Patents

Literature

573results about How to "Guaranteed smooth assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

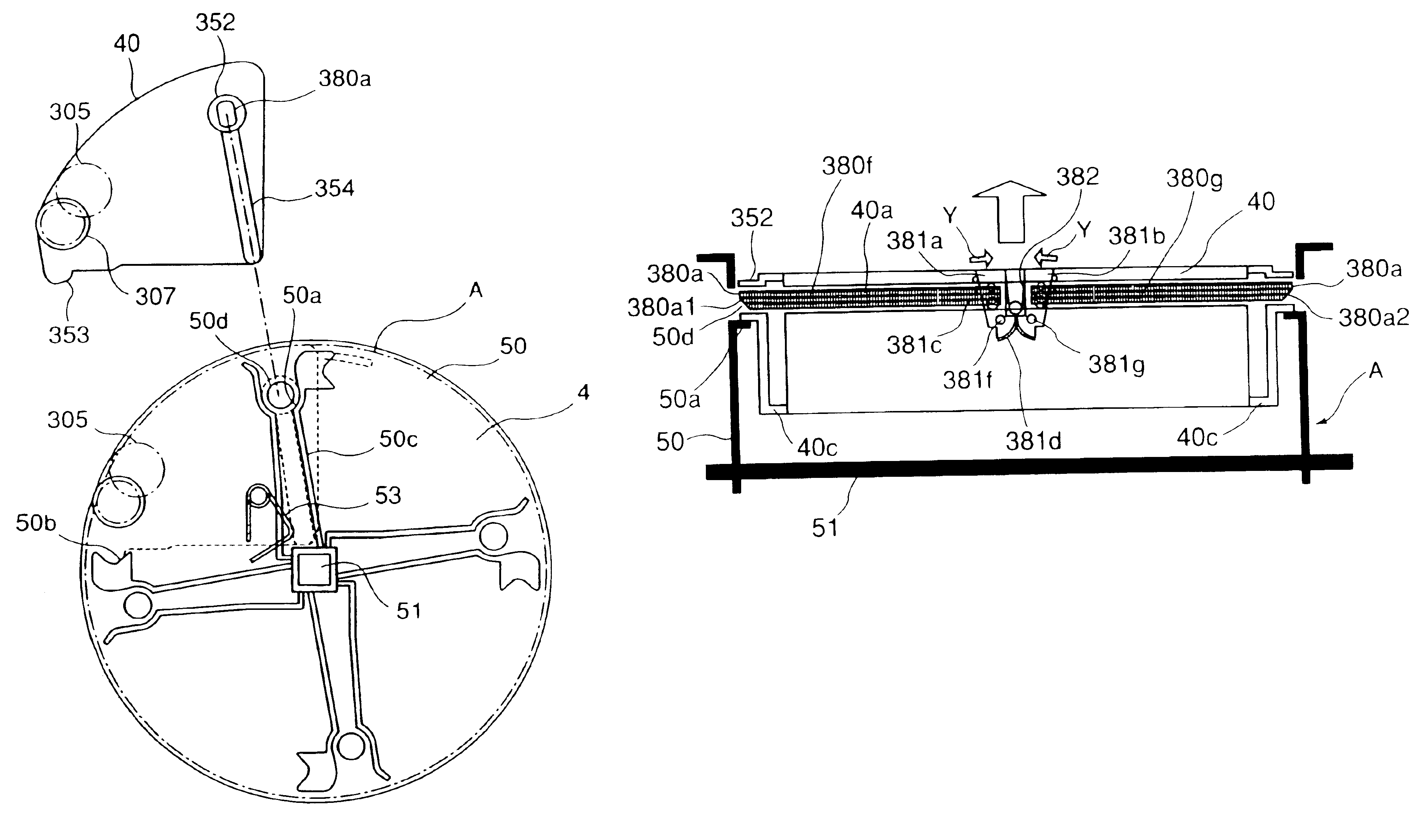

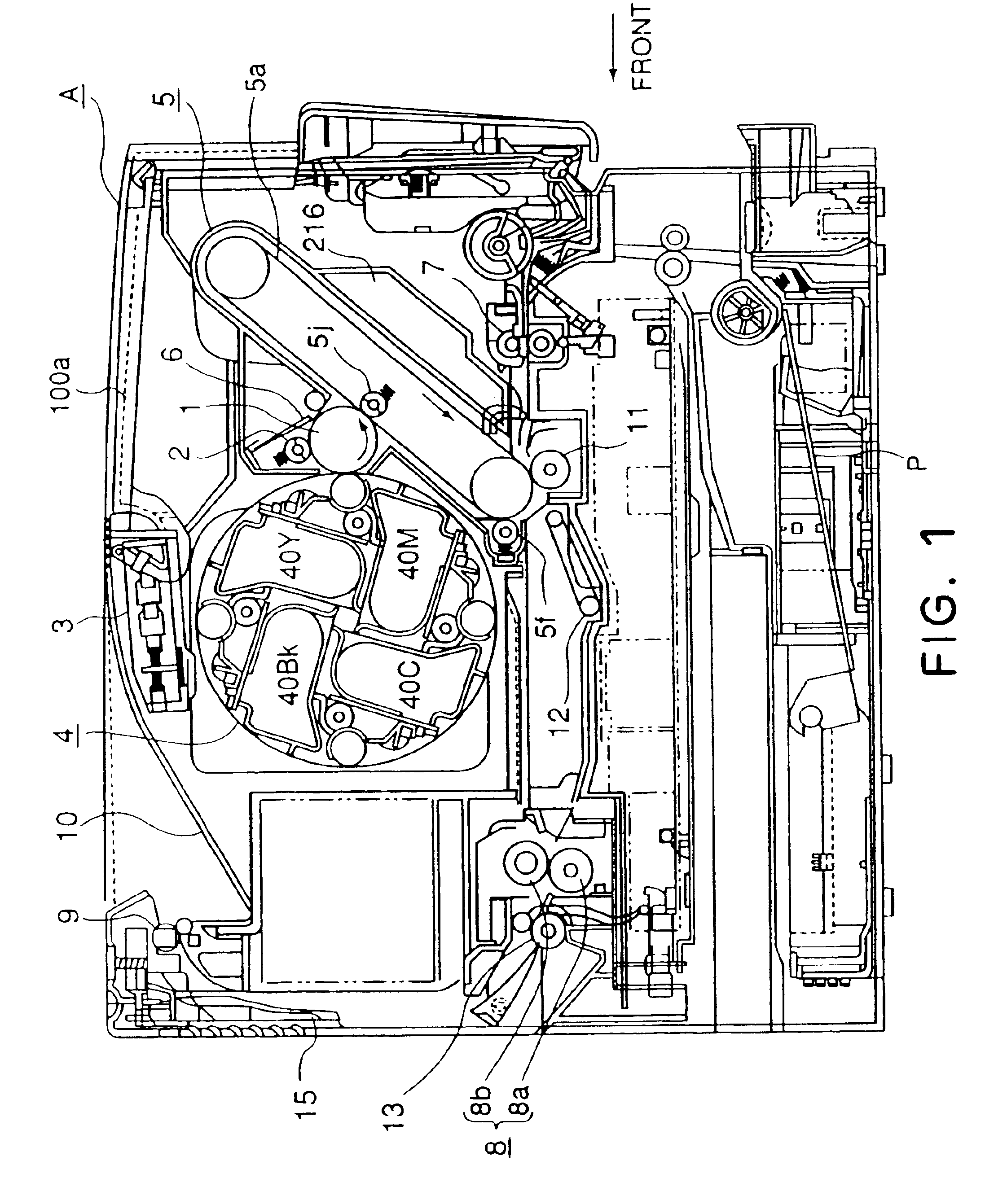

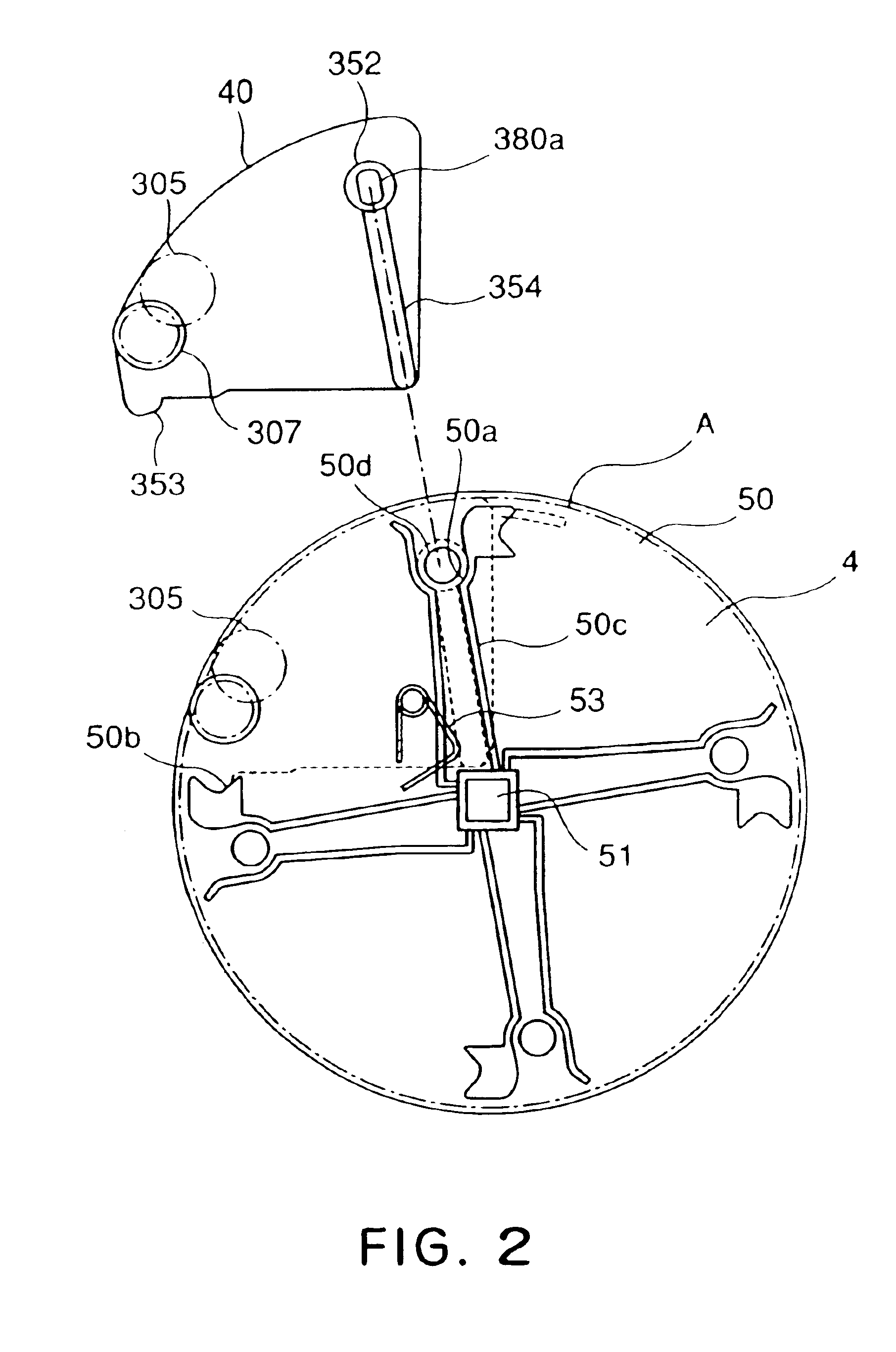

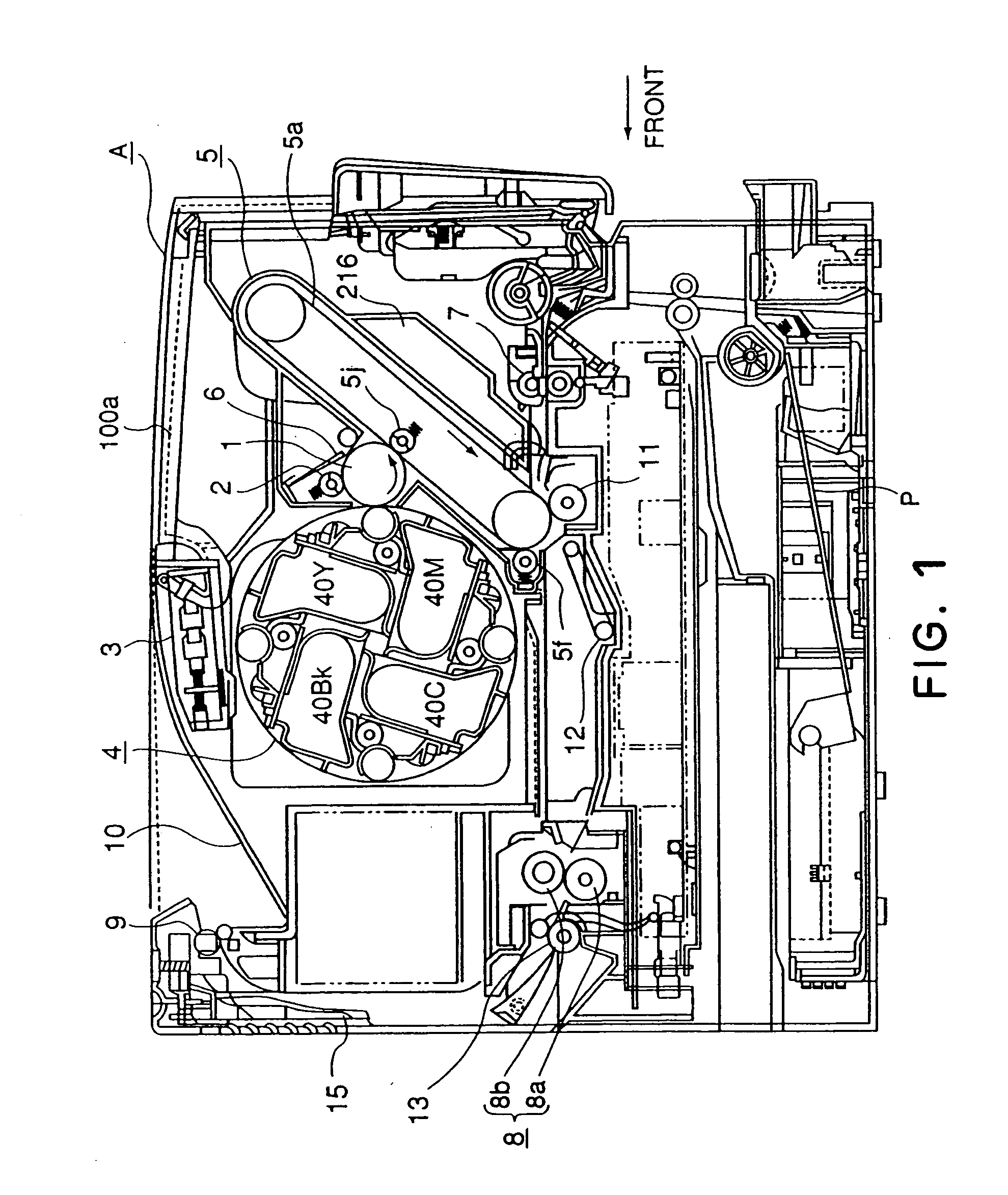

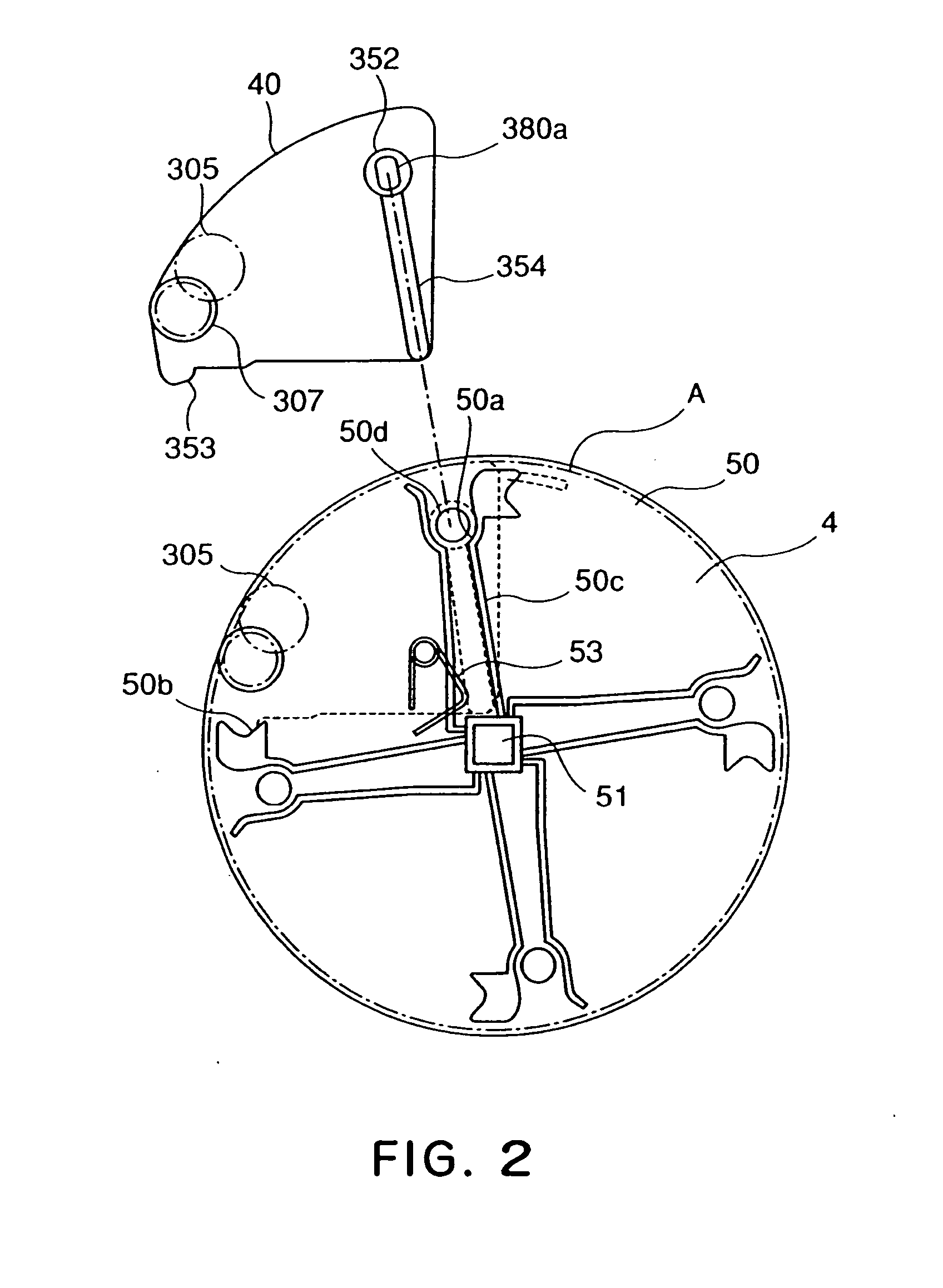

Cartridge and electrophotographic image forming apparatus

InactiveUS6961528B2Efficiently mounted into and dismountedEnsure placementElectrographic process apparatusEngineeringImaging equipment

Owner:CANON KK

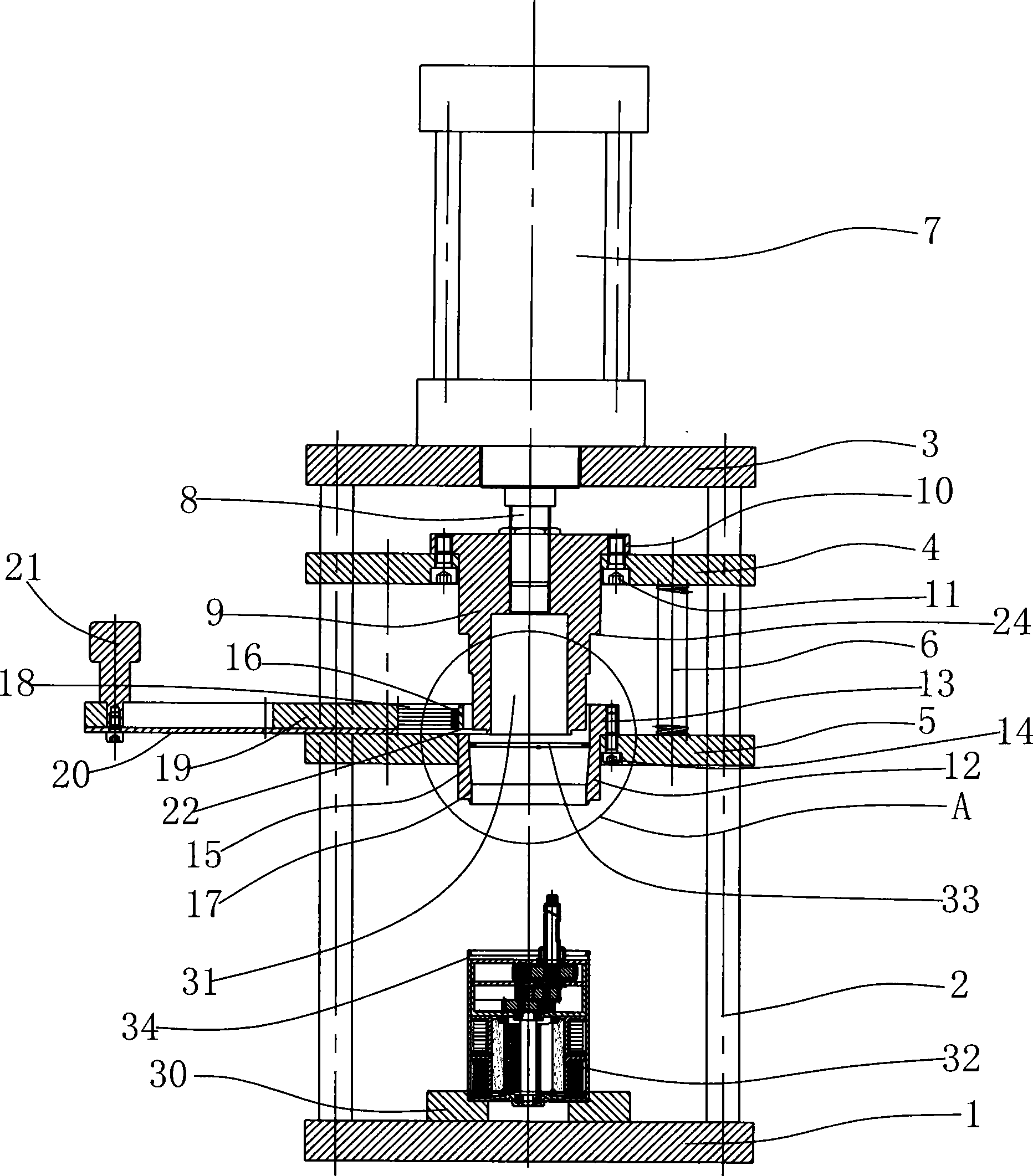

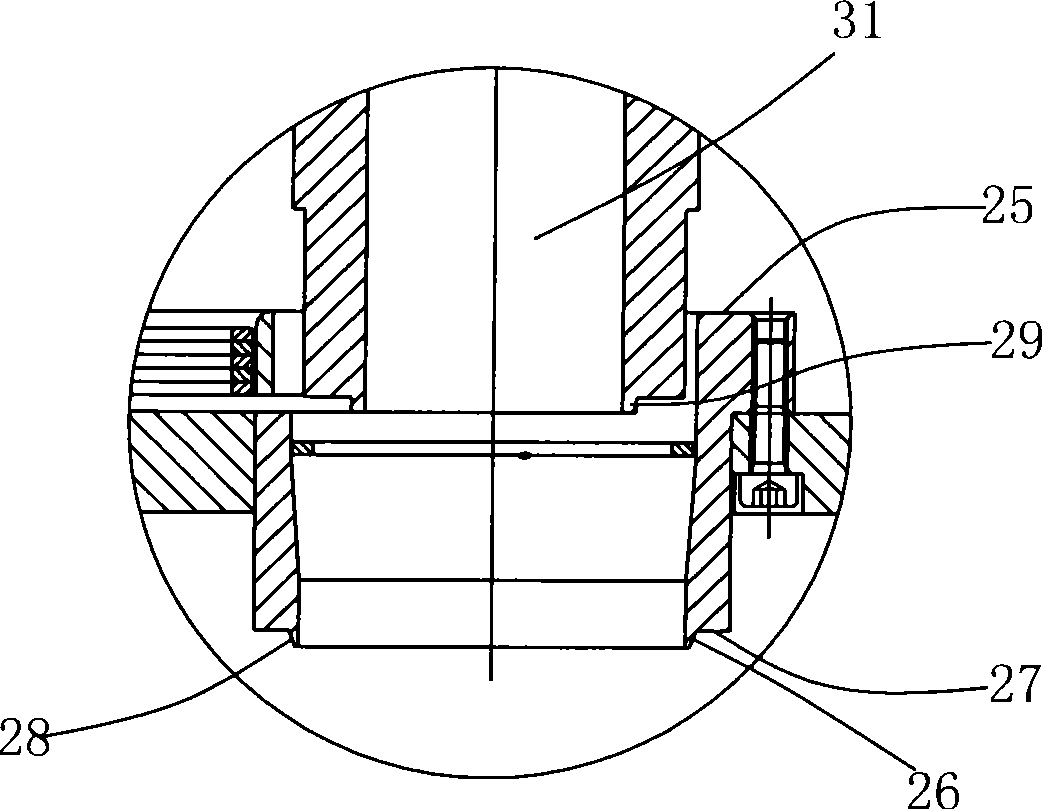

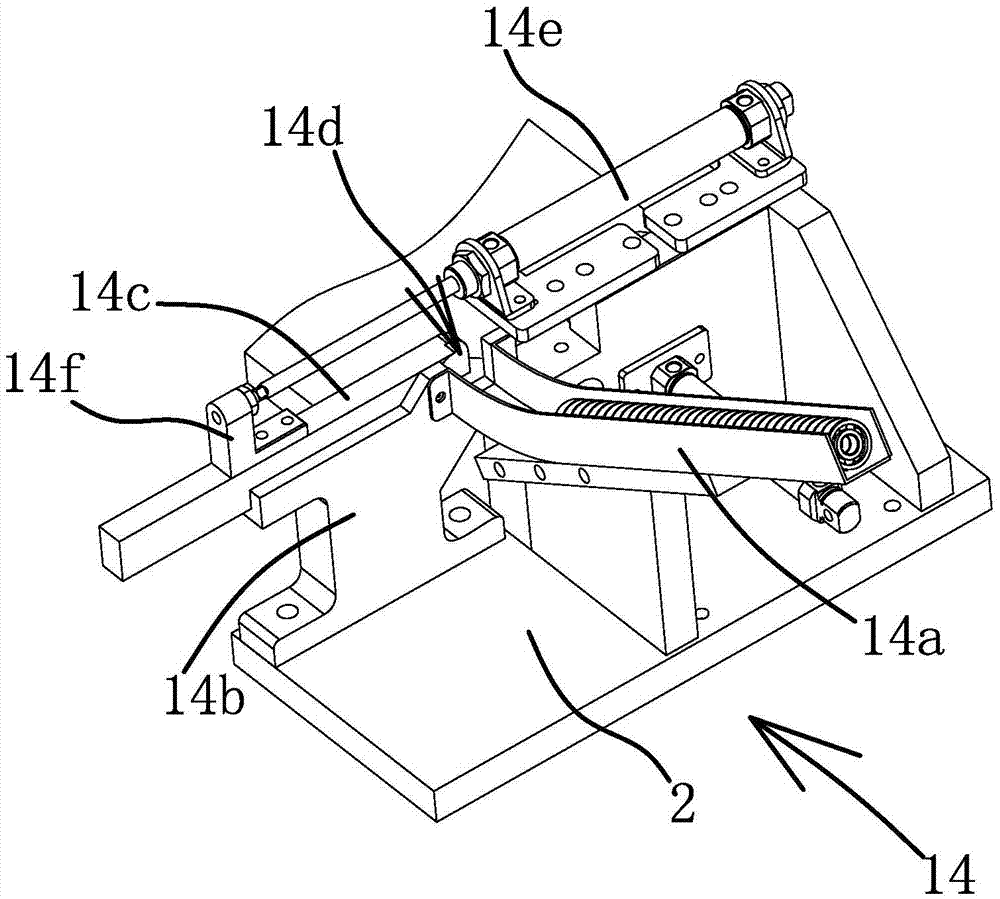

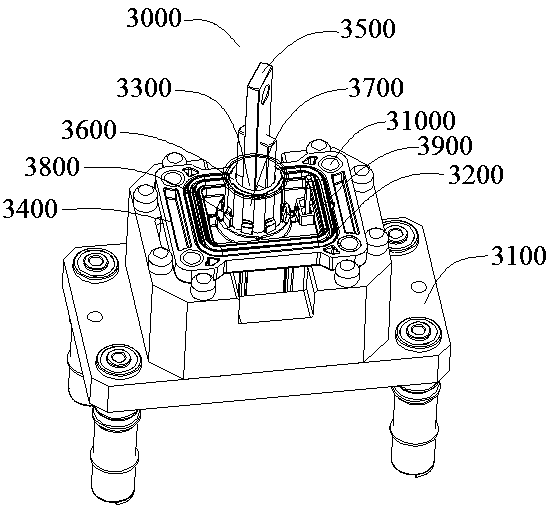

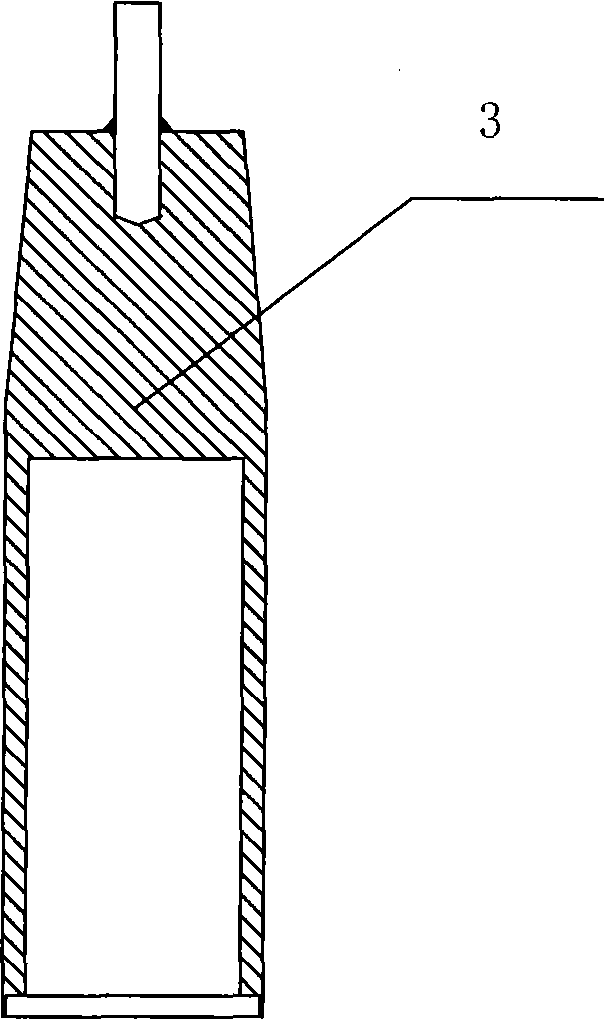

Internal circlip press-loading device

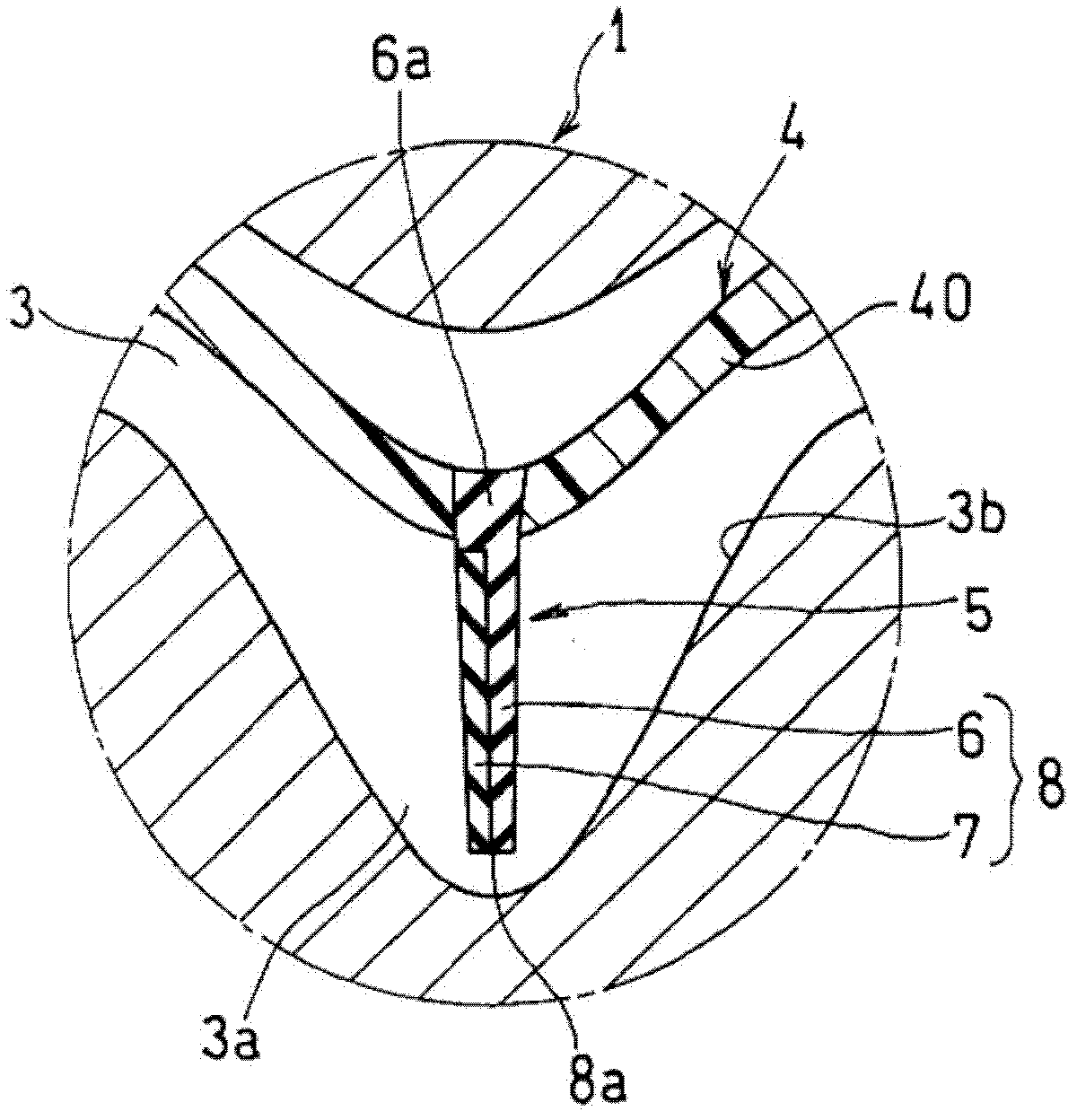

InactiveCN101386166AGuaranteed smooth assemblyGood orientationManufacturing dynamo-electric machinesMetal working apparatusEngineeringCirclip

The invention relates to an internal circlip compacting device, which belongs to the technical field of circlip mounting device. A guide pole is arranged on a bottom board; a cylinder retaining plate is arranged at the upper end of the guide pole; the guide pole between the bottom board and the cylinder retaining plate is connected with a core rod retaining plate and an outer sleeve retaining plate in a sliding way; the core rod retaining plate and the outer sleeve retaining plate are connected by a compression spring; a piston rod of the cylinder is fixed with the upper end of a core rod of a compact circlip after the piston rod of the cylinder downward passes through the cylinder retaining plate; the core rod of the compact circlip and the core rod retaining plate are fixed together; an outer sleeve is arranged on the outer sleeve retaining plate; a hollow structure of the outer sleeve is coaxial with the core rod of the compact circlip, and has a taper hole section with larger upper end and small lower end; the lower end of the core rod of the compact circlip can pass through the position with the smallest inner diameter of the taper hole section of the hollow structure of the outer sleeve; and the bottom board is provided with a workpiece positioning plate corresponding to the lower side of the outer sleeve. The internal circlip compacting device has good guidance quality, can ensure that the circlip is smoothly assembled with convenient operation.

