Hydraulic filter with filter elements capable of being replaced online and replacement method of hydraulic filter

A technology for replacing filter elements and filters, applied to fluid pressure actuating devices, fluid pressure actuating system components, mechanical equipment, etc., can solve problems such as potential safety hazards, filter damage, inability to provide filtration work by the hydraulic system, etc., to avoid Delay, the effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

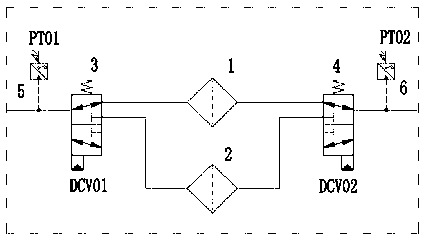

[0021] Refer to attached figure 1 , a hydraulic filter that can replace the filter element on-line, it includes two parallel single cylinder filters 1 and one cylinder filter 2; A two-position three-way electromagnetic valve 3 and 4 are respectively installed; a pressure switch 5 is arranged before the entrance of a two-position three-way electromagnetic valve 3; The through solenoid valve 3 has one inlet and two outlets, and the two outlets are respectively connected to the single cylinder filter and the inlet of the single cylinder filter; the two-position three-way solenoid valve 4 has two valve inlets and a valve outlet, its two inlet ports are respectively connected with the outlet of the single cylinder filter and the single cylinder filter. When the electromagnetic coil of the two-position three-way solenoid valve 3 is energized, the two-position three-way solenoid valve changes direction, the original oil circuit is cut off, and another oil circuit is changed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com