Modular embroidery machine

An embroidery machine, a modular technology, applied in the field of embroidery machines, can solve the problems that the strength of the main shaft cannot well meet the driving requirements of the embroidery machine, the shape of the embroidery body is increased, the size of the main shaft is limited, etc., and the transmission efficiency is improved and the structure is simple. , The effect of reducing the installation accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

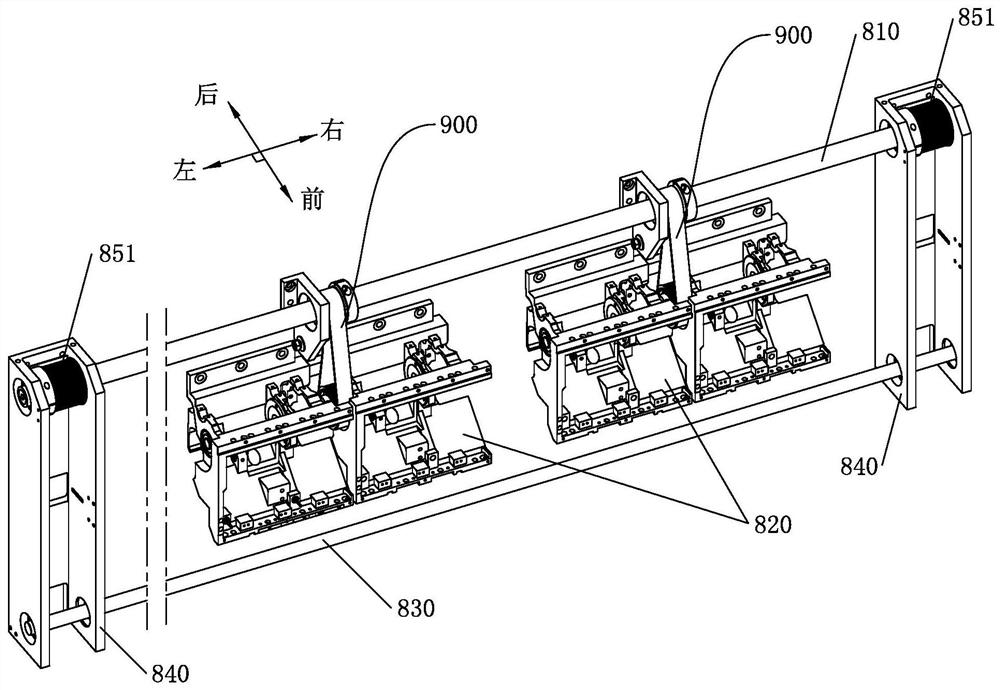

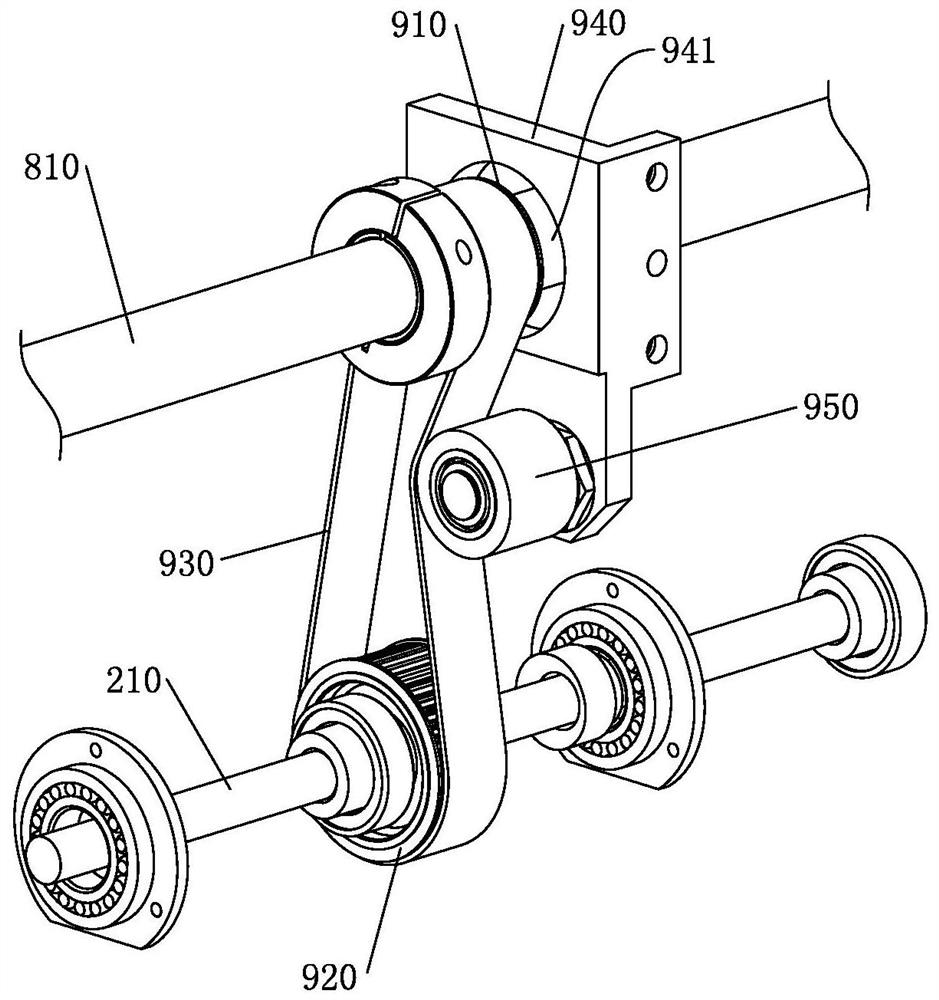

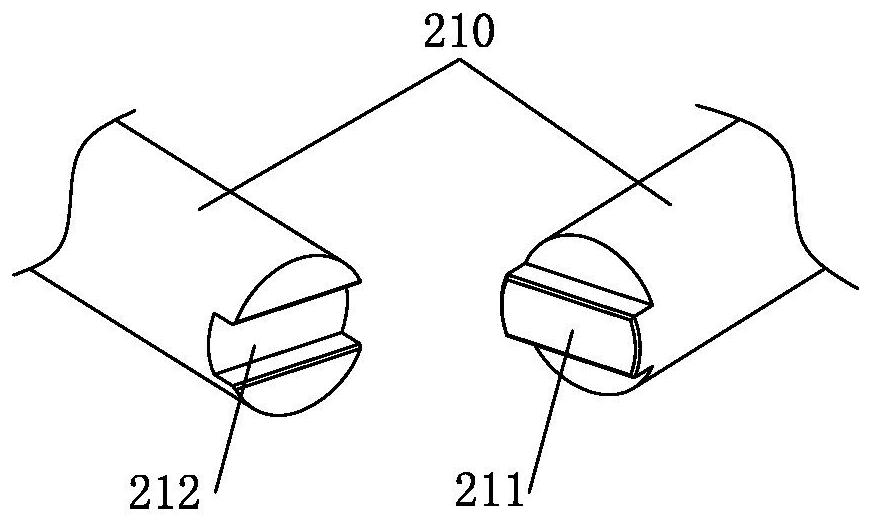

[0033] Such as figure 1 , figure 2 As shown, the present invention provides a modular embroidery machine, including a horizontal main shaft 810, a main drive motor for driving the main shaft 810, and a plurality of machine head modules 820 arranged at intervals along the transverse direction, and the main shaft 810 is arranged on each machine head Outside the modules 820 , each head module 820 is provided with a horizontal needle bar drive shaft 210 , and a split drive transmission mechanism 900 is provided between the needle bar drive shaft 210 and the main shaft 810 of each head module 820 .

[0034] Since the main shaft is located outside the head module, the strength of the main shaft can be increased by increasing the outer diameter of the main shaft to better meet the structural requirements of the embroidery machine. The internal installation space of the head will be affected. When the main shaft needs to be replaced, it is only necessary to disassemble the relevant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com