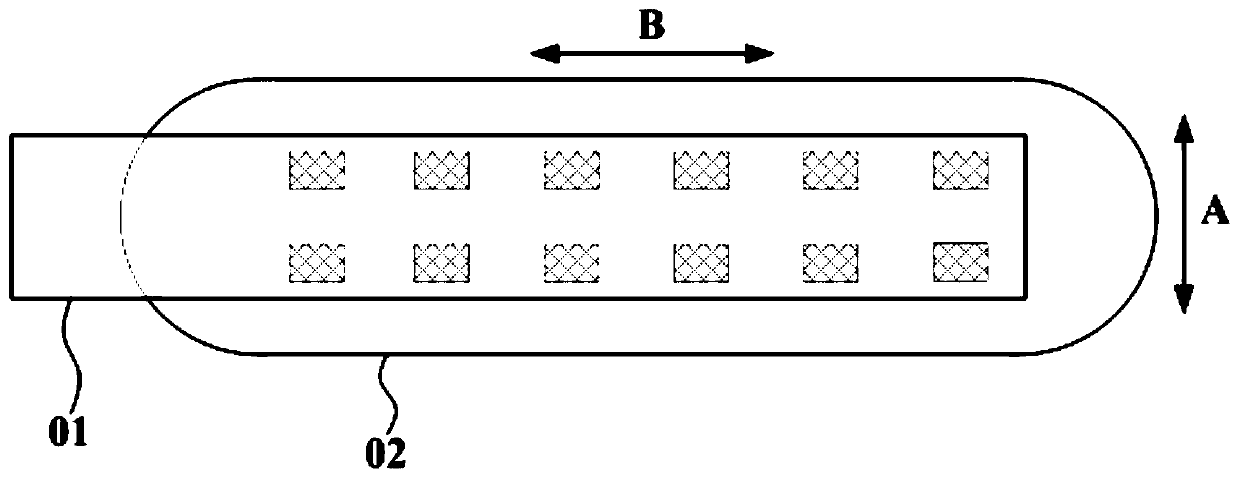

Fingerprint identification module and electronic equipment

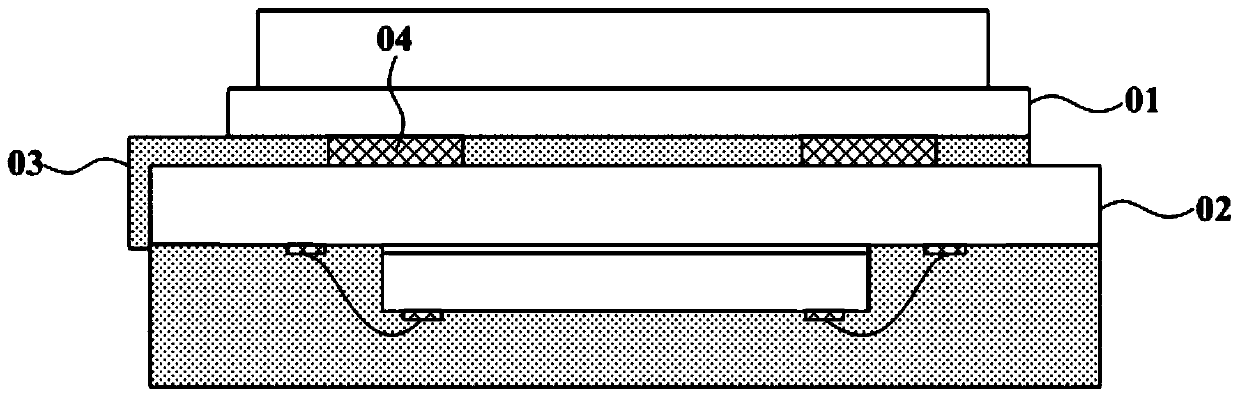

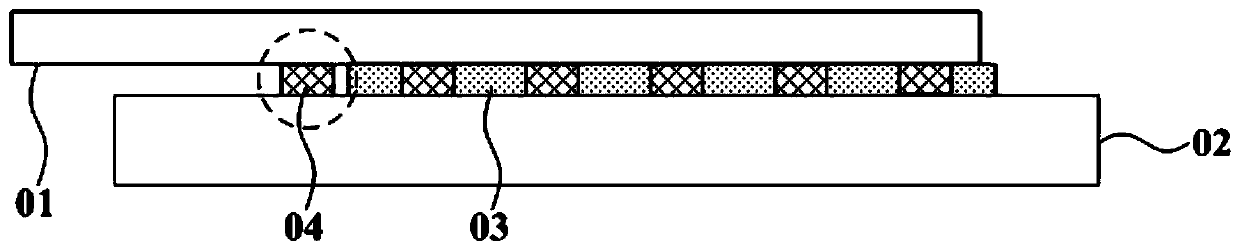

A fingerprint identification module and fingerprint identification technology, which is applied in branch equipment, equipment with sensors, character and pattern recognition, etc., can solve problems such as overflow, insufficient glue dispensing, and increase in the overall size of the fingerprint identification module. Achieve the effect of increasing dispensing volume, improving performance and structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the application clearer, the application will be further described in detail below in conjunction with the accompanying drawings.

[0034] At present, with the widespread application of fingerprint recognition technology in the field of electronic devices, various electronic devices can implement functions such as screen unlocking, fast payment, and file encryption based on this technology, which greatly improves user experience. Taking a mobile phone as an example, in the specific setting, the fingerprint identification area is usually set on the side of the screen of the mobile phone, and an installation slot is opened on the front cover of the mobile phone corresponding to the fingerprint identification area to accommodate the fingerprint identification module used to realize the above functions. Group. With the emergence of full-screen mobile phones, the fingerprint recognition area gradually shifts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com