Patents

Literature

477results about How to "Stable disassembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

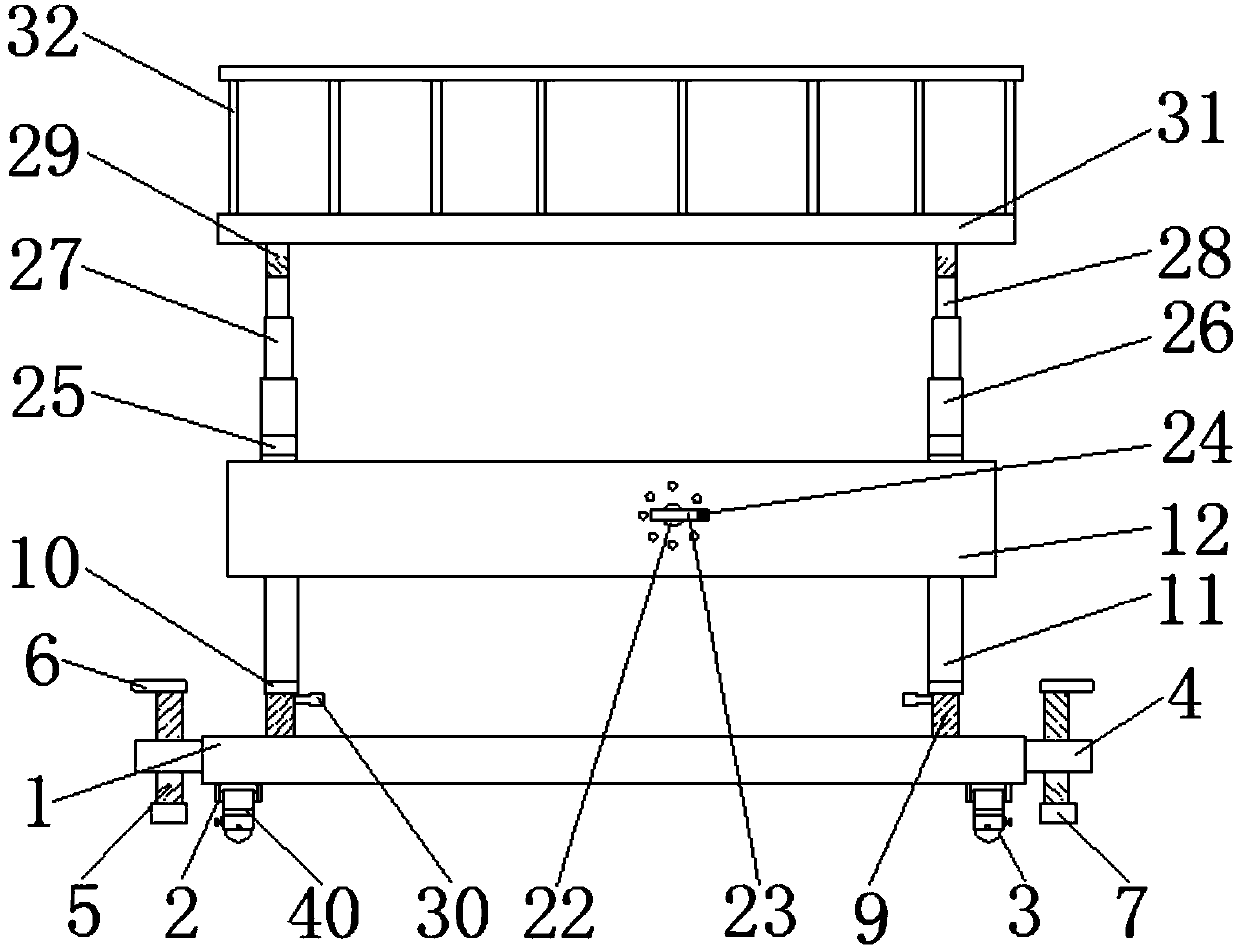

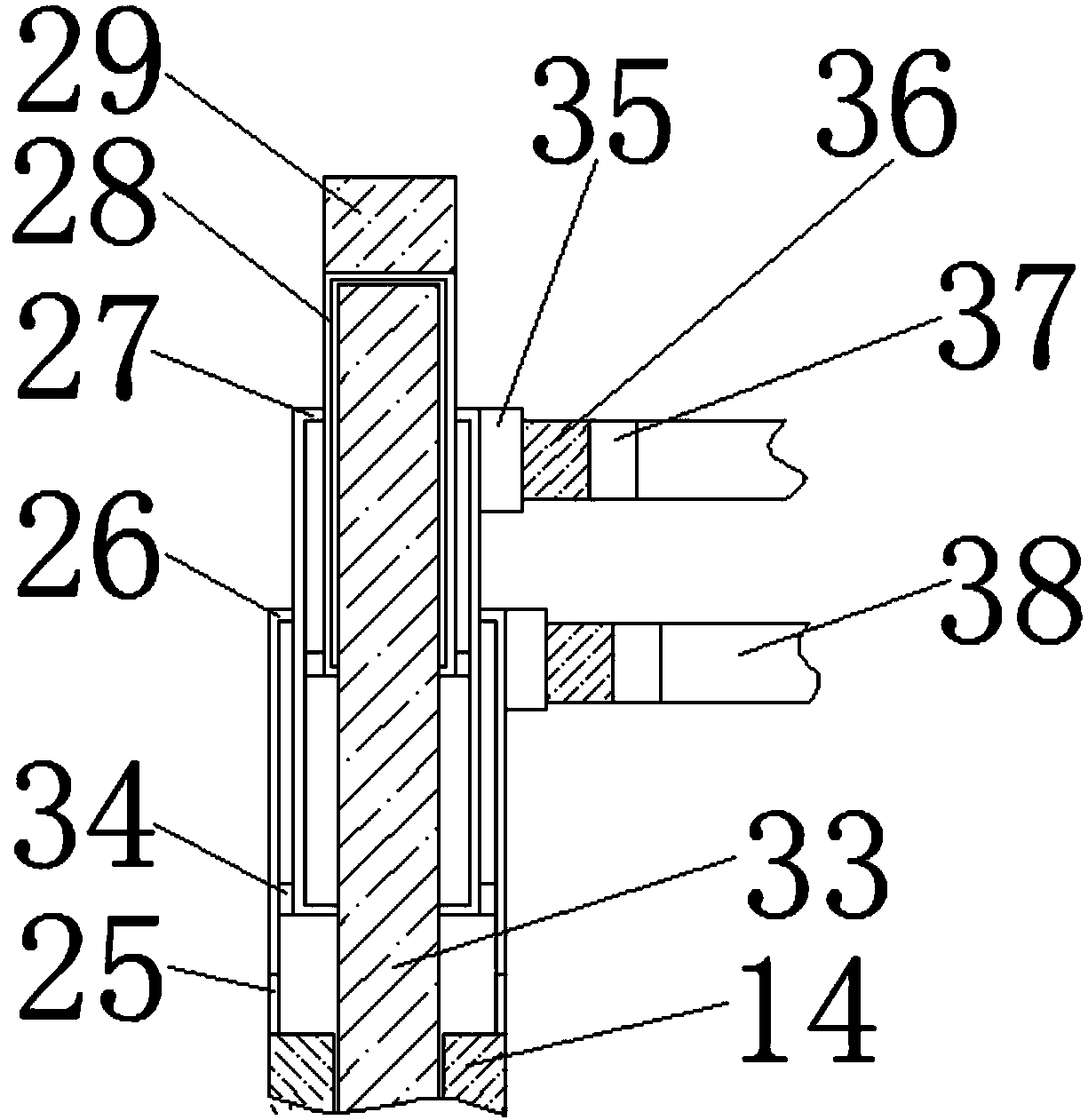

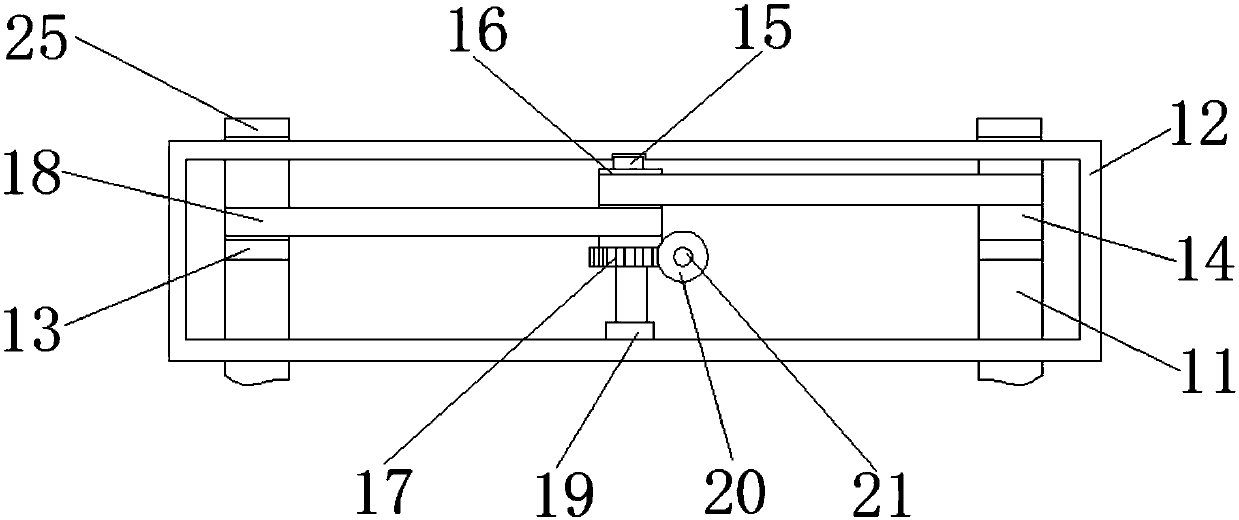

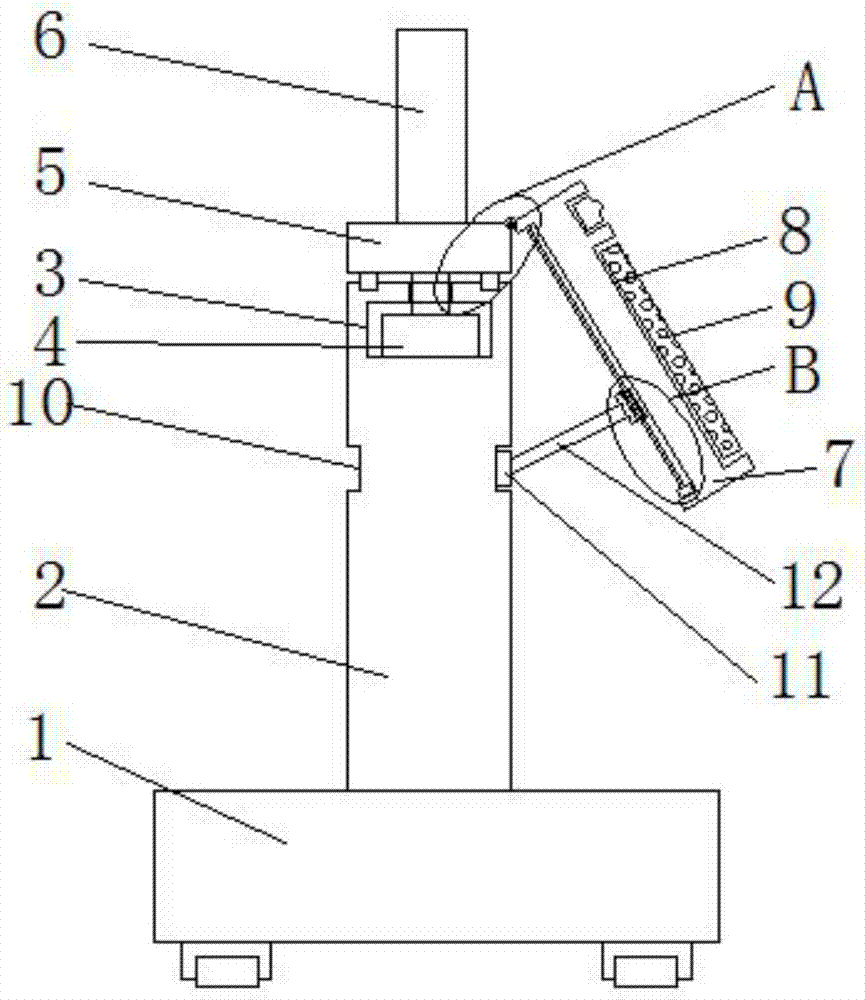

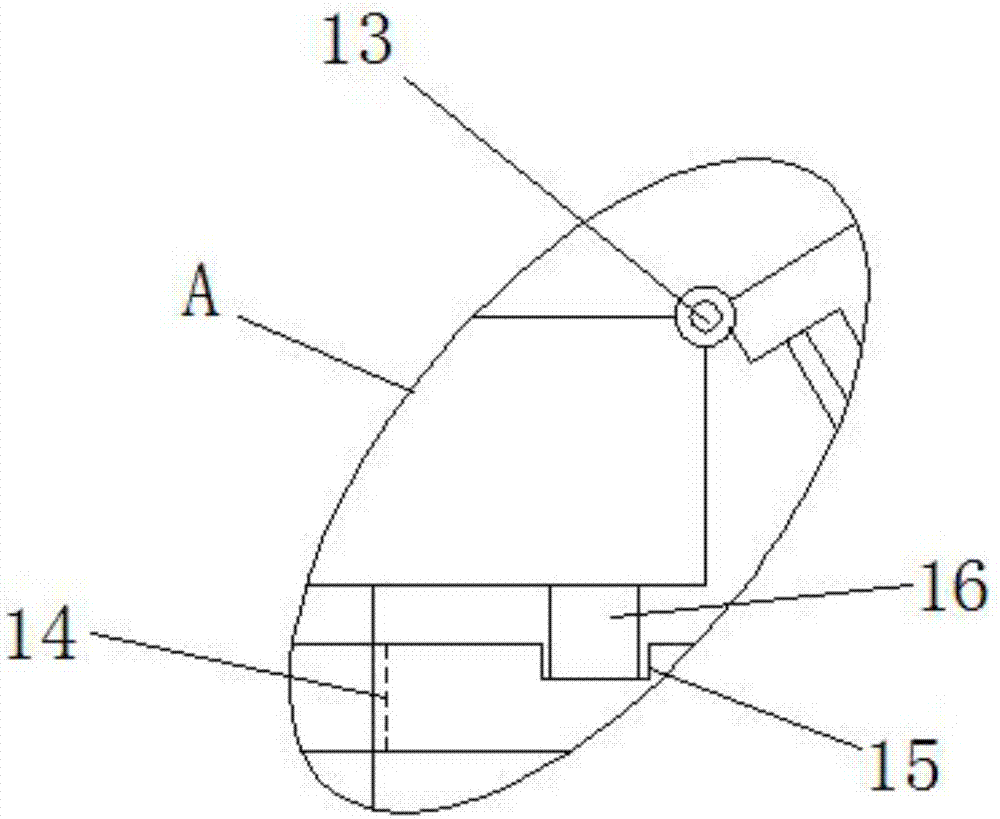

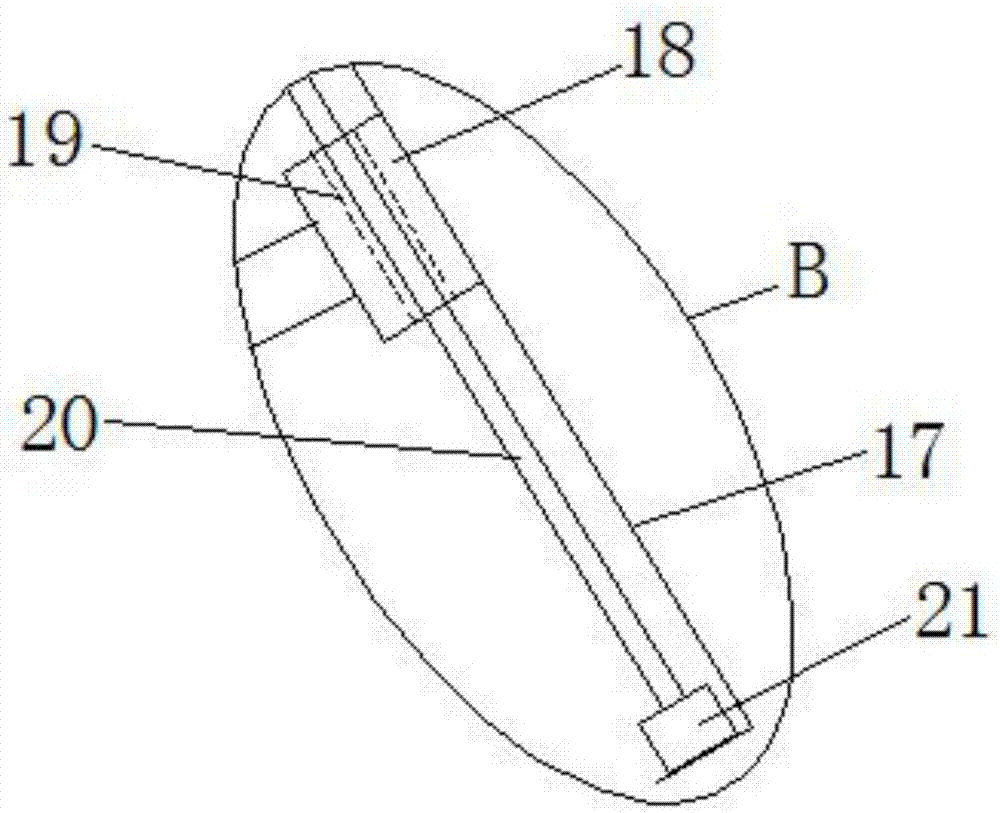

Auxiliary installation rack making transformer installation easy

ActiveCN107689291AEasy and flexible installationEasy to operateTransformers/reacts mounting/support/suspensionLifting framesTransformerEngineering

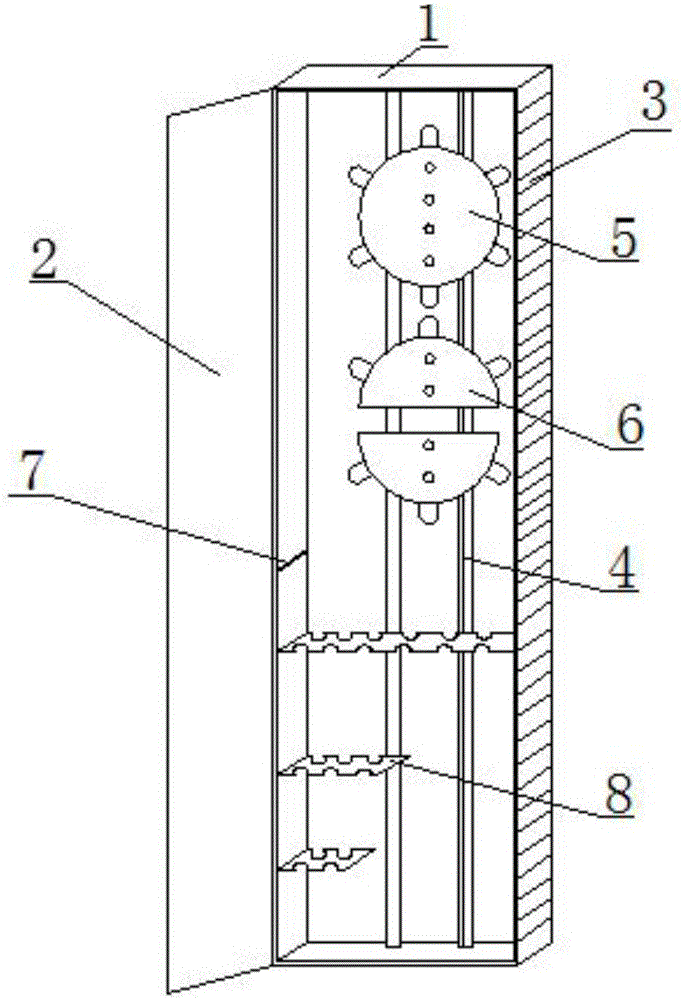

The invention provides an auxiliary installation rack making transformer installation easy and relates to the technical field of installation racks. The auxiliary installation rack making the transformer installation easy comprises a base, foot pads are welded to the bottom of the base, and the bottoms of the foot pads are movably provided with moving pieces through wheel roller bearing respectively. Bottom screws are arranged on the top of the base, the tops of the bottom screws are movably connected with the bottoms of screw cylinders through bottom bearings respectively, the tops of the screw cylinders penetrate through the bottom of a fixing base, extend into the fixing base and are fixedly connected with the fixing base, a top plate is arranged on the top of the fixing base, and railings are welded to the top of the top plate. According to the auxiliary installation rack making the transformer installation easy, the rotation of a rotating drum can be controlled by rotating a handle, the operation is simple and convenient, the installation rack is detachable, convenient and quick to operate and convenient to carry and transfer.

Owner:扬中市长江电器设备厂有限公司

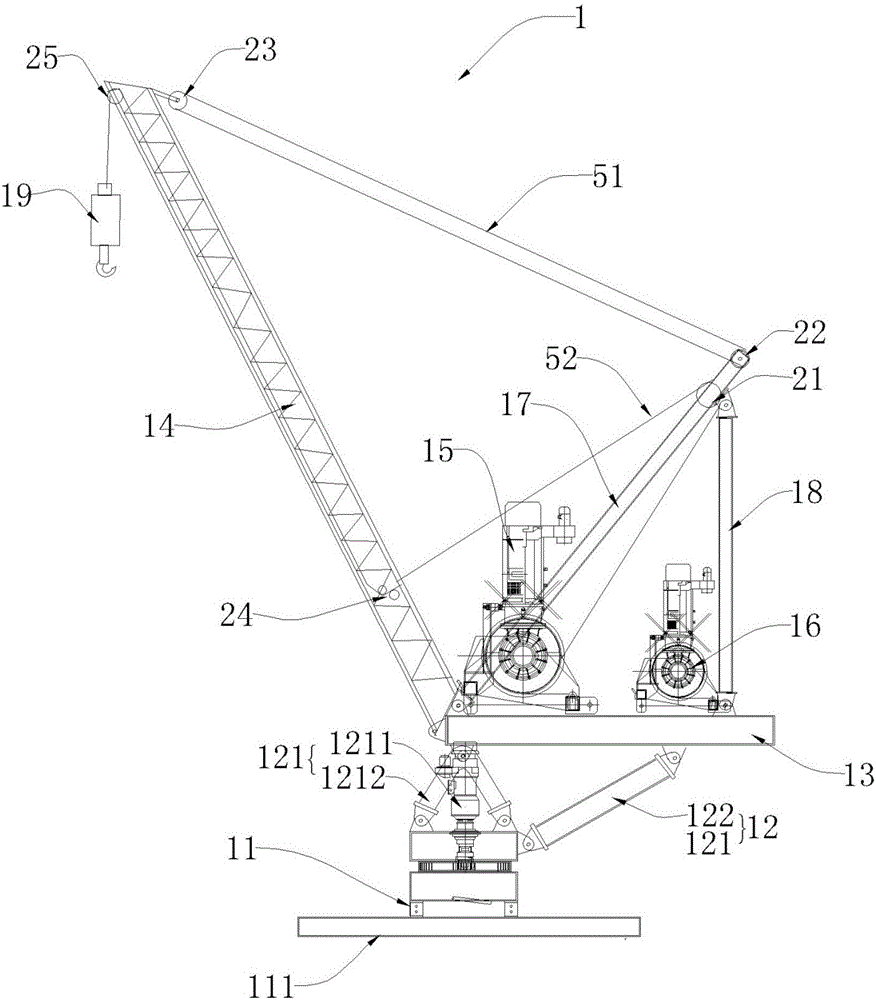

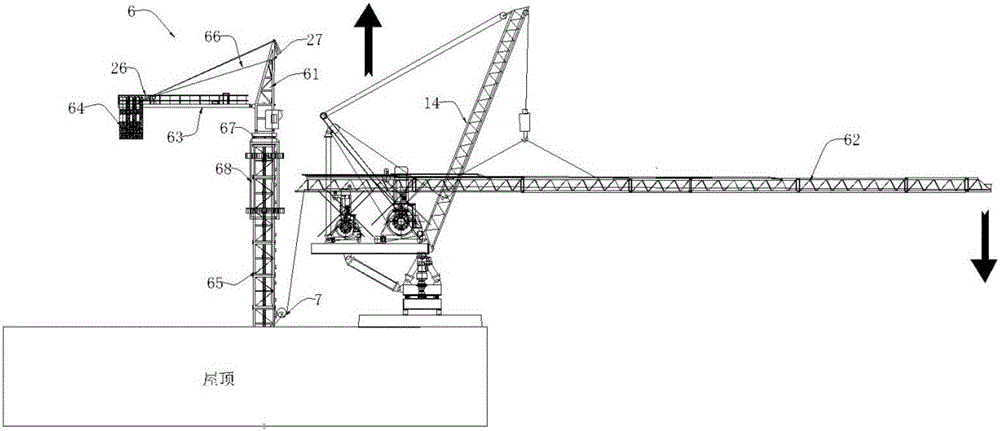

Roof hang device and crane and cargo boom disassembling method

The invention discloses a roof hang device and a crane and cargo boom disassembling method In order to better fix the roof hang device, a basic steel beam on a roof hang base is fixed through a fastening bolt penetrating through a beam plate of a roof, the basic steel beam and the beam plate are clamped and fixed by arranging parallel pressing plates so that the stability of a roof hang bearing gravity can be lowered, the roof hang can move more stably, a ground pulley is installed at the position where a tower crane and a roof make contact and intersect with each other by means of the roof hang device, the cargo boom can be kept balanced by enabling a lifting steel wire rope installed on the tower crane to penetrate through the ground pulley and the cargo boom, the cargo boom is stably and rapidly disassembled under the traction of a hanging hook on the roof hang, the method is particularly suitable for disassembling a superlong cargo boom, after the cargo boom is disassembled, a balance arm on the tower crane, a counter weight, a tower cap, a rotation assembly, a jacking wrap frame assembly and a standard knot are sequentially disassembled by means of the roof hang device, the disassembling process is simple and disassembling is stable.

