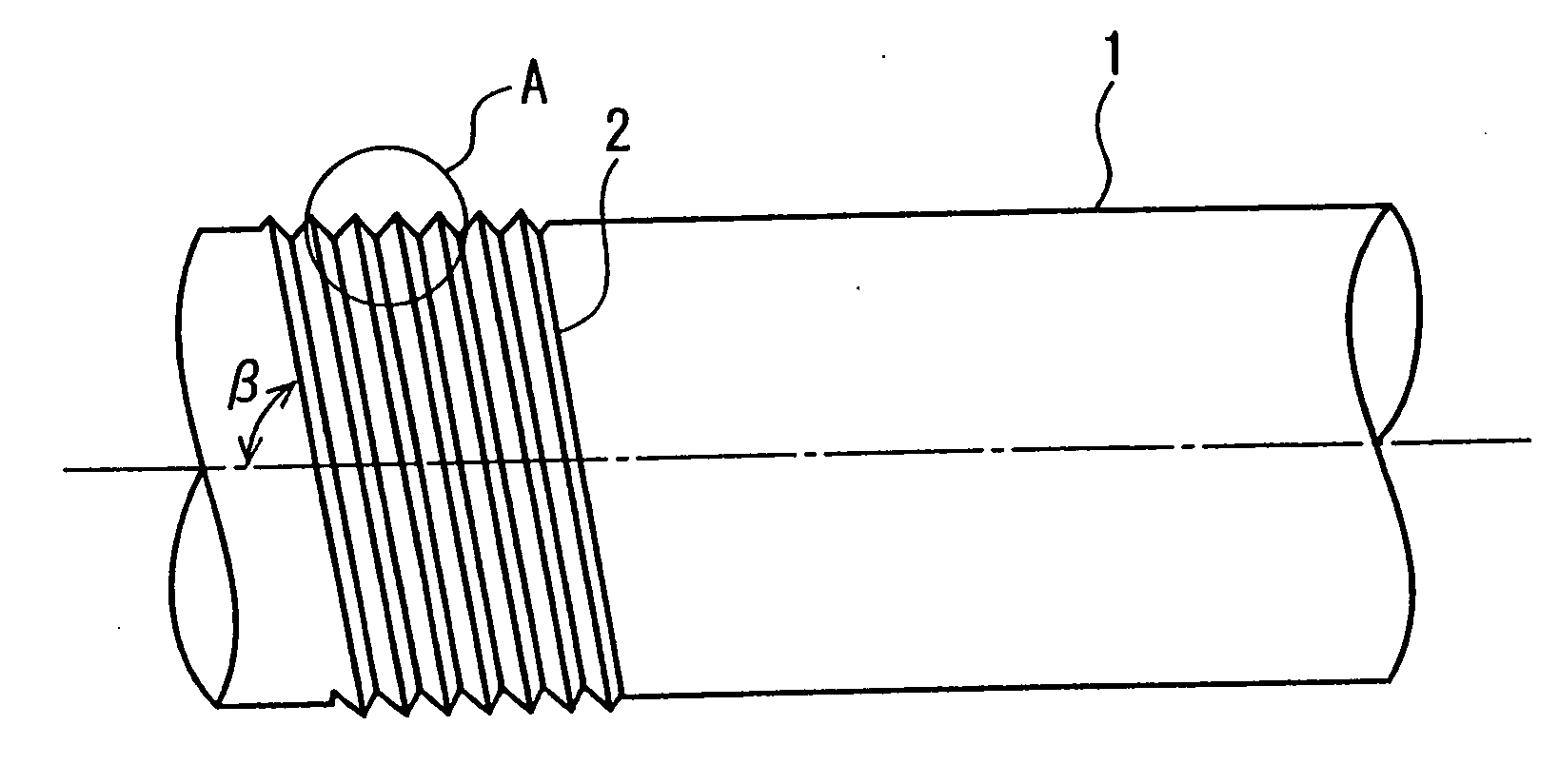

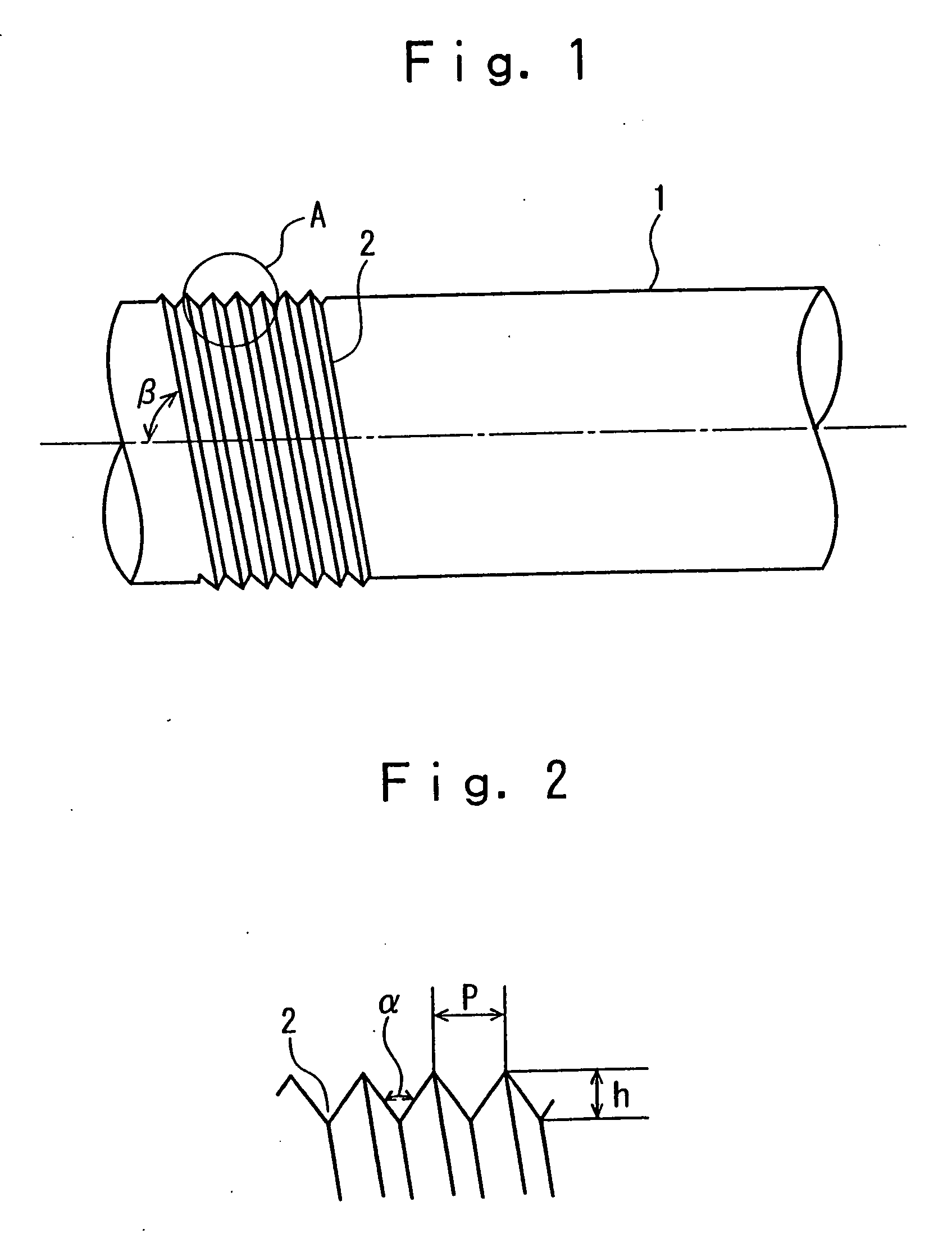

Ultrasonic elliptically vibrating boring process

InactiveCN1672839AEnsure adequate lubricationSolve the lack of cooling capacitySurface finishEllipse

The ultrasonic elliptically vibrating boring process in the field of precise machining technology includes the following steps: 1) adhering two piezoelectric ceramic chips onto two orthogonal surfaces of elliptically vibrating amplitude-varying rod; 2) applying sinusoidal voltage across the chips to make the chips to stretch and contract and the rod to bend and vibrate; 3) strengthening the bending and vibration of the rod; 4) making the boring cutter fixed to the tip of the rod obtain maximum elliptic vibration; 5) synthesizing the horizontal and vertical bending vibrations to obtain the elliptic vibration track in the edge of the boring cutter; and 6) fixing the elliptically vibrating amplitude-varying rod onto the boring rod via the vibration node. The present invention has greatly reduced boring force, reduced boring rod deformation, raised stability of the boring system and raised boring precision and surface smoothness.