Owner:ZHEJIANG LINIX MOTOR

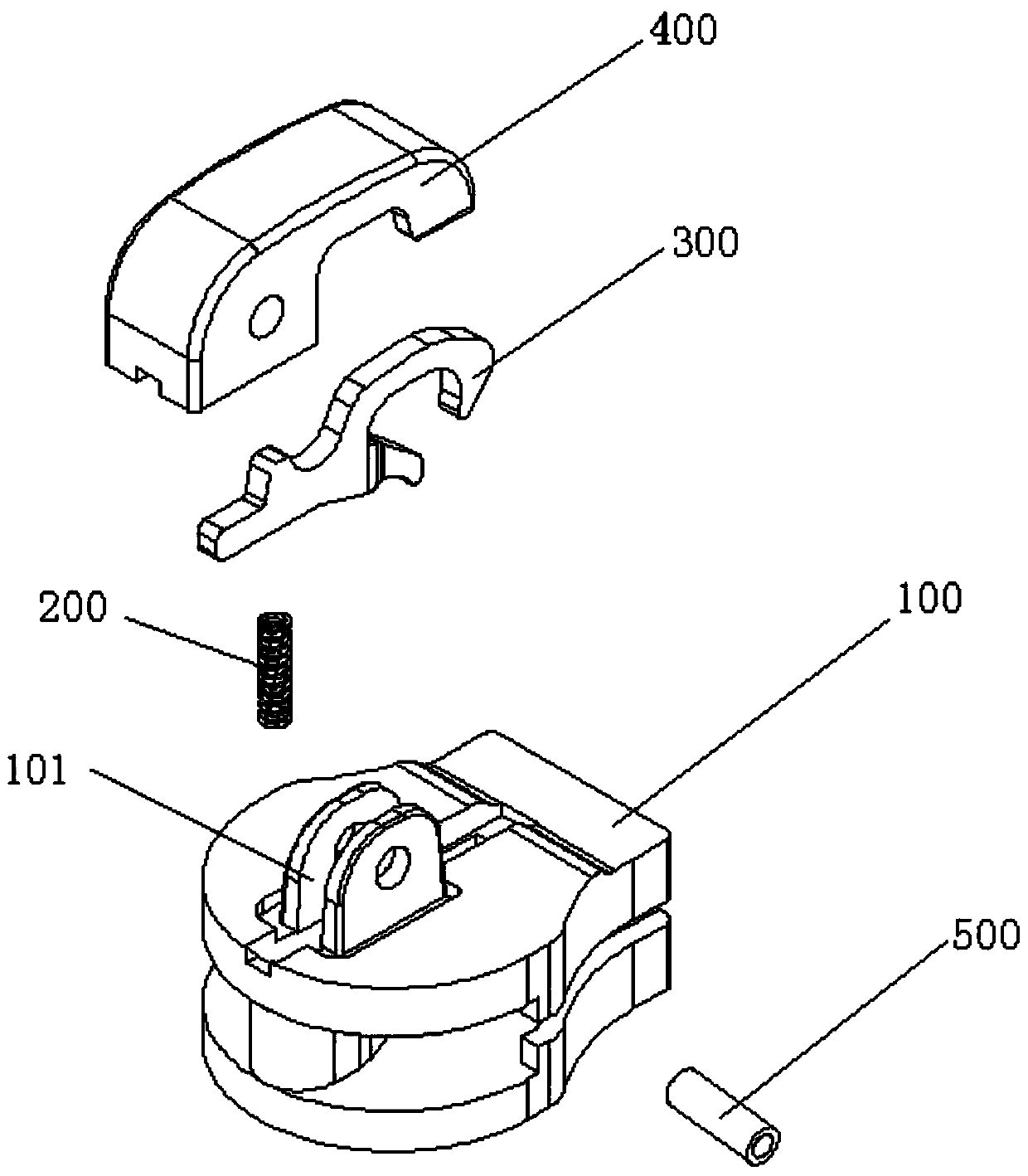

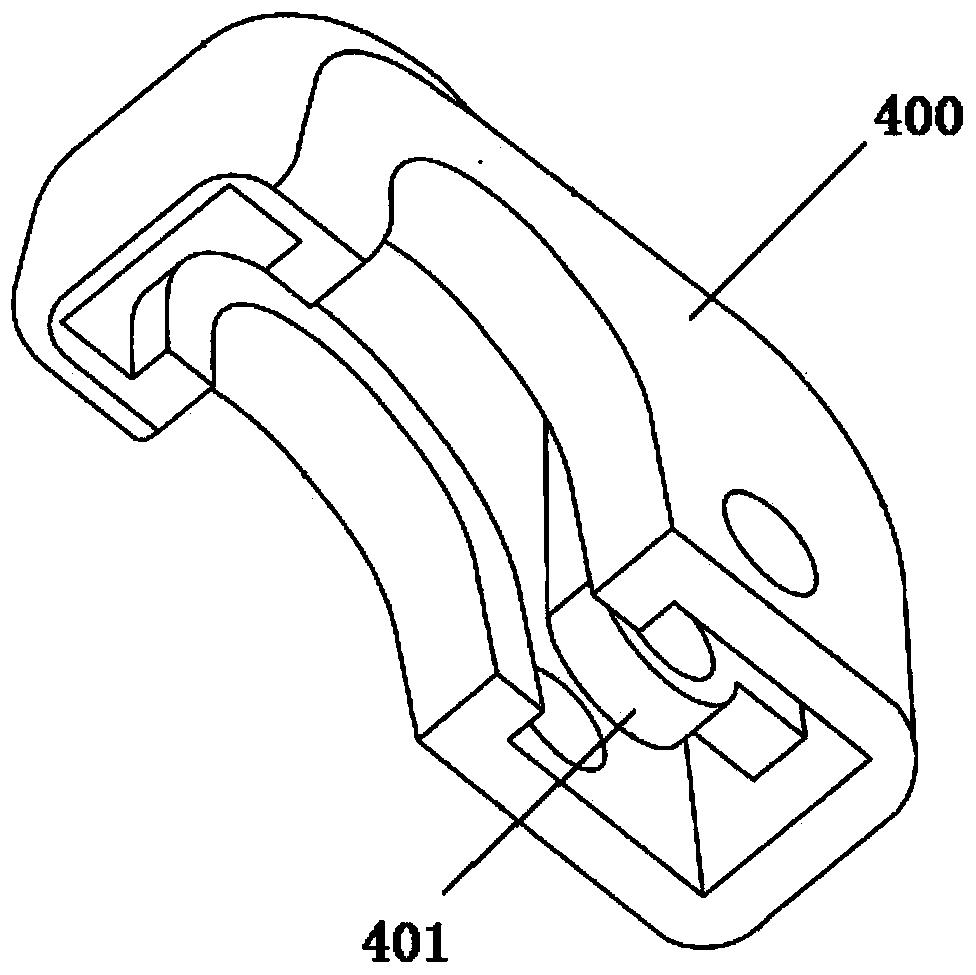

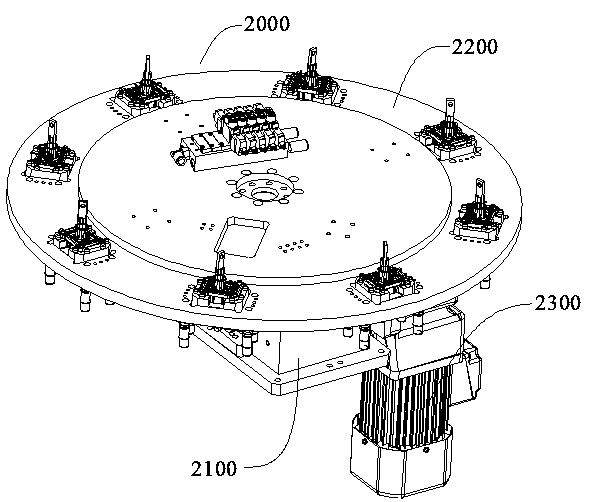

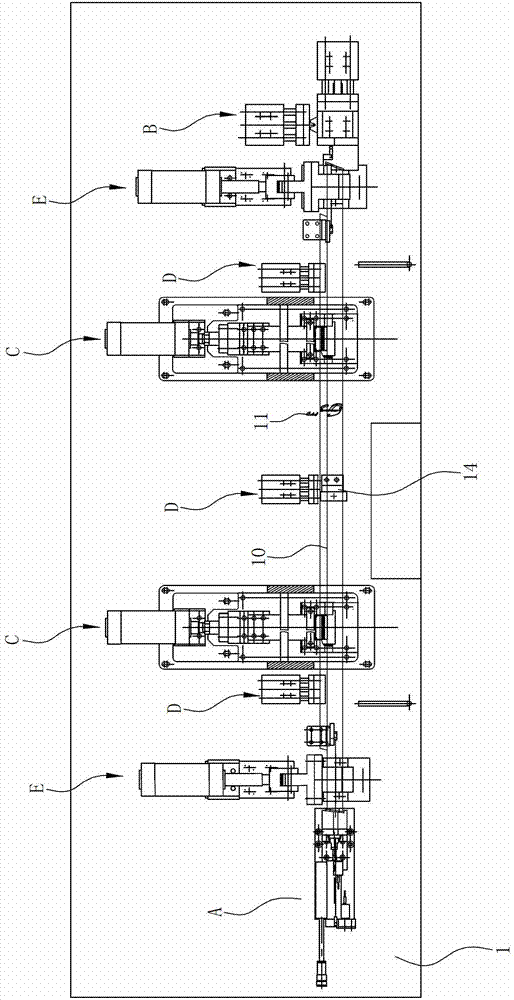

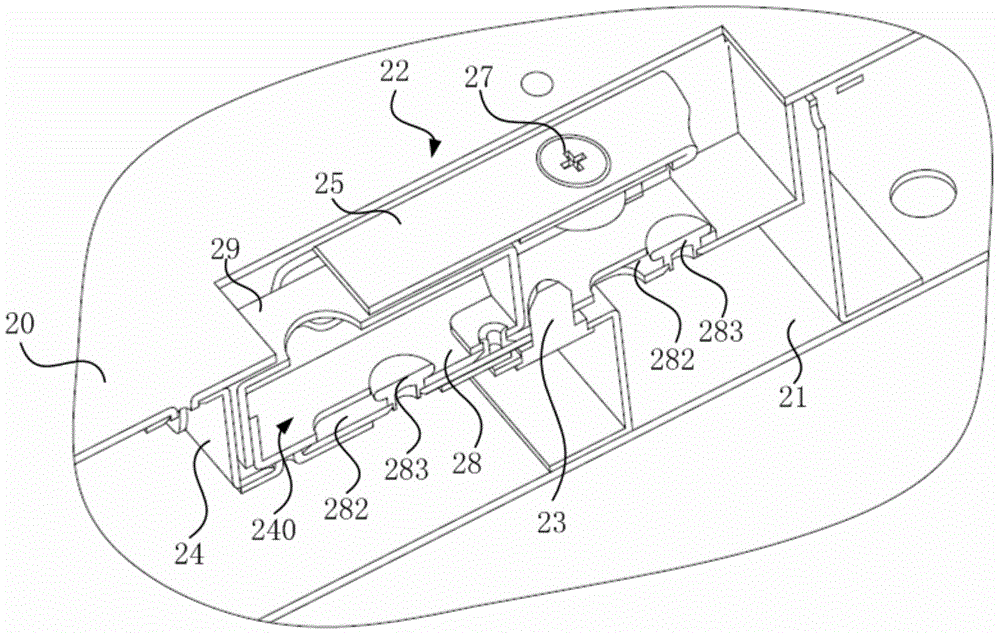

Automatic all-purpose zipper head assembly machine

ActiveCN103445407AGuaranteed smooth assemblyGuaranteed smooth productionSlide fastenersPunchingEngineering

The invention provides an automatic all-purpose zipper head assembly machine. The automatic all-purpose zipper head assembly machine comprises a machine base, wherein a power transmission device is arranged in the machine base; a rotary disc and a pressure disc are mounted above the machine base; the power transmission device not only enables the rotary disc to perform graduation intermittent rotation, but also enables the pressure disc to perform lifting movement; molds for placing a pull head are uniformly distributed on the periphery of the rotary disc; work station devices corresponding to the stop positions of the molds are fixed on the pressure disc or the table surface of the machine base; the work station devices include a feeding device, a detection device, a riveting device and a material returning device. The automatic all-purpose zipper head assembly machine is characterized by further comprising a burr removing device in front of the copper tube feeding device, and the burr removing device is formed by a cap cover pressing and fixing device mounted on the pressure disc and a punching device mounted on the table surface of the machine base. The automatic all-purpose zipper head assembly machine can automatically complete multi-wall pin penetrating all-purpose zipper head assembly, and is reliable in movement and high in production efficiency; in addition, the automatic all-purpose zipper head assembly machine is simple in structure and easy to debug and maintain, and lowers equipment cost.

Owner:FUJIAN ZIPPER SCI & TECH CO LTD

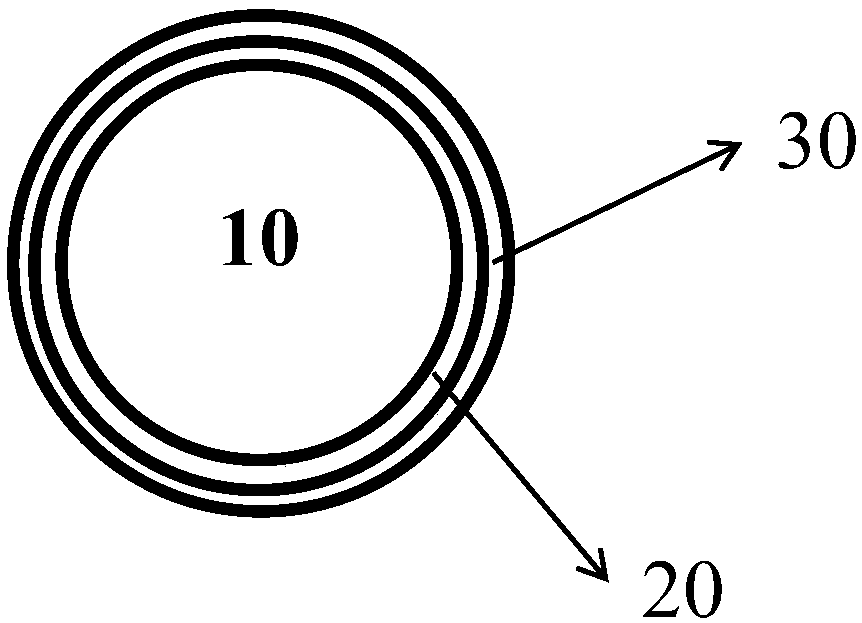

Three-layer core-shell structure positive electrode material, preparation method thereof and lithium ion battery

ActiveCN108598400AImprove ionic conductivityAvoid erosionCell electrodesSecondary cellsElectrical conductorLithium-ion battery

The invention relates to a three-layer core-shell structure positive electrode material. The three-layer core-shell structure positive electrode material comprises a three-layer structure, namely, a ternary positive electrode material inner core, an aluminum oxide layer and a rapid ion conductor layer, wherein the aluminum oxide layer wraps the ternary positive electrode material inner core, and the rapid ion conductor layer wraps the aluminum oxide layer. The invention also comprises a preparation method of the three-layer core-shell structure positive electrode material. Since the rapid ionconductor wrapping an outer layer of the three-layer core-shell structure positive electrode material has super strong ionic conductivity, the integral ionic conductivity of the Al2O3-coated positiveelectrode material can be improved, the electric energy loss is reduced, and the cycle property of a battery is improved; moreover, the aluminum oxide layer and the ternary positive electrode materialinner core form a Li-Al-Co-O co-melting body by high-temperature calcination during the preparation process, the ionic conductivity of the material can be further improved, and the electrical conductivity and the microstructure stability of the composite material are improved; and by the three-layer core-shell structure, the corrosion of an electrolyte to the ternary positive electrode material inner core can be reduced, and the battery safety is improved.

Owner:SOUNDON NEW ENERGY TECH CO LTD

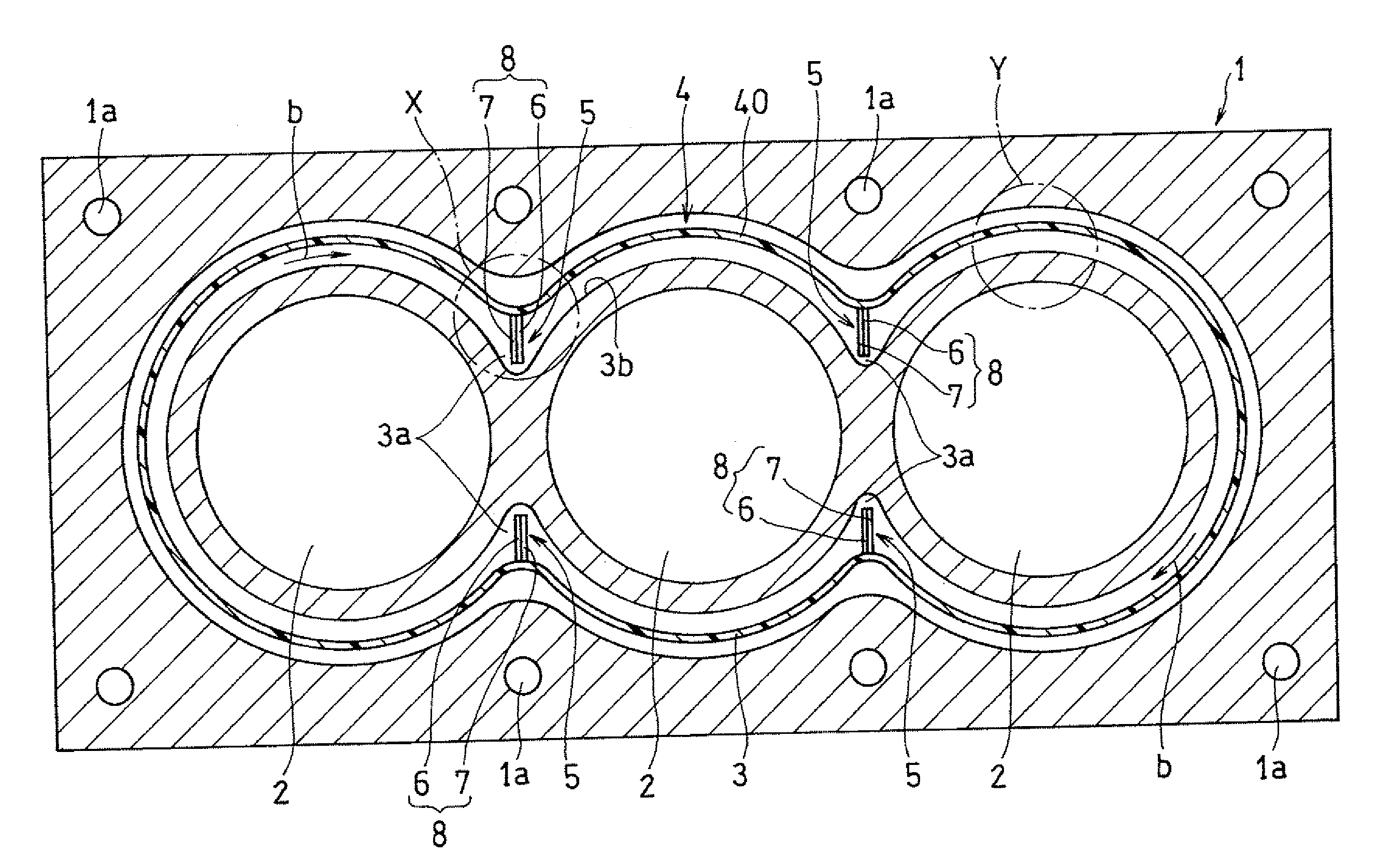

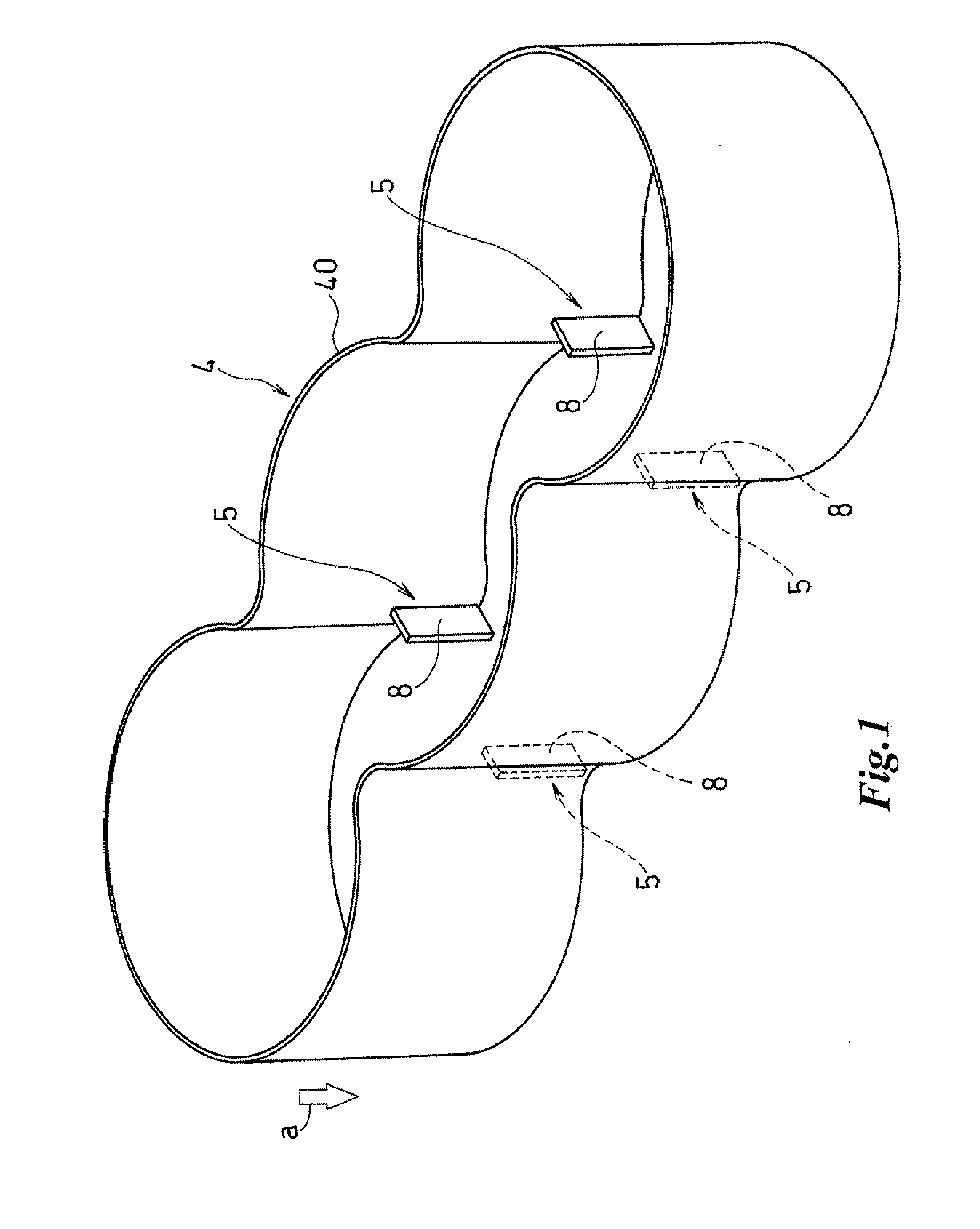

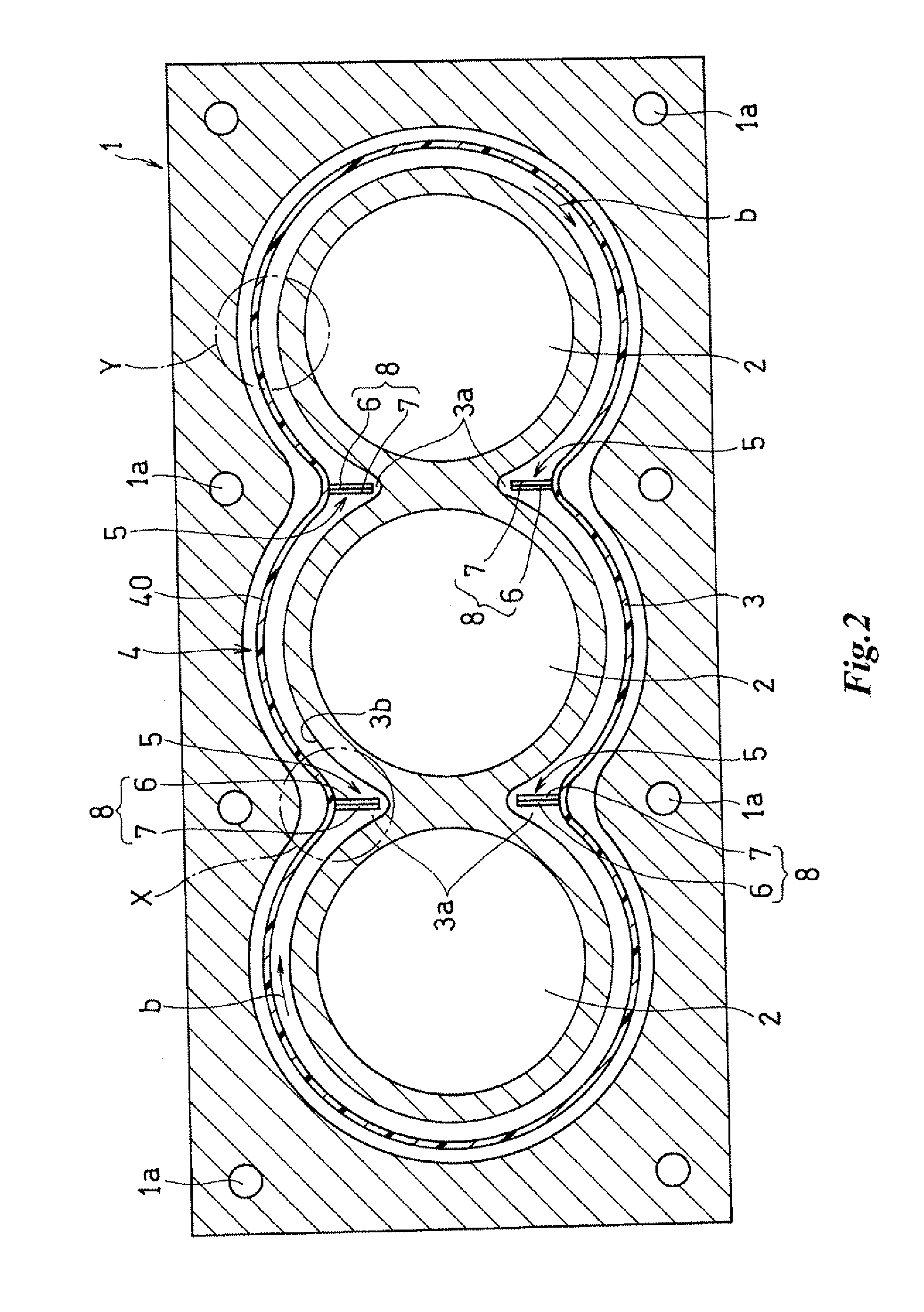

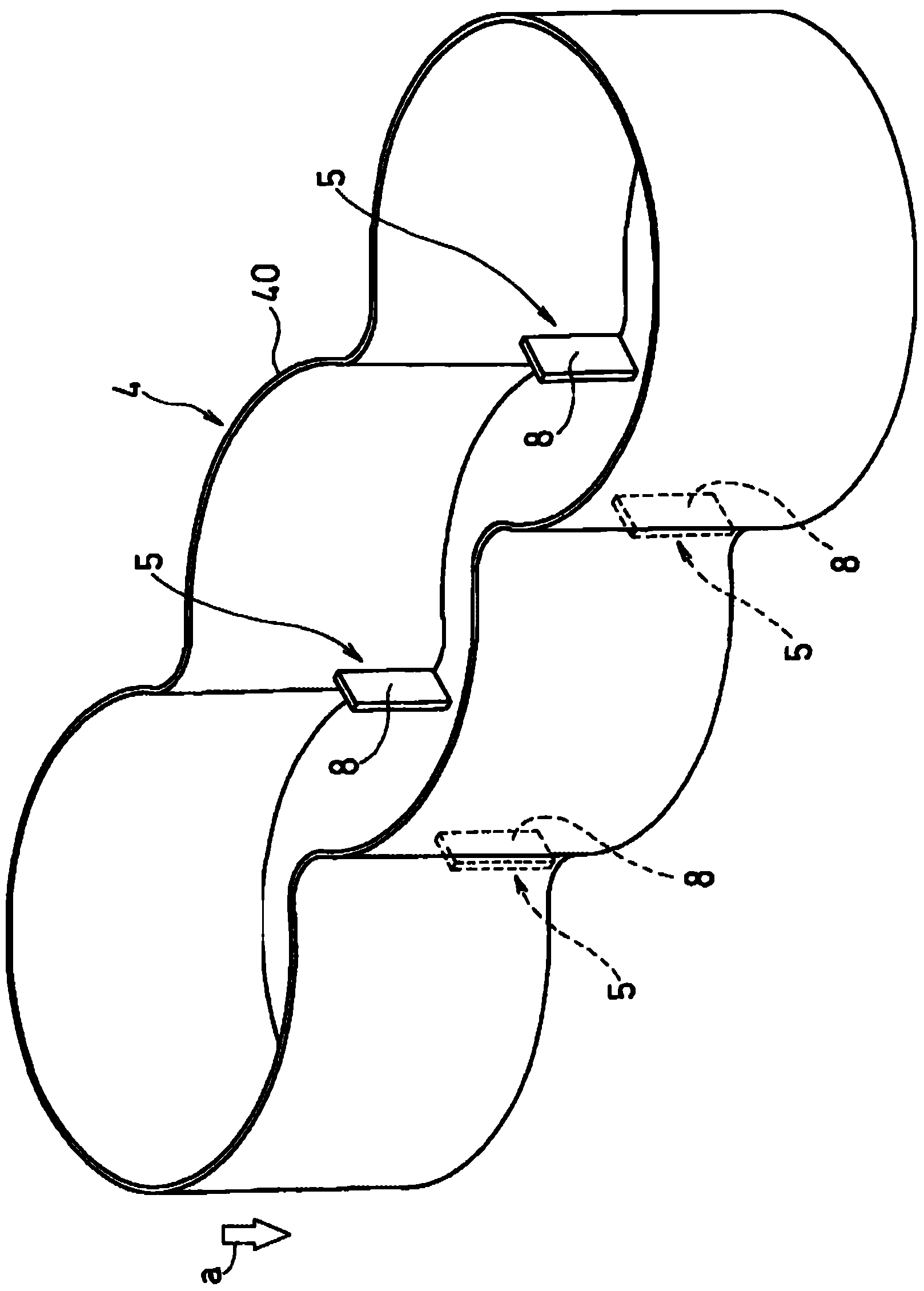

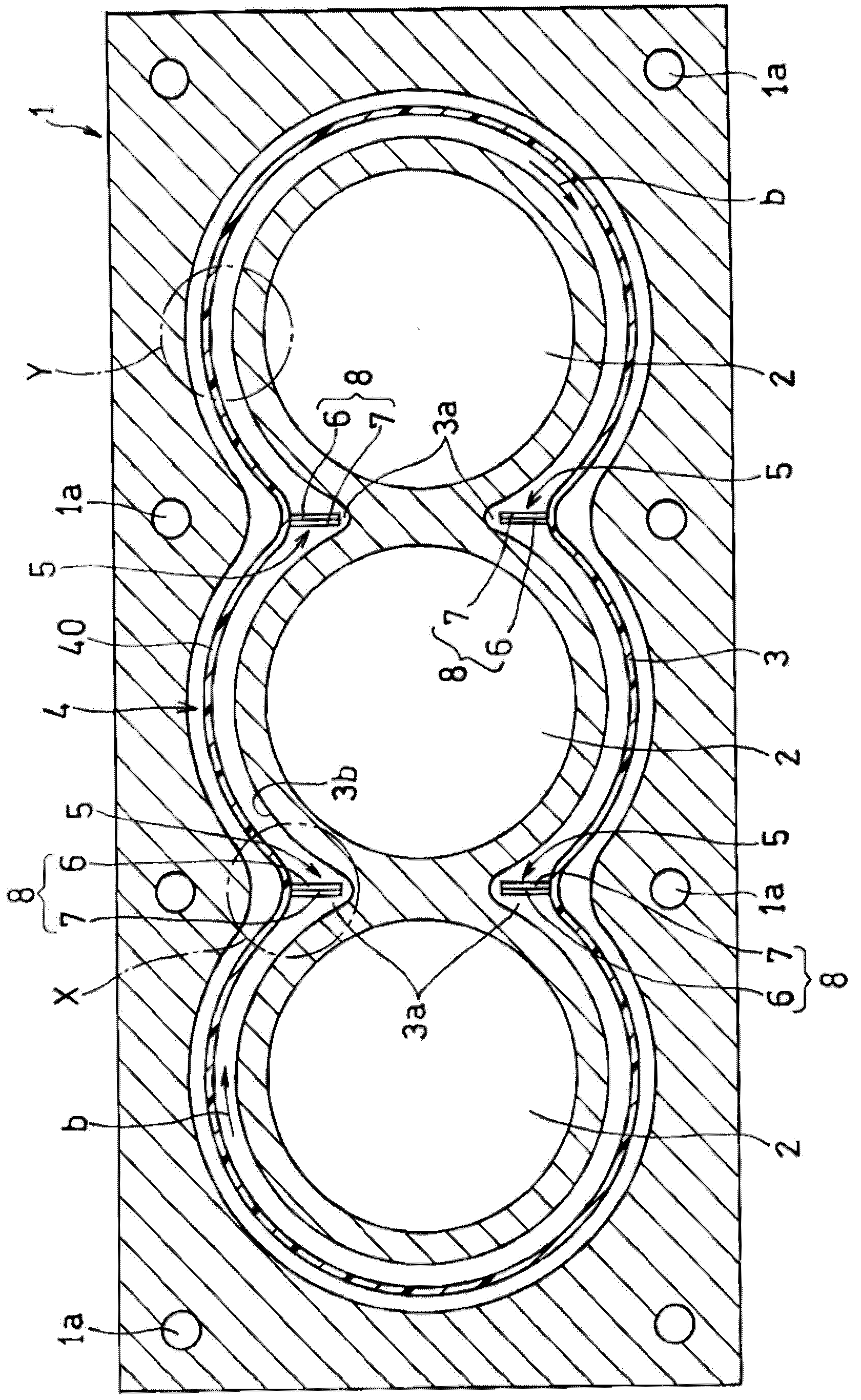

Water Jacket Spacer

InactiveUS20120132157A1Guaranteed smooth assemblySimple processLiquid coolingCylinder headsElastomerWater flow

A water jacket spacer has a spacer body molded in conformity to the shape of the water jacket and a regulating member whose one side is fixed to the spacer body. The regulating member is composed of a first member which is not water-swellable and is elastically deformable and a second member made of water-swellable elastomer which is integrally fixed to the first member. The regulating member lies in a state not-contacting an opposed wall of the water jacket when inserted into the water jacket together with the spacer body, whereas it blocks a part of cooling water flowing through the water jacket by deforming such that a side of the regulating member not fixed to the spacer body faces toward the opposed wall of the water jacket when the second member swells by absorbing cooling water flown into the water jacket and thereby the first member is elastically deformed.

