A kind of iron-based amorphous coating and laser preparation method thereof

An iron-based amorphous and coating technology, which is applied in coatings, metal material coating processes, etc., can solve the problems of changing the shape and size of parts, low corrosion resistance of coatings, and excessive thickness of coatings, etc., to achieve excellent Corrosion resistance, high interfacial bonding strength, and high industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Cladding powder pretreatment

[0020] The composition of the cladding powder material is calculated by weight percentage: 60% Fe, 25% Cr, 5% Ni, 2.5% Si, 1.5% B, 4% C, 2% W, and the particle size range of the powder is 60-150 microns , and dried in a vacuum oven at 80°C for 2 hours.

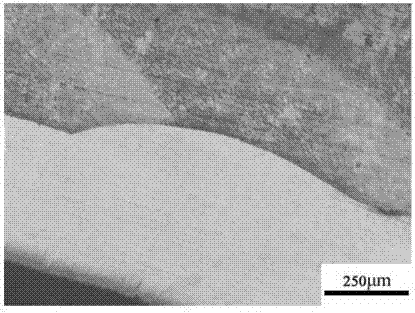

[0021] (2) Preparation of iron-based alloy coating

[0022] Put the metal cladding powder in (1) into an automatic powder feeder (commercially available, RC-PGF-D-1) for synchronous powder feeding, using a continuous fiber laser, on the surface of 45# steel (150mm×42mm×20mm) Prepare a layer of iron-based alloy coating. The specific operation is: place 45# steel flat on the processing table, fix it with a fixture, calibrate the laser starting coordinates, and set the laser process parameters as follows: laser power 200W, spot diameter 1mm, lap rate 0.3, scanning speed 400mm / min, synchronous powder feeding volume 6g / min, protective argon flow rate 15L / min. Cool to room temperature whe...

Embodiment 2

[0027] (1) Cladding powder pretreatment

[0028] The composition of the cladding powder material is calculated by weight percentage: 55% Fe, 30% Cr, 5% Ni, 3.5% Si, 2% B, 4.5% C, the particle size range of the powder is 60-150 microns, and the Dry in a drying oven at 80°C for 2 hours.

[0029] (2) Preparation of iron-based alloy coating

[0030] Put the metal cladding powder in (1) into an automatic powder feeder (commercially available, RC-PGF-D-1) for synchronous powder feeding, using a continuous fiber laser, on the surface of 45# steel (150mm×42mm×20mm) Prepare a layer of iron-based alloy coating. The specific operation is: place 45# steel flat on the processing table, fix it with a fixture, calibrate the laser starting coordinates, and set the laser process parameters as follows: laser power 800W, spot diameter 2mm, lap rate 0.3, scanning speed 800mm / min, synchronous powder feeding volume 15g / min, protective argon gas flow rate 20L / min. Cool to room temperature when do...

Embodiment 3

[0035] (1) Cladding powder pretreatment

[0036] The composition of the cladding powder material is calculated by weight percentage: 57% Fe, 30% Cr, 6% Ni, 4% Si, 1% B, 2% C, the particle size range of the powder is 60-150 microns, and the Dry in a drying oven at 80°C for 2 hours.

[0037] (2) Preparation of iron-based alloy coating

[0038] Put the metal cladding powder in (1) into an automatic powder feeder (commercially available, RC-PGF-D-1) for synchronous powder feeding, using a continuous fiber laser, on the surface of 45# steel (150mm×42mm×20mm) Prepare a layer of iron-based alloy coating. The specific operation is: place 45# steel flat on the processing table, fix it with a fixture, calibrate the laser starting coordinates, and set the laser process parameters as follows: laser power 300W, spot diameter 1mm, lap rate 0.3, scanning speed 300mm / min, synchronous powder feeding volume 8g / min, protective argon flow rate 20L / min. Cool to room temperature when done.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com