Owner:SHANGHAI JIAO TONG UNIV

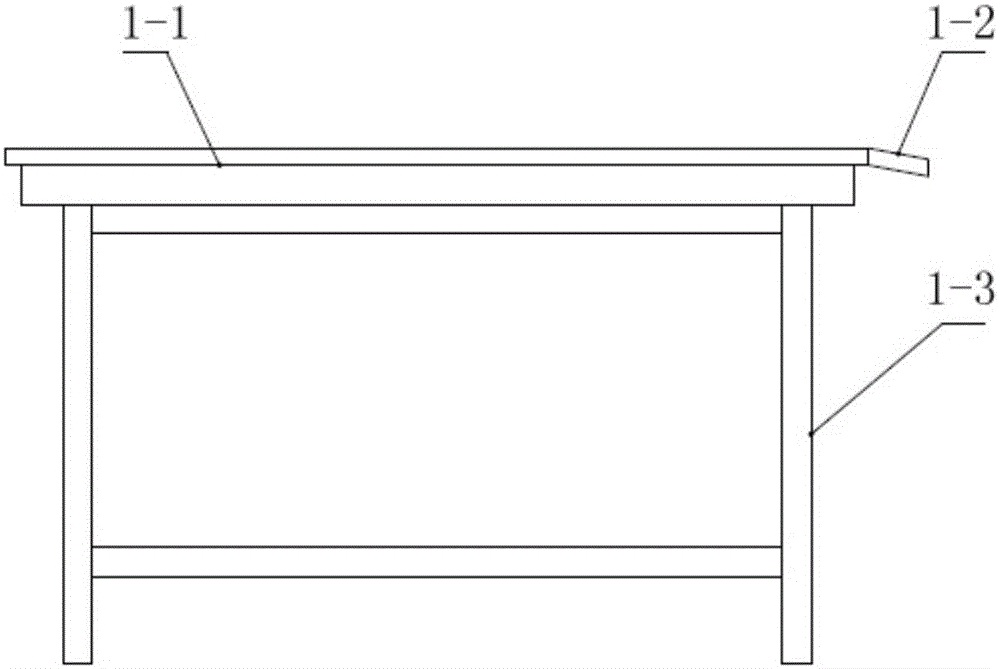

Water immersion type plastic pipe sizing device

InactiveCN101015952ASolve the lack of cooling capacityEnsure adequate lubricationTubular articlesWater immersionHollow core

The invention discloses a water immersion plastic tube diameter setter, which comprises a hollow fixed disc connected on the side wall of a cooling groove while one side of the hollow fixed disc is mounted with a laminated base. The axial outside of the laminated base is mounted with a water flux adjusting disc whose middle is disposed with a plastic tube inlet, a constant-diameter sheath is mounted between the laminated base and the water flux adjusting disc, while the outlet of the constant-diameter sheath is through the laminated base and the hollow fixed disc and the inlet is relative to plastic tube inlet. The water flux adjusting disc is disposed with a water inlet communicated with the cross between the plastic tube inlet and the inlet of the constant-diameter sheath. The laminated base is parallel mounted with a support rod at same direction with the outlet of the constant-diameter sheath, and the support rod is sheathed with laminated pads whose center is arranged with a tube constant-diameter opening same as the constant-diameter sheath. The inventive tube and device have high cooling speed and two times of improved producing efficiency.

Owner:潍坊凯德塑料机械有限公司

Turbomachine for low-temperature applications

InactiveUS20050248221A1Improve cooling effectSolve the lack of cooling capacityPositive displacement pump componentsPiston pumpsLine tubingElectric machine

A turbomachine for low-temperature applications, has a rotor shaft; at least one rotor disk that is arranged in overhung manner at one shaft end of the rotor shaft; an electric machine having a stator having windings, and an electric rotor arranged on the rotor shaft; a stage housing that surrounds the rotor disk and has connections for a cold gas that flows through the stage housing; and a machine housing in which the electric machine and shaft bearings for the rotor shaft are arranged. The machine housing is connected with the stage housing. A partition made of insulating material is arranged between the stage housing and the machine housing, which thermally separates the stage housing from the machine housing. A line provided with a flow-through regulation fitting is connected to the flow path of the cold gas, for branching off an amount-regulated cooling stream, which is passed to the electric machine within the machine housing.