Owner:UCHIYAMA MFG

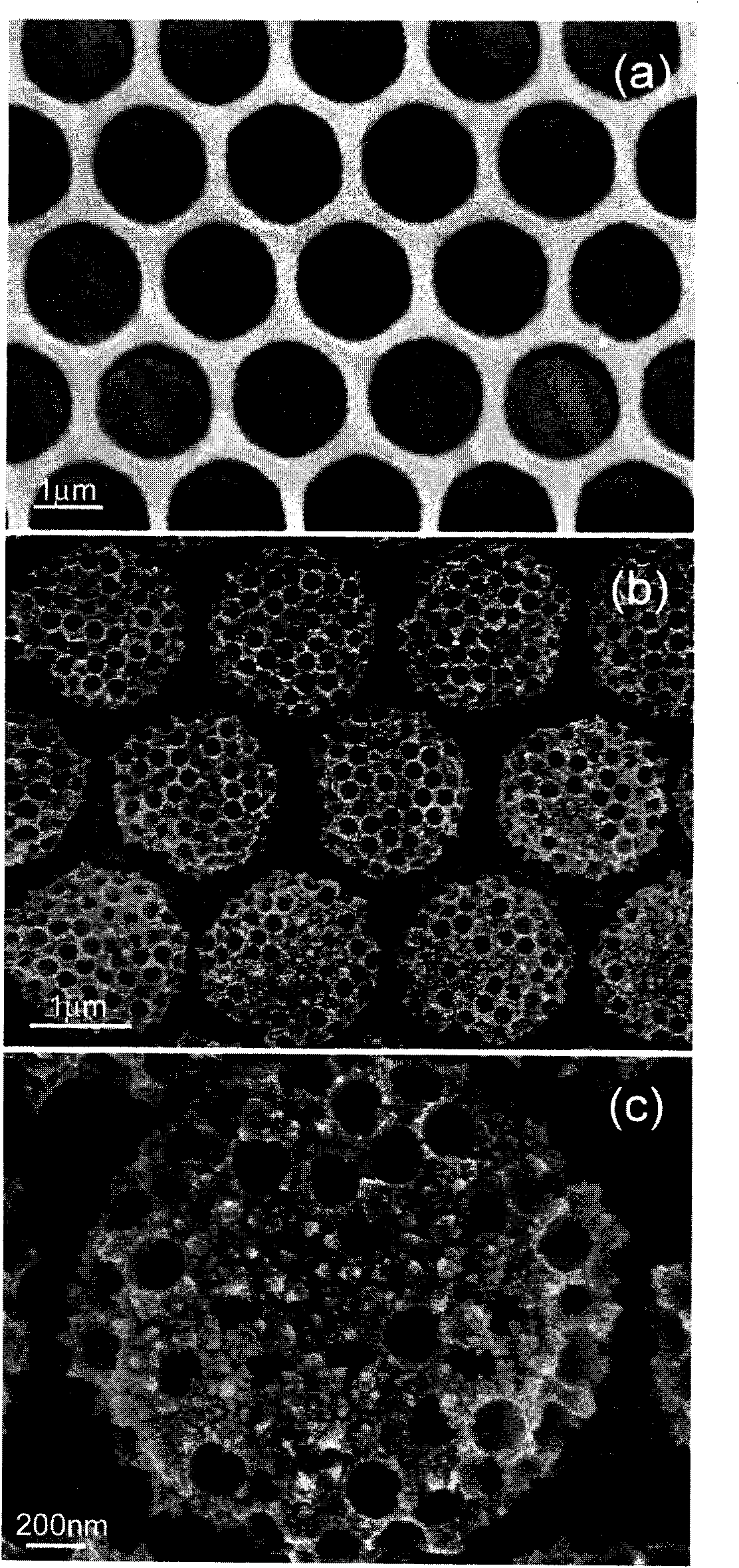

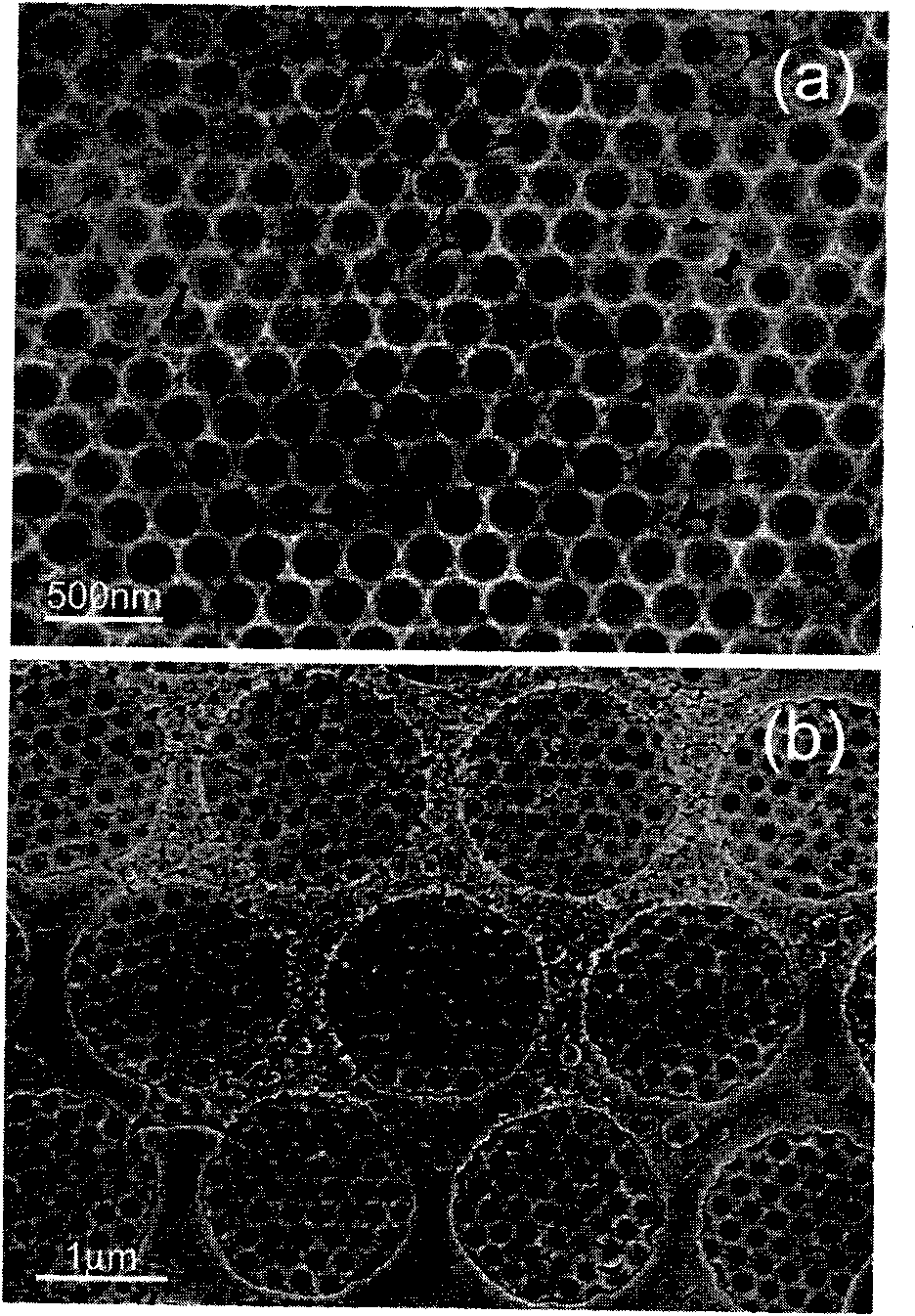

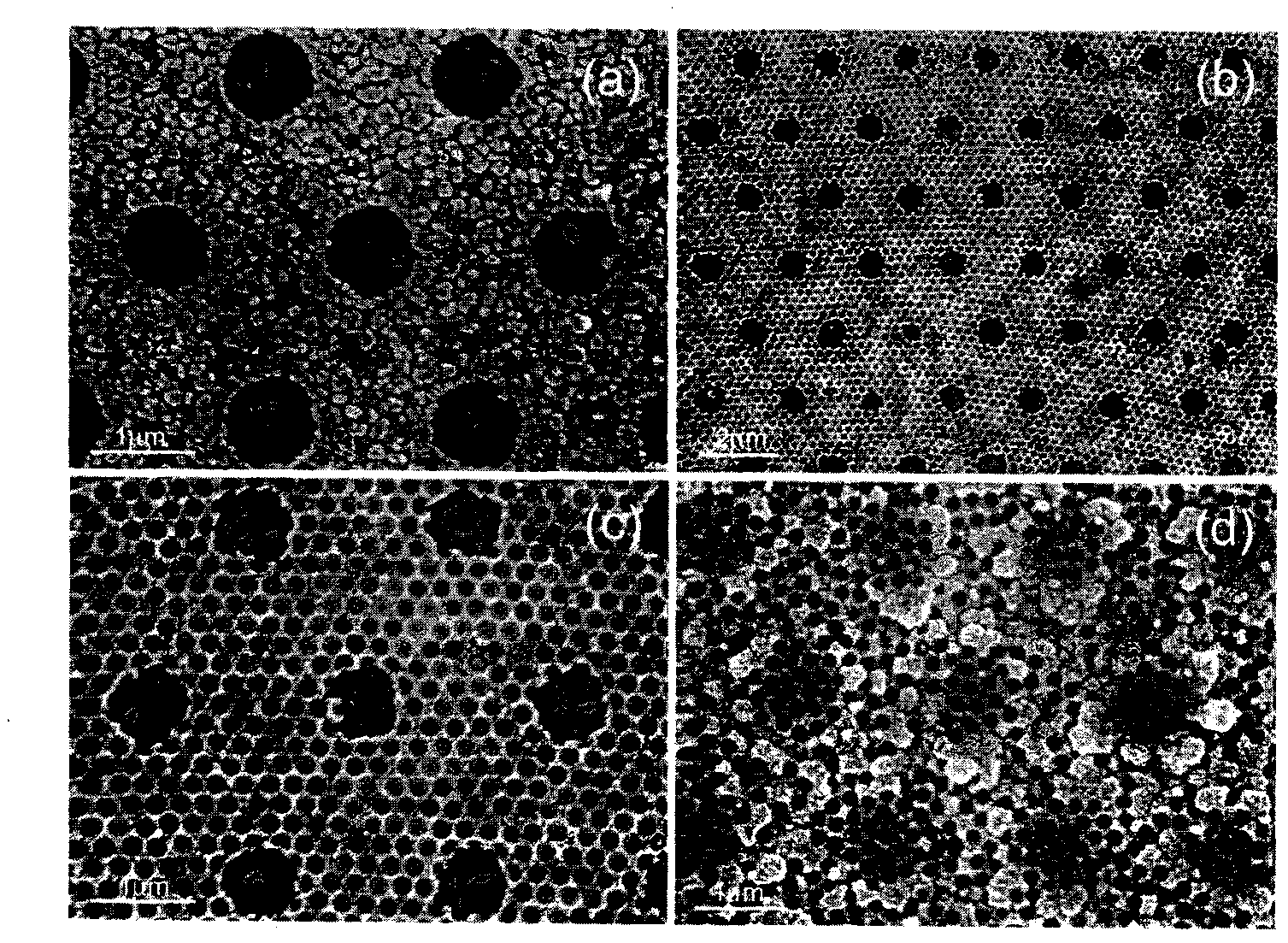

Two-dimensional and double-cycle ordered structure array and preparation method thereof

InactiveCN101891141AImprove performanceEnhanced Raman ScatteringDecorative surface effectsIndividual molecule manipulationPolystyreneConductive materials

The invention discloses a two-dimensional and double-cycle ordered structure array and a preparation method thereof. The array is an ordered porous film consisting of metals in a microparticle hole shape and a nanometer hole shape and arranged on a conductive substrate, the nanometer hole in the film is located in the microparticle hole and is in a stacking shape, or the nanometer hole is a single layer and is located at the bottom surface or the external surface of the microparticle hole or covers the internal surface and the external surface thereof, the diameter of the microparticle hole is 1,800-2,200 nm, and the diameter of the thenanometer hole is 180-220 nm. The method comprises the following steps of: firstly, self-assembling by using a polystyrene colloidal ball of one diameter in combination with a solution impregnating method or an electrodepositing method to obtain the ordered hole array of a bowl-shaped metal attached to the conductive substrate; and then self-assembling thereon by utilizing polystyrene colloidal of another diameter in combination with the electrodepositing method to prepare the two-dimensional and double-cycle ordered structure arrays in four structures. The product thereof has the characteristics of a macro-scale system, the preparation method has universality, and the two-dimensional double-cycle and ordered structure array consisting of other conductive materials can be prepared by the method.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

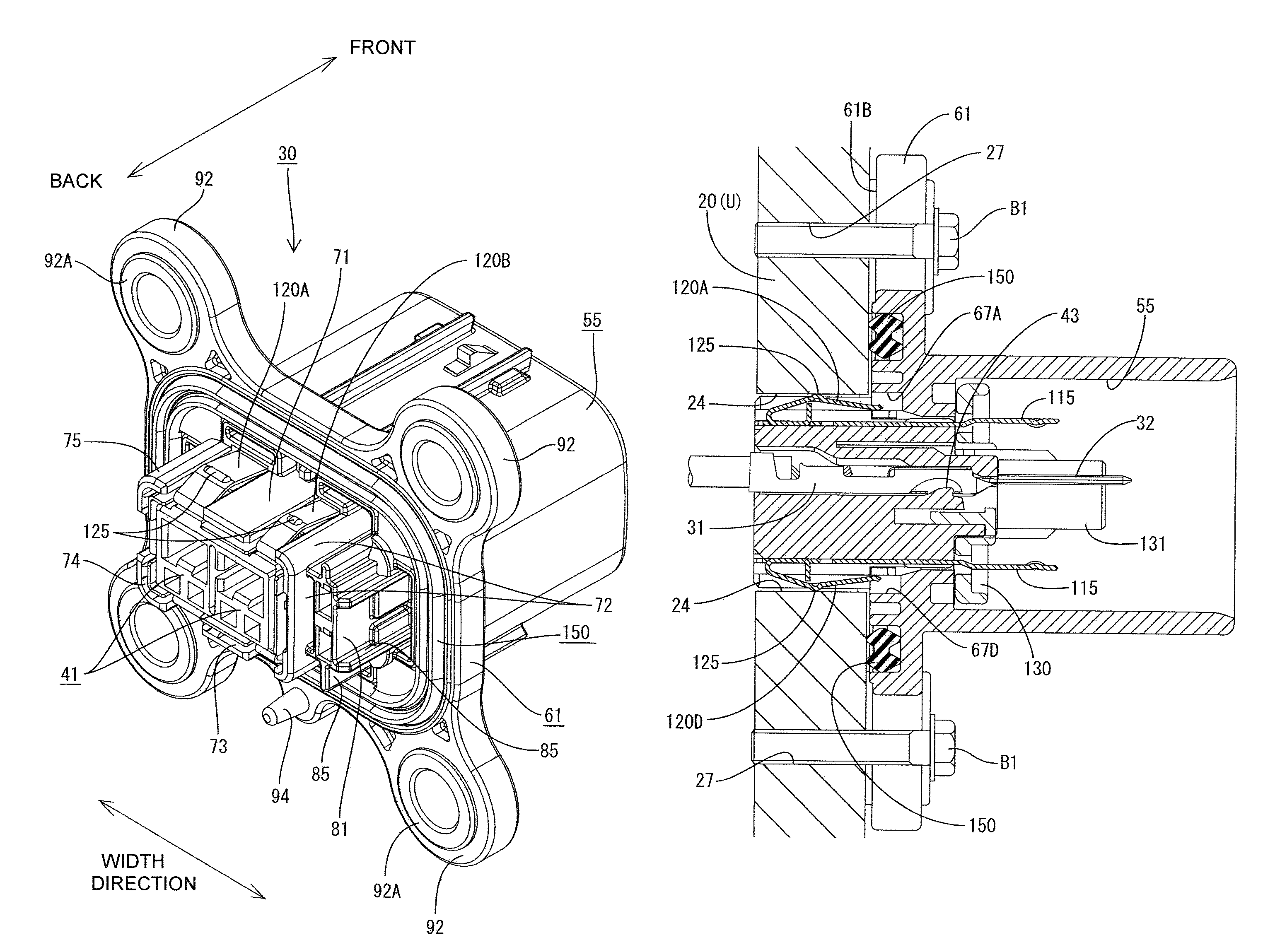

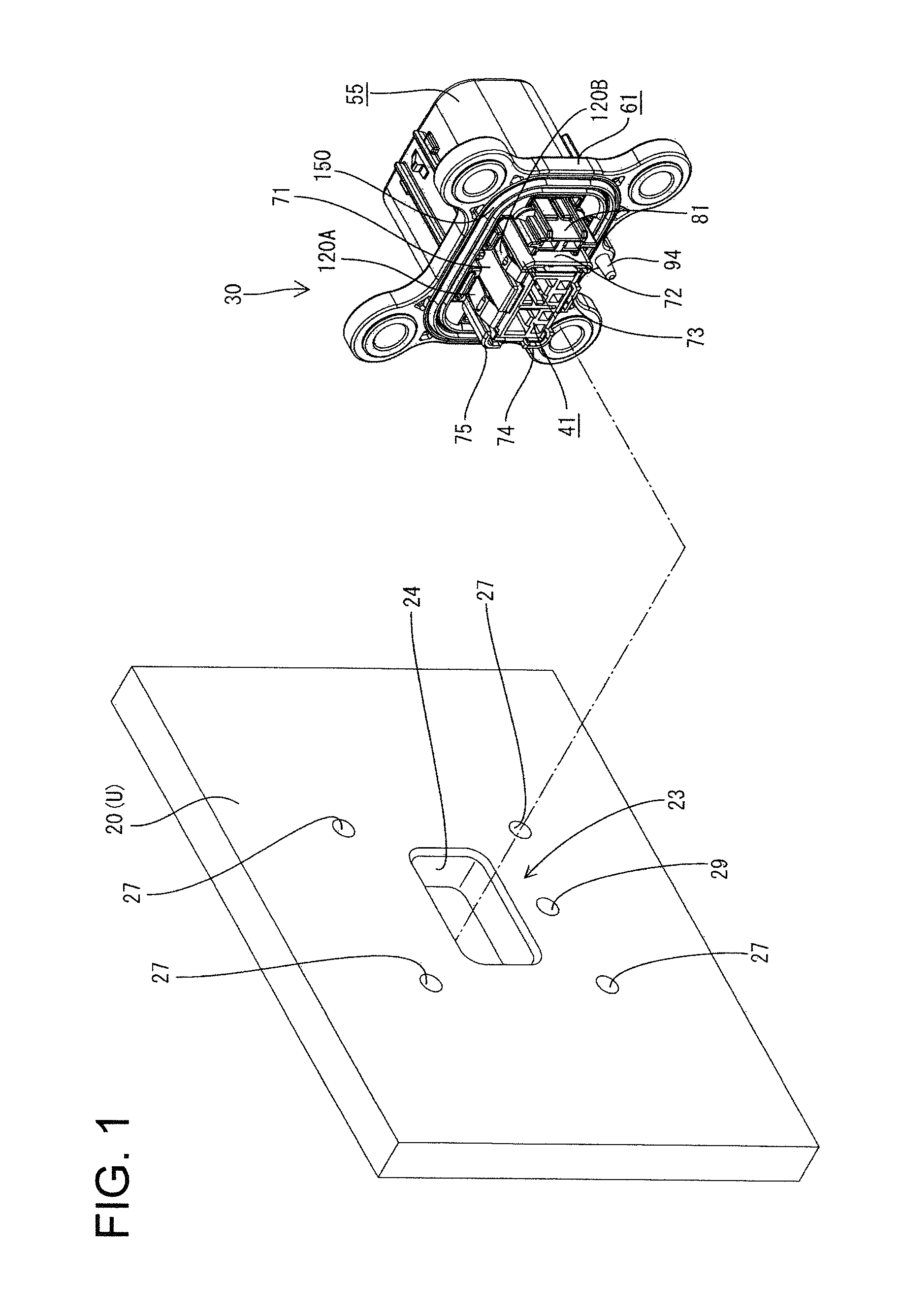

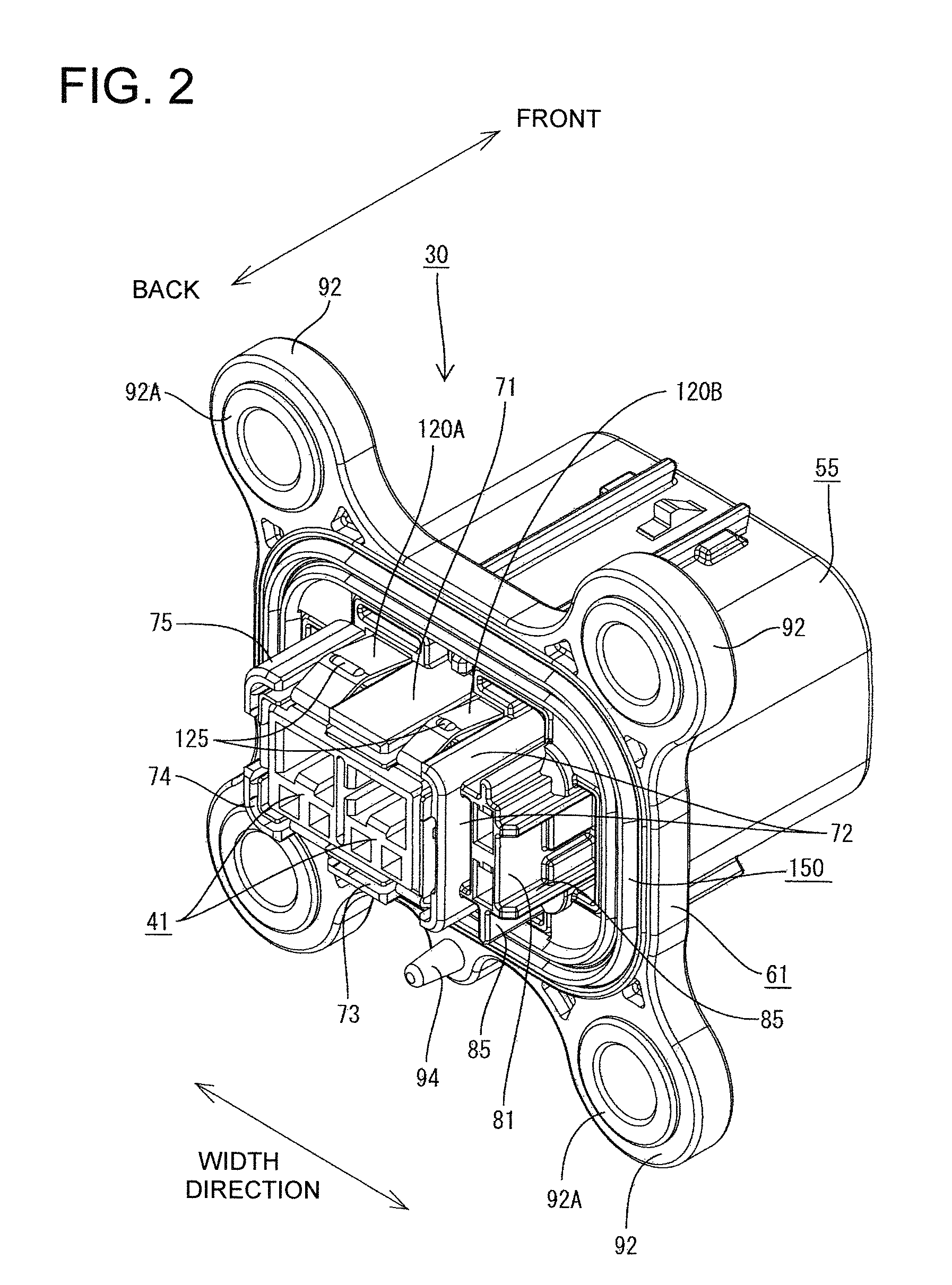

Shield connector

ActiveUS8262413B2Avoid leaningIncrease contact pressureVehicle connectorsCoupling protective earth/shielding arrangementsFlangeEngineering

A shield connector (30) has a housing (40) with a terminal mounting portion (41), a receptacle (55) and a mounting flange (61). Male terminals (31) are mounted in the terminal mounting portion (41) and have tabs that project into the receptacle (55). A shield shell (100) including a shell main body (110) and resilient contact pieces (120) for grounding the shell main body (110) to a mounting member. The resilient contact pieces (120) have leading ends (121) accommodated in accommodating portions (67) formed in the mounting flange (61), and the housing (40) includes protection walls (70) located lateral to the resilient contact pieces (120).