Owner:庄爱军

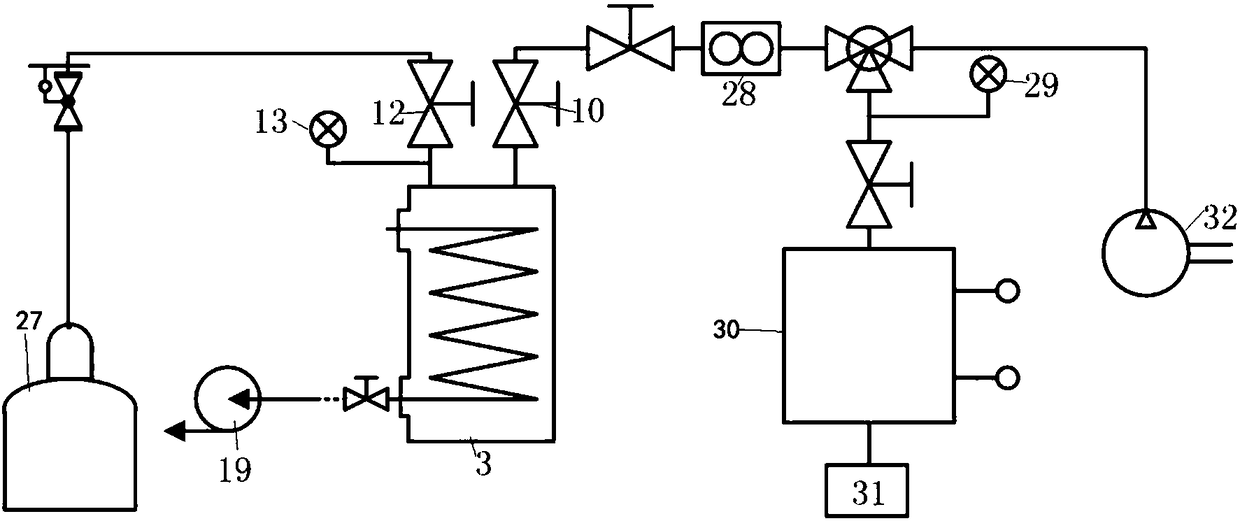

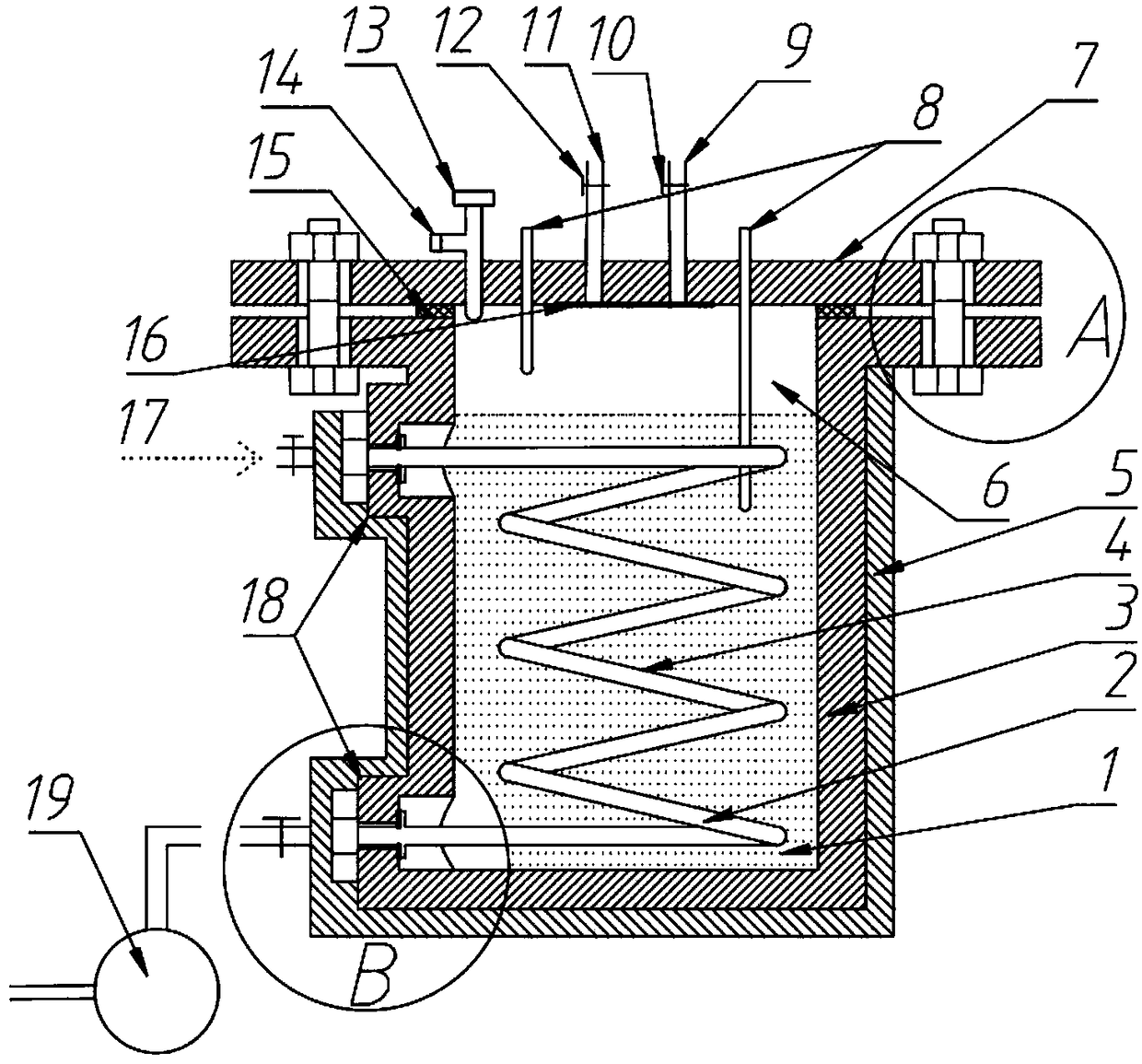

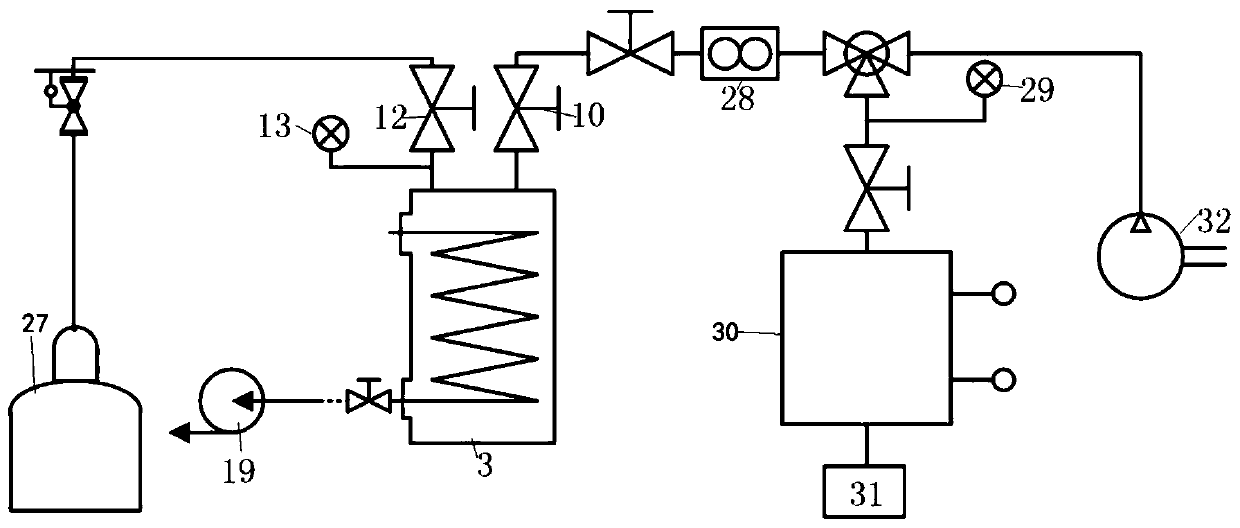

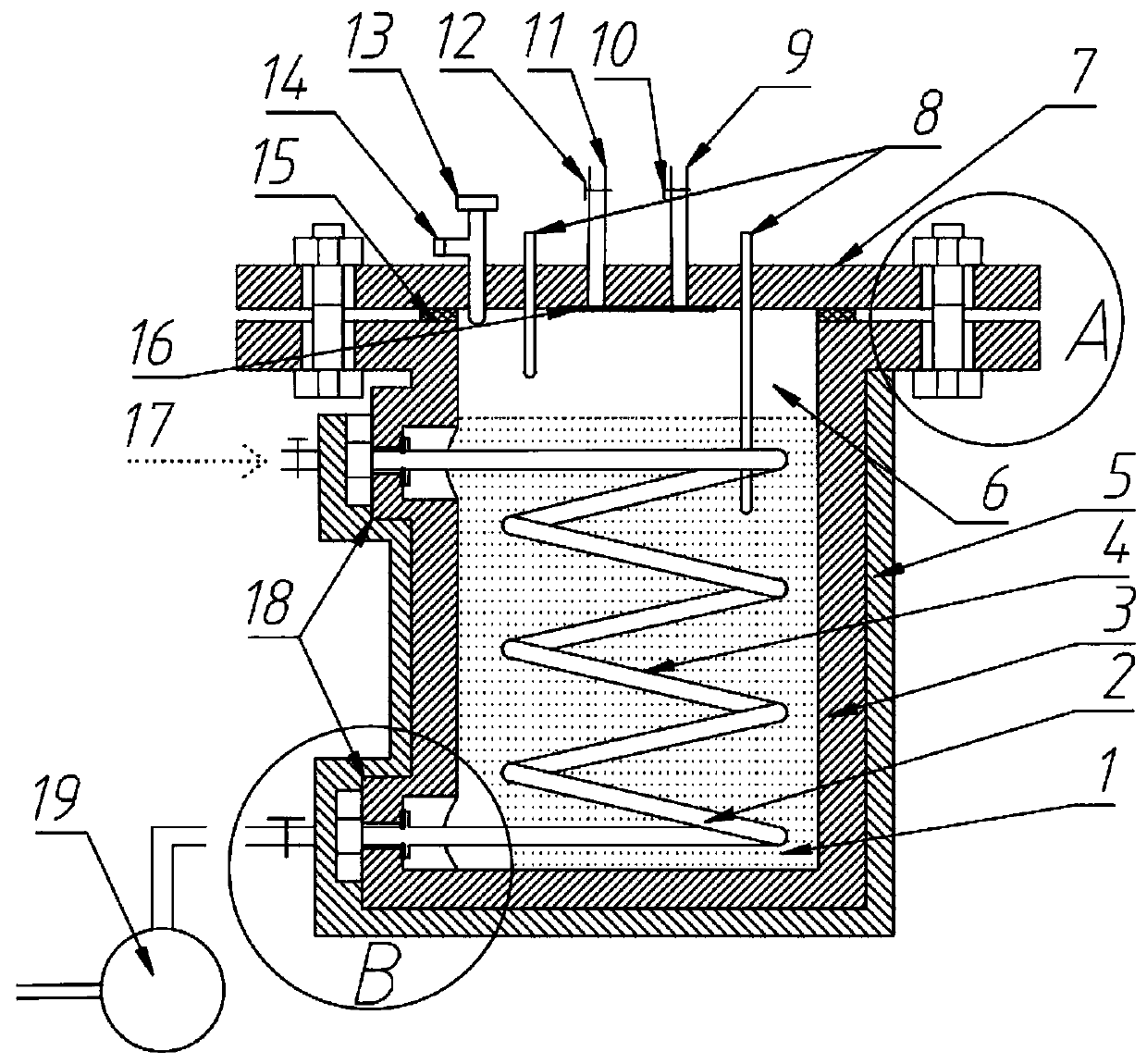

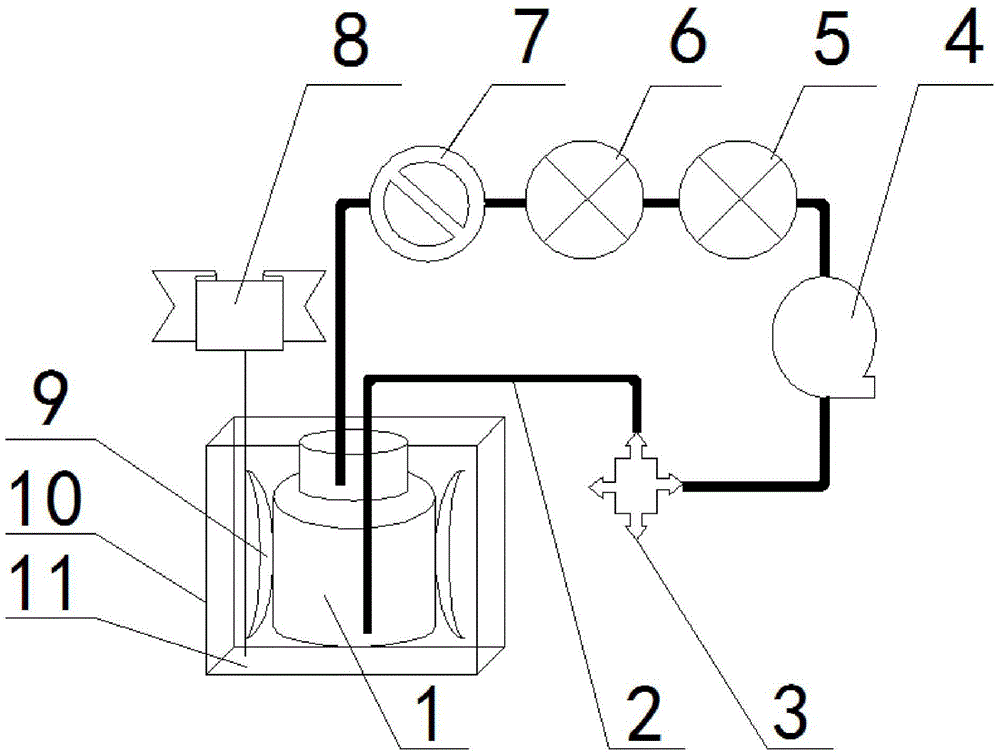

Hydrogen power system based on heat self-balancing solid hydrogen source reactor

ActiveCN108426169AIncrease profitLow costAircraft componentsVessel mounting detailsReaction rateHydrogen fuel cell

The invention discloses a hydrogen power system based on a heat self-balancing solid hydrogen source reactor. The hydrogen power system comprises a hydrogen source, the heat self-balancing solid hydrogen source reactor, a hydrogen fuel cell, an air compression system and a vacuum pump; and an inlet of the heat self-balancing solid hydrogen source reactor is connected with the hydrogen source, an outlet of the heat self-balancing solid hydrogen source reactor is divided into two paths, one path is connected with the hydrogen fuel cell, and the other path is connected with the vacuum pump. According to the hydrogen power system, a phase-change material can store heat released by hydrogen absorption reaction in a latent heat form and release the heat during hydrogen desorption reaction, thus,heat in the hydrogen absorption process is used for the hydrogen desorption process, heating and cooling devices are omitted, the cost is reduced, the energy utilization rate is increased, and meanwhile, the hydrogen absorption and desorption reaction rate can be increased.

Owner:XI AN JIAOTONG UNIV

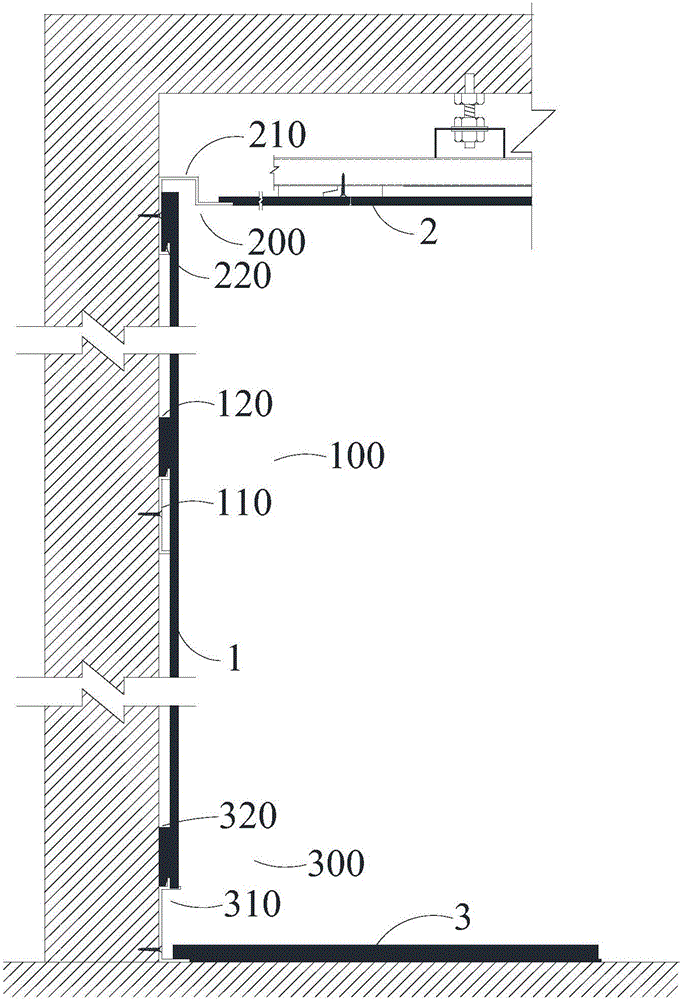

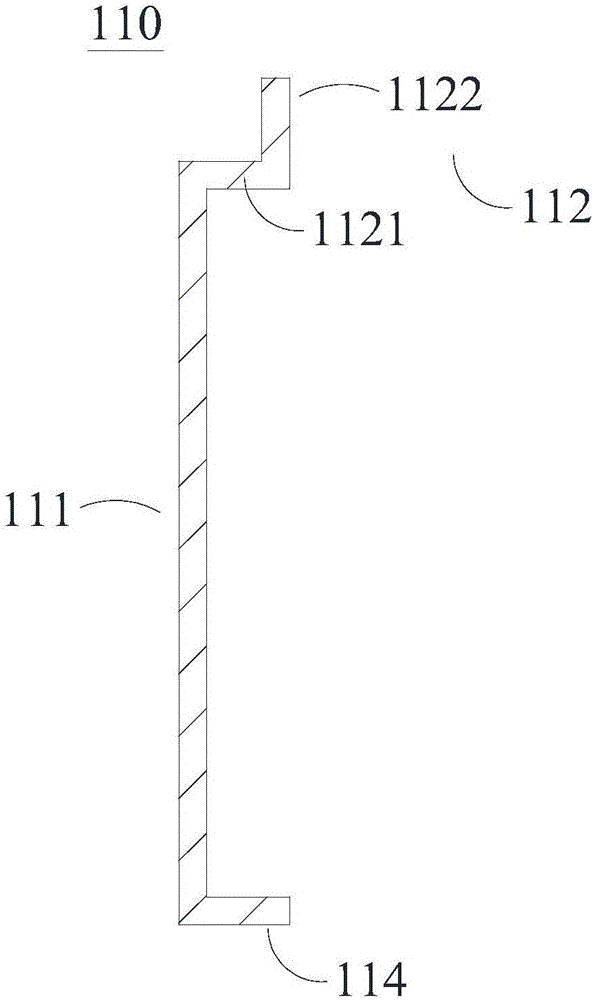

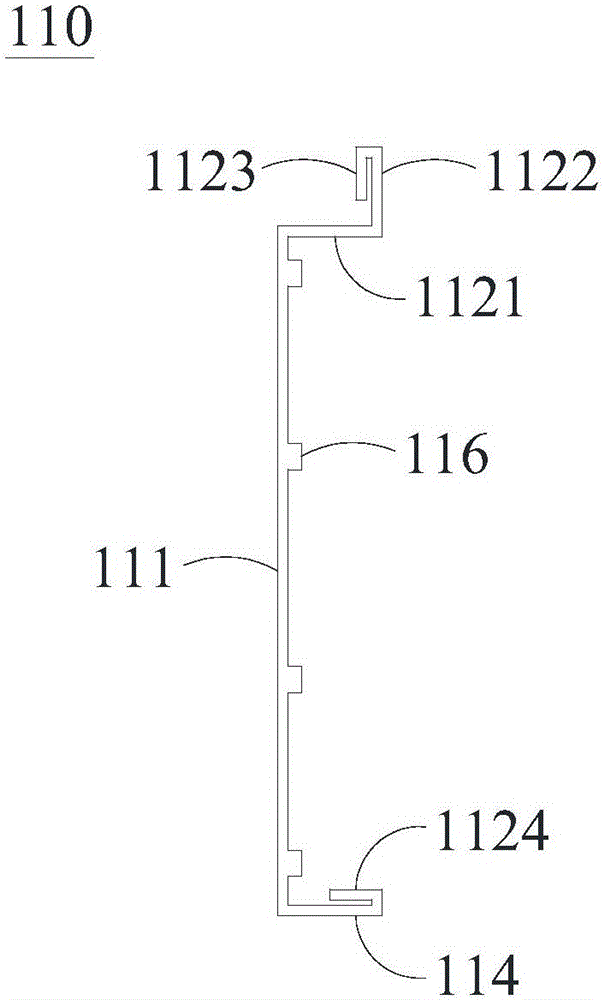

Mounting device for movable decorative plate

InactiveCN105735603ALow costQuick installationCovering/liningsFlooringWall platePetroleum engineering

The invention provides an installation device for a movable decorative panel, which includes a wall panel installation pendant, a ceiling installation pendant and a floor installation pendant, the wall board installation pendant includes a first installation part and a first connection part, the first installation part includes a first fixing part and the first supporting part; the ceiling mount pendant includes the second installing part and the second connecting part, the second installing part includes the second fixing part, the second supporting part and the ceiling supporting part, the second supporting part and the second fixing part One end is connected, the ceiling supporting part is connected with the other end of the second fixing part, and is bent into a step shape; the floor installation pendant includes a third installing part and a third connecting part, and the third installing part includes a third fixing part, a third support part and the floor supporting part, the third fixing part is provided with at least one third installation hole, the third supporting part is connected with one end of the third fixing part, the third supporting part is formed with a second groove, the floor supporting part and the third The other end of the fixing part is connected and perpendicular to the third fixing part.