Owner:ATLAS COPCO ENERGAS

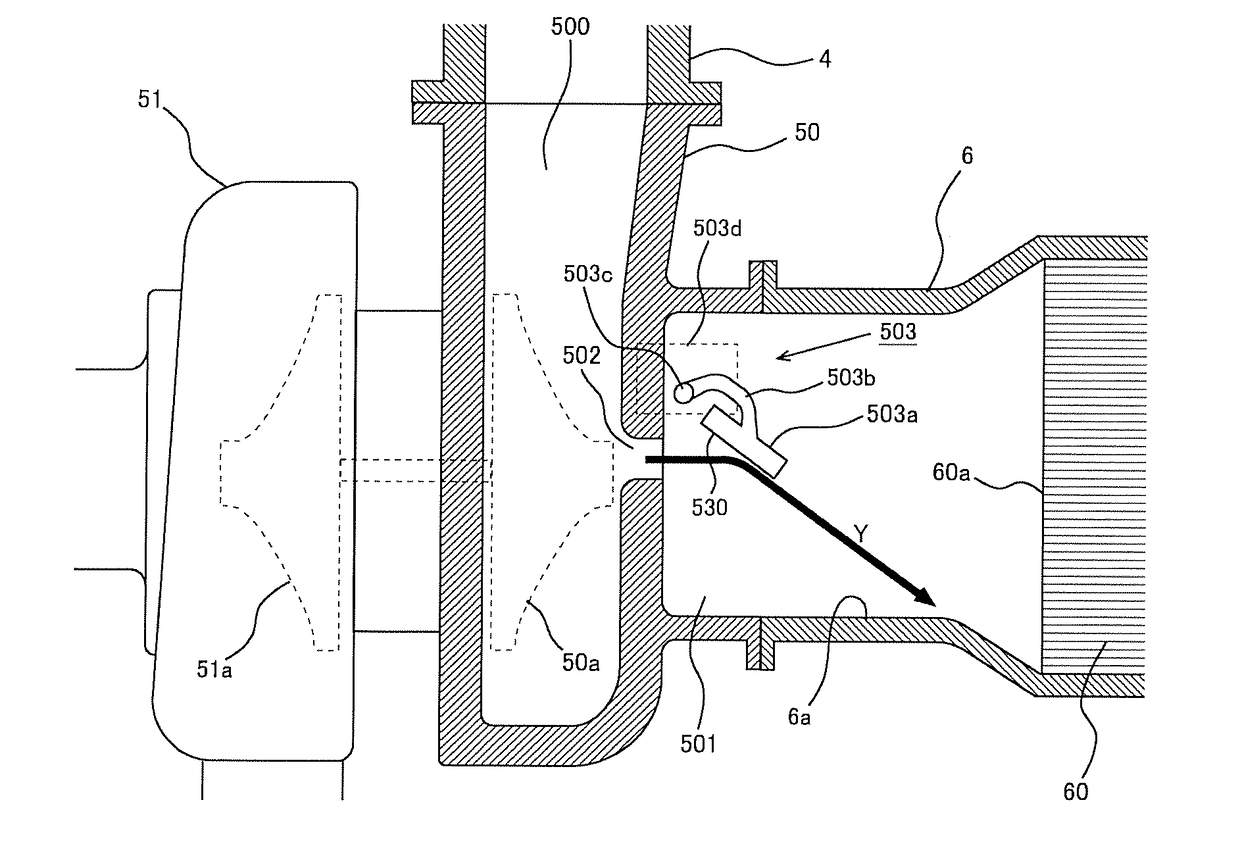

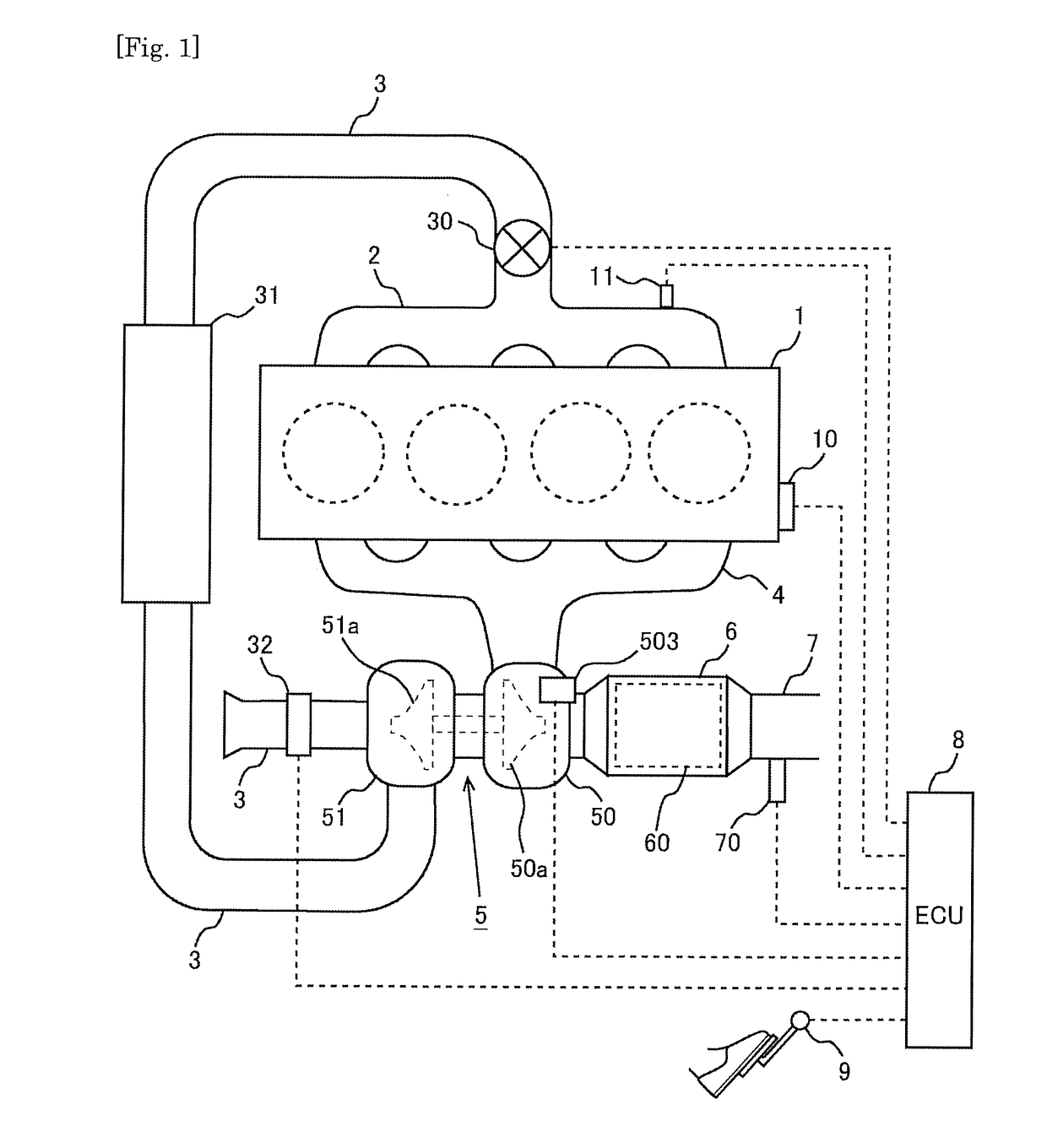

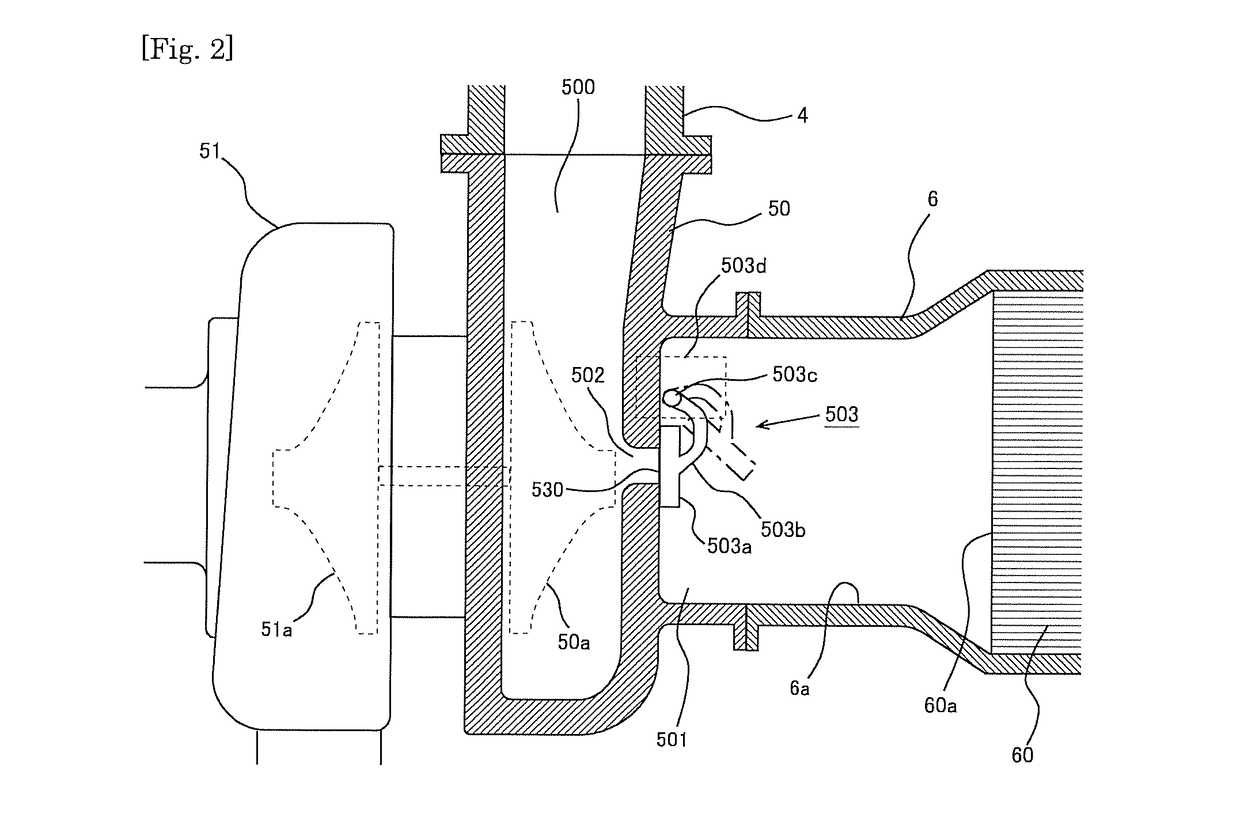

Control apparatus for an internal combustion engine

ActiveUS20170145936A1Suppressing occurrence of occurrenceSuppressing of thermal stressElectrical controlInternal combustion piston enginesEngineeringInternal combustion engine

In a control apparatus applied to an internal combustion engine in which when an opening degree of a valve body of a waste gate valve is less than the predetermined opening degree, the extension line intersects a wall surface of an exhaust passage located upstream of the upstream side end face of the exhaust gas purification catalyst, the control apparatus controls the waste gate valve so that at the time of execution of fuel cut off processing, when the temperature of the exhaust gas purification catalyst is less than a predetermined temperature, the valve body is fully closed, whereas when the temperature of the exhaust gas purification catalyst is not less than the predetermined temperature, the opening degree of the valve body is made to a deterioration suppression opening degree which is larger than when the valve body is fully closed and which is smaller than the predetermined opening degree.