Owner:SUMITOMO WIRING SYST LTD

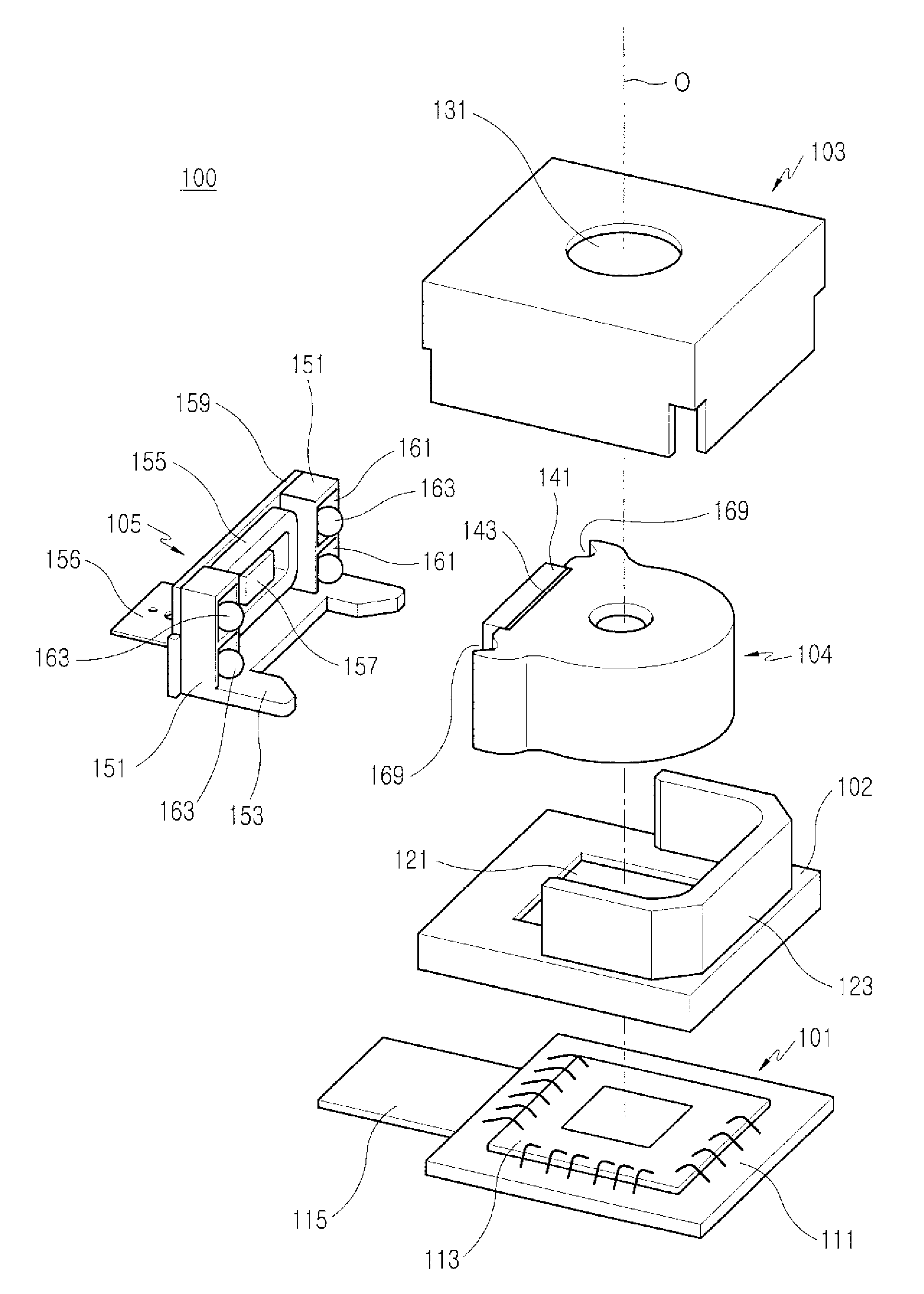

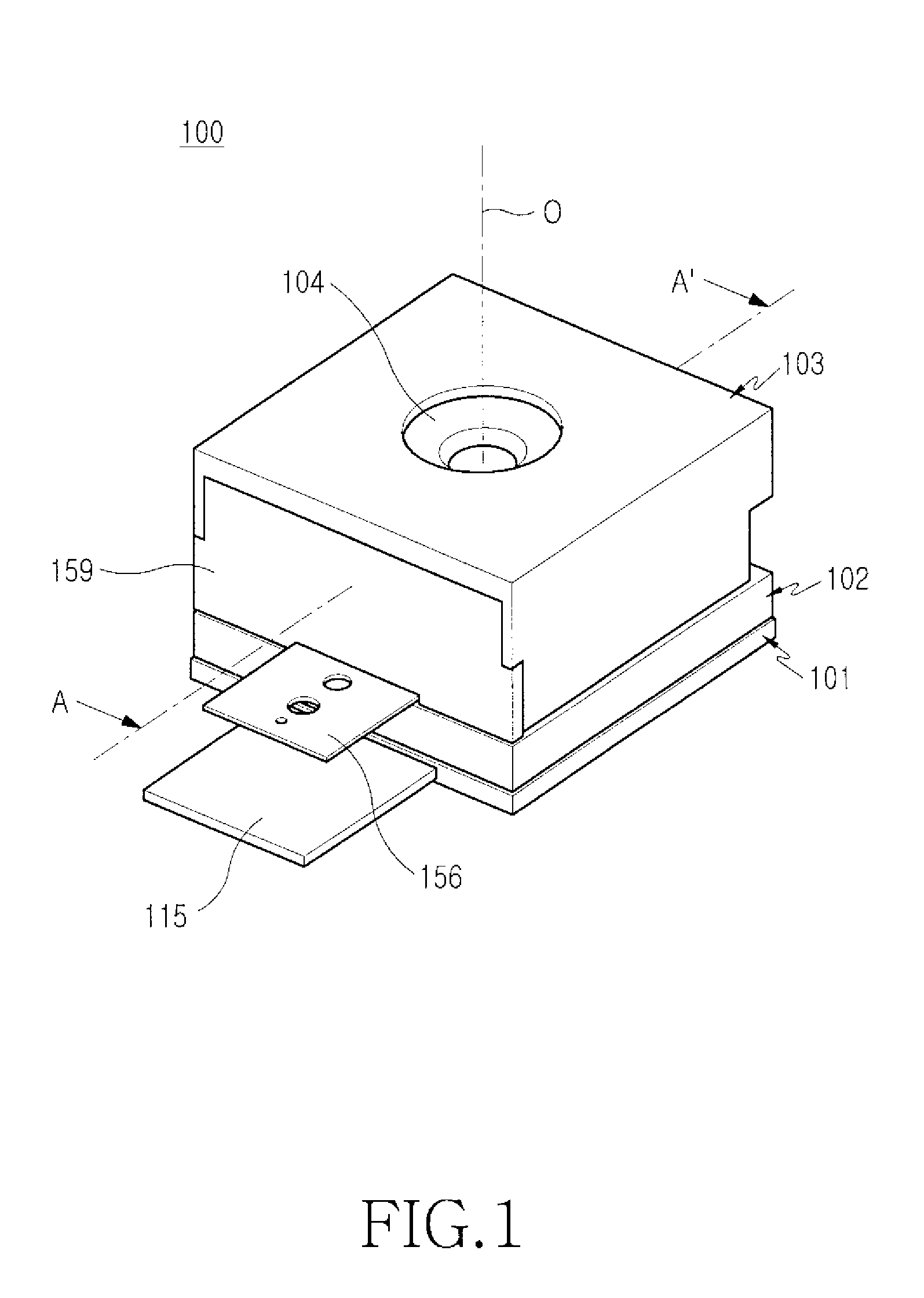

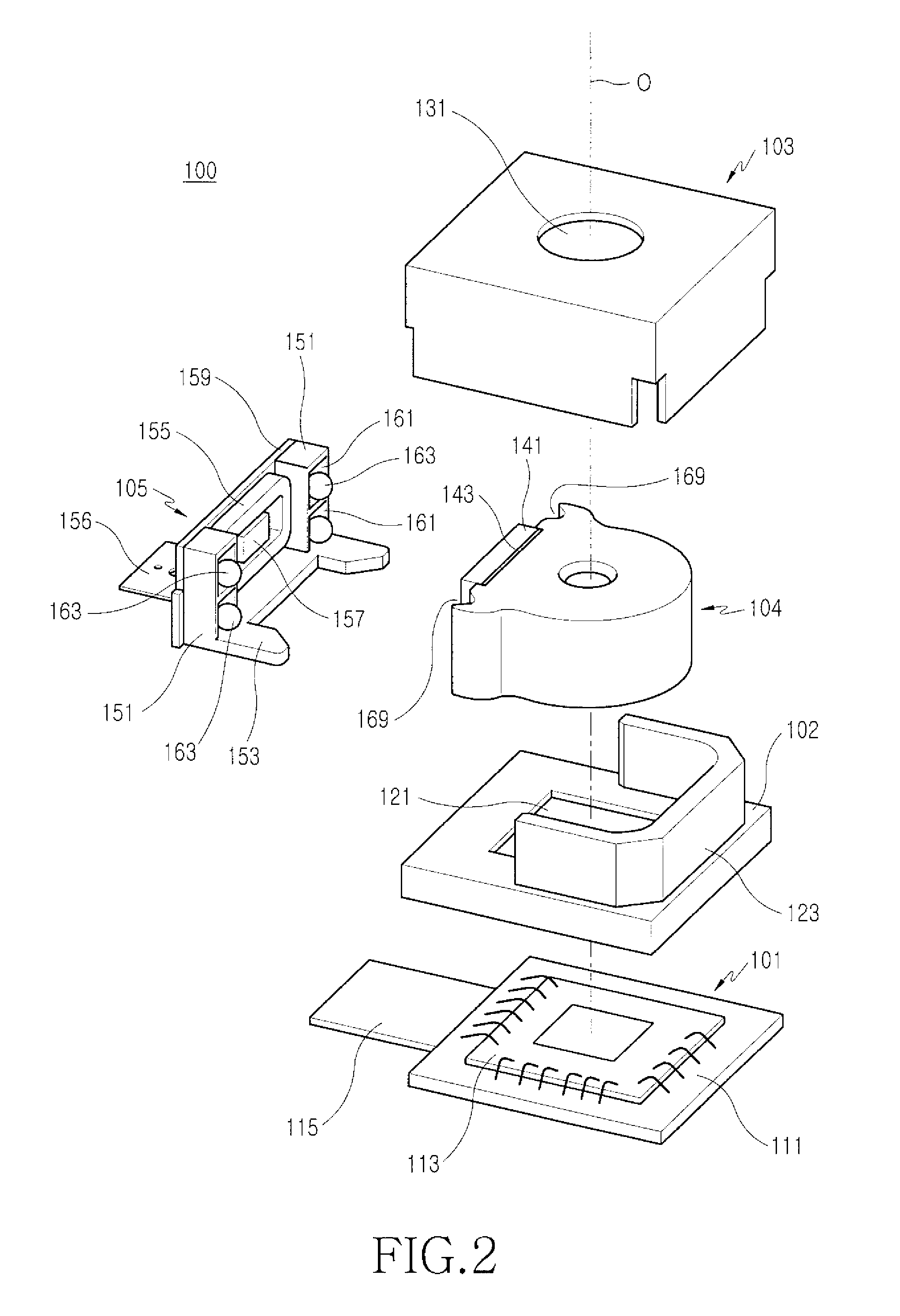

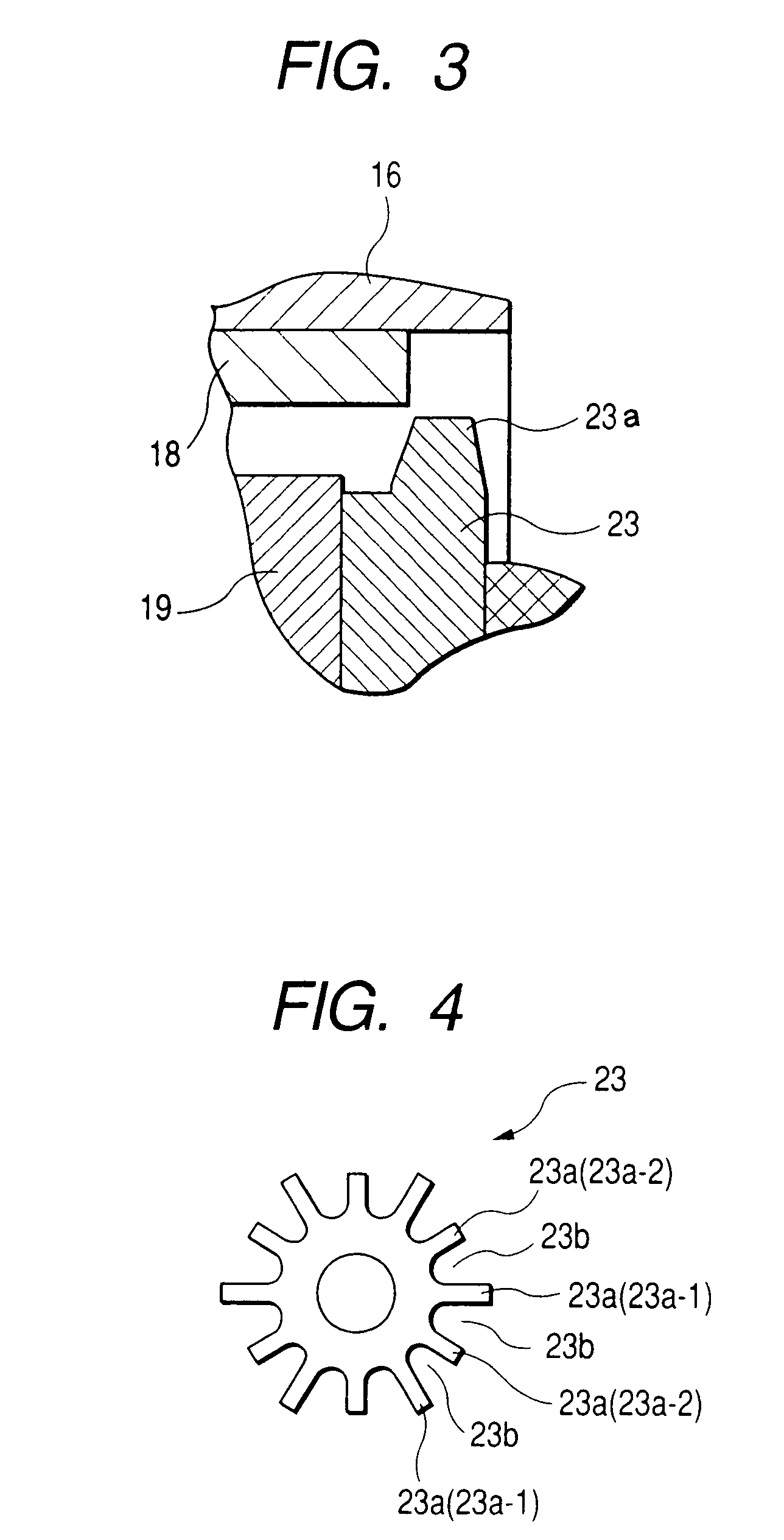

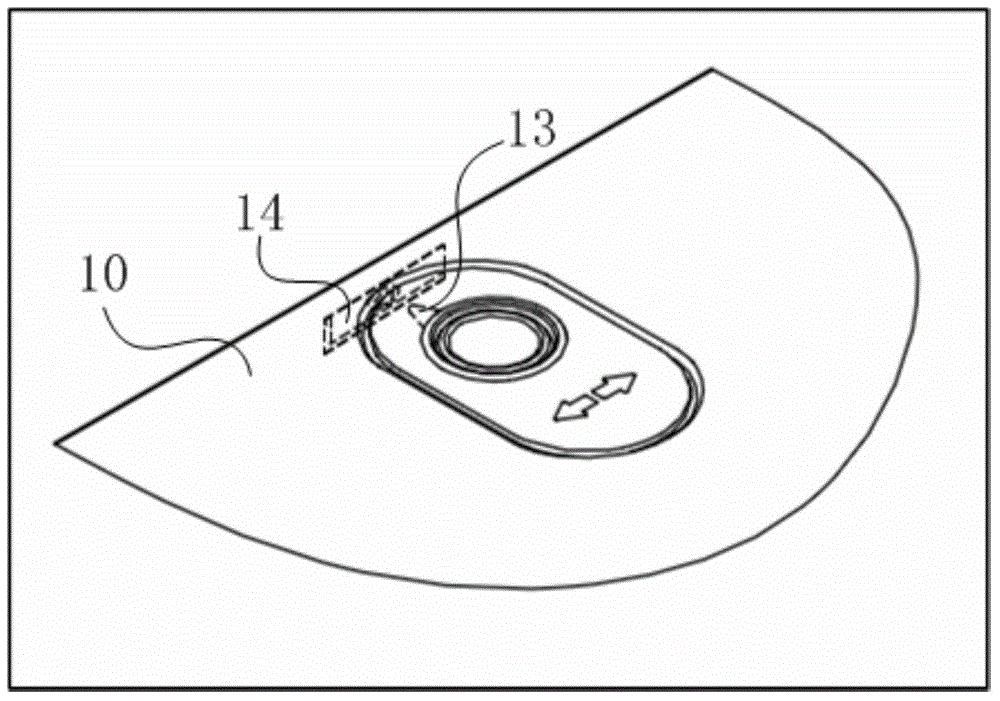

Camera lens assembly

A camera lens assembly providing focal length adjustment to permit mounting in a personal portable terminal. The camera lens assembly includes a lens assembly; a driving unit provided in one side of the lens assembly; and a guide section provided between the lens assembly and the driving unit, wherein the lens assembly moves forward and backward in a direction of an optical axis to the driving unit by guidance of the guide section. The guide section enhances an auto-focusing function and simplifies mounting of the camera lens assembly, rendering it possible to secure portability even when a camera is mounted to a miniaturized personal portable device such as a mobile communication terminal, a portable computer or the like.

Owner:SAMSUNG ELECTRONICS CO LTD +1

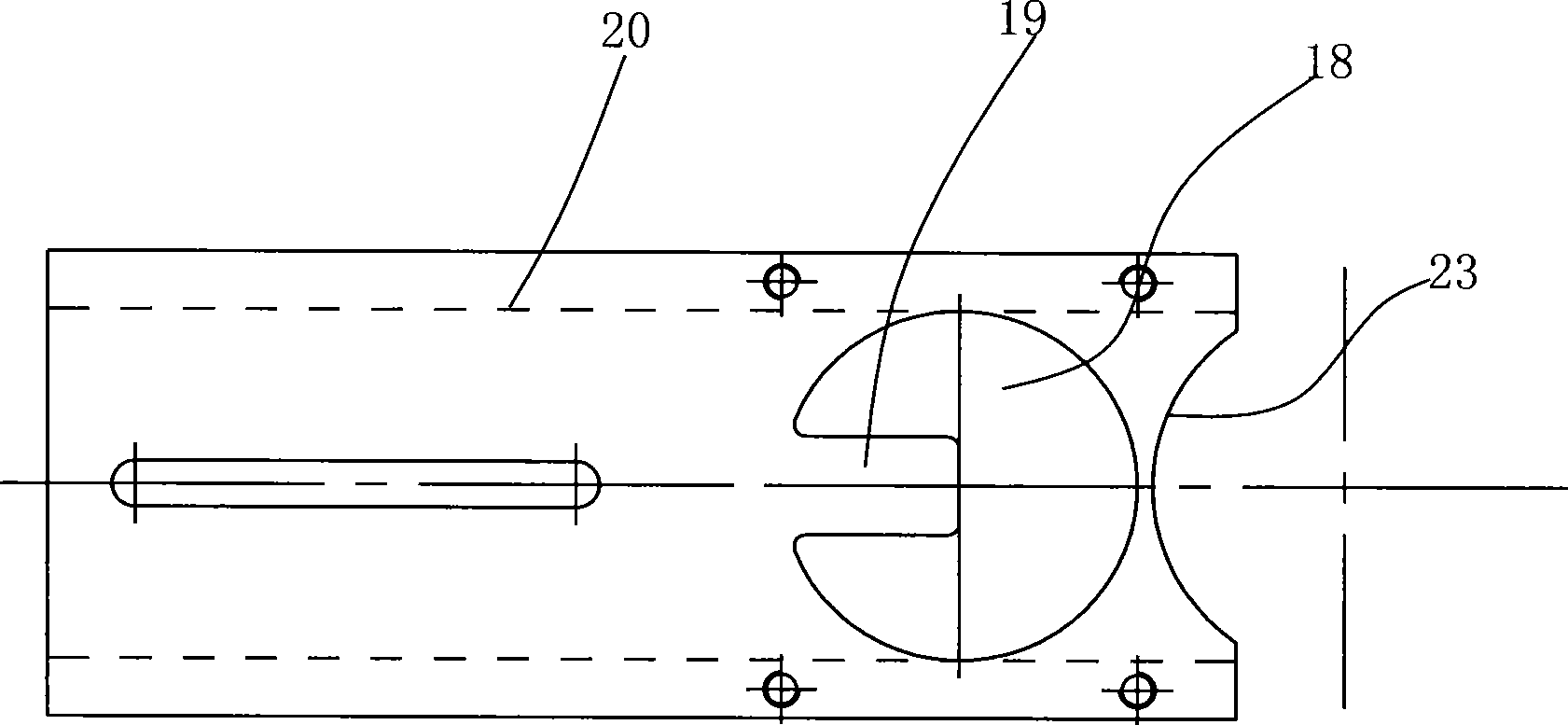

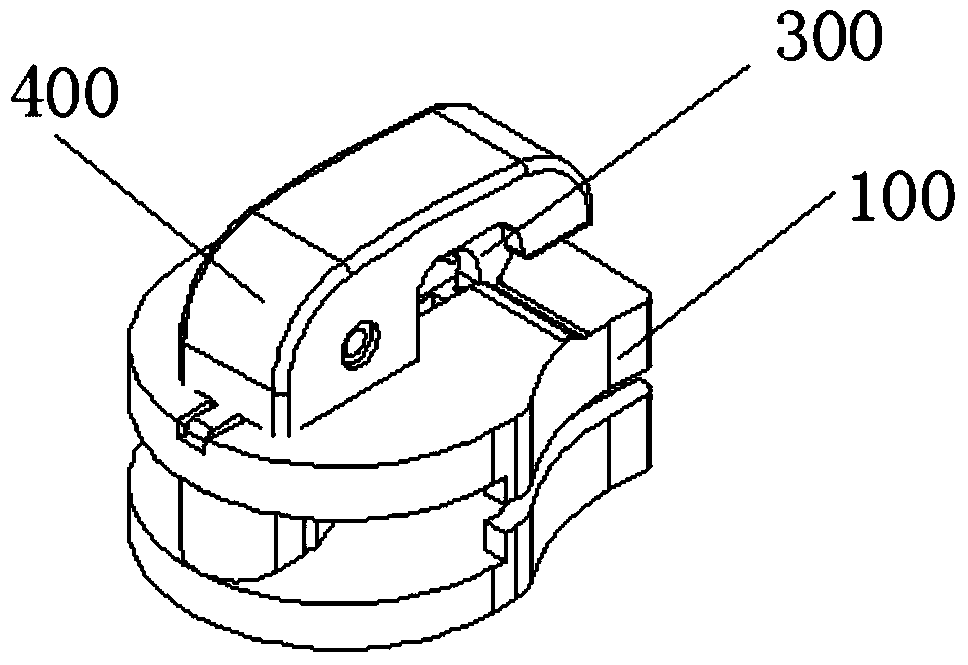

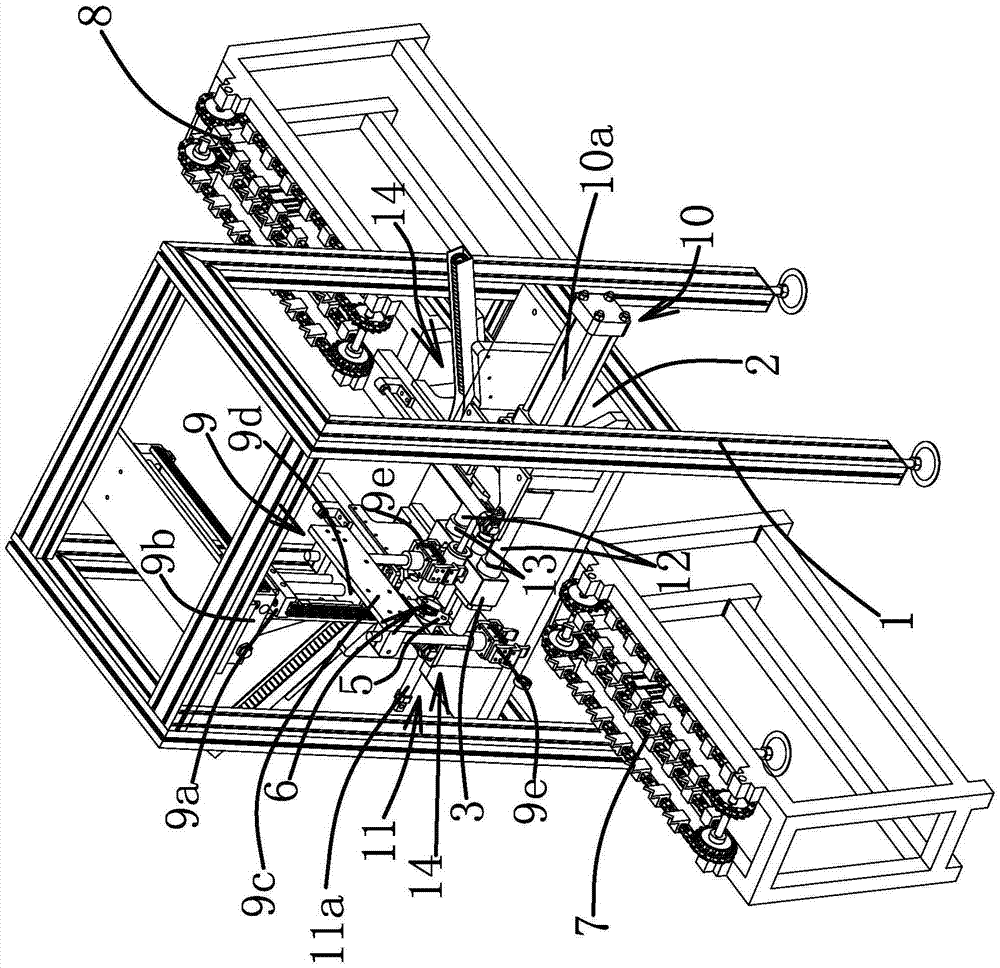

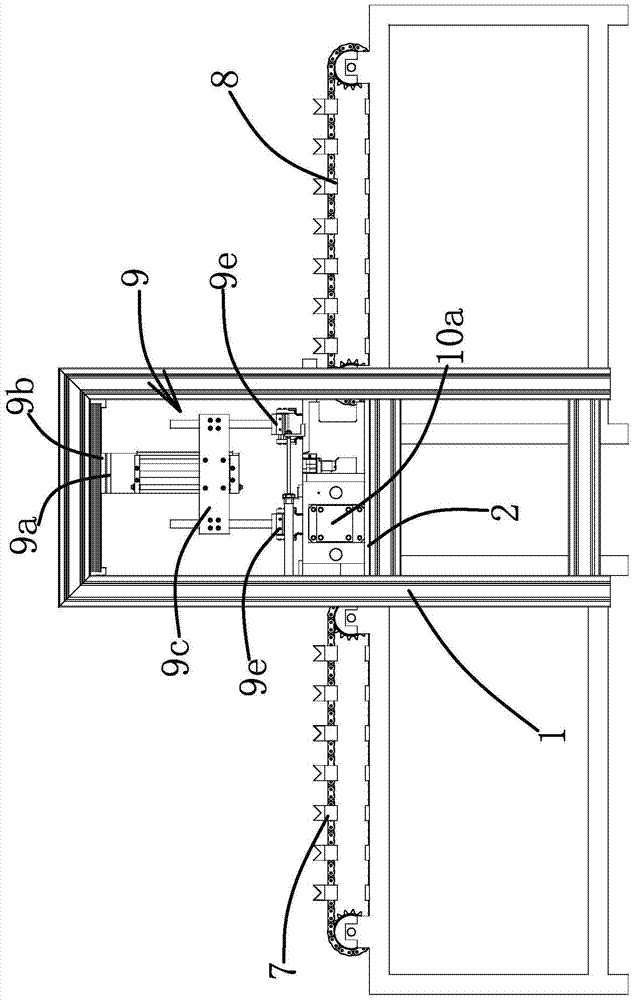

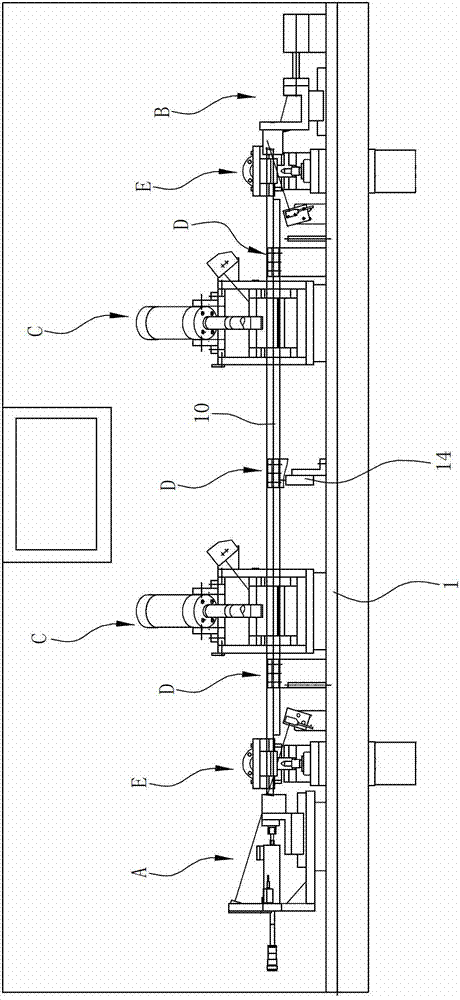

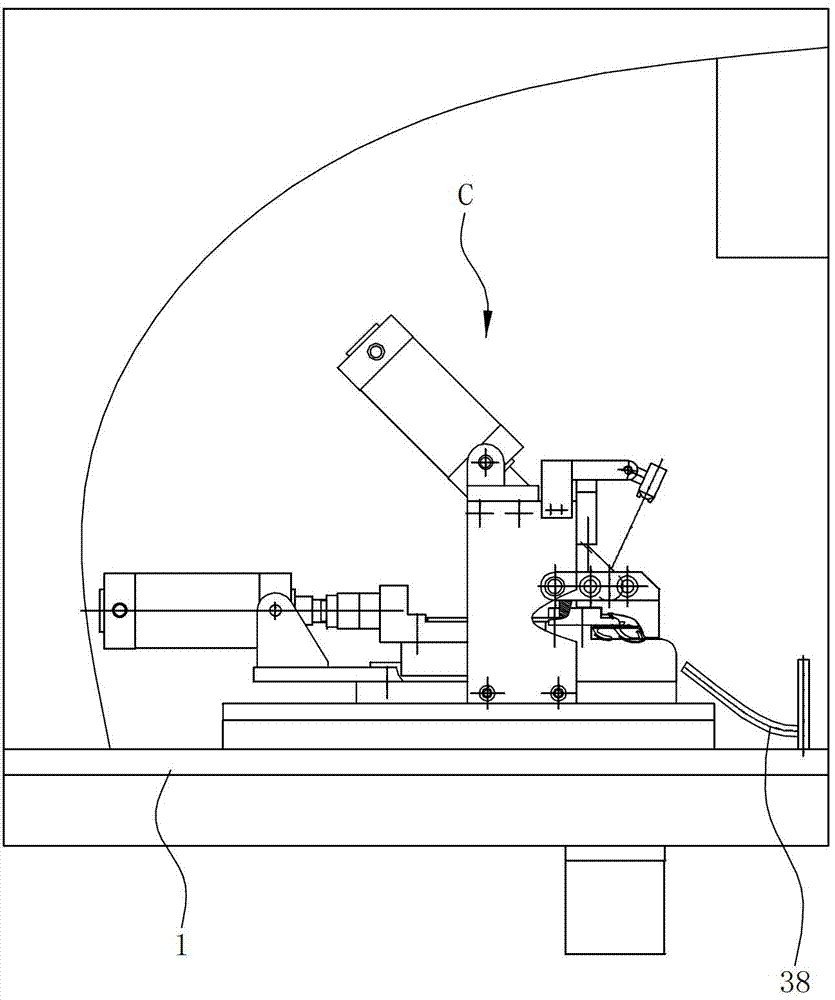

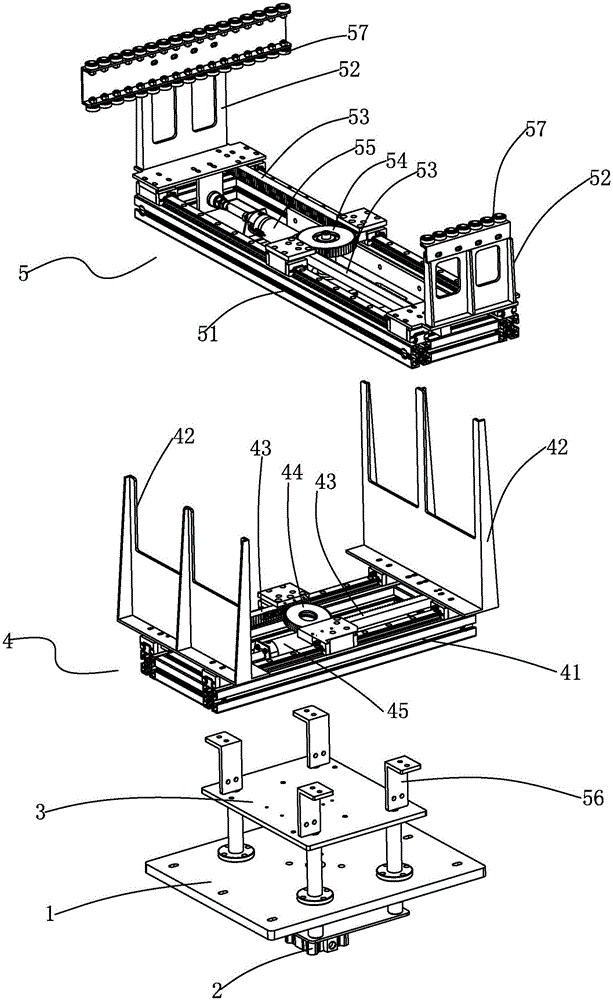

Automatic assembling machine of rotors and bearings of motors

PendingCN105436870ARealize the assemblyGuaranteed smooth assemblyMetal working apparatusMechanical equipmentEngineering

The invention provides an automatic assembling machine of rotors and bearings of motors, belongs to the technical field of mechanical equipment and solves the problem that the rotors and the bearings cannot be assembled smoothly by the existing automatic assembling machine of the rotors and the bearings of the motors. The automatic assembling machine of the rotors and the bearings of the motors comprises a frame and a workbench, wherein a positioning seat is arranged on the workbench; a material receiving block I and a material receiving block II are arranged on two longitudinal sides of the positioning seat; storage slots are formed in the material receiving block I and the material receiving block II; a conveying chain I and a conveying chain II are respectively arranged on two transverse sides of the positioning seat; a mechanical arm assembly is arranged on the workbench; a translation mechanism I capable of driving the material receiving block I to be subjected to longitudinal translation is arranged on the workbench; a resetting mechanism is arranged between the workbench and the positioning seat. The automatic assembling machine of the rotors and the bearings of the motors has the advantage that the rotors and the bearings are smoothly assembled.

Owner:LEO GRP ZHEJIANG PUMP CO LTD

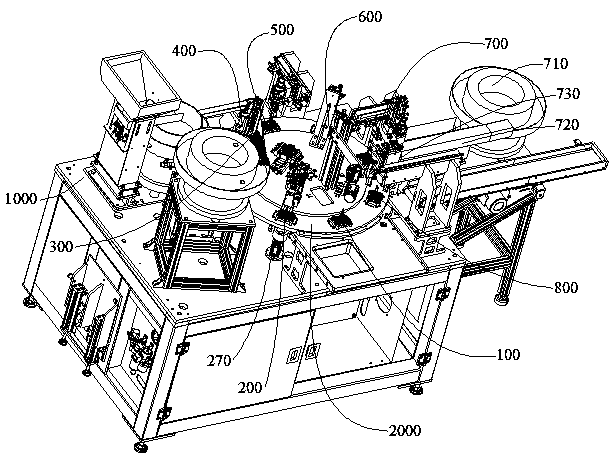

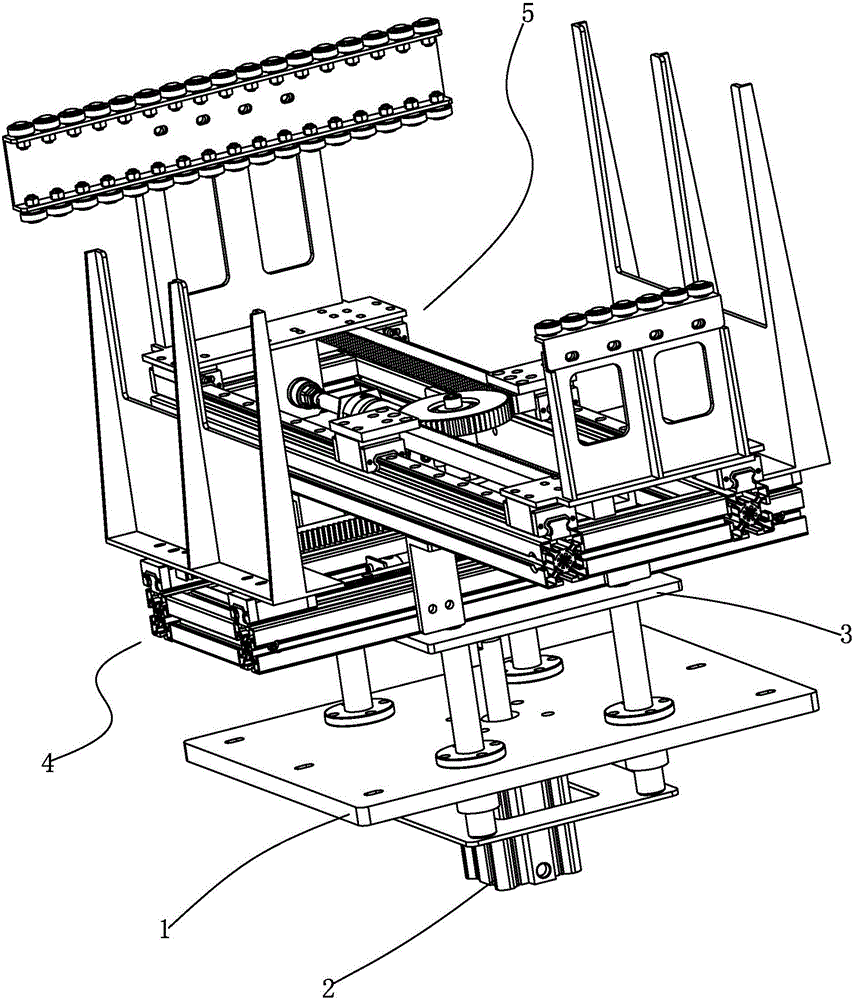

Connector assembling device

ActiveCN110695684ARealize automated assemblyGuaranteed smooth assemblyAssembly machinesMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a connector assembling device. A rotating plate mechanism is arranged on a machine frame and provided with a plurality of stations. A connector tool can be installed at each station and can rotate on the rotating plate mechanism of the machine frame and sequentially pass through a manual feeding station, a PIN press-in station, a lining installing station, a barb piece primary bending station, a lock catch installing station, a barb piece secondary bending station, a seal ring installing station and an unloading station which are circumferentially and sequentially distributed along the rotating plate mechanism to the next process. In this way, the connector assembling device can be used for producing and manufacturing connector products and automatically assemblingthe connector products, the continuity and accuracy of the whole assembling are ensured, the completion of the smooth assembling of the connector products is ensured, and the assembling efficiency isgreatly improved.

Owner:AMPHENOL AUTOMOTIVE CONNECTION SYST CHANGZHOU CO LTD

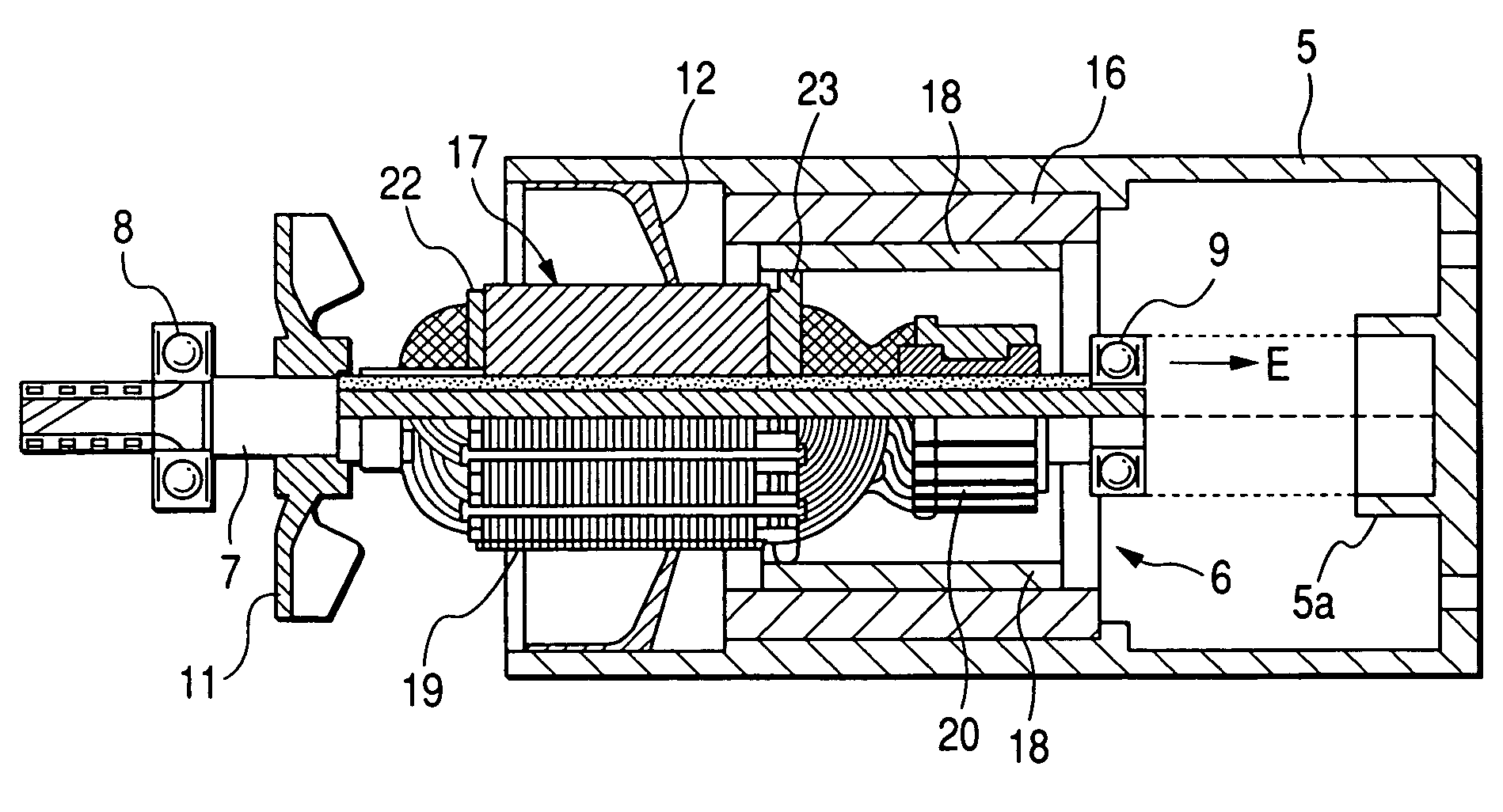

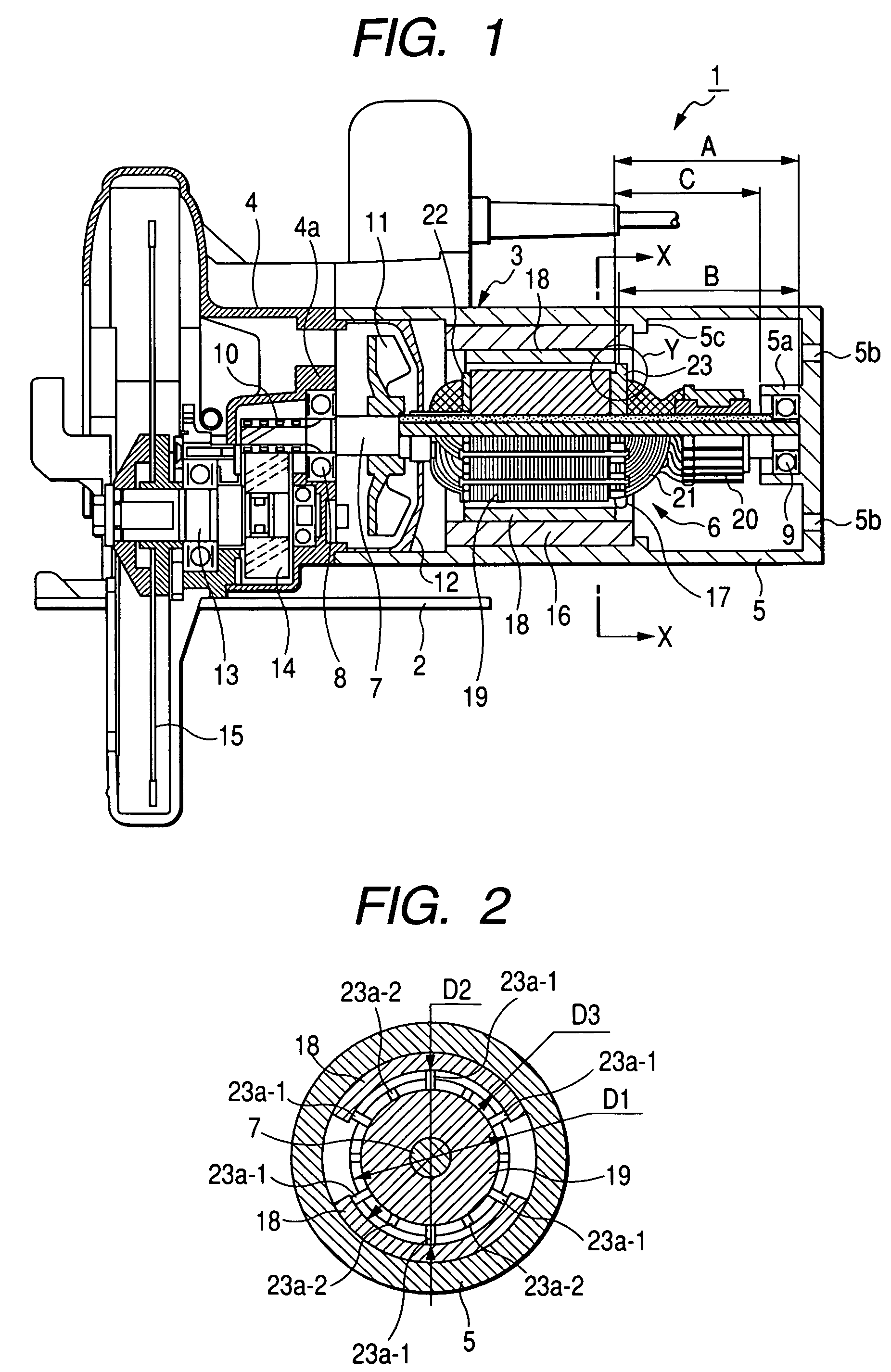

Electrical tool

InactiveUS7355316B2Easy to installSmoothly inserted into housingMetal sawing devicesMagnetic circuit rotating partsCircular sawPermanent magnet motor

In the portable electrical circular saw (electrical tool) in which a commutator motor (permanent magnet motor) is mounted in a motor case (housing) which is integrally formed in a tube shape, the commutator motor includes a stator fixed to an inner circumferential surface of the motor case and a rotor which is rotatably disposed in the stator, and a plate having a plurality of protrusions is disposed on at least one of the both axial ends of a rotor core of the rotor, an outer diameter of at least two protrusions of the plate is larger than an outer diameter of the rotor core and smaller than an inner diameter of the stator.