Owner:MEIHAOZHUJIA HOUSEHOLD DECORATION BEIJING CO LTD

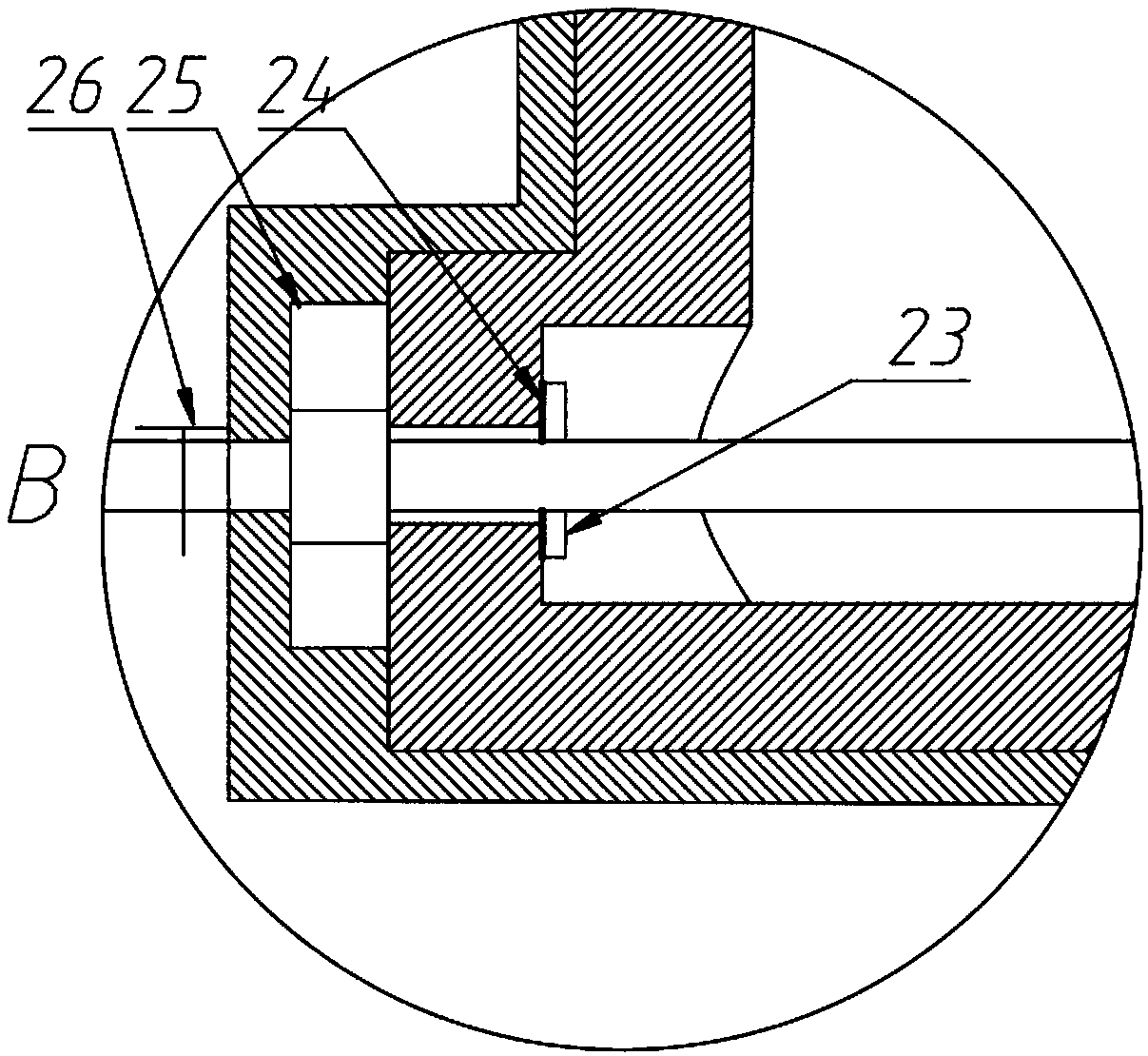

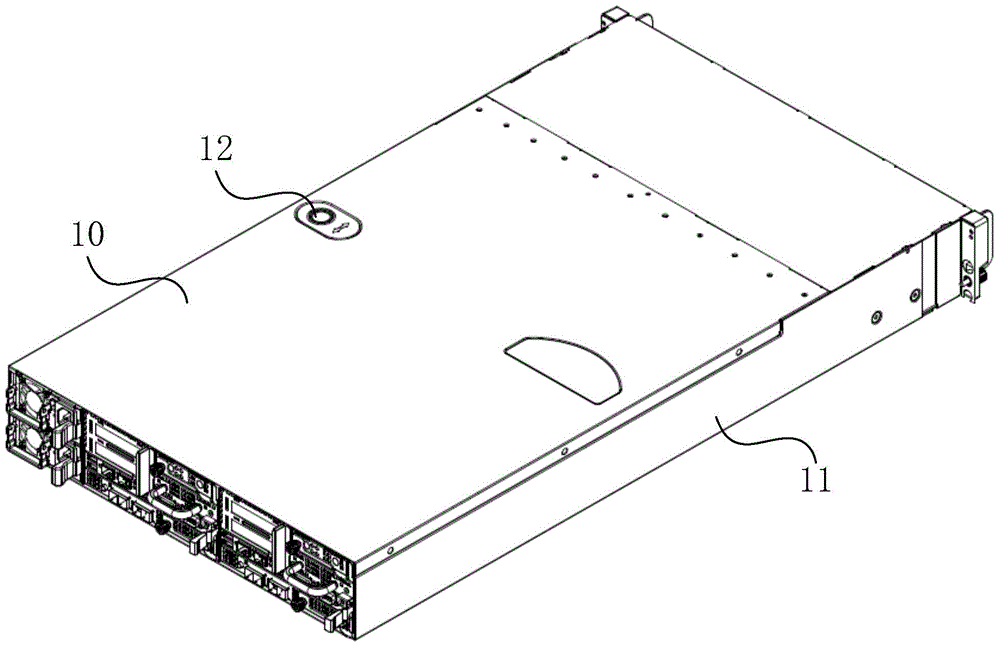

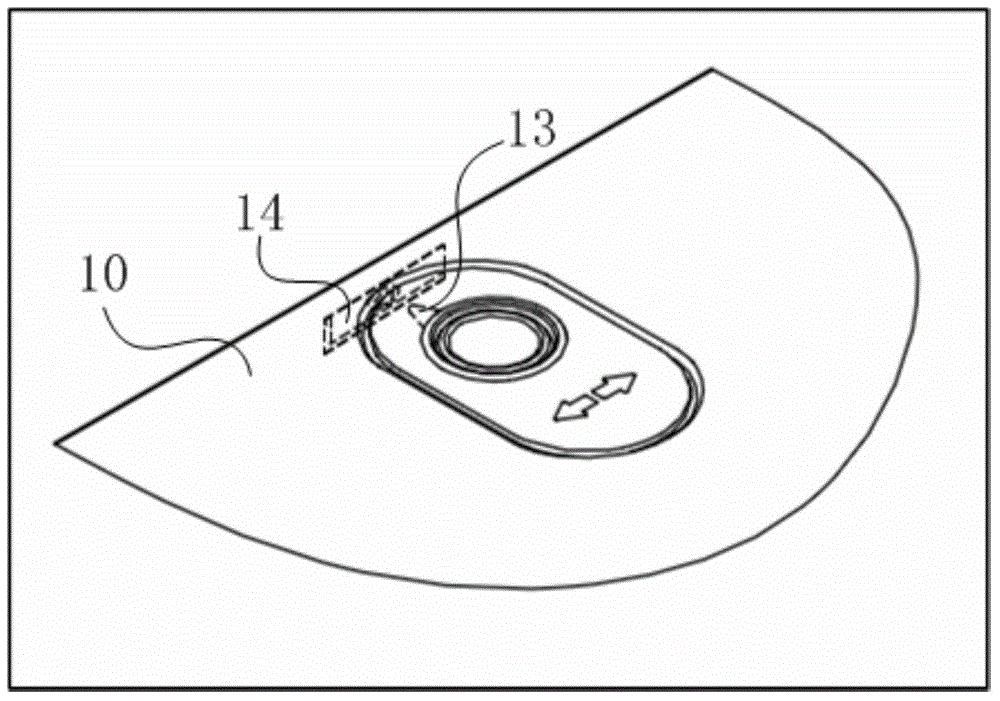

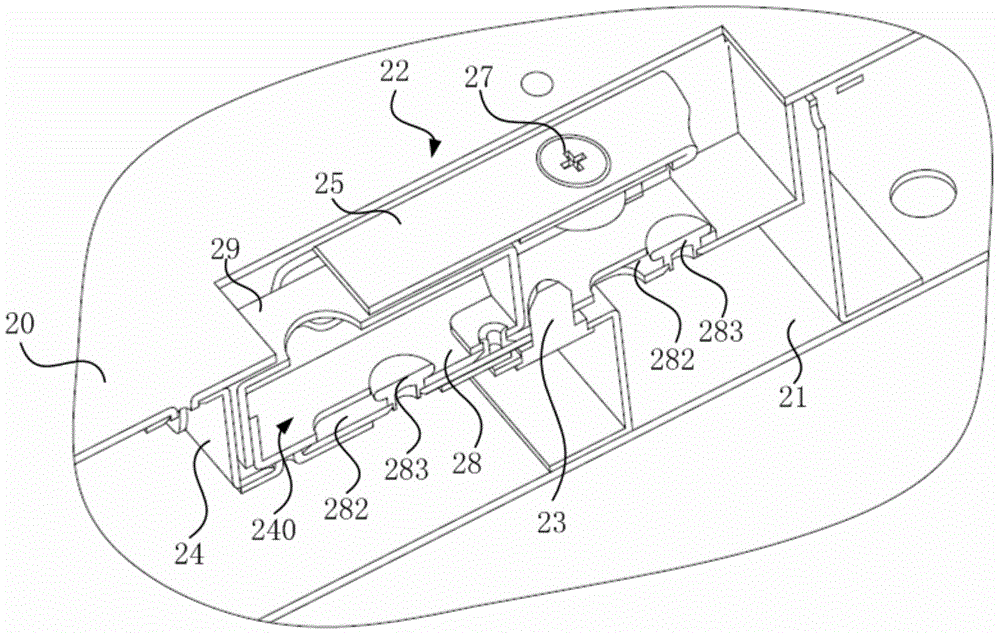

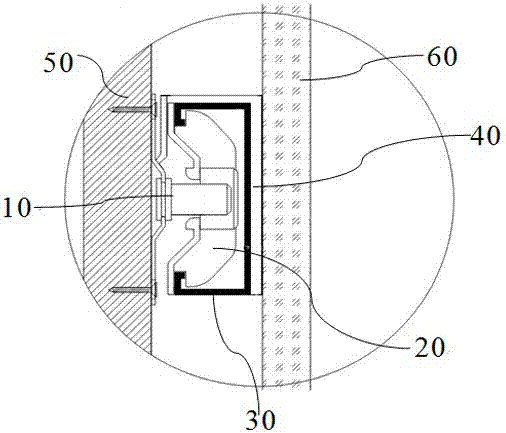

Bolt lock device and server with the same

InactiveCN104460881AGuaranteed smooth assemblyStable disassemblyServersClamping/extracting meansEngineeringMechanical engineering

The invention provides a bolt lock device which is used for a server. The bolt lock device comprises a positioning column, a containing frame, a transversely-moving plate and a rotating handle, wherein the positioning column is fixedly arranged on a machine shell of the server, the containing frame is fixedly arranged on an upper cover of the server, the transversely-moving plate is fixedly arranged in the containing frame through a positioning piece which allows the transversely-moving plate to move between a first position and a second position relative to the containing frame along an opening of the transversely-moving plate, and the rotating handle is connected to the transversely-moving plate through two rotating plates in a pivoted mode and can rotate between a first rotating position and a second rotating position. When the positioning column is inserted into an insertion hole of the transversely-moving plate in the containing frame, the rotating handle drives the containing frame to move forwards and backwards by rotating between the first rotating position and the second rotating position, and therefore the upper cover can be driven to move forwards and backwards together with the containing frame, and meanwhile the transversely-moving plate accordingly moves between the first position and the second position relative to the containing frame.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

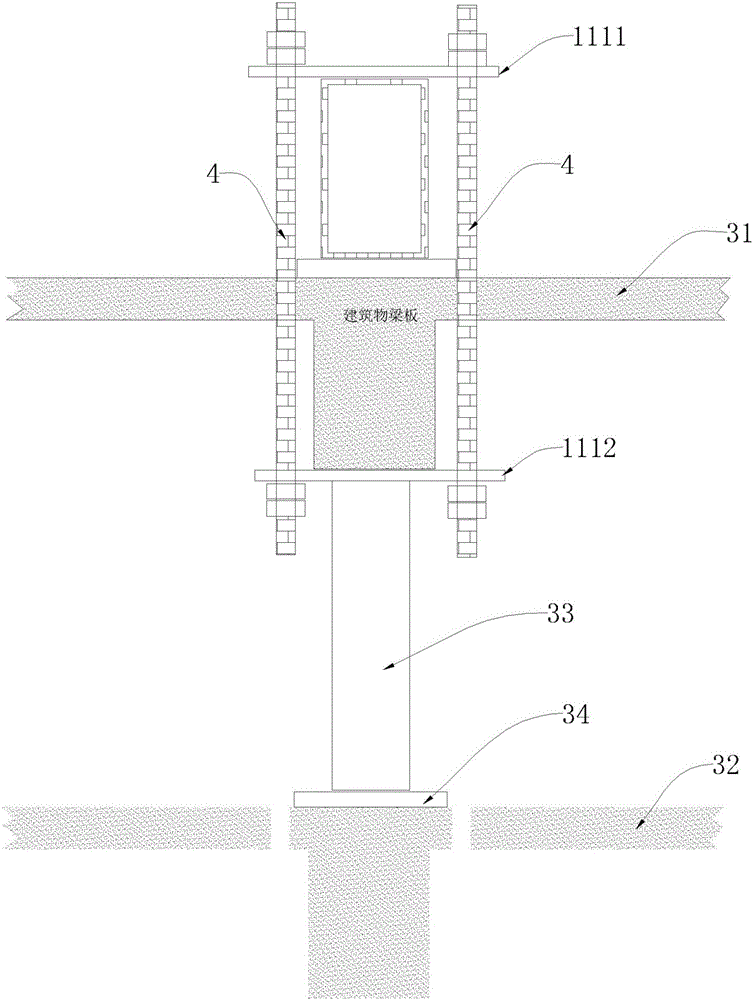

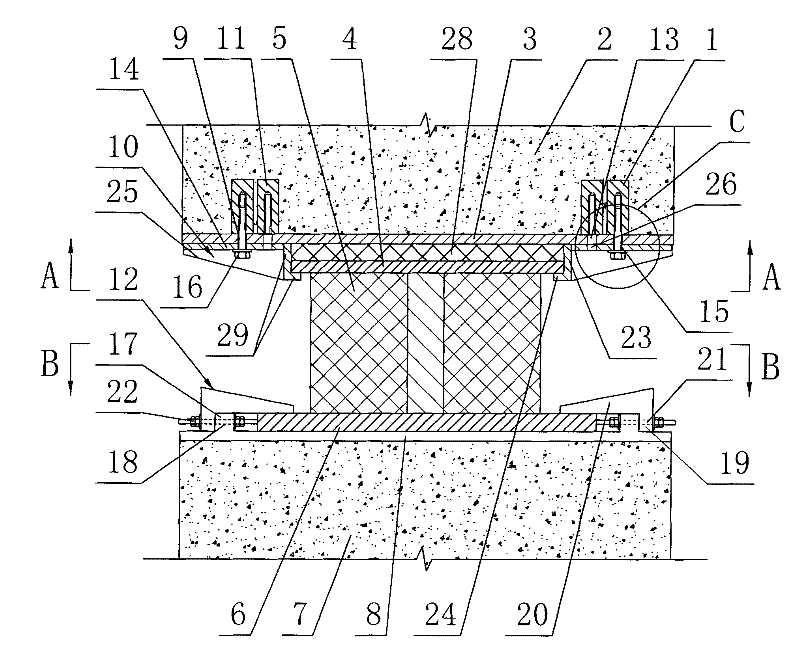

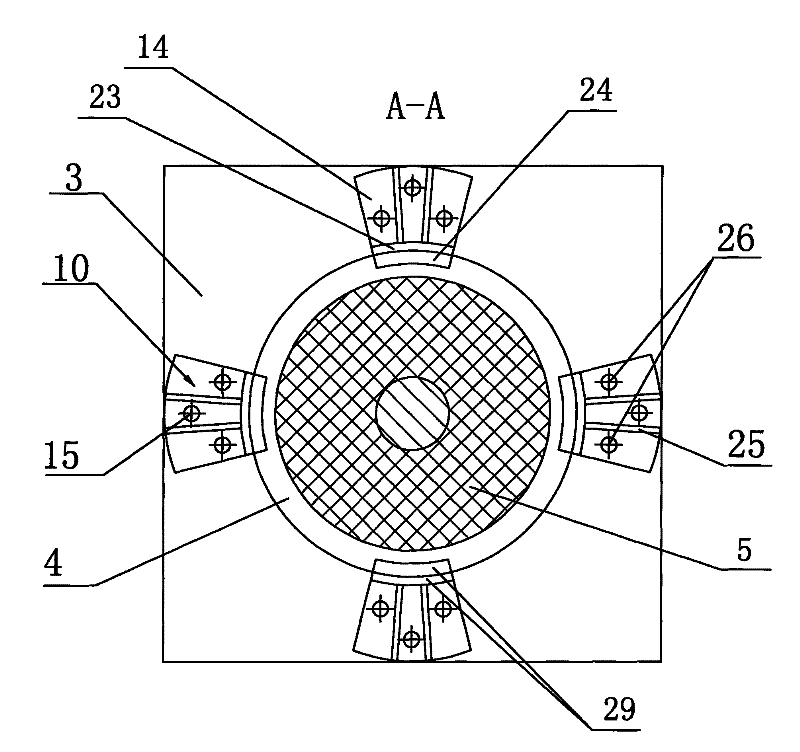

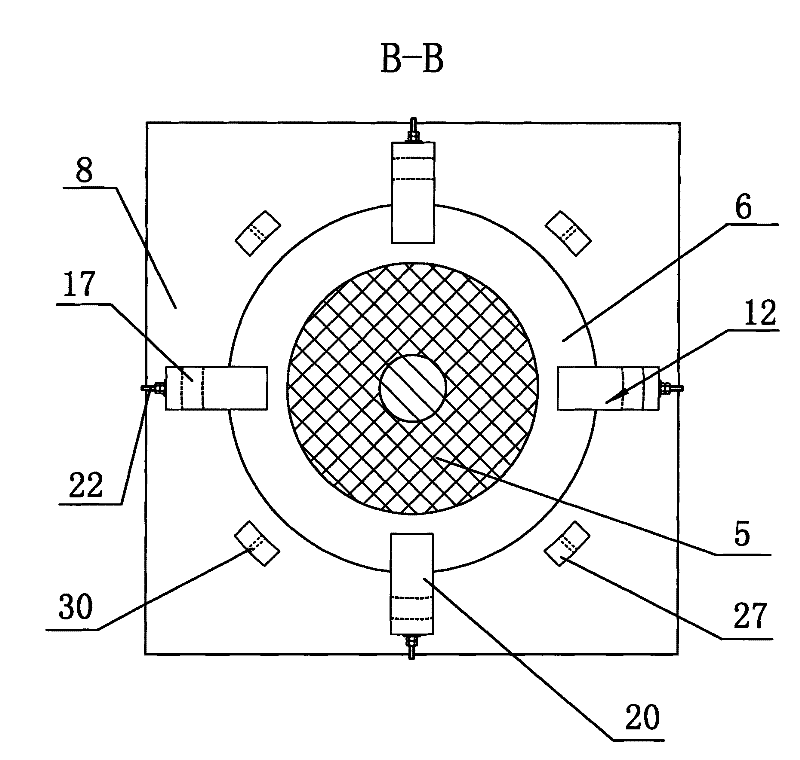

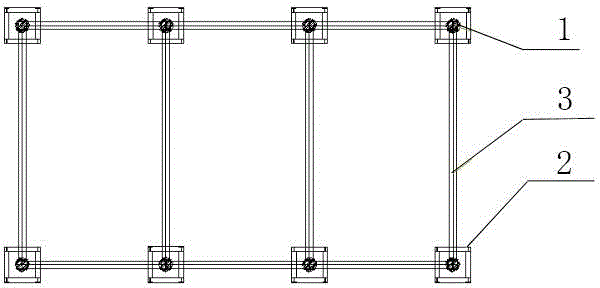

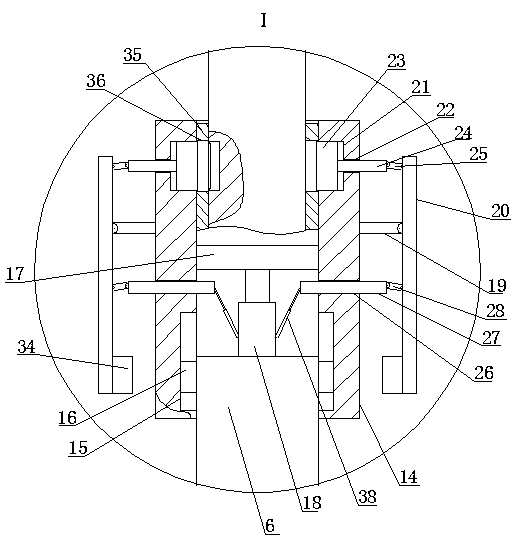

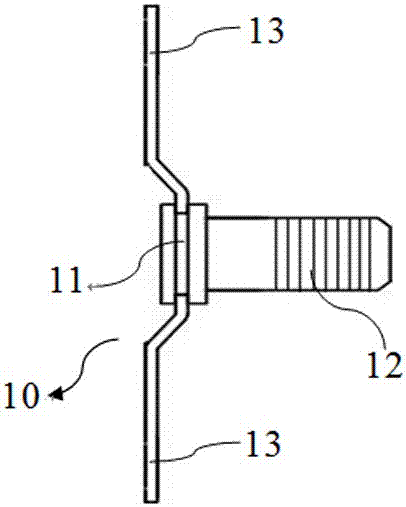

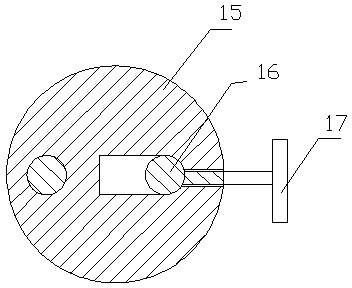

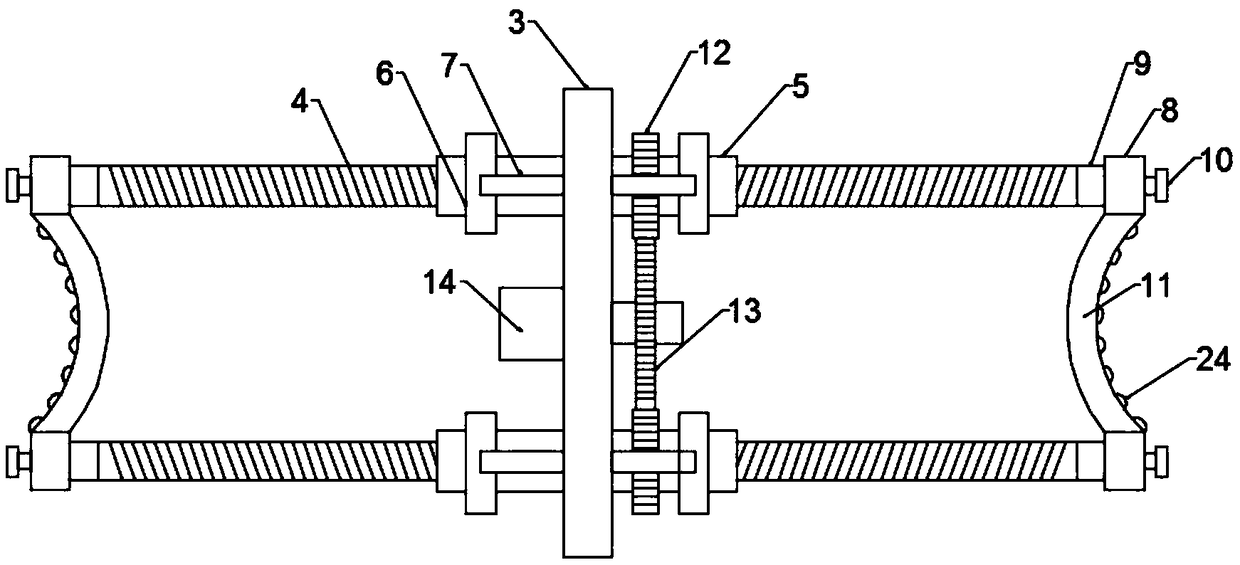

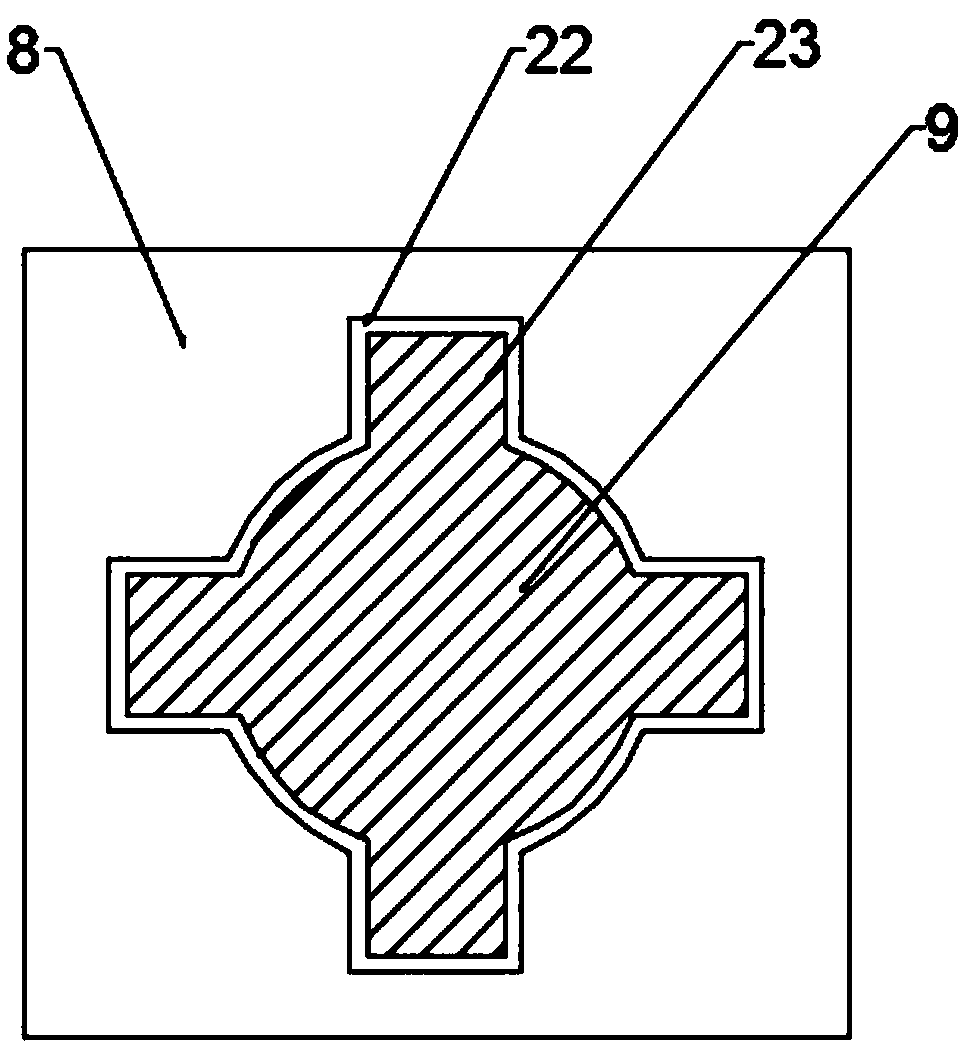

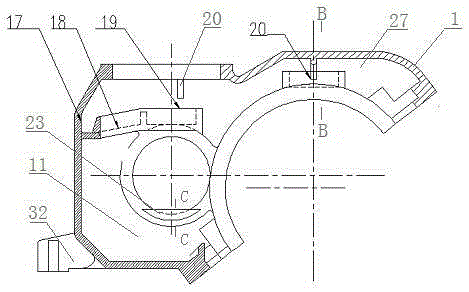

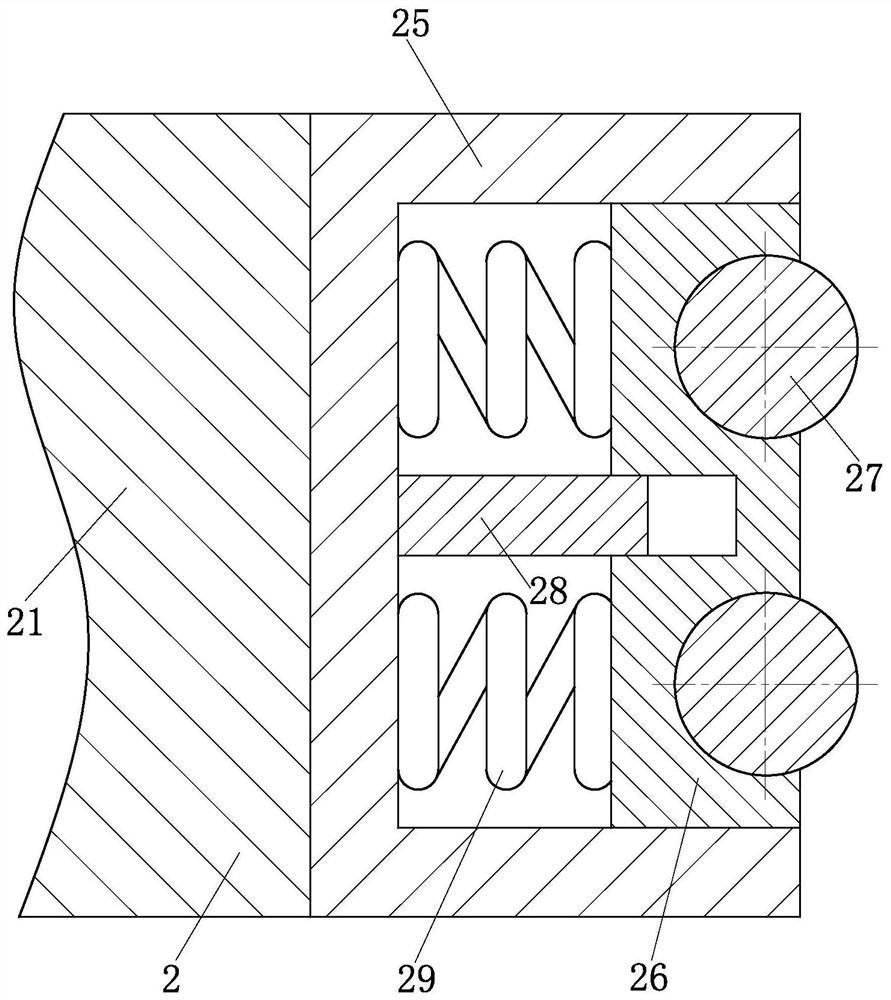

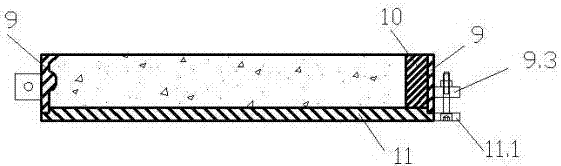

Lead rubber bearing

ActiveCN102191817AEasy to replaceStable disassemblyShock proofingAgricultural engineeringScrew thread

The invention discloses a lead rubber bearing. The lead rubber bearing comprises a main inside screw thread sleeve (1), an upper pre-buried steel plate (3), an upper connecting steel plate (4), a lead rubber bearing main body (5), a lower connecting steel plate (6), a lower pre-buried steel plate (8), an upper fastener (10), a standby inside screw thread sleeve (11) and main lower fasteners (12), wherein the upper fastener (10) is screwed with an upper buttress (2); a hanging buckle (29) of the upper fastener (10) is locked with the upper connecting steel plate (4); a main protrusion (17) is arranged on the lower pre-buried steel plate (8); a vertical plate (19) of each of the main lower fasteners (12) is screwed with the main protrusion (17); and a pressing plate (20) of each of the main lower fasteners (12) is pressed on the top surface of the lower connecting steel plate (6). The lead rubber bearing is convenient to exchange.