Owner:TOYOTA JIDOSHA KK

Self-lubricating vertical orientating vibrating wheel structure subjected to counterweight by using liquid

The invention relates to a self-lubricating vertical orientating vibrating wheel structure subjected to counterweight by using a liquid. The self-lubricating vertical orientating vibrating wheel structure comprises a vibrating wheel, a vibration exciter cylinder, a transmission shaft and a cylinder-shaped gear box, wherein a first forwards-rotating eccentric wheel, a backwards-rotating eccentric wheel and a second forwards-rotating eccentric wheel are sequentially arranged along the axial length direction of the transmission shaft, the backwards-rotating eccentric wheel and the first forwards-rotating eccentric wheel are connected with each other through a change gear set; the cylinder-shaped gear box is provided with a gear cavity and an eccentric wheel cavity corresponding to the change gear set and the first forwards-rotating eccentric wheel; the upper end of the cylinder-shaped gear box is provided with a lubricating flow channel, and the lower end of the cylinder-shaped gear box is provided with a liquid outlet; the vibration exciter cylinder is peripherally provided with oil boxes used for rain falling lubrication corresponding to the inner walls of cylinder cavities positioned on the positions of the cylinder-shaped gear box, the second forwards-rotating eccentric wheel and the backwards-rotating eccentric wheel; and the outer wall of the vibration exciter cylinder, the inner wall of the vibrating wheel and ring plates positioned on two ends of the vibrating wheel are encircled to form a sealing cavity used for filling a counterweight liquid together. The self-lubricating vertical orientating vibrating wheel structure disclosed by the invention achieves the sufficient lubrication effect of various bearings and gears inside equipment and can realize the purposes of counterweight and high-efficiency radiation of the vibrating wheel through the counterweight liquid.