Owner:KOKI HLDG CO LTD

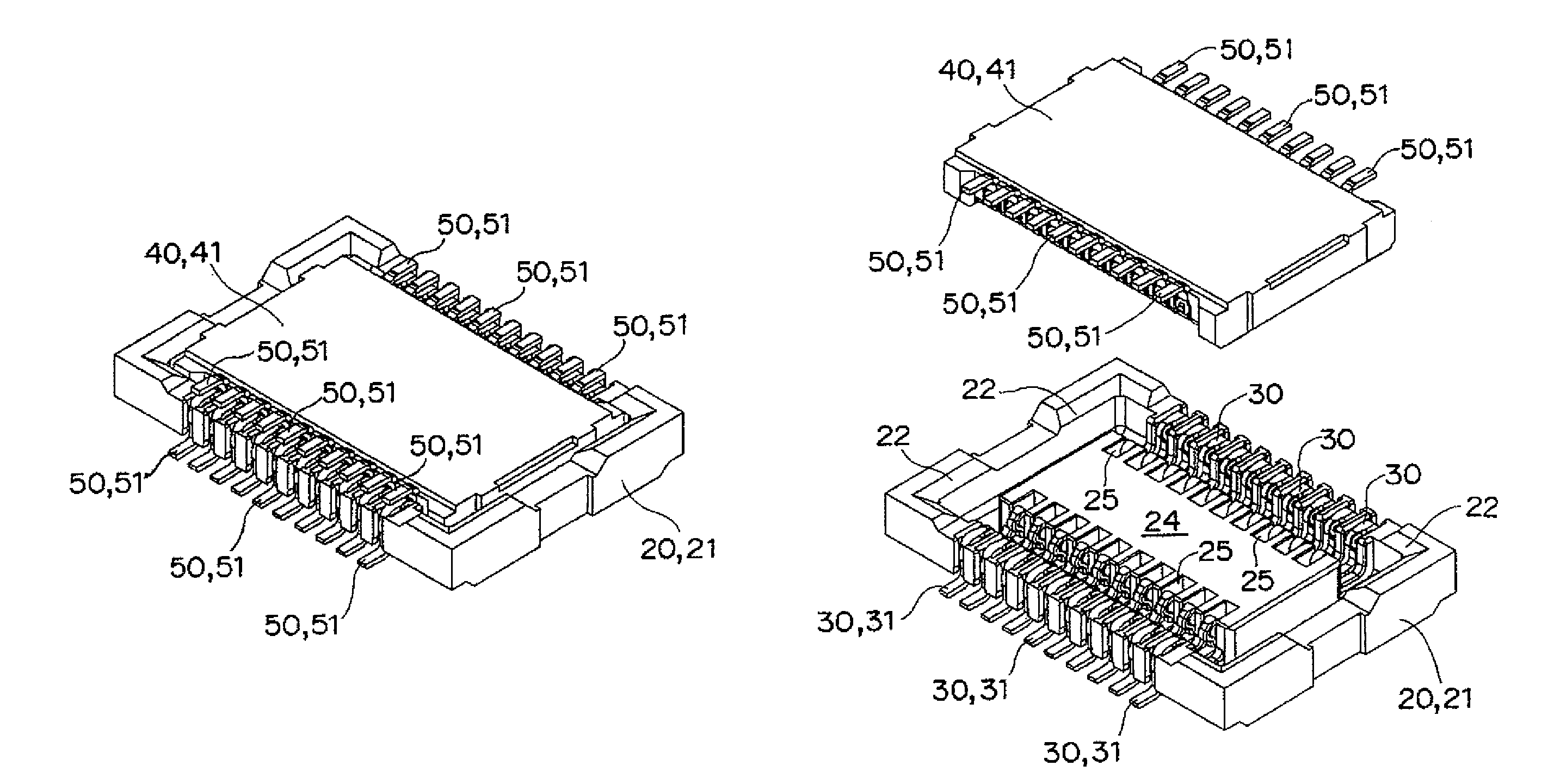

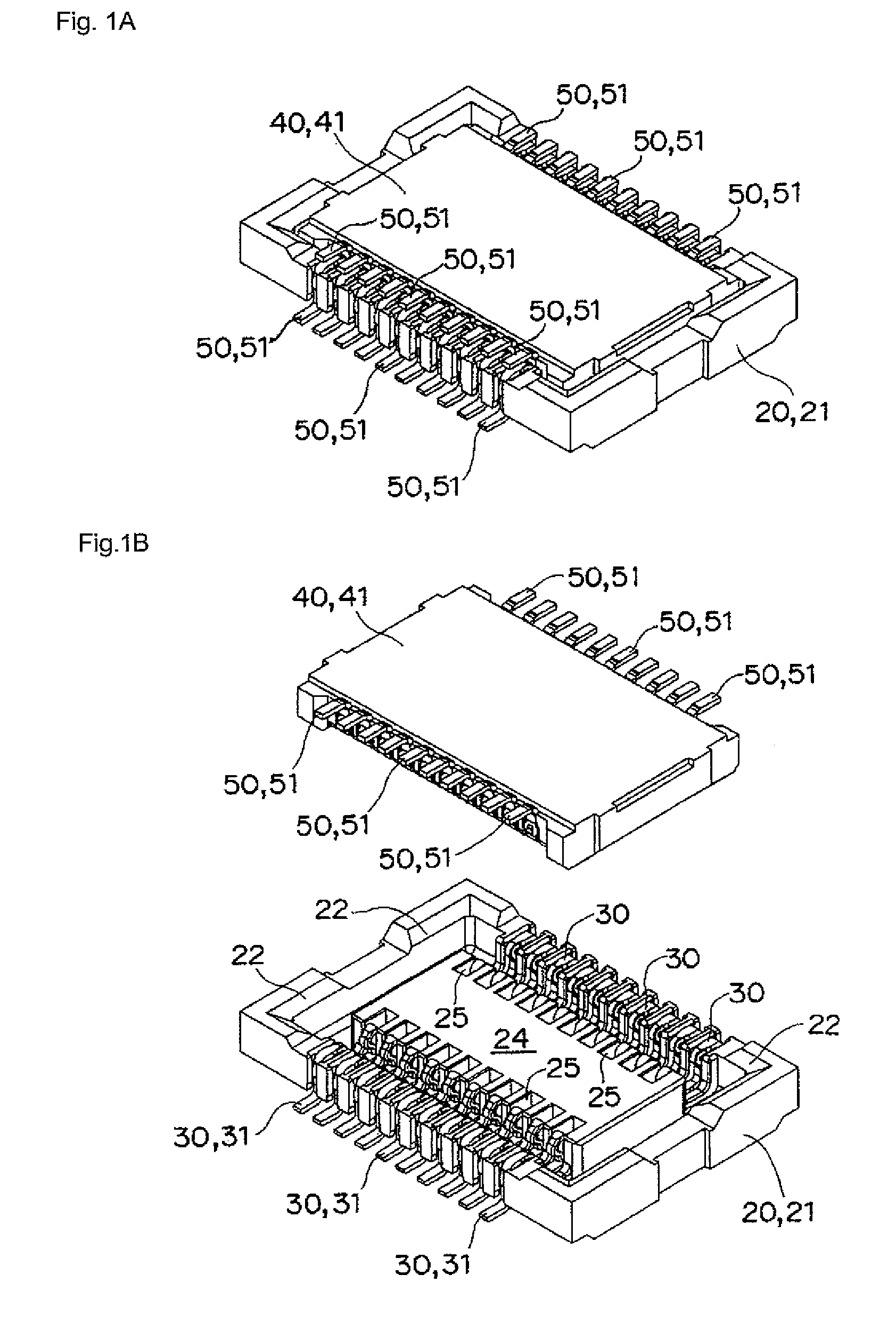

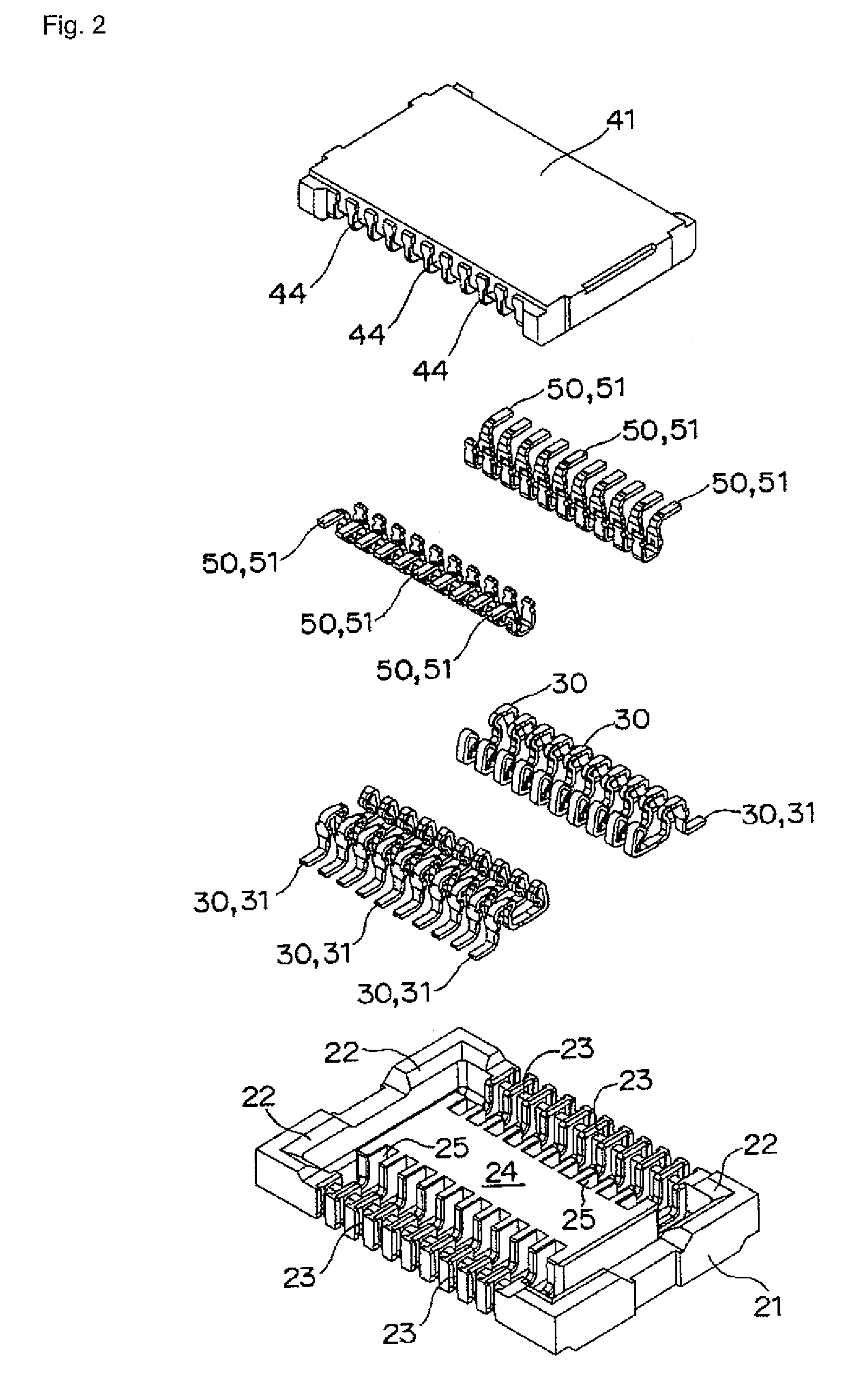

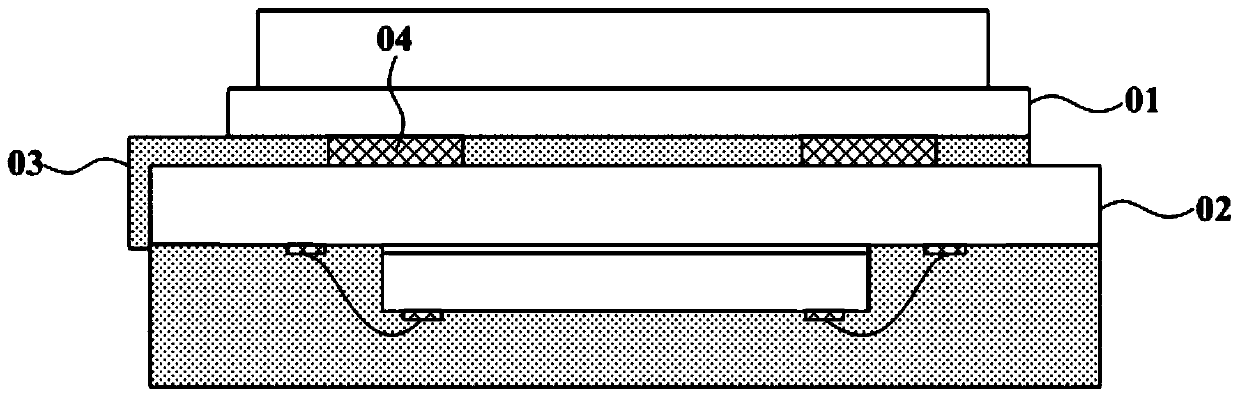

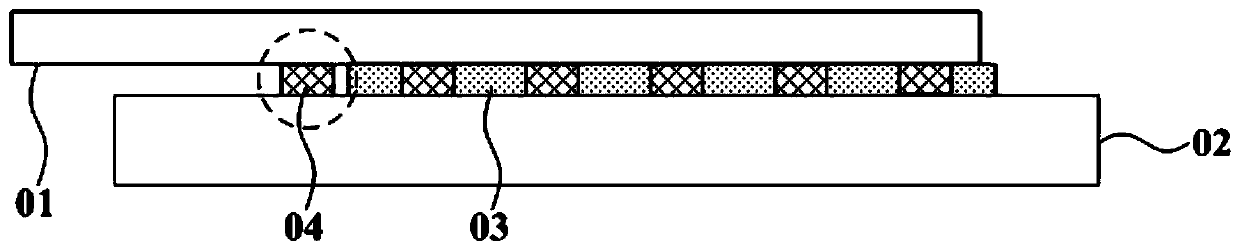

Electrical connector

InactiveUS7637786B2Simple processLow production costElectrically conductive connectionsElectric discharge tubesElectrical connectorMechanical engineering

An electrical connector includes a socket and a plug. In the socket, plural first connectors are provided in parallel, and substantially U-shaped press-fitting portions are assembled so as to cross over opening edge portions of a socket body. In the plug, plural second connectors are provided in parallel, and substantially U-shaped press-fitting portions are assembled so as to cross over opening edge portions of a plug body. The plug body has a planar shape which can be fitted in the opening edge portions of the socket body. Particularly, a free end portion of the press-fitting portion of the second connector located in the opening edge portion of the plug body is engaged with a position regulating recess formed in a bottom surface of the plug body.

Owner:ORMON CORP

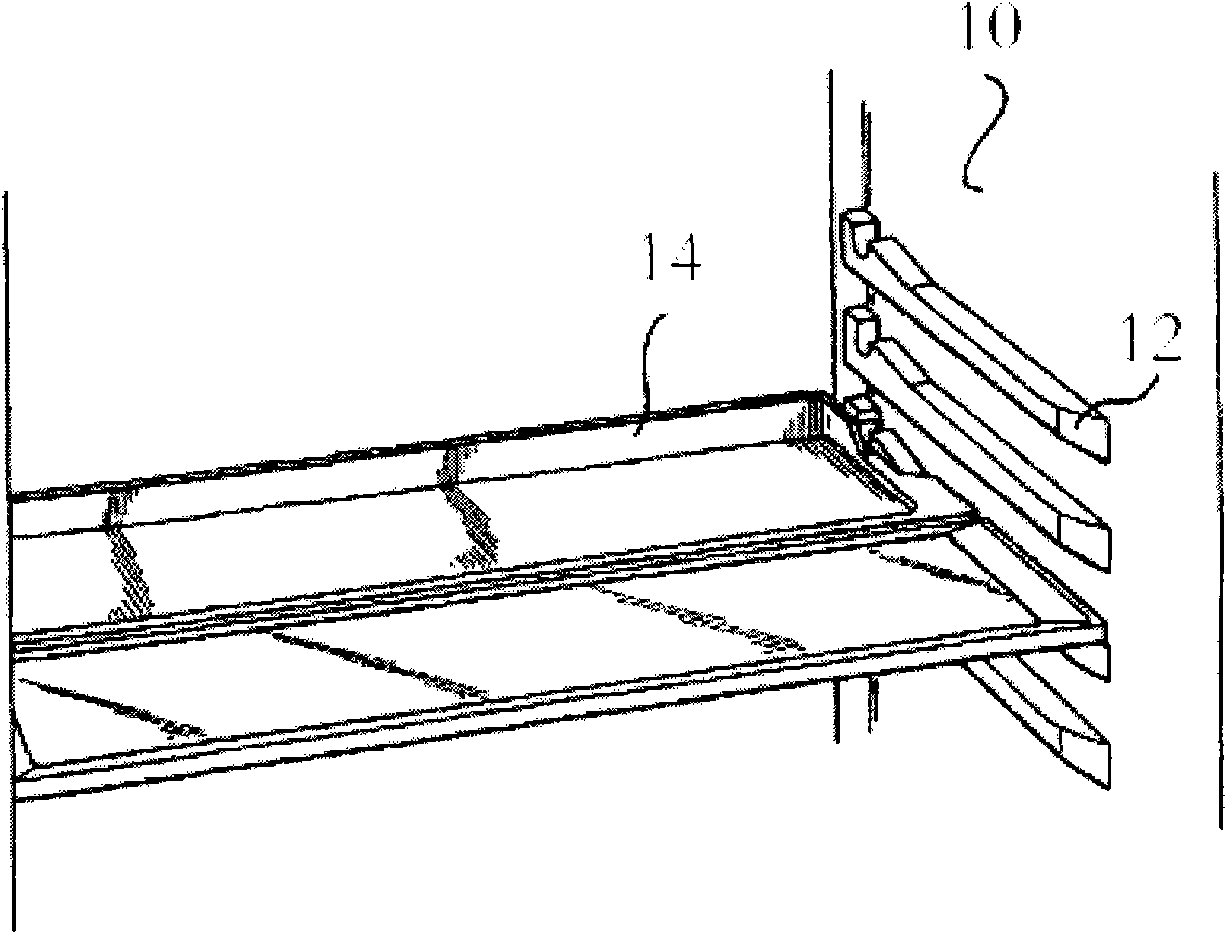

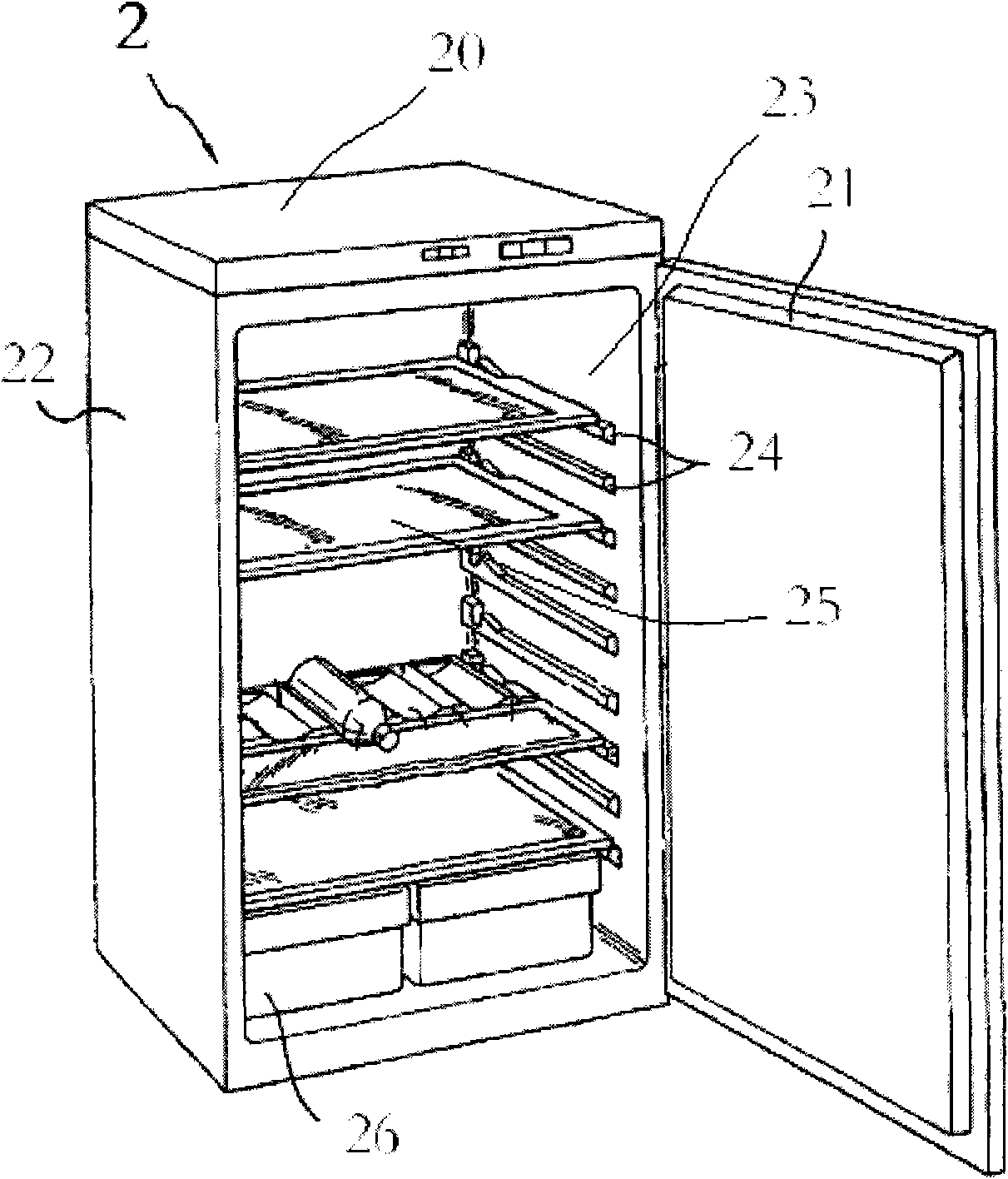

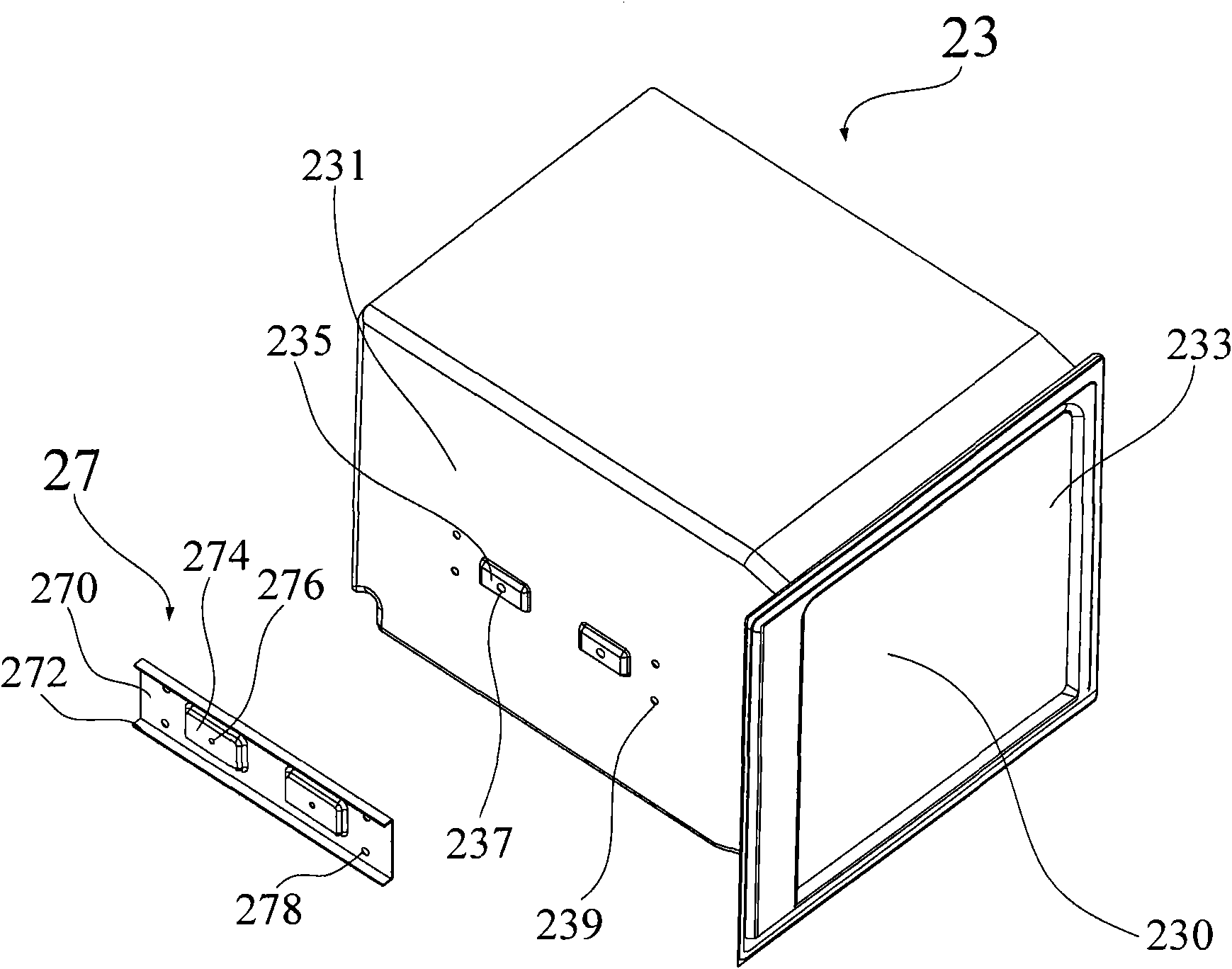

Refrigeration equipment and positioning structure for assembling reinforcer on inner container of refrigeration equipment

InactiveCN102374737APrecise positioningGuaranteed smooth assemblyDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

The invention relates to refrigeration equipment and a positioning structure for assembling a reinforcer on an inner container of the refrigeration equipment. The positioning structure comprises a first positioning piece and a second positioning piece, wherein the first positioning piece is arranged on the side wall of the inner container and comprises a first limiting boss away from the side wall of the inner container, and a positioning hole which is formed on the first limiting boss; and the second positioning piece is arranged on the reinforcer and comprises an assembly surface away from the reinforcer, a second limiting boss which is matched with the first limiting boss of the first positioning piece, and a protruding column which is arranged on the second limiting boss, faces the assembly surface of the reinforcer and is matched with the positioning hole of the first positioning piece. Compared with the prior art, the positioning structure has the advantages of accurate positioning, firm reinforcer assembly, and no damage to foaming moulds.