Owner:中和华丰建设集团有限公司 +1

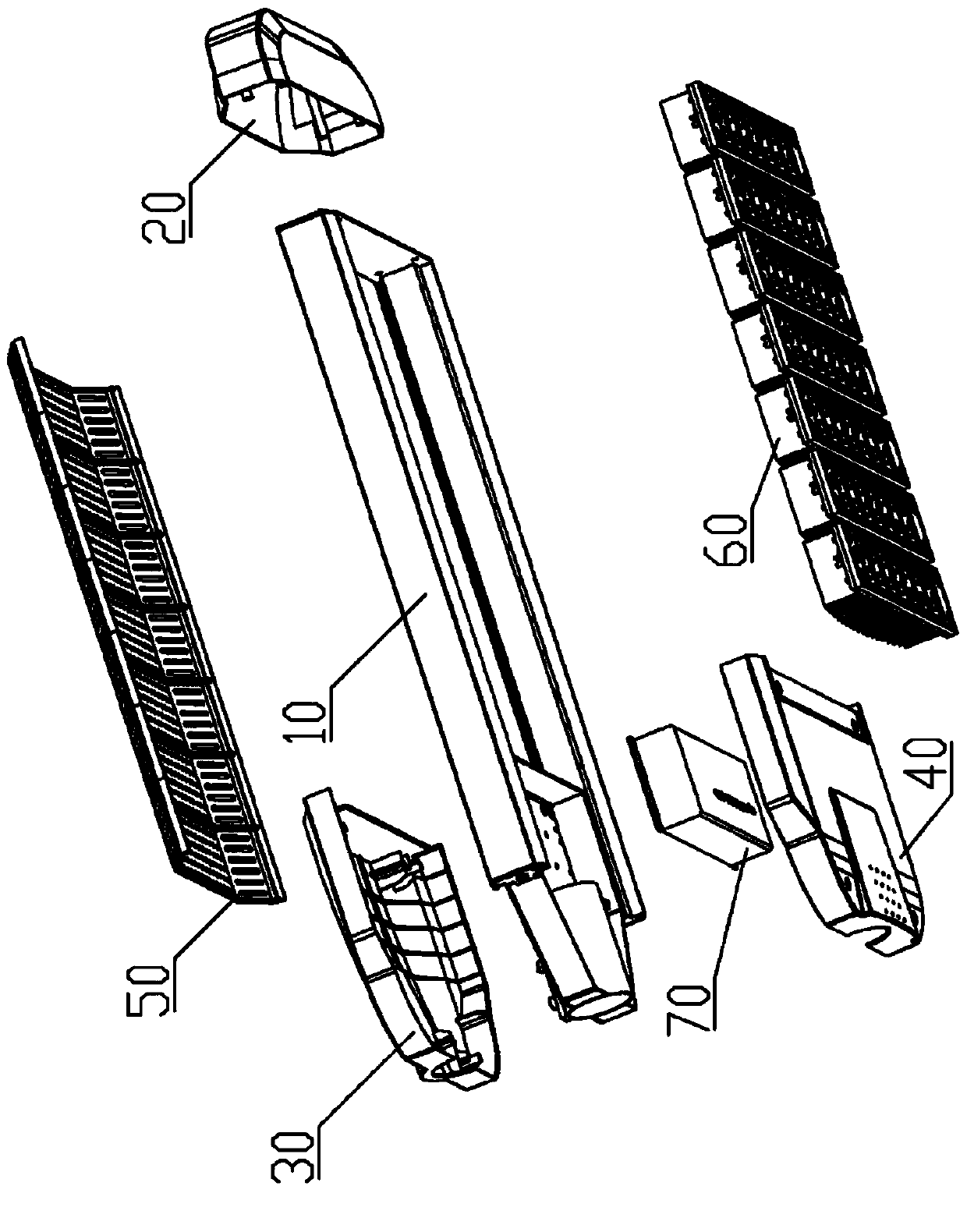

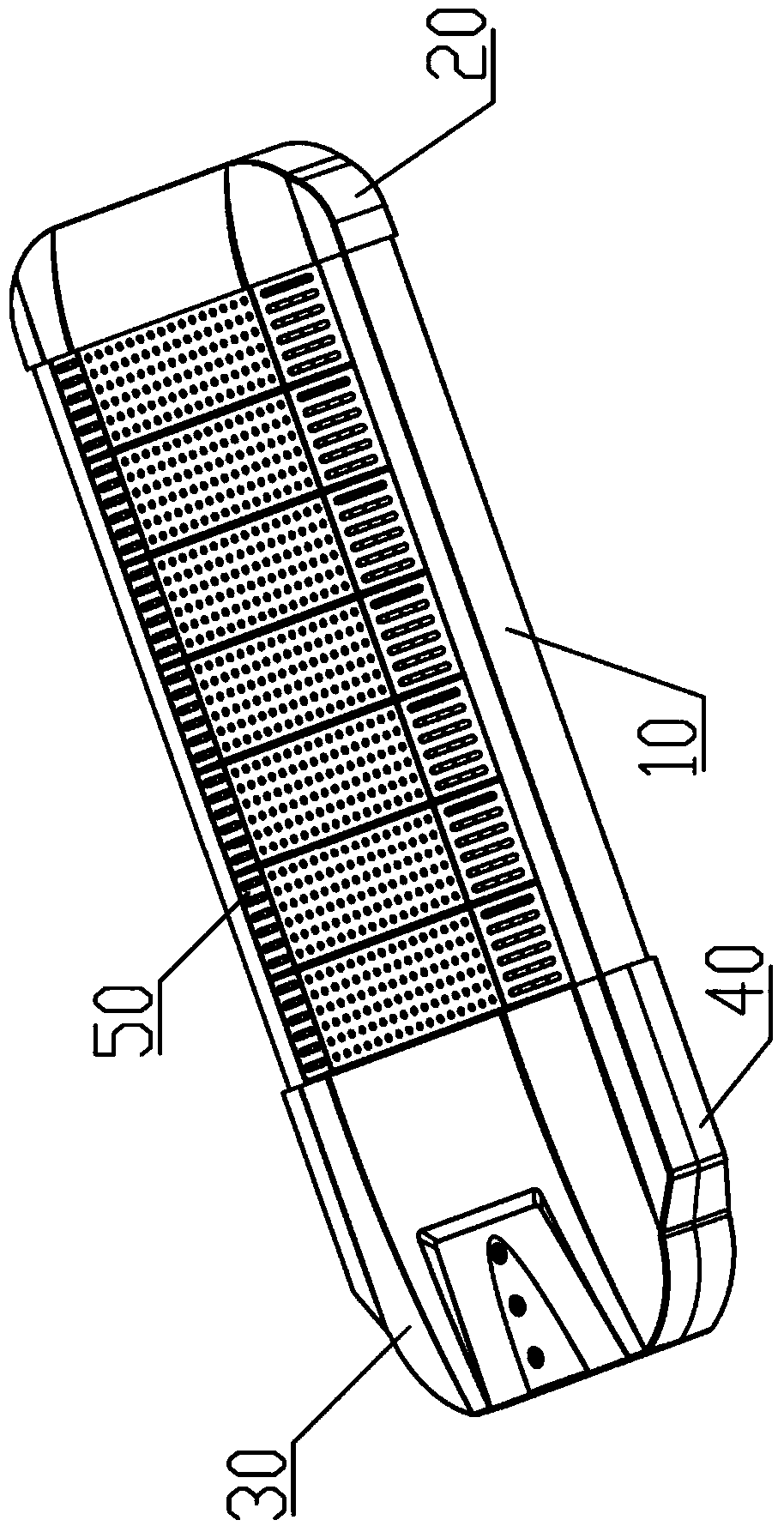

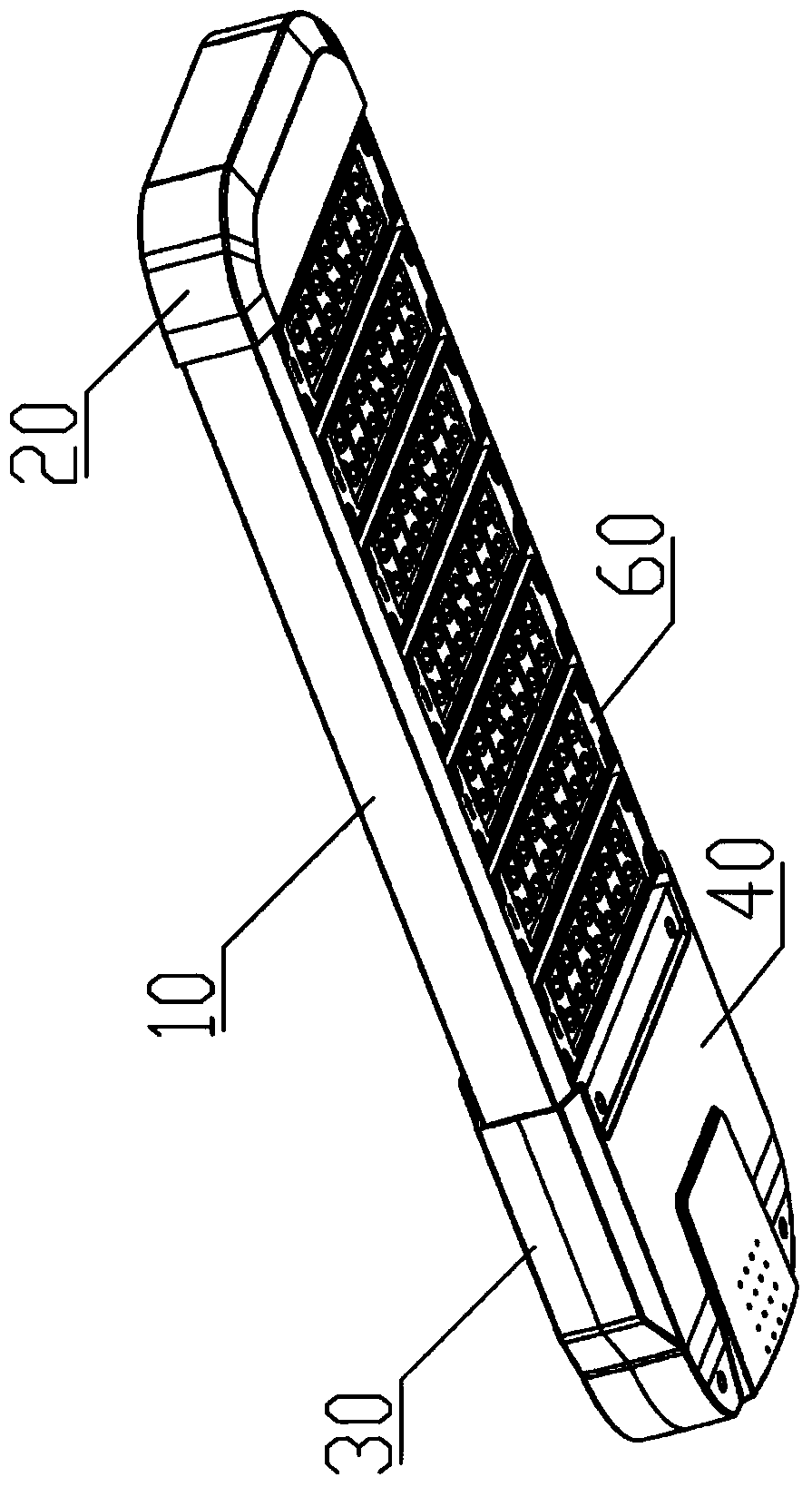

LED lamp and frame assembly of LED lamp

InactiveCN103423674AStable disassemblyEasy to installLighting support devicesPoint-like light sourceLED lampLight fixture

The invention discloses an LED lamp and a frame assembly of the LED lamp. The frame assembly comprises a connecting plate, two supports, a lamp holder and a plurality of fixing parts. The two supports are connected to the two opposite ends of the connecting plate; the lamp holder is connected to the end, far away from the connecting plate, of each support through the fixing parts, wherein the end face, connected with the connecting plate, of each support is provided with a gasket. The LED lamp further comprises a cover body, a shell body, an LED light source module, a power supply and a connecting plug, wherein the cover body is arranged on the connecting plate of the frame assembly, and the shell body wraps the lamp holder of the frame assembly. The two opposite ends of the LED light source module are detachably arranged on mounting surfaces of the two supports and electrically connected with the power supply through the connecting plug arranged in the supports, therefore, the LED light source module can be assembled and disassembled with no need to take apart the other components of the LED lamp, and the situation that a power line exposed in an external environment is damaged can be avoided.

Owner:JIANGSU JINJIN LIGHTING

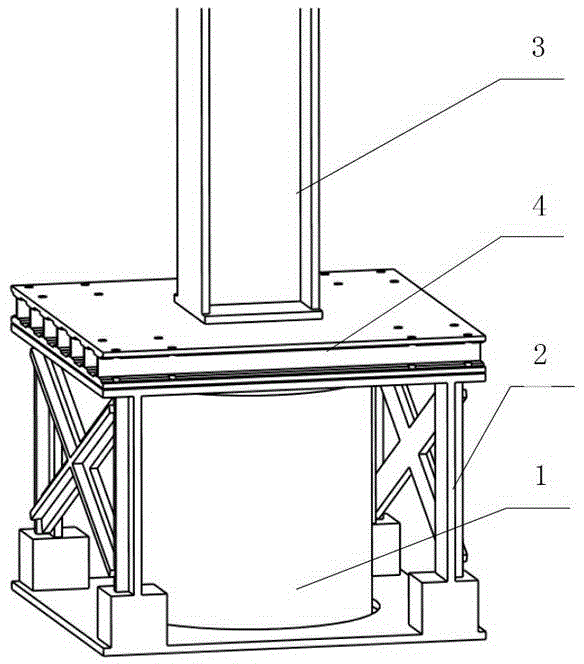

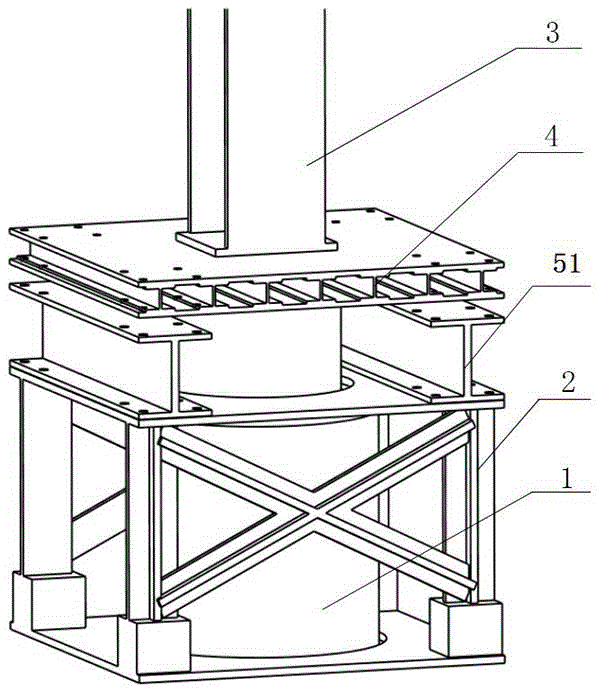

Jacking method and device of steel structure module

ActiveCN104805907AUniform jacking forceAvoid deformationBuilding constructionsProcess operationSteel structures

The invention discloses a jacking method and a jacking device of a steel structure module, and belongs to the technical field of structure module jacking. The jacking method of the steel structure module is characterized in that the sufficient number of hydraulic jacks are arranged according to the size of the steel structure module, a jacking framework platform and a foundation box are placed on the hydraulic jacks, when the hydraulic jacks are in a jacking state, standard joint pad blocks are inserted in two side positions between the foundation box and the jacking framework platform, when the hydraulic jacks are in a falling-back state, loads are transferred onto the standard joint pad blocks, standard joint inserting blocks are inserted between the standard joint pad blocks, the processes of hydraulic jack jacking, standard joint pad block insertion, hydraulic jack falling-back and standard joint inserting block insertion are repeated, and in addition, the adjacent upper and lower layers of standard joint pad blocks form 90-degree crossing until the steel structure module is jacked to the set position. The jacking method and the jacking device have the advantages that the requirements on the fields are low, the received jacking force of the steel structure module is uniform, the deformation cannot easily occur, the jacking process operation is simple and convenient, and a large amount of work can be reduced.

Owner:SINOPEC NANJING ENG & CONSTR +1

Balance weight loading and unloading mechanism for crane as well as crane and loading and unloading method for balance weight

The invention provides a balance weight loading and unloading mechanism for a crane as well as a crane and a loading and unloading method for a balance weight. The balance weight loading and unloading mechanism for the crane comprises a rotary table (10), a balance weight (30) and a frame; the mechanism further comprises a lifting mechanism which is arranged on the rotary table (10) along the vertical direction; a locking cylinder (15) which is arranged on the rotary table (10) along the horizontal direction and is provided with a locking pin; a horizontal connecting plate which is arranged on the balance weight (30) along the horizontal direction and is matched with the lifting mechanism to enable the balance weight (30) to move along the vertical direction; and a vertical connecting plate which is arranged on the balance weight (30) along the vertical direction; the vertical connecting plate is provided with connection holes; and the locking pin is matched with the connecting hole to enable the balance weight (30) to lock or unlock along the horizontal direction. According to the invention, the problem that the balance weight sway in the process of loading and unloading in the prior art is solved; and the process of loading and unloading the balance weight is safer and more stable.

Owner:ZOOMLION HEAVY IND CO LTD

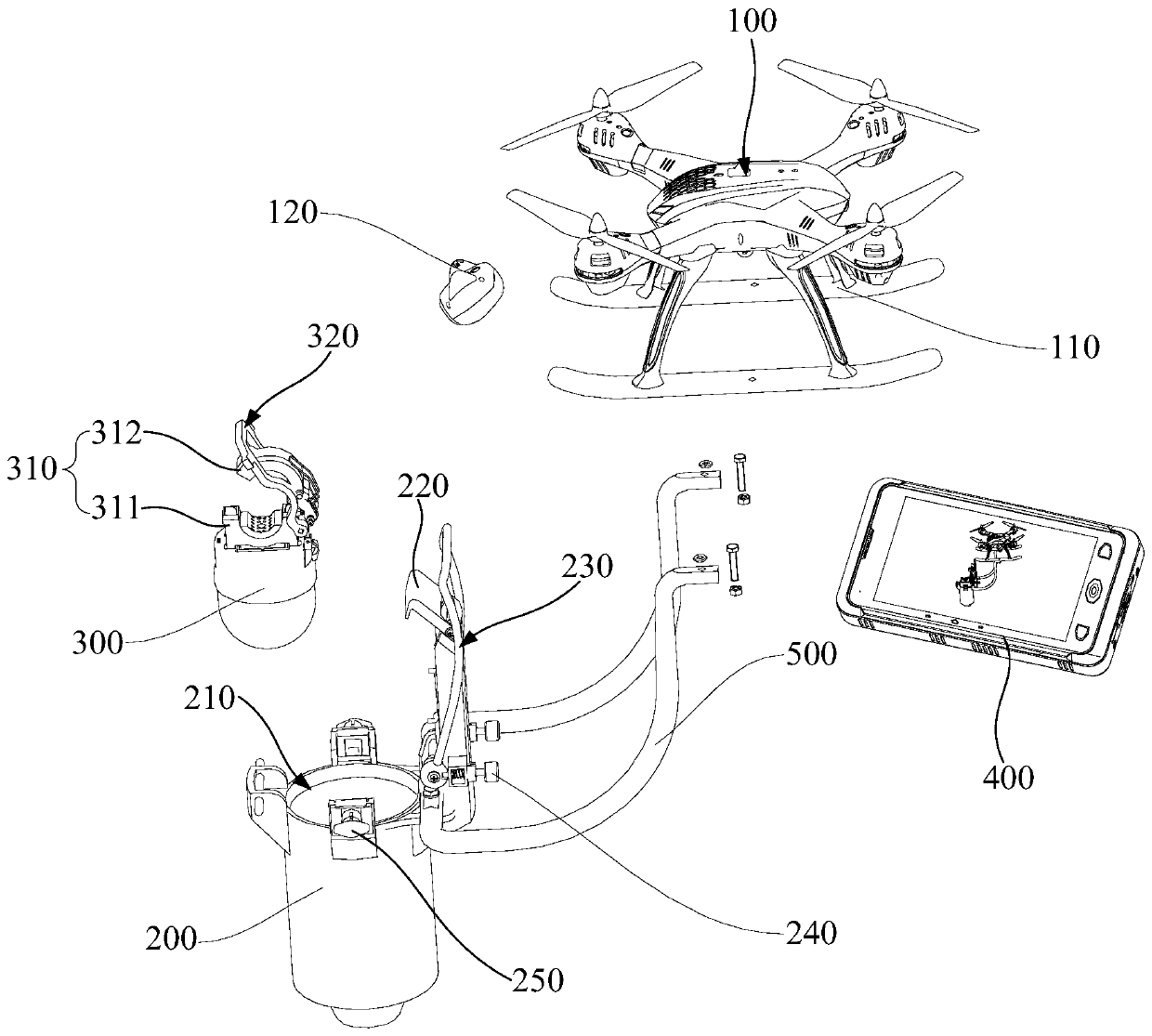

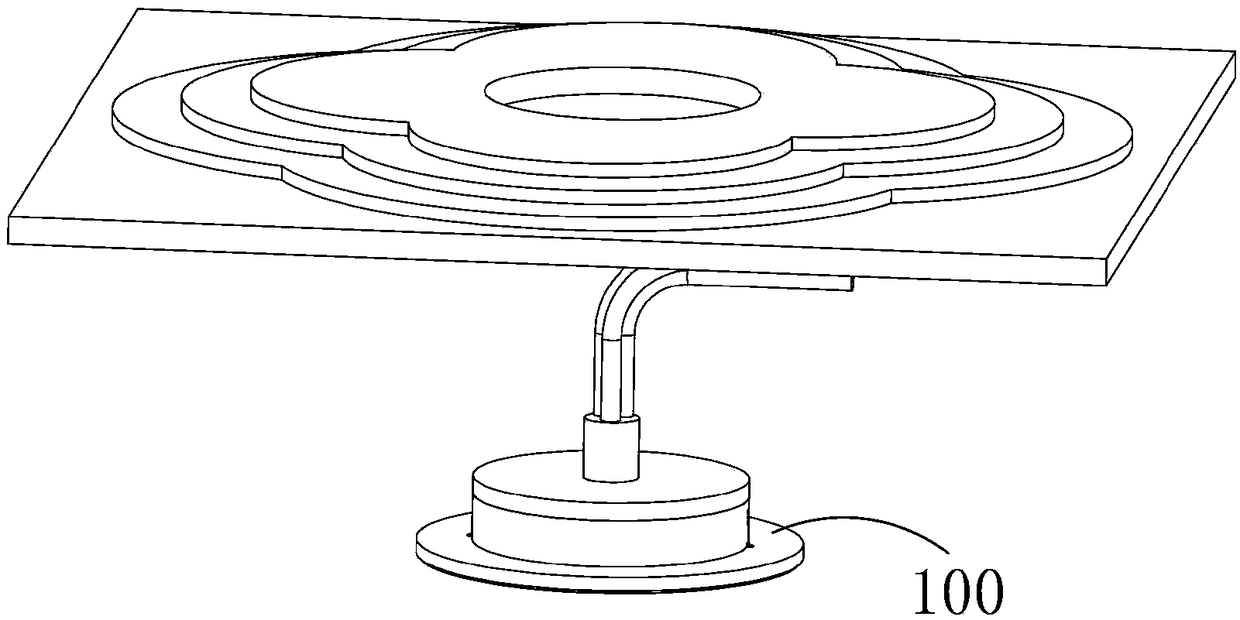

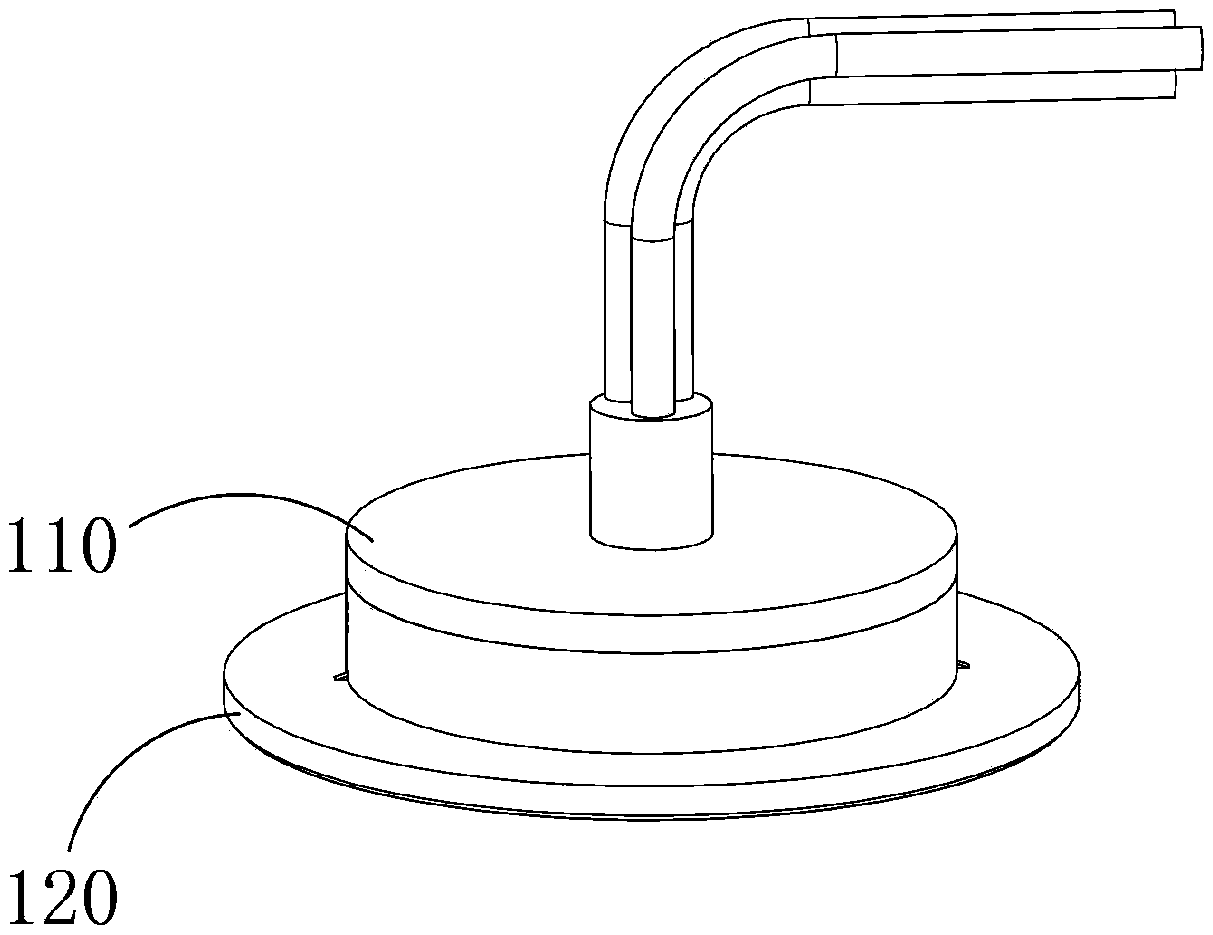

Fault indicator mounting and dismounting method, and fault indicator dismounting tool

