Water jacket spacer

A water jacket and bushing technology, applied in liquid cooling, engine components, cylinders, etc., can solve the problem of excessive cooling water capacity of the water jacket, and achieve the effects of simple cooling, simple homogenization, and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

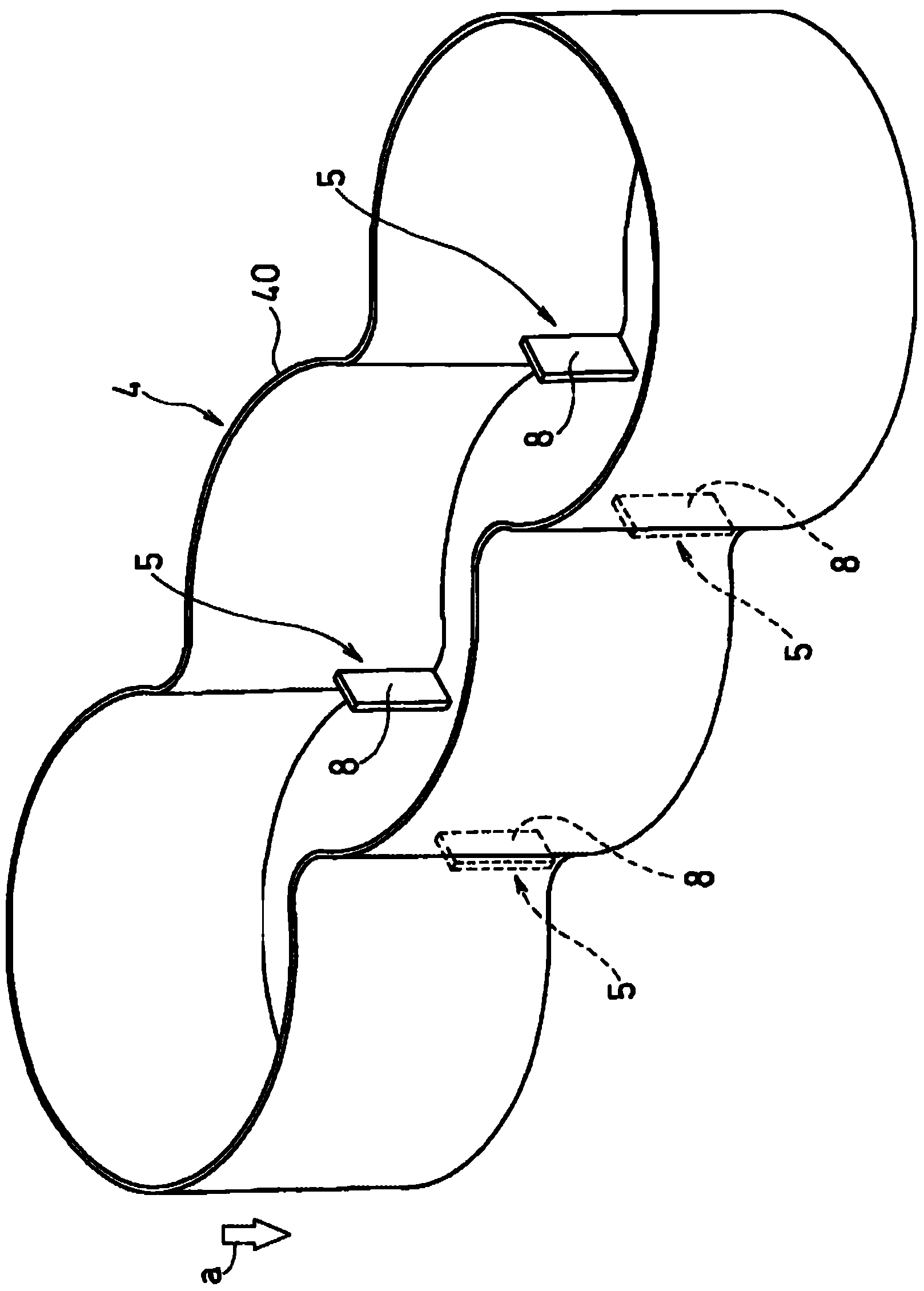

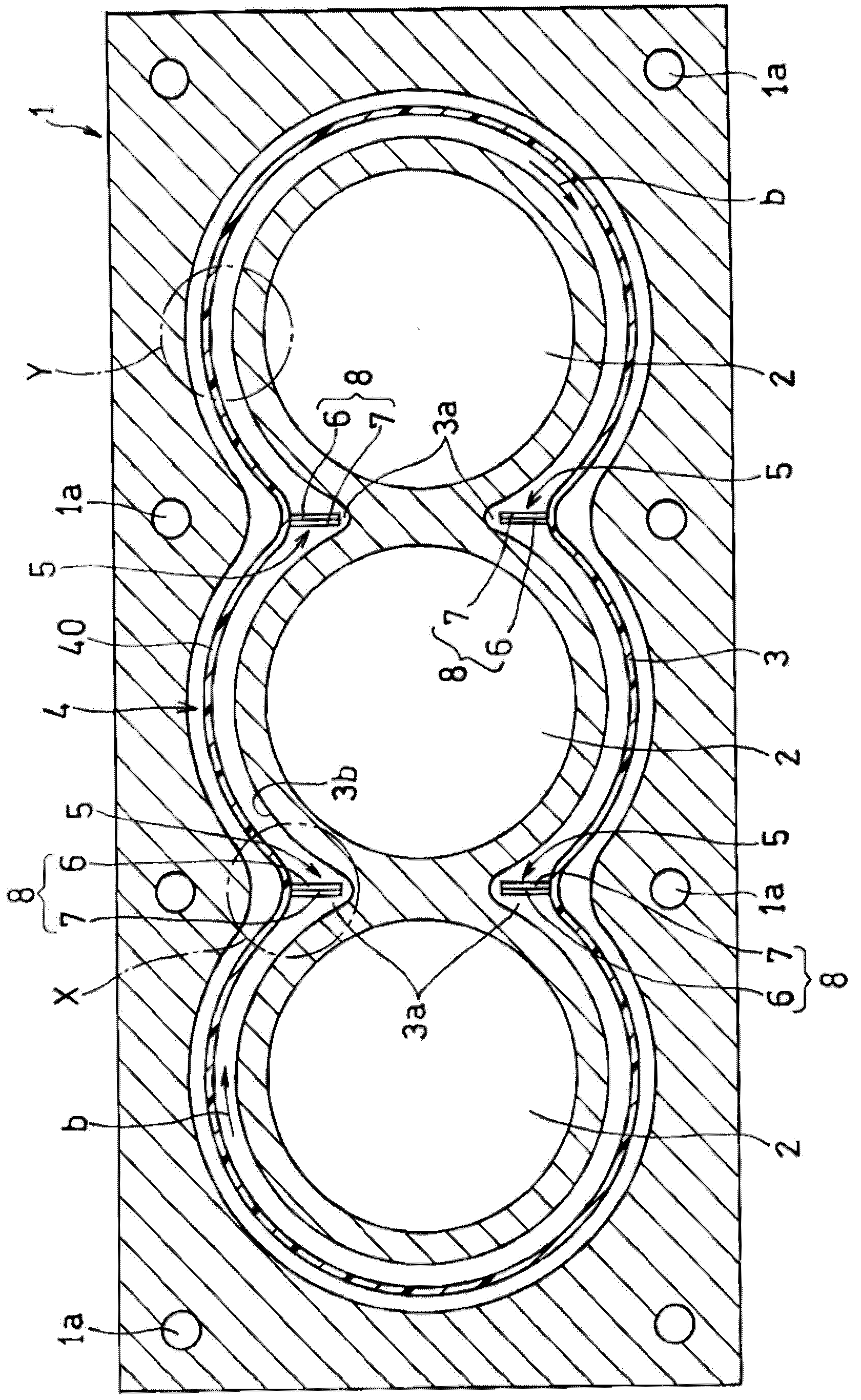

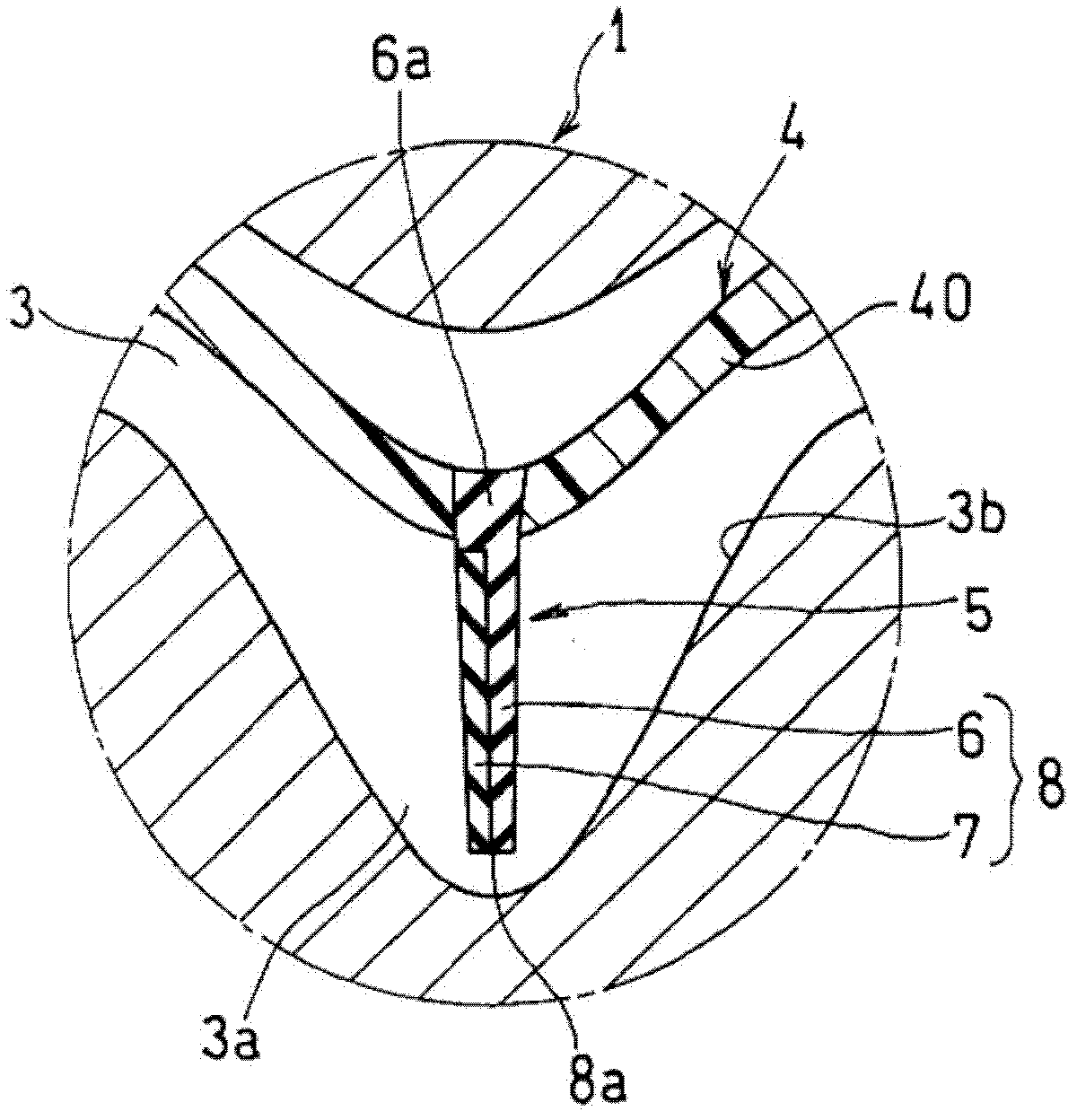

[0051] Embodiments of the present invention will be described below based on the drawings. figure 1 It is a schematic overall perspective view of one embodiment of the water jacket bushing of the present invention, figure 2 It is a schematic cross-sectional plan view of a cylinder block of a water-cooled engine provided with a water jacket fitted with the water jacket liner. figure 2 The cylinder block 1 shown is a cylinder block of a three-cylinder engine, and has three cylinder bores 2 arranged in series. The surface on one side) is excavated and is formed with the water jacket 3 of open channel type with bottom. Actually, the cylinder block 1 is made of a cast product such as aluminum alloy, so the water jacket 3 is formed of a male mold of a casting mold. In addition, in the cylinder block 1, a plurality of female screw holes 1a for integrally fastening a cylinder head (not shown) together with bolts are formed on the upper surface. In the portion between the adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com