Owner:博西华家用电器有限公司

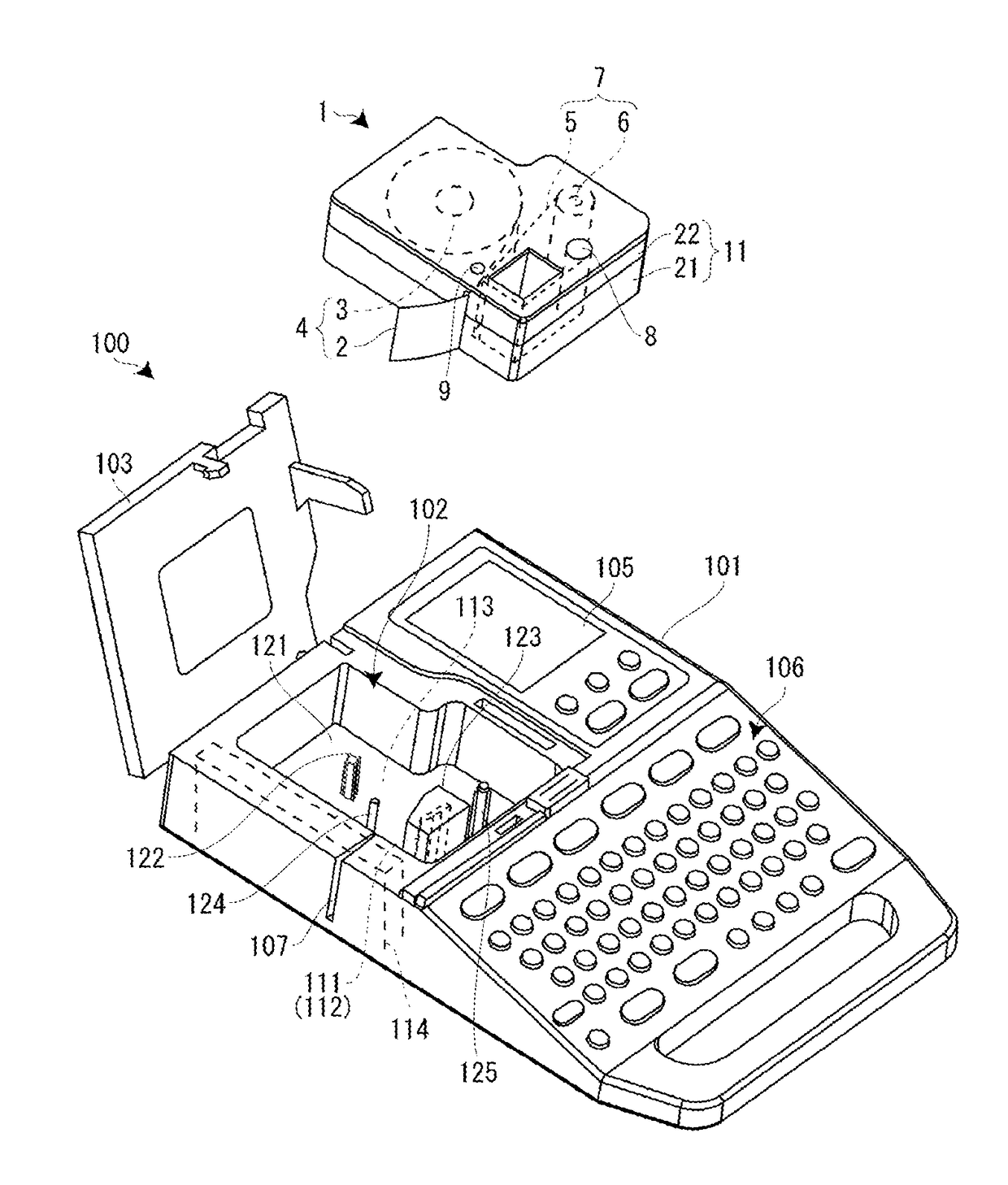

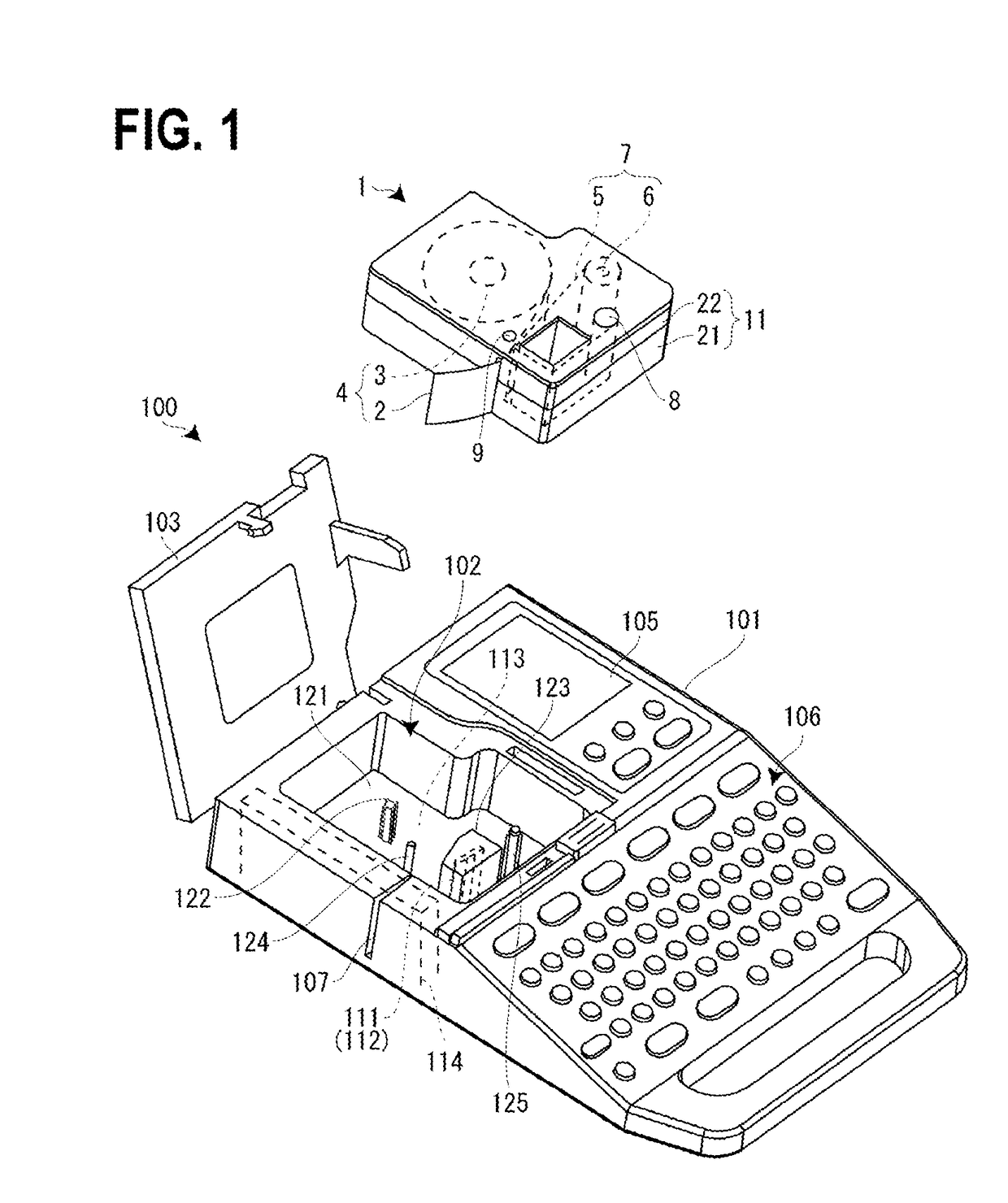

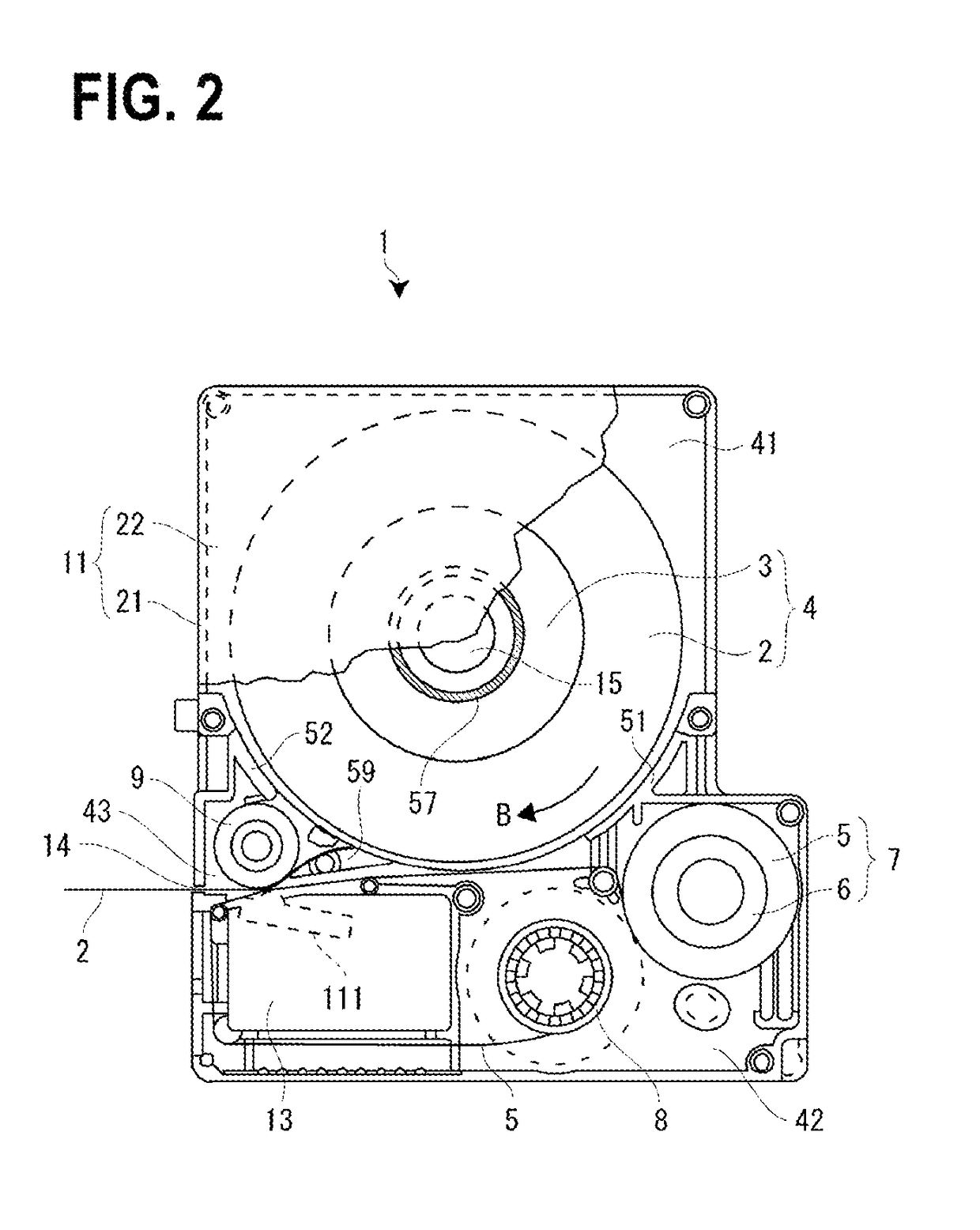

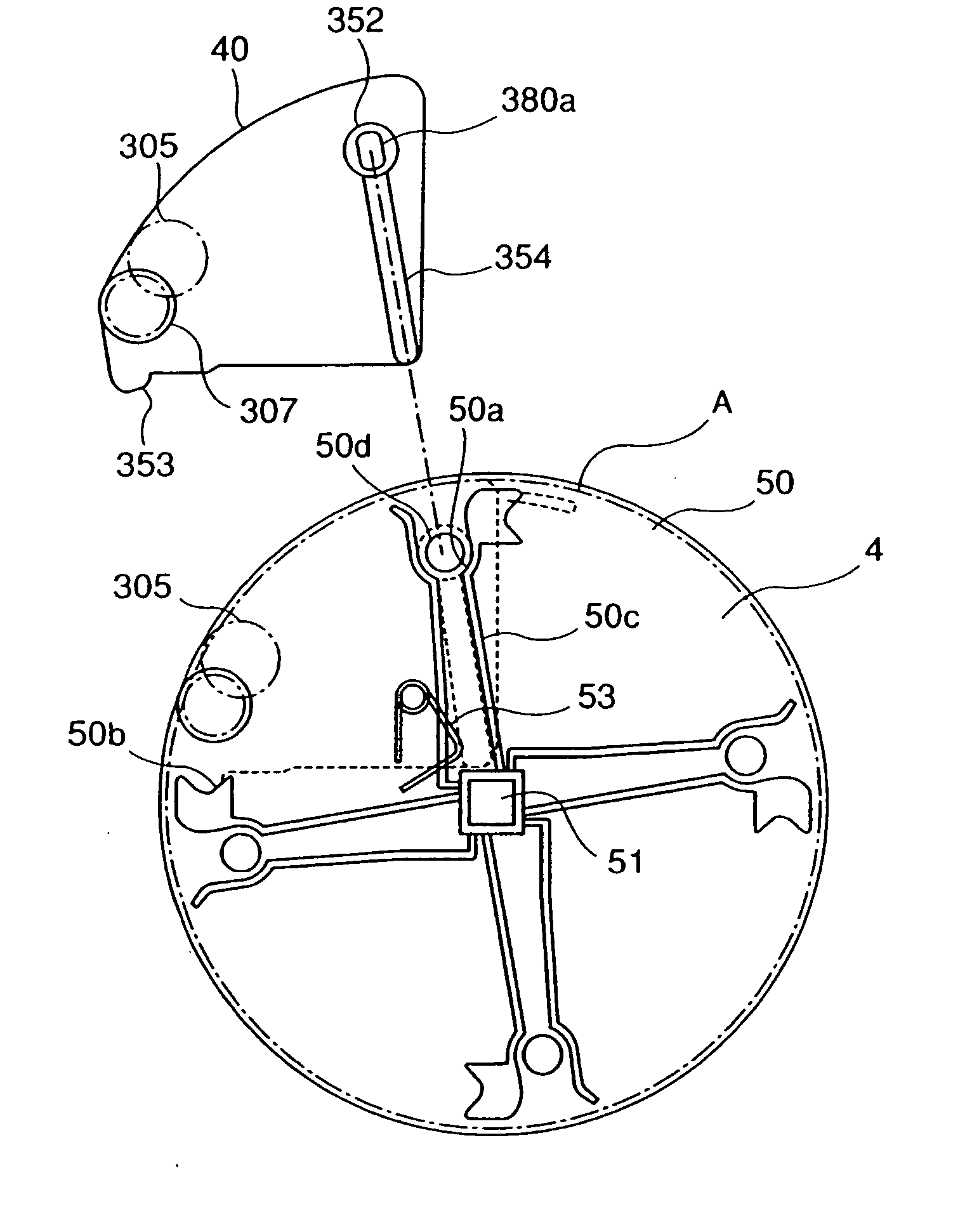

Tape cartridge

InactiveUS20170190195A1Smooth rotationGuaranteed smooth assemblyInk ribbon cartridgesPrinting mechanismsMagnetic tapeSliding contact

A tape cartridge detachably mounted to a cartridge mounting section of a tape printer includes a cartridge casing that has a first casing on a front side in a mounting direction in which the tape cartridge is mounted to the cartridge mounting section, and a second casing on a rear side with respect to the front side in the mounting direction, a tape roll that is accommodated in the cartridge casing and in which a print tape is wound around a spool, and a rotating guide section that is provided in the second casing and guides the rotation of the tape roll in sliding contact with an inner circumferential surface of the spool.

Owner:SEIKO EPSON CORP

Cartridge and electrophotographic image forming apparatus

InactiveUS20050008395A1Smoothly mountableEfficiently mounted into and dismountedElectrographic process apparatusEngineeringImaging equipment

A cartridge removably mountable to a main assembly of an electrophotographic image forming apparatus includes a developing member, a developer accommodating portion, a locking portion to engage a locking portion of the main assembly of the apparatus to prevent the cartridge from disengaging from the main assembly after mounting of the cartridge, a grip to be gripped by an operator when the cartridge is mounted to the main assembly, and a releasing portion to move the locking portion of the cartridge in interrelation with a movement of the grip which is moved when the operator grips the grip to disengage the cartridge from the main assembly of the apparatus. The locking between the locking portion of the cartridge and the locking portion of the main assembly is released by the movement of the locking portion of the cartridge.

Owner:CANON KK

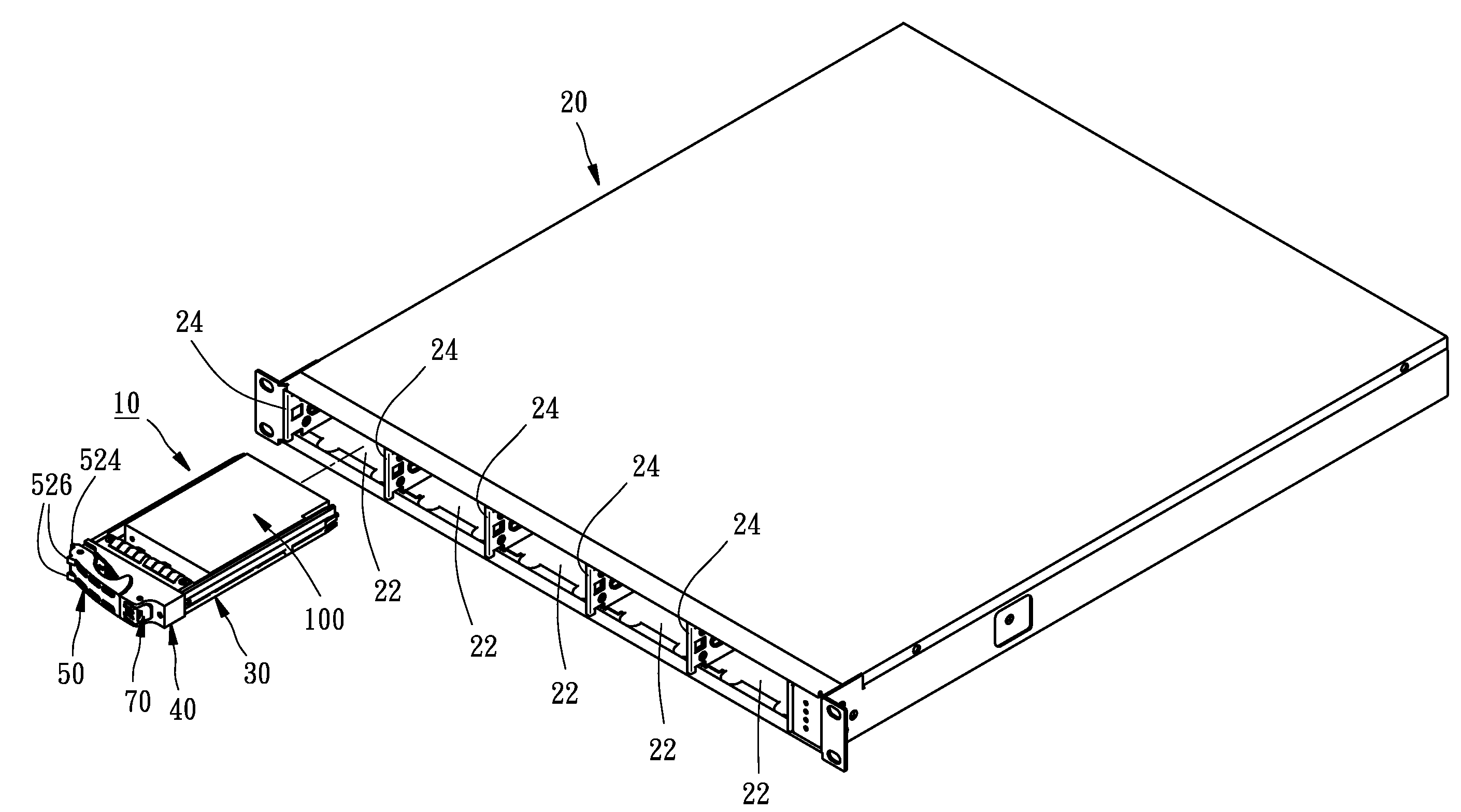

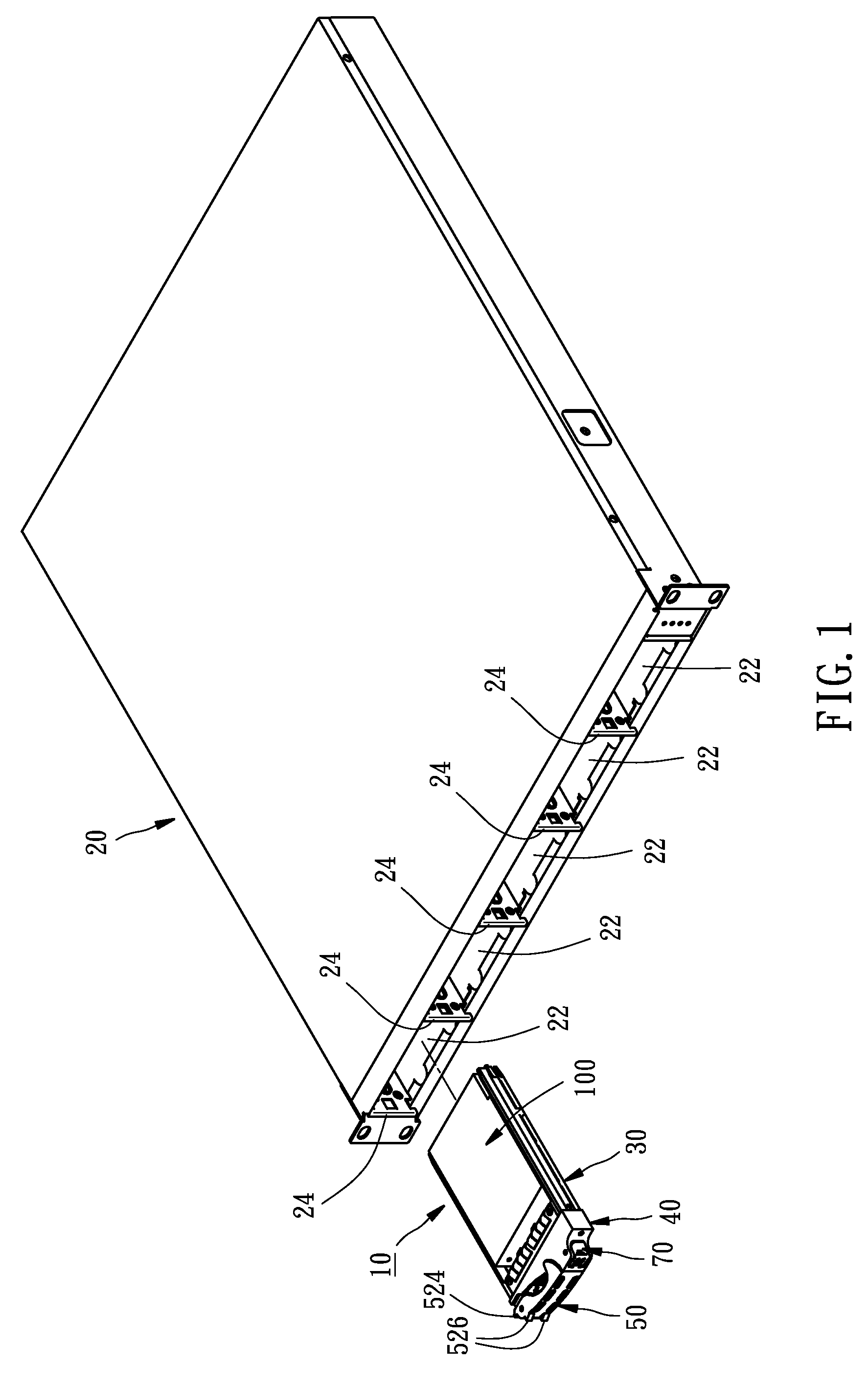

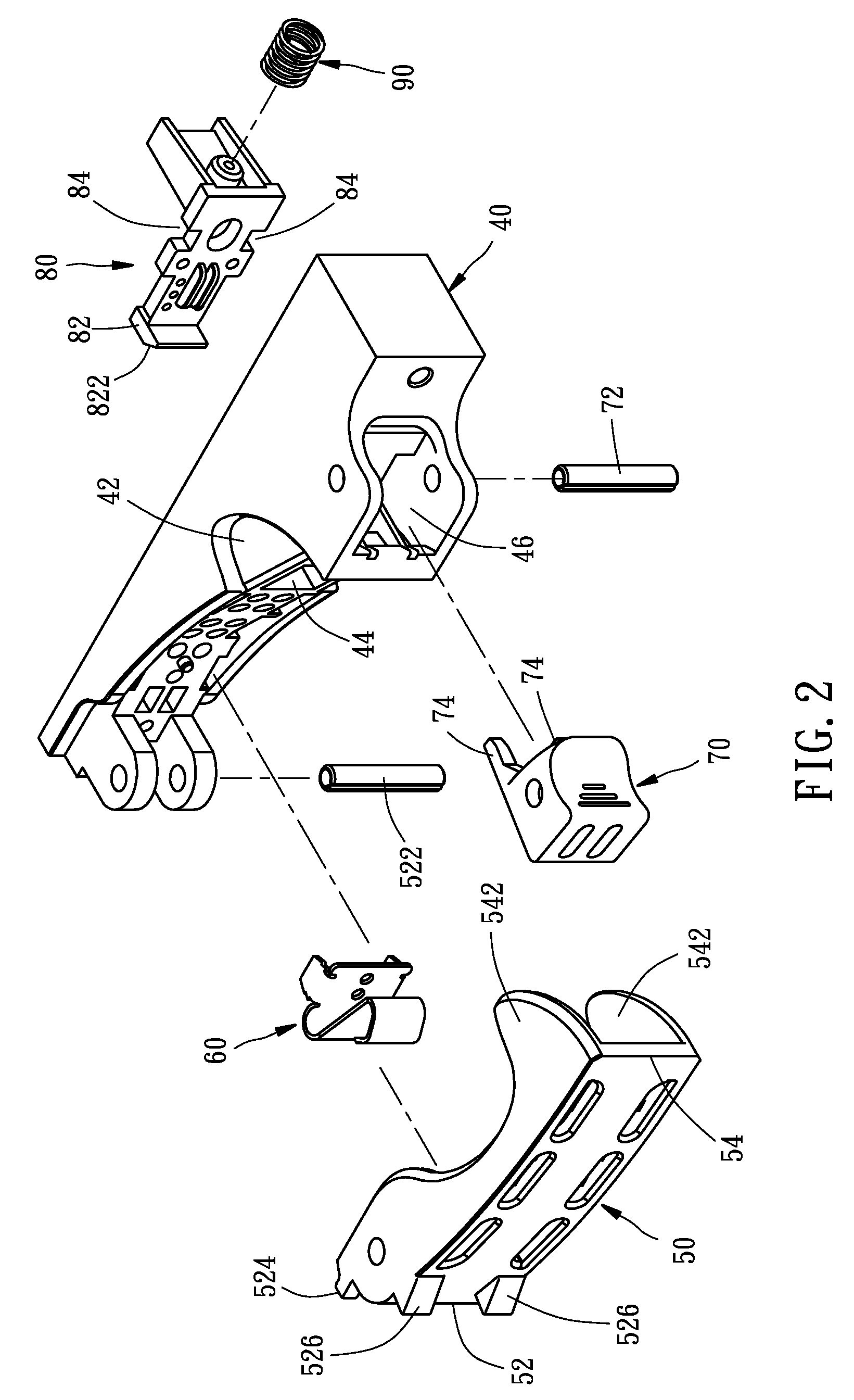

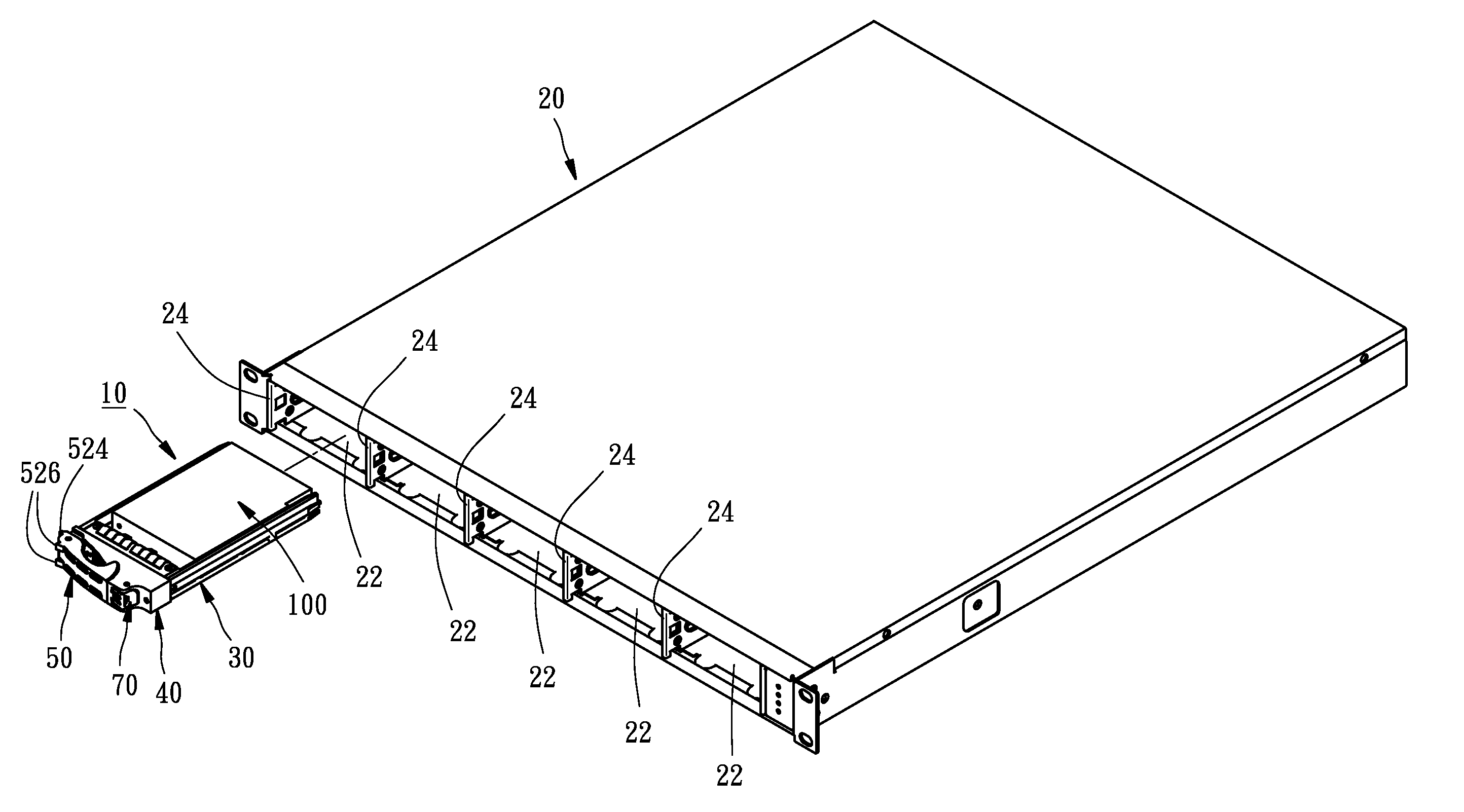

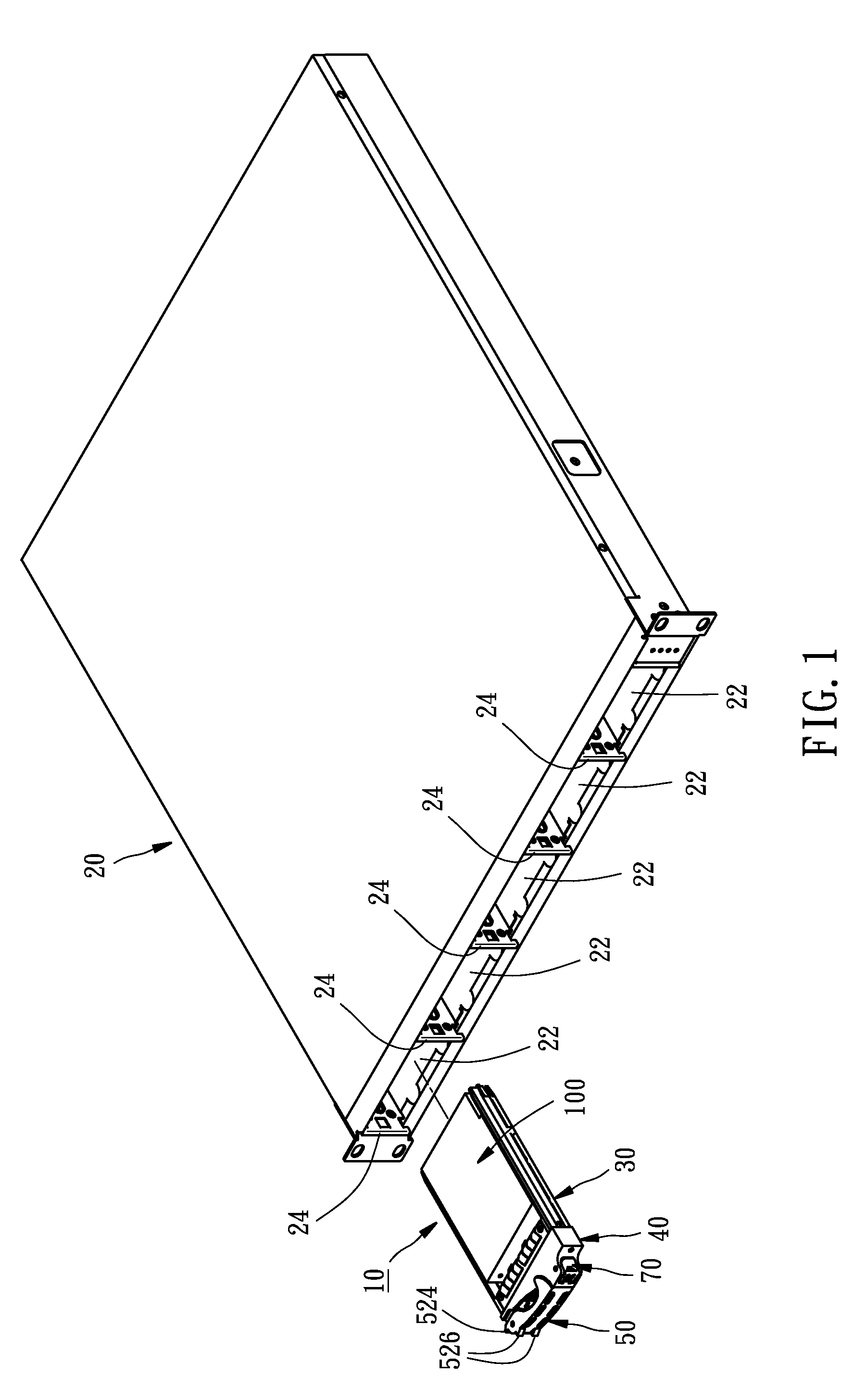

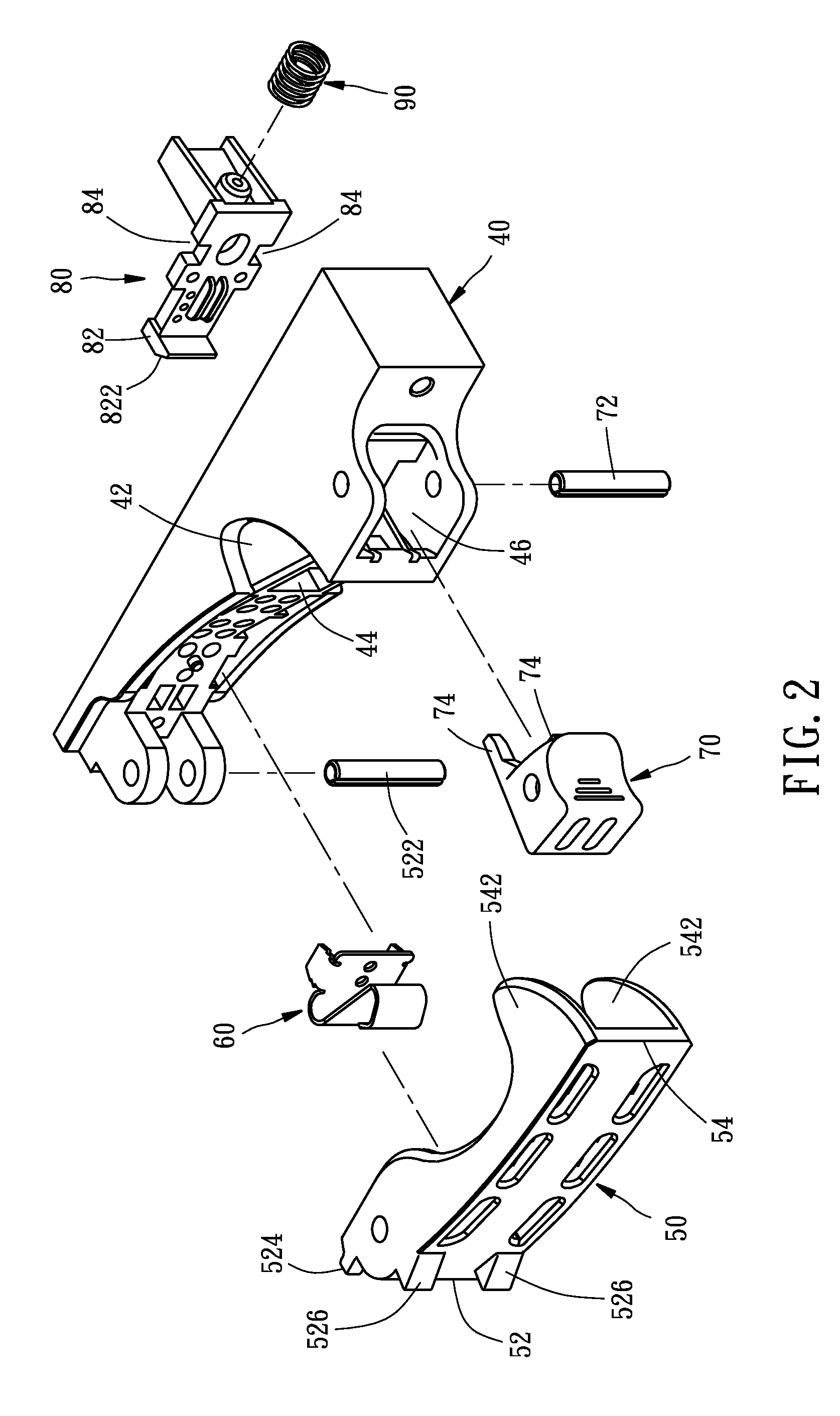

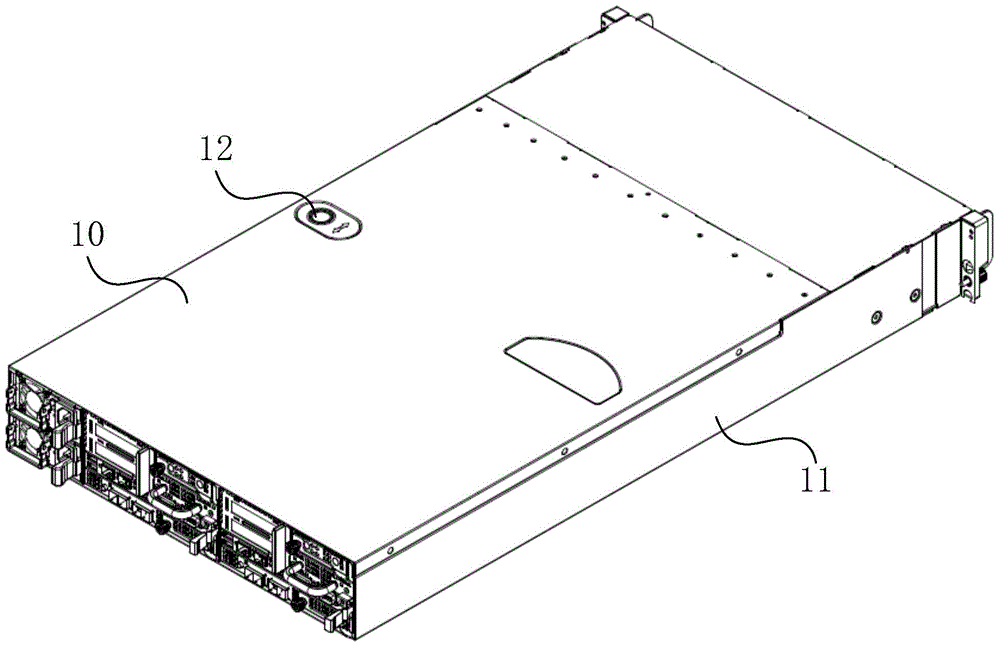

Hard disk case

InactiveUS7808777B2Guaranteed smooth assemblyTelevision system detailsPicture framesHard disc driveComputer engineering

A hard disk case for installation in a computer case includes a support frame for installation of a hard disk drive, a base mounted to the support frame, and a handle. The handle has a pivoting end pivotally connected with the base, a first protrusion insertable in an insertion portion of the computer case and pushable against a periphery wall of the insertion portion for enabling engagement of the hard disk drive with the computer case, and a second protrusion spaced from the first protrusion and pushable against a stopping portion of the computer case for enabling disengagement of the hard disk drive from the computer case. As a result, the hard disk case of the present invention is convenient in assembly and disassembly works.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