PendingCN110380358AEasy to installReliable acquisitionAircraft componentsClosed circuit television systemsFault indicatorElectric power

The invention relates to the technical field of a power line fault indicator device and particularly relates to a fault indicator mounting and dismounting method, and a fault indicator dismounting tool. The mounting method comprises steps that a power taking mechanism of a fault indicator is kept in the open position, a flying device is controlled for taking off to carry a mounting tool and the fault indicator close to a power line; when the power line enters an opening of the power taking mechanism of the fault indicator, the flying device is controlled for flying toward the power line side to make the mounting tool drive the fault indicator to mount on the power line; when the fault indicator is clamped on the power line, the flying device is controlled for flying away from the power line to disengage the mounting tool from the fault indicator. The mounting method is advantaged in that the flying device is utilized to carry the mounting tool to cooperate with the fault indicator, thefault indicator is clamped on the power line to perform power taking detection operation, operation is simple and convenient, the mounting tool can be carried by the flying device to disengage from the fault indicator to perform mounting operation of a next fault indicator, and thereby cost is reduced.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

A hydrogen power system based on heat self-balancing solid hydrogen source reactor

ActiveCN108426169BIncrease profitLow costAircraft componentsVessel mounting detailsAir compressionThermodynamics

The invention discloses a hydrogen power system based on a heat self-balancing solid hydrogen source reactor. The hydrogen power system comprises a hydrogen source, the heat self-balancing solid hydrogen source reactor, a hydrogen fuel cell, an air compression system and a vacuum pump; and an inlet of the heat self-balancing solid hydrogen source reactor is connected with the hydrogen source, an outlet of the heat self-balancing solid hydrogen source reactor is divided into two paths, one path is connected with the hydrogen fuel cell, and the other path is connected with the vacuum pump. According to the hydrogen power system, a phase-change material can store heat released by hydrogen absorption reaction in a latent heat form and release the heat during hydrogen desorption reaction, thus,heat in the hydrogen absorption process is used for the hydrogen desorption process, heating and cooling devices are omitted, the cost is reduced, the energy utilization rate is increased, and meanwhile, the hydrogen absorption and desorption reaction rate can be increased.

Owner:XI AN JIAOTONG UNIV

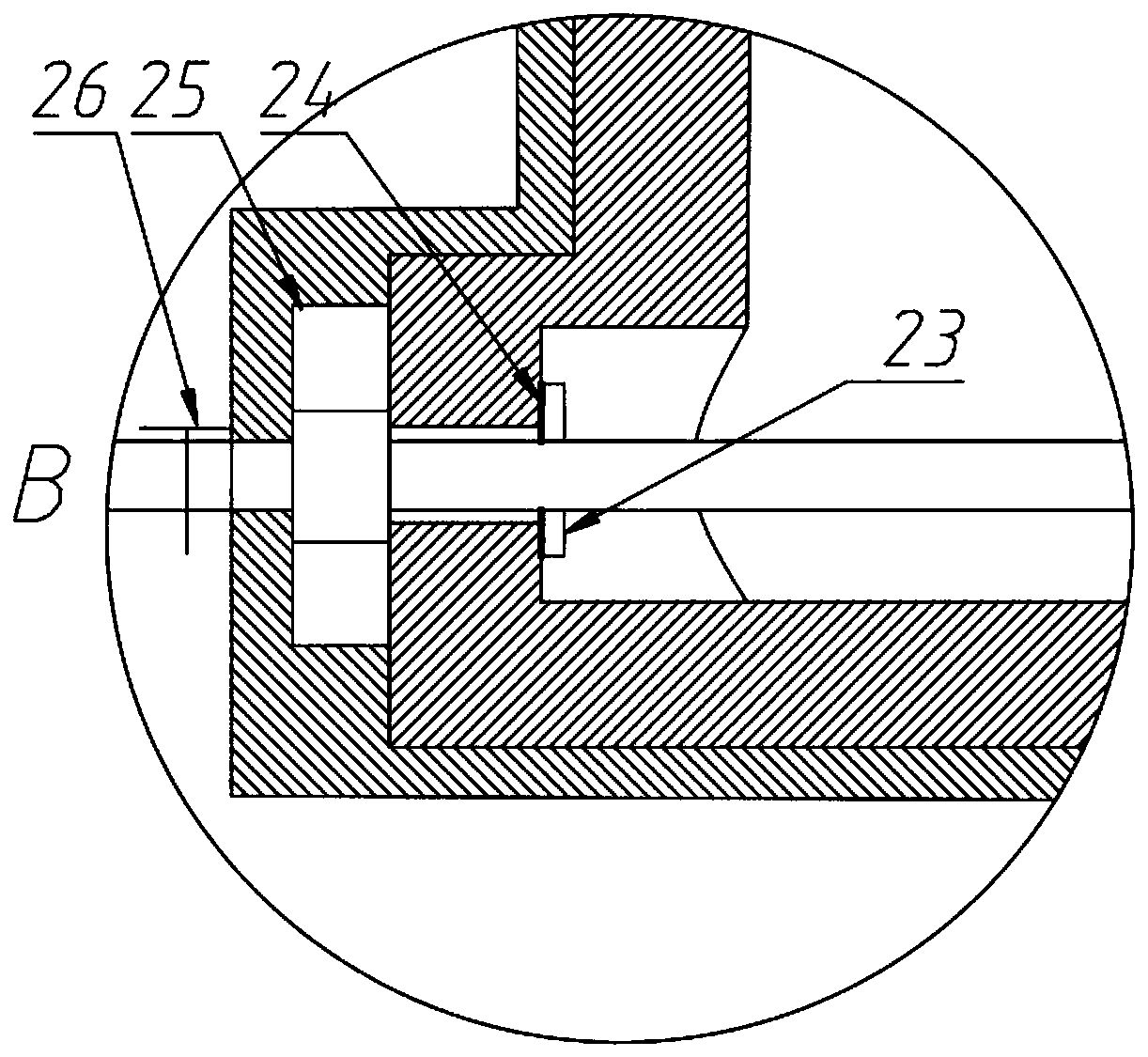

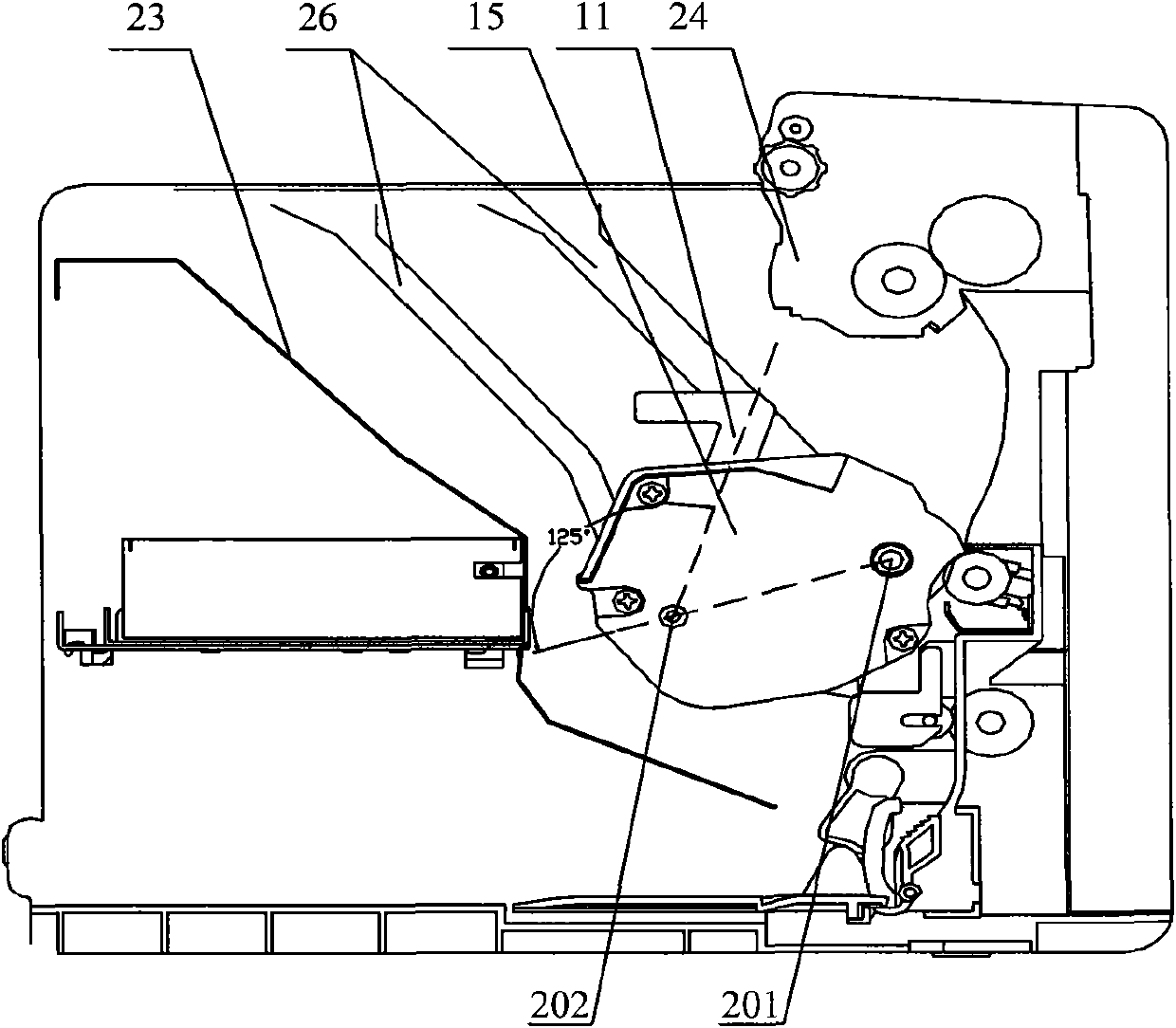

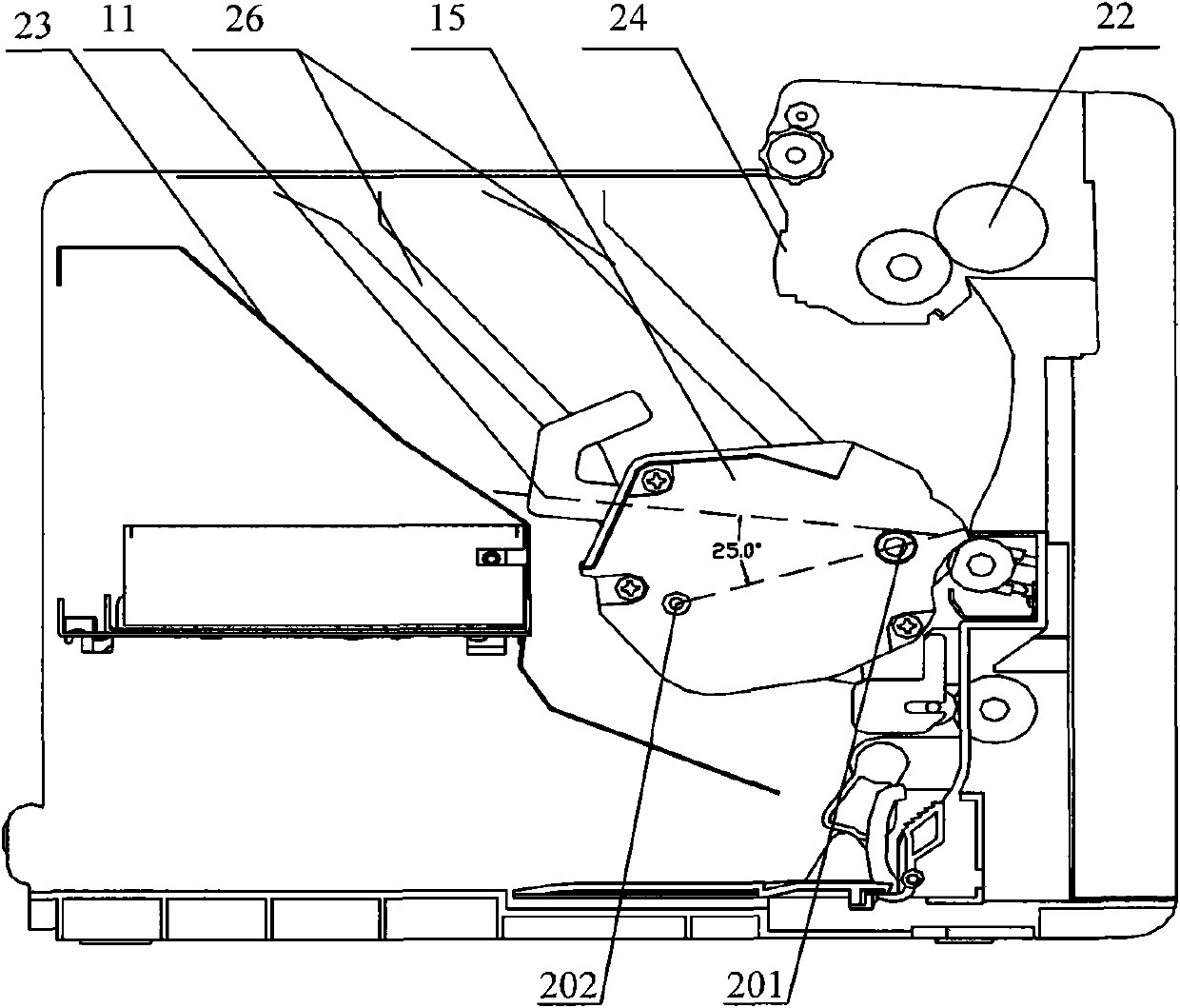

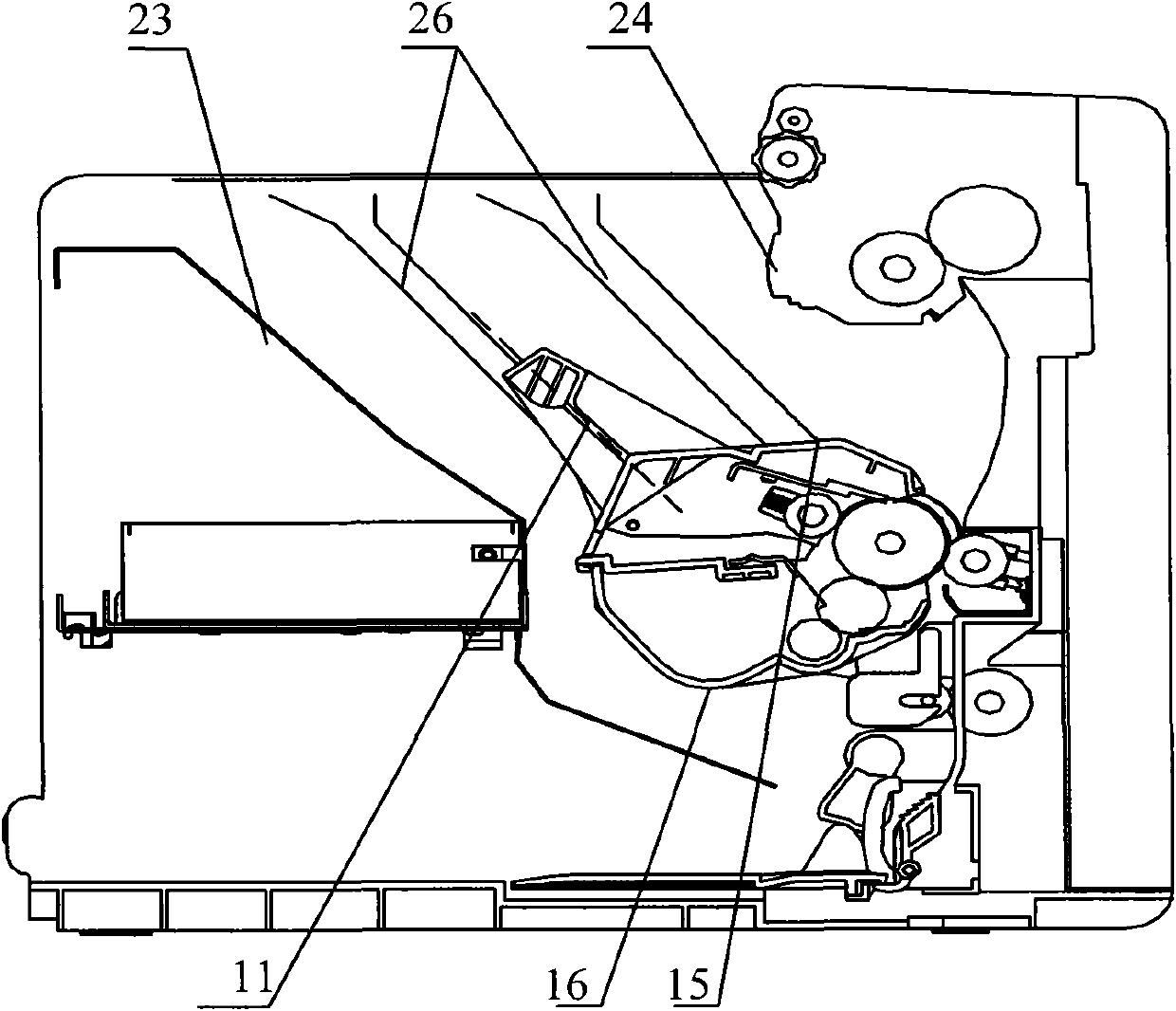

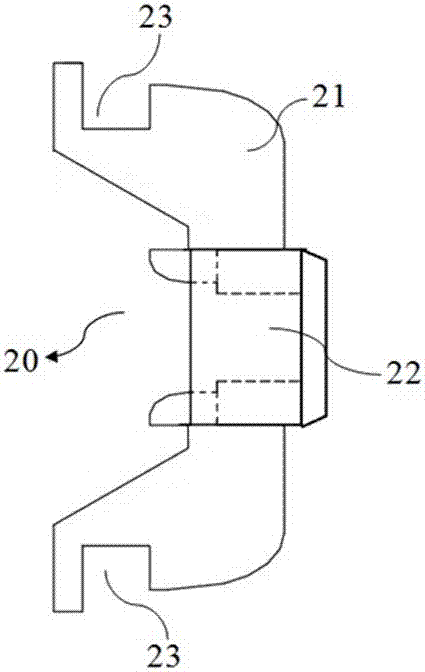

Processing box and image forming device

InactiveCN101950148AEasy to installSafe installationElectrographic process apparatusImage formationEngineering

The invention discloses a processing box and an image forming device. The processing box comprises an upper frame, a lower frame, a handle, a first protrusion and a second protrusion, wherein the first protrusion is coaxial with a photosensitive drum, and the second protrusion is arranged at the downstream side of the first protrusion along the mounting direction; the handle is fixedly connected to the upper frame; and an included angle is formed between the axis of the handle deviating from the direction of the upper frame and a central line or an extension line of the two protrusions along the direction directing to the second protrusion from the first protrusion, and the angle range of the included angle is 25-125 degrees. The invention can guarantee that the processing box can be stably, conveniently and safely arranged in the image forming device by an operator, or the processing box can be stably, conveniently and safely taken down from the image forming device.

