Automatic all-purpose zipper head assembly machine

An automatic assembly machine and zipper head technology, applied in the directions of sliding fastener elements, applications, fasteners, etc., can solve the problems of complex structure of the moving assembly, complex structure of the riveting part, and many parts, etc. Reduced equipment cost and high synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

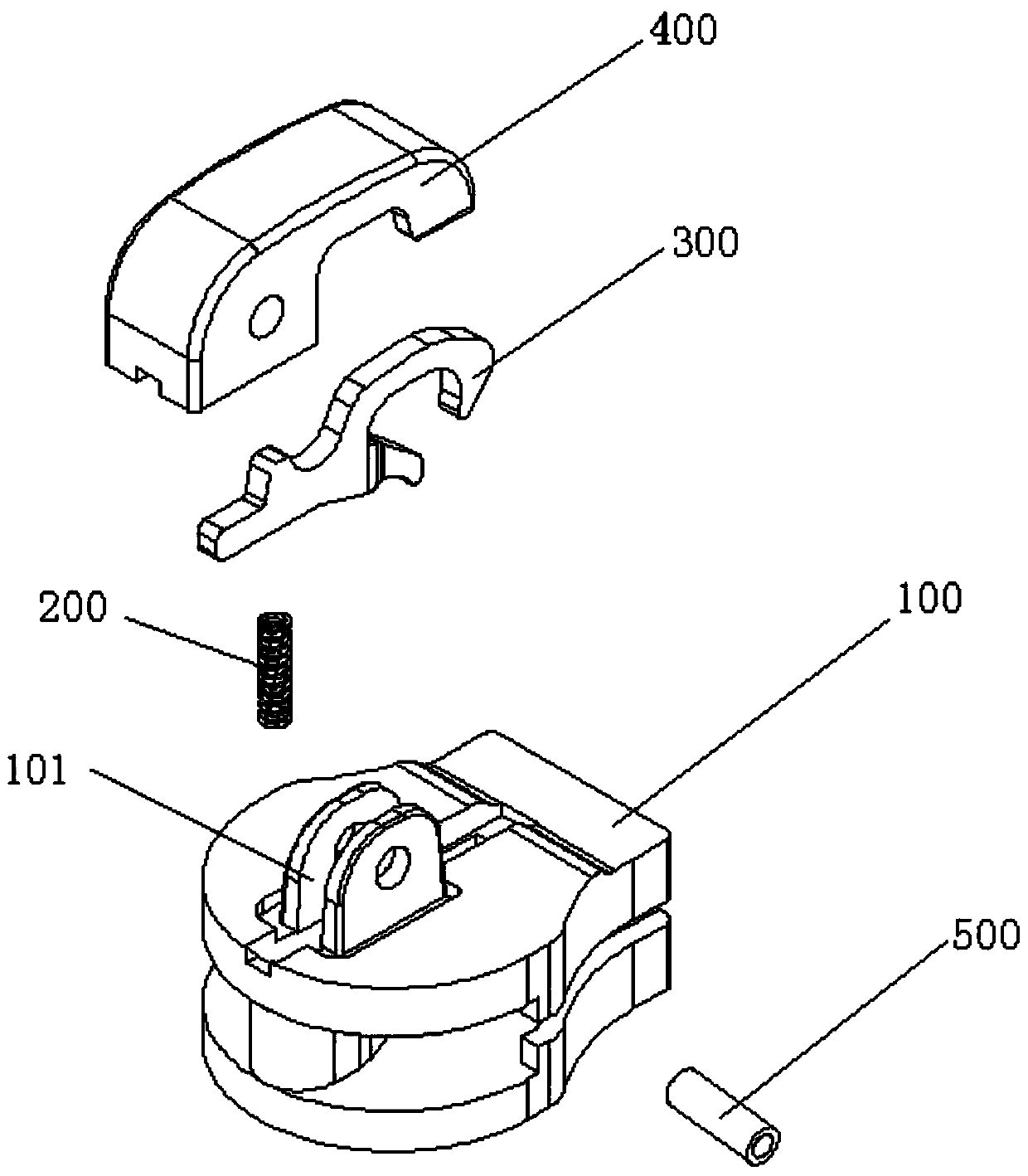

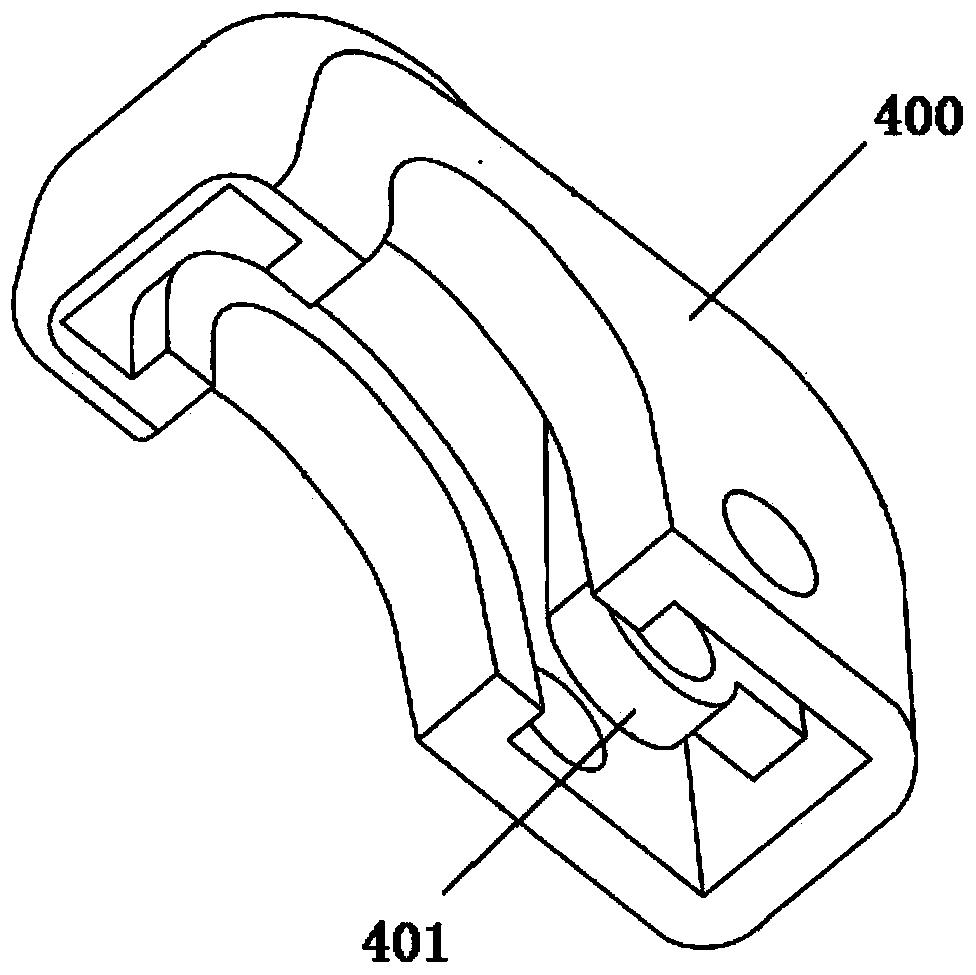

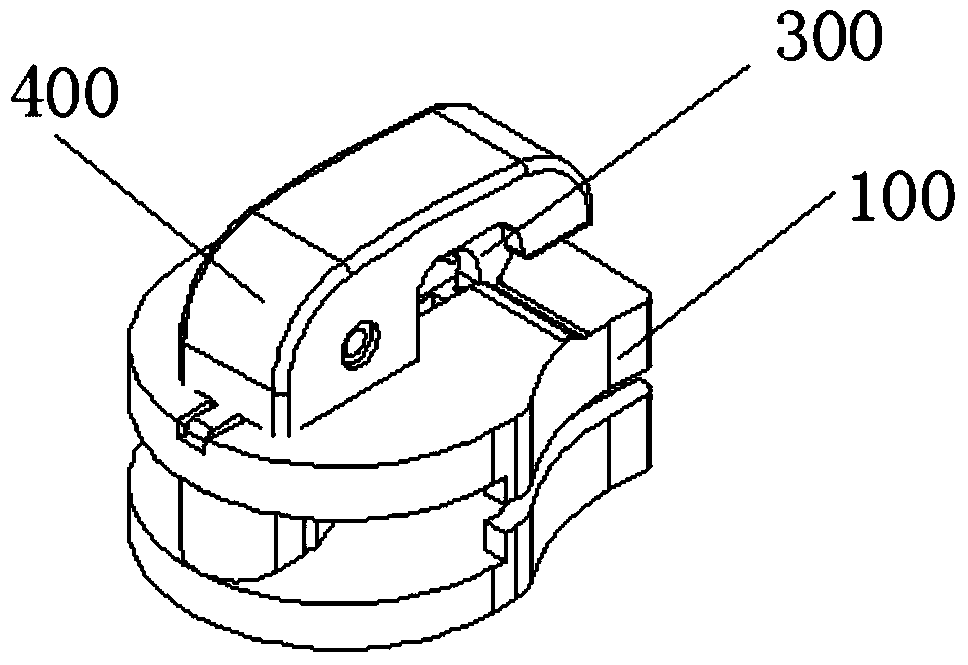

[0036] see Figure 1 to Figure 3 , the present invention is used to assemble the universal zipper assembly shown in the figure. This product is composed of five parts: a slider body 100 , a spring 200 , a horse hook 300 , a cap 400 and a copper tube 500 . On the top surface of the slider body 100 A longitudinal slot is provided, and two lugs 101 extending upward are provided on both sides of the slot, and coaxial copper pipe holes are provided on the two lugs 101, the horse hook 300 is located in the slot, and the spring 200 is placed vertically The bottom of the horse hook 300 is pressed by the horse hook 300, and the cap 400 is provided with a pivoting part 401 that matches the arc-shaped groove of the horse hook 300. The pivoting part 401 and the horse hook 300 are located between the two lugs 101. The two outer walls of the cap 400 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com