Automatic power type lubricant passage way system for transmission of satellite gears

A planetary gear transmission, lubricating oil circuit technology, applied in the direction of gear lubrication/cooling, etc., can solve the problems of poor lubrication effect and inconvenient use of electric pumps, and achieve the effects of fast shunt speed, extended service life and high transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

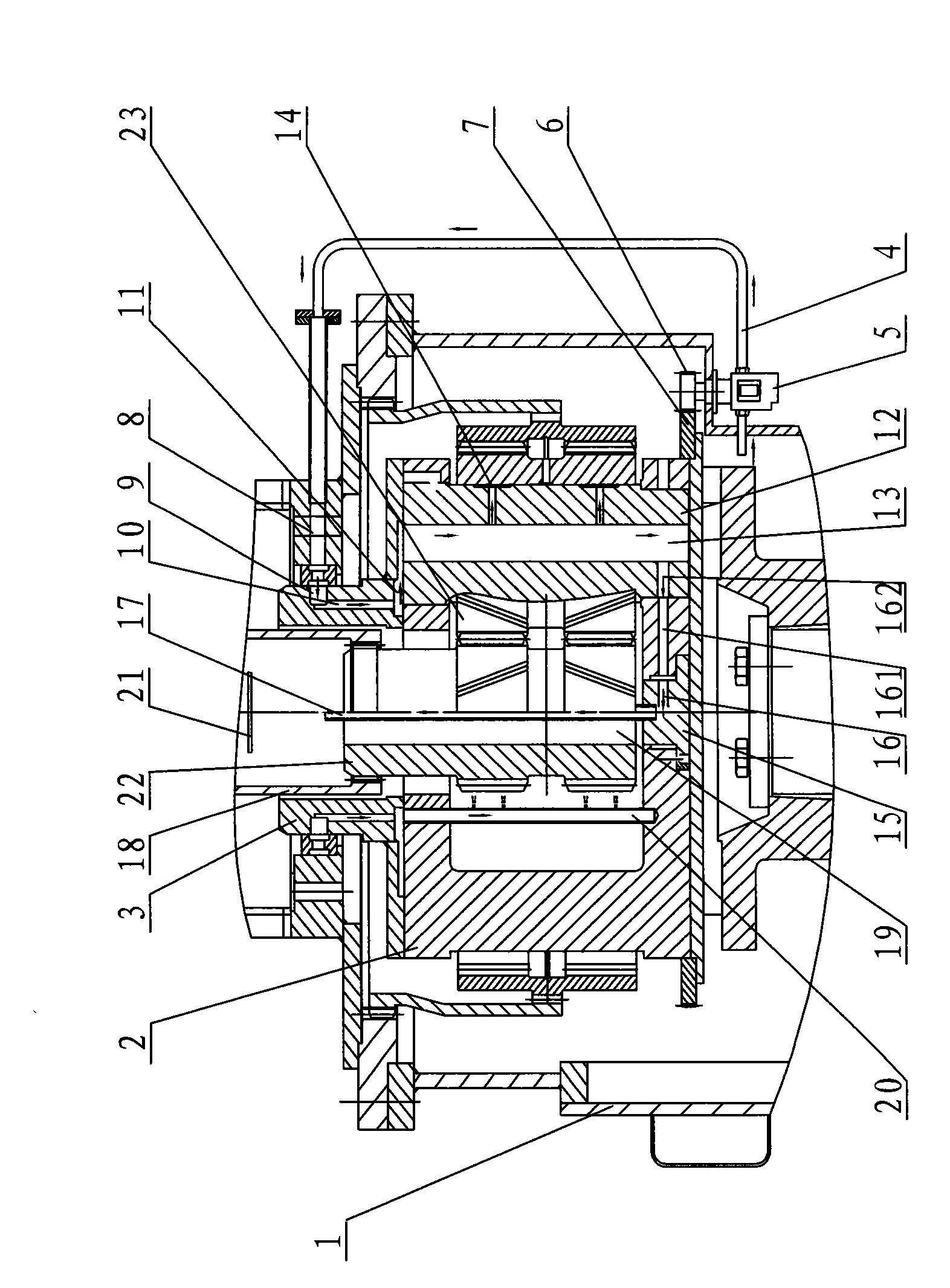

[0012] figure 1 The automatic power lubricating oil circuit system for planetary gear transmission shown mainly includes gearbox case 1, sun gear 22, planetary gear 23, planet carrier 2, outer oil pipeline 4, inner oil pipeline, outer oil pipeline 4 The oil inlet of the gear box is connected with the inner cavity of the gear box body 1, and the oil outlet of the outer oil pipeline 4 is connected with the oil inlet pipe 8 of the inner oil pipeline. Set on the outer oil pipeline 4, a small gear 6 is set on the main shaft of the mechanical pump 5, and a large gear 7 is set on the outer ring sleeve at the bottom of the planet carrier 2, and the small gear 6 and the large gear 7 are meshed.

[0013] The outer circumference of the upper cover plate 3 on the planet carrier 2 is provided with an annular oil groove 9, and a semi-closed oil storage inner cavity 11 is provided be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com