Bearing chamber oil and gas two-phase flow and heat exchange testing device

A technology of bearing cavity and heat test, which is applied in the direction of aerodynamic test, fluid dynamic test, measuring device, etc., can solve the problems of reducing the convenience of replacement, inability to connect and disconnect, large deformation of the right cover plate, etc., to achieve Effects of reducing current signal interference, quick installation and disassembly, and simplified lubrication structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Describe the present invention below in conjunction with embodiment:

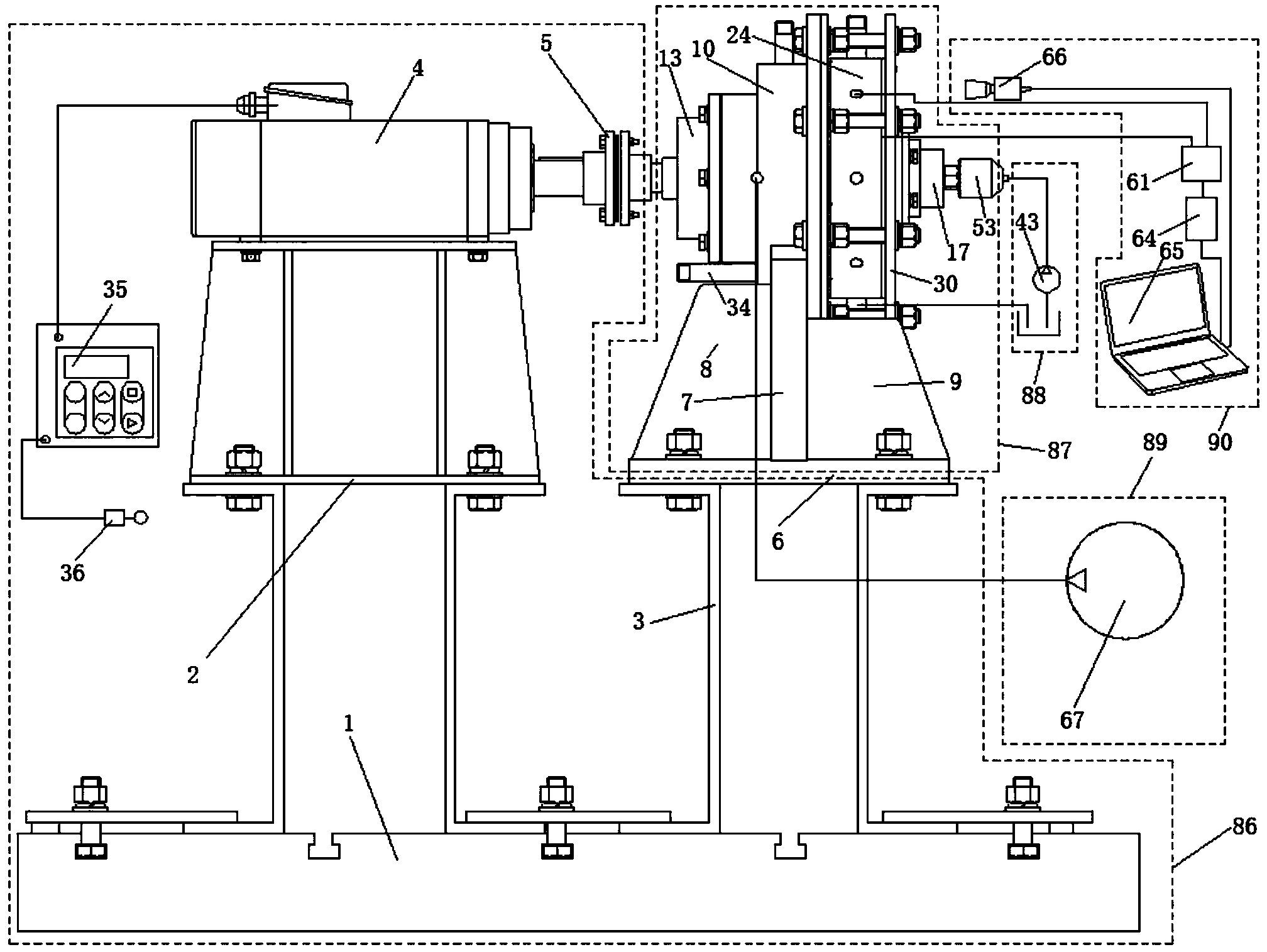

[0067] Refer to attached figure 1 , The bearing chamber oil-gas two-phase flow and heat transfer test device described in this embodiment includes a power and support system 86 , a bearing chamber mechanical body 87 , a lubricating oil circulation system 88 , an air supply system 89 and a measurement camera system 90 .

[0068] Refer to attached figure 1 On the one hand, the power and support system 86 is used to support the high-speed variable-frequency motor 4 and the mechanical body 87 of the bearing cavity, and on the other hand, it is used to adjust the speed of the high-speed variable-frequency motor 4, that is, to adjust the speed of the test bearing 18. In this embodiment, the power components include a high-speed variable frequency motor, a diaphragm coupling, a frequency converter and an air switch. The downstream of the frequency converter 35 is connected to the high-speed variable-frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com