Owner:合肥永安绿地工程机械有限公司

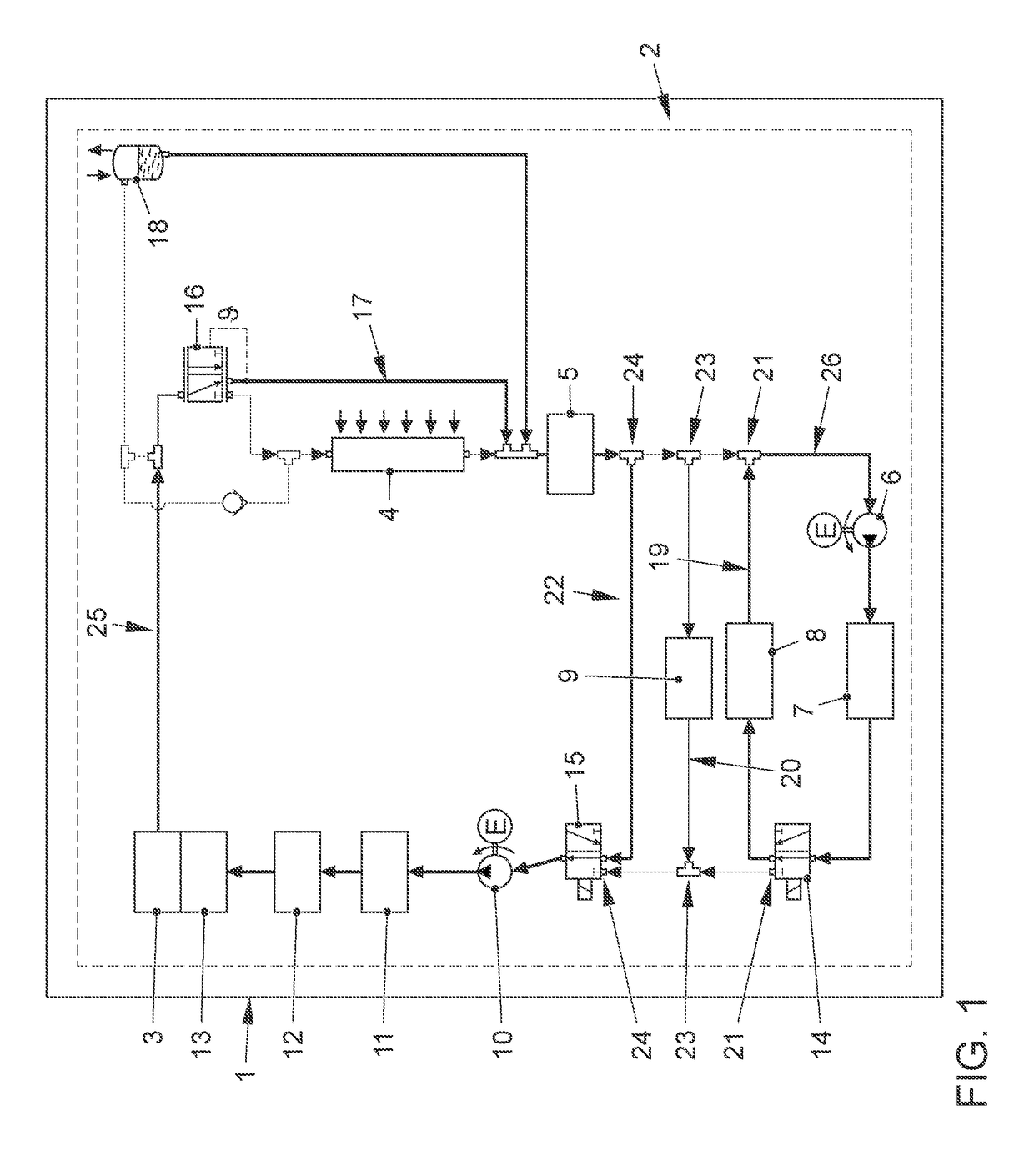

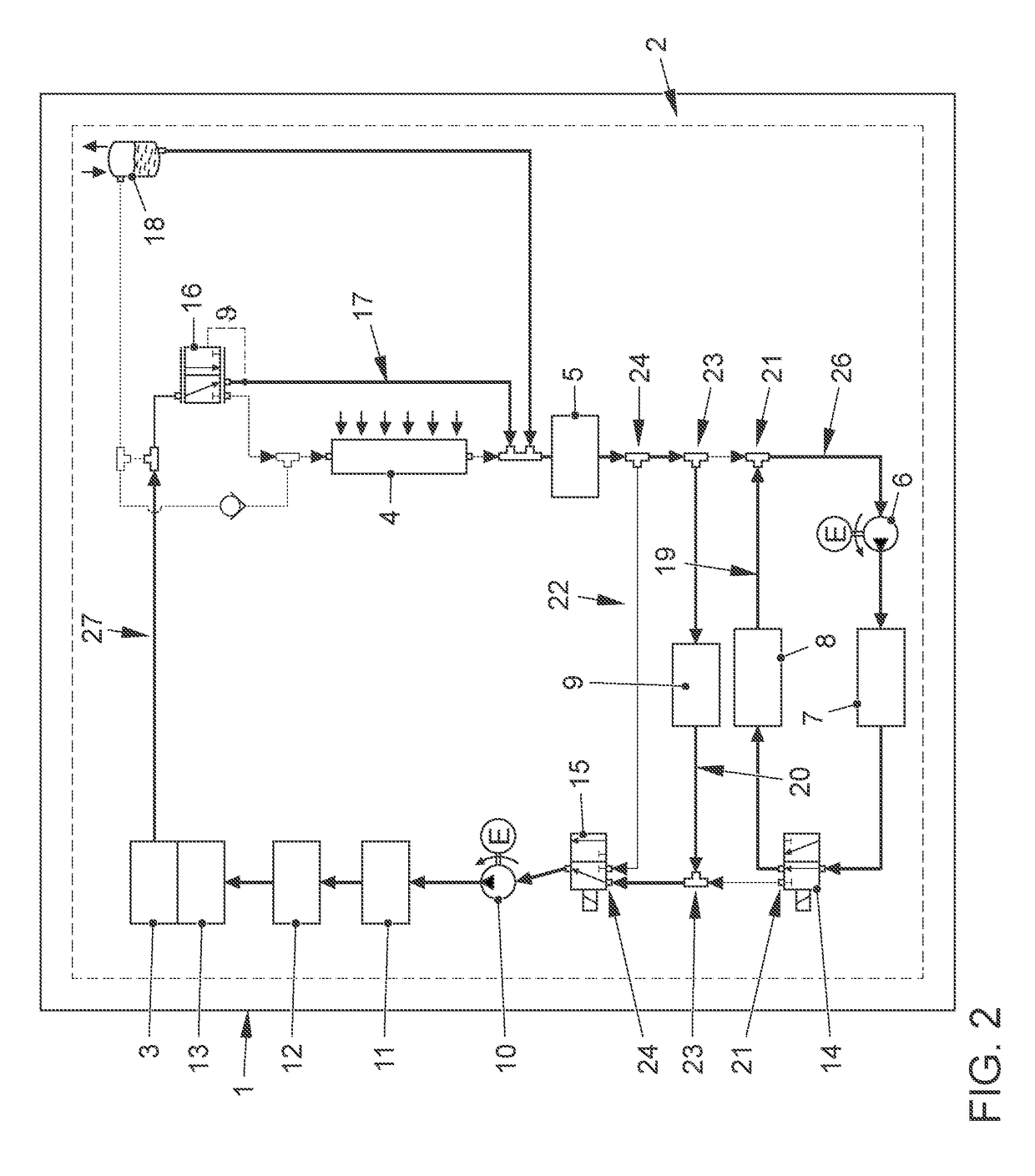

Motor vehicle with a cooling system

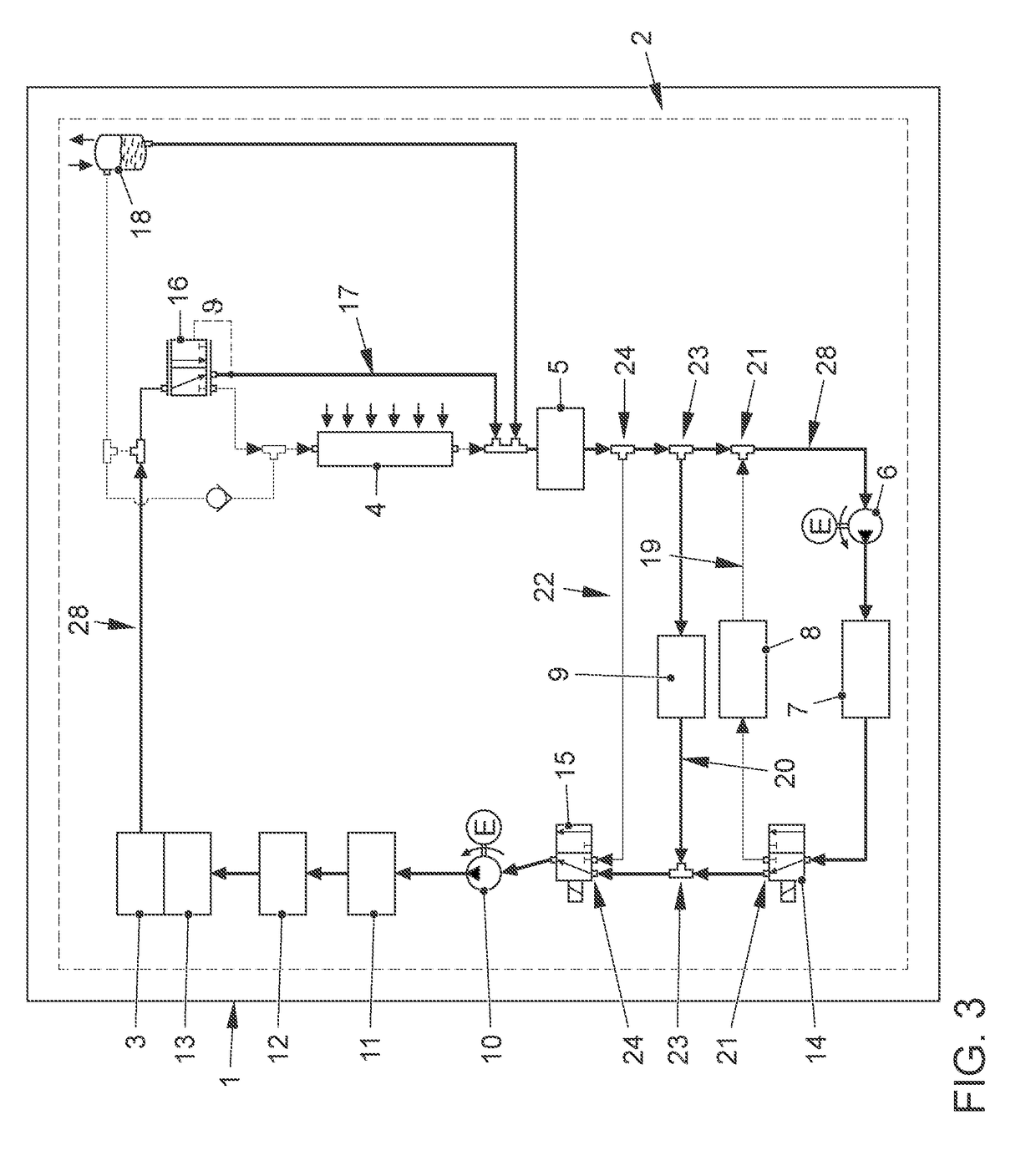

ActiveUS20190070951A1Rapid energetically advantageous heatingSolve the lack of cooling capacitySecondary cellsVehicle heating/cooling devicesPlate heat exchangerNuclear engineering

A motor vehicle with a cooling system, comprising an electric traction motor, an ambient heat exchanger, a bypass to the ambient heat exchanger, a traction battery, a coolant heater, a coolant-refrigerant heat exchanger of an air conditioner, a first coolant pump, and a second coolant pump that are directly or indirectly connected or connectable to one another via coolant lines and a distribution system, characterized in that, in a first functional position of the distribution system, coolant is conveyable, by means of the first coolant pump, in a first coolant circuit that includes the traction motor, the bypass to the ambient heat exchanger, and the coolant-refrigerant heat exchanger, and coolant is conveyable, by means of the second coolant pump, in a second coolant circuit, separate from the first coolant circuit, that includes the traction battery and the coolant heater, and in a second functional position of the distribution system, coolant is conveyable, by means of the first coolant pump, in a third coolant circuit that includes the traction motor and the ambient heat exchanger, and coolant is conveyable, by means of the second coolant pump, in a fourth coolant circuit, separate from the third coolant circuit, that includes the traction battery and the coolant-refrigerant heat exchanger.

Owner:VOLKSWAGEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com