Owner:ZHUHAI SEINE TECH CO LTD

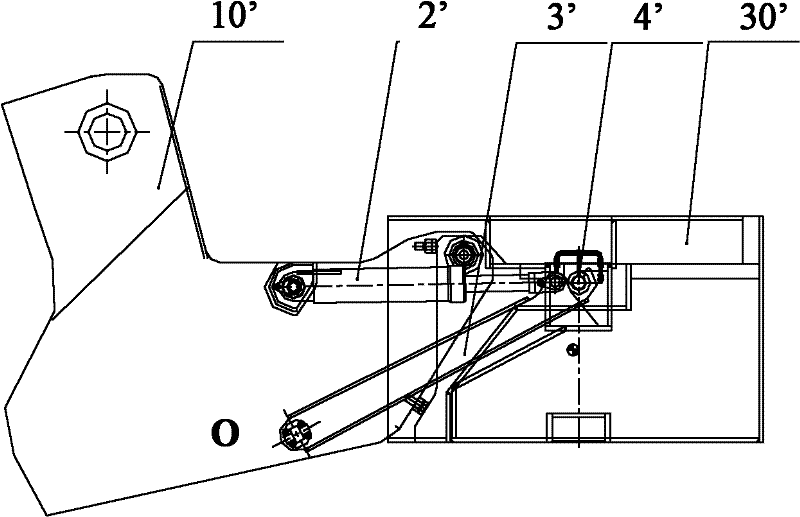

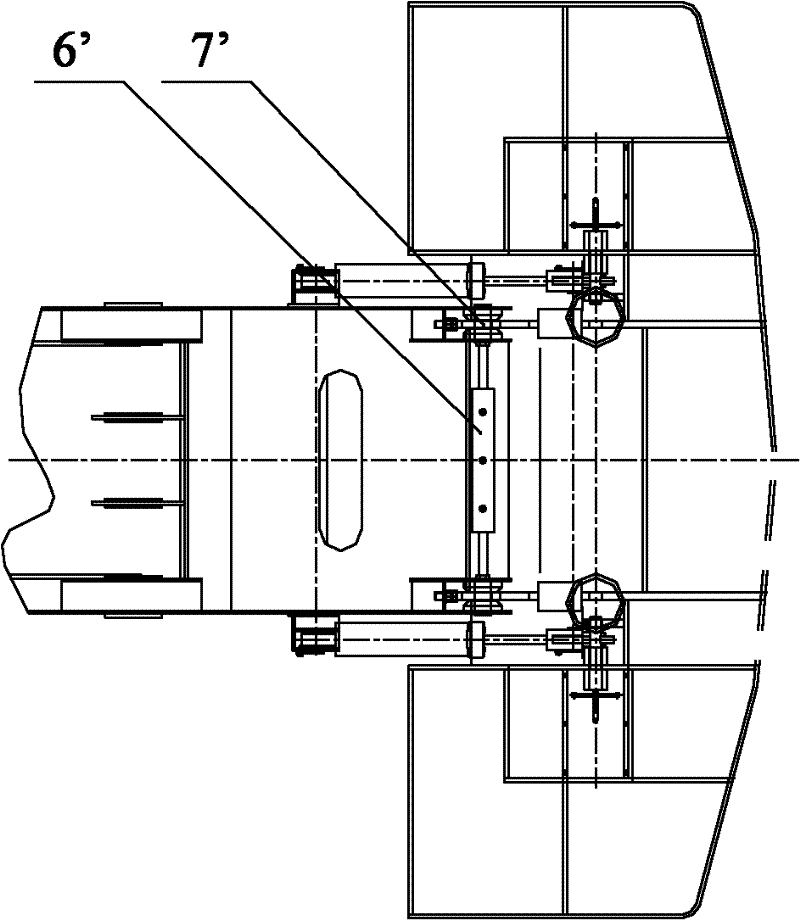

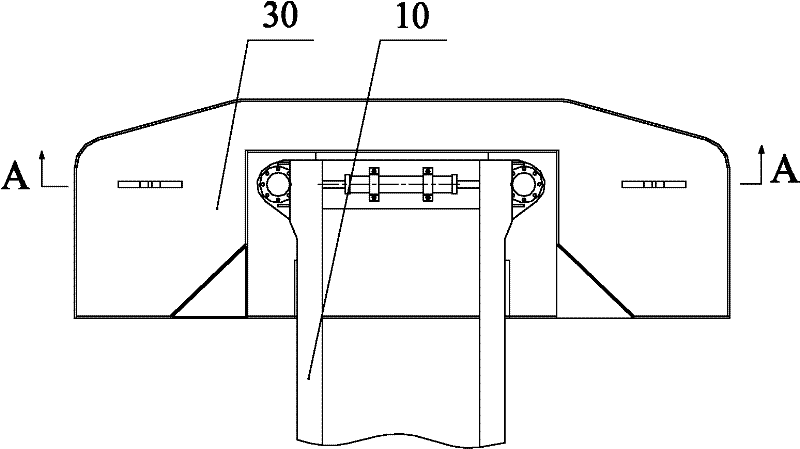

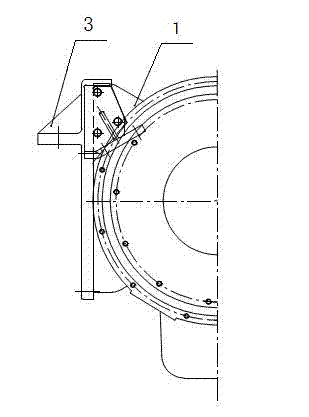

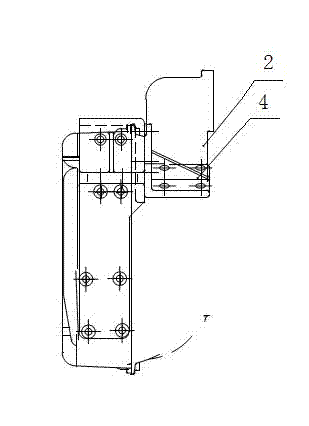

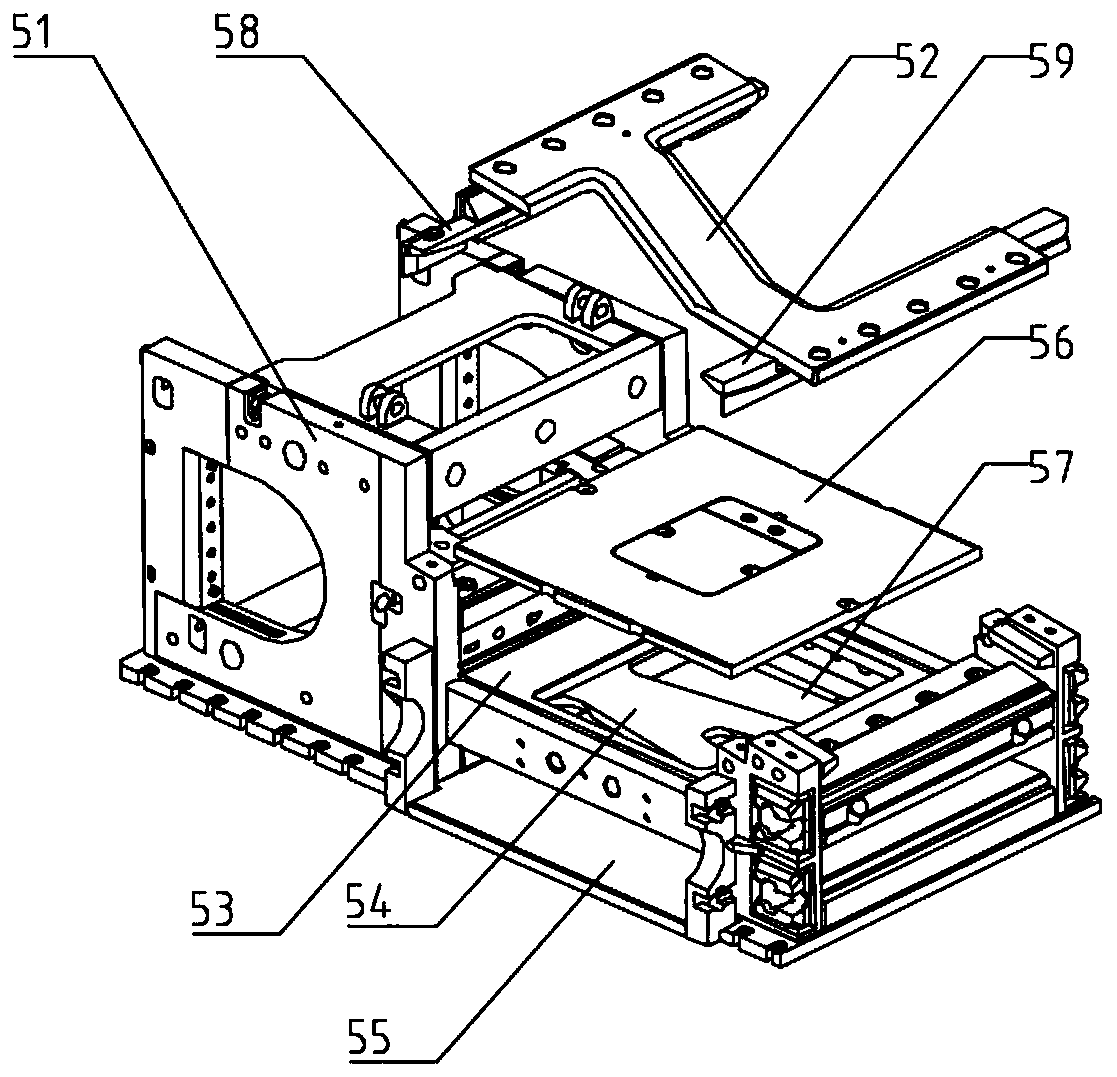

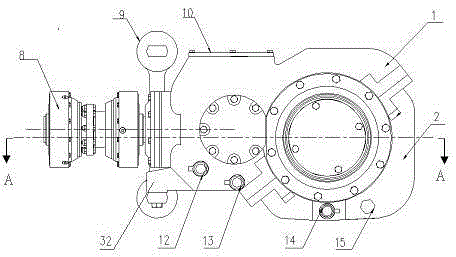

Power assembly rear suspension support mechanism for mining vehicle

InactiveCN102848895AHighlight substantive featuresReduce loadJet propulsion mountingInternal combustion mountingClutchFlywheel

The invention discloses a power assembly rear suspension support mechanism for a mining vehicle. The power assembly rear suspension support mechanism is characterized by comprising a flywheel casing (1), a clutch casing (2) and a power assembly rear suspension support. The power assembly rear suspension support comprises an engine rear suspension support (3) and a gearbox suspension support (4), the engine rear suspension support (3) and the flywheel casing (1) are fixed together, the gearbox suspension support (4) and the clutch casing (2) are fixed together, and the engine rear suspension support (3) and the gearbox suspension support (4) are fixed together. The power assembly rear suspension support mechanism is simple in structure, a load at the rear end of an engine is undertaken jointly through the flywheel casing and the clutch casing, a load at the position of the flywheel casing is reduced, the flywheel casing is effectively protected, failure frequency is reduced, and the power assembly rear suspension support mechanism is convenient to maintain simultaneously.

Owner:SHANDONG PENGXIANG AUTOMOBILE

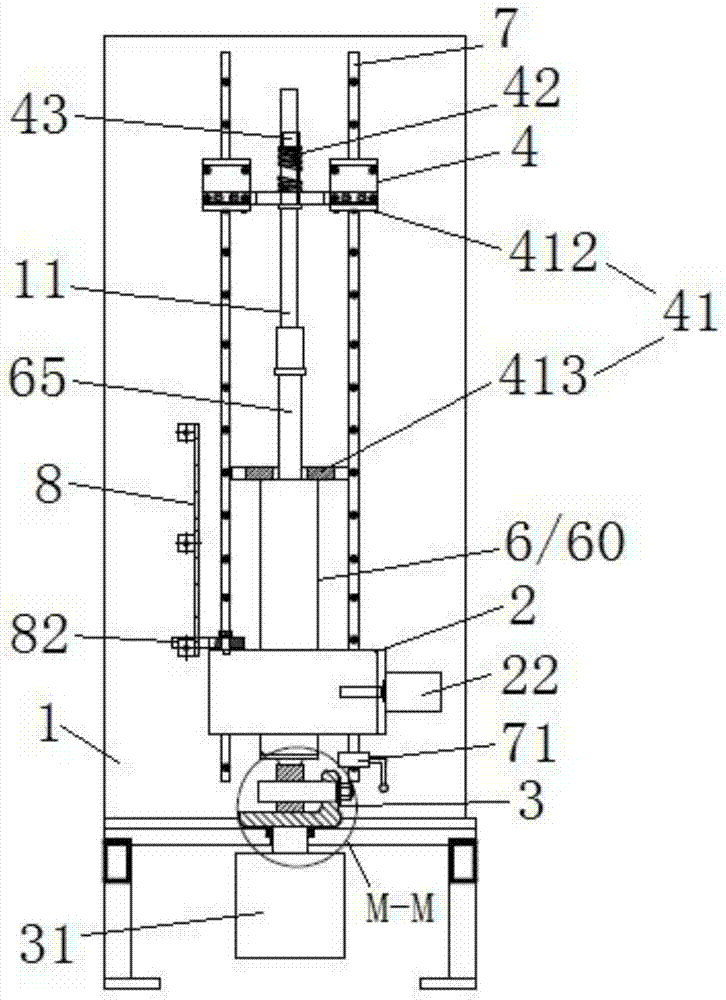

Motor test bench of new energy automobile

ActiveCN108931723ASmooth transmissionEasy to installApparatus for force/torque/work measurementDynamo-electric machine testingTest efficiencyVertical tube

The invention relates to a motor test bench of a new energy automobile. The motor test bench comprises a pedestal; and a lateral mounting plate is arranged at the upper part of the pedestal. The parts, near the four corners, of the bottom of the mounting plate are fixedly connected with the upper part of the pedestal by standing posts. A first through hole is formed in the middle of the top of themounting plate. A vertical bearing base is fixedly installed in the middle of the top surface of the mounting plate; and a vertical transmission shaft is installed in the bearing base movably througha bearing. A vertical high-speed dynamometer motor is fixedly installed in the middle of the upper part of the pedestal; and the upper end of a rotating shaft of the high-speed dynamometer motor andthe lower end of the transmission shaft are connected by a double-diaphragm coupler. On the basis of cooperation of an output shaft and a vertical tube, connection between a tested motor output shaftand the transmission shaft is carried out quickly; and a pin key is drawn out of a key slot when the lower end of a lever is pressed, so that the tested motor output shaft is separated from the vertical tube conveniently based on the design. Therefore, the tested motor is mounted or dismounted conveniently; the mounted and dismounted processes are simplified; the test efficiency is improved effectively; and the labor intensity of the staff is reduced.

Owner:HUNAN MECHANICAL & ELECTRICAL POLYTECHNIC

Wall integrated installation structure

PendingCN107035095AGuaranteed stabilityGuaranteed reliabilityCovering/liningsEngineeringMental detachment

The invention discloses a wall integrated installation structure. The structure comprises a base, a leveling element and an assembly element. A screw of the base is connected with a threaded groove of the leveling element, the threaded groove is screwed on the screw, and the leveling element can be leveled by adjusting the screwing depth of the threaded groove. A keel is arranged outside an arch-shaped plate, and the two ends of the keel are clamped into buckle notches, so that the keel and the leveling element are detachably connected, the keel can be convenient to install and detach, and the keel can be leveled through the leveling element. A decorative plate is connected with the assembly element, the decorative plate can be installed through the assembly element, the assembly element is buckled to the keel so that the assembly element can be convenient to install and detach, and the decorative plate can be convenient to install and detach. Therefore, leveling and installation of the keel and the decorative plate can be achieved through the wall integrated installation structure, installation and detachment of the keel and the decorative plate are easy to implement, the parts are stably connected, and the stability and reliability of the wall integrated installation structure can be ensured.

Owner:QINGDAO YOUZHU INFORMATION TECH CO LTD

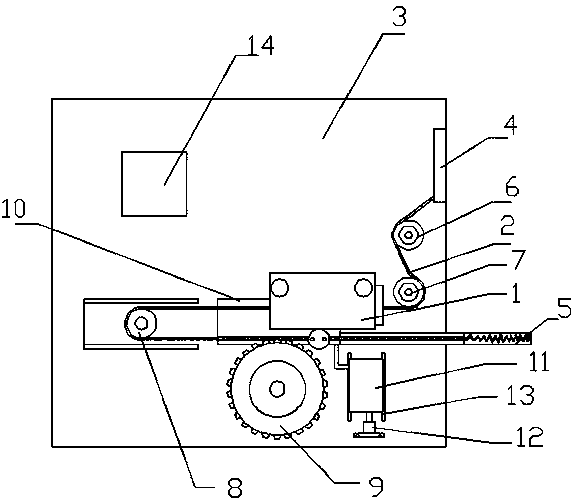

Chain dismounting device

InactiveCN104190853AReduce laborQuick disassemblyMetal chainsMetal chainmaking toolsPunch pressSprocket

The invention discloses a chain dismounting device which comprises a rack, a punching machine, a chain running rail, chain wheels and a drive mechanism. The rack is provided with a work table board, the chain running rail is arranged on the work table board, the chain wheels are arranged on the rack and protrude out of the work table board, the chain wheels are arranged next to the chain running rail, the punching machine is arranged on the work table board, a puncher pin of the punching machine is arranged over the chain running rail, and the drive mechanism is connected with the chain wheels and drives the chain wheels to rotate. According to the device, manpower is not needed for chain dismounting, mechanical chain dismounting is completely achieved, manpower is replaced with the machine, dismounting efficiency is greatly improved, usage manpower is reduced, and the production cost of enterprises is lowered.

Owner:HUZHOU GUANGHENG CHAIN

Device for robot talkback

InactiveCN107965641AEasy to installEasy to disassembleTelevision system detailsColor television detailsEngineeringScrew thread

The invention discloses a device for robot talkback. The device comprises a base. A supporting column is fixedly mounted on the top side of the base. A cavity is formed in the supporting column. A rotary motor is fixedly mounted on the inner wall of the bottom side of the cavity. An output shaft of the rotary motor extends to the upper portion of the supporting column and is fixedly provided witha rotating block. An LED lamp tube is fixedly mounted on the top side of the rotating block. A fixed block is rotationally mounted on one side of the rotating block through a hinge. A mounting grooveis formed in the side, away from the supporting column, of the fixed block. A microphone used for voice talkback is fixedly mounted in the mounting groove. A sliding groove is formed in the side, close to the supporting column, of the fixed block. A sliding block is mounted in the sliding groove in a sliding manner and provided with a threaded hole. According to the device, the direction positionsand angle positions of a camera and the microphone can adjusted conveniently and stably, use and operation are facilitated, meanwhile, the camera can be mounted and demounted conveniently and stably,and detection and maintenance of the camera are facilitated.

Owner:泉州市科恩智能装备技术研究院有限公司

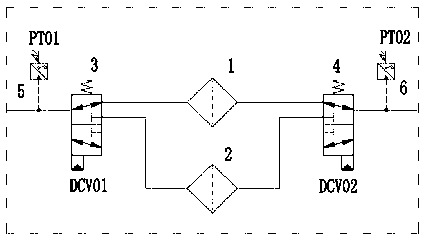

Hydraulic filter with filter elements capable of being replaced online and replacement method of hydraulic filter

PendingCN108825595ATo achieve the purpose of automatic switching controlAvoid delayFluid-pressure actuator componentsInlet valveEngineering

The invention provides a hydraulic filter with filter elements capable of being replaced online. The hydraulic filter comprises two single-barrel filters connected in parallel. Each of the joint of oil inlets of the two single-barrel filters and the joint of oil outlets of the two single-barrel filters is provided with a two-position three-way electromagnet. A pressure switch is arranged in frontof an inlet of one two-position three-way electromagnet. A pressure switch is arranged on an outlet of the other two-position three-way electromagnet. One two-position three-way electromagnet is provided with an inlet valve port and two outlet valve ports, and the two outlet valve ports of the two-position three-way electromagnet are connected with inlets of the single-barrel filters. The other two-position three-way electromagnets is provided with two inlet valve ports and an outlet valve port, and the two inlet valve ports of the two-position three-way electromagnet are connected with outlets of the single-barrel filters. Each two-position three-way electromagnet is provided with one valve element, a valve body and an electromagnetic coil. It is achieved that the blocked filter elementsare replaced and the whole filter is dismounted, mounted and maintained in the normal operation process of a hydraulic system, the delay of manual operation is avoided, the automation degree is increased, and a strong supporter is provided for normal work of the hydraulic system.

Owner:辽宁三三工业有限公司

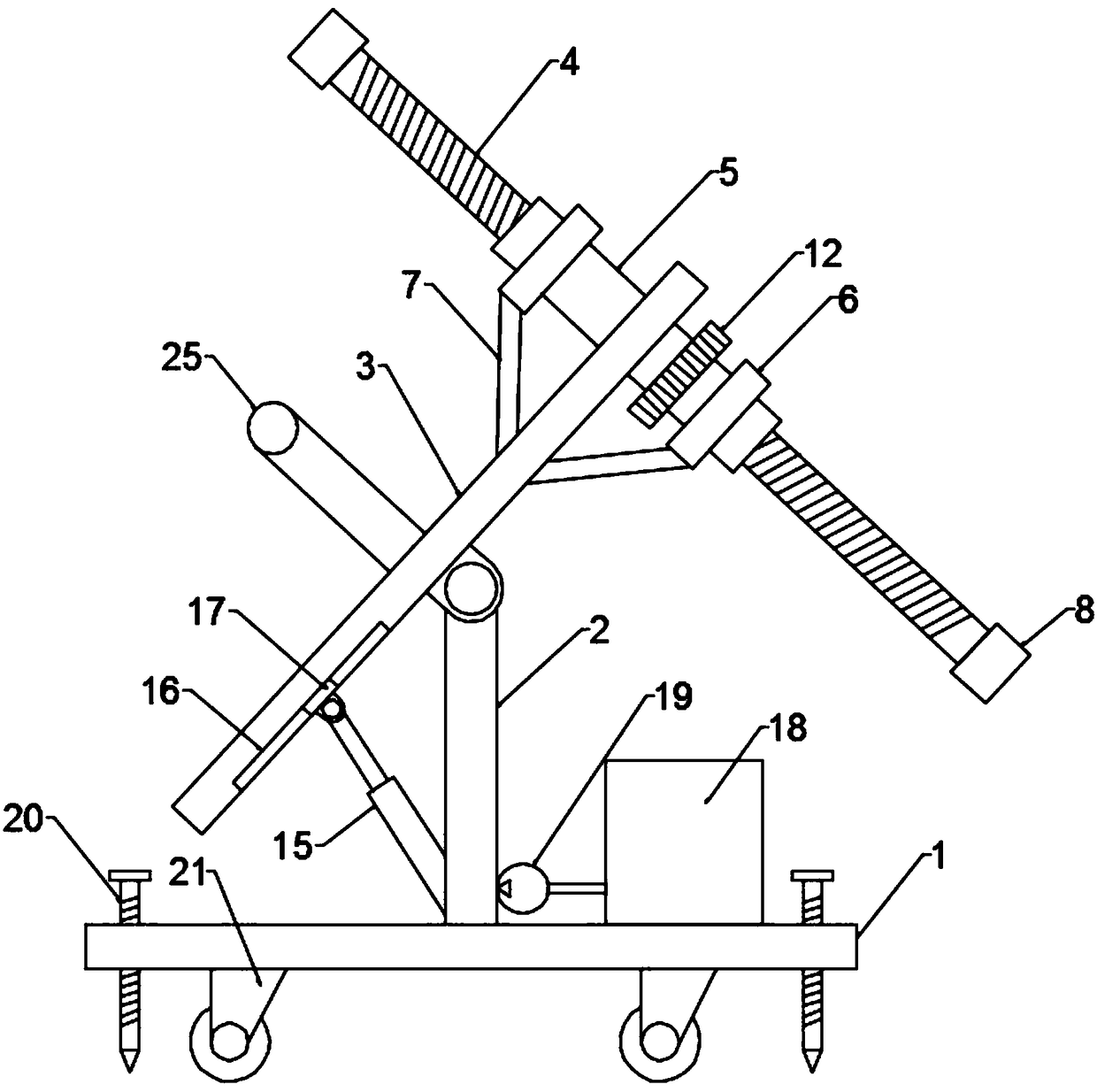

Garden toppled-tree supporting device

InactiveCN109275489AConvenient rightingHold steadyCultivating equipmentsGear wheelElectric machinery