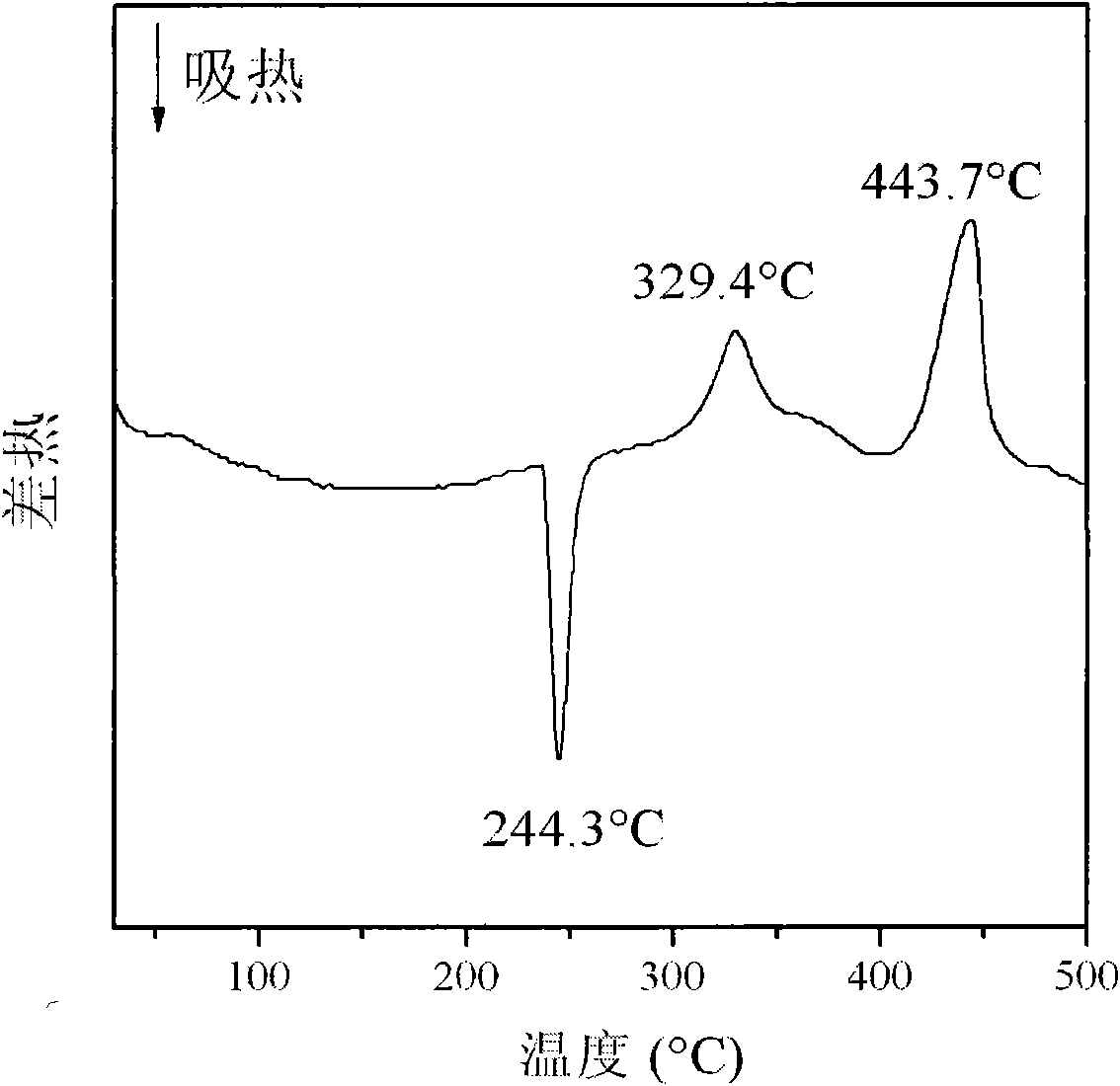

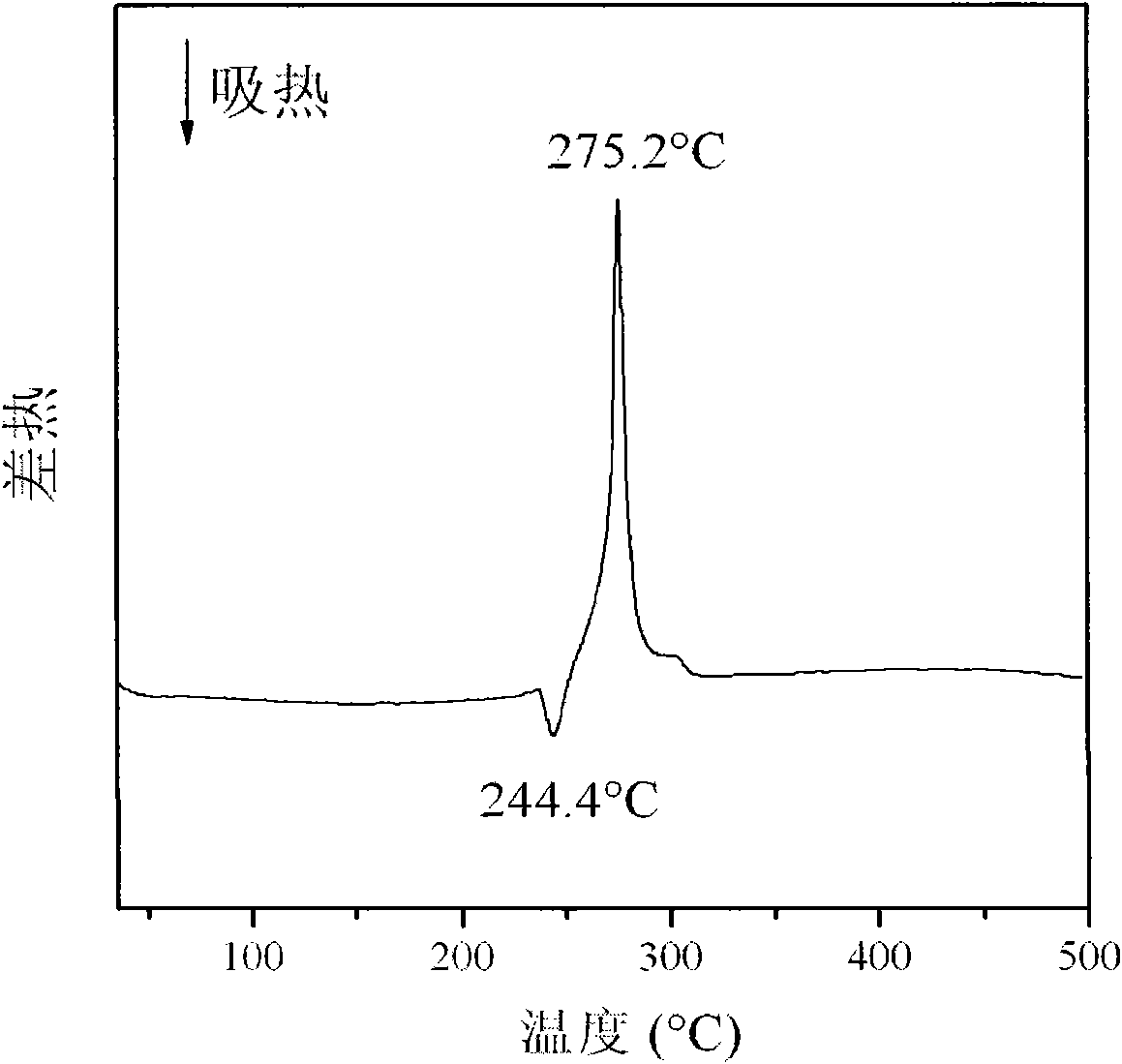

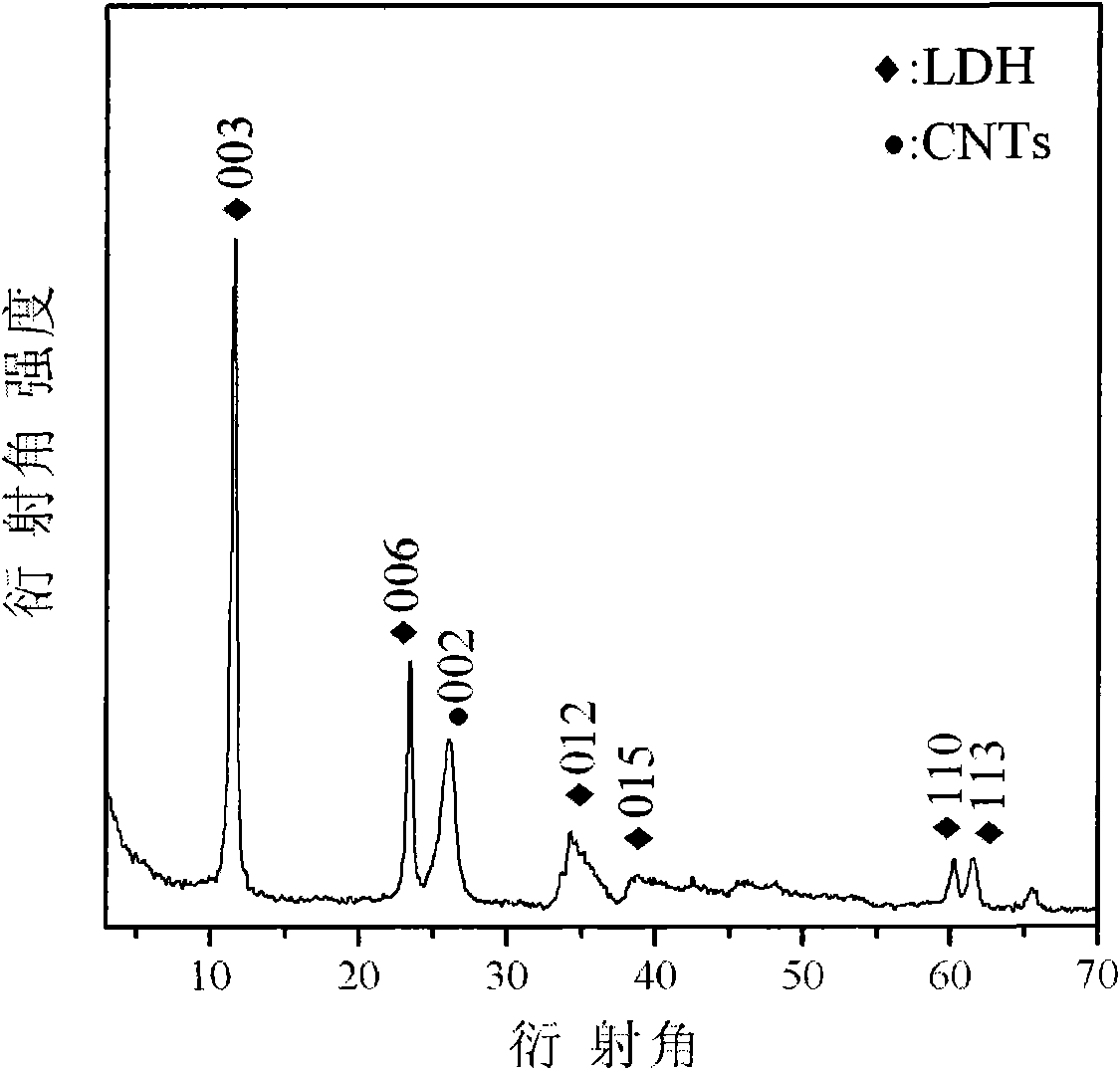

CoAl-metallic oxide/carbon nano tube composite as well as preparation method and application thereof as ammonium porchlorate catalyst

InactiveCN101869837AFirmly assembledGuaranteed smooth assemblyMetal/metal-oxides/metal-hydroxide catalystsAmmonium perchlorate explosive compositionsCross-linkDispersity

The invention provides a CoAl-metallic oxide / carbon nano tube composite as well as a preparation method and application thereof as an ammonium porchlorate catalyst. The preparation method of the composite comprises the following steps of: preparing a CoAl-layered bimetallic hydroxide / carbon nano tube composite precursor by adopting a coprecipitation method and using L-cysteine as a cross-linking agent; and roasting at 500 DEG C under N2 atmosphere to convert the CoAl-layered bimetallic hydroxide in the composite precursor into CoO and a CoAl2O4 mixedoxide so as to obtain a CoAl-metallic oxide / carbon nano tube composite. The L-cysteine which is used as a cross-linking molecule can enhance the interaction between layered bimetallic hydroxide nano particles and carbon nano tubes in the precursor and improve the dispersity of the layered bimetallic hydroxide nano particles on the surfaces of the carbon nano tubes, thereby further influencing the disperse state of the CoAl-metallic oxide on the surfaces of the carbon nano tubes. The CoAl-metallic oxide / carbon nano tube composite has good thermocatalysis property, and when the composite is used as the ammonium porchlorate catalyst, a low-temperature exothermic peak decomposed by the ammonium porchlorate can be disappeared; the high-temperature exothermic peak temperature is reduced to 271.3-299.1 DEG C, and the decomposition speed is improved to 7.0-13.0mg / min.

Owner:BEIJING UNIV OF CHEM TECH

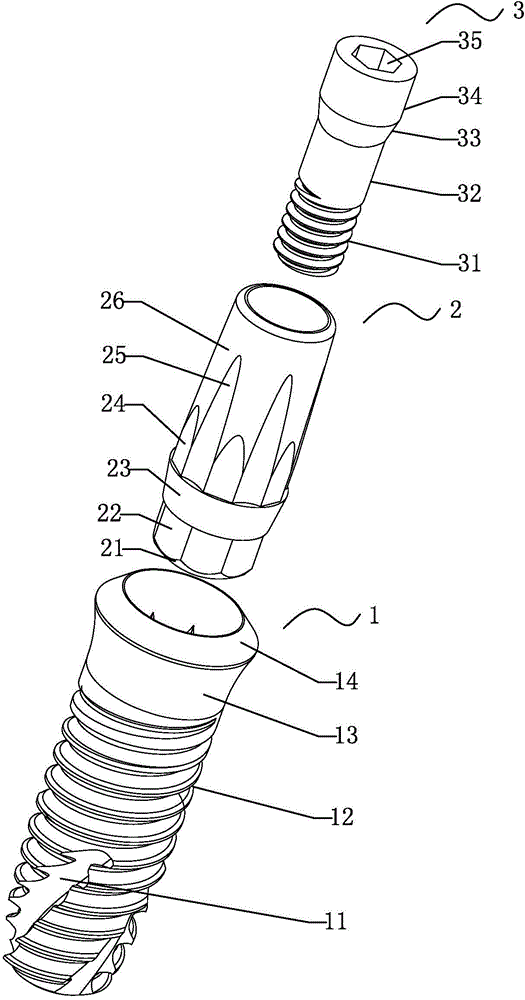

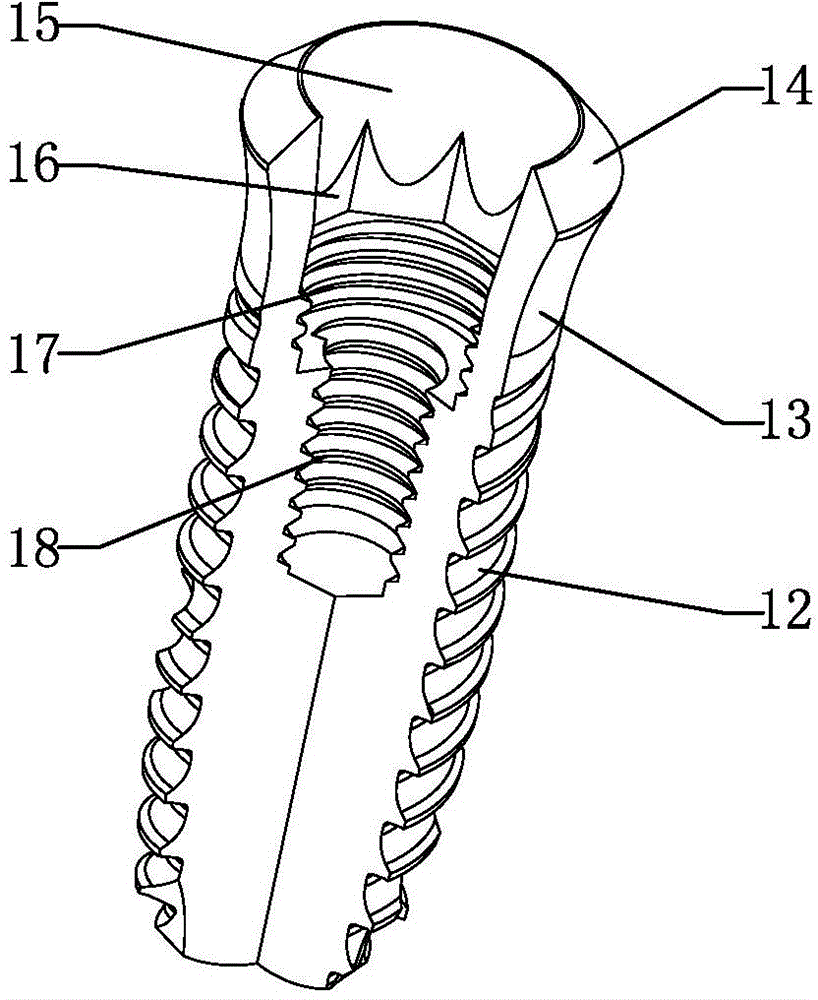

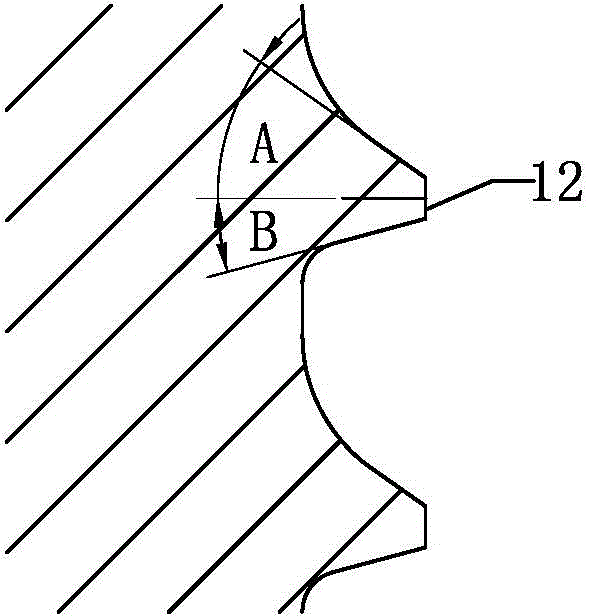

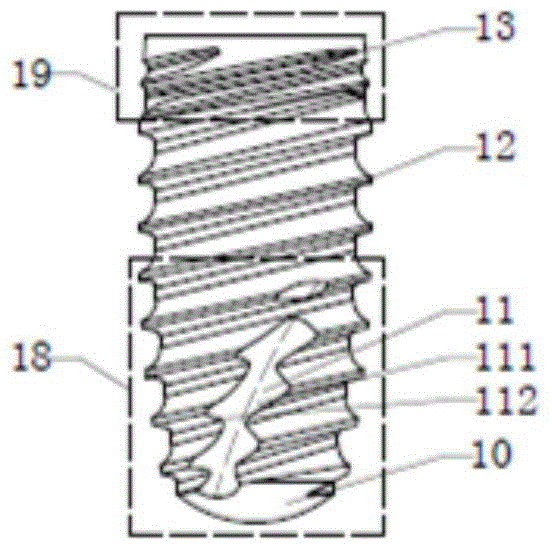

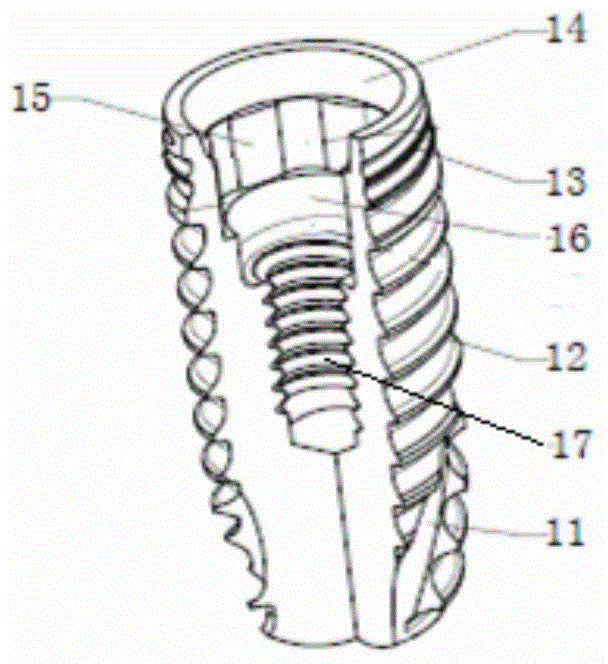

Easily-removing implant device and screwing-out tool thereof

InactiveCN103550003AReduce the risk of absorbingAvoid secondary surgeryDental implantsNeck partsImplanted device

The invention discloses an easily-removing implant device and a screwing-out tool thereof. The easily-removing implant device comprises an implant, a base station and a central bolt; the easily-removing implant device is characterized in that the implant comprises a gum-penetrating neck part and a head part, wherein a thread is formed on the outer surface of the head part, at least two spiral self-tapping grooves are also formed in the outer surface of the head part, a connecting hole coaxial with the implant is formed in the implant, the connecting hole comprises a tapered hole, an anti-rotation hole, an implant taking-out section and a blind threaded hole, which are sequentially connected coaxially, the base station comprises a dental crown connecting section and an implant connecting section, the implant connecting section comprises a conical table and an anti-rotation column, a stepped hole matched with the central bolt is formed in the base station, and the central bolt penetrates through the stepped hole to be connected with the blind threaded hole, so that the base station and the implant are fixed integrally. According to the easily-removing implant device, the implant taking-out section with a reverse thread is additionally arranged in the implant, the problem that a part of the implant, which is remained in dentale due to fracture of the implant, is difficult to take out is solved, and the easily-removing implant device has the advantages of simple structure, strong practicability, and the like.

Owner:DALIAN SANSHENG SCI & TECH DEV

Water jacket spacer

InactiveCN102606334AUniform cooling effectGuaranteed smooth assemblyLiquid coolingCylinder headsElastomerWater flow

A water jacket spacer has a spacer body molded in conformity to the shape of the water jacket and a regulating member whose one side is fixed to the spacer body. The regulating member is composed of a first member which is not water-swellable and is elastically deformable and a second member made of water-swellable elastomer which is integrally fixed to the first member. The regulating member lies in a state not-contacting an opposed wall of the water jacket when inserted into the water jacket together with the spacer body, whereas it blocks a part of cooling water flowing through the water jacket by deforming such that a side of the regulating member not fixed to the spacer body faces toward the opposed wall of the water jacket when the second member swells by absorbing cooling water flown into the water jacket and thereby the first member is elastically deformed.

Owner:UCHIYAMA MFG

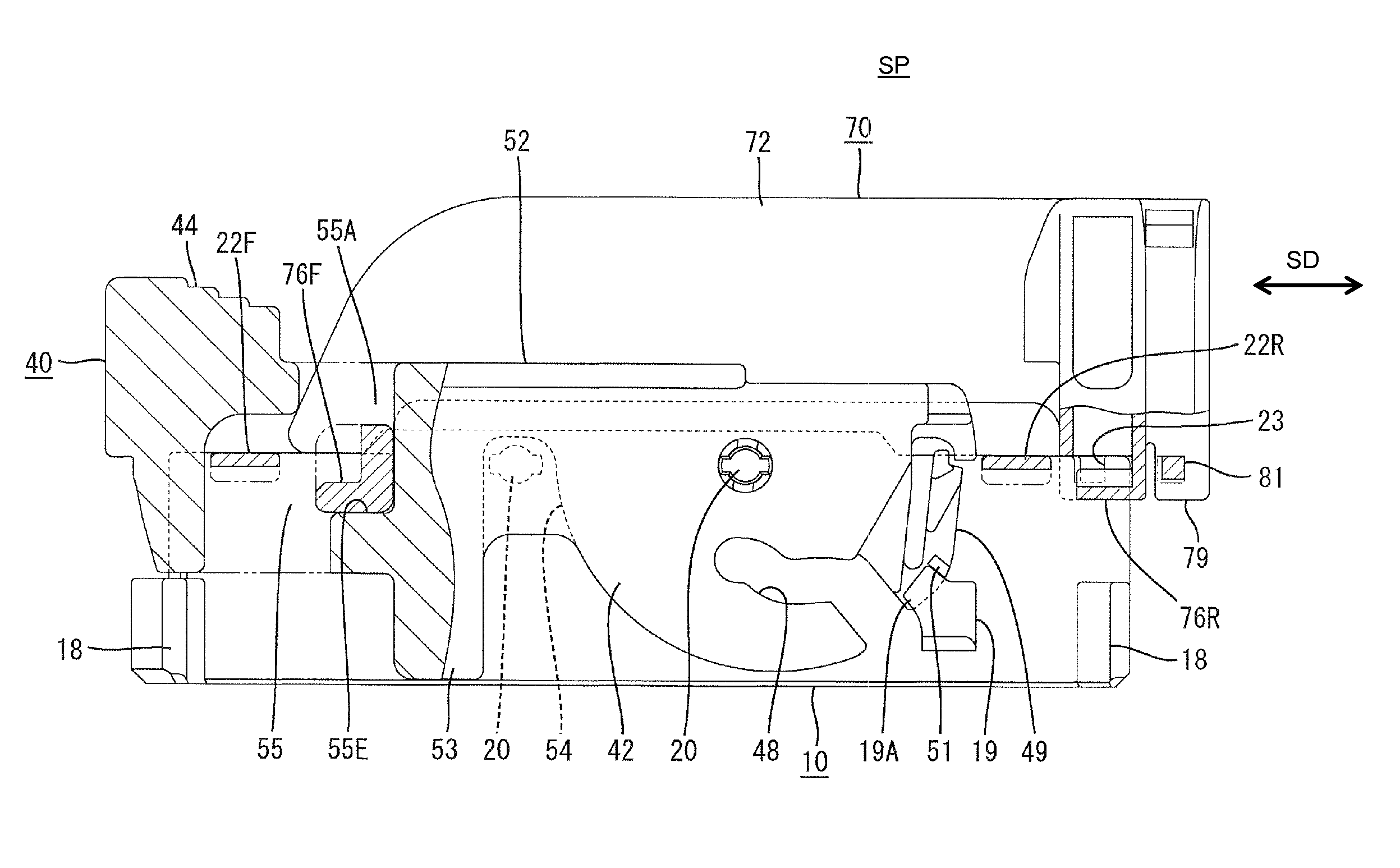

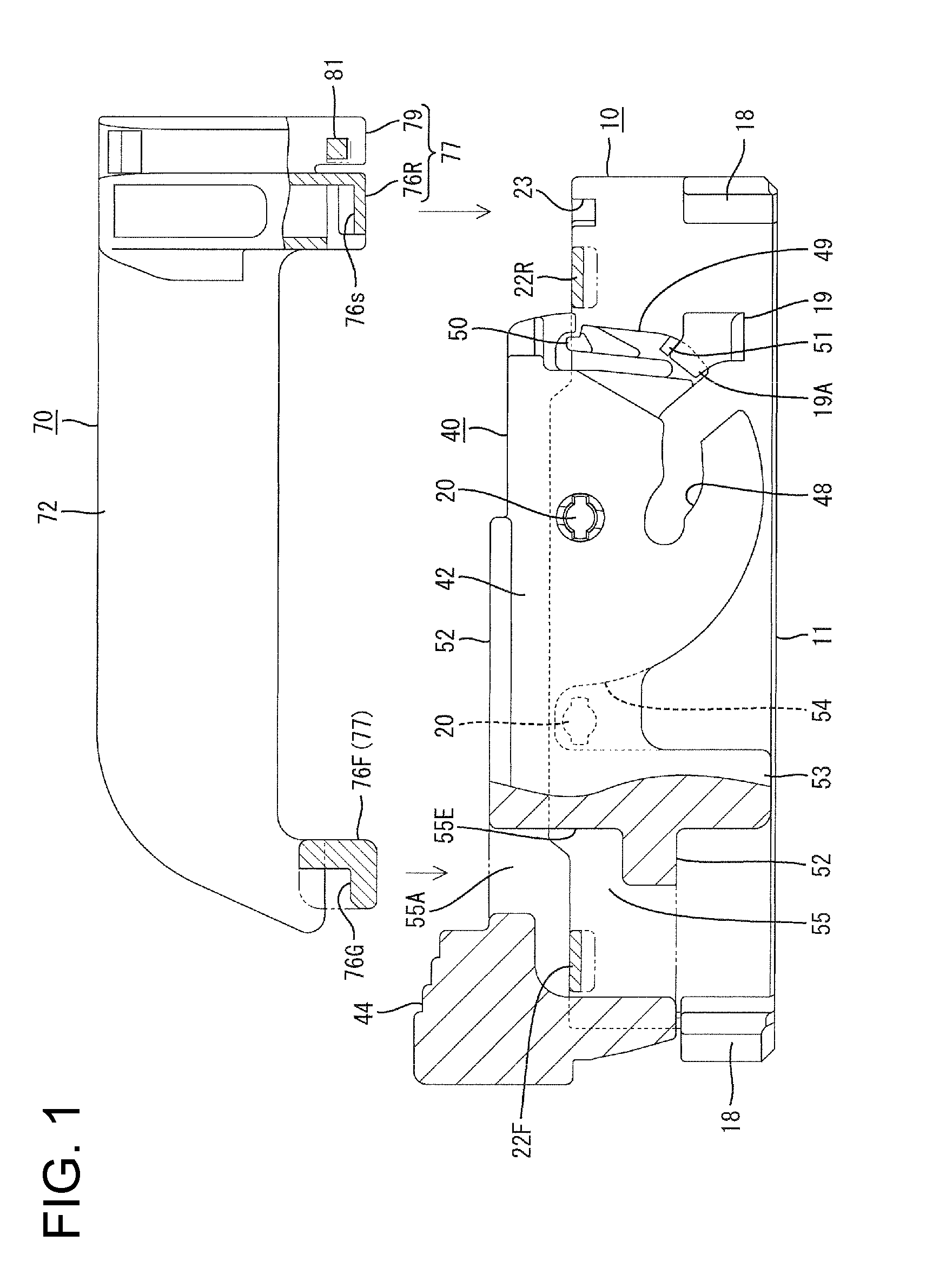

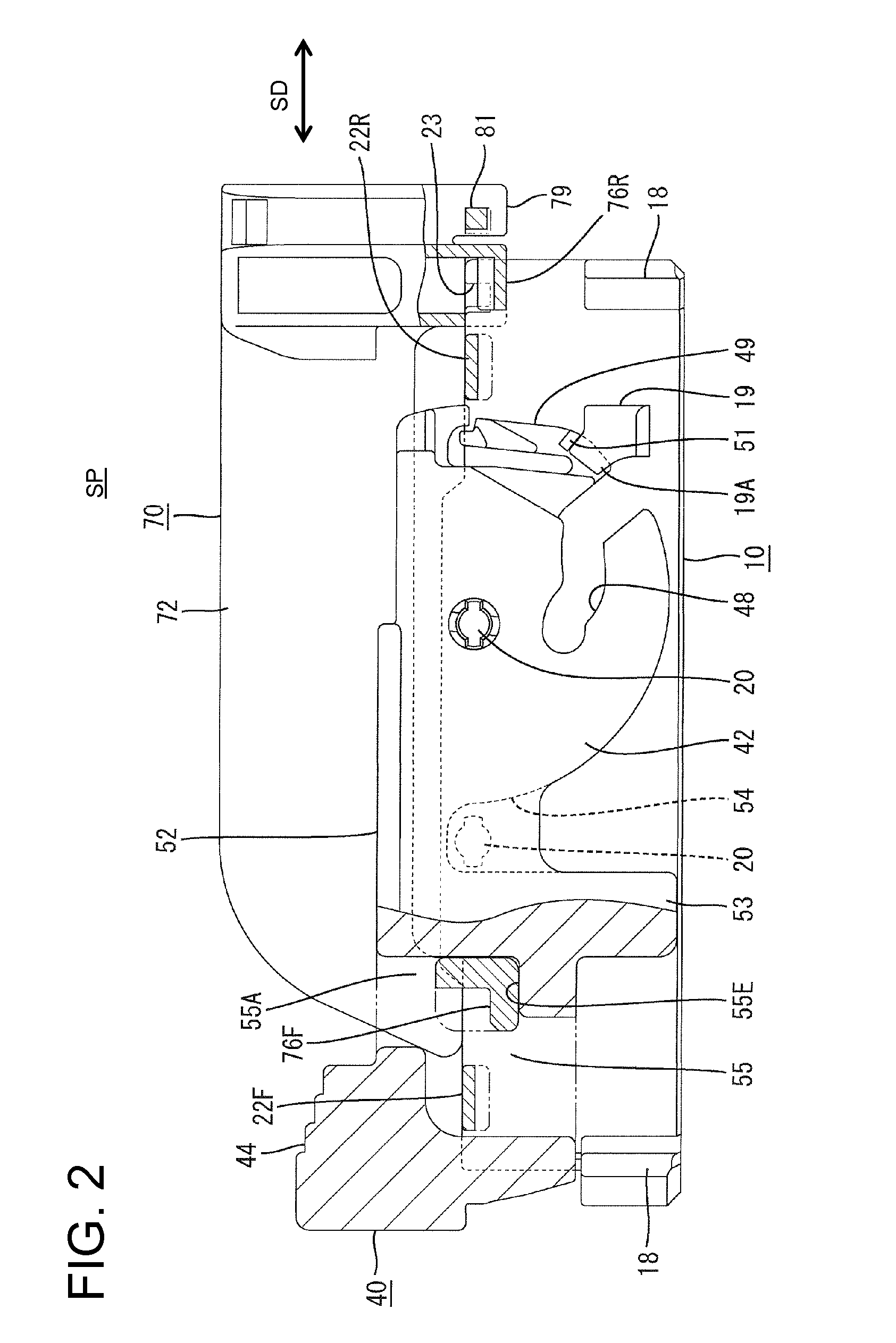

Connector

ActiveUS8251761B2Guaranteed smooth assemblyPrevent movementCouplings bases/casesLive contact access preventionEngineeringMechanical engineering

A connector member is formed with first slides (22F, 22R) and first locks (23). A cover (70) is formed with second slides (76F, 76R) and second locks (79). The cover (70) is mounted on the connector member slidably between a standby position and a mount position. The first and second slides (22F, 22R) and (76F, 76R) slide on each other to guide a sliding movement of the cover (70) from the standby position to the mount position. At the mount position, the first and second locks (23, 79) engage to prevent a returning movement of the cover (70) to the standby position. The connector member is formed with guide paths (55) for positioning and guiding the cover (70) to the standby position.

