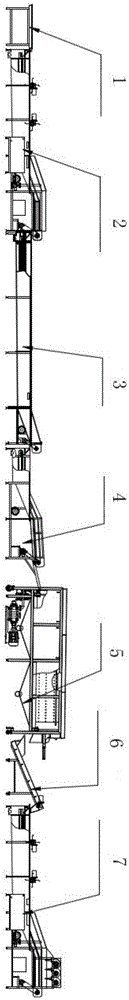

Automatic rhizome peeling and washing assembly line and method

An assembly line and rhizome technology, which is applied in the field of cleaning and rhizome peeling, can solve the problems of artificial secondary peeling, large damage, inability to meet large-scale production, etc., and achieve the effect of saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

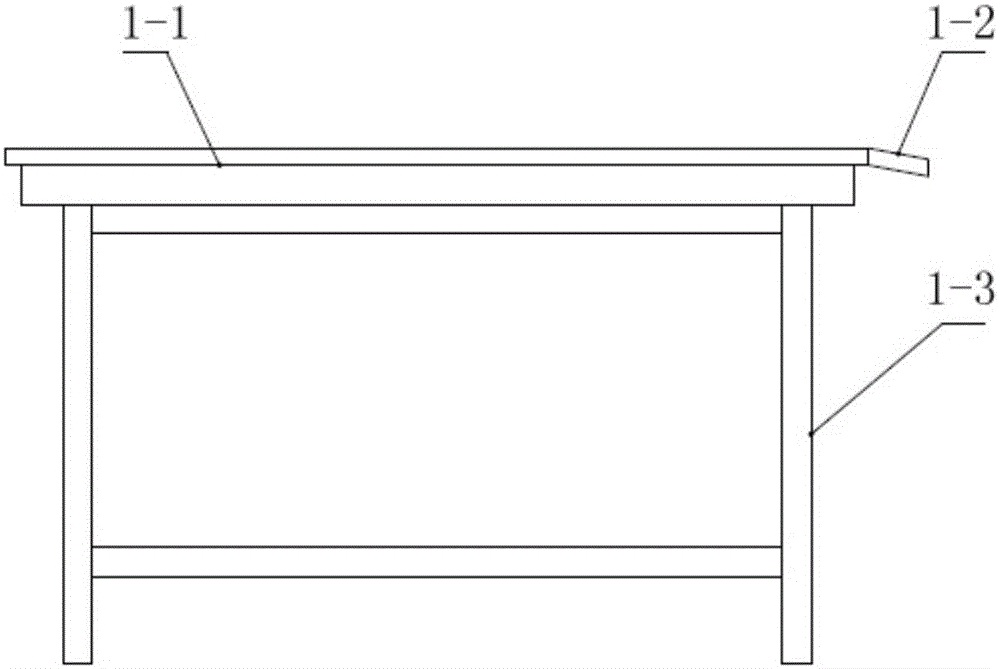

Embodiment 1

[0060] Remove the tail and fine heel of Paeoniae Alba on the unpacking platform, put it into a blower-removing bubble washing machine for cleaning; transport the cleaned Paeoniae Alba to the cooking machine, and cook it with 85-95°C water for about 10 minutes (the surface of Paeoniae Alba is just fine It is better to be able to be pinched by fingernails); transported to the cooling machine to cool to about 40°C; sent to the drum peeling machine for peeling; the peeled white peony root is transported to the bubble cleaning machine by a belt conveyor for secondary cleaning, and then After drying, the whole peeling and cleaning process is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com