Owner:吴丹花

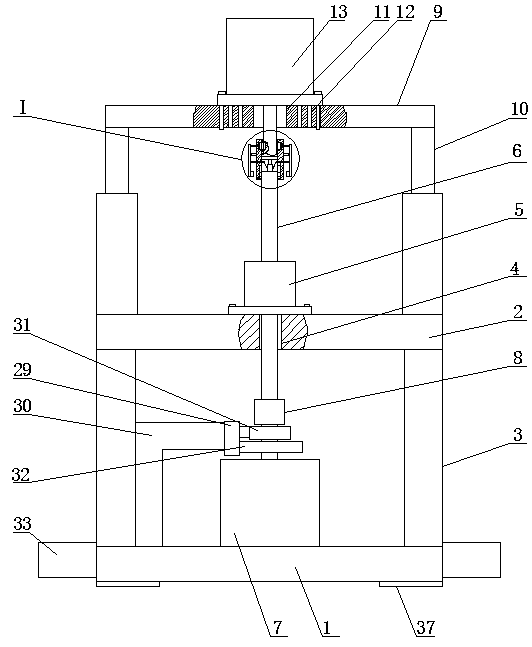

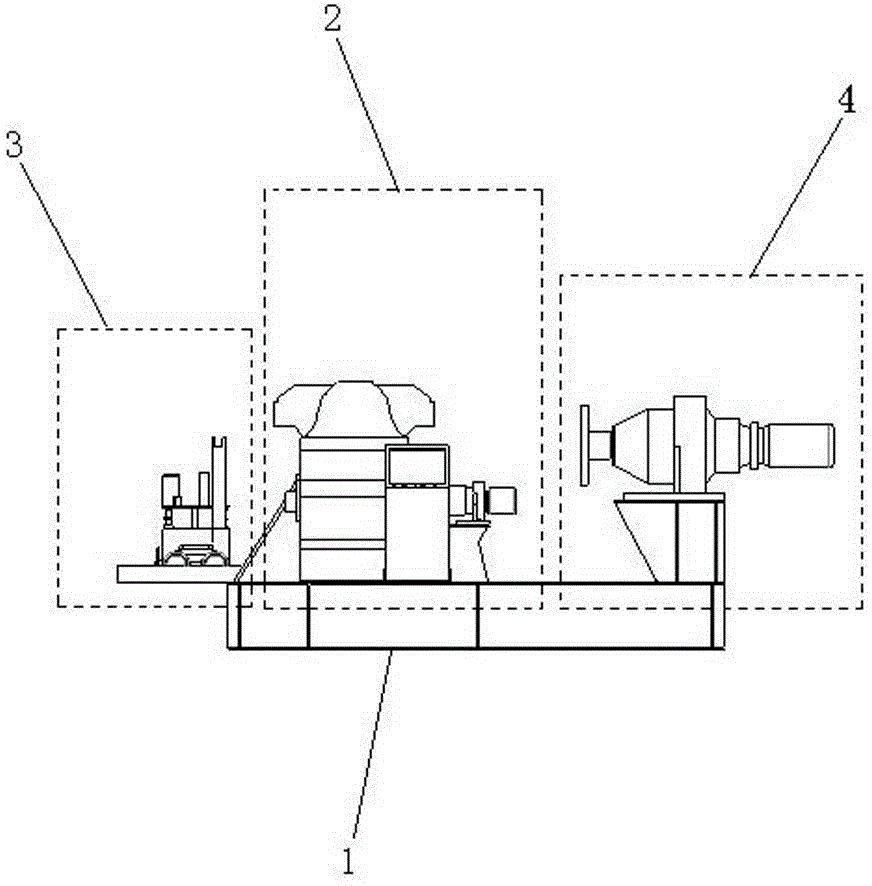

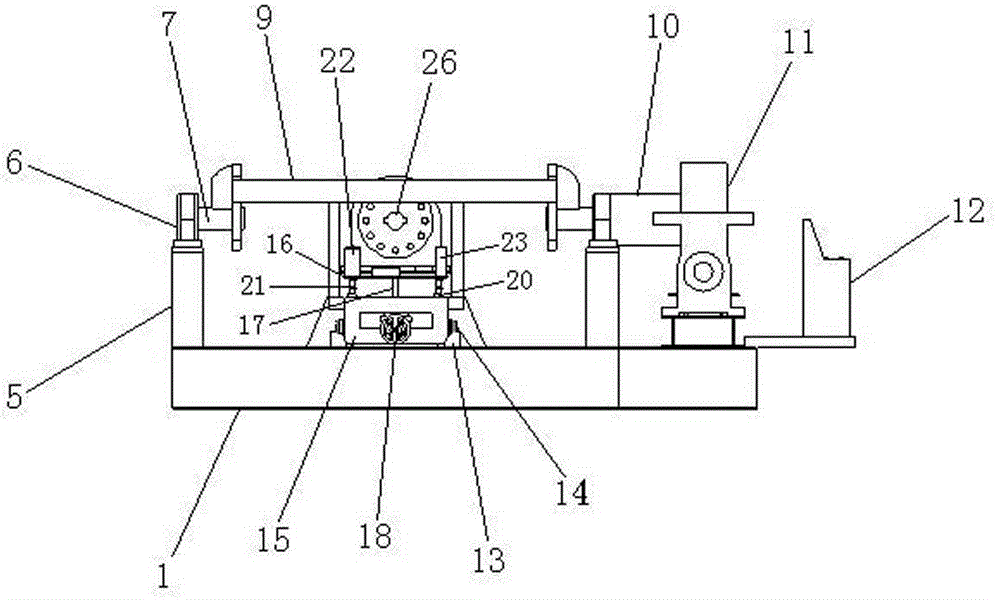

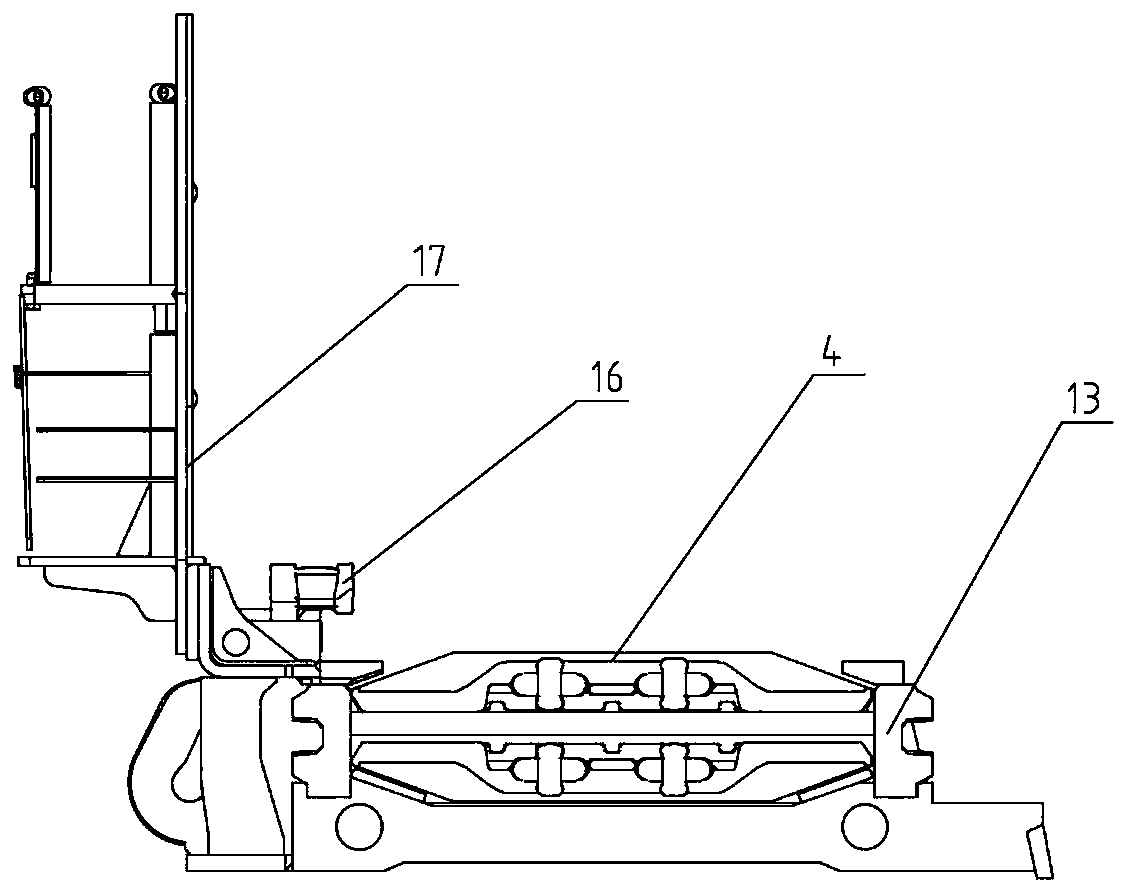

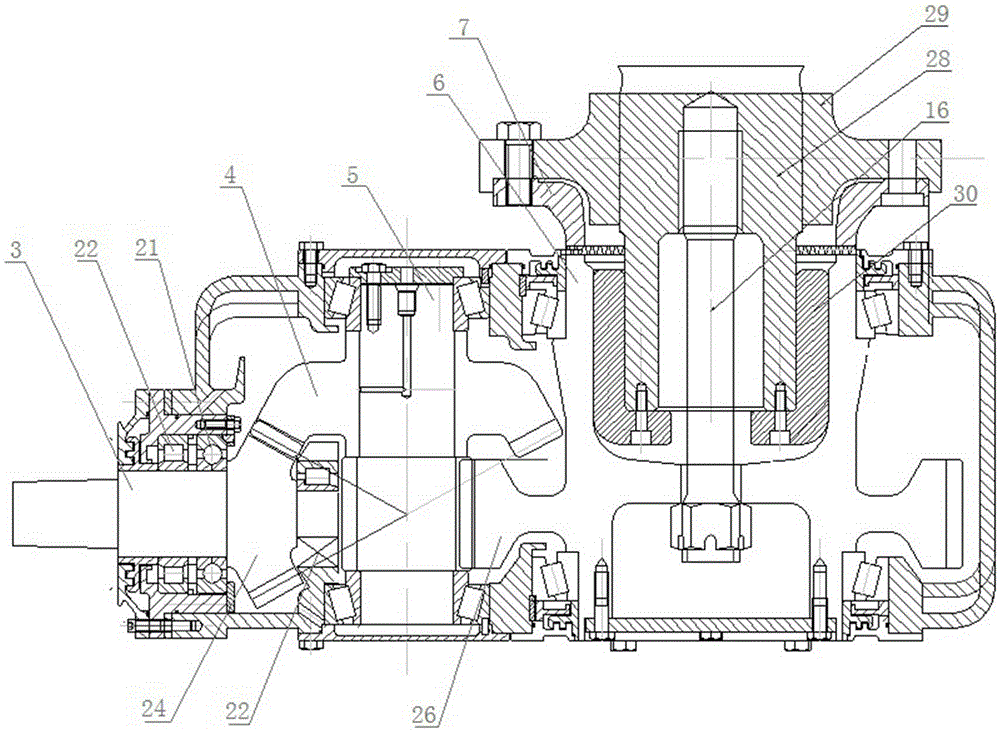

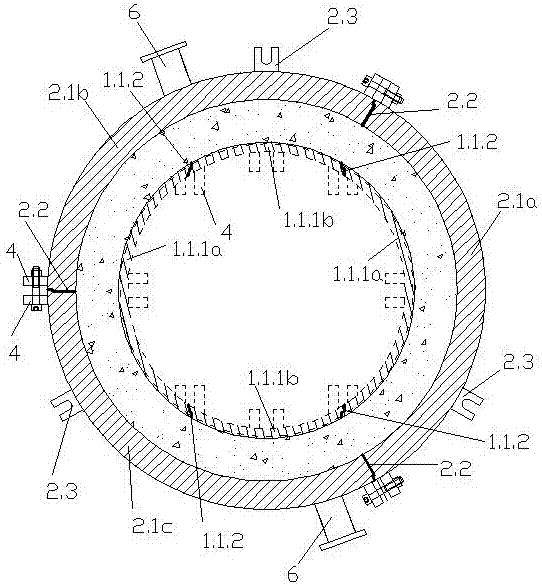

Comprehensive maintenance platform of vertical mixed-flow pump

ActiveCN104526657ATroubleshoot disassemblySolve the installationWork benchesMetal working apparatusImpellerMixed flow

The invention belongs to a comprehensive maintenance platform of a vertical mixed-flow pump. The comprehensive maintenance platform comprises a base, wherein a bearing body overturning mechanism is arranged at the left side of the upper surface of the base; an impeller adjusting mechanism is arranged below the bearing body overturning mechanism; an impeller loading / unloading mechanism is arranged at the right side of the upper surface of the base; the bearing body overturning mechanism comprises a trapezoidal bracket, bearings on the upper surface of the trapezoidal bracket, an overturning platform between the bearings, a speed reducer connected with one end of a bearing base, a driving motor connected with the speed reducer, and an electric control operation box; the impeller adjusting mechanism comprises a rail on the base, a sliding car on the rail, a lifting platform above the sliding car, a torque sensor on the upper surface of the lifting platform, and an impeller positioning block; and the impeller loading / unloading mechanism comprises a frame, a planetary speed reducer, a coupling and a motor. The comprehensive maintenance platform solves the problems of inconvenience for disassembly, mounting and detection of the vertical mixed-flow pump, is specifically suitable for the maintenance operation of large-scale assembly line total installed capacities, reduces the labor intensity of maintenance men, improves the working efficiency, and eliminates the potential safety hazards in the maintenance process.

Owner:SDIC XINJIANG LUOBUPO POTASH CO LTD

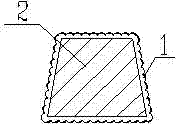

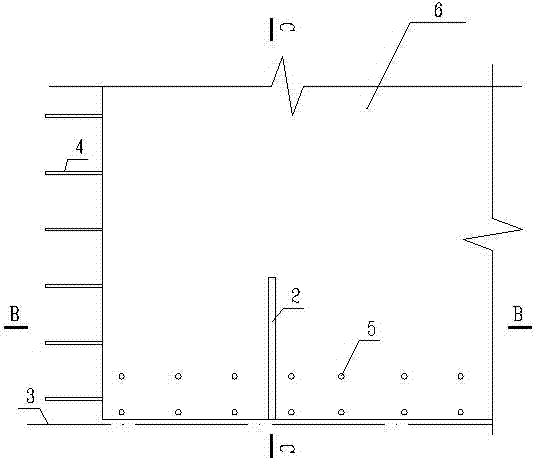

Construction method for reserving water feed pipe grooves in prefabricated shear wall

InactiveCN104727552AReduce dosageStable disassemblyForms/shuttering/falseworksBuilding material handlingRebarKraft paper

The invention provides a construction method for reserving water feed pipe grooves in a prefabricated shear wall. The method includes the following steps of firstly, manufacturing a trapezoid component (2); secondly, wrapping a layer of draft paper or plastic paper (1) on the outer side of the trapezoid component (2) for standby application; thirdly, placing a reinforcing steel bar framework (4) on a shear wall body (6) after the reinforcing steel bar framework (4) is manufactured, placing the trapezoid component (2) on the reinforcing steel bar framework (4), and then fixing the trapezoid component (2) to the reinforcing steel bar framework (4); fourthly, checking the trapezoid component (2) so that the trapezoid component (2) can not be covered with concrete after the concrete is poured on the shear wall body (6), wherein the upper side face of the trapezoid component (2) needs to be flush with the outer side face of shear wall body (6); fifthly, detaching the trapezoid component (2) after the shear wall body (6) is solidified and mold removal is conducted, wherein the trapezoid component (2) can be repeatedly used. By means of the method, material saving and environment protection are achieved, the pipe grooves and the shear wall body are formed through one-time pouring, the trapezoid component can be reused after being detached, and the construction method is suitable for the construction process of fabricated type building prefabricated shear wall components.

Owner:香港华艺设计顾问(深圳)有限公司

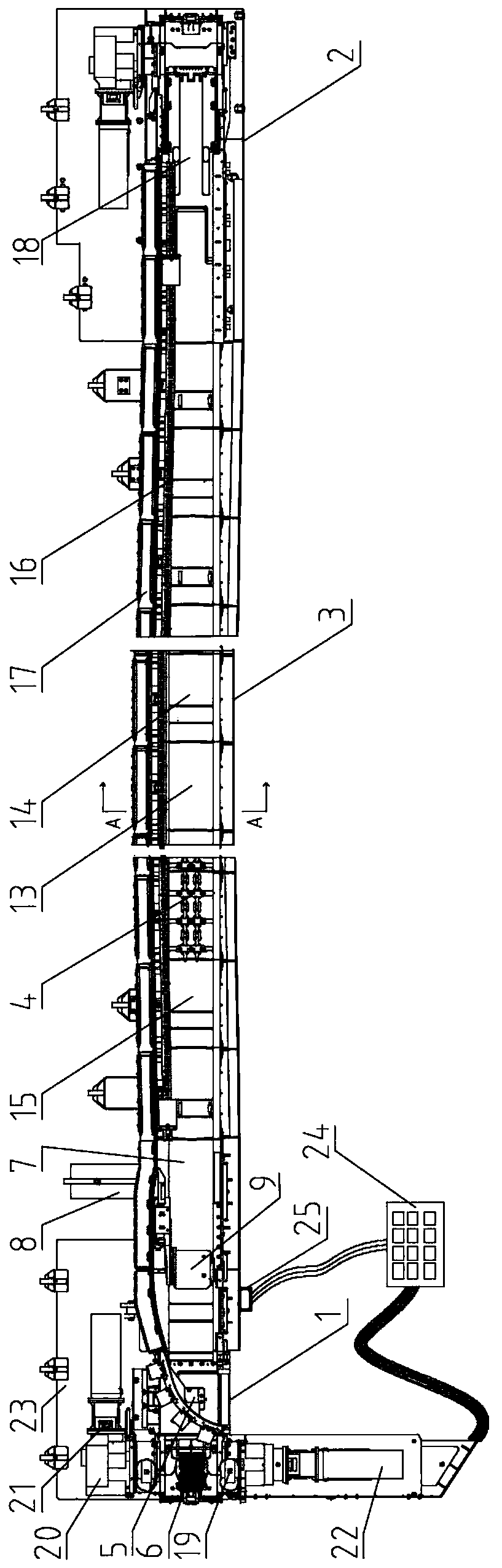

Extra-large-mining-height high-voltage frequency conversion integrated drive type scraper conveyor

The invention relates to an extra-large-mining-height high-voltage frequency conversion integrated drive type scraper conveyor, and belongs to the field of coal mine transportation equipment. The extra-large-mining-height high-voltage frequency conversion integrated drive type scraper conveyor comprises a machine head part, a machine tail part, a middle section and a circulating rotating scraper chain; the machine head part comprises a crossed side unloading machine head frame and is connected to the middle section through a transition slot; the middle section includes a middle slot, a skylight opening slot and a changeover slot, and one side of the middle section is equipped with a coal mining machine traction pin track and a cable groove; the machine tail part comprises an automatic telescopic machine tail frame; chain wheel assemblies on the machine head part and the machine tail part are connected with parallel transmission devices, and the chain wheel assembly on the machine headpart is also connected with a vertical transmission device; and the scraper conveyor is connected with a comprehensive mechanized coal mining face centralized control system, and the comprehensive mechanized coal mining face centralized control system is connected with an automatic speed regulation device. The extra-large-mining-height high-voltage frequency conversion integrated drive type scraper conveyor can be suitable for large coal mines being ten million tons or more, has the functions of automatic tensioning, automatic speed regulation and overload protection, can achieve smooth startunder the full load condition and improves the safety performance and the maintenance performance of the whole machine.