Owner:SUMITOMO WIRING SYST LTD

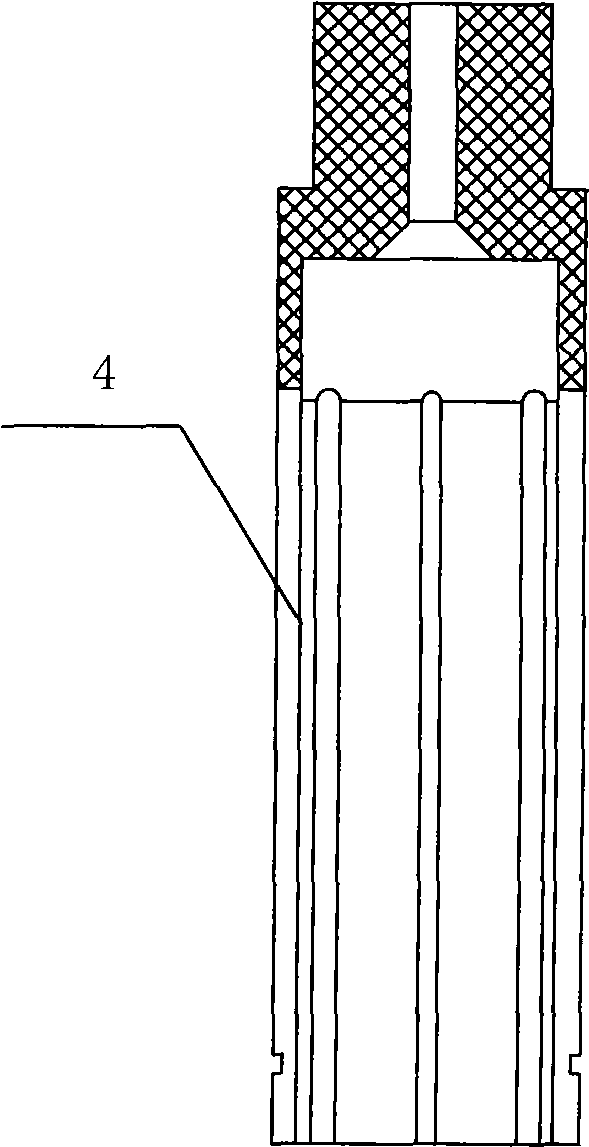

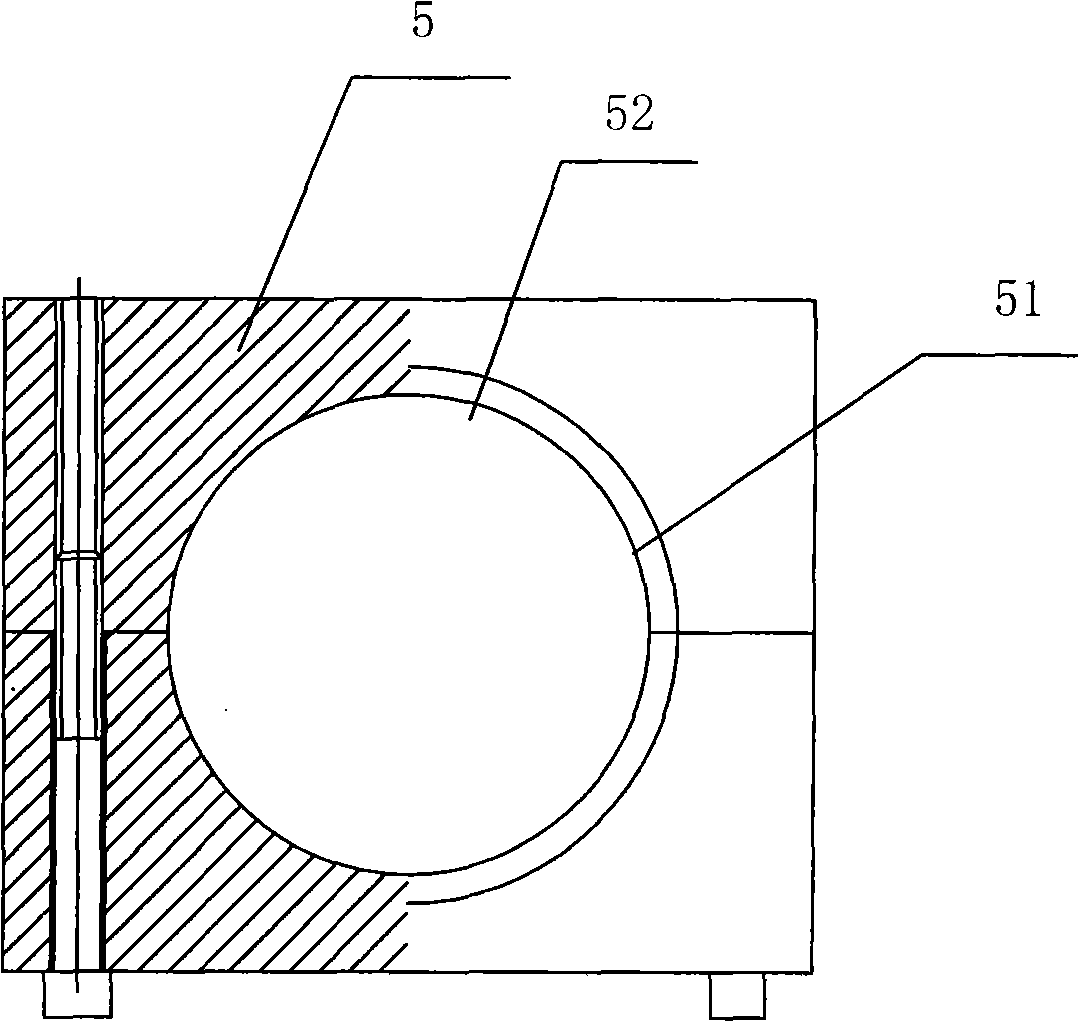

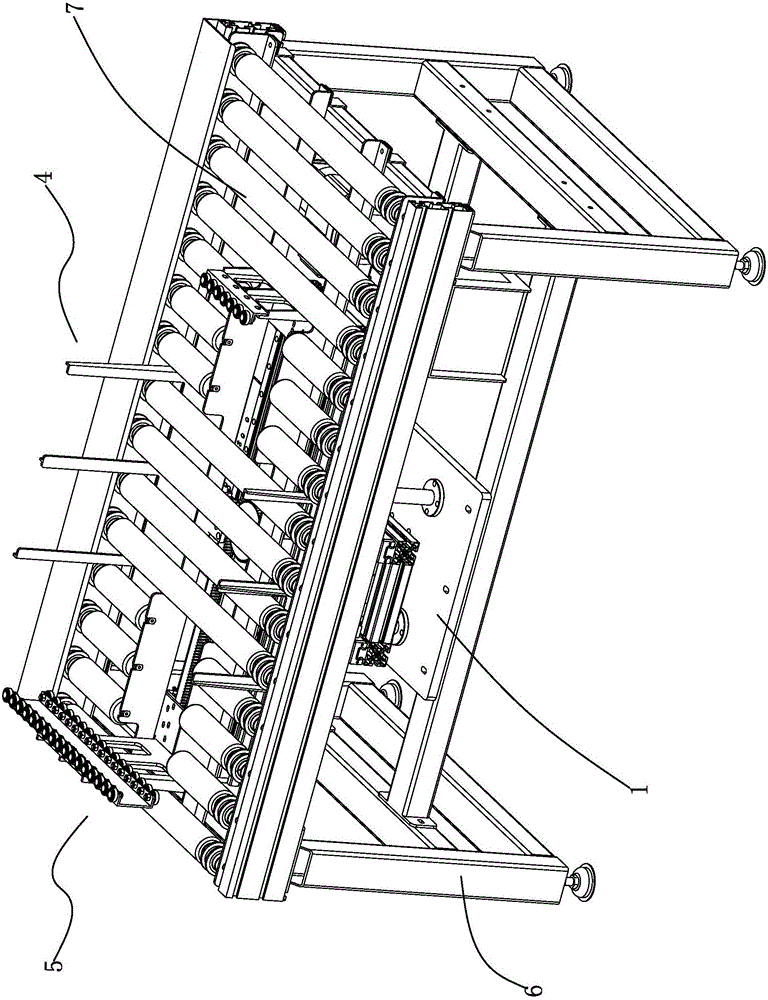

Method for assembling inelastic sealed ring and assembling device for implementing the method

InactiveCN101474737AReduce the probability of breakageGood shape recoveryMetal working apparatusFailure rateEngineering

The invention discloses a method for assembling an unelastic seal packingring and an assembly device for implementing the method. The assembly method is as follows: fixing work pieces, sheathing a guide cylinder on a rotating shaft, sheathing a seal packingring on the cylindrical guide cylinder, sheathing a cylinder on the guide cylinder, pushing the seal packingring into a seal groove on the rotating shaft, retracting the cylinder, taking down the guide cylinder, clipping the seal packingring by a clip, causing the seal packingring to be reset in a dual rectangular way, and withdrawing the clip, thereby accomplishing the assembly of the seal packingring. The unelastic seal packingring assembly device for implementing the method is characterized by comprising a workbench (1), a work piece clamp seat (11), a guide post (3), a push ring cylinder(4) and the clip(5), and has the advantages of great reduction of tensile failure rate of the unelastic seal packingring, favorable shape restoration of the seal packingring, high assembly efficiency and favorable seal effect.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

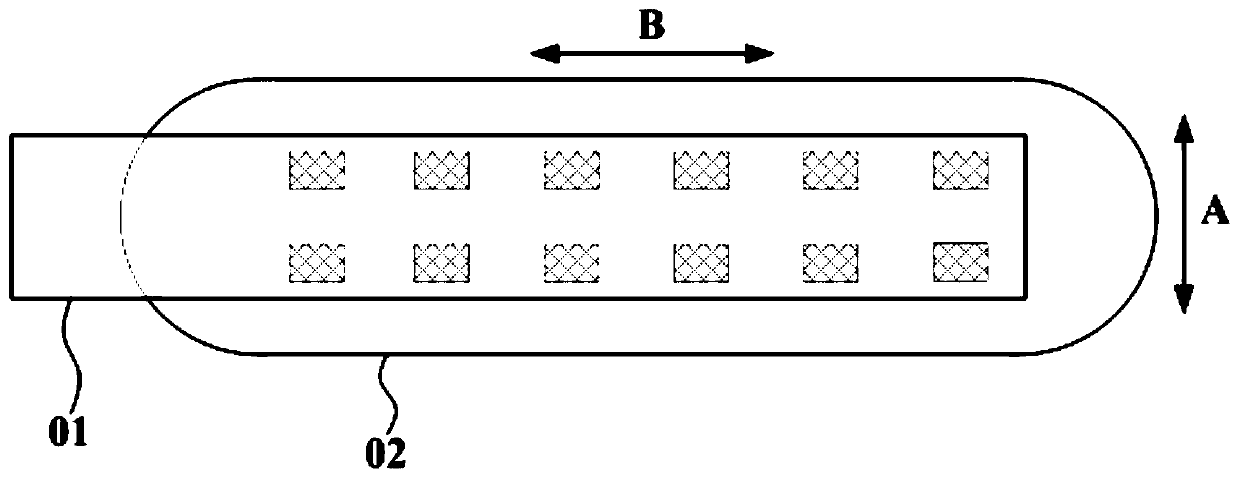

Assembling fixture for water cutter decoration bar

The invention relates to an assembling fixture for a water cutter decoration bar, which is characterized by comprising a left side end cover detecting assembling device for mounting a left side end cover on the left side of a water cutter decoration bar and a right side end cover detecting assembling device for mounting a right side end cover on the right side of the water cutter decoration bar, and a plurality of buckle assembling devices and a plurality of pushing devices, wherein the left side end cover detecting assembling device and the right side end cover detecting assembling device are positioned at the left end and the right end of the fixture respectively, and the plurality of buckle assembling devices and the plurality of pushing devices are positioned in the middle of the fixture. According to the water cutter decoration bar fixture, through the adoption of the reasonable arrangement of the left side end cover detecting assembling device, the right side end cover detecting assembling device and the plurality of the buckle assembling devices and the plurality of the pushing devices positioned in the middle, the mounting of the left end cover, the right end cover and buckles can be completed respectively, the water cutter decoration bar mounted with the end covers and the buckles is pushed out through the pushing devices after the mounting is completed, and the automation of the whole process can be realized conveniently.

Owner:NINGBO XINTAI MACHINERY

Center positioning device

ActiveCN106112427AHigh positioning accuracy and stabilityGuaranteed smooth assemblyMetal working apparatusEngineering

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

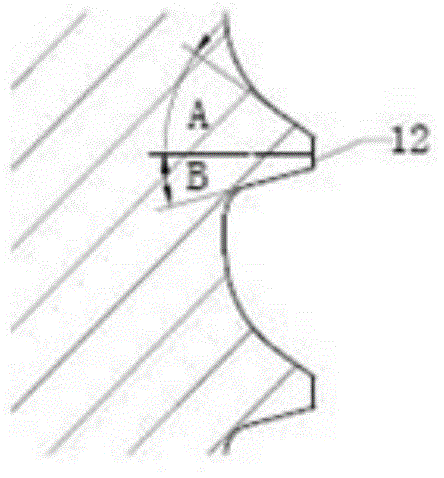

Artificial dental implant, artificial dental implanting system and implanting method

The invention provides an artificial dental implant, an artificial dental implanting system and an implanting method. A screwed thread is formed in the outer surface of an artificial dental implant, wherein a neck part and a head part are respectively arranged at two ends of the implant; a spiral tapping slot is formed in the outer surface of the head part, the spiral direction of the spiral tapping slot is the same as that of the screwed thread, and the spiral lead angle of the spiral tapping slot is different from that of the screwed thread. When the artificial dental implant is implanted, the cutting force and extrusion force of the implant to the bone tissues at the implanted position are reasonable, and the bone is effectively protected from injury; the artificial dental implant can accommodate bone chips generated in the tapping process, and the bone healing time can be shortened; the artificial dental implant is effectively prevented from rotating or loosing, and the service life of artificial tooth can be prolonged.

Owner:DALIAN SANSHENG SCI & TECH DEV

Automatic assembly apparatus system and method for automobile door lock

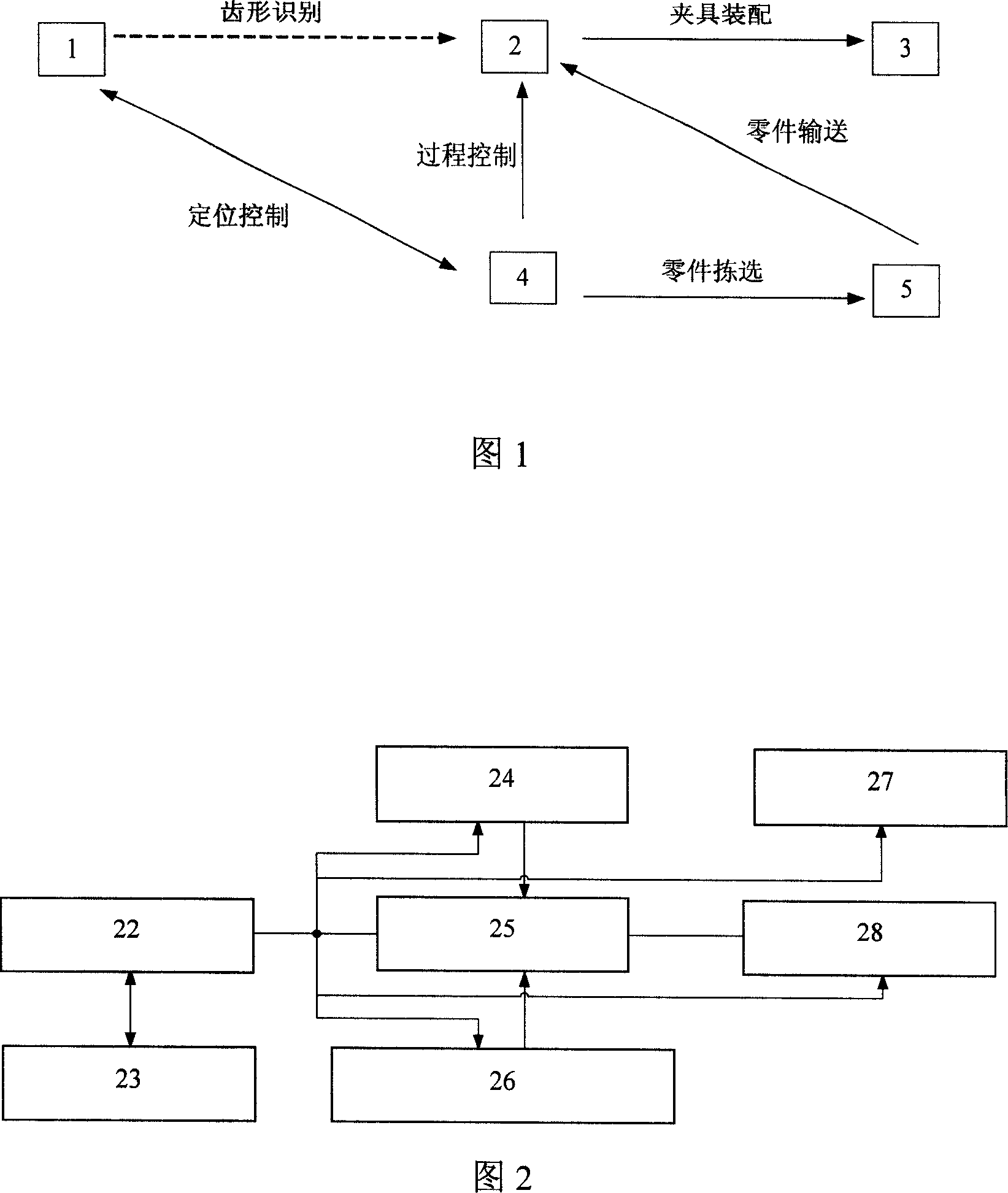

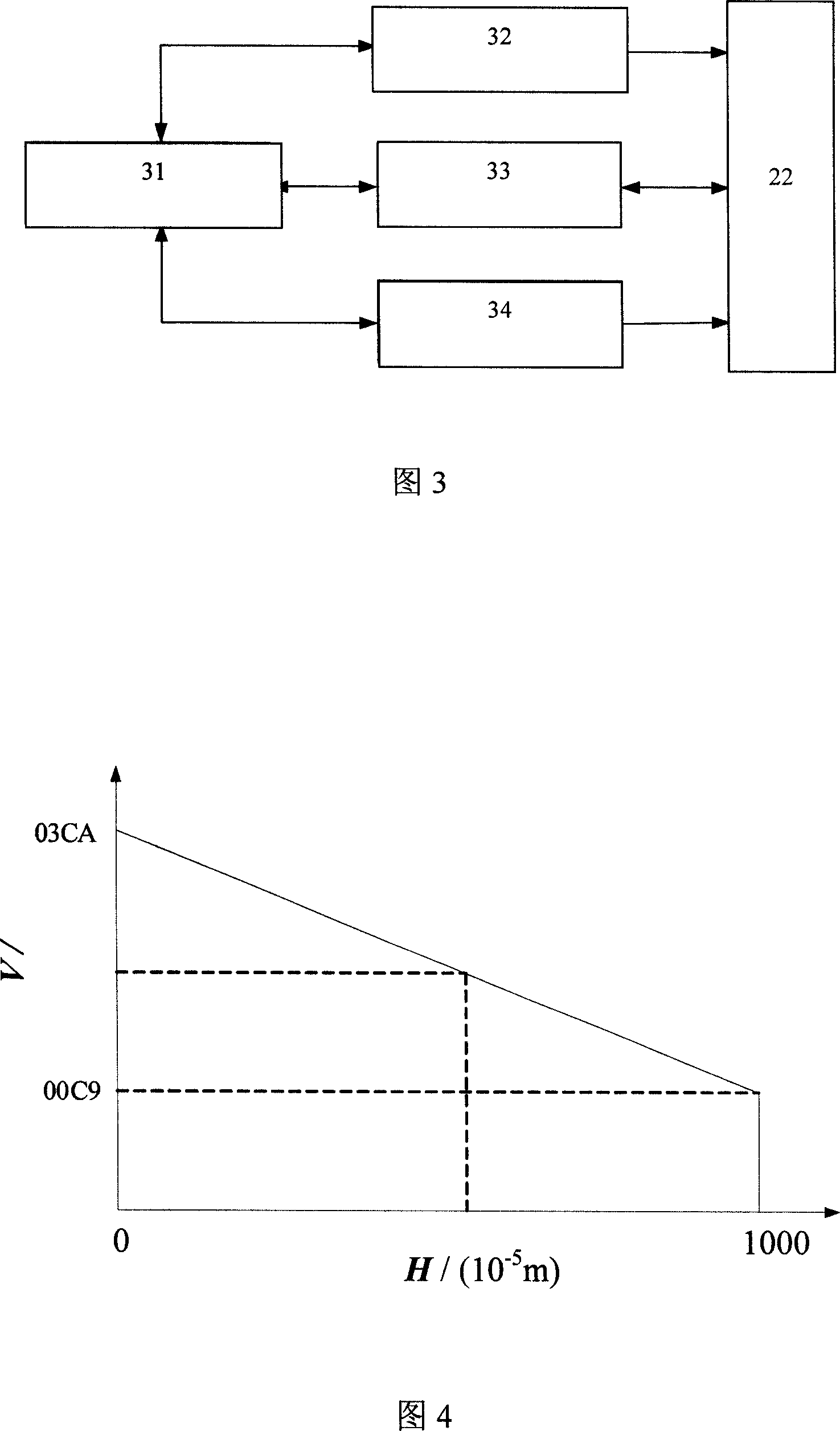

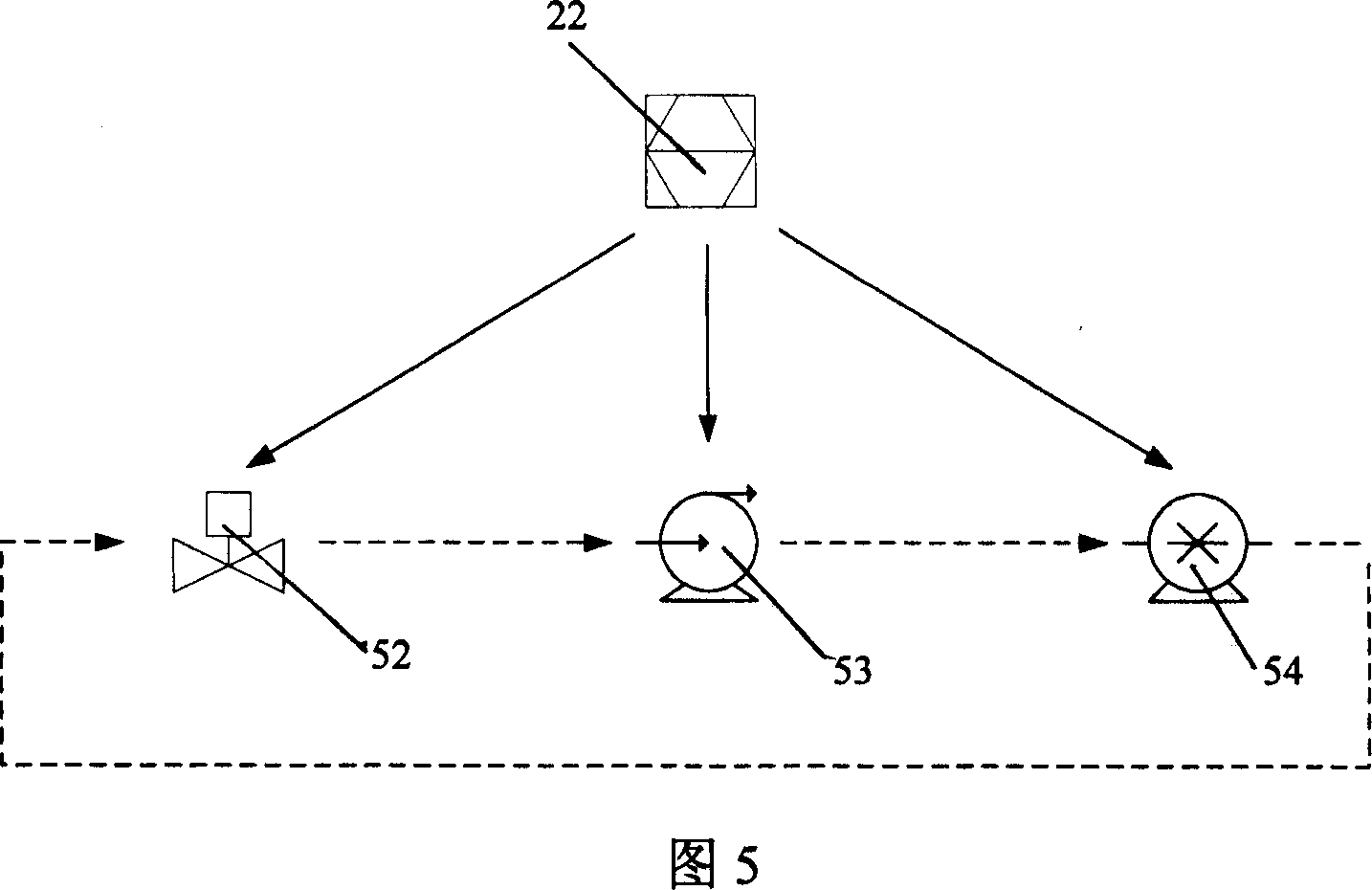

InactiveCN101011788AImprove detachabilityImprove maintainabilityComputer controlAssembly machinesComputer control systemProduction rate

The invention relates to the mechanical assembly of the door lock of vehicles, which comprises locking plate snap clip, key teeth identification device, locking plate automatic choosing device, automatic spring discharging and delivery device, locking plate snap clip moving device and its thrusting device, lock core jig and location exchange device, and embedded computer control system, with the method composed of key automatic location and identification, snap clip feeding and assembly, lock plate feeding and assembly, to finish the assembly of vehicle doors with accurate matching. Through lock core jig and location exchange device with the repetition of above procedures, it can get to the operation of next lock core. It is accurate, highly efficient, easy for operation, convenient for maintenance.

Owner:ZHEJIANG UNIV

Fingerprint identification module and electronic equipment

ActiveCN110320972ADimensions influenceImprove performanceSolid-state devicesDevices with sensorStructural reliabilityElectricity

The invention provides a fingerprint identification module and electronic equipment, and aims to improve the performance and structural reliability of the fingerprint identification module. The fingerprint recognition module comprises a flexible circuit board, a substrate, a fingerprint recognition chip and a filling adhesive layer, the flexible circuit board and the substrate are arranged in a stacked mode and comprise a first end and a second end which are opposite in position, at least one end of the first end and the second end exceeds the substrate, and a wire outlet area is formed at theend, close to the end exceeding the substrate, of the flexible circuit board; the first surface, facing the flexible circuit board, of the substrate comprises a first area and a second area, the first area is provided with a wire and a bonding pad used for being electrically connected with the flexible circuit board, and the second area is opposite to the wire outlet area and provided with an open groove. The fingerprint identification chip is arranged on the second surface, back to the flexible circuit board, of the substrate; and the filling adhesive layer is filled between the flexible circuit board and the substrate and is used for wrapping the bonding pad.

Owner:HONOR DEVICE CO LTD

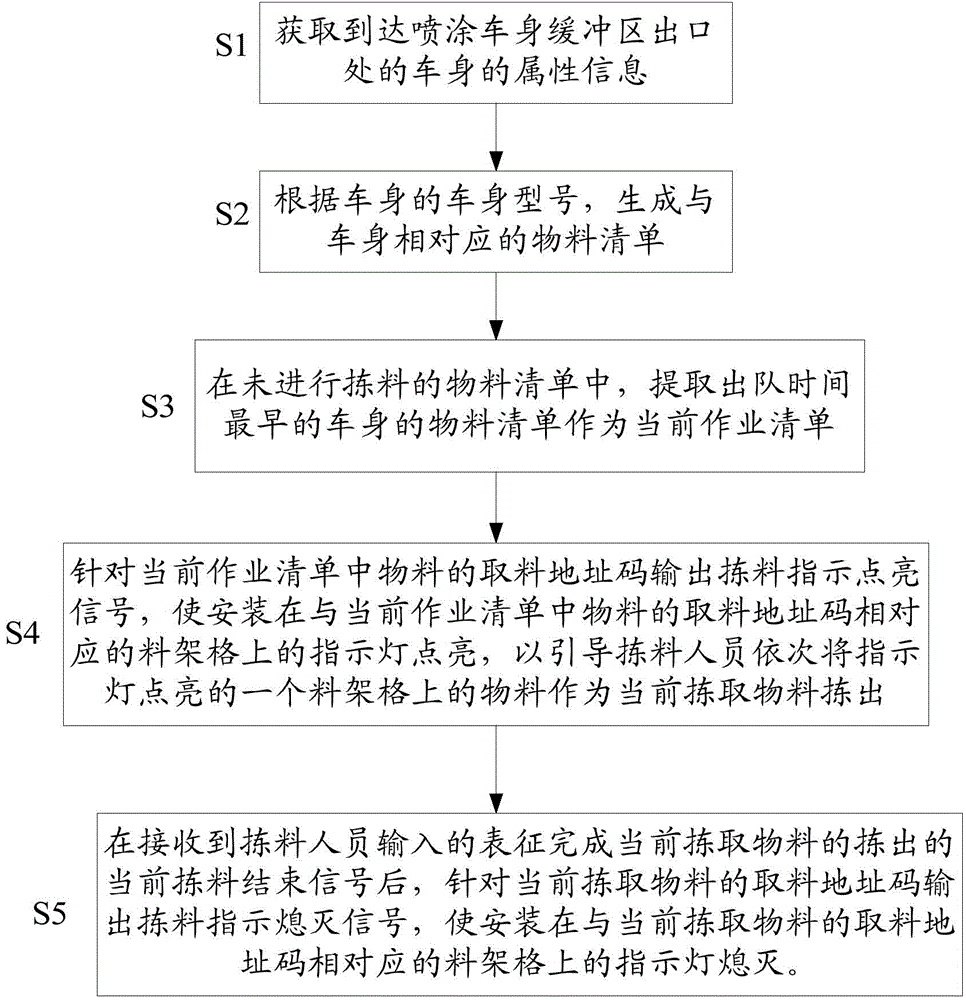

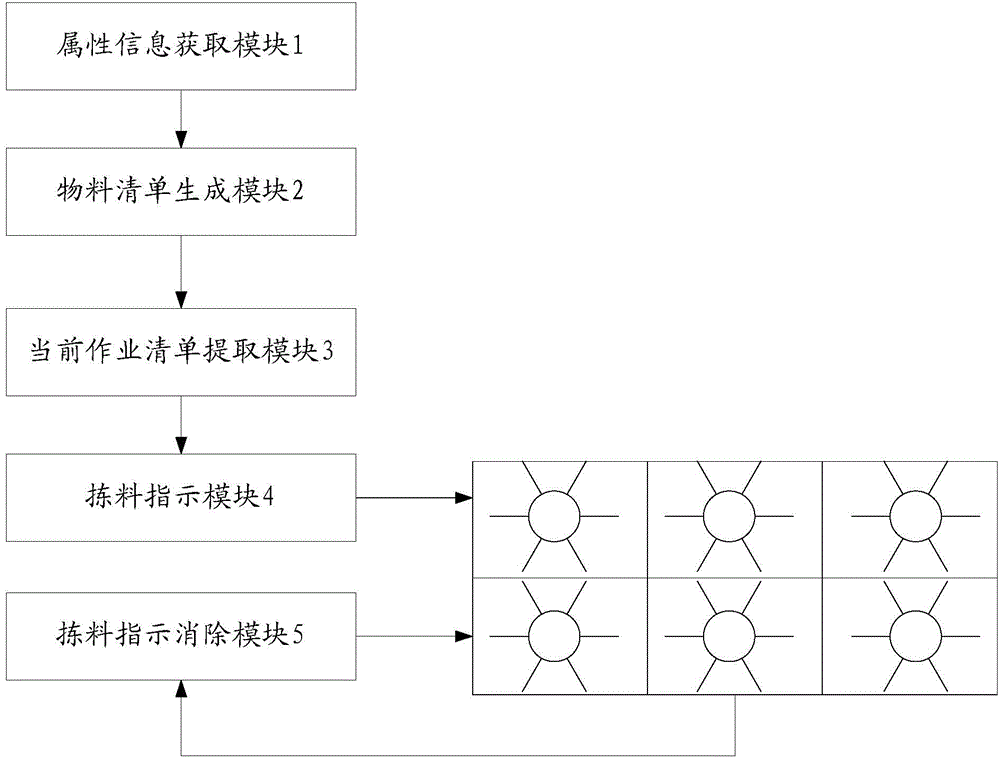

Flexible centralized assembling error-proof method and system

ActiveCN104020747AGuaranteed smooth assemblyGuaranteed speedProgramme total factory controlBlack outBill of materials

The invention discloses a flexible centralized assembling error-proof method and system. The method includes the first step of obtaining attribute information of vehicle bodies arriving at an outlet of a vehicle body spraying buffer area, the second step of generating material bills corresponding to the vehicle bodies according to the model of the vehicle body, the third step of extracting a material bill of the vehicle body which dequeues firstly as a current operating bill among material bills through which material selection is not carried out, the fourth step of outputting a material selection indicator light lightening signal according to a material taking address code of the materials in the current operating bill to enable an indicator light installed on a material rack grid corresponding to the material taking address code to be lightened so as to guide a material selection worker to pick out the materials on the material rack grid with the indicator light lightened, the fifth step of outputting a material selection indicator light blacking out signal according to the material taking address code of the materials which are picked out currently after a current material selection ending signal input by the material selection worker is received so as to enable the indicator light installed on the corresponding material rack grid to be turned off. The flexible centralized assembling error-proof method and system have the advantages of being capable of effectively avoiding missing picking or repeated picking and ensuring picking speed and stability, and high in adaptability and accuracy.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Hard disk case

InactiveUS20090168243A1Guaranteed smooth assemblyTelevision system detailsPicture framesHard disc driveComputer engineering

A hard disk case for installation in a computer case includes a support frame for installation of a hard disk drive, a base mounted to the support frame, and a handle. The handle has a pivoting end pivotally connected with the base, a first protrusion insertable in an insertion portion of the computer case and pushable against a periphery wall of the insertion portion for enabling engagement of the hard disk drive with the computer case, and a second protrusion spaced from the first protrusion and pushable against a stopping portion of the computer case for enabling disengagement of the hard disk drive from the computer case. As a result, the hard disk case of the present invention is convenient in assembly and disassembly works.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

Bolt lock device and server with the same

InactiveCN104460881AGuaranteed smooth assemblyStable disassemblyServersClamping/extracting meansEngineeringMechanical engineering

The invention provides a bolt lock device which is used for a server. The bolt lock device comprises a positioning column, a containing frame, a transversely-moving plate and a rotating handle, wherein the positioning column is fixedly arranged on a machine shell of the server, the containing frame is fixedly arranged on an upper cover of the server, the transversely-moving plate is fixedly arranged in the containing frame through a positioning piece which allows the transversely-moving plate to move between a first position and a second position relative to the containing frame along an opening of the transversely-moving plate, and the rotating handle is connected to the transversely-moving plate through two rotating plates in a pivoted mode and can rotate between a first rotating position and a second rotating position. When the positioning column is inserted into an insertion hole of the transversely-moving plate in the containing frame, the rotating handle drives the containing frame to move forwards and backwards by rotating between the first rotating position and the second rotating position, and therefore the upper cover can be driven to move forwards and backwards together with the containing frame, and meanwhile the transversely-moving plate accordingly moves between the first position and the second position relative to the containing frame.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

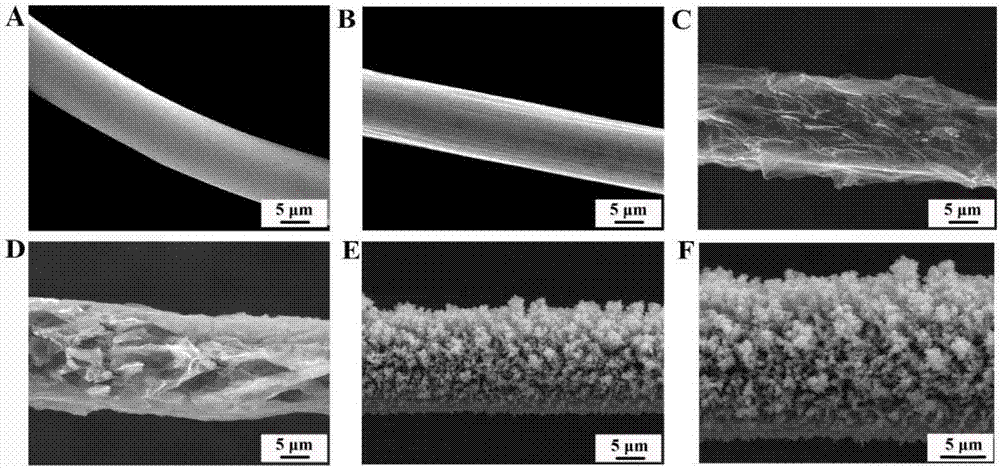

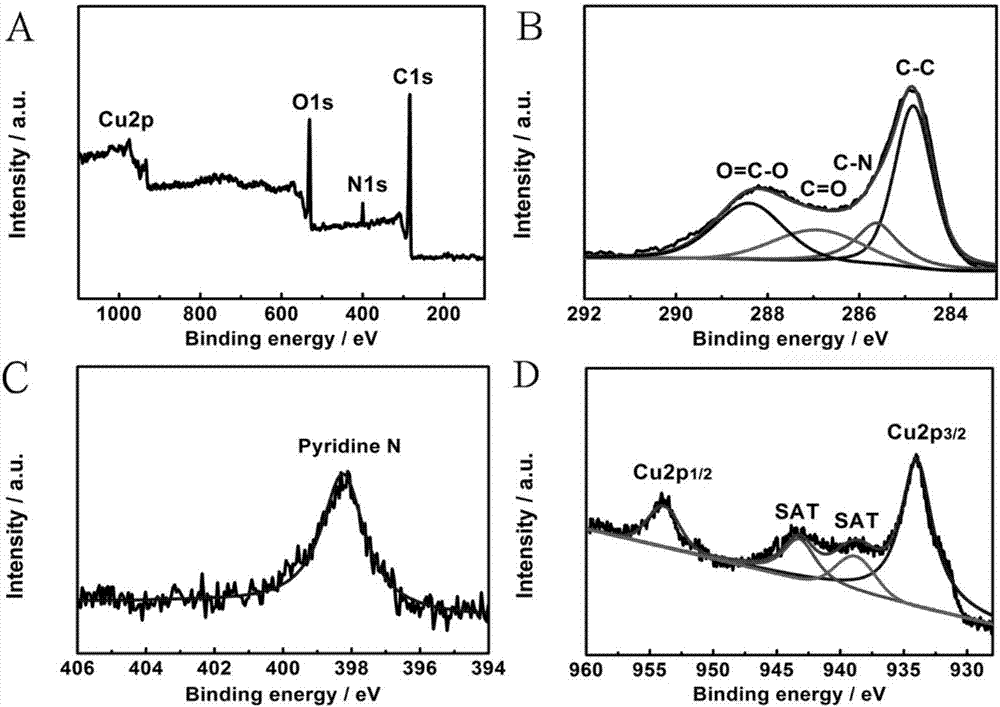

Rime-shaped metal-organic framework composite microelectrode, in-situ preparation method and application

ActiveCN107478697AAvoid harsh reaction conditions such as high temperature and high pressureEasy to operateMaterial electrochemical variablesCvd grapheneActivated carbon

The invention discloses rime-shaped [Cu(INA)2] metal-organic framework / three-dimensional graphene coated carbon fiber composite microelectrode, an in-situ preparation method and an application. The composite microelectrode comprises three-dimensional graphene coated activated carbon fibers and rime-shaped [Cu(INA)2] metal-organic frameworks on the three-dimensional graphene surface layer, wherein three-dimensional graphene is loose and porous, and the rime-shaped [Cu(INA)2] metal-organic frameworks are uniformly deposited on the three-dimensional graphene surface layer. The preparation method of the composite microelectrode comprises steps as follows: the carbon fibers are subjected to electrochemical activation in mixed acid, graphene and spongy metal copper are sequentially electro-deposited, spongy metal copper is converted into the metal-organic frameworks in situ with an electrochemical anode stripping method. The provided method is simple and convenient to operate and environmentally friendly. The composite microelectrode has lower LOD (limit of detection) and higher detection sensitivity when applied to the field of nano electrochemical sensors, and has very broad application prospects.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com