Owner:LIANYUNGANG TIANMING EQUIP

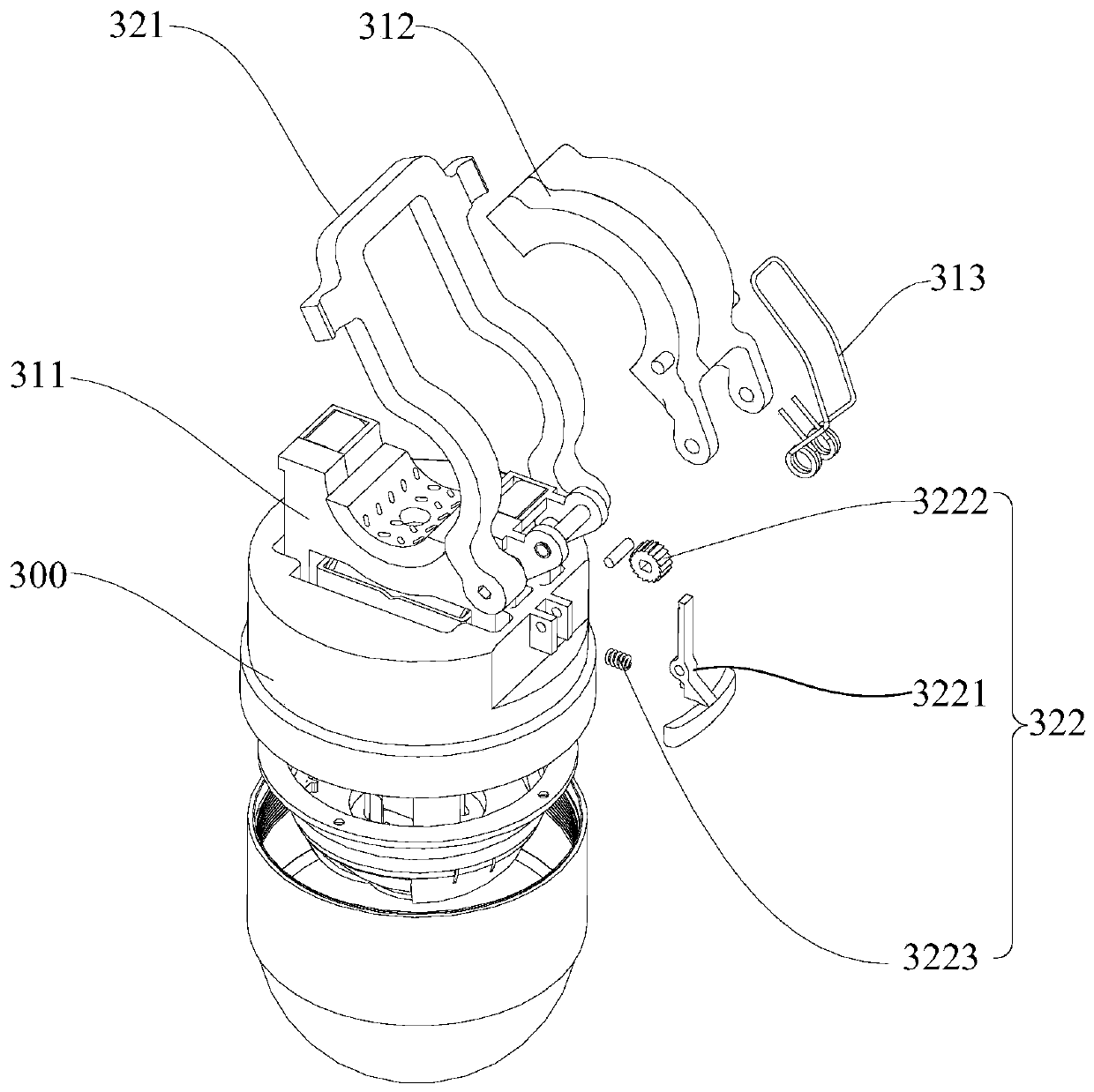

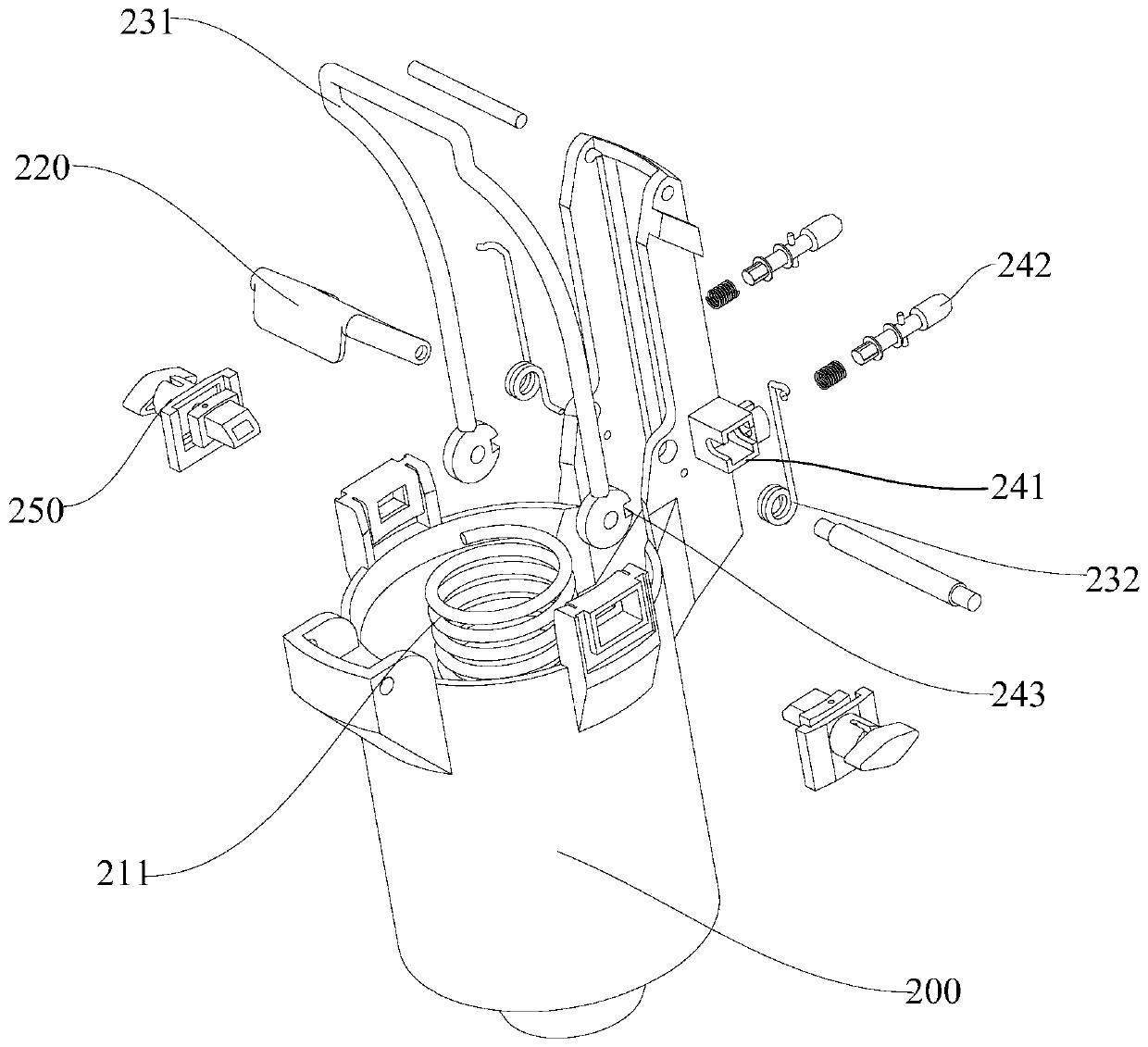

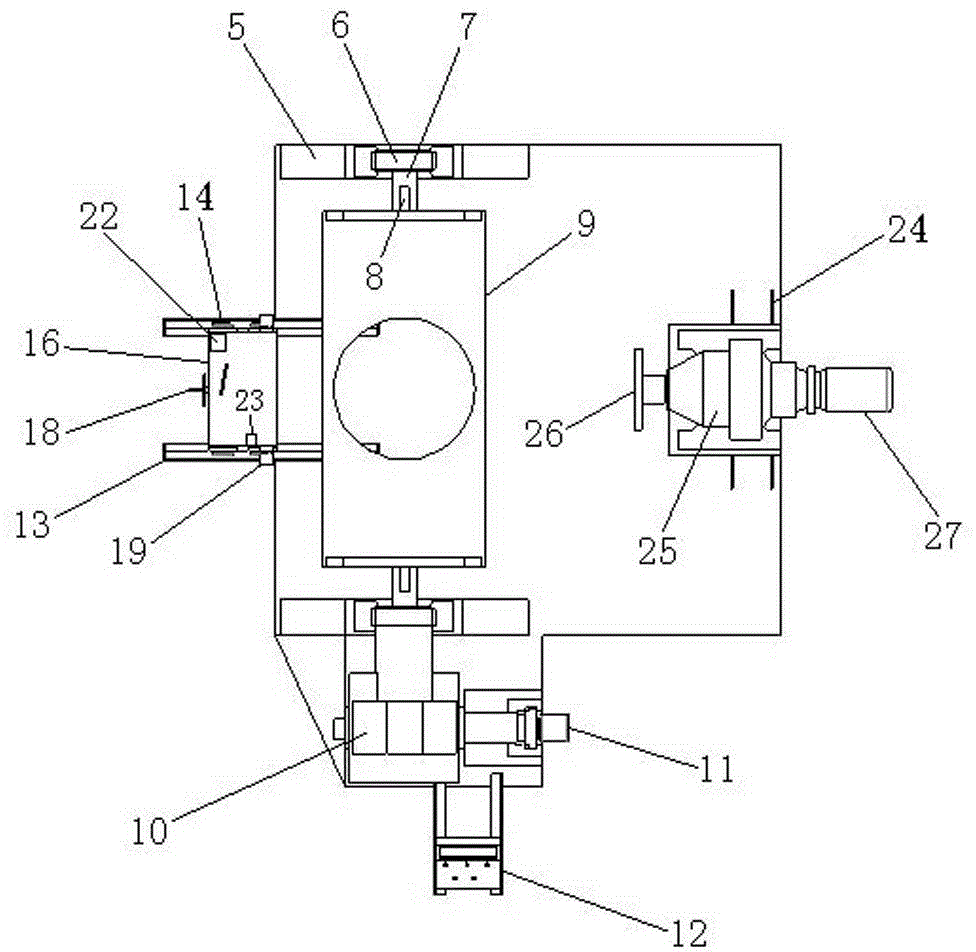

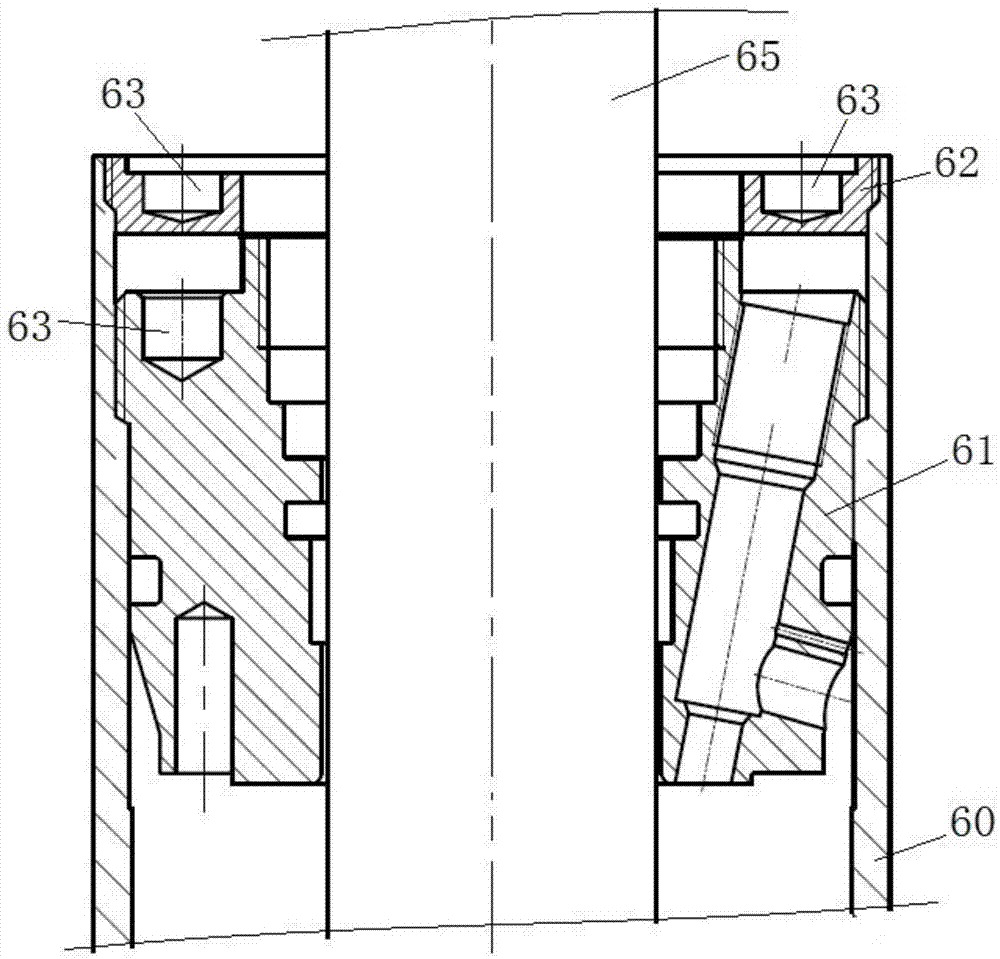

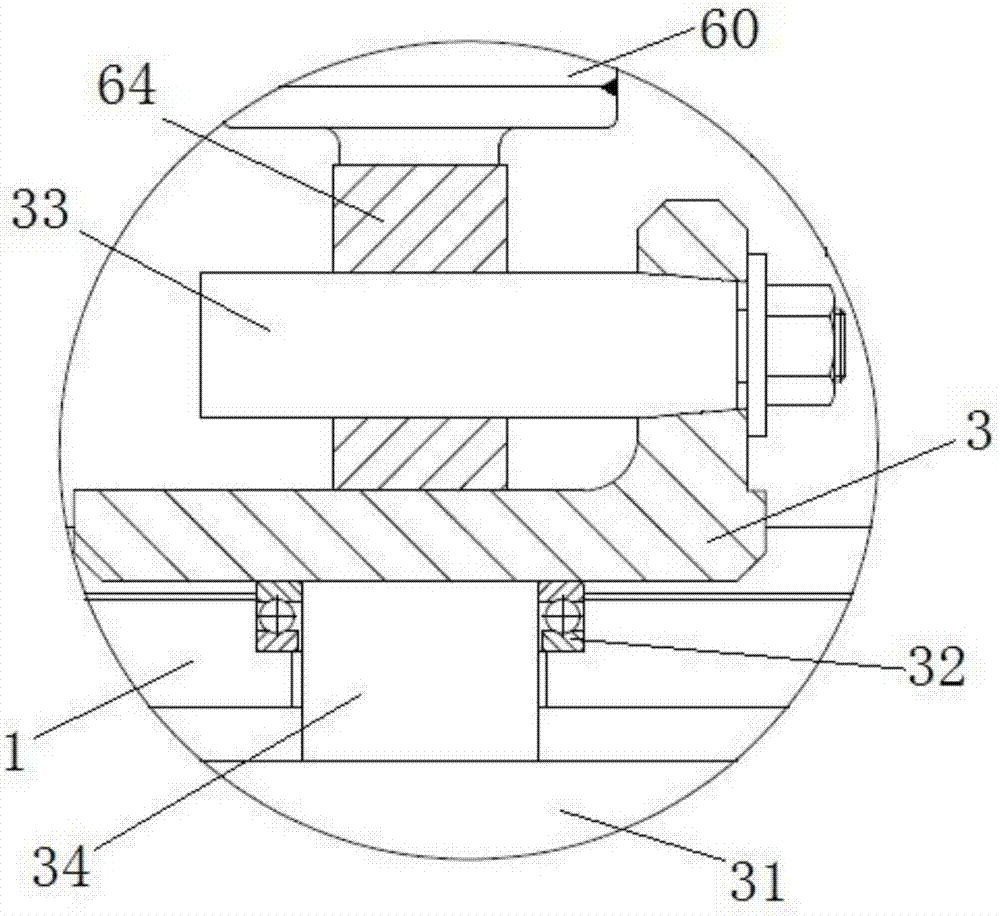

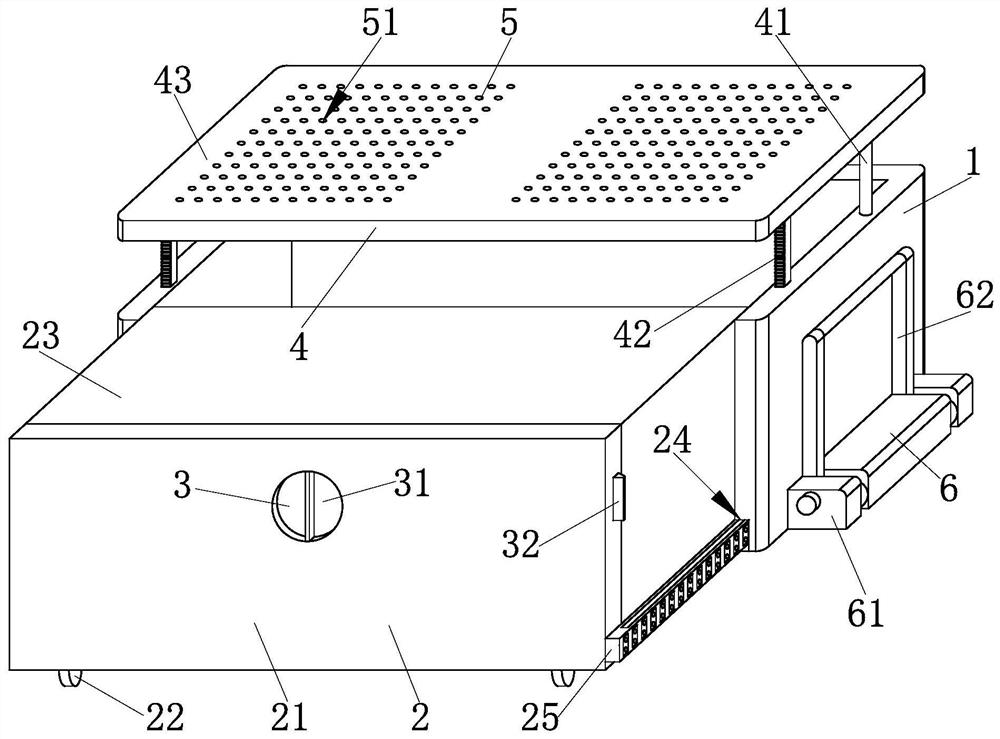

Thread dismounting device applicable to oil pressure vibration reducer

PendingCN107350782AEasy clampingClamp firmlyMetal working apparatusVehicle dissasembly recoveryElastic componentScrew thread

The invention provides a thread dismounting device applicable to an oil pressure vibration reducer. The device comprises a frame (1), and a centering clamping mechanism (2), a rotating frame (3) and a spanner module (4) respectively arranged on the frame; the centering clamping mechanism can enable the oil pressure vibration reducer to be dismounted to rotate during being positioned and clamped; the rotating frame (3) is rotationally arranged on the frame (1), and the rotating axis line of the rotating frame is overlapped with the positioning center line of the centering clamping mechanism; the spanner module (4) comprises a clamping pressure plate (41) and an elastic part (42); a positioning key (410) for preventing rotation of a guide bearing or an external screw cover in the dismounting process is arranged at the bottom of the clamping pressure plate; and the elastic part (42) is used for compensating the retreating displacement of the guide bearing or the external screw cover. The device can realize quick dismounting of the guide bearing or the external screw cover, is strong in power, needs no preheating and baking to damage fastening glue, relives the labor intensity, and improves the working efficiency and quality.

Owner:ZHUZHOU LINCE GRP +1

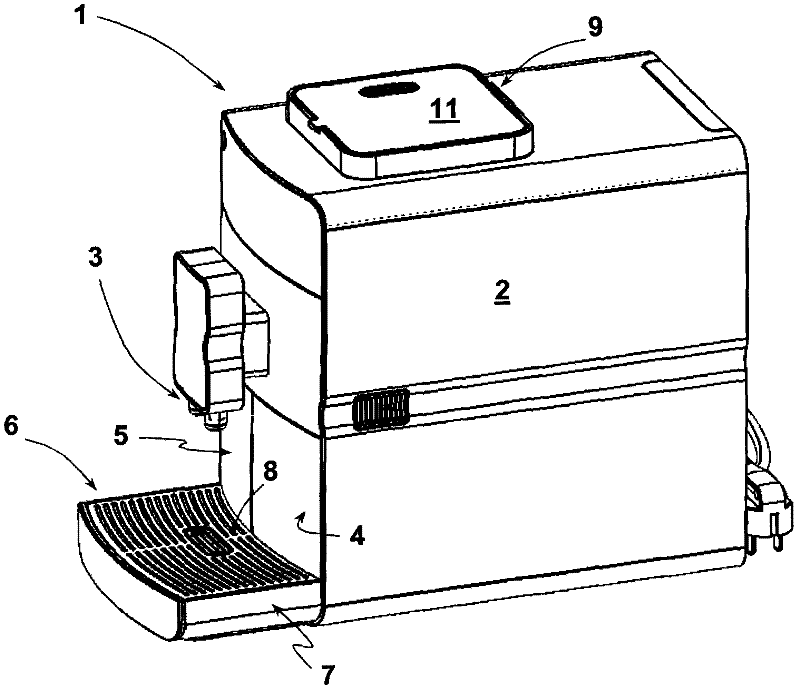

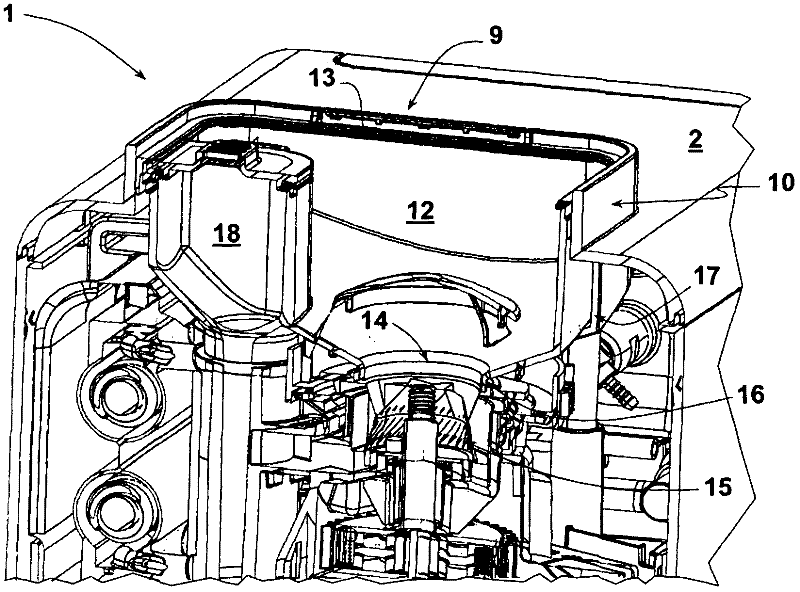

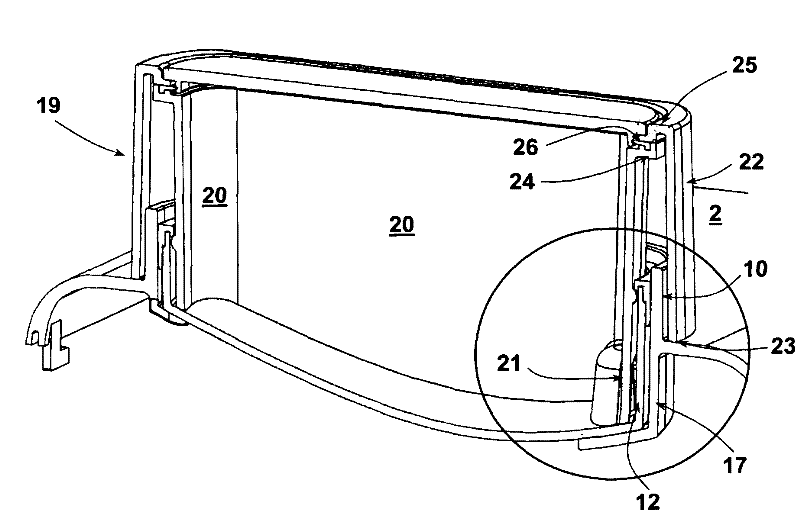

Coffee machine

ActiveCN102283578AOvercoming retentionAvoid accidental disengagementCoffee millsSpice millsEngineeringMechanical engineering

A coffee machine includes a coffee bean container provided with a receptacle for containing coffee beans. The receptacle is provided with an upper-sided opening for filling coffee beans and an outlet for discharging coffee beans to a grinding mechanism. The coffee bean container is provided with a cover member for enclosing the filling opening of the receptacle. The cover member is detachably arranged with respect to the coffee bean container. The coffee machine is equipped with a coffee bean container attachment for extending the capacity of the receptacle. When equipped on the coffee bean container, the attachment is supportedly kept on or in the casing of the coffee machine and / or the receptacle. The attachment is provided with an upper-sided opening for filling coffee beans and a circular wall held opposite to a receptacle (12) by a detachable lock, where a lower section (21) of the circular wall is fitted in the filling opening of the receptacle. The circular wall of the attachment has a first locking element at an outer side, and a receptacle wall has a locking element at an inner side complementary to the locking element of the attachment wall. The locking elements stand in engagement with each other when the attachment is attached to the container.

Owner:深圳伟嘉家电有限公司

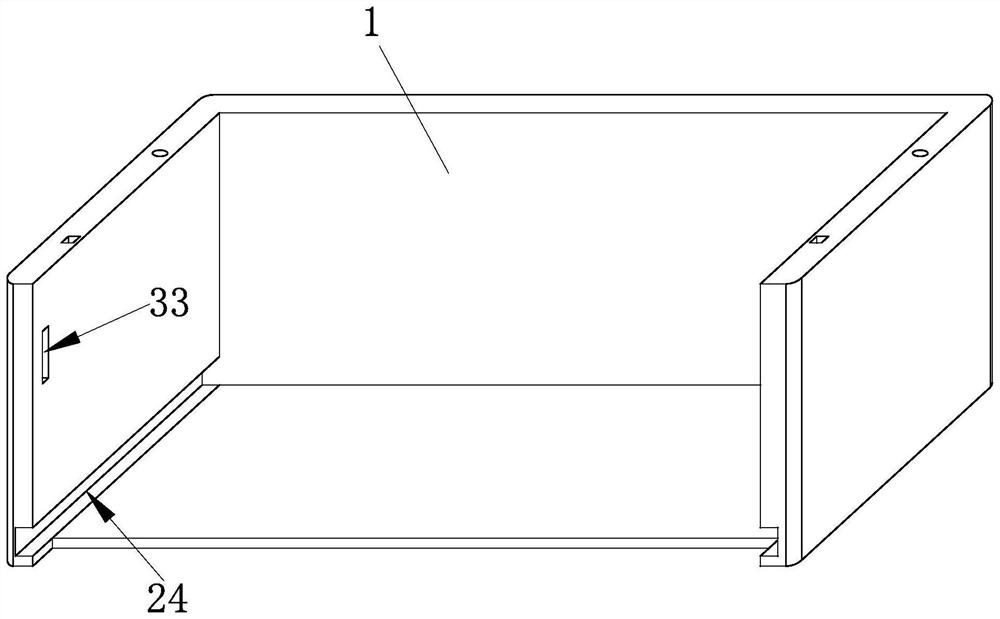

Wiring cabinet capable of storing spare cables

ActiveCN106019507ASolve the installationFix fixityFibre mechanical structuresEngineeringStructural engineering

The invention discloses a wiring cabinet capable of storing spare cables. The wiring cabinet comprises a cabinet body and a cabinet door. The wiring cabinet is characterized in that a blind is arranged on a side wall of the cabinet body; a hole of the blind is an outlet; an inlet is arranged in the bottom; a guide rail is vertically arranged in the cabinet body; a storage reel and a threading reel are fixedly arranged on the guide rail; the storage reel and the threading reel can slide along the guide rail; a clamp slot is arranged directly opposite to the blind on the side wall of the cabinet body; a cable separating frame is detachably clamped in the clamp slot; a horizontal flat plate is punched to form the cable separating frame; and the radius of the storage reel and the threading reel is more than or equal to 30mm. According to the wiring cabinet, when spare cores are stored, practical cores are put in order; cables are conveniently distinguished, which is convenient for debugging, operation and maintenance; and the cables are protected from damage.

Owner:GUIZHOU POWER GRID CO LTD

Gearbox used for rail transit vehicle

InactiveCN105422811AEasy installation and maintenanceEasy to installGear lubrication/coolingJoint surfaceSurface tooth

The invention relates to a gearbox used for a rail transit vehicle. Center lines of an input shaft and an output shaft of the gearbox are perpendicular to each other; a middle gear shaft which is parallel to the output shaft is arranged between the input shaft and the output shaft; the input shaft is engaged with a middle bevel gear of the middle gear shaft by virtue of a spiral bevel gear; supporting points at the two ends of the output shaft are hollow shafts; an output big gear is arranged on the output shaft; the middle gear shaft is engaged with the output large gear on the output shaft; an output flange plate is positioned at the output side of the output shaft; a jointed surface of the output flange plate and the output shaft is end surface teeth which are matched with each other; and the output flange plate passes through a central connecting bolt, so that end surface teeth of the jointed surface are engaged with each other. A mounting hole which is in butt joint with the output flange plate is mounted in the central axis of the output shaft, and the central connecting bolt is assembled in the mounting hole; the input shaft is supported on an upper box body by virtue of one four-point ball bearing and two cylindrical roller bearings in a input bearing base; and the two ends of each of the middle gear shaft and the output shaft are respectively supported on a box body by virtue of a bearing in the bearing base.

Owner:南京高精轨道交通设备有限公司

Hydraulic oil stability determinator

ActiveCN104007251AReduce usageSimple structureMaterial testing goodsHydraulic pumpHydraulic pressure

The invention discloses a hydraulic oil stability determinator including a constant-temperature oil storage system and a hydraulic oil circulating detection system, and is characterized in that the constant-temperature oil storage system includes a hydraulic circulating oil tank (1), and an external position of the hydraulic circulating oil tank (1) is provided with a constant-temperature device; the hydraulic oil circulating detection system includes a hydraulic pipeline (2) connected with the hydraulic circulating oil tank (1) to form a loop, and the hydraulic pipeline (2) is successively provided with a hydraulic pump (4), a pressure gauge (5) and a flow meter (6). The determinator has the advantages of simple structure, short test period, little test oil quantity, easy operation and the like.

Owner:GUANGXI LIUGONG PREMIUM GRADE LUBRICATING OIL

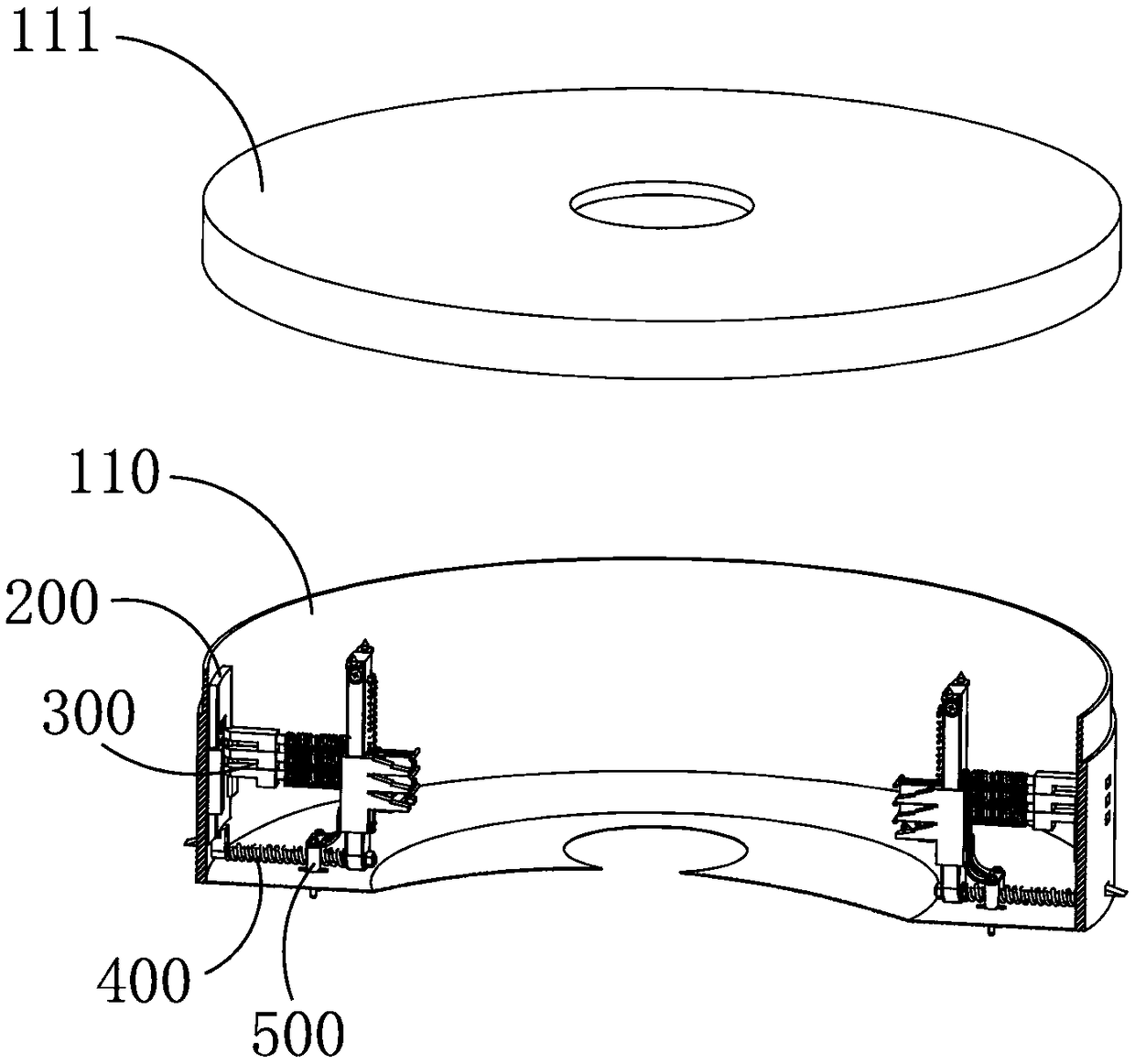

Gradual locking type LED ceiling down lamp

InactiveCN108662504AStable disassemblyLock firmlyLighting support devicesLight fasteningsEngineeringLamp shell

The invention provides a gradual locking type LED ceiling down lamp. The gradual locking type LED ceiling down lamp comprises a down lamp shell. Baffles, suspension locking devices, trigger mechanismsand reset mechanisms are arranged in the down lamp shell. The baffles are used for limiting the suspension locking devices from stretching out of the down lamp shell. The trigger mechanisms are usedfor controlling the baffles to limit the suspension locking devices or stop limiting the suspension locking devices. The suspension locking devices can stretch out of the down lamp shell and are usedfor enabling the down lamp to be fixedly mounted on a ceiling. The reset mechanisms are used for enabling the suspension locking devices to stop fixing the down lamp.

Owner:芜湖七创工业设计有限公司

Battery assembly for new energy automobile

ActiveCN112701406AEasy to pull outSmooth slidingElectric propulsion mountingSecondary cellsAutomotive batteryNew energy

The invention relates to the field of battery assemblies for new energy vehicles, in particular to a battery assembly for a new energy vehicle. The battery assembly comprises a battery box, a mounting structure, a fixing structure, a lifting structure, a heat dissipation structure and a moving structure, wherein the mounting structure is arranged at one end of the battery box, so that the assembly for mounting the automobile battery can be conveniently and smoothly pulled out from the interior of the battery box, and the automobile battery can be conveniently mounted and dismounted after the assembly for mounting the automobile battery is pulled out; with the arrangement of the fixing structure, the mounting structure and the battery box can be conveniently and quickly mounted and dismounted, that is, a mounting plate of an L-shaped structure is arranged in the battery box and can be used for mounting a battery pack; and the mounting structure can synchronously drive the lifting structure to work while working, the lifting structure can automatically open and close the battery box when the battery pack needs to be mounted and dismounted, manual control is not needed, and operation is convenient and easy.

Owner:湖北一特新能源有限公司

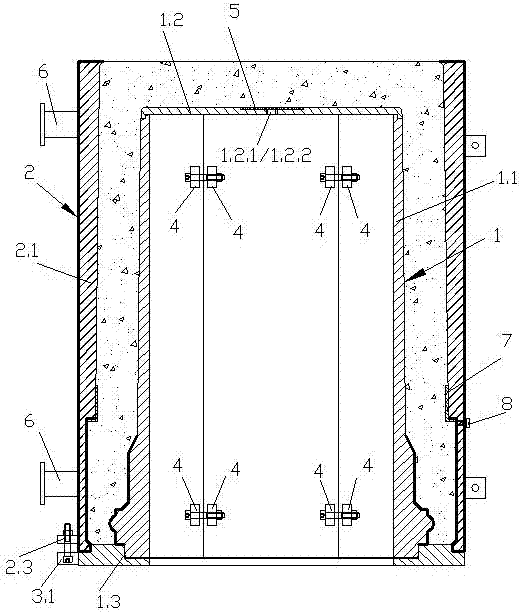

Steel pouring mould for concrete barrel-shaped container and assembly and disassembly methods thereof

PendingCN106914982APrevent or reduce pulpingPrevent or reduce the phenomenon of running fibersMouldsBarrel ShapedMaterials science

The invention discloses a steel pouring mould for a concrete barrel-shaped container and assembly and disassembly methods. The steel pouring mould comprises a barrel body mould and a barrel cover mould, wherein the barrel body mould comprises an inner mould, an outer mould and a base used for fixing the inner mould and the outer mould; a mould cavity is formed by a space among the inner mould, the outer mould and the base; the inner mould consists of a wall mould and a top plate; the wall mould is a barrel body which is spliced by at least four arc-shaped templates; the top plate covers the top end of the wall mould; the outer mould is an outer barrel body which is spliced by at least two arc-shaped templates; the mould cover mould comprises an outer mould, inserts and a base; the outer mould is a barrel body which is spliced by at least two arc-shaped templates; an insert groove is formed in the inner surface of each arc-shaped template; the inserts are embedded in the insert grooves; the outer mould is fixedly connected to the base; assembly of the barrel body mould is characterized in that the plurality of arc-shaped templates of the inner mould are separately arranged on the base sequentially and are spliced to form a barrel body; the top plate covers the top end of the wall mould; and the plurality of arc-shaped outer mould templates are spliced to form an outer barrel body and then are fixedly connected with the base.

Owner:江苏宝宸净化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com